Page 1

ColdFlow - 341000

Kämmer Series 341000 FCD KMENIM4104-01 03/18

USER INSTRUCTIONS

Cryogenic Control Valves 4K

FCD KMENIM4104-01 03/18

Maintenance

Experience In Motion

1

Page 2

STOP!

STOP!

Contents

1 Using Kämmer Valves And Actuators Correctly

2 Initial Installation

3. Trim Parts

4 Actuator

5 Identification

6 Spare Parts

7 Technical Tables

8 Trouble Shooting

Kämmer Series 341000 FCD KMENIM4104-01 03/18

1 USING KÄMMER VALVES AND ACTUATORS CORRECTLY

1.1 General

The following instructions are designed to assist in installing and performing maintenance as required on FLOWSERVE

Kämmer products. Product users and maintenance personnel should Thoroughly review this maintenance instruction prior

to installing and prior to performing any maintenance on the product.

DANGER: Please review also the general Installation and Operational Manual (IOM) for general safety instructions.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAUTION and NOTE are used in these instructions to highlight particular dangers

and/or to provide additional information on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury and / or substantial property damage will occur if proper precautions

are not taken.

WARNING: indicates that death, severe personal injury and / or substantial property damage can occur if proper precautions

are not taken.

CAUTION: indicates that minor personal injury and / or property damage can occur if proper precautions are not taken.

NOTE: indicates and provides additional technical information, which may not be very obvious even to qualified personnel.

Compliance with other, not particularly emphasized notes, with regard to transport, assembly, operation and maintenance

and with regard to technical documentation (e.g. in the operating instruction, product documentation or on the product

itself) is essential, in order to avoid faults, which in themselves might directly or indirectly cause severe personal injury or

property damage.

