Page 1

Byron Jackson Type M

Double Mechanical Seal

Submersible Pumping Unit

USER INSTRUCTIONS:

INSTALLATION, OPERATION, MAINTENANCE

PCN=85392711 1042.293/9 • Edition June 2004

Page 2

Page 3

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

CONTENTS

PAGE

1

INTRODUCTION AND SAFETY ...................5

1.1 About the product and these user

instructions........................................... 5

1.2 CE marking and approvals ..................5

1.3 Disclaimer............................................5

1.4 Copyright ............................................. 6

1.5 Duty conditions....................................6

1.6 Safety................................................... 6

1.6.1 Safety symbols................................6

1.6.2 General safety instructions..............7

1.6.3 Personnel qualification, training

and protective clothing ....................7

1.6.4 Authorized and prohibited use.........7

2 TRANSPORT AND STORAGE.....................9

2.1 Consignment receipt and

unpacking ............................................ 9

2.2 Transport ........................................... 10

2.2.1 Safety instructions.........................10

2.2.2 Equipment and personnel

required ........................................ 10

2.2.3 Transport of the motor................... 10

2.2.4 Transport of the pump bowl

assembly....................................... 11

2.3 Storage and shipping......................... 12

2.4 Recycling and end of product life ...... 13

3 DESCRIPTION.............................................14

3.1 Configurations.................................... 14

3.1.1 General Description.......................14

3.1.2 Main Components.........................14

3.1.3 Motor serial number ...................... 14

3.5 Electrical requirements.......................17

3.5.1 General electrical requirements.... 17

3.5.2 Motor protection............................ 18

3.5.3 Short circuit protection .................. 18

4 INSTALLATION AND

UNINSTALLATION..................................... 19

4.1 Fitter ...................................................19

4.2 Equipment and personnel required....19

4.2.1 Equipment and tools supplied

with motor ..................................... 19

4.2.2 Equipment and tools to be

supplied by operator ..................... 19

4.2.3 Personnel required........................ 21

4.3 Hydraulic connection..........................21

4.4 Installation..........................................23

4.4.1 Safety instructions......................... 23

4.4.2 Sequence of installation................ 23

4.4.3 Prepare installation site................. 23

4.4.4 Arrange components for

installation..................................... 24

4.4.5 Inspect components...................... 25

4.4.6 Install motor .................................. 26

4.4.7 Install coupling.............................. 27

4.4.8 Install pump bowl assembly.......... 30

4.4.9 Install impeller............................... 32

4.4.10 Vent motor..................................... 33

4.4.11 Install power cable ........................ 35

4.4.12 Fasten the power cable to the

cable guard................................... 39

4.4.13 Install riser pipe, fasten power

cable to riser pipe.......................... 40

4.4.14 Connect power cable to

terminal box .................................. 43

4.4.15 Connect terminal box to main

power supply ................................. 43

4.5 Uninstallation......................................45

4.5.1 Safety instructions......................... 45

4.5.2 Uninstallation ................................ 45

3.2 Design of major parts.........................14

3.3 Performance and operating limits......15

3.3.1 Normal operating conditions..........15

3.3.2 Design changes ............................15

3.4 Preconditions at the installation

site .....................................................16

3.4.1 Survey of well................................ 16

3.4.2 Crooked well .................................16

3.4.3 Development of the well................16

3.4.4 Suction and submergence

requirements.................................16

3.4.5 Effect of pumping sand..................16

3.4.6 Effect of air or gas.........................16

3.4.7 Oxidizing and corrosive effects

of chemicals, air and gases...........16

5 COMMISSIONING STARTUP,

OPERATION AND SHUTDOWN................ 46

5.1 Safety instructions..............................46

5.2 Direction of rotation............................46

5.3 Starting the pump...............................46

5.3.1 First-time start-up of the pump...... 46

5.3.2 Normal start-up of the pump ......... 47

5.4 Running or operation..........................47

5.4.1 Performance and operating

limits ........................................ 47

5.4.2 Motor operation............................. 48

5.4.3 Starting frequency......................... 48

5.5 Stopping and shutdown......................49

Page 3 of 68

Page 4

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

6 MAINTENANCE ..........................................50

6.1 Safety instructions .............................50

6.2 Maintenance schedule....................... 50

6.3 Working substances and auxiliary

agents................................................51

6.4 Motor maintenance............................ 51

6.5 Pump maintenance............................51

6.6 Pump test run .................................... 51

6.7 Periodic testing of motor and pump... 52

6.8 Electrical tests of the motor ...............53

6.8.1 Insulation test................................ 53

6.8.2 Continuity testing...........................53

6.9 Spare parts........................................ 54

6.9.1 Recommended spares and

consumable items ......................... 54

6.9.2 Ordering spare parts ..................... 54

6.9.3 Storage of spare parts................... 54

6.10 Tools for repair and maintenance...... 55

7 FAULTS, CAUSES AND REMEDIES.........56

8 PARTS LIST AND DRAWINGS..................59

9 CERTIFICATION.........................................60

10 OTHER RELEVANT DOCUMENTATION

AND MANUALS ..........................................61

10.1 Change notes ....................................61

10.2 Abbreviations..................................... 61

11 GLOBAL CONTACT POINTS, EU CE

MARKER AND SERVICE CONTACTS ......62

12 APPENDIX...................................................63

12.1 Scope of delivery ...............................64

12.2 Data sheet .........................................65

12.3 Tightening torques............................. 66

12.4 Safety data sheet for motor oil...........67

Page 4 of 68

Page 5

®

f

r

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

1 INTRODUCTION AND SAFETY

1.1 About the product and these user

instructions

NOTE These user instructions must always

be kept close to the product's operating location of operation or directly

with the product so that they are

available to the operating personnel at

any time.

ned, developed and

Flowserve's products are d

manufactured with state-of-the-art technologies in

modern facilities. The pumping unit is produced

with great care and commitment to continuous

quality control, utilizing sophisticated quality techniques, and safety requirements.

Flowserve is committed to continuous quality im-

ent a

provem

formation about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate familiarization

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair activity with operations personnel, and follow all plant

safety requirements and applicable safety and

health laws/regulations.

NOTE These instructions should be read

These user instructions outline the general proce-

s

that must be observed to ensure long, trou-

dure

ble free performance of the pumping unit. However, it is assumed that plant personnel are familiar

with the basic principles and tools involved in the

installation, operation and maintenance of a pumping unit. Successful pumping unit operation is dependent on careful study of these user instructions

nd being at service for any further in-

with

the product and its permitted use.

prior to ins

and maintaining the equipment in

any region worldwide.

The equipment must not be put into

ce until all the conditions relat-

i

serv

ing to safety, noted in the instructions, have been met.

esig

t

alling, operating, using

and a well planned and observed maintenance

program.

In these user instructions, the numbers in brackets

umbers, e. g.: shaft button screw

are item

(806-2). Refer to the drawings in Chapter 8 "Parts

list and drawings", Page 59, for the position of the

respective item.

n

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic Compatibility (EMC) and Pressure Equipment

Directive (PED).

Where applicable, the Directives and any addi-

ovals cover important safety aspects

tional App

relating to machinery and equipment and the satisfactory provision of technical documents and safety

instructions. Where applicable, this document incorporates information relevant to these Directives

and Approvals.

To check if the approvals apply and if the product

itself is CE marked, check

markings and the Certification, see Section 9

"Certification", Page 60.

r

the seri

al number plate

1.3 Disclaimer

Information in these user instructions is believed

to be reliable. In spite of all the efforts o

Flowserve Pump Division to provide sound and all

necessary information the content of these use

instructions may appear insufficient and is not

guaranteed by Flowserve as to its completeness

or accuracy.

Flowserve manufactures products according to

International Quality Management System Standards as certified and audited by external Quality

Assurance organizations. Genuine parts and accessories have been designed, tested and incorporated into the products to help ensure continued

product quality and performance in use.

As Flowserve cannot test parts and accessories

ced from other vendors the incorrect installa-

r

sou

tion of such parts and accessories may adversely

affect the performance and safety features of the

products. The failure to properly select, install or

use authorized Flowserve parts and accessories is

considered to be misuse. Damage or failure

caused by misuse is not covered by Flowserve's

warranty. In addition, any modification of

Page 5 of 68

Page 6

®

r

r

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

Flowserve products or removal of original components may impair the safety of these products in

their use.

1.4 Copyright

All rights reserved. No part of these user instructions may be reproduced, stored in a retrieval system or transmitted in any form or by any means

without prior permission of Flowserve Pump Division.

1.5 Duty conditions

This product has been selected to meet the specifications of your purchaser order. The acknowledgement of these conditions has been sent separately to the purchaser. A copy should be kept with

these user instructions.

NOTE The product must not be operated

beyond the parameters specified fo

the application.

If there is any doubt as to the suitability of the product for the application intended, contact Flowserve fo

advice, quoting the serial number.

If the conditions of service on your purchase order

are changed (for example liquid pumped, temperature or duty) it is requested that the user seeks our

written agreement before start up.

1.6 Safety

1.6.1 Safety symbols

These user instructions contain specific safety

symbols where non-observance of an instruction

would cause hazards.

