Page 1

GESTRA

GESTRA Steam Systems

CB 1...

CB 2...

Installation Instructions 810707-02

Swing Flap Non-Return Valves

CB 1..., CB 2...

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ............................................................................................................ 8

Safety note ............................................................................................................................................. 8

Warning ................................................................................................................................................. 8

Ratings pursuant to article 9 of the PED ................................................................................................. 9

Explanatory Notes

Scope of supply ................................................................................................................................... 10

Description........................................................................................................................................... 10

Function ............................................................................................................................................... 10

Technical data ...................................................................................................................................... 11

Corrosion resistance ............................................................................................................................. 11

Sizing................................................................................................................................................... 11

Name plate / marking........................................................................................................................... 12

Installation

CB 1..., CB 2... ..................................................................................................................................... 13

Installation notes ................................................................................................................................... 14

Commissioning

CB 1..., CB 2... ..................................................................................................................................... 15

Operation

CB 1..., CB 2... ..................................................................................................................................... 15

Maintenance

CB 1..................................................................................................................................................... 15

CB 2... Replace springs / O-ring .................................................................................................. 16 –17

Tools .................................................................................................................................................... 17

Spare Parts

Spare parts list CB 24 S ....................................................................................................................... 18

Spare parts list CB 26, CB 26 S ............................................................................................................ 19

Annex

Declaration of conformity ...................................................................................................................... 20