2

Page 3

2 INITIAL INSTALLATION

2.1 Unpacking

2.1.1 Valve and Actuator are delivered separately. This

allows for more compact transport boxes and easier

installation. After unpacking the valve and actuator,

clearly mark the parts for proper assembly. The trim is

installed inside the valve body to avoid damage during

transport. To remove the trim assembly from the valve

please refer to section 3.1

Kämmer Series 341000 FCD KMENIM4104-01 03/18

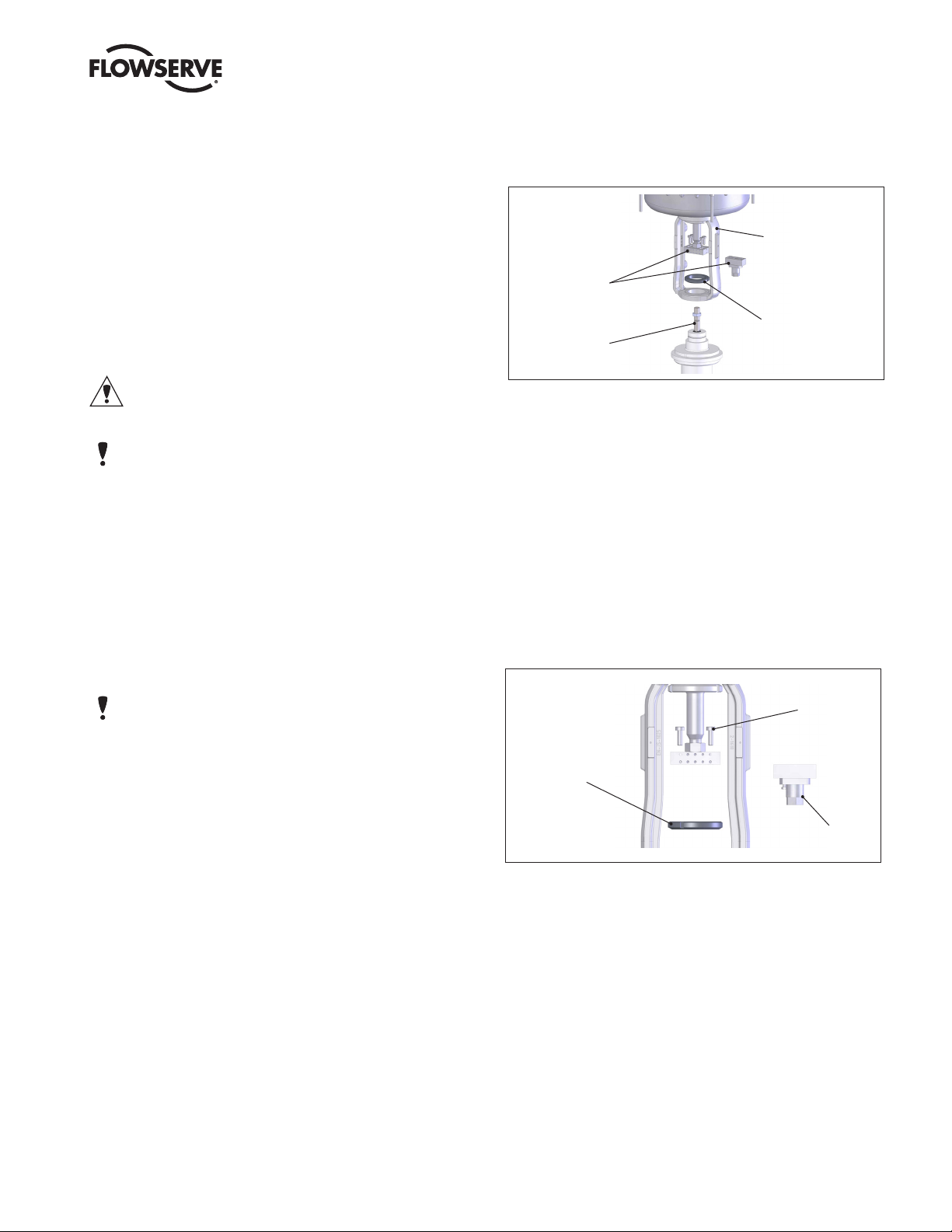

2.1.2 Marking (figure 1)

Valve components have been marked with the serial

number in order to allow a proper disassembly and

assembly. The valve body is marked on top of the

cover plate (1.1), trim kit at the upper part of the

extension(1.2) and the bonnet on the side (1.3). All

relevant technical data is shown on a stainless steel

nameplate attached to the actuator. See also section 5

Identification.

2.2 Preparation for vacuum box installation (figure 2)

2.2.1 After trim has been removed from the valve body (see

chapter 3.1) mount the installation flange (2:1) on the

bonnet flange thread of the valve.

CAUTION: Please ensure that the mounting flange has

been tightened with the correct torque (see table 7.3).

2.2.2 Attach hoisting equipment of adequate lifting capacity

to the hoisting lug (3:1) and lower the valve body into

the vacuum box. See also table 7.2 for approximate

maximum weights of this subassembly.

1.1

1.3

1.2

Figure 1: Marking

2.1

Figure 2: Mounting Preparation

CAUTION: take care when lowering the valve

subassembly into the vacuum box.

Mounting (figure 3)

Insert the mounting Tool (3.1) between the valve

cover plate (3.2) and the mounting flange (3.3) before

reaching the final position inside the box.

3.2

3.3

3.1

Figure 3: Mounting

3

Page 4

2.3 Welding

2.3.1 Pipe connections

Position the valve inside the vacuum box and secure it

with the mounting tool. The pipe connections for inlet

and outlet can now be welded.

NOTE: Ensure that the trim internals are removed and

that the mounting flange is the correct size.

For the standard pipe sizes refer to table 7.2 BW (mm).

2.3.2 Welding cover plate (figure 4)

Kämmer Series 341000 FCD KMENIM4104-01 03/18

With the mounting tool (4.1) in position tack weld the

cover plate to the vacuum box to secure it‘s position.

Rotating the mounting tool will provide space for the

tack welding.

NOTE: ensure the valve can move freely and is not

under tension while welding it to the vacuum box.

Damage to trim and trim guiding may occur.

Remove the mounting tool (4:1)and weld the entire

circumference of the cover plate to the vacuum tank.

2.4 Pressure testing

After welding all the valves into the vacuum tank

perform a pressure test with all valves. For this all

valves must be fitted with mounting flanges. This

mounting flange has a dual purpose: firstly it assists

in mounting the valves into the vacuum tank and

secondly to seal the valve at the bonnet connection in

order to pressurize the piping system without the trim

assemblies and actuators mounted.

