Page 1

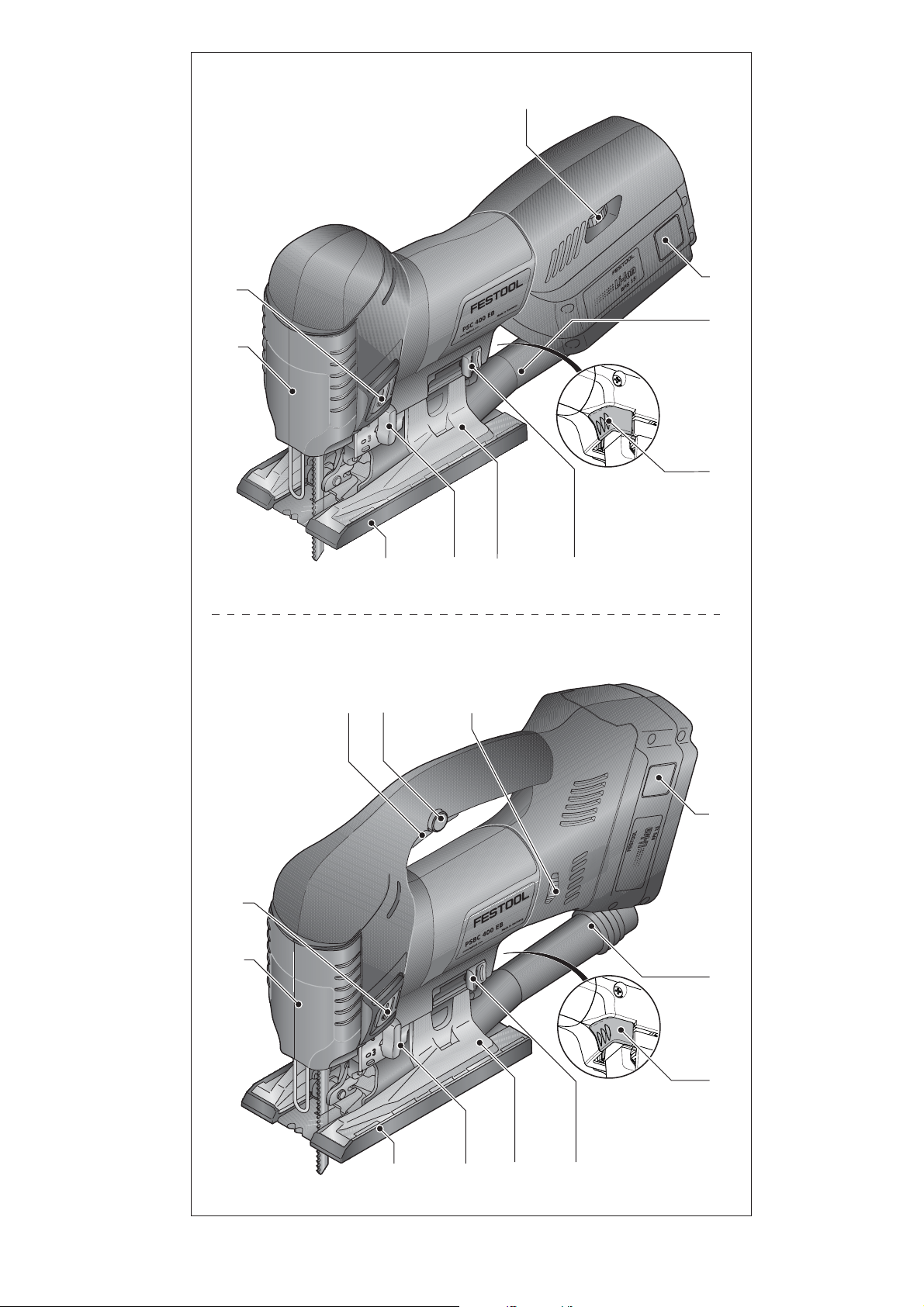

PSC 400 EB

1-5

1-2

1-1

PSBC 400 EB

1-6

1-7

1-8

1-91-101-111-12

1-51-3 1-4

1-2

1-1

1

1-6

1-7

1-8

1-91-101-111-12

Page 2

klick

2

3

4 mm

96 mm

3-1

Page 3

4-1

4-2

4-3

4

5

5-1

5-2

4-4

1.

