Page 1

USER INSTRUCTIONS

Installation

Automax CENTURA™ CE Series

Electric Rotary Valve Actuator

FCD AXENIM0037-01 – 10/05 (Replaces AUTO-37)

Operation

Maintenance

Experience In Motion

Page 2

Introduction

The Centura electric actuator is a rotary valve actuator with output

torques from 250 to 1,500 in-lbs. It has been designed for NEMA 4, 4X,

7, 9 and can come with a 4-20 mA card for modulating service.

Storage

For short and long term storage refer to short and long term storage

conditions CE Actuator.

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

CAUTION: Use heavy duty brake option ‘K’ for rubber lined

a

butterfly valves & dampers or applications that may back

drive the unit.

4. Mount Automax actuator to valve with Automax provided mounting

hardware to ensure proper alignment. Use mounting hardware

that has 1½ times bolt length engagement. (Do not use the manual

override to align actuator shaft to valve shaft, as this could drive the

actuator out of its operating range).

NOTE:

Some valves have manual stops; remove if appropriate or

set actuator to operate within those travel stops).

Maintenance

Centura Series actuators contain a permanently lubricated, precision

cut, heat treated gear train for long, reliable cycle life. There is no need

to change gear train grease; however, should it become necessary to

refill, use a multi-purpose grease such as DuBois MPG-2.

Permanent split capacitor gearmotors have been equipped with thermal

protectors. After many operations, especially in warm environments,

the motor will heat up. To guard the motor against overheating, the

thermal cut-out blocks power to the motor and maintains this state

until the motor’s temperature drops to a satisfactory level. This thermal

protection means that the actuator will not move when overheated.

Consideration must be given to the duty cycle requirements of the

actuator.

When replacing the cover, the machined joints must be clean and clear

of any obstructions. The integrity of the explosion-proof rating depends

on the care of these joints.

Installation

1. This section of the instruction sheet applies to the on-off units. For

instructions on Modulating units, please see the ESP3 Electronic

Servo Positioner Instructions.

2. Manually open and close valve to ensure freeness of operation.

CAUTION: To prevent ignition of hazardous atmospheres,

a

keep unit tight while circuits are alive. Disconnect supply

circuit before opening.

3. Be sure valve and Automax actuator rotate in the same direction

and are in the same position (i.e., valve closed, actuator closed). If

not sure, electrically operate the actuator to determine its operating

range, taking note of any explosion safety requirement. The electric

2

actuators are factory set for 90 degree operation.

5. Care should be taken to align valve stem properly with Automax

actuator output shaft (misalignment will cause premature failure of

assembly).

6. To connect power to terminal strip of actuator, remove the cover

and locate the terminal wiring schematic inside the cover.

7. Connect power to terminal strip according to schematic diagram

(power should be fused with a 5 amp slow-blow fuse). The actuator

should be wired and grounded in accordance with Local and

National Electrical Codes.

CAUTION: Consult factory when wiring multiple actuators

a

in series or parallel. Serious damage may result. User must

isolate unused winding.

8. Before replacing cover, actuate valve and check to see if it opens

and closes to preferred positions. If valve does not perform

correctly, adjust cams to set actuator travel properly.

9. Drive actuator to desired open position. The cams are adjusted in

two ways. Simply depress the splined “Quick-Set” cam against the

spring and rotate to desired location. Or, for very precise applications, turn the screw inside the cam to move the tip into the leaf of

the micro switch.

10. To adjust closed position, repeat step 9 with actuator in desired

closed position.

11. Operate the unit several times and recheck position. If unit is still

out of adjustment, reset the cams by following steps 9 and 10.

12. Installation in hazardous areas requires that the electrical leads be

sealed within 18 inches of the enclosure in accordance with Local

and National Electrical Codes.

13. Open conduit entries must be closed up after installation is

complete using a close-up plug engaging at least five full threads

and approved for use in hazardous locations.

Page 3

14. 60Hz actuator motors may be run on 50 Hz supply. However, the

cycle time increases by 1.2 times and the duty cycle decreases by a

factor of approximately 25%. The rated torque does not change.

