Page 1

Automax BUSwitchTM – Profibus-DP

Flowserve Corporation

Flow Control Division

Installation, Operating & Maintenance Instructions

Electronic Printed Circuit

Board Specifications

Power requirements

XA0231 Profibus-DP

Interface Card

Temperature

Operational

† To operate, an external 24 VDC source must be locally

supplied to the interface card.

†

Storage

- 675 mA max with

solenoid activated.

-40 °F to +185 °F

(-40 °C to +85 °C)

-40 °F to +250 °F

(-40 °C to +120 °C)

Principles of Operation

Flowserve’s BUSwitch is a valve automation and

control product that uses the Profibus-DP

communication protocol to operate and monitor

position as well as provide predictive and

preventative maintenance functions. In response to

a command from the operator, the BUSwitch

energizes the appropriate solenoid valve, which

shifts a spool valve, directing the pneumatic force to

the appropriate actuator port, thereby operating the

valve actuator.

solenoid coil is mounted internal to the BUSwitch

housing to protect it from the environment. A 4-way

spool valve is bolted externally to the housing. The

fail direction of the actuator can be established

based on which set of terminals (open or closed) the

solenoid coil is connected to. For dual coil

operation, externally mounted solenoid valves must

be used as the housing will not accommodate two

internal coils. Upon reception of an open or close

command, a timer is started whose value is

compared to a user-defined setpoint for that

particular operation. If this timer value exceeds the

setpoint, an alarm is sent back to the control

operator to indicate a possible problem exists at the

valve. In addition, an odometer counter totals the

number of transitions the valve has made, which is

then compared to a user-defined limit. If this limit is

exceeded an indication is sent back to the control

operator. The odometer limit can be reset by the

control operator after maintenance has been

performed. During operation the valve status (open,

closed or in-transit) is continuously available to the

control operator. The Profibus-DP Interface Board

(XA0231) requires 24 VDC at 175 mA maximum.

For single coil operation, the

765 South 100 East

Provo, Utah 84606

www.flowserve.com

24 VDC

Email: actuators@flowserve.com

Phone: 801 373 3028

Facsimile: 801 489 2228

Profibus

Information

Manufacturer

Device

GSD File AMAX0867.GSD

Firmware

Revision

Transmission

GSD file supplied on diskette included with every

device.

ID 0867 (Hex)

Speed

12 MBaud maximum

Current consumption with a solenoid activated will

be the sum of the solenoid current plus 175 mA.

Mechanical Installation

Installation is best performed with Flowserve

NAMUR mounting kits. These kits allow direct

mounting of the BUSwitch shaft to the actuator

pinion without a coupler. The NAMUR mounting kits

will work with any actuator conforming to the

NAMUR standard for accessory mounting hole

locations and pinion dimensions. Simply attach the

bracket to actuator and BUSwitch to the bracket with

the included fasteners. The BUSwitch shaft features

an integral alignment pin that engages the tapped

pinion hole. Flowserve also offers a full line of nonNAMUR kits.