2.

ca. 3 mm

6

6-1

6-2

6-3

Page 4

CARVEX

GB

Original operating manual

1 Symbols .................................. 15

2 Machine features ...................... 15

3 Intended use............................ 15

4 Technical data .......................... 15

5 Safety instructions .................... 16

6 Operation ................................ 17

7 Settings................................... 18

8 Working with the machine.......... 19

9 Service and maintenance ........... 20

10 Accessories .............................. 21

12 Disposal .................................. 22

13 Warranty ................................. 22

14 EU Declaration of Conformity...... 22

The illustrations specified are located at the beginning and end of the operating manual.

1Symbols

Warning of general danger

Risk of electric shock

Read the Operating Instructions/

Notes!

Wear a dust mask.

Wear ear protection.

Wear protective goggles.

Wear protective gloves.

Do not throw in the household waste.

2 Machine features

[1-1] Chip guard

[1-2]

[1-3]

[1-4]

[1-5]

[1-6]

[1-7] Extractor connector

[1-8] Saw table change lever

[1-9] Saw blade ejection

[1-10]Replaceable saw table

[1-11]Pendulum stroke switch

[1-12]Base runner

On/Off switch

Variable speed trigger (only PSBC 400 EB)

Switch lock (only PSBC 400 EB)

Adjusting wheel for stroke speed control

Buttons for releasing the battery pack

3Intended use

Jigsaws are designed for sawing wood and similar materials similar to wood. With the special

saw blades offered by Festool, these machines

can also be used for sawing plastic, steel, aluminium, non-ferrous metal and ceramic plates.

The charger TRC 3 is designed for charging the

battery packs listed.

The user bears the responsibility for damage and accidents caused by improper

use.

4 Technical data

Cordless jigsaws PSC 400 EB PSBC 400 EB

Motor voltage 10.8 - 18 V

Stroke speed 1500 - 3800 rpm 1000 - 3800 rpm

Stroke length 26 mm

Pendulum stroke 4 steps

max. inclination (only with accessory

angle table WT-PS 400)

max. cutting depth (depending on saw blade)

Wood 120 mm

Aluminium 20 mm

Steel 10 mm

Weight without battery pack 1.8 kg

Safety class /II

45° to both sides

15

Page 5

CARVEX

GB

Charger TRC 3

Mains voltage (input) 220 - 240 V ~

Mains frequency 50/60 Hz

Charging voltage (output) 7.2 - 18 V=

Rapid charging max. 3 A

Conservation charging current, pulsating (only NiCd, NiHM) approx. 0.06 A

Charging times for LiIon 1.3 Ah/ 2.6 Ah, 80 % approx. 22/ 45 min

LiIon 1.3 Ah/ 2.6 Ah, 100 % approx. 35/ 70 min

Permitted charging temperature range -5 °C to +45 °C

Temperature monitoring via NTC resistor

Battery pack BPS 12 Li BPC 12 Li BPS 15 Li BPC 15 Li BPS 18 Li

Voltage 10.8 V 10,8 V 14.4 V 14,4 V 18 V

Capacity 1.3 Ah 1,5 Ah 2.6 Ah 3,0 Ah 2.6 Ah/ 3,0 Ah

Weight 0.49 kg 0.30 kg 0.58 kg 0.55 kg 0.67 kg

5 Safety instructions

5.1 General safety instructions

WARNING! Read all safety warnings

and all instructions.

Failure to follow

the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

5.2 Machine-related safety instruc-

tions

–

Hold power tool by insulated gripping

surface, when performing an operation

where the cutting accessory may contact hidden wiring.

Cutting accessory contacting "live" wire may make exposed metal

parts of the power tool "live" and could give

the operator an electric shock.

The charger and power tool are not in-

–

tended for use by persons (including

children) with limited physical, sensory

or mental ability or without sufficient

experience and/or knowledge, unless

they are supervised by a person responsible for their safety or have been instructed on how the charger or power

tool is to be used.

Children should always be

supervised to ensure that they do not play

with the charger or the power tools.

–

Festool electric power tools must only be

installed on work tables provided by Festool for this purpose.

If the tool is installed in

–

– Do not open the battery pack or the charger. Even

– Make sure that metal objects (such as metal

– Do not charge battery packs from external

– Protect the battery pack from excessive heat

– Never use water to extinguish burning LiIon

– Deformed or cracked saw blades and saw

– Always place the pendulum jigsaw on the

– Wear suitable protection such as ear pro-

another, or self-made, work table, it can become unstable and result in serious accidents.

Wait until the power tool stops completely until placing it down.

