Page 1

Freestanding cooker

OR90SDBGFX models

Installation instructions

and User guide

NZ AU

Page 2

Page 3

Contents

1

Safety and warnings

Installation instructions

First use

Using your oven

Cooking functions

Cooking guide

Using the rotisserie

Using the electronic timer

Automatic cooking

Using your gas cooktop

Care and cleaning

Troubleshooting

Warranty and service

2

8

20

23

26

28

30

32

33

34

38

53

54

Important!

SAVE THESE INSTRUCTIONS

The models shown in this User Guide may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please go to our website www.fisherpaykel.com or

contact your local Fisher & Paykel dealer.

Page 4

2

Safety and warnings

Installation

WARNING!

Electrical Shock Hazard

Always disconnect the cooker from the mains electricity supply before

carrying out any maintenance operations or repairs.

Failure to follow this advice may result in death or electrical shock.

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

Important safety instructions

General

To avoid hazard, follow these instructions carefully before installing or using this product.

Please make this information available to the person installing the product as it could reduce

your installation costs.

These products are registered:

in New Zealand at www.energysafety.govt.nz

in Australia with AGA at www.aga.asn.au

This appliance must be installed in accordance with these installation instructions, local

gas fitting regulations, municipal building codes, water supply regulations, electrical wiring

regulations, AS/NZS5601.1:2010 - Gas Installations and any other relevant statutory regulations.

Failure to install the cooker correctly could invalidate any warranty or liability claims.

Some appliances have a protective film. Remove this film before using the cooker.

Do not modify this appliance.

Do not operate your appliance by means of an external timer or separate remote-control system.

This appliance is to be installed and serviced only by an authorised person.

Page 5

Safety and warnings

Electrical

This cooker is to be installed and connected to the electricity supply only by an authorised person.

If the installation requires alterations to the domestic electrical system, call a qualified

electrician. The electrician should also check that the electrical system is suitable for the

electricity drawn by the cooker.

The appliance must be connected to the mains electricity supply, checking that the voltage

corresponds to the value given in the rating plate and that the electrical cable sections can

withstand the load specified on the plate.

A suitable disconnection switch must be incorporated in the permanent wiring, mounted and

positioned to comply with the local wiring rules and regulations. The switch must be of an

approved type installed in the fixed wiring and provide a 3 mm air gap contact separation in all

poles in accordance with the local wiring rules.

In Australia and New Zealand, a switch of the approved type with a 3 mm air gap must be

installed in the active (phase) conductor of the fixed wiring.

The switch must always be accessible.

The power supply cable must not touch any hot parts and must be positioned so that it does not

exceed 75

To connect the cooker to the mains electricity supply, do not use adapters, reducers or branching

devices as they can cause overheating and burning.

This cooker must be connected to a suitable double pole control unit adjacent to the cooker. No

diversity can be applied to this control unit.

If the electrical supply cord is damaged, it must only be replaced by an authorised person.

This cooker must be connected to electrical supply using V105 insulated cable.

The cooker must be earthed.

O

C at any point.

3

Power supply

220-240V~ 3680W 50/60Hz - 16 A (230V)

Page 6

4

Safety and warnings

Operation

Your freestanding cooker has been carefully designed to operate safely during normal cooking

procedures. Please keep the following guidelines in mind when you are using it:

WARNING!

Explosion Hazard

Do not store flammable materials such as gasoline near the cooktop.

Do not store flammable material in the oven or storage compartment.

Do not spray aerosols near the cooktop during use.

Failure to follow this advice may result in death or serious injury.

Electrical Shock Hazard

Switch the cooker off at the wall before replacing fuses or the oven lamp.

Failure to do so may result in death or electrical shock.

WARNING!

WARNING!

Hot Surface Hazard

Accessible parts may become hot when this cooker is in use.

To avoid burns and scalds keep children away.

Do not touch hot surfaces inside the oven.

Use oven mitts or other protection when handling hot surfaces such as oven

shelves or dishes.

Take care when opening the oven door.

Let hot air or steam escape before removing or replacing food.

Do not touch the cooktop components, burners, pan supports or the base

when hot.

Before cleaning, turn the cooker off and make sure it is cool.

Failure to follow this advice could result in burns and scalds.

Page 7

Safety and warnings

Important safety instructions

Never leave the appliance unattended when in use. Boilover causes smoking and greasy

spillovers that may ignite.

Isolating switch: make sure this cooker is connected to a circuit which incorporates an isolating

switch providing full disconnection from the power supply.

Household appliances are not intended to be played with by children.

Children of less than 8 years old must be kept away from the appliance unless continuously

supervised. This appliance can be used by children aged from 8 years and above, and persons

with reduced physical, sensory or mental capabilities or lack of experience and knowledge, if

they have been given supervision or instruction concerning the use of the appliance in a safe way

and they understand the hazards involved. Cleaning and user maintenance shall not be done by

children without supervision.

Do not store things children might want above the oven. Children could be burned or injured

while climbing on the oven to retrieve items.

Safe food handling: leave food in the oven for as short a time as possible before and after

cooking. This is to avoid contamination by organisms which may cause food poisoning. Take

particular care during warmer weather.

Do not place aluminium foil, dishes, trays, water or ice on the oven floor during cooking as this

will irreversibly damage the enamel.

Do not line the walls with aluminium foil.

Do not stand on the door, or place heavy objects on it.

Do not use harsh abrasive cleaners or sharp metal scrapers to clean the oven door glass since

they scratch the surface, which may result in shattering of the glass.

Do not use a steam cleaner to clean any part of the cooker.

Do not use an asbestos mat or decorative covers between the flame and the saucepan as this may

cause serious damage to your cooktop.

Do not store flammable items in the oven or storage drawer.

5

Page 8

6

Safety and warnings

Operation

Important safety instructions

Do not place aluminium foil or plastic dishes on the cooktop burners.

Do not let large saucepans or frying pans overlap the bench as this can deflect heat onto your

benchtop and damage the surface.

Do not let large saucepans, frying pans or woks push any other pans aside. This could make them

unstable or deflect heat onto your benchtop and damage the surface.

Saucepan handles may be hot to touch. Ensure saucepan handles do not

overhang other gas burners that are on. Keep handles out of reach of children.

If the electrical supply cord is damaged, it must only be replaced by an authorised person.

This cooker is not to be used as a space heater, especially if it is installed in marine craft or in a

caravan.

The use of a gas cooking appliance results in the production of heat and moisture in the room in

which it is installed. Ensure the kitchen is well ventilated. Keep natural ventilation holes open or

install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening

of a window, or more effective ventilation, for example increasing the level of mechanical

ventilation where present.

Page 9

Safety and warnings

Operation

Important safety instructions

Never leave the appliance unattended when in use. Boilover causes smoking and greasy

spillovers that may ignite.

Wear proper apparel. Do not wear loose fitting or hanging garments when using the appliance.

They could ignite or melt if they touch an element or hot surface and you could be burned.

Always keep oven vents unobstructed.

Use only dry oven mitts or potholders. Moist or damp potholders on hot surfaces could result in

burns from steam. Do not let potholders touch hot areas or heating elements. Do not use a towel

or a bulky cloth for a potholder. It could catch fire.

Caution. Hot air can blow from the vent at the top of the oven as part of the oven’s cooling

system.

Placement of oven shelves: always position shelves in the desired location before preheating

the oven. If a shelf must be removed while the oven is hot, do not let the oven mitts or potholder

contact hot heating elements in the oven or the base of the oven.