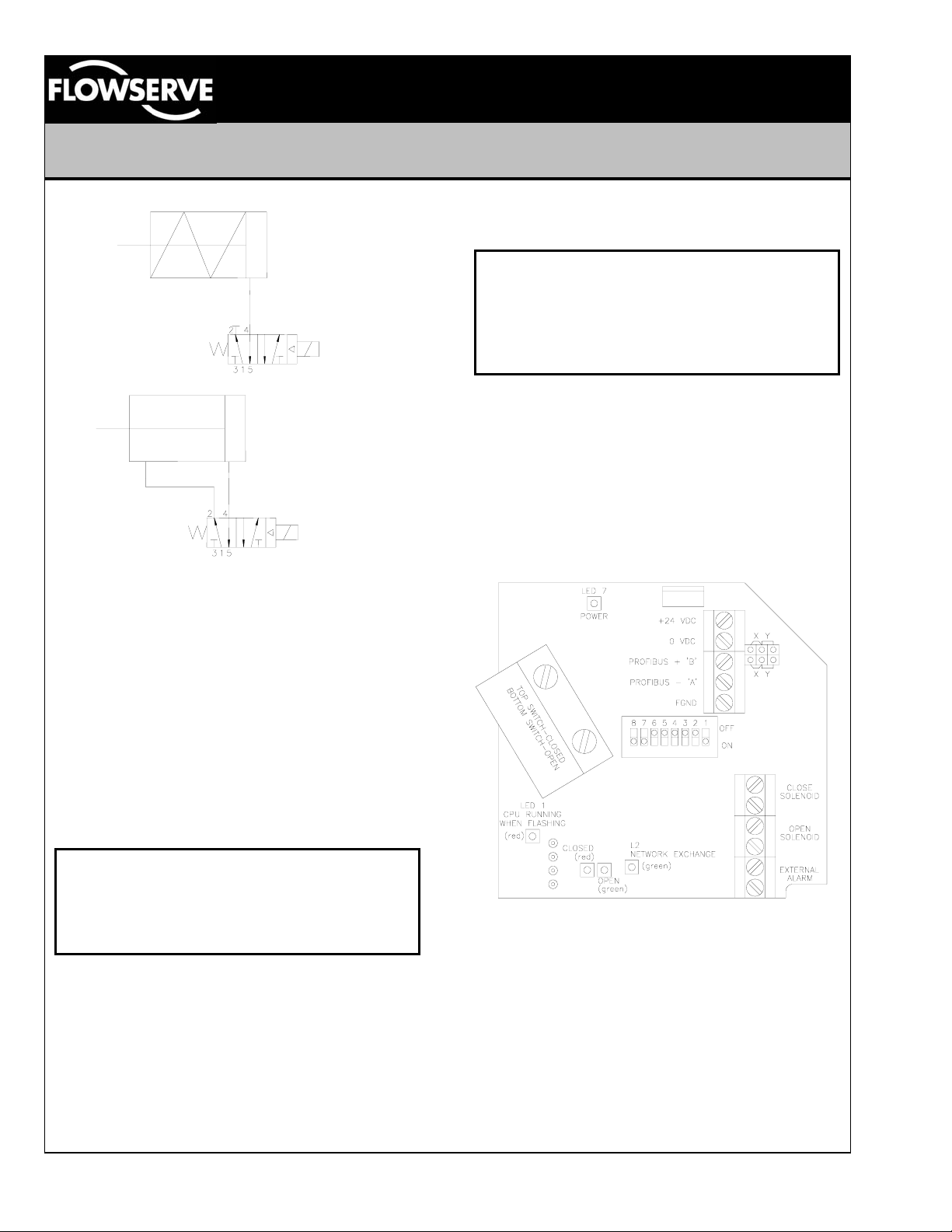

Spool and Tubing Configuration

1. For spring return actuators, a 4-way spool valve

is provided with port #2 plugged. For double

acting actuators, the same valve is provided with

no plugs. Make sure the correct spool is

selected before installing tubing. (Note: the

Flowserve APS2 purge module can be supplied

on spring return actuators to purge the spring

chamber with supply air.)

2. Make sure all air pressure is removed before

installing tubing.

3. Attach tubing according to Figures 1 or 2 below,

depending upon application. Attach supply

tubing to Port 1 and use 3 and 5 for exhaust.

4. To prolong actuator life use only clean, dry plant

air. Lubricated air is not required, although it is

recommended, particularly for high cycle

applications.

