Page 1

GESTRA Steam Systems

HV 215

Installation Instructions 818480-01

Hydraulic Loading and Unloading System HV 215

t

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose .................................................................................................................................. 8

Safety notes ............................................................................................................................................................... 8

Danger .......................................................................................................................................................................8

Legal regulations ........................................................................................................................................................ 9

Explanatory Notes

Scope of supply ........................................................................................................................................................10

Description ............................................................................................................................................................... 10

Function ...................................................................................................................................................................11

Technical data .................................................................................................................................................... 11, 12

Fluid list .............................................................................................................................................................. 13, 14

Installation

Hydraulic loading & unloading system HV 215 .......................................................................................................... 15

Mounting flange .................................................................................................................................................. 15, 16

Bottom valve HWV 205/1 - DN 80 ......................................................................................................................17 - 19

Bottom valve HWV 215/1 - DN 80 ......................................................................................................................20 - 23

Cable routing ............................................................................................................................................................24

Operating device BV 110 .......................................................................................................................................... 25

Connecting lines ................................................................................................................................................. 26, 28

Attaching operating plates HV 215 ............................................................................................................................29

Attaching list indicating fluids ................................................................................................................................... 29

Filling and venting of hydraulic system ...................................................................................................................... 30

Filling and venting of hydraulic actuating system ...................................................................................................... 30

Filling and venting of hydraulic indicating system...................................................................................................... 31

Performance test ...................................................................................................................................................... 31

Operation

Service ..................................................................................................................................................................... 32

Emergency operation ................................................................................................................................................ 33

Maintenance

Bottom valves HWV 205/1 - DN 80 / HWV 215/1 - DN 80 .......................................................................................... 34

Operating device BV 110 ...........................................................................................................................................35

Connecting lines ....................................................................................................................................................... 35

2

Page 3

Contents – continued –

Page

Servicing

Hydraulic loading & unloading system HV 215 .......................................................................................................... 36

Replacing valve plug seal ...................................................................................................................................36 - 38

Reworking seat flange .............................................................................................................................................. 39

Replacing gaskets of actuacting cylinder ............................................................................................................ 40, 41

Replacing control unit of bottom valve ......................................................................................................................42

3

Page 4

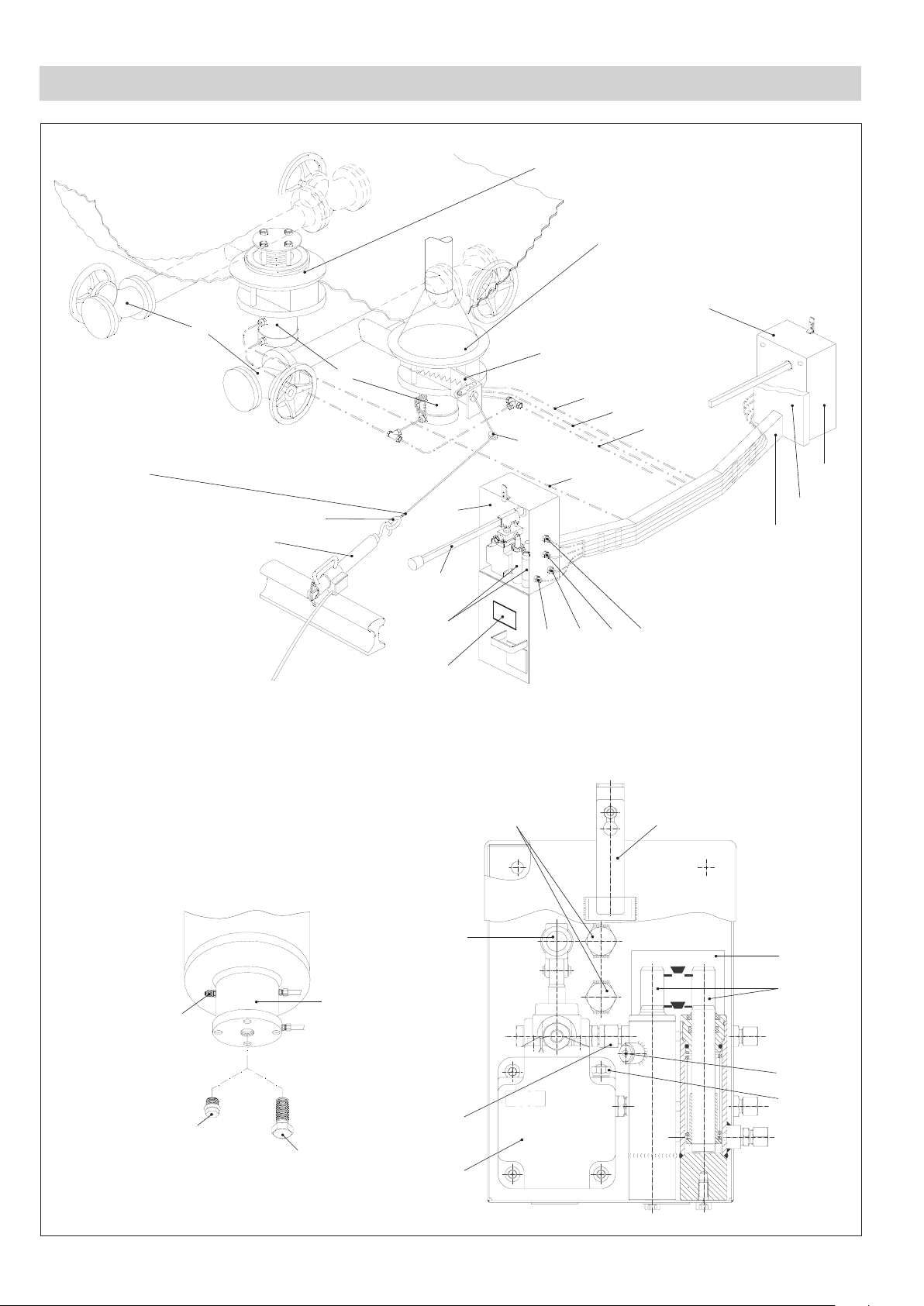

Components

F

Y

S

K

Tension rope with

wire cable clamp

A

B

HWV 205/1

X

Y

G

L

HWV 215/1

BV 110

R

P

E

C

D

E

W

V

F

H

L G R P

Z

K

M

F

gas phase liquid phaseopen

N

B

closed

O

I

Q

S

U

J

K

T

4

Page 5

Key

A Shut-off valves

B Actuating cylinder

C Rail hook

D Ring

E Operating devices

F Pump lever of hydraulic hand pump

G Line leading to the indicating cylinder of the gas phase

H Indicating cylinder

I Filling connection

J Sealing plug

K Screw for sealing off opening for emergency unloading

L Line leading to the indicating cylinder of the liquid phase

M Bolt for operating device

N Plate showing valve position of indicating pistons

O Indicating pistons

P Pressure line

Q Screw-in plug for venting facility

R Return line

S Screw for oil filling connection (with dip stick)

