Page 1

Instant power replay

solves a breaker trip

Testing Functions

Case Study

Measuring tools: Fluke 1750 Power

Recorder

After experiencing some nuisance tripping of breakers in the

subpanel feeding the second

floor of this industrial building,

we installed a Fluke 1750 Power

Recorder at the subpanel to

gather information about power

usage.

For several weeks, we experienced no circuit breaker trips,

and the recorded data from the

1750 showed excellent quality

power delivery.

The next week, using the current event detector with a 20

A threshold to match the single

phase branch feeds, we discovered that there were several

events where current exceeded

the breaker trip rating. While

there were no tripped breakers

during the week, it was clear

that something was overloading

the circuit to the point where a

breaker trip was likely to happen.

A search of the facility found

an employee who had moved

a Tenny temperature chamber

into a lab area and was using

it to perform elevated temperature tests on some products. The

Application Note

chamber was on wheels and

was plugged into a standard

120 V, 20 A branch outlet.

The power recorder captured

the operation of the temperature

chamber and its effect on the

power at the sub-panel.

Data analysis

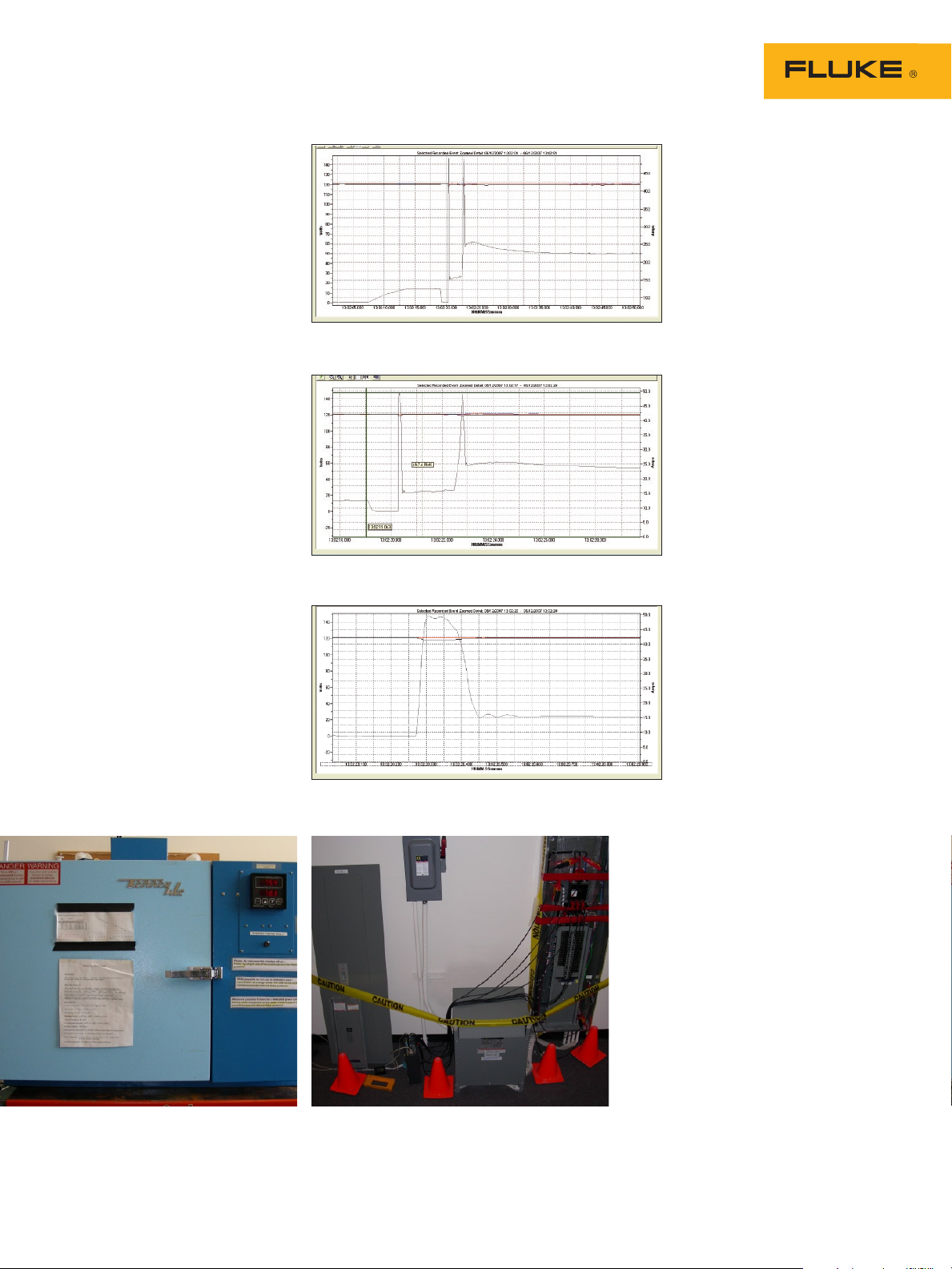

The current event view shows

several events outside the 20 A

breaker tolerance curve. The longest event is shown in Figure 1.

The event exhibits a double

initial current surge, followed

by a sustained current over

20 amps. Although the circuit

breaker did not trip during this

event, its rating was exceeded

and it would be likely to trip

occasionally under similar conditions. These conditions are

frequent during use of the temperature chamber, as can be

seen in the graph above, where

this event is immediately followed by another similar event

whose beginning can be seen at

the right side.

Operator: Michael Gipe, Fluke Power

Electronics Engineer

Tests conducted: Power quality

event recording

From the Fluke Digital Library @ www.fluke.com/library

Figure 1. Current event view, top level events

Page 2

Zooming into the initial region

of the event in Figure 2, we see

the turn-on loads of the temperature chamber’s dual compressor system. The first compressor

turns on with a large initial

surge, followed by the secondary compressor surge. This load

profile clearly identifies the temperature chamber as the cause of

the overload.

Temperature chamber peak

current is 49.7 amps. In Figure 3,

the sustained load is near

25 amps.

We can zoom in further,

in Figure 4, to see even more

detailed resolution of this initial current surge. Note that the

phase A voltage sags during this

current surge, but the voltage

drop is small, indicating that the

power feed at the sub-panel is

very stiff, and can accommodate

substantial demand.

Conclusion

The power feed to the second

floor is robust. The nuisance

tripping is most certainly due to

temporary overload of a standard

20 amp appliance branch circuit

from using an industrial temperature chamber on the circuit. The

temperature chamber should be

connected to a dedicated branch

circuit, sized to meet the requirements of the chamber, minimum

20 amps.

Figure 2. Compressor activity

Figure 3. Load evaluation

Figure 4. Interpreting voltage drop

2 Fluke Corporation Instant power replay solves a breaker trip

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2007 Fluke Corporation. Specifications subject

to change without notice. Printed in U.S.A.

11/2007 3185343 A-EN-N Rev A

®

Loading...

Loading...