2

Page 3

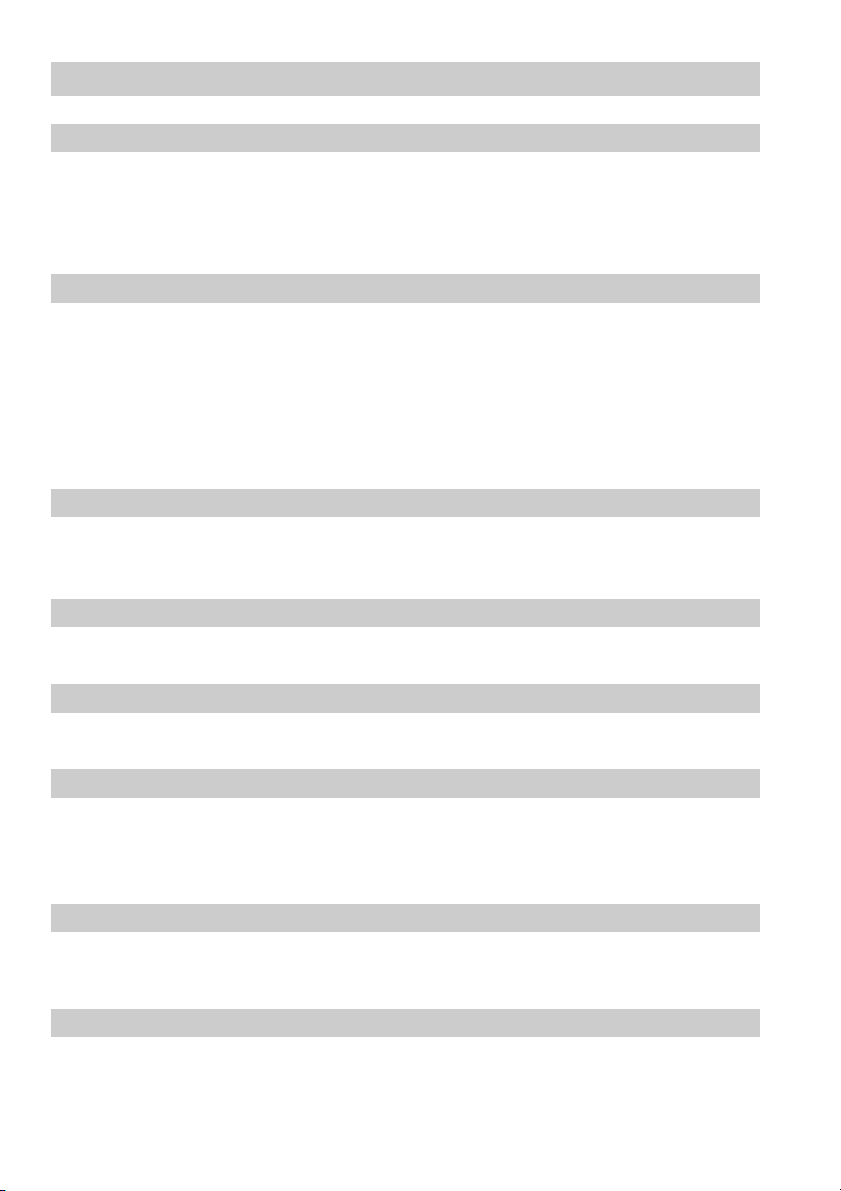

Parts Drawing CB 1...

G

A

B

D

Fig. 1

E

3

Page 4

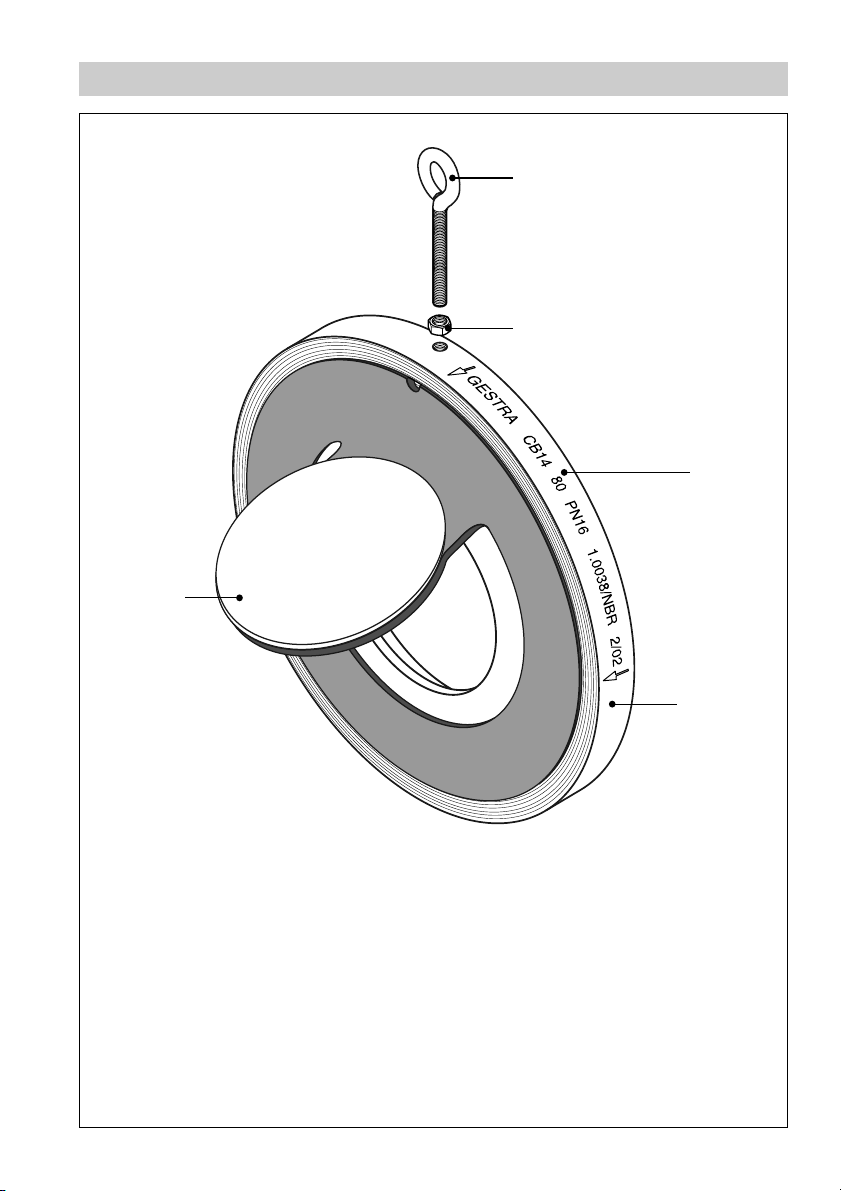

Parts Drawing CB 2...

