Page 1

Emergency Command Center

ECC-50/100

ECC-50/100E

Instruction Manual

Document LS10001-000FL-E

4/10/2013 Rev:

P/N LS10001-000FL-E:A ECN 13-186

A

Page 2

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property

insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote notification capability—can provide early warn ing of a developing fire.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire.

An emergency communication system—typically made up of

an automatic fire alarm system (as described above) and a life

safety communication system that may include an autonomous

control unit (ACU), local operating console (LOC), voice communication, and other various interoperable communication met hods—can broadcast a mass notification message. Such a

system, however, does not assure protection against property

damage or loss of life resulting from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premises following

the recommendations of the National Fire Protection Asso ciation

Standard 72 (NFPA 72), manufa cturer's recommendati ons, State

and local codes, and the recommendations contained in the

Guide for Proper Use of System Smoke Detectors, which is

made available at no charge to all installing dealers. This

document can be found at http://www.systemsensor.com/

appguides/. A study by the Federal Emergency Management

Agency (an agency of the United States government) indicated

that smoke detectors may not go off in as many as 35% of all

fires. While fire alarm systems are designed to provide early

warning against fire, they do not guarantee warning or pro tection

against fire. A fire alarm system may not provide timely or

adequate warning, or simply may not function, for a vari ety of

reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a first-floor

or basement fire.

Particles of combustion or “smok e ” from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls, chimneys, even wet or humid areas may inhibit particle or smoke

flow.

• Smoke particles may become “cold,” stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown aw a y from de tectors by air

outlets, such as air conditioning vent s.

• Smoke particles may be drawn into air returns before reaching the detector.

The amount of “smoke” present may be insufficient to alarm

smoke detectors. Smoke detectors are designe d to ala rm at various levels of smoke density. If such density levels are not created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing chambers tend to detect smoldering fires better than flaming fires,

which have little visible smoke. Detectors that have ionizing-type

sensing chambers tend to detect fast-flaming fires better than

smoldering fires. Because fires develop in different ways and

are often unpredictable in their growt h, neither type of detector i s

necessarily best and a given type of detector may not provide

adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children playing with matches

(especially in bedrooms), smoking in bed, and violent explosions

(caused by escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and al arm

only when heat on their sensors increases at a predetermined

rate or reaches a predetermined level. Rate-of-rise heat detectors may be subject to reduced sensitivity over time. For this

reason, the rate-of-rise feature of each detector shoul d be tested

at least once per year by a qualified fire protection specialist .

Heat detectors are designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the system for

the connection of alarm transmission wiring, communications,

signaling, and/or power. If detectors are not so located, a developing fire may damage the alarm system, compromising its ability to report a fire.

Audible warning devices such as bells, horns, strobes,

speakers and displays may not alert people if these devices

are located on the other side of closed or partly open doors or

are located on another floor of a building. Any warning device

may fail to alert people with a disability or those who have

recently consumed drugs, alcohol, or medication. Please note

that:

• An emergency communication system may take priority over

a fire alarm system in the event of a life safety emergency.

• Voice messaging systems must be desi gned to meet intelligibility requirements as defined by NFPA, local codes, and

Authorities Having Jurisdiction (AHJ).

• Language and instructional requirements must be clearly disseminated on any local displays.

• Strobes can, under c ertain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have sh own that certain people, even when they he ar

a fire alarm signal, do not respond to or comprehend the

meaning of the signal. Audible devices, such as horns and

bells, can have different tonal patterns and frequencies. It is

the property owner's responsibility to conduct fire drills and

other training exercises to make people aware of fire alarm

signals and instruct them on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause

temporary or permanent hearing loss.

A life safety system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries have

be

en prope

rly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control panel. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premises to a central monitoring station may be out of service or temporarily disabled. For added protection against telephone line

failure, backup radio transmission systems are recommended.

The most common cause of life safety system malfunction is

inadequate maintenance. To keep t he entire life safety sys tem in

excellent working order , ongoing mai ntenance is required per the

manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be followed. Environments with large amounts of dus t, dirt, or hig h air

velocity require more frequent maintenance. A maintenance

agreement should be arranged through the local manufacturer's

representative. Maintenance should be scheduled monthl y or as

required by National and/or local fire codes and should be performed by authorized professional life saftety system installers

only . Adequate written reco rds of all inspecti ons should be kept.

Limit-D-1-2013

2 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is

energized. Do not attempt to install, service, or operate this

unit until manuals are read and understood.

CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or

deletion of system components, or after any modification,

repair or adjustment to system hardware or wiring. All components, circuits, system operations, or sof tware functions known

to be affected by a change must be 100% tested. In addition,

to ensure that other operations are not inadvertently affected,

at least 10% of initiating devices that are not directly affected

by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º

C/32-120º F and at a relative humidity 93% ± 2% RH (noncondensing) at 32°C ± 2°C (90°F ± 3°F). However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with

a normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all initia ting and indicating device loops. Most devices cannot tol erate more than a

10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subject ed to li ght ning induced transients. Although no system is completely

immune from lightning transients and interf erence, proper

grounding will reduce susceptibility. Overhead or outside aerial

wiring is not recommended, due to an increased susceptibility

to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Overtightening may damage threads, resulting in reduced terminal

contact pressure and difficulty wit h screw terminal removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the

body . Use static suppressive packaging to protect electronic

assemblies removed from the unit.

Follow the instructions in the inst al lati on, ope rati ng, and programming manuals. These instructions must be followed to

avoid damage to the control panel and a ssociated equipment.

FACP operation and rel iability depend upon proper inst allat ion.

Precau-D1-9-2005

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual may

cause interference to radio communications. It has been

tested and found to comply with the limits for class A

computing devices pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when devices are

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the user will be required to correct

the interference at his or her own expense.

Canadian Requirements

This digital apparatus does not exce ed the Class A limit s

for radiation noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruit s radi oelectriques depassant les limites applic ables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edict e p ar l e

ministere des Communications du Canada.

LiteSpeed™ is a trademark; and FireLite® Alarms is a registered trademark of Honeywell International Inc. Microsoft® and Windows® are registered

trademarks of the Microsoft Corporation.

©2013 by Honeywell International Inc. All rights reserved. Unauth orized use of this document is strictly prohibited.

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 3

Page 4

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make

frequent upgrades to the embedded software in our products. To ensure that you are installing and programming the latest

features, we strongly recommend that you download the most current version of software for each product prior to

commissioning any system. Contact Technical Support with any questions about software and the appropriate version for a

specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about our

online Help or printed manuals, you can email us.

Please include the following information:

•Product name and version number (if applicable)

•Printed manual or online Help

•Topic Title (for online Help)

•Page number (for printed manual)

•Brief description of content you think should be improved or corrected

•Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact Technical

Services.

4 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 5

Table of Contents

Section 1: Product Description .............................................................................................12

1.1: Product Features ..........................................................................................................................................12

1.2: Input/Output Circuit Specifications .............................................................................................................13

1.2.1: ECC-50/100 Main Control Board .....................................................................................................13

1.2.2: Display Board....................................................................................................................................18

1.2.3: ECC-CE6 Circuit Expander Module .................................................................................................19

1.3: Controls and Indicators................................................................................................................................20

1.3.1: Push-Button Controls ........................................................................................................................20

1.3.2: LED Indicators (visible with door closed) ........................................................................................21

1.3.3: LED Indicators (visible with door and dress panel open) .................................................................21

1.4: Components .................................................................................................................................................21

1.5: Optional Equipment.....................................................................................................................................23

Section 2: Installation.............................................................................................................25

2.1: Mounting Options........................................................................................................................................25

2.2: Backbox Installation ....................................................................................................................................25

Removing the Dress Panel....................................................................................................................25

Removing the Chassis Assembly .........................................................................................................26

Mounting the Backbox .........................................................................................................................27

2.3: Operating Power ..........................................................................................................................................30

2.3.1: AC Power and Earth Ground Connection .........................................................................................30

2.3.2: Secondary Power Source (Batteries) .................................................................................................31

2.4: Auxiliary DC Power Output Connections ...................................................................................................32

2.5: Input/Initiating Circuits ...............................................................................................................................32

2.5.1: CMD Inputs .......................................................................................................................................32

2.5.2: External Audio Input .........................................................................................................................33

2.5.3: NAC Follower Input..........................................................................................................................34

2.5.4: Night Ring .........................................................................................................................................34

2.6: Output Circuits.............................................................................................................................................35

2.6.1: Relays ................................................................................................................................................35

MNS Active Relay - TB1 .....................................................................................................................35

Trouble Relay - TB2.............................................................................................................................35

AC Power Loss Relay - TB3................................................................................................................35

2.6.2: Speaker Circuits.................................................................................................................................36

2.6.3: Notification Appliance Circuit ..........................................................................................................37

2.6.4: Speaker Volume Control ...................................................................................................................38

2.6.5: FACP Data Bus .................................................................................................................................39

ACS Mode Wiring................................................................................................................................40

2.7: ECC-LOC Local Operator Console.............................................................................................................41

2.8: ECC-RPU Remote Page Unit ......................................................................................................................43

2.9: ECC-RM Remote Microphone ....................................................................................................................45

2.10: ECC-50/125DA Distributed Audio Amplifier...........................................................................................46

2.11: Shielding for External Device Wiring .......................................................................................................46

2.12: UL Power-limited Wiring Requirements...................................................................................................48

2.13: Installation of Option Modules..................................................................................................................49

2.13.1: ECC-CE6 Circuit Expander Module ...............................................................................................49

2.13.2: Audio Amplifier Module (ECC-50W-25/70V) ...............................................................................49

Installation ............................................................................................................................................49

Power and Control Cables....................................................................................................................51

Configuration........................................................................................................................................51

...

ECC-50/100 Configurations with ECC-50W-25/70V.......

2.13.3: 70.7 V

2.14: Addressing External Data Bus Devices.....................................................................................................54

Transformer (ECC-XRM-70V) ....................................................................................54

RMS

................................................................52

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 5

Page 6

Table of Contents

Section 3: Programming........................................................................................................58

3.1: Main Menu - User Programming.................................................................................................................59

3.1.1: Password Options ..............................................................................................................................59

3.1.2: General/NAC Options .......................................................................................................................60

General Options....................................................................................................................................60

NAC Options ........................................................................................................................................61

Console Control....................................................................................................................................62

3.1.3: Address Assignment ..........................................................................................................................62

Remote Microphone / Operator Console Address Assignments ..........................................................62

Speaker Circuit Address Assignment ...................................................................................................63

3.1.4: Message Buttons................................................................................................................................64

Message Buttons...................................................................................................................................64

CMD Input Style ..................................................................................................................................64

3.1.5: Date / Time ........................................................................................................................................65

3.1.6: Send to Panel .....................................................................................................................................65

3.2: Main Menu - Utilities...................................................................................................................................65

3.2.1: Message Recording............................................................................................................................66

3.2.2: USB File Options...............................................................................................................................66

3.3: Main Menu - Informational .........................................................................................................................67

3.3.1: Informational .....................................................................................................................................68

Speaker Circuit Buttons........................................................................................................................68

Version Information..............................................................................................................................69

History Information ..............................................................................................................................69

3.4: Recording Custom Messages.......................................................................................................................70

3.4.1: Message Record Mode ......................................................................................................................70

3.4.2: External Audio Input .........................................................................................................................70

Recording with External Audio - Example ..........................................................................................71

3.4.3: Microphone........................................................................................................................................72

Recording with Microphone - Example ...............................................................................................72

3.4.4: Erasing a User Message.....................................................................................................................73

3.4.5: Audio Programming Utility Software ...............................................................................................73

Writing a Message to the Panel ............................................................................................................74

Reading a Message from the Panel.......................................................................................................74

Moving a Message to a Different Slot..................................................................................................74

3.5: Programmed Activation by FACP ...............................................................................................................75

3.5.1: MS-9600(UD)LS and MS-9200UDLS..............................................................................................75

FACP Programming .............................................................................................................................76

FACP Message Assignment - Speaker Specific...................................................................................76

FACP Message Assignment - Zone Specific........................................................................................77

FACP Programming Menus .........................................................................................................

