Fisher IM Supplement: Using the HART Tri-Loop Converter with FIELDVUE Digital Valve Controllers Manuals & Guides

Instruction Manual Supplement

D103267X012

FIELDVUE Digital Valve Controllers

February 2020

Using the HARTR Tri‐Loop™ HART‐to‐Analog

™

Signal Converter with Fisher

FIELDVUE™ Digital

Valve Controllers

Tri‐Loop Signal Converter Operation with FIELDVUE Digital Valve

Controllers

The Rosemount™ 333U (alarm high) and 333D (alarm low) HART Tri‐Loop HART‐to‐Analog Signal Converter is used to

read values from the digital valve controller and present them as 4 to 20 mA signals accessible to AI channels on

traditional host systems. This device accepts a HART burst command 3 from a smart instrument and converts it into up

to three 4 to 20 mA analog output signals. The output signals then can be read by a control system's analog input

channels. Refer to the appropriate HART Field Device Specification instruction manual supplement for command 3

variables (see Related Fisher Documents on page 2).

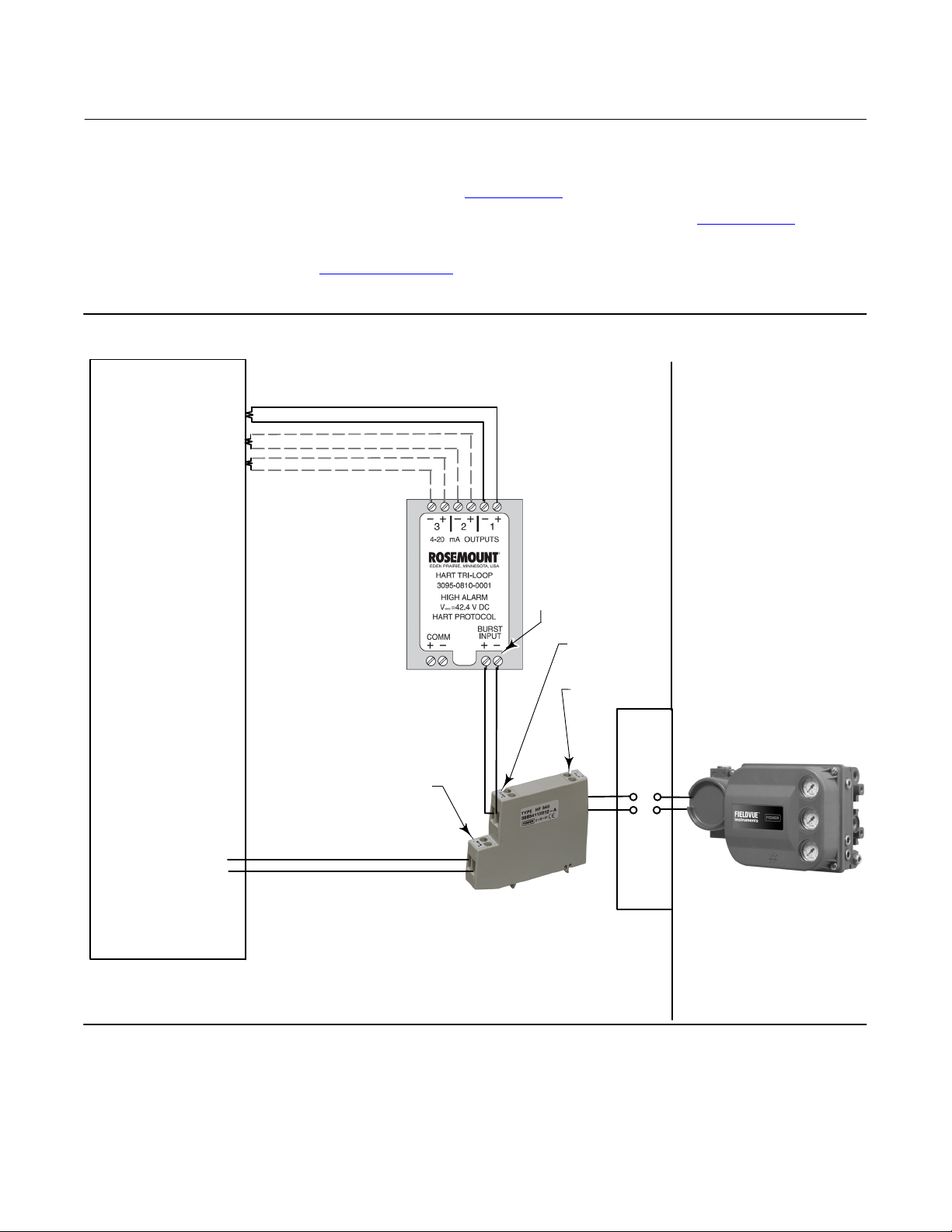

Figure 1 shows a typical installation of the Tri‐Loop signal converter with a digital valve controller.

The Tri‐Loop signal converter may be used with the following FIELDVUE digital valve controllers:

D DVC6200 or DVC6000 HW2 digital valve controllers

Note

Burst mode communication is not supported with HART 7 in firmware revisions 2-6.

D DVC2000 digital valve controllers

D DVC6000 digital valve controllers

The Tri‐Loop signal converter outputs will go to their fail state when any of the following occur:

D there is a loss of burst mode communication from the smart instrument or

D there is a device malfunction reported by the smart instrument.

Loss of power to channel 1 will cause all channels to go to no output. Loss of power to either channel 2 or 3 will not

affect the remaining channels.

When in its fail state, a 333U signal converter generates a current of 21.75 mA or greater. A 333D generates a fail state

current which is less than 3.75 mA.

The Tri‐Loop signal converter is not recommended for FIELDVUE digital valve controller in split-range applications.

www.Fisher.com

FIELDVUE Digital Valve Controllers

February 2020

Instruction Manual Supplement

D103267X102

Installation Considerations

The Tri‐Loop HART‐to‐analog signal converter design allows three different din‐rail mounting options:

D Asymmetrical 32mm G rail

D Symmetrical 35 x 7.5 mm top hat rail

