Page 1

USER INSTRUCTIONS

Limitorque Automax

CEA Series

FCD AXENIM2080-00-AQ – (01/15)

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

2

Page 3

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Contents

1. Important Notes 5

2. Actuator Quick Start Guide for C-PRO and C-MOD Versions 5

2.1 Wiring Diagrams 7,8

2.2 Menu Tree 9

3. Installation and Operation 11

3.1 Flowserve Automax Valve Products 11

3.2 Electrical Installation and Adjustment 12

4. Calibration and Commissioning 12

4.1 Travel Stop Adjustment 12

4.2 Gear Train 13

4.3 Rotation Speed Control 13

4.4 Variable Torque Output 13

4.5 Duty Cycle 13

4.6 Heater and Thermostat 13

4.7 HMI Display 14

4.8 Programmable Parameters 15

4.9 Alarm Output Setup 20

4.10 Position Indicator 21

5. Manual Override 22

6. Performance and Technical Data 23

7. Actuator Troubleshooting Guide (Electrical) 24

8. Parts List 25

flowserve.com

3

Page 4

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Using Flowserve Valves, Actuators

and Accessories

General Usage

The following instructions are designed to assist in unpacking, installing

and performing maintenance as required on Flowserve products.

Product users and maintenance personnel should thoroughly review this

bulletin prior to installing, operating or performing any maintenance.

In most cases Flowserve valves, actuators and accessories are designed

for specific applications with regard to pressure, temperature and

media. For this reason they should not be used in other applications

without first contacting the manufacturer.

Terms Concerning Safety

The safety terms WARNING, CAUTION and NOTE are used in these

instructions to provide additional information on important aspects of

the CEA.

WARNING: indicates that death, severe personal injury and/or

a

substantial property damage can occur if proper precautions are

not taken.

CAUTION: indicates that minor personal injury and/or property

a

damage can occur if proper precautions are not taken.

Qualified Personnel

Qualified personnel are people who, on account of their training,

experience and instruction, and their knowledge of relevant standards,

specifications, accident prevention regulations and operating

conditions, have been authorized by those responsible for the safety

of the plant and its employees to perform the necessary work and

who can recognize and avoid possible dangers.

Installation

WARNING: Before installation, check the order number, serial

a

number and/or the tag number to ensure the actuator is correct

for the intended application.

Do not insulate extensions that are provided for hot or cold

services.

Fire protection must be provided by the user.

Spare Parts

Use only original Flowserve spare parts. Flowserve cannot accept

responsibility for any damages that occur from using spare parts or

fastening materials from other manufacturers. If Flowserve products,

like sealing materials, have been in storage for longer periods, check

these for corrosion or deterioration before using. Fire protection for

Flowserve products must be provided by the user.

Service/Repair

NOTE: provides additional technical information, which may not

be obvious even to qualified personnel.

Compliance with all other notes regarding transport, assembly,

operation, maintenance and technical documentation is essential in

order to avoid conditions or occurrences that might directly or

indirectly cause severe personal injury or property damage.

Protective Clothing

Flowserve products are often used in dangerous applications (e.g.

extremely high pressures, or with flammable, combustible, toxic or

corrosive media). In particular, valves with bellows seals point to such

applications. When performing service, inspection or repair operations,

always ensure that the valve is depressurized, the actuator is powered

off and that the valve has been cleaned and is free from harmful substances. In such cases pay particular attention to personal protection

(protective clothing, gloves, glasses, etc.).

4

To avoid injury to personnel and damage to products, users must

strictly adhere to safety terms. Modifying this product, substituting

non-OEM parts, or using maintenance procedures other than outlined

in this instruction could affect performance and be hazardous to

personnel and equipment, and may void existing warranties. Between

the actuator and valve, there are moving parts. To avoid injury,

Flowserve provides pinch-point-protection in the form of cover plates,

especially where side-mounted positioners are fitted. If these plates

are removed for inspection, service or repair, the cover plates must be

refitted after the work is complete.

In addition to the operating instructions and the obligatory accident

prevention directives valid in the country of use, all recognized

regulations for safety and good engineering practices must be followed.

WARNING: Before products are returned to Flowserve for repair

a

or service, Flowserve must be provided with a certificate which

confirms that the product has been decontaminated and is clean.

Flowserve will not accept deliveries if a certificate has not been

provided (a form can be obtained from Flowserve).

Page 5

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Storage

In many cases, Flowserve products are manufactured from stainless

steel. Products not manufactured from stainless steel are provided

with an epoxy resin coating. This means that Flowserve products are

well protected from corrosion. Nevertheless, Flowserve products must

be stored in a clean, dry environment.

Valve and Actuator Variations

These instructions cannot claim to cover all details of all possible

product variations, nor can they provide information for every

possible example of installation, operation or maintenance. This

means that the instructions normally include only the directions to be

followed by qualified personnel where the product is being used, for

its defined purpose. If there are any uncertainties, particularly in the

event of missing product-related information, clarification must be

obtained via the appropriate Flowserve sales office.

Unpacking

Each delivery includes a packing slip. When unpacking, check the

delivered actuator and accessories using this packing slip.

Report transport damage to the carrier immediately.

In case of discrepancies, contact your nearest Flowserve sales office.

ingress and harsh environments that may result in deterioration

of internal components and void the unit’s warranty.

During final field installation, ensure that all cable entries are correctly

sealed in accordance with National Standards or Regulatory Authorities. All temporary transit plugs must be removed and any unused

cable entries closed in an approved manner.

2. Actuator Quick Start Guide

for C-PRO and C-MOD Versions

CEA model sizes 15/60/150 use ISO mounting F05/F07 with STAR

drive interface as standard. The baseplate incorporates both mounting

patterns with F07 required for size 150 torque output. A third mounting pattern with larger diameter is also provided for custom mounting

installations.

1. Prior to assembly, check the mounting surfaces, the stem adaptor

and the bracket to assure proper fit.

2. Manually open and close the valve to ensure smooth operation.

3. Be sure the valve and actuator rotate in the same direction and are

in the same position (i.e. valve open, actuator open).

4. Secure the valve with the stem vertical.

1. Important Notes

• Please read this manual entirely before attempting to install or

operate your CEA actuator. A full understanding of the installation

and operation options will assist you in installing the actuator in

the most effective manner. The CEA actuator is designed for long

life even in harsh environments.

• All actuator enclosures are sealed by O-rings and cable entries are

supplied with threaded plugs to protect the terminal compartment

until the unit is wired. If the actuator cannot be installed immediately, it is recommended that it be stored in a clean, dry place,

preferably in an area that is not subject to large fluctuations in

temperature.

• Disconnect all incoming power before opening any cover on the

actuator. The user/operator must ensure that safe working practices are employed at all times and are in accordance with local or

national standards that are enforced at the particular site.

• To install and operate the actuator, only the terminal compartment

cover needs to be removed. The actuator is factory calibrated

according to nameplate information and is ready to install and

operate upon receipt.

NOTE: If the controls cover is removed, electrical components

are exposed to the atmosphere. Avoid exposure to moisture

5. Bolt the bracket to the valve and place the stem adaptor on the

valve stem.

6. Position the actuator over the valve and lower to engage the stem

adaptor to the actuator output drive. Continue to lower until the

actuator rests on the bracket mounting surface. In order to align

the bolt holes, it may be necessary to turn or rotate the actuator a

few degrees.

7. Bolt the actuator to the bracket.

8. Stroke the actuator several times to assure proper operation with

no binding of the stem adaptor.

CAUTION: Fastener length must be less than mounting hole

a

depth for proper mounting and to avoid damage to mounting

base.

CAUTION: Misalignment may reduce actuator cycle life and

a

cause premature failure.

Travel stops are provided with 90

tory set at 0

necessary to perform an AutoCalibration to recalibrate rotation limits.

If travel stops are adjusted outward, it is recommended to perform an

AutoCalibration to recalibrate rotation limits.

o

and 90

o

position. If travel stops are adjusted inward, it is

o

rotation angle models. They are fac-

5

flowserve.com

Page 6

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Normally there are no orientation restrictions for actuator mounting;

consult factory with any questions. Typical installations include InLine mounting with the handwheel in line with the piping and CrossLine mounting with the handwheel cross line with the piping.

