Page 1

Brand and product name

Installation

Description

Code

Brand and product name

Installation

Operation

Maintenance

Description

Code

BTV/BUV 2000

Operation

FCD DVENIM0000-01

Maintenance

Page 2

MAINTENANCE SCHEDULE AND NOTES

Date Comments

Date Comments

BTV/BUV 2000

Date Comments

Date Comments

2

Page 3

BTV/BUV 2000

FOREWORD

The Flowserve Corporation, Flow Control Division has

established this Installation, Operating and Maintenance

Manual to facilitate field installation, operation and repair of

BTV-2000 and BUV-2000 Series Butterfly Valves.

It is recommended that questions or concerns regard ing the

processes described in this manual be directed to Flowserve

Field Sales Representative, authorized stocking distributor

or the Flowserve Corporation, Flow Control Division.

Part numbers referenced in the following sections are

available from the Flowserve Corporation, Flow Control

Division.

Only Flowserve replacement repair parts and assembly

tooling made or designed by the Flowserve Corporation

should be used.

HOW TO SPECIFY

12 - B T L 4 8 1 - V P1

SIZE

2” - 24”

Blank = ANSI 150

VALVE TYPE

B = Butterfly

LINER MATERIAL

T = PTFE

U = UHMWPE

BODY STYLE

W = Wafer

L = Lug

1 = Enclosed Gear

BODY MATERIAL

4 = A395 GR. 60-40-18

(2” - 24”) DCI

1 = A744 GR. CF8M

(All Sizes) D4

0 = A351/A744 GR. CD4M-CU D100

1 = A351/A744 GR. CF8M D4

2 = A351/A744 GR. CN7M D20

3 = A494 GR. M-35-1 DMM

5 = A494 GR. N7M DC2

6 = A494 GR. CW6M DC3

7 = B367 GR. TI-PD 8A TIP

8 = PFA COATED DIPA

9 = UHMWPE COATED DIPE

S = A351/A744 GR. CK-3MCuN 254 SMO*

FLANGE

DRILLING

P1 = DIN PN10

P6 = DIN PN16

ELASTOMER

SEALS

Blank = Silicone

V = Viton

ACTUATOR

0 = 10 Position

Locking Lever

9 = Bare Stem

(Specify Type)

STEM & DISC

MATERIAL

PRESSURE CONTAINING FASTENERS

Material Selection

Selecting the proper fastener material is the ultimate

responsibility of the customer because the supplier does

not typically know in what service the valves will be used

or what elements may be present in the en vironment.

Flowserve normally supplies B7 (carbon steel) for ductile

cast iron and carbon steel valves. For stain less steel and

high alloy valves, B8 (stainless steel) fasteners are supplied

as standard. All fasteners used must have a minimum yield

strength of 40,000 PSI, a minimum elongation of 12% and

be compatible with the process fluid. Determining compatibility to the process fluid goes beyond a material being

resistant to general corrosion because the more important

con sid eration is a material’s resistance to stress corrosion

cracking. Depending on the service, it may make sense to

use B7 fasteners on high alloy valves. One such service

would be marine environments because of stainless steel’s

susceptibility to stress corrosion cracking in chloride

environments. Another key aspect of fasteners is frequent

visual inspection. Because of the common practice of using

steel fasteners rather than stainless steel to avoid chloride

stress corrosion cracking, visual inspection is recommended to monitor the general corrosion of these fasteners.

If jacketing or insulation is used on a valve, it must be

periodically removed for visual inspection of the fasteners.

If you wish assistance in determining the proper fasteners

to use, please refer to the attached chart or contact

Flowserve Materials Engineering Group at (937) 226-4475.

Design & Type

The Flowserve valve design standards adopt ANSI B18.2.1

(1981) as the standard for fastener type and design. This

national standard requires that finished hex “head” cap

screws be used when the head of the fastener is turned. A

finished hex “head” cap screw and a heavy hex cap screw

have a bearing surface under the head to minimize frictional

resistance during tightening. They also comply to qualified

body dimen sions and fully formed head dimensions.

Cookeville Flow Control Division’s policy is to use finished

hex “head” and heavy hex “head” cap screws for all

pressure retaining fasteners. This includes top caps, packing

adjusters, plug adjusters, bottom caps, body halves or other

pressure retaining components. Compliance is made with

ANSI B18.2.2 (1987), Square and Hex Nuts, when studs and

heavy hex nuts are required. Additional information on these

items may be obtained from the Flowserve Corporation,

Cookeville Flow Control Division, Cookeville, Tennessee.

the

+ Coated Disc Insert Material: A395 GR. 60-40-18 (2”-24”) DCI

*Registered Trademark of Avesta AB

3

Page 4

FASTENERS

TABLE 1

Cap Screws-Studs

HHCS - Finished Heavy Hex Head Cap Screw

HCS - Finished Hex Head Cap Screw

SCS - Socket Head Cap Screw

STUD - Stud

SCYC - Socket Head Cap Screws for Retainer plates per ASTM A574-

4037 Alloy Steel, Yellow Zinc Dichromate Plated

Dimensions per ANSI B18.2.1

Alloy identification stamp required on each piece.

Certification required.

Alloy Specification (40 KSI Minimum Yield Strength,

12% Min. El.)

ASTM Material Specifications

B840 - 304 Stainless Steel per ASTM A193, Grade 8B, Class 1, 40

KSI Min. Yield Strength, 12% Min. El.

B7 - Chromium - Molybdenum Alloy Steel per ASTM A193, Grade

B7

B7M - Chromium - Molybdenum Alloy Steel per ASTM A193,

Grade B7M, 100% hardness tested

B7MT - Chromium - Molybdenum Alloy Steel per ASTM A193,

Grade B7M, 100% hardness tested, PTFE coated, DuPont

SP11C, type B - Color blue or green.

B8M - 316 Stainless Steel per ASTM A193, Grade B8M, Class 1,

40 KSI Min. Yield Strength, 12% Min. El.

B8C2 - 304 Stainless Steel per ASTM A193, Grade B8, Class 2.

