Page 1

Worcester Actuation Systems

1. Description

The I-75 Interface is designed to be used and mounted in the Series

75 Actuator as one of many standard options. Function of the I-75

Interface is to allow the Series 75 Actuator to be powered by a 120 or

240 VAC power supply, operated directly by any programmable

controller, microprocessor, and/or computer regardless of the output

rating of these devices. Depending on the control input to be used,

there are several options of the I-75 Interface:

These options are identified by the nameplate on the circuit board.

5V for 5 VDC input

XV for 12 VDC input

XX for 24 VDC input

15 for 120 VAC input

2. Installation of I-75 Interface Board into

Series 75 Electric Actuator

2.1 Check Kit for Parts:

Common Parts for Sizes 10-30 Actuators

Qty. Name

1 Circuit Board Subassembly

1 Insulating Board

5-6 Washers (Nylon)

5-6 Grommets (Rubber)

5-6 Mounting Screws

5 Cable Ties

1 Wiring Label

1 Closed-End Splice

1 Wire - White

Additional Parts for Sizes 10-23 Actuators

Qty. Name

1 Bracket - Right

1 Bracket - Left

2 Spacer (Bracket)

2 Mounting Screw (Spacer/Bracket)

Additional Parts for 240 VAC Option

Qty. Name

2 Limit Switch

1 Lead Assembly - Gray

1 Lead Assembly - Blue

Additional Parts for Sizes 25, 30 Actuators

Qty. Name

1 Mounting Bracket

2 Mounting Screw (Bracket)

Tools needed for assembly:

1

/

4" Nut Driver,

1

/

8" Screwdriver and Needle Nose Pliers.

FCD WCAIM2000-00

(Part 06094)

