Page 1

BK 212

Installation Instructions 810609-00

Steam Trap BK 212

1

Page 2

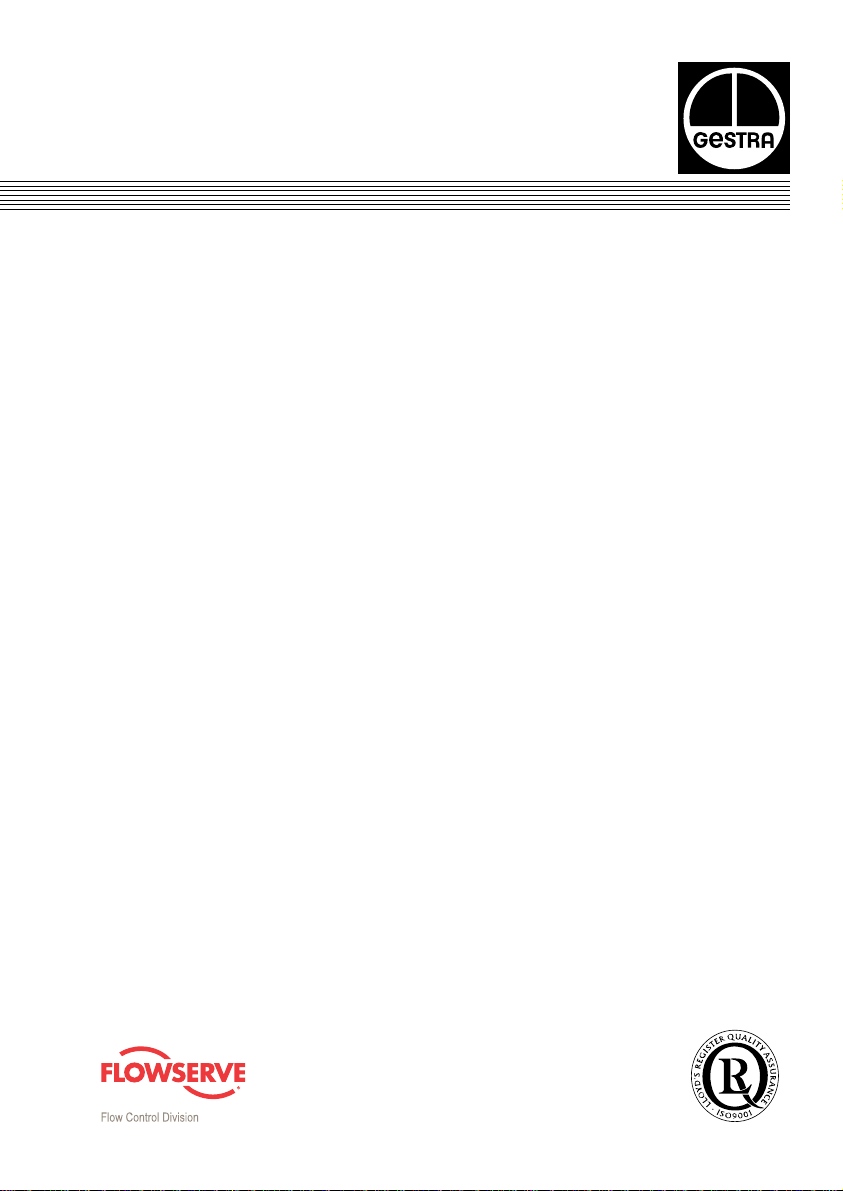

Capacity Chart

[lb/h] [kg/h]

15000

10000

8000

6000

5000

4000

3000

2000

1000

2

800

600

500

400

300

Capacity

200

Fig. 1

15 20 30 40 60 80 100 200 300 400 600 800 1000 2000 3000 3625 [psi]

Differential pressure ∆PMX (assuming discharge to atmospheric pressure)

Max. capacity of hot condensate at factory

1

setting and steam-tight shut-off

2

Max. capacity of cold condensate

1

[bar]