7

Page 10

8

Installation instructionsInstallation instructions

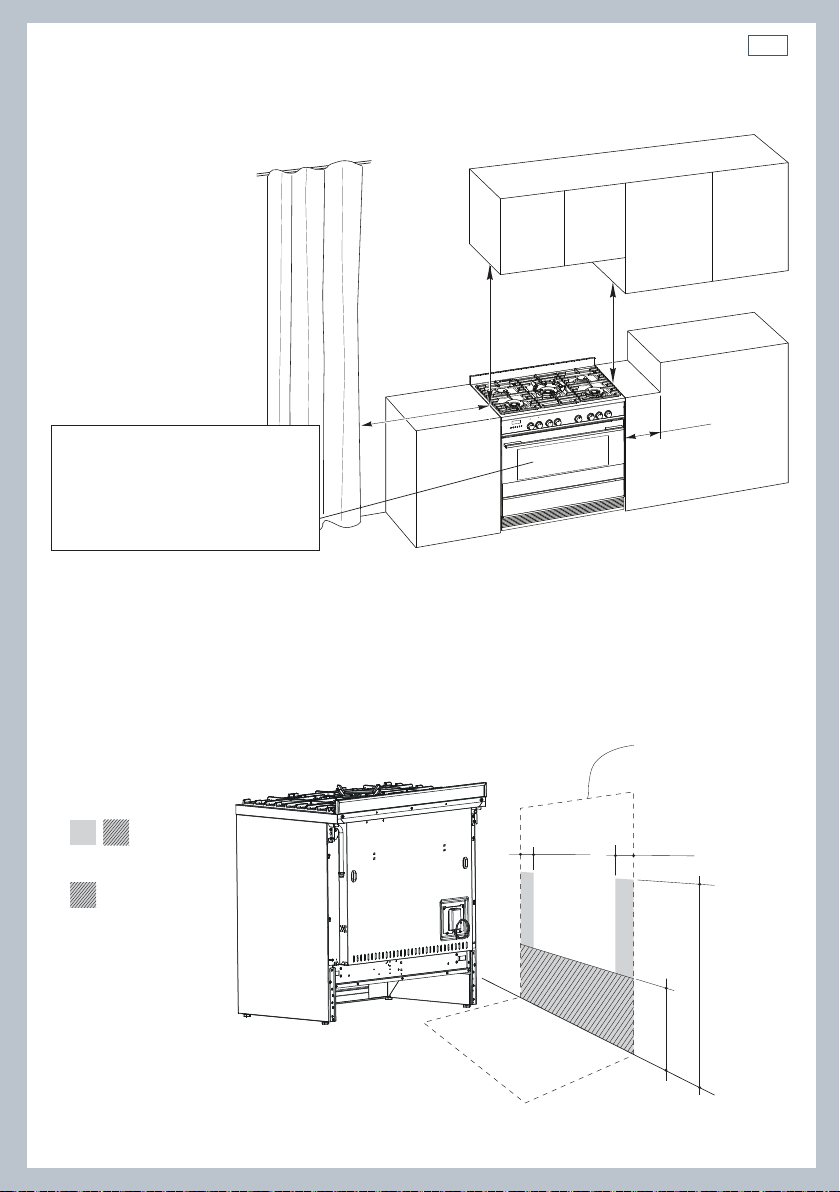

Dimensions and clearances

Installation clearances and protection of combustible surfaces shall comply with the current

local regulations eg. AS/NZS5601.1:2010 Gas Installations code. Installation shall comply with

the dimensions in Fig. 1, bearing in mind the following requirements:

Overhead Clearances

In no case shall the clearance above the highest part of the cooker be less than 600 mm or, for

an overhead exhaust fan, 750 mm. AII other downward-facing combustible surfaces less than

600 mm above the cooker surface shall be protected for the full width of the cooking surface in

accordance with the standards noted above. In no case shall the clearance be less than 450 mm.

Rear and Side Clearances

Where the distance from the periphery of the nearest burner to any vertical combustible surface

is less than 200 mm, the surface shall be protected in accordance with the standards to a height

of not less than 150 mm above the cooking surface for the full width or depth of the cooking

surface.

Where the distance from the periphery of the nearest burner to any horizontal combustible

surface is less than 200 mm, the horizontal surface shall be more than 10 mm below the

surface of the cooking surface, or the horizontal surface shall be above the pan support (see

requirements for vertical combustible surfaces above).

Protection of combustible surfaces

The standards above specify that, where required, protection shall ensure that the surface

temperature of combustible surfaces does not exceed 65°C above room temperature.

Do not install the cooker near flammable materials (eg curtains).

Page 11

Installation instructions

j

9

500 mm

Cooker overall dimensions [mm]

•

height:

•

product width: 897

•

depth: 600

•

cavity width 900

min 897 - max 910

Locating the area for gas and electrical connection

Area for gas

connection

Area for electrical

connection

750 mm

70 mm

450 mm

200 mm

Fig. 1 Dimensions and

distances from cooker

Dotted line showing

the position of the

cooker when installed

70 mm

Fig. 2 Area for gas and electrical connections

240 mm (*)

(*) Depending on

feet ad

450 mm (*)

ustment

Page 12

10

Installation instructionsInstallation instructions

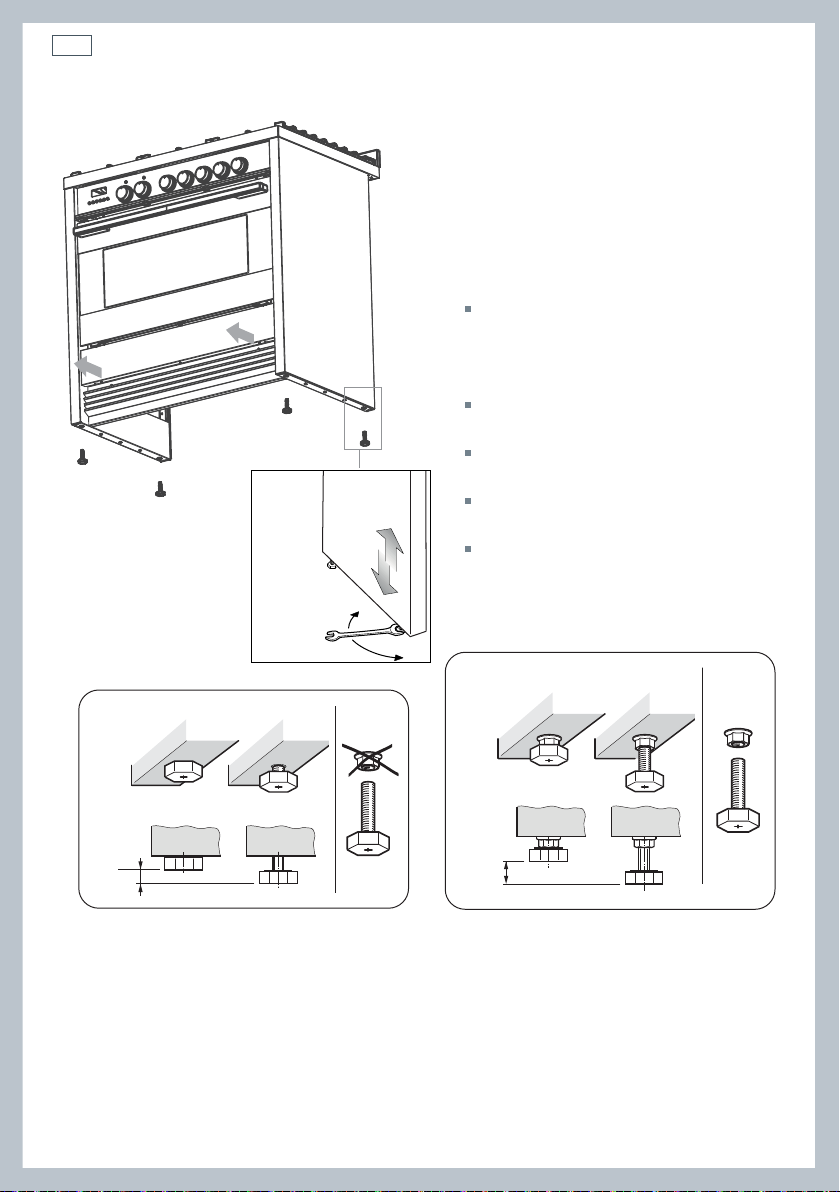

Fig. 3a Screw/unscrew the

feet to get the required height

Levelling the cooker

Important!

Using the supplied adjustable feet is

MANDATORY. For safety reasons and to

ensure adequate ventilation, the cooker

chassis MUST NOT sit directly on the floor, a

plinth, or other support surface.

For ease of installation, first remove

the kickstrip. To remove the kickstrip,

unscrew the two screws holding it in

place.

The cooker is already fitted with four

levelling feet.

Level the cooker by screwing or

unscrewing the feet.

Make sure you follow the instructions in

Figs. 3a, 3b, and 3c.

Note: nuts are supplied with the cooker

in a separate kit.

Do not refit the kickstrip until you have

installed the anti-tip bracket.

0

+ 8

mm

Fig. 3b Do not use the supplied nuts for height

adjustments between 0 and 8 mm

+ 8

mm

+ 13

mm

height adjustments between 8 and 13 mm

Fig. 3c Use the supplied nuts for

Page 13

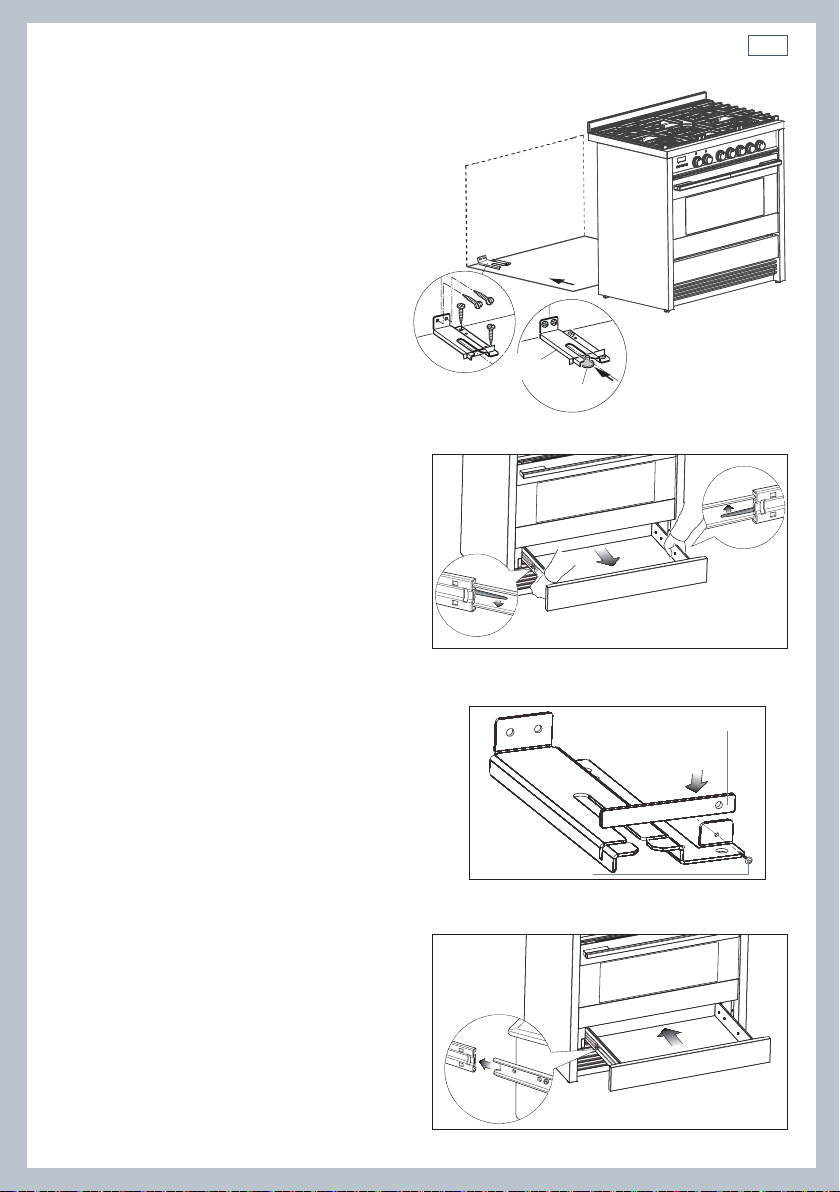

Dotted line showing the position

of the cooker when installed

Rear left

foot of cooker

Anti-tilt

bracket

Fitting the anti-tilt bracket

Important!