T Hydraulic hand pump

U Non-return valve

V Transverse pipe-run

W Frame

X Control unit

Y Guide bushing

Z Fluid list

5

Page 6

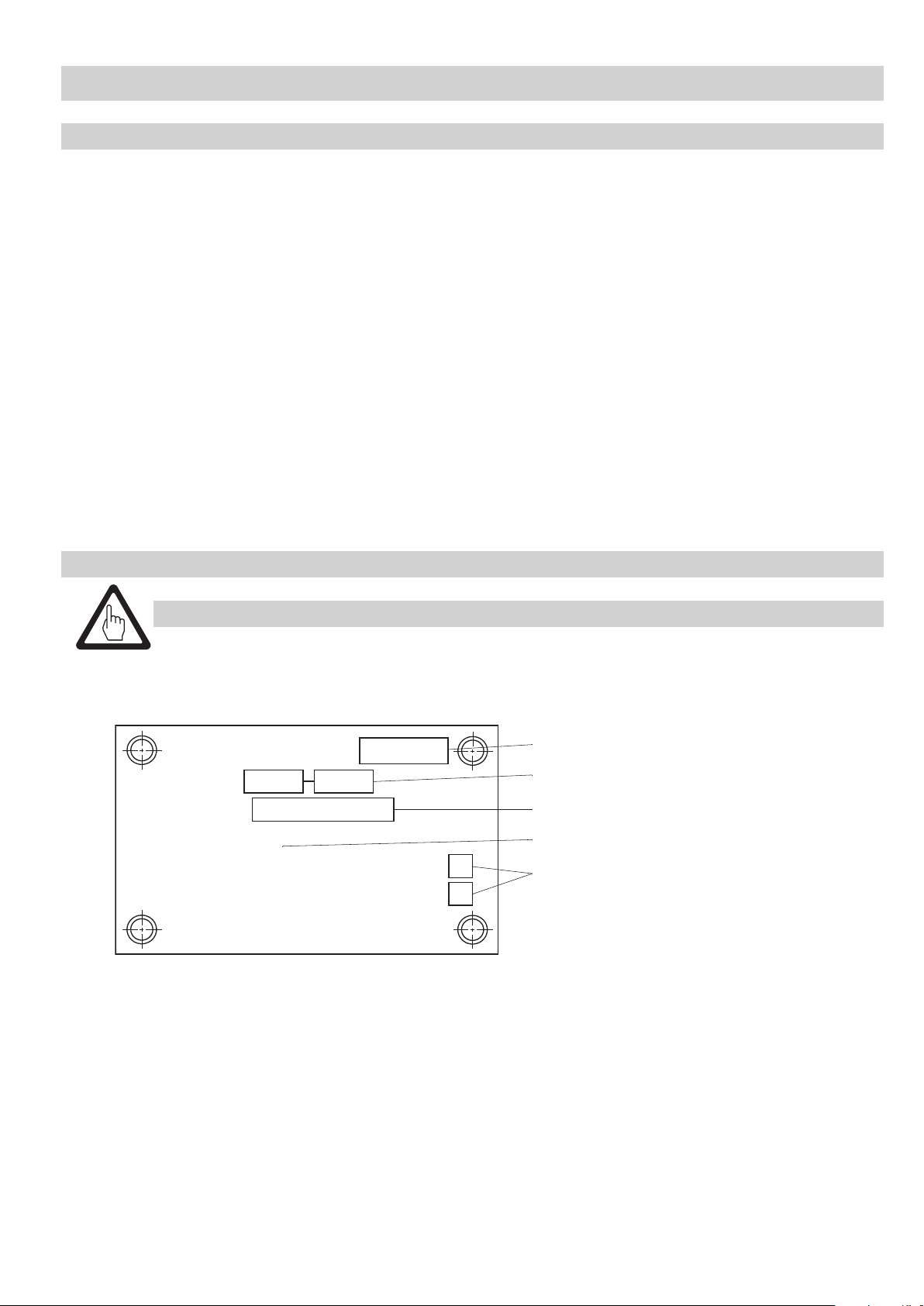

Basic Components of Bottom Valves

Mounting flange

Valve head

Body

1

2

3

4

5

6

7

8

31

j i h g

f

e

d

c

b

Actuating cylinder

6

9

0

!

"

§

$

a

=

)

(

/

&%

Page 7

Key

1 Hexagon head cap screw

2 Locking washer

3 Spring plate

4 Stay bolt

5 Sleeve

6 Gasket

7 Seat flange

8 Gasket

9 Push rod

0 Bellows

! Gasket

" Piston

§ Piston seal

$ Hexagon head cap screw

% Sealing plug

& Joint ring

/ Retaining ring

( O-ring

) O-ring

= Bushing

a Seal ring

b Hexagon head cap screw

c Socket-head cap screw

d Locking washer

e Valve plug

f Compression spring

g Washer

h Retaining ring

i Socket-head cap screw

j Washer

31

Valve plug seal

7

Page 8

Important Notes

Usage for the intended purpose

The hydraulically operated loading and unloading system HV 215 is intended solely for filling and draining stationary

and mobile tanks containing pressure liquefied gases.

Its use is permissible only within the allowable pressure and temperature ratings and only if the chemical and

corrosive influences on the equipment are taken into account. Before installing the equipment make sure that the

loading & unloading system is suitable for the intended application and the fluid to be used (corrosion resistance

and chemical suitability).

Modifications to the design may only be made if the manufacturer‘s written permission is obtained.

Any type of use differing from the usage described above must be considered as improper. The resulting risk will

have to be borne by the user alone. The manufacturer hereby expressly rejects any claims for any resulting damage.

The use of external pumps for opening or closing the bottom valves is not permitted.

Safety notes

The loading and unloading system must not be installed or commissioned by anyone other than qualified staff.

Maintenance and service work must only be performed by adequately trained persons who have a recognised

level of competence.

For installation, removal, commissioning, operation and maintenance, every person who works with the loading and

unloading system must have read and understood the complete installation manual. Furthermore, responsibilities

must have been defined clearly and unambiguously and must be adhered to.

The operating company must ensure that, whenever the loading and unloading system is being operated, it is in

perfect condition.

Attention

Working methods that jeopardise safety must not be used!

Danger

If the loading and unloading system is used in an inexpert or improper manner by unqualified staff, it can cause

danger to life and limb for the user or for third parties, possibly resulting in death.

During operation, the bottom valves of the loaded and unloaded tanks are under pressure. During the loading and

unloading procedure all other components are also under pressure. In this condition, screws as well as nuts and

bolts of the loading and unloading system must not be slackened. Liquid or vaporizing fluids might escape and

could cause severe cases of poisoning and environmental pollution.

During the loading and unloading procedure do not leave the installation unattended.

The shut-off valves might be cold during the loading and unloading procedure. Make sure that the operator wears

protective gloves when operating the handwheels.

Any installation or removal work may only be performed when the tank is at zero pressure and completely free of gas.

When carrying out installation and maintenance work, make sure that the tank cannot be operated accidentally.

8

Page 9

Important Notes – continued –

Warning

Any use of naked flames is expressly forbidden!

Before perfomring any service work inside the tank make sure that the tank is sufficiently ventilated

and all gases have been completely vented. The rules concerning MAC (= maximum allowable

concentration) values at place of work must be strictly applied!

Legal regulations

The configuration of the loading and unloading system HV 215 mounted to the tank car carrying pressurized

gas meets the requirements of DIN 26026 or of EN 12561-3.

The bottom valves HWV 205/1- DN 80 and HWV 215/1- DN 80 fulfill the legal requirements of the RID / GGVSE section 6, constituting the first inner shut-off as defined in these regulations.

9

Page 10

Explanatory Notes

Scope of supply

1 Bottom valve HWV 205/1 - DN 80

1 Bottom valve HWV 215/1 - DN 80 with tension rope

2 Hydraulic operating devices BV 110

2 Operating plates HV 215

2 Plates indicating fluids (only for bottom valves with valve plug seal made of CR)

1 Installation manual for loading & unloading system HV 215

1 Set of acceptance certificates

The following items are not scope of the supply but can be ordered separately:

1 Set of connecting lines as accessory kit

4 Shut-off valves DN 80

2 Valve mounting flanges

Description

The hydraulically operated loading and unloading system HV 215 is designed for filling and draining stationary

and mobile tanks containing pressure liquefied gases.

It is mainly used in tank cars carrying pressurized gases. These tank cars (TC) require a high degree of reliability,

ease of operation and maintenance and a long service life of the associated valves.

The loading and unloading system consists of the two rapid-action bottom valves, the two operating devices, the

shut-off valves, the rail hook and the tension rope. The connecting lines required for operating the loading and

unloading system are either made of hydraulic tubes and hydraulic hoses or entirely of hydraulic hoses.

The bottom valves type HWV 205/1 - DN 80 and type HWV 215/1 - DN 80 (with control unit) are designed for

installation in the valve-mounting flanges located at the bottom of the vessel. Both bottom valves are always

opened or closed together. A manifold connects the bottom valves directly with the shut-off valves. Both valves

can either be used for the liquid phase or the gas phase.

The operating devices consist of a hydraulic hand pump and one indicating piston for the liquid phase and one

for the gas phase. They are attached to the left and right hand side of the tank car, which means that the bottom

valves can be opened from either side of the tank car by actuating the respective operating device.

During the loading/unloading process the rail hook connected to the tension rope keeps the bottom valves in the

open position. In the event of an emergency, e. g. emergency shut-off or inadvertent moving of the tank car, the

rail hook is disengaged from the rail and the bottom valves close instantaneously (rapid-action closing).

