Page 1

Flow Solutions Division

CPM Seal Support

Reservoir Assembly

Installation Instructions

Page 2

Introduction

This manual covers the installation and operation of the CPM Seal

Support Reservoir for dual non-pressurized (API Plan 52/ANSI Plan

7352) and dual pressurized seals (API Plan 53/ANSI Plan 7353). The

following instructions describe the appropriate system, buffer/barrier

fluids, installation, start-up, and maintenance.

Reservoir

The standard CPM Seal Support Reservoir is designed in accordance

with ASME Code Section VIII, Division 1. All tanks are welded in accordance with ASME Code Section IX. Tanks include inlet, outlet, vent and

fill along with two mounting lugs as minimum connections.

Sealing System Description

CPM Seal Support Reservoir can be used as reservoirs for dual pressurized Inside, dual pressurized inside/outside or dual non-pressurized

Flowserve Seal designs. The sealing system produced is defined as

being either a thermal convection system or a forced circulation system.

Support System Descriptions

An API Plan 53/ANSI 7353 is a pressurized dual seal system which is

used in services where no process leakage to atmosphere is tolerated.

The system consists of dual mechanical seals with a barrier fluid between them. The barrier fluid in the supply tank is pressurized to a higher

pressure (normally 25 psig [1.7 bar]) than the seal chamber maximum

160 psig [11 bar]). Primary (inboard) seal leakage will be barrier fluid into

the product. Minimal leakage is customary.

An API Plan 53/ANSI Plan 7353 is usually chosen over an API Plan 52/

ASNI Plan 7352 for dirty, abrasive, or polymerizing products which would

either damage the seal faces or cause problems with the barrier fluid

system if an API Plan 52/ANSI Plan 7352 is used. Two conditions to

consider when incorporating API Plan 52/ANSI Plan 7352; first, there will

always be some leakage of barrier fluid into the product. Normally, this

leakage will be minute, and the leakage rate can be monitored via the

2

© Copyright 2004 Flowserve Corporation

Page 3

visual water flow indicator. However, when using API Plan 53/ANSI Plan

7353 the product must be able to accommodate a small amount of

contamination from the barrier fluid. Secondly, an API Plan 53/ANSI Plan

7353 system is dependent on having the supply tank pressure maintained at the proper level. If the supply tank pressure drops below seal

chamber pressure, seal leakage direction will be reversed and the barrier

fluid will be contaminated with the process fluid. The flush plan will then

become an API Plan 52/ANSI Plan 7352.

