Page 1

Worcester Controls

CAUTION: Flowserve recommends that all products which must be

stored prior to installation be stored indoors, in an environment

suitable for human occupancy. Do not store product in areas where

exposure to relative humidity above 85%, acid or alkali fumes, radiation above normal background, ultraviolet light, or temperatures

above 120°F or below 40°F may occur. Do not store within 50 feet of

any source of ozone.

A. INSTALLATION

1. Valve is designed for flow in either direction. Use care to exclude

pipe sealants from valve cavity.

2. When installing CPT 44 or CPT 51/52 flanged valves, use

standard gaskets suitable for the specific service and tighten the

flange bolts or studs evenly. On CPT 44 wafer valves it is

recommended to leave the ball in the open position while

installing, to eliminate possibility of damaging ball finish.

3. CPT 44 Weld End Valves (SW, BW):

NOTES: Prior to welding, THOROUGHLY CLEAN ALL JOINT

SURFACES to prevent contamination.

Valves with “AG”, “GG”, “PG”, “RG”, and “XG” seat/body seal

combinations and V67 option code are compatible with welding

temperatures. Therefore, these valves are weld-as-is and do not have

to be disassembled to be welded in line. These valves will have a red

welding tag attached. If these valves are disassembled, the graphite

coated stainless steel gasket body seals (code “G”), and the seat back

seals (used with “A” or “G” seats only) must be replaced. When

welding these valves, the valve must be open to prevent adhesion of

weld spatter to the ball. Use STICK or MIG welding, and allow valve

and joint to cool to the touch between passes.

For All Other Weld End Valves:

a. Tack weld the valve in place.

b. Remove actuator and all four body nuts and bolts and place

the valve in the open position.

c. Remove center section from between pipe ends by separating

the pipe ends from the body by at least !?8" to allow locating

diameter on the back of the metal characterized seat (inserted

into oversized pipe end bore) to clear pipe end flange.

d. With valve in closed position, remove seats, seat back seal(s),

body seals and ball. Return the body to its original position

and temporarily secure it with two bolts diagonally opposite

each other.

e. Weld valve in line. If gas welding is used, do not play flame on

valve body.

f. Allow valve to cool. Remove body and, with stem in the closed

position, replace ball, seats and install new seat back seal(s),

which are shipped separately from valve. Do not reuse old seat

back seal(s). The characterized seat has a “V” or “Slot” cut in it

for improved flow control, and must be properly oriented to

function. A locating pin is provided in the body, and a groove

in the seat, to assure that proper alignment is accomplished.

The seat must fit properly and not jam on the pin. The opposite

seat has a standard round port in it.

g. Open the valve and replace body seals, or add new body seals, if

they were shipped separately from the valve. Temporary Buna

body seals, if found in the valve as received, are not to be reused.

(If coated stainless steel “S” gasket body seals are used [Code M

or G], install them with wide flange facing the body [see view A-A

on page 6]). Before putting the center section between the pipe

ends, make sure that the seat back seal is centered on the back of

the seat. If it is not, it could be damaged or cause the valve to leak.

h. Place center section between pipe ends by separating the pipe

ends from the body by at least A?k" to allow locating diameter

on the back of the metal characterized seat (for insertion into

oversized pipe end bore) to clear pipe end flange. Replace

actuator and body bolts and nuts. Tighten and torque the body

bolts evenly and diagonally opposite each other, alternating in

a criss-cross pattern to the following torque figures:

