Page 1

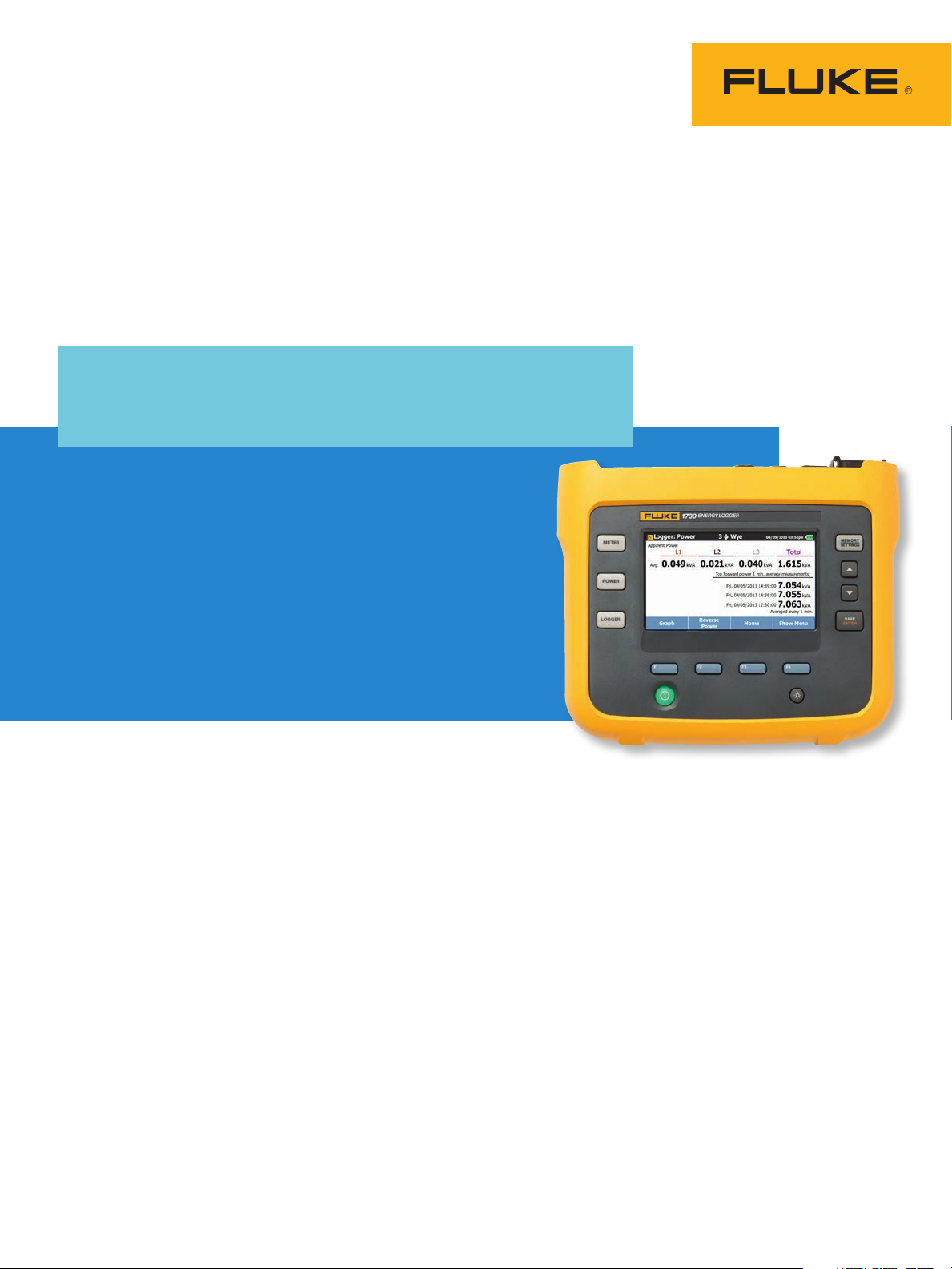

Fluke 1730

Three-Phase Electrical

Energy Logger

Energy logging is now within your reach—

discover where you’re wasting energy, optimize

your facility’s energy use and reduce your bill.