........78

Section 4: Operating Instructions.........................................................................................82

4.1: Main Control Panel Keypad Labels.............................................................................................................82

4.2: ECC-50/100 Switch Functions ....................................................................................................................82

4.3: LED Indicators.............................................................................................................................................83

4.4: Operation......................................................................................................................................................85

4.4.1: Paging from the Microphone .............................................................................................................85

4.4.2: Manual Message Control...................................................................................................................85

4.4.3: Fire Alarm Response, System Configured for Fire Only ..................................................................86

4.4.4: Fire Alarm Restoral, System Configured for Fire Only ....................................................................86

4.4.5: Manual Activation .............................................................................................................................86

4.4.6: Manual Activation Restoral...............................................................................................................87

4.4.7: Alarm/Alert Response, System Configured for Mass Notification Only ..........................................87

4.4.8: Alarm/Alert Restoral, System Configured for Mass Notification Only ............................................87

4.4.9: Alarm/Alert Response, System Configured for Combo Fire/Mass Notification with Fire Priority ..88

4.4.10: Alarm/Alert Restoral, System Configured for Combo Fire/Mass Notification with Fire Priority..88

4.4.11: Alarm/Alert Response, System Configured for Combo Fire/Mass Notification with Mass Notifica-

6 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 7

Table of Contents

tion Priority..................................................................................................................................................88

4.4.12: Alarm/Alert Restoral, System Configured for Combo Fire/Mass Notification with Mass Notification

Priority .........................................................................................................................................................89

4.4.13: Trouble Condition Response ...........................................................................................................89

4.4.14: Trouble Condition Restoral .............................................................................................................90

4.4.15: External Audio Input Operation ......................................................................................................91

Section 5: Getting Started ......................................................................................................92

5.1: System Requiring up to 50 Watts of Audio Power......................................................................................92

5.2: System Requiring Up to 100 Watts of Audio Power...................................................................................92

5.3: System Requiring Greater Than 100 Watts of Audio Power.......................................................................92

Section 6: Power Supply Calculations..................................................................................93

6.1: Overview......................................................................................................................................................93

6.2: Calculating the AC Branch Circuit..............................................................................................................93

6.3: Calculating the System Current Draw .........................................................................................................93

6.3.1: Overview ...........................................................................................................................................93

6.3.2: How to use Table 6.2 to calculate system current draws...................................................................94

6.4: Calculating the Battery Size ........................................................................................................................95

6.4.1: NFPA Battery Requirements.............................................................................................................95

6.4.2: Selecting and Locating Batteries .......................................................................................................95

Appendix A: Digital Voice Messages....................................................................................96

Appendix B: Wiring Requirements........................................................................................98

Index.......................................................................................................................................103

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 7

Page 8

This control panel has been designed to comply with standards set forth by the following regulatory agencies:

• Underwriters Laboratories

• National Fire Protection Association

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

This Fire Alarm Control Panel complies with the following NFPA Standards:

NFPA 72 National Fire Alarm Code

Note: Audible signal appliances used in public mode applications, are required to have

minimum sound levels of 75 dBA at 10 feet (3 meters) and a maximum level of 120 dBA at the

minimum hearing distance from the audible appliance.

To ensure that the appliance is clearly heard, the audible appliance sound level must be at least

15 dBA above the average ambient sound level or 5 dBA above the maximum sound level with

a duration of at least 60 seconds, depending on which level is greater, with the sound level

being measured 5 feet (1.5 meters) above the floor.

Underwriters Laboratories Documents:

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1711 Amplifiers for Fire Protective Signaling Systems

UL 2572 Communication and Control Units for Mass Notification Systems

Other:

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction (LAHJ)

Fire•Lite Documents:

Fire•Lite Device Compatibility Document Document #15384

ECC-50/125DA Manual Document #LS10027-000FL-E

ECC-FFT Manual Document #LS10031-000FL-E

ECC-LOC Installation Document Document #LS10028-000FL-E

ECC-RPU Installation Document Document #LS10030-000FL-E

ECC-RM Installation Document Document #LS10029-000FL-E

ECC-CE6 Installation Document Document #LS10033-000FL-E

ECC-CE4 Installation Document Document #LS10002-000FL-E

ECC-50W-25/70V Installation Document Document #LS10035-000FL-E

ECC-XRM-70V Installation Document Document #LS10032-000FL-E

MS-9200UDLS Series Manual Document #52750

MS-9600(UD)LS Technical Manual Document #52646

8 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 9

FIRE SYSTEM

ACTIVE

SYSTEM

CONTROL

ALL

CALL

1

2

3

4

5

6

7

8

9

10

11

12

13

18

19

20

21

22

23

24

16

17

14

15

LITFI®AL

by Honeywell

FIRE SYSTEM

ACTIVE

SYSTEM

CONTROL

ALL

CALL

1

2

3

4

5

6

7

8

9

10

11

12

13

18

19

20

21

22

23

24

16

17

14

15

LITFI®AL

by Honeywell

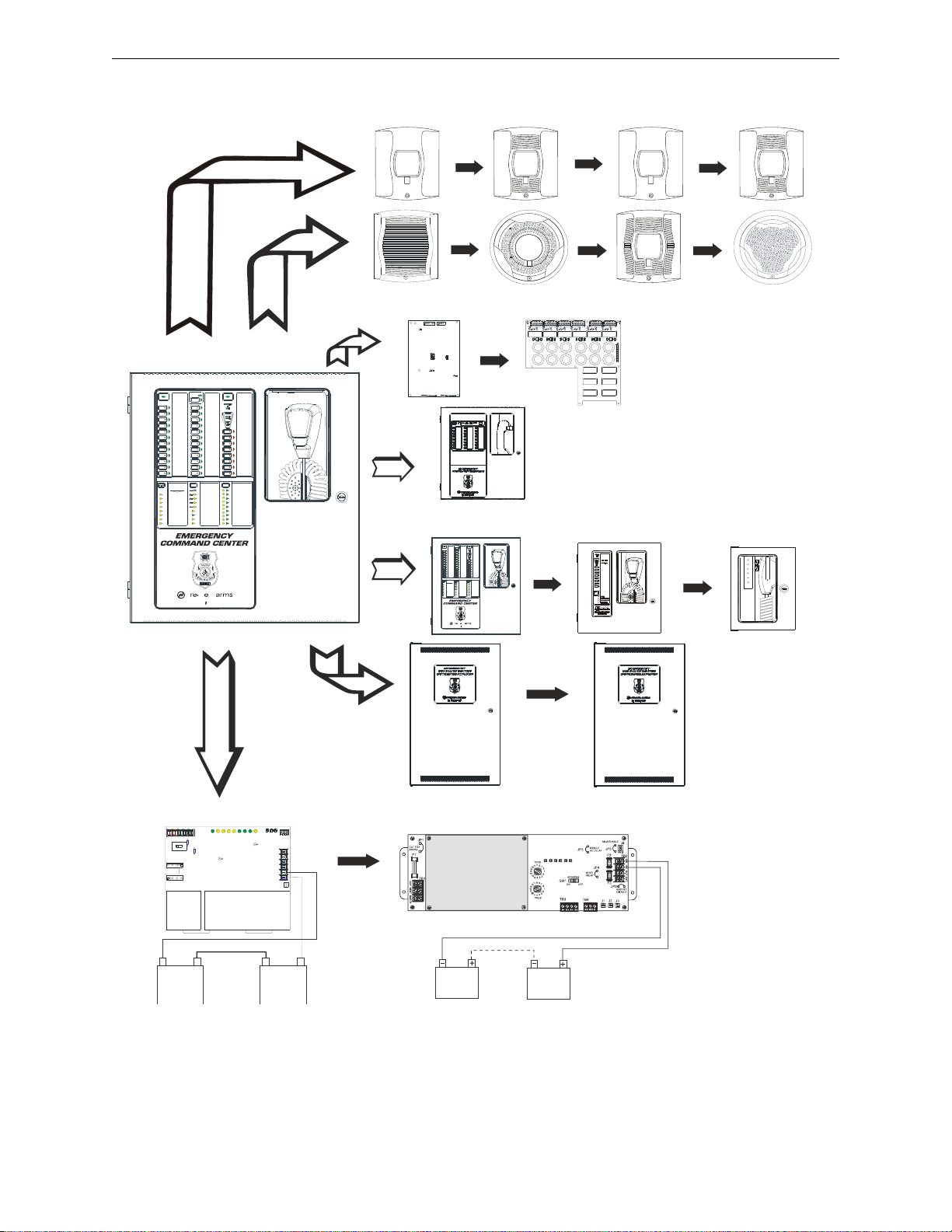

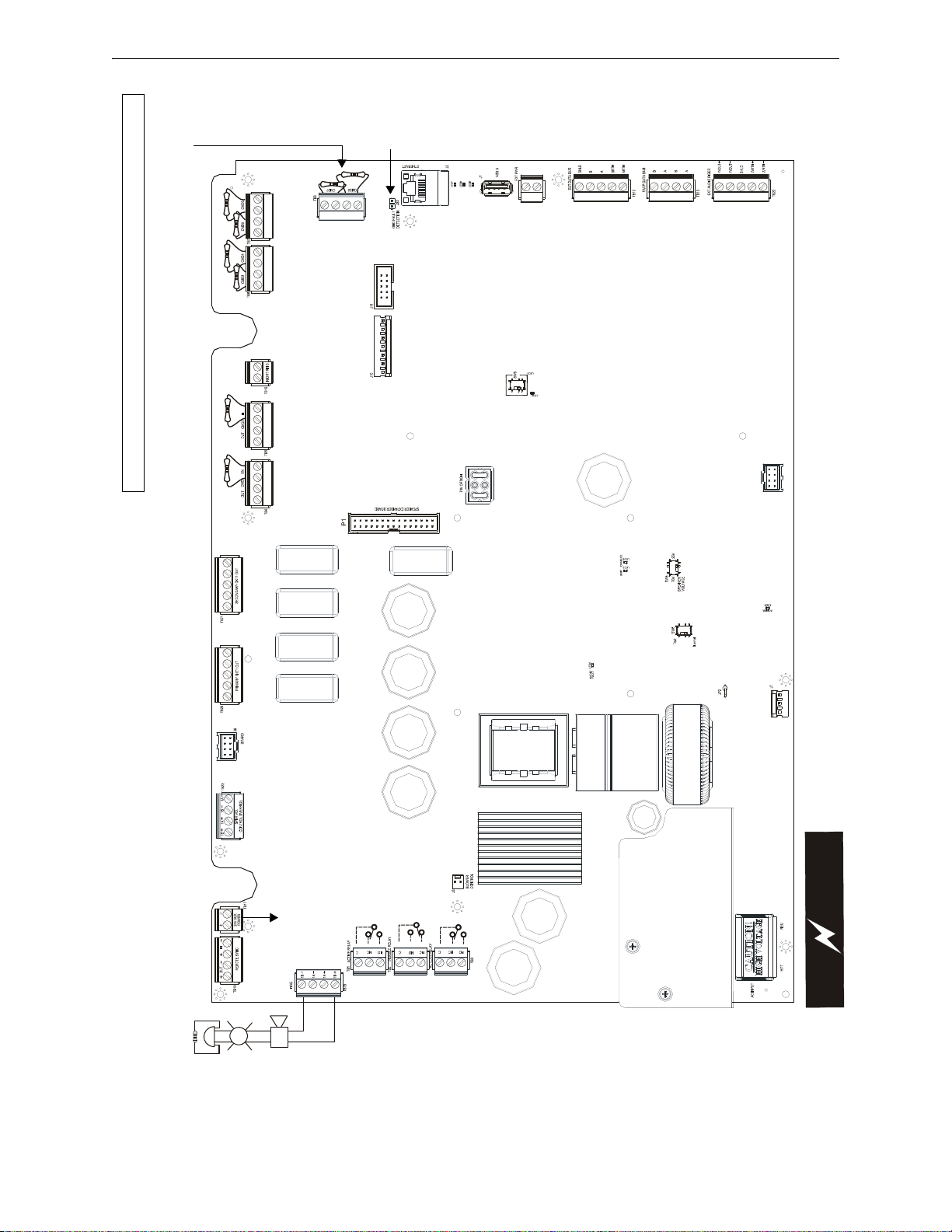

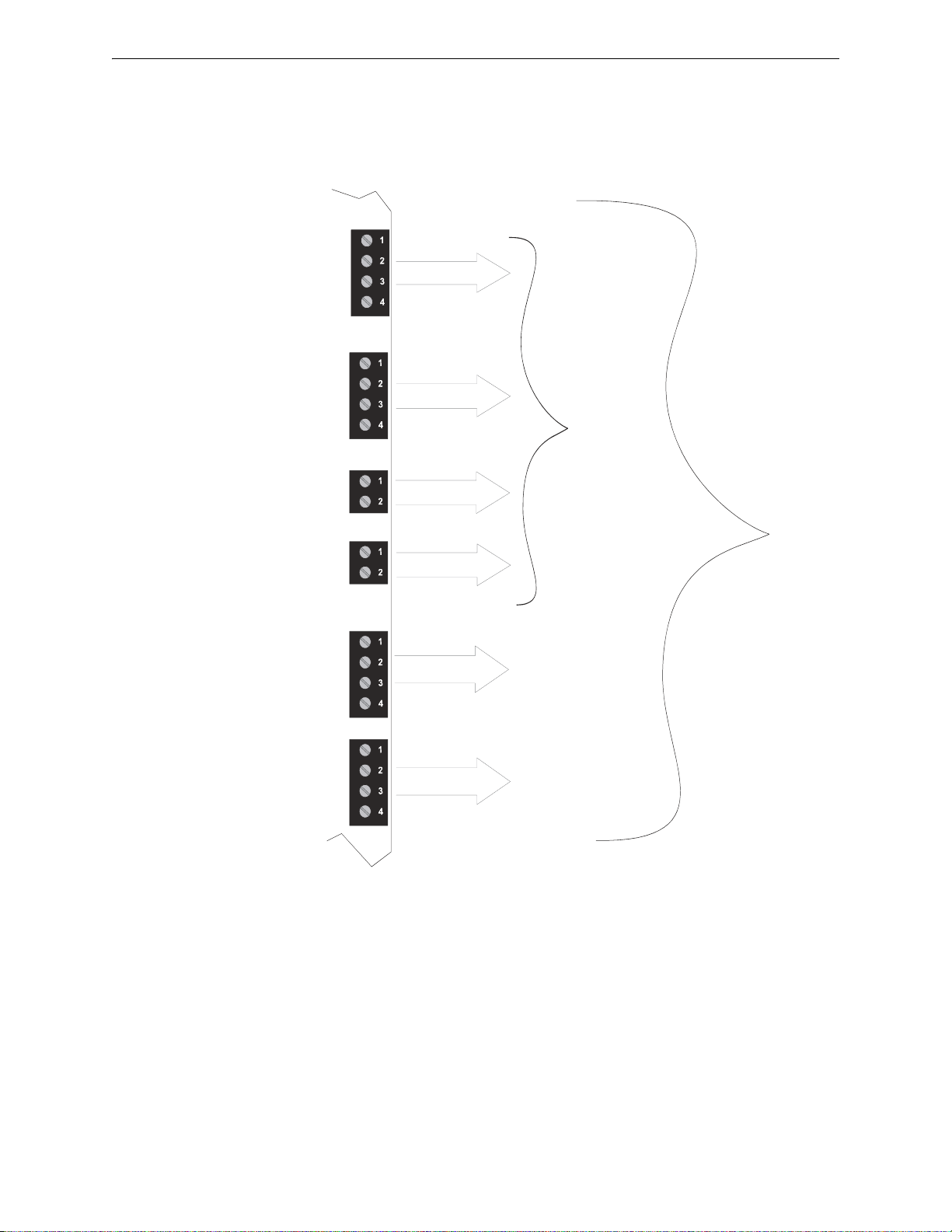

Speaker Circuits

TB20 & TB21

internal options

ECC-50W-25/70V

optional amplifier

ECC-CE6

circuit expander

ECC-50DA

50W remote amplifier

ECC-RPU

remote page unit

ECC-RM

remote microphone

remote

consoles

distributed

audio

ECC-125DA

125W remote amplifier

ECC-LOC

local operator console

CHG-120F

charger

CHG-75

charger

external battery

charger - J7

TB4

TB12

TB22

Figure 1.1 Peripheral Devices

eccperi.wmf

NAC Circuit

TB19

visual only

ECC-FFT

firefighter telephone

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 9

Page 10

+

+

+

J12

TB15

J9

RTZM

DISPLAY

C

A

U

T

I

O

N

!

H

I

G

H

V

O

L

T

A

G

E

ecc50layo.wmf

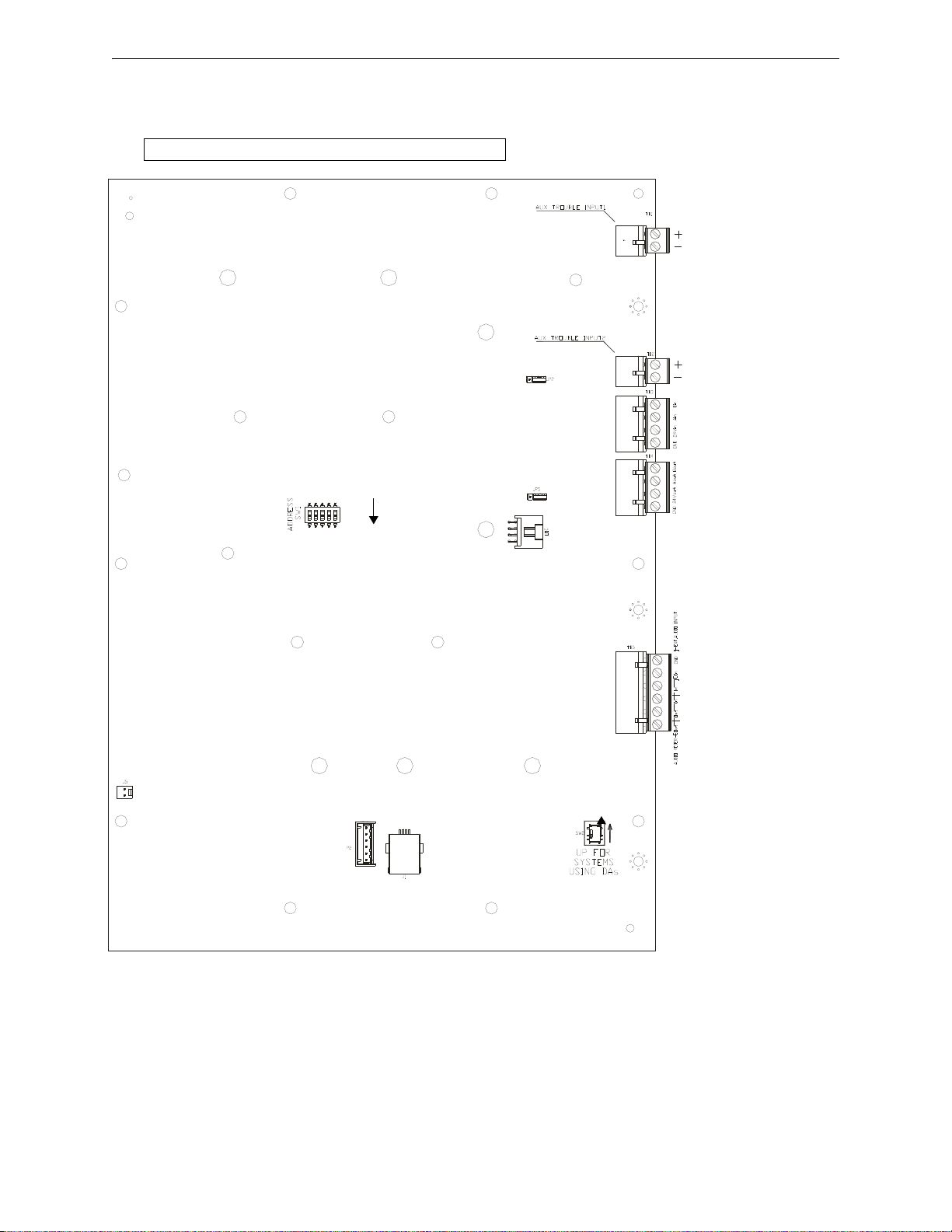

AC Power

(Supervised,

Nonpower-Limited)

120 VAC, 60 Hz, 3.5 ampsor230 VAC, 50 Hz, 2.0 amps

Special Application DC Power Output (24 VDC)

Supervised, Power-Limited (Class 2) circuit

Supervise with a power supervision relay EOLR-1

Nonresettable Power suitable for powering control

modules and power supervision relays.

NAC Follower Input

Supervised, Power-

Limited (Class 2)

circuits

24 VDC filtered (10

mA maximum),

Requires a 4.7 Kohm

End-of-Line Resistor

AC Loss, MNS Active, &

Fixed Trouble Relay

Non-supervised relay contacts

Contact rating:

2.0 amps @ 30 VDC (resistive)

0.5 amps @ 30 VAC (resistive)

Contacts shown below in

normal condition (AC power

with no alarm, trouble, or

supervisory activity)

AC Fail Safe Trouble relay

switches to the NO position

during trouble conditions and

under loss of all power.

Flash Memory Load Enable

Switch: UP is normal

position for switch, DOWN

position allows for factory

software upgrades

Ethernet Port J2/

for local programming

using a personal

computer and web-

based utility

Battery

24 VDC, supervised,

Non-power-limited,

26 AH maximum

Notification

Appliance Circuit

Style Y (Class B) or

Style Z (Class A)

Supervised, Power-

Limited (Class 2)

(Special

application) 2.0

amps max.

Regulated power:

200mA max.

ELR, 4.7K, 1/2W

(for Style Y wiring)

Optional 50W Amplifier

connectors

Optional 70V

Transformer connector

Optional CE6 Circuit

Expander Connector

Display Board

connector

Speaker Volume Control Override

Style Y (Class B) or Style Z (Class A)

Supervised, Power-Limited (Class 2)

(Special application) 0.25 amps max.

4.7K ELR, 1/2W required for Style Y

(Class B) wiring

Primary/Secondary Speaker Circuits

Style Y (Class B) or Style Z (Class A)

Supervised, Power-Limited (Class 2)

50W integrated output power. Use of

secondary circuit requires optional

ECC-50W-25/70V amplifier

15K ELR, 1W required for Style Y

(Class B) wiring

CMD1 & CMD2 Command Input Circuits

Trigger by contact closure or NAC reverse

polarity (ELR required)

alarm polarity shown.

CMD3 - CMD8 Command Input Circuits

Trigger by contact closure (ELR required)

alarm polarity shown.

(inputs only)

Night Ring Input

Trigger by contact closure

External Operator Interface Power

Supervised, Power-Limited

(Class 2) circuit

24 VDC Nonresettable Power for

external operator interface components.

External Data Bus

Supervised, Power-Limited

(Class 2) data connections to

external operator interface

components

FACP Data Bus

Supervised, Power-Limited

circuit dedicated as FACP

serial bus connection

External Audio Riser

Style Y (Class B) or Style Z (Class A)

Supervised, Power-Limited (Class 2)

audio connection to external operator

interface components

Speaker

Voltage

Switch

To disable

ground fault

detection,

remove

jumper/shunt

from JS2.