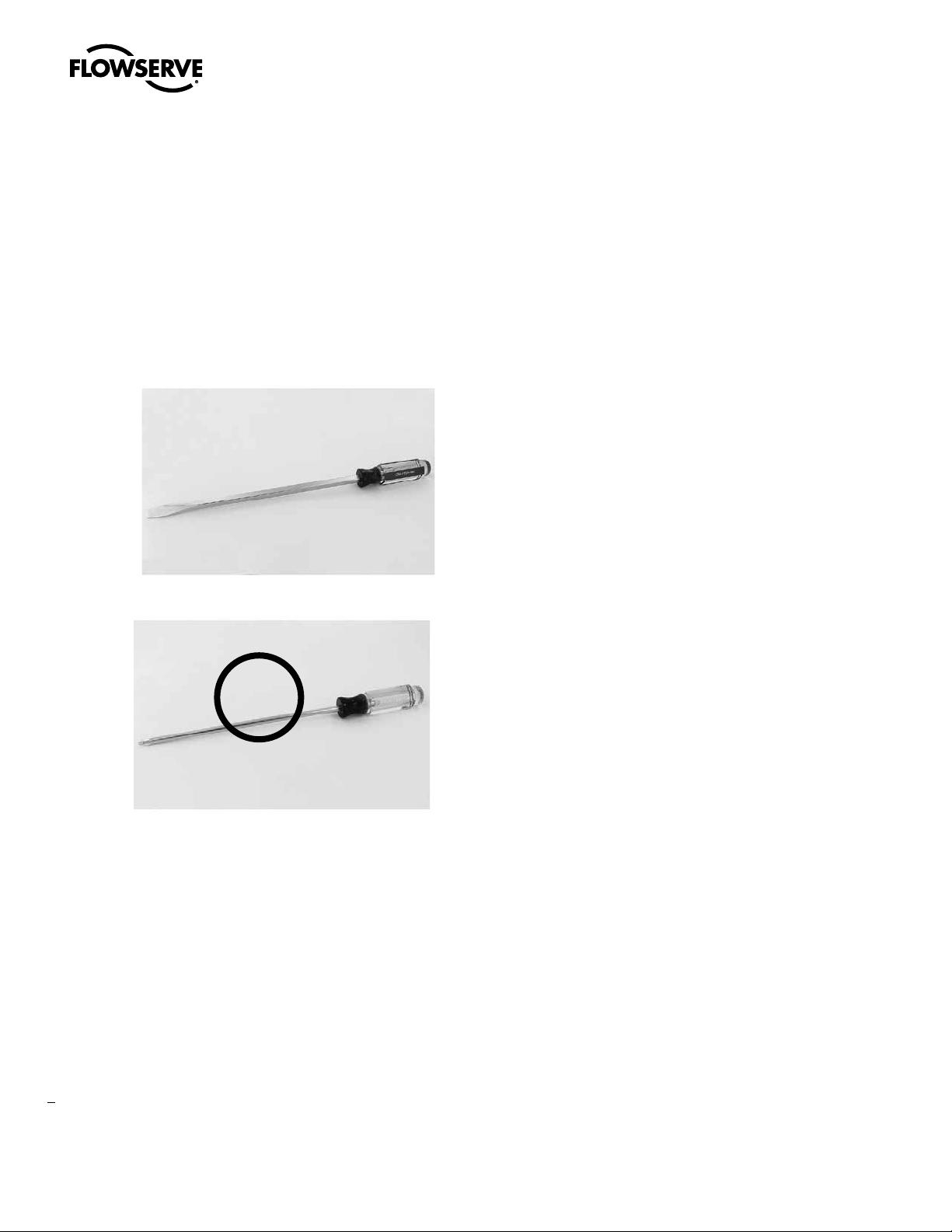

NOTE: Mechanical assistance may be required to remove and

tighten the threaded covers. A flat edge screwdriver 10 inches or

longer may be of assistance.

NOTE: It is not necessary to remove the indicator dome on the

Controls Cover for removal.

Flat Edge Screwdriver (recommended)

Round Edge Screwdriver (not recommended)

Operation

C-PRO version

The C-PRO, ON/OFF voltage control actuator ships from the factory

calibrated and ready to operate. It is not necessary to remove the Controls

Cover if factory settings are suitable. Wire the actuator according to the

wiring diagram located inside the Terminal Block cover.

Key default settings include:

• Factory calibrated for 0-90 degree operation

• CCW to Open, CW to Close

• Fastest operating speed (listed on nameplate)

• Maximum rated torque (listed on nameplate)

• L1 and L2 are for input voltage 120 or 240VAC (Consult Factory for

other AC/DC voltages)

• Terminals 20, 21, 22 and 23

- Terminal 20 = voltage command common

- Terminal 21 = voltage command OPEN

- Terminal 22 = voltage command CLOSED

- Terminal 23 = voltage command MID

• Terminals 1 and 2 are Normally Open (NO) dry relay contacts for

OUTPUT 1 (CCW)

X

After commissioning the actuator, the threaded cover(s) will need to be

installed in reverse fashion. Rotate by hand until difficult to turn (about

90% complete). Use mechanical assistance until you feel the cover

“bottom out.” For the controls cover to be properly sealed, the gap

between the cover and the housing should be no more than 0.010 inch.

With the actuator in full CW position, the entire RED closed indicator

should be shown in the viewing window of the dome. This is the

factory default setting. User may change to CCW/Open position.

WARNING: All threaded covers must be installed with the above

a

criteria, otherwise NEMA/IP and Hazardous Area ratings could

be compromised.

6

• Terminals 3 and 4 are Normally Open (NO) dry relay contacts for

OUTPUT 2 (CW)

• Terminals 5 and 6 are Normally Open (NO) dry relay contacts for

OUTPUT 3 (Torque or MID)

• Terminals 7 and 8 are Normally Open (NO) dry relay contacts for

OUTPUT 4 (Compartment Temp)

NOTE: L1 and L2 are to be powered at all times. Remote voltage

commands can be any voltage between 24VDC-240VDC or

24VAC to 240VAC: 4/5 wire power and control scheme.

For 3 wire power and control scheme, consult Flowserve.

Page 7

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

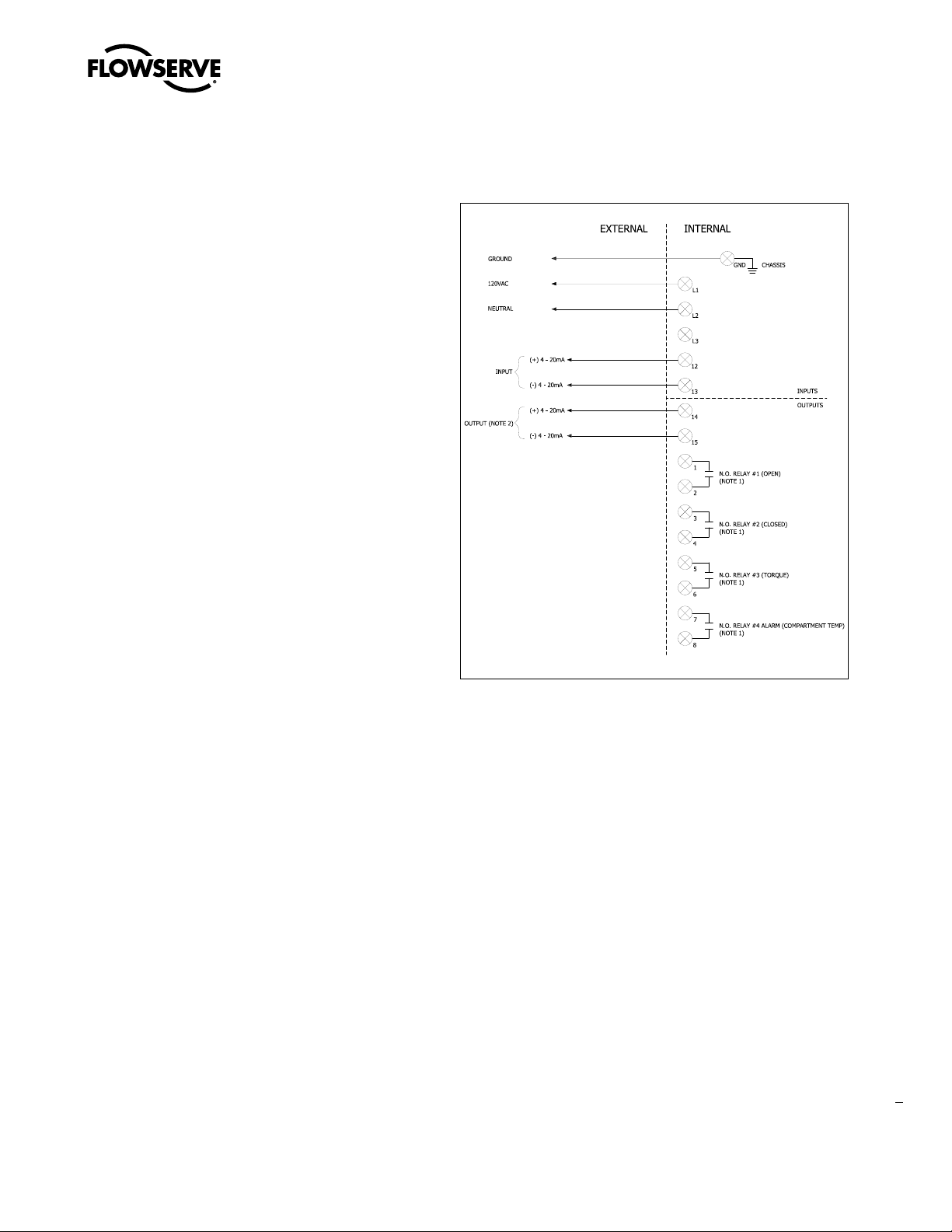

C-MOD version

The C-MOD or Modulating control actuator ships from the factory

calibrated and ready to operate. It is not necessary to remove the Controls Cover if factory settings are suitable. Wire the actuator according

to the wiring diagram located inside the Terminal Block cover.