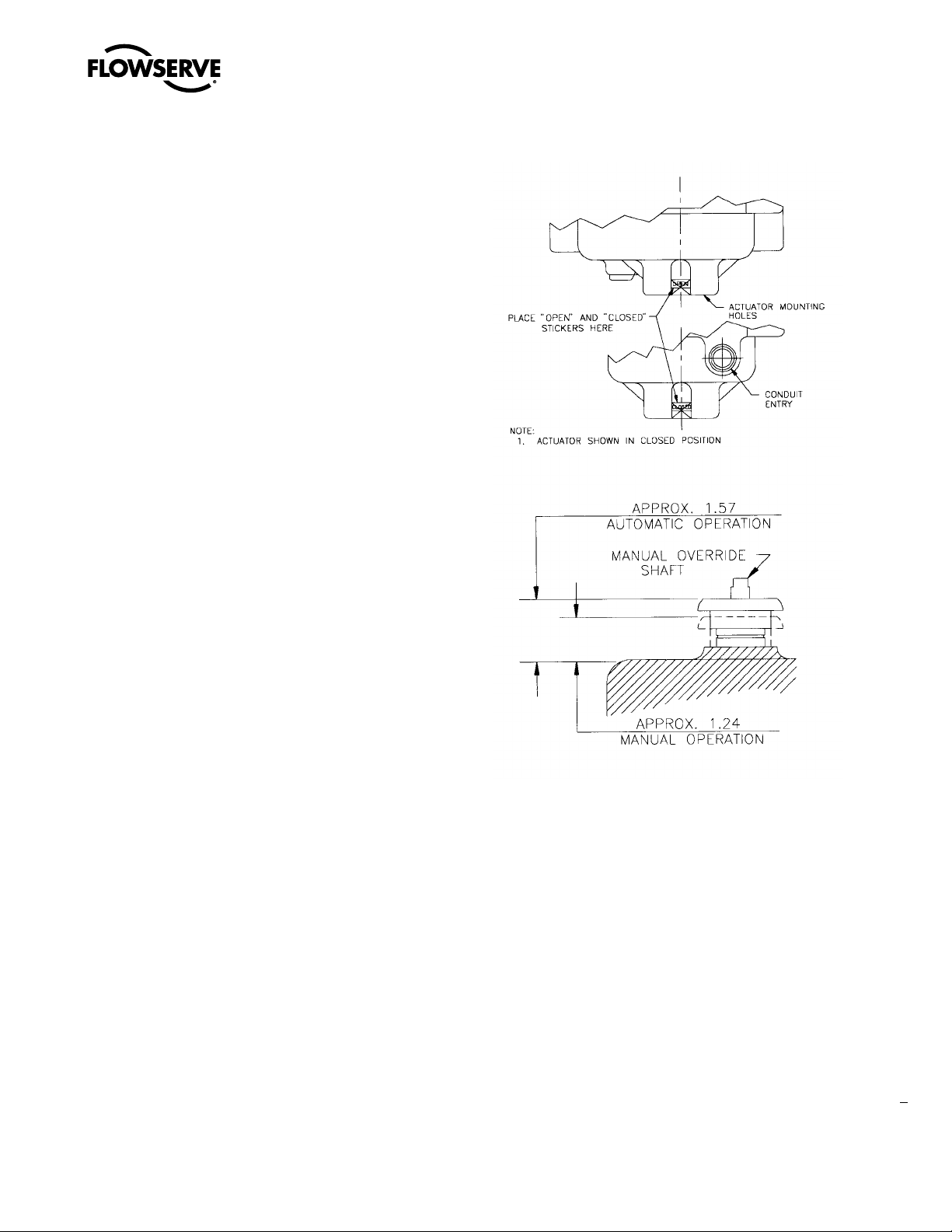

Manual Override

The principle of the design is such that when the manual override shaft

is in the up position, the shaft is disconnected from the drive train.

When the shaft is in the down position it does two things. One, the shaft

trips a switch to disconnect the power to the motor and two, it releases

the brake. By releasing the brake the motor can back drive along with

the output. For 90 degree operation, the 250 in-lbs unit requires 1.6; the

700 in-lbs unit requires 3.1; the 1000 in-lbs unit requires 4.2; and 1500

in-lbs unit requires 6.3.

CAUTION: Turn manual override shaft slowly. DO NOT jerk.

a

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Manual Operation

1. The actuator cover should be securely attached.

2. Depress hub toward actuator cover.

3. Rotate the manual override shaft slowly; do not force.

4. The motor is now electrically disconnected.

5. Turn the manual override shaft clockwise for clockwise output.

6. Do not rotate actuator past full clockwise or counter-clockwise

position.

Automatic Operation

1. Pull hub away from the actuator cover.

2. The motor is now electrically connected and ready for automatic

operation.

3. The manual override shaft will freewheel.

Position Indication Stickers

Attached to the inside of the cover is a set of stickers with the words

“CLOSED” and “OPEN”. These stickers are to be attached to the outside

of the actuator near the base between the mounting feet. The stickers

have an orange triangle on them, such that when properly attached

to the actuator, they will line up with the triangle on the output shaft.