Basic System Connections - Main Control Board (Section 1.2.1)

Cut jumper to use

external charger

Backup

amplifier

test switch

USB-A Port J1/

for local program

download

10 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 11

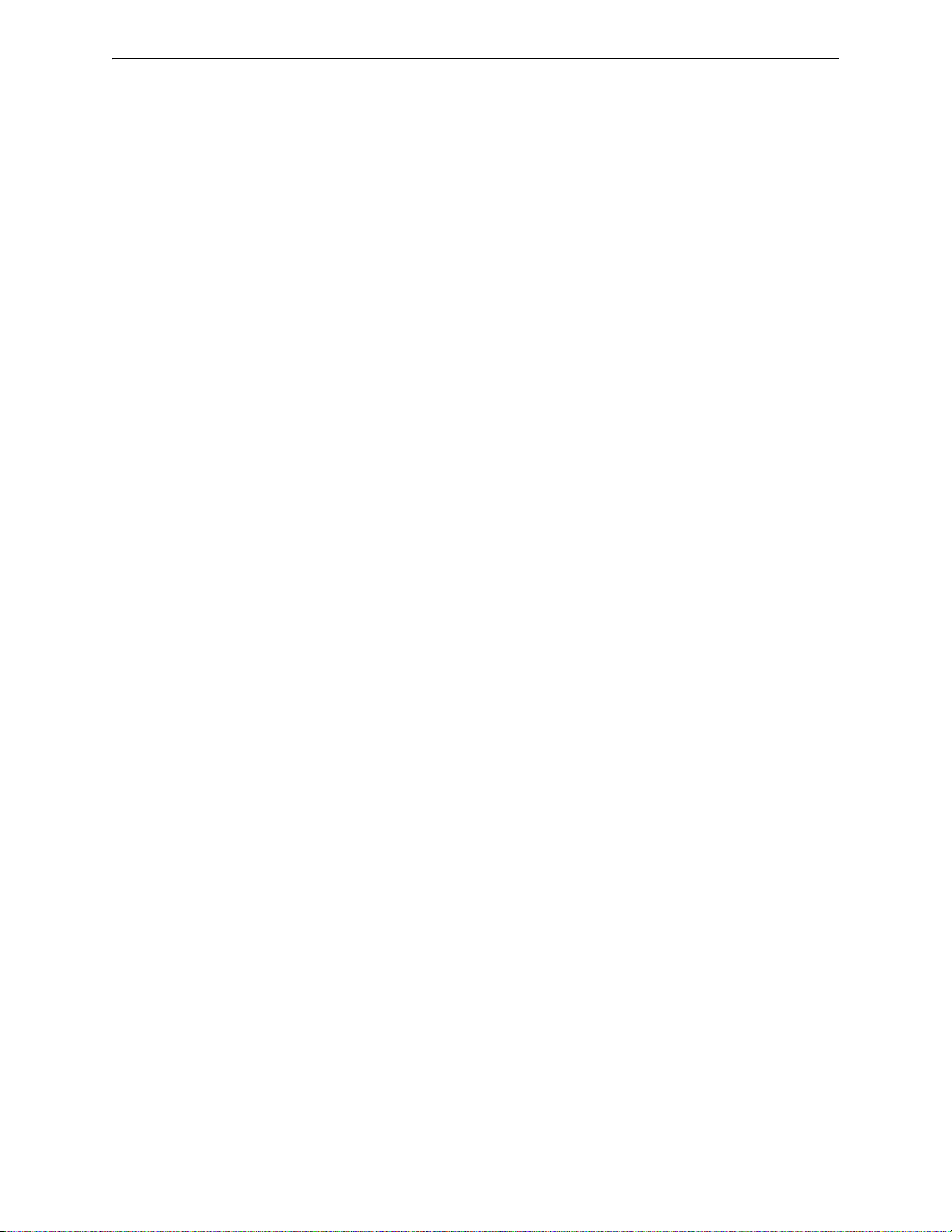

TB5- External Audio Input/

Audio Riser

SW1- Dipswitch for

BUS addressing

ON

JP5 isolation/ground

when powered by

source other than

main control board

J2- Connection to

main control board

P2- Microphone

connector

J1- USB connector -

connection to a PC for

downloading messages

Refer to Section 3.4.5

on page 73.

Basic System Connections - Display Board (Section 1.2.2)

disp.wmf

SW2- Distributed Audio Switch

set to UP position if any

ECC-50/125DAs are installed

in the system.

Default is the DOWN position.

TB1-

Aux Trouble Input 1

TB2- Aux Trouble Input 2

TB3- Data Bus/Power Input

TB4- Data Bus/Power Output

JP2 - External Data

Bus termination

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 11

Page 12

Section 1: Product Description

The Fire•Lite Emergency Command Center ECC-50/100 is a single channel, 50 watt, 25 V

emergency voice evacuation panel that may be used for fire applications, mass notification applications, or both. The ECC-50/100 comes standard with one speaker circuit. The panel provides the

ability to record fourteen field programmable messages (up to 60 seconds each) with an integral

microphone or from an external audio source. An integral power supply with battery charger supplies operational power. A 50 watt audio amplifier is built into each panel. An optional second 50

watt amplifier (ECC-50W-25/70V) is also available for backup purposes or to provide an additional

50 watts. The backup amplifier is available in either 25 volts or 70 volts depending on which application is necessary.

Automatic activation of the ECC-50/100 by an FACP is possible via eight Command Input Circuits

(CMD) or via the ACS/ANN Bus serial communications link from the MS-9600(UD)LS and

MS-9200UDLS FACPs.

Two Command Input Circuits can be independently field programmed for activation by an FACP

Notification Appliance Circuit reverse polarity or by closure of a supervised normally open contact

and six Command Input Circuits activate on contact closure. CMD 1 and CMD 2 provide terminals

for NAC input and output to allow installation of the audio panel anywhere along the NAC circuit

being used to activate it.

If the message generator fails, the system automatically reverts to a backup tone generator.

Power is fed independently

down the other. Full output power of 50 watts per amplifier is generated while in a low battery condition. Power is not diminished when the optional 70 V

is amplified utilizing modern integrated circuits as opposed to transformer technology. This provides for very low signal distortion for crystal clear audio.

to each amplifier so that a short circuit in one amplifier will not shut

transformer module is installed. Audio

RMS

RMS

,

Primary applications for the audio panels include protecting structures such as military facilities,

restaurants, schools, auditoriums, places of worship, buildings with occupancies over 50, etc. The

ECC-50/100 is designed to interface directly to addressable or conventional (CMD inputs 1-8) fire

alarm control panels or can be used with the ECC-50/125DA panel to distribute audio in systems

that require more than 100 watts.

1.1 Product Features

• Modular design for maximum system flexibility and easy expansion

• Removable terminal blocks for ease of servicing and module replacement

• 50 watts of 25 V

• 2 amp Notification Appliance Circuit (NAC) output, sync generator, or follower for protocols:

– System Sensor

– Wheelock

–Gentex

• Optional 70.7 V

speaker wiring continues to be supervised in standby, alarm and when background music is

playing with this optional transformer installed)

• Eight Command Input Circuits to activate messages 1 to 8:

– CMD1 and CMD2 are field selectable to be activated from 12 or 24 VDC Notification

Appliance Circuits (reverse polarity) or contact closures

– CMD3-CMD8 are activated by contact closures

• Speaker Circuits

– single Style Y (Class B) or Style Z (Class A) speaker circuit

RMS

audio power (expandable to 100 watts)

RMS

conversion transformer available for the primary amplifier (note that

12 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 13

Input/Output Circuit Specifications Product Description

– two Style Y (Class B) or Style Z (Class A) speaker circuits (with optional ECC-50W-

25/70V Audio Amplifier installed)

– eight Style Y (Class B) or Style Z (Class A) speaker circuits (with optional ECC-50W-

25/70V and ECC-CE6 installed)

• ECC-50/100 can be controlled by an FACP via the ANN/ACS (EIA-485) link. Compatible

FACPs include the MS-9600(UD)LS and MS-9200UDLS.

• Integral supervised microphone

• Microphone time-out feature which reverts back to prerecorded message if emergency page

exceeds the programmed time

• Up to 14 recorded messages

• 14 prerecorded messages for fire, emergency, and weather alerts

• Field-selectable message and custom message recording capability using the local

microphone, a USB port, or an external audio input

• External Audio Input can be used for background music

• Up to 60 second message duration for all messages

• Integral tone generators field selectable for multiple tone types

• Powered by integral AC power supply or batteries during AC fail

• Programmable delay of immediate, 2 hours or 6 hours reporting of AC Loss

• Piezo sounder for local trouble

• 100 event history log

• Three Form-C relays:

– AC Power Loss Relay - TB1

– System Trouble Relay - TB2

– MNS Active - TB3

• 500 mA (0.5A) Special Application (auxiliary power) output for addressable modules when

interfaced with compatible addressable FACPs and End-of-Line power supervision relays

• System Status LEDs (refer to “Controls and Indicators” on page 20)

• Integral Dress Panel

• Optional TR-CE semi-flush trim ring

• Any combination of up to eight (8) of:

– Optional ECC-RM Remote Microphone (includes cabinet).

– Optional ECC-RPU Remote Page Unit (includes cabinet)

– Optional ECC-LOC (includes cabinet)

• Optional ECC-CE6 Circuit Expander

• Optional ECC-50W-25V amplifier, 50 watts, 25 volts

• Optional ECC-50W-70V amplifier, 50 watts, 70 volts

• Optional ECC-50DA distributed amplifier, 50 watts

• Optional ECC-125DA distributed amplifier, 125 watts

1.2 Input/Output Circuit Specifications

1.2.1 ECC-50/100 Main Control Board

AC Power - TB15

ECC-50/100: 120 VAC, 60 Hz, 3.5 amps (HOT, NEU)

ECC-50/100E: 240 VAC, 50 Hz, 2.0 amps (HOT=HotLeg1, NEU=HotLeg2)

Wire size: minimum #14 AWG (2.00mm

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 13

2

) with 600 V insulation.

Page 14

Product Description Input/Output Circuit Specifications

Battery (lead acid only) - J7

Maximum Charging Circuit: Normal Flat Charge - 27.3V @ 2.8 amps

Maximum Charger Capacity: 26 Amp Hour battery. (ECC cabinet holds max. 18 Amp Hour Battery.

Minimum Battery Size: 12 Amp Hour

MNS Active Relay - TB1

Form-C relay contact rating: 2.0 amps @ 30 VDC (resistive), 0.5 amps @ 30 VAC (resistive),

Form-C Trouble Relay - TB2

Form-C relay contact rating: 2.0 amps @ 30 VDC (resistive), 0.5 amp @ 30 VAC (resistive).

AC Loss Relay - TB3

Form-C relay contact rating: 2.0 amps @ 30 VDC (resistive), 0.5 amps @ 30 VAC (resistive),

NAC Output - TB19, Terminals 1 (B+), 2 (A+), 3 (A-), & 4 (B-)

One (1) Style Y (Class B) or Style Z (Class A) circuit

Power-limited circuitry (Class 2), supervised

Nominal operating voltage: 24 VDC

Maximum signaling current for special application power: 2.0 amps

Maximum signaling current for regulated power: 200mA

Current limit: fuseless, electronic, power-limited

Maximum wiring impedance: 1

End-Of-Line Resistor: 4.7 K, ½ watt, (P/N 71252) required for Style Y (Class B) operation

Refer to the Device Compatibility Document for listed compatible devices.

NAC Follower - TB18, Terminals 3 (IN+), 4 (IN-), 1 (OUT+) & 2 (OUT-)

Connections for FACP NAC synchronization trigger signal

Output terminals: pass-through to other system components

Trigger input voltage: 9 to 32 VDC, 24 VDC rated

Input current draw in Alarm condition: 10 mA at rated voltage

Special Application Power (Aux. Power) - TB17 Terminals 1(+) & 2(-)

Up to 500 mA @ 24 VDC of special application power is available for powering addressable modules and associated End-of-Line power supervision relays.

Power-limited (Class 2) circuitry. Refer to the Device Compatibility Document for a list of compat-

ible devices.

Speaker Volume Control Override - TB23, Terminals 1 (B+), 2 (A+), 3 (A-), & 4 (B-)

Style Y (Class B) or Style Z (Class A) circuit

Special Application power

Power-limited (Class 2) circuitry, supervised

Nominal operating voltage: 24 VDC

Maximum signaling current: 0.25 amps

Current limit: fuseless, electronic, power-limited

End-Of-Line Resistor: 4.7 K, ½ watt, (P/N 71252) required for Style Y (Class B) operation

Speaker Circuits

Primary Speaker Circuit - TB20, Terminals 1(+) & 2(-) Style Y (Class B), 4(+) & 5(-) Style Z

(Class A), 3 Shield (Standby and Alarm Polarity Shown) on main control board

Secondary Speaker Circuit (with optional amplifier only) - TB21, Terminals 1(+) & 2(-)

Style Y (Class B), 4(+) & 5(-) Style Z (Class A), 3 Shield (Standby and Alarm Polarity Shown) on

main control board

14 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 15

Input/Output Circuit Specifications Product Description

Power-limited (Class 2) circuitry

Operation: Circuit can be wired Style Y (Class B) or Style Z (Class A)

Normal Operating Voltage: 25 V

(70.7 V

@ 700 mA max. with maximum Load Impedance of 100operation possible by plug-

RMS

@ 2 amps max. and maximum Load Impedance of 12.5

RMS

ging optional ECC-XRM-70V conversion transformer into J12 of the main control board).

