Field controls GVD-4, GVD-12 Manual

GAS VENT DAMPER

Model: GVD-4 through 12

Field Controls (GVD) gas vent damper was developed to reduce off cycle venting losses through boilers and draft hoods. When the boiler is in the standby mode heat escapes up the chimney. The heat comes from the boiler and the condition space. To significantly reduce these losses install a Field Gas Vent Damper. The damper is installed between the vent or chimney and as close to the draft hood as practical. When properly installed the damper opens before the burner fires and closes after the burner shuts off. The electrical circuits in this product are designed not to override the existing limit and safety controls of the boiler.

English……….. Page 1

Français……… Page 13

The plug is installed only if the appliance is equipped with an intermittent or direct ignition system. Failure to follow these instructions can cause odor problems and minor property damage due to moisture. Do not install on standing pilot systems.

Tape Plug

Here

OPERATION

When the boiler receives a call for heat, the damper rotates to the open position before the burner circuit is energized. If the damper does not rotate to the open position, the burner circuit will not be energized. When properly installed, the electrical circuits in this product are designed not to override the existing limit and safety controls of the appliance.

WARNING: Before installing the vent damper:

WARNING: Before installing the vent damper:

1.Read this manual carefully and completely.

2.Be sure to follow all procedures and safety inspections.

3.Do not negate the action of any safety or operational controls.

4.The vent damper is not for retrofit in Canada.

TO THE USER

For continued safe operation the appliance device combination should be inspected annually by a qualified service agency. It is recommended that the homeowner should have the vent system and the damper device examined annually for deterioration from corrosion or other sources. This inspection should be performed prior to and during each heating season.

GENERAL INFORMATION

DIMENSIONAL DATA

|

Dim ‘A’ |

Dim ‘B’ |

Dim ‘C’ |

Dim ‘D’ |

Dim ‘E’ |

Weight |

|

Tube Size |

Length |

Total Height |

|||

|

(Inches) |

(Inches) |

(lbs.) |

|||

|

(Inches) |

(Inches) |

(Inches) |

|||

|

|

|

|

|||

|

4 |

6 |

9-5/8 |

15/16 |

5 |

2.50 |

|

5 |

6 |

10-5/8 |

15/16 |

5 |

2.70 |

|

6 |

6-1/2 |

11-5/8 |

1-1/8 |

5-1/2 |

3.10 |

|

7 |

7-1/16 |

12-5/8 |

1-3/8 |

6-1/16 |

3.55 |

|

8 |

8-1/16 |

13-5/8 |

1-7/8 |

7-1/16 |

4.40 |

|

9 |

10-1/8 |

14-5/8 |

2-7/8 |

9-1/8 |

6.27 |

|

10 |

12-1/8 |

15-5/8 |

3-7/8 |

11-1/8 |

6.95 |

Figure 1 |

12 |

12-1/8 |

17-5/8 |

3-7/8 |

11-1/8 |

8.75 |

|

|

|

|

|

|

|

ELECTRICAL DATA |

|

|

|

|

|

|

Minimum Wiring Requirements |

24 VAC, 18 Gauge, 105C |

|

|

|

|

|

Thermostat Heat Anticipation |

Add an additional 0.1 Amp to the specified |

|

|

|

||

or measured control circuit amps |

|

|

|

|||

|

|

|

|

|||

Power Draw Requirement |

3W at 24 VAC when opening or closing |

|

|

|

||

Timing |

15 sec, Power open |

|

|

|

|

|

15 sec, Power close |

|

|

|

|

||

|

|

|

|

|

||

FEATURES

1.Service Switch – Holds damper open and allows the appliance to operate without the damper operating.

2.Five year limited warranty on motorized assembly from date of installation.

3.Two internal safety switches

4.Power open, power close – extends product life. Reduced electrical consumption

5.24 VAC for simple and low-cost wiring. Plug in harness available.

6.Flex Seal provides self cleaning action.

7.Stainless steel pipe assembly.

Page 2

UNPACKING INSTRUCTIONS

1.The Field Controls GVD Series Gas Vent Damper is packaged in a single carton containing an assembled GVD, instruction manual and a plug. NOTE: Some OEM supplied units have the wiring harness attached.