Key default settings include:

• Factory calibrated for 0-90 degree operation

• Direct Acting CCW to Open

• L1 and L2 are for input voltage 120 or 240VAC (Consult Factory for

other AC/DC voltages)

• Terminals 11, 12, 13 and 14

- Terminal 11 = + 4-20mA current source (input)

- Terminal 12 = ( - ) 4-20mA current source (input)

- Terminal 13 = + Loop Powered 24VDC + 4-20mA current

(output)

- Terminal 14 = ( - ) Loop Powered 24VDC + 4-20mA current

(output)

• Terminals 1 and 2 are Normally Open (NO) dry relay contacts for

OUTPUT 1 (CCW)

2.1 C-MOD Wiring

• Terminals 3 and 4 are Normally Open (NO) dry relay contacts for

OUTPUT 2 (CW)

• Terminals 5 and 6 are Normally Open (NO) dry relay contacts for

OUTPUT 3 (Torque or MID)

• Terminals 7 and 8 are Normally Open (NO) dry relay contacts for

OUTPUT 4 (Compartment Temp)

NOTE: L1 and L2 are to be powered at all times

NOTE: 4-20mA output is to be loop powered with 24VDC.

Voltage range 13-24VDC.

NOTE 1: Contact rating = 16amp @ 250VAC, dry contact. All outputs

are programmable, remote voltage inputs are 12VDC

to 240VAC for Open, Closed, Mid/Dribble terminals

(20,21,22,23)

7

flowserve.com

Page 8

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

2.80

71.02

3.17

80.50

10.13

257.19

.64

16.16

5.82

147.84

4.84

122.83

REVISION HISTORY

REV

EC/SO

DESCRIPTION

DATE

BY

APPV

0 5933

INITIAL RELEASE

8/15/13

BMN

MDR

1 5998

DIMENSION "W" FOR 0.875-1/4x3/16 BORE TORQUE NUT IN

THE TABLE WAS CHANGED FROM 0.188 TO 0.250

12/3/2013

JDE

JDE

2 00001713

DRAWING RE-LINKED TO LATEST ASSEMBLY FILE CY102215A

6/17/2014

THIRU

JDE

3 00002000

ADDED LARGE BOLT CIRCLE DIMENSIONS

7/23/14

BMN

MDR

4 00002090

ADDED DUAL DIMENSIONS TO OVERALL DIMENSIONS

8/6/2014

JDE

DRM

D

C

B

6

5

4

3

2

1

E

F

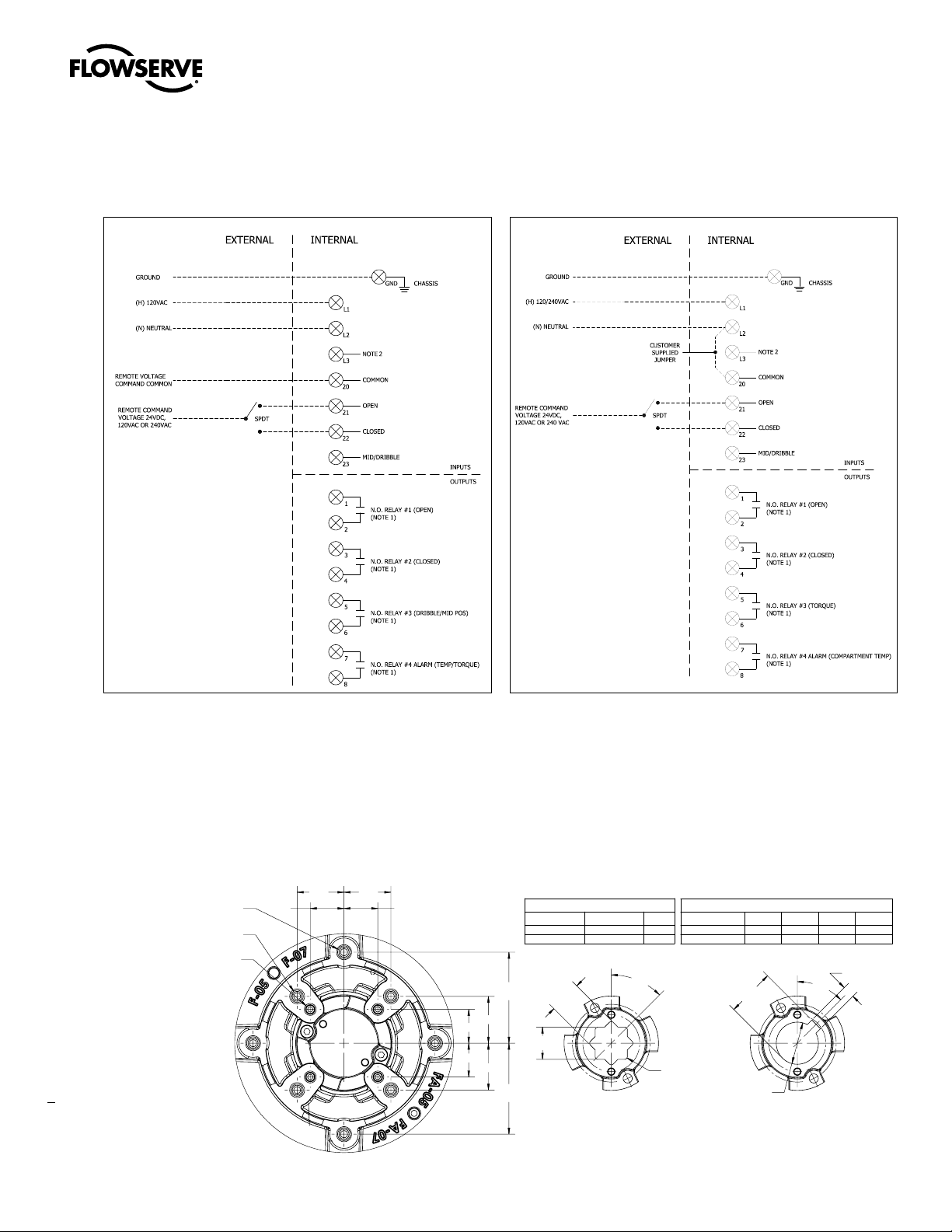

C-PRO Wiring

ON/OFF with Isolated Voltage Command Control

C-PRO Wiring

ON/OFF with Non-Isolated Voltage Command Control

NOTE 1: Contact rating = 16amp @ 250VAC, dry contact. All

outputs are programmable, remote voltage inputs are

12VDC to 240VAC for Open, Closed, Mid/Dribble terminals

(20,21,22,23).

NOTE 2: 208 - 240VAC, 3 phase (future)

Standard Baseplate Mounting

M8x1.25 - TAP

0.51 DEEP

(F07) M8X1 / (FA07) 5/16-18 UNC - TAP

(F05) M6X1 / (FA05) 1/4-20 UNC - TAP

0.67 DEEP

0.51 DEEP

8

.974 .974

.702 .702

.974

.702

.702

.974

DOUBLE SQUARE TORQUE NUT

DESCRIPTION

0.669 0.669 0.787

0.551 0.551 0.630

1.890

TYP.

1.890

TYP.

+-.004

"A"

.000

+-.004

"A"

.000

DOUBLE SQUARE TORQUE NUT

"A" (SQUARE)

45°

DEPTH

R.08 MAX.

TYP.

DESCRIPTION

0.875-1/4x1/4

0.875-1/4x3/16

"BORE"

BORE TORQUE NUT

"BORE"

0.879 0.991 0.250

0.879 0.960 0.250

+-.008

"T"

.000

+-.004

.000

BORE TORQUE NUT

"T"

"W"

DEPTH

"W"

+-.002

.000

1.63

1.63

45°

MOUNTING

BLANK TORQUE NUT

(F05/FA05 & F07/FA07)