The new Fluke 1730 Three-Phase Electrical Energy logger

introduces a new simplicity to discovering sources of

electrical energy waste. Discover when and where

energy in your facility is being consumed; from the

service entrance to individual circuits. Profiling energy

usage across your facility helps you identify opportunities

for energy savings, and provides you with the data you

need to act on them. The new Energy Analyze software

package allows you to compare multiple data points over

time to build a complete picture of energy usage, which

is the first step to reduce the cost of your energy bill.

Technical Data

• Key measurements: voltage, current, power,

power factor and associated values enable

energy saving strategies to be implemented.

• Bright, color touch screen: perform conve-

nient in-the-field analysis and data checks

with full graphical display.

• Comprehensive logging: all measured values

are automatically logged and can be reviewed

during logging and before downloading for onthe-go analysis. More than 20 separate logging

sessions can be stored on the instrument.

• Optimized user interface: quick, guided,

graphical setup ensures you’re capturing the

right data every time, and the intelligent verification function indicates correct connections

have been made, reducing user uncertainty.

• Complete ‘in-the-field’ setup through the

front panel: no need to return to the workshop

for download and setup or to take a computer

to the electrical panel.

• Wide range power: power instrument directly

from the measured circuit eliminating the

need to find a power outlet while allowing the

instrument to be secured safely inside electrical panels.

• Two USB ports: one for PC connection and

another for fast, simple download to standard

USB thumb drives, or other USB devices.

• Compact size: designed to fit in tight spaces

and panels.

• Highest safety rating in the industry: 600 V

CAT IV/1000 V CAT III rated for use at the service entrance and downstream.

• Optimized measurement accessories: flat

voltage cable and thin flexible current probes

ensure easy installation even in tight spaces.

• Battery life: four-hour operating time (backup

time) per charge on lithium-ion battery.

• Security: safeguard against theft with a

Kensington lock.

• All new, Energy Analyze application soft-

ware: download, analyze and automated

reporting for a complete picture of energy

saving potential.

Page 2

Applications

Load studies

Discover how much energy individual pieces of

equipment are consuming when they are operating at minimum and maximum capacity. Check

capacity of circuits prior to adding additional

loads (various standards exist for this process;

in the US the NEC 220-87 is the recommended

standard). Load studies can also identify situations

where you may be exceeding the allowable load

on the circuit or when an agreed peak demand

applies from the utility. For convenience, some

load studies simply measure current which makes

installation of the measuring equipment quick and

easy. It is often recommended that load surveys

be performed for 30 days so that all typical load

conditions are encountered during the test.

Energy surveys

Users often ask where measurements should be

taken for an energy survey. The answer is multiple points within the facility. Start at the main

service feeders; compare the power and energy

measured here with the readings from the utility meter to ensure you’re receiving the correct

charges. Then move downstream to the larger

loads; these should be easy to identify by the current rating of the electrical panels downstream of

the service entrances. Measuring at many points

will allow a full picture of energy usage across

the facility to be developed. The next question users typically have is how long an energy

survey should last. This of course depends on the

facility, but it is recommended that you measure

for a period that matches a typical facility activity period. If the facility operates over a five day

work week with down time on the weekend, a

seven day survey will most likely capture typical

conditions. If the facility operates at a constant

level for 24 hours a day, 365 days a year, a single

day could be reasonably representative as long as

you avoid a period where there may be planned

maintenance.

To capture a full picture of the facilities energy

usage it is not necessarily required to have

measurements made simultaneously at every

consumption point in the facility. To get a comprehensive picture, spot measurements can be made

and then compared on a sliding time timescale.

For example, you could compare the service

entrance results from a typical Tuesday between

6:00 am and 12:00 pm with those of a larger load

in the facility. Typically there will be some correlation between these profiles.

Power and energy logging

When a piece of equipment is operated it instantaneously consumes a specific amount of power in

watts (W) or kilowatts (kW). This power is accumulated over the operating time and expressed as

energy consumed in kilowatt hours (kWh). Energy

is what your electric utility charges for; there will

be a standard charge from the utility per kilowatt

hour. Utilities may have other additional charges,

such as peak demand, which is the maximum

power demand over a defined period of time,

often 15 or 30 minutes. There may also be power

factor charges, which are based on the effects of

the inductive or capacitive loads in the facility.

