Page 1

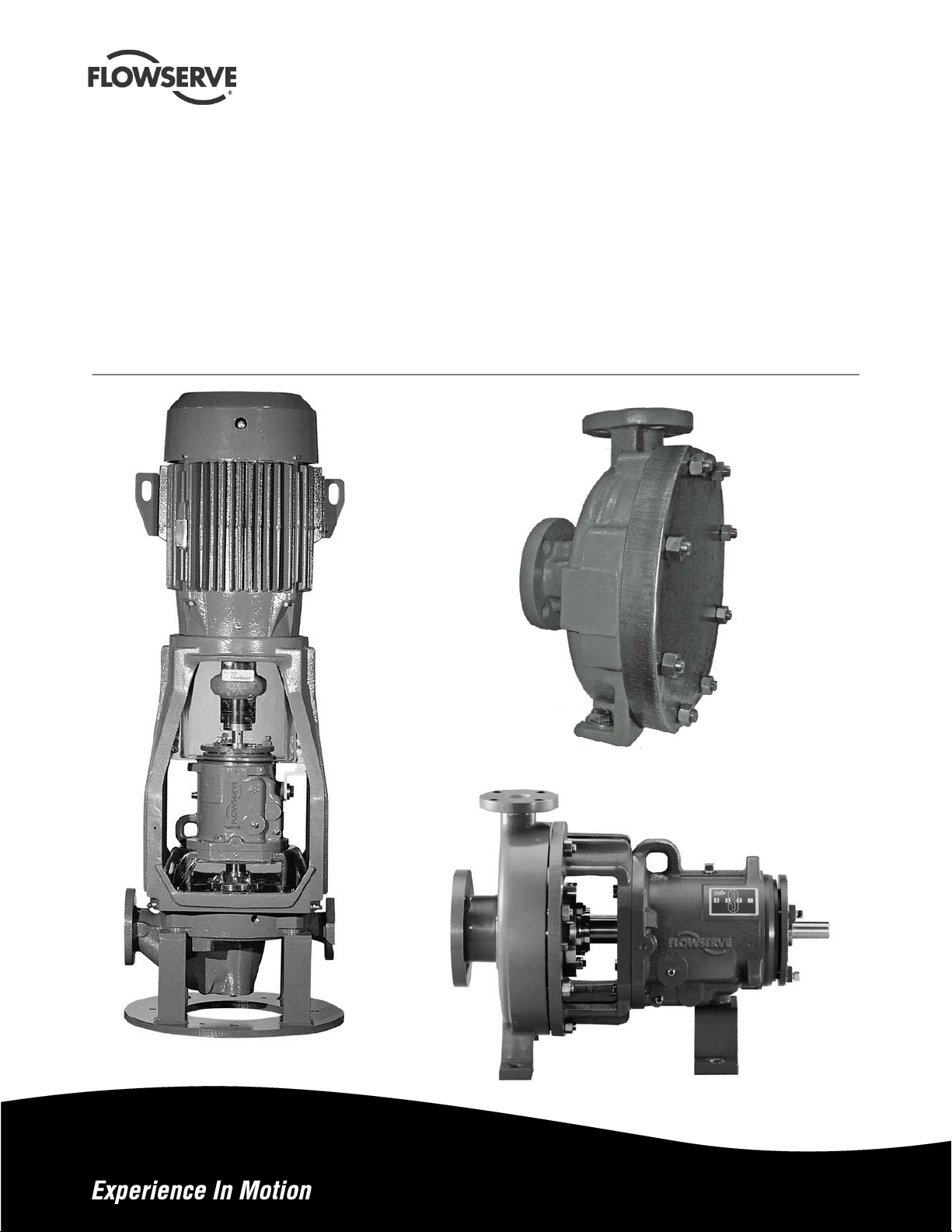

USER INSTRUCTIONS

Casing Blind Covers

Metallic Pumps

ASME (ANSI) Pumps

PCN= 75663450 – 04-10 (E)

