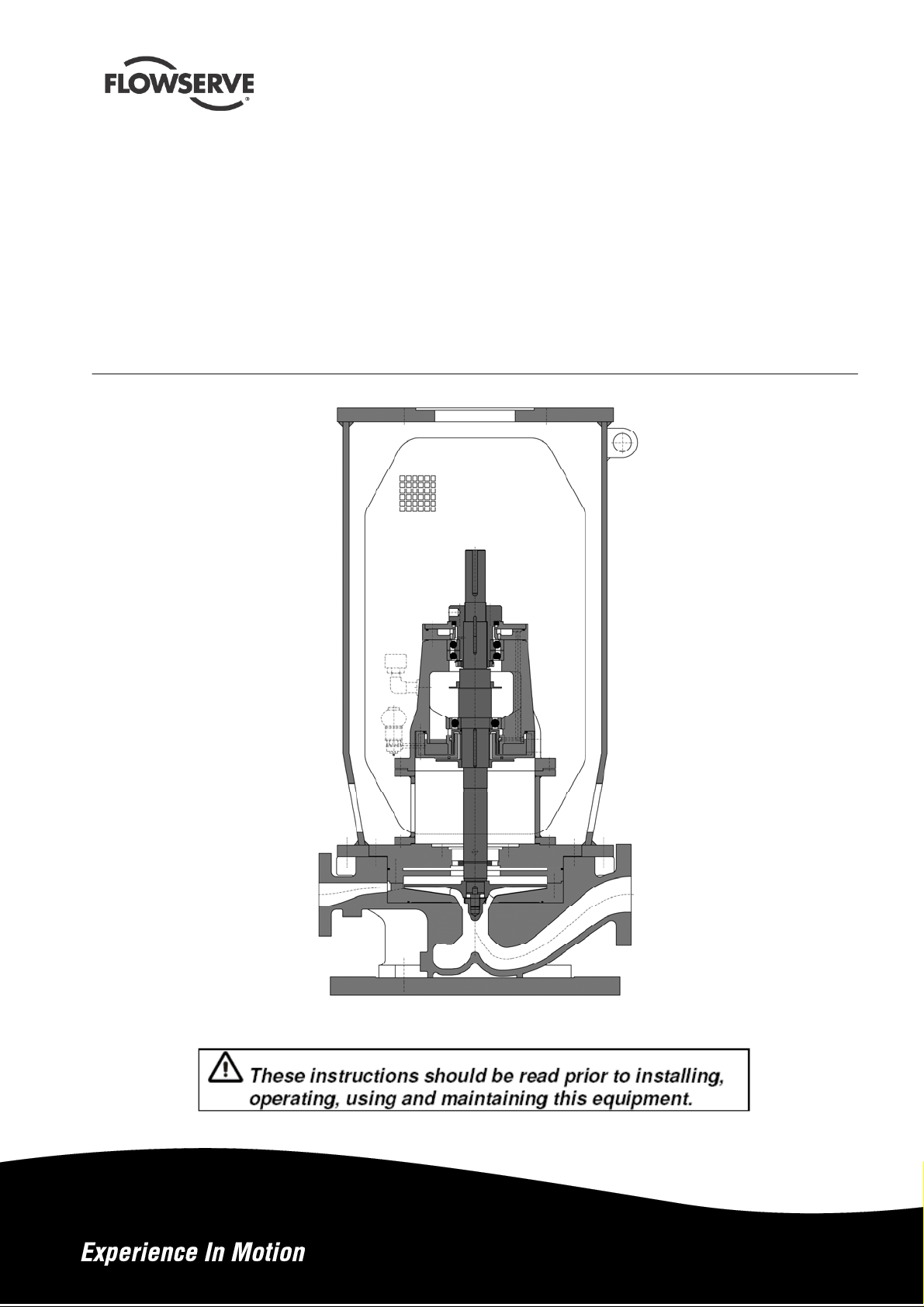

Page 1

USER INSTRUCTIONS

HWMA centrifugal pumps

ONE STAGE, VERTICAL-INLINE

Original Instructions

PCN= 26999922 11-10 (E)

Installation

Operation

Maintenance

Page 2

HWMA USER INSTRUCTIONS ENGLISH 11/10

Type: HWMA

Size: 2x3x12 HWMA

Serial No:

Customer:

Customer Order No.:

Equipment / Item No.:

Pumped Liquid:

Capacity: m3/h

Minimum Capacity: m3/h

Head: m

Speed: U/min-1

Page 3

HWMA USER INSTRUCTIONS ENGLISH 11/10

CONTENTS

PAGE

1.0 INTRODUCTION AND SAFETY............................4

1.1 GENERAL.................................................................4

1.2 CE MARKING AND APPROVALS................................4

1.3 DISCLAIMER.............................................................4

1.4 COPYRIGHT .............................................................4

1.5 DUTY CONDITIONS...................................................4

1.6 SAFETY....................................................................5

1.7 WARNING LABEL...................................................... 9

1.8 SPECIFIC MACHINE PERFORMANCE.......................10

1.9 NOISE LEVEL.......................................................... 10

1.10 CE DECLARATION............................................... 12

2.0 TRANSPORT AND STORAGE............................13

2.1 CONSIGNMENT RECEIPT AND UNPACKING............. 13

2.2 HANDLING..............................................................13

2.3 LIFTING ..................................................................13

2.4 STORAGE...............................................................13

2.5 RECYCLING AND END OF PRODUCT LIFE ............... 13

3.0 DESCRIPTION........................................................14

3.1 CONFIGURATION....................................................14

3.2 NOMENCLATURE.................................................... 14

3.3 DESIGN OF MAJOR PARTS ..................................... 14

3.4 PERFORMANCE AND OPERATING LIMITS ...............14

7.0 AUXILIARIES ......................................................... 27

8.0 FAULTS; CAUSES AND REMEDIES................ 29

9.0 CERTIFICATION.................................................... 31

10.0 OTHER RELEVANT DOCUMENTATION AND

MANUALS..................................................................... 31

6.9 ASSEMBLY............................................................. 27

7.1 SEAL AND SEAL SYSTEMS .....................................27

7.2 CHANGING OF MECHANICAL SEAL......................... 29

10.1 SUPPLEMENTARY USER INSTRUCTIONS.............. 31

10.2 CHANGE NOTES................................................... 31

10.3 ADDITIONAL SOURCES OF INFORMATION............ 31

10.4 ABBREVIATIONS .................................................. 32

4.0 INSTALLATION......................................................14

4.1 LOCATION ..............................................................14

4.2 PART ASSEMBLIES ................................................ 14

4.3 FOUNDATION .........................................................14

4.4 INITIAL ALIGNMENT ................................................15

4.5 PIPING....................................................................16

4.6 ELECTRICAL CONNECTIONS ..................................16

4.7 FINAL SHAFT ALIGNMENT CHECK...........................17

5.0 COMMISSIONING START-UP, OPERATION

AND SHUTDOWN........................................................ 17

5.1 PRECOMMISSIONING PROCEDURE ........................17

5.2 PUMP LUBRICANTS................................................17

5.3 IMPELLER CLEARANCE........................................... 21

5.4 DIRECTION OF ROTATION ...................................... 21

5.5 GUARDING.............................................................21

5.6 PRIMING AND AUXILIARY SUPPLIES ....................... 21

5.7 STARTING THE PUMP............................................. 21

5.8 OPERATION............................................................22

5.9 STOPPING AND SHUTDOWN ..................................22

5.10 HYDRAULIC, MECHANICAL AND ELECTRICAL DUTY

.....................................................................................22

6.0 MAINTENANCE.....................................................23

6.1 GENERAL............................................................... 23

6.2 MAINTENANCE SCHEDULE.....................................23

6.3 SPARE PARTS........................................................24

6.4 RECOMMENDED SPARES.......................................25

6.5 FASTENER TORQUES.............................................25

6.6 SETTING IMPELLER CLEARANCE............................26

6.7 DISASSEMBLY........................................................26

6.8 EXAMINATION OF PARTS........................................ 26

Page 3 of 34

Page 4

1.0 INTRODUCTION AND SAFETY

1.1 General

These Instructions must always be kept

close to product's operating location or directly

with the product.

Flowserve's products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great care

and commitment to continuous quality control,

utilising sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not take

into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws/regulations.

HWMA USER INSTRUCTIONS ENGLISH 11/10

1.3 Disclaimer

Information in these User Instructions is believed

to be reliable. In spite of all the efforts of

Flowserve Corporation to provide sound and all

necessary information the content of this manual

may appear insufficient and is not guaranteed by

Flowserve as to its completeness or accuracy.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organisations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use. As

Flowserve cannot test parts and accessories sourced

from other vendors the incorrect incorporation of such

parts and accessories may adversely affect the

performance and safety features of the products. The

failure to properly select, install or use authorised

Flowserve parts and accessories is considered to be

misuse. Damage or failure caused by misuse is not

covered by Flowserve's warranty. In addition, any

modification of Flowserve products or removal of

original components may impair the safety of these

products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

These instructions should be read

prior to installing, operating, using and

maintaining the equipment in any region

worldwide. The equipment must not be put into

service until all the conditions relating to safety

noted in the instructions have been met.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic

Compatibility (EMC), Pressure Equipment Directive

(PED) and Equipment for Potentially Explosive

Atmospheres (ATEX).

Where applicable the Directives, and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory

provision of technical documents and safety

instructions. Where applicable this document

incorporates information relevant to these Directives.

To establish Approvals and if the product itself is CE

Marked check the serial number plate and the

Certification.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

If the conditions of service on your purchase order

are going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user

seeks Flowserve´s written agreement before start up.