To restrain the appliance and prevent

it tipping accidentally, the antitilt bracket and restraining plate

supplied must be fitted according to

the instructions below.

1

Drill four 8mm diameter holes for

the fixing screws (two in the wall

and two in the floor-see Fig.4) and

insert the plastic plugs supplied.

Important!

Before drilling the holes, check that you will not

damage any pipes or electrical wires.

2

Attach the anti-tilt bracket to the floor and

rear wall using the four screws supplied, as

shown in Fig. 4.

3

After attaching the anti-tilt bracket securely,

slide the cooker into place. Ensure that the

left rear foot slides under the bracket, as

shown in Fig.4.

4

Access the bracket by removing the drawer

(Fig. 5):

a

Slide out the drawer completely.

b

Press the lever of the left guide rail

down and pull the lever of the right

guide rail up.

c

Holding the levers, disengage and

remove the drawer.

d

If fitted, remove kickstrip

(see ‘Levelling the cooker’)

5

Fix the restraining plate by sliding it into

place and securing it with the fixing screw

and washer supplied. See Fig. 6.

6

Replace the drawer (Fig. 7):

a

Insert the drawer rails into the guide

rails.

b

Gently push the drawer in

completely; the safety catches will

automatically hook.

7

Replace the kickstrip using the two screws.

Important!

Beware of sharp edges when removing or

replacing the drawer.

Installation instructions

Fig. 4 Attaching the

anti-tilt bracket and

sliding the cooker

Fig. 5 Accessing the anti-tilt bracket

by removing the drawer

Restraining plate

Screw & Washer

Fig. 6 Fixing the restraining plate

Fig. 7 Replacing the drawer

11

into place

Page 14

12

Installation instructionsInstallation instructions

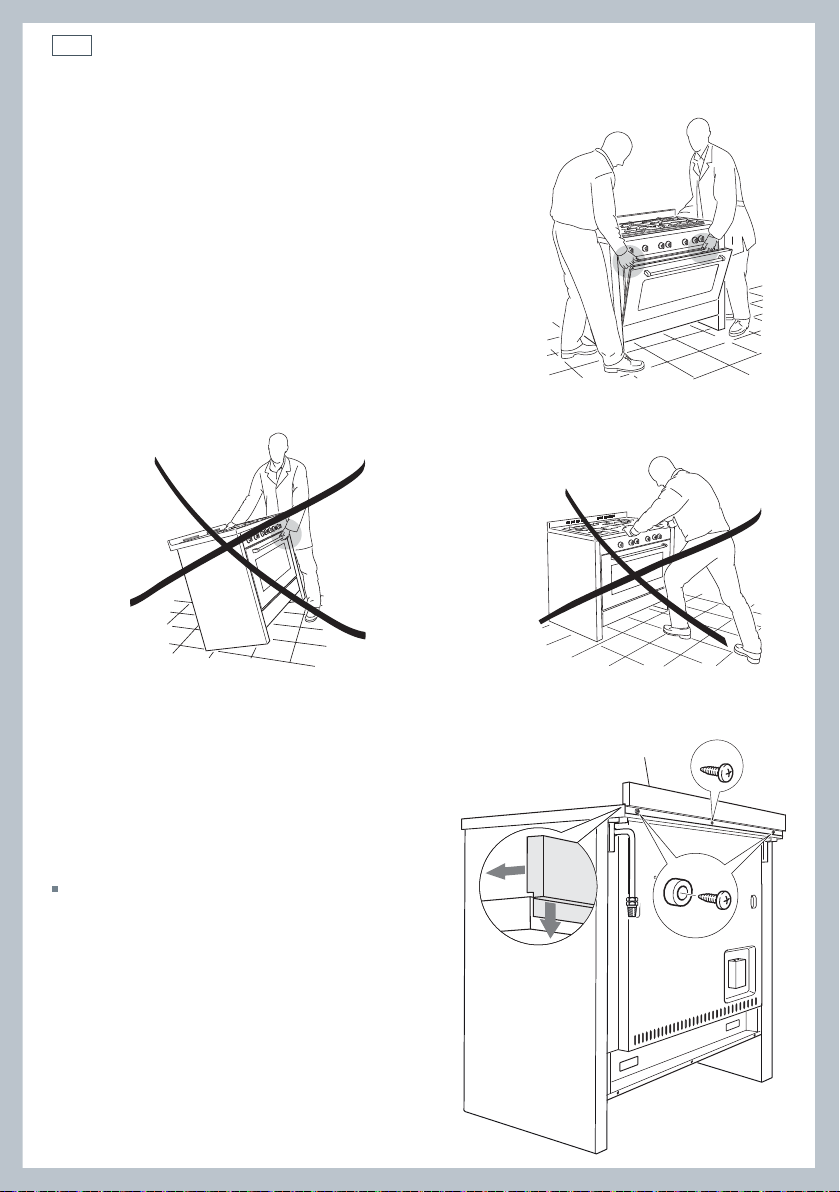

Moving the cooker

Important!

To prevent damaging the adjustable feet or lower

trim, ensure the cooker is always lifted by two

people.

Do not lift the cooker by the door handles.

DO NOT DRAG the cooker. Lift the feet clear of the

floor.

Fig. 8 Correctly lifting the cooker

Fig. 9 Incorrectly lifting the cooker

Fixing the backguard

Before installing the cooker, assemble the

backguard “C” .

The backguard “C” can be found packed

at the rear of the cooker.

1

Before assembling, remove any protective

film/adhesive tape.

2

Remove the two spacers “A” and the

screw “B” from the rear of the cooktop.

3

Assemble the backguard as shown and

fix it by screwing the central screw “B”

and the spacers “A”.

Fig. 10 Incorrectly moving the cooker

C

B

A

Fig. 11 Assembling

the backguard

Page 15

Installation instructions

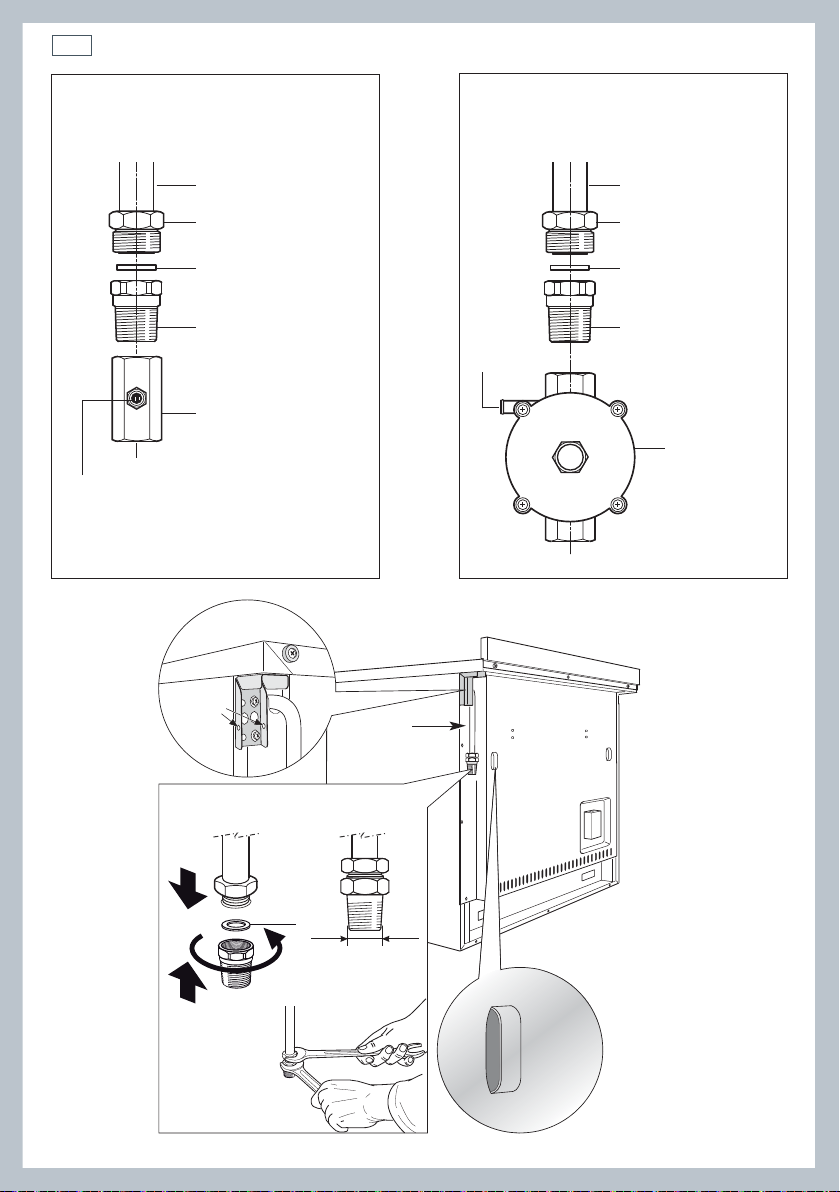

Connecting the cooker to the gas supply

The gas connection must be carried out by an authorised person according to the relevant

standards.