A

B

C

Fig. 2

4

H

G

H

D

E

F

Page 5

Key

Eye bolt

A

Lock nut

B

Centering ring

C

Type designation (on name plate or impressed on valve body)

D

Body

E

O-ring

F

Disc

G

Spring

H

5

Page 6

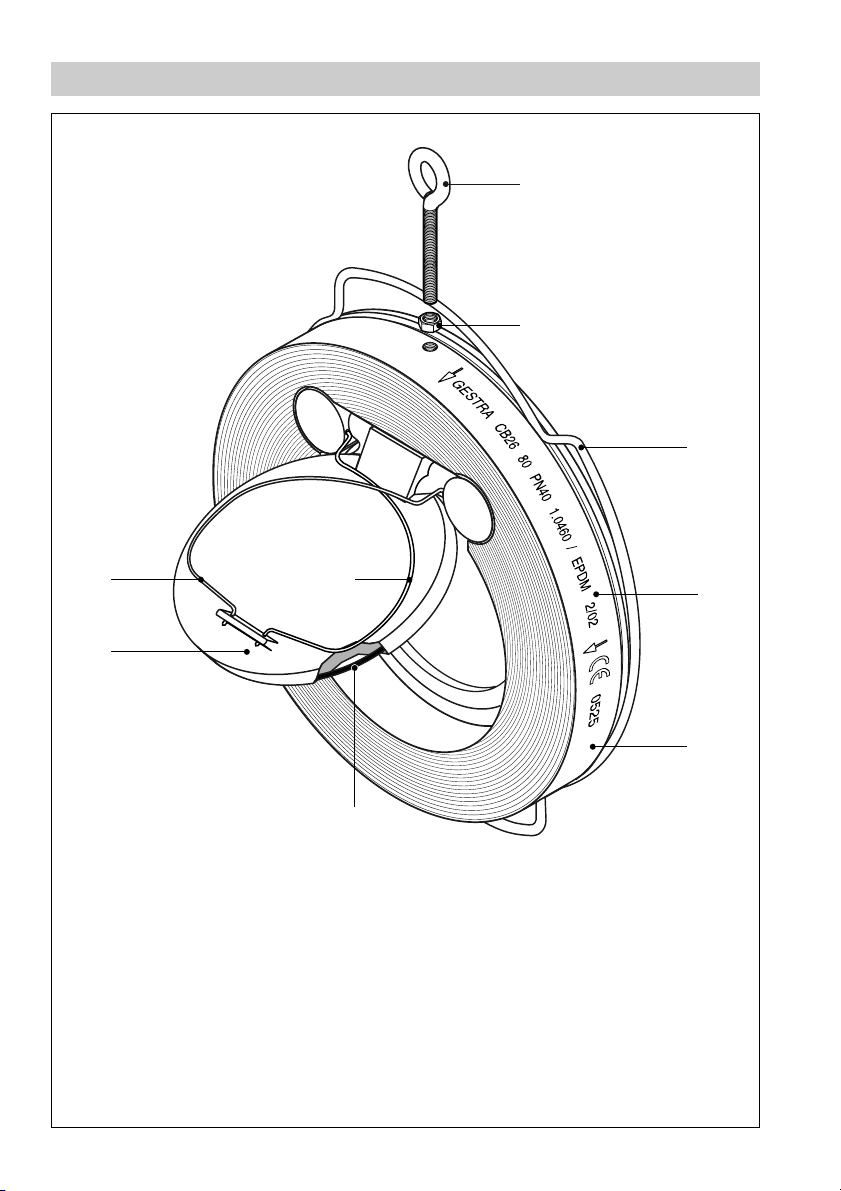

Pressure Drop Chart CB 1...

