Page 1

Firefighter’s Telephone

ECC-FFT

Instruction Manual

Document LS10031-000FL-E

9/4/2013 Rev:

P/N LS10031-000FL-E:B ECN 13-707

B

Page 2

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote notification capability—can provide early warning of a developing fire.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire.

An emergency communication system—typically made up of

an automatic fire alarm system (as described above) and a life

safety communication system that may include an autonomous

control unit (ACU), local operating console (LOC), voice communication, and other various interoperable communication methods—can broadcast a mass notification message. Such a

system, however, does not assure protection against property

damage or loss of life resulting from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premises following

the recommendations of the National Fire Protection Association

Standard 72 (NFPA 72), manufacturer's recommendations, State

and local codes, and the recommendations contained in the

Guide for Proper Use of System Smoke Detectors, which is

made available at no charge to all installing dealers. This

document can be found at http://www.systemsensor.com/

appguides/. A study by the Federal Emergency Management

Agency (an agency of the United States government) indicated

that smoke detectors may not go off in as many as 35% of all

fires. While fire alarm systems are designed to provide early

warning against fire, they do not guarantee warning or protection

against fire. A fire alarm system may not provide timely or

adequate warning, or simply may not function, for a variety of

reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a first-floor

or basement fire.

Particles of combustion or “smoke” from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls, chimneys, even wet or humid areas may inhibit particle or smoke

flow.

• Smoke particles may become “cold,” stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets, such as air conditioning vents.

• Smoke particles may be drawn into air returns before reaching the detector.

The amount of “smoke” present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at various levels of smoke density. If such density levels are not created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing chambers tend to detect smoldering fires better than flaming fires,

which have little visible smoke. Detectors that have ionizing-type

sensing chambers tend to detect fast-flaming fires better than

smoldering fires. Because fires develop in different ways and

are often unpredictable in their growth, neither type of detector is

necessarily best and a given type of detector may not provide

adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children playing with matches

(especially in bedrooms), smoking in bed, and violent explosions

(caused by escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and alarm

only when heat on their sensors increases at a predetermined

rate or reaches a predetermined level. Rate-of-rise heat detectors may be subject to reduced sensitivity over time. For this

reason, the rate-of-rise feature of each detector should be tested

at least once per year by a qualified fire protection specialist.

Heat detectors are designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the system for

the connection of alarm transmission wiring, communications,

signaling, and/or power. If detectors are not so located, a developing fire may damage the alarm system, compromising its ability to report a fire.

Audible warning devices such as bells, horns, strobes,

speakers and displays may not alert people if these devices

are located on the other side of closed or partly open doors or

are located on another floor of a building. Any warning device

may fail to alert people with a disability or those who have

recently consumed drugs, alcohol, or medication. Please note

that:

• An emergency communication system may take priority over

a fire alarm system in the event of a life safety emergency.

• Voice messaging systems must be designed to meet intelligibility requirements as defined by NFPA, local codes, and

Authorities Having Jurisdiction (AHJ).

• Language and instructional requirements must be clearly disseminated on any local displays.

• Strobes can, under certain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have shown that certain people, even when they hear

a fire alarm signal, do not respond to or comprehend the

meaning of the signal. Audible devices, such as horns and

bells, can have different tonal patterns and frequencies. It is

the property owner's responsibility to conduct fire drills and

other training exercises to make people aware of fire alarm

signals and instruct them on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause

temporary or permanent hearing loss.

A life safety system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries have

been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control panel. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premises to a central monitoring station may be out of service or temporarily disabled. For added protection against telephone line

failure, backup radio transmission systems are recommended.

The most common cause of life safety system malfunction is

inadequate maintenance. To keep the entire life safety system in

excellent working order, ongoing maintenance is required per the

manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be followed. Environments with large amounts of dust, dirt, or high air

velocity require more frequent maintenance. A maintenance

agreement should be arranged through the local manufacturer's

representative. Maintenance should be scheduled monthly or as

required by National and/or local fire codes and should be performed by authorized professional life saftety system installers

only. Adequate written records of all inspections should be kept.

Limit-D-1-2013

2 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is

energized. Do not attempt to install, service, or operate this

unit until manuals are read and understood.

CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or

deletion of system components, or after any modification,

repair or adjustment to system hardware or wiring. All components, circuits, system operations, or software functions known

to be affected by a change must be 100% tested. In addition,

to ensure that other operations are not inadvertently affected,

at least 10% of initiating devices that are not directly affected

by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º

C/32-120º F and at a relative humidity 93% ± 2% RH (noncondensing) at 32°C ± 2°C (90°F ± 3°F). However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with

a normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all initiating and indicating device loops. Most devices cannot tolerate more than a

10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning induced transients. Although no system is completely

immune from lightning transients and interference, proper

grounding will reduce susceptibility. Overhead or outside aerial

wiring is not recommended, due to an increased susceptibility

to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Overtightening may damage threads, resulting in reduced terminal

contact pressure and difficulty with screw terminal removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the

body. Use static suppressive packaging to protect electronic

assemblies removed from the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to

avoid damage to the control panel and associated equipment.

FACP operation and reliability depend upon proper installation.

Precau-D1-9-2005

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual may

cause interference to radio communications. It has been

tested and found to comply with the limits for class A

computing devices pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when devices are

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the user will be required to correct

the interference at his or her own expense.

Canadian Requirements

This digital apparatus does not exceed the Class A limits

for radiation noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

LiteSpeed™ is a trademark; and FireLite® Alarms is a registered trademark of Honeywell International Inc. Microsoft® and Windows® are registered

trademarks of the Microsoft Corporation.

©2013 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 3

Page 4

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make

frequent upgrades to the embedded software in our products. To ensure that you are installing and programming the latest

features, we strongly recommend that you download the most current version of software for each product prior to

commissioning any system. Contact Technical Support with any questions about software and the appropriate version for a

specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about our

online Help or printed manuals, you can email us.

Please include the following information:

•Product name and version number (if applicable)

•Printed manual or online Help

•Topic Title (for online Help)

•Page number (for printed manual)

•Brief description of content you think should be improved or corrected

•Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact Technical

Services.

