Page 1

AXAIM020-01 (AUTO-48) 3/03 Page 1 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

BUSwitch

™

with

F

OUNDATION

®

Fieldbus Communications Protocol

Installation, Operating and Maintenance

Instructions

Page 2

AXAIM020-01 (AUTO-48) 3/03 Page 2 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . 2

Printed Circuit Board Specifications . . . . . . . . . . . . . 3

Start-up Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . 4

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . 5

Adjustment of Switch Cams. . . . . . . . . . . . . . . . . . . 6

BUSwitch™Embedded Software Specs . . . . . . . . . . 6

Resource Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Resource Block Parameter Table. . . . . . . . . . . . . . . 7

Transducer Block. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pneumatic Actuator Operation. . . . . . . . . . . . . . . . . 9

Valve Position Monitoring and Reporting . . . . . . . . . 9

Auxiliary Dry Contact Input . . . . . . . . . . . . . . . . . . 10

Odometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Transducer Block Parameter Table. . . . . . . . . . . . . 11

DI Function Block Parameter Table . . . . . . . . . . . . 14

DO Function Block Parameter Table . . . . . . . . . . . 15

Introduction

Flowserve’s BUSwitch™uses the FOUNDATION

®

Fieldbus communication protocol to operate

pneumatic valve actuators and monitor/report their

position. BUSwitch™also provides an odometer and

stroke timer to assist in preventative maintenance.

Principles of Operation

BUSwitch™utilizes two discrete output function

blocks (DO-1 and DO-2) to energize piezo or

coil actuators, which act as pilots to shift a large

capacity spool valve.For spring retur n and double

acting applications with a desired fail position (open

or closed) DO-1 is used to operate a single pilot.

For applications requiring fail in last position,

both DO blocks are used with a “dual coil” pilot

configuration.

In dual coil mode, users may choose to de-energize

piezo/coil elements after the valve has reached its

desired position or may configure the elements to

remain energized (factory default)(see “Transducer

Block”).

Valve position is sensed with two limit switches.

BUSwitch™communicates the state of these limits

in the transducer block’s SOLENOIDE_CLOSED

and SOLENOIDE_OPENED parameters and in the

READBACK_D parameters of DO-1 and DO-2.

The transducer block’s ODOMETER parameter tracks

the number of valve strokes. It may be reset using

RESET_ODOMETER.

The transducer block’s transition alarm alerts the

used if the stroke time exceeds the time in the

parameter TIME_OUT, this alarm is also passed

to the OUT_D of the DI-1 block.

Two discrete input blocks are factory-configured.

DI-1 is a discrete value indicating the stroke exceeded

a specific time. DI-2’s OUT_D parameter provides a

link to an external dry-contact input (terminal P4).

This input is jumper-selectable to normally open or

normally closed (jumper J1/J2). Common uses for

this input include valve packing pressure monitoring.

A 2-wire cable using the FF H1 (31.25 Kbps)

protocol provides communication and power to the

FF Communication Board.The communications

board, switches, and piezo/coil pilots are all

connected to an interface board.Two versions

of this interface card are available:

• 2-Wire for bus-powered pilot applications.

Utilizes ultra-low power piezo pilot valves.

• 4-Wire for externally powered pilot applications.

Utilizes a wide range of 24VDC coil pilot valves.

The communications card operates from 9.5 to

32 VDC. BUSwitches are configured to draw

18 mA of current. Current consumption from the

fieldbus segment will remain constant whether a

piezo/coil actuator is activated or not.

Page 3

AXAIM020-01 (AUTO-48) 3/03 Page 3 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Start-up Guide

CAUTION

The BUSwitch™may cycle during a configuration download. Exercise caution in handling

valves that may be stroked during these

procedures.

For best results, Flowserve strongly recommends reading this entire document before

attempting to configure and commission

BUSwitches.

1 Following the instructions in “Mechanical

Installation,” install the BUSwitch™onto a

pneumatic actuator and turn supply air on.

2. Following the instructions in “Electrical connections,” connect fieldbus and optional dry-contact

wiring.

3. Referring to control system or configuration system

documentation, install BUSwitch™device description (DD) files onto system hard drive. Note:

Readme file on DD floppy contains instructions.

Note: For Fisher DeltaV systems, the DD files

must be copied to a directory or folder named

“464C4F” in order for the system to find them.

4. Initialize communications with device and bring

up the “Live List.” BUSwitches have been

configured from the factory with an ID of

“464C4F5053:BUSWITCH: [serialnumber]” and

a default tag of “FLOWSERVE BUSWITCH.”

Note the serial number.

5. Change the BUSwitch™attribute Device ID to the

value noted in step 4 and change the Device Tag

to the appropriate value.

6. Assign the Tag configuration in step 5.

7. BUSwitches are shipped with resource block,

transducer block, (2) DO blocks and (2) DI blocks

pre-configured unless specially configured by

agreement with customer.Refer to the appropriate

sections in this manual for the default configuration.

Make any desired changes to this configuration

and download.

Printed Circuit Board Specifications

F

OUNDATION

®

Fieldbus Information

Power Requirements: Communications Card

XA0239

Communication Card

Power requirements: 2-Wire Version

XA0238 Interface

Card Version 2.0

Power requirements

XA0242 Interface

Card

Temperature

Operational -40°F to +185°F

Storage -40°F to + 250°F

†

To operate, an external 24 VDC source must be locally

supplied to the interface card.

Bus powered

9.5-32 VDC at 18 mA

Bus powered by

XA0239 Communication

Card

†

: 4-Wire Version

24 VDC

• 10 mA quiescent

• 510 mA max. with

solenoid activat

(-40°C to + 85 °C)

(-40°C to + 120°C)

ed

Manufacturer

ID 464C4F (Hex)

Name 46 6C 6F 77 73 65 72 76 65

Device

Type 0x0x5053 (Hex)

ID

Device Descriptions are supplied on included

disk

ette

F l o w s e r v e

464C4F5053:BUSWITCH:xxxxxx

Max. length of 32 characters.

Characters 21 through 32 are

used for board serial number

.

Page 4

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

8. Using the DO-1.OUT_D value parameter (and

DO-2.OUT_D for dual coil mode), stroke the valve

(Discrete 0 = de-energized; Discrete 1 = energized)

and set limit switches, referring to “Adjustment of

Switch Cams” section. Circuit board mounted LED’s

light when switches are tripped.

9. This is the minimum configuration to operate

the actuator and read valve position.Refer to

FOUNDATION®Fieldbus standards for DO and DI

blocks to establish more sophisticated control

strategies. Refer to the block sections in this manual

for more information on BUSwitch™functionality.