2

Page 3

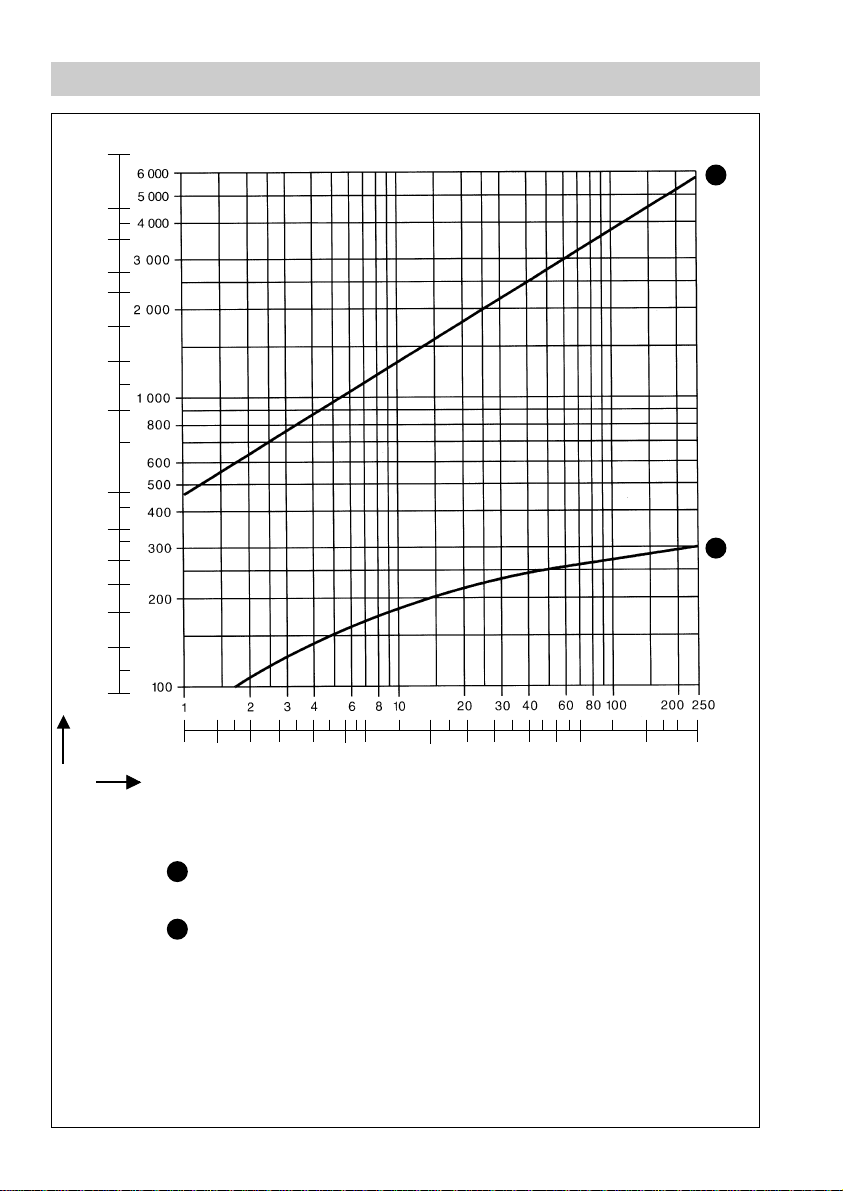

Dimensions

150

Space required

for opening trap

102

~

~

182

~

~

Fig. 1

Butt-weld ends according to DIN 3239-1-R6

edge form 22 to DIN 2559

∅ 140

330

Temperature feeler of

Duo stainless steel plates

2

d1d

1.5

Fig. 2

30°

Butt-weld ends according to DIN 3239-2-R8

edge form 22 to DIN 2559

12°

2

d1d

1.5

Fig. 3

30°

DN d

d

1

2

15 15 22 21.3x3.2

20 19 28 26.9x4.0

PN 320

25 24 35 33.7x5.0

DIN 3239-1-R6

15 18.5 34 33.7x8.0

PN 630

25 25 49 48.3x12.5

DIN 3239-2-R8

for pipe

3

Page 4

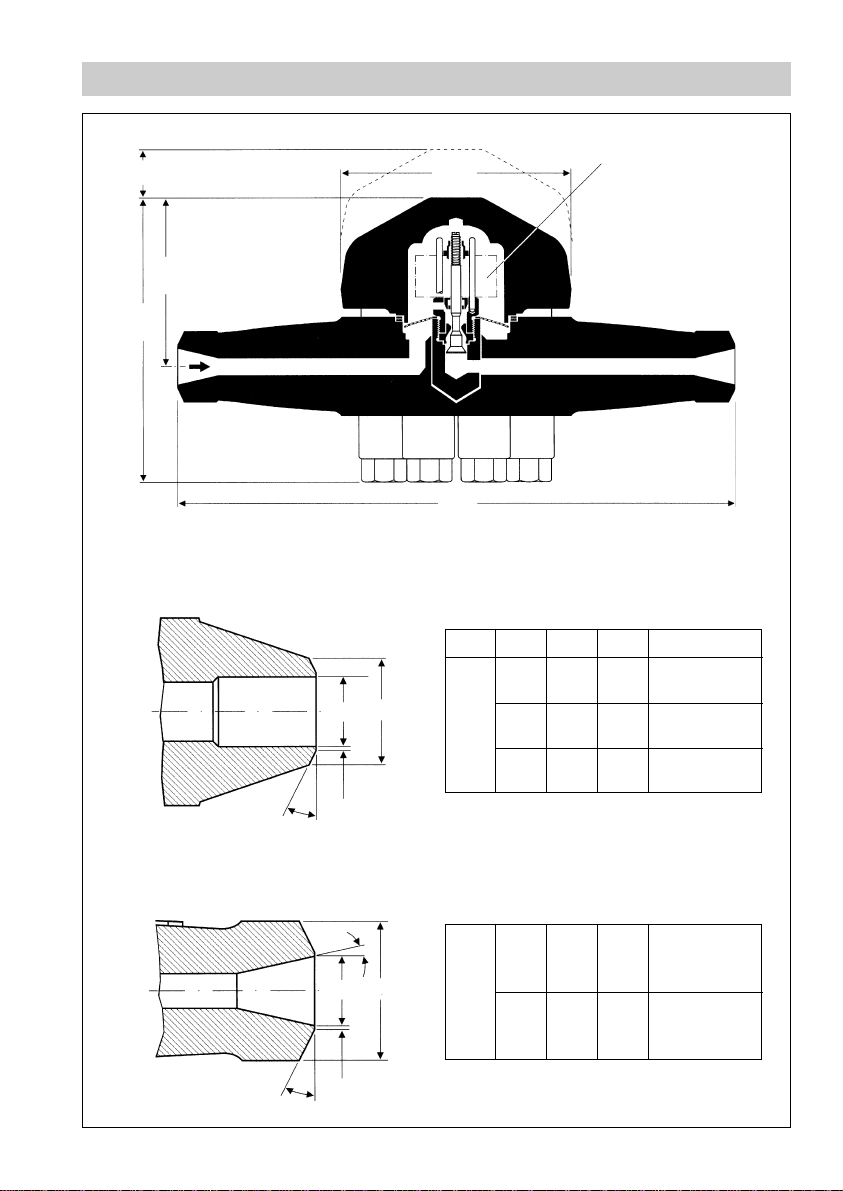

Parts Drawings

G

A

B

C

D

E

4

F

Fig. 4

Page 5

Key

A

Cover

B

Strainer

C

Gasket

D

Regulator

E

Body

F

Cap nut

G

Cover bolt

10

5

Page 6

Contents

Page

Important Notes

Safety note ...................................................................................................................... 7

Danger ............................................................................................................................ 7

Explanatory Notes

Scope of supply .............................................................................................................. 8

Description ...................................................................................................................... 8

Function .......................................................................................................................... 8

Technical data ........................................................................................................... 9-10

Installation

BK 212 ........................................................................................................................... 10

Heat treatment of welds ............................................................................................... 10

Regulator ......................................................................................................................11

Maintenance

Replacing of regulator................................................................................................... 11

Spare Parts List

Spare parts ................................................................................................................... 12

6

Page 7

Important Notes

Safety Note

Use steam trap BK 212 only for the discharge of steam condensate. The steam trap

may only be installed by qualified staff. Qualified staff are those persons who – through

adequate training in engineering, the use and application of equipment in accordance

with regulations concerning steam systems, and first aid & accident prevention – have

achieved a recognised level of competence appropriate to the installation and

commissioning of this device.