Page 4 of 34

Page 5

1.6 Safety

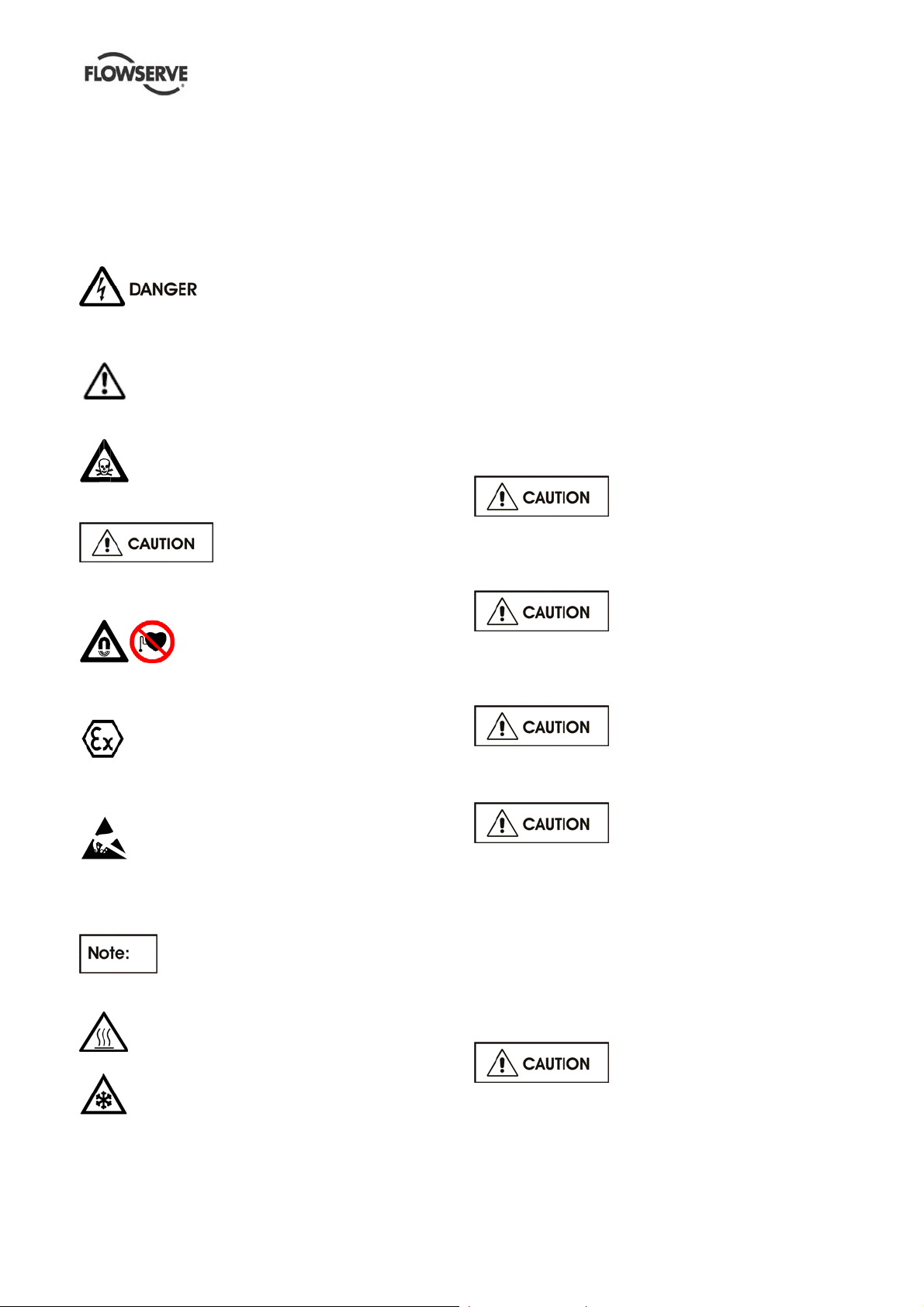

1.6.1 Summary of safety markings

These user instructions contain specific safety

markings where non-observance of an instruction

would cause hazards. The specific safety markin gs

are:

This symbol indicates electrical safety instructions

where non-compliance will involve a high risk to

personal safety or the loss of life.

This symbol indicates safety instructions

where non-compliance would affect personal safety

and could result in loss of life.

This symbol indicates "hazardous and toxic

fluid" safety instructions where non-compliance would

affect personal safety and could result in loss of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates "strong magnetic

field" safety instructions where non-compliance would

affect personal safety, pacemakers, instruments or

stored data sensitive to magnetic fields.

HWMA USER INSTRUCTIONS ENGLISH 11/10

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer / supplier

to provide applicable training.

Always co-ordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws/regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

PREVENT EXCESSIVE

EXTERNAL PIPE LOAD

Do not use pump as a support for piping. Do not

mount expansion joints so that their force, due to

internal pressure, acts on the pump flange.

ONLY CHECK DIRECTION OF

MOTOR ROTATION WITH COUPLING ELEMENT/

PINS REMOVED

Starting in reverse direction of rotation will damage

the pump.

This symbol indicates explosive atmosphere

marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

The sign is not a safety symbol but

indicates an important instruction in the assembly

process.

This symbol indicates potential risks

connected with extremely high temperatures.

This symbol indicates potential risks

connected with extremely low temperatures.

ENSURE CORRECT

LUBRICATION

(See section 5 Commissioning, startup, operation and

shutdown.)

START THE PUMP WITH

OUTLET VALVE PART OPENED

(Unless otherwise instructed at a specific point in the

user instructions.)

This is recommended to avoid the risk of overloading

and damaging the pump motor at full or zero flow.

Pumps may be started with the valve further open

only on installations where this situation cannot

occur. Pump outlet valve shall be adjusted to comply

with the duty following the run-up process (See

section 5 Commissioning, startup, operation and

shutdown).

START THE PUMP WITH

OUTLET VALVE FULLY OPEN

This is recommended to avoid the risk of overloading

and damaging the pump motor where greater power

is taken at low or shut off flow. Pump outlet valve

shall be adjusted to comply with the duty following the

Page 5 of 34

Page 6

HWMA USER INSTRUCTIONS ENGLISH 11/10

run-up process (See section 5 Commissioning,

startup, operation and shutdown).

NEVER RUN THE PUMP DRY

INLET VALVES TO BE FULLY

OPEN WHEN PUMP IS RUNNING

Running the pump at zero flow or below the

recommended minimum flow continuously will cause

damage to the seal.

DO NOT RUN THE PUMP AT

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher than normal or at a

flow rate with no back pressure on the pump may

overload the motor and cause cavitation. Low flow

rates may cause a reduction in

overheating of the pump, instability and

cavitation/vibration.

When ambient temperatures are

likely to drop below freezing point, the pump and any

cooling and flushing arrangements must be drai ned

or otherwise protected.

pump/bearing life,

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lbs) use a crane

corresponding to the mass and in accordance with

current local regulations.

NEVER DO MAINTENANCE WORK WHILST THE

UNIT IS CONNECTED TO POWER

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate sitting of the pump, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive strict safety procedures

must be applied.

Gland Packing must not be used when pumping

hazardous liquids.

condition these are extremely dangerous and skin

contact must be avoided.

GUARDS MUST NOT BE REMOVED WHILE

PUMP IS OPERATIONAL

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should b e

avoided.

NEVER APPL Y HEAT TO REMOVE

IMPELLER

Trapped lubricant or vapour could cause an

explosion.

HOT AND COLD PAR TS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators, they

must

be shielded to avoid accidental contact. If

complete protection is not possible, the machine

access must be limited to maintenance staff only.

Note: bearing housings must not be insulated and

drive motors and bearings may be hot.

If the temperature is greater than 68 °C (155 °F) or

below 5 °C (41 °F) in a restricted zone, or exceeds

local regulations, action as above shall be taken.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent build up of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

Both electrical and non-electrical equipment must

meet the requirements of European Directive

94/9/EC.

1.6.4.1 Scope of compliance

DRAIN PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted)

When a pump has experienced temperatures over

250 °C (482 ºF), partial decomposition of fluoroelastomers (example: Viton) will occur . In this

Page 6 of 34

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of

the specific atmosphere in which they are to be

installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The

Page 7

HWMA USER INSTRUCTIONS ENGLISH 11/10

party responsible for assembling the pump set shall

select the coupling, driver and any additional

equipment, with the necessary CE Certificate/

Declaration of Conformity establishing it is suitable for

the area in which it is to be installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so,

for pump sets with a VFD, the ATEX Certification for

the motor must state that it covers the situation where

electrical supply is from the VFD. This is particular

requirement still applies even if the VFD is in a safe

area.

