Page 1

Instruction manual

Page 6

IMPORTANT:

Guide d’utilisation

Page 17

IMPORTANT:

les travaux.

Manual de instrucciones

Página 29

IMPORTANTE:

Read all instructions before using.

Lire toutes les instructions avant de démarrer

Lea totas las instrucciones antes de usar.

479367_002

Instruction manual

Guide d’utilisation

Manual de instrucciones

C 12 Li

C 15 Li

Page 2

Page 3

Page 4

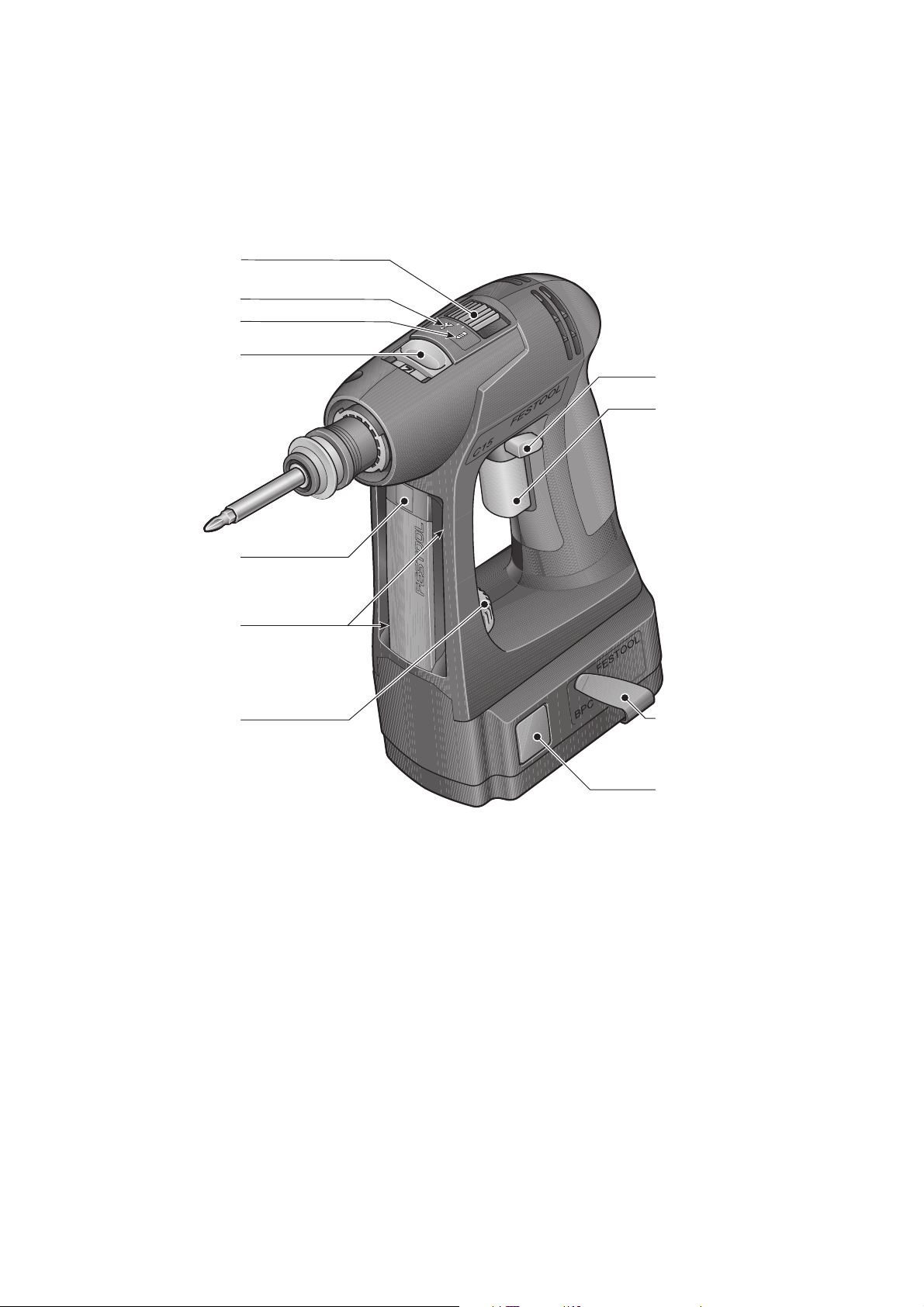

1-7

1-6

1-5

1-4

1-3

1-2

1-8

1-9

1-1

1-10

1-11

1

Page 5

Page 6

Contents

Symbols.................................. 6

Symbols

Safety instructions.................... 6

Technical data .......................... 8

Functional description ............... 9

Intended use ........................... 9

Operation ................................ 10

Settings .................................. 11

Tool holder, attachments............ 11

Working with the machine.......... 13

Service and maintenance........... 14

Accessories.............................. 14

Disposal .................................. 15

Transport................................. 15

Warranty ................................. 15

Vvolts

Aamperes

Hz hertz

~ alternating current

n

rpm revolutions per minute

no load speed

0

Class II Construction

diameter

tip, hint

Warning of general danger

Risk of electric shock

Read the Operating Instructions/

Notes!

Wear ear protection.

Wear protective gloves.

Safety instructions

General safety instructions

WARNING! Read all safety warnings and all instructions.

follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1 WORK AREA SAFETY

a)

Keep work area clean and well lit.

tered and dark areas invite accidents.

Do not operate power tools in explo-

b)

sive atmospheres, such as in the presence of flammable liquids, gases or

dust.

ignite the dust or fumes.

c)

Keep children and bystanders away

while operating a power tool.

tions can cause you to lose control.

Power tools create sparks which may

Failure to

Clut-

Distrac-

2 ELECTRICAL SAFETY

a)

Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with

earthed (grounded) power tools.

modified plugs and matching outlets will

reduce risk of electric shock.

Avoid body contact with earthed or

b)

grounded surfaces, such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

Do not expose power tools to rain or

c)

wet conditions.

tool will increase the risk of electric shock.

d)

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving

parts.

crease the risk of electric shock.

e)

When operating a power tool outdoors, use an extension cord suitable

for outdoor use.

Damaged or entangled cords in-

Water entering a power

Use of a cord suitable for

Un-

6

Page 7

outdoor use reduces the risk of electric

shock.

If operating a power tool in a damp lo-

f)

cation is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of elec-

tric shock.

3 PERSONAL SAFETY

a)

Stay alert, watch what you are doing

and use common sense when operating a power tool. Do not use a power

tool while you are tired or under the

influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious

personal injury.

b)

Use personal protective equipment.

Always wear eye protection.

Protective

equipment such as dust mask, non skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c)

Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying

the tool.

Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites accidents.

d)

Remove any adjusting key or wrench

before turning the power tool on.

wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e)

Do not overreach. Keep proper footing

and balance at all times.

This enables

better control of the power tool in unexpected situations.

f)

Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts.

Loose clothes, jewellery or long

hair can be caught in moving parts.

g)

If devices are provided for the connection of dust extraction and collection facilities, ensure these are

connected and properly used.

Use of

dust collection can reduce dust-related

hazards.

4 POWER TOOL USE AND CARE

a)

Do not force the power tool. Use the

correct power tool for your applica-

tion.

The correct power tool will do the job

better and safer at the rate for which it was

designed.

Do not use the power tool if the switch

b)

does not turn it on and off.

tool that cannot be controlled with the

switch is dangerous and must be repaired.

c)

Disconnect the plug from the power

source and/or battery pack from the

power tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or

these instructions to operate the power tool.

Power tools are dangerous in the

hands of untrained users.

e)

Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool‘s

operation. If damaged, have the power tool repaired before use.

dents are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean.

f)

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

A

and are easier to control.

Use the power tool, accessories and

g)

tool bits etc. in accordance with these

instructions taking into account the

working conditions and the work to be

performed.

Use of the power tool for operations different from those intended

could result in a hazardous situation.

5 BATTERY TOOL USE AND CARE

a)

Recharge only with the charger specified by the manufacturer.

is suitable for one type of battery pack may

create a risk of fi re when used with another battery pack.

b)

Use power tools only with specifically

designated battery packs.

other battery packs may create a risk of injury and fire.

c)

When battery pack is not in use, keep

it away from other metal objects like

paper clips, coins, keys, nails, screws,

or other small metal objects that can

Any power

Many acci-

A charger that

Use of any

7

Page 8

make a connection from one terminal

to another.

nals together may cause burns or a fire.

Under abusive conditions, liquid may

d)

be ejected from the battery; avoid

contact. If contact accidentally occurs,

fl ush with water. If liquid contacts

eyes, additionally seek medical help.

Liquid ejected from the battery may cause

irritation or burns.

6 SERVICE

a)

Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

ensure that the safety of the power tool is

maintained.

Shorting the battery termi-

This will

Machine-related safety

instructions

–

Wear ear protectors with impact drills.

Exposure to noise can cause hearing loss.

–

Use auxilliary handle supplied with

the tool.

sonal injury.

–

Hold power tools by insulated gripping

surface when performing an operation

where the cutting tool may contact

hidden wiring or its own cord.

with a "live" wire will mak exposed metal

Loss of controll can cause per-

Contact

parts of the tool "live" and shock the operator.