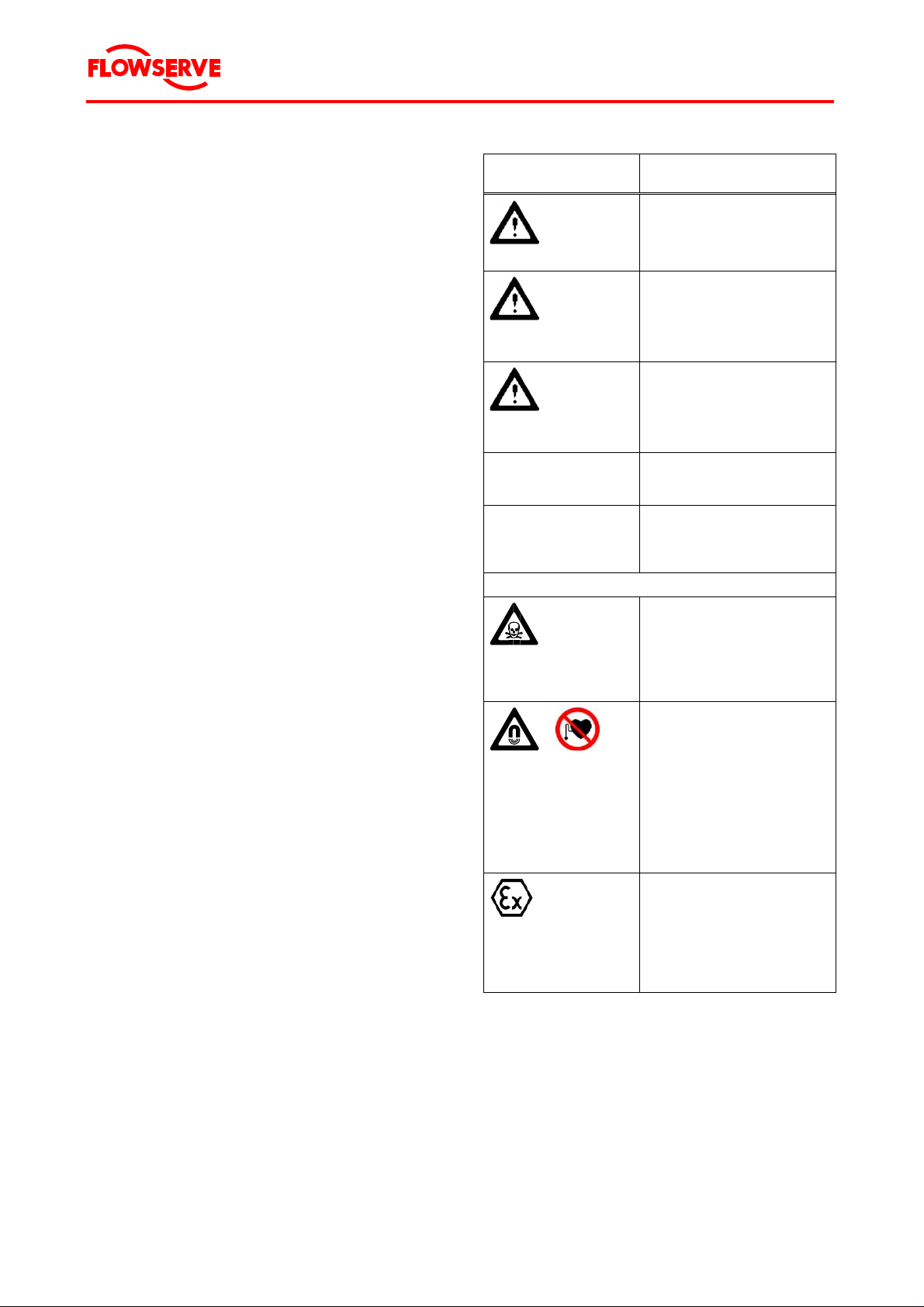

Safety symbol and safety

word

DANGER This symbol indicates an

This symbol indicates a

CAUTION This symbol indicates a

The following symbols may be added to the above symbols

CAUTION This word indicates a situation

NOTE This sign is not a safety symbol

This symbol indicates a

This symbol indicates a

Table 1 Safety symbols in these user instructions

Meaning

imminent hazardous situation.

The situation, if not avoided, will

result in death or serious injury.

potentially hazardous situation.

The situation, if not avoided,

could result in death or serious

injury.

potentially hazardous situation.

The situation, if not avoided,

could result in minor or moderate

injury.

which, if not avoided, could

damage the equipment.

but indicates an important

instruction in the assembly

process.

potentially hazardous situation

due to hazardous and toxic fluid.

The situation, if not avoided,

could result in death or serious

injury.

This symbol indicates a

potentially hazardous situation

due to strong magnetic field.

The situation, if not avoided,

could result in death or serious

injury to persons with pacemaker

implant.

Further, the situation could

damage instruments and stored

data sensitive to magnetic fields.

potentially hazardous situation in

an explosive atmosphere

according to ATEX.

The situation, if not avoided in

the hazardous area, could cause

an explosion.

Page 6 of 68

Page 7

®

r

r

A

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

1.6.2 General safety instructions

NOTE Always follow

• legal regulations

• plant regulations

• these user instructions

concerning safety.

Absolutely heed all information placed directly on

the pumping unit and given in Chapter 12.2 "Data

sheet", as for example

• rotation arrow

• labeling of connections

• rating plate.

Danger of injury by

• knocking against parts, tools o

equipment

• jamming fingers or hands in o

between parts, tools or equipment

• dropping parts, tools or equipment on parts of the body.

DANGER

ll work on the electrical system

may only be performed by qualified

electricians!

All work on the hydraulic connections may only be performed by

qualified fitters.

Protective clothing

During transport, installation and removal of the

pumping unit, all personnel must wear

• helmet

• safety boots

•

protective gloves

During operation of the pumping unit at the control

center, all personnel must wear

•

protective gloves

NOTE Also follow

• legal regulations

• plant regulations

concerning protective clothing.

1.6.3 Personnel qualification, training and protective clothing

Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the pumping unit

must be qualified and authorized to carry out the

work involved.

If the personnel in question do not already possess

the necessary knowledge and skill, appropriate

training and instruction must be provided. If required, the operator may commission the manufacturer / supplier to provide applicable training.

Always co-ordinate repair activity with operations

and health and safety personnel, and follow all

plant safety requirements and applicable safety

and health laws and regulations.

1.6.4 Authorized and prohibited use

The safe operation of the pumping unit can only be

guaranteed if it is operated as authorized.

The only authorized utilization of the pumping unit

is to pump water from a well. The pumping unit is

to be operated submerged in water.

NOTE Not all components or sub-

assemblies of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the components or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

By not heeding this user instructions, product liability is rendered void.

Page 7 of 68

Page 8

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

Non-authorized utilization of the pumping unit includes:

• operating the pumping u

nit in a known mal-

functioning state

• operating the pumpin

g unit in conditions other

than those given in Chapter 3.3.1 "Normal operating conditions", Page 15.

• making modifications of the pumping unit that

are not auth

orized by Flowserve

• using spare parts that are not authorized by

Flowse

rve.

CAUTION Alterations to the pumping unit are

only

permitted a

fter written permis-

sion by Flowserve.

Only use spare parts that have been

autho

rized b

y Flowserve.

Flowserve is not liable for any dam-

ause

age c

d by the use of parts ob-

tained from third parties.

Page 8 of 68

Page 9

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpack-

ing

A submersible pumping unit consists of

• Motor

• Pump bowl assembly

• Non-return valve

• Powe

• Riser pipe

• Cable or bracket to fasten the motor power

• Wellhead (surface plate)

• Terminal box or jun

• Tools for inst

NOTE Not all components or sub-

Flowserve generally ships the pumping unit in two

packa

• Main compon

• Tools described in

All components and parts are suitably protective

ppe

wra

ate.

The motor is shipped nearly completely filled with

oil, with

mounted outside of the motor to allow thermal expansion and contraction of the motor oil.

r cable

(discharge column)

cabl

e onto the riser pipe

ction box

allation and maintenance.

assemblies

of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the c

omponen

ts or subassemblies supplied by Flowserve

in this delivery, see Chapter 12

"Scope of delivery".

s:

ge

ents described in Chapter 3.1.2

"Main Components", Page 14.

Chapter 4.4.4 ”Arrange

components for installation", Page 24.

d, crated or mounted on skids as appropri-

oil expansion bag (shipping bladder)

an

The power cable, if included in the delivery, is

ship

ped on a reel with a sh

ipping cap or other pro-

tective covering installed to protect the connectors.

Immediately after receipt of the equipment

1. Uncrate all parts.

Check all crates, boxes and wrappings for any

accessorie

s or spare parts which may be

packed separately with the equipment or attached to side walls of the box or equipment.

2. Check the scope of delivery.

• Che

ck the delivery against the delivery

and shippi

ng documents for its com-

pleteness.

Each product has a unique serial num-

at this number corresponds

ber. Ch

eck th

with that advised.

NOTE Make sure you can always quote

t

each par

's serial number in correspondence and when ordering

spare parts or further accessories.

• Ins

pect the delivery for trans

damage.

Immediately report any shortage and or dam-

age to Flowserve and the ship

ping company.

Claims must be reported in writing within one

month of receipt of the equipment. Flo

does not accept latter claims.

3. Check the available power against the res given on the motor data plate and

ment

quire

in Chapter 12.2 "Data sheet".

If the equipment is to be stored

• continue with Chapter 2.3 "Storage and ship-

ping", Page 1

2.

If the equipment is to be installed

• contin

ue with Chapter 4.4 "Installation",

Page 23.

portation

wserve

Page 9 of 68

Page 10

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

2.2 Transport

2.2.1 Safety instructions

Transport is the process of moving the pumping

unit or its components from the installation site to a

storage site, maintenance site or repair site, or vice

versa.

During transport, always

• Work carefully to avoid accidents.

• Handle equipment carefully.

• Be sure lifting devices are in good condition

and are capable of safely handling the

weights to be lifted.

• Mark and seal off the transport route so that

unauthorized personnel do not enter the danger area.

• Take precautions to prevent foreign materials

or dirt from entering the working parts of pump

and motor.