4 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 5

Table of Contents

Section 1: Product Description ...............................................................................................7

1.1: Features..........................................................................................................................................................7

1.2: Optional Accessories .....................................................................................................................................7

1.3: Compatible Devices.......................................................................................................................................7

1.4: ECC-FFT Board Layout ................................................................................................................................8

1.5: Electrical Specifications ................................................................................................................................9

1.5.1: Power Requirements............................................................................................................................9

1.5.2: Current Ratings....................................................................................................................................9

1.5.3: Wiring Specifications ........................................................................................................................10

Section 2: Installation.............................................................................................................11

2.1: Mounting Options........................................................................................................................................11

2.2: Backbox Installation ....................................................................................................................................11

2.3: Installing the ECC-FFT ...............................................................................................................................13

2.3.1: Operating Power................................................................................................................................13

2.3.2: DIP switch settings on ECC-FFT ......................................................................................................13

DIP Switch............................................................................................................................................13

2.4: UL Power-limited Wiring Requirements.....................................................................................................14

2.5: ECC-FFT Fire Fighter Telephone Module Connection...............................................................................15

2.6: FPJ-F Installation.........................................................................................................................................16

2.7: SLC Device Installation...............................................................................................................................17

2.7.1: List of SLC Devices ..........................................................................................................................17

2.7.2: Maximum Number of Devices ..........................................................................................................17

2.7.3: Wiring Requirements for SLC Device ..............................................................................................17

Wiring SLC in Style 4 (Class B) Configuration...................................................................................17

Wiring SLC Devices in Style 6 & 7 (Class A) Configuration .............................................................19

2.7.4: Addressing MMF-301 SLC Devices .................................................................................................19

2.8: Audio Phone Circuit Installation .................................................................................................................20

2.8.1: Maximum Number of Devices ..........................................................................................................20

2.8.2: Wiring Requirements for the Audio Telephone Circuit ....................................................................20

Single Phone Jack Audio Circuit in Class B Configuration.................................................................21

Single Phone Jack Audio Circuit in Class A Configuration.................................................................22

Multi-Phone Jack Audio Circuit in Class B Configuration..................................................................23

Multi-Phone Jack Audio Circuit in Class A Configuration..................................................................24

Telephone Jack Only Audio Circuit.....................................................................................................25

Section 3: System Operation.................................................................................................27

3.1: Push-button Operations ...............................................................................................................................27

3.2: LED Operations ...........................................................................................................................................27

3.3: Autoprogram Operation...............................................................................................................................28

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 5

Page 6

This control panel has been designed to comply with standards set forth by the following regulatory agencies:

• Underwriters Laboratories/Underwriters Laboratories Canada

• National Fire Protection Association

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

This Fire Alarm Control Panel complies with the following NFPA Standards:

NFPA 72 National Fire Alarm Code

Note: Audible signal appliances used in public mode applications, are required to have

minimum sound levels of 75 dBA at 10 feet (3 meters) and a maximum level of 120 dBA at the

minimum hearing distance from the audible appliance.

To ensure that the appliance is clearly heard, the audible appliance sound level must be at least

15 dBA above the average ambient sound level or 5 dBA above the maximum sound level with

a duration of at least 60 seconds, depending on which level is greater, with the sound level

being measured 5 feet (1.5 meters) above the floor.

Underwriters Laboratories Documents:

UL 38 Manually Actuated Signaling Boxes

UL 464 Audible Signaling Appliances

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1480 Speakers for Fire Protective Signaling Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1711 Amplifiers for Fire Protective Signaling Systems

UL 1971 Signaling Devices for Hearing Impaired

UL 2572 Communication and Control Units for Mass Notification Systems

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

UFC Unified Facilities Criteria UFC 4-021-01: Mass Notification Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction (LAHJ)

Fire•Lite Documents

Fire•Lite Device Compatibility Document Document #15384

ECC-50/100 Manual Document #LS10001-000FL-E

ECC-50/125DA Manual Document #LS10027-000FL-E

MS-9200UDLS Series Manual Document #52750

MS-9600(UD)LS Technical Manual Document #52646

FCPS-24FS6/8 Field Charger/Power Supply Document #51883

HP300ULX Power Supply Document # 52386

This product has been certified to comply with the requirements in the Standard for Control Units and Accessories for Fire

Alarm Systems, UL 864, 9th Edition. Operation of this product with products not tested for UL 864, 9th Edition has not

been evaluated. Such operation requires the approval of the local Authority Having Jurisdiction (AHJ).

6 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 7

Section 1: Product Description

An ECC-FFT Fire Fighter Telephone System provides supervision, annunciation, and control for

local and remote telephone handsets. The ECC-FFT with keypad, provides indications of phone

activation, and corresponding trouble conditions.

1.1 Features

• One Form-C system trouble relay - TB6

• ECC-FFT Fire Fighter Telephone module for control and annunciation of up to 24 remote

telephone jacks

• A maximum of ten (10) Fire Fighter Remote Handsets (FHS-F) can be used at one time to

communicate over the telephone circuit connected to the ECC-FFT

• Fire Fighter Phone Jack (FPJ-F) provides a plug-in location for the FHS-F

• Fire Fighter Handset Cabinet (FHSC-RF/SF) is used to store up to five (5) Fire Fighter

Handsets (FHS-F)

• System Status LEDs

1.2 Optional Accessories

This manual also contains information on how to install the following compatible accessories with

the FFT series equipment:

Model Number Description

FPJ-F Remote Phone Jack

FHS-F Fire Fighters Remote Handset

FHSC-RF Fire Fighters Handset Cabinet Recessed

FHSC-SF Fire Fighters Handset Cabinet Surface Mount

MMF-301 Addressable Mini-Monitor Module

I300 SLC Line Isolation Module

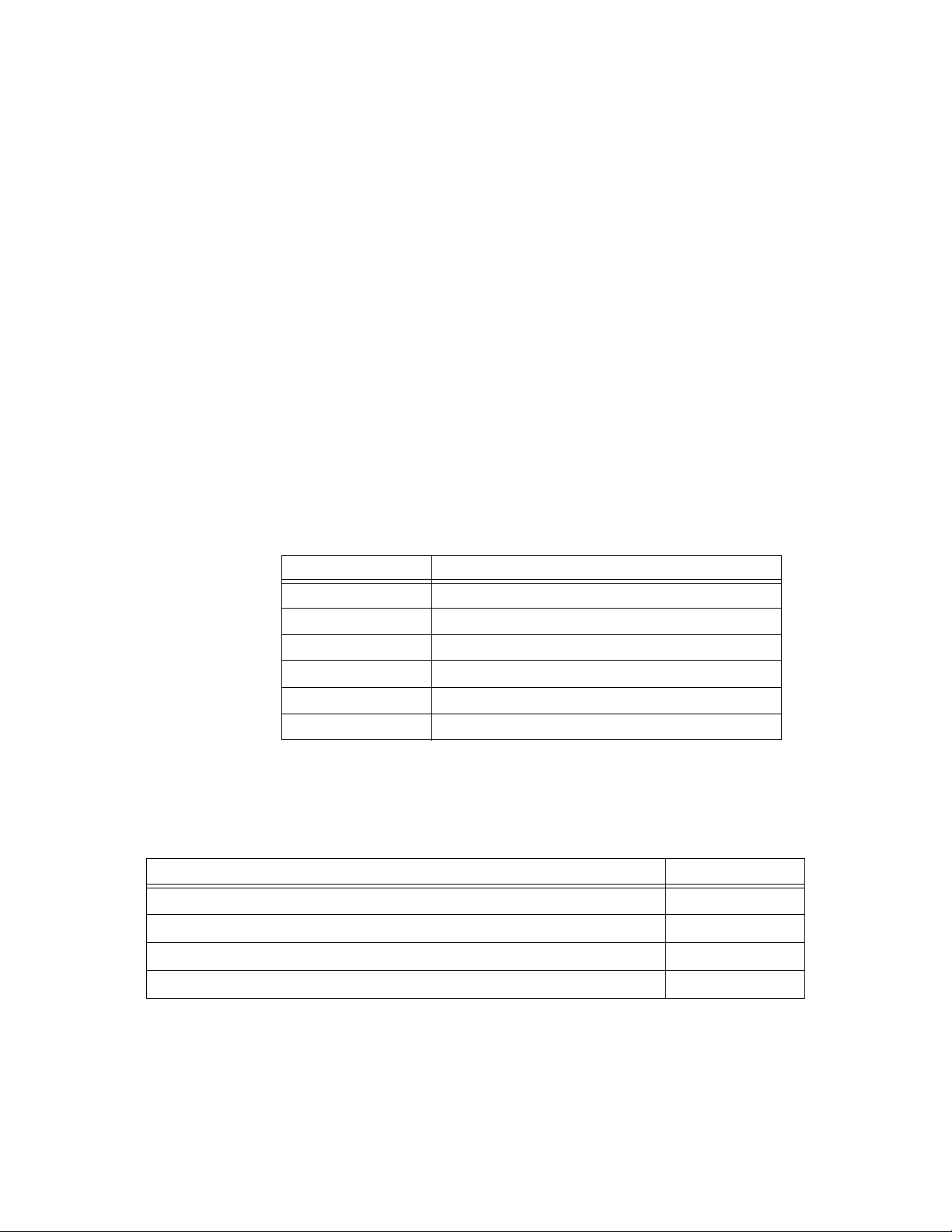

1.3 Compatible Devices

Table 1.1 lists the available FireLite fire alarm control panels/systems and power supplies compatible with the ECC-FFT.