Health hazard by dust

WARNING!

power sanding, sawing, grinding, drill-

ing and other construction activities

contains chemicals known (to the State of

California) to cause cancer, birth defects or

other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemical-

lytreated lumber.

area, and work with approved safety equipment, such as dust masks that are specially

designed to filter out microscopic particles.

Wash hands after handling.

Various dust created by

The risk from these exposures varies, depending on

how often you do this type

of work. To reduce your exposure to these chemicals:

work in a well ventilated

WARNING

TO REDUCE THE RISK OF INJURY, USER

MUST READ INSTRUCTION MANUAL.

Technical data

Cordless drill C12 Li C15 Li

Motor voltage 10.8 – 12 V 14.4 – 15.6 V

Idling speed* 1st gear 0 - 450 rpm

2nd gear 0 - 1500 rpm

Max. torque Soft material (wood) 20 Nm 25 Nm

Hard material (metal) 34 Nm 40 Nm

Adjustable torque** 1st gear 0.5 - 8 Nm

2nd gear 0.5 - 6 Nm

Chuck clamping range 1.5 - 13 mm

Drill diameter max. Wood 25 mm 35 mm

Metal 14 mm 16 mm

Tool holder in drill spindle 1/4 ’’ 1/4 ’’

Weight without battery pack with Centrotec 0.9 kg 1.0 kg

8

Page 9

Charger TRC 3

Mains voltage (input) 120 V ~

Mains frequency 60 Hz

Charging voltage (output) 7.2 - 18 V (DC)

Rapid charging max. 3 A

Conservation charging current, pulsating approx. 0.06 A

Charging times for LiIon 1.3 Ah/ 2.6 Ah, 80 % approx. 22/ 45 min

LiIon 1.3 Ah/ 2.6 Ah, 100 % approx. 35/ 70 min

Permitted charging temperature range -5 °C to +45 °C

Temperature monitoring via NTC resistor

Battery pack BPC 12 Li BPC 15 Li

Order number 497019 497020

Voltage 10.8 V 14.4 V

Capacity 1.3 Ah 2.6 Ah

Weight 0.3 kg 0.6 kg

* Speed specifications with fully charged battery pack.

** The maximum speed is reduced in the

lower torque stages.

Functional description

The pictures for the functional description

are on a fold-out page at the beginning of the

instruction manual. When reading of the

manual you can fold out this page for having

always an overview of the machine.

[1-1] Torque thumbwheel

[1-2] Bit store

[1-3] LED lamp

[1-4] Gear switch

Intended use

Cordless drills are suitable for drilling into

metal, wood, plastics and similar materials

as well as inserting and tightening screws.

The charger TRC 3 is design for charging the

battery packs listed.

[1-5] Drilling symbol

[1-6] Screwdriving symbol

[1-7] Drilling/Fastening selector switch

[1-8] Right/left switch

[1-9] On/Off switch

[1-10] Belt clip

[1-11] Buttons for releasing the battery

pack

WARNING

The user bears the responsibility for

damage and accidents caused by improper use; this also includes damage

and wear caused by continuous use in

industry.

9

Page 10

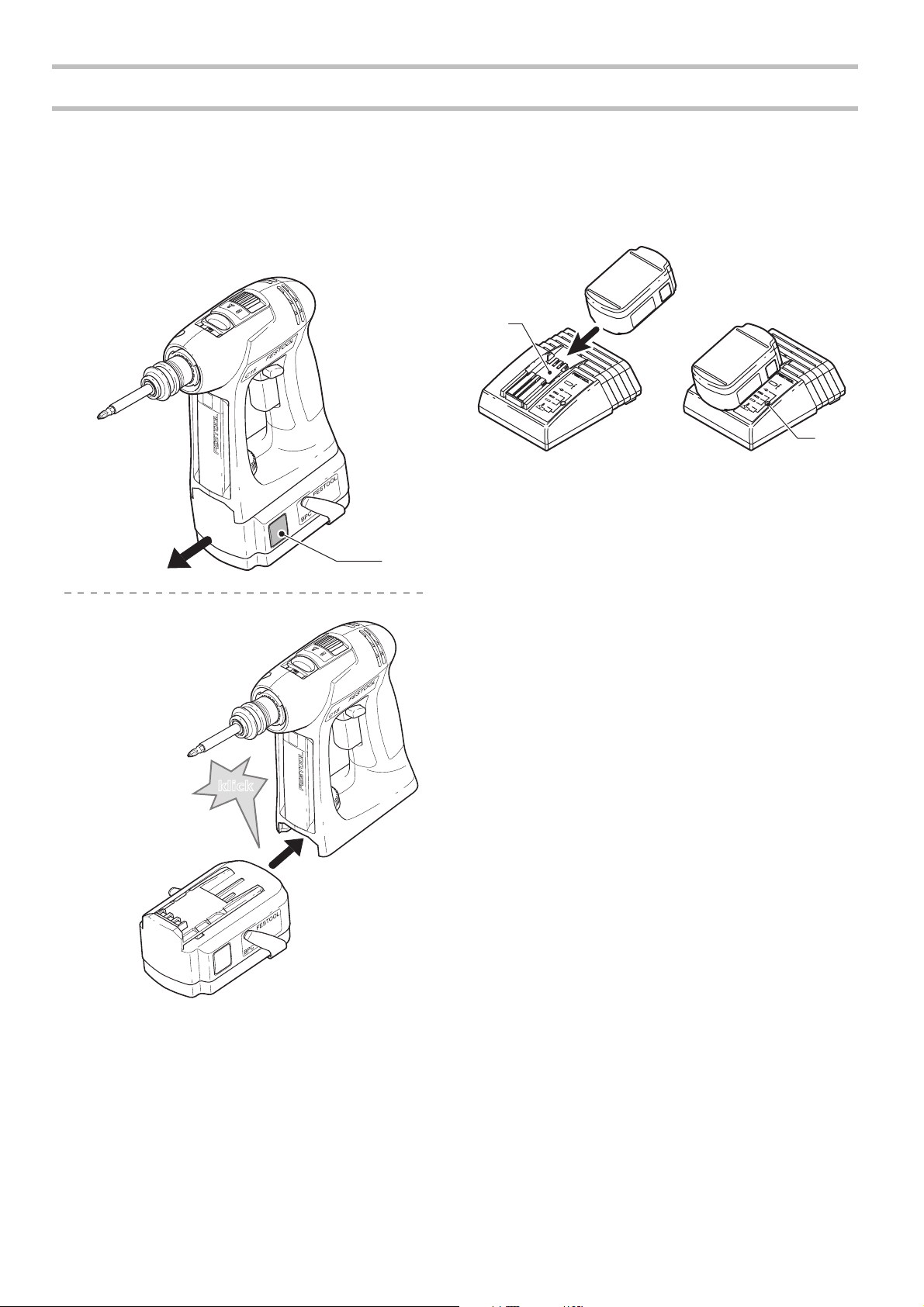

Changing the battery pack [2]

Removing the battery pack

X

Press and hold the two buttons [2-1].

X

Slide the battery pack forwards to remove.

remove

insert

Operation

X

X

3-1

The charger TRC 3 can be used to charge all

Festool battery packs of the BPS and BPC series. The charger automatically detects the

2-1

type of the inserted battery (NiCd, NiMH or

LiIon). A microprocessor controls the charging process in line with the charging state,

temperature and voltage of the battery pack.

The LED [3-2] on the charger indicates the

respective operating status of the charger.

To charge the battery pack, slide all the

way onto the retainer [3-1] on the charger.

To remove, slide off the charged battery

pack in similar fashion.

3-2

klick

2

Inserting the battery pack

X

Slide the battery pack onto the retainer

on the underside of the handle shown in

Fig. until it engages..

Charging the battery pack [3]

LED yellow - lit continuously

Charger is ready to use.

LED green - flashing quickly

Battery pack is charged to maximum capacity.

LED green - flashing slowly

Battery pack is charged with reduced current, LiIon is charged to 80 %.

LED green - lit continuously

Battery pack is fully charged, or charging is

not started again, because the battery is

charged to more than 80 %.

LED red - flashing

Battery temperature is outside the permitted

range.

LED red - lit continuously

General fault display, e.g. incomplete contact, short circuit, battery pack faulty, etc.

L

The battery pack is delivered partially

charged. Charge the battery pack completely before using for the first time.