10

Page 11

Explanatory Notes – continued –

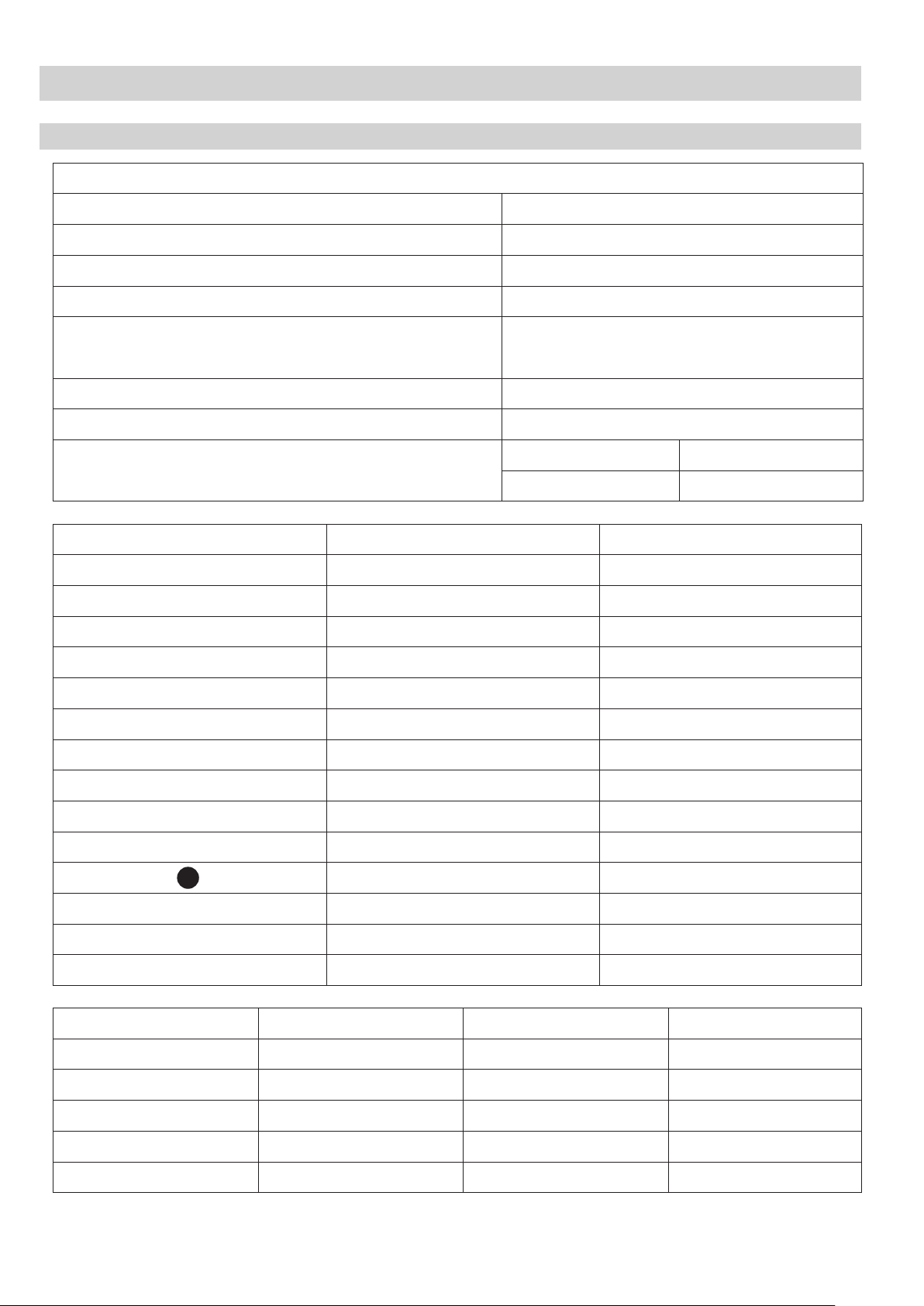

TÜ. AGG.

Manu.-no.:

P

test

: 37.5bar

T

min.

: - 50°C valve plug seal PTFE

T

min.

: - 40°C valve plug seal CR

GESTRA HWV

MADE BY GESTRA

Function

The loading and unloading system HV 215 is designed for filling and draining tanks that contain pressureliquefied gases.

One bottom valve opens for the liquid phase and the other opens for the gas phase. Both opening processes

always take place simultaneously.

The operating device of the tension rope (e. g. rail hook VZ 10) engaged to one of the rails provides the required

tension of the rope. This tension keeps the ball valve of the control unit of the hydraulic system closed.

The hydraulic hand pump of the operating device BV 110 can then be used to apply pressure to the hydraulic

system. The pressure acts on the actuating cylinders of the bottom valves, forcing the piston to go up and thereby

causing the bottom valves to open.

The current lift position of both bottom valves is indicated separately by the indicating cylinders of the operating

device BV 110.

When the rail hook is disengaged, i. e. when the load on the tension rope is reduced, the hydraulic system opens,

leading to the rapid-action closing of the bottom valves within less than 1 second.

The non-return valve integrated in the operating device BV 110 prevents the premature closing of the bottom

valves caused by leaking fluids in the hydraulic hand pump and the pressure-reducing valve.

Technical data

Attention

For pressure / temperature ratings of the bottom valves see name plate.

Name plate drawing

Name plate specifications

Type of bottom valve

Type approval

GESTRA manufacturing no.

Test pressure

Type of valve plug seal used

in valve head

11

Page 12

Explanatory Notes – continued –

Technical data – continued –

Pressure/Temperature Ratings of Bottom Valves

Nominal pressure PN [bar]

Test pressure [bar]

Temperature range for valve plug seal CR [°C] – 40 to + 50

Temperature range for valve plug seal PTFE [°C] – 50 to + 50

Connection of bottom valve body

Spring pressure on valve plug [N] 322 ± 30

Lift of valve plug [mm] > 21.2

Drag coefficient

ζ

Item no. Component Material

– Body 1.0566

b

$

Hexagon head cap screw M16 A2-70 or A4-70

Hexagon head cap screw M12 A2-70

Socket-weld ends for manifold

with O. D. 88.9 mm

Loading Unloading

3.3 2.8

25

37.5

7

e

f

3

4

0

68!

31

c

()