Page 9

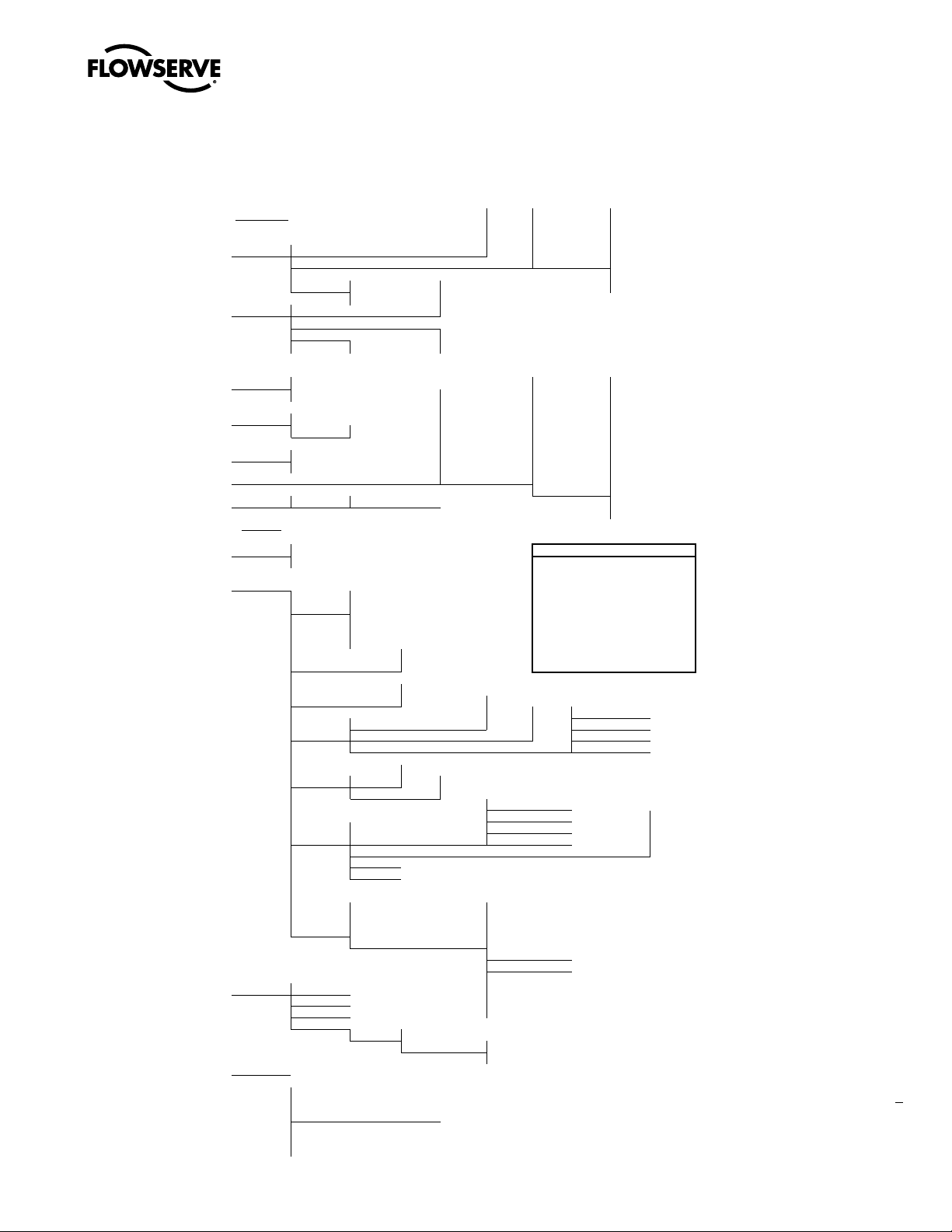

2.2 Menu Tree

Full Menu show LCS Pos graph BakEMFFaul

Read Statistics Reset stats IRAM Fault

Diagnostic HWOv erTorq

Man/Auto AUT, OK=MAN MAN,OK=AUTO COP Fault

IGBT Short

Full Menu

Setup Full

linear*

Character equal %

quick open

custom

sqr root

# of points

Custom char custom curve

0% = 4.0mA*

Current range 100% = 20.0mA* free*

cutoff free* Cutoff Low L O = 1.0%

Set low limited cut off Cutoff High HI = 99.0%

Trvl ctrl Set high limited Limit Low LO = 0.0%

Values Limit High HI = 100.0%

Direct

Transmitter Direction Reverse Position

Pos/Set Setpoint

Setpoint %*, mA, degrees

Position %*, degrees Position

Language Torque Nm, Lb-in*, Lb-Ft Set & Pos*

Appearance Units Temp C, F*, K Set & Dev

Default Display Menu

Start Logo On*/OFF

Orientation Norma l*,Flipped

HW rev Message

SW rev Tag

Devicedata Capa bility Descriptor

HART/MBUS Date

Device ID ID = XXXXXX (= serial no)

Modbus adr ADDR = XXX

Assembly No.

Tuning Clos e Time MIN = 0.0s Universal Cmd Rev

Open Time MIN = 0. 0s Special Cmd Rev

Deadband D = 1.0% Burst

Expert

Control PID Parameters

Stroketime CCW = X.Xs

CW = Y.Ys

FACT SET (press OK for 3 se conds to set default settings)

Read

MAN/AUTO

Calibrate Duplicated - se e Basic Menu tree

Setup Pro

Status

Protection

Note: (*) indicate s factory default setting

Slow shaft detection percentage

Unit address

C-MOD Dedicated

Character

Custom char

Current range (sp lit range)

Trvl ctrl

Loss of setpoint signal position

Loss of setpoint signal time

Setpoint selector

Loss of position feedback action

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

C-PRO & C-MOD Menu Tree - SW120

Basic Menu* Standard* 1 (Pos*/Alarm) Show alarm

Calibrate Rotation Mid Pos 4 (Pos/Alarm*) Limit 2

Set Up Pro Torque Closed

Outputs ALARMS Torque

AutoCal Compa temp

Expert Cal Set Point Model Motor temp

Speed

Direction Open Speed

Curr Limit CCW/CW Close Speed

Transm Open

Turns 2 (Pos*/Alarm) Deviation

Manual 3 (Pos/Alarm*) Limit 1

Status 0 0 Service N cycles Lo MotrVlt

Protection NO* Set & Dev # of reset IGBT Op en

Shift Basic Menu* comp temp Histogram Ha llldxLmp

IN Service* Pos Acc travel MotrTmpOOR

YES Enter Code Torque Run time Ha llldxCrt

Set & Pos* Mean dev MotrOvrTrq

motor temp Extreme Temp PMCB Reset

Full Menu

Shift Basic Menu

9

flowserve.com

Page 10

10

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Basic Menu

Calibrate

Setup Pro

Status

Protection

Shift

Read

Man/Auto

Calibrate

Rotation

Standard

90, 180, 270, 360, Multi

Turns

set turns (1,6,10,12,17,20)

Manual

subset of Standard Rotation,+/- 6 degrees of min/max rotation.

(i.e. if 90 selected, select value (-)6 - (+) 96 (XX); 180 selected, select (-)6 - 186 (XXX)

Mid Positio (dribble Off/On)

subset of Standard Rotation,+/- 6 degrees of min/max rotation.

(i.e. if 90 selected, select value 5 - 85 (XX); 180 selected, select 5 - 175

Outputs (XXX) Factory Default

1 (Pos/Alarm)

2 (Pos/Alarm)

3 (Pos/Alarm)

4 (Pos/Alarm)

ALARMS

Show alarm

Deviation

Limit 1 Limit

2 Torque

Compa temp

Motor temp

AutoCal

start cal (press "OK"), note: must be Out of Service

Expert cal

Set Point (Setpoint LO, Setpoint HI)

Transm (Transm low, Transm hi)

Set Up Pro

Torque Factory Default (Max per model size)

Model

Open torq

Close torq

15, 60, 150, 250, 500

100%, 95%, 90%, …(10 selections 100% - 40%)

Speed Factory Default (fastest per model size)

Open speed

5,10,15, 20…180 (10 selections min to max)

Clos speed

5,10,15, 20…180 (10 selections min to max)

Direction

CCW or C (define the parameter) Factory Default

(CCW) Current Limit

1, 1.5, 2,2.5, … to max (selectable with 0.5 amp increments up to 10 amp) Factory Default (5 amp)

Status

0 0 service

in service

Protection

Shift

Basic Full

menu

Pos

Set & Pos

Set & Dev

Torque

motor temp

comp temp

show LCS

Statistics

Man/Auto

Auto

Man Set

(press "OK", enter 4 digit code)

(No/Yes)Read Factory Default (Set & Pos)

N cycles (define parameter)

Acc travel

Mean dev (modulating only)

# of reset

Run time (power on time)

Extreme Temp (hi, l

Histogram

Pos graph

Reset stats

Diagnostic

Pos - CCW

Pos - CW

Alarm - compartment temp

Alarm - Torque

(No/

Yes)

ow)

Page 11

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

3. Installation and Operation

Description

Flowserve CEA actuators are reversible electric rotary valve

actuators. Standard units can provide up to 5000 in-lb of torque and

use a Brushless DC (BLDC) motor and permanently lubricated gear

trains. These actuators are equipped with integral thermal overload

protection with automatic reset and electronically adjustable position

and rotation limit switches. In the event of electrical power failure, all

models feature manual override capabilities.

WARNING: SERIES CEA ACTUATORS ARE

a

ELECTROMECHANICAL DEVICES SUBJECT TO NORMAL

WEAR AND TEAR. ACTUATOR LIFE DEPENDS UPON

APPLICATION AND ENVIRONMENTAL CONDITIONS. IF

APPLIED IN HAZARDOUS SERVICES, SUCH AS BUT NOT

LIMITED TO, MEDIA TEMPERATURE EXTREMES, TOXINS,

FLAMMABLES, OR OTHER SERVICES WHERE IMPROPER OR

INCOMPLETE OPERATION COULD PRODUCE A SAFETY

HAZARD, IT IS INCUMBENT UPON THE SYSTEM DESIGNER

AND THE USER TO PROVIDE PROPER WARNING DEVICES

SUCH AS TEMPERATURE SENSORS, OXYGEN SENSORS AND

FLOW SENSORS. AT ELEVATED TEMPERATURES THE DUTY

CYCLE HAS TO BE DERATED, CONSULT FACTORY.

FLOWSERVE ALSO RECOMMENDS THAT THE OPTIONAL

AUXILIARY LIMIT SWITCHES BE USED FOR MONITORING

AND/OR ELECTRICAL INTERLOCK.

CAUTION: If necessary, Flowserve recommends indoor, controlled

a

temperature storage of all products prior to installation. Do not

store product in areas with exposure to relative humidity above

85%, acid or alkali fumes, radiation above normal background,

ultraviolet light, or temperatures above 120°F or below 40°F. Do

not store within 50 feet of any source of ozone.