Original Instructions

Installation

Operation

Maintenance

Page 2

CONTENTS

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

Page

1 INTRODUCTION AND SAFETY ...........................3

1.1 General ........................................................ 3

1.2 CE marking and approvals...........................3

1.3 Disclaimer .................................................... 3

1.4 Copyright...................................................... 3

1.5 Duty conditions ............................................3

1.6 Safety...........................................................4

1.7 Specific machine performance.....................5

2 TRANSPORT AND STORAGE.............................5

2.1 Consignment receipt and unpacking ...........5

2.2 Handling.......................................................5

2.3 Lifting............................................................6

2.4 Storage.........................................................6

2.5 Recycling and end of product life.................6

3 DESCRIPTION......................................................6

3.1 Configurations..............................................6

3.2 Nameplate.................................................... 6

3.3 Performance and operation limits................ 7

4 MAINTENANCE...................................................10

4.1 Maintenance schedule...............................10

4.2 Tools required.............................................10

4.3 Examination of parts..................................10

5 INSTALLATION...................................................11

5.1 Pump Power End Removal........................ 11

5.2 Casing Blind Cover Installation.................. 11

6 REMOVAL...........................................................11

7 PARTS LIST AND DRAWINGS...........................12

8 CERTIFICATION.................................................13

9 OTHER RELEVANT DOCUMENTATION AND

MANUALS..........................................................13

9.1 Supplementary User Instructions...............13

9.2 Change notes.............................................13

9.3 Additional sources of information...............13

Page 2 of 13

Page 3

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at your service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws/regulations.

These instructions provide information relative to the

Casing Blind Covers only. These instructions must

be used in conjunction with the manuals provided

with the pump.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. These

supplemental instructions must be used in

conjunction with the pump user instruction

manual. The equipment must not be put into

service until all the conditions relating to safety

noted in the instructions, have been met.

1.2 CE marking and approvals

It is a legal requirement that machinery and equipment

put into service within certai n regions of t he world sha ll

conform with the applicable CE Marking Directive s

covering Machinery and, where ap plicable, L ow Voltag e

Equipment, Electromagnetic Compatibility (EMC),

Pressure Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions. Where

applicable this document incorporates information

relevant to these Directives and App rovals.

To confirm the Approvals applying and if the product is

CE marked, check the serial number plate markings

and the Certification. (See section 7, Certificatio n.)

1.3 Disclaimer

Information in these User Instructions is believed

to be reliable. In spite of all the efforts of

Flowserve to provide sound and all necessary

information the content of this manual may appear

insufficient and is not guaranteed by Flowserve as

to its completeness or accuracy.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organizations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use.

As Flowserve cannot test parts and accessories

sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety features

of the products. The failure to properly select, install

or use authorized Flowserve parts and accessories is

considered to be misuse. Damage or failure caused

by misuse is not covered by the Flowserve warranty.

In addition, any modification of Flowserve products or

removal of original components may impair the safety

of these products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

Page 3 of 13

Page 4

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice.

The blind cover has been provided with a

standard gasket material which may not be

appropriate for your service. Please ensure

material compatibility before installation.

Cover plate material compatibility is the

responsibility of the end user.

If the conditions of service on your purchase order are

going to be changed (for ex ample li quid pum ped,

temperature or duty) it is requested that the user seeks

the written agreement of Flowserv e befo re sta rt up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction would

cause hazards. The specific safety markings are:

This sign is not a safety symbol but indicates

an important instructio n in the assembly pro cess.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer/supplier

to provide applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instruct ions where

non-compliance would affect personal safety and

could result in loss of life.

This symbol indicates “hazardous and toxic fluid”

safety instructions where non-compliance would affect

personal safety and could result in loss of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

(Lock out.)

DRAIN THE PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUOROELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of

fluoroelastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

NEVER OPERATE THE PUMP WITHOUT THE

COUPLING GUARD AND ALL OTHER SAFETY

DEVICES CORRECTLY INSTALLED

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

Page 4 of 13

Page 5

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should be

avoided.

Refer to the instruction manual provided

with the pump for more information.

1.6.4.1 Maintenance of the centrifugal pump to avoid a hazard

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

equipment can present a danger to operators and

persons entering the immediate area, actio n must be

taken to avoid accidental contact (suc h as shieldi ng). If

complete protection is not possible, the mach ine access

must be limited to maintenance staff only with cl ear

visual warnings and indicators to those e ntering the

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be hot.