Before connecting the appliance to the gas main, mount the brass conical adaptor onto the gas

inlet pipe, upon which the washer has been placed (see Fig.s 12-13 following).

Conical adaptor and washer are supplied with the appliance (packed with conversion kit for use

with Natural gas or LPG).

This appliance is suitable for use with Natural gas or LPG. (Check the “gas type” sticker attached

to the appliance).

For Natural gas, connect the gas supply to the gas pressure regulator which is supplied with the

appliance (Fig.13). Adjust the regulator to obtain a test point pressure of 1 kPa with two semirapid burners operating at the maximum.

For LPG, connect the gas supply to the test point adaptor which is supplied with the appliance

(Fig.12). Ensure that the supply pressure is regulated to 2.75 kPa.

The connection must be made at the rear of appliance; the pipe is not to cross the cooker.

IMPORTANT: Use two spanners to tighten or loosen the connecting pipe (Fig.14).

Installation with a flexible hose assembly

If this appliance has to be installed with a hose assembly, the installer shall refer to the network

operator or gas supplier for confirmation of the gas type, if in doubt.

When used with a flexible hose, the connector on the wall should be between 450 mm to 500

mm from the floor and 200 mm to 300 mm from the right-hand side of the appliance as viewed

from the front. The hose connection on the appliance shall face downwards.

It is important that the hose does not come in contact with the metal of the appliance and is

secured as per appropriate gas installation codes. A chain 80% of the length of the flexible gas

hose must be used to prevent stress being applied to the hose. The chain should be attached

securely to the product where shown (see Fig.14), and on the wall.

Flexible hose assemblies should be AS/NZS 1869 Class B or Class D certified. The thread

connection shall be Rp ½ ” (ISO 7-1) male.

13

Important!

After connection the installer must check that the hose is not kinked, subjected to abrasion or permanently

deformed. The installer must check also that the hose is not near or in contact with any hot surfaces.

The hose assembly shall be as short as practicable and comply with relevant AS5601 / NZS5261

requirements.

Page 16

14

Installation instructions

Gas connection for

LPG

Test

point

Gas inlet pipe

Nipple

Washer

Brass conical adaptor

(Thread tight: use

suitable seal)

Test point adaptor

Test

point

Gas connection for

NATURAL GAS

Gas inlet pipe

Nipple

Washer

Brass conical adaptor

(Thread tight: use

suitable seal)

Gas pressure

regulator

Fig. 13 Natural gas connectionFig. 12 LPG connection

Chain

security

hole

Fitting the brass conical adaptor

Washer

(ISO 7-1) male

Gas

inlet pipe

Rp ½ ”

Chain

security

anchor

Fig. 14 Gas supply inlet

Page 17

Installation instructions

Leak-testing and flame-testing the cooker

After installing the freestanding cooker and connecting the gas supply:

1

Using a suitable leak detection fluid solution, check each gas connection one at a time by

brushing the solution over the connection.

The presence of bubbles will indicate a leak. If there is a leak, tighten the fitting and then

recheck for leaks.

Important!

2

Adjust the test point pressure or supply pressure to the value that is appropriate for the gas

type.

3

Test the operation of the appliance:

Turn on the appliance gas controls and light each burner individually and in combination.

Check for a well-defined blue flame without any yellow tipping. If any abnormality is

maximum to the minimum position. The flame must not go out. If you need to adjust the

setting, see ‘Adjusting the minimum burner setting’ following.

4

If satisfacfory performance cannot be obtained, the installer shall check the installation and

evident, then check that the burner cap is located properly and the injector nipple is

aligned correctly.

Check the minimum burner setting by quickly rotating the gas control dial from the

notify the local gas supply authority for a gas supply problem, or if it is an appliance problem,

our Customer Service Centre should be called to obtain the nearest authorized Service Agent.

Converting to a different gas type

Do not use a naked flame to test for leaks.

15

This appliance is suitable for use with Natural gas or LPG (check the “gas type” sticker attached

to the appliance). To convert from one gas type to another, you need to replace the injectors,

and then adjust the minimum burning setting.

Replacing the injectors

1

Remove the pan supports and burners from the cooktop.

2

Using a spanner, remove the injectors (shown in Figs. 15-16-17 following) and replace them with

ones according to the gas type (see the ‘Table for the choice of injectors’).

3

Fix the warning label (supplied with the conversion kit) at the back of the cooker, near the gas

inlet connections. This label states that the gas cooktop has been converted for use with LPG/

Natural gas.

Adjusting the minimum burner setting

4

See ‘Adjusting the minimum burner setting’ for instructions.

Important!

If you are converting the cooker from Natural gas to LPG,remove the gas pressure regulator

before connecting the cooker to the gas supply and replace with the test point adaptor supplied

with the conversion kit.

If you are converting the cooker from LPG to Natural gas, remove the test point adaptor before

connecting the cooker to the gas supply and replace with the gas pressure regulator supplied

with the conversion kit.

Notes:

- The burners are designed so that regulation of primary air is not required.

Page 18

16

Installation instructions

Injector

Fig. 15 Semi-rapid burner Fig. 16 Triple-ring wok burner

Injector

J

Injector for

Injector for

inner crown

ner crown

J

Injectors for

Injectors for

outer crown

outer crown

J

Fig. 17 Dual burner

Page 19

Installation instructions

Adjusting the minimum burner setting

Check whether the flame spreads to all burner ports when the burner is lit with the gas valve set

to the minimum position.

If some ports do not light, increase the minimum gas rate setting. Check whether the burner

remains lit even when the gas valve is turned quickly from the maximum to the minimum

position.

If the burner does not remain lit, increase the minimum gas rate setting.

To adjust the minimum gas rate setting:

Semi-rapid and triple-ring burners:

1

Turn on the burner.

2

Turn the valve to the MINIMUM position.

3

Take off the dial.

4

Using a small flat screwdriver, turn the screw (see Fig. 18) to the correct regulation.

Inside crown of dual burner:

1

Turn on the burner.

2

Turn the valve to the MINIMUM position of the inner crown only.

3

Take off the dial.

4

Using a small flat screwdriver, turn the screw (see Fig. 19) to the correct regulation.

Outside crown of dual burner:

1

Turn on the burner.

2

Turn the valve to the MINIMUM position of the inner and outer crowns.

3

Take off the dial.

4

Using a small flat screwdriver, turn the screw (see Fig. 19) to the correct regulation.

17

Note: for LPG, the regulation screw is normally tightened up.

regulation screw

regulation screw

regulation screw

(outside crown)

Fig. 18 Adjusting the minimum burner setting:

semi-rapid and triple-ring wok burner

regulation screw

(inside crown)

Fig. 19 Adjusting the minimum burner setting:

dual burner

Page 20

18

Installation instructions

Natural gas LPG

Test Point Pressure [kPa] 1.0 2.75

BURNER

Semi-rapid

Triple-ring wok

Dual

Injector

Orifice Dia.

[mm]

1.17 6.50 0.70 6.30

1.54 11.88 0.98 12.00

0.76

(inner crown)

1.23 - no.2

(outer crown)

Gas

Consumption

[MJ/h]

16.20

(inner and

outer crowns

operating)

Injector

Orifice Dia.

[mm]

0.50

(inner crown)

0.73 - no.2

(outer crown)

Gas

Consumption

[MJ/h]

16.20

(inner and

outer crowns

operating)

Page 21

Wiring diagram

IS

Installation instructions

IC

19

R2

R1

S1

P8

TL

PT1

PR

PR

PT2

12

12a

2

2a

P9

1

1a

GIR

V

LF

LF

F1

TR

S2

C Oven top heating element

G Oven grill heating element

S Oven bottom heating element

CI Oven circular heating element

GIR Rotisserie motor

V Oven fan motor

CF Cooling fan motor

IC Gas igniter

IS Ignition switches group

M Terminal block

T Earth connection

CF

ST

P4

TS

X0

PB

PR

EC

X1

ELECTRIC DIAGRAM KEY

F1 Oven switch

ST Safety thermostat

TL Thermal overload

PR Electronic programmer

PB Temperature probe

TS Oven temperature selector

EC Oven function selector (encoder)

R1 Relay 1

R2 Relay 2

LF Oven lamp

TR Oven lamps transformer

S1 Thermostat pilot lamp

M

S2 Line pilot lamp

11a

10a

9a

8a

7a

6a

5a

4a

3a

11

10

9

8

7

6

5

4

3

GSCI C

F1

42

T

Page 22

20

First use

21011

1 34 5 67 89

Fig. 20 Control panel

8

1

Control buttons

2

Clock display

3

Temperature dial

4

Function dial

5

Front left (triple-ring wok) burner dial

6

Rear left (semi-rapid) burner dial

7

Central (dual) burner dial

Rear right (semi-rapid) burner dial

9

Front right (triple-ring) burner dial

10

Function indicator light

11

Temperature indicator light

Page 23

First use

Buttons

sets the timer

sets the cooking time

sets the stop time for automatic cooking

set the oven temperature /

select Celsius or Fahrenheit

decreases the time and temperature

increases the time and temperature

Fig. 21 Clock display and control buttons

Illuminated symbols

If the display shows It means that... For more information

12:00

21

A

flashing

steadily lit

A

flashing and

beeping

steadily lit The timer is set See section ‘Using the electronic timer’

steadily lit The oven is heating up See section ‘Using your oven’

12:00

The clock needs to be set. See instructions below.