CAUTION: FOR WIRING OF ACTUATOR, INCLUDING OPTIONS,

a

PLEASE REFER TO WIRING DIAGRAM(S) LOCATED INSIDE OF

ACTUATOR TERMINAL BLOCK COVER. Wiring diagrams are also

included in this manual on pages 6 and 7 for reference.

CAUTION: The gear train compartment is oil filled. High perfor-

a

mance Mobil 1 oil is used for standard temperature requirements.

The compartment volume is 12oz. Oil replacement is not required

under normal operating conditions.

3.1 Installation – Flowserve Automax Valve Products

1. Attach mounting bracket to actuator using the four (4) screws and

lockwashers provided in the mounting kit, and tighten securely.

For small size, top mount style valves, attach bracket so the

bracket nameplate will be to the side of the valve.

2. Attach bracket/actuator assembly to valve as follows:

NOTE: If cross-line mounting of actuator is desired, note the

following: Mount the actuator with conduit hole perpendicular to

the flow axis (center line) of the valve and reverse the open/close

decals.

For diverter and three-way valves with V1 porting, and CPT valves,

also see Electrical Installation and Adjustment Section for cam and

limit switch adjustments to facilitate cross-line mounting operation.

CAUTION: Ball valves can trap pressurized media in the cavity.

a

If the valve is or has been in operation and it is necessary to remove any valve body bolts, stem nuts, or the valve from the line,

make sure there is NO pressure to or in the valve and operate the

valve one full cycle before and after removal.

Valve Models Top Mount 44 (1/4”–2”), 45 (2.5”–6”), 51/52 (1/2”–

10”), 151/301 (3”–6”), Top Mount 59 (1/4”–4”), WK70/WK74 and

H71 (1/2”–2”), 818/828 (2”–8”), 82/83 (1/2”–10”) and 94 (1/2”–6”):

NOTE: For above listed valves, it is not necessary to remove any

valve body bolts or the valve from line in order to mount the

actuator.

3. Close valve:

• For valves 1/4”–2”, the valve is closed when flats on valve stem

are perpendicular to the line of flow.

• For valves 3” and larger, where the valve stem is square, the

indicator line on top of stem will be perpendicular to the line of

flow or check ball position for closure.

• If any valve information is marked on stop plate or handle, it

will be necessary to transfer this information to the bracket

nameplate.

For 1/4”–2” 44 and 1/2”–2” WK70/WK74, 1/4”–1 1/2” 59 and 1/2”–2”

H71 Series top mount style valves and 1/2”–2” 51/52, 1/2”–1 1/2”

82/83 Series valves with high cycle stem packing as standard:

4. Remove handle nut, lockwasher, handle, separate stop plate (if

any), retaining nut and stop pin(s).

5. Add the two additional Belleville washers with their larger diameter sides touching each other.

6. Add the self-locking nut to the stem and tighten while holding the

stem flats with wrench.

7. Tighten until Belleville washers are flat, the nut will “bottom”, and

then back nut off 1/3 turn. The two additional Belleville washers

and the self-locking nut are included in the mounting kit.

CAUTION: The self-locking stem nut is difficult to tighten and

a

must fully flatten Belleville washers before backing off the nut by

one third of a turn.

For 2” 59, H71, 82/83, and 2.5” 45, 82/83 Series valves and valves

3” and larger with square stem, remove handle assembly (if any),

retaining nut, stop and stop screws.

Replace with valve stem spacer or, if valve has graphite stem packing,

11

flowserve.com

Page 12

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

with two Belleville washers (except 8”, 10” 82/83 and 10” 51/52) and

replace retaining nut.

NOTE: Belleville washers are installed with larger diameters so

they are touching each other. Using a wrench to prevent stem

from turning, tighten retaining nut until the stem packing is fully

compressed or until Bellevilles (if used) are fully flattened. Then,

back off nut 1/6 turn. Excessive tightening causes higher torque

and shorter seal life.

NOTE: 3” size and larger valves with V51 high cycle stem

packing (no handle assembly) are ready to automate without

modification.

For 1/2”–2” 94 valves, remove handle (if any). For 3”–6” 94 and 2”–8”

E818/E828 valves, remove handle assembly, stop, and spacer (if any).

Do NOT remove gland plate or gland bolts.

For 2”–8” 818/828 valves, remove handle assembly, locking plates

and hardware, and stop screw (if any). Do not remove stop plate

(2”–6” sizes) or spacer (8” size).

1. Center coupling on valve stem.

2. Lower mounting bracket/actuator assembly over coupling and

onto valve, making sure that male actuator shaft engages slot in

coupling.

3. Secure bracket to valve using cap screws and lockwashers, or

bolts and nuts provided in mounting kit. Tighten securely. For

small size top mount style valves, bracket nameplate will be to

side of valve.

4. Install set screws (if any) in the coupling and tighten securely.

tor housing. Connect power supply to actuator terminal strip as

shown on electrical schematic diagram(s) located inside terminal

block cover and also in this manual.

The actuator should be electrically grounded in accordance with

standard procedures.

See table below for minimum fuse rating when overcurrent protection

is used in motor power circuit.

Minimum Fuse Rating for Overcurrent Protection

Actuator Size Voltage Fuse Rating (A)

15/60/150 120 VAC 2A

15/60/150 240 VAC 1A

15/60 24 VDC 3A

150 24VDC 5A

NOTE: The table shows the minimum rating to prevent in-rush

current from blowing the fuse.

4. Calibration and Commissioning

The CEA actuator ships from the factory calibrated for 0-90 degree

rotation.

4.1 Travel Stop Adjustment

CAUTION: do not rotate travel stops counter clockwise (CCW)

a

beyond the inward/second “position orientation” groove as this

will result in oil leakage. If accidentally rotated beyond this position and leakage is observed, adjust clockwise (CW) to reposition

to the sealing zone between the two position grooves.

12

3.2 Electrical Installation and Adjustment

NOTE: The CEA actuator has 3 threaded covers on the actuator

housing: Controls cover, Terminal Block cover and Motor cover.

Cover(s) use an O-Ring to provide environmental sealing and

proper installation/assembly is required to prevent moisture

ingress.

ATEX hazardous area installation

Each cover incorporates a locking bracket attached by a screw that

must be loosened prior to cover(s) being removed.

Each cover is designed with 4 raised tabs and mechanical assistance

is required to remove the cover. A common “tool belt” screwdriver, 10

inches or longer, is recommended for mechanical assistance. Place

the tool between 2 adjacent tabs and rotate counter clockwise (CCW)

to remove the cover. Once O-Ring compression is relaxed the cover

will rotate freely by hand.

A. To gain access to terminal block, it is necessary to remove the

terminal block cover

B. Make conduit connection(s) to NPT/Metric fitting taps on actua-

CAUTION: it is not recommended to use the travel stops to

a

control normal rotation. Rotation limits should be electronically

set using the HMI menu Calibrate/Rotation with travel stops set

1-2 degrees outside calibrated rotation

Mechanical travel stops are provided on 90 degree rotation units to

provide over-travel protection. They are adjustable to provide +/- 6

degrees of adjustment. They are factory set 1-2 degrees outside the calibrated rotation. Adjust CW to reduce travel and CCW to extend travel.

One 360 degree rotation provides 3.2 degree position output change.

Each travel stop bolt has 2 position orientation grooves to identify the

min and max rotation position. Adjustment must be maintained within

these 2 grooves. CCW rotation beyond the inward groove will result in

potential oil leakage.

To calibrate the unit after a travel stop adjustment, simply navigate

using the arrow down key to the CALIBRATE menu and then to AUTO

CALIBRATE and select OK. This will recalibrate the actuator to the new

travel stop endpoints.

Please note that if any adjustments are made to the travel stops due to

mount issues or special valve requirements then the unit will require a

field AUTO CALIBRATION before it is placed IN SERVICE.

Page 13

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

4.2 Gear Train

A precision cut bronze or ductile iron worm gear set delivers maximum strength and durability. For optimum performance the gear set

is permanently lubricated and submerged in oil in a sealed compartment.

High performance Petro Canada Syndro SHB-68 oil is used for standard temperature requirements. The compartment volume is 12oz. Oil

replacement is not required under normal operating conditions.

Options and Adjustments (Factory Installed)

Magnetic Rotary Positioner Sensor

Shaft position feedback is accomplished using a 12-bit magnetic

rotary position sensor directly coupled to the output drive. Specifically

designed for brushless DC (BLDC) motor control, this technology

provides the highest accuracy and reliability.

Position and Alarm Outputs

4 outputs are provided as standard and pre-wired to the terminal

block. Standard outputs are non-latching, dry contact,15A rated.

Optional latching contacts are available; consult Flowserve.

Outputs may be configured for remote position indication and/or

alarm feedback.

When alarms are activated, additional “action” may be programed:

> DO NOTHING (factory default)

> GO to OPEN

> GO to CLOSED

> MANUAL MODE

Also note that the relay stays energized during an alarm condition. It

deenergizes when the value is outside of the MIN/MAX range entered.

Factory default settings:

Output 1: position CW

Output 2: position CCW

Output 3: Alarm High Torque

4.3 Rotation Speed Control

Selectable Rotation Times

Nominal

Model

150 1500(170) 10* 12 15 20 30 50 80 110 150 180

*Factory Default

Torque

in-lbs

(Nm)

15 150(17) 5.0* 7.5 10 15 20 50 80 110 150 180

60 600(68) 5.0* 7.5 10 15 20 50 80 110 150 180

o

rotation time in seconds

90

Rotation speed is factory set to the fastest 90 degree rotation per the

actuator model code specification (Example: M60 = 5 seconds). Both

the CCW and CW rotation speed is independently adjustable with 10

pre-set selections that increase rotation speeds up to 180 seconds.