Partial opening

= instable range

Full opening

= stable range

Fig. 3

6

w

˙

Volume flow V

Pressure drop ∆p [bar]

The curves given in the chart are valid for

water at 20 °C. To read the pressure drop for

other fluids the equivalent water volume

flowrate must be calculated and used in the

graph.

The values indicated in the chart are applicable

to valves with horizontal flow. With vertical

flow insignificant deviations occur only within

the range of partial opening.

˙

V

= V˙ ·

w

˙

V

= Equivalent water volume flow

w

ρ

1000

in [l/s] or [m³/h]

ρ = Density of fluid (operating condition)

in kg/m³

˙

V

= Volume of fluid (operating condition)

w

in [l/s] or [m³/h]

Page 7

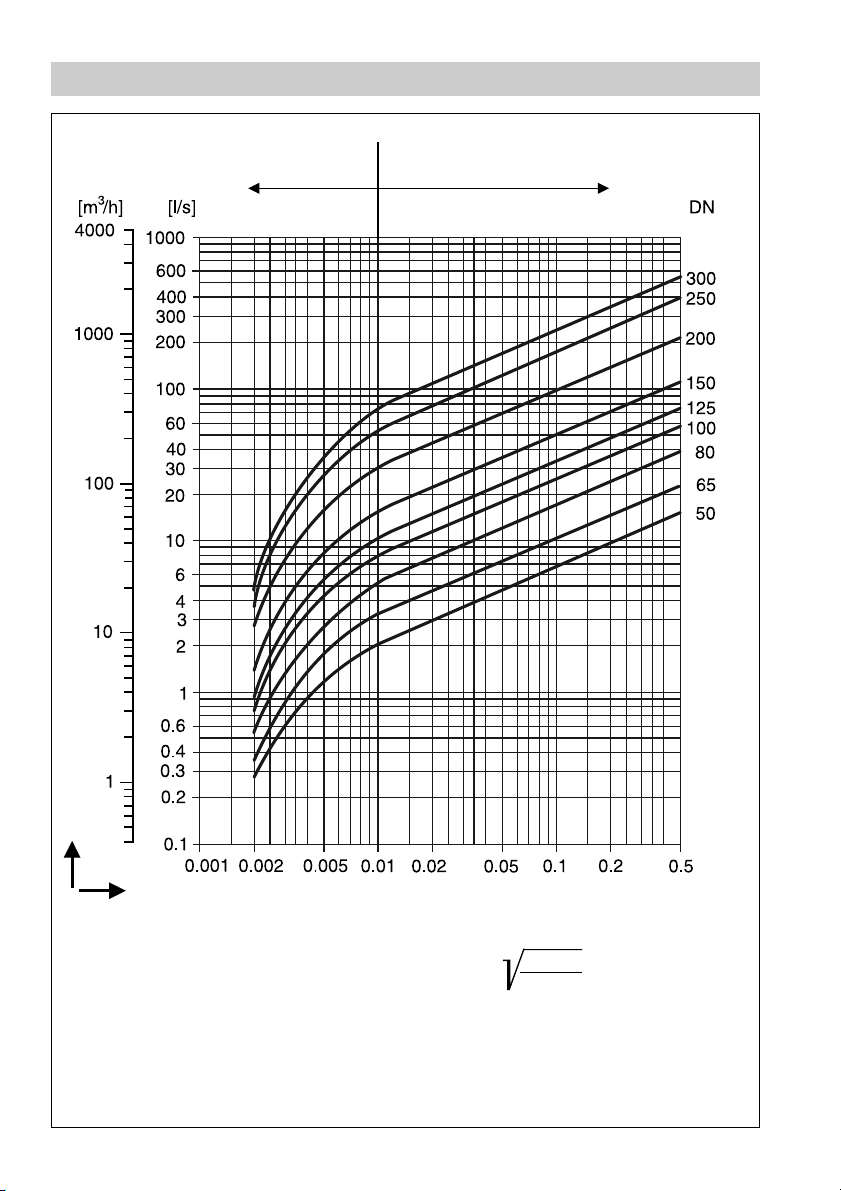

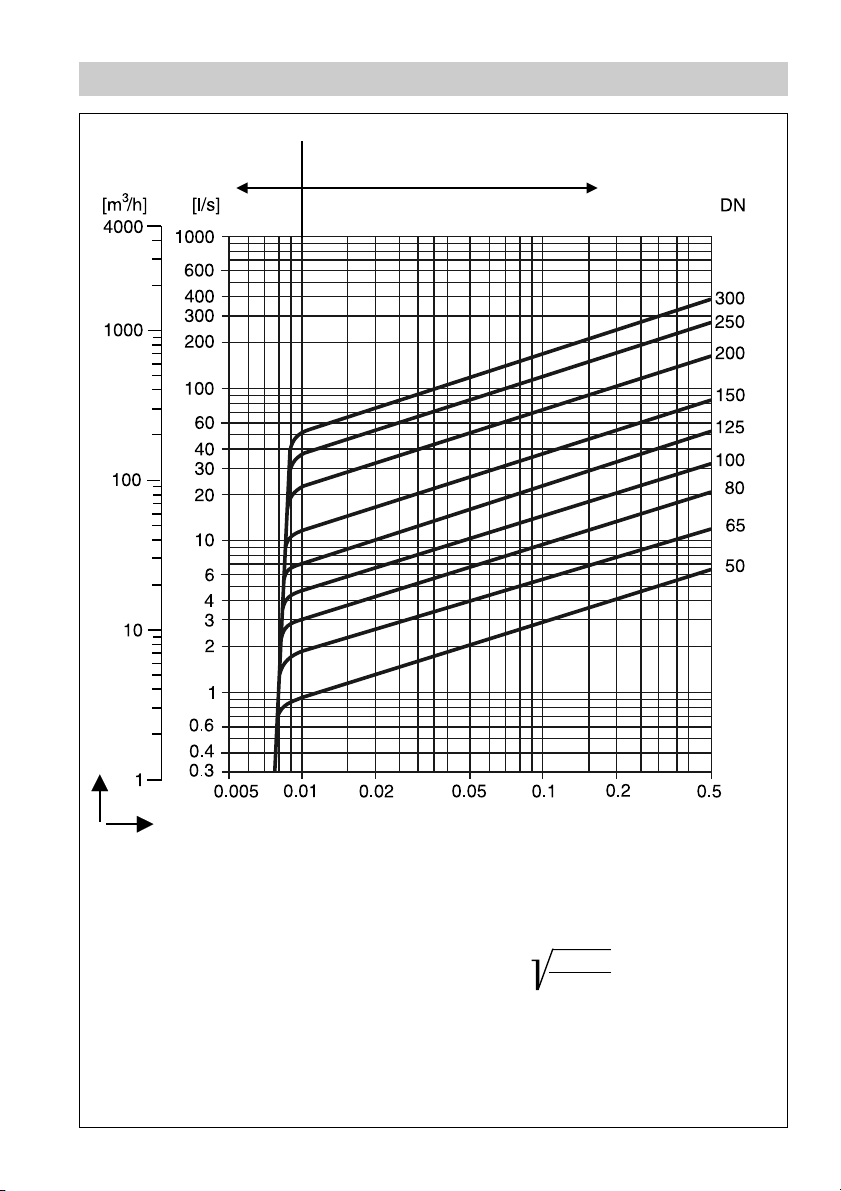

Pressure Drop Chart CB 2...

Partial opening

= instable range

w

˙

Full opening

= stable range

Volume flow V

Pressure drop ∆p [bar]

Fig. 4

The curves given in the chart are valid for

water at 20 °C. To read the pressure drop for

other fluids the equivalent water volume

flowrate must be calculated and used in the

graph.