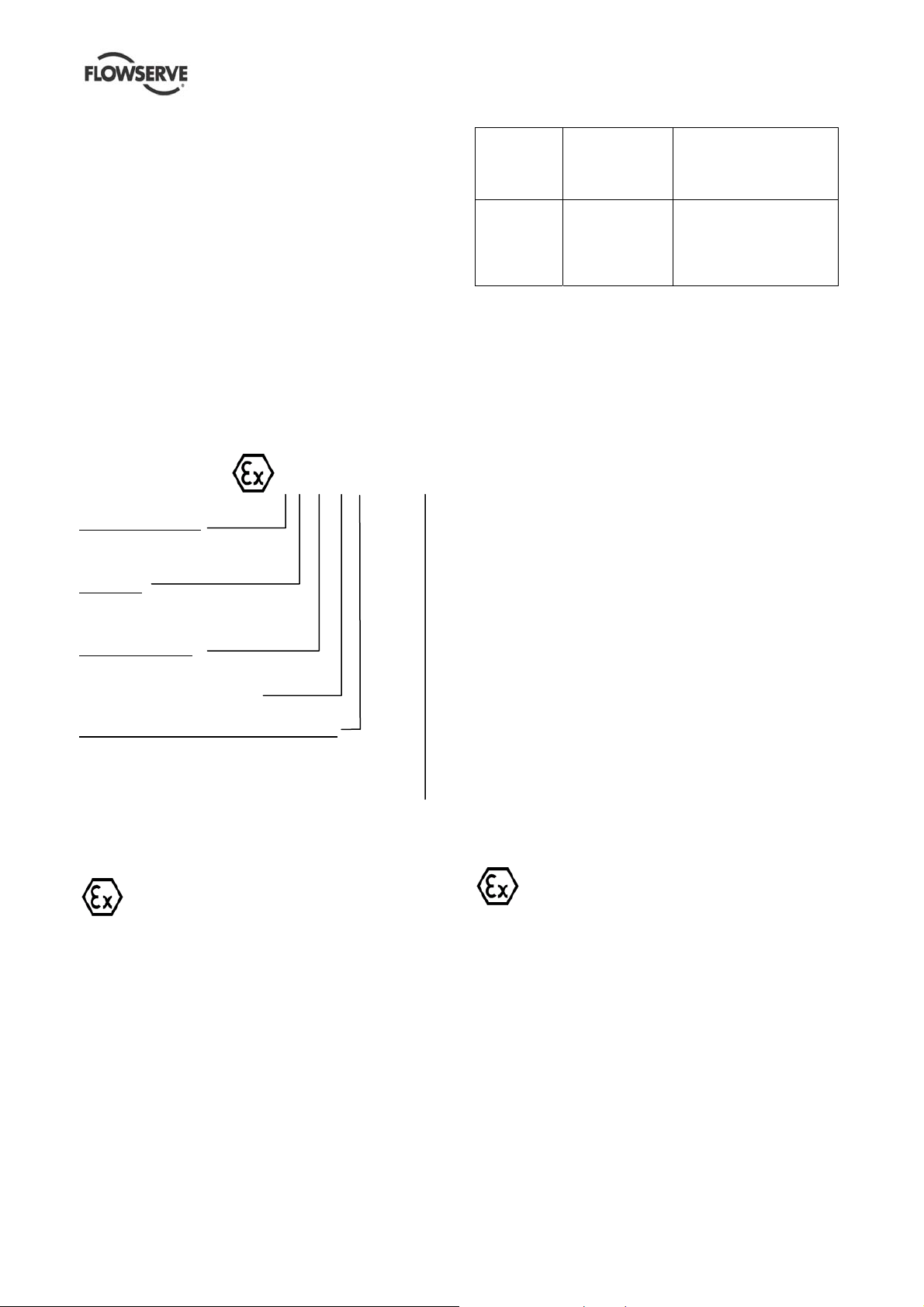

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC135ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = High level protection

3 = normal level of protection

Gas and/or Dust

G = Gas; D= Dust

c = Constructional safety

(in accordance with En13463-5)

Gas Group (Equipment Category 2 only)

IIA – Propane (Typical)

IIB – Ethylene (Typical)

IIC – Hydrogen (T y pical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3)

1.6.4.3 Avoiding excessive surface temperatures

Temperature

class to

EN 13463-1

T6

T5

T4

T3

T2

T1

Maximum

surface

temperature

permitted

85 °C (185 °F)

100 °C(212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperature limit of liquid

handled (* depending on

material and construction

variant - check which is

lower)

Consult Flowserve

Consult Flowserve

110 °C (230 °F) *

175 °C (347 °F) *

270 °C (518 °F) *

350 °C (662 °F) *

The responsibility for compliance with the

specified maximum liquid temperature is with the

plant operator.

Temperature classification “Tx” is used when the

liquid temperature varies and when the pump is

required to be used in differently classified potentially

explosive atmospheres. In this case the user is

responsible for ensuring that the pump surface

temperature does not exceed that permitted in its

actual installed location.

Do not attempt to check the direction of rotation with

the coupling element/pins fitted due to the risk of

severe contact between rotating and stationary

components.

Where there is any risk of the pump being run against

a closed valve generating high liquid and casing

external surface temperatures it is recommended that

users fit an external surface temperature protection

device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips or a Power Monitor and

make routine vibration monitoring.

In dirty or dusty environments, regular checks must

be made and dirt removed from areas around close

clearances, bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximum ambient of 40 °C (104 °F); refer to

Flowserve for higher ambient temperatures.

The surface temperature on the pump is influenced

by the temperature of the liquid handled. The

maximum permissible liquid temperature depends on

the temperature class and must not exceed the

values in the table that follows. The temperature rise

at the seals and bearings and due to the minimum

permitted flow rate is taken into account in the

temperatures stated.

Page 7 of 34

ENSURE THE PUMP IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heating and cooling systems are

properly filled.

If the operation of the system cannot avoid this

condition the fitting of an appropriate Dry Run

protection device is recommended (eg liquid

detection or a Power Monitor).

Page 8

HWMA USER INSTRUCTIONS ENGLISH 11/10

To avoid potential hazards from fugitive emissions of

vapour or gas to atmosphere the surrounding area

must be well ventilated.

1.6.4.5 Preventing sparks

To prevent a potential hazard from mechanical

contact the coupling guard must be non-sparking and

anti-static.

To avoid the potential hazard from random induced

current generating a spark the earth contact on the

baseplate must be used.

Avoid electrostatic charge: do not rub nonmetallic surfaces with a dry cloth; ensure cloth is

damp.

The coupling must be selected to comply with

94/9/EC and correct alignment must be maintained.

1.6.4.5 Preventing leakage

The pump must only be used to handle liquids

for which it has been approved to have the correct

corrosion resistance.

Avoid entrapment of liquid in the pump and

associated piping due to closing of suction and

discharge valves, which could cause dangerous

excessive pressures to occur if there is heat input to

the liquid. This can occur if the pump is stationary or

running.

Bursting of liquid containing parts due to freezing

must be avoided by draining or protecting the pump

and ancillary systems.

Where there is the potential hazard of a loss of a seal

barrier fluid or external flush, the fluid must be

monitored.

If leakage of liquid to atmosphere can result in a

hazard, the installation of a liquid detection device is

recommended.

1.6.4.6 Maintenance to the centrifugal pump to

avoid the hazard

CORRECT MAINTENANCE IS REQUIRED

TO AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with

maintenance instructions is with the plant

operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions. Where there

is a risk from such tools or materials, maintenance

must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted (see section 6, Maintenance).to

include the following.

a) Any auxiliary systems installed must be

monitored, if necessary, to ensure they function

correctly.

b) Gland packings must be adjusted correctly to

give visible leakage and concentric alignment of

the gland follower to prevent excessive

temperature of the packing or follower.

c) Check for any leaks from gaskets and seals. The

correct functioning of the shaft seal must be

checked regularly

d) Check bearing lubricant level, and if the hours run

show a lubricant change is required.

e) Check that the duty condition is in the safe

operating range for the pump.

f) Check vibration, noise level and surface

temperature at the bearings to confirm

satisfactory operation.

g) Check dirt and dust is removed from areas

around close clearances, bearing housings and

motors.

h) Check coupling alignment and re-align if

necessary.