CAUTION: Ensure all mounting flanges are in place and

properly tightened. A loose mounting flange cannot

sustain the pressure and will result in unwanted or

unsecure leakage.

4.1

Figure 4: Cover Plate Welding

2.5 Cleaning

With the mounting flanges in place, clean and purge the

entire piping system with a cleaning media to remove

dirt and welding residues from the system.

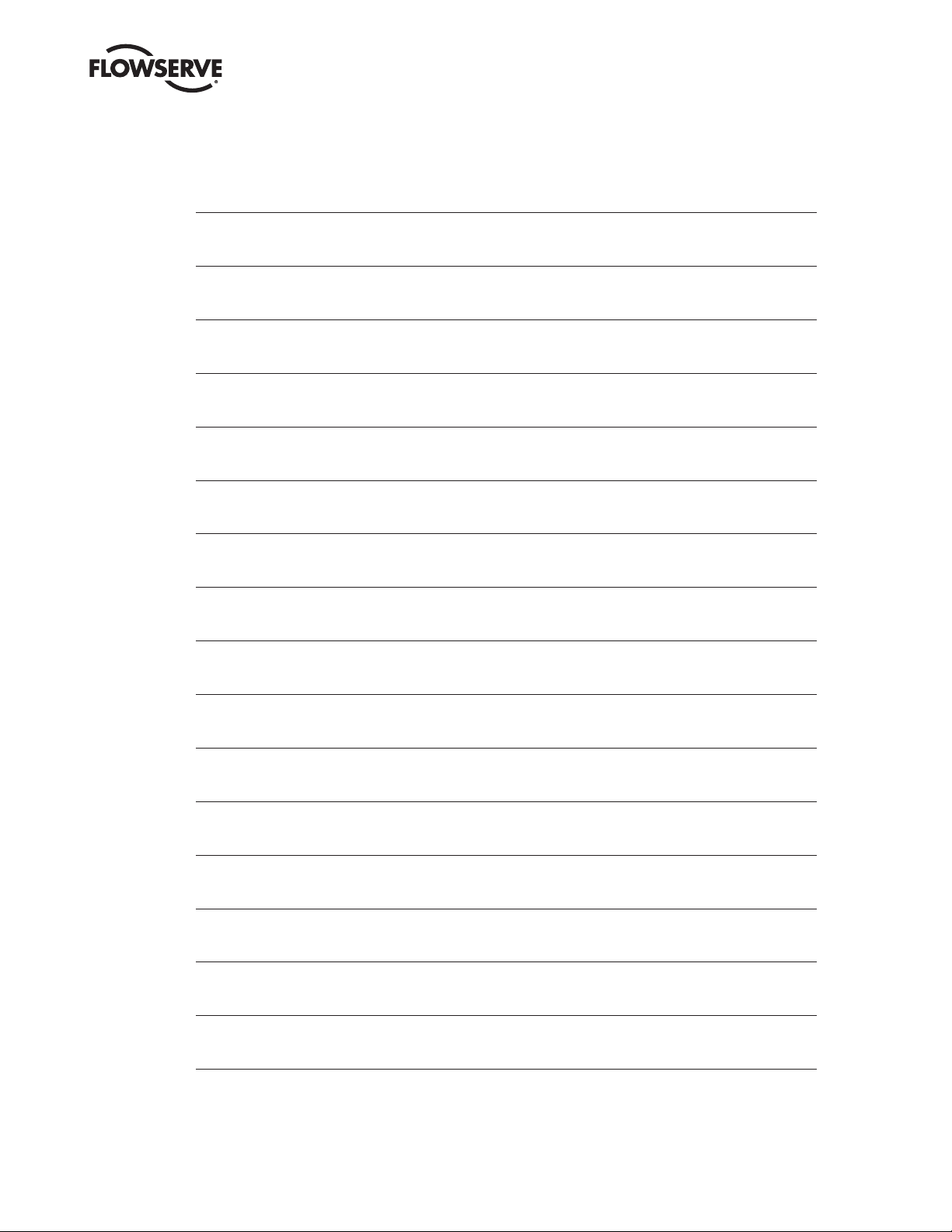

2.6 Remove mounting flanges (Figure 5)

After completing all tests, cleaning and mounting

procedures, remove all mounting flanges (5.1) and

spacer plates (5.2) from the valves. Flowserve Essen

offers a refund system for returning the mounting

flanges and mounting tools after use. For further details

please contact Flowserve Essen Order administration.