C20 - Carpenter C20, CB-3 (UNS N08020), ASTM B473, 40 KSI

Min. Yield Strength, 12% Min. El.

HC - Hastelloy C276 (UNS N10276), ASTM B574

I625 - Inconel 625 (UNS N006625), ASTM B446

I825 - Incoloy 825 (UNS N08825), ASTM B425, 40 KSI Min. Yield

Strength, 12% Min. El.

IN - Inconel 600 (UNS N0660), ASTM B166, 40 KSI Min. Yield

Strength, 12% Min. El.

M - Monel (UNS N04400), ASTM B164, Class A or B, 40 KSI Min.

Yield Strength, 12% Min. El.

HB - Hastelloy B (UNS 10665), ASTM B335

I718 - Incoloy 718, AMS 5596B

MKH - Monel K-500, Cold drawn and aged hardened, QQN-286

and ASTM F468

L7 - Chromium-Molybdenum Alloy Steel per ASTM A320, Grade

L7

L7M - Chromium-Molybdenum Alloy Steel per ASTM A320, Grade

L7M, 100% hardness tested

L7T - Chromium-Molybdenum Alloy Steel per ASTM A320, Grade

L7, PTFE coated, DuPont SP11C, Type B - Color blue or green

L7MT - Chromium-Molybdenum Alloy Steel per ASTM A320,

Grade L7M, 100% hardness tested, PTFE coated, DuPont

SP11C, Type B - Color blue or green.

N - Nickel per ASTM B160 (UNS N0220), 40 KSI Min. Yield

Strength, 12% Min. El.

B7YC - Chromium-Molybdenum Steel per A193, Grade B7, Yellow

Zinc Dichromate Plated

BTV/BUV 2000

TABLE 2

Nuts

HN - Finished Heavy Hex Nut

XN - Finished Hex Nut

HXN - Regular Heavy Hex Nut

Dimensions per ANSI B18.2.2

Alloy identification stamp is required on each piece.

Certification required.

ASTM Material Specifications

8 - 304 Stainless Steel per ASTM A194, Grade 8

8M - 316 Stainless Steel per ASTM A194, Grade 8M

2H - ASTM A194, Grade 2H

2HM - ASTM A194, Grade 2HM

7M - ASTM A194, Grade 7M, 100% hardness tested

7MT - ASTM A194, Grade 7M, 100% hardness tested, PTFE

coated, DuPont SP11C, Type B - Color blue or green

M - Monel (UNS N04400), ASTM B164, Class A or B, or QQN-

281, Class B

HB - Hastelloy B (UNS N10665), ASTM B335

HC - Hastelloy C276 (UNS N10276), ASTM B574

I625 - Inconel 625 (UNS N06625), ASTM B446

I718 - Incoloy 718, AMS 5596B

I825 - Incoloy 825 (UNS N08825), ASTM B425

L7 - Chromium-Molybdenum Alloy Steel per ASTM A194,

Grade 7

L7M - Chromium-Molybdenum Alloy Steel per ASTM A194,

Grade 7M, 235 BHN Max, ASTM A320, Section 9

MKH - Monel K-500, Cold drawn and aged hardened, QQN-286

and ASTM F467

8F - 303 Stainless Steel per ASTM A194, Grade 8F

2HYC - ASTM A194, Grade 2H, Yellow Zinc Dichromate Plated

4

Page 5

BTV/BUV 2000

SECTION V

Section Title Page

A. VALVE ASSEMBLY –

1

/2” & 3/4” G4, G4R

TABLE OF CONTENTS

Foreword 3

I. Safety Precautions 5

II. Installation 6

III. Disassembly Procedure 7

IV. Parts List 7

V. Repair Kits 9

VI. Assembly Instructions 10

VII. Gear Operator Installation 17

VIII. Changing Gear Operator Quadrants 17

IX. Locking Lever Installation 18

X. Changing Locking Lever Quadrants 18

XI. Stud Bolts and Cap Screw Lengths – Wafer Style Body 19

XII. Cap Screw Lengths – Lug Style Body 19

SECTION I

Safety Precautions

To ensure that the valve is installed in a safe manner, please

adhere to the following precautions before removal or

disassembly of any valve.

1. There is a possibility of pressurized media build

up behind the valve liner. Wear suitable protective

equipment for the fluid involved when removing a

valve from the pipeline.

2. Depressurize and bleed the line on both sides of the

valve before removing the valve.

Design Changes

In order to follow the Flowserve commitment to contin uous

improvement, we reserve the right to change product and

performance specifications without notice.

3. Check nameplate before installation to ensure that the

valve is not installed in systems where service conditions

exceed those for which the valve was designed.

4. Remove or install the valve with the disc in the closed

position.

5. Never attempt to adjust the disc in the seat while the

valve is pressurized.