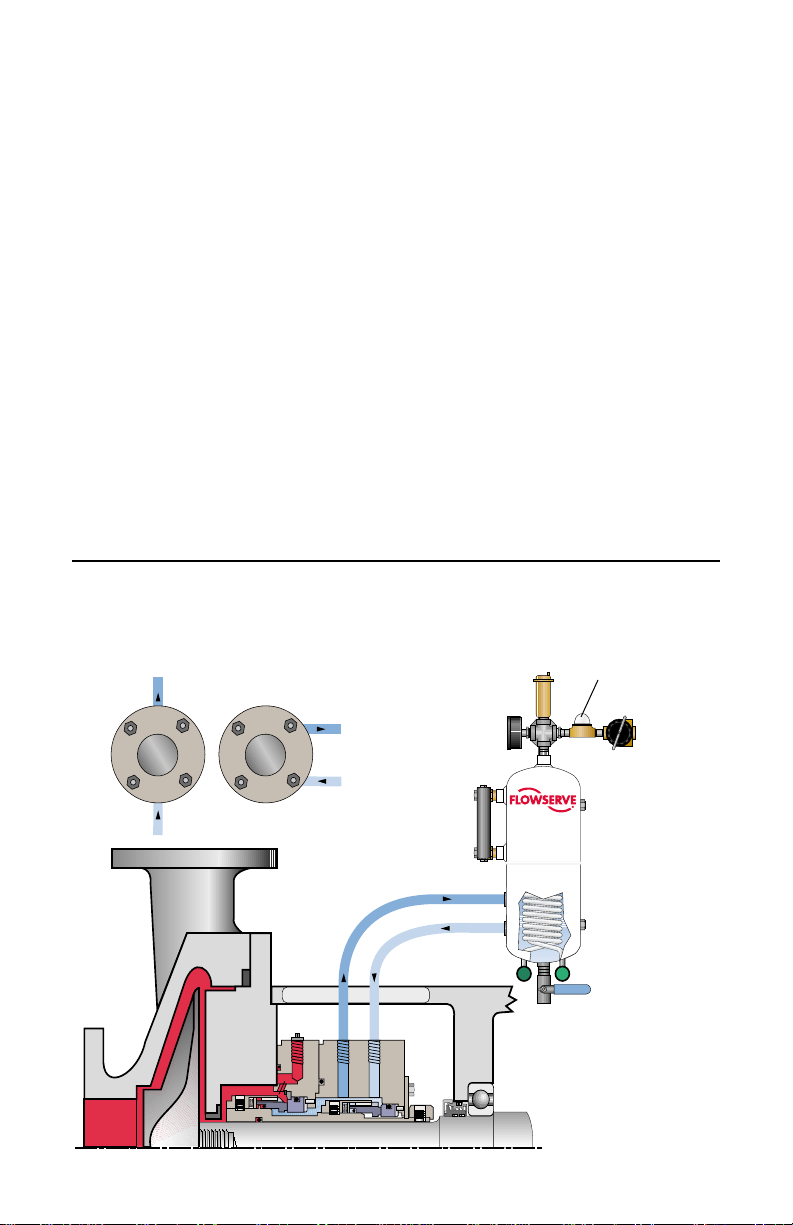

An Induced Circulation System is essentially the same as the thermal

convection system except for the addition of a circulating device in the

seal cavity which provides for positive flow in the system. The addition of

a circulating device provides for positive flow of buffer fluid shown in

Figure 1. To maximize dual seal cooling add cooling coils inside the

reservoir as a means of removing heat.

Dual Pressuzied Inside Seal with Induced Circulation

through CPM Seal Support Reservoir with Cooling Coil

Figure 1

Plan 53/ANSI Plan 7353

vertical

porting

outlet

end view

inlet

seal

tangential

or

porting

seal

end view

outlet

inlet

vent valve

pressure

gage

level

gage

cooling out

visual water

flow indicator

water

pressure

regulator

and inlet

port

304SS,

2 gallon

reservoir

cooling in

drain

3

Page 4

Buffer/Barrier Fluid Selection

The CPM Seal Support Reservoir is designed for use with water barrier

only in conjunction with a water header system.

For an API Plan 53/ANSI Plan 7353 pressurized barrier fluid system

where the method of pressurization is a gas blanket, special attention is

given to the application conditions. Gas solubility in the barrier fluid

increases with the rising temperature and pressure. However, the CPM

Seal Support Reservoir is designed for pressurization from a water

header system. The water header system provides pressure to the seal

when pressurized above operating conditions in a dual pressurized

operating mode. Should consumption of barrier water increase the

header system will automatically refill the tank. The water regulator on

the inlet of the tank determines the point of re-supply. The pressure level

at which re-supply is accomplished is adjustable to suit the application

need.

The condition of the water within the tank should be checked over the

entire operating curve of the application. Particular attention should be

paid during start up conditions. Water on the seal at the time of start up

is a critical condition for longevity of seal life. Also close care should be

taken to ensure water conditions are maintained to avoid pressure

reversals contaminating barrier water with process fluids.

1. The water should not freeze at the minimum site ambient temperature.

2. The water should have an initial boiling point at least 50°F above the

temperature to which it will be exposed.

3. The water should not have a flash point higher than the service

temperature.

4

Page 5

Installation

1. The reservoir is mounted vertical not more than 3 feet (.9 m) from

the seal gland to the vertical centerline of the reservoir. The bottom

of the reservoir is mounted 12 to 24 inches (.3m to .6 m) above the

horizontal centerline of the pump.

2. All lines from the seal cavity to the reservoir must slope upward at

all points. The upward slope should be a minimum of 1/4" per foot

(24 cm/m) with all bends being large radius. The minimum size for

pipe or tubing should be 1/2" (13 mm) diameter.