Mechanical Installation

BUSwitch™Mounting:

1. Installation is best performed with Flowserve

NAMUR mounting kits.These kits allow direct

mounting of the BUSwitch™shaft to the actuator

pinion without a coupler.The NAMUR mounting

kits will work with any actuator conforming to the

NAMUR standard for accessory mounting hole

locations and pinion dimensions. Simply attach the

bracket to actuator and BUSwitch™to the bracket

with the included fasteners.The BUSwitch™shaft

features an integral alignment pin that engages the

tapped pinion hole. Flowserve also offers a full line

of non-NAMUR mounting kits.

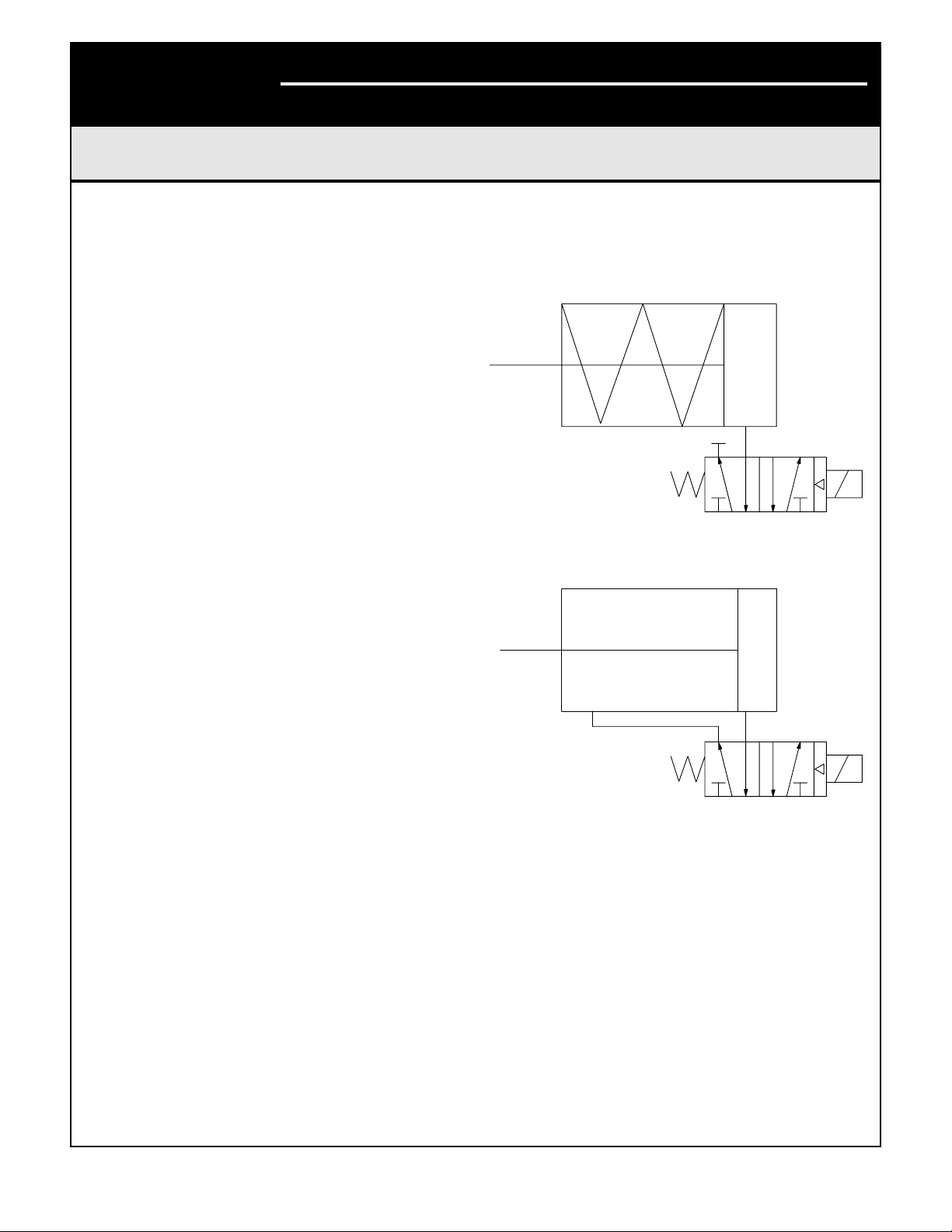

Spool and Tubing Configuration:

The following instructions apply to BUSwitch™configured with integral pilot valves and spool valve.For

non-integral pilot/spool valves, follow manufacturer's

instructions for piping.

1. For spring return actuators, a 4-way spool valve is

provided with port #2 plugged. For double acting

actuators, the same valve is provided with no

plugs. Make sure the correct spool is selected

before installing tubing.

2. Make sure all air pressure is removed before

installing tubing.

3. Attach tubing according to Figures 1 or 2 at right,

depending upon application. Attach supply tubing

to Port 1 and use 3 and 5 for exhaust.

4. To prolong actuator life use only clean, dry plant

air.Lubricated air is not required, although it is recommended, particularly for high cycle applications.

4

2

315

531

2 4

Figure 1

Figure 2

Lubrication

All BUSwitch™spool valves are pre-lubricated

and will operate dry (with no additional lubrication).

The use of lubricated air will not interfere with the

functioning of the BUSwitch™. If air lubrication

is used, the oils listed below are popular, easily

obtainable, fluids that are recommended for use

with the BUSwitch™spool valve:Gulf Harmony 47,

Mobil DTE Medium, Shell Tellus 29, Texaco Rondo B,

Sohivis 47 and Sunnis 921. Many other lubricants are

acceptable providing they do not contain detergents

that will attack Buna N or Viton Seals.

AXAIM020-01 (AUTO-48) 3/03 Page 4 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