Model Manual PN

ECC-50/100 Emergency Command Center LS10001-000FL-E

MS-9200UDLS Addressable Fire Alarm Control Panel 52750

MS-9600(UD)LS Addressable Fire Alarm Control Panel 52646

FCPS-24FS6/8 Field Charger/Power Supply 51883

Table 1.1 Compatible Powering Devices

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 7

Page 8

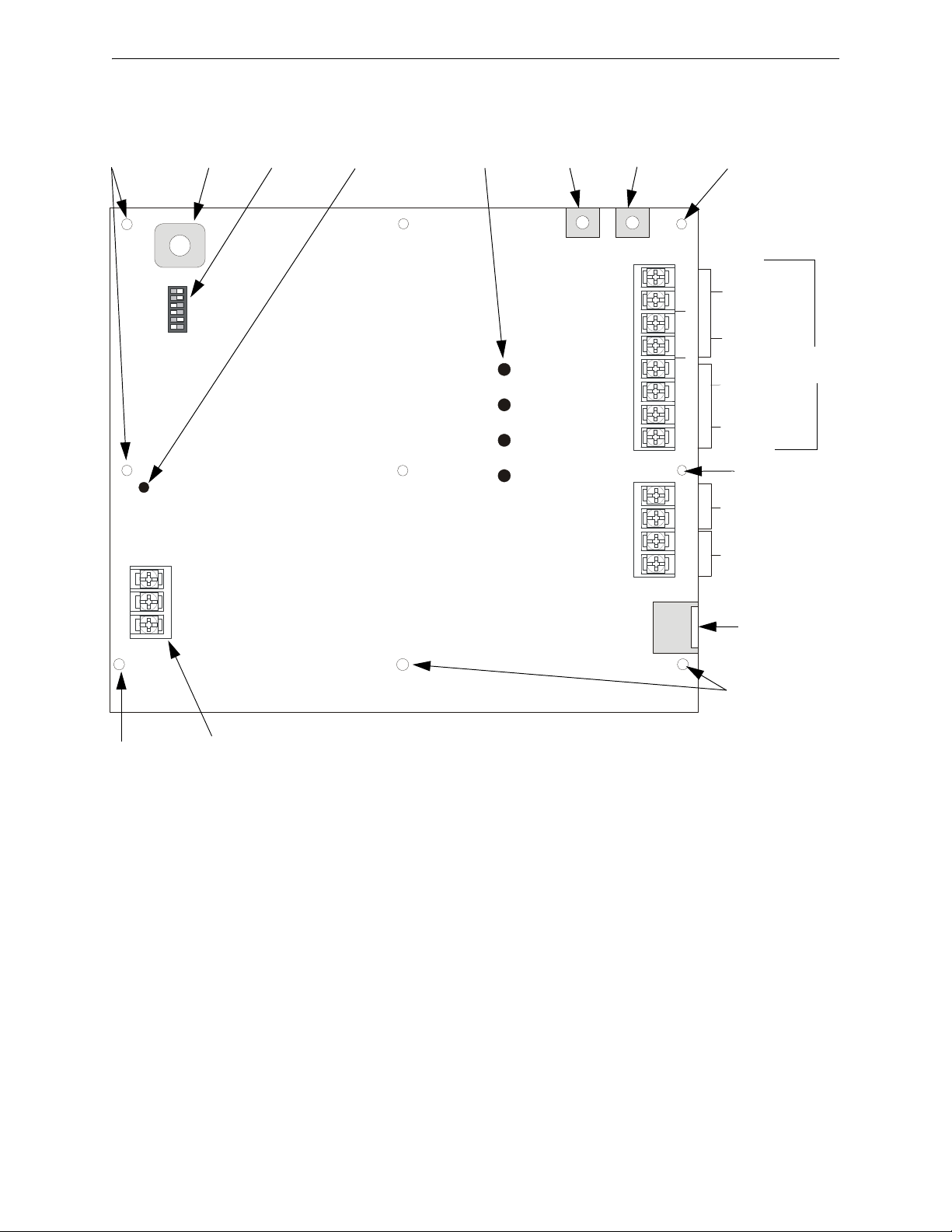

Product Description ECC-FFT Board Layout

ON

12345

6

SLC OUT SLC IN PHONE OUT PHONE IN

- + - + - + - +

- + A B

TROUBLE

NO COM NC

1

234

Autoprogram AcceptStatus LEDs

Local Handset

piezo

Phone In

Phone Out

SLC IN

SLC Out

mounting stud

mounting studs

Supervised,

Power-Limited

All circuits are inherently power-limited

except the trouble relay

Not

Used

DC

Power

System Trouble Relay

Non Power-Limited

mounting studs

mounting stud

mounting stud

Figure 1.1 Back view of ECC-FFT

DIP Switch

f

f

t

b

r

d

.

w

m

f

Power Status LED

1.4 ECC-FFT Board Layout

Figure 1.1 above shows the circuit board that attaches to the cabinet. If you should need to remove

the board assembly for repair, remove the seven mounting nuts which hold the assembly in the cabinet. Then lift the control board out of the cabinet.

8 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 9

Electrical Specifications Product Description

Zone 1-

Zone 8

Zone 9 Zone 16

Zone 17 -

Zone 24

Figure 1.2 ECC-FFT Keypad

e

c

c

f

f

t

k

y

p

d

.

w

m

f

1.5 Electrical Specifications

1.5.1 Power Requirements

Voltage for the ECC-FFT must be a UL-listed, power-limited, filtered, non-resettable nominal 24

VDC source. The voltage source must be within the range of 17-29 VDC.

Circuits Voltage Current

SLC Circuit 32 V 150 mA

Audio Circuits 17 V 53 mA

Trouble Relay 12 VDC 1 A

Table 1.2 Electrical Ratings

1.5.2 Current Ratings

Maximum current ratings for determining backup battery requirements for alarm (active) and

standby conditions over the input voltage range of 17-29 VDC are shown in Table 1.3 below.

ECC-FFT 230 mA 120 mA

Table 1.3 ECC-FFT Current Draw

Active Standby

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 9

Page 10

Product Description Electrical Specifications

1.5.3 Wiring Specifications

Induced noise (transfer of electrical energy from one wire to another) can interfere with telephone

communication or cause false alarms. To avoid induced noise, follow these guidelines:

• Isolate input wiring from high current output and power wiring. Do not pull one multiconductor cable for the entire panel. Instead, separate the wiring as follows:

– SLC Loops

– Relay Circuit

– Audio Circuits

• Do not pull wires from different circuits (listed above) through the same conduit. If you must

run them together, do so for as short a distance as possible or use shielded cable. Twisted,

shielded wire on the Audio Circuits is recommended for maximum protection against EMI and

AFI emissions and susceptibility. Connect the shield to earth ground at the panel. You must

route high and low voltages separately.

• Route the wiring around the inside perimeter of the cabinet. It should not cross the circuit

board where it could induce noise into the sensitive microelectronics or pick up unwanted RF

noise from the high speed circuits. See Figure 2.4 for an example.

• High frequency noise, such as that produced by the inductive reactance of a speaker or bell,

can also be reduced by running the wire through ferrite shield beads or by wrapping it around a

ferrite toroid.

10 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 11

Section 2: Installation

!

ON

12345

6

SLC OUT SLC IN PHONEOUT PHONE IN

-+-+-+-+

-+AB

TROUBLE

NOCOM NC

1

2

3

4

remove screws

disconnect

earth ground

lift up dress panel,

pull out,

slide down to remove

Figure 2.1 Dress Panel Removal

fft-dpopn.wmf

2.1 Mounting Options

The cabinet may be semi-flush or surface mounted. The cabinet mounts using three key slots at the

top of the backbox and two additional 0.250" diameter holes located at the bottom.

Carefully unpack the system and check for shipping damage. Mount the cabinet in a clean, dry,

vibration-free area where extreme temperatures are not encountered. The area should be readily

accessible with sufficient room to easily install and maintain the panel. Locate the top of the cabinet approximately five feet above the floor with the hinge mounting on the left. Determine the

number of conductors required for the devices to be installed. Sufficient knockouts are provided

for wiring convenience. Select the appropriate knockout(s) and pull the required conductors into

the box. Note that knockouts are also located on the back of the cabinet. All wiring should be in

accordance with the National and/or Local codes for fire alarm systems.

