Page 1

i800

AC Current Clamp

Instruction Sheet

Introduction

The i800 AC Current Clamp, the Clamp, has been designed for use

with multimeters, recorders, power analyzers, safety testers, etc., for

accurate non-intrusive ac current measurement.

Using the latest transformer technology, the Clamp measures

currents from 100 mA to 800 A.

The Clamp complies with the safety standards EN61010-2-032 for

input and output circuits.

Symbols

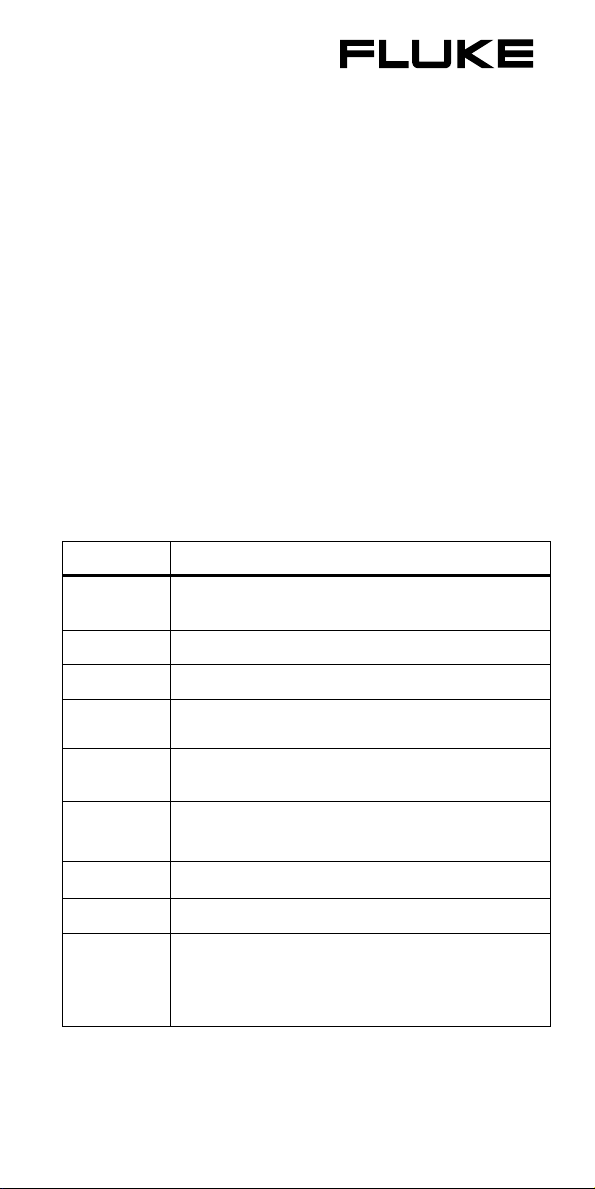

The table below lists the symbols used on the Clamp and/or in this

manual.

Symbol Description

®

~

W

X

T

,

)

P

;

CAT III

PN 2842289

June 2007 Rev.1, 8/08

©2007-2008 Fluke Corporation. All rights reserved. Product

specifications are subject to change without notice. Printed in

France.

Do not dispose of this product as unsorted municipal

waste. Go to Fluke’s website for recycling information.

Important Information. See manual.

Hazardous Voltage. Risk of electric shock.

Double insulation.

Application around and removal from HAZARDOUS LIVE

conductors is permissible.

Conforms to Canadian Standards Association.

Complies with the relevant European standards.

Conforms to Australian standards.

Equipment designed to protect against transients in

equipment in fixed-equipment installations, such as

distribution panels, feeders and short branch circuits, and

lighting systems in large buildings.

Page 2

Safety Instructions

Please read this section carefully. It will make you familiar with the

most important safety instructions for handling the Clamp. In this

instruction sheet, a

pose hazard(s) to the user. A

actions that may damage the Clamp or the test instruments.