Output Power: 50 watts (5 watts when background music is employed);

Frequency Range: 800 - 2,800 Hz

Maximum total capacitance for each speaker circuit: 250 µF.

End-of-Line Resistor required for Style Y circuit: 15 K, 1 watt (P/N: ELR-15K)

Command Input Circuits (alarm polarities shown)

• CMD1 - TB4 Terminals 3(+) & 4(-) are input terminals and Terminals 1(-) and 2(+) are output

terminals which provide feed through of the NAC circuits to NAC devices downstream;

provides internal trouble relay rated at 3.0 amps maximum

• CMD2 - TB5 Terminals 3(+) & 4(-) are input terminals and Terminals 1(-) and 2(+) are output

terminals which provide feed through of the NAC circuits to NAC devices downstream

• CMD3 - TB6 Terminals 1(+) & 2(-) are input terminals for contact closure only

• CMD4 - TB6 Terminals 3(+) & 4(-) are input terminals for contact closure only

• CMD5 - TB7 Terminals 1(+) & 2(-) are input terminals for contact closure only

• CMD6 - TB7 Terminals 3(+) & 4(-) are input terminals for contact closure only

• CMD7 - TB8 Terminals 1(+) & 2(-) are input terminals for contact closure only

• CMD8 - TB8 Terminals 3(+) & 4(-) are input terminals for contact closure only

Power-limited (Class 2) and supervised circuitry

Normal Operating Voltage Range: 10.5 VDC - 29 VDC; Maximum Voltage: 29 VDC

NAC Reverse Polarity Current (requires End-of-Line Resistor from NAC): 1.6 mA maximum.

Contact Closure Operation Current (requires 4.7K, ½ watt End-of-Line Resistor P/N 27072): 6.6

mA maximum

Maximum Wiring Impedance CMD1 - CMD8 (Contact Closure Operation): 200

Maximum Input Impedance:

• CMD1 & CMD2 (Reverse Polarity Operation): 20K

• CMD1 - CMD8 (Contact Closure Operation): 4.75K

Night Ring Input - TB16, Terminals 1 (+) & 2 (-)

Contact closure input

Isolated, nonsupervised

Operation current: 3.8 mA, maximum

Maximum wiring impedance: 30K

Minimum isolation withstand voltage: 1500 V

RMS

External Operator Interface Power Output - TB24, Terminals 1 (PWR, +) & 2 (GND, -)

Non-resettable power for external operator interface components

Power-limited (Class 2) circuitry, Supervised

Nominal operating voltage: 24 VDC

Maximum output current: 0.80 amps

Current limit: fuseless, electronic, power-limited circuitry

External Data Bus (EIA-485) - TB12, Terminals 2 (B), 3 (A) , 4 (BRTN), 5 (ARTN), &

1(SHLD)

Data connections for external operator interface components

Redundant transceiver circuitry for Class A operability

Power-limited (Class 2) circuitry, supervised

Maximum wiring impedance: 13.2

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 15

Page 16

Product Description Input/Output Circuit Specifications

FACP Data Bus (EIA-485) - TB13, Terminals 1 (B IN), 2 (A IN), 3 (B OUT), & 4 (A OUT)

Dedicated connection to FACP serial bus

Output terminals: pass-through to other system components

Isolated, supervised

Minimum isolation withstand voltage: 1500 V

RMS

Maximum wiring impedance: 40 (ANN-BUS)/26 (ACS BUS)

External Audio Riser TB22, Termina ls 1 (OUT+), 2 (OUT-), 4 (IN+), 5 (IN-), & 3 (SHLD)

Style Y (Class B) or Style Z (Class A) audio connections to external operator interface components

Power-limited (Class 2) circuitry, supervised

Audio signal level: 3.85 V

, maximum

RMS

Frequency range: 800 - 2,800 Hz

Frequency range (ECC-50/125DA): 800 Hz - 2.8 KHz

NOTE: Zero impedance to ground will cause a ground fault.

16 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 17

Input/Output Circuit Specifications Product Description

TB20

TB21

TB19

TB24

TB23

TB17

Primary 50W

Speaker Circuit

3.3 amps max.

Secondary 50W

Speaker Circuit-

Optional Amplifier

Installed

3.3 amps max.

NAC Circuit

2.0 amps max.

Aux. Power

0.5 amp max.

Speaker Volume

Control Override

0.25 amp max.

External Operator

Interface Power

0.8 amp max.

Standby

2.0 amps max.

(includes background

music) with external

charger. Refer to

Section 6.

Alarm

7.5 amps

max.

Figure 1.2 Current Availability - 100 Watt System

Current Availability

The following figures illustrate the maximum current possible for each panel output circuit and the

total output current available from the power supply. Refer to Section 6, “Power Supply Calculations” for additional current draw by option cards that must be considered when determining total

standby and alarm currents.

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 17

Page 18

Product Description Input/Output Circuit Specifications

TB20

TB19

TB17

TB23

TB24

Primary 50W

Speaker Circuit

3.3 amps max.

NAC Circuit

2.0 amps max.

Aux. Power

0.5 amp max.

Speaker Volume

Control Override

0.25 amp max.

External Operator

Interface Power

0.8 amp max.

Standby

2.0 amps max.

(includes background

music) with external

charger. Refer to

Section 6.

Alarm

7.5 amps max.

Figure 1.3 Current Availability - 50 Watt System

1.2.2 Display Board

External Audio Input - TB5, Terminals 1(-), 2 (+)

Input Impedance: 8.5K, nominal @ 1 KHz

Input Voltage: 700 mV

Input Current: 0.1 mA, maximum @ 700 mV

Background Music Input Voltage: 225mV

NOTE: Some laptops/personal computers only provide an audio output for headphones. It may

be necessary to adjust the headphone output level for proper recording of voice messages.

maximum

RMS

maximum

RMS,

18 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 19

Input/Output Circuit Specifications Product Description

1.2.3 ECC-CE6 Circuit Expander Module

Power-limited (Class 2) circuitry

Up to six (6) circuits on the ECC-CE6 can be wired as Style Y (Class B) or Style Z (Class A).

Normal Operating Voltage for Speaker Circuits: 25 V

Impedance of 12.5

@ 2 amps max. and maximum Load

RMS

(70.0 V

@ 700 mA max. with maximum Load Impedance of 100operation possible for

RMS

the primary circuit by plugging optional ECC-XRM-70V conversion transformer into J12 of

the main control board. The same operation is possible for the optional 50W amplifier by

selecting the ECC-50W-70V model.)

Speaker circuit wiring is supervised during standby, background music, and alarm.

Output Power: 50 watts total; Frequency Range: 800 - 2,800 Hz

Maximum total capacitance: 250 µF. (Note that the total

capacitance for the speaker outputs must

not exceed the maximum of 250 µF).

End-of-Line Resistor required for Style Y (Class B) speaker circuit: 15 K, 1 watt (P/N: ELR-15K)

TB13 on the main control board: ACS/ANN (EIA-485) electrically isolated link to FACP provides

programmed speaker control

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 19

Page 20

Product Description Controls and Indicators

FIRE SYSTEM

ACTIVE

SYSTEM

CONTROL

ALL

CALL

1

2

3

4

5

6

7

8

9

10

11

12

13

18

19

20

21

22

23

24

16

17

14

15

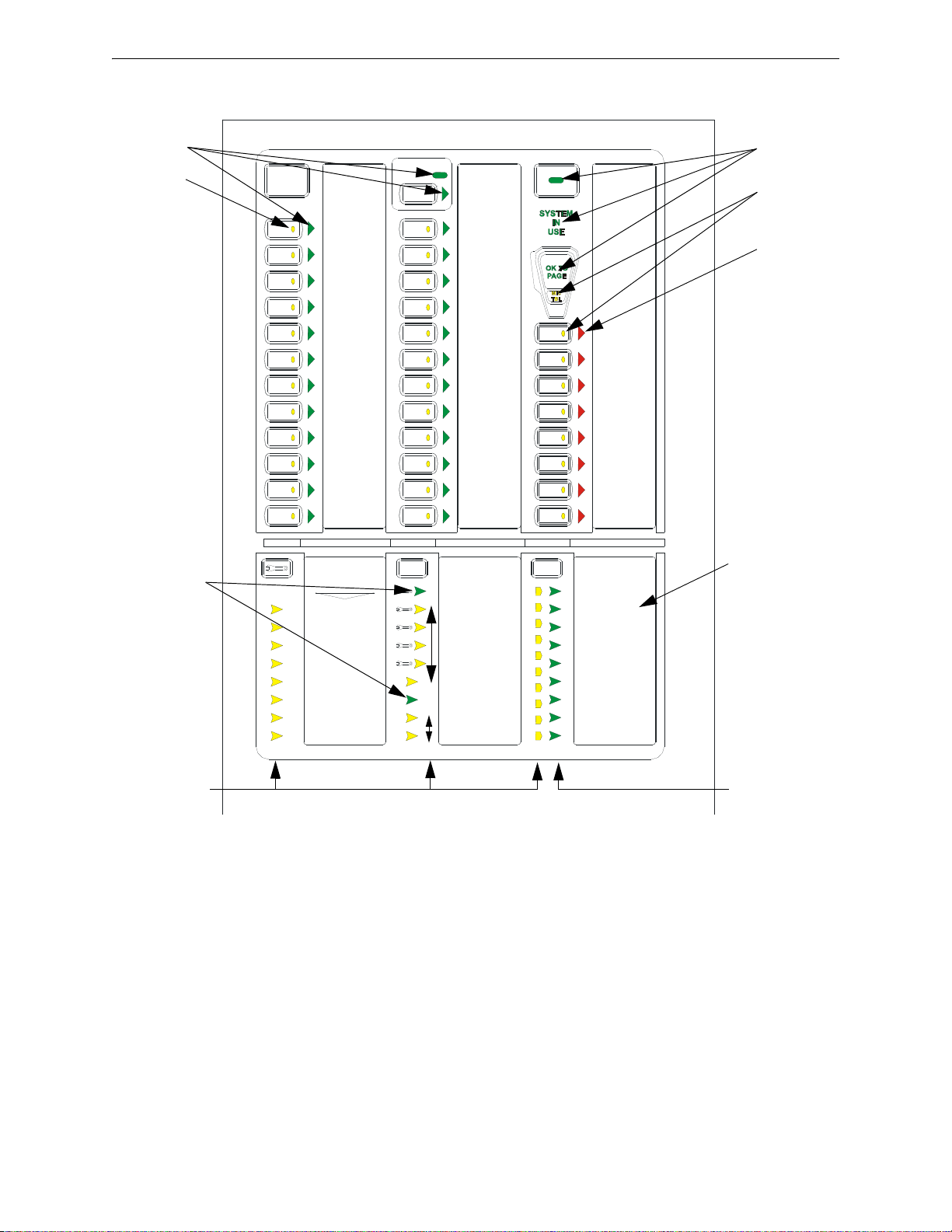

ecckyd.wmf

Figure 1.4 ECC-50/100 Keypad

SPEAKER

ZONE 1

SPEAKER

ZONE 2

SPEAKER

ZONE 3

SPEAKER

ZONE 4

SPEAKER

ZONE 5

SPEAKER

ZONE 6

SPEAKER

ZONE 7

SPEAKER

ZONE 8

SPEAKER

ZONE 9

SPEAKER

ZONE 10

SPEAKER

ZONE 11

SPEAKER

ZONE 12

SPEAKER

ZONE 13

SPEAKER

ZONE 14

SPEAKER

ZONE 15

SPEAKER

ZONE 16

SPEAKER

ZONE 17

SPEAKER

ZONE 18

SPEAKER

ZONE 19

SPEAKER

ZONE 20

SPEAKER

ZONE 21

SPEAKER

ZONE 22

SPEAKER

ZONE 23

SPEAKER

ZONE 24

MESSAGE 1

MESSAGE 2

MESSAGE 3

MESSAGE 4

MESSAGE 5

MESSAGE 6

MESSAGE 7

MESSAGE 8

DIST. AMP 1

DIST. AMP 2

DIST. AMP 3

DIST. AMP 4

DIST. AMP 5

DIST. AMP 6

DIST. AMP 7

DIST. AMP 8

DIAGNOSTIC

REMOTE AMPS

TROUBLE SILENCE

AC POWER

GROUND FAULT

CHARGER FAULT

BATTERY FAULT

DATA BUS FAULT

NAC FAULT

NAC ACTIVE

SYSTEM TROUBLE

AUDIO RISER FAULT

LOC 1

LOC 2

RPU 1

RPU 2

RPU 3

RM 1

RM 2

RM 3

CONSOLE LAMP TEST

MAIN CONSOLE

MNS

CONTROL

OK TO PAGE

MICROPHONE

TROUBLE

green green

yellow

yellow

red

green

green

yellow

Note: Console

assignments are

shown here as an

example only.