4

5.1

5.2

Figure 5: Remove Mounting Flange

Page 5

3. TRIM PARTS

Kämmer Series 341000 FCD KMENIM4104-01 03/18

3.1 Remove Trim assembly

3.1.1 Remove actuator (See section 4)

3.1.2 Remove bonnet (figure 6)

3.1.3 Unscrew the bonnet (6.1) counter clockwise with a

suitable tool and carefully remove the bonnet from

the stem.

CAUTION: do not rotate the stem in any direction.

Severe damage to the bellows seal and/or the trim

assembly may occur.

3.1.4 Carefully remove the trim assembly (7.1) - consisting

of bellows seal, extension and plug - from the valve

housing (Figure 7)

CAUTION: do not rotate the trim assembly within the

valve body. Remove the trim assembly in an upright

position avoiding any contact of the trim assembly with

the valve housing. Severe damage of the bellows seal

and/or the trim assembly may occur.

6.1

Figure 6: Bonnet

7.1

Figure 7: Trim Assembly

3.2 Install Trim assembly (Figure 8)

3.2.1 Insert body O-Ring seal (8.1)

3.2.2 Carefully insert trim assembly (8.2) into valve housing.

CAUTION: do not rotate the trim assembly within the

valve body in any direction. Insert the trim assembly

in an upright position. Avoid any contact of the trim

assembly with the valve housing. Severe damage of

the bellows seal and/or the trim assembly may occur.

3.2.3 Bonnet assembly

(Figure 9)

Carefully place the bonnet (9.1) over the stem (9.2)

and tighten the bonnet clockwise with the suitable tool

to the correct torque (see table 7.3). Ensure that

the

wiper ring (9.3) seats correctly on the stem

8.2

9.3

8.1

Figure 8: Body O-Ring

9.1

9.2

Figure: 9 Bonnet assembly

5

Page 6

3.3 Disassemble trim assembly (figure 11)

3.3.1 The trim assembly consists out of 3 parts: the stem

with bellows (11.1), the extension (11.2) and the plug

(11.3). All three components can be disassembled and

replaced individually. These parts are secured with pins

(11.4). To remove the pins carefully drive them out by

a suitable tool. When replacing one or more parts of

the assembly always use new pins (see spare parts

table) and make sure that they are in place and secure.

Kämmer Series 341000 FCD KMENIM4104-01 03/18

Figure 10: Trim Assembly

11.1

11.2

11.4

11.4

11.3

Figure 11: Trim Parts

6

Page 7

4 ACTUATOR

Kämmer Series 341000 FCD KMENIM4104-01 03/18

4.1 KP Diaphragm Actuator

4.1.1 First Installation after unpacking (figure 12)

ColdFlow Series 341000 will be delivered in two parts:

valve subassembly and actuator. Especially for small

sizes the mounted actuator might cause damage to

the valve. Also for welding the valve into the vacuum

cold box actuator and trim must be removed from the

valve body.

Remove the locknut (12.1) from the valve bonnet.

Place the actuator with the installed yoke plate (12.2 )

onto the valve bonnet. Before connecting the coupling

(12.3) slip the locknut over the valve stem (12.4)

and screw the locknut onto the bonnet thread. For

tightening torques please refer to chapter 7.3

CAUTION: Be careful while placing the yoke plate over

the stem. Damage of the stem and/or the entire trim

assembly may occur.

NOTE: Make sure that the Serial Number of the valve

(engraved at the bonnet) and of the actuator (Tag plate)

correspond to each other.

4.1.2 Removing for repair or maintenance (figure 13)

12.1

12.4

Figure 12: Actuator Mounting

12.3

12.2

We recommend separating the actuator from the valve

during all repair work. However, many maintenance

and adjusting operations can be carried out in an

installed condition.

4.1.2.1 Shut off air supply

4.1.2.2 Disconnect all air tubing from the actuator

4.1.2.3 Remove and install actuator (figure 14)

Typically for a quick removal of the actuator the 2 yoke

nut screws (14.1) are removed. After this remove the

coupling screws (14.2) from the coupling and take off

both coupling parts.