4.4 Variable Torque Output

Selectable Torque Output

Nominal

Model

150 1500 (170) 100* 95 90 85 80 75 70 60 55 40

*Factory Default

Torque

in-lbs

(Nm)

15 150 (17) 100* 95 90 85 80 75 70 60 55 40

60 600 (68) 100* 95 90 85 80 75 70 60 55 40

Torque times percent equals maximum output torque

(valves listed below are percent (%)

Example Model 60: 600 in-lbs set at 100% = 600 in-lbs;

set at 75% = 450 in-lbs.

Torque output is factory set to the maximum value per the actuator model code specification (example: M60 = 600 in.lbs.). Output

torque is adjustable from 100% to 40% of rated value with 10 pre-set

selections.

4.5 Duty Cycle

Model Open/Close Service Modulating Service

15 360/hr 1800 Starts/hr

60 360/hr 1800 Starts/hr

150 180/hr 1800 Starts/hr

Output 4: Alarm Compartment Temperature

The CEA actuator is rated for 1800 starts per hour, under full load

conditions, within the normal operating temperature limits per

specification listing.

4.6 Heater and Thermostat

Heaters are not required for operation to -40C and/or to control

condensation. Condensation does not occur due to non-breathing

enclosure and internal compartment temperature stabilization. The

customer may order a factory-installed heater and thermostat if

desired.

flowserve.com

13

Page 14

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

ATTENTION: Actuator is factory calibrated for standard

rotation, max speed, max torque and output settings per model code

on nameplate. Unit ships with Output shaft in the CW position for

mounting. Standard rotation is CCW to Open, CW to Close.

HMI Interface (see IOM for complete detail)

The actuator is User configurable using the 5 push

bottons and the display. Default display is position.

Press the ESC button to display the Main Menu. Use the

UP/DN push buttons to browse through the Main Menu

and Sub-Menus.

OTHER FUNCTIONS:

ESC- exit the menu or return to previous level

FUNC - Select a function and change parameters

OK- To confirm a citical selection or change of parameters

In Service - Normal status, actuator responds to remote

commands

Out of Service - Actuator off-line, critical parameters may be

changed

Manual - Actuator rotation may be adjusted manually via

push buttons

Unprotcted - Parameters may be changed without

passcode

MENUS:

Basic Menu - Supports primary setup (read, man/auto, calibrate, setup, status, protection,

shift); Use status to change service and shift to advance to full menu

Full Menu - Supports advanced configuration

Analog Output

Available option will provide analog 4-20mA continuous position

feedback.

CAUTION: In cases where the conduit connected to the actuator

a

may be partially or completely run underground, or through which

moisture may contact energized live parts, or where the actuator

and/or conduit is exposed to temperature differences, the conduit

should be sealed within 18” of the actuator in accordance with the

National Electrical Code.

When electrical installation is complete, it is advisable to check the

indexing of the actuator to ensure proper valve rotation.

Replace actuator cover(s).

NOTE: The CEA actuator has 3 threaded covers on the actuator

housing: Controls cover, Terminal Block cover and Motor cover.

Each cover is designed with 4 raised tabs and mechanical assistance is required to properly secure the cover. A common “tool

belt” screwdriver, 10” or longer, is recommended for mechanical

assistance. Rotate the cover by hand until difficult to rotate.

Place the tool between 2 adjacent tabs and rotate clockwise (CW)

to properly secure/install the cover (approximately 1.5 additional

turns).

Cover is properly installed when no cover-to-housing gap is visible.

Use a feeler gauge according to the listed procedure to confirm.

If using the ATEX locking tab, tighten screw to secure tab.

Feeler Gauge Procedure

Use a .010 inch feeler gauge inserted at the location of the nameplate

just above the word MODEL, between the housing and controls cover.

The feeler gauge should feel tight and be inserted approximately .060

inches

4.7 HMI Display

Menus and Push Buttons

The actuator is user configurable using the five pushbuttons and the

LCD display, which are accessible when the top Controls Cover is

removed. For normal functioning, the display shows the current value.

Press the ESC button for two seconds to display the main menu.

Other Functions

ESC

Exit the menu without making any changes (as long as any changes

have not been confirmed with OK).

FUNC

To select function and change parameters.

OK

To confirm selection or change of parameters.

MENU INDICATOR

Displays the position of the current menu row in the menu.

IN SERVICE

The actuator will respond to discrete input commands. This is the

normal status when the actuator is working properly.

OUT OF SERVICE

The actuator will not respond to discrete input commands. Critical

parameters can be changed.

MANUAL

The actuator can be adjusted manually using the pushbuttons. See

section ”Man/Auto”, page 15.

UNPROTECTED

Most of the parameters can be changed when the actuator is in the

”Unprotected” position. However, critical parameters are locked when

the actuator is in the ”In service” position.

Menus:

Use the Up/Dn buttons to browse through the main menu and the

sub-menus.

14

OUT OF SERVICE

MANUAL

BASIC MENU

MAN/AUTO

UNPROTECTED

ESC

OK

FUNC

Page 15

Menu Indicator

There are indicators at both sides of the display window and they

indicate as follows:

Flashing in position

Out of service

FULL MENU

MAN/AUTO

Flashing in position Manual

FULL MENU

CALIBRATE

Displayed in position

Unprotected

FULL MENU

SHIFT MENU

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Menu System

Basic Menu Full Menu

Calibrate Shift Menu

Setup Pro Setup Full

Status Tuning

Protection Fact Set

Shift Menu Read

Read Man/Auto

Man/Auto Calibrate

Setup Pro

Status

Protection

BASIC MENU

READ

BASIC MENU

MAN/AUTO

BASIC MENU

CALIBRATE

BASIC MENU

SETUP PRO

The indicators on the right-hand side show the position in the current

menu.

Menus

To display the menus you can select:

- Basic menu, which means you can browse through seven different

steps

- Full menu, which comprises ten steps. Use the Shift Menu to

browse through the steps

Full Menu can be locked out using a passcode.

The main menus and sub-menus are shown on the following pages.

4.8 Programmable Parameters

Changing Parameter Values

Change by pressing until the desired figure is flashing.

Press to step to the desired figure. Confirm by pressing OK.

A change can be undone by pressing the ESC button, which returns

you to the previous menu.

BASIC MENU

STATUS

BASIC MENU

PROTECTION

BASIC MENU

SHIFT MENU

flowserve.com

15

Page 16

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

The menu contents are shown in the figures on the right and the texts

are described below:

BASIC MENU

CALIBRATE

Calibrate/Rotation:

The Calibrate Menu is used to calibrate rotation variations, discrete

outputs, Auto Calibration and Expert (advanced) Calibration. 4 configurable parameters are available: Standard, Turns, Manual and Mid

Position.

1. Rotation/Standard: depending on product model, multiple

rotation angles are available for selection. Option examples: 90,

180, 270, 360, Multi

2. Rotation/Turns: multiple 360o rotation turns are available for the

multi-turn (MT) option only

3. Rotation/Manual: the user may manually select alternate

positions for CCW/Open and CW/Closed rotation.

a. A known value may be entered (i.e. 0% = 10.0% or 100% =

70%) to change rotation position.

b. Use Set 0% or Set 100% and press the Up/Dn arrow to

“step” position changes in 0.5% increments. Press “OK”

button for 3 seconds to accept the new value. CAUTION:

do not rotate outside the factory calibrated 0% and 100%

positions without first adjusting the associated Travel Stop

bolt CCW. This will prevent driving the output gear into the

mechanical stop.

4. Rotation/Mid Position: Mid Position parameter is used for

3-position control (i.e. multi-port 3-way valves). To enable: go

to Rotation/MIDPOS/dribble – select ON; next: mid = 050.0%

(example); next: set midpos/press “OK” for 3 seconds.

Calibrate/Outputs:

The CEA provides 4 discrete programmable outputs. Each output

may be configured for either Position Output or Alarm Output. Alarm

outputs are further programmable to perform specific Valve Action

when activated. See section 4.8 and 4.9 for more detail.

Calibrate/Expert Cal

This parameter provides advanced calibration for analog setpoint

input and analog output.

1. Analog setpoint input may be configured for minimum signal

input (i.e. LO = 4.0mA) and maximum signal input (i.e. HI =

20.0mA)

2. Analog output option should be calibrated to match the rotation

minimum and maximum positions (i.e. Transm low/LO = 4.0ma;

Transm hi/HI = 20.0mA)

BASIC MENU

SETUP PRO

The Setup Pro menu is used to calibrate Torque, Speed, Direction and

Current Limit.

1. Setup/Torque: Clockwise (CW) and counterclockwise (CCW) rotation torques may be independently configured using 10 preset

values. Selectable values include: 100%, 95%, 90%... (10 selections 100% - 40%). Values are selected based on percentage

of Rated Torque. For example: rated torque 600in-lbs.: 100% =

600in-lbs.; 50% = 300in-lbs.