1.13

LML0012-0 8/99 Page 1 of 6

©1999, Flowserve Corporation, Provo, Utah

Page 2

Flowserve Corporation

Flow Control Division

Automax BUSwitchTM – Profibus-DP

765 South 100 East

Provo, Utah 84606

www.flowserve.com

Email: actuators@flowserve.com

Phone: 801 373 3028

Facsimile: 801 489 2228

Figure 1

Figure 2

Lubrication

All BUSwitch™ spool valves are pre-lubricated and

will operate dry (with no additional lubrication). The

use of lubricated air will not interfere with the

BUSwitch’s functioning. If air lubrication is used, the

oils listed below are popular, easily obtainable, fluids

that are recommended for use with the BUSwitch

spool valve: Gulf Harmony 47, Mobil DTE Medium,

Shell Tellus 29, Texaco Rondo B, Sohivis 47 and

Sunnis 921. Many other lubricants are acceptable

providing they do not contain detergents that will

attack Buna-N or Viton Seals.

Electrical Connections

marked ‘OPEN’ and ‘CLOSE’. External power (24

VDC) is connected to the indicated location.

CAUTION

BE SURE TO OBSERVE CORRECT POLARITY

OF THE EXTERNAL POWER CONNECTIONS

OR DAMAGE TO THE PRINTED CIRCUIT

BOARD WILL OCCUR!

A ‘dry-contact’ device can be connected to the

terminals marked ‘EXTERNAL ALARM’, the

meaning of which is determined by the customer.

Refer to figure three. The data cable connection is

made to the locations marked PROFIBUS + B and

PROFIBUS – A, observing polarity. If this is the last

device on the segment, move the shorting jumpers

to the Y position to enable the termination resistor.

Refer to figure three for data cable connection

locations.

CAUTION

To prevent ignition of hazardous atmospheres,

keep cover bolts tight while circuits are live.

Disconnect supply circuit before opening.

Entry into the BUSwitch housing is made through

three ½” NPT conduit entries. All electrical

connections (power, data, external alarm, open and

close solenoids) are made to captive screw cage

terminal strips located on the Profibus-DP Interface

board (XA0231). BUSwitch models with an internal

pilot valve will have the valve connected to the

appropriate circuit board terminals by the factory.

For dual solenoid applications, connect the

respective solenoids to the terminal strip locations

For hazardous locations, Underwriters Laboratories

(UL) and the National Electric Code (NEC) require

an approved sealing fitting within eighteen inches of

the switch enclosure. Sealing fittings are not

required for Division 2 non-incendive applications.

Open conduit entries must be closed after

installation using a close-up plug approved for

hazardous locations. Conduit and plugs must

engage a full five threads. Flowserve can provide

the sealing fitting with a union and junction box for

‘daisy chain’ wiring applications.

LML0012-0 8/99 Page 2 of 6

©1999, Flowserve Corporation, Provo, Utah

Profibus-DP Interface Card (XA0231)

Figure 3

Page 3

Flowserve Corporation

Flow Control Division

Automax BUSwitchTM – Profibus-DP

765 South 100 East

Provo, Utah 84606

www.flowserve.com

Email: actuators@flowserve.com

Phone: 801 373 3028

Facsimile: 801 489 2228

Special notes on the fieldbus cabling.

Due to the high-speed communication capability of

Profibus-DP networks, it is important to follow

established specifications closely to ensure full

communication capability. Governance of the

physical level requirements is specified in the

European Norm EN50170: "General Purpose Field

Communication System.” To obtain the maximum

communication capability it is highly recommended

to only use type ‘A’ cable as defined in table one

below. As a rule, data speed and maximum

segment length are inversely related. At 9.6 kBaud,

segment lengths up to 1200 meters are allowed. At

12 MBaud the segment length falls to 100 meters.

The following tables were obtained from The Rapid

Way to Profibus-DP by Manfred Popp; available

from the PROFIBUS Nutzerorganisation (PNO) as

order number 4.072. To order, contact the Profibus

Trade Organization (PTO) in your area.

