Page 1

Common power

Unbalanced load:

kVA

TOTAL

= kVA1 + kVA2 + kVA

3

kVA

1

Red

Red

Red

Black

Black

Black

kVA

2

kVA

3

ø1

ø2

ø3

N

quality factors

affecting transformers

Application Note

Commercial buildings commonly

have a 208/120 V transformer in

a delta-wye configuration to

feed receptacles. Single-phase,

non-linear loads connected to

the receptacles produce triplen

harmonics, which add up in the

neutral. When this neutral current reaches the transformer, it is

reflected into the delta primary

winding where it causes overheating and transformer failures.

Another transformer problem

results from core loss and copper

loss. Transformers are normally

rated for a 60 Hz phase current

load only. Higher frequency harmonic currents cause increased

core loss due to eddy currents

and hysteresis, resulting in more

heating than would occur at the

same 60 Hz current.

Transformers supplying nonlinear loads should be checked

periodically to verify operation

within acceptable limits. Transformers are also critical to the

integrity of the grounding system.

Factors

1. Transformer loading (kVA)

Start by measuring kVA and

determine wether the transformer

load is balanced.

Connect voltage probes on

•

Phase 1 and Neutral and

clamp current probe on same

phase. Repeat for Phase 2 and

3.

Use a single phase power

•

quality analyzer to read kVA of

each phase and sum all three

for total transformer kVA.

Or, connect all four current

•

clamps and all five test leads

for the three phase power

quality analyzer to read kVA

for each phase and the total.

Compare actual load kVA to

•

nameplate kVA rating to determine % loading.

When using a single phase

analyzer on a balanced load, a

single measurement is suffic

ient.

Transformers loaded at less than

50 % are generally safe from

overheating. However, as loads

increase, measurements should

be made periodically. At some

point the transformer may require

derating.

Figure 2. Harmonic spectrum.

2. Harmonic spectrum

The harmonic spectrum of the

secondary (load) current will give

us an idea of the harmonic orders

and amplitudes present:

In a transformer feeding sin

•

-

gle-phase loads, the principal

n is the

er

onc

ill add arith-

ye transformer

y

.

harmonic of c

. The 3rd w

3rd

metically in the neutral and

irculate in the delta primar

c

of a delta-w

The good news is that the

delta-w

rest of the system from the 3rd

(though not the 5th, 7th or

ye tends to isolate the

other non-triplen harmonics).