D Symmetrical 35 x 15 mm top hat rail

As shown in figure 1, the signal converter must be installed on the safe side of an Intrinsic Safety (IS) barrier. It is

approved for FM and CSA ordinary location, and bears the CE marking to indicate compliance with applicable EC

directives. It is not approved nor designed for nuclear‐qualified applications.

Figure 1 also shows a HART filter as a convenient connection point for the two additional connections to the loop

wires. The necessity of a HART filter depends upon the control system; the Tri‐Loop signal converter does not add a

requirement for a filter. If a filter is required, the HF340 din rail mount filter provides a convenient method for

connecting field wiring between the control system, the signal converter and the digital valve controller. If no filter is

required, the HF341 is available without filter action (straight‐through).

Related Fisher Documents

DVC6200 and DVC6200 SIS

D DVC6200 Series Digital Valve Controller Quick Start Guide (D103556X012)

D DVC6200 HW2 Digital Valve Controller Instruction Manual (D103605X012

D HART Field Device Specification for DVC6200 Digital Valve Controller (D103639X012

D DVC6200 HW1 Digital Valve Controller Instruction Manual (D103409X012

D HART Field Device Specification for DVC6000 and DVC6200 HW1 Digital Valve Controller (D103649X012

D DVC6200 SIS Digital Valve Controller Instruction Manual (D103557X012

D HART Field Device Specification for DVC6200 SIS Digital Valve Controller (D103638X012

DVC6000 HW2

D DVC6005 Series Remove Mount Digital Valve Controller Quick Start Guide (D103784X012)

D DVC6200 HW2 Digital Valve Controller Instruction Manual (D103785X012

D HART Field Device Specification for DVC6000 HW2 Digital Valve Controller (D103782X012

DVC2000

D DVC2000 Digital Valve Controller Quick Start Guide (D103203X012)

D DVC2000 Digital Valve Controller Instruction Manual (D103176X012

D HART Field Device Specification for DVC2000 Digital Valve Controller (D103783X012

)

)

)

)

)

)

)

)

)

)

Miscellaneous

D HF340 Filter Instruction Manual (D102796X012)

2

Instruction Manual Supplement

FIELDVUE Digital Valve Controllers

D103267X012

DVC6000 (Supported)

D DVC6000 Digital Valve Controllers Instruction Manual (D102794X012)

D HART Field Device Specification for DVC6000 and DVC6200 HW1 Digital Valve Controller (D103649X012

February 2020

)

Documents are available from your Emerson sales office

or at Fisher.com.