Page 8 of 34

Page 9

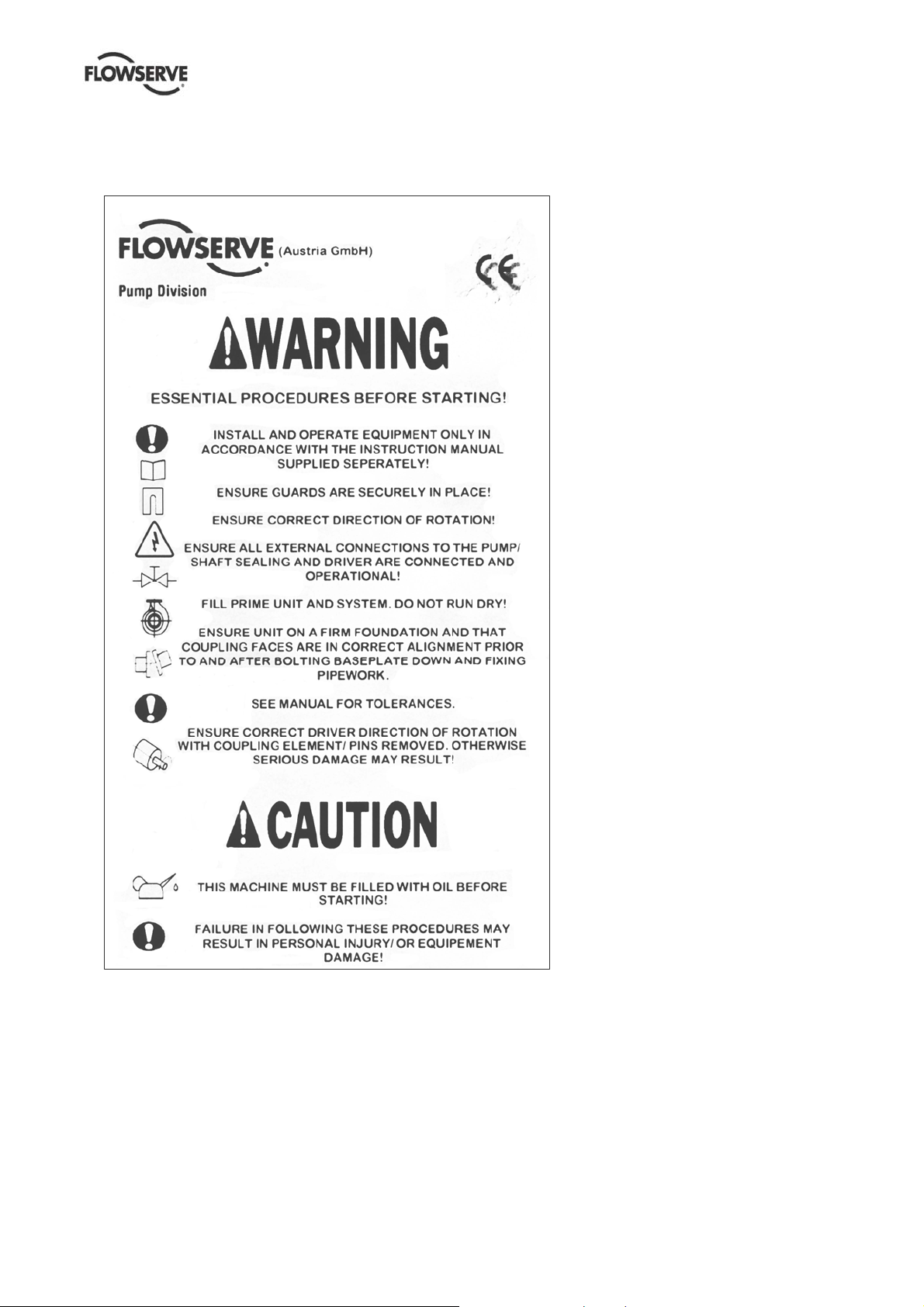

1.7 Warning label

HWMA USER INSTRUCTIONS ENGLISH 11/10

Page 9 of 34

Page 10

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. When the Contract requirement specifies

these to be incorporated into user instructions these

are included here. Where performance data has been

supplied separately to the purchaser these should be

obtained and retained with these user instructions if

required.

1.9 Noise level

Attention must be given to the exposure of

personnel to the noise, and local legislation will

define when guidance to personnel on noise

limitation is required, and when noise exposure

reduction is mandatory. This is typically 80 to 85

dBA.

The usual approach is to control the exposure

time to the noise or to enclose the machine to

reduce emitted sound. You may have already

specified a limiting noise level when the

equipment was ordered, however if no noise

requirements were defined, then attention is

drawn to the following table to give an indication

of equipment noise level so that you can take

the appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipework design

and acoustic characteristics of the building, and

so the values given are subject to a 3 dBA

tolerance and cannot be guaranteed.

Similarly the motor noise assumed in the “pump

and motor” noise is that typically expected from

standard and high efficiency motors when on

load directly driving the pump. Note that a motor

driven by an inverter may show an increased

noise at some speeds.

If a pump unit only has been purchased for fitting

with your own driver then the “pump only” noise

levels in the table should be combined with the

level for the driver obtained from the supplier.

Consult Flowserve or a noise specialist if

assistance is required in combining the values.

It is recommended that where exposure

approaches the prescribed limit, then site noise

measurements should be made.

The values are in sound pressure level L

m (3.3 ft) from the machine, for “free field

conditions over a reflecting plane”.

For estimating sound power level L

WA

then add 14 dBA to the sound pressure value.

at 1

pA

(re 1 pW)

HWMA USER INSTRUCTIONS ENGLISH 11/10

Page 10 of 34

Page 11

HWMA USER INSTRUCTIONS ENGLISH 11/10

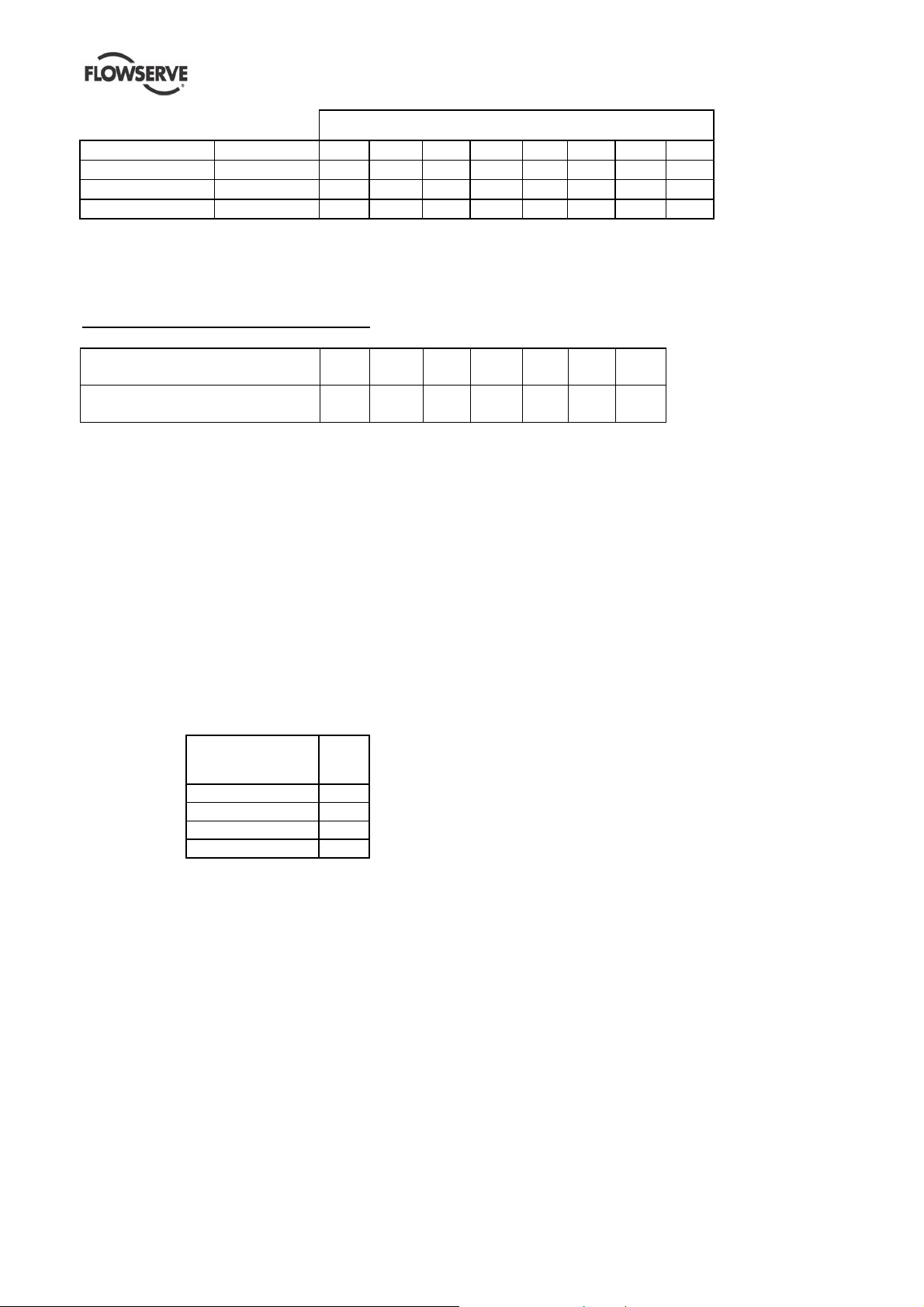

Octave MID BAND frequency [Hz]

3000 rpm

1500 rpm

3600 rpm

1800 rpm

Sound pressure readings are for information only and are not subject to guarantee by Flowserve/IDP.

Decibel readings do not include driver or system noise.

Pump tested at 100% of the best efficiency point at max.impeller diameter with water.

dB correction for combining noises (pump+motor)

72 62 66 66 64 64 64 62 57

66 56 60 60 58 58 58 56 51

74 64 68 68 66 66 66 64 59

67 57 61 61 59 59 59 57 52

Difference between two

levels to be combined, dB

Add to the higher level to obtain

the combined noise level,dB

Note :

1) The values showed are measured at a distance of 1 mt. (horizontally) from major pump

surfaces and 1.5 mt. above the floor.

2) The values shown are expressed in dB (A)

3) For Noise Test Procedure refer to Works Standard L-109

4) The values shown have been derived from actual noise-test data and are based on the following conditions:

- Equipment is located in a free field above a reflecting plane in which the reductionin noise level

in all directions is 6db in each octave band for each doubling of distance.

- Background noise is 10dB minimum below all noise levels in each octave band.

- The values shown are at a distance of 1 meter (horizontally) from the major pump surface and

1,5 meters above the floor, using a standard pressure reference of 0,00002 newton per square meter.

- Overall noise level, dB(A) is determined at points of maximum noise level and the values of all

mid-band frequences are basis A scale readings.

When the required condition flow is outside the range of 75 to 125% BEP, a part load correction (PLC) must be

added to the noise level as follows:

Percent of BEP @

required impeller

diameter

74 to 62 or 126 to 136 +1

61 to 50 or 137 to 150 +2

49 to 38 +3

37 to 25 +4

01246910

10.5 03 2.5 2 1.5

PLC in

dB

Page 11 of 34

Page 12

1.10 CE Declaration

HWMA USER INSTRUCTIONS ENGLISH 11/10

Page 12 of 34

Page 13

2.0 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/ shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and or damage must

be reported immediately to Flowserve and received in

writing within one month of receipt of the equipment.

Latter claims cannot be accepted.