The tool can

become entangled and lead to a loss of control of the power tool.

after disconnection from the mains, there is still a

high capacitor voltage inside the charger.

chips) or fluids do not collect in the battery pack

retaining slots or enter the machine through the

air vent slits (danger of short circuit).

manufacturers. The charger is designed for

charging original battery packs only. Never

charge the battery packs in chargers from

external manufacturers. Otherwise there is a

danger of fire and explosion.

or constant heat sources such as sunlight or

naked flames. There is a risk of explosion.

battery packs, always use sand or a fire blanket.

blades with blunt or broken cutting edges

must not be used.

workpiece with the saw blade running.

tection, safety goggles, a dust mask for

16

Page 6

CARVEX

GB

work which generates dust, and protective

gloves when working with raw materials

and when changing tools.

– Always secure the workpiece in such a man-

ner that it cannot move while being sawed.

– Always connect the machine to a dust ex-

tractor when work involves dust generation.

–

Stroboscopic light can cause epileptic

seizures.

Do not use this machine if you are

susceptible to epileptic seizures.

– Do not look into the stroboscope light. Looking

into the light source can damage your vision.

5.3 Metal processing

When processing metal, the following

measures must be taken for safety reasons:

– Connect the machine to a suitable dust ex-

tractor.

– Regularly remove dust deposits in the motor

housing.

– Use a metal saw blade.

– Close the chip guard.

Wear protective goggles.

5.4 Emission levels

Levels determined in accordance with EN

60745 are typically:

Sound pressure level L

Noise level L

Measuring uncertainty

= 88 dB(A)

PA

= 99 dB(A)

WA

K = 3 dB

allowance

CAUTION

Operating noise

Damage to hearing

X

Use ear protection!

Vibration emission value a

three directions) and uncertainty K measured in accordance with EN 60745:

(vector sum for

h

PSC 400 EB PSBC 400 EB

Sawing wood

Handle ah= 6,0 m/s2ah= 10.0 m/s

2

K = 2,0 m/s

2

2

Gear

head

K = 2,0 m/s

ah= 11,0 m/s

K = 2,0 m/s

2

2

Sawing metal

Handle ah= 7,0 m/s2ah= 11.0 m/s

2

K = 2,0 m/s

2

2

Gear

head

K = 2,0 m/s

ah= 12,0 m/s

K = 2,0 m/s

2

2

The emission values specified (vibration, noise)

were measured in accordance with the test

conditions stipulated in EN 60745 and are intended for machine comparisons. They are also

used for making preliminary estimates regarding vibration and noise loads during operation.

The emission values specified refer to the main

applications for which the power tool is used. If

the electric power tool is used for other applications, with other tools or is not maintained sufficiently prior to operation, however, the vibration and noise load may be higher when the tool

is used. Take into account any machine idling

times and downtimes to estimate these values

more accurately for a specified time period.

This may significantly reduce the load during

the machine operating period.