A sticker can be placed on either side of the unit to produce a visual

indication of the opened and closed position of the actuator.

3

flowserve.com

Page 4

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Common Parts Related to All Actuators

No. Item Material P/N Qty

1 Painted Cover Cast Aluminum 106100 1

2 5⁄16-24UNF HHCS/Shank Stainless Steel 103233 8

3 5⁄16 Type A Washer Stainless Steel 103715 8

4 ½" Sleeve Bearing Sintered Bronze 105590 1

5 Molded Oil Seal Nitrile 105585 1

6 Manual Override Hub Black 141 Lexan 105567 1

7 7/16 I.D. Klipring Stainless Steel 106174 1

8 Handwheel (Optional) Black Plastic 105974 1

9 Manual Override Shaft Steel/Plated 105591 1

10 Brake Trip Washer Aluminum 107065 1

11 Manual Override Coupler Steel/Plated 106129 1

Manual Override Spring Spring Steel 105593 1

1

⁄16 Dia. Roll Pin Spring Steel 103621 1

12 O-Ring, Base N674-70 Nitrile 105584 1

13 CE1/CE2 Machined Base Cast Aluminum 106098 1

CE4/CE7 Machined Base Cast Aluminum 106099 1

CE5 Machined Base Cast Aluminum 107503 1

143⁄8" Needle Bearing Steel/Plated 105582 1

153⁄8" Sleeve Bearing Sintered Bronze 105581 4

16 O-Ring, Output Shaft N674-70 Nitrile 105583 1

17 1½" Sleeve Bearing Sintered Bronze 409944 1

18 CE1/CE2 Motor Plate Cast Aluminum 106080 1

CE4/CE7 Motor Plate Cast Aluminum 106081 1

CE5 Motor Plate Cast Aluminum 107504 1

195⁄8" Sleeve Bearing Sintered Bronze 105694 1

20 8-32 UNC Ground Screw Steel/Plated 103627 1

21 #8 Cup Washer Brass 105626 1

22 8-32 UNC x 5⁄8" Hex Screw Steel/Plated 105577 5

23 8-32 UNC x 5⁄8" Phillips Hd. Steel/Plated 105576 1

24 Actuator Bracket Steel/Plated 108099 1

27 M.O. Cut-off Switch Plastic/Steel 105769 1

28 Switch Insulator Gasket Vulcanized Fiber 103675 5

29 4-40 UNC x 5⁄8" Phillips Hd.S Steel/Plated 106146 2

30 4-40 UNC x 1¼" Phillips Hd. Steel/Plated 100159 2

313⁄16" Higher Spacer Nylon 105679 2

32 15 Amp Switch Plastic/Steel 107765 2

333⁄16" Pop-in Bearing Plastic 105851 1

34 Camshaft Steel/Plated 107005 1

35 Large 4-Deg. Spline Shaft Plastic 103571 1

1

⁄16" Dia. Roll Pin Spring Steel 103621 1

36 Small 4-Deg. Spline Shaft Plastic 103572 1

1

4

⁄16" Dia. Roll Pin Spring Steel 103621 1

37 Switch Spring Spring Steel 103714 1

38 Hi-Ramp Cam Plastic 107322 2

Continued on Page 5

Page 5

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Common Parts Related to All Actuators (continued from Page 4)