2.2 Backbox Installation

CAUTION: STATIC SENSITIVE COMPONENTS

THE CIRCUIT BOARD CONTAINS STATIC-SENSITIVE COMPONENTS. ALWAYS GROUND

YOURSELF WITH A PROPER WRIST STRAP BEFORE HANDLING ANY BOARDS SO THAT

STATIC CHARGES ARE REMOVED FROM THE BODY. USE STATIC SUPPRESSIVE PACKAGING TO PROTECT ELECTRONIC ASSEMBLIES.

1. Open the door and lift the door off the pin hinges.

2. Loosen the two (2) screws that secure the dress panel to the backbox. Then, lift up to swing

the dress panel open.

3. Disconnect the ground wire from the dress panel.

4. Lift the dress panel up and gently pull the lower hinge out of the backbox. Gently pull down to

remove the top hinge. Store the dress panel in a safe place.

5. Mark and predrill hole in the wall for the center top keyhole mounting bolt using the

dimensions illustrated in Figure 2.2 on page 12.

6. Install center top fastener in the wall with the screw head protruding.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 11

Page 12

Installation Backbox Installation

Figure 2.2 Cabinet Dimensions & Knockout Locations

9050udencl.wmf

Semi-Flush Mounting

Do not recess box more

than 3.875” into wall to

avoid covering venting

holes on top of box.

Hinge Slot for

Dress Panel

Hinge Slot for

Dress Panel

Semi-flush

mounting hole

Mounting

slots for

optional

Trim Ring

7. Place backbox over the top screw, level and secure.

8. Mark and drill the left and right upper and lower mounting holes.

Note: Outer holes (closest to sidewall) are used for 16” O.C. stud mounting.

9. Install remaining fasteners and tighten.

10. Carefully reinstall the chassis assembly and dress panel by reversing the steps above. Use

appropriate precautions to prevent damage to components due to static discharge.

11. Draw wires through the respective knockout locations.

An optional Trim Ring (P/N TR-CE) is available for semi-flush mount installations.

12 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 13

Installing the ECC-FFT Installation

Figure 2.3 DIP Switch

2.3 Installing the ECC-FFT

2.3.1 Operating Power

Connect the ECC-FFT to the appropriate DC power source. See Section 1.3 for compatible equipment and Section 1.5 for power requirements.

2.3.2 DIP switch settings on ECC-FFT

Use the on-board DIP switch to assign the configuration setting to the ECC-FFT.

1. Refer to Figure 2.3 for location of the DIP switches on the ECC-FFT board.

2. Configure the ECC-FFT using the dip switch settings in Table 2.1. Add SLC modules to the

system through Autoprogram feature. See Section 3.3 for Autoprogram Operation.

DIP Switch

DIP Switch ON OFF

1 SLC Devices Installed SLC Devices not Installed

2 Trouble Piezo Enabled Trouble Piezo Disabled

3 SLC Class A Supervision SLC Class B Supervision

4 Phone Circuit Class A Supervision Phone Circuit Class B Supervision

5 Not Used Leave in OFF position

6 Not Used Leave in OFF position

Table 2.1 ECC-FFT DIP Switch Configurations

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 13

Page 14

Installation UL Power-limited Wiring Requirements

Figure 2.4 UL Power-Limited Wiring Requirements

back view of dress panel

Note: The dress panel is shown swung

open for illustration purposes only.

Nonpowerlimited

circuit

Power-limited

circuits

fftulpwr.wmf

2.4 UL Power-limited Wiring Requirements

Power-limited and nonpower-limited circuit wiring must remain separated in the cabinet. All

power-limited circuit wiring must remain at least 0.25” (6.35 mm) away from any nonpower-limited circuit wiring and nonpower-limited circuit wiring must enter and exit the cabinet through different knockouts and/or conduits. A typical wiring diagram for the ECC-FFT is shown below.

14 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 15

ECC-FFT Fire Fighter Telephone Module Connection Installation

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

TB1

TB2

3

2

1

1

2

3

+ -

+

-

To FFT - SLC Terminal TB4

Connectors or other MMF-301

The wiring between the monitor

module and FPJ-F is supervised

by the monitor module. A 47K

End-of-Line resistor is built into

the FPJ-F.

To FFT-Phone TB4 phone

In/Out + – connections or other

FPJ-Fs

4.7K, 1/2 watt ELR

(install on last device for Style Y

[Class B] telephone circuit only

FFT-FPJ

Figure 2.5 ECC-FFT Connections

violet

yellow

black

red

2.5 ECC-FFT Fire Fighter Telephone Module Connection

The ECC-FFT provides connection for a single Class B or Class A telephone audio circuit. See

page 21 through page 26 for examples of audio zone configurations. An MMF-301 monitor module

can be used to monitor the connection of the Fire Fighter Telephone remote handset (FHS-F) into

the FPJ-F, which is then displayed on the ECC-FFT active zone LED during the Autoprogram feature.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 15

Page 16

Installation FPJ-F Installation

Figure 2.6 FPJ-F (Phone Jack) and FHS-F (Handset)

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

012346789

5

TB1

TB2

3

2

1

1

2

3

+ -

+

-

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- + - + - + -

+

Figure 2.7 FFT to FPJ-F Connection

Class A wiring

Audio

Audio

To FFT-SLC

terminal TB4

connectors or other

MMF-301s

4.7K, ½ watt ELR

(install on last device

for Style Y [Class B]

telephone circuit only)

contact ELR connected

FFT

FPJ-F

2.6 FPJ-F Installation

The FPJ-F Firefighter Phone Jack mounts to a single-gang electrical box (4 x 2⅛ x 2½) or, when

the addressable mini-monitor module is installed with it, a deep single-gang electrical box (4" x

2⅛” x 3¼”).

Connect the telephone audio loop between the FPJ-F and FFT as detailed below. All circuits are

power-limited and supervised.

16 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 17

SLC Device Installation Installation

!

2.7 SLC Device Installation

WARNING: RISK OF EQUIPMENT DAMAGE AND PERSONAL INJURY

SEVERAL DIFFERENT SOURCES OF POWER CAN BE CONNECTED TO THIS UNIT. ALWAYS

DISCONNECT ALL SOURCES OF POWER BEFORE INSTALLING OR SERVICING.