NOTE: If there are accessories such as positioners and/

or limit switches connected to the coupling, please

carefully disconnect the lever or if necessary the entire

accessory.

NOTE: Ensure that the plug assembly is not rotated

with the plug seated. This may cause irreparable

damage to the seating faces.

Figure 13: Actuator Assembly

14.2

14.1

14.1

Figure 14: Remove and install actuator

7

Page 8

4.1.3 Install Actuator (figure 15)

The actuator stem must be fully extended:

Kämmer Series 341000 FCD KMENIM4104-01 03/18

Actuators with air-to-open action must be fully vented.

Actuators with air-to close action apply pressure.

Manually depress the plug stem to ensure the plug is

fully seated.

4.1.3.1 Screw coupling insert locknut (15.1) and coupling

insert (15.2) as far as possible onto plug stem (15.3)

4.1.3.2 Place the actuator assembly on the valve engaging the

yoke rod threads in the lower yoke plate (15.4) and

ensuring the actuator faces in the right direction.

4.1.3.3 Unscrew the coupling insert until the lower yoke rods

are raised from the lower yoke plate by around 2 mm.

NOTE: Ensure that the plug assembly is not rotated with

the plug seated. This may cause irreparable damage to

the seating faces.

4.1.3.4 Refit the coupling (figure 16)

Refit the coupling (16.1), ensuring that the arrows

(16.2 ), embossed on the coupling halves, point upward

towards the actuator, and secure with 2 coupling

screws (16.3).

4.1.3.5 Apply supply pressure respectively vent actuator to

50% stroke and refit and tighten yoke nuts.

4.1.3.6 Connect all tubing.

15.3

Figure 15: Install Actuator

16.1

16.3

15.115.2

15.4

16.2

Figure 16: Refit the Coupling

8

Page 9

4.2 FlowAct Actuator

4.2.1 First Installation (figure 17)

The FlowAct actuator is equipped with a casted yoke,

for all assembly and disassemble the entire actuator

including the yoke must be installed or removed.

Remove the locknut (17.1) from the valve bonnet. Place

the actuator and yoke assembly (17.2 ) onto the valve

bonnet. Before connecting the coupling (17.3 ) slip

the locknut over the valve stem (17.4 ) and screw the

locknut onto the bonnet thread. For tightening torques

please refer to chapter 7.3

CAUTION: Be careful while putting the yoke plate

through the stem. Damage of the stem and/or the

entire trim assembly may occur.

NOTE: Ensure that the serial sumber of the valve

(engraved at the bonnet) and actuator (Tag plate)

correspond to each other.

4.2.2 Removing for repair or maintenance

Kämmer Series 341000 FCD KMENIM4104-01 03/18

17.2

17.3

17.1

17.4

Figure 17: Actuator Mounting

We recommend separating the actuator from the valve

during all repair work. However, many maintenance and

adjusting operations can be carried out in an installed

condition.

4.2.2.1 Shut off air supply

4.2.2.2 Disconnect all air tubing from the actuator

4.2.2.3 Remove actuator coupling (figure 18)

NOTE: If there are accessories such as positioners and/

or limit switches connected to the coupling, please

carefully disconnect the lever or if necessary the entire

accessory. Remove four screws (18.1) from the upper

coupling half.

4.2.2.4 Remove locknut (18.2)

NOTE: The lower coupling half is still connected to the

stem and can’t be removed from the actuator at this

stage.

4.2.2.5 Carefully raise the actuator assembly vertically around

40 mm. Be aware that most of the FlowAct actuators

are heavy, please use suitable lifting equipment.

4.2.2.6 Remove the lower coupling half (18.3) counter

clockwise from the stem.

18.1

18.2

18.3

Figure 18: Remove and install actuator

NOTE: Ensure that the plug assembly is not rotated with

the plug seated. This may cause irreparable damage

to the seating faces and/or the bellows seal.

9

Page 10

4.2.3 Installation

The actuator stem must be fully extended. Actuators

with air-to-open action must be fully vented. Actuators

with air-to close action apply pressure. Manually

depress the plug stem to ensure the plug is fully

seated.

4.2.3.1 Using suitable lifting equipement, carefully place the

actuator onto the valve assembly. Before the actuator

is fully lowered slip the locknut onto the bonnet and

thread on the lower coupling half onto the stem.

