Page 1

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway Phone: 801 489 8611

Flow Control Division Springville, Utah 84663-3004 Facsimile: 801 489 2228

www.flowserve.com

SR Limit Switch Method

CENTURA™ CPL Series

Installation Instructions

Introduction

The Centura CPL Series electric actuator is a rotary valve

actuator with output torques of 100 and 225 in-lbs. It has

been designed for NEMA 4, 4X and can come with an

externally mounted 20mA card for modulating service.

Storage

1. Keep conduit entries plugged.

2. Store in a dry environment.

3. Periodically cycle the actuator if possible.

Maintenance

Centura Series actuators contain a permanently lubricated,

precision cut, heat treated gear train for long, reliable cycle

life. There is no need to change gear train grease.

Permanent split capacitor gearmotors have been

equipped with thermal protectors. After many operations

especially in warm environments the motor will heat up. To

guard the motor against overheating the thermal protector

opens the circuit to the motor and maintains this state until

the temperature of the motor drops to a satisfactory level.

This thermal protection means that the actuator will not

move when overheated. Consideration must be given to the

duty cycle requirements of the actuator.

Installation

1. This section of the instruction sheet applies to the onoff units. For instructions on modulating units, please

see the ESP3 Electronic Servo Positioner Instructions.

2. Manually open and close valve to ensure freeness of

operation.

Caution:

while circuits are alive. Disconnect supply circuit

before opening.

3. Be sure valve and Automax actuator rotate in the same

direction and are in the same position (i.e., valve closed,

actuator closed). If not sure, electrically operate the

actuator to determine its operating range. The electric

actuators are factory set for 90 degree operation.

4. Mount Automax actuator to valve with Automax

provided mounting hardware to assure proper

alignment. (

remove if appropriate or set actuator to operate within

those travel stops.)

To prevent electrical shock keep unit tight

NOTE:

Some valves have manual stops;

5. Care should be taken to properly align valve stem and

Automax actuator output shaft (misalignment will cause

premature failure of assembly).

6. To connect power to terminal strip of actuator it is

necessary to remove the cover.

7. After cover has been removed, locate the terminal

wiring schematic inside the cover.

8. Connect power to terminal strip according to schematic

diagram (power should be fused with a 5 amp slowblow fuse). The actuator should be wired and grounded

in accordance with Local and National Electrical Codes.

Caution:

in series or parallel, serious damage may result. User

must isolate unused winding.

9. Before replacing cover, actuate valve and check to see

if it opens and closes to preferred positions. If valve

does not perform correctly, adjust cams to properly set

actuator travel.

10.Drive actuator to desired open position. The cams are

adjusted in two ways. Simply depress the splined

“Quick-Set” cam against the spring and rotate to

desired location.

11.To adjust closed position, repeat step 10 with actuator

in desired closed position.

12.Operate the unit several times and recheck position.

If unit is still out of adjustment, reset the cams by

following steps 10 and 11.

13.60Hz actuator motors may be run on 50Hz supply,

however, the cycle time increases by 1.2 times and the

duty cycle decreases by a factor approx. 25%. The

rated torque does not change.

Consult factory when wiring multiple actuators

Position Indication Stickers:

Attached to the inside of the cover is a set of stickers with

the words "CLOSED" and "OPEN." These stickers are to be

attached to the outside of the actuator base. The stickers

have an orange triangle on them, such that when properly

attached, the actuator will line up with the triangle on the

output shaft. A sticker can be placed on either side of the

unit to produce a visual indication of the opened and

closed position of the actuator.

