Page 1

KV 10

Installation Instructions 810656-00

GESTRA Outer Butterfly Valve

Page 2

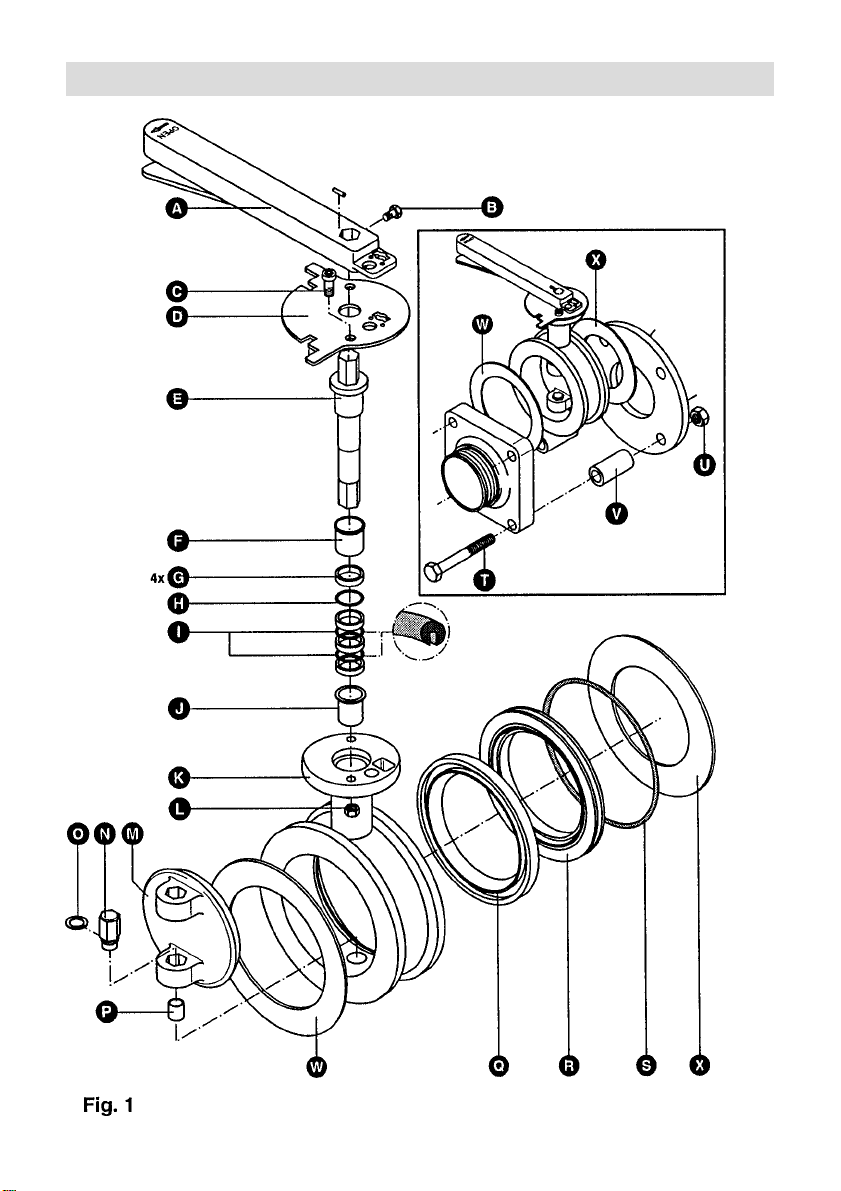

Parts Drawing

2

Page 3

Important Safety Note

Technical Data

Butterfly valves for tank containers must only

be installed by qualified staff.

Carefully read through installation instructions

before mounting the valve.

Use GESTRA genuine spare parts only.

Danger

Do not carry out any installation or

maintenance work unless the tank container

is completely empty and degassed.

Escaping vapours and gas can endanger life

and health of the person responsible for

installation and maintenance and cause

material damage.