Figure 1. Example HART Tri‐Loop HART‐to‐Analog Signal Converter Installation with a FIELDVUE DVC6200 Digital

Valve Controller

CHANNEL 1 MUST BE

POWERED FOR THE

TRI‐LOOP TO OPERATE

EACH TRI‐LOOP

CHANNEL RECEIVES

POWER FROM

CONTROL ROOM

CONTROL ROOM

VALVE TRAVEL

CHANNEL 2 CONFIGURED OUTPUT (OPTIONAL)

CHANNEL 3 CONFIGURED OUTPUT

(OPTIONAL)

BURST INPUT

HART

COMMUNICATION

CONNECTION

FIELD

INSTRUMENT

CONNECTION

HAZARDOUS AREANON‐HAZARDOUS AREA

ANALOG OUTPUT

CONTROLLING

DIGITAL VALVE

CONTROLLER

CONTROL

SYSTEM

CONNECTION

FISHER HF340 HART FILTER

USE AN HF340 IF FILTER

ACTION IS REQUIRED. USE AN HF341

IF NO FILTER ACTION IS REQUIRED.

−

+

−

+

INTRINSIC SAFETY

BARRIER

IF REQUIRED

BY APPLICATION

W9713

FIELDVUE DIGITAL

VALVE CONTROLLER

IN BURST MODE

(COMMAND 3)

3

FIELDVUE Digital Valve Controllers

(1)

February 2020

Instruction Manual Supplement

D103267X102

Tri‐Loop Signal Converter Configuration From Fisher

The Tri‐Loop HART‐to‐analog signal converter ships from Fisher pre‐configured with one of the choices listed in table

1. As shown in the table the unit is available with either a high or low fail state. The channel 1 variable is always travel

and the channel 2 variable is always travel target. Channel 3 is disabled, but can be configured by the user, using a Trex

Device Communicator, a 475 Field Communicator, or AMS Suite: Intelligent Device Manager.

Table 1. Tri‐Loop HART‐to‐Analog Signal Converter Configuration Choices

CHANNEL

TRI‐LOOP MODEL FAIL STATE

333D Low

333U High

1. Configurations of channels are preset, but can be changed with the HART or Field Communicator, or AMS Device Manager.

The burst message from FIELDVUE digital valve controllers configured for fail‐open actuators associates 0% travel with

an open valve. Therefore, channel 1 of the Tri‐Loop should be configured to provide a 20 mA output when the valve is

open and a 4 mA output when the valve is closed (range is 100 to 0 rather than 0 to 100).

1

(Travel)

0 to 100% 0 to 100% Disabled

2

(Travel Target)

3

(Not Configured)

Power Source

Each output channel on the signal converter connects to a separate control system analog input channel. Each channel

operates on a terminal voltage of 11 to 42.4 VDC. The signal converter is powered from the channel 1 power source.

Enabling Burst Mode

For a FIELDVUE digital valve controller to communicate with the Tri‐Loop signal converter, the burst mode must be

enabled. You can use a Field Communicator, ValveLink software, or AMS Device Manager to enable burst mode in the

digital valve controller.

Note

The path to access Burst varies depending on the DD revision of the digital valve controller. Refer to the appropriate instruction

manual to verify path.

Note

HART devices connected to an instrument which is actively using burst mode communication may experience some HART

communication errors. You should not be concerned unless the errors do not clear after a few moments or if they disrupt ValveLink

software configuration, calibration, or diagnostic activities. If a disruption occurs, disable burst mode during these activities and

turn it back on when completed.

4

Instruction Manual Supplement

(1)

D103267X012

FIELDVUE Digital Valve Controllers

February 2020

Once burst mode is enabled, the digital valve controller will continue to burst HART command 3 until the burst mode

is disabled. Even if instrument power is lost, the instrument will continue to burst command 3 when power is restored.