Danger

The steam trap is under pressure when the system is operating.

When loosening flanged connections or plugs hot water or steam may

escape. This presents the risk of severe scalds to the whole body.

Before carrying out installation and maintenance work it is therefore

essential to isolate and depressurize the trap.

The trap becomes hot during operation.

This presents the risk of severe burns to hands and arms.

Before carrying out any installation or maintenance work make sure that

the trap is cold.

Sharp edges on internals present a danger of cuts to hands.

Always wear industrial gloves when replacing the regulator.

7

Page 8

Explanatory Notes

Scope of Supply

BK 212

1 Steam trap type BK 212

1 Installation manual

Description

Thermostatic/thermodynamic steam trap with corrosion-resistant regulator unaffected

by waterhammer. The trap features:

■

Integral strainer

■

Non-return valve action

■

Asbestos-free cover gasket (graphite/1.4541)

■

Installation in any position

Function

The BK 212 is a thermostatic/thermodynamic steam trap with corrosion-resistant Duo

S. S. regulator unaffected by waterhammer. The trap opens and closes irrespectively

of the temperature and pressure prevailing inside the trap. The BK 212 vents air

automatically at start-up and during continuous operation.

8

Page 9

Technical Data

Pressure/Temperature Rating for standard equipment

TMA (admissible temperature) in [°C] for butt-weld ends

to DIN 3239

PMA

(allowable pressure)

[bar] [psi] 15 (

Form 1 – R6 Form 2 – R8

DN [mm] (in) DN [mm] (in)

1

/2") 20*) (3/4") 25 (1") 15 (1/2") 25 (1")

105 1523 550 550 550 550 550

121 1755 540 550 550 550 550

123 1784 539 549 550 550 550

150 2175 525 535 536 550 550

180 2610 511 521 523 550 550

211 3060 500 509 511 550 550

225 3263 494 505 506 546 550

250 3625 485 497 499 538 542

275 3988 476 487 490 531 535

300 4350 467 481 484 525 528

∆PMX (max. differential pressure) 250 bar (3625 psi)

(inlet pressure minus outlet pressure)

Pressure/Temperature Rating for special design (with special bolts and nuts)

TMA (admissible temperature) in [°C] for butt-weld ends

to DIN 3239

PMA

(allowable pressure)

[bar] [psi] 15 (

167 0972 580 580 580 580 580

178 1131 571 580 580 580 580

180 1160 569 579 580 580 580

110 1595 546 556 557 580 580

137 1987 532 541 542 580 580

144 2088 528 538 539 577 580

162 2350 519 529 530 569 580

180 2610 511 521 523 560 573

200 2900 504 513 515 554 565

225 3263 494 505 506 546 557

250 3625 485 497 499 538 550

275 3988 476 487 490 531 543

300 4350 467 481 484 525 537

*) DN 20 not covered by DIN standards.

Form 1 – R6 Form 2 – R8

DN [mm] (in) DN [mm] (in)

1

/2") 20*) (3/4") 25 (1") 15 (1/2") 25 (1")

9

Page 10

Technical Data – continued –

Materials DIN reference

Body 10CrMo 9 10 (1.7380)

Cover bolts (standard) 21 CrMoV 5 7 (1.7709)

Nuts (standard) 24 CrMo 5 (1.7258)

Special cover bolts and nuts X 22 CrMoV 12 1 (1.4923)

Regulator Corrosion-resistant Duo stainless steel

sealing surfaces:

wear-resistant titanium alloy

Other internals Stainless steel

Installation

BK 212

1. The steam trap BK 212 can be installed in any position. In the case of a horizontal

installation, make sure that the cover is at the top.

2. Take care of flow direction. The flow arrow is on the trap body.

3. Consider space required for opening trap. When the trap is installed a minimum

space of 150 mm is required for removing the cover .

4. Remove plastic plugs. They are only used as transit protection.

5. Clean socket-weld ends.

6. Arc-weld trap only manually (welding process 111 in accordance with

DIN EN 24063).