The oven is set for automatic

cooking.

Automatic cooking has finished

See section ‘Automatic cooking’

To set the clock

When the power to the appliance is turned on or restored after a power failure 12:00 will flash in

the display.

1 Press

2 Press

3 Press

time is set.

and together - the display will stop flashing. The clock is now set for 12:00.

and together again to change the time. The display will flash

and to set the time. After a few minutes the display will be steadily lit, showing the

To change the time

1 Press and together. The display will flash.

2 Press

After a few seconds the display will remain steadily lit, showing the time is set.

and to set the time.

Page 24

22

First use

Remove the side racks to fit the Catalytic panels (if not already fitted)

1

Remove all shelves and trays.

2

For easier access to the fixing screws, you may remove the oven door first. See ‘Removing and

refitting the oven door’ in Care and Cleaning.

3

Remove the side racks on both sides:

4

Using a small coin or a flat-head screwdriver, loosen and remove both fixing screws.

5

Gently remove the side rack.

Fig. 22 Refitting the side racks

Fitting the Catalytic panels

6

Fit the catalytic panel. When fitting the catalytic panel make sure that

- the arrows are pointing upwards

-the panel with the hole in it is on the right oven wall.

Refitting the side racks

7

To refit the side racks

- make sure that they are the right way up, as in the illustrations, and that you

tighten the fixing screws.

8

If not already fitted, fit the telescopic sliding shelf supports. See “Care and cleaning’ for

instructions.

Page 25

Using your oven

Before using your new oven, please:

1

Read this user guide, taking special note of the ‘Safety and warnings’ section.

2

Remove all accessories and packaging. Peel the protective film off all surfaces and accessories.

3

Set the clock. The oven will not work until the clock has been set. See ‘Setting the clock’.

4

Fit the Catalytic panels and side racks. See opposite.

5

If not already fitted, fit the sliding shelf supports. See ‘Care and cleaning’ for instructions.

6

Slide in the shelves you will need, making sure that:

7

Heat the oven on maximum for:

8

Once cooled, wipe out the oven with a damp cloth and mild detergent, and dry thoroughly.

they are between the two wires of a shelf position;

the stop notches point down;

the guard rail is at the back.

Note: the grill tray should be positioned between the two wires of a shelf position and

orientated as shown.

60 minutes in the position

30 minutes in the position

15 minutes in the position

There will be a distinctive smell while you are conditioning your oven. This is normal, but

make sure your kitchen is well ventilated during the conditioning.

23

Guard rail

Stop notch

Stop

notch

Fig. 23 Correct position of shelves

and grill tray

Page 26

24

Using your oven

Temperature

indicator light

Fig. 24 Function and temperature dials

FUNCTION TEMPERATURE

indicator light

210 C 225C

1

Select a function

Rotate the function dial to select a function

The function indicator light will come on.

The preset function temperature will flash

in the display. (Each cooking function has a

preset temperature)

If you wish to use the oven at the preset

temperature After a few seconds, the display will stop

flashing and the oven will turn on and

heat up. The display will revert to show the

actual oven temperature.

The indicator will show in the display.

Note: if you select , the display will

show dEF. The temperature cannot be

adjusted when using this function.

2a

There are two ways to set the

OR

Note: if the temperature display stops

2b

2c

Function

Adjust the temperature

temperature while the display is

flashing:

Rotate the temperature dial (clockwise

to increase and anticlockwise to

decrease the temperature);

Use the and buttons to increase

or decrease the set temperature.

After a few seconds, the display will stop

flashing and the oven will turn on and

heat up. The display will revert to show

the actual oven temperature.

The indicator will show in the

display.

flashing before you have set the

required temperature, you can:

Press the button

The display will flash

Use the and buttons to increase

or decrease the set temperature.

Page 27

C89

3

When the oven is preheating and during

cooking

The indicator will show in the display.

The indicator will go out when the oven

has reached the set temperature.

Note: this indicator may turn on and off

during cooking as the oven maintains the

set temperature.

The temperature indicator light will

also come on when the oven is

heating and will turn on and off as

the oven maintains its set temperature.

The temperature indicator light goes

out when the oven has reached the set

temperature.

Using your oven

4a

To check the set temperature

Press the button.

The display will flash showing the set

temperature

After a few seconds the display will return

to the actual oven temperature and the

display will be steadily lit.

4b

To check the time of day

Press the button.

After a few seconds the display will show

the oven temperature again.

5

When you have finished cooking

Turn the function dial to o (off) to turn the

oven off.

25

Page 28

26

Cooking functions

OVEN LAMP

Only the oven light comes on. It remains on in all the cooking functions.

BAKE

The upper and lower heating elements come on. BAKE is the traditional method of cooking. It

is best to cook on only one shelf at a time in this function. Ideal for large cakes and dishes that

bake for several hours.

ROTISSERIE

A delicious way to cook meat and poultry. The slowly rotating meat is basted continuously

in its own juices, making it tender on the inside and well browned and full of flavour on the

outside. See ‘Using the rotisserie’.

GRILL

Grill is the most suitable function for ‘finishing off’ many meals, for example browning the top

of potato gratin and frittata. Use Grill to toast bread or to grill your favourite chicken, fish and

steak. Use with the oven door closed and the temperature set to a maximum of 225°C. For best

results, use the topmost shelf position when you want quick browning (eg toast).

DEFROST

this is not a cooking function

Only the oven fan comes on. The fan circulates air around the oven, speeding up the defrosting

process by approximately 30%. Note: this function is not for cooking food.

FAN FORCED

The circular heating element and the fan come on. The oven set on FAN FORCED can cook

several different foods together. Use FAN FORCED for multi-shelf cooking.

FAN GRILL

Both the grill and the fan come on. Use with the oven door closed and the temperature set to a

maximum of 225°C. Ideal for roasting tender cuts of meat and poultry. Use lower shelf positions

for larger items (eg a whole chicken).

Page 29

Cooking functions

WARM

this is not a cooking function

Always reheat food until piping hot and then select the warm function to keep food hot.

FAN BAKE

The upper and lower heating elements and the fan come on. Ideal for dishes like lasagne that

need to brown on top and also single trays of small cakes or biscuits that bake in less than an

hour.

Important!

Safe food handling: leave food in the oven for as short a time as possible before and after cooking or

defrosting. This is to avoid contamination by organisms which may cause food poisoning. Take particular

care during warmer weather.

27

Page 30

28

Cooking guide

Using the fat filter

Use the fat filter when roasting meat and poultry on

Fan Bake, Fan Grill or Fan Forced. It helps to keep

your oven clean and reduces splatter and smoking.

Remove the fat filter before baking.

Clean the fat filter after every use. See ‘Care and cleaning’.

Fig. 25 Fat filter

Changing the oven from Celsius to Fahrenheit

You can set your oven to display the temperature in Fahrenheit or Celsius.

1

Select a cooking function.

2

While the display is flashing, press to reduce the oven to the minimum temperature

o

(50

3

4

C / 120 oF)

When the display stops flashing , press and hold the button until C or F flashes in the display

Press the button to change between Celsius (C ) and Fahrenheit (F).

After a few moments the oven will turn off and the display will show the time of day.

Turn the function dial back to o (Off).

Cooking Guide

The settings in the following chart are guidelines only. Follow the instructions in your recipe or

on packaging and be prepared to adjust the oven settings and baking times to achieve the best

possible results for you.

Shelf positions are counted from the oven floor up (1 is the lowest, 5 is the highest).

Arrange oven shelves before you turn the oven on, then preheat the oven to the desired

temperature.

Single shelf positions below use the flat oven shelf; where a multi-shelf arrangement is

recommended, the lower position uses the step-down shelf.

Due to the width of the oven, a single shelf can usually accommodate double the standard

recipe.

Always preheat the oven before baking.

For models with a fat filter:

Always use the fat filter when roasting meat or poultry.

Always remove the fat filter before baking.

Do not place anything, including water or ice, on the oven floor

Keep the door completely shut when grilling foods.

Do not open the door during the first 3/4 of baking time.