Warning identifies conditions and actions that

Caution identifies conditions and

WX Warning

The Clamp may only be used and handled by qualified

personnel. To avoid electric shock or personal injury,

follow these precautions:

• Do not use the Clamp if damaged. Always

connect to display device before it is installed

around the conductor.

• If the Clamp is not used as specified by the

manual, protection provided by the Clamp may

be impaired.

• Do not clamp around a conductor before

connecting clamp output to the measuring

equipment.

• Do not disconnect the output from the measuring

equipment while the Clamp is still around a

conductor.

• Connect the Clamp output to measuring

equipment having safety receptacles.

• Do not use prior to consulting local and national

safety codes and use of protective equipment is

recommended.

• Do not hold the Clamp beyond the tactile barrier.

• Before each use, inspect the Clamp. Look for

cracks or missing portions of the housing or

output cable insulation. Also look for loose or

weakened components. Pay particular attention

to the insulation surrounding the jaws. Open and

close the Clamp, noting detent action indicating

proper mechanical operation of SIAC

circuit feature.

• Use caution when working with voltages above

60 V dc, 30 V ac rms or 42 V ac peak. Such

voltages pose a shock hazard.

• Do not use Clamp in wet environments or in

locations that hazardous gases exist.

TM

anti short

Page 3

SIAC™ (Security Internal Anti Short

Circuit)

SIAC™ (Security Internal Anti Short Circuit), patent applied for,

provides protection against short circuits between adjacent primary

conductors when clamped around conductors. This mechanism

ensures that the magnetic circuit separates at the bottom of the jaw

prior to the jaw opening at the top.

A detent action produced by SIAC™ can be felt when opening the

jaws. This detent action should always be present in use. If the jaws

open smoothly, service is indicated and the Clamp should be

inspected at the nearest Fluke Service Center. See “Contacting

Fluke”.

Operating Instructions

WX Warning

To avoid electric shock or personal injury when using

the Clamp:

• Ensure that your fingers are behind the tactile

barrier as shown in Figure 1.

• Do not use the Clamp if any part, including the

lead and connector(s), appears to be damaged or

if a malfunction of the instrument is suspected.

• Clamp around the current carrying conductor

ensuring good contact between the jaw faces.

Center the cable between the Clamp jaws.

Note

The arrow on the labels shows the direction of the current

flow from the source to the load. In order to have a correct

phase relationship between the primary current and the

clamp output, care must be taken regarding the direction

of current flow.

1. Connect the Clamp output connectors between the

common and the appropriate current input jack of a

suitable meter, then switch the meter on.

2. Select a 20 mA ac or greater current range.

3. Clamp the probe around the current-carrying conductor to

be measured (see Figure 1). Make sure the probe jaws

are tightly closed around the conductor.

Page 4

Note

Wire size and the position of the wire within the probe

jaws does not affect measurement accuracy.

4. Multimeter readings displayed in milliamps (mA) can be

read directly as amperes of conductor current. Readings

displayed in amperes (A) must be multiplied times 1000 to

obtain the amperes of conductor current.

320 A

Tactile

Barrier

mA

MIN MAX

RANGEHOLD

mA

CAT

Single

Current Carrying

Conductor

CAT

eyd001f.eps

Figure 1. Current Measurement

Meter Readings

When the Clamp is connected to a compatible current meter and

clamped around a single current-carrying conductor, the meter

reading will be one 1000th of the actual current in the conductor. For

example, a 5 A input current will be transformed into a 5 mA output

current (see Figure 1). When measuring current in an ac line cord,

the jaws should be clamped around only one conductor (the black or

hot wire in a three wire cord). If the jaws are clamped around both

current carrying conductors, the currents will cancel and produce a

zero reading. If the probe is clamped around two wires carrying

current in the same direction, the sum will be read. Reversing one of

the wires causes the difference to be read.

Low-Level Current Measurement

The Clamp is specified to measure currents of 100 mA or greater.