Page 5

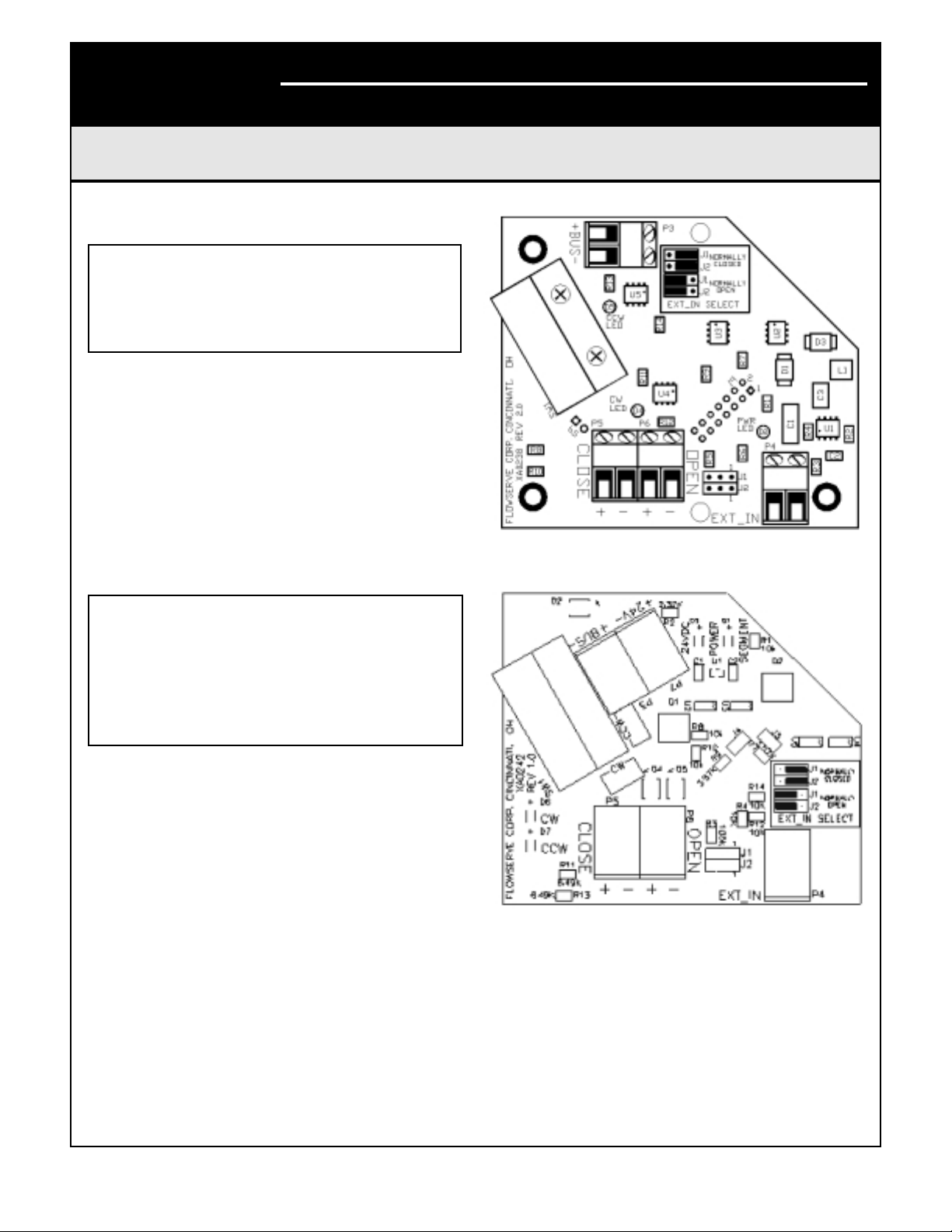

Electrical Connections

CAUTION

To prevent ignition of hazardous atmospheres, keep cover bolts tight while circuits

are live. Disconnect supply circuit before

opening.

Entry into the BUSwitch™housing is made through

three 1/2

” NPT conduit entries. Figures 3 and 4

provide terminal locations on the interface card.

Connection of the data cable is made to connector

P3 – observing polarity.Incorrect polarity will not

damage the electronics, but it will prevent communication. For hazardous locations, Underwriters

Laboratories (UL) and the National Electric Code

(NEC) require an approved sealing fitting within

eighteen inches of the switch enclosure.Sealing

fittings are not required for Division 2 non-incendive

applications.

CAUTION

Make sure power is turned off when making

electrical connection. Inadvertent power

cycling will result in BUSwitch

™

shutdown.

After a power shut-down wait at least five

seconds before attempting to turn power

back on to assure BUSwitch™start-up.

Open conduit entries must be closed after installation

using a close-up plug approved for hazardous

locations. Conduit and plugs must fully engage

five threads.

Ter minal P4 is provided for the input of a signal from

an external dry-contact switch. Jumper J1 and J2

change the configuration of this input. Factory setting

is Normally Closed with DI-2 OUT_D value Discrete

1 = contact open and Discrete 0 = contact closed.

Change the jumper setting to “normally open” for

Discrete 0 = contact open.

AXAIM020-01 (AUTO-48) 3/03 Page 5 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Figure 3

Interface Card: 2-Wire Version XA0238

Figure 4

Interface Card: 4-Wire Version XA0242

Page 6

AXAIM020-01 (AUTO-48) 3/03 Page 6 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Special Notes on the fieldbus cabling

Minimum voltage requirement for the BUSwitch

™

is 9.5 VDC supply. The output voltage of the fieldbus

power supply, the current drawn and the electrical

characteristics of the data cable determine the maximum distance that a particular segment can span.

With data cable that conforms to the FF cable type ‘A’

specification, distances of 1900 meters are guaranteed. If a shielded cable is used, connect the shield to

ground at one point only. Multiple grounds can lead

to ground loops which can impair the proper operation of the segment. For this reason, a shield connection has not been provided inside the BUSwitch

™

housing. Radio frequency grounding at multiple

points through the use of capacitors, allowed by

the FF protocols, can be used for increased high

frequency EMI (electromagnetic interference)

shielding. For a more thorough treatment of data

cable wiring and aspects of installation refer to the

FOUNDATION®Fieldbus application guide AG-140:

Wiring and Installation 31.25 Kbit/s,Voltage Mode,

Wire Medium. Its reference section lists additional

documentation that can be consulted for further

information.

Adjustment of Switch Cams

1. Loosen five captive cover screws

and remove lid, turning slightly

while lifting.

2. Place the actuator in the clock-wise

(CW) position and connect to the

fieldbus segment.

3. Push down on the top cam until it

clears the splined coupler, rotating

clockwise until the CW LED is

illuminated (Figure 5).

4. Release the cam and insure that

it fully engages the spline.

5. Place the actuator in the counterclockwise (CCW) position.

6. Pull up on the lower cam until it clears its

splined coupler, rotating counter-clockwise

until the CCW LED is illuminated (Figure 5).

BUSwitch™Embedded Software

Specifications

Flowserve’s BUSwitch™utilizes the SMAR communications stack. Factory-configured embedded software

includes the resource block, transducer block,

(2) DO blocks and (2) DI blocks.The next sections

provide information about each of these blocks.

Flowserve assumes the reader has a fundamental

understanding of the nature, nomenclature, and

geometry of these blocks.

DISCLOSURE

The Flowserve BUSwitch™has been certified by

FOUNDATION®Fieldbus (FF) to be interoperable

in accordance with FF standards. In addition, the

BUSwitch™device has been proven interoperable

with Fisher’s DeltaV Control System.The term

interoperable DOES NOT mean the BUSwitch

™

device will behave exactly like other FF-interoperable

devices.Because of some flexibility in the interpretation of FF standards, some minor differences exist

between many manufacturers.These differences

DO NOT affect the function of this device.

Flowserve has disclosed, in an addendum to this

document, known issues with individual control

systems we have tested.Users and systems

integrators should make allowances for these

issues. Flowserve will not be responsible for

modifying software to change the behavior of the

BUSwitch™relative to these issues.