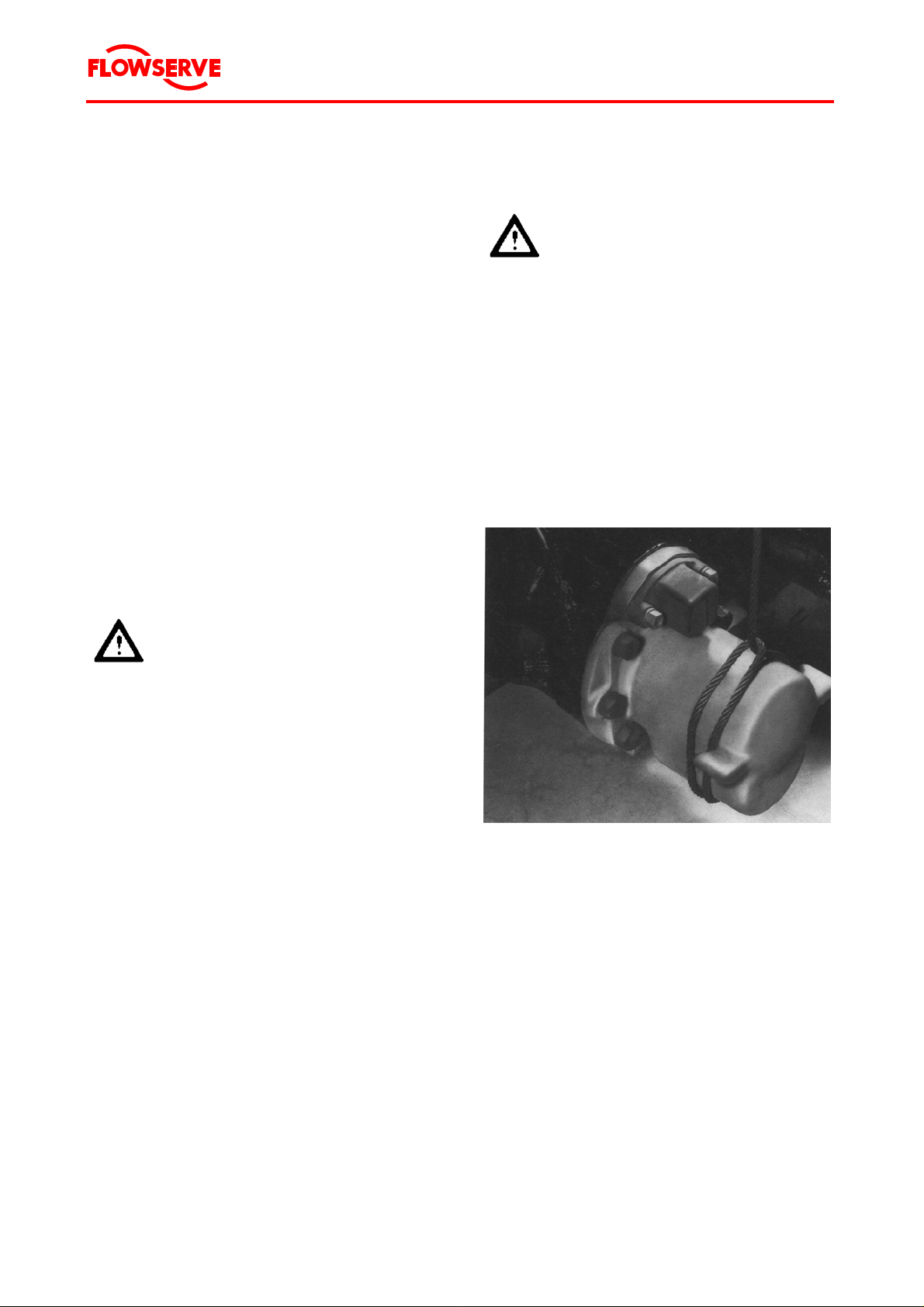

2.2.3 Transport of the motor

Do not raise or move the motor by

the power cables!

CAUTION The motor is a dynamically bal-

anced machine and should be handled accordingly.

Take precautions to prevent foreign

materials or dirt from entering the

working parts of the motor.

1. Refer to Figure 1.

Place hitching line under lifting lugs.

Take care that the hoist has an adequate carrying force. For weight see

Chapter 12.2 "Data sheet".

Never step under floating load.

Watch for and avoid overhead ob-

structions including power lines.

2.2.2 Equipment and personnel required

Provide the following equipment for the transport:

• Portable crane with adequate carrying force.

For weight see Chapter 12.2 "Data sheet.

• Also see Chapter 4.2 "Equipment and personnel required", Page 19.

Flowserve recommends that 2 persons plus 1

crane operator perform the transport.

Figure 1 Hitching line under lifting lugs

Page 10 of 68

Page 11

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

2. Refer to Figure 2.

Place a wire around the motor. The wire is to

be positioned between stator and lower casing, approx. 1/3 from bottom of motor.

Figure 2 Lifting motor for installation

3. Lift the motor horizontally by 2 points.

4. Transport the motor horizontally to the installation or storage site.

5. Carefully lower the motor at the respective

site and place it on the floor.

If the motor is to be stored:

• Continue with Chapter 2.3 "Storage and shipping", Page 12.

If the motor is to be installed in a well:

• Continue with Chapter 4 "Installation",

Page 19.

2.2.4 Transport of the pump bowl assembly

NOTE Not all components or sub-

assemblies of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the components or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

CAUTION Use care to prevent bumping, push-

ing, or scraping of pump bowl assembly parts, especially the shafts,

or other machined surfaces.

Take precautions to prevent foreign

materials or dirt from entering the

working parts of the pump bowl assembly.

NOTE The following description refers to

pumps without auxiliary carriers.

Should the pump be delivered on an

auxiliary carrier, refer to the pump

manual for transportation instructions.

1. Connect the pump

• directly to the hoists, or

• to the cross-beam

If the motor is to be maintained:

• Continue with Chapter 6 "Maintenance",

Page 50.

Page 11 of 68

of a portable crane.

2. By means of the crane, carefully lift the pump

and move it to the desired site.

If the pump bowl assembly is to be stored:

• Continue with Chapter 2.3 "Storage and shipping", Page 12.

If the pump bowl assembly is to be installed in a

well:

• Continue with Chapter 4 "Installation",

Page 19.

If the pump bowl assembly is to be maintained:

• Continue with Chapter 6 "Maintenance",

Page 50.

Page 12

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

2.3 Storage and shipping

For the removal of the pump from the well see

Chapter 4.5 "Uninstallation", Page 45, if necessary.

Requirements for the storage area

• Safe

• Clea

• Away from extended p

n

eriods of direct sunlight

• Well ventilated

• Dry

Air humidity:

................................40 % to 60 %

• Cool

Air temperatur

e for motors

originally filled by Flowserve:...+50 °C to -5 °C

CAUTION Always s tore mot or and pump bowl

assembly

separately

.

Prepare motor for storage or shipping after removing the motor from the well

1. Arrange the motor horizontally.

2. If pump and coupling are to be stored or

shipped sep

nents on motor shaft.

3. Install power terminal shipping cap (112),

power te

shipping caps (112-1).

4. If the motor is to be stored in a vertical position, proceed

a. Remove the adapter bracket (808).

b. Drill a vent hole in the motor shipping cap

(112-1

If the motor is returned to factory at a

later time, se

plug.

5. If the motor is to be returned to the factory,

eed as follows:

c

pro

a. Remove motor half-coupling (529) or mo-

tor one-pie

b. Lubricate shaft with some form of pene-

trating oil.

c. Place coupling and components in motor

ship

minal gasket (744-6) and bolt cap securely in place.

arately: Install coupling compo-

nal gasket (744-6), and motor

rmi

as follo

ws:

).

al the vent hole by a pip

ce coupling (531).

ping cap

(112-1) with its power ter-

e

d. Elevate motor over a sump or drum to

nd

drain oil a

water from motor.

e. Remove lower casing drain plug (806)

from bottom of motor, then remove vent

plugs (806-4 and 806-5) at top of motor

and allow motor to fully drain.

f. Replace drain and vent plugs.

Prepare pump bowl assembly for storage or

shipping

NOTE Not all components or sub-

assemblies

of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the c

omponen

ts or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

NOTE The following description refers to

w

pumps

ithout auxiliary carriers.

Should the pump be delivered on an

y

auxiliar

carrier, refer to the pump

manual for storage and shipping

instructions.

1. Install blocks in the strainer to restrain the

pump shaft.

This prevents shaft end float and possible in-

e during handling.

ternal da

mag

2. Make sure the bowl assembly is thoroughly

dry.

3. Install suitable covers to seal off all openings.

Page 12 of 68

Page 13

®

V

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

Store pumping unit

NOTE The following description refers to

pumps without auxiliary carriers.

Should the pump be delivered on an

auxiliary carrier, refer to the pump

manual for storage and shipping

instructions.

Store the pumping unit as follows:

• Motor:

Preferably vertically

Filled with oil

• Pump bowl assembly with rubber bearing

bushes:

Vertically

• Pump bowl assembly with other than rubber

bearing bushes:

Preferably vertically

DANGER

Horizontally stored motors and

pump bowl assemblies must be secured against rolling.

ertically stored motors and pump

bowl assemblies must be secured

by appropriate means in this storage position to prevent tipping over.

• Power cable:

Leads protected from moisture

NOTE Do not bend power cable during

storage.

Maintenance during storage

• Storage up to four weeks

At the beginning and end of the storage pe-

riod: Carefully check the motor to be sure

there are no signs of oil leakage.

• Storage between 1 and 24 months

Maintenance of the motor, every 6 to 8 weeks:

1. Remove the motor shipping cap (112) at

the motor.

3. Mount the motor shipping cap (112) to

the motor.

Maintenance of the pump, every 6 to 8 weeks:

1. Remove the discharge housing and the

non-return valve for the pump shaft.

2. Turn the pump shaft several times by

means of a wrench.

4. Mount the discharge housing and nonreturn-valve to the pump.

• Storage for over 24 months

After a storage of more than 24 months, we

recommend a complete visual inspection at

our main factory or at your nearest Flowserve

representative.

Shipping

Ship motor and pump bowl assembly

• in non-airtight protection film

• in wooden box or similar transport packaging.

2.4 Recycling and end of product life

At the end of the service life of the pumping unit or

its parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and heeding local regulations.

If the product contains substances which are harmful to the environment, these should be removed

and disposed of in accordance with local regulations. This also includes the liquids and or gases in

the "seal system" or other utilities.

DANGER

Make sure that hazardous sub-

stances are disposed of safely and

that the correct personal protective

equipment is used.

The safety specifications must be in

accordance with the local regulations at all times.

Hazardous substances in the pumping unit are

• Motor oil

2. Turn the motor shaft several times by

means of a wrench.

Page 13 of 68

Page 14

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

3 DESCRIPTION

3.1 Configurations

3.1.1 General Description

The Flowserve submersible pumping unit is a

combination of

• a vertic

chanical seal

• a vertical pump bowl a

designed for sustained operation submerged in

water.

The

pump bowl assembly.

The rotating element of the pump bowl assembly is

driven from the bottom

connected to the motor shaft by a coupling.

Power is supplied to the motor through a submarine po

we

and extends to the starting equipment. Motor and

pump bowl assembly are connected to the riser

pipe. The riser pipe is threaded or flanged and

coupled in random lengths and the entire unit is

coupled to a wellhead assembly.

