Page 1

Experience In Motion

Circpac MD

Split Segmented

Circumferential Gas Seal

Installation

Instructions

Page 2

1 Equipment Check and Seal Preparation

1.1 Refer to Figure 1 for sleeve/shaft and equipment requirements.

1.2 The equipment sleeve/shaft must be clean and free of any burrs, nicks or scratches.

1.3 Checksealassemblydrawingforspecicequipmentrequirements,reference

dimensions, special instructions, piping connections, and materials of construction.

Figure 1

Seal chamber squareness to the shaft

centerline should be within 0.25 mm per

25 mm shaft diameter (0.010” per 1” shaft

diameter). Seal chamber face surface

nishshouldbe125RMSorbetter.

1.4 Segmented rings have matched joints and must be mated together per the segment

numbering scheme shown in Figure 2 for 3 segment rings. During assembly, keep all

numbers facing the same direction. The polished side is a sealing surface and should

be handled carefully.

Note: Do not use grease or other lubricants on segmented carbon rings, housing,

or shaft.

1.5 Use caution when handling heavy gland ring halves. Maneuver and support large

parts carefully to avoid personal injury and/or damage to segmented rings.

Shaft runout should not exceed 0.10 mm

(0.004”)FIM.Shaftsurfacenishshould

be 16 RMS or better.

Figure 2

Polished Face

2

2

Back Front

Drive Pin

2

2

Page 3

2 Seal Installation (Split Housing Designs)

Seal components are assembled in the following order: housing gasket (if separate),

bottom housing half, segmented rings, and upper housing half. Housing gasketing, housing

weight support, centering methods, and multiple ring sequencing should be considered

prior to starting.