Check any create/boxes/wrappings for any

accessories or spare parts, which may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check that

this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their

size and construction.

2.3 Lifting

Four lifting lugs are provided on the baseplate to lift

the complete unit.

Take care by applying slings or ropes about

auxiliary piping and seal systems.

HWMA USER INSTRUCTIONS ENGLISH 11/10

A crane must be used for all pump sets in

excess of 25kg (55lb). Fully trained personnel must

carry out lifting, in accordance with local regulations.

The driver and pump weights are recorded on their

respective nameplates.

2.4 Storage

If the unit will not be put immediately into service, it

should be stored in a dry room. To avoid any damage

during the storage period, the influence of any low or

high frequency vibration must be totally inhibited. If

the pump is delivered sealed in a plastic-wrapper, it is

of max. importance to avoid any damage of that

wrapper, because this will protect the pump against

humidity. Therefore it must be checked if this wrapper

has become cracked and if so, the wrapper must be

renewed.

2.4.1 Long period storage

If the pump is delivered in a plastic bag, the

preservations stands up for one year. If the storage

period exceeds this time, the preservation must be

checked and renewed. Also the air tight plastic bag

must be changed. Moreover we recommend to order

a Flowserve Service Engineer for checking the pump

before the first start up.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

Page 13 of 34

Page 14

HWMA USER INSTRUCTIONS ENGLISH 11/10

acceptable method and local regulations. If the

product contains substances, which are harmful to

the environment, these should be removed and

disposed of in accordance with current regulations.

This also includes the liquids and or gases in the

"seal system" or other utilities.

Make sure that hazardous substances are

disposed of safety and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3.0 DESCRIPTION

3.1 Configuration

The model HWMA belongs to Flowserves family of

API 610 vertical inline pumps.

The hydraulics are designed for operating flexibility

and consist of:

• a semi open radial vaned impeller to guarantee

optimum performance

• a circular volute with a single caned diffuser to

minimize hydraulic forces

The pump unit is available in two stage opposed

impeller configuration. For low NPSHA applications

an inducer is available.

The sense of rotation of the pump is counter

clockwise (CCW), looking from the coupling to the

shaft end of the pump.

3.2 Nomenclature

Example:

2x3x12HWMA - Ind.

2 Discharge flange in inch

3 Suction flange in inch

12 max. impeller size in inch

Ind indicates Inducer as option

3.3 Design of major parts

3.3.1 Pump casing

The pump casing is directly flanged to the motor

stand, which itself is flanged to the motor. Back pull

out design for easy maintenance, so the casing

remains on its foundation in case of repair.

3.3.2 Hydraulics

A circular volute in combination with a single caned

diffuser is inserted into the pump casing. A radial

vaned semi open impeller is used to ensure optimal

performance.

3.4 Performance and operating limits

In the interest of operator safety

the unit must not be operated above the nameplate

conditions. Such operation could result in unit failure

causing injury to operating personnel. Consult

instruction book for correct operation and

maintenance of the pump and its supporting

components.

4.0 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations, see section 1.6.4, Products used in

potentially explosive atmospheres.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Refer to the general arrangement drawing for the

pump set.

4.2 Part Assemblies

The pumps are delivered completely mounted and

prealigned with the motor. Also the shaft seal is in the

correct position. Final alignment after complete

installation is necessary. If drivers and/or seal systems

are delivered separately, follow the assembly

procedure in section 6.8.

4.3 Foundation

The foundation shall be located on a place that allows

a minimum of pipe work and that is easily accessible

for inspection during operation. According to the

environment the foundation may consist of concrete

or of steel. It must be rigid and heavy enough to

absorb normal vibrations and shocks.

4.3.1 Horizontal alignmen t of the bas eplate

Horizontal alignment is done with levelling screws.

Use a spirit level for correct horizontal alignment of

the baseplate.

baseplate length.

Page 14 of 34

The max. misalignment is 0.5 mm/m

Page 15

HWMA USER INSTRUCTIONS ENGLISH 11/10

4.3.2 Steel foundation

When the pump unit is mounted directly on structural

steel frame, it shall be well supported by constructural

beams. It is recommended to check the natural

frequency of the steel frame, because it shall not

coincide with the pump speed. The exact horizontal

alignment is very important!

4.3.3 Concrete foundation

A concrete foundation must have an exact horizontal

alignment and must be placed on solid ground. First a

basic foundation shall be built with square shaped

holes for embedding the foundation bolts. After

putting the base plate into the foundation the proper

alignment can be obtained by adjusting it with shims

under the base plate. Now insert the foundation bolts

and grout the space between the basic foundation

and the base plate with grouting cement (refer to

illustration)

It is very helpful to use a properly made and stable

wooden frame around the base plate. So the grouting

cement will not flow side. When the grouting is totally

set and hardened the foundation bolts shall be

tightened in a firm and symmetrical way.

Align the motor to the pump, not the pump to the

motor. Alignment of the motor is achieved by using

the adjustment screws.

4.4.1 Permissible misalignment limits at working

temperature

When checking parallel alignment, the total indicator

read-out (TIR) shown is twice the value of the actual

shaft displacement.

The pump is only pre-aligned! Carefully check

and readjust alignment before start of the unit.

Take out the spacer of the coupling and check the

alignment of shafts end of pump and driver. The

maximum parallel offset should not exceed 0.05 mm

(0.002 in.)and the axially offset can be ± 1 mm (0.04

in.).

For more details refer to the manufacturer’s

instruction manual of coupling.

a)

4.4 Initial alignment

The adjustment of motor and pump must be checked

(if necessary, make a new adjustment) before first

start up of the unit.

b)

a) Parallel Offset: The median lines run parallel. The

maximum allowable parallel offset depends on

the size of coupling and is indicated in the

instruction manual of manufacturer of coupling

b) Axially Offset: Another offset is the displacement

of one or both of the shafts. A typical example is

thermal expansion.

The DBSE (distance between shaft ends)

is shown on the General Arrangement Drawing and is

larger than the length of the coupling spacer. This is

necessary to compensate all manufacturing

tolerances of line shafts and column pipes and to

allow correct axial adjustment of the rotor (refer to

5.3.1 Adjusting of the rotor).

For installation of the coupling spacer the coupling

hub on the pump shaft must be axially moved to

match the spacer. This results in an axial clearance

"x" between coupling hub and shaft end, which is

taken into account by the coupling selection.

Ensure pump and driver are isolated electrically and

the half couplings are disconnected.

Page 15 of 34

Page 16

HWMA USER INSTRUCTIONS ENGLISH 11/10

pressure and hence reverse rotation when the unit is

stopped.

Piping and fittings shall be flushed before use. To

avoid damages of the pump install a Y-strainer or a

strainer of 40 mesh.

Piping for corrosive liquids shall be arranged to allow

pump flushing before removal of a unit.

How the alignment of the coupling should be done

you can see on the sketches and explanations below!

a) b)

a) Fix the dial gauge on the driven shaft and check

the concentricity by turning of both hubs; correct it if

necessary.

b) Fix the dial gauge on the driving shaft and check

the concentricity by turning of both hubs; correct it if

necessary.

If the pump is handling hot liquid, the alignment must

be rechecked in warm condition of the unit.

The alignment of the unit shall be checked again after

200 service hours.

4.5 Piping

4.5.2 Drain

This connection is used for total drainage of the pump

casing. A flanged drain is standard and can be

optionally equipped with various kinds of valves.

Refer to GA drawing for details of the drain

connection.

By pumping toxic or explosive

media, provide the necessary security actions, e.g.

flushing with nitrogen.

4.6 Electrical connections

Electrical connections must be made by a qualified

Electrician in accordance with the relevant local

national and international regulations.

It is important to be aware of the EUROPEAN

DIRECTIVE on hazardous areas where compliance

with IEC60079-14 is an additional requirement for

making electrical connections.

4.5.1 General

Protective covers are fitted to the pipe connections to

prevent foreign particles entering during

transportation and installation. Ensure that these

covers are removed from the pump before connecting

any pipes.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. To

minimize these forces and moments which may

cause misalignment, hot bearings, worn couplings,

vibration and a possible failure of the pump, the

following points shall be strictly followed:

a) Prevent excessive external pipe load.

b) Do not connect piping by applying external force

(use of wrenches, crane,...). Piping shall be

aligned without residual stress.

c) Do not mount expansion joints so that their force,

due to internal pressure, acts on the pump flange.

Fitting an isolator and non-return valves can allow

easier maintenance. Never throttle pump on suction

side and never place a valve directly on the pump

inlet nozzle.

A non-return valve shall be located in the discharge

pipework to protect the pump from excessive back

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used

during wiring/installation do not increase

electromagnetic emissions or decrease the

electromagnetic immunity of the equipment, wiring or

any connected devices. If in any doubt contact

Flowserve for advice.

The motor must be wired up in accordance with the

motor manufacturer's instructions (normally supplied

within the terminal box) including any temperature,

earth leakage, current and other protective devices

as appropriate. The identification nameplate should

be checked to ensure the power supply is

appropriate.

A device to provide emergency stopping must

be fitted.

If not supplied pre-wired to the pump unit the

controller/starter electrical details will also be supplied

within the controller/starter.

Page 16 of 34

Page 17

HWMA USER INSTRUCTIONS ENGLISH 11/10

For electrical details on pump sets with controllers

see the separate wiring diagram.

See section 5.5, Direction of

rotation before connecting the motor to the electrical

supply.

4.7 Final shaft alignment check

After connecting piping to the pump, rotate the shaft

several times by hand to ensure there is no seizure

and all parts are free.