Figure 5

Page 7

AXAIM020-01 (Auto-48) 3/03 Page 7 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

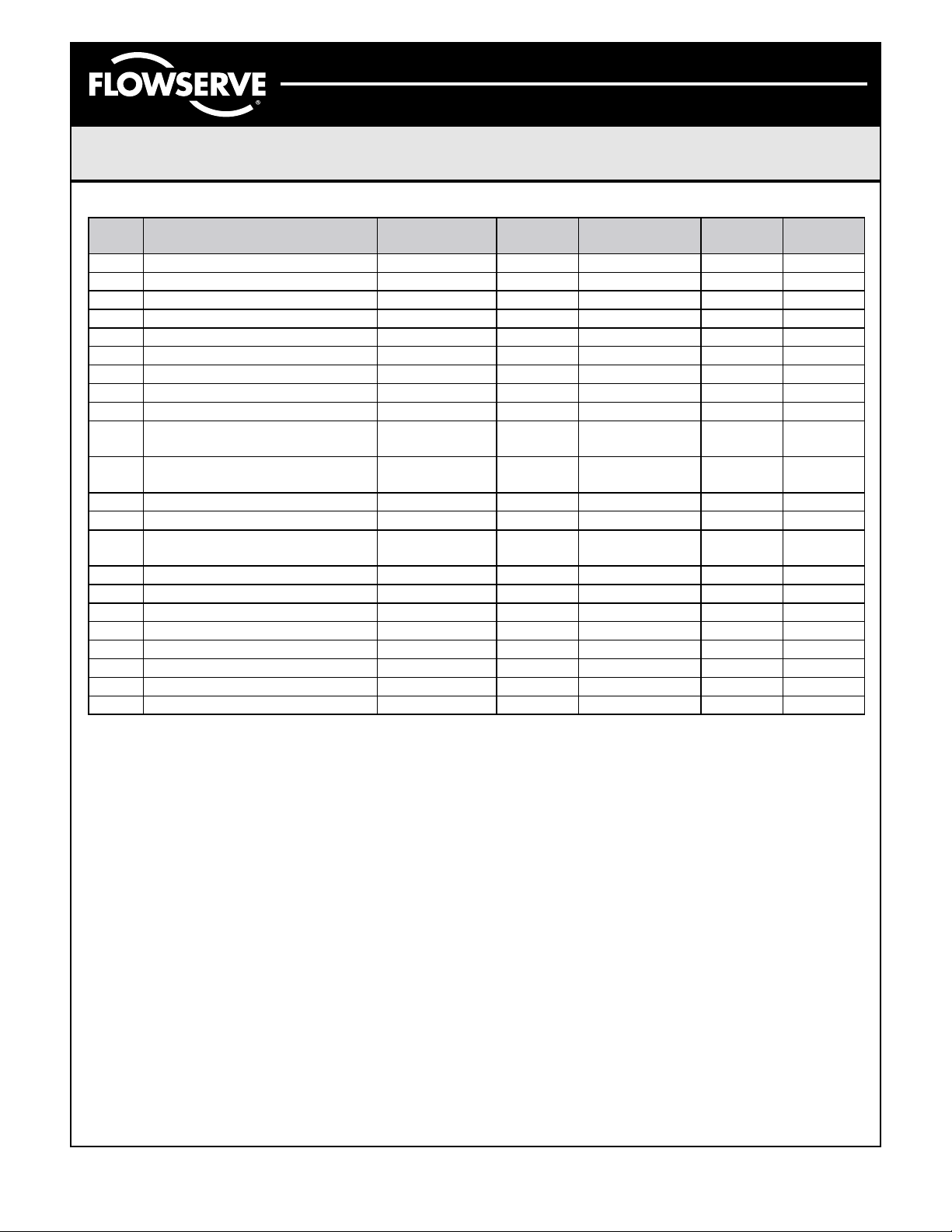

Resource Block Parameter Table

Resource Block

The Resource Block (RB) contains a set of parameters that define characteristics of the physical

BUSwitch™sub-components (function blocks and

transducer block).Some of these parameters are

considered “operational” because they affect or reflect

the operation of function blocks.Others contain more

general data about the device.

MANUFAC_ID, DEV_TYPE, DEV_REV, and DD_REV

provide information to the control system about which

device description to use. All of the RB parameter

data is “contained” meaning no links are made to

this block.No device configuration data is stored in

this block.

General function block operation is reflected in the

RB. MODE_BLK may be used to override the Target

Modes of all function blocks and transducer block.

Supported Modes (MODE_BLK)

O/S, IMAN, AUTO (Factory default = Auto)

Alarm Types

Standard block alarm plus a discrete alarm for

write lock.

Device Initialization

The parameter RESTART permits varying degrees

of initialization.

CAUTION

Initializing with the setting “Defaults” will

reset the device to the board manufacturer’s

defaults, not the Flowserve defaults shown in

this document.When using this command,

users will have to reestablish all the critical

Flowserve factory defaults highlighted in each

block section. Items shaded “black” must be

configured.

1.Write the value “Defaults” to RESTART.

2. Read the RESTART value. It should equal 1.

3.Turn off and then tur n on the device.

Users may utilize the other levels of restart at their

discretion.

Resource Block Parameter Table

The following table provides a complete list of all

RB parameters.There are no cr itical default RB

parameter settings affected by a “Default” RESTART,

however Flowserve recommends setting the

MODE_BLK value to “Auto.”

Rel.

Index

1 ST_REV The revision level of the static data associated with the function block. To support

2 TAG_DESC The user description of the intended application of the block.

3 STRATEGY The strategy field can be used to identify grouping of blocks. This data is not

4 ALERT_KEY The identification number of the plant unit. This information may be used in the host

5 MODE_BLK The actual, target, permitted, and normal modes of the block.

6 BLOCK_ERR This parameter reflects the error status associated with the hardware or software

7 RS_STATE State of the function block application state machine.

8 TEST_RW Read/write test parameter – used only for conformance testin

9 DD_RESOURCE String identifying the tag of the resource, which contains the Device Description for

10 MANUFAC_ID Manufacturer identification number – used by an interface device to locate the DD file

Parameter Description

tracking changes in static parameter attributes, the associated blockís static revision

parameter will be incremented each time a static parameter attribute value is writt

checked or processed by the block.

for sorting alarms, etc.

components associated with a block. It is a bit string, so that multiple errors may be

shown.

this resource

for the resource

en.

g.

.

.

Page 8

AXAIM020-01 (AUTO-48) 3/03 Page 8 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Rel.