2.Inspect for damage prior to the installation.

3.Retrofit installations require a wire harness. Order the universal wire harness #46390008.

PRE-INSTALLATION WARNINGS

PRE-INSTALLATION WARNINGS

1.The Field Controls Automatic Vent Damper must be installed by a qualified installing agency in accordance with the manufacturer’s installation instructions. The definition of a qualified installation agency is: any individual, firm, corporation or company which either in person or through a representative is engaged in, and is responsible for, the installation and operation of gas appliances and automatic vent damper devices, who is experienced in such work, familiar with all the precautions required, and has complied with all the requirements of the authority having jurisdiction. The qualified installer shall fill in the installer’s name, address and installation date on the label attached to the vent damper device.

2.Do not negate the action of any existing safety or operational controls.

3.When servicing controls, all wires must be LABELED prior to disconnection. Wiring errors can cause improper and dangerous operation.

4.Device must be installed by a qualified installer, in compliance with local codes or the National Fuel Gas Code (ANSI Z223.1 NFPA 54 or CAN/CGA-B149) and the National Electric Code (ANSI C1-NFPA 70).

5.Device conforms to ANSI Z21.66. CSA design certified.

6.Use only with a listed gas fired appliance equipped with a draft hood, the outlet area of which is not greater than the inlet area of the device.

7.Install after the appliance draft hood, as close to the draft hood as practicable, and without modification to the draft hood or the vent damper.

8.Locate in a venting system or section of a venting system so that it services only the single appliance for which it is intended.

9.A minimum clearance of 6 inches (153mm) between the damper device and combustible construction must be maintained and that there be provisions for access and service of the damper device.

10.Position indicator and service switch must be accessible to the user.

11.The installer must fill in the label on the side of the motor assembly cover.

12.This device must be installed only on a listed gas appliance connected to a factory built chimney or vent complying with a recognized standard, or a masonry or concrete chimney lined with a lining material acceptable to the authority having jurisdiction.

13.This vent damper device shall not be installed on an appliance with an automatic valve having a manual valve control unless the manual valve control has been rendered in-operative or the automatic valve has been replaced with a redundant automatic valve not equipped with a manual valve control.

PRE-INSTALLATION INSPECTIONS

PROCEDURE FOR SAFETY INSPECTION OF AN EXISTING APPLIANCE INSTALLATION

The following procedure is intended as a guide to aid in determining that an appliance is properly installed and is in a safe condition for continuing use.

This procedure is predicated on central furnace, boiler and water heater installations, and it should be recognized that generalized procedures cannot anticipate all situations. Accordingly, in some cases deviation from this procedure may be necessary to determine safe operation of the equipment.

1.This procedure shall be performed prior to installation of the automatic vent damper device.

2.If it is determined there is a condition which could result in unsafe operation, the appliance should be shut off and the owner advised of the unsafe condition. Do not install the automatic vent damper device until the unsafe condition has been corrected.

Page 3

Safety Inspection

1.Conduct a gas leakage test of the appliance piping and control system downstream of the shutoff valve in the supply line to the appliance.

2.Visually inspect the venting system for proper size, horizontal pitch and vent termination, and determine there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition.

3.Determine that the chimney or vent is acceptable to the authority having jurisdiction.

4.Shut off all gas to the appliance and shut off any other fuel-gas burning appliance within the same room. Use the shutoff valve in the supply line to each appliance.

5.Inspect burners and crossovers for blockage and corrosion.

6.Applicable only to furnaces – inspect heat exchanger for cracks, openings or excessive corrosion.

7.Applicable only to boilers – inspect for evidence of water or combustion product leaks.

8.Insofar as is practical, close all building doors and windows and all doors between the space in which the appliance is located and other spaces of the building. Turn on clothes dryers, stove top barbecues and central vacuum cleaners. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers. If, after completing Steps 9 through 14, it is believed sufficient combustion air is not available, refer to local codes, or in the absence of local codes, to the National Fuel Gas Code, ANSI Z223.1 or CAN/CGAB149 Installation Codes, for guidance.

9.Place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously.