2. Setup/Speed: Clockwise (CW) and counterclockwise (CCW) rotation speeds may be independently configured using 10 preset

values. Selectable values are listed in “seconds” and include:

5,10,15,20…180 seconds.

3. Setup/Direction: 2 settings are available CCW and CW. CCW:

When setpoint power is applied to TB point 21, the unit will rotate in the CCW direction. CW: when setpoint power is applied

to TB point 21, the unit will rotate in the CW direction.

4. Setup/Current Limit: The user may select a maximum current

load for the actuator not to exceed. This feature may support

low power DC applications, torque seating and valve “jam”

conditions. Available settings are 1amp up to 10amp in 0.5 amp

increments.

16

Calibrate/AutoCal

AutoCal may be used to recalibrate the actuator at any time. This

feature is most commonly used when rotation values are modified

from factory default. When AutoCal is performed the unit will rotate

to the mechanical stops or electronic limits and automatically update

all 4 outputs for position and/or alarm.

Page 17

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

BASIC MENU /

STATUS

The Status Menu is used to select whether or not the actuator is in

service.

o o service Not in service. Flashing indicator in upper

left-hand corner of display.

in service Positioner in service.

Critical parameters cannot be changed.

STATUS

O O service

STATUS

in service

When changing between

In service and Out of Service,

the OK button must be

pressed for 3 seconds.

OK

OK

OK

OK

BASIC MENU

SHIFT MENU

The Shift Menu is used to choose between the basic menu and the full

menu.

The menu contents are shown in the figures on the right and the

various texts are described below:

No Full menu selected.

Yes Basic menu selected.

Full menu

no

Full menu

yes

Full Menu can be locked with a

passcode, see Setup menu.

OK

OK

OK

OK

BASIC MENU /

PROTECTION

The Write Protect menu is used to protect all essential settings.

No Entered values are not write protected.

”Unprotected” is displayed in the lower

left-hand corner.

Yes Entered values are write protected. Passcode

needed for change to No (Applicable when a passcode has

been set up in SETUP menu).

PROTECTION

no

PROTECTION

yes

When changing between

Yes and No mode, the OK

button must be pressed

for 3 seconds.

OK

OK

OK

OK

17

flowserve.com

Page 18

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

BASIC MENU

READ

Values can be read using the Read Menu and some values can be

reset.

Pos shows current position

Set & pos shows current setpoint

and position

Set & dev shows current setpoint

and deviation

Torque shows current load torque

Motor temp shows current motor temp

Compa temp shows current compartment temp

Statistics shows statistics and

diagnostic data

Statistics

n cycles Shows number of movements

(turns)

Acc travel Shows accumulated

movement

mean dev Shows accumulated deviation in %

runtime Shows accumulated runtime

since last reset

Extr temp Shows extreme min and max

temperature

Histogram Shows position and time for

PV

Alarms Displays tripped alarms

READ

pos

READ

set&pos

READ

set&dev

READ

torque

READ

motor temp

READ

comp temp

READ

statistics

Statistics

n cycles

Statistics

acc travel

Statistics

mean dev

Statistics

# of reset

Statistics

run time

Statistics

extreme temp

Statistics

histogram

Statistics

pos graph

Statistics

reset stats

Statistics

diagnostics

BASIC MENU

MAN / AUTO

The Man/Auto menu is used to change between manual and automatic

modes.

AUT, OK = MAN

Positioner in automatic mode

MAN, OK = AUT

Positioner in manual mode

In the MAN mode, the value of POS can be changed using the UP/

DN push buttons. The push-buttons increase/decrease the value in

steps. The value can also be changed in the same way as for the other

parameter values, as described on page 14.

AUT, OK=MAN

POS= 12.3%

When changing between

MAN and AUT mode, the OK

button must be pressed for 3

seconds.

MAN, OK=AUT

OK

POS= 12.3%

18

Page 19

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Basic Menu

Outputs - Expanded View

Outputs

1(Pos/Alarm)

2(Pos/Alarm)

3(Pos/Alarm)

4(Pos/Alarm)

Postion

CW/CCW/MID

Alarm

Show Alarm

M, C, 1, 2, D, T

Deviation

ON/OFF

Distance

value=%

Time

value=seconds

Alarm out

on

off

Valve Action

no action

go to close

go to open

manual

Limit 1

ON/OFF

Min Position

value=%

Max Position

value=%

Hysteresis

value=%

Alarm out

on

off

Valve Action

no action

go to close

go to open

manual

Limit 2

ON/OFF

Min Position

value=%

Max Position

value=%

Hysteresis

value=%

Alarm out

on

off

Valve Action

no action

go to close

go to open

manual

Torque

ON/OFF

Min Torque

value=%

Max Torque

value=%

Hysteresis

value=%

Alarm out

on

off

Valve Action

no action

go to close

go to open

manual

Comp Temp

ON/OFF

Min Temp

degrees F

Max Temp

degrees F

Hysteresis

value=%

Alarm out

on

off

19

flowserve.com

Page 20

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Valve Action

no action

go to close

go to open

manual

Motor Temp

ON/OFF

Min Temp

degrees F

Max Temp

degrees F

Hysteresis

value=%

Alarm out

on

off

Valve Action

no action

go to close

go to open

manual

Status

Man/Auto

Auto (press up/down arrow for options, press enter to

change selection)

Man Set (select value 0-100% (XXX.X) or press up/

down arrows to jog position CW/CCW)

Protection

Shift

Basic

Advanced

4.9 Alarm Output Setup

The actuator is equipped with (4) four configurable outputs. The alarm

OUTPUT parameters are set in the ALARMS menu.

Alarm definitions are as follows:

M= Motor Temperature (Alm mtrtmp)

C= Compartment Temperature(cmptmp)

1=Alarm Limit 1 (Alm Lim 1)

2=Alarm Limit 2 (Alm Lim 2)

T-Torque (Alm Torque)

D=Deviation (Alm dev)

Each alarm can be viewed on the display and/or read by activating the

selectable relay output. If the alarm is set to ON and an alarm condition has occurred, the display will flash. The user can then navigate to

the alarms menu to view the above defined alarm(s). NOTE: The alarm

relay output will not be activated until the alarm is turned on in the

alarms menu.

Basic Menu Calibrate/Outputs/Alarms/Compartment Temp

>>>> ON/OFF

Low temp

High temp

Hysteresis

Alarm out

Valve action

The above setting will indicate an alarm condition by flashing the

display to indicate that one or more alarm conditions has occurred

(M:C:1:2:T:D)

For example, to activate the relay output for compartment temperature, navigate to the ALARMS menu as follows:

20

Basic Menu Calibrate/Outputs/Alarms/Compartment Temp

>>>> ON/OFF

Min temp

Max temp

Hysteresis

Alarm out

>>>> ON

OFF

For example, to set the compartment temperature relay output alarm

to active when the temperature exceeds the MAX value of 125 degrees

F or falls below the MIN value of -5 degrees F, perform the following:

Page 21

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Basic Menu Calibrate/Outputs/Alarms/Compartment Temp

>>>> ON/OFF

Min temp

>>>> -5

Max temp

>>>> 125

Hysteresis

Alarm out

>>>> ON

All (4) four relay outputs are configured in the same manner. Below is

a list of the parameters.

Alm dev

Alm Lim 1

Alm Lim 2

Alm Torque

Alm mtrtmp

cmptmp

The default outputs are as follows:

4.10 Positioner Indicator

High visibility position indicator is standard with each actuator.

Indicator rotation is accomplished using high performance neodymium magnets that eliminate cover shaft holes and potential path for

moisture ingress.

Indicator is self-indexing and does not require removal to remove the

top cover.

Dome Indicator Adjustment

The dome indicator will come preset from the factory. The indicator

will display CLOSED in the clockwise (CW) position in the viewing

window. The indicator dome may be rotated 90

the CW position.

The dome indicator also has adjustment slots to further align the OPEN

and CLOSED display after the controls cover is completely tightened

down. Loosen the 4 pan head screws that hold down the dome and

rotate CW or CCW as needed. The screws holding down the dome

should only be loosened (not removed) to ensure that the O-ring under

the dome is not pinched when the screws are re-tightened.

o

to display OPEN in

OUTPUT 1= CCW (activates upon full CCW travel. NOTE: normally

open dry contact closes)

OUTPUT 2=CW (activates upon full CW travel. NOTE: normally open

dry contact closes)

OUTPUT 3 = TORQUE (activates when torque is below the low limit or

above the high limit NOTE: normally open dry contact closes)

OUTPUT 4 = COMPARTMENT TEMPERATURE (activates when torque

is below the low limit or above the high limit. NOTE: normally open

dry contact closes)

Setting the dome indicator and internal magnet puck inside the

controls cover

flowserve.com

21

Page 22

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

Magnet Puck Adjustment

If for any reason the black plastic EMC/EMI controls cover is removed

the indicator “puck” magnet will need to be timed such that the correct indication will be shown on the dome window when the actuator

controls cover is screwed down to the proper height.

Prior to adjustment the actuator must be in the Closed/CW position.

Using a 3/32 hex head wrench, loosen the socket head cap screw

and align the wrench with the controls cover set tab located on the

housing. See Figure below.

22

5. Manual Override

Manual override is provided as standard with each actuator. The

override requires minimum force to operate (less than 7lbs force) and

is spring loaded, push to engage. When engaged the worm shaft is

declutched from the motor drive to provide safe operation. The spring

loaded design ensures the override will not accidentally be left in the

By-Pass condition.