Index

11 DEV TYPE Manufacturer’s model number associated with the resource – used by interface

12 DEV__REV Manufacturer revision number associated with the resource – used by an interface

13 DD_REV Revision of the DD associated with the resource – used by an interface device to

14 GRANT_DENY Options for controlling access of host computer and local control panels to operating,

15 HARD_TYPES The types of hardware available as channel numbers.

16 RESTART Allows a manual restart to be initiated. Several degrees of restart are possible. They

17 FEATURES Used to show supported resource block options

18 FEATURE_SEL Used to select resource block options

19 CYCLE_TYPE Identifies the block execution methods available for this resource

20 CYCLE_SEL Used to select the block execution method for this resource

21 MIN_CYCLE_T Time duration of the shortest cycle interval of which the resource is capab

22 MEMORY_SIZE Available configuration memory in the empty resource. To be checked before

23 NV_CYCLE_T Minimum time interval specified by the manufacturer for writing copies of NV

24 FREE_SPACE Percent of memory available for further configuration. Zero in a pre-configured

25 FREE_TIME Percent of the block processing time that is free to process additional blocks

26 SHED_RCAS Time duration at which to give up on computer writes to function block RCAS

27 SHED_ROUT Time duration at which to give up on computer writes to function block ROUT

28 FAULT_STATE Condition set by loss of communication to an output block. When FAULT_STATE

29 SET_FSTATE Allows the FAULT_STATE condition to be manually initiat

30 CLR_FSTATE Writing to this parameter will clear the FAULT_STATE condition as long as the

31 MAX_NOTIFY Maximum number of unconfirmed notify messages possible.

32 LIM_NOTIFY Maximum number of unconfirmed alert notify messages allowed.

33 CONFIRM_TIME The time the resource will wait for confirmation of receipt of a report before trying

34 WRITE_LOCK If set, writes to parameters within the device are not allowed, except to clear

35 UPDATE_EVT This alert is generated by any change to the static data

36 BLOCK_ALM The block alarm is used for all configuration, hardware, connection failure, or system

37 ALARM_SUM The current alert status, unacknowledged states, unreported states, and disabled

38 ACK_OPTION Selection of whether alarms associated with the block will be automatically

39 WRITE_PRI Priority of the alarm generated by clearing the write lock.

40 WRITE_ALM This alert is generated if the write lock parameter is clear

Parameter Description

devices to locate the DD file for the resource.

device to locate the DD file for the resource

locate the DD file for the resource

tuning and alarm parameters of the block.

are 1: Run, 2: Restart resource, 3: Restart with defaults, and 4: Restart processor.

attempting a download. MIN_CYCLE_T Time duration of the shortest cycle interval

of which the resource is capab

parameters to non-volatile memory. Zero means it will never be automatically copi

resource

locations. Shed from RCAS shall never happen when SHED_RCAS =

locations. Shed from Rout shall never happen when SHED_ROUT

condition is set the function blocks will perform their FSTATE actions.

problem which initially caused the FAULT_STATE has been clear

again. Retry shall not happen when CONFIRM_TIME

WRITE_LOCK. Block inputs will continue to be updated

problems in the block. The cause of the alert is entered in the subcode fiel

states of the alarms associated with the function block.

acknowledge

.

.

.

.

.

.

.

le.

le.

ed.

.

0.

= 0.

ed.

ed.

= 0.

.

.

d.

d.

ed.

Page 9

AXAIM020-01 (AUTO-48) 3/03 Page 9 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Transducer Block

The Transducer Block (TB) provides the link between

standard function blocks (DO-1, DO-2, DI-1, & DI-2)

and the sensors and piezo/coil actuators within the

BUSwitch™device.It tracks number of valve strokes.

The TB also provides some configuration flexibility.

This section details those parameters affecting the

function and configuration of the BUSwitch™device.

This discussion includes all operational aspects

of the function blocks as well. A complete list of

TB parameters follows at the end of the section.

Complete function block parameter lists are

provided in Appendices A and B.

Pneumatic Actuator Operation – Single Coil,

Fail Open or Fail Closed

For operation requiring a consistent fail position

(either open or closed), select the “Single Coil”

TB.OPERATION parameter. One DO block (DO-1)

is used.The TB reads DO-1 OUT_D Value and

energizes both the OPEN (P6) and CLOSE (P5)

terminals as shown in the Single Coil Truth Table.

To reverse the actuator fail mode for double acting

actuators, reverse ports 2 and 4. To reverse springreturn actuators, actuator modification is necessary.

Single Coil T ruth T able

When in Auto mode, DO1.OUT_D follows the SP_D

Value. If the user wishes to invert the above truth

table relative to SP_D, change the function block

IO_OPTS parameter to “Invert.” This will energize the

coil on an SP_D Discrete 0 and de-energize on an

SP_D Discrete 1.This toggle has the same effect

when “dual coil” mode is selected; it is necessar y to

select “Invert” for both DO blocks.

Pneumatic Actuator Operation – Dual Coil,

Fail in Last Position

Select the “Dual Coil”TB.OPERATION parameter.

Dual Coil Operation uses both DO1.OUT_D and

DO2.OUT_D block parameters configured in an

interlocking manner.For valve movement to take

place, the OUT_D parameters must take on opposite

values as shown in the next table.

Dual Coil T ruth T able

Referring to Figure 2, energizing the “OPEN” terminals will provide air to Port 4 and energizing the

“CLOSE” ter minals will provide air to Port 2. To

reverse the valve operation, either reverse the

solenoid valve wires on P5 and P6, or reverse the

actuator tubing connections on Port 2 and 4.

The TB.OUTPUT_CONFIGURATION parameter

selects whether solenoid pilot elements stay

energized or become de-energized after the valve

reaches its desired position. If the “Pulse” option

is selected, the elements will de-energize after

the length of time selected in the TB.TIME_OUT

parameter.The “Constant” setting maintains

element voltage until new DO-1 and DO-2 OUT_D

values are selected.

Valve Position Monitoring and Reporting

The BUSwitch

™

TB monitors the status of two limit

switches.SW1 is the upper switch and is set to trip

when the valve reaches the closed position.SW2 is

the lower switch and is set to trip when the valve is

open.The TB.SOLENOIDE_CLOSED parameter

displays SW1 status as False when not tripped and

Tr ue when tripped. TB.SOLENOIDE_OPENED

parameter displays SW2 status the same way.

The TB provides limit switch status to the READBACK_D parameters of DO-1 and DO-2 respectively

per the following truth table.

T ruth T able for READBACK_D V alues

FOUNDATION®Fieldbus DO blocks write the READBACK_D value to the PV_D variable within each

block.PV_D may then be linked to the BKCAL_OUT

variable.Figure 6 shows a schematic of a DO block

illustrating this feature.

DO1.OUT_D OPEN/CLOSE

0

1

De-energized

Energized

DO1

OUT_D

0 0

1 Energized De-ener

1 1

0 De-energized Ener

DO2

OUT_D

0

1

OPEN CLOSE

No Change No Change

gized

No Change No Chang

gized

e

SW1 SW2 DO-1

RDBK

A A 1 1 Improper switch adj.