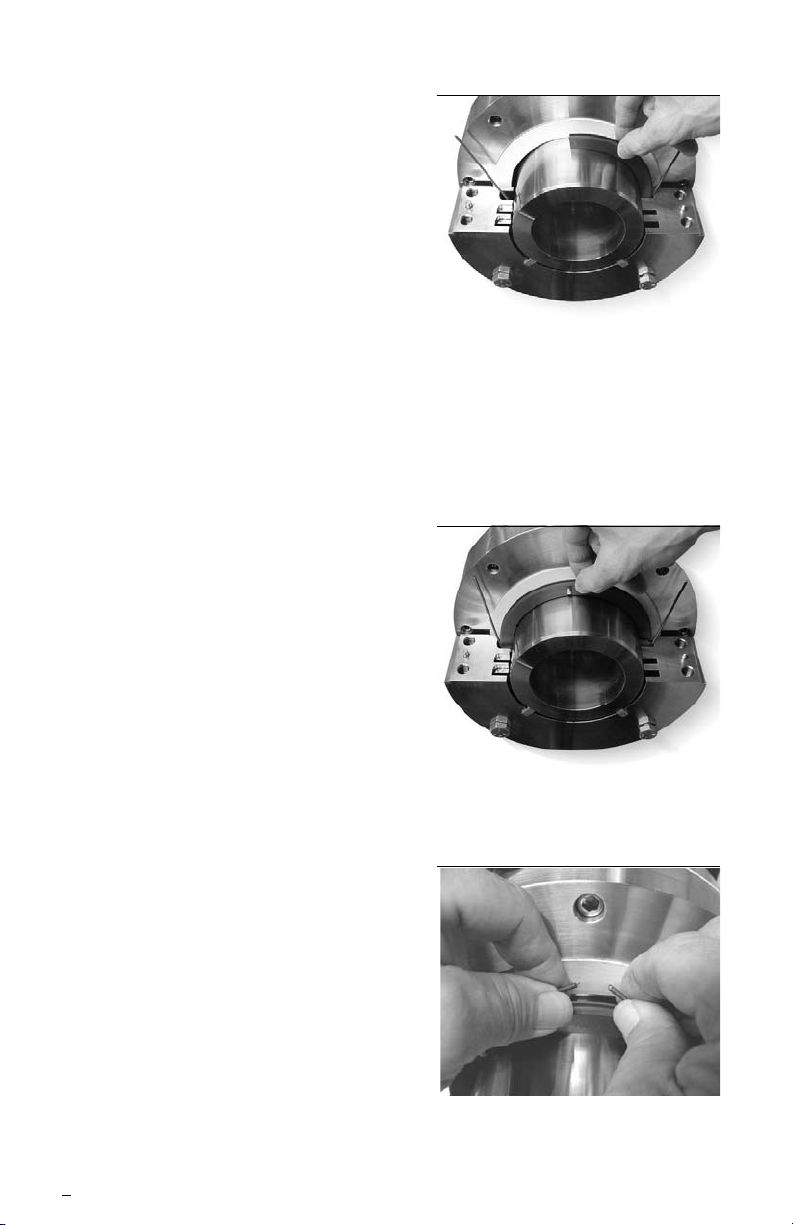

Figure 3

2.1 The housing gasket may be supplied split

and bonded to the housing halves or as a

solid ring, depending on gasket type. If the

gasket is already bonded to the housing

halves, no extra preparation is necessary.

Otherwise, with a sharp cutting instrument,

carefully cut the gasket tangential to the

gasket ID with a 45° bias in the thickness, as

shown in Figure 3. At the cut joint, bend the

gaskettotaroundtheshaft.Positionthe

gasket near the equipment face.

Figure 4

2.2 The housing half with drive pin slots at the

joint surface is the bottom half of the housing

ringandisinstalledrst.Orientthelower

housing half toward the equipment in the

direction indicated on the seal assembly

drawing or marked on the housing. Support

the lower half of the housing on the

equipment with loosely engaged bolts or

studs such that the gasket area is accessible

and the segmented ring grooves are fully

exposed.

2.3 If the seal is designed with multiple

segmented rings, start at the housing end

that will be obstructed by additional rings.

Complete each ring before starting the next.

2.4 Feed the garter spring into the ring groove

in the lower housing half. Leave an equal

amount of spring hanging out on each side.

Figure 5

3

Page 4

2.5 Select a ring segment that does not

havethedrivepin.Positionitoverthe

groove in the lower housing half. Make

sure the numbered side faces the pin slot

in the housing joint surface. Rotate the

rstsegmentintothegroove.Thegarter

spring should be on the outside diameter

of the segment.

2.6 For 3 segment rings, select the other ring

segment that does not have the drive

pin, keeping the numbered ends in order

as described in Figure 2. Make sure the

numbered side faces the pin slot in the

housing joint surface. Rotate the second

segment into the groove such that the

segment ends are exposed. The garter

spring should be on the outside diameter

of both segments.

2.7 Completetheringwiththenalsegment,

again with the numbered side facing the

pin slot in the housing joint surface. There

will be a gap between one of the joints.