10

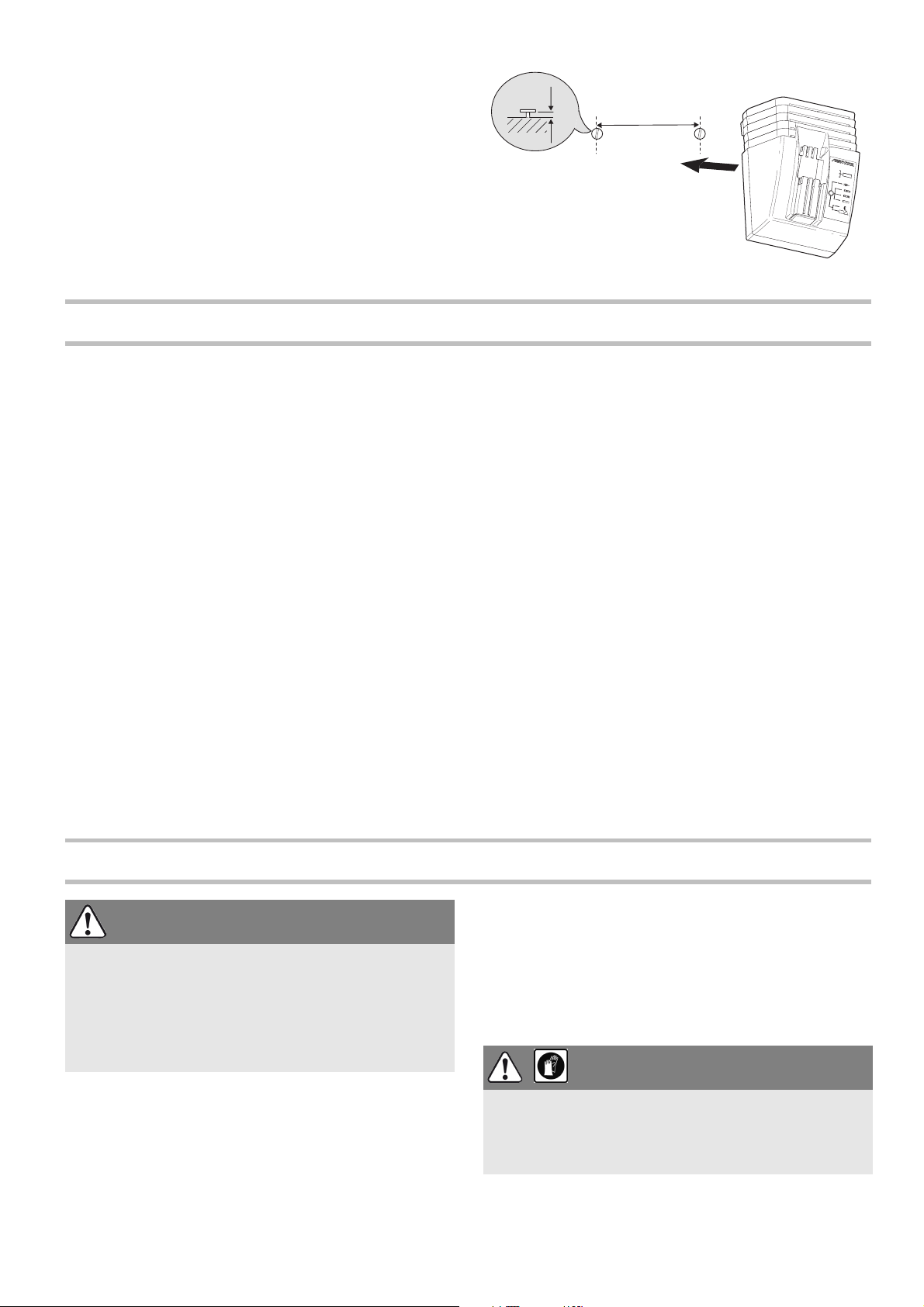

Charger wall mounting TRC 3

There are two elongated holes on the back of

the TRC 3 for mounting the charger to a wall

Page 11

using two screws (e.g. round head or flat

4 mm/

0.16''

96 mm/

3.78 ''

head screw with shank diameter of 5 mm).

X

Insert the two screws into the wall at a

distance of 96 mm from one another and

leave the screw heads protruding approx.

4mm.

Settings

Consider the pictures on the fold-out page.

Changing the direction of rotation

The right/left switch [1-8] changes the direc-

tion of rotation.

• Move switch from right to left = clockwise

rotation

• Move switch from left to right = anticlockwise rotation

Changing gear

L

Always switch off the machine before

changing gear!

You can change gear using the gear switch

[1-4].

• Switch forwards (Number 1 visible) = first

gear

• Switch backwards (Number 2 visible) =

second gear

Fastening

Adjust the switch [1-7] so that its marking

faces the screw symbol [1-6]. The torque

can be adjusted in this position.

L

The switch-over function only works if the

machine is switched off.

X

Adjust the torque accordingly at the

torque wheel [1-1]:

Position 1 = low torque

Position 25 = high torque

The machine switches off when the preset

torque is reached and an acoustic signal

sounds. The machine only continues running

when the on/off switch [1-9] is released and

then pressed again.

Drilling

Adjust the switch [1-7] so that its marking

faces the drilling symbol [1-5]. Maximum

torque is set in this position.

Risk of injury

X

Make sure that the machine is switched off

and the battery pack has been removed

before changing the tool holding fixure,

attachments and tools.

WARNING

Tool holder, attachments

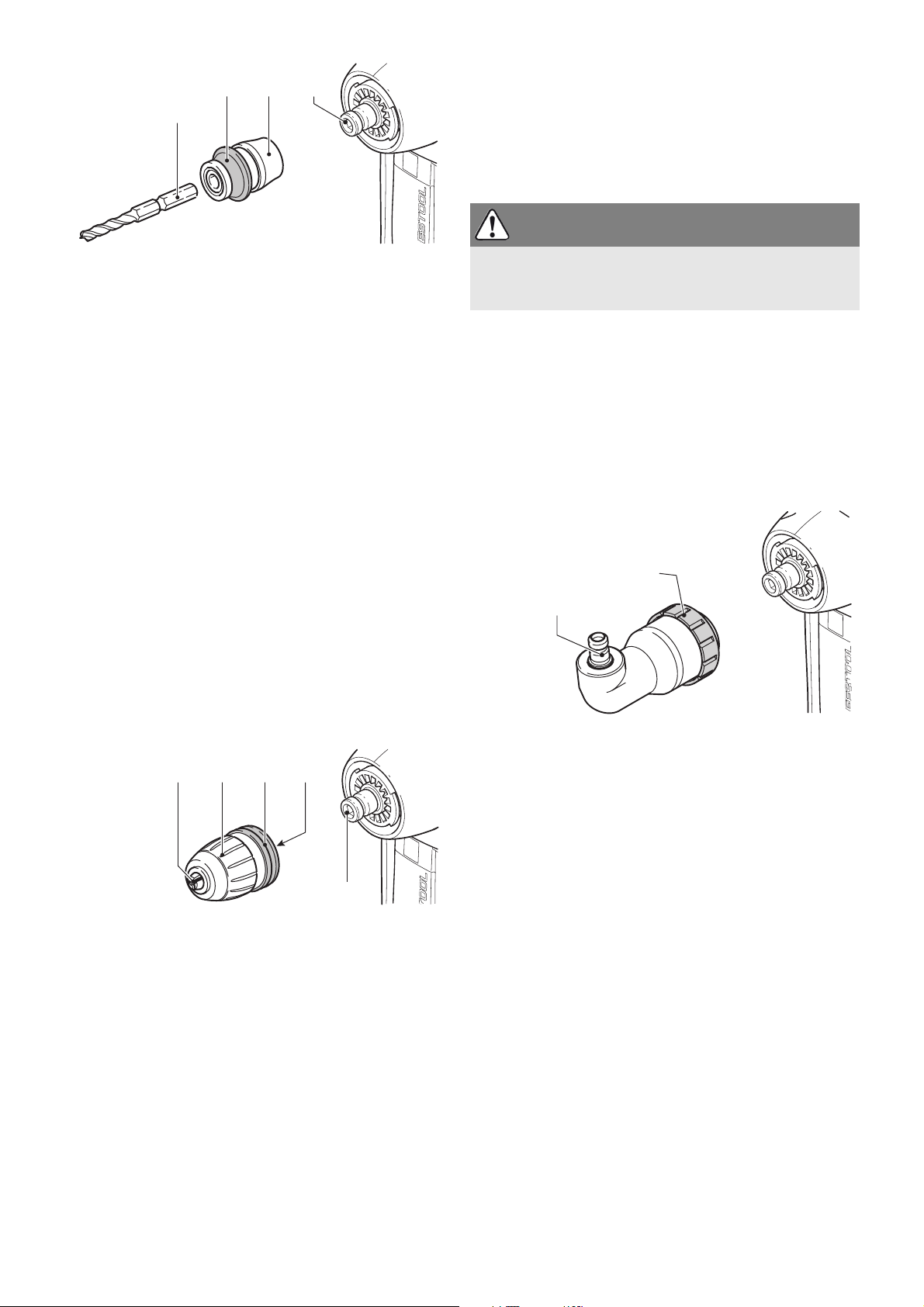

Tool chuck CENTROTEC WH-CE

The tool chuck CENTROTEC WH-CE allows

you to change tools with a CENTROTEC

shank in a matter of seconds.

L

Always use a CENTROTEC tool chuck to

clamp CENTROTEC tools.

Risk of cutting injuries when changing

the tool!

X

Wear protectiv gloves!

CAUTION

11

Page 12

WH-CE

DD-AS

2-7

1-7

CENTROTEC

®

5-1

5-2 5-3 5-4

Changing tools

X

Turn the clamping sleeve [6-2] anticlockwise to open the clamping jaws [6-1].

L

The arrow on the spindle indicates the

opening direction.

X

Insert the tool into the chuck.

CAUTION

Attaching the CENTROTEC

X

Pull the release ring [5-3] forwards.

X

Attach the tool chuck to the drill spindle

[5-4].