2.7.1 List of SLC Devices

The following SLC device can be used with the Fire Fighters Phone. See the device installation

instructions for more information (packaged with the device). Refer also to the SLC Wiring Manual #51309for more information.

Part Number Model Name/Description Install Sheet PN

MMF-301 Mini Monitor Module I56-3654

I300 Fault Isolator Module I56-1381

2.7.2 Maximum Number of Devices

The ECC-FFT supports up to 24 MMF-301 devices on one FFT system.

2.7.3 Wiring Requirements for SLC Device

The following information applies to the MMF-301 - Mini Monitor module.

Wiring SLC in Style 4 (Class B) Configuration

No special wire is required for the ECC-FFT SLC loop. The wire can be untwisted, unshielded,

solid or stranded as long as it meets the National Electric Code 760-51 requirements for power limited fire protective signaling cables. Wire distances are computed using copper wire.

Maximum wiring resistance is 40 ohms to the farthest SLC device.

Maximum loop length depends on the wire gauge.

Wire Gauge Max. Distance

22 AWG 1200 feet

18 AWG 3100 feet

16 AWG 4900 feet

14 AWG 7900 feet

12 AWG 10,000 feet

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 17

Page 18

Installation SLC Device Installation

Figure 2.8 Calculating Wire Run Length

The dotted line path shows how the

wire distance is calculated for the

SLC device at the end of the run.

The wire distance must be less than

the maximum per wire gauge.

SLC device

SLC device

SLC device

SLC device max loop resistance = 40 ohms

SLC Circuit

Figure 2.9 Calculating Wire Run Length for a T-tap

In this example:

= 1000 feet

= 1600 feet

= 3500 feet

16 AWG wire can be used

because the greatest distance is

3500 feet

The device located farthest from

the SLC must be less than the

maximum distance per wire gauge.

SLC device

SLC device

SLC device

SLC device max loop resistance = 40 ohms

SLC Circuit

Figure 2.8 and Figure 2.9 show how length is determined for out and return style wiring.

When using T-taps, the total length of all taps and the main bus must not exceed 40,000 feet. This

requirement must be met in addition to the maximum distance requirements for the various wire

gauges.

18 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 19

SLC Device Installation Installation

MMISO ISO ISO ISO ISO ISO

ISOISOISOISOISO ISO

MM MM

MMMM

MM

ISO

= SLC Device, Mini monitor module, MMF-301

= Isolator Device, I300

MMISO

ISO

MM MM

MMMM

MM MM

MM

SLC

Circuit

SLC

Circuit

SLC IN

SLC OUT

+

-

+

-

SLC IN

SLC OUT

+

-

+

-

Note: A maximum of 20

isolator modules can be

attached to the ECC-FFT

Style 6 Wring

Style 7 Wring

Figure 2.10 Class A SLC Configuration

Wires must be in conduit and close-nippled if isolator modules are used.

Wires must be in conduit and close-nippled at the

control panel and on each side of all devices.

!

Wiring SLC Devices in Style 6 & 7 (Class A) Configuration

Figure 2.10 illustrates how to wire the SLC loop for Style 6 or Style 7 Class A installations.

NOTE: Style 6 does not require the use of short circuit isolator devices.

NOTE: T-taps are not allowed on Class A SLC loops.

.

CAUTION: PROPER SYSTEM SUPERVISION

FOR PROPER SYSTEM SUPERVISION DO NOT USE LOOPED WIRE UNDER TERMINALS

MARKED SLC + AND – OF THE SLC DEVICE CONNECTORS. BREAK WIRE RUNS TO PROVIDE

SUPERVISION OF CONNECTIONS.

2.7.4 Addressing MMF-301 SLC Devices

All MMF-301 devices are addressed using the two rotary dials that appear on the device board. Use

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 19

the ONES rotary dial to set the ones place in a one or two digit number, and use the TENS rotary

dial to set the tens place in a two digit number.

MMF-301 modules can be assigned any unique address from 1 to 24.

Page 20

Installation Audio Phone Circuit Installation

Example 1: MMF-301 SLC Device set to Address 10

Example 2: MMF-301 SLC Device set to Address 42

Example 1: To select device address 10, turn the ONES rotary dial to 0 and the TENS rotary dial to

1 as shown below.

Example 2: To select device address 42, turn the ONES rotary dial to 2 and the TENS rotary dial to

4 as show below.

2.8 Audio Phone Circuit Installation

2.8.1 Maximum Number of Devices

The ECC-FFT supports up to 24 zones. Each zone consists of one addressable monitor module

(MMF-301) and a minimum of one Fire Fighter Telephone Jack (FPJ-F).

2.8.2 Wiring Requirements for the Audio Telephone Circuit

No special wire is required for the Audio Telephone Circuit. The wire can be untwisted, unshielded,

twisted or shielded as long as it meets the National Electric code 760-51 requirements for power

limited fire protective signaling cables.

54 Ohm maximum impedance - 12 to 18 AWG.

Twisted, shielded wire is recommended for maximum protection against EMI and AFI emissions

and susceptibility.

If using shielded cable, attach the shield to Grounding Stud below TB6 of the FFT.

NOTE: Do not ground the shield on both ends.

20 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 21

Audio Phone Circuit Installation Installation

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- + - + - + - +

Contact EOL

Connected

+ Audio

- Audio

+ SLC

- SLC

Caution

For system supervisionFor terminals 2 and 3, do not

use looped wire under

terminals. Break wire run to

provide supervision of

connections.

4.7K, 1/2 watt ELR

(install on last device for

Style Y [Class B]

telephone circuit only)

Figure 2.11 Single Phone Jack Audio Circuit in Class B

FPJ-F

FPJ-F

FPJ-F

FFT

Conne

cted

N

ot Connected

Single Phone Jack Audio Circuit in Class B Configuration

Figure 2.11 illustrates a single phone jack configuration wiring the audio circuit and SLC for Class

B Configuration. Audio circuits must be connected to FFT phone out terminals for all Class B

audio configurations.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 21

Page 22

Installation Audio Phone Circuit Installation

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- + - + - +

- +

Figure 2.12 Single Phone Jack Audio Circuit in Class A

Contact EOL

Connected

+ Audio

- Audio

+ Audio

- Audio

+ SLC

- SLC

Caution

For system supervisionFor terminals 2 and 3, do not

use looped wire under

terminals. Break wire run to

provide supervision of

connections.