Each pumping unit has been individually manufac-

ccording to the special requirements of the

a

tured

customer. The technical data is given in Chapter

12.2 "Data sheet".

al, oil filled motor with double me-

ssembly

motor is positioned directly below the

where its extended shaft is

r cable which is fastened to the riser pipe

These user instructions apply only

to the componen

ts or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

3.1.3 Motor serial number

The motor serial number is on the name plate on

the stator.

3.2 Design of major parts

The motor is filled with, lubricated and cooled by a

special mineral oil of high dielectric strength.

This oil

• allows high efficiency rotor-stator design,

• provides

qualities, and

• protects the motor from internal corrosion.

CAUTIO

excellent insulation and lubrication

N The oil used in this pumping unit is

specifie

d in Chap

ter 12.2 "Data

sheet".

Use of other oil

3.1.2 Main Components

A pumping unit consists of

• Motor

• Pump bowl assembly

• Non-return valve

• Power cable

• Riser pipe

(discharge column)

• Cable or bracket to fasten the motor power

cabl

e onto the riser pipe

• Wellhead (surface plate)

• Terminal box or jun

• Tools for inst

ction box

allation and maintenance.

NOTE Not all components or sub-

assemblies of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

• ma

y cause damage to the

pumping unit

• renders Flo

wserve's warranty

void.

The motor does not require periodic oil changes.

The oil is circulated within the motor by pumping

action of the

thrust bearing disc. Separation between the motor oil and pump liquid at the shaft

exit is maintained by two mechanical seals.

The motor is pressure compensated.

The double mechanical seal system uses a pres-

balan

sure

ce process to equalize the pressure differential across the seals, minimizing leakage and

providing years of maintenance free service. The

inner seal diverts any pumped fluid leakage via a

communication line to a storage reservoir at the

bottom of the motor. The motor is vented to the

well by the balance line. As the oil expands, some

oil is pushed out of the motor through the balance

tube. As the oil cools down, pumped fluid is drawn

back into the lower casing at the bottom of the motor through the balance tube.

Page 14 of 68

Page 15

®

r

f

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

3.3 Performance and operating limits

3.3.1 Normal operating conditions

Operating purpose

Submersible pumps serve to transport water under

the operating con

ditions described in the following.

tion

Opera

• Operation

wit

hin prescribed voltage tolerance,

see Chapter 12.2 "Data sheet"

• No operation against closed slide valve

• Permissible o

perational range: 50 % to 120 %

of the optimal delivery rate

CAUTION Other uses, operating purposes o

operating conditions must be

agreed upon by Flowserve.

Water characteristics

• Water temperature: .............

• Sand content:

......................Maximum 25 mg/l

Also see Chapter 3.4.3 "

well", Page 16, and Chapter 3.4.5 "Effect of

pumping sand", Page 16.

• No impuritie

s which could lead to deposits

and blockages within the pump or to deposits

on the motor surface.

Also see Chapter 3.4.6 "Effect of air or gas",

nd Chapter 3.4.7 "Oxidizing and

16 a

Page

corrosive effects of chemicals, air and gases",

Page 16.

• No occurrence of water hammer

CAUTIO

N At higher surrounding temperatures

and/or lo

er flow velocities on the

w

external motor surfaces, or if there

is risk of clogging, special measures for heat dissipation are required.

Inform Flowserve of the surrounding conditio

ns.

See Chapter 12.2

"Data sheet"

evelopment of the

D

• Observation of the

starting frequency

maximum permissible

Installation position

Take the following criteria into account when determinin

• Vertical installation in a

g the installatio

n position and depth:

well above the filter

line, so that a perfect flow is guaranteed along

the external motor wall.

• Sufficient water cover

• A static wat

er level at least 2 m above the

pump exit

• A dynamic water level above the suction

hou

sing, taking into account the required net

positive suction head for the pump (see Chapter 12.2 "Data sheet")

• Flow rate (see Cha

• Supply cond

pter 12.2 "Data sheet")

itions of the pumping medium

(dependent upon the installation conditions)

CAUTION The pumping unit should be in-

stalled above the

well filter.

If this is not possible, prevent direct

w

suction

ithin the filter line by suitable measures (e.g. blind tube in

the filter, outer pump mantle, pump

with sand protection jacket.

Flo

of the p

application and confirm its use, i

applicable.

Pumping unit

• Corre

ctly selected and adjusted motor protec-

tion

wserve will check the suitability

ump

ing unit for its planned

Page 15 of 68

3.3.2 Design changes

Alternation or addition of the pumping unit may

c

only take pla

• by Flowserve,

e

or

• after written consent by Flowserve.

Page 16

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

3.4 Preconditions at the installation

site

3.4.1 Survey of well

Always sound the well to make sure it is deep

enough to permit install

consisting of pump bowl assembly and motor. If

the exact diameter and depth of the well casing is

not known, "cage" the well following the procedure

outlined in Chapter 3.4.2 "Crooked well", Page 16.

Experience indicates that many wells have more

stri

that one

ng of casing installed and frequently

the lower sections are smaller in diameter than the

surface casing. Be certain the submersible pumping unit will pass into the well freely and hang well

above of the well bottom.

3.4.2 Crooked well

A well that is known to be crooked and that has not

ly accommodated a pumping unit of com-

previou

s

parable size must be "caged" before the submersible pumping unit is installed.

1. Prepare a cage of the same length and di-

the combined motor and pump

ameter a

s

bowl assembly, with 12 m to 15 m (40 feet to

50 feet) of the proper size of riser pipe.

2. Lower the cage into the well to the point at

h the pumping unit is to be placed.

c

whi

3. If the cage can be lowered to this point with-

out touching

the inner wall of the well, the

submersible pumping unit can be installed.

3.4.3 Development of the well

Do not use a new pumping unit to develop the well.

Developing, surging and freeing the well of sand

s

are con

idered a part of the well drillers contract

and should be accomplished by the use of a test

pumping unit.

ation of the pumping unit

maximum well draw-down level, although some

installations may require more submergence.

3.4.5 Effect of pumping sand

Flowserve does not guarantee the pumping unit to

be resistant

against the erosive action of sand, silt

or other abrasive materials suspended in water.

Pumping sand will adversely affect the motor be-

e the vibration produced in a worn pump bowl

s

cau

assembly will be transmitted to the motor and

could result in a shortened motor life.

3.4.6 Effect of air or gas

The presence of gases in the water may reduce

a

city and head of the pumping unit, thus de-

cap

creasing the hydraulic performance. Further, air or

gas in the water will cause deterioration of materials of the pumping unit sooner than under normal

conditions.

3.4.7 Oxidizing and corrosiv e effects of

r and gases

chemicals, a

i

Even if the composition of the pumped water is

n due to chemical analysis, it is not always

know

possible to predict the corrosive action of water on

the metals of the pumping unit.

In addition to chemicals, water may also contain

entrain

ed air or ga

ses that have a definite oxidizing

or corrosive action of their own. This action is accentuated by high velocities within the pump.

Such conditions are not recognizable in the chemical analysis of the water.

Conforming with the Standards of the Hydraulic

Institute of th

e United States and the p

ractice of all

reliable pump manufacturers, Flowserve does not

guarantee its pumps and motors to be resistant

against corrosive or electrolytic action.

Should you require motors or pumps to perform

unde

r oxidizi

ng or corrosive conditions, contact

Flowserve for further information.

3.4.4 Suction and submergence requires

ment

Pumping th

unit br

e well at a rate at which the pumping

eaks suction will cause pump deterioration.

It is suggested that a method be provided for keeping a record of the water level above the suction

inlet.

The minimum submergence recommended is 3 m

(10

feet) of

riser pipe submergence below the

Page 16 of 68

Page 17

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

3.5 Electrical requirements

3.5.1 General electrical requirements

The Byron Jackson submersible motor is designed

for across-line start, eliminating the need for reduced voltage starting equipment. Maximum current inrush when the motor is connected across the

line at full voltage will be limited to about 700 % of

the rated load current.

Because starting the motor at full voltage results in

high starting torque, the motor accelerates to operating speed very rapidly (within 0.8 seconds, typically), and current consumption correspondingly

drops to normal. The rated power requirements of

the motor are stated on the pump nameplate located on the wellhead.