The values indicated in the chart are applicable

to valves with horizontal flow. With vertical

flow insignificant deviations occur only within

the range of partial opening.

˙

V

= V˙ ·

w

˙

V

= Equivalent water volume flow

w

ρ

1000

in [l/s] or [m³/h]

ρ = Density of fluid (operating condition)

in kg/m³

˙

V

= Volume of fluid (operating condition)

w

in [l/s] or [m³/h]

7

Page 8

Important Notes

Usage for the intended purpose

The swing flap non-return valves CB 1.../CB 2... ensure unidirectional flow in pipes by preventing a

backflow of liquids or gases.

Use this equipment only within the specified pressure and temperature ratings and check corrosion

resistance and chemical suitability for the application in question.

Safety note

The valve must only be installed by qualified staff.

Qualified staff are those persons who - through adequate training in engineering, the use and

application of safety equipment in accordance with regulations concerning safety systems, and first aid

& accident prevention - have achieved a recognised level of competence appropriate to the installation

and commissioning of this device.

Danger

The valve is under pressure during operation.

When loosening flanged connections or sealing plugs, hot water, steam, corrosive liquids

or toxic gases may escape. This presents the danger of severe burns and scalds to the

whole body or severe cases of poisoning.

Installation and maintenance work should only be carried out when the system is

depressurized.

The valve becomes hot or extremely cold during operation. This presents the risk of

severe burns to hands and arms. Installation and maintenance work should only be

carried out at room temperatures.

Sharp edges on internals present a danger of cuts to hands. Always wear industrial

gloves for installation and maintenance work.

8

Page 9

Important Notes – continued –

Ratings pursuant to article 9 of the PED1)

Fluid group

Use

CB 14

CB 24 S

CB 26

CB 26 A

Category IIIIIIIV

Nominal size DN DN DN DN DN

CB 14 50–80 100–200 250–300

CB 24 S 50–80 100–200 250– 300

CB 26 50–100 125–300

CB 26 A 50–100 125–300

CE marking no yes yes yes no

1

) PED = Pressure Equipment Directive

Gas Liquid

1212

no yes no yes

yes yes yes yes

Exception

pursuant to

article 3.3

9

Page 10

Explanatory Notes

Scope of supply

CB 14

1 Swing flap non-return valve CB 14

1 Installation manual

CB 24 S

1 Swing flap non-return valve CB 24 S

1 Installation manual

CB 26

1 Swing flap non-return valve CB 26

1 Installation manual

CB 26 A

1 Swing flap non-return valve CB 26 A

1 Installation manual

Description

The CB 1.../CB 2... are very compact swing flap non-return valves used to prevent the backflow of

fluids. The flap opens and closes automatically as a function of the direction of flow, thus ensuring

unidirectional flow of the fluid. The opening pressure and closing time can be matched to the

application in question by adjusting the spring characteristic. However, this does not apply to CB 14

since this valve is not fitted with a spring. Installation in horizontal or vertical upward flow lines, with

due regard to our installation recommendations.

The CB 1.../CB 2... are equipped with an eyebolt for ease of installation and transport.

Please note that dual-plate check valves should not be used on reciprocating compressor, piston

pumps or where pulsating flow exists.

Function

As the pressure and volume flow rise, the opening angle of the flap increases symmetrically. If

centrifugal pumps are installed upstream of the valve it becomes necessary to arrange for a defined

stabilizing section. Installation in horizontal or vertical upward flow lines, with due regard to our

installation recommendations.

Please observe our installation recommendations outlined in the following pages.

10

Page 11

Explanatory Notes – continued –

Technical Data

Pressure/Temperature Ratings*) CB 14, steel down to –10°C at nominal pressure

DN 50– 300

Temperature [°C] 20 40 60 80 PN

Max. service

pressure

*) When used for its intended purpose.