No. Item Material P/N Qty

39 CE2/CE4 Output Shaft Ass’y Steel 106096 1

CE5 Ouput Shaft Ass’y Steel 107700 1

CE1/CE7 Output Shaft Ass’y Steel 106097 1

40 CE1/2/5/& 7 Offset Shaft Steel 86L20 104864 1

1

⁄8 x 1⁄8 x 1.19" Long Key Steel 105589 1

41 CE1 Offset Pinion Steel -Heat Treated 104893 1

CE2 Offset Pinion Steel -Heat Treated 104887 1

CE4 Offset Pinion Steel -Heat Treated 104889 1

CE7 Offset Pinion Steel -Heat Treated 104891 1

CE5 Offset Pinion Steel -Heat Treated 107169 1

42 CE1/CE7 Offset Gear Steel -Heat Treated 104890 1

CE2 Offset Gear Steel -Heat Treated 104885 1

CE4 Offset Gear Steel -Heat Treated 104884 1

CE5 Offset Gear Steel -Heat Treated 107168 1

43 1.00 O.D.x 0.031 Spacer Steel 105587 1

449⁄16" I.D. Snap Ring Spring Steel 100678 2

58 Nameplate Stainless Steel 105578 1

Ty-Rap Cable Tie Plastic 101066 2

3

⁄32" Dia. Drive Pins Stainless Steel 105454 2

Cam Adjustment Sticker Mylar 105757 1

Manual Override Sticker Mylar 105756 1

Automax Logo Sticker Mylar 105862 2

Position Indication Sticker Mylar 106187 1

¾" NPT Conduit Plug Plastic 103685 1

Open/Close Stickers Mylar 106186 1

59 Press Fit Washer Steel 107178 1

60 Plug Steel/Plated 107126 2

Additional Parts Specific To 115 VAC Actuators CE2, CE4, CE7, CE1, CE5

No. Item Material P/N Qty

49 115 VAC PSC Motor Int. Steel/Copper 105675 1

16 Fin Impeller Fan Plastic 105703 1

10-32 UNC x 3⁄16" SHCS Steel/Plated 105599 2

54 Capacitor Plastic Encapsulated 106619 1

55 Wire Tie Plastic 106243 2

56 Quick Connect Plastic/Steel 106761 4

25 6 Position Terminal Strip Plastic/Steel 103997 1

2 Screw Marker Strip Plastic 103996 1

26 3-48 UNC x ½" Pan Head Steel/Plated 104837 2

115 VAC Wire Harness Copper/Plastic 106111 1

115 VAC Schematic Sticker Gloss Paper 815169 1

5

flowserve.com

Page 6

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

6

Page 7

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

flowserve.com

7

Page 8

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Additional Parts Specific To 115 VAC With ESP Servo Positioner

Actuators CE2ATA, CE4ATA, CE7ATA, CE1ATA, CE5ATA

No. Item Material P/N Qty

49 115 VAC PSC Motor Ext. Steel/Copper 105676 1

Fan Hub Pressed Metal 107939 1

Fan Plastic 107940 1

Compression Spring Steel 108431 1

Brake Hinge Ass’y Steel/Plastic 108600 1

52 Brake Solenoid Coil 108022 1

Switch Spring Steel 103714 1

Wave Spring Steel 108198 1

10-32UNF Set Screw Stainless Steel 103486 1

.75 x .459 x .042 Washer Brass 108361 1

Klip Ring Stainless Steel 106174 1

6-32 x ½ Phil. Screw Steel 106061 1

.350 x .118 Lg. Spacer Bronze 108296 2

6-32 Hex. Nut Nylon/Steel 105864 1

10-32UNF SHCS Steel 105599 2

#6 Type A Plain Washer Steel 100986 3

Brake Shim Steel 108199 1

8-32 x 5⁄8 Phil. Screw Steel 105576 3

55 Wire Tie Plastic 106243 2

56 Quick Connect Plastic/Steel 106761 4

54 Capacitor

#6 x 0.19 lg. Spacer Aluminum 100839 1

6-32 UNC x 3⁄8"

Phillips Hd.

¼ Turn Standoff Plastic 105168 2

ESP3 Servo Positoner Fiberglass 105005 1

Potentiometer Plastic 106195 1

85- Tooth Gear Aluminum 107312 1

85- Tooth Gear Aluminum 105853 1

115 VAC ESP3 Wire

26

Harness

ESP3 Schematic Sticker Glass Paper 815224 1

Plastic

Encapsulated

Steel/Plated 100881 1

Copper/Plastic 106194 1

106618 1

Additional Parts Specific To 12 VDC Actuators CE2B, CE4B, CE7B,

CE1B, CE5B

No. Item Material P/N Qty

49 12 VDC Gearmotor Steel/Copper 106088 1

Motor Bracket Spacer Aluminum 106193 2

25 6 Piston Terminal Strip Plastic/Steel 103997 1

2 Screw Marker Strip Plastic 103996 1

26 3-48 UNC x ½" Pan Head Steel/Plated 104837 2

12 VDC Wiring Harness Copper/Plastic 106196 1

12 VDC Schematic

Sticker

Gloss Paper 815176 1

Additional Parts Specific To 24 VDC Actuators CE2C, CE4C, CE7C,

CE1C, CE5C

No. Item Material P/N Qty

49 24 VDC Gearmotor Steel/Copper 106088 1

Motor Bracket Spacer Aluminum 106193 2

6 Position Terminal

25

Strip

2 Screw Marker Strip Plastic 103996 1

3-48 UNC x ½" Pan

26

Head

24 VDC Wiring Harness Copper/Plastic 106197 1

24 VDC Schematic

Sticker

Plastic/Steel 103997 1

Steel/Plated 104837 2

Gloss Paper 815176 1

8

Page 9

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Wiring Diagrams

CAUTION: To prevent ignition of hazardous atmospheres, keep

a

unit tight while circuits are alive. Disconnect supply circuit

before opening.