LME0009-1 (Auto-39) 04/03

©

2003, Flowserve Corporation, Printed in USA

Page 1 of 4

Page 2

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway Phone: 801 489 8611

Flow Control Division Springville, Utah 84663-3004 Facsimile: 801 489 2228

www.flowserve.com

SR Limit Switch Method

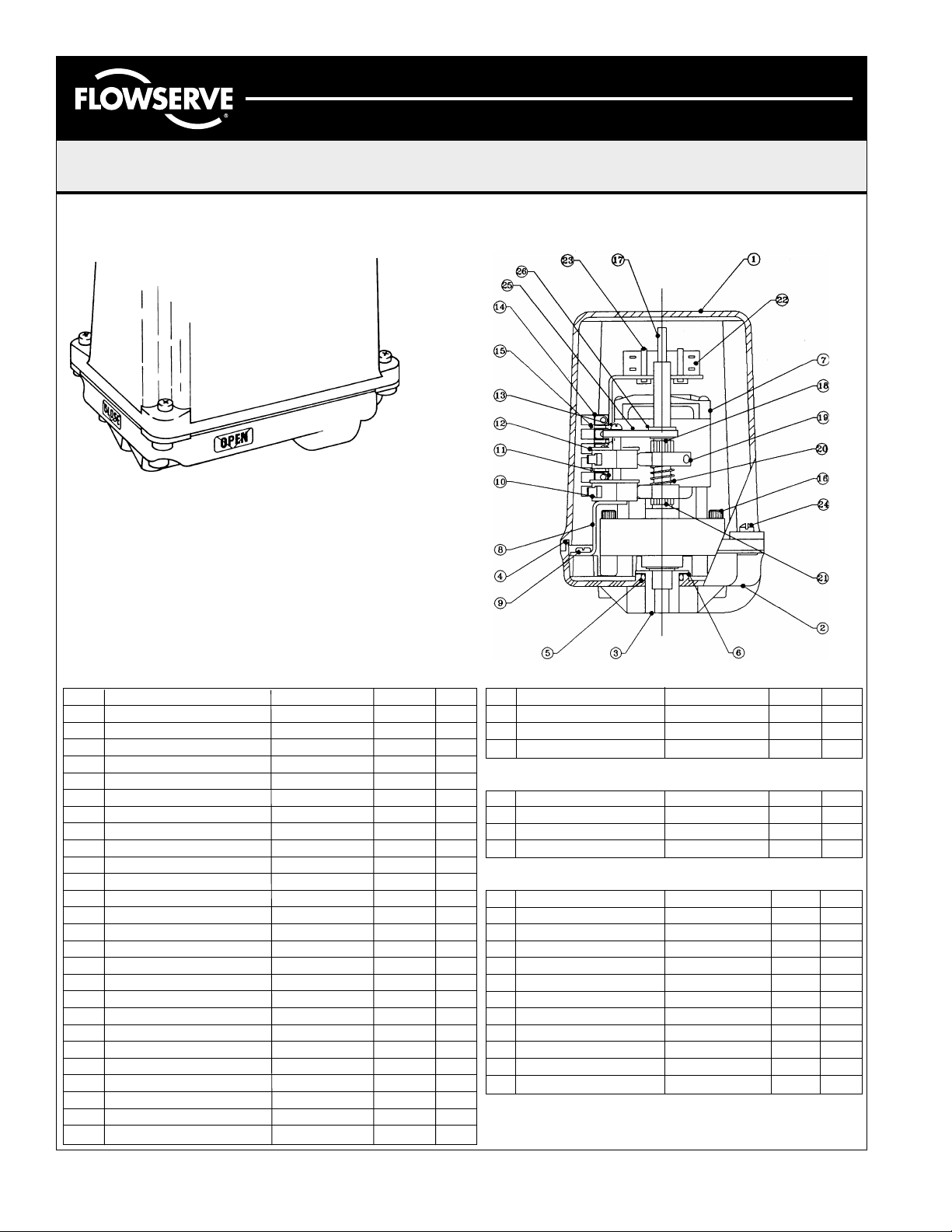

Parts & Materials CENTURA CPL Series

COMMON PARTS RELATED TO ALL ACTUATORS

NO. ITEM MATERIAL P/N QTY

1 Cover Zytel 106451 1

2 Base Zytel 106452 1

3 Output Adapter Steel/Plated 106453 1

4 ‘O’-ring Cover N674-70 Nitrile 106751 1

5 ‘O’-ring Base N674-70 Nitrile 102262 1

6 Shim Bearing Steel 106759 1

8 Switch Mounting Bracket Steel/Plated 107139 1

9 8-32UNCx3/8" Pan Head Steel/Plated 106755 3

10 Micro Switch with Leaf Plastic/Steel 105720 2

11 3/16" High Spacer Nylon 105679 6

12 Switch Insulator Gasket Vulcanized Fiber 103675 3

13 4-40UNCx1-1/2" Phillips Hd. Steel/Plated 108349 2

14 6 Position Terminal Strip Plastic/Steel 103997 1

2 Screw Marker Strip Plastic 103996 1

15 3-48UNCx1/2" Pan Head Steel/Plated 104837 2

17 Camshaft Steel/Plated 107005 1

18 Large 4-Deg. Spline Shaft Plastic 103571 1

1/16" Dia. Roll Pin Spring Steel 103621 1

19 4-Deg. Quick Set Cam Plastic 105655 2

20 Switch Spring Spring Steel 103714 1

21 Small 4-Deg. Spline Shaft Plastic 103572 1

1/16" Dia. Roll Pin Spring Steel 103621 1

23 Ty-Rap Cable Tie Plastic 106574 2

24 10-24x5/8" Captive Screw Stainless Steel X00360 4

25 Switch Support Bracket Aluminum 108997 1

26 3/8" Pop in Bearing Plastic 108998 1

ADDITIONAL PARTS SPECIFIC TO 115VAC 100IN-LBS.

NO. ITEM MATERIAL P/N QTY

7 115VAC PSC Gear Motor Steel/Copper 106617 1

16 6-32UNCx1/16"Pan Head Steel/Plated 106753 2

22 Capacitor Film Wrapped 107128 1

ADDITIONAL PARTS SPECIFIC TO 115VAC 225IN-LBS.

NO. ITEM MATERIAL P/N QTY

7 115VAC PSC Gear Motor Steel/Copper 106616 1

16 10-24UNCx1-5/8”Soc. Hd. Steel/Plated 106754 4

22 Capacitor Film Wrapped 107120 1

ADDITIONAL COMMON PARTS ** NOT SHOWN **