17812-N

Metal Characterized-seated Control Valve

1

/4" – 4" CPT 44 and 1/2" – 4" CPT 51/52

Installation, Operation and Maintenance Instructions

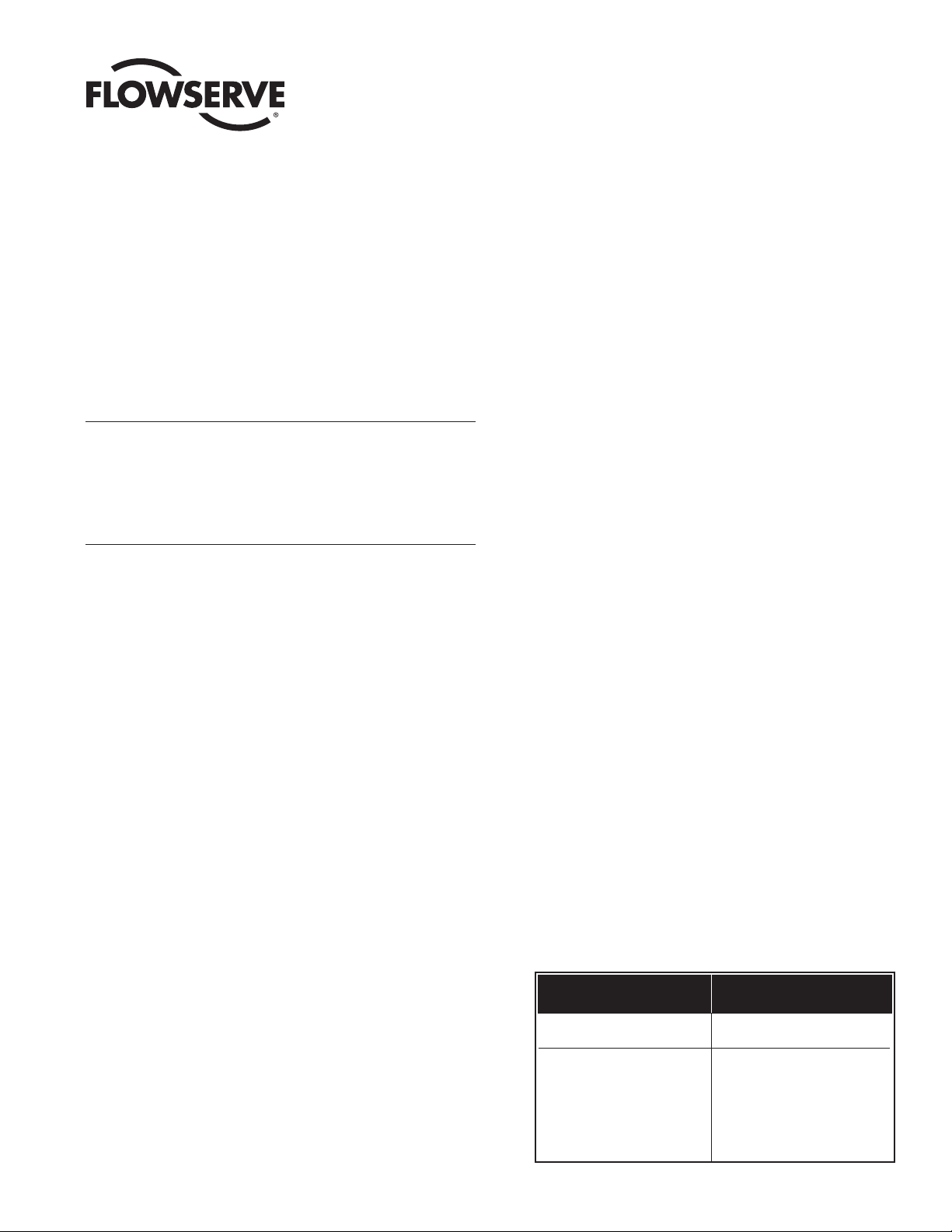

Carbon Steel Stainless Steel and

Bolts Alloy 20 Bolts

Bolt Bolt

Diameter in-lb ft-lb Diameter in-lb ft-lb

!?4" 96-120 8-10 !?4" 72-94 6-8

%?16" 156-204 13-17 %?16" 120-144 10-12

#?8" 216-264 18-22 #?8" 192-216 16-18

/?16" 480-540 40-45 /?16" 336-384 28-32

!?2" 720-780 60-65 !?2" 504-552 42-46

Page 2

2 Metal Characterized-Seated Control Valve !?4"–4" CPT 44 and !?2"–4" CPT 51/52 Installation, Operation and Maintenance 17812-N

Flow Control Division

Worcester Controls

NOTE: Stainless steel bolts and nuts are used in all three-piece valves

with stainless steel bodies and also valves with “GG” seats and body

seals.