5

Weight [kg] HWV 205/1 HWV 215/1 BV 110

Body 20 20 –

Valve head

Seat flange 1.4571

Valve plug 1.4571

Compression spring 1.4310

Spring plate 1.4301

Stay bolt 1.4301

Bellows, complete 1.4541 and 1.4571

Gasket PTFE

Valve plug seal PTFE or CR

Socket-head cap screw A2-70

O-ring NBR 70 Shore

Sleeve 1.4313

9 9 –

Hydraulic actuator

Control unit

Total 36 39 2 x 16

12

7 7 –

– 3 –

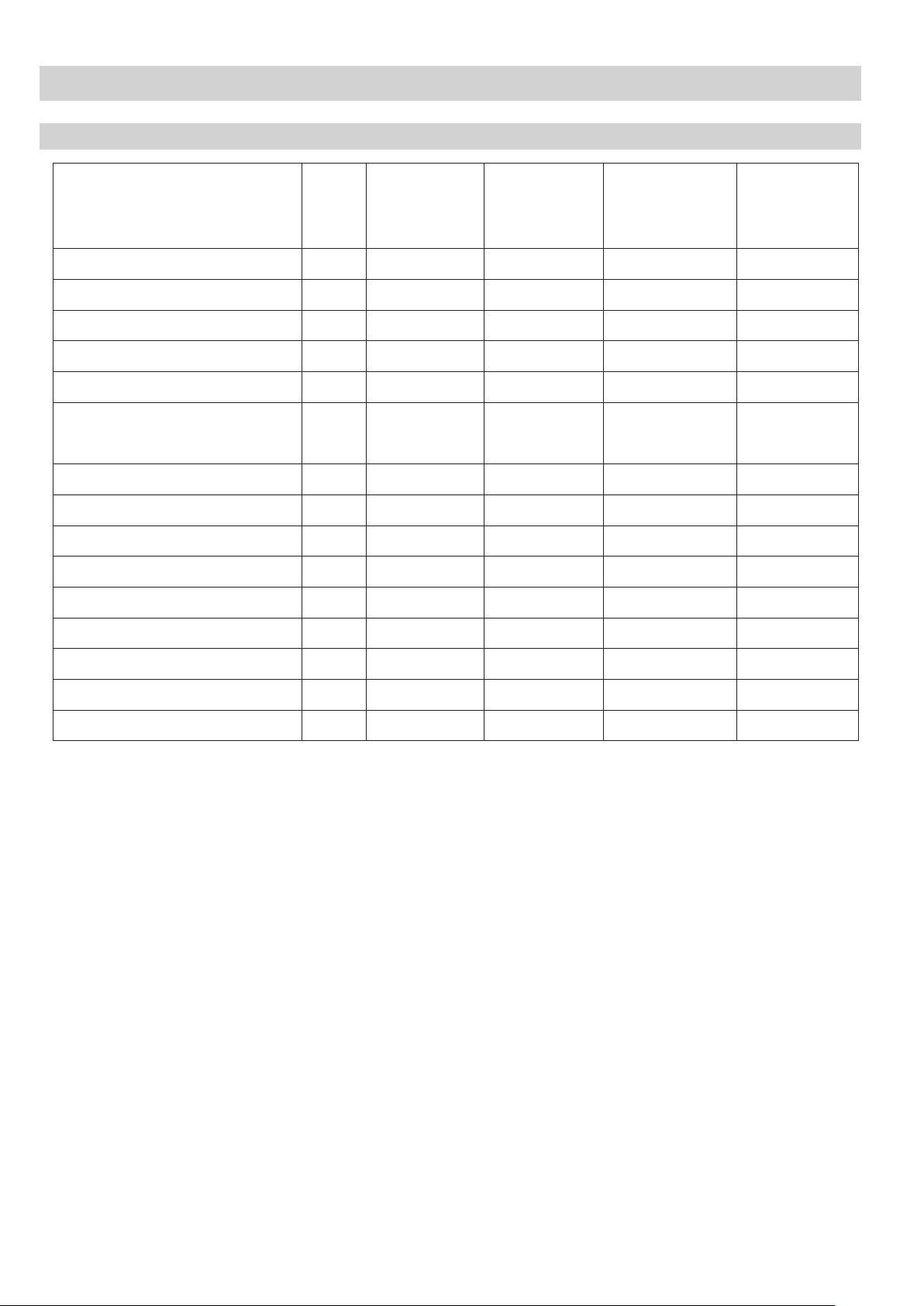

Page 13

Explanatory Notes – continued –

Fluid list

Media Class

Propane 2 2F 1978 X X

Butane 2 2F 1011 X X

Propene 2 2F 1077 X X

Butene-1

Butadiene-1.3

Ammonia 2 2TC 1005 X X

Ethyl chloride

Methyl chloride

Vinyl chloride

Gas R12

Gas R21

Gas R22

Classification

code

2 2F 1012 X X

2 2F 1010 X X

2 2F 1037 X

2 2F 1063 X

2 2F 1086 X

2 2A 1028 X

2 2A 1029 X

2 2A 1018 X

UN No.

Valve plug seal

PTFE down to

-50 °C

Valve plug

seal CR down

to

Gas R114

Gas R115

Gas R12 B1

Methyl bromide

Methylamine (free from water)

Dimethylamine (free from water)

Trimethylamine (free from water)

Ethylamine (free from water)

Hexafluoropropylene R1216

Dimethyl ether

Chlorotrifluoroethane R133a

Ethylene oxide with

max. 10% carbon dioxide

Ethylene oxide with

nitrogen up to 10 bar at 50 °C

2 2A 1958 X

2 2A 1020 X

2 2A 1974 X

2 2T 1062 X

2 2F 1061 X

2 2F 1032 X

2 2F 1083 X

2 2F 1036 X

2 2A 1858 X

2 2F 1033 X

2 2A 1983 X

2 2TF 1040 X

2 2TF 1040 X

Mixture F1

Mixture F2

Mixture P1

2 2A 1078 X

2 2A 1078 X

2 2F 1060 X

13

Page 14

Explanatory Notes – continued –

Fluid list – continued –

Media Class

Mixture A (trade name butane)

Mixture AO (trade name butane)

Mixture A1

Mixture B

Mixture C (trade name propane)

Mixtures of hydrocarbons with

butadiene -1.3

Iso butane

Iso butene

Cis -2-butene

Trans -2-butene

Cyclopropane 2 2F 1027 X

Classification

code

2 2F 1965 X X

2 2F 1965 X X

2 2F 1965 X X

2 2F 1965 X X

2 2F 1965 X X

2 2F 1010 X X

2 2F 1969 X

2 2F 1055 X

2 2F 1012 X X

2 2F 1012 X X

UN No.

Valve plug seal

PTFE down to

-50 °C

Valve plug

seal CR down

to

Gas mixture R500

Gas mixture R502

Carbon dioxide

Ethylene 2 3F 1038 X

2 2A 2602 X

2 2A 1973 X

2 3A 2187 X

14

Page 15

Installation

Hydraulic loading & unloading system HV 215

We highly recommend that only qualified staff should carry out installation work in accordance with these

installation instructions. The manufacturer expressly rejects any claims for damage caused by improper installation.

All parts to be fitted must meet the technical requirements specified by the manufacturer. All genuine parts are

guaranteed to comply with these requirements.

For installation work choose lifting devices that are specified for the respective weights. Use only suitable and

proper lifting devices.

When welding observe legal regulations and in-house guidelines concerning welded connections. Before welding

clean all spots to be welded.

Make sure that the gaskets of the flanged connections are exactly placed between the flanges. Clean all seating

surfaces before installing the equipment.

Before installing the valves remove the transport packing and all transit protection plugs for end connections.

Install the equipment in the following order:

n Mounting flanges

n Bottom valve HWV 205/1 - DN 80

n Bottom valve HWV 215/1 - DN 80

n Cable routing

n Operating devices BV 110

n Connecting lines

n Attaching operating plates HV 215

n Attaching plates indicating fluids

Mounting flange

The mounting flanges for bottom valves type HWV 205/1 - DN 80 and HWV 215/1 - DN 80 have the same

form and can be installed in the same way.

They are not scope of supply of the loading & unloading system HV 215 but can be ordered from Gestra.

Valve mounting flanges made from the following materials are available:

n P355NL1 (1.0566, old: TStE 355)

n S420NL (1.8912, old: TStE 420)

n P460NL1 (1.8915, old: TStE 460)

Further materials are available on request.

Gestra supplies valve mounting flanges with a standard diameter of 430

+6

mm. To avoid a wall thickness

misalignment between the valve mounting flange and the tank wall, adjust the outside diameter D to the

thickness S of the tank car (see drawing on page 16). Make sure that the weld joint produced is in compliance

with the specifications of the tank manufacturer.

The valve mounting flanges are welded into the bottom of the vessel according to the specifications of the

local welding authority.

To calculate the dimensions of the pressure vessel to AD-B1/ B9, refer to the drawing ( see page 16) in which

the dimensions of the reinforcement are indicated.

15

Page 16

Installation – continued –

Mounting flange – continued –

Attention

After the annealing process check the seating surfaces and, if necessary, clean, rework or cut them.

The reference dimension S varies as a function of the drop forging tolerance and must be

compensated for by the diameter D of the valve mounting flange.

Reference dimension varies as a function of the drop forging tolerance

∅ 430

+6

∅ D

+4.3

-1.6

S

∅ 365

∅ 155

Valve joint as specified

by local authority

32°

-1.6

+4.3

10

35

16

Longitudinal axis of boiler

Page 17

Installation – continued –

Bottom valve HWV 205/1 - DN 80

The supplied bottom valve consists of two component parts - the valve head and the body with the actuating

cylinder. The valve comes with a set of assembly parts.

The assembly parts of the valve head comprise:

n 1 Gasket ∅ 125

n 12 Locking washers

n 12 Socket head cap screws M16 x 30

First attach the valve head from the outside to the valve mounting flange.

See drawing on page 19

1. Put the gasket

2. Place the valve head onto the mounting flange and insert the supplied socket-head cap screws

6 onto the valve head.

c and locking

washers d in the valve mounting flange and tighten them with a torque of 120 Nm. Apply a commerically

available lubricant to the screws and tighten them in several steps in diagonally opposite pairs.

3. Check spacing between bottom of valve plug

e and seat flange 7 (reference dimension 1 see page 19). For this

purpose you can hold a try square to the bottom of the valve head and read off the distance to the bottom of the

valve plug. A distance of 7±1 mm is required. If the reading exceeds this tolerance check the position of the

seal of the valve plug e. If necessary push the valve plug e slightly upwards.

Dirty seals or the incorrect position of the valve plug seal

31

31

may have caused this problem. Should even after

this examination the actual readings still exceed the specified tolerances, please contact our Technical Service in

your country, stating the Gestra manufacturing number indicated on the name plate.

Attention

Check and, if necessary, clean sealing surfaces.

The specified torques must be strictly observed.

17

Page 18

Installation – continued –

Bottom valve HWV 205/1 - DN 80 – continued –

After the valve head install the body with the actuating cylinder.

The assembly parts of the valve body comprise:

n 1 Gasket ∅ 125

n 6 Hexagon head cap screws M16 x 140

n 1 Gasket (spare part for replacement)

The body is supplied together with the actuating cylinder as a complete component part.