1.3 Controls and Indicators

1.3.1 Push-Button Controls

•All Call

• MNS Control

• System Control

• Speaker Select 1-24

• Message Select 1-8

• Diagnostic Select

• Trouble Silence

•Console Lamp Test

20 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 21

Components Product Description

1.3.2 LED Indicators (visible with door closed)

• Fire System Active (green)

• MNS Control (green)

• System Control (green)

• System in Use (green)

• Speaker Zone 1-24 Active (green)

• Speaker Zone 1-24 Fault (yellow)

• OK to Page (green)

• Microphone Trouble (yellow)

• Message 1-8 Active (red)

• Message 1-8 Fault (yellow)

• Remote Amplifier 1-8 Fault (yellow)

• LOC/RPU/RM 1-8 Fault (yellow)

• LOC/RPU/RM 1-8 Active (green)

• Main Console Fault (yellow)

• AC Power (green)

• Ground Fault (yellow)

• Charger Fault (yellow)

• Battery Fault (yellow)

• Data Bus Fault (yellow)

• NAC Fault (yellow)

• NAC Active (green)

• System Trouble (yellow)

• Audio Riser Fault (yellow)

1.3.3 LED Indicators (visible with door and dress panel open)

• Speaker Volume Control Fault (yellow)

• Option Card Fault (yellow)

• Amplifier Over Current Fault (yellow)

1.4 Components

Main Control Board

The ECC-50/100 main control board contains the system's CPU, power supply, battery charger,

other primary components and wiring interface components. One 50W amplifier is integrated into

the main control board.

Display Board

The display board contains the user interface along with tone generators, digital message

recorder/generator, integral microphone input, and preamplifier.

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 21

Page 22

Product Description Components

FIRE SYSTEM

ACTIVE

SYSTEM

CONTROL

ALL

CALL

1

2

3

4

5

6

7

8

9

10

11

12

13

18

19

20

21

22

23

24

16

17

14

15

LIT

FI®AL

by Honeywell

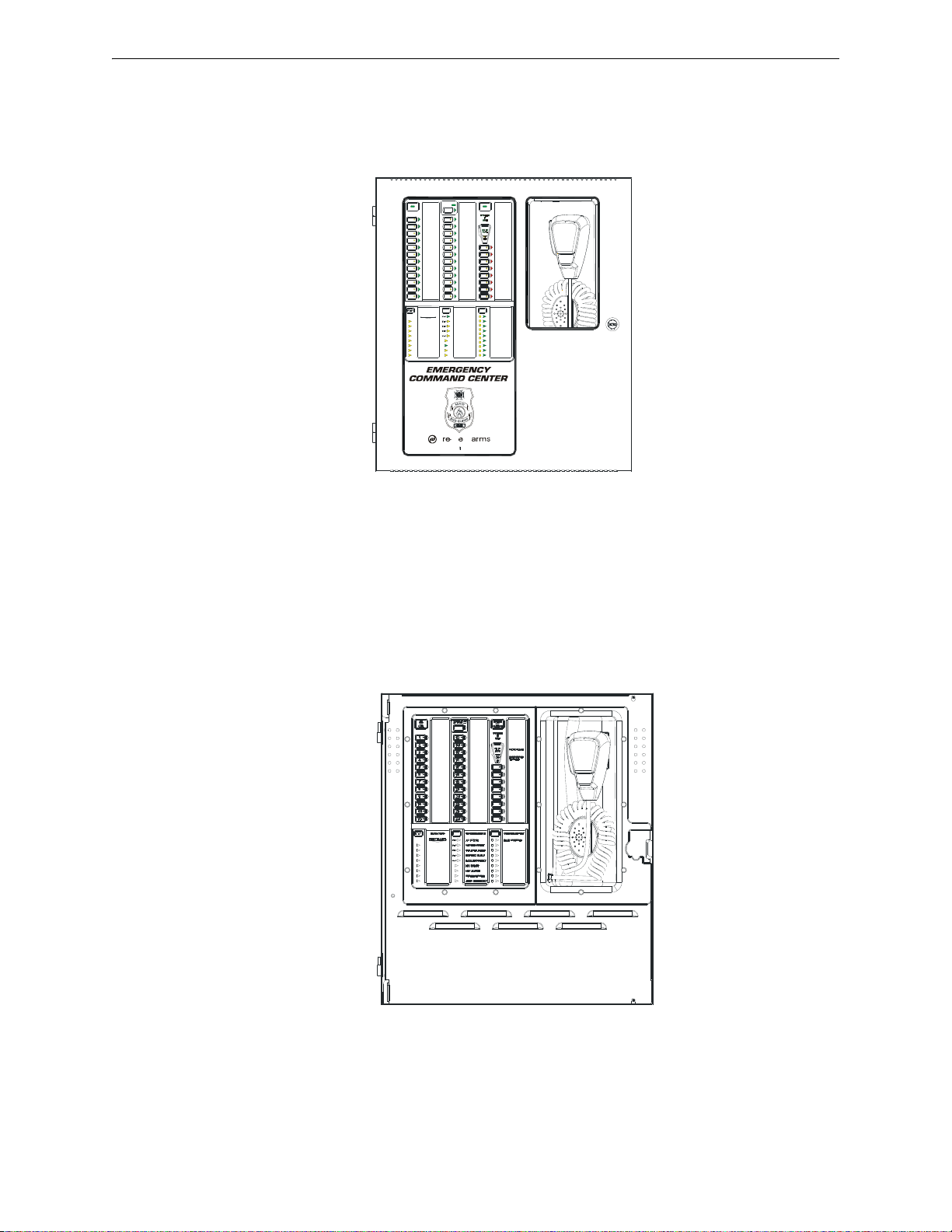

Figure 1.5 Cabinet

eccfront.wmf

Figure 1.6 Dress Panel

ecc_dp.wmf

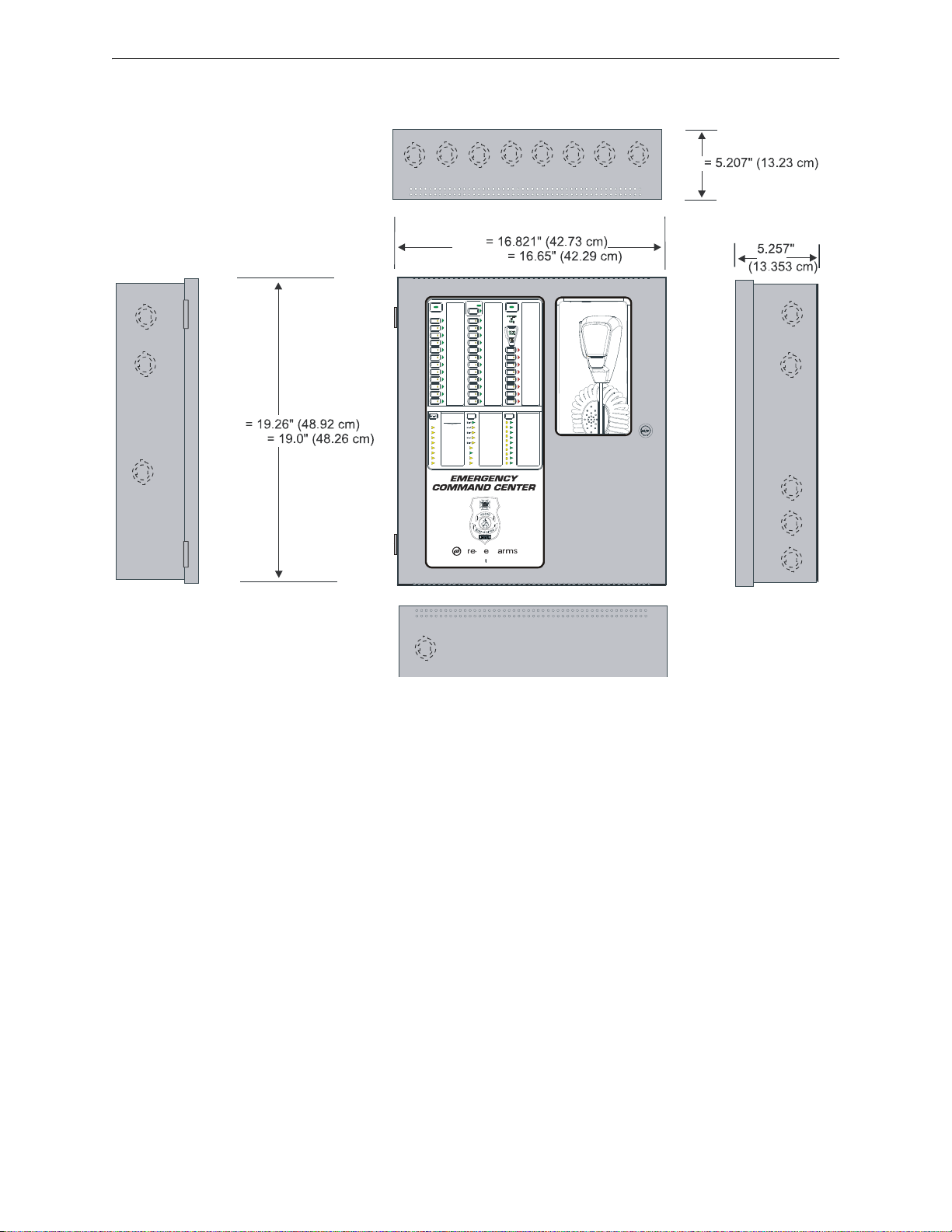

Cabinet

The cabinet is red with an attractive navy blue front overlay. A clear window allows viewing of the

display board, status LEDs and location of microphone. The backbox measures 16.65" x 19.0" x

5.2" D (42.29cm x 48.26cm x 13.23cm) and provides space for two 12AH or two 18AH batteries.

Batteries

The cabinet provides space for up to 18 Amp Hour batteries (charged by integral Power Supply/Battery Charger) with all options installed.

Dress Panel

The Dress Panel is supplied standard with the system. It mounts to the cabinet with two supplied

screws. The Dress Panel protects the user from high voltages and circuit boards from accidental

damage.

Trim Ring

An optional TR-CE trim ring is available for semi-flush mounting of the audio panel.

22 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 23

Optional Equipment Product Description

1.5 Optional Equipment

ECC-50W-25/70V Audio Amplifier Modules

An optional second audio amplifier can be plugged into connectors J10 & J11 located in the upper

right of the main control board in the ECC-50/100. This amplifier also provides 50 watts of power

RMS

or 70 V

at 25 V

to 100 watts (providing dual 50 watt speaker circuits) or it can be used as a backup amplifier. The

output is power-limited (Class 2) and speaker circuit connections to it are provided on the main

control board and optional speaker circuit expander module. The circuit can be wired for Style Y

(Class B) or Style Z (Class A) operation.

LEDs are provided to indicate Amplifier Supervision (green indicates amplifier is functional) and

Circuit Trouble (yellow indicates field wiring fault or amplifier fault). The LEDs are only visible

with the panel door open.

ECC-CE6 Circuit Expander Module

This optional module plugs into connector P1 in the upper middle of the main control board. The

ECC-CE6 adds three primary speaker circuits to the ECC-50/100. The ECC-CE6 adds three secondary circuits to the system when the ECC-50W-25/70V Audio Amplifier Module is also

installed.

, depending on the model, and can therefore be used to expand system power

RMS

ECC-XRM-70V Transformer 70.7 V

RMS

This optional module plugs into connector J12 of the main control board and provides conversion

for the integral audio amplifier from 25 V

to 70.7 V

RMS

at full rated 50 watts output power.