4. CAUTION:

a. The seat back seals, fluoropolymer body seals (T), and the

coated stainless steel gasket body seals (M and G) are not

reusable. Upon disassembly of the valve these seals must

be replaced. Also ensure that the fluoropolymer seals, or

the coating of the stainless steel gaskets is not scratched or

damaged during installation. Light lubrication of these seals

can help to prevent damage.

b. Care must also be taken when handling graphite thrust bear-

ings, stem seals or seat back seals. These parts can be

easily damaged by squeezing the O.D. of the seal. Parts are

to be handled on the flat surfaces rather than the O.D.

c. The ball used in CPT valves is round to special tolerances

to ensure proper contact with the seat. Do not drop, dent or

scratch the ball during handling. The ball also has a

special anti-galling coating; DO NOT use an uncoated ball

in CPT valves.

B. OPERATION

1. The operation consists of turning the stem A?f turn clockwise to

close and !?4 turn counter-clockwise to open. When stem flats

(!?4" – 2") or stem groove (3", 4") are in line with the pipeline, the

valve is open. This valve is designed to be automated.

2. CPT valves meet the leakage rates of ANSI B16.104 Class VI.

3. As shipped from the factory, valves contain a silicone-based

lubricant. This is for break-in purposes. Lubricant may be

removed with a solvent, such as lacquer thinner, if found to be

objectionable for a particular application, and replaced with a

non-silicone based lubricant. CPT valves should not be operated

without a break-in lubricant.

4. Media which can solidify, crystallize or polymerize should not be

allowed to stand in valve cavities.

5. Torque Requirements: Operating torque requirements will vary

depending on the length of time between cycles, line pressure, type

of valve seats, and the media in the system. All figures in the

following table are based in laboratory tests with water as the

media. They are measured at WOG rated pressure, 70°F, with clean

tap water, after 24 hours. For a more detailed analysis of valve

torque requirements, see Worcester’s Actuator Sizing Manual.

C. MAINTENANCE

1. For 3"– 4" CPT 44/51/52 Revision RO-R2 valves, if seepage is noted

at stem, tighten retaining nut 1/6 turn at a time until seepage stops.

2. Tighten stem seal retaining nut (!?2"– 2" CPT 44 Revision RO valves)

or self-locking stem nut (!?4"– 2" CPT 44 & !?2"– 2" CPT 51/52

Revision R1-R4 valves) if seepage is noted at stem.

CAUTION: For maximum stem seal life, proper stem adjustment

procedures must be followed. Excessive tightening causes higher

torque and shorter stem seal life.

Revision RO Valves:

a. Loosen top retaining nut.

b. While holding the stem to prevent turning, tighten bottom-

retaining nut until Belleville washers are flat (the nut will bottom).

c. Back off bottom retaining nut !?6 turn.

d. Tighten the top retaining nut securely to lock the bottom

retaining nut in place with the lockwasher in between. Hold the

bottom nut securely with wrench while tightening the top nut to

lock the two nuts in place.

Revision R1 -R4 Valves:

e. Tighten self-locking stem nut until Bellevilles washers are flat,

then back off nut !?3 turn.

CAUTION: The self-locking stem nut is difficult to tighten, and

must fully flatten Bellevilles before backing off.

D. REBUILDING

a WARNING: - BALL VALVES CAN TRAP PRESSURIZED FLUIDS IN

THE BALL CAVITY WHEN CLOSED.

If the valve has been used to handle hazardous media, it must be

decontaminated before disassembly. It is recommended that the

following steps be taken for safe removal and disassembly.

• Relieve the line pressure. Operate the valve prior to attempting

removal from line.

• Place the valve in half-open position and flush the line to

remove any hazardous material from the valve body.