NOTE: If power is present and the handwheel is engaged and

rotated, the motor will power on but not impact rotation.

Page 23

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

6. Performance and Technical Data

Performance Specifications

Output

Torque

(Continuous

Start/Run

Torque)

Stall

Torque

(1.25X)

Cycle Time

(90°)

24VDC

120/240VAC

Version

Standard

On/Off

Modulating

Actuator

Platform

(PF)

Units Nm (in-lbs) Nm (in-lbs) Sec. RPM 24VDC 120/VAC 240VAC

PF1

PF2

Model

M15 17 (150) 21 (187) 5 3 0.8A 0.15A 0.08A

M60 68 (600) 85 (750 5 3 2.1A 1.0A 0.49A

M150 169 (1500) 211 (1875) 10 1.5 4.2A 1.4A 0.75A

M250 282 (2500) 422 (3125) 16 0.9 6.5A 1.6A 0.85A

M500 565 (5000) 706 (6250) 33 0.5 6.5A 1.6A 0.85A

Materials of Construction

Component Material

Housing and Cover Die cast aluminum

Aluminum surface treatment Non-chrome conversion coating

Worm Gear set Ductile iron (M15, M60), Bronze (M150, M250, M500)

Output Drive Ductile iron

Baseplate ISO 5211, F05/07, FA05/07

Paint

Polyester powder coat

Salt Spray: ASTM B117, 1050 hrs.

Output

Speed

24VDC

120/240VAC

Full Load Amps

Technical Data

Voltage Rating 120/240 VAC/VDC; 12*/24 VDC; Single (and optional 3-phase)

Temperature -40C to +70C, low temp. option -48C

Environmental

Vibration Testing IEC60068-2-6 Appendix B

CE Declaration Low voltage, EMI/EMC approval

Weight M15/60: 24 lbs (10.9kgs) M150: 25.5 lbs (11.6kgs)

* For 12VDC, consult factory

Type 4, 4X,6, IP66/68 (3m for 48hrs)

Class 1, Div 1,2, Gps B,C,D (CSA,FM)

ATEX II 2G Ex d IIB +H2 T4: IECEx II 2G Ex d IIB +H2 T4

23

flowserve.com

Page 24

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

7. Actuator Troubleshooting Guide

(Electrical)

The actuator contains (5) five electrical devices, a 3 phase BLDC

motor, Motor Controller, Main Control Board, Relay Board and a 12 bit

Rotary Encoder Board. This is an electro-mechanical device and will,

after many years of service, require inspection of mechanical components to ensure the root cause is not hidden there.

Symptom Resolution

Actuator is commanded to move but does not move.

NO Relay Output 1 or 2 (CW or CCW)

The actuator main position control is derived from the 12 bit magnetic

rotary encoder. The actuator will be calibrated from the factory but if

for any reason field service is performed on the actuator e.g. travel

stop adjustment or board replacement, the actuator will

require recalibration.

Before replacing any parts always check for loose field wiring at the

terminal block. This usually solves most known issues with the actuator. If no loose wiring is found proceed below.

1. Use hand wheel to move actuator to check for binding in valve mounting.

2. Is there power to the actuator? Check voltage at terminals L1 and L2 must

be between 90VAC and 240VAC

3. If a PRO unit check voltage between terminals 20 and 21 then check

voltage between terminals 20 and 22 must be between 24vdc and 240VAC

for AC models.

4. If unit is a MOD, remove the field wires from terminals 11&12. Apply

20 mA signal using a process output meter to terminals 11 &12 noting

11 is positive and 12 is negative. Apply a 4 mA signal, if still no actuator

movement, replace main control board.

5. Check open and closed torque setting. Change to 100% and retry step 3 or

step 4 depending on MOD or PRO unit.

6. Check the compartment temperature and motor temperature for excessive

heat as motor controller or motor could have shut down due to excessive

heat.

7. If unit still does not move when commanded then factory service will be

required.

1. Check physical endpoint position using hand wheel.

2. Is there power to the actuator? Check voltage at terminals L1 and L2 must

be between 90VAC and 240VAC for AC models

3. Remove field wiring from terminals 1 & 2 and measure continuity using a

DMM. If output is activating resistance value will be zero. Check terminals

3 & 4 in a similar fashion for output 2.

4. Recalibrate unit and recheck. In Full CCW or Full CW output 1 or 2 should

read ZERO continuity, if not ZERO replace relay board.

5. In the menu check for POS CCW and POS CW for output 1 and 2. If they

are not POS CCW and POS CW change accordingly.

6. Beacon drive assembly has failed and will need to be replaced. (Factory

service recommended)

24

No 4-20mA output at terminals 13 and 14.

Actuator is hunting (oscillating) back and forth

1. Confirm model code for this option

2. Is there 24vdc loop power on terminals 13 and 14? If so and there is still

no output on terminals 13 and 14 replace Main Control Board (MCB)

1. For C-PRO unit check voltages between terminals 20 and 21 then check

voltage between terminals 20 and 22. Is the supply voltage being commanded ON and OFF from the source? If not replace PMCB.

2. For C-MOD unit check that deadband setting is not set below 0.1%

3. If unit is still oscillating replace encoder board and then recalibrate using

autocal.

4. Beacon drive assembly has failed (factory service recommended)

Page 25

8. Parts List

15-2

15-1

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

15-3

15-4

19

19

15-13

15-6

15-5

15-11

15-11

ITEM NO. PART NUMBER DESCRIPTION QTY. ITEM NO. PART NUMBER DESCRIPTION QTY.

15-1 DY102026A EMC Shield, Resin, CEA, 15, 60, 150 1 15-11 EY102004GV Pipe Plug (conduit) 3

15-2 EY102004BH EMI Screws M3x.5X10mm 4 15-13 EY102004M Locking Cover Screws 3

15-3 DY101938A Cover, Controls, CEA, 15, 60, 150 1 19 CY102219A Indicator Assembly Kit 1

15-4 EY102004DE Seal - Control Cover O-ring 1

15-5 DY101936A Cover, Motor, CEA, 15, 60, 150 1

15-6 EY102004DC Seal - Motor Cover O-ring 1

15-13

15-13

25

flowserve.com

Page 26

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

15-5

15-6

15-1

15-2

15-13

19191919

26

15-8

15-7

ITEM NO. PART NUMBER DESCRIPTION QTY.

15-7 DY101937A Cover, Terminal, CEA, 15, 60, 150 1

15-8 EY102004DD Seal - Terminal Cover O-ring 1

15-9 DY102323A Nameplate, CEA, 15, 60, 150 1

15-10 EY102004G Nameplate screw 2

15-11 EY102004GV Pipe Plug (conduit) 3

15-12 HXU-3/4-NPT Pipe Plug (conduit - plastic) 1

15-14 DY102048A Torque Nut 05/07, CEA, 15, 60, 150 1

15-15 EY102004BA Screw - Torque Nut 2

19 CY102219A Indicator Assembly Kit 1

15-12

15-11

Page 27

Limitorque Worcester Controls CEA Series FCD WCENIM2080-00-AQ 12/14

flowserve.com

27

Page 28

FCD AXENIM2080-00-AQ Printed in USA. January 2015

To find your local Flowserve representative

or for more information about Flowserve Corporation, visit

www.flowserve.com.

Flowserve Flow Control (UK)

Burrell Road

Haywards Heath

West Sussex United Kingdom RH16 1TL

Phone: +44 1444 314400

Fax: +44 1444 314401

Flowserve Corporation

Flow Control Division

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: +931 432 4021

Fax: +931 432 5518

Flowserve Pte Ltd

No. 12 Tuas Avenue 20

Singapore 638824

Phone: +65 6879 8900

Fax: +65 6862 4940

Flowserve Flow Control Benelux BV

Rechtzaad 17

4703 RC Roosendaal NB

Netherlands

Phone: +31 165 598 800

Fax: +31 165 555 670

Flowserve Australia Pty Ltd

Flow Control Division

14 Dalmore Drive

Scoresby, Victoria 3179

Austrialia

Phone: +61 3 9759 3300

Fax: +61 3 9759 3301

Flowserve Flow Control GmbH

Rufolf Plank Str. 2

D-76275 Ettlingen

Germany

Phone: +49 7243 103 0

Fax: +49 7243 103 222

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should

read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in

connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2015 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

Flowserve do Brasil Ltda

Rua Tocantins, 128 - Bairro Nova Gerti

São Caetano do Sul,

São Paulo 09580-130 Brazil

Phone: +5511 4231 6300

Fax: +5511 4231 6329 - 423

Flowserve Corporation

Unit 01\02\06\07 9F

China Fortune Tower

No. 1568, Century Avenue, Pudong

Shanghai China 200122

Phone: +86 21 38654800

Fax: +86 21 50811781

Flowserve Corporation

No. 35, Baiyu Road

Suzhou Industrial Park

Suzhou 215021, Jiangsu Province, PRC

Phone: +86-512-6288-1688

Fax: +86-512-6288-8737

Flowserve China

Hanwei Building

No. 7 Guanghua Road

Chao Yang District

1000004 Beijing

CHINA

Phone: +86 (10) 6561 1900

Fax: +86 (10) 6561 1899

flowserve.com

Loading...

Loading...