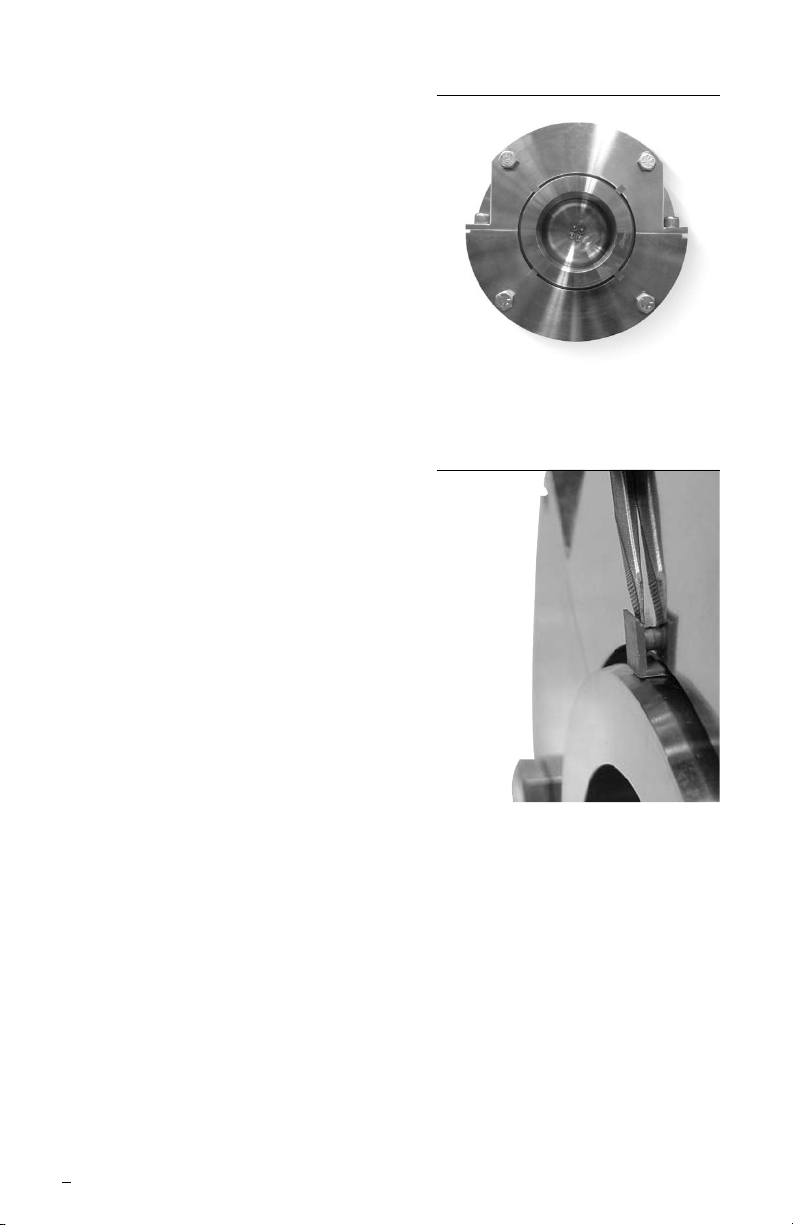

Figure 6

Figure 7

2.8 Carefully hook the ends of the garter

spring within the groove in the segmented

ring. Do not overstretch the spring.

4

Figure 8

Page 5

2.9 Rotate the ring assembly until the drive pin

engages the pin slot at the housing joint.

2.10 Repeat steps 2.3-2.9 with all segmented

rings. Figure 10 shows a completed 3 ring

assembly.