Page 31

SAVOURY

Food Shelves

Roast Chicken

Lasagne

Quiche

Pizza

Casserole

Roast Lamb

(bone in)

Baked

Potatoes

Beef Steak

Beef Burgers

BAKING

Cooking guide

Recommended

Function

Rotisserie Rotisserie 1 180-210

Single Fan Bake 3 175-180 45-50

Single Pastry Bake 1 180-200 30-40

Single Pastry Bake 3 225-250 10-15

Single Fan Forced 3 170-190 55-70

Single

Single Bake 4 175-190 40-50

Single Grill 4 Hi 6-8 min / side

Single Grill 4 Hi

Fan Grill

(medium)

Shelf

positions

3 160-170

Temp (°C) Time (mins)

15-20

min/450g

18-28

min/450 g

12-15

min / side

29

Food Shelves

Small cakes

Scones

Sponge

Light fruit

cake

Rich fruit cake

Apple pie

Quiche

Meringues

Bread rolls

Mu ns

Pastry case

(baked ‘blind’)

Recommended

Function

single shelf Bake 2 180-190 20-30

multi shelf Fan Forced 1 and 3 160-170 30-40

single shelf Bake 2 210-230 15-20

multi shelf Fan Forced 1 and 3 210-230 15-20

two small pans

(20 cm), on

single shelf

one large pan

(26 cm)

two pans (21

cm) on single

shelf

Single Bake 2 130-150 3-6 hrs

Single Bake 1 185 35-45

Single Bake 1 180-200 30-40

Single Bake 1 100-120 60

Single Bake 1 210-230 15-20

2 x 12 muffin

trays on single

shelf

one 21 cm flan

tin

Bake 2 170-180 30-45

Bake 2 175 30-40

Bake 2 155-165 90

Fan Forced or

Fan Bake

Pastry Bake 1 200

Shelf

positions

3 190-200 10-15

Temp

(°C)

Time (mins)

10 with beans,

then 10 without

Page 32

30

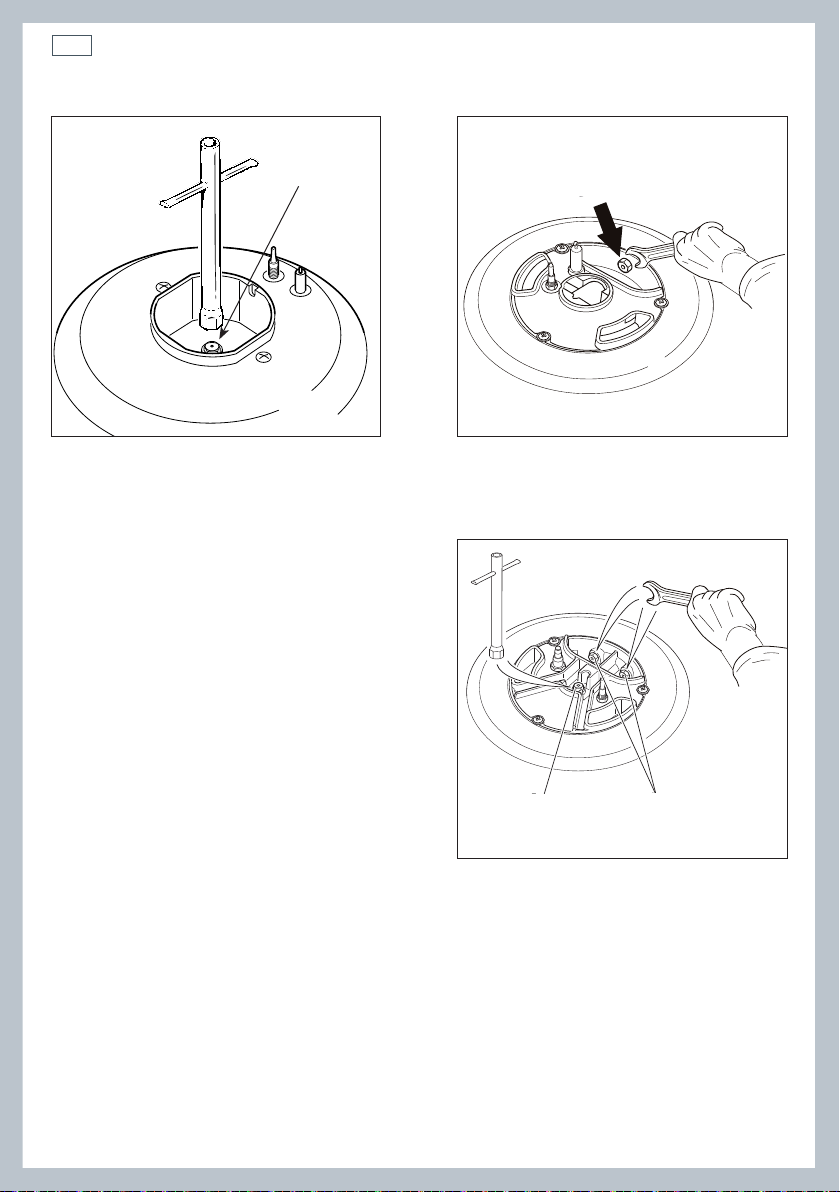

Using the rotisserie

Important!

If fitted, remove the sliding shelf supports from shelf position 1 before using the rotisserie.

Remove all oven shelves and trays.

1

Prepare the rotisserie supports.

2

Place the grill tray on the benchtop.

Insert the supports into the lock studs.

Push the supports all the way down to lock them in firmly.

Secure the meat.

Important!

Take care, the forks are sharp!

When securing the meat, ensure that:

the skewer goes through the centre of the meat

the forks hold the meat firmly in place

the fork screws are tightened

there are no loose or projecting parts. Poultry should be trussed.

Note: the rotisserie can rotate up to 6 kg of meat and is long enough to cook two chickens at the

same time.

Lock stud

Fig. 26a Prepare the rotisserie supports

Rotate the fork screws to loosen and tighten

Fork

Skewer

Fig. 26b Secure the meat

Page 33

Using the rotisserie

3

Position the skewer on the supports.

4

5

Place the skewer on the supports, and check that the meat does not touch the grill tray.

Twist the handle off. It must not be left in the oven.

Place the rotisserie in the oven.

Check the fat filter is in place.

Slide the grill tray all the way to the back on shelf position 1.

Move the rotisserie drive hole cover aside (right-hand wall of the oven). Insert the skewer

fully into the rotisserie drive hole. Ensure the left hand side of the skewer is properly

located on the supports.

Start the rotisserie

Select the Rotisserie function.

Set the temperature.

The rotisserie will start to rotate.

Important!

Always turn the function dial to o (off) before removing the rotisserie.

Always ensure that poultry is cooked thoroughly.

During use, the rotisserie components become hot. If you leave the oven door open after using

the rotisserie, parts of the control panel may also become hot. Use oven mitts and take extra care,

especially when removing the rotisserie support rack from the hot oven.

Always clean the fat filter after every use. See ‘Care and cleaning’.

31

Fig. 26c Position the

skewer on the supports

Fig. 26d Rotisserie drive hole cover

Rotisserie drive hole

Fig. 26e Place the rotisserie in the oven

Page 34

32

Using the electronic timer

You can use the timer at any time, even when

the oven is not in use.

12:00

Important!

The timer does NOT turn the oven off.

To set the timer

1

Press the timer button.

2

Press and buttons to set the time you want (up to 3 hours in one minute steps).

3

Press the timer button.

seconds.

The time will show

The timer

After a few seconds the time will start counting down, the display will show the time of

day (if the oven is off) or temperature (if the oven is on) and will be steadily lit.

To check the remaining time

The timer counts down in minutes (hr:min) until the last minute, when it counts down in

0:00

indicator will come on.

A

To cancel the timer

4

Press the timer button.

The remaining time will be displayed. Press the

After a few seconds the clock will show the time of day (if the oven is off) or temperature

(if the oven is on).

When the time is up

The timer will beep and the timer

Press any button to stop the beeping.

button to scroll the time down to 0:00

indicator go out.

Page 35

Automatic cooking

To set the oven for automatic cooking

12:00

1

Set the oven

Check the clock shows the correct time (eg 12:07).

Select the function and set the temperature.

2

Set the cooking time

3

Set the stop time

The oven will turn on.

Decide how long the food will take to cook, allowing

time for preheating if necessary (eg 40 minutes).

Press

Use

Decide when you want your food to be ready by (eg 13:30).

Press

Use

You can turn the oven on manually and set it to turn off automatically by setting the stop time

(step 3 above).

When automatic cooking is set

If there is time before cooking starts, the oven will turn off and the pre-set temperature and

will show in the clock display, indicating the oven is set for automatic cooking. Note: the cooling

fan may stay on.

The oven will automatically turn on at the required time (eg 12:50) and turn off at the set stop

time (eg 13:30).

To see the remaining cooking time, press

To see the set stop time, press

.

and to set the cooking time. A will show in the display.

.

and to set the stop time.

.

.

A

33

A

To cancel automatic cooking

1

Press and hold and together for 3 seconds.

2

Turn the function dial to o (Off ).

When the stop time is reached

The oven will turn off, the timer will beep.

The display will show End and the

1

Press any button to stop the beeping.

2

Turn the function dial to o (Off ).

will flash.

A

Page 36

34

Using your gas cooktop

2

1

1

Triple-ring wok burner

2

Semi-rapid burner

3

Dual burner

Gas burners

The dial controls the flow of gas through the safety valve.