If the temperature is greater than 80 °C (176°F) or

below -5 °C (23 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate pump placement, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive, strict safety procedures

must be applied.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump as a support for piping. Do not

mount expansion joints, unless allowed by Flowserve

in writing, so that their force, due to internal pressure,

acts on the pump flange.

NEVER EXCEED THE MAXIMUM

DESIGN PRESSURE (MDP) AT THE

TEMPERATURE SHOWN ON THE PUMP

NAMEPLATE

See section 3 for pressure versus temperature

ratings based on the material of construction.

1.6.4 Products used in potentially explosive atmospheres

Measures are required to:

Avoid excess temperature

Prevent build up of explosive mixtures

Prevent the generation of sparks

Prevent leakages

Maintain the pump to avoid hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with main tenance

instructions is with the plant operator.

To avoid potential explosion hazards during maintenance,

the tools, cleaning and painting materials used must not

give rise to sparking or adversely affect the ambient

conditions. Where there is a risk from such tools or

materials, maintenance must be conducted in a safe area.

It is recommended that a maintenance plan and schedule

is adopted. (See section 6, Maintenance.)

1.7 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. Where performance data has been

supplied separately to the purchaser these should be

obtained and retained with these User Instructions if

required

.

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and/or damage must

be reported immediately to Flowserve Pump Division

and must be received within ten days of receipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their

size and construction.

Page 5 of 13

Page 6

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

2.3 Lifting

Pumps and motors often have integral

lifting lugs or eye bolts. These are intended for use in

only lifting the individual piece of equipment.

Do not use eye bolts or cast-in lifting

lugs to lift pump, motor and baseplate assemblies.

Care must be taken to lift components

or assemblies above the center of gravity to prevent

the unit from flipping. This is especially true with

In-Line pumps.

2.3.1 Lifting pump components

Casing Blind Cover [1220]

Insert an eye bolt in the tapped hole as provided.

Use either a sling or hook through the eye bolt.

2.4 Storage

Store the pump in a clean , dry location

away from vibration. Leave flange covers in place to

keep dirt and other foreign material out of pump

casing. The pump may be stored as above for up to

6 months. Consult Flowserve for preservative actions

when a longer storage period is needed.

2.4.1 Short term storage and packaging

Normal packaging is designed to protect the pump

and parts during shipment and for dry, indoor storage

for up to six months or less. The following is an

overview of our normal packaging:

All loose unmounted items are packaged in a

water proof plastic bag and placed under the

coupling guard

The internal surfaces of ferrous casings, covers,

flange faces, and the impeller surface are

sprayed with Cortec VCI-389, or equal

The pump must be stored in a covered, dry

location

2.4.2 Long term storage and packaging

Long term storage is defined as more than six

months, but less than 12 months. The procedure

Flowserve follows for long term storage of pumps is

given below. These procedures are in addition to the

short term procedure.

Each assembly is hermetically (heat) sealed from

the atmosphere by means of tack wrap sheeting

and rubber bushings (mounting holes)

Desiccant bags are placed inside the tack

wrapped packaging

This packaging will provide protection for up to

twelve months from humidity, salt laden air, dust

etc.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and in accordance with local

regulations. If the product contains substances that

are harmful to the environment, these should be

removed and disposed of in accordance with current

local regulations. This also includes the liquids

and/or gases that may be used in the "seal system"

or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

local regulations at all times.

3 DESCRIPTION

3.1 Configurations

The Casing Blind Covers are designed to replace the

back pull out unit and prevent product leakage during

maintenance.

3.2 Nameplate

Figure 3-1: Nameplate mounted to blind cover

Serial No.

Equipment No.

Purchase Order

Model

Size

MDP

Material

Date DD/MMM/YY

The casing blind cover nameplate, at a minimum will

contain the following information:

Model – Description of pump model and size

MDP - Maximum design pressure at 38˚C(100˚F)

Material – Flowserve Material Code. See section 3.2

Page 6 of 13

Page 7

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

3.3 Performance and operation limits

This product has been selected t o meet t he

specification of your purchase order. See section 1. 5.

The following data is included as additional information

to help with your installation. It is typical, and factors

such as liquid being pumped, temperature, material of

construction, and seal type may influence this data. If

required, a definitive statement f or your appl ication can

be obtained from Flowserve.