A

Attention

■

Only qualified welders certified e. g. according to DIN EN 287 may weld

the steam trap into pressurized lines.

■

Do not insulate the steam trap.

Heat T reatment of Welds

After the steam trap has been welded into the pipeline the welds require special heat

treatment (we recommend resistance annealing according to DIN EN 100529).

Remove the regulator before carrying out the heat treatment (see Maintenance).

Annealing must be restricted to the region of the welds.

10

Page 11

Installation – continued –

Regulator

The regulator is set at our factory to close steam-tight and open as soon as

condensate is formed.

Tools

■

Spanners A.F. 24 mm

Maintenance

The BK 212 does not require any special maintenance. However, if used in new

installations which have not been rinsed it may be necessary to check and clean the

trap.

Replacing Regulator

11.Remove cover from body , Fig. 4

12.Undo regulator using a spanner.

13.Unscrew regulator and take off strainer .

A E

D

D

B

14.Clean body, regulator, cover and strainer.

15.Clean gasket seating surfaces and insert new gasket .

16.Clean sealing surfaces of regulator and body .

17.Replace strainer .

18.Screw in regulator and tighten with a torque of 100 Nm.

19.Apply heat-resistant lubricant to threads of cover bolts (use for instance

MOLYKOTE HSC

10.Replace cover . Insert bolts and tighten cap nuts at room temperature in

B

D

+®

)

A G F

C

ED

G

diagonally opposite pairs with a torque of 225 Nm.