10.Determine that the pilot(s) is burning properly and that main burner ignition is satisfactory by interrupting and reestablishing the electrical supply to the appliance in any convenient manner. Test the pilot safety device to determine it is operating properly by extinguishing the pilot burner(s) when the main burner(s) is off and determining, after 3 minutes, that the main burner gas does not flow upon a call for heat.

11.a. Visually determine that main burner gas is burning properly: i.e., no floating, lifting or flashback. Adjust the primary air shutter(s) as required.

b.If the appliance is equipped with high and low flame controlling or flame modulation, check for proper main burner operation at low flame.

12.Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Vent connected gas utilization equipment shall be operated for several minutes and checked to see that the combustion products are going up the chimney, or gas vent, properly by passing a lighted match, taper or candle round the edge of the relief opening of the draft hood. If the chimney or gas vent is drawing properly, the match flame will be drawn into the draft hood. If not, the combustion products will tend to extinguish the flame. If the combustion products are escaping from the relief opening of the draft hood, the equipment should not be operated until proper adjustments or repairs are made to provide adequate draft through the chimney or gas vent.

13.Turn on all other fuel-burning appliances within the same room so they will operate at their full inputs. Follow lighting instructions for each appliance.

14.Repeat Steps 11 and 12 on the appliance being inspected.

15.Return doors, windows, exhaust fans, fireplace dampers and any other fuel-gas burning appliances to their previous conditions of use.

16.Applicable only to furnaces – Check both the limit control and the fan control for proper operation. Limit control operation can be checked by blocking the circulating air inlet or temporarily disconnecting the electrical supply to the blower motor and determining that the limit control acts to shut off the main burner gas.

17.Applicable only to boilers –

a.Determine that the water pumps are in operating condition.

b.Test low water cutoffs, automatic feed controls, and relief valves in accordance with the manufacturer’s recommendations to determine they are in operating condition.

Page 4

HOW TO INSTALL AN ADDITIONAL GAS VALVE

Determine if the appliance has a redundant gas valve. If it has a redundant gas valve proceed to install the damper assembly.

WARNING: If the appliance does not have a redundant

WARNING: If the appliance does not have a redundant

gas valve, an additional gas valve or a redundant gas valve must be installed.

gas valve, an additional gas valve or a redundant gas valve must be installed.

1.Shut off the gas and electricity to the gas burner (use the manual shut off valve in the supply line to the appliance).

2.Locate a position in the supply line between the appliance automatic gas valve and the burner.

3.Both gas valves must terminate the main gas supply to the burner(s). Both gas valves must be piped in series and wired in parallel. See wiring diagram.

4.Install an approved appropriately sized single function automatic gas valve in this location downstream of the existing automatic gas valve. (Follow the gas valve manufacturers’ instructions for flow directions and position).

Diagram A: Note: Terminals 1,2 and 3 must be the same polarity. Add 0.10 amps to the specified or measured heat anticipator setting.

5.Restore gas line supply, conduct a leak test on the gas piping and control system downstream of the appliance shut off valve.

6.A typical standing pilot hookup with an added gas valve is shown in Diagram A. Terminals one, two, and three must be the same polarity. Failure to obtain correct polarity may damage the damper motor assembly. To set the room thermostat heat anticipator add an additional 0.10 amps to the specified or measured control circuit amps.

7.For best results we suggest measuring the current across the thermostat with a meter. Set the heat anticipator according to the reading plus 0.10 amps.

NOTE: The damper must be open and the burner(s) operating to obtain an accurate reading.

INSTALLATION OF THE PILOT VENT PLUG

CAUTION: The pilot vent plug is to be installed only on intermittent or direct ignition systems. Do not install the pilot vent plug on standing pilot systems. Failure to follow these instructions can cause odor problems and minor property damage due to moisture.

1. To avoid motor assembly damage be careful not to turn the damper gate manually, while installing the pilot vent plug.

2. The pilot vent plug is located on the front cover of this installation manual.

3. Insert pilot vent plug into gate and fold over tabs. (See Figure 2)

Figure 2

Page 5

INSTALLATION OF THE UNIT

WARNING: Install the automatic vent damper to service only the single appliance for which it is intended. See

WARNING: Install the automatic vent damper to service only the single appliance for which it is intended. See

Figure 4. If improperly installed a hazardous condition such as an explosion or carbon monoxide poisoning could result.