3.3.1 Alloy cross reference chart

Figure 3-2 is the Alloy cross-reference chart for

Flowserve ASME (ANSI) pumps.

Figure 3-3 is the Alloy cross reference chart for

wrought casing blind covers.

3.3.2 Pressure-temperature ratings

The pressure–temperature (P-T) ratings for blind

covers are shown in figure 3-4. Determine the

appropriate cover “Material Group No.” in Figure 3-2.

Interpolation may be used to find the pressure rating

for a specific temperature.

The following provides pressuretemperature ratings for the blind covers only.

The lowest rating of all parts connected to the

casing must be used. Consult the user

instructions provided with the pump.

Example:

The pressure temperature rating for a Mark 3 GP2

blind cover, 316 construction, with an operating

temperature of 149˚C is found as follows:

a) From Figure 3-2, the correct material group is 2.2

Cover plate material compatibility is

the responsibility of the end user.

b) From Figure 3-4C, the pressure-temperature

rating is 21.5 bar.

Figure 3-2: Casing Blind Cover Alloy cross-reference chart

Flowserve

Material Code

D3041 316 Plate

D3134 Steel Plate A515 Gr. 70 (Gr. 485 - S.I. units) 1.1

Generic

Designation

A240 Type 316 (UNS Designation S31600)

Specifications Material Group No.

Figure 3-3: Casing Cast Alloy cross-reference chart

Flowserve

Material Code

E3020 Ductile iron DCI A395, Gr. 60-40-18 1.0

E3033 High chrome iron CR28 A532 class 3 Cr

E4027 High chrome iron CR29 None Cr

E4028 High chrome iron CR35 None Cr

C3009 Carbon steel DS A216 Gr. WCB 1.1

C3062 304 D2 A744, Gr. CF8 2.1

C3069 304L D2L A744, Gr. CF3 2.1

C3063 316 D4 A744, Gr. CF8M 2.2

C3067 316L D4L A744, Gr. CF3M 2.2

C3107 Duplex Stainless CD4M A995, Gr. CD4MCuN 2.8

C4028 Alloy 20 D20 A744, Gr. CN7M 3.17

C4029 Durcomet 5 DV None 2.2

K3005

K3007

K3008 Nickel DNI A494, Gr. CZ100 3.2

K4007

K4008

E3041

E3042

E4035

D4036 Durco DC8 DC8 None -

H3004 Titanium Ti B367, Gr. C3 Ti

H3005 Titanium-Pd TiP B367, Gr. C8A Ti

H3007 Zirconium Zr B752, Gr. 702C Ti

Duriron, Durichlor 51 and Superchlor are registered trademarks of Flowserve Corporation.

Hastelloy is a registered trademark of Haynes International, Inc.

Inconel and Monel are registered trademarks of International Nickel Co. Inc.

Generic

Designation

Inconel 600

Monel 400

Hastelloy B

Hastelloy C

Duriron

Durichlor 51

Superchlor

Durco Legacy

Codes

DINC A494, Gr. CY40 3.5

DMM A494, Gr. M35-1 3.4

DC2 A494, Gr. N7M 3.7

DC3 A494, Gr. CW6M 3.8

D A518, Gr. 1 No load

D51 A518, Gr. 2 No load

SD51 A518, Gr. 2 No load

ASTM

Specifications

Material

Group No.

2.2

Page 7 of 13

Page 8

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

Figure 3-4A Blind Cover Ratings

Durco Mark 3 GP3 Pumps, Durco Mark 2, Durco Mark 2 In-Line, Durco Mark 3 In-Line

Worthington D1000 Pumps

Material Group No.