Recheck the coupling alignment, as previously

described, to ensure no pipe strain. If pipe strain

exists, correct piping.

5.0 COMMISSIONING START-UP,

OPERATION AND SHUTDOWN

These operations must be

carried out by fully qualified personnel.

5.1 Precommissioning procedure

a) The bearing housing must be filled with the

indicated oil. Check also the oil level.

b) The pump must be completely filled with liquid to

avoid running dry and to guarantee a correct

performance of the pump.

c) During filling the pump shall reach the speci fied

temperature, so pumps for hot liquids (T > 100 °C

(212 °F)) shall be warmed up by preflushing.

d) Check the sense of rotation of the pump (Coupling

spacer dismantled).

Sense of rotation is counter clockwise viewed to

the drive end of the pump.

e) The pump rotor and the shaft seal must be in

correct axial position. Mounting plates of

mechanical seal must be locked at the seal gland

in open position. Drive-collar of the mechanical

seal sleeve must be tightened.

f) Check the readiness of all auxiliary systems (seal

sys., lubrication sys.,...) for start up.

g) All pipe work, including the internal and the

auxiliary pipe work, must be connected correctly

and must be absolutely tight. Check the tightness

of all connections of the auxiliary pipe work. The

suction valve must be open, the discharge valve

shall be closed.

h) Turn the pump by hand, if required with the help of

a lever, to check the free rotation of the rotor. The

rotor must turn uniformly and noiselessly. Some

resistance may be felt due to friction in bearings

and seals.

i) Check the readiness of the driver for start up. Refer

to the manual of the driver (preheating for

explosion proof E-motor).

5.2 Pump Lubricants

5.2.1 Oil Lubricated Ball Bearings

The leveling rod of the oiler (see figure) must be

adjusted when the oiler is installed and the bearing

housing is filled with oil for the first time, and the rod

should be checked for proper adjustment each time

the reservoir of the oiler is replenished. To install the

oiler and to establish the correct oil level which the

oiler will automatically maintain, proceed as follows:

1) Loosen thumb screw, and remove reservoir.

Place the adjusting nut so that the edge of the

reservoir will rest 0.35 to 0.39 in. (9 to 10 mm)

above the centerline of the side port. This should

result in the lock nut and adjusting nut being 0.08”

(2) mm above the bottom of the leveling rod.

2) Install short piece of ¼ in. pipe in threaded

connection on side of inner bearing housing

cover. Mount oiler body on free end of ¼ in. pipe,

leaving it upright and level.

Use high grade turbine type mineral oil

(ISO GRADE 68) which has qualities for inhibiting

rust, oxidation and foam; has no free acid, chlorine or

sulfur; and has no more than a trace of free alkali.

3) Remove the oil breather and watch the oil

sightglass on side of the inner bearing housing

cover. Slowly fill housing with the specified

lubricating oil (see Note above) until the oil level

rises to the middle of the sightglass on side of the

inner bearing housing cover. Approximately

amount of oil is 40 oz. (1,2 l).

Do not overfill bearing housing

4) Fill the oiler reservoir with lubricating oil so that it

is 100 percent full, install it on oiler body, and

tighten thumb screws.

5) Oiler reservoir should not empty completely. It

should maintain oil level set up by overfill hole.

Page 17 of 34

Page 18

HWMA USER INSTRUCTIONS ENGLISH 11/10

5.2.2 Purge oil mist l ubric atio n

For preventing, that dirt or humidity get into the bearing

housing, this pump is equipped with a ¼“ NPT

connection for air or nitrogen supply.

Also at standstill the air or nitrogen supply shall be

maintained.

The pressure shall be between

0.01 bar (0.14 psi) and 0.02 bar (0.29 psi), otherwise

you have to consider an oil leakage and as a result a

bearing damage.

The provided flow rate shall be 0,1 SCFM.

The supplied air or nitrogen shall be clean and dry.

5.2.3 Adjusting of DENCO Constant Level Oiler

If the pump is fitted with a Constant Level Oiler type

„DENCO“, the correct oil level has to be checked after

fitting the pump! Dimension a is the distance from the

centerline of the pump to the minimum oil level (marks

at the bearing housing).

5.2.4 Oil change

After first start up, the oil shall be changed after 200

service hours.

Every further oil change shall take place after about

2000 service hours or at least every 6 month.

To change the oil use the following procedure:

a) Remove the reservoir (for some type of oilers you

must loose a fixing screw or lock nut, refer to

section 5.2.4 Oil level).

b) Open the oil drain on the bearing housing to

remove the oil.

c) Close the oil drain and fill in Oil through the oiler

until the oil level reaches the bottom of the sight

glass.

d) Fill the reservoir and put it quickly to the body of the

oiler. Observe the lev el in the r eserv oir. It will

decrease until the required oil level is reached

(middle of the sight glass). Ensure that enough oil

remains in the reservoir.

e) If necessary, the oil level can be adjusted by

referring to section 5.2.4 Oil level.

5.2.5 Oil level

The correct oil level is in the middle of the oi l sight gla ss

and shall be checked when pump is not in operation.

Periodically check if the lubricating oil is mixed with any

condensed water. Careful opening of the oil drain

during a stop of the pump will show any water.

1 Denco Oiler 2 lock nut 3 adjusting sleeve;

4 oil sight glass; 5 oil drain; 6 counternut;

a) The oiler body is mounted so that the required oil

level is approximately level with the centre line of

the side port of the body. The oil level may be

„fine tuned“ by turning the adjusting sleeve (3)

and finally locked into position by tightening the

lock nut (2). To replenish, the reservoir and

adaptor (1) may be removed by sliding it out of

the body, removing the adaptor and fill the

reservoir. Fully reinserting the adaptor / reservoir

into the body ensures the previously adjusted oil

level is maintained. The oiler is equipped with an

overflow tube to avoid a rise of the oil level. This

is necessary to maintain a constant level in an oil

bath lubrication system, where an oil mist is used

as primary lubrication.

b) Additionally you can check the correct oiler

adjustment by an oil sight glass (minimum oil

level is the middle of the oil sight glass).

Use a spirit level to check the horizontal

alignment of the bearing housing.

A too high oil level will result in higher bearing

temperatures and therefore poorer lubrication.

5.2.6 Oil quality

Oil used for lubrication should only be of high quality.

The viscosity of the oil at working temperature must

be at least 10 cSt. The pouring point of the oil must

be in accordance with the lowest expected

temperature of the bearing housing during a stop of

the pump. For recommended lubricating oils refer to

the lubrication table.

Having selected the corresponding oil quality the

actual oil temperature at the bearing housing must be

checked after two service hours of the pump.

Considering this measured oil temperature the actual

viscosity must be determined by using the data sheet

of the oil, to verify the minimum required viscosity of

10 cSt. Do not forget, the oil temperature in the

bearing itself is about 10 °C (50 °F) higher than the oil

temperature at the bearing housing. On the following

table the oil viscosity is given at 40 °C (104 °F).

Determining the correct lubricating oil one must take

into consideration that all bearings will have higher

temperatures during the first 20 service hours. In

constant operation the bearing temperature will

decrease about 10 °C (50 °F). The oil temperature

shall be lower than 85 °C (185 °F) after this running-

Page 18 of 34

Page 19

in time. The bearing outer race temperature should

not exceed 95°C (204°F). If the temperature is higher,

the reason may be a wrong oil quality, wrong oil level

or overload of the pump because of excessive wear.

If the humidity at the site is high, the roller bearings

become easily rusty during stand still periods. To

avoid that, we recommend to mix the lubricating oil

with a corrosion inhibitor contact your lubrication oil

supplier for proper additives inhibitors.

HWMA USER INSTRUCTIONS ENGLISH 11/10

Page 19 of 34

Page 20

5.2.7 Lubrication Table

HWMA USER INSTRUCTIONS ENGLISH 11/10

Oil lubrication / Recommendation

Bearing temp.

Ambient temp.

Mobil

BP

+40 °C - +70 °C

(+104 °F - +158 °F)

-5 °C - +40 °C

(-23 °F - +104 °F)

MOBIL SHC 624(synthetic)

MOBIL DTE 24

Energol HLP-HM 32

Energol HLP-HM 46

32,4

31

32

46

1

1

1

1

+70 °C - +100 °C

(+158 °F - +212 °F)

-5 °C - +40 °C

(-23 °F - +104 °F)

+100 °C - +120 °C

(+212 °F - +248 °F)

-5 °C - +40 °C

(-23 °F - +104 °F)

Mobil DTE 27 951Mobil SHC 629 ( synthetic) 143

Energol HLP-HM 100 941

Shell Shell Turbo T 46 491Shell Turbo T 100 1001Shell Morlina 220 220

1

Esso

TERESSO 32

TERESSO 46

NUTO H 100

30

1

43

NUTO H 150

Castrol Hyspin AWS 32 321Alpha SP 100 100

1

100

SPARTAN EP 220 220

1

150

Alpha SP 220

1

Alphasyn T 150 ( synthetic)

OMV OMV turb HTU 46 461OMV gear HST 100 97,81OMV gear HST 220 226

Aral

Aral Degol BG 46

Aral Vitam GF 46

1

46

Aral Degol BG 100 100

1

46

1

For temperatures below -5 °C (-23 °F) use lubrication oil class SAE 5W-50 or API-SJ.

Seal System / Pumped Liquid Quench-Oil General Features

Barrier/Buffer Fluid for

Mech. Seal

Tandem Seal to -60°C (-76 °F) Ethanol/Propanol

The sequence of the suppliers of the lubricants does not represent any indication of their superiority .