X

Release the ring [5-3].

Detaching the CENTROTEC

X

Pull the release ring [5-3] forwards.

X

Remove the tool chuck.

Changing tools

X

Pull back the green release ring [5-2] to

attach or detach tools with a CENTROTEC

shank.

X

When attaching the tool, rotate until the

hexagon shank [5-1] engages in the

hexagon holder on the drill spindle.

X

Release the ring [5-2].

Chuck BF-FX

The chuck BF-FX is used for clamping drill

and screwdriver bits.

BF-FX

Attaching the chuck BF-FX

X

Attach the chuck to the drill spindle [6-5].

X

Pull the release ring [6-3] forwards.

X

Turn until the hexagon pin [6-4] on the

chuck engages in the hexagon socket

holder in the drill spindle.

X

Push the chuck all the way onto the drill

spindle.

X

Release the ring [6-4].

Detaching the chuck BF-FX

X

Pull the release ring [6-4] forwards.

X

Remove the chuck.

6-2

6-3 6-46-1

6-5

Risk of injury

X

Clamp the tool centrally in the chuck!

X

Turn the clamping sleeve [6-2] clockwise

to clamp the tool.

Angle attachment DD-AS

The angle attachment DD-AS (partly accessories) allows you to work (drill, fasten) vertically in relation to the longitudinal axis on

the machine.

Fitting the angle attachment DD-AS

X

Fit the angle attachment to the drill spindle.

X

Turn the attachment until is engages in

the required position.

L

You can engage the angle attachment in

16 different positions.

X

Turn the securing ring [7-2] firmly clockwise to lock the angle attachment.

Removing the angle attachment DD-AS

X

Turn the securing ring [7-2] anticlockwise

all the way.

X

Remove the angle attachment.

Attaching/Detaching the chuck

The chuck is secured to the shaft [7-1] of the

angle attachment and the drill spindle on the

machine in the same way.

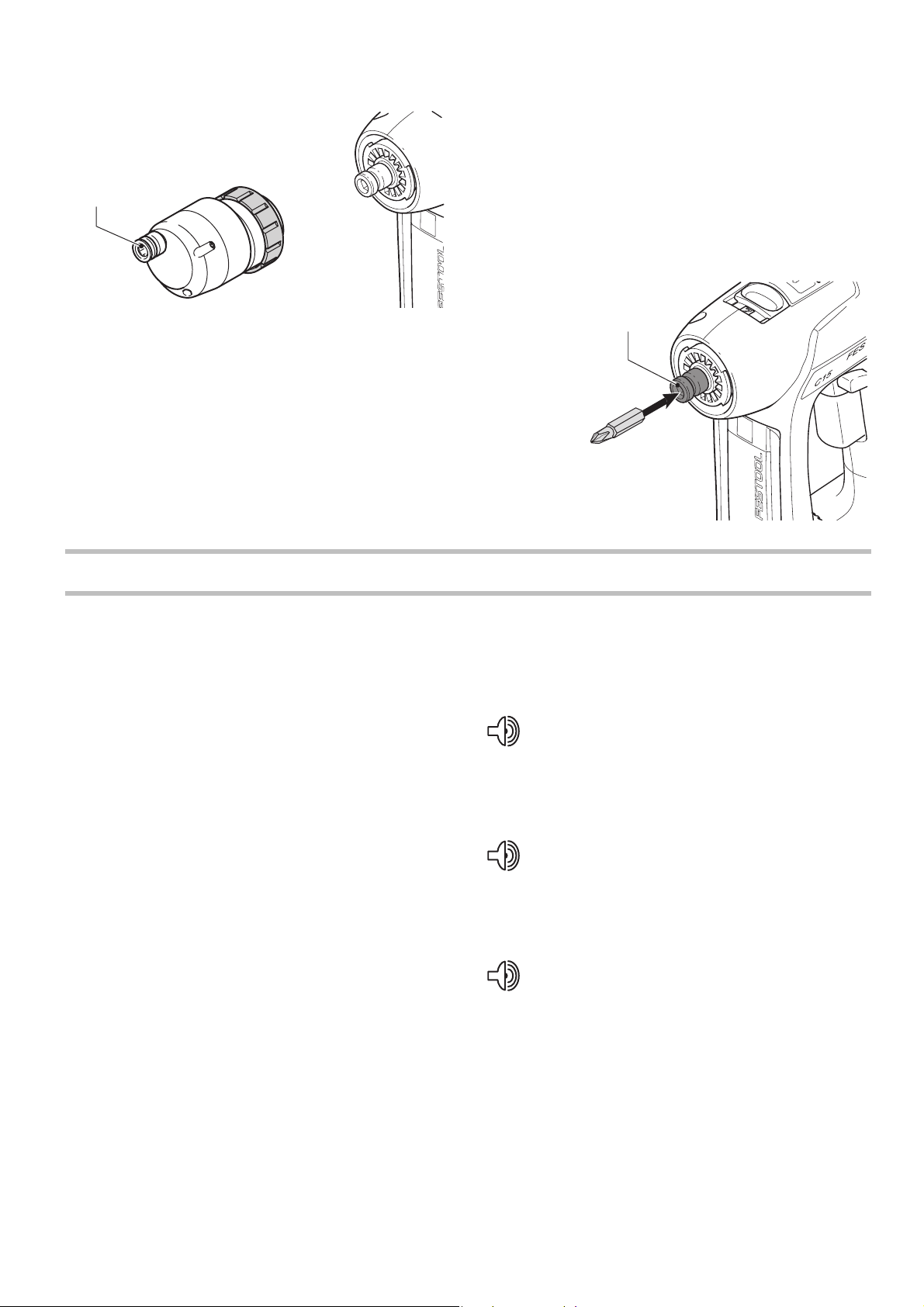

Eccentric attachment DD-ES

The eccentric attachment (partly accessories) enables you to fasten close to abutting

12

Page 13

edges. The tool holder was designed for bits

9-1

in accordance with DIN 3126.

DD-ES

Attaching/Detaching the chuck

The chuck is secured to the shaft [8-1] of the

eccentric attachment and the drill spindle on

the machine in the same way.

Tool holder in the drill spindle

1-8

Attaching/Detaching eccentric attachment DD-ES

The eccentric attachment is attached/detached in the same way as the angle attachment (Section "Angle attachment DD-AS").

Working with the machine

Consider the pictures on the fold-out page.

Bits can be inserted directly in the hexagon

socket holder on the drill spindle [9-1] to

shorten and reduce the weight of the machine.

Acoustic warning signal

Switch on/off

The switch [1-9] is an on/off switch (press =

ON, release = OFF).

L

The speed of the machine depends on

how far the ON/OFF switch is pressed in.

L

When the ON/OFF switch is released, the

working spindle (chuck) stops immediately.

The LED lamp [1-3] lights up when the on/off

switch [1-9] is pressed and lights up the

working area.

Bit store

Bits or bit holders are inserted sideways into

the bit store [1-2].

Acoustic warning signals sound and the machine switches off in the following operating

states:

peep ― ―

– Battery flat or machine overloaded.

X

Change the battery.

X

Place the machine under reduced stress.

peep peep ―

– Machine is overheating.

X

You must allow the machine to cool before

using again.

peep peep peep

– LiIon battery pack is faulty or has over-

heated.

X

Once the battery pack has cooled, perform a functional check using the charger.

13

Page 14

Service and maintenance

10-1

10-2

10-3

WARNING

Any maintenance or repair work that

requires opening of the motor or gear

housing should only be carried out by

an authorised Customer Service Centre

(name supplied by your dealer)!

X

Maintenance or repair work carried out by

an unauthorised person can lead to the

wrong connection of the power leads or

other components, which in turn can lead

to accidents with serious consequences.

Observe the following instructions:

– Keep the air slits on the machine and the

charger free and clean to ensure adequate

cooling.

– Keep the contacts on the machine, charger

and battery pack clean.

Information on battery packs

– Where possible, store the battery pack in a

cool, dry place at a temperature between

5°C and 25 °C.

– Battery packs are most efficient at temper-

atures between 20 °C and 30 °C.

– Protect the battery pack from moisture,

water and heat.

– Significantly shorter operating times after

each charge indicate that the battery pack

is worn and should be replaced with a new

one.

– The LiIon battery pack is fully compatible

with the charger! Integrated electronics

prevent overloading and overheating during the charging process.

– Do not leave flat battery packs in a charger

disconnected from the mains power supply

for longer than one month. There is a risk

of total discharge and the maximum power

of the battery pack may decrease.

– Store the battery pack in its packaging to

reduce the risk of short circuits..

– If LiIon battery packs are to be stored for

long periods without use, they should be

charged to 40 % capacity (approx.

15 mins. charging period).

Accessories

Use only original Festool accessories and

Festool consumable material intended for

this machine because these components are

designed specifically for the machine. Using

accessories and consumable material from

other suppliers will most likely affect the

quality of your working results and limit any

warranty claims. Machine wear or your own

personal workload may increase depending

on the application. Protect yourself and your

machine, and preserve your warranty claims

by always using original Festool accessories

and Festool consumable material!

The accessory and tool order number can be

found in yout festool catalog or on the Internet at „www.festool-usa.com“.