˚C

-73 24.1 24.1 24.1 17.4 24.1 24.1 24.1 24.1 24.1 24.1

-29 24.1 24.1 24.1 24.1 17.4 24.1 24.1 24.1 24.1 24.1 24.1

-18 24.1 24.1 24.1 24.1 17.4 24.1 24.1 24.1 24.1 24.1 24.1

38 24.1 24.1 24.1 24.1 17.4 24.1 24.1 24.1 24.1 24.1 24.1

93 22.0 20.1 20.8 23.2 17.4 21.3 22.9 24.1 24.1 20.9 21.4

149 21.4 18.1 18.8 21.4 17.4 19.9 21.4 23.5 23.5 18.7 18.7

204 20.7 16.6 17.3 19.8 17.4 19.3 19.9 22.7 22.7 16.9 15.9

260 19.6 15.3 16.1 18.5 17.4 19.1 19.3 21.4 21.4 15.7 13.2

316 17.9 14.6 15.1 17.9 17.4 19.1 19.2 19.5 19.5 14.5 10.5

343 17.4 14.4 14.9 19.1 19.0 19.0 19.0 9.1

371 17.4 14.2 14.4 19.1 18.9 18.3 18.3 7.7

1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

bar

Material Group No.

˚F

-100 350 350 350 252 350 350 350 350 350 350

-20 350 350 350 350 252 350 350 350 350 350 350

100 350 350 350 350 252 350 350 350 350 350 350

200 319 292 301 336 252 309 332 350 350 303 310

300 310 263 272 310 252 289 310 341 341 271 271

400 300 241 250 287 252 280 288 329 329 245 231

500 284 222 233 268 252 277 280 310 310 228 191

600 260 211 219 259 252 277 278 282 282 210 152

650 253 209 216 277 276 275 275 132

700 253 207 209 277 274 266 266 112

1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

psi

0 350 350 350 350 252 350 350 350 350 350 350

Figure 3-4B Blind Cover Ratings

HOC Pumps

Material Group No.

˚C

-73 25.9 25.9 25.9 18.7 25.9 25.9 25.9 25.9 25.9 25.9

-29 25.9 25.9 25.9 25.9 18.7 25.9 25.9 25.9 25.9 25.9 25.9

-18 25.9 25.9 25.9 25.9 18.7 25.9 25.9 25.9 25.9 25.9 25.9

38 25.9 25.9 25.9 25.9 18.7 25.9 25.9 25.9 25.9 25.9 25.9

93 23.7 21.6 22.4 25.0 18.7 22.9 24.6 25.9 25.9 22.5 23.0

149 23.0 19.5 20.2 23.0 18.7 21.4 23.0 25.3 25.3 20.1 20.1

204 22.3 17.9 18.6 21.3 18.7 20.8 21.4 24.4 24.4 18.2 17.1

260 21.1 16.5 17.3 19.9 18.7 20.6 20.8 23.0 23.0 16.9 14.2

316 19.3 15.7 16.3 19.3 18.7 20.6 20.7 21.0 21.0 15.6 11.3

343 18.7 15.5 16.0 20.6 20.4 20.4 20.4 9.8

371 18.7 15.3 15.5 20.6 20.3 19.7 19.7 8.3

˚F

-100 377 377 377 271 377 377 377 377 377 377

-20 377 377 377 377 271 377 377 377 377 377 377

100 377 377 377 377 271 377 377 377 377 377 377

200 343 314 324 362 271 333 357 377 377 326 334

300 334 283 293 334 271 311 334 367 367 292 292

400 323 259 269 309 271 301 310 354 354 264 249

500 306 239 251 288 271 298 301 334 334 245 206

600 280 227 236 279 271 298 299 303 303 226 164

650 272 225 232 298 297 296 296 142

700 272 223 225 298 295 286 286 121

1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

bar

Material Group No.

1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

psi

0 377 377 377 377 271 377 377 377 377 377 377

Page 8 of 13

Page 9

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

Figure 3-4C Blind Cover Ratings

Durco Mark 3 GP1 and GP2

Material Group No.