• All persons involved in the removal and disassembly of the

valve should wear the proper protective clothing such as a face

shield, gloves, apron, etc.

1. A standard repair kit can be ordered for these valves consisting

of seats, control seat or control seat insert (3"– 6" valves only),

body seal(s), seat seal(s), Belleville washers, stem seal(s), thrust

bearing(s), and a self-locking stem nut (!?4"– 2" Revision R1-R4

valves only). Specify the valve size and series, the material of the

seat and body seal, the characterized seat configuration (if

needed), and the “R” number (Revision Number) of the valve or

for non-standard valve, the “P” number, “T” number, “C”

number, or similar, as found on either the mounting bracket

nameplate or the valve nameplate.

Maximum Expected

Valve Size Breakaway Torque

!?4", !?2" 150 in-lb

#?4" 175 in-lb

1" 250 in-lb

1!?2" 400 in-lb

2" 700 in-lb

3" 1900 in-lb

4" 3300 in-lb

Page 3

17812-N Metal Characterized-Seated Control Valve !?4"–4" CPT 44 and !?2"–4" CPT 51/52 Installation, Operation and Maintenance 3

CAUTION: If the seats and seals installed differ from those removed,

the valve nameplate must be replaced or remarked to indicate the

altered materials and ratings, or valve tagged to so indicate.

2. To Disassemble !?4"– 2" CPT 44 Valves (All Revisions):

a. Remove actuator and all four body nuts and bolts, and place the

valve in the open position.

b. Remove center section from between pipe ends by separating

the pipe ends from the body by at least !?8" to allow locating

diameter on the back of the metal characterized seat (inserted

into oversized pipe end bore) to clear pipe end flange.

c. With valve in closed position, remove old seats, seat back

seal(s), body seals and ball.

d. Revision RO Valves: Using a wrench to prevent stem from

turning, remove top retaining nut, lockwasher, bottom retaining

nut, and (2) Belleville washers from stem.

Revision R1-R4 Valves: Using a wrench to prevent stem from

turning, remove self-locking stem nut, and (4) Belleville washers

from stem.

e. Remove the follower, stem, stem seal(s), stem seal protector (if

any), thrust bearing, and thrust bearing protector (if any), which

may be on the stem or in the body cavity. Retain the follower.

To Disassemble !?2"– 2" CPT 51/52 Valves (All Revisions):

f. Remove actuator from valve. Remove valve from line. Unscrew

end plug and set aside. If the body seal was not removed with the

end plug, remove it from the body and discard. Also remove the

near seat and seat back seal, if applicable. Place valve in closed

position and remove the ball, the far seat and seat seal.

NOTE: If required, end plug removal tools are available from your

supplier or from your Worcester representative.

g. Using a wrench to prevent stem from turning, remove self-

locking stem nut, and (4) Belleville washers from stem.

NOTE: On the !?2" valve, the far seat must be removed before pushing

stem into cavity.

h. Remove the follower, stem, stem seal(s), stem seal protector

(if any), and thrust bearing, and thrust bearing protector (if

any), which may be on the stem or in the body cavity. Retain

the follower.

To Disassemble 3"– 4" CPT 44/51/52 Valves (All Revisions):

i. Remove actuator from valve. Unscrew all flange bolts and nuts

and remove valve from line. Remove all end plug retaining set

screws from the valve body. Remove end plug. If necessary, drive

end plug from the valve using a wooden drift applied to the ball.

If the body seal was not removed with the end plug, remove it

from the body and discard. Also remove the near seat and seat

back seal (if any). Place valve in closed position and remove the

ball, the far seat, seat insert (if used), and seat back seal.

General Note: Due to different valve series and body styles, one

or two metal stem centering washers may be used and the stem

seal may be one-piece or three-piece, and may include a stem

seal protector.

j. Prevent the stem from turning by holding inside body. (The ball

can be inserted and prevented from rotating with a non-metallic

rod such as a screwdriver handle.) This will hold the stem

stationary without damaging the ball. Remove retaining nut and

stem spacer (if used).

k. Remove Belleville washers (if any). Remove and retain the

follower and push stem into ball cavity and remove. Discard old

stem seal protector (if any), stem seal(s) and thrust bearing,

which may be stuck on the stem or in the body cavity. Remove

stem-centering washer(s) and retain.