Tools

■

Spanner A.F. 24 mm

■

Torque spanner 20–120 Nm to DIN ISO 6789

MOLYKOTE® is a registered trademark of Dow Corning GmbH, Wiesbaden

11

Page 12

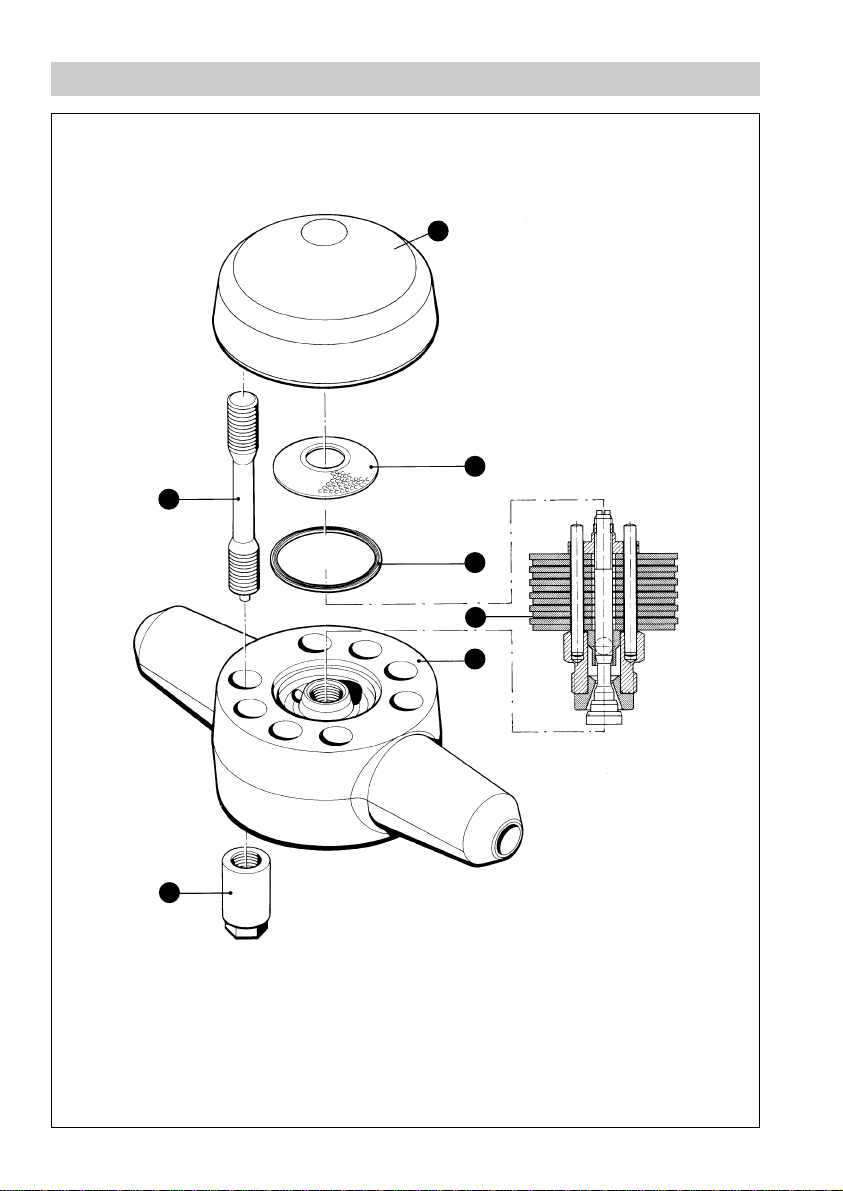

Spare Parts

Fig. 5

Spare Parts List

Item no. Designation Ref. no.

2 Regulator, complete, including

D

C

4.1 Gasket (graphite/1.7335) 374009

B

4.2 Strainer 096345

cover gasket (item 4.2)

C

D

B

C

371862

12

Page 13

13

Page 14

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

España

España

GESTRA ESPAÑOLA S.A.

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

Luis Cabrera, 86-88

E-28002 Madrid

E-28002 Madrid

Tel. (091) 5 152 032

Tel. 003491/5152032

Fax (091) 4 136747; (091) 5 152 036

Fa x003491/41 3674 7; 51 52036

E-mail: gestra@gestra.es

E-mail: gestra@gestra.es

France Portugal

France Portugal

Invensys Flow Control

Flowserve Flow Control S.A.S.

France SAS

10 Avenue du Centaure, BP 8263

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

F-95801 CERGY PONTOISE

Tél. 0 0331/34432660

Tél. (01) 34.43.26.60

Fax 00331/34432687

Fax (01) 34.43.26.87

E-mail: gnation@flowserve.com

E-mail: gnation@gestra.fr

Italia

Italia

Invensys Flow Control Division

Italgestra S.r.l.

Italgestra S.r.l.

Via Carducci 125

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

l-20099 S.S. Giovanni (MI)

Tel. 003902/241012.1

Tel. (02) 24 10 121

Fax 003902/241012.460

Fax (02) 24 10 12460

E-mail: info@italgestra.it

E-mail: info@italgestra.it

Polska

Polska

GESTRA POLONIA Spolka z o. o.

GESTRA POLONIA Spolka zo.o.

Ul. Schuberta 104

Ul. Schuberta 104, P. O. Box 71

PL-80-172 Gdansk

PL-80-172 Gdansk

Tel. (058) 306 1002

Tel. 004858/3061002 oder 306 1010

Fax (058) 306 10 03

Fax 004858/3061003 oder 306 3300

E-mail: gestra@gestra.pl

E-mail: gestra@gestra.pl

GESTRA PORTUGUESA VALVULAS LDA.

GESTRA PORTUGUESA VALVULAS LDA.

Av. Dr. Antunes Guimarães, 1159

Av. Dr. Antunes Guimarães, 1159

P-4100 Porto

Porto 4100-082

Tel. (022) 6 19 87 70

Tel. 0035122/6 19 8770

Fax (022) 6 10 7575

Fax 0035122 /6 107575

E-mail: gestra@gestra.pt

E-mail: gestra@gestra.pt

®

®

GESTRA GmbH

GESTRA GmbH

Postfach 10 54 60

Postfach 10 54 6 0

D-28054 Bremen

D-28054 Bremen

Hemmstraße 130

Münchener Str. 77

D-28215 Bremen

D-28215 Bremen

Tel. + 49 (0) 421 35 03-0

Tel. +49 (0) 421 35 03-0

Fax +49 (0) 421 35 03-393

Fax+49 (0) 421 35 03-393

E-mail

gestra.gmbh@gestra.de

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

Internet www.gestra.de

A Unit of Flowserve Corporation

An Invensys company

810609-00/1100c · ©1999 GESTRA GmbH · Bremen · Printed in Germany

14

Loading...

Loading...