¹ Viscosity at 40 °C (104 °F) in cSt [mm²/s] DIN 51562

Tandem Seal to -40 °C (-40 °F)

Back to back Seal with gascoffer-dam

Conventional back to back Seal

- Raffinated Hydraulic Oil

- Synthetic Oil

- Mixture of water / glykol

ATTENTION:

Do not use Methanol

appr. 10-15 cST at 40°C

(104 °F)

below -40°C (-40 °F)

Pourpoint vaporization

above 80°C (176 °F)

220

150

1

1

1

1

1

1

Page 20 of 34

Page 21

5.3 Impeller clearance

Correct axial rotor setting is essential for trouble free

operation of the pump.

5.3.1 Adjusting of the rotor

a) Remove coupling spacer, coupling hub on pump

shaft and fan [8161] (when delivered).

b) Fix the position of the mechanical seal by putting

the assembly jigs, mounted on the seal end plate,

into the groove in the shaft sleeve.

No requirements for softpacking,

c) Open screws from the clamping unit, located on

the end of the shaft sleeve (refer to shaft seal

drawing).

d) Loose and remove socket head cap screws

[6579.3] from the shaft nut [2910].

e) Turn shaft nut upside till the rotor moves in the

lowest position and cannot turned by hand.

f) Measure the dimension from the shaft nut to the

end of the shaft.

g) Now lift the rotor by turning the shaft nut in the

other direction till it is in the highest position.

For heavy pumps

(rotor weight > 150 kg (331 lb.)) we recommend

the following practice. The rotor is already in its

lowest position. Screw in an Eyebolt into the

thread at the top of the shaft. Use a lever or a

crane to lift the shaft (do it slowly, the axial

clearance is only a few millimetres).

h) Measure again the dimension from the shaft nut

to the end of the shaft.

i) Take the mean value of the two dimensions and

adjust the rotor to this value by turning the shaft

nut.

The type of hydraulic is shown on the

nameplate (refer to section 3.2 Nomenclature)

j) Fix the shaft nut with the socket head cap

screws.

HWMA USER INSTRUCTIONS ENGLISH 11/10

5.4 Direction of rotation

The sense of rotation of the

pump is counter clockwise (CCW); looking from the

coupling to the shaft end of the pump.

The rotation of the driver shall be checked.

5.5 Guarding

Be sure that the coupling guard is mounted correctly

at the baseplate prior to start up.

5.6 Priming and auxiliary supplies

The pump must be completely primed prior to start

up.

a) The pump casing is considered as self venting,

so no vent connections are provided.

b) Auxiliary systems, e.g. barrier /buffer fluid

systems, cooling circuits, shall be filled according

to the user instructions.

5.7 Starting the pump

a) Start the driver according to the specification.

(Refer to driver IOM).

Pumps are usually started against

closed discharge valve.

b) Check the discharge and suction pressure gauge

to verify the pumps delivered head. Open the

discharge valve slowly, until the pump reaches the

specified operation point. The pump must operate

smoothly, and the vibration must be below 5 mm/s

(0.2 in./sec) (API 610 vibration limits).

The discharge valve must be opened

within 30 sec. after start up. Longer operation

against closed discharge valve will damage the

pump. If a minimum flow valve is installed, take

pressure gauge readings to verify the correct

operation.

Turn the shaftnut always in

downwards direction to meet the whole for the

socket head cap screw.

k) Fix the shaft sleeve with the clamping unit and

turn the tools out of the groove from the shaft

sleeve and fix them on the seal end plate.

l) Check if the shaft can be turned easy by hand

m) Mount fan (when delivered) coupling hub and

spacer again.

Page 21 of 34

If the backpressure of the discharge

pipe is sufficient, pumps can be started against

open valve.

Ensure that your driver is capable deliver

the higher torque required by starting against

open valve.

To prevent the pump from reverse rotation

after shut down, the installation of a check valve

is recommended.

Although the pump is not affected by reverse

rotation because of spezial couppling design , it

can be an issue with the driver.

Page 22

HWMA USER INSTRUCTIONS ENGLISH 11/10

Check the discharge and suction pressure gauge

to verify the pumps delivered head.

The pump must operate smoothly, and the

vibration must be below 5 mm/s (0.2 in./sec) (API

610 vibration limits).

If a minimum flow valve is installed, take pressure

gauge readings to verify the correct operation.

c) Check the pipe system against any leakage.

d) Check the mechanical seal against any leakage.

Right after start up a minor leakage

of the mechanical seal is quite normal. Normally

this leakage disappears after few minutes of

operation.

5.8 Operation

a) Verify that the pump is operating within the

specified limits, min/max flow, pressure,

temperature, vibration, power

b) The bearing housing temperature shall not exceed

80 °C (176 °F). If higher bearing temperature are

observed, check the viscosity grade of the used

lubrication oil.

The minimum viscosity is 10

cSt at the expected oil temperature.

(Oil temperature = bearing gland temperature

+ 10 °C (50 °F))

c) From time to time check the pump shaft seal.

Leakage of 10 - 20 drops per hour is also with a

mechanical shaft seal unavoidable.

d) Observe the power consumption of the pump to

detect excessive wear.

5.9 Stopping and Shutdown

a) Close the outlet valve, but ensure that the pump

runs in this condition for no more than a few

seconds.

b) Stop the pump.

c) Switch off flushing and/or cooling/ heating liquid

supplies at a time appropriate to the process.

d) For prolonged shut-downs and especially when

ambient temperatures are likely to drop below

freezing point, the pump and any cooling and

flushing arrangements must be drained or

otherwise protected.

For automatic start/stop operation of the

pump, ensure that all steps described in chapter 5.6,

5.7, 5.8 and 5.9 are implemented in the control logic.

5.10 Hydraulic, mechanical and electrical

duty

This product has been supplied to meet the

performance specifications of your purchase order,

however it is understood that during the life of the

product these may change. The following notes will

help the user to decide how to evaluate the

implications of any change. If in doubt contact your

nearest Flowserve office.

5.10.1 Specific gravity (SG)

Pump capacity and total head in meters (feet) do not

change with SG, however pressure displayed on a

pressure gauge is directly proportional to SG. Power

absorbed is also directly proportional to SG.

It is therefore important to check that any change in

SG will not overload the pump driver or overpressurize the pump.

5.10.2 Viscosity

For a given flow rate the total head reduces with

increased viscosity and increases with reduced

viscosity. Also for a given flow rate the power

absorbed increases with increased viscosity, and

reduces with reduced viscosity. It is important that

checks are made with your nearest Flowserve office if

changes in viscosity are planned.

5.10.3 Pump speed

Changing pump speed effects flow, total head, power

absorbed, NPSHR, noise and vibration. Flow varies

in direct proportion to pump speed. Head varies as

speed ratio squared. Power varies as speed ratio

cubed. If increasing speed it is important therefore to

ensure the maximum pump working pressure is not

exceeded, the driver is not overloaded,

NPSHA>NPSHR, and that noise and vibration are

within local requirements and regulations.

5.10.4 Net positive suction head (NPSH

NPSH available (NPSHA.) is a measure of the

energy available in the pumped liquid, above its

vapour pressure, at the pump suction branch.

NPSH required (NPSHR.) - is a measure of the

energy required in the pumped liquid, above its

vapour pressure, to prevent the pump from cavitating.

It is important that NPSHA >NPSHR. The margin

between NPSHA >NPSHR should be as large as

possible. If any change in NPSHA is proposed,

ensure these margins are not significantly eroded.

Refer to the pump performance curve to determine

exact requirements particularly if flow has changed. If

in doubt please consult your nearest Flowserve

for advise and details of the minimum allowable

margin for your application.

5.10.5 Pumped flow

Flow must not fall outside the minimum and

maximum continuous safe flow shown on the pump

performance curve and/or data sheet.

A)

office

Page 22 of 34

Page 23

HWMA USER INSTRUCTIONS ENGLISH 11/10

6.0 MAINTENANCE

6.1 General

It is the plant operator's responsibility to

ensure that all maintenance, inspection and assembly

work is carried out by authorized and qualified

personnel who have adequately familiarized

themselves with the subject matter by studying this

manual in detail.

(See also section 1.6.2.)

Any work on the machine must be performed when it

is at a standstill. It is imperative that the procedure

for shutting down the machine is followed, as

described in section 5.9.

On completion of work all guards and safety devices

must be re-installed and made operative again.

Before restarting the machine, the relevant

instructions listed in section 5, Commissioning, start

up, operation and shut down must be observed.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and the

exterior of the machine.

If platforms, stairs and guard rails are required for

maintenance, they must be placed for easy access to

areas where maintenance and inspection are to be

carried out. The positioning of these accessories

must not limit access or hinder the lifting of the part to

be serviced.

When air or compressed inert gas is used in the

maintenance process, the operator and anyone in the

vicinity must be careful and have the appropriate

protection.

Do not spray air or compressed inert gas on skin.

Do not direct an air or gas jet towards other people.

Never use air or compressed inert gas to clean

clothes.

Before working on the pump, take measures to

prevent an uncontrolled start. Put a warning board

on the starting device with the words:

"Machine under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning board

on the fuse box or main switch with the words:

"Machine under repair: do not connect".

Never clean equipment with inflammable solvents or

carbon tetrachloride. Protect yourself against toxic

fumes when using cleaning agents.