Pressure/Temperature Ratings*) CB 24 S, bronze down to –200 °C

at nominal pressure

DN 50– 300

Temperature [°C] 20 100 150 200 250 PN

Max. service

pressure

*) When used for its intended purpose. With springs made of bronze up to max. 90 °C.

Pressure/Temperature Ratings*) CB 26, steel down to –10°C at nominal pressure

DN 50– 200

Temperature [°C] 20 100 150 200 250 300 350 PN

Pressure DN 50–200 [bar]

Pressure DN 250–300 [bar]

*) When used for its intended purpose.

Use CB... without springs for temperatures above 300 °C.

Pressure/Temperature Ratings*) CB 26 A, stainless steel down to –10 °C

at nominal pressure

DN 50– 300

Temperature [°C] 20 100 150 200 250 300 350 400 450 PN

Max. service

pressure

*) When used for its intended purpose.

Use CB... without springs for temperatures above 300 °C.

[bar] 16 10 6 4 6–16

[bar] 16 16 16 14 13 6–16

40 38 34 30 27 24 20 6–40

40 32 29 27 24 21 6–40

[bar] 40 38 35 32 30 29 28 27 26 6–40

Corrosion Resistance

If the unit is used for the intended purpose, its safety is not impaired by corrosion.

Sizing

The valve body must not be subjected to pulsating loads. Welds and flanges of the valve are designed

to withstand dynamic loading (bending and alternative stress).

The dimensional allowances for corrosion reflect the latest state of technology.

11

Page 12

Explanatory Notes – continued –

Name Plate / Marking

Direction of flow

Specification impressed on valve body: CB 14, DN 50-80 to EN 19

Size Nominal pressure Material

Fig. 5

Specification impressed on valve body: CB 14, DN 100-200 to EN 19

Fig. 6

Specification (plate): CB 14, DN 250-300 to EN 19

Fig. 7

Specification (plate): CB 24 S, DN 50-80 to EN 19

Fig. 8

Specification (plate): CB 24 S, DN 100-200 to EN 19

Fig. 9

Manufacturing year

(e. g. “02” = 2002)

Specification (plate): CB 26, DN 50-200 to EN 19

Fig. 10

Specification (plate): CB 26 A, DN 50-200 to EN 19

Fig. 11

Specification (plate): CB 24 S, CB 26, CB 26 A, DN 250-300 to EN 19

Fig. 12

12

Page 13

Installation

Note

When the volume flow reaches the instable range (see Pressure Drop Chart) during

operation clatter may occur which gives rise to wear on the oscillating flap. Fig. 3, Fig. 4

Do not install swing flap non-return valves in vertical downward flow lines.

CB 1..., CB 2...

1. Observe installation instructions on page 14.

2. Clean seating surfaces.

3. Installation in horizontal lines: Insert bolts through lower flange holes, fasten nuts. Insert off-the-

shelf seals.

4. Install and align swing flap non-return valve CB.... Make sure that eyebolt

and tighten them evenly.

5. Installation in vertical lines: Insert off-the-shelf seal (bottom).

6. Install and align swing flap non-return valve CB... Insert off-the-shelf seal (top). Insert bolts and

tighten them evenly.

A is on top. Insert bolts

13

Page 14

Installation – continued –

incorrect correct

Fig. 13

Fig. 14

optimum with pump

Fig. 15

14

Fig. 16

Page 15

Commissioning

CB 1..., CB 2...

Swing flap non-return valves do not require any special preparation prior to commissioning.

Unfavourably or incorrectly positioned swing flap non-return valves will lead to loud clattering of the

oscillating flap.

In case of clattering increase pump capacity. Please observe the installation instructions on page 14.

Operation

CB 1..., CB 2...

Unfavourably or incorrectly positioned swing flap non-return valves will lead to loud clattering of the

oscillating flap.

In case of clattering increase pump capacity. Please observe the installation instructions on page 14.

Maintenance

CB 1...