I-75 Interface

Installation, Operation and Maintenance Instructions

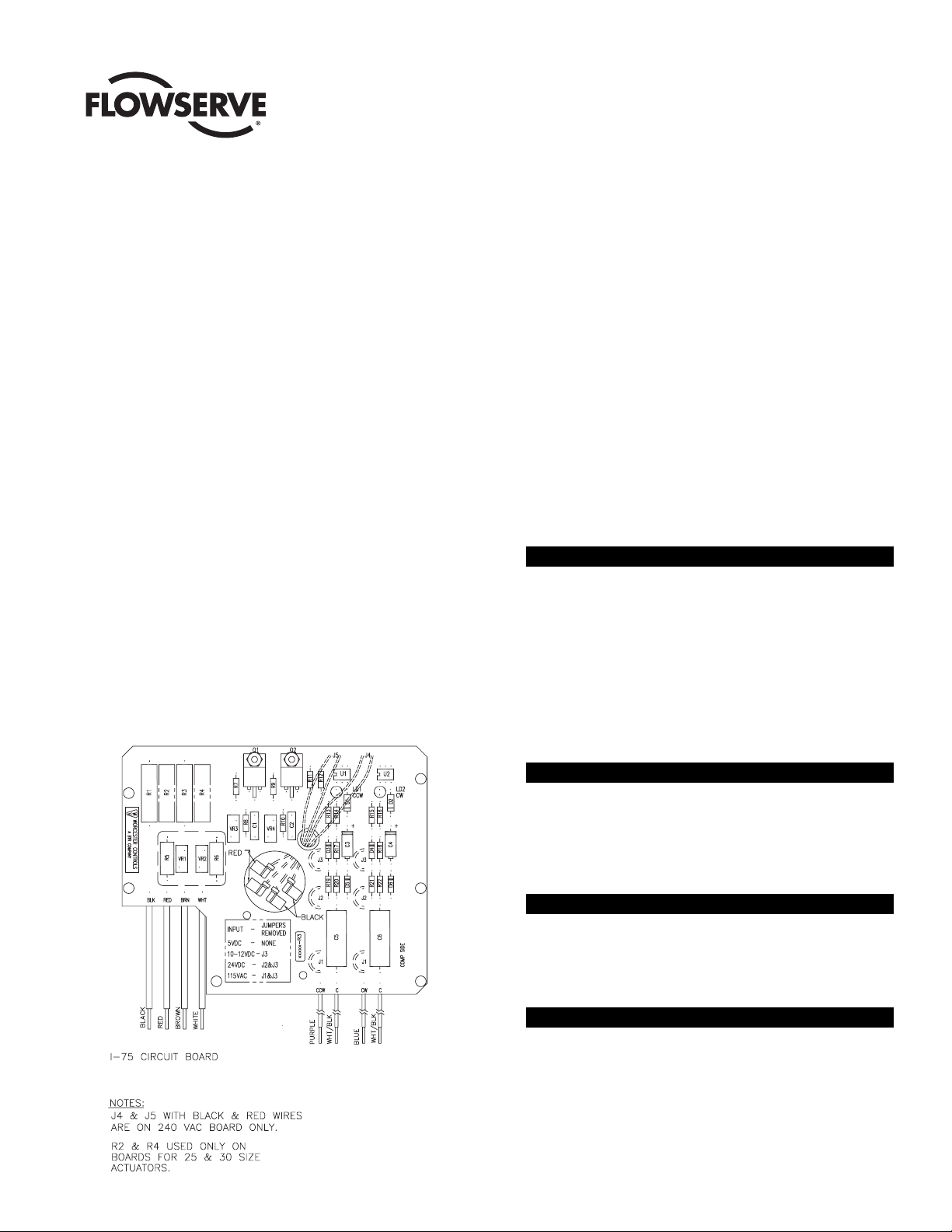

Figure 1

Page 2

2

Flow Control

Worcester Actuation Systems

2.2 Assembly Procedure

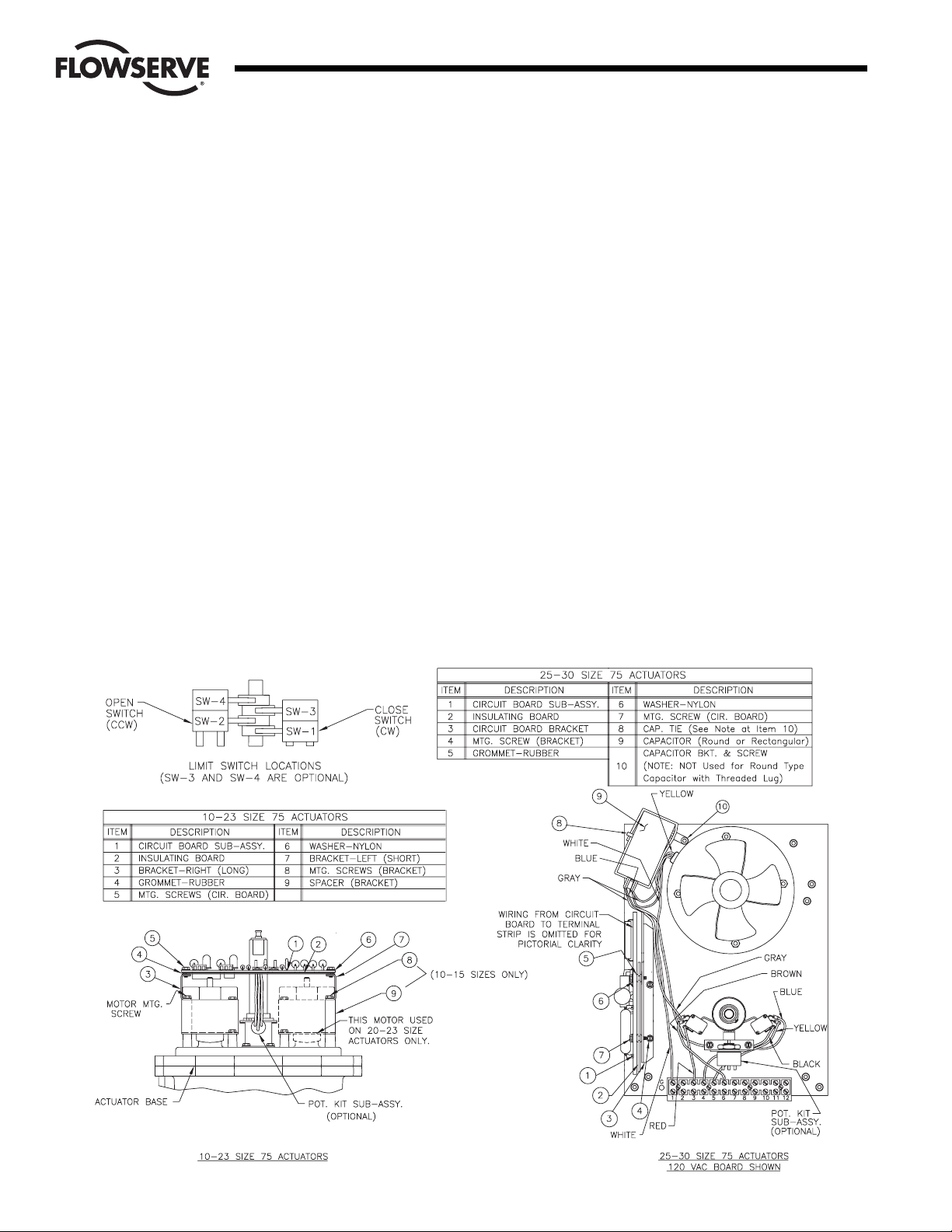

2.2.1 For 10-23 Size Electric Actuators (See Figure 2):

A. Pre-tap circuit board bracket holes with the self-tapping

screws. Mount these brackets to the actuator motors or

spacers as provided. The longer bracket is mounted to the

right side of the actuator when facing the terminal strip. Use

the motor mounting screws.

B. Remove and replace motor screws carefully to avoid stripping

the threads of these self-tapping screws.

C. Once these motor screws and brackets are firmly secured,

firmly tap the motor stator to ensure realignment of the top

motor bearing.

D. Loosen all terminal strip screws to connect the circuit board

wiring to the actuator terminal strip. See Section 3 for proper

wiring of circuit board to the actuator terminal strip. Wire

routing is important. Ensure that wiring is not pinched and is

not near cams or mechanical brake (if used).

E. Assemble circuit board into actuator. Slide rubber grommets

onto insulating board. Put nylon washers under heads of selftapping screws.

F. Put circuit board onto brackets. Fasten board to brackets

loosely using mounting screws. Use a nylon washer and a

rubber grommet under the self-tapping screw mounted on the

right side of board when facing terminal strip.

G. Snug down the circuit board and firmly secure mounting

screws.

2.2.2 For 25 and 30 Size Electric Actuators (See Figure 2):

A. Assemble circuit board to bracket as shown.

B. Place four of the rubber grommets onto the insulating board.

Put nylon washers on the screws and place screws through

the circuit board and insulation board. Start screws into the

bracket.

C. Where no insulation board is used, place a rubber grommet

between the board and the bracket. Firmly tighten all screws.

D. Use two screws to fasten circuit board bracket to the motor