6Operation

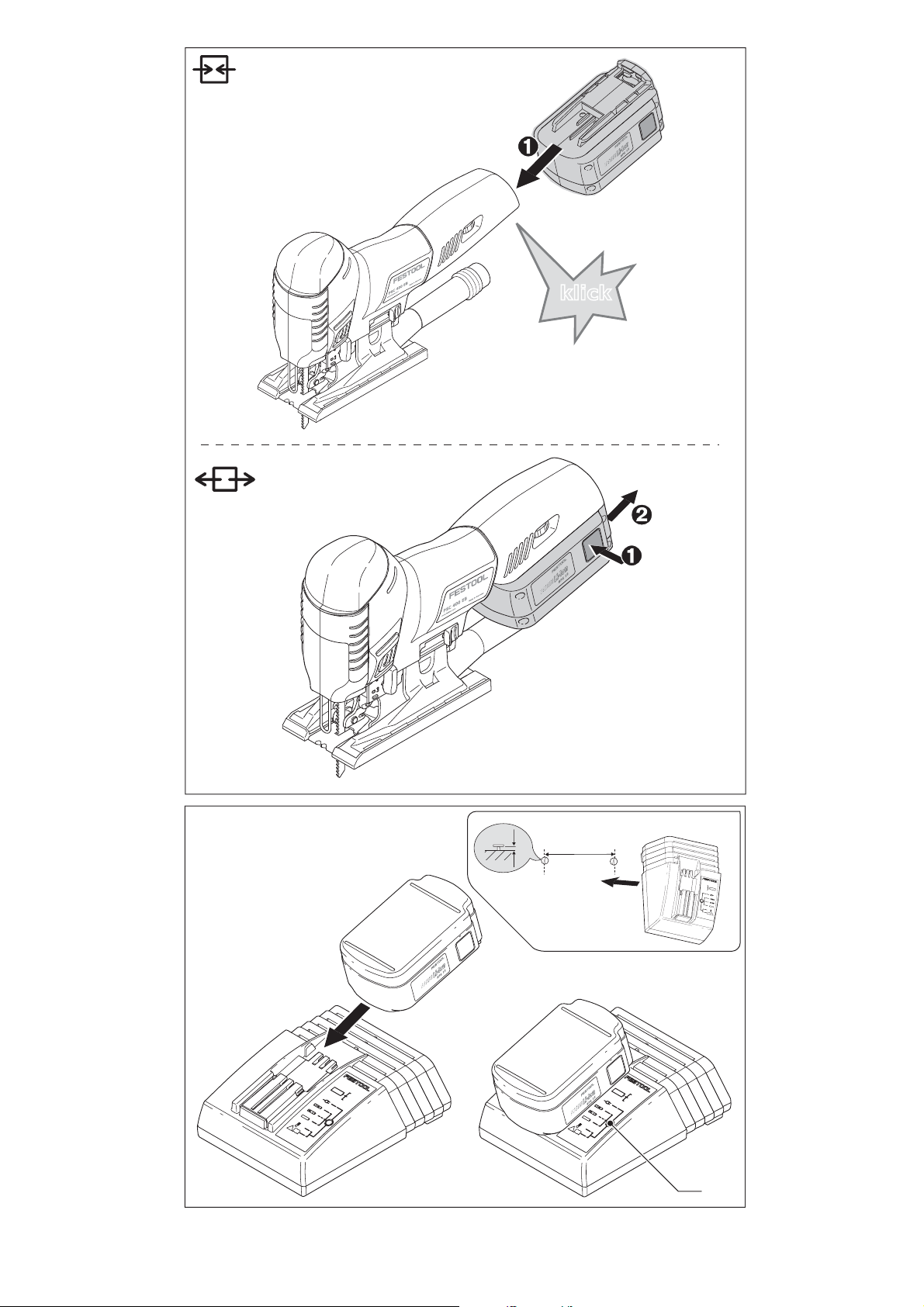

6.1 Changing the battery pack [2]

L

The cordless jigsaws can be charged using

any Festool battery pack from the

Ion and BPC

Risk of injury!

series.

Always remove the belt

clip from battery packs from the BPC series prior to use.

6.2 Switch on/off

The electric power tool has one button [1-2] on

each side for switching on/off.

The PSBC 400 EB also has a variable speed trigger [1-3] with switch lock [1-4]. For continuous

operation, use the button [1-2].

BPS Li-

6.3 Charging the battery pack [3]

L

The battery pack is delivered partially

charged. To guarantee the full battery power, charge it completely before using it for

the first time.

17

Page 7

GB

CARVEX

The charger TRC 3 can be used to charge all

Festool battery packs of the BPS and BPC series. The charger automatically detects the type

of the inserted battery (NiCd, NiMH or LiIon). A

microprocessor controls the charging process in

line with the charging state, temperature and

voltage of the battery pack.

The LED [3-1] on the charger indicates the respective operating status of the charger.

LED yellow - lit continuously

Charger is ready to use.

LED green - flashing quickly

Battery pack is charged to maximum capacity.

LED green - flashing slowly

Battery pack is charged with reduced current,

LiIon is charged to 80 %.

LED green - lit continuously

Battery pack is fully charged, or charging is not

started again, because the battery is charged

to more than 80 %.

LED red - flashing

General fault display, e.g. incomplete contact,

short circuit, battery pack faulty, etc.

LED red - lit continuously

Battery temperature is outside the permitted

range.

6.4 Charger wall mount

The charger TRC 3 has two elongated holes on

its back. It can be mounted on a wall using two

screws (e.g. round head or flat head screw with

shank diameter of 5 mm) (see Fig. [3]).

7 Settings

WARNING

Risk of injury, electric shock

X

Always disconnect the battery pack before

any type of work on the machine!