Figure 4. If improperly installed a hazardous condition such as an explosion or carbon monoxide poisoning could result.

WARNING: To be used only with an appliance bearing a marking showing the make and model of the device.

WARNING: To be used only with an appliance bearing a marking showing the make and model of the device.

Required for installations in Canada.

Required for installations in Canada.

CAUTION: Horizontal and Vertical Applications:

VERTICAL

The vent damper is not position sensitive. You may mount the vent damper in any position. A minimum of 6 inches between the device and combustible construction shall be maintained.

HORIZONTAL

To avoid premature failure of the vent damper refer to Figure 3. Avoid mounting the damper directly above or below the vent pipe. We suggest 1:00 to 5:00 or 7:00 to 11:00 ‘o clock positions. A minimum of 6 inches between the device and combustible construction shall be maintained.

1. Install the vent damper device after the appliance draft hood, as close to the draft |

Figure 3 |

hood as practical, and without modification of either the draft hood or the vent |

|

damper device. |

|

2.Locate a position in the vent pipe connector between the draft hood and ventor chimney for the damper device. (See Figure 4)

3. A minimum clearance of 6 inches between the device and combustible construction must be maintained and there must be provisions for access and service of the damper device.

4. The vent damper device shall be connected to a chimney or vent complying with a recognized standard, or a masonry or concrete chimney lined with a lining material acceptable to the enforcing authority.

5. Remove the appropriate section of vent pipe connector and reinstall the shorter vent pipe connector and vent damper.

6. The directional arrow and crimped end of the vent damper must point toward the venter chimney. The motor assembly must be assessable for wiring and the damper position indicator visible.

7. Secure the vent damper to the vent pipe. Use 1/2 inch sheet metal screws or pop

rivets. The spacing should be equally distributed 120° apart around the |

Figure 4 |

|

|

circumference. Three fasters shall be used at the inlet and outlet of the pipe |

|

assembly. |

|

8.Be careful not to allow the fasteners to obstruct the damper gate.

9.It may be necessary to provide a suitable hanger to support the vent damper independent of the venting system.

10.Check to see the vent damper service switch is in the automatic position.

11.Check to see the flat shaft is fitted into the motorized assembly.

Page 6

APPLIANCE WIRING

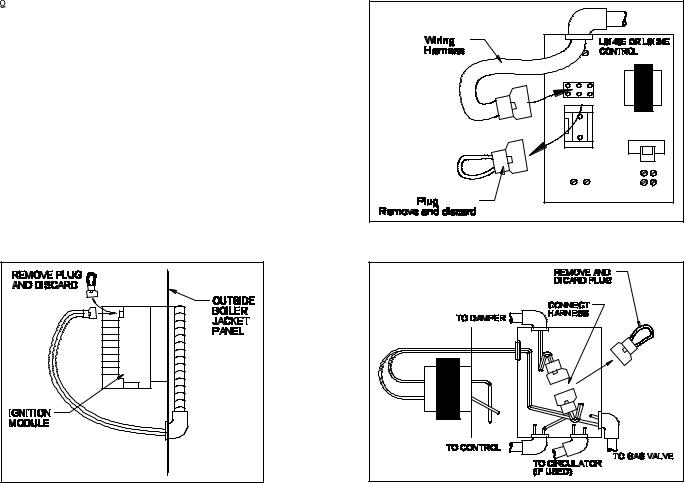

1.To locate the vent damper wire harness (if supplied) receptacle on the appliance, refer to the appliance manufacturer instruction manual and follow accordingly. (See Figures 5,6,7)

2.The wire harness shall be securely fastened thru the conduit bracket, located on the vent damper motor assembly.

3.The GVD series vent damper must be electrically connected with appliance burner control circuit.

4.Be careful not to allow the wire harness to come in contact with hot surfaces. Stand off brackets may be required to prevent contact to hot surfaces.

NOTE: Plug in control circuits may contain internal fuses. A vent damper connected to an appliance with a fused control circuit will not allow the burner to operated unless the vent damper is connected.

NOTE: Internal fuse blow after the first complete cycle.