Optimizing peak demand and power factor often

results in lower monthly electricity bills. The

1730 Three Phase Electrical Energy logger has

the capability to measure and characterize these

effects enabling you to analyze the results and

save money.

Simplified load studies

For situations where it’s either difficult or impractical to make a voltage connection the simple load

study feature allows users to perform a simplified

load study by measuring current only. The user

can enter the nominal expected voltage to create

a simulated power study. For accurate power

and energy studies it is required to monitor both

voltage and current but this simplified method is

useful in certain circumstances.

2 Fluke Corporation Fluke 1730 Three-Phase Electrical Energy Logger

Page 3

Specifications

Accuracy

Parameter Range Resolution Intrinsic Accuracy at Reference Conditions

Voltage 1000 V 0.1 V ± (0.2 % + 0.01 %)

150 A 0.1 A ± (1 % + 0.02 %)

150 0 A 1 A ± (1 % + 0.02 %)

300 A 1 A ± (1 % + 0.02 %)

3000 A 10 A ± (1 % + 0.02 %)

600 A 1 A ± (1.5 % + 0.03 %)

6000 A 10 A ± (1.5 % + 0.03 %)

4 A 1 mA ± (0.7 % + 0.02 %)

40 A 10 m A ± (0.7 % + 0.02 %)

Current:

Direct input

iFle x15 0 0 -12

iFlex3000-24

iFlex6000-36

i40s-EL clamp

Frequency 42.5 Hz to 69 Hz 0.01 H z ± (0.1 %)

Aux input ± 10 V dc 0.1 mV ± (0.2 % + 0.02 %)

Voltage Min/Max 1000 V 0.1 V ± (1 % + 0.1 %)

Current Min/Max defined by

accessory

defined by

accessory

Cosϕ/DPF 0 <= Cosϕ <=1 0.01 ± 0.025

Power factor 0 <= PF <=1 0.01 ± 0.025

THD on voltage 1000 % 0.1 % ± (2.5 % ± 0.05 %)

THD on current 1000 % 0.1 % ± (2.5 % ± 0.05 %)

(% of Reading + % of Full Scale)

± (5 % + 0.2 %)

Intrinsic uncertainty ± (% of reading + % of range)

Parameter Influence

quantity

Active power P PF ≥ 0.99 1.2 % +

0.5 <PF <0.99 1.2 % + 7 x

Apparent power S, S fund. 0 ≤ PF ≤ 1 1.2 % +

1

iFlex1500-12 iFlex3000-24 iFlex6000-36 i40s-EL

150A/1500A 300A/3000A 600/6000A 4A/40A

0.005 %

(1-PF)

+0.005 %

0.005 %

1.2 % +

0.0075 %

1.2 % + 7 x

(1-PF)

+ 0.0075 %

1.2 % +

0.0075 %

1.7 % +

0.0075 %

1.7 % + 7 x

(1-PF)

+ 0.0075 %

1.7 % +

0.0075 %

Reactive power N, Q fund. 0 ≤ PF ≤ 1 2.5 % of measured apparent power

Additional uncertainty in %

1

of range

1

Range = 1000 V x Irange

Reference conditions:

Environmental: 23 °C ± 5 °C, instrument operating for at least 30 minutes, no external electrical/magnetic field, RH <65 %

Input conditions: Cos

Current and power specifications: Input voltage 1 ph: 120 V/230 V or 3 ph wye/delta: 230 V/400 V

Input current: I > 10 % of Irange

Primary conductor of clamps or Rogowski coil in center position

Temperature coefficient: Add 0.1 x specified accuracy for each degree C above 28 °C or below 18 °C

ϕ/PF=1, Sinusoidal signal f=50 Hz/60 Hz, power supply 120 V/230 V ±10 %.