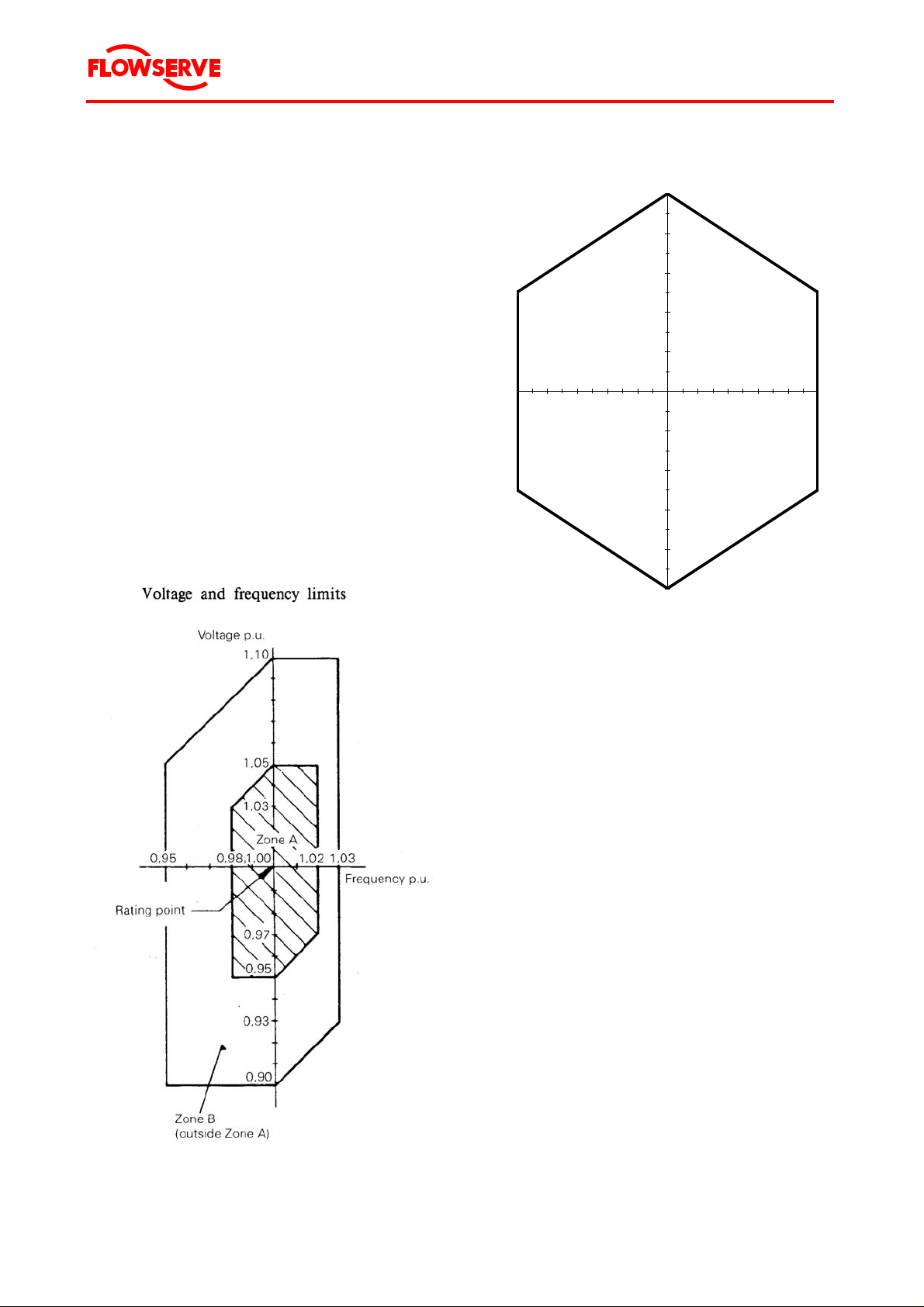

Allowed combinations of voltage and frequency

variations during operation are classified according

IEC 60034 as being either Zone A or Zone B

(Figure 3) or according NEMA (see Figure 4).

Voltage and frequency limits

0,1

0,08

0,06

0,04

0,02

0

-0,05 -0,04 -0,03 -0,02 -0,01 0 0,01 0,02 0,03 0,04 0,05

-0,02

Voltage Variation p.u.

-0,04

-0,06

-0,08

-0,1

Frequency Variation p.u.

Figure 3 Voltage and frequency limits acc. IEC 60034

Figure 4 Voltage and frequency limits acc. NEMA

The motor is capable of performing its rated torque

continuously within Zone A, but need not comply

fully with its performance at rated voltage and frequency (see rated point in Figure 3), and may exhibit some deviations. Temperature rises may be

higher than at rated voltage and frequency. For

conditions at the extreme boundaries of Zone A,

the temperature rises and temperatures may exceed the specified limits of temperature rise and

temperature by approximately 10 K.

Operation outside Zone A (within Zone B) may exhibit greater deviations from its performance at

rated voltage and frequency than in Zone A. Temperature rises may be higher than at rated voltage

and frequency and most likely will be higher than

those in Zone A. Extended operation at the

perimeter of Zone B is not recommended.

Low voltage is a serious problem since the operating motor current is increased, resulting in additional motor heating. However, the motor is designed to operate continuously at 110 % of rated

current, so that some reduction in voltage can be

tolerated as long as it is not also accompanied by

an overload of the motor.

Page 17 of 68

Page 18

®

f

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

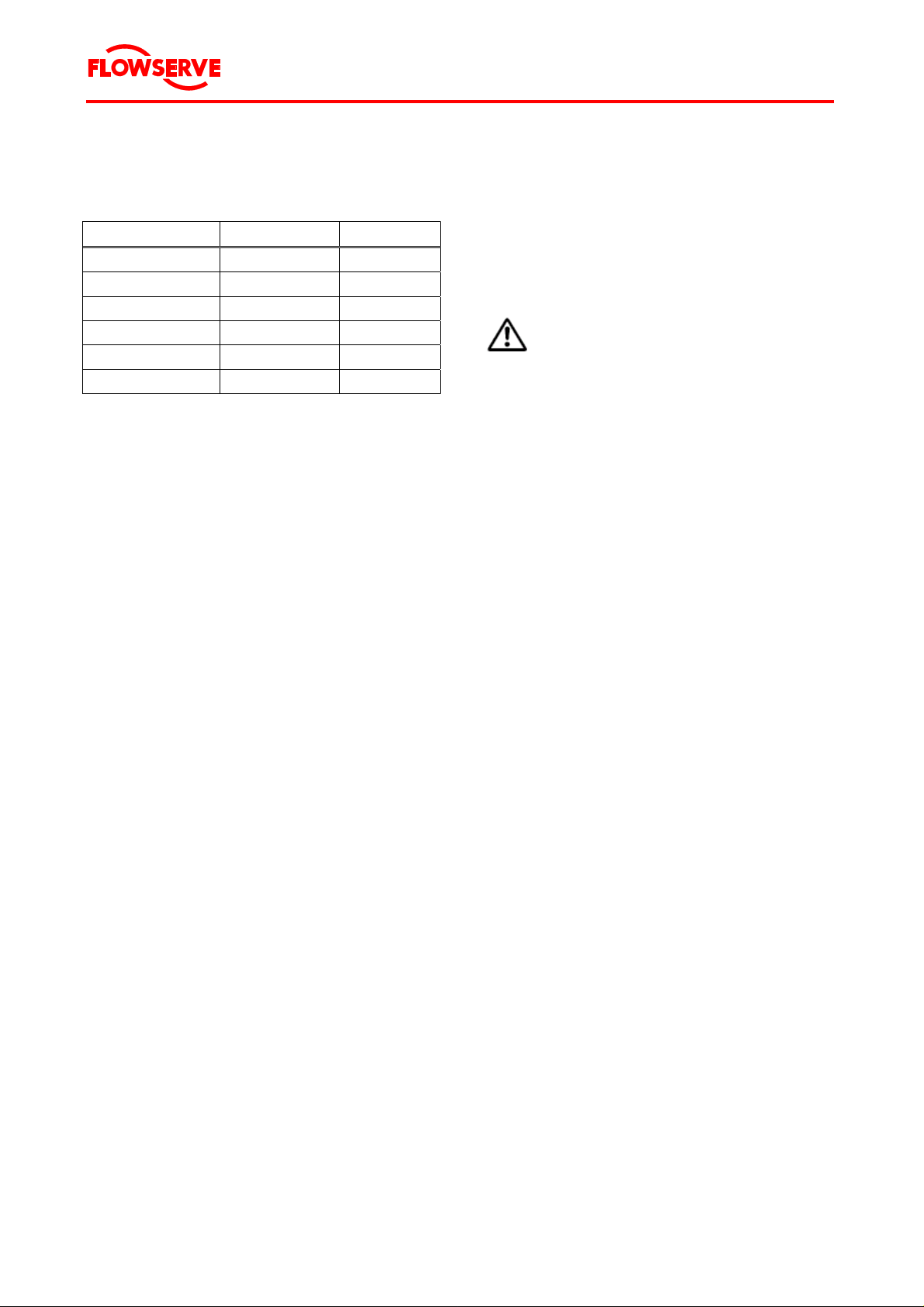

With variations in voltage, the motor characteristics

will, in general, vary as given in Table 2.

Voltage 110 % 90 %

Speed Increase 1 % Decrease 1.5 %

Efficiency (full load) Increase 0.5 % Decrease 1 %

Power factor (full load) Decrease 3 % No change

Current (starting) Increase 11 % Decrease 11 %

Current (full load) Decrease 8 % Increase 11 %

Temperature Decrease 2 % Increase 5 %

Table 2 Motor characteristics at varying voltage

Rated or full load current refers to the amperage

drawn by the motor at nameplate output, frequency

and voltage at the motor terminals. The maximum

allowable current (except momentarily at start-up)

is 110 % of the rated value.

The voltage on all three phases should be evenly

balanced as closely as can be read on the usually

available commercial voltmeter, because the current unbalance will be in the order of 6 to 10 times

the voltage unbalance. Running the motor with the

unbalanced voltage will lead to increased temperature and decreased motor life time, and therefore

must be avoided.

The value given in Chapter 12.2 "Data sheet", is a

standard value for the operating point. If the actual

operational current in the operating point of the

pump bowl assembly lies under this given value,

the switch must be adjusted lower so that there is

effective protection and malfunctions can be indicated in time.

DANGER

Do not set the motor protection ad-

justment higher than the highest permissible value given in Chapter 12.2

"Data sheet".

Do not test the perfect functioning o

a motor protection switch by intentional single-phasing.

3.5.3 Short circuit protection

To prevent short circuiting of the power cable and

the motor, safety measures must be taken according to local ordinances.

Guide values for the safety fuse sizes can be taken

from Chapter 12.2 "Data sheet".

Poor voltage regulations of an engine-driven generator, if the power is derived from such a source,

can be very disadvantageous to the motor. Thus,

Flowserve assumes no responsibility for pumping

units operated on such equipment unless agreed

on in writing.

Also, because of the unpredictable characteristics

and past experiences associated with the use of

phase converters, Flowserve must void all guarantees for applications that incorporate these devices

as a means of obtaining three phase power.

3.5.2 Motor protection

To protect the motor against power overload, an

inverse time-lag overload relay must be provided,

sensitive to phase failure and which compensates

for temperature.

The over current relay for the switchgear and the

safety fuses can be adjusted or selected according

to Chapter 12.2 "Data sheet".

The adjustment of the motor protection switch

(thermally delayed over current relay) must be

done according to the value given in Chapter 12.2

"Data sheet".

Page 18 of 68

Page 19

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4 INSTALLATION AND UNINSTALLA-

TION

4.1 Fitter

It is recommended that the services of Flowserve

be employed for the installation and initial starting

of a Byron Jackson pump.

Such service will ensure the purchaser that the

properly installed, and will provide an

equipm

ent is

excellent opportunity for the plant operator to receive special instructions relative to the pumping

unit.

4.2 Equipment and personnel re-

quired

4.2.1 Equipment and tools supplied with mo-

tor

Equipment and tools supplied with motor and

half coupling

• Hex so

(806-2)

• Hex socket wrench for coupling set screw

(806

• Hex socket wren

• Hex socket wren

cket wrench for shaft button screw

-1)

ch for vent plug (806-4)

ch for vent plug (806-5)

4.2.2 Equipment and tools to be supplied by

opera

tor

Provide the followin

g equipment and tools:

• Lifting Equipment.