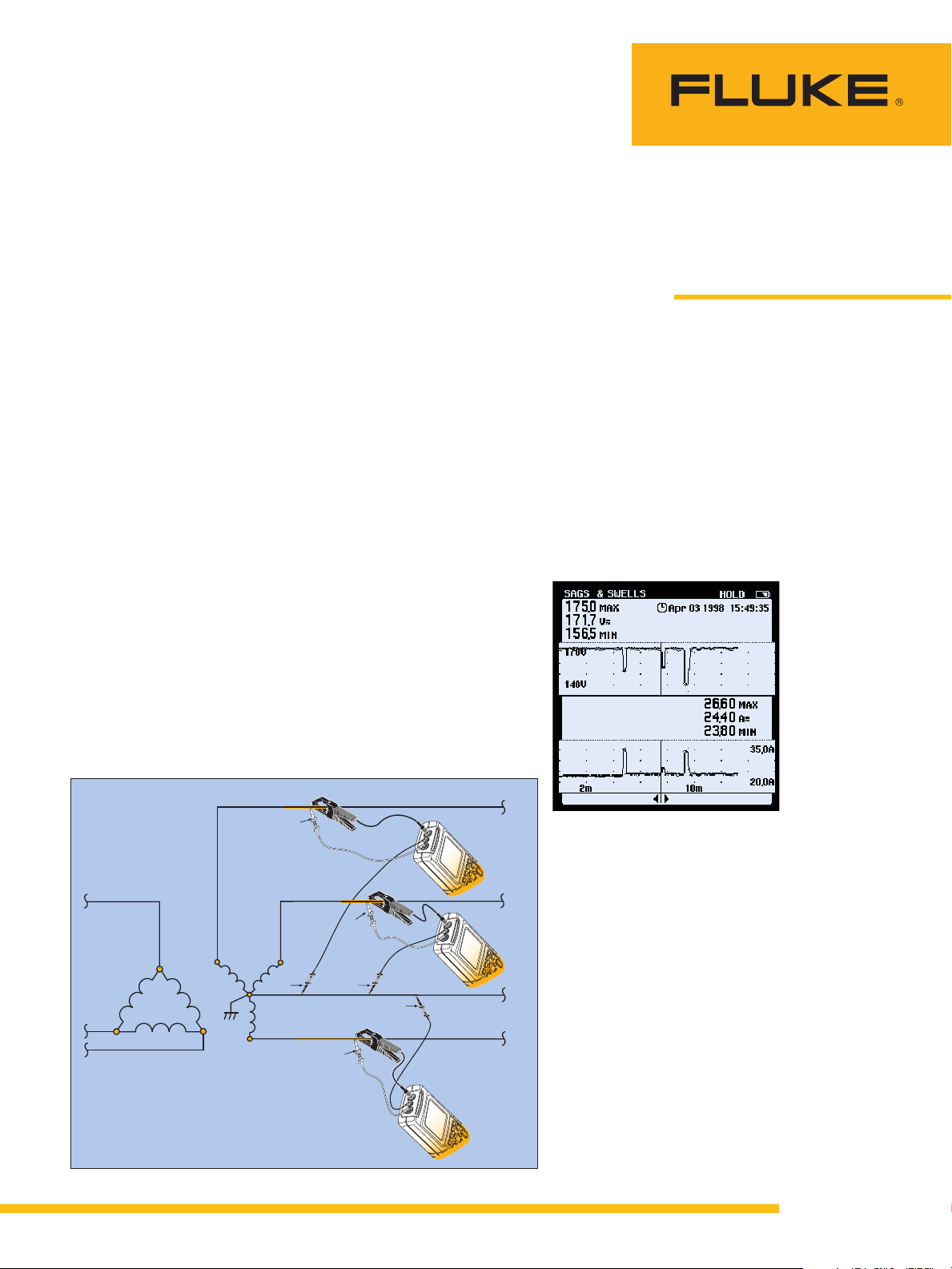

e 1

Figur

. Measuring transformer load (unbalanc

From the Fluke Digital Library @ www.fluke.com/library

ed) using a single phase power quality analy

The bad new

transformer pa

w

.

zer

ith additional heat

s is that the

ys the pric

.

e

Page 2

Table 1: Measurements at the distribution transformer

Measurement

. kVA Transformer loading. If loading exceeds 50 %, check for harmonics

1

2. Harmonic

spectrum 3rd harmonic (single-phase loads)

3. THD Harmonic loading within limits:

-factor Heating effect on transformer from harmonic loads

4. K

5. Ground currents

In a transformer feeding three-

•

phase loads which include

drives or UPS systems with 6pulse converters, the 5th and

7th harmonic will tend to predominate. Excessive 5th is of

particular concern because it is

negative sequence. It will tend

to produce counter-torque and

overheating in polyphase

motors.

Harmonic amplitudes normally

•

decrease as the frequency

goes up. If one frequency is

significantly higher in amplitude than lower frequencies,

we can suspect a resonant

Look for

and possible need for derating.

Harmonic orders/amplitudes present:

•

5th, 7th (primarily three-phase loads)

e of higher order harmonics

Resonanc

•

Effectiveness of harmonic trap filters

•

Voltage %THD < 5 %

Current %T

•

•

•

HD < 5-20 % (Table 2)

Objectionable ground currents are not quantified but are

prohibited by the N

eutral-ground bond in place

N

ESG (Electrical Safety Ground) connector to ground electrode

(typically building steel) in place

EC

condition at that frequency. If

such a condition is detected,

be sure to take readings at

capacitor banks to see if the

caps are experiencing overcurrent/overvoltage conditions.