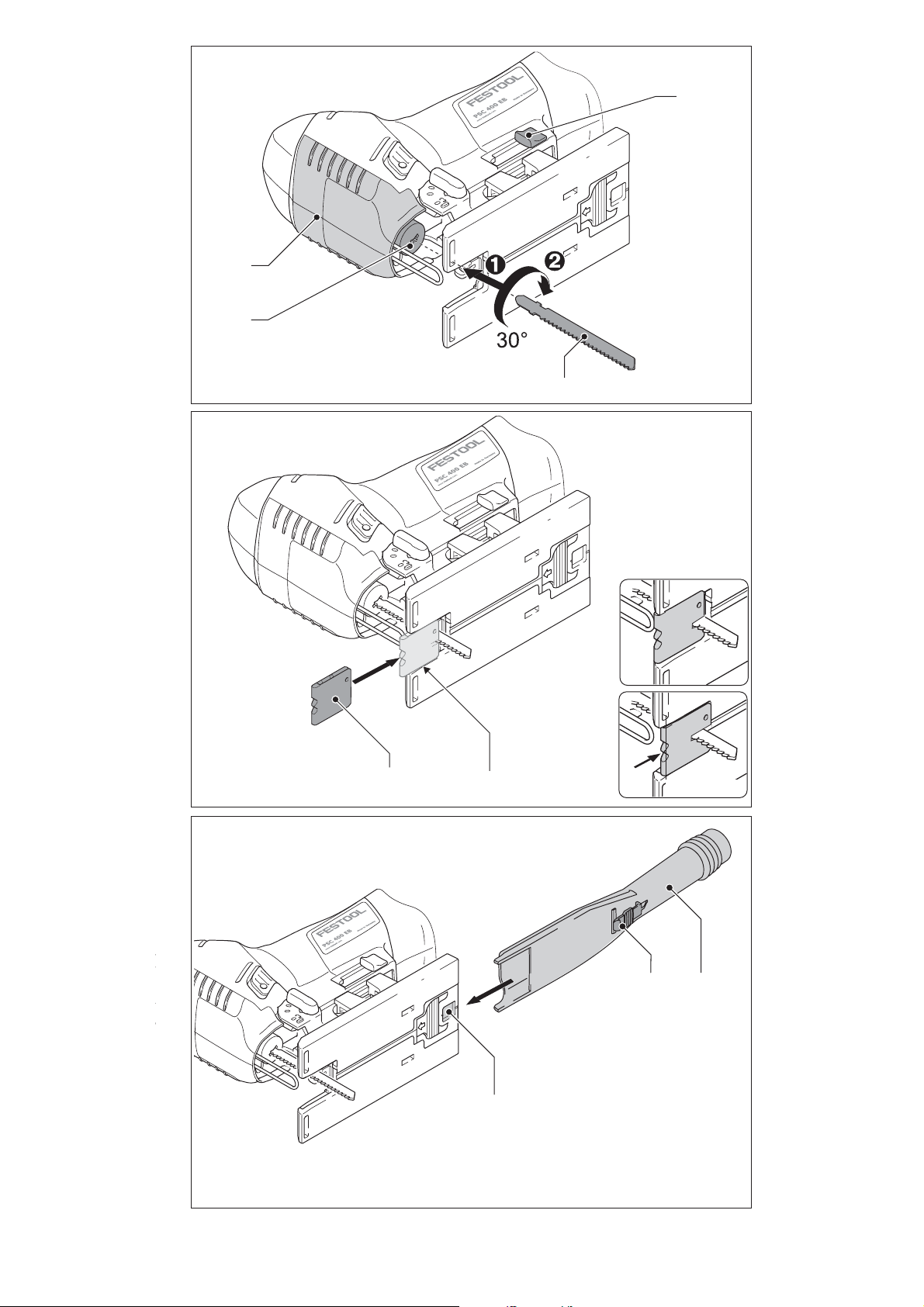

7.1 Changing tools

Selecting saw blade

Only use saw blades with a T-shank. The

saw blade should not be longer than that

required for the intended cut. To ensure

safe guidance, during the cut the saw blade

should emerge at the bottom of the workpiece

at every point.

L

Only use cross-set saw blades when using

the angle and adapter table. We recommend

Festool saw blade S 105/4 FSG.

Inserting saw blade

Always disconnect the battery pack from

the machine before every tool change!

X

If necessary, push the chip guard [4-1] upwards.

X

Push the saw blade [4-4] into the opening as

far as the stop with its teeth in cutting direction [4-2].

X

Turn the saw blade [4-4] approx. 30° clockwise until it engages.

The guidance jaws adjust automatically to the

saw blade used.

Check that the saw blade is secure. A

loose saw blade can fall out and cause an

injury.

L

In the case of very short saw blades, it is advisable to remove the saw table (see chap-

7.4

ter

) before inserting the saw blade.

Ejecting saw blade

L

When ejecting the saw blade, hold the electric power tool such that no persons or animals can be injured.

X

Push the saw blade ejection [4-3] forwards

as far as the stop.