Do not hold the device by means of the

operating lever.

Function

Butterfly valve (outer valve) with operating

lever for loading and unloading systems for

hazardous tank containers of IMO classes 1

and 2.

Opening:

Turn operating lever A anticlockwise through

90° and snap into position.

Closing:

Turn operating lever A clockwise through 90°

and snap into position.

Design

■ Main components:

Body for installation between flanges

Stem

Disc

Operating lever

Seat ring and gasket

■ Ancillary components:

Heating jacket

Hemisphere (as closure device)

Pressure/Temperature

Ratings

DN/NPS 80/3"

Service pressure [bar] 6

Min. service temp. [°C] –10

Max. service temp.[°C] 190

Test pressure [bar] 10

Connection

For dimensions and further specifications

see data sheet.

[psig] 87

[psig] 145

Waf er design for

installation between

flanges with

centering sleeve

Installation

Important Note

The disc must be in the closed position when

installing the valve.

Fitting (Fig. 1)

1. Introduce two hexagon-head bolts

through bottom holes of the square flange

and place guide sleeves V onto bolts.

2. Introduce now the bolts with sleeves T and

through bottom holes of the CV 10

V

flange and secure with two nuts U.

3. Place the closed butterfly valve type KV 10

onto the two guide sleeves.

4. Put gaskets W and X between the KV 10

guide sleeves V and flanges. The gaskets

must be flush with the valve.

5. Introduce hexagon-head bolt T through top

left hole of the square flange.

6. Introduce this bolt T through the

corresponding hole of the CV 10 flange and

secure with nut U.

7. Proceed in the same way with top right

hexagon-head bolt.

8. Align the valve KV 10 and tighten nuts

manually. Take care that the gaskets are

flush with the valve.

9. Tighten the hexagon-head bolts T and nuts

gradually and in diagonally opposite

U

pairs with a torque of 80 ± 5 Nm.

T

3

Page 4

Dismantling

For the remov al of the valve proceed

in reverse order.

Important Note

Do not damage gaskets during

installation.

Maintenance

The butterfly valve does not require any special

maintenance.

Important Note

Check main seal

of the fixing bolts T when inspecting the valve,

at least on the occasion of the “Inspection and

Examination” of the tank container which takes

place every 2½ years and whenever carrying

out maintenance or repair work.

Q

and the torque (80 ± 5 Nm)

Replacemente of disc

main seal

■ Main seal can be replaced without having to

extract the disc.

1. Remove the butterfly valve and the square

spigot outlet.

2. Remove seat ring R and seal Q from the

body.

3. Insert new seal, with the disc being in the

closed position.

Replacement of bearing bush and

stem sealing

4. Pull out stem E with the aid of operating

lever.

5. Remove bushes F + J and rings from

the stem guide.

6. Clean location hole for stem. Do not

damage the sealing surface for the

O-rings.

7. Insert new bushes J and F.

8. Apply a smear of lubricant to the new

O-rings I + H and ring G and push

them onto the stem. Consider correct order

and right position. Remove surplus

lubricant from the stem bearing surface.

9. Push stem E into stem guide.

10. Install notch plate D and operating lever

in reverse order.

11. Secure screw B (e. g. with the aid of

Loctite 222).

12. Re-establish wire seal so that you can see

if the valve has been tampered with.

Replacement of sleeve

and journal

1. Press retaining ring O out of the groove

and push towards the body.

2. Press journal N out of the body upwards

through disc lug by using the retaining ring

groove.

3. Pull bush P out of the body and insert new

bush.

4. Put retaining ring O onto bottom hexagon

lug and introduce journal N through the

hexagon socket disc lug.

5. Push journal completely into the body and

press retaining ring into the corresponding

groove.

Important Note

In order to remove the operating lever you must

destroy the wire seal between operating lever

and stem. There is a second seal between the

notch plate D and the body flange K. (Fig. 1)

1. Loosen screw B (secured with retainer,

e. g. Loctite 222) and remove operating lever

from stem.