5

Page 6

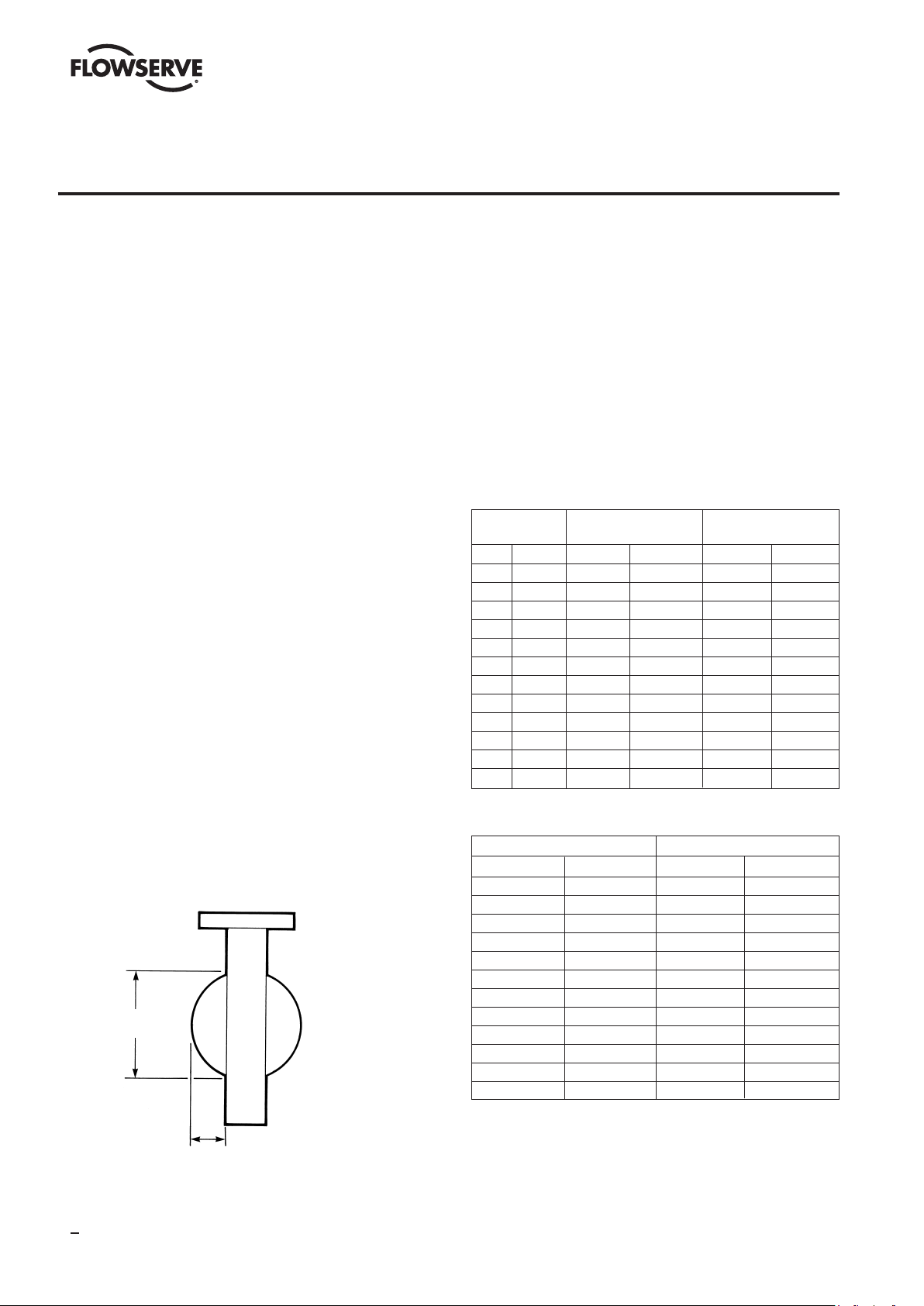

SECTION II

INSTALLATION

BTV/BUV 2000

1. The protective covers provided on each valve should

remain in place during any storage and handling

operations.

2. The Durco Butterfly Valve is designed for installation

between ANSI Class 150 flanged piping systems. All

types of flanges are permissible if clearance is provided

for the swing of the disc and support is provided for the

valve liner. Table 3 lists disc swing clearance requirements for mating pipe flanges. IMPORTANT – Fittings

such as tees and elbows cannot be bolted directly to the

valve. Spacers must be used.

3. Check the valve nameplate before installation to ensure

that the pressure rating and materials of construction

are compatible with the intended service conditions.

4. Inspect adjoining pipelines and remove any material that

could damage the valve liner.

5. Use flange gaskets to protect the valve liner during

installation.

6. Keep the valve in the closed position during all handling

and installation operations. This is necessary to protect

the disc sealing edge from damage and to ensure proper

positioning of the liner until the valve is installed.

7. Keep the valve liner clean. Any dirt or debris left in the

valve can scratch the liner or disc edge. Such damage

can impair the bubble tight shutoff provided by this

valve.

8. Do not allow the liner to catch on the mating pipe I.D.

and fold over. This will cause flange leakage and severe

damage to the liner.

9. While the BTV valve is bidirectional and will function

properly with the shaft orientation either vertical or

horizontal, the preferred orientation is with the shaft

horizontal and the disc lower edge opening downstream

for optimal service life.

10. Proper alignment of the valve in mating flanges is

required. This is especially true if oversize bolt holes

are used in piping flanges.

Flange bolts should be torqued to values listed in Table 4.

11.

12. After the valve has

been installed between

flanges and all

flange bolts have

been tightened, slowly

turn the disc and

check for freedom of

Disc Dimension

disc movement.

at Valve Face

13. If the valve is to be

removed from the

pipeline for any

reason, the

valve must be closed

Disc Projection

loosened. The valve must remain closed until removed

before any of the

flange bolts are

from the pipeline. SEE SAFETY PRECAUTIONS.

14. For recommended flange bolting sizes and lengths, refer

to Tables in Section XI and XII.

DO NOT run sharp instruments between the valve and liner

or between the liner and the pipe flanges. This practice will

result in severe liner damage.

TABLE 3

TABLE 4

Flange Bolting Torques

These are minimum torque values as established in Section

VIII of the ASME Boiler Code. Your piping practices,

materials and gaskets may dictate the use of torque values

greater than those listed. Refer to Section VIII of the ASME

Code for proper bolting torques.

