Field controls CAS-3 Manual

COMBUSTION AIR SYSTEM

Model: CAS-3

ITEMS INCLUDED IN KIT:

1)Motorized Blower

1)4" galvanized intake air Vent Hood

2)Mounting brackets to secure the CAS to a wall

2)Wire/conduit connector(s)

1)4" x 6" Pipe Increaser Fitting

1)6" Orifice Ring

1)Instruction Sheet

1)High/Low Motor Speed Switch

This product is designed for use with any oil burning furnace, water heater, or boiler with 120 VAC control systems. It may also be used with more than one appliance. The CAS unit mechanically draws air into a structure and disperses it near the combustion air intake of an appliance. If an optional

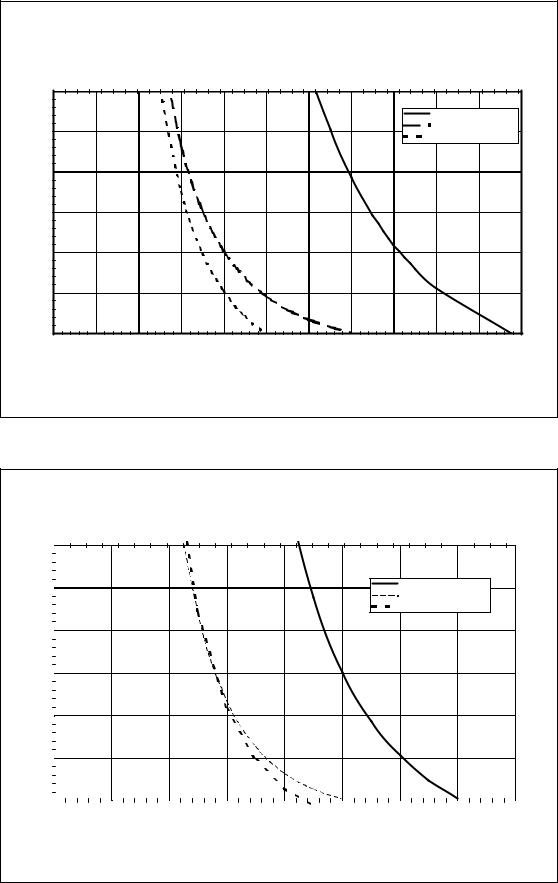

Vacuum Relief Valve (VRV) is used, the incoming air is tempered before entering the structure's airspace. Refer to Diagram A and B for guidance in setting up the CAS system based on the size and length of the connecting duct-work and the input rating of the appliance.

This device MUST be installed by a qualified agency in accordance with the manufacturers installation instructions.

The definition of a qualified agency is: any individual, firm, corporation or company which either in person or through a representative is engaged in, and is responsible for, the installation and operation of gas appliances, who is experienced in such work, familiar with all the precautions required, and has complied with the requirements of the authority having jurisdiction.

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

2630 Airport Road · Kinston, NC 28504

Phone: 252-522-3031· Fax: 252-522-0214

www.fieldcontrols.com

GENERAL SYSTEM OPERATION

1.The thermostat (wall thermostat, or aquastat) calls for heat and energizes a relay which activates the CAS unit. After the CAS fan has come up to speed, an internal air pressure switch closes and completes the circuit to allow the burner to fire. If the appliance is power vented, the venter and CAS activate simultaneously. After the CAS comes up to speed, a pressure switch in the unit closes and allows the appliance to fire.

2.After the heating requirement has been satisfied, the thermostat circuit will open and deactivate the burner and CAS unit.

3.For power vented systems with a post purge device, the power venter and CAS operate for a period of time after the burner has shut off to purge remaining flue gases from the vent system.

INSTALLATION SAFETY INSTRUCTIONS

CAUTION: This device must be installed by a qualified installer in accordance with the manufacturer's installation instructions.

1.This combustion air system must be installed by a qualified installer. "Qualified Installer" shall mean an individual who has been properly trained or a licensed installer.

2.Plan the system layout before installation to avoid the possibility of accidental contact with concealed wiring or plumbing inside walls.

3.Disconnect power supply before making wiring connections to prevent electrical shock and equipment damage.

SIZING AND SETUP

Diagrams A and B and Table 1 shows the maximum equivalent length and size of duct pipe that should be used when installing the CAS system. Using these charts will help ensure that the proper amount of air is drawn into the structure as needed by the appliance. The defined regions shown correspond to the CAS's airflow characteristics when using 4" and 6" diameter sheet metal duct pipe and the included orifice ring. Follow the guidelines below to properly size and setup the CAS.

1.Determine the maximum input firing rate of the appliance, or the maximum total firing rate of multiple appliances that will be used.

2.Position the motorized CAS unit according to the guidelines in the "Installation" section.

3.Determine where the intake air vent hood will be located based on the recommendations in the

"Installation" section.

4.The CAS is equipped with a High/Low motor speed control switch. When calculating the maximum equivalent feet, determine which speed is appropriate for the application. (Refer to

Diagram A or B or Table 1)

5.Calculate the total equivalent length of duct pipe including elbows and fittings needed to connect the CAS unit to the vent hood. (Refer to Diagram A or B or Table 1)

6.On Diagram A or B, locate the point that corresponds to the firing rate along the horizontal axis and the equivalent length of the duct pipe along the vertical axis, if using for make up air.

7.The point should fall within one of the three regions on the table. Each region corresponds to a duct pipe diameter of 4", 4" using the orifice ring, and 6" respectively. If the point falls near the rightward border of a particular region then the VRV is not necessary. If the point falls away from the rightward border, then a VRV is needed to reduce the amount of air drawn in.