GESTRA Swing flap non-return valves CB 1... do not require special maintenance.

The swing flap non-return valves have to be replaced in case of damage or considerable wear. Parts

subject to wear and spare parts are not available.

15

Page 16

Maintenance – continued –

GESTRA Swing flap non-return valves CB 2... do not require special maintenance.

However, in certain cases it may be necessary to replace the springs or O-rings.

Danger

Note that springs are preloaded which means that they can jump out of the valve body

when the valve is being installed or removed.

This presents the risk of injuries to hands, arms and face.

CB 2... Replace springs / O-ring

1 2

Swing flap non-return valve CB 2...

3 4

Remove springs and O-rings (if fitted).

Insert new O-ring.

16

Detach springs from support.

Insert new springs into the lateral guide.

Page 17

Maintenance – continued –

CB 2... Replace springs / O-ring – continued –

5 6

Insert left and right spring into the support. Check smooth operation of the flap. Install swing flap

Tools

■

Combination pliers 180 mm, DIN 5244

■

Aligning punch, 80 mm

non-return valve in line.

17

Page 18

Spare Parts

Spare Parts List CB 24 S

Item

F

H

Stock code

DN

50 039276 037556 038624 038626

65 031443 033910 038633 038635

80 031753 033911 038642 038644

100 031493 033912 038651 038654

125 031769 033913 038662 038665

150 031525 033914 038673 038675

200 031540 033915 038683 038686

250 039283 033916 038694 038697

300 031573 033917 038705 038708

O-ring EPDM

O-ring FPM

Stock codeStock code

O-ring NBR

Stock code

Spring

Two springs are required per valve. Contact your local dealer for small quantities.

No spare parts available for CB 14.

18

Page 19

Spare Parts – continued –

Spare Parts List CB 26, CB 26A

Item

F

H

Stock code

DN

50 039276 037556 175843 039294

65 031443 033910 703368 039295

80 031753 033911 173844 039296

100 031493 033912 175839 039297

125 031769 033913 703369 039298

150 031525 033914 175841 039299

200 031540 033915 177839 039300

250 039283 033916 174450 039301

300 031573 033917 175131 039302

O-ring EPDM

O-ring FPM

Stock codeStock code

O-ring NBR

Stock code

Spring

Two springs are required per valve. Contact your local dealer for small quantities.

No spare parts available for CB 14.

19

Page 20

Annex

Declaration of Conformity

We hereby declare that the pressure equipment CB 1... and CB 2... conform to the following European

Directive:

■ EC Pressure Equipment Directive (PED) No. 97/23 of 29 May 1997

Swing flap non-return valves are pressure equipment as defined in article 1, section 2.1.4 of the PED.

Applied conformity assessment procedure as described in Annex III for CB 24 and

CB 24 S: Module A1

Applied conformity assessment procedure as described in Annex III for CB 26 and

CB 26 A: Module H - verified by the Notified Body (Registration No.0525).

This declaration is no longer valid if modifications are made to the equipment without consultation

with us.

Bremen, 15th April 2002

GESTRA GmbH

Head of the Design Dept.

Uwe Bledschun

Academically qualified engineer

Quality Assurance Representative

Lars Bohl

20

Page 21

For your notes

21

Page 22

For your notes

22

Page 23

For your notes

23

Page 24

Agencies all over the world

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 3491 /51 52 032

Fax 00 34 91/ 41 36 747; 51 52 036

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02/ 66 32 51

Fax 00 39 02/66 32 55 60

E-mail: infoitaly@flowserve.com

Poland

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 /306 10 -02 od 10

Fax 00 48 58 /306 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/6198770

Fax 0035122/6107575

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-Mail: dgoodwin@flowserve.com

GESTRA AG

Postfach 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telefon +49 (0) 421 35 03- 0

Telefax +49 (0) 421 35 03 - 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

810707-02/604cm · © 2001 GESTRA AG · Bremen · Printed in Germany

24

Loading...

Loading...