˚C

-73 27.6 27.6 27.6 17.4 24.1 24.1 27.6 27.6 24.1 27.6

-29 27.6 27.6 27.6 27.6 17.4 24.1 24.1 27.6 27.6 24.1 27.6

-18 27.6 27.6 27.6 27.6 17.4 24.1 24.1 27.6 27.6 24.1 27.6

38 27.6 27.6 27.6 27.6 17.4 24.1 24.1 27.6 27.6 24.1 27.6

93 25.2 23.0 23.7 26.5 17.4 21.3 22.9 27.6 27.6 20.9 24.5

149 24.4 20.7 21.5 24.5 17.4 19.9 21.4 26.8 26.8 18.7 21.3

204 23.7 19.0 19.7 22.6 17.4 19.3 19.9 25.9 25.9 16.9 18.2

260 22.4 17.5 18.4 21.1 17.4 19.1 19.3 24.5 24.5 15.7 15.1

316 20.5 16.7 17.2 20.4 17.4 19.1 19.2 22.2 22.2 14.5 12.0

343 19.9 16.5 17.0 19.1 19.0 21.7 21.7 10.4

371 19.9 16.3 16.5 19.1 18.9 21.0 21.0 8.8

˚F

-100 400 400 400 252 350 350 400 400 350 400

-20 400 400 400 400 252 350 350 400 400 350 400

100 400 400 400 400 252 350 350 400 400 350 400

200 365 333 344 384 252 309 332 400 400 303 355

300 354 300 311 355 252 289 310 389 389 271 309

400 343 275 286 328 252 280 288 376 376 245 264

500 324 253 267 307 252 277 280 355 355 228 219

600 297 242 250 296 252 277 278 323 323 210 173

650 289 239 247 277 276 315 315 151

700 289 236 239 277 274 304 304 128

1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

bar

Material Group No.

1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

psi

0 400 400 400 400 252 350 350 400 400 350 400

Figure 3-4D Durco Mark 3 Group2-13” Lo-Flo Pumps with Class 300 Flanges

Material Group No.

˚C

-73 31.0 31.0 31.0 17.4 24.1 27.6 31.0 31.0 24.1 31.0

-29 31.0 31.0 31.0 31.0 31.0 17.4 24.1 27.6 31.0 31.0 24.1 31.0

-18 31.0 31.0 31.0 31.0 31.0 17.4 24.1 27.6 31.0 31.0 24.1 31.0

38 31.0 31.0 31.0 31.0 31.0 17.4 24.1 27.6 31.0 31.0 24.1 31.0

93 29.1 28.3 25.9 26.7 29.8 17.4 21.3 26.1 31.0 31.0 20.9 27.5

149 27.4 27.5 23.3 24.1 27.5 17.4 19.9 24.4 30.2 30.2 18.7 24.0

204 25.5 26.6 21.3 22.2 25.4 17.4 19.3 22.7 29.2 29.2 16.9 20.5

260 24.0 25.2 19.7 20.7 23.8 17.4 19.1 22.1 27.5 27.5 15.7 17.0

316 22.5 23.1 18.7 19.4 23.0 17.4 19.1 21.9 25.0 25.0 14.5 13.4

343 21.8 22.4 18.5 19.2 19.1 21.8 24.4 24.4 11.7

371 22.4 18.3 18.5 19.1 21.6 23.6 23.6 9.9

1.0 1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

bar

Material Group No.

˚F

-100 450 450 450 252 350 400 450 450 350 450

-20 450 450 450 450 450 252 350 400 450 450 350 450

100 450 450 450 450 450 252 350 400 450 450 350 450

200 422 410 375 388 432 252 309 379 450 450 303 399

300 397 398 338 350 399 252 289 354 438 438 271 348

400 369 386 309 322 369 252 280 330 423 423 245 297

500 348 365 285 300 345 252 277 320 399 399 228 246

600 327 334 272 281 333 252 277 318 363 363 210 195

650 316 325 269 278 277 316 354 354 170

700 325 266 269 277 313 342 342 144

1.0 1.1 2.1 2.2 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Temp

psi

0 450 450 450 450 450 252 350 400 450 450 350 450

Page 9 of 13

Page 10

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

4 MAINTENANCE

It is the plant operator's responsibility to ensure

that all maintenance, inspection and assembly work

is carried out by authorized and qualified personnel

who have adequately familiarized themselves with

the subject matter by studying this manual in detail.

(See also section 1.6.2.)

Any work on the machine must be performed when it

is at a standstill. It is imperative that the procedure

for shutting down the machine is followed.

If platforms, stairs and guard rails are required for

maintenance, they must be placed for easy access to

areas where maintenance and inspection are to be

carried out. The positioning of these accessories

must not limit access or hinder the lifting of the part to

be serviced.

When air or compressed inert gas is used in the

maintenance process, the operator and anyone in the

vicinity must be careful and have the appropriate

protection.