Page 2

8.Draw a horizontal line on Diagram A or B that passes through the point located in step 5. The position of the point along this line relative to the left and right borders of the region it falls into indicates the relative position that the balance weight of the VRV should be adjusted to. If the point falls near the leftward border of a region, then the VRV balance weight should be adjusted to it's minimum position. This corresponds to turning the balance weight screw as far counterclockwise as possible.

EXAMPLE: An oil fired appliance firing at 1.0 gph where the CAS unit needs to be placed 30 equivalent feet from the intake hood.

From Diagram A or B, the point at 1.0 gph on the "Oil Firing Rate" scale and 30 equivalent feet falls in the "4 inch Duct, Hood, and Orifice Ring" region. The point is in between the left and right boundary of the region. The left boundary is the edge of the graph, the right boundary is the diagonal line that says "4 inch Duct, Hood & Orifice Ring." Therefore, place the Orifice Ring into the inlet on the CAS so that it sits on the ledge above the fan. It does not matter which way the Orifice Ring is turned as long as it is pushed down against the ledge completely. Use 4" diameter pipe to connect the vent hood and the CAS unit. Install a VRV and the included 4x6 Increaser on top of the CAS unit and adjust the balance weight to 3/4 of the distance of it's full adjustment range from it's minimum setting. The minimum setting is with the balance weight turned all of the way counterclockwise.

Table 1

|

Total Input of |

|

|

|

|

|

Maximum Equivalent Feet of Installation |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Appliance |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAS-3 |

|

|

4” Duct And Hood |

|

|

4” Duct And 4” |

|

|

|

6” Duct And 6” |

|

||||||||||

|

|

|

W/Restrictor |

|

|

Intake Air Hood |

|

|

|

Intake Air Hood |

|

|||||||||||

|

Oil (gph) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HI |

|

|

LOW |

|

|

HI |

|

|

|

LOW |

|

|

|

HI |

|

|

LOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.50 |

|

300 |

|

300 |

|

300 |

|

300 |

|

|

300 |

|

300 |

|

|||||||

|

0.75 |

|

300 |

|

300 |

|

300 |

|

300 |

|

|

300 |

|

300 |

|

|||||||

|

0.90 |

|

300 |

|

220 |

|

300 |

|

220 |

|

|

300 |

|

300 |

|

|||||||

|

1.00 |

|

174 |

|

108 |

|

232 |

|

118 |

|

|

300 |

|

300 |

|

|||||||

|

1.25 |

|

99 |

|

48 |

|

152 |

|

63 |

|

|

300 |

|

300 |

|

|||||||

|

1.35 |

|

52 |

|

14 |

|

102 |

|

32 |

|

|

300 |

|

300 |

|

|||||||

|

1.55 |

|

20 |

|

|

NA |

|

68 |

|

13 |

|

|

300 |

|

239 |

|

||||||

|

1.75 |

|

|

NA |

|

|

NA |

|

45 |

|

|

|

NA |

|

|

300 |

|

150 |

|

|||

|

2.00 |

|

|

NA |

|

|

NA |

|

16 |

|

|

|

NA |

|

|

300 |

|

53 |

|

|||

|

2.50 |

|

|

NA |

|

|

NA |

|

|

NA |

|

|

|

NA |

|

|

193 |

|

8 |

|

||

|

2.75 |

|

|

NA |

|

|

NA |

|

|

NA |

|

|

|

NA |

|

|

109 |

|

|

NA |

|

|

|

3.25 |

|

|

NA |

|

|

NA |

|

|

NA |

|

|

|

NA |

|

|

56 |

|

|

NA |

|

|

Page 3

HIGH SPEED SIZING CHART

OIL INPUT FIRING RATE (gallons per hour) (1 gallon oil/hr = 140,000 BTU/hr)

|

0.00 |

0.50 |

|

1.00 |

1.50 |

|

2.00 |

2.50 |

3.00 |

|

3.50 |

|

|

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6" Duct & Hood |

|

|

|

250 |

|

|

|

|

|

|

|

|

4" Duct & Hood |

|

|

|

|

|

|

|

|

|

|

|

4" Duct, Hood, & Orifice |

|

||

(ft.) |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

DUCT LENGTH |

200 |

|

|

|

|

|

|

|

|

|

|

|

150 |

|

|

|

|

|

|

|

|

|

|

|

|

MAX. EQUIVALENT |

|

|

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

GAS INPUT FIRING RATE (1000 BTU/hr.)

Diagram A

LOW SPEED SIZING CHART

OIL INPUT FIRING RATE (gallons per hour) (1 gallon oil/hr = 140,000 BTU/hr.)

|

0.00 |

|

0.50 |

1.00 |

1.50 |

|

2.00 |

2.50 |

|

|

300 |

|

|

|

|

|

|

|

|

|

250 |

|

|

|

|

|

6" Duct & Hood |

|

|

|

|

|

|

|

|

4" Duct & Hood |

|

||

(ft.) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

4" Duct & Hood w/ Orifice |

|

||

DUCT LENGTH |

200 |

|

|

|

|

|

|

|

|

150 |

|

|

|

|

|

|

|

|

|

MAX. EQUIVALENT |

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

0 |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

|

|

|

|

GAS INPUT FIRING RATE (1000 BTU/hr.) |

|

|

|

||

Diagram B

Page 4

Loading...

Loading...