4.2.3.2 Tighten the locknut. For tightening torques please refer

to chapter 7.3

4.2.3.3 Reinstall the coupling

4.2.3.4 Connect all tubing

Kämmer Series 341000 FCD KMENIM4104-01 03/18

Figure 19: Actuator Assembly

10

Page 11

5 IDENTIFICATION

5.1 The complete valve assembly (valve plus actuator) are

clearly marked with the serial number.

CAUTION: Ensure that only parts of the same serial

number are assembled together. Serious damage of

the parts may occur.

Kämmer Series 341000 FCD KMENIM4104-01 03/18

Figure 20: Body Identification

Figure 21: Trim Identification

Figure 22: Bonnet Identification

11

Page 12

6 SPARE PARTS

6.1 Miscellaneous parts

Kämmer Series 341000 FCD KMENIM4104-01 03/18

DN ANSI

4 0.16“

6 0.25“

8 0.31“

10 0.39“

20 0.79“

25 1“

32 1.25“

40 1.5“

50 2“

65 2.5“

80 3“

100 4“ 70-341KA0274.00

125 5“ 70-341KA2274.00

150 6“ 70-341KA5284.00 70-S46031084 ID 175 x 3,55

200 8“ 70-341KB0284.00 70-S46031086 ID 225 x 4

Stem with bellows Pin O-Ring Bellows O-Ring Bellows Adapter

part # qty part # part # Dimension part # Dimension

2 70-0100375A2

70-341B20471.00

2 70-0100376A215 0.59“

70-341B50471.00 2 70-0100380A2 70-S46031165 ID 59,92 x 2,62

70-341K80271.00 1 70-0100377A2 70-S46031024 ID 104,37 x 3,53

1 70-0100378A2 70-S46031031 ID 158,43 x 3,53

70-S46031147 ID 33,4 x 2,4

12

Page 13

6.2 Spare Parts Table Plug

Kämmer Series 341000 FCD KMENIM4104-01 03/18

DN ANSI Kvs Cv

0,011 0,013 3H 0.12H 70-3419421ACT 70-3419451ACT

0,017 0,02 3G 0.12G 70-3419422ACT 70-3419452ACT

0,025 0,029 3F 0.12F 70-3419423ACT 70-3419453ACT

4 0.16“

0,04 0,047 3E 0.12E 70-3419424ACT 70-3419454ACT

0,063 0,074 3D 0.12D 70-3419425ACT 70-3419455ACT

0,1 0,12 3C 0.12C 70-3419426ACT 70-3419456ACT

0,16 0,19 3B 0.12B 70-3419427ACT 70-3419457ACT

0,25 0,29 3A 0.12A 70-3419428ACT 70-3419458ACT

6 0.25“

8 0.31“

10 0.39“

15 0.59“

20 0.79“

25 1“

32 1.25“

40 1.5“

50 2“

65 2.5“

80 3“

100 4“

125 5“

150 6“

200 8“

0,4 0,47 4,5B 0.18B 70-3419429ACT 70-3419459ACT

0,63 0,74 4,5A 0.18A 70-3419430ACT 70-3419460ACT

1 1,2 7B 0.28B 70-3419431ACT 70-3419461ACT

1,6 1,9 7A 0.28A 70-3419432ACT 70-3419462ACT

1,6 1,9 10B 0.40B 70-3419432XCT 70-3419462XCT

2,5 2,9 10A 0.40A 70-3419433XCT 70-3419463XCT

4 4,7 15B 0.63B 70-3419434XCT 70-3419464XCT

6,3 7,4 15A 0.63A 70-3419435XCT 70-3419465XCT

6,3 7,4 20B 0.80B 70-3419435VCT 70-3419465VCT

10 12 20A 0.80A 70-3419436VCT 70-3419466VCT

10 12 25B 1.00B 70-3419436ECT 70-3419466ECT

16 19 25A 1.00A 70-3419437ECT 70-3419467ECT

16 19 32B 1.25B 70-3419437GCT 70-3419467GCT

25 29 32A 1.25A 70-3419438GCT 70-3419468GCT

25 29 40B 1.60B 70-3419438HCT 70-3419468HCT