3. Visual Inspection:

a. As noted in part A.4.c, the ball is round to special tolerances and

should be visually checked for defects. Light marring from the

action of the ball against the seats is normal and will not affect

the operation of the valve. Visible tracking is normal. Tracking

which can be felt is a potential problem.

b. The stem and body surfaces that the thrust bearing and stem

seal contact should be clean, undamaged, and free of pit marks

and scratches.

4. Reassembly:

NOTE: For all valves, lightly lubricate the ball, seats, seat back seal(s),

body seal(s), stem seal(s), and thrust bearing(s) with a lubricant

compatible with the media and temperature being handled. White

petroleum jelly is a good general-purpose lubricant.

When a repair kit is purchased, the seats will be lubricated at the

factory. If they are not, they should be lubricated as noted in

Paragraph D.4. and B.3. DO NOT operate a newly rebuilt valve

without break-in lubricant. The seat back seals will be preassembled to the seat backs.

If graphite parts are used, handle them gently on the flat surfaces

rather than the O.D. These parts can be easily damaged by

squeezing the O.D. These parts will not work if they are cracked or

broken. Light flaking of the material is acceptable.

For stem area rebuilding of all CPT valves, refer to exploded views,

stem build illustrations, and stem component color chart on the

following pages that pertain to the particular valve being rebuilt.

Please note that PEEK thrust bearing and stem seal protectors are

placed outside of seals and bearings. The seals and bearings must

contact the body.

Flow Control Division

Worcester Controls

Repair Kit Order Example

1" CPT RK 44 GG G60 R1 or TO914

(Size) (Valve Series) (Repair Kit) (Valve Type) (Seat, Seal) (Characterized Seat Configuration) (Revision # or P, T, C, etc., #)

Not Used with A?s"– 2" CPT

44 Revision RO Valves

Page 4

4 Metal Characterized-Seated Control Valve !?4"–4" CPT 44 and !?2"–4" CPT 51/52 Installation, Operation and Maintenance 17812-N

A?f"– 2" CPT 44 Valves:

Revision RO Valves:

a. Place new thrust bearing on stem and insert through body cavity.

The stem seal is generally thicker than the thrust bearing.

b. Place new stem seal, new stem seal protector of PEEK material

(only if valve has High-per Fill (“X”) seat on one end), follower

and (2) new Belleville washers, with outer edges touching, on

stem. If the stem seal does not easily go down over stem or into

the body, use the follower to gently push the seal down.

c. Place bottom retaining nut on stem and, using a wrench to

prevent rotation, tighten retaining nuts as noted in Paragraph C

(Maintenance). Excessive tightening causes higher torque and

shorter seal life. For graphite stem trim, tighten retaining nut to

35 inch pounds, do not bottom.

Revision R1-R4 Valves:

d. Place a new PEEK thrust bearing protector (except for Revision

R1 valves) and a new thrust bearing on the stem and insert

assembly through body cavity. Place a single new thick stem seal

or a new thin stem seal and a new thick stem seal, depending on

seat material, a new stem seal protector, and the follower in

position. Stem seals, stem seal/thrust bearing protectors and

thrust bearings that are the same size and color are generally

interchangeable.

e. Add (4) new Belleville washers (two pairs of Belleville washers

must have the larger diameter sides touching each other).

f. Place the self-locking stem nut on stem and, using a wrench to

prevent stem from turning, tighten as noted in Paragraph C

(Maintenance).