If the saw blade is not ejected:

run jigsaw 3

- 10 seconds at a high speed. Actuate saw

blade ejector mechanism [4-3] once again.

7.2 Using the chip guard

The chip guard [4-1] prevents chips flying away

and improves the efficiency of the chip extraction system.

X

Using minimal pressure, push the chip guard

[4-1] downwards.

CAUTION

Hot and sharp tools

Risk of injury

X

Wear protective gloves!

18

7.3 Inserting splinterguard

The splinterguard makes cuts with splinter-free

cutting edges possible, even on the exit side of

the saw blade.

X

With the machine switched off, push the

splinterguard [5-1] onto the guide up to the

saw blade [5-2],

X

switch on the jigsaw,

Page 8

X

with the machine running (Speed range 5),

push the splinterguard in on a flat plane until it is flush with the front edge of the saw

table. This beds in the splinterguard.

L

When it is worn, push the splinterguard approx. 3 mm further to the rear and continue

using it.

L

To guarantee reliable operation of the splinterguard, it must seal tightly on both sides

of the saw blade. For splinter-free cuts,

therefore, a new splinterguard should also

be used after every saw blade change.

7.4 Changing saw table

X

Open the change lever [1-8].

X

Removing the saw table downwards.

L

Assembly is performed in reverse sequence

to removal. Ensure that the saw table is

firmly seated in the guide.

Instead of the saw table, the angle table WTPS 400 or adaptation table ADT-PS 400 can be

installed at the support.

Never saw without the saw table, or one

of the other tables offered in the Festool

accessories program.

7.5 Dust extraction

CARVEX

GB

7.6 Adjusting the pendulum stroke

The pendulum stroke on pendulum jigsaws can be

adjusted to machine different materials with the

correct rate of advance. Select the required setting using the pendulum stroke switch [1-11]:

Position 0 = pendulum stroke off

Position 3 = maximum pendulum stroke

Recommended pendulum stroke setting

Softwood, chip board, wood fibreboard 1 - 3

Blockboard, plywood, plastic 1 - 2

Ceramics 0

Aluminium, non-ferrous metals 0 - 2

Steel, hardwood 0 - 1

7.7 Stroke speed control

The number of strokes can be adjusted steplessly with the adjusting wheel [1-5] between

1500

and 3800 rpm (PSBC 400 EB:

rpm). This enables you to optimise the

3800

1000 -

cutting speed to suit the respective material.

A

In position

, the automatic load detection is

activated: The stroke speed is reduced in idling

and is controlled to the highest value when the

blade enters the workpiece.

WARNING

Dust hazard

X

Dust can be hazardous to health. Always

work with a dust extractor.

X

Always read applicable national regulations before extracting hazardous dust.

The extraction adapter [6-3] allows jigsaws to

be connected to a dust extractor (hose diameter 27 mm).

X

Insert the extraction adapter into the rear

opening of the saw table so that the hook

[6-2] engages in the [6-1] recess.

X

To remove the extraction adapter, press the

hook [6-2].

L

Due to the low power consumption of the

machine (low energy consumption), dust

extractors with an automatic switch-on

function will sometimes only start up

when the actual cut is made.

X

Set the dust extractor to continuous operation for special applications (e.g. low

stroke rate, soft wood).

Recommended stroke speed (position

of the adjusting wheel)

Hard and soft wood, plywood board,

A

plywood, chip board

Hardboard 4 - A

Plastic 3 - A

Ceramic, aluminium, non-ferrous metals

3 - 5

Steel 2 - 4

8 Working with the machine

CAUTION

Material with high dust generation (e.g.

plasterboard)

Damage to machine through dust penetration, risk of injury

X

Do not work overhead!

When working on small or thin workpieces, always use a stable base, or the CMS module (accessory).

When working, hold the electric power tool by

the handle and guide it along the desired cutting line. For precise cuts and smooth running,

use two hands to guide the electric power tool.

19

Page 9

GB

CARVEX

Freely guided sawing along a scribe mark

The triangular shape of the splinterguard [5-1]

points to the cutting line of the saw blade. This

facilitates sawing along a scribe mark.

8.1 Lighting

WARNING

The stroboscope light may make it difficult to determine the saw blade position

Risk of injury

X

Ensure the work area is well illuminated.

A continuous light or stroboscope is installed for

illuminating the cutting line:

up to approx. 2100 rpm: continuous light

from approx. 2100 rpm: stroboscope light

L

In overhead position (+/- 45°), the lighting

is switched off completely.

If required, you can adjust the lighting:

X

Press both buttons simultaneously [1-2] and

hold for approx. 10 s until a beep sounds.