40 47 40A 1.60A 70-3419439HCT 70-3419469HCT

40 47 50B 2.00B 70-3419439LCT 70-3419469LCT

63 74 50A 2.00A 70-3419440LCT 70-3419470LCT

63 74 63B 2.50B 70-3419440MCT 70-3419470MCT

100 120 63A 2.50A 70-3419441MCT 70-3419471MCT

100 120 80B 3.20B 70-3419441PCT 70-3419471PCT

160 190 80A 3.20A 70-341944APCT 70-341947APCT

160 190 100B 3.90B 70-341944ARCT 70-341947ARCT

250 290 100A 3.90A 70-341944BRCT 70-341947BRCT

250 290 125B 4.90B 70-341944BZCT 70-341947BZCT

400 470 125A 4.90A 70-341944CZCT 70-341947CZCT

400 470 140B 5.50B 70-341944CTCT 70-341947CTCT

560 650 140A 5.50A 70-341944ETCT 70-341947ETCT

560 650 190B 7.48B 70-341944EICT 70-341947EICT

900 1040 190A 7.48A 70-341944HICT 70-341947HICT

Trim # Part #

mm in equal percentage linear

13

Page 14

7 TECHNICAL TABLES

7.1 Cv Table

Kämmer Series 341000 FCD KMENIM4104-01 03/18

Kvs Cv

0,011 0,013

0,017 0,02 0.12G 3G

0,025 0,029 0.12F 3F

0,04 0,047 0.12E 3E

0,063 0,074 0.12D 3D

0,1 0,12 0.12C 3C

0,16 0,19 0.12B 3B

0,25 0,29 0.12A 3A

0,4 0,47

0,63 0,74 0.18A 4,5A

1 1,2

1,6 1,9

2,5 2,9 0.40A 10A

4 4,7

6,3 7,4

10 12

16 19

25 29

40 47

63 74

100 120

160 190

250 290

400 470

560 650

900 1040 7.48A 190A

Seat Trim#

mm in mm 10 20 40 60

0.12H 3H

3

0.18B 4.5B

4,5

0.28B 7B

7

0.28A 7A

0.40B 10B

10

0.63B 15B

15

0.63A 15A

0.80B 20B

20

0.80A 20A

1.00B 25B

25

1.00A 25A

1.25B 32B

32

1.25A 32A

1.60B 40B

40

1.60A 40A

2.00B 50B

50

2.00A 50A

2.50B 63B

63

2.50A 63A

3.20B 80B

80

3.20A 80A

3.90B 100B

100

3.90A 100A

4.90B 125B

125

4.90A 125A

5.50B 140B

140

5.50A 140A

7.48B 190B

190

4 6 8 10 15 20 25 32 40 50 65 80 100 125 150 200

0.16˝ 0.25˝ 0.31˝ 0.39˝ 0.59˝ 0.79˝ 1˝ 1.25˝ 1.5˝ 2˝ 2.5˝ 3˝ 4˝ 5˝ 6˝ 8˝

* Alloy 6 plug only / equal percentage characteristic only

14

Page 15

7.2 Dimensional Data

Kämmer Series 341000 FCD KMENIM4104-01 03/18

DN ANSI

D2 D3 D30 D31 D35 BW weight

[mm] [mm] [mm] [mm] [mm] [mm] [kg]

4 0,16˝ 45 35 600 39 70 8 x 1 1,5

D31

6 0,25˝ 45 35 600 39 70 8 x 1 1,5

8 0,31˝ 45 35 600 39 70 12 x 1 1,5

D35

10 0,39˝ 65 45 875 39 70 12 x 1 2,4

15 0,59˝ 65 45 875 39 70 21,3 x 1,6 2,4

20 0,79˝ 65 45 875 39 70 26,9 x 1,6 2,4

25 1˝ 80 65 875 48 110 28 x 1,5 5,0

D30

32 1,25˝ 80 65 875 48 110 42,4 x 2 5,3

40 1,5˝ 85 65 875 48 120 48,3 x 2 7,1

50 2˝ 85 62 875 48 120 60,3 x 2 7,1

65 2,5˝ 125 105 875 57 190 76,1 x 2,6 30

80 3˝ 125 105 875 57 190 88,9 x 3,05 30

100 4˝ 175 125 1000 59 230 114 x 3 53

D2

125 5˝ 175 140 1000 59 270 139,7 x 3 63

150 6˝ 225 175 1000 60 330 168,3 x 3 85

D3

200 8˝ 300 225 1000 60 430 219,1 x 3 117

7.3 Bonnet Torque Table

DN ANSI

Bonnet Flange

[Nm]