Before-and-after harmonic

•

spectrum measurement is

extremely valuable to determine if harmonic mitigation

techniques, like trap filters,

which are tuned to specific

frequencies, are sized properly

and are working as expected.

Different harmonic frequencies

•

affect equipment in different

ways (see below).

Harmonic Sequences

Name F 2nd 3rd 4th 5th 6th 7th 8th 9th

180 240 300 360 420 480 540

20

Frequenc

Sequence +—0+—0+—0

Rule: If waveforms are symmetrical, even harmonics disappear.

Eff

Sequence Rotation Effects (from skin effect, eddy currents, etc.)

Positive Forward Heating of conductors, circuit breakers, etc.

N

Zero None Heating, + add in neutral of 3-phase, 4-wire system

Harmonics are classified as follows:

1. Order or number: Multiple of fundamental, hence, 3rd is three times the fundamental, or

2.

3. Sequence:

y

ects of Harmonic Sequences

egative

0 Hz

8

1

Odd or even order: Odd harmonics are generated during normal operation of nonlinear

loads. Even harmonics only appear when there is dc in the system. In power circuits, this

only tends to occur when a solid state component(s), such as a diode or SCR, fails in a

onverter c

c

Positive sequence. Main effect is overheating.

•

Negative sequence. Create counter-torque in motors, i.e., will tend to make motors go

•

backwards, thus causing motor overheating. Mainly 5th harmonic.

Zero sequenc

•

Reverse

.

.

ircuit

e. Add in neutral of 3-phase, 4-w

1

0

6

Heating as above + motor problems

ire system

. Mainly 3rd harmonic.

3. Total Harmonic Distortion

Check for THD of both voltage

and current:

For voltage, THD should not

•

exceed 5 %

For current, THD should not

•

exceed 5-20 % (see Odd

Harmonics table)

IEEE 519 sets limits for har-

monics at the PCC (Point of

Common Coupling) between the

utility and customer (EN50160 is

the European standard). IEEE 519

is based on THD measurements

taken at the PCC. Technically, the

PCC is the primary of the utility

supply transformer (although

there are cases where the PCC is

at the secondary if the secondary

feeds a number of customers). In

practice, these measurements are

often made at the secondary of

the customer’s main transformer,

since that is the point most easily

accessible to all parties (and also

since that is generally a Low

Voltage measurement).

Some PQ practitioners have

broadened the concept of PCC to

include points inside the facility,

such as on the feeder system,

where harmonic currents being

generated from one set of loads

could affect another set of loads

by causing significant voltage

distortion. The emphasis is on

improving in-plant PQ, rather

than on simply not affecting utility PQ.

3a. Voltage THD

THD has a long history in the

industry. The underlying concept

is that harmonic currents generated by loads will cause voltage

distortion (E=IZ) as they travel

through the system impedance.

This voltage distortion then

becomes the carrier of harmonics

system-wide: if, for example, the

distorted voltage serves a linear

load like a motor, it will then create harmonic currents in that

linear load. By setting maximum

limits for voltage distortion, we

set limits for the system-wide

impact of harmonics.

2 Fluke Corporation Common power quality factors affecting transformers

Page 3

Table 2: IEEE 519 limits for harmonic currents at the point of

common coupling

CR=Isc/IL <11 11-17 17-23 23-35 >35 TDD

S

<20

20-50

00 10.0 % 4.5 % 4.0 % 1.5 % 0.7 % 12.0 %

50-1

00-1000 12.0 % 5.5 % 5.0 % 2.0 % 1.0 % 15.0 %

1

000 15.0 % 7.0 % 6.0 % 2.5 % 1.4 % 20.0 %

>1

Short circuit ratio (Isc/I

SCR=

Available short circuit current at PCC

Isc =

Maximum demand load current (rms amps)

IL=

TDD = Total demand distortion

Note: IEE E allows these limits to be exceeded for up to one hour per day, while IEC allows

them to be exceeded for up to 5 % of the time.