RMS

ECC-FFT Fire Fighter Telephone

The ECC-FFT has a telephone handset and user interface that allows an operator to communicate

with remotely located telephone handsets in a building. It is housed in its own cabinet with key

lock. It requires an external operator interface power connection (24 volts DC) from the ECC50/100 main console or it may be powered from an external 24 VDC power supply such as

HP300ULX. The ECC-FFT provides supervision, annunciation, and control for the local handset

and for up to 24 remote telephone handsets. It provides indications of phone activation and corre-

sponding trouble conditions. Refer to the ECC-FFT Fire Fighter Telephone manual.

ECC-50DA Distributed (Remote) Audio

The ECC-50DA is a 50-watt audio amplifier (audio booster) with its own cabinet and key lock. It

requires an external data bus connection and an external audio riser connection from the ECC50/100 main console. The unit comes standard with 4 speaker circuits. An option card, ECC-CE4,

provides 4 more speaker circuits for a total of 8. Speaker circuits are activated/de-activated manually or automatically by the ECC-50/100 main console. The unit is capable of either 25 V

70.7 V

operation. Refer to the ECC-50/125DA Distributed Audio manual.

RMS

RMS

or

ECC-125DA Distributed (Remote) Audio

The ECC-125DA is a 125-watt audio amplifier (audio booster) with its own cabinet and key lock. It

requires an external data bus connection and an external audio riser connection from the ECC50/100 main console. The unit comes standard with four (4) speaker circuits. An option card, ECCCE4, provides 4 more speaker circuits for a total of eight (8). Speaker circuits are activated/de-activated manually or automatically by the ECC-50/100 main console. The unit is capable of 25 V

RMS

operation. Refer to the ECC-50/125DA Distributed Audio manual.

NOTE: Any combination of up to eight audio boosters comprised of ECC-50DA and ECC-125DA

can be used in the system. Their external data bus addresses must be unique and must be

sequential. Addresses are set via dipswitches on each unit's PC board. Refer to Section 2.14 on

page 54.

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 23

Page 24

Product Description Optional Equipment

ECC-RM Remote Microphone

The ECC-RM has a hand held microphone and is housed in its own cabinet with keyed lock. It

requires an external data bus connection, an external audio riser connection, and an external operator interface power connection (24 volts DC) from the ECC-50/100 main console. ALL CALL paging can be broadcast over the speaker circuits by depressing the microphone's push-to-talk switch.

Not for use in UL2572 Mass Notification applications.

ECC-RPU Remote Page Unit

The ECC-RPU has a hand held microphone and 8 message buttons. It is housed in its own cabinet

with a keyed lock or thumb lock (requires AHJ approval). It also has a 9th button that will activate

an MMF-300 monitor module mounted inside the cabinet. This may be used for HVAC shutdown

applications when the monitor module is connected to the FACP SLC polling loop. The remote

page unit requires an external data bus connection, an external audio riser connection, and an external operator interface power connection (24 volts DC) from the ECC-50/100 main console. ALL

CALL paging can be broadcast over the speaker circuits by depressing the microphone's push-totalk switch. ALL CALL broadcast of a stored message can be done by pressing a message button.

The message buttons operate in the same fashion as the message buttons on the ECC-50/100 main

console. Not for use in UL2572 Mass Notification applications.

ECC-LOC Local Operator Console

The ECC-LOC has a complete operator interface like the ECC-50/100 main console and is housed

in its own cabinet with a keyed lock or thumb lock (requires AHJ approval). The local operator

console requires an external data bus connection, an external audio riser connection, and an external operator interface power connection (24 volts DC) from the ECC-50/100 main console.

NOTE: Any combination of up to eight remote consoles comprised of ECC-RM(s), ECC-RPU(s),

and ECC-LOC(s) can be used in the system. Their external data bus addresses must be set via

dipswitches on each unit's PC board. Refer to Section 2.14 on page 54.

24 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 25

Section 2: Installation

!

2.1 Mounting Options

The cabinet may be semi-flush or surface mounted. The cabinet mounts using three key slots at the

top of the backbox and two additional 0.250" diameter holes located at the bottom.

Carefully unpack the system and check for shipping damage. Mount the cabinet in a clean, dry,

vibration-free area where extreme temperatures are not encountered. The area should be readily

accessible with sufficient room to easily install and maintain the panel. Locate the top of the cabinet approximately five feet above the floor with the hinge mounting on the left. Determine the

number of conductors required for the devices to be installed. Sufficient knockouts are provided

for wiring convenience. Select the appropriate knockout(s) and pull the required conductors into

the box. Note that knockouts are also located on the back of the cabinet. All wiring should be in

accordance with the National and/or Local codes for fire alarm systems. Refer to Figure 2.4 for

knockouts that cannot be used.

2.2 Backbox Installation

CAUTION: STATIC SENSITIVE COMPONENTS

THE CIRCUIT BOARD CONTAINS STATIC-SENSITIVE COMPONENTS. ALWAYS GROUND

YOURSELF WITH A PROPER WRIST STRAP BEFORE HANDLING ANY BOARDS SO THAT

STATIC CHARGES ARE REMOVED FROM THE BODY. USE STATIC SUPPRESSIVE PACKAGING TO PROTECT ELECTRONIC ASSEMBLIES.

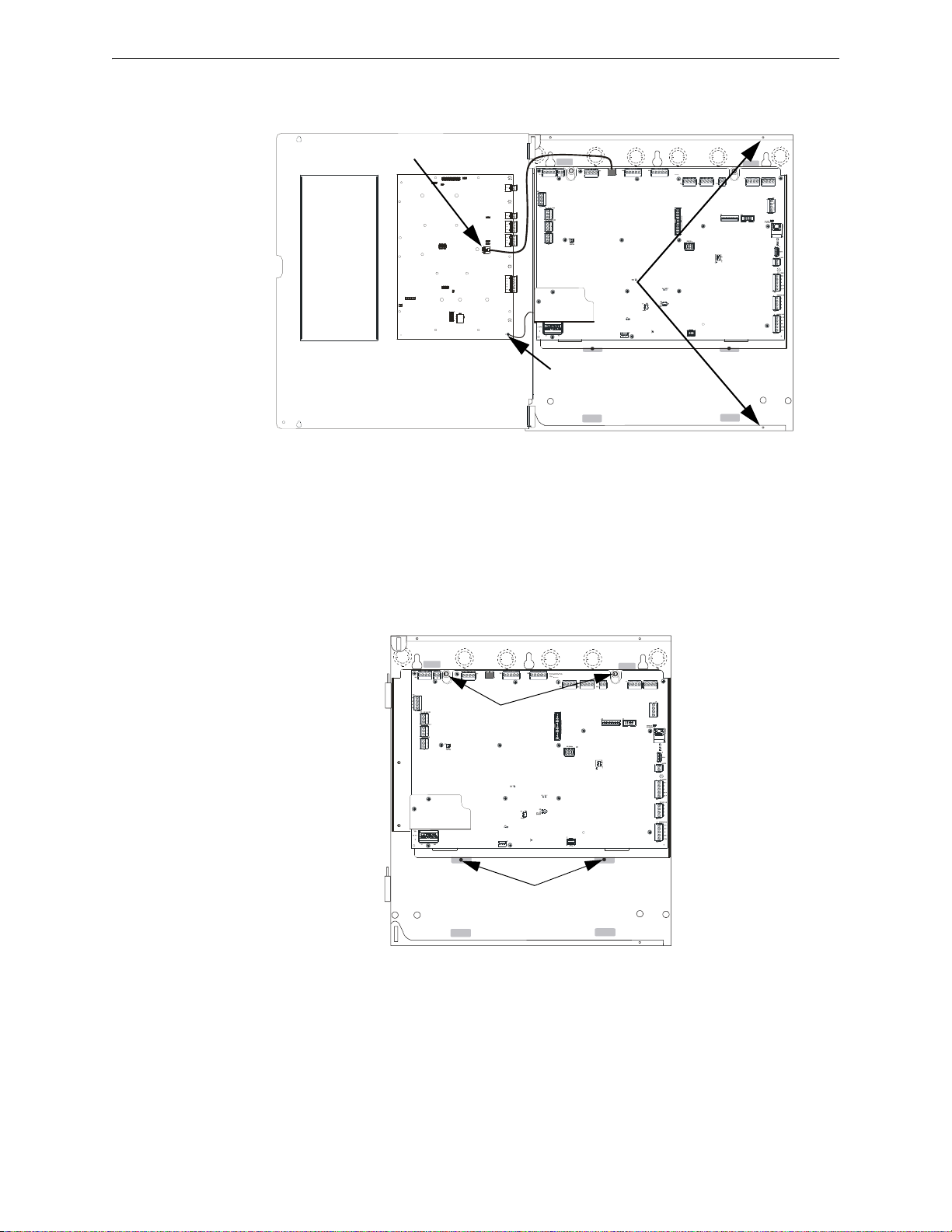

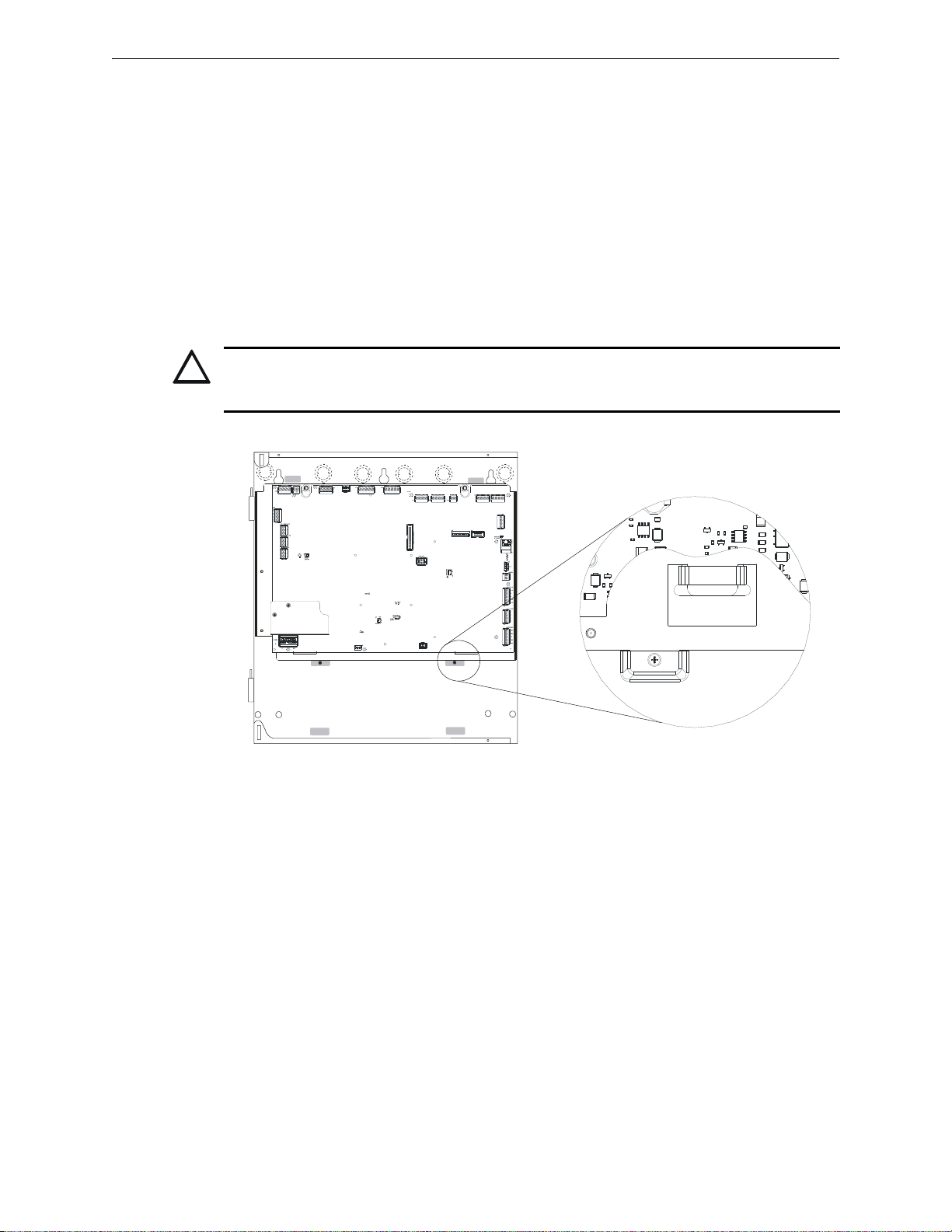

Removing the Dress Panel

1. Open the door and lift the door off the pin hinges.

2. Loosen the two (2) screws that secure the dress panel to the backbox. Then, lift up to swing

the dress panel open.