FPJ-F

FPJ-F

FPJ-F

FFT

+ SLCSLC -

Class A

Wiring

Single Phone Jack Audio Circuit in Class A Configuration

Figure 2.12 illustrates a phone jack audio circuit (Class A) and SLC for Style 6 & 7 (Class A) configuration.

22 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 23

Audio Phone Circuit Installation Installation

0101112131415

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

012346789

5

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- + - + - + - +

+ Audio

- Audio

Caution

For system supervisionFor terminals 2 and 3, do not

use looped wire under

terminals. Break wire run to

provide supervision of

connections.

4.7K, 1/2 watt ELR

(install on last device

for Style Y [Class B]

telephone circuit only)

FPJ-FFPJ-FFPJ-F

FFT

+ SLCSLC -

FPJ-FFPJ-FFPJ-F

Contact EOL

Connected

Contact EOL

Disconnected

Contact EOL

Disconnected

Contact EOL

Connected

Figure 2.13 Multi-Phone Jack Audio Circuit in Class B

Multi-Phone Jack Audio Circuit in Class B Configuration

Figure 2.13 illustrates how to wire the Multi-Phone Jack audio circuit (Class B) and SLC for for

Style 4 (Class B) configuration. In the Multi-Phone Jack configuration, the maximum mini-monitor

contact wiring resistance between to first and last FPJ-F must be less than 100 ohms.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 23

Page 24

Installation Audio Phone Circuit Installation

0101112131415

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

012346789

5

0

10

11

12

13

14

15

ADDRESS

LOOP

1

2

3

4

TENS

ONES

6

7

8

9

5

0

1

2

3

4

6

7

8

9

5

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- + - + - + - +

+ Audio

- Audio

+ Audio

- Audio

Caution

For system supervisionFor terminals 2 and 3, do not

use looped wire under

terminals. Break wire run to

provide supervision of

connections.

FPJ-FFPJ-FFPJ-F

FFT

FPJ-FFPJ-FFPJ-F

Contact EOL

Connected

Contact EOL

Disconnected

Contact EOL

Disconnected

Contact EOL

Connected

Figure 2.14 Multi-Phone Jack Audio Circuit in Class A

+ SLC

- SLC

+ SLC

- SLC

Multi-Phone Jack Audio Circuit in Class A Configuration

Figure 2.14 illustrates how to wire the Multi-Phone Jack audio circuit (Class A) and SLC for Style

6 & 7 (Class A) configuration. In the Multi-Phone Jack configuration, the maximum Mini-Monitor

Contact wiring resistance between to first and last FPJ-F must be less that 100 ohms.

24 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 25

Audio Phone Circuit Installation Installation

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- +-+-+- +

+ Audio

- Audio

Caution

For system supervisionFor terminals 2 and 3, do not

use looped wire under

terminals. Break wire run to

provide supervision of

connections.

4.7K, 1/2 watt ELR

(install on last device for

Style Y [Class B]

telephone circuit only)

Figure 2.15 Telephone Jack Only Audio Circuit in Class B

FPJ-F

FPJ-F

FPJ-F

FFT

Telephone Jack Only Audio Circuit

The FFT can also be configured using only the Fire Fighters Phone Jack (FPJ-F). In this configuration, the MMF-301 module is not required for system operation. To configure the FFT for Telephone Jack only, the DIP Switch position 1 must be off (SLC Devices not Installed). See Table 2.1

on page 13.

Audio wiring for this configuration is detailed below. See Figures 2.15 and 2.16.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 25

Page 26

Installation Audio Phone Circuit Installation

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

TB1

TB2

3

2

1

1

2

3

SLC

PHONE

PHONE

OUT

OUT

IN

IN

SLC

- + - + - + - +

Figure 2.16 Telephone Jack Only Audio Circuit in Class A

+ Audio

- Audio

+ Audio

- Audio

Caution

For system supervisionFor terminals 2 and 3, do not

use looped wire under

terminals. Break wire run to

provide supervision of

connections.

FPJ-F

FPJ-F

FPJ-F

FFT

Class A

Wiring

26 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 27

Section 3: System Operation

The operation of the ECC-FFT Fire Fighter Telephone system allows audio communication from

24 remote connections through remote handsets to a single local handset. Up to 10 remote handsets

can be connected and communicating at one time.

3.1 Push-button Operations

Autoprogram (on inside of FFT dress panel)

The Autoprogram key will cause the FFT to search the SLC loop for devices. The Active LED

(green) will then blink for each zone where a device was found. Press and hold the Autoprogram

button for 2 seconds in order to initiate this feature.

Accept (on inside of FFT dress panel)

The Accept button is used after Autoprogram. It will save the current SLC device configuration and

re-initialize the FFT. If the Accept button is not pressed within one minute after the Autoprogram is

complete, its configuration will be discarded and the FFT will be restarted.

Answer Call

When a remote handset is connected to one of the FPJ-F phone jacks, the Answer Call LED will

blink and the FFT's piezo will sound. Pressing the Answer Call button will connect the local handset to the phone circuit, turn the Answer Call LED on steady, and silence the piezo. Communication

between the local and remote handset is now possible. Up to ten remote handsets can be connected

to the phone circuit simultaneously. After the initial remote handset, the connection of additional

handsets does not cause the piezo to sound or the Answer Call LED to blink.

Trouble Silence

The Trouble Silence button is used to silence a system type trouble that has occurred in the FFT

system. Once pressed, the piezo will silence.

3.2 LED Operations

Power Status LED (on Inside of FFT dress panel)

The status LED is located on the right side of the FFT board. On power-up, the power status LED

will blink at a 50% on/off rate until FFT initialization is complete (which takes approximately 20

seconds). Once initialization is complete, the status LED will blink at a 10% on and 90% off rate.