U >250 V 0.015 % 0.0225 % 0.0225 % 0.015 %

1.2 % +

0.005 %

1.2 % + 10 x

(1-PF)

+ 0.005 %

1.2 % +

0.005%

3 Fluke Corporation Fluke 1730 Three-Phase Electrical Energy Logger

Page 4

Electrical specifications

Power supply

Voltage range 100 V to 500 V using safety plug input when powering from the measurement

circuit

100 V to 240 V using standard power cord (IEC 60320 C7)

Power consumption Maximum 50 VA (max. 15 VA when powered using IEC 60320 input)

Efficiency ≥ 68.2 % (in accordance with energy efficiency regulations)

Maximum no-load consumption < 0.3 W only when powered using IEC 60320 input

Mains power frequency 50/60 Hz ± 15 %

Battery Li-ion 3.7 V, 9.25 Wh, customer-replaceable

On-battery runtime Four hours in standard operating mode, up to 5.5 hours in power saving mode

Charging time < 6 hours

Data acquisition

Resolution 16-bit synchronous sampling

Sampling frequency 5120 H z

Input signal frequency 50/60 Hz (42.5 to 69 Hz)

Circuit types 1-ϕ, 1-ϕ IT, Split phase, 3-ϕ delta, 3-ϕ wye, 3-ϕ wye IT, 3-ϕ wye balanced, 3-ϕ

Aron/Blondel (2-element delta), 3-ϕ delta open leg, Currents only (load studies)

THD THD for voltage and current is calculated using 25 harmonics

Averaging period User selectable: 1 sec, 5 sec, 10 sec, 30 sec, 1 min, 5 min, 10 min, 15 min, 30 min

Demand interval User selectable: 5 min, 10 min, 15 min, 20 min, 30 min

Data storage Internal flash memory (not user replaceable)

Memory size Typical 20 logging sessions of 10 weeks with 10-minute intervals

Logging period

Averaging period

Recommended

for 20 sessions

1

Logging Period

for 1 session

1 second 3 hours 2.5 days

5 seconds 15 ho u r s 12 days

10 seconds 28 hours 24 days

30 seconds 3.5 days 10 weeks

1 minute 7 days 20 weeks

5 minutes 5 weeks 2 years

10 m inutes 10 week s > 2 years

15 m i nute s 3.5 months > 2 years

30 minutes 7 months > 2 years

1

Interfaces

USB-A File transfer via USB flash drive, firmware updates

Max. current: 120 mA

USB-mini Data download device to PC

Extension port Accessories

Voltage inputs

Number of inputs 4 (3 phases and neutral)

Maximum input voltage 1000 V

, CF 1.7

rms

Input impedance 10 MΩ

Bandwidth (-3 dB) 2.5 kHz

Scaling 1:1, 10:1, 100:1, 1000:1 and variable

Measurement category 1000 V CAT III/600 V CAT IV

Current inputs

Number of inputs 3, mode selected automatically for attached sensor

Input voltage Clamp input: 500 mV

Rogowski coil input 150 mV

rms

/15 mV

/50 mV

rms

at 50 Hz, 180 mV

rms

; CF 2.8

rms

rms

/18 mV

at 60 Hz; CF 4; all at nominal

rms

probe range

Range 1 A to 150 A/10 A to 1500 A with thin iFlex flexible current probe, 12 inches

3 A to 300 A/30 A to 3000 A with thin Flex flexible current probe, 24 inches

6 A to 600 A/60 A to 6000 A with thin iFlex flexible current probe, 36 inches

40 mA to 4 A/0.4 A to 40 A with 40 A clamp i40s-EL

Bandwidth (-3 dB) 1.5 k H z

Scaling 1:1 and variable

1

The num ber of possible logging sessions and logging period depends on user requirements.

4 Fluke Corporation Fluke 1730 Three-Phase Electrical Energy Logger

Page 5

Auxiliary inputs

Number of inputs 2

Input range 0 to ± 10 V dc, 1 reading/s

Scale factor (available 2014) Format: kx + d user configurable

Displayed units (available 2014) User configurable (7 characters, for example, °C, psi, or m/s)

Environmental specifications

Operating temperature -10 °C to +50 °C (14 °F to 122 °F)

Storage temperature -20 °C to +60 °C (−4 °F to 140 °F)

Operating humidity 10 °C to 30 °C (50 °F to 86 °F) max. 95 % RH

30 °C to 40 °C (86 °F to 104 °F) max. 75 % RH

40 °C to 50 °C (104 °F to 122 °F) max. 45 % RH

Operating altitude 2000 m (up to 4000 m derate to 1000 V CAT II/600 V CAT III/300 V CAT IV)