VALVE DISC DISC DIM. AT

SIZE PROJECTION VALVE FACE

IN (MM) IN (MM) IN (MM)

2 (51) 0.390 (9.91) 1.805 (45.85)

3 (76) 0.672 (17.06) 2.586 (65.68)

4 (102) 0.994 (25.24) 3.487 (88.56)

6 (152) 1.860 (47.24) 5.510 (139.9)

8 (203) 2.688 (68.27) 7.379 (187.4)

10 (254) 3.626 (92.10) 9.569 (243.0)

12 (305) 4.438 (112.7) 11.564 (293.7)

14 (356) 5.071 (128.8) 12.758 (324.1)

16 (406) 5.626 (142.9) 14.718 (373.8)

18 (457) 6.407 (162.7) 16.719 (424.7)

20 (508) 7.157 (181.8) 18.656 (473.9)

24 (610) 7.781 (197.6) 20.750 (527.2)

VALVE SIZE TORQUE

in (mm) Ft.-Lbs. (Nm)

2 (51) 49 (66)

3 (76) 84 (114)

4 (102) 61 (83)

6 (152) 123 (167)

8 (203) 164 (222)

10 (254) 155 (210)

12 (305) 198 (268)

14 (356) 246 (334)

16 (406) 230 (312)

18 (457) 331 (449)

20 (508) 303 (411)

24 (610) 458 (620)

6

Page 7

SECTION III

DISASSEMBLY PROCEDURE

NOTE: BEFORE REMOVING THE VALVE FROM THE PIPE-

LINE, THE VALVE DISC MUST BE IN THE CLOSED POSITION

SO AS NOT TO DAMAGE THE SEALING EDGE OF THE DISC.

1. Place the valve in a vice or other suitable support. Do

not clamp on the face of the liner. Leave the disc in the

closed position during disassembly.

2. Remove the wrench, gear or actuator assembly from

the mounting plate.

3. Remove the mounting plate from the top of the valve by

removing two socket head screws.

4.

Loosen several turns but do not remove the retainer

plate screws on the top and bottom. CAUTION – Retainer

plates are under spring loading.

5. Loosen and remove the four bolts that hold the body

halves together.

6. Remove the top body half. Be careful not to lose the

body half bushings as they may drop out.

7. Remove the disc and liner assembly from the bottom

body half.

8. Complete the disassembly of top and bottom body

halves by removing the retainer plate screws, glands,

springs, bearings and stem seals.

9. CAREFULLY remove the disc from the liner. Use

extreme caution to avoid damaging the disc stem seal

convolutions or disc O.D. sealing surface. Once the liner

has been removed from the disc, it cannot be reused.

10. Clean and inspect all parts not contained in the repair kit

and replace if worn, damaged or heavily corroded.

11. If the disc is to be used again, carefully polish the

sealing edge of the disc to remove any scratches. Use

only 400 grit or finer sandpaper.

BTV/BUV 2000

SECTION IV

PARTS LIST

Indicates Repair Kit Parts

For 3” Only

Figure 3 - Exploded View of 2” and 3” Valves

7

Page 8

4”, 5” & 6”

Sizes Only

BTV/BUV 2000

Indicates Repair Kit Parts

Figure 4 - Exploded View of 4” - 16” Valves

For 20”, & 24”

Wafer and Lug

Body

For 20”, & 24” Only

Indicates Repair Kit Parts

Figure 5 - Exploded View of 18” - 24” Valves

8

Page 9

TABLE 5 - Bill of Materials

85

BTV/BUV 2000

Item Description

1 Body - (2 Piece) A395 GR. 60-40-18 A351-/A744 GR. CF8M 1 11111111111 1

1A Hex Head Cap Screw A193 GR. B7 A193 GR. B8* 4 444444444444

1B Hex Nut A194 GR. 2H A194 GR. 84444444444444

1C Body Bushing Carbon Steel 304 Stainless Steel 2 222222222222

2 Disc See Chart How to Specify See Chart How to Specify 1 111111111111

3 Retainer Plate Zinc Plated Carbon Steel 304 Stainless Steel 1 122222222222

4 Socket Head Cap Screw Zinc Plated A574-4037 Alloy Steel A193 GR. B8* 2 22222222222 2

4A Socket Head Cap Screw Zinc Plated A574-4037 Alloy Steel A193 GR. B8* 2 26666666666 6

5Top Gland 304 Stainless Steel 304 Stainless Steel 1 111111111111

5A I.D. O-Ring Viton Viton 1 111111111122

5B O.D. O-Ring Viton Viton 1 122222222222

6 Spring 302 Stainless Steel 302 Stainless Steel 1 122222222222

7 Bearing Glass-Filled Phenolic Glass-Filled Phenolic 1 122222222444

8 Stem Wedge Ring 302 Stainless Steel 302 Stainless Steel 1 122222222222

9 Stem Compression Ring Silicone or Viton Silicone or Viton 1 12222222222 2

10 Liner PTFE or UHMWPE PTFE or UHMWPE 1 11111111111 1

11 Seat Energizer Silicone or Viton Silicone or Viton 2 222222222222

12 Bottom Gland 304 Stainless Steel 304 Stainless Steel 1111111111 1

13 Actuator Mounting Plate Carbon Steel Nickel Plated Carbon Steel 1 11111111111 1

14 Stem Extension 304 Stainless Steel 304 Stainless Steel 111

15 Shim 303 Stainless Steel 303 Stainless Steel As Required

16 Disc Support Bracket Carbon Steel Carbon Steel 11

17 Disc Support Stud 304 Stainless Steel 304 Stainless Steel 11

18 Hex Nut A194 GR. 8 A194 GR.

19 Washer 303 Stainless Steel 303 Stainless Steel 22

20 Thrust Washer PTFE PTFE 22

21 Sleeve Carbon Steel 304 Stainless Steel 1

22 Ground Spring 300 Series Stainless 300 Series Stainless 1 111111111111

*Grade B8 fasteners must have 40,000 psi minimum yield strength.

Material of Construction Material of Construction

Standard Stainless

Quantity Required by Size

2 3456810 12 14 16 18 20 24

5

SECTION V

REPAIR KITS

IMPORTANT NOTE: The use of parts or repair tools other

than those supplied by the Flowserve Corpora tion could

adversely affect the operation and perfor mance of this

valve. Unauthorized modifications or substitution of

components could lead to premature valve failure due

to corrosion and/or functional problems with the

substituted parts.

Complete repair parts kits and repair tooling kits are available

from the Flowserve Corporation. Compo nents of the parts kits

are shown in Figures 3, 4, 5. Compo nents of the repair tooling

kits are shown in Figure 6.

IMPORTANT – Stem packing/bearing kits are calibrated to

a specific stack height. Top and bottom kits are packaged

separately. DO NOT MIX parts between kits.