Line Parameters

Line Type A Line Type B

Impedance (Ω)

Capacitance per

unit length (pF/m)

Loop resistance

(Ω/km)

Core diameter

(mm)

Core cross

section (mm

2

)

135 to 165 100 to 130

<30 <60

110 ---

0.64 >0.53

>0.34 >0.22

Table 1

Recommended Line Lengths

Transmission rate (kBaud) 9.6 19.2 93.75

Line Type A 1200 1200 1200

Line Type B 1200 1200 1200

Transmission rate (kBaud) 187.5 500 1500

Line Type A 1000 400 200

Line Type B 600 200 -

Transmission rate (kBaud) 1200

Line Type A 100

Line Type B -

Table 2

Adjustment of Switch Cams

1. Loosen five captive cover screws and remove

lid, turning slightly while lifting.

2. Place the actuator in the clock-wise (CW)

position and apply 24 VDC to the Profibus-DP

Interface Card.

3. Push down on the top cam (figure 4)

until it clears the splined coupler and

rotate clockwise until the CW LED (red)

is illuminated.

4. Release the cam and insure that it

fully engages the spline.

5. Place the actuator in the counterclockwise (CCW) position.

6. Pull up on the lower cam (figure 4)

until it clears its splined coupler and

rotate counter-clockwise until the

CCW LED (green) is illuminated.

7. Release the cam and insure that

it fully engages the spline.

Figure 4

8. Cycle the actuator to insure that

each LED is illuminated at the appropriate time.

Some minor readjustment might be necessary.

9. Clean base, lid flanges, and replace lid on base.

Make sure wires are NOT caught between

flanges, and tighten captive screws.

BUSwitch Configuration

Configuration of the BUSwitch is accomplished

through three main steps; physically connecting to

the network, setting the device address / operating

mode and sending operating parameters over the

Profibus segment. The physical connection to the

segment was covered previously in this document.

Setting of the device address and operating mode is

accomplished by a printed circuit board (PCB)

mounted switch assembly (refer to figure three).

The switch assembly has eight numbered positions,

each of which can be set to either ON or OFF.

Switch #1 sets dual coil operation when in the ON

position, or single coil operation when placed in the

OFF position. Switches 2 through 8 are used to set

the address of the BUSwitch on the Profibus

segment. The switches are a binary representation

of the address with switch number 2 being the most

significant digit and switch number 8 being the least

significant digit. The decimal value of each switch

when set to the ON position is as follows.

Switch # 2 3 4 5 6 7 8

Decimal Value 64 32 16 8 4 2 1

Table 3

LML0012-0 8/99 Page 3 of 6

©1999, Flowserve Corporation, Provo, Utah

Page 4

Flowserve Corporation

Flow Control Division

Automax BUSwitchTM – Profibus-DP

765 South 100 East

Provo, Utah 84606

www.flowserve.com

Email: actuators@flowserve.com

Phone: 801 373 3028

Facsimile: 801 489 2228

A simple algorithm that can be used to set the board

to a specific address is.

1. Put switches 2 through 8 into the OFF position.

2. Determine the address where the BUSwitch will

reside. This value will be known as the ‘target’

value.

3. Referring to Table 3, locate the switch with the

highest decimal value that is less than or equal

to the target value. Move that switch to the ON

position. For example if the target value is 33,

switch #3, with a decimal value of 32, would be

moved to the ON position.

4. Subtract the decimal value of the switch that

was just turned on from the target value. The

difference, if it is not equal to zero, will become

the new ‘target’ value. From the example

above, 1 will be the new target value (33-32=1).

5. Repeat steps 3 and 4 until the difference

between the switch value and the target value is

zero. Upon application of power to the board,

the address will be read from the switches.

Communication of the operating parameters to the

BUSwitch is accomplished by reading and writing of

six, 16-bit words. To ensure that the BUSwitch

sends and receives the correct data, all six words

should be read or written anytime one of the

parameters is changed.

Board Indicators

The Profibus-DP Interface Board (XA0231) contains

several indicators that are helpful when initially

configuring the device or when troubleshooting.