The concept of

ties,

ILis calculated by a

(information a

Transformer rating could be used and would be the most conservative estimate (i.e., it would

result in the lowest SCR), since it assumes that the transformer would be used at full capacity.

IL, maximum demand load current, is key to using Table 2. For existing facili-

vailable in billing records). For new installations,

Voltage distortion, however,

depends on source impedance,

i.e., on system capacity. It was

quite possible for the first (or second or third) customer to inject

significant harmonic currents into

the system and not cause voltage

THD to exceed 5 %. The entire

responsibility for harmonic mitigation could fall on the last

customers unlucky enough to

push V-THD over 5 %, even if

their particular harmonic load

was relatively small-literally the

straw that broke the camel’s

back.

3b. Current T

To restore some fairness to this

(All percentages are % of IL, maximum demand load current)

Odd Harmonics

4.0 % 2.0 % 1.5 % 0.6 % 0.3 % 5.0 %

7.0 % 3.5 % 2.5 % 1.0 % 0.5 % 8.0 %

)

L

ing the maximum demand current for 12 consecutive months

verag

ILmust b

e estimated.

For equipment manufacturers,

IEC 1000-3-2, published in 1995,

is the applicable standard. It

specifies maximum current levels

out to the 40th harmonic. Its

expected effective date is projected to be early 2001. To certify

for CE, a requirement for the

European market, manufacturers

will have to meet this standard.

This edict will have a major effect

on power supply design.

For the facility, IEEE 519 is the

standard (EN 50160 in Europe).

The limits set in IEEE 519 for

harmonic currents depend on the

D

H

size of the customer relative to the

system capac

ity. (See Table 2.)

situation, standards for maximum

current harmonics were added,

e current harmonics were

sinc

under the control of the local

ility and equipment manufac

fac

turer (rememb

er, harmonic

“loads” act as “generators” of harmonics). This emphasis on the

mitigation of current harmonics at

the load, including the not-too-

Table 3

Inspection of Transf

-

Check for N-G bond. A high impedance N-G bond will cause

Check for g

integrity of connection to building steel these connections, so they should be as low

(exothermic weld). impedance as possible.

Check for tightness of all

conduit connections. will tend to act as a “choke” for higher

rounding c

ormer Ground Explanation

onductor and

distant requirement that the load

generate virtually no harmonics,

has become the prevailing regu-

y philosophy

lator

. It puts the

burden of responsibility on the

Measure for

grounding conductor. always be some ground current due to

ground currents on the Ideally there should be none, but there will

local site and on the equipment

manufacturers

.

The SCR (Short Circuit Ratio) is

a measure of the electrical size of

the customer in relation to the

utility source. The smaller the

customer (higher SCR), the less

the potential impact on the utility

sourc

e and the more generous

the harmonic limits. The larger

the customer (smaller SCR), the

more stringent the limits on harmonic currents.

3c. TDD and THD

TDD (Total Demand Distortion) is

the ratio of the current harmonics

to the

maximum load (IL). It dif-

fers from THD in that THD is the

ratio of harmonics to the

taneous

load. Why TDD instead

instan-

of THD? Suppose you were running a light load (using a small

fraction of system capacity), but

those loads were nonlinear. THD

would be relatively high, but the

harmonic currents actually being

generated would be low, and the

effect on the supply system

would in fact be negligible. So

who cares? TDD acknowledges

this, and allows harmonic load to

be referenced to the maximum

load: if harmonic load is high at

maximum load, then we have to

watch out for the effect on the

supply source. So where does

that leave current THD as a useful

measurement.

The closer the current THD reading(s) is taken to

conditions of maximum load, the

D.