See drawings on page 4 and page 19

1. First weld the manifold to the body, taking the specifications of the local welding authority into account. The body

end is sized for a pipe having an outside diameter of 88.9 mm. To weld the manifold it might be necessary to

remove the actuating cylinder B from the body. For this purpose unscrew the hexagon head cap screws $ and

carefully push the actuating cylinder B downwards. Remove the gasket !. Do not re-use this gasket! Insert the

supplied spare gasket !.

2. Check the torque (50 Nm) required for tightening the hexagon head cap screws

has been removed, tighten the hexagon head cap screws $ with a torque of 50 Nm. Apply a commerically

available lubricant to the screws and tighten them in several steps in diagonally opposite pairs.

3. Then check the lift of the push rod

reference dimension 2 and 3 (see page 19) from the upper edge of the push rod 9 to the sealing surface of the

unloaded bellows 0 and to the lower stop of the bellows 0. If the distance exceeds the admissible tolerance,

check the push rod 9 for smooth operation. If the push rod is jammed, first eliminate the cause and then gently

knock with your hand against the push rod 9 until it can move freely. If you cannot find a fault please contact our

Technical Services in your country, stating the GESTRA manufacturing number.

4. Insert the supplied gasket

the body to the mounting flange, applying a torque of 120 Nm. Apply a commerically available lubricant to the

screws and tighten them in several steps in diagonally opposite pairs.

8 in the bottom of the valve head and use the hexagon head cap screws b to screw

9 in the body with actuating cylinder B. For this purpose measure the

$. If the actuating cylinder B

Attention

Make sure that welding and, if necessary, annealing work does not damage the seals and gaskets!

Check and, if necessary, clean sealing surfaces.

Always replace gasket when removing the actuating cylinder.

The specified torques must be strictly observed.

Note: Do not use the push rod

9 as handle!

18

Page 19

Installation – continued –

,

6

Bottom valve HWV 205/1 - DN 80 – continued –

∅ 210 / 12 x M16

∅ 146

M12

e

Manifold

∅ 88.9

292

78116.5

turned

through 90°

8

31

0

!

9

7

6

Torque 120 Nm

c

turned through 15°

Torque 120 Nm

b

turned through 90°

32

d

Torque 50 Nm

$

turned through 45°

Reference dimension 1

on valve head

±1

7

∅ 112

Reference dimension 2

on body with actuating cylinder

(bellows unloaded)

+9

16

Reference dimension 3

on body with actuating cylinder

(bellows at lower stop)

±1

1

19

Page 20

Installation – continued –

Bottom valve HWV 215/1 - DN 80

The supplied bottom valve consists of three component parts - the valve head, the body with the actuating cylinder

and the control unit. The valve comes with a set of assembly parts.

The assembly parts of the valve head comprise:

n 1 Gasket ∅ 125

n 12 Locking washers

n 12 Socket head cap screws M16 x 30

First attach the valve head from the outside to the valve mounting flange.

See drawing on page 23

1. Put the gasket

2. Place the valve head onto the mounting flange and insert the supplied socket-head cap screws

6 onto the valve head.

c and locking

washers d in the valve mounting flange and tighten them with a torque of 120 Nm. Apply a commerically

available lubricant to the screws and tighten them in several steps in diagonally opposite pairs.

3. Check the spacing between the bottom of the valve plug

e and the seat flange 7 (cf. reference dimension

1 on page 23). For this purpose you can hold a try square to the bottom of the valve head and read off the

distance to the bottom of the valve plug e. A spacing of 7±1 mm is required. If the reading exceeds this

tolerance, check the position of the seal of the valve plug e. If necessary push the valve plug e slightly

upwards. Dirty seals or the incorrect position of the valve plug seal may have caused this problem.

31

31

Should even after this examination the actual readings still exceed the specified tolerances, please contact our

Technical Services in your country, stating the Gestra manufacturing number indicated on the name plate.

Attention

Check and, if necessary, clean sealing surfaces.

The specified torques must be strictly observed.

20

Page 21

Installation – continued –

Bottom valve HWV 215/1 - DN 80 – continued –

After the valve head install the body with the actuating cylinder.

The assembly parts of the valve body comprise:

n 1 Gasket ∅ 125

n 6 Hexagon head cap screws M16 x 140

n 1 Gasket (spare part for replacement)

The body is supplied together with the actuating cylinder as a complete component part.

See drawings on page 4 and page 23

1. First weld the manifold to the body, taking the specifications of the local welding authority into account. The body

end is sized for a pipe having an outside diameter of 88.9 mm. To weld the manifold it might be necessary to

remove the actuating cylinder B from the body. For this purpose unscrew the hexagon head cap screws $ and

carefully push the actuating cylinder B downwards. Remove the gasket !. Do not re-use this gasket! Insert the

supplied spare gasket !.

2. Check the torque (50 Nm) required for tightening the hexagon head cap screws

$. If the actuating cylinder B

has been removed, tighten the hexagon head cap screws $ with a torque of 50 Nm. Apply a commerically

available lubricant to the screws and tighten them in several steps in diagonally opposite pairs.

3. Then check the lift of the push rod

9 in the body with actuating cylinder B. For this purpose measure the

reference dimension 2 and 3 (see page 23) from the upper edge of the push rod 9 to the sealing surface of the

unloaded bellows 0 and to the lower stop of the bellows 0. If the distance exceeds the admissible tolerance,

check the push rod 9 for smooth operation. If the push rod is jammed, first eliminate the cause and then gently

knock with your hand against the push rod 9 until it can move freely. If you cannot find a fault please contact our

Technical Services in your country, stating the GESTRA manufacturing number.

4. Insert the supplied gasket

8 in the bottom of the valve head and use the hexagon head cap screws b to screw

the body to the mounting flange, applying a torque of 120 Nm. Apply a commerically available lubricant to the

screws and tighten them in several steps in diagonally opposite pairs.

5. Engage the loop of the tension spring of the control unit

42

Attention

Make sure that welding and, if necessary, annealing work does not damage the seals and gaskets!

Check and, if necessary, clean sealing surfaces.

Always replace gasket when removing the actuating cylinder.

The specified torques must be strictly observed.

X to the hexagon head cap screw b.

21

Page 22

Installation – continued –

Bottom valve HWV 215/1 - DN 80 – continued –

Attach the control unit to the body.

The assembly parts of the control unit comprise:

n 2 Stud bolts M16 x 35

n 2 Locking washers

n 2 Nuts M16

The control units comes with the ball valve.

See drawings on page 4

1. Screw stud bolts into the body, applying a torque of 120 Nm.

2. Use the locking washers and nuts to fit the control unit

3. Engage the tension spring in the lever of the ball valve .

35

33

42 36

34

X to the body with a torque of 120 Nm.

Attention

The specified torques must be strictly observed.

In addition make sure that the stem of the ball valve can always run smoothly. If the stem does not

move smoothly, apply a commercially available lubricant. Do not treat or paint the surface!

Make sure that the cable routing does not touch the manifold!

Note: Do not use the push rod

9 as handle!

22

Page 23

Installation – continued –

6

Bottom valve HWV 215/1 - DN 80 – continued –

∅ 210 / 12 x M16

∅ 146

M12

e

Torque 120 Nm

c

turned through 15°

78

116.5

292

Manifold

∅ 88.9

Torque 120 Nm

b

8

turned through 90°

!

31

0

∅ 112

9

6

33

34

32

turned through 90°

$

d

Torque 120 Nm

Torque 50 Nm

turned through 45°

41

42

35 36 37 38 39 40

Reference dimension 1

on valve head

±1

7

Reference dimension 2 on

body with actuating cylinder

(bellows unloaded)

±9

16

Reference dimension 3 on

body with actuating cylinder

(bellows at lower stop)

±1

1

23

Page 24

Installation – continued –

Cable routing

Provide tank car with a guide sleeve Y for the tension rope.

The position of the guide sleeve

at an angle of 45°.

See drawing on page 4

1. The tension rope supplied by the manufacturer is 1500 mm long and must be cut to the required length.

2. To connect the tension rope with the rail hook

rope with a ring D according to DIN 26026.

Note that this ring D is not scope of the GESTRA supply!

Use the supplied wire clamp to attach the ring D. Fasten the screws of the wire clamp with a torque of 2 Nm.

Y must enable the tension rope to leave the control unit X of the bottom valve

C or the tension rope operating device, provide the tension

If the valve is open

Tension rope

Guide sleeve

At damper level 1060

Ring for attaching the tension

rope operating device

Attention

Do not pass the tension rope over sharp edges.

The lay-out of the tension rope, the guide sleeve

operating device must comply with DIN 26026 and EN 12561-3.