Troubleshooting

Refer to table 2 for Tri‐Loop diagnostic status messages.

To reach the Diagnostic Status menu using the Trex communicator or the Field Communicator, select

Diagnostics/Service, Test Device, and Status (fast key sequence 1‐1‐1).

Other Tri‐Loop parameters can be access using the Trex communicator, Field Communicator or AMS Device Manager.

Refer to figure 2 for the menu tree, and table 3 for the fast‐key sequence.

Table 2. Tri‐Loop Diagnostic Status Messages

Error Message Interpretation

CH1 Burst mode variable 'Not a Number'

CH2 Burst mode variable 'Not a Number'

CH3 Burst mode variable 'Not a Number'

CH1 Burst mode variable at saturation

CH2 Burst mode variable at saturation

CH3 Burst mode variable at saturation

Burst mode message is invalid Parity or checksum error with burst message

Burst mode message timeout Tri‐Loop not receiving burst command “3”

Non‐volatile memory checksum error Internal problem with the Tri‐Loop

Field device reporting failure “Device Malfunction” status from the digital valve controller

CH1 Channel output is fixed

CH2 Channel output is fixed

CH3 Channel output is fixed

CH1 Burst mode message units error

CH2 Burst mode message units error

CH3 Burst mode message units error

1. “ON” = error is in effect. “OFF” = error is not active.

Not applicable to the digital valve controller (always “off”)