Must be of sufficient strength and rigidity to lift

the com

lete unit safely, see Table 3,

p

Page 20, and of sufficient height to allow

clearance between load hook and foundation.

For weight see Chapter 12.2 "Data sheet".

• Two pai

rs of corre

• One correc

• One correc

tly sized column U-plate

tly sized motor U-plate (see Figure

ctly sized pipe elevators

5, Page 21 and Table 4, Page 21)

• One 1.2 - 1.8 m (4 - 6 feet) section of column,

thread

ed and coupled, to be attached to the

top case and used for handling the pump bowl

assembly.

Deduct this length from total column length

specifications.

• Colum

n

A supply of pipe, in random lengths, threaded

and

pled, of correct size to handle the unit

cou

capacity and total weight and of adequate

length to set the unit at the correct pumping

level in the well. The threading is 8 threads

per 25 mm (1 inch) and 19 mm (0.75 inch) taper per foot.

• Aligning jig as

sembly, including the following

parts:

- Shim, shaft adjusting (262-6)

- Shim, shaft adjusting (262-7)

- Button, thrust (130)

- Screw, thrust Button (806-2)

- Washer, coupling lock screw (690-4)

- Screw, coupling lock (806-3)

- Aligning jig (265)

- Coupling, driver (529)

- Key, coupling (676-1)

- Screw, set, coupling (806-1)

• One pai

r of cable re

el stands, with axle

• One portable insulation resistance tester

("Megg

• One clamp

er"), 0 - 100 MΩ / 1000 Volts

-on ammeter

• One volt/ohmmeter

• Components for water level indicating system

• Special ba

nding tool ("Band-it") for cable

bands

• A length of 1.27

cm (0.5 inch) hemp rope and

a cable installation wheel. Diameter must be

at least 14 times cable outer diameter.

• Ordinary hand tools (mechanical and electrial) used in this kind of work

c

• Two sets of chain tongs

• Rubber mat and insulated gloves for electrical

work in da

mp conditions

Page 19 of 68

Page 20

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

• An adequate supply of approved thread compounds, as follows

- For installation of the short section of col-

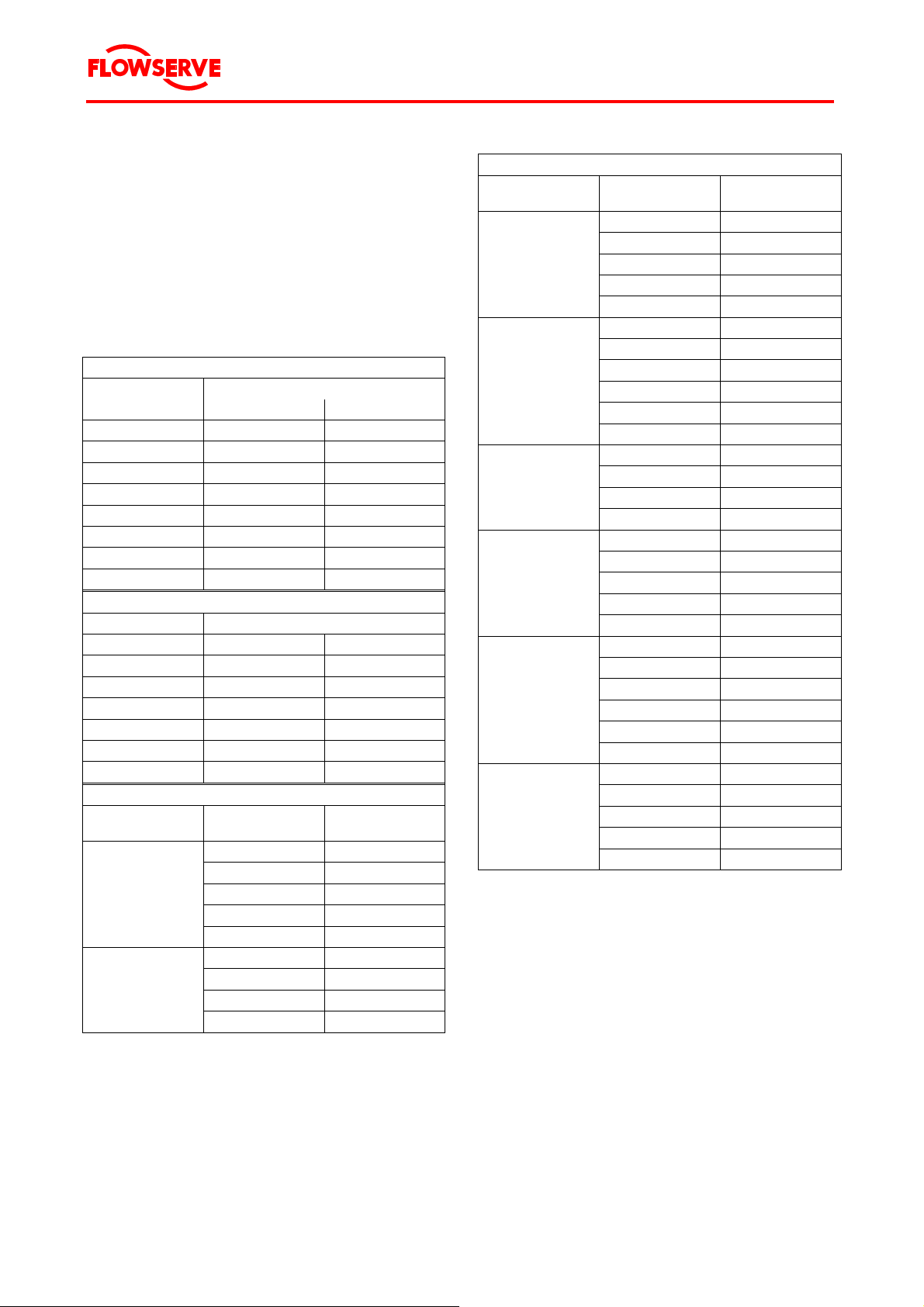

Motors

Nominal motor

size

umn pipe, next to top case or top case

flange, use only Loctite 277 (Red) &

Primer T or equal.

- For remaining column pipe threads, use a

8"

pipe thread compound that is capable of

lubricating and sealing.

Column

Size Weight per foot in kg (pounds)

Empty Full

2-1/2 2.6 (5.8) 3.6 (7.9)

3 3.4 (7.6) 4.9 (10.8)

4 4.9 (10.9) 7.4 (16.4)

5 6.7 (14.8) 10.7 (23.5)

6 8.7 (19.2) 14.4 (31.7)

8 11.3 (25.0) 21.4 (47.2)

10 14.5 (32.0) 30.2 (66.6)

12 20.4 (45.0) 42.6 (93.9)

Bowl Slumps

Size Weight in kg (pounds)

1

8MQ 36 (80) 7 (15)

10MQ 79 (175) 17 (37)

11MQ 132 (290) 32 (70)

12MQ 200 (440) 57 (125)

13MQ 284 (625) 79 (175)

15MQ 386 (850) 120 (265)

Cable

Volts Size Weight per foot

600

5000

st

Stage Additional Stage

in kg (pounds)

8 0.14 (0.30)

4 0.35 (0.77)

2 0.50 (1.10)

300MCM 2.00 (4.40)

500MCM 3.08 (6.80)

6 0.41 (0.90)

2 0.54 (1.20)

1/0 1.00 (2.20)

4/0 1.54 (3.40)

10"

12"

14"

17"

21"

Table 3 Component weight chart for calculating

foundation, derrick and hoist loads

Horsepower Weight

in kg (pounds)

7-1/2 211 (465)

10 211 (465)

20 227 (500)

25 249 (550)

30 249 (550)

40 431 (950)

50 431 (950)

60 458 (1 010)

75 458 (1 010)

100 490 (1 080)

125 553 (1 220)

125 915 (2 018)

150 953 (2 100)

175 1 002 (2 210)

200 1 027 (2 265)

125 1 170 (2 580)

150 1 288 (2 840)

200 1 424 (3 140)

250 1 485 (3 273)

300 1 485 (3 273)

300 1 690 (3 725)

350 1 860 (4 100)

400 1 928 (4 250)

450 1 996 (4 400)

500 1 996 (4 400)

600 2 087 (4 600)

600 1 950 (4 300)

800 2 359 (5 200)

1 000 2 767 (6 100)

1 200 3 221 (7 100)

1 500 3 720 (8 200)