A

O 0 1 Actuator O

O O 0 0 Actuator is moving

A = Activated or Tripped, O = Open or Not Tripped

O 1 0 Actuator CLOS

A

DO-2

RDBK

Meaning

ED

PENED

Page 10

AXAIM020-01 (AUTO-48) 3/03 Page 10 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

To link DO.PV_D to DO.BKCAL_OUT, configure

the IO_OPTS for the desired block to “PV for

BKCAL_OUT.” Note: This action prevents the use

of “Invert” as an IO Option. Then, link BKCAL_OUT

to the BKCAL_IN of the function block sending the

CAS_IN_D signal.

Auxiliary Dry Contact Input

The BUSwitch™TB also monitors continuity across

terminals P4. This status is seen in the external alarm

parameter and in the OUT_D of DI-2. DI-2.OUT_D

will read Discrete 1 when no continuity exists and the

“Normally Closed” J1 and J2 jumpers are selected.

When contact is made in this jumper mode, the output changes to Discrete 0.

To reverse the outputs, change the J1 and J2 settings

to “Normally Open.” Refer to Figures 3 and 4 for the

jumper settings.

Odometer Function

TB Parameter ODOMETER reports the number of

open-closed and closed-open transitions. It may be

reset using the RESET_ODOMETER parameter.

Simply write a “True” value to this parameter to reset.

Valve Stroke Time Out Function

The BUSwitch™times each valve stroke and

reports the time from the move command until the

appropriate position switch is tripped.The stroke

time is displayed in the transducer block parameter

“TRANSITION TIME.” If the “TRANSITION TIME” is

greater than the value entered in “TIME-OUT,” an

alarm is generated.This alarm is displayed in the

transducer block parameter “TRANSITION-ALARM”

and is also sent to the DI-1 block “OUT-D.” This is

a “linkable” input and can be used to alter process

control.The alarm will stay present until the “RESETTIMEOUT” parameter is set to “TRUE” in the transducer block.

Additional TB Parameter s

Several TB parameters exist to store information

about the valve, actuator and BUSwitch™device.

In addition, calibration information may be stored.

Refer to the complete list of BUSwitch™TB

parameters starting on page 11 for a description

of these parameters.

Figure 6 – DO Block Schematic

Page 11

AXAIM020-01 (AUTO-48) 3/03 Page 11 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

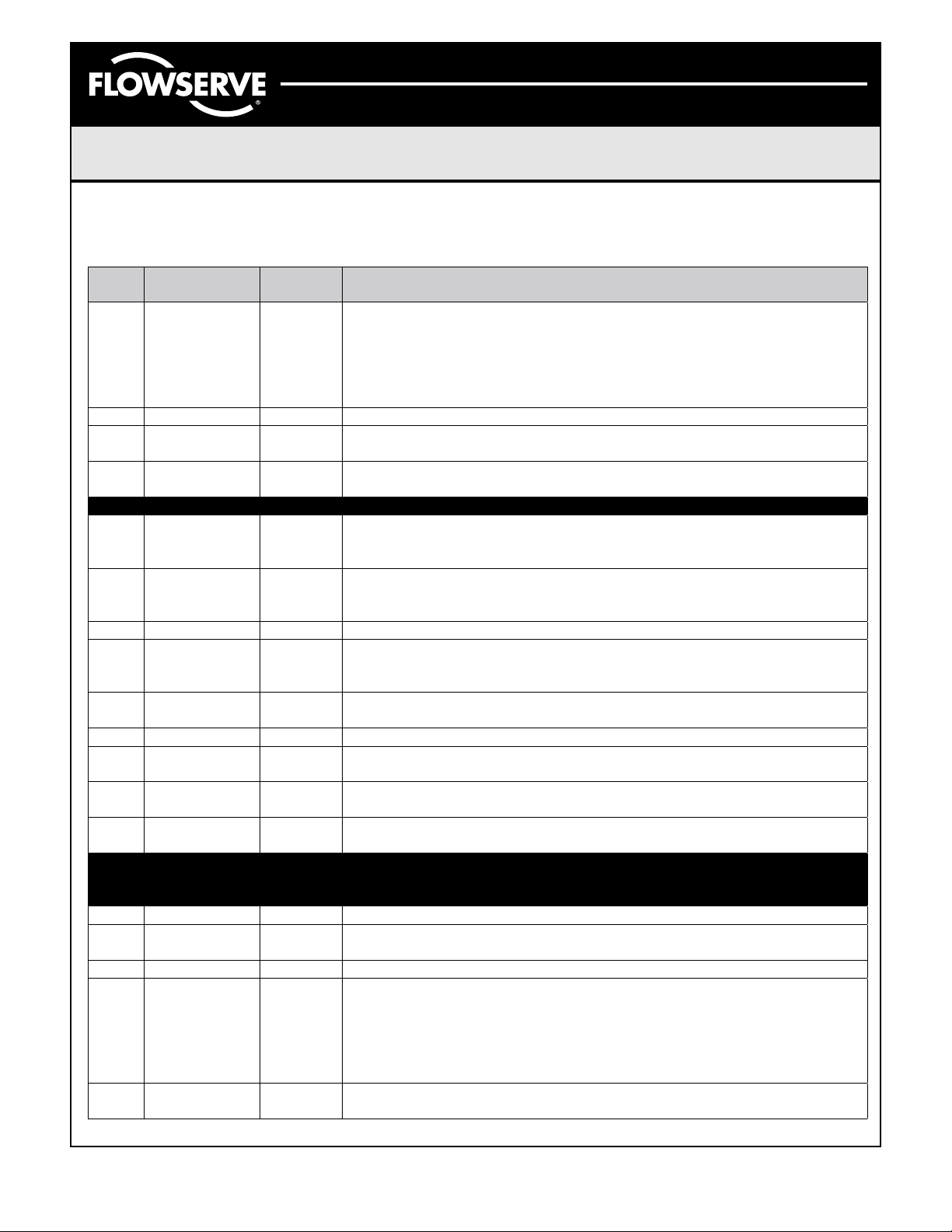

Transducer Block Parameters

Rel.