Channel commanded into “Output fixed” mode

Channel's units do no match digital valve controllers units

5

FIELDVUE Digital Valve Controllers

February 2020

Figure 2. Menu Tree for the Tri‐Loop Signal Converter

Instruction Manual Supplement

D103267X102

Online Menu

1DEVICE SETUP

1DIAGNOSTICS /

SERVICE

2BASIC SETUP

1 TEST DEVICE

2 LOOP TEST

3CALIBRATION

4 D/A TRIM

1Tag

2CONFIGURE

CHANNELS

3DEVICE

INFORMATION

1Status

2Reset

1CH1

2CH2

3CH3

1CONFIGURE

CHANNELS

2RECALL FACTORY

TRIM

1CH1

2CH2

3CH3

1CONFIGURE CH1

2CONFIGURE CH2

3CONFIGURE CH3

1Model

2Dev ID

3Tag

4Date

5Descriptor

6Message

7Final Asmbly Num

8REVISION #'s

14mA

220mA

3Other

4End

1CONFIGURE CH1

2CONFIGURE CH2

3CONFIGURE CH3

1CH1

2CH2

3CH3

4All

1Burst Variable

2Units

3LRV

4URV

5Enabled

1Universal Rev

2Fld Dev Rev

3Software Rev

1Burst Variable

2Units

3LRV

4URV

5Enabled

3DETAILED SETUP

4REVIEW

1OUTPUT

CONDITION

2DEVICE

INFORMATION

Model

Manufacturer

Dev ID

Tag

Descriptor

Message

Date

Final Asmbly Num

Universal Rev

Fld Dev Rev

Software Rev

Poll Addr

Num Req Preams

1ANALOG

OUTPUT

2HART OUTPUT

1Model

2Dev ID

3Tag

4Date

5Descriptor

6Message

7Final Asmbly Num

8REVISION #'s

1 LOOP TEST

2 D/A TRIM

3 SCALED D/A TRIM

1Poll Addr

2Num Req Preams

3Num Rsp Preams

1Universal Rev

2Fld Dev Rev

3Software Rev

1CH1

2CH2

3CH3

1CH1

2CH2

3CH3

1CH1

2CH2

3CH3

14mA

220mA

3Other

4End

1Proceed

2Change

6

Instruction Manual Supplement

D103267X012

FIELDVUE Digital Valve Controllers

February 2020

Table 3. Fast‐Key Sequence for the Tri‐Loop Signal Converter

Function Fast‐Key Sequence Function Fast‐Key Sequence

20 mA (Loop Test) 1‐2‐1‐2 Final Asmbly Num (Detailed Setup) 3‐2‐7

20 mA (Output Condition) 3‐1‐1‐1‐1‐2 Fld Dev Rev (Basic Setup) 2‐3‐8-2

4 mA (Loop Test) 1‐2‐1‐1 Fld Dev Rev (Detailed Setup) 3‐2‐8‐2

4 mA (Output Condition) 3‐1‐1‐1‐1‐1 LRV (Calibration) 1‐3‐1‐1‐3

All (Calibration) 1‐3‐2‐4 LRV (Configure Channels) 2‐2‐1‐3

Burst Variable (Calibration) 1‐3‐1‐1‐1 Message (Basic Setup) 2‐3‐6

Burst Variable (Configure Channels) 2‐2‐1‐1 Message (Detailed Setup) 3‐2‐6

CH1 (Calibration) 1‐3‐2‐1 Model (Basic Setup) 2‐3‐1

CH1 (D/A TRIM) 1‐4‐1 Model (Detailed Setup) 3‐2‐1

CH1 (Output Condition) 3‐1‐1‐2‐1 Num Req Preams 3‐1‐2‐2

CH2 (Calibration) 1‐3‐2‐2 Num Rsp Preams 3‐1‐2‐3

CH2 (D/A TRIM) 1‐4‐2 Other (Loop Test) 1‐2‐1‐3

CH2 (Output Condition) 3‐1‐1‐2‐2 Other (Output Condition) 3‐1‐1‐1‐1‐3

CH3 (Calibration) 1‐3‐2‐3 Poll Addr 3‐1‐2‐1

CH3 (D/A TRIM) 1‐4‐3 Proceed (Scaled D/A Trim) 3‐1‐1‐3‐1‐1

CH3 (Output Condition) 3‐1‐1‐2‐3 Reset 1‐1‐2

Change (Scaled D/A Trim) 3‐1‐1‐3‐1‐2 Software Rev (Basic Setup) 2‐3‐8‐3

Date (Basic Setup) 2‐3‐4 Software Rev (Detailed Setup) 3‐2‐8‐3

Date (Detailed Setup) 3‐2‐4 Status 1‐1‐1

Descriptor (Basic Setup) 2‐3‐5 Tag 2‐1

Descriptor (Detailed Setup) 3‐2‐5 Tag (Basic Setup) 2‐3‐3

Dev ID (Basic Setup) 2‐3‐2 Tag (Detailed Setup) 3‐2‐3

Dev ID (Detailed Setup) 3‐2‐2 Units (Calibration) 1‐3‐1‐1‐2

Enabled (Calibration) 1‐3‐1‐1‐5 Units (Configure Channels) 2‐2‐1‐2

Enabled (Configure Channels) 2‐2‐1‐5 Universal Rev (Basic Setup) 2‐3‐8‐1

End (Loop Test) 1‐2‐1‐4 Universal Rev (Detailed Setup) 3‐2‐8‐1

End (Output Condition) 3‐1‐1‐1‐1‐4 URV (Calibration) 1‐3‐1‐1‐4

Final Asmbly Num (Basic Setup) 2‐3‐7 URV (Configure Channels) 2‐2‐1‐4

Related Rosemount Documents

For more information on the Tri‐Loop HART‐to‐analog signal converter, refer to the following Rosemount documents,

available from the Rosemount Measurement division:

D Model 333 HART Tri‐Loop HART‐to‐Analog Signal Converter product manual (00809‐0100‐4754

D Model 333 HART Tri‐Loop HART‐to‐Analog Signal Converter product data sheet (00813‐0100‐4754

D AMS Trex Device Communicator User Guide

D 475 Field Communicator User's Manual

Documents are available from your Emerson sales office or at Emerson.com.

)

)

7

FIELDVUE Digital Valve Controllers

February 2020

Instruction Manual Supplement

D103267X102

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, FIELDVUE, Tri-Loop, Rosemount, and ValveLink are marks owned by one of the companies in the Emerson Automation Solutions business unit of

Emerson Electric Co. Emerson Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. HART is a

registered trademark of FieldComm Group. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

8

E 2006, 2020 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...