mounting plate. Component side of the board is facing out.

Figure 2

Page 3

3

Flow Control

Worcester Actuation Systems

3. Wiring

3.1 External Power - 120/240 VAC Option (Figures 3 and 4):

NOTE: All wiring to terminal strip should be inserted only to mid-point

of terminal strip.

AC power connections are made to terminals 1 and 2 of the terminal

strip. The AC neutral, or common, wire should be connected to

terminal 1 and the AC “HOT” wire to terminal 2. Grounding wire

should be connected to green colored grounding screw (if present) on

actuator base or to any base plate mounting screw in the actuator.

Signal and power wiring for an actuator may be run for short

distances in the same conduit.

See table below for minimum fuse rating when overcurrent protection

is used in motor power circuit.

Minimum Fuse Rating for Overcurrent Protection

Actuator Size Voltage Fuse Rating

10-23 120 VAC 5 A

25/30 120 VAC 10 A

10-23 240 VAC 3 A

25/30 240 VAC 5 A

NOTE: The table shows the minimum rating to prevent inrush current

from blowing the fuse.

3.2 External Input Signal Connections - 120/240 VAC Option

(Figures 3 and 4):

There are two isolated inputs, one for counterclockwise (CCW); the

other for clockwise (CW) directions. CCW input positive (more

positive) or hot (in case of AC) is connected to terminal 10, CW input

positive (more positive) or hot (in case of AC) is connected to

terminal 12. Other input wires, negative (less positive) or common

(in case of AC) for CCW and CW directions are connected to

terminals 9 and 11 respectively. For complete wiring diagram see

Figures 3 or 4 below, or wiring label which is to be attached to inside

of actuator cover.

3.3 Internal Wiring - Common to 120/240 VAC Options

(Figures 3 and 4):

NOTE: When there are multiple wires going to terminal 1, use the

short white wire included in kit. Connect it to terminal 1 and then

splice it to the other white wires (common) using the closed-end

splice.