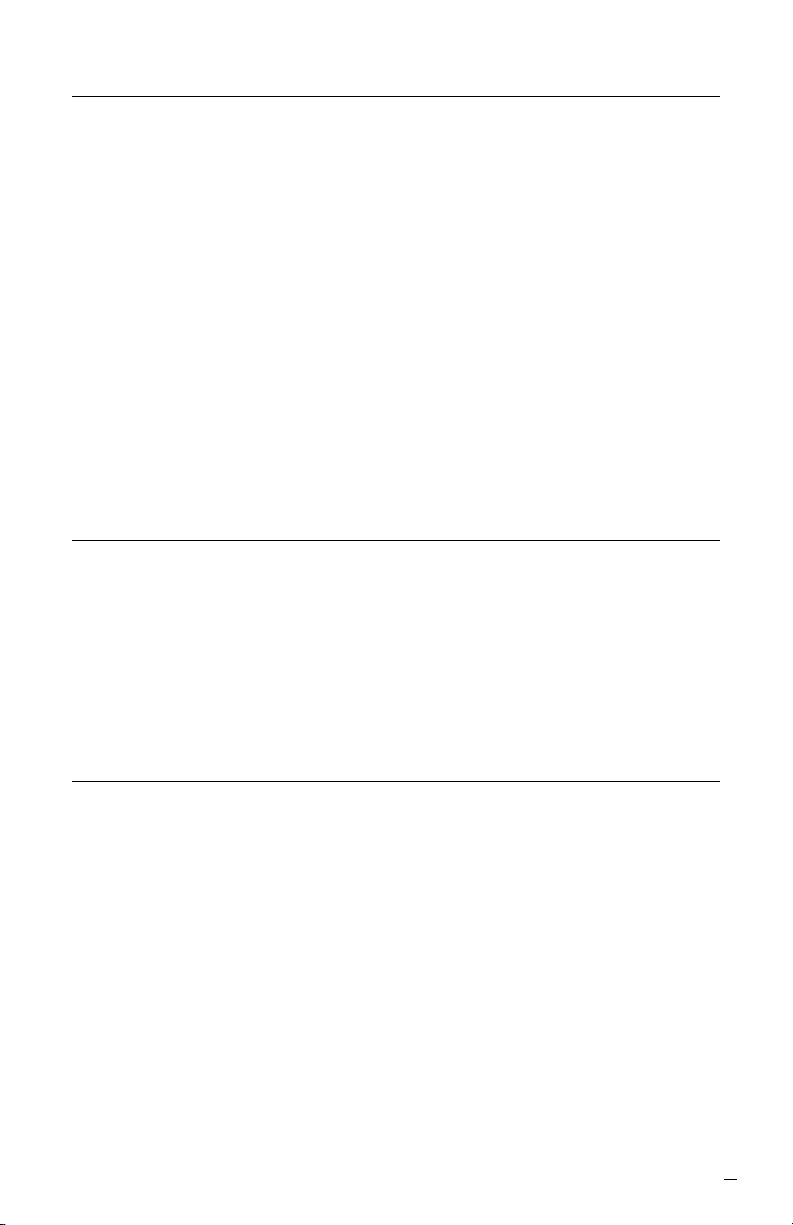

Figure 9

Figure 10

2.11 Carefully and slowly lower the upper

housing half onto the lower housing half.

Install the housing joint cap screws and

tighten to 14 N-m (10 ft-lbs) minimum.

2.12 If necessary, complete the housing gasket

installation as shown on the assembly

drawing. A general purpose adhesive may

be used to hold the gasket in place. Take

care not to contaminate the shaft or rings.

Figure 11

5

Page 6

2.13 Center the housing assembly on the shaft

as required. If centering devices are used,

release any housing supports so that the

centering devices are properly engaged on

the shaft.

2.14 Evenly tighten the housing to the

equipment until the face gasket is fully

compressed and the housing is squarely

seated. Torque housing bolts to 34 N-m

(25 ft-lbs) minimum.

Figure 12

2.15 Remove centering devices, if applicable.

2.16 Connect piping if required.

Figure 13

6

Page 7

3 Seal Installation (Non-split Housing Designs)

3.1 Circpac MD seals with non-split housings are pre-assembled at the factory for

cartridge installation. Unless otherwise indicated on the seal assembly drawing, an

installation plug is installed in the seal bore to guide the rings onto the equipment

shaft during installation. If no installation plug is used, the shaft/sleeve end must

have a smooth, 30 degree by 3.2 mm (0.125”) lead-in chamfer to ramp the rings onto

the shaft.

3.2 Check that the housing gasket is properly installed at the face of the housing.

3.3 Carefully slide the housing assembly onto the shaft. The installation plug should be

displaced by the shaft and fall away once the last ring has mounted the shaft.

3.4 Center the housing assembly on the shaft as required.

3.5 Evenly tighten the housing to the equipment until the face gasket is fully compressed

and the housing is squarely seated. Torque housing bolts to 34 N-m (25 ft-lbs)

minimum.

3.6 Remove centering devices, if applicable.

3.7 Connect piping if required.

4 Operational Recommendations

For dual seals, barrier pressure and other controls should be energized prior to starting the

equipment or introducing product. Likewise, do not remove pressure or controls until the

equipment has been fully shut down and vented.

The Circpac MD is designed to operate with clean air or nitrogen barrier gas. Check seal

assembly drawing for recommended barrier pressure setting.

For special problems encountered during installation, contact your nearest Flowserve Sales

and Service Representative or Authorized Distributor.

5 Repairs

This product is a precision sealing device. The design and dimension tolerances are critical

to seal performance. Only parts supplied by Flowserve should be used to repair a seal. To

order replacement parts, refer to the part code and B/M number. A spare backup seal

should be stocked to reduce repair time.

When seals are returned to Flowserve for repair, decontaminate the seal assembly and

include an order marked "Repair or Replace." A signed certicate of decontamination

must be attached. A Material Safety Data Sheet (MSDS) must be enclosed for any

product that came in contact with the seal. The seal assembly will be inspected and, if

repairable, it will be rebuilt, tested, and returned.

7

Page 8

TO REORDER REFER TO

flowserve.com

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Roosendaal, the Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

B/M #

F.O

.

FIS153eng REV 01/03 Printed in USA

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When

properly selected, this Flowserve product is designed to perform its intended function safely during its useful life.

However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used

in numerous applications under a wide variety of industrial service conditions. Although Flowserve can provide

general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user

must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and

maintenance of Flowserve products. The purchaser/user should read and understand the Installation Instructions

included with the product, and train its employees and contractors in the safe use of Flowserve products in connection

with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for

informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance

thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design,

the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of

its worldwide operations or offices.

© Flowserve Corporation (2011)

Loading...

Loading...