Revision R0-R4 Valves:

g. With the valve in the closed position (stem flats going across

pipeline), replace ball, seats and seat back seal(s) (used with “A”

or “G” filled metal seats only). The characterized seat has a “V”

or “Slot” cut in it for improved flow control. It must be properly

oriented to function and the seat can only fit in the pipe end with

an oversized port hole. A locating pin is provided in the body and

a groove in the seat to assure that proper alignment is

accomplished. This valve seat can only be assembled one way

and must fit properly, not jam, on the pin. The opposite seat has

a standard round port in it.

h. Open the valve and add body seals (if coated stainless steel “S”

gasket body seals are used, install them with wide flange facing

the body. See View A-A on page 6). Before putting the center

section between the pipe ends, make sure that the seat back seal

is located on the seat correctly. If it is not, it could be damaged

or cause the valve to leak.

i. Place center section between pipe ends by separating the pipe

ends from the body by at least !?8" to allow locating diameter on

the back of the metal characterized seat (for insertion into

oversized pipe end bore) to clear pipe and flange. Replace

actuator and body bolts and evenly tighten and torque the body

bolts to the figures in Paragraph A.3.h.

A?s"– 2" CPT 51/52 Valves (All Revisions):

j. On all sizes except the !?2", insert far (characterized) seat and seat

back seal. The seat has a “V” or “Slot” cut in it for improved flow

control, and must be properly oriented to function. A locating pin

is provided in the body, and a groove in the seat, to assure that

proper alignment is accomplished. This valve seat can only be

assembled one way and must fit properly, not jam, on the pin.

The seat should appear to sit flat into the back of the cavity

indicating that the seat back seal is properly located on the seat.

If the seat back seal is not correctly positioned, it could be

damaged or cause the valve to leak.

k. Place a new PEEK thrust bearing protector and a new thrust

bearing on the stem and insert assembly through body cavity.

Place a single new thick stem seal or a new thin stem seal and a

new thick stem seal, depending on seat material, a new PEEK

stem seal protector, and the follower in position. Stem seals,

stem seal/thrust bearing protector and thrust bearings that are

the same size and color are generally interchangeable.

l. Add (4) new Belleville washers (two pairs of Belleville washers

must have the larger diameter sides touching each other).

m. Place the self-locking stem nut on stem, and using a wrench to

prevent stem from turning, tighten as noted in Paragraph C

(Maintenance).

n. (Insert the far [characterized] seat and seat back seal into A?s"

valves per Paragraph j.)

o. With valve closed, install ball, opposite seat, seat back seal (used

with “A” or “G” filled metal seats only) and body seal (if coated

stainless steel “S” gasket body seal is used, install it with wide

flange facing center of valve. See View A-A on page 6). The

opposite seat has a standard round port in it.

p. Install end plug into body until body and end plug are metal to

metal. The end plug may project up to .009" beyond

surrounding serrated surface. End plug must be fully tightened

against machined step in body. If in doubt, assemble end plug

without seat and seal, make a witness mark and reassemble the

full assembly.

3"– 4" CPT 44/51/52 Valves (All Revisions):

q. Assemble the far (characterized) seat insert and seat (A or G

filled metal), or for Revision R2 and later valves only, one-piece

characterized seat, and seat back seal into the body cavity. The

one-piece characterized seat or seat insert has a “V” cut in it for

improved flow control and must be properly oriented to

function. To assure that proper alignment is accomplished,

Revision R0-R1 valves have a locating pin provided in the body

cavity, and a groove in the seat insert. This valve seat insert can

only be assembled one way and must fit properly, not jam, on

the pin. For Revision R2 and later valves, the one-piece seat has

a locating nib that aligns with a groove in the body cavity. The

seat should appear to sit flat into the back of the cavity

indicating that the seat back seal is properly located on the seat.

If the seat back seal is not correctly positioned it could be

damaged or cause the valve to leak.

r. Reinstall stem centering washer(s) into the recesses in the body.

When only one washer is used, it goes inside recess on top of

the body and under the stem seal(s).