Page 20 of 68

Page 21

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

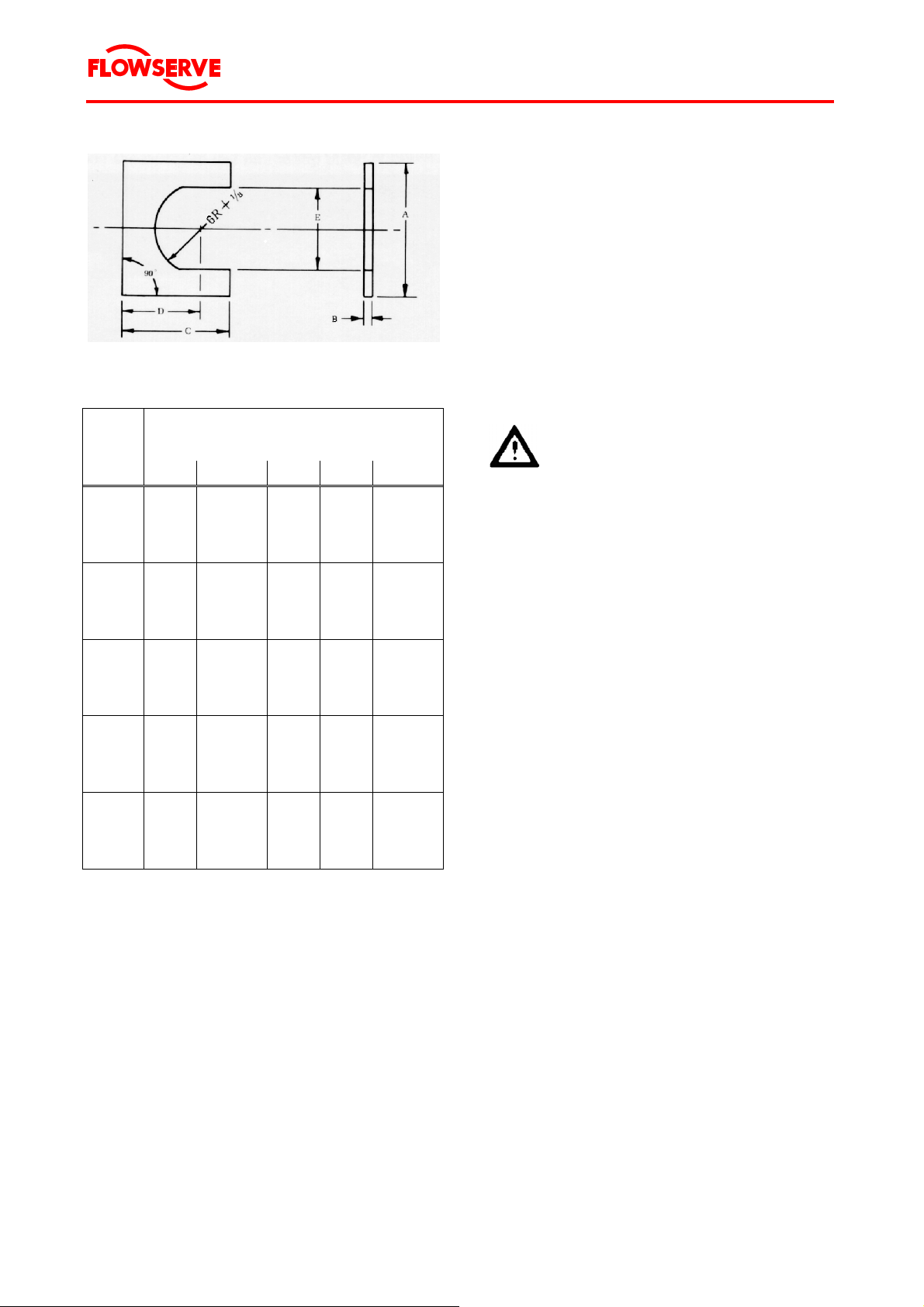

Figure 5 Motor U-plate

Nominal

motor

size

A B C D E

8" 38.10

10" 40.64

12" 45.72

14" 50.80

21" 91.44

Table 4 Motor U-plate chart

Dimensions in cm

(inches)

(15)

(16)

(18)

(20)

(36)

0.95 +

0.32

(0.375 +

0.125)

0.95 +

0.32

(0.375 +

0.125)

1.27 +

0.32

(0.500 +

0.125)

1.27 +

0.32

(0.500 +

0.125)

1.27 +

0.32

(0.500 +

0.125)

25.40

(10)

30.48

(12)

35.56

(14)

35.56

(14)

73.66

(29)

25.40

(10)

25.40

(10)

25.40

(10)

25.40

(10)

53.34

(21)

14.61 +

0.32

(5.750 +

0.125)

18.10 +

0.32

(7.125 +

0.125)

19.05 +

0.32

(7.500 +

0.125)

24.77 +

0.32

(9.750 +

0.125)

42.57 +

0.32

(16.760

+ 0.125)

4.2.3 Personnel required

Flowserve recommends that 2 persons plus 1

crane operator perform the installation or uninstallation procedure.

4.3 Hydraulic connection

Exemplary construction of a water supply system is

depicted in Figure 6, Page 22. As this shows a basic arrangement, the actual layout must be suited

to local and technical conditions.

DANGER

All work on the hydraulic connec-

tion may only be done by qualified

fitters.

Page 21 of 68

Page 22

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

Figure 6 Scheme of water supply system

Page 22 of 68

Page 23

®

f

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4 Installation

4.4.1 Safety instructions

DANGER

Before starting any installation work

or removing any parts of the pumping unit, read Chapter 1.6 "Safety",

Page 6.

Tighten all screws in accordance

with Chapter 12.3 "Tightening

torques".

4.4.2 Sequence of installation

Perform the installation in the following order:

1. Prepare installation site, see Chapter 4.4.3,

Page 23.

2. Arrange components for installation, see

Chapter 4.4.4, Page 24.

3. Inspect components, see Chapter 4.4.5,

Page 25.

4. Install motor, see Chapter 4.4.6, Page 26.

5. Install coupling, see Chapter 4.4.7, Page 27.

6. Install pump bowl assembly, see Chapter 4.4.8, Page 30.

7. Install impeller, see Chapter 4.4.9, Page 32.

8. Vent motor, see Chapter 4.4.10, Page 33.

9. Install power cable, see Chapter 4.4.11,

Page 35.

10. Fasten the power cable to the cable guard,

see Chapter 4.4.12, Page 39.

11. Install riser pipe, fasten power cable to riser

pipe, see Chapter 4.4.13, Page 40.

12. Connect power cable to terminal box, see

Chapter 4.4.14, Page 43.

13. Connect terminal box to main power supply,

see Chapter 4.4.15, Page 43.

4.4.3 Prepare installation site

1. Verify that the wellhead foundation is poured

and cured, if made of concrete.

The total load on the wellhead foundation will

consist of the motor, pump bowl assembly,

riser pipe (full of water), wellhead assembly

and power cable. See Chapter 12.2 "Data

sheet", for weights.

2. Verify that open discharge run-off, ditch, etc.

for flushing out well and testing unit is provided for.

3. Verify that a log of the well recording depth,

straightness, casing variations, standing water

level, rated capacity, pumping level, etc., is at

the installation site.

4. Ensure that the well diameter is large enough

down to the installation depth so that the

pumping unit can be fitted without difficulties.

See Chapter 3.4.1 "Survey of well", Page 16.

5. Check the dependability of auxiliary equipment, particularly of hoists.

6. Compare the information in Chapter 12.2

"Data sheet" with that on the rating plate on

the motor.

7. Ensure that the line voltage (measured between two phases) is equal to the motor voltage according to the rating plate.

The maximum permissible voltage fluctuation

is given in Chapter 12.2 "Data sheet".

Greater voltage and frequency fluctuations

must be reported to Flowserve and be confirmed by Flowserve in written. In case of

doubt, ask Flowserve before starting up the

pumping unit.

8. Measure the insulating resistance of the motor

according to Chapter 6.8.1 "Insulation test",

Page 53.

CAUTION If the ascending riser pipe is made

of flanged pipes, the flanges must

have recesses for the power cable i

the well diameter is narrowly proportioned.

Page 23 of 68

Page 24

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.4 Arrange components fo r installation

Figure 7 Components arranged for installation

Refer to Figure 7. An orderly arrangement of subassemblies will reduce the installation time.

1. Lay out the parts in order of installation, as

follows:

• Motor

Arranged horizontally.

• Pump bowl assembly

Uncrated and arranged horizontally.

• Riser pipes

Place all riser pipe sections with coupling

end toward the well.

Check couplings with chain tongs to

make sure they are screwed tight.

Place riser pipe check valve sections so

that each will be installed in the proper

sequence.

• Power cable

• Wellhead

• Tools for installation, see Chapter 4.2

"Equipment and personnel required",

Page 19.

• U-plate

2. Record the complete motor serial number

from the motor, see Chapter 3.1.3 "Motor serial number", Page 14.

NOTE Make sure you can always quote each

part's serial number in correspondence and when ordering spare parts

or further accessories.

3. Check motor rating, horsepower, poles, volts,

and frequency against job requirements.

Page 24 of 68

Page 25

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.5 Inspect components

1. Remove the nuts (003-3) and lock washers

(690-3) to remove the motor terminal shipping

cap (112), and gasket (747-10).

2. Verify that motor terminal gland plate (111)

and power terminals (019) are clean and free

of dirt and foreign matter.

3. Megger the motor for ground and continuity

(see Figure 8).

The reading should be 10 MΩ or more.

Figure 8 Megger test

4. Remove the shipping cap from the power cable terminal box.

5. Verify that the terminal box and connectors

are clean and free of dirt and foreign matter.

6. Verify that the power terminals (019) at the

motor will fit the connectors of the terminal

box:

• Refer to Figure 9.

Check position of power terminals (019)

against that of connectors.

The terminals (019) and connectors may

be arranged in either an equilateral triangle or a right triangle positioning.

• Check height of terminal against depth of

connector to assure proper engagement.

Figure 9 Arrangement of terminals

7. Mount motor power terminal shipping cap

(112), gasket (747-10), lock washers (690-3)

and nuts (003-3).

8. Reinstall power cable shipping cap.

9. Verify that all riser pipe threads are clean and

free of dirt and foreign matter.

Page 25 of 68

Page 26

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.6 Install motor

Transport the motor to the well site, see Chapter

2.2.3 "Transport of the motor", Page 10.

Never step under floating load.

Watch for and avoid overhead ob-

structions including power lines.

1. Install motor U-plate on foundation.

Use to 2 persons to install the

U-plate.

Handle the U-plate carefully.

Danger of injury by dropping the

U-plate onto parts of the body.

2. Cover the U-plate and foundation with a tarpaulin.

3. Orient the motor horizontally so that the terminal shipping cap is on top.

Remove motor shipping cap (112-1), power

terminal gasket (744-6), nuts (003-8), and lock

washers (690-5). Some oil may be present in

the shipping cap.

Be certain to put the power terminal gasket

(744-6) in a safe area until it can be stored in

the motor shipping cap (112-1).

NOTE The power terminal gasket is not

used in the unit assembly.

Then remove the tools and the power terminal

gasket (744-10) from the power terminal shipping cap.

4. Reinstall motor shaft shipping cap (112-1),

nuts (003-8), and lock washers (690-5).

5. Lift the motor as described in Chapter 2.2.3

"Transport of the motor", Page 10.

6. Slowly elevate the motor to vertical position.

7. Center the motor over the well casing opening.

8. Lower the motor to rest on the U-plate.

Refer to Figure 10.

Figure 10 Motor in place on U-plate

9. Remove motor shipping cap (112-1), nuts

(003-8), and lock washers (690-5).

10. Cover coupling (529 or 531) and shaft with a

clean cloth.

The motor is now ready to receive the coupling.