X

Release both buttons [1-2].

X

Press the left button (on the pendulum

stroke side) to select the required mode:

Mode Display during

configuration

1 Light flashes with stroboscope

2Light on

3 Light off Light switched off

X

Press the right button to save the setting.

8.2 Acoustic warning signal

Acoustic warning signals sound and the machine switches off in the following operating

states:

peep ― ―

– Battery flat or machine overloaded.

X

Change the battery.

X

Place the machine under reduced stress.

peep peep ―

– Machine is overheating.

X

You must allow the machine to cool before

using again.

peep peep peep

Performance during operation

(standard)

Permanent light

without stroboscope

– LiIon battery pack is faulty or has overheated.

X

Once the battery pack has cooled, perform a

functional check using the charger.

9 Service and maintenance

WARNING

Risk of injury, electric shock

X

Always disconnect the battery pack from the

machine before any maintenance or care work!

X

All maintenance and repair work which requires the motor housing to be opened,

must only be carried out by an authorised

service workshop.

Damaged safety devices and components must

be repaired or replaced in a recognised specialist workshop, unless otherwise indicated in the

operating manual.

Observe the following instructions:

– Keep the air slits on the machine and the

charger free and clean to ensure adequate

cooling.

– Keep the contacts on the machine, charger

and battery pack clean.

– Check the guidance roller regularly for wear.

– Regularly remove dust deposits from the chip

guard.

– Regularly clean the base runner to prevent

scratches and cores on the surface.

Information on battery packs

– Where possible, store the battery pack in a

cool, dry place at a temperature between

5°C and 25 °C.

– Battery packs are most efficient at tempera-

tures between 20 °C and 30 °C.

– Protect the battery pack from moisture, wa-

ter and heat.

– Significantly shorter operating times after

each charge indicate that the battery pack is

worn and should be replaced with a new one.

– The LiIon battery pack is fully compatible

with the charger! Integrated electronics pre-

vent overloading and overheating during the

charging process.

– Do not leave flat battery packs in a charger

disconnected from the mains power supply

for longer than one month. There is a risk of

total discharge and the maximum power of

the battery pack may decrease.

– Store the battery pack in its packaging to re-

duce the risk of short circuits..

20

Page 10

CARVEX

GB

– If LiIon battery packs are to be stored for

long periods without use, they should be

charged to 40 % capacity (approx. 15 mins.

charging period).

10 Accessories

Angle table position Application

Picture [8A] Angle, interior angle

Picture [8B]

Picture [8C]

Use only original Festool accessories and Festool consumable material intended for this machine because these components are designed

specifically for the machine. Using accessories

and consumable material from other suppliers

will most likely affect the quality of your working results and limit any warranty claims. Machine wear or your own personal workload may

increase depending on the application. Protect

yourself and your machine, and preserve your

warranty claims by always using original Festool accessories and Festool consumable material!

The order numbers of the accessories and tools

can be found in the Festool catalogue or on the

Internet under "www.festool.com".

10.1 Saw blades, other accessories

In order to saw different materials quickly and

cleanly, Festool offers saw blades for all applications that are specially designed for your Festool jigsaw.

10.2 Sawing with special base runners

The special base runners protect high-quality

surfaces against scratches and scores.

X

Press in the base runner at position [7-1].

X

At the same time, push the base runner forwards.

X

Mount another base runner and push it to

the rear until it engages.

10.3 Sawing with the angle table

The angle table WT-PS 400 is used for sawing interior and exterior angles up to 45° and pipes.

Dust extraction is not possible when

sawing with the angle table!

Installing the angle table

X

Remove the saw table [1-10], (see chapter

X

Position the angle table against the saw ta-

7.4

).

ble support.

X

Close the change lever [1-8].

Ensure that the angle table is firmly seated in

the guide.

Setting the angle

X

Turn the adjusting wheel [8-1] to set the desired angle.

You can set the values -45°, 0° and +45° using

the scale [8-2].

Angle

Exterior angle, pipes

WARNING

Sawing cutting depths

Risk of injury

X

Select the saw blade length and cutting

depth so that the saw blade always stays

in the workpiece.

L

For 90° cuts, we recommend setting the angle table to a small negative degree value to

guarantee stable running.

10.4 Sawing with the adaptation table

The adaptation table ADT-PS 400 is used for fitting your jigsaw on the Festool guide rail and

the circle cutter KS-PS 400.

Installing the adaptation table

X

Remove the saw table [1-10], (see chapter

7.4

).

X

Mount the adaptation table [9-1] on the saw

table support.