D

closer it appr

voltage fluctuation.

ault currents will return to the source via

F

onduit is not itself g

If the c

frequencies and limit fault current

(remember that fault currents are not just

at 60 Hz but have high-f components).

normal operation or leakage of protective

components (MOVs, etc.) connected from

phase or neutral to ground. However,

anything above an amp should be cause

for suspic

but experienc

a feel for possible problems).

oximate

ion (there is no hard and fast rule,

ed PQ troubleshooters develop

s T

rounded, it

3 Fluke Corporation Common power quality factors affecting transformers

Page 4

A final word on measuring

480 V

208 Y/120 V

Neutral

Grounding electrode nearby,

preferably structural metal

THD: the one place not to apply

the specs is at the individual harmonic-generating load. This will

always be a worst-case distortion

and a misleading reading. This is

b

ecause as harmonics travel

upstream, a certain amount of

cancellation takes place (due to

phase relationships which, for

practical purposes, are unpredictable). Measure at a PCC, or at

the source transformer.

4. K-factor

K-factor is a specific measure of

the heating effect of harmonics in

general and on transformers in

particular. It differs from the THD

calculation in that it emphasizes

the frequency as well as the

amplitude of the harmonic order.

This is because heating effects

increase as the square of the frequency.

A K-4 reading would mean

that the stray loss heating effects

are four times normal. A standard

transformer is, in effect, a K-1

transformer. As with THD, it is

misleading to make a K-factor

reading at the load or receptacle

because there will be a certain

amount of upstream cancellation;

transformer K-factor is what

counts. Once the K-factor is

determined, choose the next

higher trade size. K-factor rated

transformers are available in

standard trade sizes of K-4, K-13,

K-20, K-30, etc. K-13 is a common rating for a transformer

supplying office loads. The higher

ratings tend to be packaged into

PDUs (Power Distribution Units)

which are spec

ially designed to

supply computer and other PQsensitive installations.

5. Ground currents

Two prime suspects for excessive

ground current are illegal N-G

bonds (in subpanels, receptacles

or even in equipment) and socalled isolated ground rods:

Subpanel N-G bonds create a

•

parallel path for normal return

current to return via the

grounding conductor. If the

neutral ever becomes open, the

equipment safety ground

becomes the only return path;

if this return path is high

impedance, dangerous voltages

could develop.

Separate isolated ground rods

•

almost always create two

ground references at different

potentials, which in turn

causes a “ground loop” current

to circulate in an attempt to

equalize those potentials. A

safety and equipment hazard is

also created: in the case of

lightning strikes, surge currents

travelling to ground at different

earth potentials will create

hazardous potential differences.

Transformer grounding

The proper grounding of the

transformer is critical. (Table 3.3.)

NEC Article 250 in general and

250-26 in particular address the

grounding requirements of the

SDS.

A ground reference is estab-

•

lished by a grounding

connection, typically to building steel (which, in turn, is

required to be bonded to all

cold water pipe, as well as

any and all earth grounding

electrodes). Bonding should be

by exothermic weld, not

clamps that can loosen over

time. The “grounding electrode

conductor” itself should have

as low a high-frequency

impedance as possible (not

least because fault current has

high frequency components).

Wide, flat conductors are preferred to round ones because

they have less inductive reactance at higher frequencies.

For the same reason, the distance between the “grounding

electrode conductor connection

to the system” (i.e., N-G bond

at the transformer) and the

grounding electrode (building

steel) should be as short as

possible: in the words of the

Code, “as near as practicable

to and preferably in the same

...”

area

The neutral and ground should

•

be connected at a point on the

transformer neutral bus

.

Although permitted, it is not

advisable to make the N-G

ond at the main panel, in

b

order to maintain the segregation of normal return currents

and any g

round currents

. This

point at the transformer is the

only point on the system

G should be bonded.

where N

-

Figure 3. Transformer grounding.