270

520

Y and the ring D for attaching the tension rope

Upper edge of rail

24

Page 25

Installation – continued –

Operating device BV 110

Fit the operating devices to both sides of the vessel such that they are easily accessible.

Each operating device consists of:

n 1 Hand lever

n 1 Adhesive label for valve position (no. 048561)

The operating devices are supplied completely mounted.

See drawing on page 4

1. Weld or screw the operating devices

The body of the operating device E is provided with two bore holes (diameter 13 mm) for screwed unions.

The associated screws and locking washers are not scope of the GESTRA supply.

Note that welding processes must be supervised by the local welding authority.

2. When you have finished welding and painting, stick the adhesive label

the back of the body behind the indicating piston O.

Dimensions indicated in mm

Depth 164

E to the frame W.

∅ 13

25

384

32

N indicating the valve position to

270

200

260

Attention

The hand lever supplied by Gestra protrudes approx. 300 mm out of the rear wall of the body

when the flap is closed.

If necessary you can shorten the hand level by max.150 mm.

If the welding process has affected the coat of paint, make sure that the damaged paintwork

is repaired.

25

Page 26

Installation – continued –

Connecting lines

The connecting lines have different lengths due to the different dimensions of the vessels or tanks. Use the table on

page 28 to ascertain the required lengths.

Hydraulic tubes in combination with hydraulic hoses or only hydraulic hoses can be used as connecting lines.

The specific lay-out of the connecting lines depends on the design of the tank car.

See drawings on page 4 and page 28

1. For one possible arrangement weld a transverse pipe-run

V (sectional steel, e. g. L-type steel to EN 10056 -1

with dimensions 100 x 50 x 6 mm) between the two frames W of the operating device E.

In this case you can provide a recess at the left side of the transverse support V for the installation of the

hydraulic lines without any kinks.

The requirements and specifications of the local welding authority must be observed.

2. The length and form of the hydraulic tubes have to be matched to the transverse pipe-run

V. Install the hydraulic

tubes at the inside (the side facing the bottom valves) of the transverse pipe-run V. The transverse pipe-run V

can then also protect the tubes.

3. Use pipe clamps to fix the hydraulic tubes to the tansverse pipe-run

4. To connect the lines to the longitudinal pipe-run use T-type screw joints

5. For a flexible connection between the hydraulic tubes and the operating devices

hoses with a length of approx. 280 mm.

c

g

V.

.

a

E use prefabricated hydraulic

At the side for connecting the operating device E they are provided with a 90° bend and a union nut M16 x1.5

and at the side for connecting the hydraulic tubes they have a stub M16 x1.5 for connecting the hydraulic tubes.

6. Several connecting lines from the transverse pipe-run

hydraulic tubes , , , .

p q r s

7. Use flexible hydraulic hoses with screwed end connections M16 x1.5 as connecting lines ,

V to the bottom valves can be made by using the

e

d

f

, to the

control unit.

8. If necessary use pipe clamps to connect the connecting lines. Recommended distance between pipe clamps:

approx. 500 mm. Due to the length of the line most connecting lines , will therefore require these clamps.

g

r s

If only hydraulic hoses are used adapt the lengths accordingly and use suitable end connections.

26

Page 27

Installation – continued –

Connecting lines – continued –

If the design of the installation makes it difficult or impossible to run the connecting lines to the end attachments

of the actuating cylinders of the bottom valves HWV 205/1 - DN 80 or HWV 215/1 - DN 80, you can swop the end

connections of the actuating cylinders with the filling connections.

For this purpose use a spanner 19 mm A. F. Apply a torque of 40 Nm to fasten the connections (see below).

Socket-weld end

for manifold

Filling

connection

Connection for

indicating cylinder

P

HWV 205/1

Standard arrangement when supplied

Attention

The hydraulic tubes must meet the requirements of DIN 2391 and must be made of St 37.4 NBK

with a wall thickness of 10 x 1 mm.

The hydraulic hoses must be in accordance with EN 853 - 1SN 8.

When installing the connecting lines make sure that the lines have a slight inclination towards the

middle such that the hydraulic system can be vented.

If necessary take additional precautions to prevent the transverse pipe-run from swinging.

The hydraulic tubes leading to the actuating cylinders must be provided with expansion loops in

order to absorb vibrations.

Check the soft seals of the connections for damage. Only soft seals that are not damaged can be

used again. Replace damaged gaskets and seals.

Filling

connection

P

HWV 215/1

Standard arrangement when supplied

27

Page 28

Installation – continued –

l

h

p

R

c

Hydraulic connecting lines for loading & unloading system HV 215

Provide expansion bend for liquid

phase (only with hydraulic tubes)

g

Control unit HV 215

Provide expansion loop for gas

phase (only with hydraulic tubes)

C

BV 110

g

h

i

s

r

b

q

d

P

R

j

k

a

GL

Reference Designation Qty.

a

b

c

T-type screw joint

Adjustable

T-type screw joint

Hydraulic hose with 90° pipe

bend and connecting stub

f

p

a

e

g

m

l

c

P

R

L

n o

e.g. Company Walterscheid,

Company Ermeto

e.g. Company Walterscheid,

Company Ermeto

G

5

1

8

e

d

f

g

Item Length [mm] Item Length [mm] Item Length [mm]

h

i

j

k

l

m

Hydraulic hose with

2 x union nuts

Dual-type pipe clamp, e.g. Company Stauff 10

n

o

p

q

r

s

d

e

f

Items h-s: Permanent piping with

O. D. of pipe = 10 mm possible.

The tubes supplied by GESTRA

are not bent.

1 each

28

Page 29

Installation – continued –

GESTRA

Attaching operating plates HV 215

Attach the operating plates at both sides of the tank car near the valves so that they are clearly visible.

1. Make sure that the surface onto which you want to stick the adhesive label is clean, dry and free of grease.

2. Remove the protective paper (“Controltac” printed on it) from the adhesive label.

3. Attach the operating plate at the desired position but do not yet stick it firmly to it.

As long as the operating plate is not firmly pressed against die surface you can still change its position.

4. To fix the operating plate permanently use a plastic spatula to press the adhesive label firmly against the surface.

Start in the middle of the label and make sure that no air gets trapped in.

5. Carefully strip off the protective sheet and, if necessary, press the corners of the operating plate again firmly

against the surface.

6. If there are air blisters prick a needle into them and then press the lable again firmly against the surface.

Attaching list indicating fluids

The fluid list must only be attached if bottom valves are used with a valve plug joint CR at both operating devices.

See drawing on page 4

Attach the fluid plates

Z at the middle of the inside of both flaps of the operating devices E so that they are

clearly visible.

29

Page 30

Installation – continued –

Filling and venting of hydraulic system

To fill the whole hydraulic system of the loading system carry out the following two steps:

1. Filling the hydraulic actuator system

Sequence: Both sides separately one after the other.

2. Filling the hydraulic indicating system

Sequence: 1. Liquid phase

2. Gas phase

The hydraulic system has to be filled after installing the loading system or when maintenance work or repairs have

been carried out.

Attention

Use only oils that are recommended by the manufacturer. Recommended oils are ESSO Zerice 22,

ARAL Vitamol 4004 or other oils with similar properties.

Filling and venting of hydraulic actuating system

Depressurise system before filling the hydraulic system.

See drawings on page 4 and page 23

1. Release the tension rope - the ball valve

36

of the control unit X of the bottom valve HWV 215/1 - DN 80

will automatically open the hydraulic system.

2. Unscrew the red plug

S and the dip stick of the oil filling connection of the hydraulic hand pump T

and fill oil into the tank.

3. Pull the tension rope in order to close the ball valve

36

of the control unit X of the bottom valve

HWV 215/1 - DN 80.

4. Operate the hydraulic hand pump

T until the resistance first increases perceptibly, the pressure limiting valve

responses audibly and then there is a distinct pressure relief. Then carry out 20 to 30 strokes with the pump

lever F of the hydraulic hand pump T in order to discharge the air in the hydraulic system via the pressure limiting valve.

5. Use the oil dip stick

S in the cover to check the oil level. If necessary refill oil and screw in plug S of oil filling

connection with a torque of 20 Nm.

6. Finally loosen the tension rope in order to re-open the hydraulic system.

Repeat the whole procedure with the second hydraulic hand pump

T.

30

Page 31

Installation – continued –

Filling and venting of hydraulic indicating system

Open both bottom valves before filling the hydraulic indicating system.

See drawing on page 4

1. Use the operating device

2. Loosen the venting plug

E to open the bottom valves.

Q of the actuating cylinder H of the liquid phase in the operating device E

by half a turn.