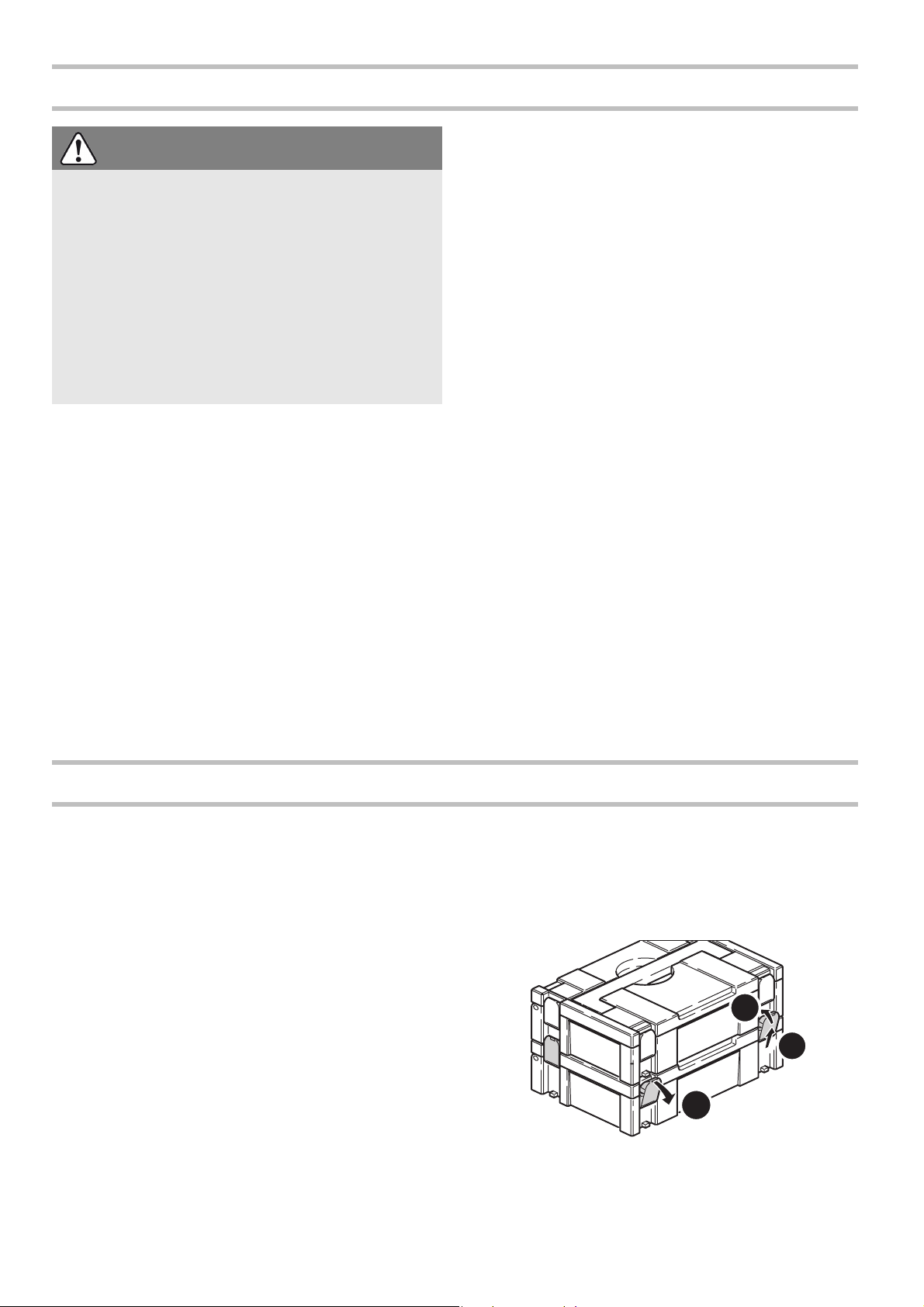

Systainer

Many Festool products are shipped in a

unique system container, called "Systainer".

This provides protection and storage for the

tool and accessories. The Systainers are

stackable and can be interlocked together.

They also can be interlocked atop Festool CT

dust extractors.

X

Place one systainer on top of the other.

X

Release all four latches on the lower systainer by pulling back at their top edges

[10-1].

14

Page 15

X

Slide all four latches upward [10-2].

X

Snap all four latches back to their flat position [10-3] so they engage the stacking

tabs of the upper systainer.

Disposal

Do not throw the power tool in your

household waste!!

Dispose of machines,

accessories and packaging at an environ-

Transport

The equivalent amount of lithium in the LiIon

battery pack is less than the applicable limit

value and certifi ed as per UN manual ST/SG/

AC.10/11/rev. 3 part III, subsection 38.3.

The LiIon battery pack is therefore not subject to national and international dangerous

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty

(1 year + 2 years = 3 years) for your Festool

power tool. Festool shall be responsible for

all shipping costs during the first year of the

warranty. During the second and third year

of the warranty the customer is responsible

for shipping the tool to Festool. Festool will

pay for return shipping to the customer using

UPS Ground Service. All warranty service is

valid 3 years from the date of purchase on

your receipt or invoice.

Festool Limited Warranty

This warranty is valid on the pre-condition

that the tool is used and operated in compliance with the Festool operating instructions.

Festool warrants, only to the original consumer purchaser, that the specified tool will

be free from defects in materials and workmanship for a term of one year from the date

of procurement. Festool makes no other warranty, express or implied, for Festool portable power tools. No agent, representative,

distributor, dealer or employee of Festool has

the authority to increase or otherwise

change the obligations or limitations of this

warranty. The obligations of Festool in its

sole discretion under this warranty shall be

limited to the repair or replacement of any

mentally responsible recycling centre. Observe the valid national regulations.

goods regulations, neither as an individual

component nor as a fitted machine component. However, dangerous goods regulations

may apply when several battery packs are

transported, in which case you may have to

fulfil special conditions

Festool portable power tool that is found to

be defective as packaged with the User Manual.

Excluded from coverage under this warranty

are: normal wear and tear; damages caused

by misuse, abuse or neglect; damage caused

by anything other than defects in material

and workmanship. This warranty does not

apply to accessory items such as circular saw

blades, drill bits, router bits, jigsaw blades,

sanding belts, and grinding wheels. Also excluded are “wearing parts”, such as carbon

brushes, lamellas of air tools, rubber collars

and seals, sanding discs and pads, and batteries.

Festool portable power tools requiring replacement or repair are to be returned with

the receipt of purchase to Festool (call 800554-8741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF

THIS OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED WHATSOEVER.

ALL WARRANTIES IMPLIED BY STATE

LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE,

15

Page 16

ARE HEREBY LIMITED TO THE DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian

provinces do not allow the limitations on how

long an implied warranty lasts, so the above

limitation may not apply to you. With the exception of any warranties implied by state or

province law as hereby limited, the foregoing

express limited warranty is exclusive and in

lieu of all other warranties, guarantees,

agreements and similar obligations of Festool.

This warranty gives you specific legal rights

and you may also have other rights which

vary from state to state in the U.S. and province to province in Canada.

16

Page 17

Sommaire

Symboles ................................ 17

Symboles

Consignes de sécurité ............... 17

Caractéristiques techniques........ 20

Description functionnelle............ 21

Utilisation en conformité avec les ins-

tructions.................................. 21

Mise en service ........................ 22

Réglages ................................. 23

Porte-outil, embouts ................. 23

Travail avec la machine ............. 25

Entretien et maintenance........... 26

Accessoires.............................. 27

Recyclage................................ 27

Transport................................. 27

Garantie.................................. 27

VVolt

AAmpère

Hz Hertz

~Tension alternative

n

tr/

min

Vitesse de rotation à vide

0

Classe II conception

tours ou course par minute

Diamètre

Information, astuce

Avertissement de danger général

Risque d'électrocution

Lire les instructions / les remarques !

Port d'une protection acoustique !

Consignes de sécurité

Consignes de sécurité d'ordre gé-

néral

ATTENTION ! Lire toutes les consignes de sécurité et indications.

non-respect des avertissements et instructions indiqués ci-après peut entraîner un

choc électrique, un incendie et/ou de graves

blessures.

Conserver tous les avertissements et

toutes les instructions pour pouvoir s'y

reporter ultérieurement.

Le terme " outil " dans les avertissements fait

reference à votre outil électrique alimenté

par le secteur (avec cordon d'alimentation)

ou votre outil fonctionnant sur batterie (sans

cordon d'alimentation).

1 PLACE DE TRAVAIL

a)

Maintenez l'endroit de travail propre

et bien éclairé.

sordre ou mal éclairé augmente le risque

d'accidents.

N'utilisez pas l'appareil dans un envi-

b)

ronnement présentant des risques

Un lieu de travail en dé-

Le

Porter des gants de protection !

d'explosion et où se trouvent des liquides, des gaz ou poussières inflammables.

génèrent des étincelles risquant d'enflammer les poussières ou les vapeurs.

Tenez les enfants et autres personnes

c)

éloignés durant l'utilisation de l'outil

électroportatif.

risquez de perdre le contrôle sur l'appareil.