Figure 6 - Repair Tools

9

Page 10

BTV/BUV 2000

Repair Tools

Item Description Use

1 Liner Stem Seal Die To re-form the liner stem seal around the disc stem prior to installing the disc-liner

assembly into the body.

2 Stem Seal Push Rod To push the stem seal components and bearings into position in the body stem bore.

3 Disc Stem Liner Guide To protect the liner stem seal and ease assembly of the disc into the liner.

4 Disc Stem Body Guide To guide the disc-liner assembly into the stem bore of each body half.*

*On the 14”-24” sizes, there are 2 Disc Stem Body Guides. The longest one is for the long disc stem, the shortest one is for the short disc stem.

SECTION VI

ASSEMBLY PROCEDURE

1. All Sizes

To assemble the disc (2) into the liner (10), first slide the

disc stem liner guide (repair tool item 3) over the long stem

of the disc. Then slide the long stem through either of the

liner stem seal necks (Figure 7). Push the liner down the

stem until it touches the edge of the disc.

Figure 7

2.

Sizes 2” - 8”

Rotate the disc 90 degrees (open position in the liner).

Using a vise, carefully squeeze the liner until the short

disc stem can slide through the other liner stem seal neck

(Figure 8). Exercise care to avoid gouging or damaging

the liner.

10

Figure 8

Sizes 10” - 24”

Clamp the long disc stem in a vise. Rotate the liner 90

degrees (disc open position) and by hand, squeeze the

liner until the short disc stem can slide into the other liner

stem seal neck (Figure 9). Exercise care to avoid gouging or

damaging the liner. This is a strenu ous operation especially

with UHMWPE liners. Heating the liner to 150° F prior to

attempting this operation will help. Two people may be

required to perform this operation on the larger sizes.

Page 11

Figure 9

3. All Sizes

Make sure the liner and disc are clean and then close the

disc into the liner to stretch the liner back into shape. Slide

the liner stem seal die (repair tool item 1) and push it up

tightly against the liner (Figure 10). Allow the dies to remain

in place for at least 5 minutes. Note that the end of the liner

stem seal die with the internal chamfer should be towards

the liner when installed.

Figure 10

BTV/BUV 2000

Figure 11

5.

Sizes 2” - 12”

Place the seat energizer (11) in the bottom body half

(Figure 12). Be sure that the energizer is firmly pushed

into the groove in the body. Also note the orientation of the

angled cuts on the ends of the energizer. When placing the

seat energizer into the top body half, the orientation of the

angled cuts must be opposite to the bottom half.

Figure 12

4. All Sizes

Clamp the bottom body half in a vise and place the body

bushings (1C) into the counterbored holes on diagonal

corners (Figure 11). Either body half can be used as top or

bottom, except for the 2” and 3”. On these sizes, the body

half with the blind stem bore is the bottom.

Sizes 14” - 24”

The seat energizers on these sizes must be trimmed to

length. Place the seat energizer in the bottom body half.

Be sure that the energizer is firmly pushed into the groove

in the body. Mark the seat energizer where it reaches the

machined end of the body half (Figure 13). Remove the seat

energizer and cut each end square at the mark. Place the

seat ener

pushed into the groove. The cut end of the seat energizer

should be flush to 1/16” above the machined end of the

body half.

gizer back into the groove being sure it is firmly

11

Page 12

Figure 13

BTV/BUV 2000

Size 20” and 24”

Prior to putting the liner-disc assembly into the body, the

disc support stud (17) must be attached to the short stem

of the disc. Thread one nut (18) on the short threaded end

of the stud all the way up to the flat on the stud. Apply a

thread locking material such as LOCKTITE® to the threads

on the short end of the stud and screw the stud into the

tapped hole on the short stem end of the disc. Torque the

stud to 100 ft-lbs, then tighten the nut against the disc stem

end to a torque of 100 ft-lbs.

6.

Size 2”

Spread the liner flanges apart and firmly push the linerdisc assembly into the lower body half.

Size 3”

Slide the liner stem sleeve (21) over the liner stem seal

neck on the short stem of the disc. Spread the liner flanges

apart and firmly push the liner-disc assembly into the lower

body half.

Sizes 4” - 24”

Remove the liner stem seal die from the short stem end

of the disc. Place the disc stem body guide (repair tool item

4) over the short stem of the disc (Figure 14). The end of

the disc stem body guide must cover the liner stem seal

neck for the tool to work properly. Spread the liner flanges

apart and carefully lower the liner-disc assembly into the

lower body half (Figure 15). Firmly push the liner-disc

assembly into the lower body half. Pull the disc stem body

guide off the short disc stem.

Figure 14

Figure 15

7.

Sizes 2” - 12”

Orient the top body half so that when put together with

the bottom half, the counterbored bolt holes will line up

with the body bushings (1C) in the bottom half. The DURCO

logo on the top body half should be on the opposite side of

the bottom half when bolted to gether. Firmly push the seat

energizer into the groove in the top body half. Orientate the

angled cuts on the ends of the energizers such that when

the body halves are bolted together, the ends on the top half

will mate with the bottom half. (Figure 16).

Figure 16

Sizes 14” - 24”

12

Page 13

BTV/BUV 2000

Trim the seat

energizers to length

per instructions in Step

6 and firmly push the

energizer into the

groove in the body.

8. All Sizes

Remove the liner

stem seal die from

the long stem of the disc.

Slide the disc stem

body guide (repair

tool item 4) over the

long stem making

sure that the end of

the body guide covers

the liner stem seal neck.

Orient the top body

half so that when put together with the bottom half, the

counterbored bolt holes will line up with the body bushings

(1C) in the bottom half.

half should be on the opposite side of the bottom half when

bolted together. Carefully lower the top body half over the disc

stem and push firmly in place (Figure 17). The gap between

the body halves should be approximately 1/4” when properly

assembled.

9. All Sizes

Install the four body bolts (1A) and finger tighten the nuts

(1B) maintaining an even gap between body halves (Figure

18). See note – Table 6.