From the circuit board connect white wire to the back of terminal 1,

brown wire to the back of terminal 2, red wire to the front of terminal

3, and black wire to the front of terminal 4. Connect white/black

(input common) wires of CCW and CW to back of terminals 9 and 11

respectively.

3.3.1 PC Board - 120 VAC (Figure 3):

Connect purple wire of CCW input to back of terminal 10, and

blue wire of CW input to back of terminal 12.

Figure 3 Figure 4

Page 4

3.3.2 PC Board - 240 VAC (Figure 4):

For I-75, 240 VAC option only, the limit switches (SW-1, SW-2)

are used to interrupt CW, CCW input signals, therefore the wiring

will be different.

Connect purple wire of CCW input to back of terminal 10, and

blue wire of CW input to back of terminal 12.

If the installed switches SW-1, SW-2 are wired per standard

wiring, remove the brown, red, yellow, and black wires from the

limit switches and the internal side of terminal strip. Remove the

original #18 gauge gray and blue wires from capacitor to switches

(make a note of which wire is on which capacitor terminal) and

discard. Replace with new #18 gauge gray and blue wires from

Interface Kit and connect the gray wire to the capacitor and to

terminal 3 and the longer blue wire to the capacitor and to

terminal 4.

The two black wires (#20 gauge) from the Interface board

connect to the common and normally closed contacts of switch

no. 1 (lower right-hand switch), and the two red wires (#20

gauge) from the Interface board connect to the common and

normally closed contacts of switch no. 2 (lower left-hand switch).

Route the wires so they will not interfere with switch, or feedback

pot operation, if used.

Securely tighten terminal screws. Keep wiring away from all

rotating parts and secure with cable ties.

3.4 Wiring Different Options:

If Series 75 actuator is equipped with I-75 Interface and additional

option has to be added, wire the additional option per instructions

included in the option kit. If there are no available locations on

terminal strip for wiring option, relocate wires accordingly and always

mark the change on wiring diagram inside the cover. If the terminal

strip is full, the connections have to be hard-wired using splices.

4. Indication and Repair

(Use Figure 1 for component location.)

LED Indicators - Light emitting diodes marked LD1, LD2 are in input

circuits and indicate what particular input is on. Right LED, LD2,

indicates that CW, close, signal is on. Left LED, LD1, indicates that

CCW, open, signal is on.

If a malfunction occurs, look for the following:

If particular input is energized and corresponding LED light is not on,

check for component damage or other continuity disruption in

corresponding CCW and/or CW input circuit. If everything appears to

be OK, replace matching opto-coupler U2 or U1.

Input circuit is OK. LED is lighted and actuator is not running. If

components and continuity in corresponding power circuit are alright,

then failed component is triac Q2 or Q1 depending which way the

actuator doesn’t run, CCW or CW.

If the actuator doesn’t run in either direction, it is likely that the

actuator is defective. To check this, remove the red and black leads

from terminals 3 and 4 of the actuator (coming from Interface board)

and the AC line connections from terminals 1 and 2. Tape these leads.

Using a test cable, apply power to actuator terminals 1 and 3. The

120 VAC actuator only (see note below) should rotate CCW until

stopped by the CCW limit switch. Then apply power to terminals 1

and 4 to check CW 120 VAC actuator and the CW limit switch. If the

actuator does not operate, check 120 VAC associated wiring, terminal

strip, the limit switches, motor and capacitor. Check switch continuity.

Check for an open motor winding, and check for a shorted capacitor.

If the problem in the actuator still cannot be determined, return the

unit for service. If the actuator functions properly, the problem is in

the interface board.

NOTE: The limit switches for the 240 VAC I-75 actuator do not control

the motor circuit, they control input circuit only. When applying power

to terminals 1 & 3, and 1 & 4 to check CCW, CW rotations, do this

momentarily so that you do not override 0-90° quadrant.

Request RMA (Return Material Authorization) number from the

factory, replace defective board, and return it to the factory with

proper description of problem and application.

Flow Control

Worcester Actuation Systems

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, visitt www.flowserve.com or call USA 1 800 225 6989.

FLOWSERVE CORPORATION

Flow Control

Worcester Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone (434) 528-4400

Fax (434) 845-9736

www.flowserve.com

© 2004 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. FCD WCAIM2000-00 Printed in USA.

(Part 06094)

Loading...

Loading...