2 SECURITE RELATIVE AU SYSTEME

ELECTRIQUE

a)

La fiche de secteur de l'outil électroportatif doit être appropriée à la prise

de courant. Ne modifiez en aucun cas

la fiche. N'utilisez pas de fiches

d'adaptateur avec des appareils avec

mise à la terre.

et les prises de courant appropriées réduisent le risque de choc électrique.

Evitez le contact physique avec des

b)

surfaces mises à la terre tels que

tuyaux, radiateurs, fours et réfrigérateurs.

Les outils électroportatifs

En cas d'inattention vous

Les fiches non modifiées

Il y a un risque élevé de choc élec-

17

Page 18

trique au cas où votre corps serait relié à la

terre.

N'exposez pas l'outil électroportatif à

c)

la pluie ou à l'humidité.

La pénétration

d'eau dans un outil électroportatif augmente le risque d'un choc électrique.

N'utilisez pas le câble à d'autres fins

d)

que celles prévues, n'utilisez pas le

câble pour porter l'appareil ou pour

l'accrocher ou encore pour le débrancher de la prise de courant. Maintenez

le câble éloigné des sources de chaleur, des parties grasses, des bords

tranchants ou des parties de l'appareil

en rotation.

Un câble endommagé ou torsadé augmente le risque d'un choc électrique.

Au cas où vous utiliseriez l'outil élec-

e)

troportatif à l'extérieur, utilisez une

rallonge autorisée homologuée pour

les applications extérieures.

L'utilisation d'une rallonge électrique homologuée

pour les applications extérieures réduit le

risque d'un choc électrique.

Si l'usage d'un outil dans un emplace-

f)

ment humide est inévitable, utiliser

une alimentation protégée par un dispositif à courant différentiel résiduel

(RCD).

L'usage d'un RCD réduit le risque

de choc électrique.

avant de retirer la fiche de la prise de

courant.

Le fait de porter l'appareil avec le

doigt sur l'interrupteur ou de brancher

l'appareil sur la source de courant lorsque

l'interrupteur est en position de fonctionnement, peut entraîner des accidents.

Enlevez tout outil de réglage ou toute

d)

clé avant de mettre l'appareil en fonctionnement.

Une clé ou un outil se trouvant sur une partie en rotation peut causer

des blessures.

Ne surestimez pas vos capacités.

e)

Veillez à garder toujours une position

stable et équilibrée.

Ceci vous permet de

mieux contrôler l'appareil dans des situations inattendues.

Portez des vêtements appropriés. Ne

f)

portez pas de vêtements amples, ni de

bijoux. Gardez les cheveux et les vêtements à distance des pièces mobiles.

Des vêtements amples, des bijoux ou des

cheveux longs peuvent être happés par les

pièces en mouvement.

Si des dispositifs servant à aspirer ou

g)

à recueillir les poussières doivent être

utilisés, vérifiez que ceux-ci soient effectivement raccordés et qu'ils sont

correctement utilisés.

L'utilisation de

tels dispositifs réduit les dangers dus aux

poussières.

3 SECURITE DES PERSONNES

a)

Restez vigilant, surveillez ce que vous

faites. Faites preuve de bon en utilisant l'outil électroportatif. N'utilisez

pas l'appareil lorsque vous êtes fatigué ou après avoir consommé de l'alcool, des drogues ou avoir pris des

médicaments.

Un moment d'inattention

lors de l'utilisation de l'appareil peut entraîner de graves blessures sur les personnes.

Portez des équipements de protec-

b)

tion. Portez toujours des lunettes de

protection.

Le fait de porter des équipements de protection personnels tels que

masque anti-poussières, chaussures de

sécurité antidérapantes, casque de protection ou protection acoustique suivant le

travail à effectuer, réduit le risque de blessures.

Evitez une mise en service par mégar-

c)

de. Assurez-vous que l'interrupteur

est effectivement en position d'arrêt

4 UTILISATION ET EMPLOI SOIGNEUX

DE L'OUTIL ELECTROPORTATIF

a)

Ne surchargez pas l'appareil. Utilisez

l'outil électroportatif approprié au travail à effectuer.

Avec l'outil électroportatif approprié, vous travaillerez mieux et

avec plus de sécurité à la vitesse pour laquelle il est prévu.

N'utilisez pas un outil électroportatif

b)

dont l'interrupteur est défectueux.

Un

outil électroportatif qui ne peut plus être

mis en ou hors fonctionnement est dangereux et doit être réparé.

Retirer la fiche de la prise de courant

c)

avant d'effectuer des réglages sur

l'appareil, de changer les accessoires,

ou de ranger l'appareil.

Cette mesure de

précaution empêche une mise en fonctionnement par mégarde.

Gardez les outils électroportatifs non

d)

utilisés hors de portée des enfants. Ne

permettez pas l'utilisation de l'appareil à des personnes qui ne se sont pas

18

Page 19

familiarisées avec celui-ci ou qui n'ont

pas lu ces instructions.

troportatifs sont dangereux lorsqu'ils sont

utilisés par des personnes non initiées.

Prenez soin des outils électroporta-

e)

tifs. Vérifiez que les parties en mouvement fonctionnent correctement et

qu'elles ne soient pas coincées, et

contrôlez si des parties sont cassées

ou endommagées de telle sorte que le

bon fonctionnement de l'appareil s'en

trouve entravé. Faites réparer les parties endommagées avant d'utiliser

l'appareil.

dus à des outils électroportatifs mal entretenus.

Maintenez les outils de coupe aiguisés

f)

et propres.

tretenus avec des bords tranchants bien

aiguisés se coincent moins souvent et peuvent être guidés plus facilement.

Utilisez les outils électroportatifs, les

g)

accessoires, les outils à monter etc.

conformément à ces instructions et

aux prescriptions en vigueur pour ce

type d'appareil. Tenez compte également des conditions de travail et du

travail à effectuer.

électroportatifs à d'autres fins que celles

prévues peut entraîner des situations dangereuses.

5 UTILISATION ET EMPLOI SOIGNEUX

DES APPAREILS SANS FIL

a)

Ne chargez les accumulateurs que

dans des chargeurs recommandés par

le fabricant.

type spécifique d'accumulateur peut engendrer un risque d'incendie lorsqu'il est

utilisé avec d'autres accumulateurs.

Dans les outils électroportatifs, n'uti-

b)

lisez que les accumulateurs spécialement prévus pour celui-ci.

de tout autre accumulateur peut entraîner

des blessures et des risques d'incendie.

Tenez l'accumulateur non-utilisé à

c)

l'écart de toutes sortes d'objets métalliques tels qu'agrafes, pièces de

monnaie, clés, clous, vis ou autres,

étant donné qu'un pontage peut provoquer un court-circuit.

De nombreux accidents sont

Des outils soigneusement en-

L'utilisation des outils

Un chargeur approprié à un

Les outils élec-

L'utilisation

Un court-circuit

entre les contacts d'accu peut provoquer

des brûlures ou un incendie.

En cas d'utilisation abusive, du liquide

d)

peut sortir de l'accumulateur. Evitez

tout contact avec ce liquide. En cas de

contact par mégarde, rincez soigneusement avec de l'eau. Au cas où le liquide rentrerait dans les yeux,

consultez en plus un médecin.

de qui sort de l'accumulateur peut entraîner des irritations de la peau ou causer des

brûlures.

6 SERVICE

a)

Ne faites réparer votre outil électroportatif que par un personnel qualifié

et seulement avec des pièces de rechange d'origine.

la sécurité de l'appareil.

Ceci permet d'assurer

Le liqui-

Consignes de sécurité spécifiques

à la machine

–

Portez une protection acoustique lors

de l'utilisation de perceuses à percussion.

pertes auditives.

Utilisez les poignées additionnelles

–

fournies avec l'outil électrique.

du contrôle de l'outil électrique peut entraîner des blessures.

Tenez l'appareil uniquement au ni-

–

veau des surfaces isolées de la poignée lorsque vous effectuez des

travaux au cours desquels la vis risque

de toucher des câbles électriques cachés.

sous tension peut également mettre des

pièces métalliques de l'appareil sous tension et provoquer un choc électrique.

L'effet du bruit peut occasionner des

perte

Le contact de la vis avec un câble

La poussière, un risque

pour la santé

AVERTISSEMENT!

res créées par le ponçage mécanique,

le sciage, le meulage, le perçage et

autres activités reliées à la construction contiennent des substances chimiques connues

(dans l’État de la Californie) comme pouvant

causer le cancer, des anomalies congénitales

ou représenter d’autres dangers pour la reproduction. Voici quelques exemples de telles substances:

Certaines poussiè-

19

Page 20

• plomb provenant de peintures à base de

plomb,

• silice cristallisée utilisée dans les briques,

le ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’oeuvre traité

avec un produit chimique.

d’exposition à ces substances chimiques :

travaillez dans un endroit adéquatement

ventilé et utilisez un équipement de sécurité

approuvé, tel que masques antipoussières

spécialement conçus pour filtrer les particules microscopiques.

AVERTISSEMENT

Le risque d’exposition à de

tels produits varie selon la

fréquence à laquelle vous

faites ce genre de travail.

Pour réduire les risques

POUR RÉDUIRE LE RISQUE DE DOMMAGES, L'UTILISATEUR DOIT LIRE LE MANUEL D'INSTRUCTION.