10. All Sizes

There are two individually packaged stem packing kits

on all sizes (except for 2” and 3” which only have one).

The DURCO logo on the top body

Figure 17

Figure 18

top stem packing kit. This kit has a packing gland (5) with a

large hole bored through for the disc stem. Place the rubber

stem compression ring (9) into the top body stem bore with

the conical end facing upward, away from disc. Next place

the stem wedge ring (8) into the stem bore with the flat side

upward, away from the disc (Figure 19). The conical end

of the stem compression ring is designed to mate with the

conical bore in the wedge ring. Using the stem seal push

rod (repair tool item 2), push the compression ring and

wedge ring to the bottom of the body stem bore (Figure 20).

Figure 19

Figure 20

11. All Sizes

Next, place the bearing (7) over the disc stem and push

it into the body stem bore. Do not use excessive force to

prevent damage to the bearing. Using the stem seal push

rod, push the bearing to the bottom of the body stem bore.

If necessary, use a hammer and lightly tap on the stem seal

push rod to push the bearing into position. The 18” - 24”

sizes have two bearings. Install the second bearing in the

The packing sets are calibrated for stack height so it is

very important not to mix parts between kits. Locate the

same manner. Next place the metal shims (15) on top of

the bearing. Slide the spring (6) over the stem and into the

13

Page 14

bore. Take the larger diameter o-ring (5B) and put it into

the outside groove of the top gland (5). Place the smaller

diameter o-ring into the inside groove of the gland. Slide

the gland over the disc stem. The outside o-ring must be on

top, away from the disc (Figure 21). Place the ground spring

(22) over the disc stem.

Figure 21

BTV/BUV 2000

12. All Sizes

Place the retainer plate (3) over the disc stem on top of

the ground spring and gland. Find the two longest socket

head screws (4) and finger tighten them 3 to 4 turns into

diagonally opposite holes as follows: facing the valve body,

put one in the front hole on the left side of the body stem

bore and the other in the back hole on the right side. Put

two short socket screws (4A) in the other two holes and

finger tighten 3 to 4 turns (Figure 22). See note – Table 6.

Figure 22

13.

Sizes 4” - 6”

Turn the valve over and place the stem extension (14)

into the hole in the bottom disc stem. Install the stem

compression ring, stem wedge ring, bearing, shims, spring,

and bottom gland (12) with o-ring per the instructions in

steps 10,11 and 12. Note that the retainer plate screws on

the bottom are all the same length. See note – Table 6.

Sizes 8” - 18”

Turn the valve over and install the stem compres sion

ring, stem wedge ring, bearing, shims, spring, and bottom

gland (12) with o-ring per the instructions in steps 10, 11,

and 12. Note that the retainer plate screws on the bottom

are all the same length. See note – Table 6.

Size 20” and 24”

Turn the valve over and install the stem compres sion

ring, stem wedge ring, bearing, shims and spring per the

instructions in steps 10, 11 and 12. Place the small o-ring

(5B) in the groove on the inside bore and the large o-ring

in the groove on the outside of the bottom gland. Orient the

gland with the outside o-ring on top, away from the disc

and carefully slide the gland over the disc support stud.

Place the retainer plate on top of the gland. Next, thread 2

nuts (18) onto the disc support stud until they are touching

the retainer plate. Slide the metal washer (19) over the disc

support stud such that the recessed counterbore is facing

upwards, away from the disc. Next place the PTFE thrust

14

Page 15

BTV/BUV 2000

washer (20) on top of the metal washer. It should fit into

the counterbore of the metal washer. Place the disc support

bracket on next with the large center hole facing down,

towards the disc. Install 4 socket head screws and finger

tighten 3 to 4 turns (Figure 23). See note – Table 6.

Figure 23 - 20”

and 24”

Disc Support

Jam Nut

Bottom

Gland

Retainer

Plate

Disc

Support

Bracket

Disc

Support

Stud

Metal

Washer

PTFE

Thrust Washer

Outer

O-Ring

Inner

O-Ring

Retainer

Plate Bolt

Inner

Jam Nuts

Outer

Jam Nuts

Assembly Detail

14. All Sizes

Align the disc in the closed position so the disc is

centered in the liner. Close alignment is important so use

a scale to ensure the disc is closely centered. Measure at

the 3 o’clock and 9 o’clock positions (Figure 25). These

measurements will be identical with the disc properly

centered. In a criss-cross pattern, tighten the 4 body bolts

and torque to the values listed in Table 4. Be sure to bring

the body halves together evenly. This will require gradual

tightening of each bolt. As the body bolts are tightened,

the disc may rotate out of alignment with the seat. If this

occurs, stop tighten ing immediately, realign the disc in the

seat, and then continue tightening the bolts. Failure to bolt

the body halves evenly will cause them to bind. This may

pre vent the body halves from mating completely using

the specified bolting torques. DO NOT EXCEED TORQUE

SPECIFICATIONS ON BODY BOLTS. See note – Table 6.

15.

Sizes 4” - 12”

Tighten the 4 bottom retainer plate screws in a crisscross pattern and torque to the values listed in Table 6.

Be sure to bring the retainer plate down evenly. This will

require gradual tightening of each bolt. Failure to do so will

cause the bolts to bind on the retainer plate and may bend

the retainer plate. When properly in stalled, the retainer

plate will be tight against the body end. DO NOT EXCEED

TORQUE SPECIFICA TIONS ON RETAINER PLATE BOLTS.

See note – Table 6.

Sizes 14” - 18”

Check to make sure that the bottom gland is aligned

with the body stem bore. Tighten the 4 bottom retainer

plate screws in a criss-cross pattern and torque to the

values listed in Table 6. Be sure to bring the retainer plate

down evenly. This will require gradual tightening of each

bolt. Check to make sure that the bottom gland remains

aligned with the body stem bore. If not proper ly aligned,

the gland can bind in the stem bore and may bend the

retainer plate. When properly installed, the retainer plate will

be tight against the body end. DO NOT EXCEED TORQUE

SPECIFICA TIONS ON RETAINER PLATE BOLTS.