23

1

Fig 27 Cooktop layout

Semi-rapid and triple-ring wok burners

o = closed valve (OFF)

=

= maximum flow of semi-rapid and triple-ring burner burners

minimum flow of semi-rapid and triple-ring burner burners

You can choose to cook at any heat between

between

Dual burner

and o (OFF).

and , but never

o = closed valve (OFF)

= maximum flow of inner crown only (turn dial clockwise)

= minimum flow of inner crown only (turn dial clockwise)

= maximum flow of inner & outer crowns (turn dial anticlockwise)

= minimum flow of inner & crowns (turn dial anticlockwise)

You can choose to cook at any heat between

and , but never between and o (OFF) or between and

and or between

o (OFF).

Page 37

Using your gas cooktop

35

Before using your cooktop

Before using your new cooktop, please:

Read this user guide, taking special note of the ‘Safety and warnings’ section.

Make sure all burner control dials are turned off.

Turn the power to the cooker on at the wall.

Using the gas burners

1

Choose the control dial for the burner you want to use.

2

Semi-rapid and triple-ring burners: press the dial in gently and turn it anticlockwise to the

position. The ignitors on all the burners will spark.

Dual burner: press the dial in gently and turn it anticlockwise to the

inner and outer crowns) or press the dial it gently and turn it clockwise to the

ignite the inner crown only). The ignitors on all the burners will spark.

Hold in the dial for approximately 10 seconds after the burner has lit. Releasing the dial too soon

will extinguish the flame.

3

Adjust the flame anywhere between and or and or and positions. Do not

adjust the flame between

Note: If the burner does not light within 15 seconds, turn the control dial off and wait at least

one minute before trying again.

or or and o (OFF).

position (to ignite the

position (to

4

To turn the burner off, turn the dial clockwise (semi-rapid and triple-ring burners or dual burner

when using both crowns) or anticlockwise (dual burner when using the inner crown only) to

(OFF) until you hear the safety click.

5

After use, always turn the dials to the o (OFF) position.

Flame failure safety feature

The flame failure probe cuts off the gas supply to the burner if the flame is blown out.

When lighting the burner on flame failure models, hold down the dial for approximately 10

seconds after the burner has lit. Releasing the dial too soon will extinguish the flame.

If the flames are accidentally extinguished, turn off the burner and do not try to light it again for

at least one minute (to allow the gas to disperse).

o

Page 38

36

Using your gas cooktop

If a burner does not light

Check that:

The cooker is plugged in and the electricity is switched on.

The gas is turned on.

The gas bottle is not empty (if you are using bottled gas).

You have held down the dial for at least 10 seconds.

The ignitors are sparking. If the ignitors are not sparking, they may be dirty or wet. Clean them

with a toothbrush and methylated spirits, as shown in Fig.28.

Flame failure probe

Ignitor

Fig. 28 Cleaning the probe and ignitor

If the flame is irregular

If the flame is yellow or irregular, check that the burner parts, including the burner cap, are:

clean and dry.

positioned correctly. See ‘Care and cleaning’.

See also ‘Cooktop troubleshooting’.

Page 39

Using your gas cooktop

Matching cookware to burner

Use flat-bottomed pans, and make sure they match the size of the burner, as shown in the

following table. A small pot on a large burner is not efficient.

Diameters of pans which may be used on the cooktop

Burners Minimum Maximum

Semi-rapid 10 cm 24 cm

Triple-ring wok 26 cm 28 cm

Maximum diameter for woks 36 cm

Dual (inner crown only) 12 cm 14 cm

Dual (inner and outer

crowns)

26 cm 28 cm

Maximum diameter for woks 36 cm

37

matching of cookware and burner size

Fig. 30 Efficient and inefficient saucepan bottomsFig. 29 Correct and incorrect

Wok stand

The wok stand fits over the dual or triple ring burner pan support.

Important!

Using a wok without the stand may cause the wok to tip or the triple ring or dual burner to

operate incorrectly.

Do not use the stand for ordinary, flat-bottomed saucepans.

The wok stand MUST BE PLACED ONLY over the pan support for the triple ring or dual burner.

The cooktop becomes very hot during operation. Keep children well out of reach.

WRONG CORRECT

Fig. 31 Correct placement of wok stand

Page 40

38

Care and cleaning

Important!

Before you start cleaning your cooker, please:

Read these cleaning instructions and the ‘Safety and warnings’ section at the start of this user

guide.

Turn the cooker off at the wall.

Make sure the cooker is a safe temperature to touch.

Do not use a steam cleaner.

Do not keep flammable substances in the oven.

General advice

Wipe down the cooktop and wipe out the oven after every use.

Wipe up spills. Avoid leaving alkaline or acidic substances (such as lemon juice or vinegar) on

the surfaces.

Do not use cleaning products with a chlorine or acidic base.

Cleaning the outside of the cooker

Important!

Do not use abrasive cleaners, cloths or pads on the outside surfaces.

Immediately wipe off any caustic cleaners if they are spilled onto the oven door handle.

Wipe the outside surfaces often, using warm water and a mild household detergent. The

stainless steel may also be cleaned with a suitable cleaner and polish.

Note: if you choose to use a commercial stainless steel cleaner, please read the label to make

sure it does not contain chlorine compounds as these are corrosive and may damage the

appearance of your cooker.

Cleaning the gas cooktop

Maintenance Period Description

•

Daily

Monthly

Every 3-4 years

Clean gas cooktop as per following instructions.

•

Remove all burner parts, and clean using a non-abrasive

detergent. Rinse in cold water, dry thoroughly, and replace.

•

Clean the ignitor carefully, using a toothbrush and

methylated spirits.

•

Contact your local authorised gas Service Agent to perform

a thorough check on all gas components on the gas

cooker.

Page 41

Care and cleaning

Burner parts and pan supports

You can remove and clean these parts with hot soapy water or non-abrasive detergents. Clean

spills regularly before they become burnt on. Do not wash these parts in a dishwasher.

After cleaning, check that the burners and their flame spreaders are dry before replacing

correctly.

It is very important to check that the burner flame spreader and the cap have been correctly

positioned. Failure to do so can cause serious problems.

Note: to avoid damage to the electronic ignition, do not try to light a burner without all burner

parts in place.

Replacing the semi-rapid burners

Carefully replace the burner parts as per the following Figs.

Check that:

the ignitor is always clean to ensure trouble-free sparking.

the probe is always clean to ensure correct operation of the safety valves (some models only)

Note: both the ignitor and probe must be very carefully cleaned using a toothbrush and

methylated spirits (see Fig.28).

39

Cap

C

Flame

F

spreader

Fig. 32 Correct line-up of semi-rapid burner parts

Probe

T

Ignitor

S

Fig. 33 Replacing the semi-rapid burner caps

Page 42

40

Care and cleaning

Replacing the triple-ring wok and dual burners

Carefully replace the burner parts as per the following Figs.

Fit the flame spreader to the housing as shown by the arrow in the Figs.34a-34b. Make sure the

burner is not able to rotate (Fig. 35).

Check that:

the ignitor is always clean to ensure trouble-free sparking.

the probe is always clean to ensure correct operation of the safety valves (some models only).

Note: both the ignitor and probe must be very carefully cleaned using a toothbrush and

methylated spirits (see Fig.28).

Probe

T

Fig. 34a Correct positioning of

flame spreader - triple-ring wok burner

Ignitor

S

Cap

A

Ring

B

Probe

Ignitor

Fig. 34b Correct positioning of

flame spreader - dual burner

cap and ring - triple-ring wok and dual burner

Fig. 35 Correct positioning of

Fig. 36 Incorrect and correct positioning

of cap and ring - triple-ring wok and dual burner

Page 43

Care and cleaning

Cleaning the inside of your oven

Do not use oven cleaner on catalytic panels. Remove the catalytic panels if additional oven cavity

cleaning is required. See ‘Fitting and removing catalytic panels’

Do not use abrasive cleaners, cloths or pads to clean the enamel.

To make cleaning easier, you can remove the side racks, the oven door, and the fat filter.

Fig. 37 Removing the side racks

41

Drop-down grill element

To lower the grill element: use a flat-head screwdriver or a small coin to loosen the element

fixing screws.

When you have finished cleaning the oven ceiling, raise the grill element and screw the element

fixing screws back onto the studs. Make sure that the fixing screws are tightened and the

element is held securely in place.

The grill element itself is self-cleaning.

Fixing screw

Fig.38 Drop-down grill element

Stud

Page 44

42

Care and cleaning

Cleaning the enamel cavity

Clean the enamel on the inside of the oven when it has cooled down, using household

detergents. You may use ‘off the shelf’ oven cleaners, if you carefully follow the manufacturers’

instructions.

Important!

Do not use oven cleaner on catalytic panels.

Cleaning the fat filter

Clean the fat filter after every use. If the filter is not

cleaned, it will block and shorten the life of the fan

element. If the filter is lightly soiled, place it in a

dishwasher on normal wash. If the filter is very dirty,

place in a saucepan with either two tablespoons

of clothes washing powder, or one tablespoon of

dishwashing powder. Bring to the boil and leave

to soak for at least 30 minutes. Rinse the filter in

clean water and dry.

Fig. 39 Fat filter

Cleaning the grill tray and shelves

Clean these in hot, soapy water.

After cleaning slide in the shelves, making sure that:

they are between the two wires of a shelf position;

the stop notches point down;

the guard rail is at the back.

Note: the grill tray should be positioned between

the two wires of a shelf position and orientated

as shown.