Flow Control Division

Worcester Controls

Page 5

17812-N Metal Characterized-Seated Control Valve !?4"–4" CPT 44 and !?2"–4" CPT 51/52 Installation, Operation and Maintenance 5

s. Place new thrust bearing onto stem and insert through body

cavity. The thrust bearing can be distinguished from the stem

seals by the darker color of the 25% filled fluoropolymer used in

the thrust bearing. A graphite stem seal which is metallic silver

gray in color is larger than the thrust bearing. Stem seals and

thrust bearings of the same size and color are generally

interchangeable.

t. Assemble new stem seal(s) over the top of the stem and down

into the recess in the top of the body. For Revision R1 and R2

valves only, install a new PEEK stem seal protector over stem

seals. The follower is assembled on top of the stem seal(s). If the

stem seal does not easily seat into the body recess, use the

follower to gently push it in place. Place spacer onto the valve

stem. For valves with graphite stem seal and all Revision R1 and

R2 valves, add two Belleville washers with large diameter sides

touching each other and do not use stem spacer.

u. Place retaining nut on stem. Using a wrench to prevent rotation,

tighten retaining nut to fully compress packing, then back off 1/6

turn. Excessive tightening causes higher torque and shorter stem

seal life. For graphite stem trim, tighten retaining nut to fully

flatten Bellevilles, then back nut off !?6 turn.

v. With the valve in the closed position (stem groove going across

pipeline), place ball inside the body cavity engaging the stem

slot. Assemble body seal into its recess in the body making sure

that it is seated properly. (Caution: If the body seal is installed on

the end plug, it will be damaged.) Assemble round port seat and

seat back seal (used with “A” or “G” filled metal seats only) into

the seat recess of the end plug. Then slide the end plug into the

body as far as it will go.

w. Finally, secure end plug in place by threading in the end plug

retaining set screws, and tightening each one firmly. Proper

installation will allow not more than .010" protrusion of the end

plug beyond the valve body.

Upon reinstallation of the valve in the line, retighten the end plug

retaining screws after the flange bolts are fully torqued up.

After the valve is assembled, it should be cycled a few times to ensure

that the valve operates smoothly with no chattering of the ball. The

normal operation is an initial high torque to “break” from the closed

position to a smooth running lower torque mid-cycle, to a high torque

at the end of the 90° cycle or open position. The torque is similar

when closing.

When ordering parts, please provide the part name and the

following information from the valve nameplate or mounting bracket

nameplate: Valve Size, Style and Revision Number, e.g.,

!?2" CPT 44 46 GG SE G30 R1 Ball; or for non-standard product,

valve size and “P” number, “T” number, “C” number, or similar e.g.,

1" CPT 44 66 XG SW A30 T0726 Stem.

The terminology shown in the following exploded view parts listings

is standard.

Flow Control Division

Worcester Controls

3" and 4" 150# and 300# Flanged Construction

3" and 4" 151/301 Wafer Construction

Page 6

6 Metal Characterized-Seated Control Valve !?4"–4" CPT 44 and !?2"–4" CPT 51/52 Installation, Operation and Maintenance 17812-N

"

"

"

1

/2"–2" CPT 51/52

(11/2" and 2" size valves shown)

1

/4"–2" CPT 44

(11/2" and 2" size valves shown)

View A-A

Flow Control Division

Worcester Controls

Page 7

17812-N Metal Characterized-Seated Control Valve !?4"–4" CPT 44 and !?2"–4" CPT 51/52 Installation, Operation and Maintenance 7

""

""

"

1

/4"–2" CPT Valve Stem Builds

Revision R2-R4 Valves

with A, G, P, R or T Seat

Revision R2-R4 Valves

with High-per Fill X Seat

Revision R1 Valve

with G, P, T or X Seat

Revision R1 Valve

with UHMWPE U Seat

Flow Control Division

Worcester Controls

NOTE: For part colors, see color chart on back page.

Page 8

Flow Control Division

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. 17812-N 8/03 Printed in USA

"

"

"

"

"

"

1

/4"–2" CPT Valve Stem Builds

Revision R0 Valve with P or T Seat

Revision R0 Valve with High-per Fill X Seat

Revision R0 Valve with G Seat

Revision R0 Valve with UHMWPE U Seat

Loading...

Loading...