Caractéristiques techniques

Perceuses-visseuses sans fil C12 Li C15 Li

Tension du moteur 10,8 - 12 V 14,4 - 15,6 V

Vitesse à vide * 1ère vitesse 0 - 450 tr/mn

2ème vitesse 0 - 1500 tr/min

Couple max. Cas de vissage "doux"

(bois)

Cas de vissage "dur"

(métal)

Couple réglable ** 1ère vitesse 0,5 - 8 Nm

2ème vitesse 0,5 - 6 Nm

Mandrin de perçage, plage de serrage 1,5 - 13 mm

Diamètre de perçage max. Bois 25 mm 35 mm

Métal 14 mm 16 mm

Porte-outil dans la broche de perçage 1/4 ’’ 1/4 ’’

Poids sans batterie, avec mandrin Centrotec 0,9 kg 1,0 kg

Chargeur TRC 3

Tension de réseau (entrée) 120 V ~

Fréquence du réseau 60 Hz

Tension de charge (sortie) 7.2 - 18 V (DC)

Charge rapide max. 3 A

20 Nm 25 Nm

34 Nm 40 Nm

Charge de maintien, pulsée env. 0.06 A

Temps de charge pour LiIon 1.3 Ah/ 2.6 Ah, 80 % env. 22/ 45 minutes

LiIon 1.3 Ah/ 2.6 Ah, 100 % env. 35/ 70 minutes

Plage de température de charge admissible -5 °C a +45 °C

Surveillance de la température au moyen d’une résistance

CTN

20

Page 21

Batterie BPC 12 Li BPC 15 Li

Référence 497019 497020

Tensi on 10,8 V 14,4 V

Capacité 1,3 Ah 2,6 Ah

Poids 0,3 kg 0,6 kg

* Indications de vitesse de rotation avec batterie entièrement chargée.

** La vitesse de rotation maximale est réduite dans les plages de couple inférieures.

Description functionnelle

Des eléments fournis sont disponibles sur le

volet qui se trouve au début de cette notice

d'utilisation. Vous pouvez ainsi déplier cette

page et visualiser en permanence les différentes parties de l'outil lorsque vous lisez la

notice.

[1-1] Molette de réglage du couple

[1-2] Support d’embouts

[1-3] Lampe à LED

[1-4] Commutateur de vitesses

Utilisation en conformité avec les instructions

Les perceuses-visseuses sans fi l sont appropriées pour le perçage dans le métal, le bois,

les matières plastiques et autres matériaux

similaires, ainsi que pour le vissage et le serrage de vis.

Le chargeur TRC 3 est conçu pour la charge

des batteries indiquées.

[1-5] Symbole de perçage

[1-6] Symbole de vissage

[1-7] Commutateur perçage / vissage

[1-8] Commutateur pour rotation à droite

/ rotation à gauche

[1-9] Interrupteur de marche/arrêt

[1-10] Clip-ceinture

[1-11] Touches pour desserrer l’accumula-

teur

AVERTISSEMENT

L'utilisateur est responsable des dommages et accidents provoqués par une

utilisation non conforme; cela concerne

également les endommagements et

usures du fait d’un fonctionnement industriel continu.

21

Page 22

Mise en service

Remplacement de la batterie [2]

Retirer la batterie

X

Pressez les deux touches [2-1].

X

Retirez la batterie par l'avant.

retirer

2-1

insérer

X

Insérez la batterie à charger jusqu'en butée, dans le logement [3-1] du chargeur.

X

Vous pouvez retirer la batterie chargée

dans le sens inverse.

3-1

3-2

Le chargeur TRC 3 permet de charger toutes

les batteries Festool des séries BPS et BPC.

Le chargeur reconnaît automatiquement le

type de batterie inséré (NiCd, NiMH ou Liion). Un microprocesseur pilote le processus

de charge, en fonction de l'état de charge, de

la température et de la tension de la batterie.

La LED [3-2] du chargeur indique l'état de

service respectif du chargeur.

klick

2

Insérer la batterie

X

Insérez la batterie jusqu'à l'enclenchement dans le logement sur la partie inférieure de la poignée, comme indiqué sur

la figure.

Charge de la batterie [3]

LED jaune - allumée en continu

Le chargeur est opérationnel.

LED verte - clignotement rapide

La batterie est chargée avec le courant maximal.

LED verte - clignotement lent

La batterie est chargée avec un courant réduit, la batterie Li-ion est chargée à 80 %.

LED verte - allumée en continu

Le processus de charge est terminé ou n'est

pas redémarré, étant donné que l'état de

charge actuel est supérieur à 80 %.

LED rouge - clignotement

La température de la batterie est en-dehors

des valeurs limites admissibles.

LED rouge - allumée en continu

Affichage de défaut général, p. ex. pas de

contact total, court-circuit, batterie défectueuse, etc.

L

La batterie est livrée partiellement chargée. Avant la première utilisation, chargez

entièrement la batterie.

22

Fixation murale du chargeur TRC 3

Le chargeur TRC 3 est pourvu sur sa face arrière de deux trous oblongs. Il peut être fixé

à un mur au moyen de deux vis (p. ex. vis à

Page 23

tête demi-ronde ou vis à tête plate, avec un

4 mm/

0.16''

96 mm/

3.78 ''

diamètre de tige de 5 mm).

X

Vissez les deux vis dans le mur à une distance de 96 mm, de manière à ce que les

têtes de vis se trouvent encore à env.

4mm du mur.

Réglages

Attention aux illustrations au début de la présente notice d’utilisation.

Commutation du sens de rotation

Le commutateur gauche - droite [1-8] vous

permet de définir le sens de rotation.

• Commutateur de la droite vers la gauche

= rotation à droite

• Commutateur de la gauche vers la droite

= rotation à gauche.

Commutation du réducteur

L

Actionner la commutation du réducteur

uniquement lorsque l'appareil est à l'arrêt.

Le commutateur de vitesses [1-4] vous permet de commuter le réducteur.

• Commutateur vers l'avant (chiffre 1 visible) = 1ère vitesse

• Commutateur vers l'arrière (chiffre 2 visible) = 2ème vitesse

Vissage

Réglez le commutateur inverseur [1-7] de

manière à ce que son repère soit pointé sur

le symbole de vissage [1-6]. Le couple peut

être réglé dans cette position.

L

La commutation fonctionne uniquement

lorsque la machine est arrêtée.

X

Réglez le couple via la molette de réglage

du couple [1-1] :

Position 1 = petit couple,

Position 25 = grand couple

La machine s'arrête en atteignant le couple

réglé et un signal sonore indique l'atteinte de

la valeur de désactivation. La machine redémarre seulement après avoir relâché et pressé à nouveau l'interrupteur de marche/arrêt

[1-9].

Perçage

Réglez le commutateur inverseur [1-7] de

manière à ce que son repère soit pointé sur

le symbole de perçage [1-5]. Le couple maximal est réglé dans cette position.

Risque de blessures

X

A chaque remplacement du porte-outil, du

groupe d’appui et de l’outil, assurez-vous

que la machine est convenablement inactivée et que l’accumulateur est enlevé..

Porte-outil, embouts

AVERTISSEMENT

Mandrin CENTROTEC WH-CE

Le mandrin CENTROTEC WH-CE permet un

remplacement rapide des outils avec tige

CENTROTEC.

L

Montez uniquement les outils CENTROTEC

dans le mandrin CENTROTEC.

23

Page 24

ATTENTION

DD-AS

2-7

1-7

Lors du remplacement d'outil, l'outil

peut occasionner des blessures par

coupure !

X

Portez des gants de protection !

WH-CE

CENTROTEC

®

5-2 5-3 5-4

5-1

Montage du mandrin CENTROTEC

X

Tirez la bague de déverrouillage [5-3]

vers l'avanct.

X

Montez le mandrin jusqu'en butée sur la

broche de la perceuse [5-4].

X

Relâchez la bague de déverrouillage [5-

3].

Démontage du mandrin CENTROTEC

X

Tirez la bague de déverrouillage [5-3]

vers l'avant.

X

Retirez le mandrin.

Remplacement d'outil

X

Pour monter ou démonter un outil avec

tige CENTROTEC, tirez la bague de déverrouillage verte [5-2] en arrière.

X

Lors du montage, tournez l'outil jusqu'à

ce que sa tige à six pans [5-1] s'engage

dans le logement six pans de la broche de

la perceuse.

X

Relâchez la bague de déverrouillage [5-

2].

Mandrin de perçage BF-FX

Le mandrin de perçage BF-FX sert au serrage

de forets et d'embouts.

Montage du mandrin de perçage BF-FX

X

Montez le mandrin de perçage sur la broche de la perceuse [6-5].

X

Tirez la bague de déverrouillage [6-3]

vers l'avant.

X

Tournez-la jusqu'à ce que la broche carrée

[6-4] du mandrin de perçage s'engage

dans le logement six pans creux de la broche de la perceuse.

X

Pressez le mandrin de perçage jusqu'en

butée sur la broche de la perceuse.

X

Relâchez la bague de déverrouillage [6-

4].

Démontage du mandrin de perçage BFFX

X

Tirez la bague de déverrouillage [6-4]

vers l'avant.

X

Retirez le mandrin de perçage.