Currents less than 100 mA will produce meter readings that are

below the true value. Low-level currents can be measured by

looping the input wire through the jaws so that the sum of the current

through the jaws is greater than 100 mA. The actual current can

then be calculated by dividing the meter reading by the number of

turns looped through the jaws. For example, to measure a current of

40 mA (0.04 A), form a 10-turn loop and clamp the jaws around all

10 turns. The meter reading will be 0.4 mA, which corresponds to a

primary current of 0.4 A (400 mA). The actual current in the

conductor is 400 mA divided by 10-turns, or 40 mA.

Note

The probe output is equal to 1 mA per amp of primary

current. Since the primary current is equal to 400 mA

(40 mA x 10 and the probe divides it by 1000) the meter

reading will be 0.4 mA, which represents 400 mA.

Page 5

Maintenance

Performance Test

Verify Probe accuracy by measuring the output of a 20 A (±0.15 %),

60 Hz current source (Fluke 5520A or equivalent). When used with a

compatible DMM with ±0.35 %, or better, ac current accuracy (Fluke

8808A or equivalent), the probe should measure 20.000 A ±0.400 A

(20.000 mA, ±0.400 mA). There are no calibration adjustments in

the Clamp.

Cleaning

Clean the case periodically by wiping it with a damp cloth and

detergent. Do not use abrasive cleaners or solvents. Do not

immerse the Clamp in liquids.

Contacting Fluke

To contact Fluke, call:

USA: 1-888-993-5853

Canada: 1-800-363-5853

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your product, visit http://register.fluke.com.

.

Specifications

Electrical Characteristics

Specified Current Range 100 mA to 800 A rms

Overload Capability for 1 Hour,

33 % Duty Cycle 1500 A rms (50/60 Hz)

Output Sensitivity 1 mA / A

Turns Ratio 1000:1

Accuracy ±2 % of reading, 50 Hz to

Load Impedance ≤20 Ω

Phase Shift at 2 kHz ±1 degree typical

Bandwidth 30 Hz to 10 kHz (-3 dB)

Working Voltage

(see Safety Standards section) 600 V ac rms or dc

1 kHz, ±3 % of reading

(typical), 30 Hz to 50 Hz or

1 kHz to 10 kHz (Maximum

load ≤10 Ω)

General Characteristics

Maximum Conductor Size 54 mm diameter

Output Connection 4 mm safety plugs

Operating Temperature Range -10 to +55 °C

Storage Temperature Range -40 to +70 °C

Page 6

Operating Humidity 15 % to 85 %

Weight 650 g

Cable Length 1.6 meters

Overload Conditions Operation above 1200 A

Duty Cycle 1500 A at 50 / 60 Hz for

(non condensing)

should be limited to

frequencies below 1 kHz

1 hour, 33 % duty cycle

(20 min ON, 40 min OFF).

Safety Standards

EN 61010-1: 2001

EN 61010-2-032: 2002

EN 61010-031: 2002

600 V rms, Category III, Pollution Degree 2

Use of the clamp on uninsulated conductors is limited to 600 V ac

rms or dc and frequencies below 1 kHz.

CAT III equipment is designed to protect against the transients in the

equipment in fixed equipment installations, such as distribution

panels, feeders and short branch circuits, and the lighting systems in

large buildings.

EMC Standards

EN 61326 :1998 +A1, A2, & A3

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and

workmanship for one year from the date of purchase. This warranty

does not cover fuses, disposable batteries, or damage from

accident, neglect, misuse, alteration, contamination, or abnormal

conditions of operation or handling. Resellers are not authorized to

extend any other warranty on Fluke’s behalf. To obtain service

during the warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information, then send

the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY

CAUSE OR THEORY. Since some states or countries do not allow

the exclusion or limitation of an implied warranty or of incidental or

consequential damages, this limitation of liability may not apply to

you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Loading...

Loading...