6.2 Maintenance schedule

It is recommended that a maintenance plan

and schedule is adopted, in line with these User

Instructions, to include the following:

a) Any auxiliary systems installed must be monitored,

if necessary , to ensure they

b) Gland packings must be adjusted correctly to

give visible leakage and concentric alignment of

the gland follower to prevent excessive

temperature of the packing or follower.

c) Check for any leaks from gaskets and seals. The

correct functioning of the shaft seal must be

checked regularly.

d) Check bearing lubricant level, and if the hours run

show a lubricant change is required.

e) Check that the duty condition is in the safe

operating range for the pump.

f) Check vibration, noise level and surface

temperature at the bearings to confirm

satisfactory operation.

g) Check dirt and dust is removed from areas

around close clearances, bearing housings and

motors.

h) Check coupling alignment and re-align if

necessary.

Our specialist service personnel can help with

preventative maintenance records and provide

condition monitoring for temperature and vibration to

identify the onset of potential problems.

If any problems are found the following sequence of

actions should take place:

a) Refer to section 8, Faults; causes and remedies,

for fault diagnosis.

b) Ensure equipment complies with the

recommendations in this manual.

c) Contact Flowserve if the problem persists.

6.2.1 Routine Inspection (daily/weekly)

The following checks should be

made and the appropriate action taken to remedy any

deviations.

a) Check operating behavior; ensure noise, vibration

and bearing temperatures are normal.

b) Check that there are no abnormal fluid or

lubricant leaks (static and dynamic seals) and

that any sealant systems (if fitted) are full and

operating normally.

c) Check that shaft seal leaks are within acceptable

limits.

d) Check the level and condition of lubrication oil.

On grease lubricated pumps, check running

function correctly.

Page 23 of 34

Page 24

HWMA USER INSTRUCTIONS ENGLISH 11/10

hours since last recharge of grease or complete

grease change.

e) Check any auxiliary supplies eg. heating/cooling

(if fitted) are operating correctly.

f) Refer to the manuals of any associated

equipment if routine checks needed.

6.2.2 Periodic Inspection (every 6 Month)

a)

security of attachment and corrosion.

b) Check pump operation hours to determine if

bearing lubricant shall be changed.

c) The coupling should be checked for correct

alignment and worn driving elements.

Check foundation bolts for

Refer to the manuals of any associated

equipment for periodic checks needed.

6.3 Spare parts

6.3.1 Ordering of spares

When ordering spare parts we need the following

information:

1. pump type and pump size

2. serial number of the pump

3. number of the required spare parts

4. reference nu mber and name of the part as listed

in the part list or in the sectional drawing

Example: for HWMA pump:

HWMA, serial number G202222/01

1 piece impeller Pos. 2200

The serial number of each pump is indicated on the

name plate. If the material should be changed from

the original delivered one, additionally indicate the

exact material specification. If ordered impellers shall

have smaller or larger outer diameter, indicate also

with your order. Without a special remark the spare

impellers will be delivered with the diameter of the

original impellers.

If you need the wear rings oversized or undersized,

please indicate, otherwise the wear rings will be

delivered with standard size.

To ensure continuous satisfactory operation,

replacement parts to the original design specification

should be obtained from Flowserve.

Any change to the original design specification

(modification or use of a non-standard parts) will

invalidate the pump’s safety certification.

surfaces (if necessary) with preservative is

recommended at a 6 monthly interval.

6.3.2 Storage of spares

Spares should be stored in a clean dry area away from

vibration. Inspection and retreatment of metallic

Page 24 of 34

Page 25

HWMA USER INSTRUCTIONS ENGLISH 11/10

6.4 Recommended spares

Spares Recommended

Part Start up Normal Maintenance

No. of identical pumps 1 - 3 4 - 6 7+ 1 - 3 4 - 6 7 - 9 10+

Case 1

Head (case cover and stuffing box) 1

Diffuser 1

Motor 1

Shaft (w/key) 1 1 2 1

Impeller 1 1 2 3

Mechanical seal complete (Cartridge) 1 2 3 1 2 3 3

Shaft sleeve and stage bushing (set) 1 2 3 1 2 3 3

Gaskets, O-rings (set) 1 2 3 1 2 3 3

6.5 Fastener torques

Tightening torque MA Nm (lbf.ft)

Size of

screw

M 4 2 (1,5) 2,4 (1,8) 2,8 (2,1) 0,9 (0,7) 2 (1,5)

M 5 3,9 (2,9) 4,8 (3,6) 5,6 (4,1) 1,8 (1,4) 3,9 (2,9 )

M 6 6,8 (5) 8,3 (6,1) 9,7 (7,1) 3,2 (2,3) 6,8 (5)

M 8 16,2 (12) 19,8 (14,6) 23,1 (17) 7,6 (5,6) 16,2 (12)

M 10 31,9 (23,6) 39 (28,8) 45,4 (33,5) 14,9 (11) 31,9 (23,6)

M 12 55,4 (40,9) 67,8 (50) 78,8 (58,2) 25,9 (19,1) 55,4 (40,9)

M 14 87,9 (64,9) 107,5 (79,3) 125,1 (92,3) 41 (30,3) 87,9 (64,9)

M 16 134,6 (99,3) 164,5 (121,4) 191,4 (141,3) 62,8 (46,4) 134,6 (99,3)

M 18 188 (139) 230 (170) 267 (197) 88 (65) 188 (139)

M 20 263 (194) 321 (237) 373 (276) 123 (90) 263 (194)

M 22 353 (260) 431 (318) 502 (370) 165 (121) 196 (145)

M 24 453 (334) 553 (408) 644 (475) 211 (156) 251 (186)

M 27 654 (483) 799 (590) 930 (686) 305 (225) 363 (268)

M 30 892 (658) 1090 (805) 1269 (936) 416 (307) 496 (366)

M 33 1200 (886) 1467 (1082) 1707 (1260) 560 (413) 667 (492)

M 36 1550 (1144) 1895 (1398) 2205 (1627) 723 (534) 861 (636)

M 39 1988 (1467) 2430 (1793) 2827 (2086) 928 (685) 1104 (815)

M 42 2472 (1824) 3021 (2229) 3515 (2594) 1153 (851) 1373 (1013)

M 45 3061 (2259) 3741 (2761) 4354 (3213) 1429 (1054) 1701 (1255)

M48 3703 (2732) 4526 (3340) 5266 (3886) 1728 (1275) 2057 (1518)

M64 8862 (6539) 10831 (7993) 12604 (9301) 4136 (3052) 4923 (3633)

Duplex SS

(S32760, S31803,

1.4462)

Carbon Steel (NACE)

(A 193 Gr.B7M,

A 320 Gr. L7M)

Carbon Steel

(A 193 Gr. B7,

A 320 Gr. L7, 8.8)

Austenitic SS

(A 193Gr. B8MA)

(NACE)

Austenitic SS

(A 193 Gr. B8/B8M,

A4-70,A2-70)

Above mentioned torques are for all screwed unions, which works under dynamical load. For all other

connections you can use a corresponding smaller torque.

Page 25 of 34

Page 26

6.6 Setting impeller clearance

For axial rotor setting see section 5 Commissioning

startup, operation and shutdown.

6.7 Disassembly

Refer to section 1.6, Safety, before

dismantling the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

Refer to sectional drawings for part numbers and

identification.

6.7.1 Dismantling of pump

1) Remove the coupling guards [7450] and secure the

mechanical seal by putting the setting plates into

the groove of the shaft sleeve. Loose the drive

collar to prepare further disassembly.

HWMA USER INSTRUCTIONS ENGLISH 11/10

6.7.4 Dismantling of the bearing housing

1) Loose the hexagon head bolt [6577.3] and pull off

the stuffing box housing [4110].

2) Pull off the deflector [2540] from the shaft after

loosing the grub screw [6814.2].

3) Unsecure shaft nut [2910] by loosing the cap

screw [6579.3].

4) Unscrew the shaft nut [2910], the hexagon head

bolt [6577.4] and remove the bearing cover

[1220] and [3260]. Take care about labyrinth ring

[4330].

5) Now you can pull out the shaft assembly from the

bearing housing. Pull off the bearing adaptor

sleeve [2471].

Take care of the key

[6700.3].

6) To pull off the angular contact bearings unsecure

lockwasher [6541.2] and loose bearing lock nut

[3712].

7) Pull off the distance sleeve [2460], the pumping

ring [4223] and the radial ball bearing [3011].

Refer to mechanical seal drawing for

details.

Drain the seal system, if

applicable.

2) Uncouple the motor from the pump and take off the

motor.

3) Loose the hexagon head bolt [6577.1] and pull off

the bearing lant er n [3 140] .

4) Loose the stud [6572.2] and pull out the pump

assembly from the casing. Eventually use hexagon

head bolt [6577.2] to support this.

6.7.2 Dismantling of hydraulic section

1) After loosing the socket screws [6579.4], remove

the insert.

2) Loose the impeller nut [2912] (right hand thread)

If the pump is equipped with an

inducer [2215] loose inducer.

3) Pull the impeller from the shaft. As the impeller is

fitted relatively strong on the shaft, use as support

the two threads on the shroud of the impeller .

4) After loosing the socket head cup screws [6579.1] ,

it is possible to remove the interst age plate [1471]

of the pump casing cover [1221].

6.7.3 Dismantling for changing the mechanical seal

1) Loose stud [6572.3] and pull off pump casing

cover [1221] including mechanical seal cartridge.

2) Loose hex nuts [6581.4] to remove mechanical

seal cartridge from pump casing cover [1221].

Take care of the key

[6700.2].

6.8 Examination of parts

1) Check whether any part of pump casing or impeller

was damaged by corrosion or erosion. Liquid

channels have to be clean and clear.

2) All liquid channels must be cleaned and free of rust