Index

1 ST_REV The revision level of the static data associated with the function

2 TAG_DESC The user description of the intended application of the block.

3 STRATEGY The strategy field can be used to identify grouping of blocks. This

4 ALERT_KEY The identification number of the plant unit. This information may

5 MODE_BLK Auto The actual, target, permitted, and normal modes of the block.

6 BLOCK_ERR This parameter reflects the error status associated with the

7 UPDATE_EVT This alert is generated by any change to the static data

8 BLOCK_ALM The block alarm is used for all configuration, hardware, and

9 T RANSDUCER_DIREC

10 TRANSDUCER_TYPE Identifies the transducer that follows.

11 XD_ERROR One of the error codes defined in section 4.8 of the FF-903

12 COLLECTION_DIREC

13 FINAL_VALUE_D The requested valve position and status written by a discrete

14 ACT_FAIL_ACTIN Specifies the final failure position of the actuator as defined in

15 ACT_MAN_ID 4607055 The BUSwitch manufacturer identification number

16 ACT_MODEL_NUM The actuator model number

17 ACT_SN The actuator serial number

18 VALVE_MAN_ID The valve manufacturer identification number

19 VALVE_MODEL_NUM The valve model number

20 VALVE_SN The valve serial number

21 VALVE_TYPE The type of the valve as defined in section 4.7 of the FF-903

22 XD_CAL_LOC The location of last calibrati

23 XD_CAL_DATE Date of the last calibration.

24 XD_CAL_WHO Name of the person responsible for last calibratio

Parameter Factory

Default

A directory that specifies the number and starting indices of the

TORY

A directory that specifies the number, starting indices, and DD

TORY

Description

block. To support tracking changes in static parameter attributes,

the associated block’s static revision parameter will be

incremented each time a static parameter attribute value is

changed. Also, the associated block’s static revision parameter

may be incremented if a static parameter attribute is written but

the value is not change

data is not checked or processed by the block.

be used in the host for sorting alarms, etc.

hardware or software components associated with a block. It is a

bit string, so that multiple errors may be show

connection failure or system problems in the block. The cause of

the alert is entered in the sub-code field. The first alert to become

active will set the Active status in the Status attribute. As soon as

the Unreported status is cleared by the alert reporting task,

another block alert may be reported without clearing the Active

status, if the sub-code has change

transducers in the transducer block.

document on the XD_ERROR and Block Alarm sub-codes.

Item IDs of the data collections in each transducer within a

transducer block.

Function Block.

section 4.6 of the FF-903 document on the Actuator Failure

Actions.

document on the Valve Type

d.

n.

.

d.

.

.

.

.

.

.

.

on.

n.

Page 12

AXAIM020-01 (AUTO-48) 3/03 Page 12 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Transducer Block Parameter Specifications

Rel.

Index

Parameter Mnemonic Data

Type

Size Valid

Range

Units Class

1 ST_REV Unsigned 16 2 Positive N/A Read

2 TAG_DESC Visible String 32 String Data N/A R/W

3 STRATEGY Unsigned 16 2 N/A R/W

4 ALERT_KEY Unsigned 8 1 1-255 N/A R/W

5 MODE_BLK DS-69 4 N/A R/W

6 BLOCK_ERR Bit String 2 N/A

Read

7 UPDATE_EVT DS-73 5 N/A

Read

8 BLOCK_ALARM DS-72 13 N/A

Read

9 TRANSDUCER_DIRECTORY Unsigned 16

Array

Variable N/A

Read

10 TRANSDUCER_TYPE Unsigned 16 2 E

R/W

11 XD_ERROR Unsigned 8 1 N/A

Read

12 COLLECTION_DIRECTORY Unsigned 32

Array

Variable

N/A

13 FINAL_VALUE_D DS-66 2 N/A R/W

14 ACT_FAIL_ACTION Unsigned 8 1 0=Undefined

1=Close

2=Open

3=Last

ER/W

R/W

R/W

15 ACT_MAN_ID Unsigned 32 4

E

Rel.

Index

25 OPERATION Note 1 Configures the piezo/coil element terminals for single coil or dual

26 OUTPUT_CONFIGUR

27 ODOMETER This variable counts the transitions from open to closed and

28 RESET_ODOMETER Resets the ODOMETER counter.

29 FAILURE_RECOVERY Enable/Disable FAILURE_RECOVERY action.1: Act with or

30 RESET_TIMEOUT Resets a TIME_OUT occurrenc

31 TRANSITION_TIME How much time for the last transiti

32 TIME_OUT 10 The time allowed for a transition before the DI associated with the

33 SOLENOIDE_CLOSED SW1 state

34 SOLENOIDE_OPEND SW2 st

35 TRANSITION_ALARM DI1 state = transition TIME-OUT st

36 EXTERNAL_ALARM DI2 state = It read the status of the Temperature/Pressure Limit

37 ACTION_TIME Time since last command for transition.

Notes:

1. Selected by Factory in accordance with customer PO specifications.

Parameter Factory

Default

Note 1 Configures the piezo/coil signals to shut-off or remain continuous

ATION

Description

coil modes

after TIME_OUT period. Applies to Dual Coil mode only

closed to open states. It is reset-able to 0, after maintenanc

without change in the input, 2: Do not act until a new change in the

inpu

TIME-OUT Alarm is Activated. Also, the length of the One-Shot

pulse voltage output to the coils in the Dual Coil Operation Mo

(CN1.12 pin) Data is passed on to DI2.

.

.

e.

t.

e.

on.

de.

ate

ate

Page 13

AXAIM020-01 (AUTO-48) 3/03 Page 13 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Rel.

Index

16 ACT_MODEL_NUM Visible String 32 String Data N/A

17 ACT_SN Visible String 32 String Data

18 VALVE_MAN_ID Unsigned 32 4

19 VALVE_MODEL_NUM Visible String 32 String Data

20 VALVE_SN Visible String 32 String Data

21 VALVE_TYPE Unsigned 8 1 N/A R/W

22 XD_CAL_LOC Visible String 32 N/A R/W

23 XD_CAL_DATE Time of Day 7 N/A R/W

24 XD_CAL_WHO Visible String 32 N/A R/W

25 OPERATION Unsigned 8 1 1=Single

26 OUTPUT_CONFIGURATION Unsigned 8 1 1=Pulse

27 ODOMETER Unsigned 32 4 N/A

28 RESET_ODOMETER Unsigned 8 1 True/False N/A R/W

29 FAILURE_RECOVER Unsigned 8 1 1=Enabled

30 RESET_TIMEOUTS Unsigned 8 1 True/False N/A R/W

31 TRANSITION_TIME Float 4 Sec.

32 TIME_OUT Float 4 Sec. R/W

33 SOLENOIDE_CLOSED Unsigned 8 1 True/False N/A

34 SOLENOIDE_OPENED Unsigned 8 1 True/False N/A

35 TRANSITION_ALARM Unsigned 8 1 True/False N/A

36 EXTERNAL_ALARM Unsigned 8 1 True/False N/A

37 ACTION_TIME Float 4 Sec.

Abbreviations: R/W – Read/Write

Parameter Mnemonic Data

Type

Sec. – Seconds

Size Valid

Range

2=Double

2=Constant

2=Disabled

Units Class

N/A

N/A

N/A

N/A

N/A R/W

N/A

N/A

R/W

R/W

R/W

R/W

R/W

R/W

Read

R/W

Read

Read

Read

Read

Read

Read

Page 14

AXAIM020-01 (AUTO-48) 3/03 Page 14 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Appendix A. Discrete Input Block Parameters

The following table provides a list of all DI block parameters. Critical Factory Default values are highlighted.