Refer to figure three for the locations of the

indicators.

BUSwitch Input Data Packet

Word

Bit→

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

LED 7 – Power Illuminated when 24 VDC is

present.

LED 1 – CPU Running When Flashing This

indicator will flash red approximately every 2

seconds to indicate that the microprocessor is

operating normally. If the indicator glows steadily or

does not come on, remove device power for 10

seconds and then reapply to reset.

L2 – Network Exchange This indicator will be

green when communication with the device is taking

place over the network.

Terminations

For proper communication to take place, each end

of the network segment must have terminators.

Terminators are resistive devices used to insure the

proper network impedance is maintained. In most

systems, one of the terminators will be located at the

PLC. The other terminator is located at the last

device on the segment. If the BUSwitch is the last

device on the segment, move the two jumpers on

the ‘X” locations over to the ‘Y’ locations to enable

the on board terminator. If the BUSwitch is located

within the center of the segment, the jumpers should

be set on the ‘X’ locations. Refer to figure five.

Figure 5

1

2

3

4

5

6

OP CL RS AL FA FO Reserved

Odometer Limit (Most significant word)

Odometer Limit (Least significant word)

Oneshot Duration ( 50 millisecond ‘ticks’ )

Valve Opening Response Timeout ( 50 millisecond ‘ticks’ )

Valve Closing Response Timeout ( 50 millisecond ‘ticks’ )

Table 4 – Input Data Packet

LML0012-0 8/99 Page 4 of 6

©1999, Flowserve Corporation, Provo, Utah

Page 5

Flowserve Corporation

Flow Control Division

Automax BUSwitchTM – Profibus-DP

765 South 100 East

Provo, Utah 84606

www.flowserve.com

Email: actuators@flowserve.com

Phone: 801 373 3028

Facsimile: 801 489 2228

OP (OPen) Changing this bit from a zero to a one

will result in the valve actuating to the open position

- only if the valve is in the closed position. If the

valve is currently in the ‘OPEN’ state, this bit will be

ignored. This bit is dependent on the value written

to the closed bit (CL). If CL contains a one when OP

is set to one, actuation will not occur until CL is

reset.

CL (CL

osed) Changing this bit from a zero to a one

will result in the valve actuating to the closed

position - only if the valve is in the open position. If

the valve is currently in the ‘CLOSED’ state, this bit

will be ignored. This bit is dependent on the value

written to the open bit (OP). If OP contains a one

when CL is set to one, actuation will not occur until

OP is reset.

RS (Odometer R

eSet) Setting this bit to a value of

one will result in the odometer counter being set to

zero subject to the following conditions:

1. RS is set to one

2. OP is set to zero

3. CL is set to zero

4. The odometer limit has all bits set to 1

5. No valve actuation is currently in process

AL (ALarm) The value written to this bit will affect

the meaning of the external alarm input of the

BUSwitch. When a zero is placed in this position,

the external alarm bit (EX) of the BUSwitch output

data packet will be set to a one when the connection

to the external alarm input terminals is broken.

Placing a one in this position will result in the EX bit

being set when a closed connection is made to the

external alarm input terminals.

FA (F

ailsafe Arm) If communication over the

network is lost, the default action of the valve is to

fail in place. By setting this bit to one, either fail

open or fail close can be enabled. The fail direction

is determined by the state of the FO bit described

below.

FO (F

ail Open) This bit determines the direction of

the fail action when the FA bit has been enabled.

When this bit is set to zero and the FA bit is set to

one, the valve will fail close upon loss of

communication with the master. If it is desired for

the valve to fail open, set this bit to one.

The following truth table illustrates the interactions

between the FA and FO bits.