3. To fill the hydraulic indicating system connect an external oil hand pump with a pressure gauge

(measuring range: 0 - 20 bar) to the filling connection I of the bottom valve for the liquid phase.

Operate the pump until the oil leaves the venting plug Q of the indicating cylinder H without any bubbles.

4. Then fasten the venting plug

5. Continue to operate the external oil hand pump until the indicating piston

Q tightly.

O is completely moved out

and a pressure of approx. 10 to 20 bar is indicated by the pressure gauge.

6. Finally remove the external oil hand pump from the filling connection

I of the bottom valve and open

the hydraulic system by loosening the tension rope. The bottom valve closes automatically.

Follow the same steps when filling the bottom valve for the gas phase.

Performance test

Use both operating devices

E for the performance test.

See drawings on page 4 and page 23

1. To close the hydraulic system, pull the tension rope that closes the ball valve of the control unit

36

X

of the bottom valve HWV 215/1 - DN 80.

2. Use the pump lever

F of the hydraulic hand pump T in the operating device E and perform approx.

six strokes until you detect a slight resistance. The indicating pistons O of both bottom valves must now

be in the open position and they must be extended by approx. 46 mm.

3. During the hold time of approx. 2 hours the pressure must not decrease.

4. Check all connections and screwed unions for oil leaks. If necessary re-tighten the connections.

5. Then re-open the hydraulic system by loosening the tension rope.

6. Both bottom valves must close automatically and the indicating pistons

O in the operating devices E

must be at the lower position.

31

Page 32

Operation

Service

During the loading process the following actions will take place:

n Opening of bottom valve

n Closing of bottom valve

To open / close the bottom valves operate one of the operating devices

See drawing on page 4

When opening the operating device

1. To open the operating device

You can now swing down the lid.

2. Make sure that the pump lever of the hydraulic pump

3. Connect the rail hook

The ball valve of the control unit X of the bottom vale will close and the hydraulic system is ready for operation.

4. The up-strokes and down-strokes of the lever of the hydraulic hand pump

build up pressure in the hydraulic system, causing the two bottom valves to open simultaneously.

After approx. six strokes of the pump lever both bottom valves will be completely open. Check position

of bottom valves: The opening position of the bottom valves is indicated by the two completely extended

indicating pistons O of the indicating cylinders H (lift of indicating pistons approx. 46 mm).

5. Open the lateral shut-off valves

6. The pump lever of the hydraulic pump

Attention

If only one operating device for the loading system was opened, the lid of the other operating device

cannot be opened when the bottom valves are open.

C (e. g. rail hook VZ 10) to the tension rope and engage it in the rail.

E remove - if necessary - the custom‘s lead seal from the bolt M.

E push the bolt M upwards and then turn it by 90° to one side.

F is completely extended towards the front.

A to start the loading/unloading process.

F is no longer required and must be returned to its original position.

E at either side of the tank.

F in the operating device E

Close bottom valves immediately after loading or unloading the tank.

See drawing on page 4

7. To close the bottom valves disengage the the rail hook

The ball valve of the control unit X opens the hydraulic system and both rapid-action bottom valves will be

closed instantaneously. Be sure that both bottom valves are closed by checking the indicating pistons

of the indicating cylinders H. Both indicating pistons must be retracted.

8. Then close and latch the operating device

9. To finish the loading/unloading process close the shut-off valves

shut-off valves.

Attention

Note: If the lid cannot be closed, one or both bottom valves are still open!

The inside of the lid of the operating device features a bracket. This bracket prevents the closing

of the lid when one or both bottom valves are open. The lid can only be closed when the indicating

pistons are retracted. The cause of this malfunction must be ascertained and eliminated!

If only one operating device for the loading system was opened, the lid of the other operating device

cannot be opened when the bottom valves are open.

E.

C from the rail. This will loosen the tension rope.

O

A and attach the sealing plugs to the

32

Page 33

Operation – continued –

Emergency operation

During emergency unloading the following actions will take place:

n Opening of bottom valve

n Closing of bottom valve

If both bottom valves are to be opened, open first the bottom valve for the gas phase and then the one for

the liquid phase.

See drawing on page 4

1. Unscrew the sealing plug

A small amount of oil might escape. Put the sealing plug J in the operating device E.

2. Unscrew one or two of the required screws for sealing off the opening for emergency unloading

one of the two operating devices E and apply a smear of commercially available lubricant to them.

They are screwed one below the other at the back of the operating device E.

4. Screw the sealing-off screw

the bottom valve.

5. Open the lateral shut-off valves

Warning

Use the emergency operation of the bottom valves only if both hydraulic hand pumps have

failed or, for any other reason, there is not enough pressure for opening one or both bottom valves.

In case of emergency operation a rapid-action closing of the bottom valve is not possible.

If both bottom valves are to be closed via emergency operation, first close the bottom valve for the liquid

phase and then the one for the gas phase.

See drawing on page 4

J of the bottom valve located in the bottom of the actuating cylinder B.

K from

K into the thread at the bottom of the actuating cylinder B in order to open

A to start the loading / unloading process.

1. To close the bottom valve unscrew the sealing-off screw for emergency unloading

of the actuating cylinder B. The spring in the bottom valve effects the closing.

2. Once the emergency loading/unloading process has been accomplished, screw the sealing-off screws

back into the rear wall of the operating device E.

3. To finish the loading/unloading process, close the shut-off valves

the shut-off valves.

4. Defective bottom valves must be permanently marked in order to avoid inadvertent re-commissioning.

Do not screw sealing plugs J into defective bottom valves.

5. The cause of the malfunction must be ascertained and eliminated by qualified personnel!

Warning

In case of emergency operation a rapid-action closing of the bottom valve is not possible.

When the emergency operation of one or both bottom valves is finished, find and eliminate the

cause for the malfunction. Note that the repeated or continuous application of the emergency

operation is considered as improper usage. The resulting risk will have to be borne by the user alone.

The manufacturer hereby expressly rejects any claims for any resulting damage.

A and attach the sealing plugs to

K out of the bottom

K

33

Page 34

Maintenance

Bottom valves HWV 205/1 - DN 80/ HWV 215/1 - DN 80

Type of maintenance Time interval Activity

Check

valve plug seal

31

Replace

valve plug seal

31

Check

actuating cylinder B

Check

torque of 50 Nm

$

Check

torque of 120 Nm b

When necessary,

during main inspection

If a leak is detected replace valve plug seal

at the latest (every 4 yrs.)

Main inspection

(every 4 yrs.)

When necessary,

during main inspection

cylinder and body. If you detect an oil leak

at the latest (every 4 yrs.)

When necessary,

during main inspection

Check the torques of the four hexagon-head cap screws

of the actuating cylinder and, if necessary, retighten the

at the latest (every 4 yrs.)

When necessary,

34

during main inspection

at the latest (every 4 yrs.)

Check and, if necessary, re-tighten the six hexagon-head

cap screws of the body and the two hexagon nuts that fix

the control unit to the body with a torque of 120 Nm.

Check valve head for leaks.

as described in section “Maintenance”.

Replace valve plug seal as described

in section “Maintenance”.

Check connection between actuating

replace the PTFE seal and the O-ring

as described in section “Maintenance”.

screws to a torque of 50 Nm.

Check

smoothness of operation

of ball valve shaft

36

Replace

piston seal

(

When necessary,

during main inspection

at the latest (every 4 yrs.)

When necessary,

every 8 years at the latest

Check smooth operationg of switching shaft.

If the switching shaft does not move smoothly apply

a commercially available lubricant.

Replace piston seal

as described in section “Maintenance”.

34

Page 35

Maintenance – continued –

Operating device BV 110

Type of maintenance Time interval Activity

Check

oil level

Check

tightness

Check

valve lift

Check

holding pressure

Check

rapid-action closing

When necessary,

during main inspection

at the latest (every 4 yrs.)

When necessary,

during main inspection

at the latest (every 4 yrs.)

When necessary,

during main inspection

at the latest (every 4 yrs.)

When necessary,

during main inspection

at the latest (every 4 yrs.)

When necessary,

during main inspection

at the latest (every 4 yrs.)

The level in the tank of the hydraulic hand pump

must be above the lower marking on the dip stick.

Make sure that oil cannot escape at connections,

joints and T-type screwed unions.

If necessary, retighten respective connections.

With the hydraulic system closed, after approx. 6 lifts

of the hydraulic hand pump both indicating pistons

must be completely extended (height approx. 46 mm).

With the hydraulic system closed, both bottom valves

must withstand a constant pressure for two hours

without closing.

When disengaging the tension rope the rapid-action

closing must take place within one second and

the indicating pistons must be at the lower marking.