3. Connect the supply connection (lower seal connection on the

reservoir) to the bottom (inlet) gland connection.

4. Connect the return connection (upper seal connection on the

reservoir) to the upper (outlet) gland connection.

5. If valves are used to isolate the seal chamber and the reservoir

make sure these are fully open while filling and during operation.

6. If the reservoir is equipped with cooling coils, connect cooling water

lines to the reservoir at the cooling coil points.

7. Remove all plastic plugs and properly seal or attach tubing with

metal fittings.

5

Page 6

8. It is highly recommended that the reservoir be flushed with clean

fluid prior to equipment start up to remove any foreign matter from

the system.

Caution:

The CPM Seal Support Reservoir System is not for use with

hazardous materials.

9. Fill reservoir with water barrier fluid to the middle of the sight

glass. Gas volume of the system should be at least 25 percent of

the reservoir volume to allow for thermal expansion during operation.

10. Before starting the system, bleed all air from highest point in the

system, the vent valve.

11. Connect external water supply to reservoir on Plan 53 (dual seal). A

pressure regulator and check valve are required to maintain a

constant pressure on the system. The pressure in the reservoir

should be maintained at least 25 psi above the seal cavity pressure.

Make sure reservoir is filled before pressurizing.

6

Page 7

Start-Up

1. API Plan 52/ANSI Plan 7352 - open valve to the vent or process

recovery system slowly.

2. API Plan 53/ ANSI 7353 - slowly open valve between reservoir and

external pressurization source. Slowly increase the pressure to avoid

gas ingestion. Check for leaks as unit is being pressurized. Operating

pressure is normally 25 psi above seal cavity pressure. The pressure

gauge on system can be used to monitor system pressure.

3. If system is equipped with cooling coils open valve to allow water to

flow through coils.

4. The main pump can now be started.

Maintenance

During planned plant shutdowns it is recommended that the buffer/barrier

fluid be drained, reservoir flushed and new fluid put in the reservoir. This

will ensure the quality of the buffer/barrier fluid used to lubricate the seals

and to remove any particles that may have accumulated in the reservoir.

When changing or cleaning the glass on armored sight gages (weld pad

level gage) always install new gaskets and retorque bolts to proper

amount. It is also recommended that the bolts be checked and retorqued

prior to first operation. They can come loose during shipping and transport.

7

Page 8

TO REORDER REFER TO

B/M #

F.O

.

All Flowserve Corporation, Flow Solutions Division, products must be installed in accordance with Flowserve

installation instructions. Failing to do so or attempting to change or modify Flowserve products will void

Flowserve’s limited warranty. Flowserve’s limited warranty is described fully in Flowserve’s Standard Terms

and Conditions of Sale. Flowserve makes no warranty of merchantability or fitness for a particular purpose

and in no event shall Flowserve be liable for consequential or incidental damages.

Flowserve Corporation Flow Solutions Division

Primary Worldwide Flow Solutions Division Locations Licensees, authorized agents, and affiliated companies located worldwide

United States

Kalamazoo, MI

Phone 269-381-2650

Fax 269-382-8726

Edmonton, Alberta

Phone 780-464-1188

Fax 780-464-1801

Canada

Scarborough, Ontario

Phone 416-292-2877

Fax 416-292-5190

Singapore Japan

Phone 65-6-8465100

Fax 65-6-7471963

Printed in U.S.A.

Tlaxcala

Phone 52-2-461-6791

Fax 52-2-461-6847

Sao Paulo

Phone 55-11-4231-6300

Fax 55-11-4231-6326

www.flowserve.com

Netherlands

Roosendaal

Phone 31-165-581400

Fax 31-165-552622

Osaka

Phone 81-72-885-5571

Fax 81-72-885-5575

Argentina

Buenos Aires

Phone 54-11-4709-6800

Fax 54-11-4709-6800 ext 123

GermanyBrazilMexico

Dortmund

Phone 49-231-6964-0

Fax 49-231-6964-248

Marayong NSW

Phone 61-2-8822-7100

Fax 61-2-9679-7511

Australia

ORG 01/04 USA

FIS168

Loading...

Loading...