Actuator Nut

[Nm]

4 0.16“ 70 210

6 0.25“ 70 210

8 0.31“ 70 210

10 0.39“ 70 210

15 0.59“ 70 210

20 0.79“ 70 210

25 1“ 120 210

32 1.25“ 120 210

40 1.5“ 120 210

50 2“ 120 210

65 2.5“ 200 430

80 3“ 200 430

100 4“ 280 -

125 5“ 280 -

150 6“ 315 -

200 8“ 380 -

15

Page 16

Kämmer Series 341000 FCD KMENIM4104-01 03/18

7.4 Actuator Selection

KP Diaphragm KF Diaphragm FlowAct

DN Inch

4 0.16˝ 10 0.394 X X X

6 0.25˝ 10 0.394 X X X

8 0.31˝ 10 0.394 X X X X

10 0.38˝ 10 0.394 X X X X

15 0.5˝ 10 0.394 X X X X

20 0.75˝ 10 0.394 X X X X

25 1˝ 20 0.787 X X X X X

32 1.25˝ 20 0.787 X X X X X

40 1.5˝ 20 0.787 X X X X X

50 2˝ 20 0.787 X X X X X

65 2.5˝ 40 1.575 X X X X

80 3˝ 40 1.575 X X X X

100 4˝ 60 2.362 X X

125 5˝ 60 2.362 X X

150 6˝ 60 2.362 X X

200 8˝ 80 3,150 X X

Stroke

[mm]

Stroke

[in]

P1 P2 P3 P4 P5 F2 F3 F4 1502 3002

220

daN

400

daN

900

daN

2000

daN

3500

daN

675

daN

1000

daN

1500

daN

3900

daN

6000

daN

16

Page 17

Kämmer Series 341000 FCD KMENIM4104-01 03/18

8 TROUBLE SHOOTING

Problem Possible cause Remedy

Actuator or

stem moves

stiffly

Excessive

leakage

Inadequate flow

1 Operating temperature too high for selected

1 Note the operating data and contact Flowserve

fittings

2 Inadequate air supply 2 Check system for leaks in air supply or signal lines, re

tighten connections or replace lines if necessary

3 Positioner defect 3 See operating instructions for positioner

1 Bonnet is loose 1 See step 3.2.3 for re-tightening the bonnet correctly

2 Worn or damaged plug 2 Rework or replace plug

3 Gaskets damaged 3 Renew gaskets

4 Inadequate actuator thrust 4 Check air feed. If air feed is OK, contact Flowserve

5 Plug incorrectly adjusted 5 Correctly adjust plug according to step 3.3.1

6 Incorrect direction of flow 6 Check specification. Contact Flowserve

7 Handwheel incorrectly adjusted (acts as an

7 Adjust handwheel

end-stop)

1 Plug incorrectly adjusted (short stroke 1 Correctly adjust plug according to step 3.3.1

2 Positioner defect 2 See operating instructions for positioner

3 Operating requirements too high 3 Check operating data. Contact Flowserve

1 Plug adjustment incorrect 1 Correctly adjust plug according to step 3.3.1

Plug slams

2 Inadequate supply pressure 2 Check air supply, seal leaks, remove blockages

3 Trim too large for flow rate 3 Replace trim

17

Page 18

Notes:

Kämmer Series 341000 FCD KMENIM4104-01 03/18

18

Page 19

Notes:

Kämmer Series 341000 FCD KMENIM4104-01 03/18

19

Page 20

Kämmer Series 341000 FCD KMENIM4104-01 03/18

Flowserve Essen GmbH

Schederhofstrasse 71

45145 Essen

Germany

Phone: +49 (0)201 8919 5

Fax: +49 (0)201 8919 662

Your contact:

All data subject to change without notice

©04.2017 Flowserve Corporation. Flowserve and Kämmer are registered trademarks of Flowserve Corporation

20

Alle Angaben ohne Gewähr. Änderungen vorbehalten

Loading...

Loading...