Rel.

Index

1 ST_REV The revision level of the static data associated with the function block. To

2 TAG_DESC The user description of the intended application of the block.

3 STRATEGY The strategy field can be used to identify grouping of blocks. This data is

4 ALERT_KEY The identification number of the plant unit. This information may be used in

5 MODE_BLK Auto The actual, target, permitted, and normal modes of the block.

6 BLOCK_ERR This parameter reflects the error status associated with the hardware or

7 PV_D Either the primary discrete value for use in executing the function or a

8 OUT_D The primary discrete value calculated as a result of executing the function

9 SIMULATE Allows the transducer analog input or output to the block to be manually

10 XD_STATE Index to the text describing the states of a discrete for the value obtained

11 OUT_STATE Index to the text describing the states of a discrete out

12 GRANT_DEN

13 IO_OPTS Options which the user may select to alter input and output block

14 STATUS_OPT

15 CHANNEL 1 for DI-1

16 PV_FTIME Time constant of a single exponential filter for the PV, in seconds.

17 FIELD_VAL_D Raw value of the field device discrete input, with a status reflecting the

18 UPDATE_EVT This alert is generated by any change to the static data

19 BLOCK_ALM The block alarm is used for all configuration, hardware, and connection

20 ALARM_SUM The current alert status, unacknowledged states, unreported states, and

Parameter Factory

Default

Y

S

2 for DI-2

Description

support tracking changes in static parameter attributes, the associated

block’s static revision parameter will be incremented each time a static

parameter attribute value is changed. Also, the associated block’s static

revision parameter may be incremented if a static parameter attribute is

written but the value is not change

not checked or processed by the block.

the host for sorting alarms, etc.

software components associated with a block. It is a bit string, so that

multiple errors may be show

process value associated with it. May also be calculated from the

READBACK_D value of a DO block.

supplied when simulate is enabled. When simulation is disabled, the

simulate value and status track the actual value and status

from the transducer

Options for controlling access of host computer and local control panels to

operating, tuning and alarm parameters of the block.

processi

Options which the user may select in the block processing of status

The number of the logical hardware channel that is connected to this I/O

block. This information defines the transducer to be used going to or from

the physical world.

Transducer conditi

failure or system problems in the block. The cause of the alert is entered in

the subcode field. The first alert to become active will set the Active status

in the Status attribute. As soon as the Unreported status is cleared by the

alert reporting task, another block alert may be reported without clearing the

Active status, if the subcode has change

disabled states of the alarms associated with the function block.

ng.

.

on.

d.

n.

.

put.

.

.

d.

.

Page 15

AXAIM020-01 (AUTO-48) 3/03 Page 15 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Appendix B. Discrete Output Block Parameters

The following table provides a list of all DO block parameters. Critical Factory Default values are highlighted.

Rel.

Index

21 ACK_OPTION Selection of whether alarms associated with the block will be automatically

22 DISC_PRI Priority of the discrete alarm.

23 DISC_LIM State of discrete input, which will generate an alarm.

24 DISC_ALM The status and time stamp associated with the discrete alarm.

Parameter Factory

Default

Description

acknowledged.

Rel.

Index

1 ST_REV The revision level of the static data associated with the function block. To

2 TAG_DESC The user description of the intended application of the block.

3 STRATEGY The strategy field can be used to identify grouping of blocks. This data is not

4 ALERT_KEY The identification number of the plant unit. This information may be used in

5 MODE_BLK Auto The actual, target, permitted, and normal modes of the block.

6 BLOCK_ERR This parameter reflects the error status associated with the hardware or

7 PV_D Calculated from the READBACK_D value of a DO block, this variable

8 SP_D The discrete setpoint of this block.

9 OUT_D 0 The primary discrete value calculated as a result of executing the function

10 SIMULATE_D Allows the transducer discrete input or output to the block to be manually

11 PV_STATE Index to the text describing the states of a discrete PV.

12 XD_STATE Index to the text describing the states of a discrete for the value obtained from

13 GRANT_DEN

14 IO_OPTS Options which the user may select to alter input and output block processi

15 STATUS_OPT

16 READBACK_

17 CAS_IN_D This parameter is the remote setpoint value of a discrete block, which must

Parameter Factory

Default

Y

S

D

Description

support tracking changes in static parameter attributes, the associated block’s

static revision parameter will be incremented each time a static parameter

attribute value is changed. Also, the associated block’s static revision

parameter may be incremented if a static parameter attribute is written but the

value is not change

checked or processed by the block.

the host for sorting alarms, etc.

software components associated with a block. It is a bit string, so that multiple

errors may be show

indicates the valve position. It may be linked to BKCAL_OUT and fed back to

the sending block.

supplied when simulate is enabled. When simulation is disabled, the simulate

value and status track the actual value and status

the transducer

Options for controlling access of host computer and local control panels to

operating, tuning and alarm parameters of the block.

Options which the user may select in the block processing of status

This indicates the readback of the actual discrete valve or other actuator

position, in the transducer st

come from another Fieldbus block, or a DCS block through a defined link

d.

n.

.

.

.

ate.

.

ng.

.

Page 16

AXAIM020-01 (AUTO-48) 3/03 Page 16 of 16

© 2003, Flowserve Corporation, Printed in U.S.A.

BUSwitch™with FOUNDATION®Fieldbus Protocol

Installation, Operating and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

0518 II 2 G EEx d II T5

18 CHANNEL 1 for

DI-1

2 for

DI-2

19 FSTATE_TIM

E

20 FSTATE_VAL

_D

21 BKCAL_OUT_

D

22 RCAS_IN_D Target setpoint and status provided by a supervisory Host to a discrete

23 SHED_OPT *** Defines action to be taken on remote control device timeout.

24 RCAS_OUT_

D

25 UPDATE_EVT This alert is generated by any change to the static data

26 BLOCK_ALM The block alarm is used for all configuration, hardware, and connection failure

*** = NormalShed_NormalReturn

The number of the logical hardware channel that is connected to this I/O

block. This information defines the transducer to be used going to or from the

physical world.

The time in seconds from detection of fault of the output block remote setpoint

to the output action of the block output if the condition still exists

The preset discrete SP_D value to use when fault occurs. This value will be

used if the I/O option Fault State to value is selected

The output value and status provided to an upstream discrete block. This

information is used to provide bumpless transfer to closed loop control.

control or output block.

Block setpoint and status provided to a supervisory Host for back calculation

and to allow action to be taken under limiting conditions or mode c

or system problems in the block. The cause of the alert is entered in the

subcode field. The first alert to become active will set the Active status in the

Status attribute. As soon as the Unreported status is cleared by the alert

reporting task, another block alert may be reported without clearing the Active

status, if the subcode has chang

ed.

.

.

.

hange.

Loading...

Loading...