3. Disconnect the ground wire from the dress panel.

4. Unplug the cable on the display board at J2. This is the connection to the main control board on

the chassis.

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 25

Page 26

Installation Backbox Installation

J12

TB15

J9

RTZM

Rev.

ECC-MCB-PCA

loosen screws

disconnect

earth ground

unplug cable

lift up dress panel,

pull out,

slide down to remove

Figure 2.1 Dress Panel Removal

ecc-dpopn.wmf

remove screws

loosen nuts

chassisinst.wmf

Figure 2.2 Chassis Removal

5. Lift the dress panel up and gently pull the lower hinge out of the backbox. Gently pull down to

remove the top hinge. Store the dress panel in a safe place.

Removing the Chassis Assembly

1. If present, remove the two (2) screws which fasten the lower chassis tabs to the backbox.

These are for shipping purposes only and do not need to be reinstalled.

2. Loosen the two nuts which secure the top of the chassis with an 11/32” socket.

3. Carefully lift up and remove the chassis assembly from the backbox and store in a safe, clean

place. Avoid static discharge which may damage static sensitive components on the board.

26 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 27

Backbox Installation Installation

!

J12

TB15

J9

RTZM

Rev.

ECC-MCB-PCA

Figure 2.3 Chassis Installation

chassistab.wmf

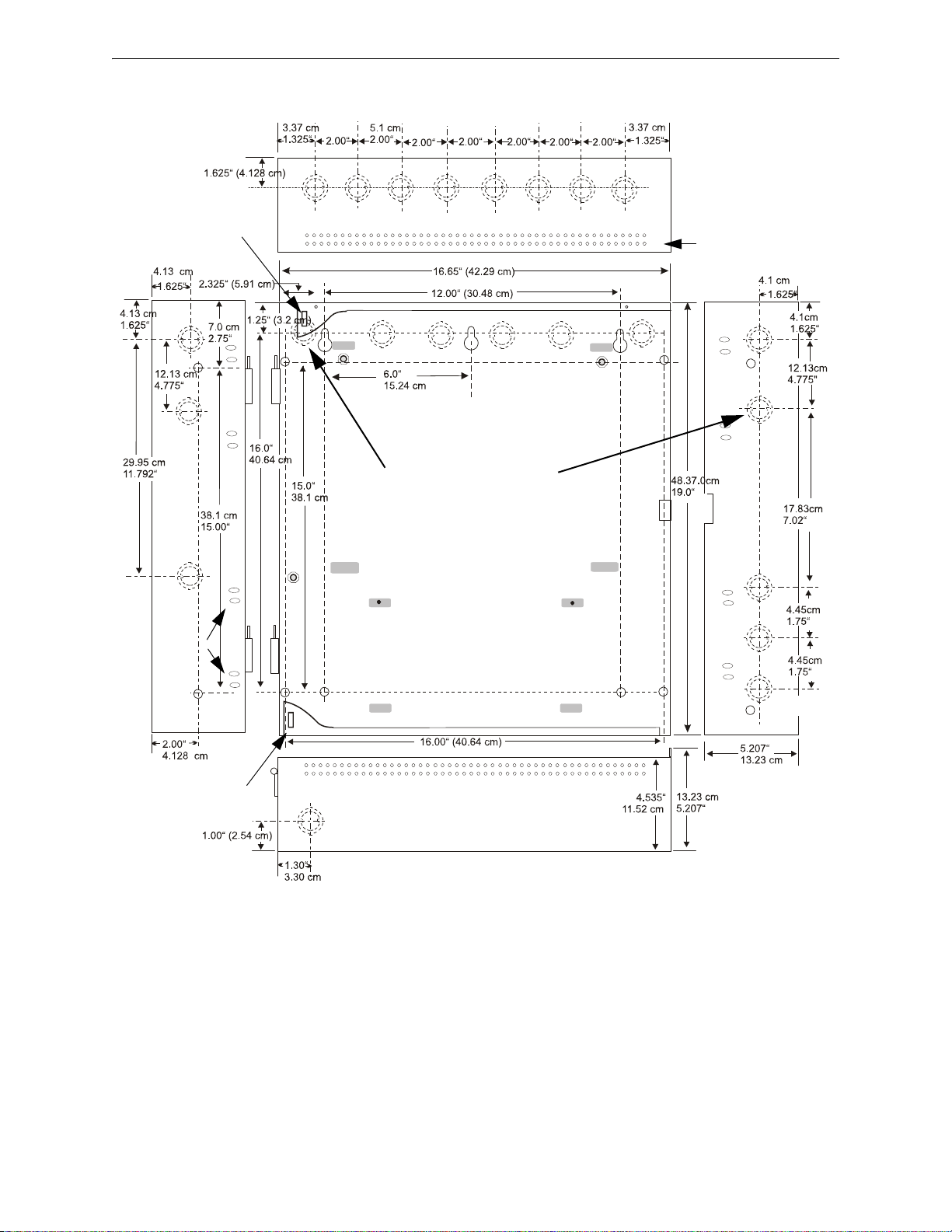

Mounting the Backbox

1. Mark and predrill hole in the wall for the center top keyhole mounting bolt using the dimensions illustrated in Figure 2.4 on page 28.

2. Install center top fastener in the wall with the screw head protruding.

3. Place backbox over the top screw, level and secure.

4. Mark and drill the left and right upper and lower mounting holes.

Note: Outer holes (closest to sidewall) are used for 16” O.C. stud mounting.

5. Install remaining fasteners and tighten.

6. Carefully reinstall the chassis assembly and dress panel by reversing the steps above. Use

appropriate precautions to prevent damage to components due to static discharge. When

reinstalling the chassis assembly, be sure that all four (4) tabs are seated properly in the slots of

the backbox to avoid possible damage to the unit.

CAUTION: POSSIBLE EQUIPMENT DAMAGE

REINSTALL THE CHASSIS ASSEMBLY CAREFULLY , MAKING SURE TO PROPERLY SEAT THE

UNIT TO THE BACKBOX.

7. Draw wires through the respective knockout locations.

An optional Trim Ring (P/N TR-CE) is available for semi-flush mount installations.

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 27

Page 28

Installation Backbox Installation

Figure 2.4 Cabinet Dimensions & Knockout Locations

9050udencl.wmf

Semi-Flush Mounting

Do not recess box more

than 3.875” into wall to

avoid covering venting

holes on top of box.

Hinge Slot for

Dress Panel

Hinge Slot for

Dress Panel

Semi-flush

mounting hole

Mounting

slots for

optional

Trim Ring

Do not use these knock-outs!

28 Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013

Page 29

Backbox Installation Installation

FIRE SYSTEM

ACTIVE

SYSTEM

CONTROL

ALL

CALL

1

2

3

4

5

6

7

8

9

10

11

12

13

18

19

20

21

22

23

24

16

17

14

15

LIT

FI

®

AL

by Honeywell

Figure 2.5 ECC-50/100 Backbox Dimensions

ecc-cab.wmf

Left Side

Right Side

Bottom

Door

Door

Backbox

Backbox

Depth =

Depth

Top

Emergency Command Center Manual — P/N LS10001-000FL-E:A 4/10/2013 29

Page 30

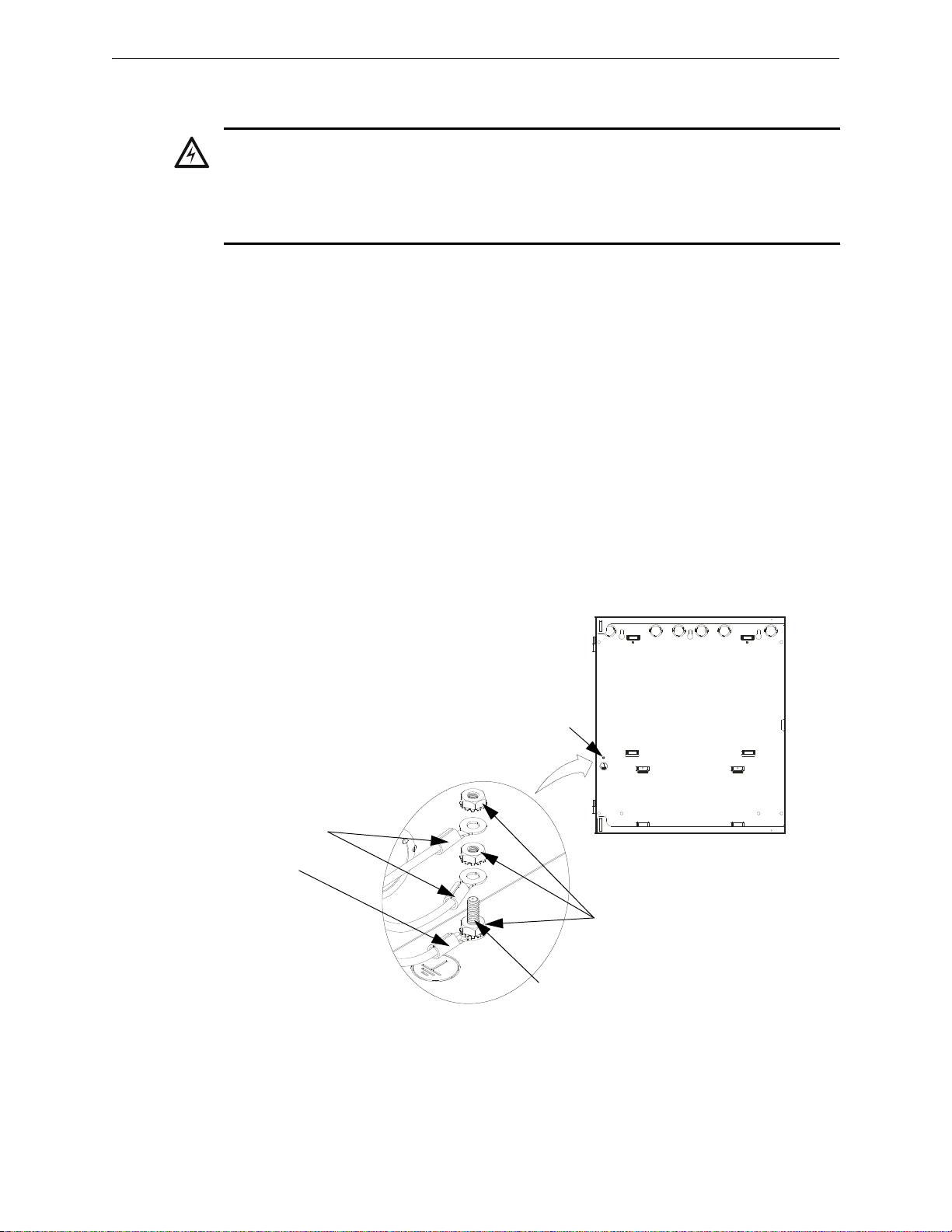

Installation Operating Power

!

Figure 2.6 Earth Ground Connection

e

c

c

g

n

d

.

w

m

f

grounding stud

keps nuts

Grounding

Cable #71073

grounding stud

Equipment

Ground

2.3 Operating Power

WARNING: RISK OF EQUIPMENT DAMAGE AND PERSONAL INJURY

SEVERAL DIFFERENT SOURCES OF POWER CAN BE CONNECTED TO THIS PANEL. DISCONNECT ALL SOURCES OF POWER BEFORE SERVICING. THE PANEL AND ASSOCIATED

EQUIPMENT MAY BE DAMAGED BY REMOVING AND/OR INSERTING CARDS, MODULES OR

INTERCONNECTING CABLES WHILE THIS UNIT IS ENERGIZED. BE SURE TO OBSERVE

PROPER GROUNDING AND HANDLING PROCEDURES.

2.3.1 AC Power and Earth Ground Connection

Primary power source for the ECC-50/100 is 120 VAC, 60 Hz, 3.5 amps. Primary power source for