X

Close the change lever [1-8].

Ensure that the adaptation table is firmly seated in the guide.

L

Use the extractor connector [1-7] also with

the adaptation table.

Adaptation to the guide rail FS 2

Using the Festool guide system FS 2 (Fig.

[10]) makes it easier to produce straight and

precise cuts, in particular, with material thicknesses up to 20 mm.

X

Place the jigsaw with attached adaptation

table [9-1] on the guide rail.

Adaptation to the circle cutter

The circle cutter can be used to create circular

cuts with a diameter between 120 and 3000

mm. The circle cutter can be installed from both

sides on the adaptation table.

X

Place the jigsaw with attached adaptation

table on the adapter [11-1] on the circle

cutter.

X

Insert the centring mandrel [11-2] in the

hole [11-4] on the circle cutter aligned with

the saw blade.

X

Clamp the measuring tape to the circle cutter using the rotary knob [11-5].

21

Page 11

GB

CARVEX

Recommended when using the circle cutter:

X

Cut in an anticlockwise direction.

X

Work at a slow rate of advance.

X

Set the pendulum stroke [1-11] to 0 - 1.

X

Set the stroke rate [1-5] to 1 - 5.

L

Store the centring mandrel in the depot [11-3].

11 Transport

The equivalent amount of lithium in the LiIon

battery pack is less than the applicable limit

value and certified as per UN manual ST/SG/

AC.10/11/rev. 3 part III, subsection 38.3. The

LiIon battery pack is therefore not subject to

national and international dangerous goods

regulations, neither as an individual component

nor as a fitted machine component. However,

dangerous goods regulations may apply when

several battery packs are transported, in which

case you may have to fulfil special conditions.

Refer to ADR special regulation 230 for more information relevant for the EU.

12 Disposal

Do not throw the power tool in your household

waste! Dispose of machines, accessories and

packaging at an environmentally responsible

recycling centre. Observe the valid national

regulations.

EU only:

ulates that used electric power tools must be

collected separately and disposed of at an environmentally responsible recycling centre.

Return used or faulty battery packs to your local

specialist retailer, Festool after-sales service or a

designated public waste management facility. The

battery packs will then be recycled. (Observe the

regulations applicable in your country). The batteries must be discharged on return.

EU only:

ulates that faulty or used battery packs/batteries must be recycled.

European Directive 2002/96/EC stip-

European Directive 91/157/EEC stip-

Complaints can only be accepted if the tool is

returned while still assembled to the supplier or

an authorised Festool Customer Service workshop. Keep the operating manual, safety instructions, spare parts list and purchase receipt

in a safe place. Otherwise the current warranty

conditions of the manufacturer shall apply.

Note

Due to continuous research and development

work, we reserve the right to make changes to

the technical content of this documentation.

14 EU Declaration of Conformity

Cordless jigsaw Serial no.

PSBC 400 EB 496059

PSC 400 EB 496058

Year of CE mark: 2010

We declare under sole responsibility that this

product complies with the following directives

and standards:

2006/42/EC, 2004/108/EC, EN 60745-1, EN EN

60745-2-11, EN 55014-1, EN 55014-2.

Charger Serial no.

TRC 3 494635, 494636, 494637

Year of CE mark: 2007

We declare under sole responsibility that this

product complies with the following directives

and standards:

2004/108/EC, 2006/95/EC, EN 60335-1, EN EN

60335-2-29, EN 61000-3-2, EN 61000-3-3, EN

61204-3.

Festool GmbH

Wertstr. 20, D-73240 Wendlingen, Germany

13 Warranty

We offer a warranty for material and production

defects for all our tools in accordance with the

locally applicable legal provisions, but for a

minimum of 12 months. Within the EU member

states, the warranty period is 24 months (verification through invoice or delivery note). Damage caused by the operator, natural wear, overloading, incorrect handling or through the use

of the equipment not specified in the operating

manual, or damage which was known at the

time of purchase, is not covered by the warranty. Furthermore, damage caused by the use of

non-original accessories and consumable materials (e.g. sanding pads) is also excluded.

22

Dr. Johannes Steimel

Head of Research, Development and Technical

Documentation

08.02.2010

REACh for Festool products, its accessories and consumable materials:

REACh is a European Chemical Directive that came into effect

in 2007. As "downstream users" and product manufacturers,

we are aware of our duty to provide our customers with information. We have set up the following website to keep you updated with all the latest news and provide you with information

on all the materials used in our existing products: www.fes-

tool.com/reach

Loading...

Loading...