See note – Table 6.

TABLE 6 - Bolting Torques

Carbon Steel Fasteners

Part Body Body Retainer Retainer

Alloy B7 (8.8) 4037 (8.8)

Size Ft-Lbs (NM) Ft-Lbs (NM)

2 40 (54) 30 (41)

3 40 (54) 30 (41)

4 40 (54) 30 (41)

5 40 (54) 40 (54)

6 40 (54) 40 (54)

8 80 (108) 40 (54)

10 120 (163) 100 (136)

12 160 (217) 100 (136)

14 180 (244) 100 (136)

16 200 (271) 100 (136)

18 200 (271) 100 (136)

20 250 (339) 100 (136)

24 250 (339) 100 (136)

Stainless Steel Fasteners

Part Body Body Retainer Retainer

Alloy B8-40 (A2-70) B8-40 (A2-70)

Size Ft-Lbs (NM) Ft-Lbs (NM)

2 20 (41) 20 (41)

3 20 (41) 20 (41)

4 20 (41) 20 (41)

5 20 (41) 40 (54)

6 20 (41) 40 (54)

8 40 (54) 40 (54)

10 120 (81) 60 (81)

12 160 (81) 60 (81)

14 180 (163) 100 (136)

16 200 (217) 100 (136)

18 200 (217) 100 (136)

20 250 (339) 100 (136)

24 250 (339) 100 (136)

15

Page 16

BTV/BUV 2000

Important Note: For stainless steel or other high alloy

fasteners with a yield strength below 70,000 psi, it may

be necessary to use B7 fasteners for the initial assem bly.

Once the valve is fully assembled, each fastener must then

be removed one at a time and replaced with the high alloy

fastener. The high alloy fasteners must be torqued to the

levels specified in Table 6.

Size 20” and 24”

Check to make sure that the bottom gland is aligned with

the body stem bore. Tighten the 4 bottom retainer plate

screws in a criss-cross pattern and torque to the values

listed in Table 6. Be sure to bring the retainer plate down

evenly. This will require gradual tightening of each bolt.

Check to make sure that the bottom gland remains aligned

with the body stem bore. If not proper ly aligned, the gland

can bind in the stem bore and may bend the retainer plate.

Also, check to make sure that the jam nuts do not bottom

on the disc support bracket as the retainer screws are

tightened. It may be necessary to thread the nuts further

down on the disc support stud as the retainer screws are

tightened to maintain clearance. When properly installed,

the retainer plate will be tight against the body end. DO NOT

EXCEED TORQUE SPECIFICATIONS ON RETAINER PLATE

BOLTS. See note – Table 6.

After the retainer bolts are tightened, finger tighten the

inner jam nuts against the disc support bracket. Place the

outer PTFE thrust washer, the metal thrust washer with

the shallow counterbore facing down against the PTFE

washer, and 2 outer jam nuts on the disc support stud.

Finger tighten the jam nuts against the disc support bracket.

Using a wrench on the inner and outer jam nuts located

against the inner and outer metal washers, simultaneously

torque the nuts to approximately 40 ft-lbs. This will seat

the PTFE thrust washers against the bearing surface of

the disc support bracket. Then tighten the second jam nut

against the first jam nut to 100 ft-lbs. Make certain that when

tightening the second jam nut, the first jam nut or the disc

support stud does not turn. When complete, tack weld the

jam nuts together (Figure 23).

sealing edge of the disc or liner which will com pro mise the

bubble tight shutoff provided by this valve.

Figure 24

18. All Sizes

Align the disc in the closed position so that the disc is

centered in the liner. Close alignment is important so use

a scale to ensure the disc is closely centered. Measure at 3

o’clock and 9 o’clock positions. These measurements will

be identical with the disc properly centered (Figure 25). The

valve is now ready for the actuator to be installed.

16. All Sizes

Tighten the 4 top retainer plate screws following the

instructions in step 15. After all four screws are torqued to

the values listed in Table 6, remove the two longest retainer

screws (installed in step 5). Place the mount ing plate (13)

on top of the retainer plate, reinstall the two long retainer

screws (Figure 24) and torque to the values listed in Table

6. See note – Table 6.

17. All Sizes

Carefully clean all exposed liner surfaces. Cycle the valve

5 to 6 times making sure the disc swings com pletely through

the liner in both directions. The initial breaking torque will

be high. Cycling the disc several times helps to “set” the

liner and seat energizer plus smooth out any ridges that may

have formed in the liner during assembly. A small amount of

lubricant, such as silicon, applied to the disc sealing diameter

will help reduce the initial torque. BE CAREFUL to avoid dirt

or grit contamination in the liner as

16

this can scratch the

Figure 25

Page 17

SECTION VII

MANUAL GEAR OPERATOR INSTALLATION

BTV/BUV 2000

1. Close the valve. The flats on top of the stem should be

parallel with the valve flange face. NOTE: At this time

adjustments should be made to assure that the valve

body machined flanged surface (6) is parallel with the

disc. To accomplish this, place the valve body machined

flanged surface (6) on a level plate. Then position a

bubble level on the upper side of the shaft square and

adjust the shaft until com pletely level.

2. Rotate the gearbox handwheel (1) clockwise until the

gearbox pointer (2) indicates the “shut” position.

3. Place the gearbox on the valve mounting pad as shown in

Figure 26.

4. Loosen the gearbox stopping screws (3) and (7).

5. Install and tighten the gearbox bolts (4) with their

lockwashers.

6. Turn the gearbox closing stop screw (7) clockwise until it

stops, then tighten the lock nut (8).

7. Turn the gearbox handwheel (1) counterclockwise to

open the valve until the disc face is perpendicular to the

valve body flange face.

8. Turn the gearbox opening stop screw (3) clockwise until

it stops, then tighten the lock nut (5).