4 Fluke Corporation Common power quality factors affecting transformers

Page 5

Solutions

There are a number of solutions

for transformer-related PQ

problems:

Install additional distribution

•

transformers (Separately

Derived Systems)

Derate transformers

•

Install K-rated transformers

•

Used forced air cooling

•

1. Separately Derived System

(SDS)

The distribution transformer is

the supply for a Separately

Derived System (SDS), a term

which is defined in the NEC

(Article 100). The key idea is that

the secondary of this transformer

is the new source of power for all

its downstream loads: this is a

powerful concept in developing a

PQ distribution system. The SDS

accomplishes several important

objectives, all beneficial for PQ:

It establishes a new voltage

•

reference

taps which allow the secondary voltage to be stepped up

or down to compensate for

any voltage drop on the feeders.

It lowers source impedance by

•

decreasing, sometimes drastically, the distance between

the load and the source. The

potential for voltage disturbances, notably sags, is

minimized.

It achieves isolation. Since

•

there is no electrical connection, only magnetic coupling,

between the primary and secondary, the SDS isolates its

loads from the rest of the electrical system. To extend this

isolation to high frequency disturbances, specially

constructed “isolation transformers” provide a shield

between the primary and secondary to shunt RF (radio

frequency) noise to ground.

Otherwise, the capacitive coupling between primary and

secondary would tend to pass

these high-frequency signals

right through.

. Transformers have

A new ground reference is

•

established

tion of the SDS is that it “has

no direct electrical connection,

including a solidly connected

grounded circuit conductor, to

supply conductors originating

in another system.” (NEC 100)

The opportunity exists to segregate the subsystem served

by the SDS from ground loops

and ground noise upstream

from the SDS, and vice versa.

rated transformers

2. K-

Figure 4. Typical K-factor in commercial

building.

Harmonics cause heating in

transformers, at a greater rate

than the equivalent fundamental

currents would

of their higher frequency. There

are three heating effects in transformers that increase w

frequency:

Hysteresis. When steel is

•

mag

all line up, so that the North

poles all point one way, the

South poles the other

poles switch with the polarity

of the applied current. The

higher the frequenc

often the switching occurs,

and, in a process analogous to

the effects of friction, heat

losses increase.

Eddy currents. Alternating

•

mag

whirlpools of current that create heat loss. This effect

increases as a square of the

. Part of the defini-

. This is because

ith

netized, mag

netic fields create localized

netic dipoles

. These

y, the more

frequency. For example, a 3rd

harmonic current will have

nine times the heating effect

as the same current at the fundamental.

Skin effect. As frequency

•

increases, electrons migrate to

the outer surface of the conductor. More electrons are

using less space, so the effective impedance of the

onductor has increased; at

c

the higher frequency, the conductor behaves as if it were a

lower gauge, lower ampac

higher impedanc

The industry has responded

with two general solutions to the

effects of harmonics on transformers: install a K-factor rated

transformer or derate a standard

transformer. Let’s look at pros

and cons of the K-factor approach

first. K-factor is a calculation

based on the rms value, %HD

(harmonic distortion) of the harmonic currents, and the square of

the harmonic order (number). It is

not necessary to actually perform

the calculation because a harmonic analyzer will do that for

you. The important thing to

understand is that the harmonic

e w

ity,

ire.

5 Fluke Corporation Common power quality factors affecting transformers

Page 6

order is squared in the equation

0

0

20

40

60

80

100

20 40 60 80 100

Transformer Capacity (%)

After Derating for

Electronic Load

Switched-Mode Power Supply Load (% of Overall Load)

and that is precisely where the

high- frequency heating effects,

like eddy current losses, are

taken into account.

K-rated transformers are

desig

ned to minimize and accommodate the heating effects of

harmonics. K-rated transformers

do not eliminate harmonics

(unless additional elements like

filters are added). They accommodate harmonics with

techniques such as the use of a

number of smaller, parallel windings instead of a single large

inding: this gives more skin for

w

the electrons to travel on. The

primary delta winding is up-sized

to tolerate the c

irculating third

harmonic currents without overheating. The neutral on the

secondary is also up-sized for

third harmonics (typically sized at

twice the phase ampacity).