Do not spray air or compressed inert gas on skin.

Do not direct an air or gas jet towards other people.

Never use air or compressed inert gas to clean

clothes.

Before working on the pump, take measures to

prevent the pump from being accidentally started.

Place a warning sign on the starting device:

"Machine under repair: do not start."

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning sign on

the fuse box or main switch:

"Machine under repair: do not connect."

Never clean equipment with flammable solvents or

carbon tetrachloride. Protect yourself against toxic

fumes when using cleaning agents.

Refer to the parts list shown in section 8 for item

number references used throughout this section.

4.1 Maintenance schedule

b) Check that the duty condition is in the safe

operating range for the pump.

4.2 Tools required

A typical range of tools that will be required to

maintain these pumps is listed below.

Standard hand tools SAE

Hand wrenches

Socket wrenches

Allen wrenches

Soft mallet

Screwdrivers

4.3 Examination of parts

Cleaning/inspection

All parts should now be thoroughly cleaned and

inspected. New gaskets should be used. Any parts

that show wear or corrosion should be replaced with

new genuine Flowserve parts.

It is important that only non-flammable,

non-contaminated cleaning fluids are used. These

fluids must comply with plant safety and environmental

guidelines.

It is recommended that a maintenance plan and

schedule be implemented, in accordance with these

User Instructions, to include the following:

a) Check for any leaks from gaskets and seals

Page 10 of 13

Page 11

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

5 INSTALLATION

5.1 Pump Power End Removal

Remove the power end according to

the user instruction provided with the pump.

a) Before performing any maintenance, disconnect the

driver from its power supply and lock it off line.

Lock out power to driver to prevent

personal injury.

b) Close the discharge and suction valves, and

drain all liquid from the pump.

c) Close all valves on auxiliary equipment and

piping, then disconnect all auxiliary piping.

d) Decontaminate the pump as necessary.

If Flowserve pumps contain

dangerous chemicals, it is important to follow

plant safety guidelines to avoid personal injury or

death.

e) Remove casing fasteners [6580.1]. On GP1 In-

Line pumps the studs [6572.1] must be removed.

f) Remove the fasteners holding the bearing

housing foot to the baseplate (not applicable on

In-Line pumps).

g) Move the power end, rear cover, and seal chamber

assembly away from the casing. On In-Line pumps

the simplest method of power end removal is to first

remove the motor and motor adapte r with a crane.

However this is often not practical and the power

end must be removed by hand

h) Discard the casing/cover gasket [4590.1].

Lock out power to driver to prevent

personal injury.

b) Close the discharge and suction valves, and

drain all liquid from the pump.

c) Close all valves on auxiliary equipment and

piping, then disconnect all auxiliary piping.

d) Decontaminate the pump as necessary.

If Flowserve pumps contain

dangerous chemicals, it is important to follow

plant safety guidelines to avoid personal injury or

death.

e) Support the cover [1220] with appropriate

equipment.

f) Remove casing fasteners [6580.1]. On GP1 In-

Line pumps the studs [6572.1] must be removed.

g) Move the cover away from the casing.

h) Discard the casing/cover gasket [4590.1].

The cover assembly is heavy. It is

important to follow plant safety guidelines when

lifting it.

The power end and rear cover

assembly is heavy. It is important to follow plant

safety guidelines when lifting it.

5.2 Casing Blind Cover Installation

a) Install a new rear cover gasket [4590.1] between

the blind rear cover [1220] and the casing [1100].

b) Use studs [6572.1] and nuts [6580.1] and torque

to values found in user instructions provided with

the pump.

5.2.1 Pre start-up checks

All fasteners tightened to the correct torque

6 REMOVAL

a) Before performing any maintenance, disconnect the

driver from its power supply and lock it off line.

Page 11 of 13

Page 12

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

7 PARTS LIST AND DRAWINGS

Page 12 of 13

Page 13

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

8 CERTIFICATION

Certificates, determined from the contract

requirements are provided with these instructions

where applicable. Examples are certificates for CE

marking and ATEX marking etc. If required, copies of

other certificates sent separately to the Purchaser

should be obtained from Purchaser for retention with

these User Instructions.