Guard rail

Stop

notch

Fig. 40 Oven shelves and grill tray

Stop notch

Page 45

Care and cleaning

Fitting and removing the sliding shelf supports

When fitting the sliding shelf supports, make sure that you fit:

the catalytic panels first. See ‘Fitting the catalytic panels’ .

the side racks.

the slides to the top wire of a shelf position.

both sides of each pair of slides.

both slides on the same level.

Important!

Remove the side racks first to make removing the sliding shelf supports easier.

1

43

Fig. 41 Fitting the sliding shelf supports

2

1

Fig. 42 Removing the sliding shelf supports

Page 46

44

Care and cleaning

Storage Drawer

The drawer opens like a normal drawer. The drawer slides stop the drawer from sliding all the

way out.

To remove the drawer

1

Open the drawer fully.

2

Press the lever on the left guide rail down and the right guide rail up.

3

Holding the levers, disengage and remove the drawer. Do not use excessive force or you may

damage the drawer slides.

Fig. 43 Removing the drawer

Replace the drawer

1

Insert the drawer rails into the guide rails.

2

Gently push the drawer in completely, the catches will automatically hook.

Fig. 44 Replacing the drawer

Page 47

Care and cleaning

Replacing the oven light bulbs

The oven light bulbs (12V/20 W halogen) have a very long life, but if you should need to replace

one, use only a replacement bulb purchased from your nearest Fisher & Paykel dealer and follow

these steps. Note: oven bulb replacement is not covered by your warranty.

OFF

1

Allow the oven to cool down, then turn

it off at the mains power supply (wall

switch).

2

Remove any oven shelves that may get in

the way.

45

3

Using a flat-head screwdriver, twist and

lift the retainer clip upwards to release the

glass cover. Hold the glass cover to prevent

it falling.

5

Hold the replacement bulb in a soft cloth

or tissue (touching the bulb will reduce its

life span) and insert it into the socket.

4

Carefully lift the glass cover out of the

retaining bracket in the back and pull out

the faulty bulb.

6a

Reposition the glass cover and twist the

retainer clip back in place.

6b

Turn the oven back on at the mains power

supply (wall switch).

Page 48

46

Care and cleaning

Removing and replacing the door glass panes for cleaning.

Make sure you follow the precautions and instructions below very carefully. Replacing the

glass panes and the door incorrectly may result in damage to the oven and may void

your warranty.

Your oven door has 3 panes of glass. The inner and middle panes may be removed for

cleaning.

inner

C

middle

B

A

outer

Important!

Switch the oven off at the wall before removing the door.

Take care, the oven door is heavy. If you have any doubts, do not attempt to remove the door.

Make sure the oven and all its parts have cooled down. Do not attempt to handle the parts of a

hot oven.

Take extreme care when handling the glass panes. Avoid the edges of the glass bumping against

any surface. This may result in the glass shattering.

Don’t use oven cleaners or any other harsh/abrasive cleaners, cloths, scouring pads, steel wool

or sharp metal scrapers to clean the glass surfaces. These scratch the glass and may damage its

special coating, which in turn could result in the glass cracking or shattering.

If you notice any sign of damage on any of the glass panes (such as chipping or cracks), do not

use the oven. Call your Authorised Repairer or Customer Care.

Make sure you replace all the glass panes correctly. Do not use the oven without all glass panes

correctly in place.

If the glass panes feel difficult to remove or replace, do not force them. Call your Authorised

Repairer or Customer Care for help.

Note: service visits providing assistance with using or maintaining the oven are not covered by

your warranty.

Page 49

Care and cleaning

C

Removing the door

1a

Turn the oven off at the wall. Make sure

you have prepared enough space for

resting the door and its glass panes on a

clean, flat surface.

1b

Open the door to its full extent.

2

Open the levers on the left and right

hinges to their full extent, as shown.

47

3

Gently close the door until the left and

right hinge levers are hooked to the door.

5a

Lift the door and disengage the hinges.

Rest the door on a soft surface. Ensure you lay

5b

it with the handle side down.

4

Hold the door firmly, as shown.

Page 50

48

1

2

Care and cleaning

Remove the inner and middle glass pane

Glass retainer

1

Press down on both tabs (1) to release the

glass retainer (

2).

3

1

2

1

2

Lift the inner pane (C) slightly (1), then

gently slide out (

2).

2

3

Slide the middle pane (B) slightly towards

yourself (

1), then lift (2) and slide out (3).

Page 51

Care and cleaning

3

After cleaning, replace the glass panes

When replacing the glass panes, make sure that:

you replace all panes correctly, as shown. Each pane must be in the position described below in

order to fit into the door and to ensure that the oven operates safely and correctly.

you take extra care not to bump the edges of the glass against any object or surface.

you do not force any of the panes into place. If you are experiencing difficulties replacing the

panes, remove them and start the process again from the beginning. If this still does not help, call

Customer Care.

3

2

49

1

Middle

pane (B)

Empty grooves

1

Take the middle pane (B) and hold it firmly.

Important!

Check you are holding the pane the correct way. You should be able to read the wording on it as it faces you.

2

Insert the pane into the middle pair of grooves (1), push it slightly towards yourself (2) and

gently lower into place (

3).

Important!

Use the middle pair of grooves. The pair of grooves closest to the outer pane must remain empty.

Page 52

50

1

Care and cleaning

D

3

Take the inner pane (C), holding it with the angle-cut corner orientated as shown. Insert it in the

uppermost pair of grooves (

(

3).

1), push it slightly towards yourself (2) and gently lower into place

Angle-cut corner

2

3

Important!

Make sure that the angle-cut corner of the inner pane (C) is at the bottom of the oven door, on the left-hand

side. It has to be in this position for the door to function correctly.

Check that the gasket (D) is in place. It should sit on the inner pane of glass in the centre as shown.

Page 53

Care and cleaning

Clamp

Clamp

Glass retainer

4

Position the glass retainer, as shown. It should sit on the bottom edge of the outer glass (A).

Check that the clamps of the glass retainer are not deformed or damaged.

Glass retainer“Click”

51

5

Gently push the glass retainer back into place. You should be able to hear the tabs on both sides

click as they lock the glass retainer in.

Important!

Make sure the glass retainer is correctly and firmly in place and that the glass panes are secure.

Page 54

52

Care and cleaning

Refit the door

1

Hold the door firmly.

2

Insert the hinge tongues into the slots,

making sure that the notches on both

sides drop into place as shown.

Notch

3

Open the door to its full extent.

4a

Fully close the levers on the left and right

hinges, as shown.

4b

Close the door, turn the power supply to

the oven on at the wall.

Page 55

Troubleshooting

Problem Possible solutions

A burner does not light. Check the cooker is switched on at the wall.

My burner flames are yellow or

hard to start.

One of my burners has an uneven

flame.

The flame goes out at low

settings.

My burners do not turn down

much (when running on bottled

gas or LPG).

The flame tips are very yellow. Call your service person to service the cooker.

Check the gas supply valve is turned on and the

supply to the house is working. You should hear the

gas when you turn a burner on.

Check the gas bottle is not empty.

The ignitors may be dirty. Clean them with a

toothbrush and methylated spirits.

The burner parts may not be located properly. Check

the assembly and make sure the burner cap is sitting

flat.

The burner parts may not be located properly. Check

the assembly and make sure the burner cap is sitting

flat.

If you use bottled gas, this may indicate you are

getting near the end of the bottle.

Check the burner parts are clean and dry.

The gas pressure may not be at the correct level.

Check with your service person or installer.

Your cooker may not be set up for the gas you are

using. Check this with your service person or installer.

Check the burner parts are clean and dry. Check the

assembly and make sure the burner cap is sitting flat.

The gas supply pressure may be low. Check this with

your service person or installer.

The low setting may have been adjusted incorrectly.

Check this with your service person or installer.

If you use bottled gas, this may indicate you are

getting near the end of the bottle.

Your cooktop may not have been adjusted correctly.

Check this with your service person or installer.

53

There are objectionable odours. Call your service person to service the cooker.

The flame appears to lift off the

burner.

There is an electricity failure. If there is an electricity failure, you can still use your

The fan comes on when I select

the Light function

.

Call your service person to service the cooker.

cooktop. Light the burners by holding a match close

to the side of the burner and turning the control dial

to the High position. Wait until the flame is burning

evenly before adjusting.

This is normal.

Page 56

54

Warranty and service

Before you call for service or assistance ...

Check the things you can do yourself. Refer to the installation instructions and your user guide

and check that:

1

Your product is correctly installed.

2

You are familiar with its normal operation.

If after checking these points you still need assistance, please refer to the Service & Warranty

book for warranty details and your nearest Authorised Service Centre, or contact us through our

website:

www.fisherpaykel.com

This cooker has been designed and constructed in accordance with the following

codes and specifications:

In New Zealand and Australia:

AS 4551 Approval Requirements for Domestic Gas cooking appliances

AS/NZS 60335-1 General Requirements for Domestic electrical appliances

AS/NZS 60335-2-6 Particular Requirements for Domestic electrical cooking appliances

AS/NZS CISPR 14.1:2010 Electromagnetic Compatibility Requirements.

Product details

Fisher & Paykel Ltd

Model Serial No.

Date of Purchase Purchaser

Dealer Suburb

Town Country

Page 57

55

Page 58

Page 59

Page 60

www. sherpaykel.com

Copyright © Fisher & Paykel 2013. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

NZ AU 03.2013F&P PN - 590535 A F&P ITALY PN - 1104284-ß1

Loading...

Loading...