Application issues with

K-factor transformers

K-rated transformers have been

widely applied, but there are certain issues with them. Many

consultants do not see the need

for using transformers with a rating higher than K-13 although

K-20 and higher might be supplied as part of an integrated

Power Distribution Unit (PDU).

Also, early applications sometimes overlooked the fact that

K-rated transformers necessarily

have a lower internal impedance.

Whereas a standard transformer

has an impedanc

5-6 % range, K-rated transformers can go as low as 2-3 %

(lower as the K

In retrofit situations, where a

standard transformer is being

ed by a K

replac

of equivalent kVA, this may

require new short circuit calculations and re-sizing of the

secondary overcurrent protective

devices.

6 Fluke Corporation Common power quality factors affecting transformers

e typically in the

-rating increases).

-rated transformer

3. Derating standard

transformers

Some facilities managers use a

50 % derating as a rule-of-thumb

for their transformers serving

single-phase, predominantly

nonlinear loads. This means that

a 150 kVA transformer would

only supply 75 kVA of load. The

derating curve, taken from IEEE

1100-1992 (Emerald Book),

shows that a transformer with

60 % of its loads consisting of

SMPS (switched-mode power

supplies), which is certainly

possible in a commercial office

building, should in fact be

derated by 50 %.

The following is an accepted

method for calculating transformer derating for single-phase

loads only. It is based on the very

reasonable assumption that in

single-phase circuits, the third

harmonic will predominate and

cause the distorted current waveform to look predictably peaked.

Use a

true-rms meter to make

these current measurements:

1. Measure rms and peak current

of each secondary phase.

(Peak refers to the instanta-

neous peak, not to the inrush

or “peak load” rms current).

2. Find the arithmetic average of

the three rms readings and the

three peak currents and use

this average in step 3 (if the

load is essentially balanc

this step is not nec

3. Calculate Xformer Harmonic

Derating Factor:

xHDF = (1.414 * IRMS) / IPEAK

4. Or, since the ratio of

Peak/RMS is defined as Crest

Factor, this equation can be

ritten as:

rew

DF = 1.414 / CF

xH

If your test instrument has the

capability, measure the CF of

each phase directly. If the load

is unbalanced, find the aver-

age of the three phases and

use the average in the above

formula.

Since a sine wave current

waveform has a CF=1.414, it will

ve an xH

ha

DF=1; there will be

no derating. The more the 3rd

harmonic, the higher the peak,

ed,

essary).

Figure 5. Transformer derating curve (IEEE 1100-1992)

the higher the CF. If the CF were

2.0, then the xH

DF=1.414 / 2

=.71. A CF=3 gives us an xHDF

=.47. A wave with CF=3 is about

as badly distorted a current

waveform as you can expect to

see on a single-phase distribution

transformer.

Caution: This method does not apply to

transformers feeding three-phase loads,

where harmonics other than the third tend to

predominate and CF is not useful as a simple

predictor of the amount of distortion. A calculation for three-phase loads is available in

ANSI /IEEE C57.110. However, there is some

controversy about this calculation since it

may underestimate the mechanical resonant

vibrations that harmonics can cause, and that

accelerate transformer wear above and

beyond the effects of heat alone.

4. Forced air cooling

If heat is the problem, cooling is

the solution. Break out the fan,

turn it on the transformer and use

forced air cooling. Some experi-

ed hands fig

enc

20-30 % on the up side. In any

case, it can only help.

ure that’s worth

eping your world

Fluke. K

e

up and running.

Fluke Corporation

O Box 9

P

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The N

For more information call:

In the U.S.A. (800) 443-5853 or

ax (425) 446-5

F

In Europe/

Fax (31 40) 2 675 222

In Canada (800) 36-FLUKE or

ax (9

F

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2004 Fluke Corporation

Printed in U.S.A. 10/2004 2403202 A-US-N Rev A

0

05) 89

9

M

0, Everett, W

East/

-

0-6866

A USA 98206

etherlands

6

1

1

Africa (3

. All rights reserved.

1 40) 2 6

5 200 or

7

Loading...

Loading...