NO. ITEM MATERIAL P/N QTY

8-32UNC Ground screw Steel/Plated Green 103627 1

#8 Cup Washer Brass 105626 1

3/4” NPT Conduit Plug Plastic 103685 1

115VAC Wiring Harness Copper/Plastic 106749 1

Nameplate Mylar 106613 1

Flowserve Logo Sticker Mylar 106612 1

Cam Adjustment Sticker Mylar 105757 1

Switch I.D. Sticker Mylar 107135 1

Open/Close Stickers Mylar 106186 1

Position Indication Sticker Mylar 106187 1

115VAC Schematic Sticker Mylar 106758 1

LME0009-1 (Auto-39) 04/03

©

2003, Flowserve Corporation, Printed in USA

Page 2 of 4

Page 3

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

SR Limit Switch Method

Flowserve Corporation 1350 N. Mountain Springs Parkway Phone: 801 489 8611

Flow Control Division Springville, Utah 84663-3004 Facsimile: 801 489 2228

www.flowserve.com

Troubleshooting

Problem:

There is power to the unit, but it does not respond.

Solution:

Check the nameplate to see that the correct voltage has

been applied.

Check the wiring to see that it is per the wiring schematic.

Check the limit switches to see if they are in the normal

operating range.

Problem:

Power is getting to the motor, but it merely hums.

Solution:

Check to see that the proper voltage is applied.

Make sure all the connections are tight.

Check to see that CW and CCW power connections are not

powered at the same time.

Reversible A. C. Actuator

SYMBOLS & DESCRIPTIONS

1. WHITE - Motor Common.

2. BLUE - Full CW Position

Indic ator

3. BLACK - AC Hi will Turn

Actua tor CW.

4. YELLOW - Full CCW

Position Indicator.

5. RED - AC Hi will Turn

Actuator CCW.

TERMINAL

STRIP

Reversible D. C. Actuator

SYMBOLS & DESCRIPTIONS

1. RED - DC+ (CW)

2. BLACK - DC- (CW)

3. BROWN - DC+ (CCW)

4. WHITE - DC- (CCW)

Reversible A. C. Actuator with 2 extra switches

NO - Normally Open

NC - Normally Closed

C - Common

NO - Normally Open

NO - Normally Open

NC - Normally Closed

NC - Normally Closed

C - Common

C - Common

Problem:

The actuator performs erratically.