FA FO Failsafe Action

0 0 Fail in place

0 1 Fail in place

1 0 Fail closed

1 1 Fail Open

Table 5

Odometer Limit: The odometer limit is a 32-bit

value that is comprised of words 3 and 4 of the input

data packet. When the odometer counter exceeds

this value, the Odometer Limit (LI) bit of the output

data packet is set to one, indicating an alarm

condition. When set to zero the BUSwitch will

default to 2,000,000. Valid range is from 0 to

4,294,967,295 (2

32

-1).

One-shot Duration: Integer value that when

multiplied by 0.05, represents the number of

seconds to energize the solenoids in dual coil mode.

Any integer value between 0 and 65535 can be

input, however, values below 10 (0.5 seconds) will

result in a value of 10 being used. Integer values

above 6000 (300 seconds) will result in 6000 being

used. To calculate the value to enter from a desired

time value, divide the time value by 0.05 and round

to the nearest integer.

Valve Opening Timeout / Valve Closing Timeout:

When a either the OPEN or CLOSE solenoid is

activated, the response time for the valve to

complete the transition is monitored and compared

to the limit specified by the user for that respective

operation. If the transition time exceeds the value

specified for that operation, the time-out (TO) bit will

be set to one in the BUSwitch output data packet.

As with the one-shot duration value above, the value

entered into these words represent 50 millisecond

intervals. Values entered that are below 10 (0.5

seconds) will default to 10 (0.5 second). Values

above 6000 (300 seconds) will default to 6000.

Allowable input range is from 0 to 65535.

LML0012-0 8/99 Page 5 of 6

©1999, Flowserve Corporation, Provo, Utah

Page 6

Flowserve Corporation

Flow Control Division

BUSwitch Output Data Packet

Word

Bit→

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Automax BUSwitchTM – Profibus-DP

765 South 100 East

Provo, Utah 84606

www.flowserve.com

Email: actuators@flowserve.com

Phone: 801 373 3028

Facsimile: 801 489 2228

1

2

3

4

5

6

VO VC EX LI TO

Odometer Counter (Most significant word)

Odometer Counter (Least significant word)

Reserved

Transition Timer ( 50 millisecond ‘ticks’ )

Firmware Version

Table 6 – Output Data Packet

VO (Valve is Open) This reflects the actual state of

the valve position by monitoring the state of the

OPEN proximity switch. A one in this bit position

indicates the OPEN proximity switch is closed.

VC (V

alve is Closed) Reflects the actual state of the

valve by monitoring the CLOSED proximity switch.

A one in this position indicates the CLOSED

proximity switch is closed.

EX (EX

ternal Limit) This bit is set to one to indicate

an alarm condition depending on the state of the

external alarm input AND the value of the AL bit in

the input data packet. When AL is set to 0, if the

circuit connected to the external alarm input is

broken, the EX bit will be set to one. When AL is set

to 1, the circuit connected to the external alarm input

must be made for EX to be set.

LI (Odometer LI

mit) When the number of valve

transitions exceeds the odometer limit value, this bit

will be set to one.

TO (Valve T

imeOut) This bit is set when the valve

has not reached its end of travel within the time

specified by either Valve Opening Response

bit is cleared upon reversal of motion. For example,

if the TO bit was set during a close operation, it will

only clear when the valve has been commanded to

open and the valve subsequently leaves the closed

position.

Transition Timer: This integer value indicates the

number of 50 millisecond periods that have elapsed

since the last request of valve motion and

completion of the valve movement. This value is

reset to zero upon change of direction.

Odometer Counter: This value is the cumulative

number of valve transitions since the counter was

reset. The value is incremented when the valve

completes a transition.

Firmware Version: Expresses the firmware version

of the BUSwitch in decimal form. The value should

be divided by 100 to obtain the correct form. For

example, a value of 113 in this word corresponds to

firmware version 1.13.

Reserved bits are reported back to the controller as

zero.

Timeout or Valve Closing Response Timeout. This

0518 II 2 G EEx d II T5

LML0012-0 8/99 Page 6 of 6

©1999, Flowserve Corporation, Provo, Utah

Loading...

Loading...