No key input will be valid until the FFT completes its initialization.

Answer Call

When a remote handset connects to the audio channel, the Answer Call LED will blink and the

piezo will sound. The operator at the FFT then picks up the local handset and presses the Answer

button which causes the Answer Call LED to remain on steady and the piezo goes silent. Communication between the local and remote handset is now established. Additional remote handsets can

be attached to the audio connection without any intervention at the FFT. Once the last remote handset has disconnected from the FFT, the answer LED will turn off and the system will return to normal.

Power

The Power LED indicates that 24 VDC is connected to the FFT.

Local Trouble

The local handset trouble LED will activate and blink when there is a problem with the local handset.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 27

Page 28

System Operation Autoprogram Operation

Trouble (yellow)

Active (green)

Figure 3.1 LED Operations

Remote Trouble

The remote handset trouble LED will activate and blink when there is a problem with the phone circuit.

General Trouble

The General Trouble LED will blink active when system troubles are detected. When the Trouble

Silence button is pressed, the General Trouble LED will light steady. Once all system troubles have

been restored, the General Trouble LED will turn off.

Status LEDs (on Inside of FFT dress panel)

• LED 1 - SLC Supervision

• LED 2 - SLC Extra Point Detected

•LED 3 - Future Use

• LED 4 - Audio Circuit Supervision

NOTE: Troubles that will turn these LEDs on are: SLC shorted, SLC Class A Open Trouble, and

Wrong Device Type.

Zone Active

Each zone has an Active LED (see Figure 3.1). The zone's Active LED will illuminate when a

remote handset is plugged into that zone. The LED will turn off when the handset is removed from

the zone.

Zone Trouble

Each zone has a Trouble LED. The zone's Trouble LED will blink when specific SLC issues occur

such as a missing device or double address. Pressing the Trouble Silence Key will cause the zone

trouble LED to turn on steady. Once the zone trouble is corrected, the LED will turn off.

3.3 Autoprogram Operation

The Autoprogram feature will attempt to locate all SLC Mini-Monitor devices installed in the system, indicate all devices found on the FFT and allow the user to accept the configuration, repeat the

Autoprogram, or allow the configuration to be discarded.

1. To perform the FFT Autoprogram press and hold the Autoprogram button for 2 seconds.

2. The FFT will search for installed SLC devices and activate the Active LEDs of all zone/point

addresses found.

3. When the Autoprogram is complete, the first four status LEDs will blink. The user can now

press the ACCEPT key causing the FFT to save the configuration and restart.

4. The user presses the Autoprogram key again to repeat the SLC search process.

5. If the user does not press the Accept key within one minute after the Autoprogram is complete,

its configuration will be discarded and the FFT will be restarted.

28 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 29

Slide-in Labels

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Zone 8

Zone 9

Zone 10

Zone 11

Zone 12

Zone 13

Zone 14

Zone 15

Zone 16

Zone 17

Zone 18

Zone 19

Zone 20

Zone 21

Zone 22

Zone 23

Zone 24

Carefully cut along the outside of each label. Identify the keypad buttons as desired and slide the

labels in. The labels slide upwards through the slits in the bottom of the keypad, covering the white

spaces.

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 29

Page 30

Slide-in Labels Autoprogram Operation

30 ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013

Page 31

Manufacturer Warranties and Limitation of Liability

Manufacturer Warranties. Subject to the limitations set forth herein,

Manufacturer warrants that the Products manufactured by it in its

Northford, Connecticut facility and sold by it to its authorized

Distributors shall be free, under normal use and service, from defects

in material and workmanship for a period of thirty six months (36)

months from the date of manufacture (effective Jan. 1, 2009). The

Products manufactured and sold by Manufacturer are date stamped at

the time of production. Manufacturer does not warrant Products that

are not manufactured by it in its Northford, Connecticut facility but

assigns to its Distributor, to the extent possible, any warranty offered

by the manufacturer of such product. This warranty shall be void if a

Product is altered, serviced or repaired by anyone other than

Manufacturer or its authorized Distributors. This warranty shall also

be void if there is a failure to maintain the Products and the systems in

which they operate in proper working conditions.

MANUFACTURER MAKES NO FURTHER WARRANTIES, AND

DISCLAIMS ANY AND ALL OTHER WARRANTIES, EITHER

EXPRESSED OR IMPLIED, WITH RESPECT TO THE PRODUCTS,

TRADEMARKS, PROGRAMS AND SERVICES RENDERED BY

MANUFACTURER INCLUDING WITHOUT LIMITATION,

INFRINGEMENT, TITLE, MERCHANTABILITY, OR FITNESS FOR

ANY PARTICULAR PURPOSE. MANUFACTURER SHALL NOT BE

LIABLE FOR ANY PERSONAL INJURY OR DEATH WHICH MAY

ARISE IN THE COURSE OF, OR AS A RESULT OF, PERSONAL,

COMMERCIAL OR INDUSTRIAL USES OF ITS PRODUCTS.

This document constitutes the only warranty made by Manufacturer

with respect to its products and replaces all previous warranties and is

the only warranty made by Manufacturer. No increase or alteration,

written or verbal, of the obligation of this warranty is authorized.

Manufacturer does not represent that its products will prevent any loss

by fire or otherwise.

Warranty Claims. Manufacturer shall replace or repair, at

Manufacturer's discretion, each part returned by its authorized

Distributor and acknowledged by Manufacturer to be defective,

provided that such part shall have been returned to Manufacturer with

all charges prepaid and the authorized Distributor has completed

Manufacturer's Return Material Authorization form. The replacement

part shall come from Manufacturer's stock and may be new or

refurbished. THE FOREGOING IS DISTRIBUTOR'S SOLE AND

EXCLUSIVE REMEDY IN THE EVENT OF A WARRANTY CLAIM.

Warn-HL-08-2009.fm

ECC-FFT Instruction Manual — P/N LS10031-000FL-E:B 9/4/2013 31

Page 32

World Headquarters

1 Firelite Place

Northford, CT 06472-1653 USA

203-484-7161

fax 203-484-7118

www.firelite.com

Loading...

Loading...