9. Cycle the valve from closed to open to closed again

using the gear operator. Recheck to make sure the disc

is centered on the seat by measuring the distance from

the machined surface on the disc edge to the inner edge

of the liner flanged surface (6) on the body. This should

be done at two points, at the 3 o’clock and 9 o’clock

positions. Both measurements should be equal.

Gearbox Stop

Screw (7)

Lock Nut (8)

Machined Flanged

Surfaced (6)

Body

Gearbox

Pointer (2)

Figure 26

Gearbox Stop

Screw (3)

Lock Nut (5)

Gearbox

Handwheel (1)

SECTION VIII

CHANGING MANUAL GEAR OPERATOR QUADRANTS

CAUTION: Do not attempt to change the manual gear

operator quadrant while the valve is in service.

1. Close the valve. The flats on top of the stem should be

parallel with the valve flange face. Depressurize system if

valve is installed as valve could open when manual gear

operator is removed.

2. Remove manual gear operator. Rotate the gearbox

handwheel (1) until the gearbox pointer (2) indicates the

“shut” position.

3. Place the gearbox on the valve mounting pad in the

desired quadrant.

4. Follow Steps 4 through 8 of the Manual Gear Operator

Installation instructions.

Mounting

Pad

Gearbox

Bolts (4)

17

Page 18

SECTION IX

LOCKING LEVER AND INDICATOR PLATE INSTALLATION

BTV/BUV 2000

1. Close the valve. The flats on top of the stem should be

parallel with the valve flange face. NOTE: At this time

adjustments should be made to assure that the valve

body machined flanged surface (5) is parallel with the

disc. To accomplish this, place the valve body machined

flanged surface (5) on a level plate. Then position a

bubble level on the upper side of the shaft square and

adjust the shaft until completely level.

2. Mount the indicator plate (1) to the valve as shown in

Figure 27 with the shakeproof washers placed between

the indicator plate (1) and the valve body mounting pad.

Do not tighten the indicator plate bolts (4) at this time.

3. Place the locking lever (2) on the valve stem as shown in

Figure 27. Tighten the pinch bolt (3) on the handle.

4. Position the indicator plate (1) so that the locking lever

fits in the “closed” position of the indicator plate (1).

Tighten the indicator plate bolts (4).

5. Cycle the valve from closed to open to closed again using

the locking lever handle. Recheck to make sure the disc

is centered on the seat by measuring the distance from

the machined surface on the disc edge to the inner edge

of the liner flanged surface (5) on the body. This should

be done at two points, at the 3 o’clock and 9 o’clock

positions. Both measurements should be equal.

Figure 27

Machined Flanged

Surface (5)

Body

Indicator Plate (1)

Pinch Bolt (3) Handle (2)

Indicator Plate Bolts (4)

SECTION X

CHANGING LOCKING LEVER QUADRANTS

CAUTION: Do not attempt to change locking lever handle

quadrants while the valve is in service.

1. Close the valve. The flats on top of the stem should be

parallel with the valve flange face. Depressurize system if

valve is installed as valve could open when locking lever

handle is removed.

2. Remove the locking lever (2) and indicator plate (1).

3. Mount the indicator plate (1) 180° from the position

shown in Figure 27. Do not tighten the indicator plate

bolts (4) at this time.

4. Follow Steps 3 and 4 in the Locking Lever and Indicator

Plate Installation instructions.

18

Indicator Plate

Bolts (4)

Locking

Lever

Page 19

SECTION XI

STUD BOLTS AND CAPSCREWS FOR INSTALLATION OF WAFER BODIES

Valve Size 18 20 24

Number of Stud Bolts 12 16 16

Dia. & Thread 11/8 - 8N 11/4 - 8N

“A” Length of Stud Bolts 103/4 111/2 13

Number of Capscrews 8 8 8

Dia. & Thread 11/8 - 8N 11/4 - 8N

“B” Length of Capscrews 3 3 3

Class 150#

ANSI B16.5

Flange Thickness

1

/8” Thick Gasket

“B”

“A”

BTV/BUV 2000

“B”

Valve Size 2 3 4 5 6 8 10 12 14 16

Number of Stud Bolts 4 4 8 8 8 8 12 12 12 16

Dia. & Thread

“A” Length of Stud Bolts 5 51/2 53/4 61/2 61/2 63/4 73/4 81/4 83/4 93/4

5

/8 - 11 UNC

3

/4 - 10 UNC

7

/8 - 9 UNC 1 - 8 UNC

SECTION XII

CAP SCREWS FOR INSTALLATION OF LUG BODIES

“A”

Class 150#

ANSI B16.5

Flange Thickness

“A”

1

/8” Thick Gasket

Valve Size 2 3 4 5 6 8 10 12 14 16 18 20 24

Number of Capscrews 8 8 16 16 16 16 24 24 24 32 32 40 40

5

Dia. & Thread

“A” Length of Capscrews 11/2 13/4 13/4 13/4 2 21/4 21/2 21/2 23/4 3 3 3 3

/8 - 11 UNC

3

/4 - 10 UNC

“A”

7

/8 - 9 UNC 1 - 8 UNC 11/8 - 8 11/4-8

“A”

19

Page 20

For more information, contact:

USA

Flowserve Corporation

Flow Control Division

1978 Foreman Drive

Cookeville, Tennessee 38501

Phone: 931 432 4021

Fax: 931 432 3105

Germany

Flowserve Ahaus GmbH

Flow Control Division

Von Braun Straße 19a

D-48683 Ahaus

Phone: +49 2561 686-100

Fax: +49 2561 686-200

FCD_Ahaus@Flowserve.com

FCD DVENIM0000-01 03.2013

For more information about the Corporation Flowserve,

visit: www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve

product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be

aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve

can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user

must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve

products. The purchaser/user should read and understand the Installation and Maintenance (I & M) instructions included with the product, and

train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only

and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed

as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is continually improving and

upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations

or offices.

Singapore

Flowserve Pte. Ltd.

12 Tuas Avenue 20

Republic of Singapore 638824

Phone: 65 862 3332

Fax: 65 862 2800

www.owserve.com

Loading...

Loading...