Storage altitude 12,000 m

Enclosure IP50 in accordance with EN60529

Vibration MIL 28800E, Type 3, Class III, Style B

Safety IEC 61010-1: Overvoltage CAT IV, Measurement 1000 V CAT III/600 V CAT IV,

Pollution Degree 2

EMI, RFI, EMC EN 61326-1: Industrial

Electromagnetic compatibility Applies to use in Korea only. Class A Equipment (Industrial Broadcasting and

Communication Equipment)

Radio frequency emissions IEC CISPR 11: Group 1, Class A

Temperature coefficient 0.1 x accuracy specification/°C

General specifications

Color LCD display 4.3-inch active matrix TFT, 480 pixels x 272 pixels, resistive touch panel

Warranty 1730 and power supply: Two-years (battery not included)

Accessories: One-year

Calibration cycle: Two-years

Dimensions 1730: 19.8 cm x 16.7 cm x 5.5 cm (7.8 in x 6.6 in x 2.2 in)

Power supply: 13.0 cm x 13.0 cm x 4.5 cm (5.1 in x 5.1 in x 1.8 in)

1730 with power supply attached: 19.8 cm x 16.7 cm x 9 cm

(7.8 in x 6.6 in x 3.5 in)

Weight 1730: 1.1 kg (2.5 lb)

Power supply: 400 g (0.9 lb)

External protection Holster, Kensington lock slot

5 Fluke Corporation Fluke 1730 Three-Phase Electrical Energy Logger

Page 6

1500-12 iFlex Flexible Current Probe specifications

Measuring range 1 to 150 A ac / 10 to 1500 A ac

Nondestructive current 100 kA (50/60 Hz)

Intrinsic error at reference condition* ± 0.7 % of reading

Accuracy 1730 + iFlex ± (1 % of reading + 0.02 % of range)

Temperature coefficient over operating temperature range 0.05 % of reading/°C 0.09 % of reading/°F

Working voltage 1000 V CAT III, 600 V CAT IV

Probe cable length 305 mm (12 in)

Probe cable diameter 7.5 mm (0.3 in)

Minimum bending radius 38 mm (1.5 in)

Output cable length 2 m (6.6 ft)

Weight 115 g

Transducer cable material TPR

Coupling material POM + ABS/PC

Output cable TPR/PVC

Operating temperature -20 °C to +70 °C (-4 °F to 158 °F) temperature of conductor

Temperature, non-operating -40 °C to +80 °C (-40 °F to 176 °F)

Relative humidity, operating 15 % to 85 % non-condensing

IP rating IEC 60529:IP50

Warranty One-year

*Reference condition:

• Environmental: 23 °C ± 5 °C, no external electrical/magnetic field, RH 65 %

• Primary conductor in center position

under test shall not exceed 80 °C (176°F)

Ordering information

1730/BASIC Three-Phase Electrical Energy logger (excludes current probes).

1730/US Portable Energy Logger US version

1730/EU Portable Energy Logger EU version

1730/INTL Portable Energy Logger INTL version

Accessories

i1730-flex1500 iFlex flexible current probe 1500A 12 inch

i1730-flex3000 iFlex flexible current probe 3000A 24 inch

i1730-flex6000 iFlex flexible current probe 6000A 36 inch

i40s-EL i40s-EL Clamp-on Current Transformer

i1730-flex1500/3pk iFlex flexible current probe 1500A 12 inch, 3 pack

i1730-flex3000/3pk iFlex flexible current probe 3000A 24 inch, 3 pack

i1730-flex6000/3pk iFlex flexible current probe 6000A 36 inch, 3 pack

i40s-EL/3pk i40s-EL Clamp-on Current Transformer, 3 pack

1730-TL0.1M Test Lead Set; 1000 V CAT III, straight plug; 0.1 m; silicone; red/black

1730-TL2M Test Lead Set, 1000 V CAT III; straight plug; 2 m; PVC red/black

3PHVL-1730 Cable Assembly, Voltage Test Lead 3-Phase+N

C1730 1730 Soft Case

WC100 Color Localization Set

1730-Hanger Hanging strap

1730-Cable AUX input cable

Fluke. The Most Trusted Tools

in the World.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2013 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2013 4314073B_EN

Pub ID: 12028-eng Rev. 01

Modification of this document is not permitted

without written permission from Fluke Corporation.

6 Fluke Corporation Fluke 1730 Three-Phase Electrical Energy Logger

Loading...

Loading...