Solution:

Check to see that the actuator is not stalling.

Check the ambient temperature rating. The permanent split

capacitor units are equipped with thermal cut-outs. Excessive

temperatures and cycle frequencies may heat the motor up and

the thermal cut-out turns it off.

Wiring Diagrams

Notes:

1. Consult factory when wiring multiple actuators in series or

parallel, serious damage may result.

2. Wiring diagrams show internal wire connections and

suggested customer connection for proper use. Switches

shown in "customer wiring" are for illustration only and are

not supplied with the actuator.

LME0009-1 (Auto-39) 04/03

©

2003, Flowserve Corporation, Printed in USA

SYMBOLS & DESCRIPTIONS

1. WHITE - Motor Common.

2. BLUE - Full CW Position

Indicator.

3. BLACK - AC Hi will Turn

Actuator CW.

4. YELLOW - Full CCW

Position Indicator.

5. RED - AC Hi will Turn

Actuator CCW.

6. ORANGE - Switch Common.

Reversible A. C. Actuator wired for 3 position

SYMBOLS & DESCRIPTIONS

1. WHITE - Motor Common.

2. YELLOW - AC Hi will Turn

Actua tor to M ID.

4. BLACK - AC Hi will Turn

Actua tor CW.

6. RED - AC Hi will Turn

Actuator CCW.

NO - Normally Open

NC - Normally Closed

C - Common

NO - Normally Open

NC - Normally Closed

C - Common

Page 3 of 4

Page 4

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway Phone: 801 489 8611

Flow Control Division Springville, Utah 84663-3004 Facsimile: 801 489 2228

www.flowserve.com

Typical Actuator Specifications

Action Reversible

Supply Voltages AC: +/ 115VAC (1 Ph)

10% 230VAC (1 Ph)

50/60Hz 24VAC (1 Ph)

DC: 12VDC

24VDC

Temperature Rating -20°F (-28°C) to 160°F (70°C)

Enclosure Ratings / Device Testing CSA Enclosure 4

NEMA 4, 4X

89/336/EEC Directive for CE Marking

Range of Operation 0° to 180°

AC Motor Thermal Protection Automatically resetting

Motor Types AC: Permanent Split Capacitor

DC: Brush

Travel and Aux. Switches SPDT, Form C 15 amp 125 1/2 HP 10 amp

250VAC, 1/2 amp 125 VDC

Conduit Connections (1) 3/4-14 NPT

Corrosion Protection Enclosure: Zytel engineered resin

Cover Screws: Stainless Steel

Output Shaft: Dacromet Coating

Terminal Strip Hookup 300V, 30A, 12-26 AWG

Lubrication Permanently lubricated

Gear Train Heat treated alloy steel, rated to stall torque

SR Limit Switch Method

Note: The above ratings may change depending on model configurations and options provided.

Products may differ as the result of the Company policy of continuous product improvement.

Actuator Model

CPL1 CPL2

Cycle Times

Sec/90°

56

34

34

87

100 225 Torque (in-lbs)

11 25 Torque (Nm)

4 5 Weights Lbs (kg.)

1. Cycle times are approximate under no load conditions and may vary slightly under actual

operating conditions.

2. Duty cycles are rated at 70°F. The duty rates may be less under loaded conditions.

3. Do not lock up DC motors.

LME0009-1 (Auto-39) 04/03

©

2003, Flowserve Corporation, Printed in USA

Opt.

Motor

Desig.

Std 115 50 0.3 0.5 .04 0.5

B 12 100 1 1.6 * *

C 24 100 0.5 0.8 * *

D 230 50 0.11 0.18 0.12 0.2

Motor

Voltage

Duty

Cycle

(%)

Run Current

(amp)

CPL1 CPL2 CPL1 CPL2

Locked Rotor

(amp)

Page 4 of 4

Loading...

Loading...