Check

completeness

Connecting lines

Type of maintenance Time interval Activity

Check

tightness

When necessary,

during main inspection

at the latest (every 4 yrs.)

When necessary,

during main inspection

at the latest (every 4 yrs.)

Both operating devices must have two emergency operating

screws each. These emergency operating screws must be

screwed in the rear wall.

Make sure that no oil can escape

at connecting joints and T-type screwed unions.

If necessary, retighten respective connections.

35

Page 36

Servicing

Hydraulic loading & unloading system HV 215

Observe the following servicing instructions whenever carrying out:

n Visual examinations as part of the main inspection

n Repair work due to leaks or other malfunctions

The bottom valves HWV 205/1 - DN 80 and HWV 215/1 - DN 80 require maintenance and servicing. The operating

device BV 110 is maintenance free.

We recommend removing the bottom valves HWV 205/1 - DN 80 and HWV 215/1 - DN 80 and checking them for

wear and damage when performing visual inspections.

Do not re-use parts subject to wear, such as gaskets and seals. Worn or damaged parts must be replaced after ascer

taining and eliminating the cause of the damage. Use only genuine GESTRA parts.

GESTRA supplies the following seal kits:

1. Stock code 049387

n 1 Valve plug seal PTFE

31

n 2 Gaskets ∅ 125 68

2. Stock code 049395

n 1 Valve plug seal CR

31

n 2 Gaskets ∅ 125 68

3. Stock code 049563

n 1 Piston seal §

n 1 Seal ring a

n 2 O-rings ()

n 1 Gasket !

n 1 Gasket &

Modifications to the design may only be made if the manufacturer‘s written permission is obtained.

-

Replacing valve plug seal

The valve head can be removed directly inside the tank. This option is highly recommended since in this case the

bottom valves, the connecting lines and the hydraulic system do not require any additional preparation.

If, however, the valve head can only be removed from the outside, please proceed as follows:

See drawings on page 4, page 6 and page 38

1. First disconnect all connections of the actuating cylinder

B. A small amount of oil might escape.

Collect the oil and dispose of it correctly.

2. If possible separate the manifold from the body.

3. To remove the body and the actuating cylinder

B unscrew the six hexagon-head cap screws b of the body

and remove the body and the associated actuating cylinder together. Remove gasket 8.

4. Undo the 12 socket-head cap screws

c and take the valve head from the mounting flange. For this purpose

you can screw two hexagon-head cap screws M 10 into the two through threads of the seat flange.

Note that these screws are not scope of the supply.

36

Page 37

Servicing – continued –

Replacing valve plug seal – continued –

Remove gasket 6.To remove the valve head proceed as follows:

See drawing on page 38

1. Secure the preloaded compression spring

f. For this purpose you can use a device (not scope of the supply)

that bears the load of the spring by means of leverage so that the 6 hexagon-head cap screws can be safely

loosened.

2. Then unscrew the six hexagon-head cap screws

1 with the locking washer 2 out of the stay bolt 4.

Take the valve plug e together with the spring plate 3 and the compression spring f out of

the seat flange. 7.

3. Then remove the retaining ring

4. Unscrew the four socket-head cap screws

h and the washer g.

i, take out the washer j and remove the valve plug seal .

31

Carefully clean all removed and dismantled parts.

Warning

Any use of naked flames is expressly forbidden!

Before performing any service work inside the tank make sure that the tank is sufficiently

ventilated and all gases have been completely vented. The rules concerning MAC (= maximum

allowable concentration) values at place of work must be strictly applied!

Note that an inadequately secured compression spring can lead to parts flying around, causing

serious injuries.

To mount the valve head proceed in reverse order of the removing procedure:

See drawing further down

1. Put the valve plug seal onto to valve plug

31

e and screw in the four socket-head cap screws i together

with the washer j, applying a torque of 15 Nm. Apply a commercially available lubricant to the screws

and tighten them in several steps in diagonally opposite pairs.

2. Then secure the washer

3. Screw the six hexagon-head cap screws

g by using the retaining ring h.

1 together with the locking washers 2 into the stay bolts 3,

using a torque of 25 Nm. Apply a commerically available lubricant to the screws and tighten them in several

steps in diagonally opposite pairs.

To mount the bottom valves from the outside follow the instructions given in section “Installation” (see page 17 for

HWV 205/1 - DN 80 and page 20 for HWV 215/1 - DN 80).

Attention

The specified torques must be strictly observed.

37

Page 38

Servicing – continued –

Replacing valve plug seal – continued –

1

2

3

4

5

6

7

31

ji h g

f

e

d

c

38

Page 39

Servicing – continued –

Reworking seat flange

If the seatings surface of the seat flange is slightly damaged you can remove and rework the seat flange.

For more details see drawing below.

To remove the seat flange please proceed as follows:

See drawing on page 38

1. Remove body and actuating cylinder.

2. Unscrew the 12 socket-head cap screws

the seat flange. Take out the gasket 6.

3. Unscrew the six stay bolts

Re-assembly in reverse order:

See drawing on page 42

1. First push the sleeves

to the seat flange 7. Apply a commerically available lubricant to the screws and tighten them.

2. To mount the valve head follow the indicated steps (see page 38).

3. Then put a new gasket

4. Use the 12 socket-head cap screws

to the mounting flange. Tighten them with a torque of 120 Nm. Apply a commercially available lubricant

to the screws and tighten them in several steps in diagonally opposite pairs.

4 together with their sleeves 5 out of the seat flange 7.

5 onto the six stay bolts 4 and then screw them with a torque of 25 Nm

6 onto the seat flange 7.

c and their associated locking washers d and remove

c together with their locking washers d to mount the valve head

Attention

The specified torques must be strictly observed.

∅ 85

Ra 0.8

max. 5 x 45°

39

Page 40

Servicing – continued –

Replacing gaskets of actuating cylinder

To remove the actuating cylinder proceed as follows:

See drawings on page 6 and page 41

1. If connecting lines are still attached to the actuating cylinder, you have to detach these connections

A small amount of oil might escape. Collect the oil and dispose of it correctly.

32

first.

2. Unscrew the four hexagon-head cap screws

$ in the bottom of the actuating cylinder and remove

the actuating cylinder.

3. First take out the sealing plug

% and the joint ring &. Use this opening to carefully pull the piston ",

the push rod 9 and the bellows 0 out of the actuating cylinder.

4. Take out the piston seal

5. Pull the piston

" out of the bellows 0.

6. Remove the retaining ring

§.

/ of the lower part of the bellows 0 and pull out the bushing =.

Take out the O-ring ) and the seal ring a.

7. Then remove the O-ring

To install the actuating cylinder

( from the actuating cylinder.

B proceed as follows:

See drawing on page 41

1. First insert a new O-ring

2. Insert first the seal ring

( in the actuating cylinder.

a and the O-ring ) in the lower part of the bellows 0. Then put the bushing =

into the bellows 0 and secure it with the retaining ring /.

3. Then place the piston seal

4. Put the piston

" into the bellows 0. Apply a light smear of hydraulic oil to the piston seal §.

§ onto the piston ".

Then put this component into the actuating cyclinder.

5. Screw the sealing plug

% with the joint ring & into the actuating cylinder.

40

Page 41

Servicing – continued –

Replacing gaskets of actuating cylinder – continued –

9

a

0

=

)

!

(

32

/

"

§

32

&%

41

Page 42

Servicing – continued –

Replacing control unit of bottom valve

In the control unit the ball valve with the tension rope will be replaced.

To remove the item proceed as follows:

See drawing further down

1. Disengage the spring from the lever of the ball valve .

2. Detach the hydraulic hoses .

3. Unscrew the two hexagon nuts and their locking washers and remove the ball valve .

42 36

41

39 40 36

To install the item proceed as follows:

1. Use two hexagon-head cap screws and hexagon nuts with washing lockers to fix the ball valve

to the support with a torque of 25 Nm.

37

2. Attach the connections for the hydraulic hoses .

3. Engage the spring in the lever of the ball valve .

42 36

38 39 40 36

41

Attention

The specified torques must be strictly observed.

42 41

36 37 38 39 40

42

Page 43

43

Page 44

Agencies all over the world:

www.gestra.de

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03 - 0

Fax +49 (0) 421 35 03 - 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

818480-01/1005cm · © 2003 GESTRA AG · Bremen · Printed in Germany

44

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel. 00 15 02 / 4 95 01 54, 4 95 17 88

Fax 00 15 02 / 4 95 16 08

E-mail: dgoodwin@flowserve.com

Loading...

Loading...