CAUTION: Consult factory when wiring multiple actuators in

a

series or parallel. Serious damage may result.

NOTE:

Wiring diagrams show internal wire connections and suggested

customer connection for proper use. Switches shown in “customer

wiring” are for illustration only and are not supplied with the actuator.

Reversible AC Actuator

Reversible DC Actuator

Reversible AC Actuator with 2 Extra Switches

Reversible Modulating AC Actuator

9

flowserve.com

Page 10

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Typical Actuator Specifications

Action Reversible

Range of Adjustability 0° -270°

Supply Voltages AC: 115 VAC

+/-10% 230 VAC

50/60 Hz 24 VAC

DC: 12 VDC

24 VDC

Temperature Rating -40°F (-40°C) to 160°F (70°C)

Enclosure Ratings Nema 4, 4X, 7, 9 Watertight and Explosion-proof

Class I Groups C&D, Div. 1&2

Class II Groups E, F&G, Div. 1&2

Motor Types AC: Permanent Split Capacitor, Class B Insulation

DC: Brush

AC Motor Thermal Protection Automatically resetting

Travel and Aux. Switches SPDT, Form C

15 amp 125 VAC ½ HP, 10 amp 250 VAC, ½ amp 125 VDC

Conduit Connections ¾-14 NPT

Manual Override 300 In-lbs max input

Corrosion Protection Chromate conversion undercoat with polyester electrostatic powder top coat

Terminal Strip Hookup 300V, 30 amp, 12-26 AWG

Lubrication Permanently lubricated

Gear Train Heat treated alloy steel able to withstand stall torque

Note: The above ratings may change depending on model configurations and options provided. Products may

differ as the result of the Company policy of continuous product improvement.

Motor

Option

Torque and Weights

Torque (In-Lbs) 250 400 700 1000 1500

Torque (N-M) 28 45 79 113 169

Weight (Lbs) 18 18 18 18 20

Weight (Kg) 8 8 8 8 9

Notes:

1. Duty cycle is the limit of “on” time as percentage of total cycle time. For example, the CE2 with standard motor

2. Do not lock up DC motors.

3. CE5 duty cycles for AC motors are 20% for standard duty and 70% for extended duty.

10

4. For 180 degree applications, simply multiply the above cycle times by 2.

Motor

Voltage

Std. 115 AC 25 1.1 1.3 3 5 6 11 18

A 115 AC Extended: 75 0.5 0.6 6 10 17 24 36

B 12 DC 100 1.6 3.0

C 24 DC 100 0.9 2.0

D 230 AC 25 0.7 0.8 3 5 6 11 18

F 230 AC Extended: 75 0.3 0.4 6 10 17 24 36

J 24 AC 100 0.5 0.8 3 5 6 11 18

runs 3 seconds to open or close the valve. The motor must remain off for 9 seconds prior to starting the close

cycle. DC motors may be operated continuously.

Duty

Cycle

(1,3)

Run

Current

(Amps)

Locked

Rotor

(Amps)

(2)

(2)

Cycle Times in Seconds per 90 Degrees

Actuator Model

CE2 CE4 CE7 CE1 CE5

6 9 16 21 32

6 8 15 20 30

Page 11

Troubleshooting

Problem

There is power to the unit, but it does not respond.

Solution

Check the nameplate to see that the correct voltage has been applied.

Check the wiring to see that it is per the wiring schematic.

Check the limit switches to see if they are in the normal operating

range.

Check the manual override. If it is in the down position, the motor is

electrically disconnected.

Problem

Power is getting to the motor, but it merely hums.

Automax CENTURA™ CE Series FCD AXENIM0037-01 – 12/05

Solution

Check to see that the proper voltage is applied. Make sure all the

connections are tight.

Check to see that the brake coil is pulling the brake pad and hinge away

from the fan.

Check to see that CW and CCW power connections are not powered at

the same time.

Problem

The actuator performs erratically.

Solution

Check to see that the actuator is not stalling.

Check the ambient temperature rating. The permanent split capacitor

units are equipped with thermal cut-outs. Excessive temperatures and

cycle frequencies may heat the motor up and the thermal cut-out turns

it off.

flowserve.com

11

Page 12

FCD AXENIM0037-01 Printed in USA. (Replaces AUTO-37)

To find your local Flowserve representative:

For more information about Flowserve Corporation, visit

www.flowserve.com or call USA 1 800 225 6989

United States

Flowserve Corporation

Flowserve Flow Control

1978 Foreman Drive

Cookeville, TN 38501

Tel 931 432 4021

Fax 931 432 5518

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should

read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in

connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2005 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Loading...

Loading...