9 OTHER RELEVANT DOCUMENTATION AND MANUALS

9.1 Supplementary User Instructions

Supplementary instructions such as for a driver,

instrumentation, controller, seals, sealant systems etc

are provided as separate documents in their original

format. If further copies of these are required they

should be obtained from the supplier for retention

with these User Instructions.

9.2 Change notes

If any changes, agreed with Flowserve Pump

Division, are made to the product after it is supplied,

a record of the details should be maintained with

these User Instructions.

9.3 Additional sources of information

The following are excellent sources for additional

information on Flowserve Mark 3 pumps, and

centrifugal pumps in general.

Pump Engineering Manual

R.E. Syska, J.R. Birk,

Flowserve Corporation, Dayton, Ohio, 1980.

Specification for Horizontal End Suction Centrifugal

Pumps for Chemical Process, ASME B73.1M

The American Society of Mechanical Engineers,

New York, NY.

Specification for Vertical In-Line Centrifugal Pumps

for Chemical Process, ASME B73.2M

The American Society of Mechanical Engineers,

New York, NY.

BLANK

American National Standard for Centrifugal Pumps

for Nomenclature, Definitions, Design and Application

(ANSI/HI 1.1-1.3)

Hydraulic Institute, 9 Sylvan Way, Parsippany,

New Jersey 07054-3802.

American National Standard for Vertical Pumps for

Nomenclature, Definitions, Design and Application

(ANSI/HI 2.1-2.3)

Hydraulic Institute, 9 Sylvan Way, Parsippany,

New Jersey 07054-3802.

American National Standard for Centrifugal Pumps for

Installation, Operation, and Maintenance (ANSI/HI 1.4)

Hydraulic Institute, 9 Sylvan Way, Parsippany,

New Jersey 07054-3802.

Flowserve Durco Pump Parts Catalog.

Flowserve Mark 3 Sales Bulletin.

Flowserve Mark 3 Technical Bulletin (P-10-501).

RESP73H Application of ASME B73.1M-1991,

Specification for Horizontal End Suction Centrifugal

Pumps for Chemical Process, Process Industries

Practices

Construction Industry Institute, The University of

Texas at Austin, 3208 Red River Street, Suite 300,

Austin, Texas 78705.

Pump Handbook

2nd edition, Igor J. Karassik et al, McGraw-Hill, Inc.,

New York, NY, 1986.

Centrifugal Pump Sourcebook

John W. Dufour and William E. Nelson,

McGraw-Hill, Inc., New York, NY, 1993.

Pumping Manual, 9th edition

T.C. Dickenson, Elsevier Advanced Technology,

Kidlington, United Kingdom, 1995.

Page 13 of 13

Page 14

CASING BLIND COVER USER INSTRUCTIONS ENGLISH 75663450 04-10

Your Flowserve factory contacts:

Flowserve Pump Division

3900 Cook Boulevard

Chesapeake, VA 23323-1626 USA

Telephone +1 757 485 8000

Fax +1 757 485 8149

Flowserve Pumps Limited

PO Box 17, Newark, Notts NG 24 3BU

United Kingdom

Telephone (24 hours) +44 (0)1636 494 600

Sales & Admin Fax +44 (0)1636 705 991

Repair & Service Fax +44 (0)1636 494 833

E-mail inewark@flowserve.com

Your local Flowserve representative:

To find your local Flowserve representative please

use the Sales Support Locator System found at

www.flowserve.com

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

Pump

5215 North O’Connor Blvd.,

Suite 2300

Irving, Texas 75039-5421 USA

Telephone 1 972 443 6500

Fax 1 972 443 6800

Europe, Middle East,

Africa

Worthing S.P.A.

Flowserve Corporation

Via Rossini 90/92

20033 Desio (Milan) Italy

Telephone 39 0362 6121

Fax 39 0362 303396

Latin America and

Caribbean

Flowserve Corporation

Pump

6840 Wynnwood Lane

Houston, Texas 77008 USA

Telephone 1 713 803 4434

Fax 1 713 803 4497

Asia Pacific

Flowserve Pte. Ltd

10 Tuas Loop

Singapore 637345

Telephone 65 6771 1600

Fax 65 6779 4607

Loading...

Loading...