Page 26 of 68

Page 27

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.7 Install coupling

NOTE Not all components or sub-

assemblies of a pumping unit are

neces

sarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the c

omponen

ts or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

The coupling between motor and pump bowl as-

nds on the type of pump bowl assem-

sembly de

pe

bly delivered.

Flowserve manufactures two coupling variants for

the Byron Ja

ckson Doubl

• Variant A: Motor half coup

• Variant B: One-pie

e Mechanical Seal Motor:

ling

ce coupling

Both are described in the following. See Chapter

12.1 "Sco

of delivery" to determine the coupling

pe

delivered and follow the respective instructions.

Variant A: Motor half coupling

1. Motor half coupling is factory installed. Refer

to Figure 11

.

washers (690-4), shaft button screw (806-2)

and shims (262-6 and 262-7).

7. Remove string from shaft button screw

) which holds shim in place.

(806-2

Verify that the shims (262-6 and 262-7) are

attach

ed to the screw (806-2).

8. Install alignment jig assembly in motor half

pling (265

cou

).

9. Install cap screw (806-2) and use wrench pro-

vided to tighten screw (80

6-2).

10. Remove the coupling lock screws (806-3) and

a

shers (690-4).

w

Set these pieces aside for later use (see

p

ter 4.4.8 "Install pump bowl assembly",

Cha

Page 30).

11. Remove alignment jig (265) and hold for stor-

ping cap (112-1).

age in moto

r ship

12. Clean the motor flange face of any dirt or for-

eign matter.

Verify that the balance line hole in the flange

pen

face is o

and clear.

13. Cover the coupling (529) and shaft with a

n cloth.

clea

The m

otor is now ready to receive the pump bowl

assembly.

2. Clean coupling and shaft, and lightly oil both.

3. Slip coupling on shaft with keyways aligned.

NOTE Do not attempt to force the cou-

pling.

If the coupling will not seat freely:

- remove the coupling

- verify that the shaft is free of dirt

and foreign matte

r

- replace the coupling.

4. Insert key (676-1), round end down, in the

key

w

ay.

5. Install socket head set screw (806-1) through

in th

its hole

e coupling (529) to engage its

hole in the shaft.

Use wrench provided to tighten set screw

).

-1

(806

6. Identify the shaft adjusting button (130),

alignmen

t jig (265), screws (806-3) with

Page 27 of 68

Page 28

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

Figure 11 Motor half coupling components

Page 28 of 68

Page 29

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

Variant B: One-piece coupling

See Figure 12.

1. Clean the coupling (531) and shaft and lightly

oil both.

2. Identify the thrust button (130), thrust button

screw (806-2) and shaft adjusting shims

(262-6 and 262-7) as required. These pieces

are factory installed.

3. Insert key (676-1), round end down, in the

keyway.

4. Slip coupling (531) on shaft with keyways

aligned.

CAUTION Do not force the coupling.

If the coupling will not seat properly, again verify that shaft and

coupling are clean.

5. Install the coupling pins (697) into the coupling holes and the thrust button.

The thrust button may need to be rotated to

align holes.

Install the coupling lock screws (806-6), flat

washers (004-1), a nd lock washers (6 90-6) to

secure the pins in the coupling.

6. Tighten the thrust button socket head screw

(806-2).

7. Rotate the motor shaft and coupling until the

pin holes on the coupling are pointed 90 °

from the power terminal shipping cap.

This aligns pin holes in coupling with adapter

bracket to allow pump coupling pin (697-1) to

be installed later. Also see Figure 12.

8. Clean the motor flange face of any dirt or foreign matter. Verify that the balance line hole is

open and clear.

9. Cover the coupling (531) and shaft with a

clean cloth.

Figure 12 Components for one-piece coupling

The coupling is now ready to receive the pump

bowl assembly.

Page 29 of 68

Page 30

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.8 Install pump bo wl assembly

NOTE Not all components or sub-

assemblies of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the components or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

Lift pump bowl assembly

Never step under floating load.

Watch for and avoid overhead ob-

structions including power lines.

NOTE The following description refers to

pumps without auxiliary carriers.

The motor hangs in the well on the U-plate.

1. Disassemble discharge housing or non-return

valve from the pump bowl assembly.

2. Install the discharge housing or non-return

valve in the short section of riser pipe.

Additional information for threaded riser pipes:

a. Clean the mating pipe threads of the pipe

and the case or flange as shown in

Figure 13.

Should the pump be delivered on an

auxiliary carrier, refer to the pump

manual for lifting instructions.

To transport the pump bowl assembly to the well

site see Chapter 2.2.4 "Transport of the pump bowl

assembly", Page 11.

1. Connect the pump to two lifting lines of a

portable crane.

The attachment points may vary according to

pump type and local requirements.

2. Carefully lift the pump to a vertical position

over the well head.

Install pump bowl assembly

The riser pipes are connected among each other

by

• threads or

• flanges.

Figure 13 Cleaning riser pipe threads

b. Apply thread locking fluid, e. g. Loctite

242 or DELO 5249/5349 or equivalent, to

the threads as shown in Figure 14.

Figure 14 Applying thread locking fluid

Page 30 of 68

Page 31

®

r

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

c. Install the pipe using chain tongs.

Figure 15 shows the proper method of

applying chain tongs to the flange.

Thereby most of the force is exerted on

the upper flange rather than the on the

discharge housing or the non-return

valve.

Apply torque approximating the values

given in Table 5.

CAUTION The discharge section may require

modification to provide protective

clearance to the flat cable and

splice which will be mounted late

on the riser pipe just above the

pump.

3. Mount the first length of the riser pipe, which

should not be longer than 0.5 m, onto the assembled pump bowl assembly.

4. Remove the cable clamps or cable guard from

the pump bowl assembly.

5. Remove the cloth from the coupling.

6. Lift the pump bowl assembly above the motor.

7. Check the end float settings that are preadjusted by Flowserve.

Figure 15 Proper method of applying chain tongs

Pipe Torque Torque

Size [Nm] [ft-lbs]

2-1/2 620 500

3 950 700

4 1 220 900

5 1 425 1 050

6 1 625 1 200

8 2 170 1 600

10 2 710 2 000

12 4 070 3 000

Table 5 Torque for riser pipe assembly

Page 31 of 68

Page 32

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.9 Install impeller

NOTE Not all components or sub-

assemblies of a pumping unit are

necessarily supplied by Flowserve

or part of this delivery.

These user instructions apply only

to the components or subassemblies supplied by Flowserve

in this delivery, see Chapter 12.1

"Scope of delivery".

Flowserve manufactures two impeller variants for

the Byron Jackson Double Mechanical Seal Motor:

Figure 16 Verify end float

• Variant A: Closed impeller

• Variant B: Open impeller

Both are described in the following. See Chapter

12.1 "Scope of delivery" to determine the coupling

delivered and follow the respective instructions.

Variant A: Closed impeller

1. Refer to Figure 16.

Scale from the face of the adapter bracket

(808) to the end of the pump shaft (167) with

the shaft down.

2. Remove adapter bracket (808) from bowl assembly.

3. Install adapter bracket (808) on motor top

flange, using fasteners for motor shipping cap

(112-1).

4. Scale from the face of the motor top case

(076) to the face of the shaft adjusting button

(130).

5. The distance recorded in step 1 should be

3.175 mm to 6.350 mm (1/8" to 1/4") less than

that of step 4.

Variant B: Open impeller

1. Remove adapter bracket (808) from bowl assembly.

2. Install adapter bracket (808) on motor top

flange, using fasteners from motor shipping

cap (112-1).

3. Remove the pump half coupling (530) or onepiece coupling (531).

4. Provide four pieces of shim stock, each

(50.8 mm x 50.8 mm x 0.508 mm (2" x 2" x

0.020") thick, and place each shim 90 degrees

apart on the face of the adapter bracket.

5. Lower the pump bowl assembly into the

adapter bracket (808) to rest on the shims.

6. Put a feeler gauge through the plug opening

in the adapter bracket (808) and check the

gap from shaft adjusting button (130) to pump

shaft (167).

7. If gap, step 6, is less than 0.0381 mm (0.015")

or more than 0.4572 mm (0.018"), the shims

beneath the shaft button (130) must be

changed.

8. Reinstall the pump half coupling (530) or onepiece coupling (531).

Page 32 of 68

Page 33

®

r

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

4.4.10 Vent motor

1. Remove the oil vent plugs (806-4) and (806-5)

in the flange located at the power terminals

and 90° or 180° from the power terminals.

Add oil into the adapter bracket as shown in

Figure 17. See Chapter 12.2 "Data sheet",

Page 65, for oil quality.

NOTE Do not add more than two full moto

shipping caps' amount of oil during

the venting process. The oil level in

the motor will then rise and expel

any air in the upper case cavity.

Figure 18 Removing vent plug

Figure 17 Adding oil

2. Continue to add oil until bubble free oil flows

from the vent located near the power terminals.

Reinstall vent plug (806-4). Refer to Figure

18.

Continue to add oil until bubble free oil flows

from the vent located 90° or 180° from the

power terminals.

Reinstall vent plug (806-5) and tighten to

27 Nm (20 foot pounds). Refer to Figure 18.

Figure 19 Reinstalling vent plug

3. Remove oil vent plug next to power terminals

(806-4) and again check for bubble free oil.

Reinstall vent plug (806-4) and tighten to

27 Nm (20 foot pounds).

4. Place power terminal shipping cap (112-2),

power terminal gasket (744-7), jig (265), hex

socket wrenches (806-1, 806-2, 806-4, and

806-5), and power terminal gasket (744-6)

into the motor shipping cap (112-1).

Send to storage.

The motor is now ready to receive the pump

bowl assembly.

6. Verify that the pump half coupling (530) or

one-piece coupling (531) is securely locked in

place

- by the coupling pin (697-1) and retainer

ring (526) on pump half coupling or

Page 33 of 68

Page 34

®

Byron Jackson Double Mechanical Seal Submersible Pumping Unit • 1042.293/9 • June 04

- by the coupling pin (697-1) and the retainer

screws (806-6), flat washers (004-1), and

lock washers (690-5) on the one-piece

coupling.

Also verify that the coupling bore and motor

shaft are clean and free of dirt and foreign

matter.

7. Refer to Figure 20.

Lower the bowl assembly to engage

- the jaws of the pump half coupling (530)

and those of the motor half coupling (529)