Figure 6

Typical Electronic Ignition Connections

INSTALLATION ON EXISTING APPLIANCES

Figure 5

Typical Aquastat

Figure 7

Typical Junction Box Connection

This procedure is intended as a guide to aid in safely installing an electrically operated automatic vent damper device on an existing appliance so that the modified appliance will continue to operated safely and satisfactorily.

This procedure is based on the assumption that the history of the specific appliance has been one of safe and satisfactory operation.

This procedure is predicated on central furnace, boiler and water heater installations, and it should be recognized that generalized procedures cannot anticipate all situations. Accordingly, in some cases deviation from this procedure may be necessary to determine safe operation of the equipment.

Page 7

The following steps are to be followed in making the modifications:

1.Perform a safety inspection of the existing appliance installation. See PRE-INSTALLATION INSPECTIONS section for the recommended procedure for such a safety inspection.

2.Shut off all gas and electricity to the appliance. To shut off gas use the shutoff valve in the supply line to the appliance.

3.Install the automatic vent damper device in strict accordance with the manufacture’s installation instructions. Make certain the device is not located in that portion of the venting system which serves any appliance other than the one for which the damper is installed.

4.Make certain wiring connections are tight and wires are positioned and secured so they will not be able to contact high temperature locations.

5.When an additional automatic valve has been incorporated or an existing gas control replaced, conduct a gas leakage test of the appliance piping and control system downstream of the shutoff valve in the supply line to the appliance.

6.Visually inspect the modified venting system for proper horizontal pitch.

7.Check that the damper and gas valve(s) are in the correct operating sequence.

a.The damper must be in the full open position before the gas valve(s) opens.

b.The damper must remain in the full open position while the gas valve(s) is open.

c.The gas valve(s) must be closed before the damper begins its return to the closed positon

d.The damper shall remain in the closed position during the off cycle of the appliance.

8.Determine the amperage draw of the gas control circuit and damper device.

a.Check the appliance transformer for adequate capacity.

b.Check heat anticipator in comfort thermostat to determine it is properly adjusted.

9.Do not install a damper device unless sufficient combustion and ventilation air is available. This can be determined by demonstrating satisfactory operation of the appliance as described in steps 10 through 14. Sequence the appliance through at least three normal operating cycles.

10.Insofar as it is practical, close all building doors and windows and all doors between the space in which the appliance is located and other spaces of the building except in a room where an exhaust fan is located. Turn on clothes dryers, stove top barbecues and central vacuum cleaners. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers.

11.Place appliance in operation. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously.

12.Test for spillage at the draft hood relief opening after 5 minutes of main burner operation.

a.Vent connected gas utilization equipment shall be operated for several minutes and checked to see that the combustion products are going up the chimney, or gas vent, properly by passing a lighted match, taper or candle around the edge of the relief opening of the draft hood. If the chimney or gas vent is drawing properly, the match flame will be drawn into the draft hood. If not, the combustion products will tend to extinguish the flame. If the combustion products are escaping from the relief opening of the draft hood, the equipment should not be operated until proper adjustments or repairs are made to provide adequate draft through the chimney or gas vent.

13.a. Visually determine that main burner gas is burning properly: i.e., no floating, lifting or flashback. Adjust the primary air shutter(s) as required.

b.If the appliance is equipped with high and low flame controlling or flame modulation, check for proper main burner operation at low flame.

14.Determine that the pilot(s) is burning properly and that main burner ignition is satisfactory by interrupting and reestablishing the electrical supply to the appliance in any convenient manner. Test the pilot safety device to determine it is operating properly by extinguishing the pilot burner(s) when the main burner(s) is off and determining, after 3 minutes, that the main burner gas does not flow upon a call for heat.

15.Applicable only to furnaces – Check both the limit control and the fan control for proper operation. Limit control operation can be checked by blocking the circulating air inlet or temporarily disconnecting the electrical supply to the blower motor and determining that the limit control acts to shut off the main burner gas.

16.Applicable only to boilers –

a.Determine that the water pumps are in operating condition.

b.Test low water cutoffs, automatic feed controls, pressure and temperature limit controls and relief valves in accordance with the manufacturer’s recommendations to determine they are in operating condition.

17.Complete the device label:

a.Name of qualified agency responsible for damper installation.

b.Date of installation.

Page 8

Loading...

Loading...