2. Unscrew socket-head cap bolts C and lock

nuts L.

3. Remove notch plate D.

4

Page 5

Spare Parts

Item Designation Order No.

Disc 049 081

M

Main seal 048 870

Q

Seat ring 048 871

R

Retaining ring A 12 014 479

O

Collar bush 048 875

F

18 x 15 x 24

Collar bush 048 759

J

14 x 18 x 18

Bush 9.0 x 10 048 899

P

★SO-ring 049 345

★IO-ring 048 765

★HO-ring 048 766

Ring 048 767

G

Operating lev er incl. 048 878

A

notch plate and

assembly parts

Gasket 80 KV 10 048 887

W

Square spigot outlet 048 894

cpl.

Square spigot outlet 048 891

Assembly parts KV 10 048 888

★ ★

★ Parts subject to wear

★ ★

5

Page 6

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

España

España

GESTRA ESPAÑOLA S.A.

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

Luis Cabrera, 86-88

E-28002 Madrid

E-28002 Madrid

Tel. (091) 5 152 032

Tel. 00 3491/5152032

Fax (091) 4 136 747; (091) 5 152036

Fa x0 0349 1/413674 7; 5152036

E-mail: gestra@gestra.es

E-mail: gestra@gestra.es

France Portugal

France Portugal

Invensys Flow Control

Flowserve Flow Control S.A.S.

France SAS

10 Avenue du Centaure, BP 8263

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

F-95801 CERGY PONTOISE

Tél. 003 31/34432660

Tél. (01) 34.43.26.60

Fax 00331/34432687

Fax (01) 34.43.26.87

E-mail: gnation@flowserve.com

E-mail: gnation@gestra.fr

Italia

Italia

Invensys Flow Control Division

Italgestra S.r.l.

Italgestra S.r.l.

Via Carducci 125

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

l-20099 S.S. Giovanni (MI)

Tel. 003902 /2410 12.1

Tel. (02) 24 10 12 1

Fax 0039 02/24 1012.460

Fax (02) 24 10 12460

E-mail: info@italgestra.it

E-mail: info@italgestra.it

Polska

Polska

GESTRA POLONIA Spolka zo.o.

GESTRA POLONIA Spolka z o. o.

Ul. Schuberta 104

Ul. Schuberta 104, P.O. Box 71

PL-80-172 Gdansk

PL-80-172 Gdansk

Tel. (058) 306 10 02

Tel. 004858/3061002 oder 306 1010

Fax (058) 306 10 03

Fax 0048 58/3061003 oder 3063300

E-mail: gestra@gestra.pl

E-mail: gestra@gestra.pl

GESTRA PORTUGUESA VALVULAS LDA.

GESTRA PORTUGUESA VALVULAS LD A.

Av. Dr. Antunes Guimarães, 1159

Av. Dr. Antunes Guimarães, 1159

P-4100 Porto

Porto 4100-082

Tel. (022) 6 1987 70

Tel. 0035122/6 198770

Fax (022) 6 1075 75

Fax 00351 22/6107575

E-mail: gestra@gestra.pt

E-mail: gestra@gestra.pt

®

®

GESTRA GmbH

GESTRA GmbH

Postfach 10 54 60

Postfach 10 5460

D-28054 Bremen

D-28054 Bremen

Hemmstraße 130

Münchener Str. 77

D-28215 Bremen

D-28215 Bremen

Tel. +49 (0) 421 3503-0

Tel. +49 (0) 421 35 03- 0

Fax+49 (0) 421 3503-393

Fax +49 (0) 421 35 03- 393

E-mail

gestra.gmbh@gestra.de

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

Internet www.gestra.de

A Unit of Flowserve Corporation

An Invensys company

810656-00/401c · ©2000 GESTRA GmbH · Bremen · Printed in Germany

Loading...

Loading...