Remplacement d'outil

X

Tournez la douille de serrage [6-2] dans

le sens inverse des aiguilles d'une montre,

afin d'ouvrir les mâchoires de serrage [6-

1].

L

La flèche se trouvant sur la broche indique

le sens de rotation pour l'ouverture.

X

Montez l'outil dans le mandrin de perçage.

ATTENTION

Risques de blessures

X

Serrez l'outil de façon centrée dans le

mandrin !

X

Tournez la douille de serrage [6-2] dans le

sens des aiguilles d'une montre, afin de

serrer l'outil.

Renvoi d'angle DD-AS

Le renvoi d'angle DD-AS (certaines sont des

accessoires) permet de travailler (percer,

visser) perpendiculairement par rapport à

l'axe longitudinal de la machine.

24

BF-FX

6-2

6-3 6-46-1

6-5

Page 25

Montage du renvoi d'angle DD-AS

9-1

X

Montez le renvoi d'angle sur la broche de

la perceuse.

X

Tournez-le jusqu'à ce qu'il s'engage dans

la position souhaitée.

L

Le renvoi d'angle peut être fixé dans 16

positions angulaires différentes.

X

Tournez la bague de fixation [7-2] dans le

sens des aiguilles d'une montre, afin de

verrouiller le renvoi d'angle.

Démontage du renvoi d'angle DD-AS

X

Tournez la bague de fixation [7-2] dans le

sens inverse des aiguilles d'une montre,

jusqu'en butée.

X

Retirez le renvoi d'angle.

Montage / démontage du mandrin de

perçage

Le mandrin de perçage est fixé sur l'arbre [7-

1] du renvoi d'angle de la même manière que

sur le broche de la perceuse.

Montage / démontage du module excentrique DD-ES

Le montage / démontage du module excentrique s'effectue de manière analogue au

montage / démontage du renvoi d'angle

(chapitre "Renvoi d'angle DD-AS").

Montage / démontage du mandrin de

perçage

Le mandrin de perçage est fixé sur l'arbre [8-

1] du module excentrique de la même ma-

nière que sur le broche de la perceuse.

Porte-outil dans la broche de la

perceuse

Afin d'alléger et de raccourcir la longueur de

la machine, les embouts peuvent être montés directement dans le logement six pans

creux de la broche de la perceuse [9-1].

Module excentrique DD-ES

Le module excentrique DD-ES (certaines

sont des accessoires) permet un vissage au

ras des bords. Le porte-outil est conçu pour

des embouts selon DIN 3126.

DD-ES

1-8

Travail avec la machine

Attention aux illustrations au début de la présente notice d’utilisation.

Marche/Arrêt

L'interrupteur [1-9] fait office d'interrupteur

de marche/arrêt (pression = MARCHE, relâchement = ARRET).

L

La vitesse de rotation est réglable en

fonction de la pression sur l'interrupteur

MARCHE / ARRET.

L

Après avoir relâché l'interrupteur MARCHE / ARRET, la broche (mandrin de perçage) est freinée, ce qui empêche une

marche par inertie de l'outil.

La lampe à LED [1-3] est allumée lorsque

l'interrupteur de marche/arrêt [1-9] est

pressé et éclaire la zone de travail.

Support d'embouts

Des embouts ou des porte-embouts peuvent

être insérés latéralement dans le support

d'embouts [1-2].

25

Page 26

Signaux d'avertissement sonores

Des signaux d'avertissement sonores retentissent lors des états de fonctionnement suivants et la machine s'arrête :

peep ― ―

– Batterie déchargée ou machine surchar-

gée.

X

Remplacez la batterie.

X

Réduisez la charge de la machine.

Entretien et maintenance

AVERTISSEMENT

Tout travail de maintenance ou de réparation, qui nécessite l'ouverture du moteur ou du carter d'engrenages doit

uniquement être effectué par un centre

service-client autorisé (nom fourni par

votre revendeur) !

X

Les travaux de maintenance ou de réparation effectués par un personnel non autorisé peuvent conduire à la mauvaise

connexion de câbles d'alimentation ou

d'autres composants, ce qui peut entraîner à son tour des accidents avec des conséquences graves.

Observez les consignes suivantes :

– Maintenez les ouvertures d'aération sur la

machine électrique et sur le chargeur dans

un état propre, afin de garantir le refroidissement.

– Maintenez les contacts de raccordement

sur la machine électrique, le chargeur et la

batterie dans un état propre.

Remarques concernant les batteries

– Stockez de préférence les batteries dans

un endroit sec et frais, dans une plage de

température comprise entre 5 °C et

25 °C.

– La capacité de rendement optimale des

batteries est obtenue dans une plage de

peep peep ―

– La machine est surchauffée.

X

Après refroidissement, vous pouvez remettre la machine en marche.

peep peep peep

– La batterie Li-ion est surchauffée ou défec-

tueuse.

X

Contrôlez sa capacité de fonctionnement

avec le chargeur, avec la batterie refroidie.

température comprise entre 20 °C et

30 °C.

– Protégez les batteries contre l'humidité et

l'eau, ainsi que contre la chaleur.

– Une durée d'utilisation nettement raccour-

cie après chaque charge indique que la

batterie est usagée et qu'elle doit être

remplacée par une batterie neuve.

– La batterie Li-ion et le chargeur sont par-

faitement adaptés l'un à l'autre ! Une électronique intégrée empêche une surcharge

dommageable ou une surchauffe lors du

processus de charge.

–Du fait de la conservation de la batterie

dans le chargeur opérationnel, la batterie

est maintenue en permanence à l'état

chargé par maintien continu de la charge.

– Ne laissez pas les batteries déchargées

pendant plus d'environ un mois dans le

chargeur, si le chargeur est débranché du

réseau. Il y a risque de décharge profonde

et par conséquent de limitation de la capacité de l'accumulateur.

– L'accumulateur devrait être conservé dans

son emballage d'origine, afin d'exclure tout

risque de court-circuits.

– Si des batteries Li-ion devaient être stoc-

kées sans utilisation pendant une période

prolongée, elles devraient être chargées à

40 % de la capacité (durée de charge env.

15 minutes).

26

Page 27

Accessoires

10-1

10-2

10-3

Utilisez uniquement les accessoires Festool

et consommables Festool d'origine prévus

pour cette machine, car ces composants systèmes sont parfaitement adaptés les uns par

rapport aux autres. Si vous utilisez des accessoires et consommables d'autres marques, la qualité du résultat peut être dégradée et les recours en garantie peuvent être

soumis à des restrictions. L'usure de la machine ou votre charge personnelle peuvent

augmenter selon chaque application. Pour

cette raison, protégez-vous, votre machine

et vos droits à la garantie en utilisant exclusivement des accessoires Festool et des

consommables Festool d'origine !

Les références des accessoires et des outils

figurent dans le catalogue Festool ou sur Internet sous „www.festool-usa.com“.

Systainer

De nombreux produits Festool sont fournis

dans une caisse exclusive, appelée "Systainer". Celle-ci permet de protéger et de ranger des outils et des appareils complémentaires. Les Systainer sont empilables et peu-

vent être solidarisés. En outre, il se fixent sur

les aspirateurs CT Festool.

X

Poser deux Systainer l'un sur l'autre.

X

Défaire les quatre éléments de verrouillage du Systainer inférieur en les tirant en

arrière par leur bord supérieur [10-1].

X

Pousser les quatre éléments de verrouillage vers le haut [10-2].

X

Manoeuvrer les quatre éléments de verrouillage [10-3] de sorte qu'ils s'enclenchent au niveau des éléments récepteurs

du Systainer supérieur..

Recyclage

Ne jetez pas les outils électriques avec

les ordures ménagères!

Eliminez les appa-

reils, les accessoires et les emballages de fa-

Transport

La quantité équivalente de lithium contenue

dans la batterie Li-ion se situe sous les valeurs limites applicables et est contrôlée

d'après le manuel UN ST/SG/AC.10/11/Rev.3

partie III, sous-paragraphe 38.3. Pour cette

raison, la batterie Li-ion n'est soumise, ni en

tant que composant individuel, ni insérée

dans un appareil, aux prescriptions nationa-

Garantie

çon compatible avec l'environnement. Respectez en cela les dispositions nationales en

vigueur .

les et internationales concernant les matières dangereuses. Les prescriptions concernant les matières dangereuses peuvent toutefois être applicables en cas de transport de

plusieurs batteries. Dans ce cas il peut s'avérer nécessaire de respecter des conditions

particulières.

Conditions de la garantie (1+2 ans)

Vous avez droit à une prolongation de garantie gratuite (1 an + 2 ans = 3 ans) sur votre

outil électrique Festool. Festool assumera

tous les coûts d’expédition pendant la première année de la garantie alors que les

deuxième et troisième années, les coûts de-

27

Page 28

vront être assumés par le client. Festool

paiera les frais de retour de l’outil au client

par service de livraison terrestre UPS. La garantie est valable pour une période de 3 ans

à compter de la date d’achat indiquée sur votre reçu ou votre facture.

Garantie limitée de Festool

Cette garantie est valable à condition que

l’outil soit utilisé conformément aux instructions de Festool. Festool garantit, à l’acheteur initial seulement, que l’outil indiqué sera

exempt de tout défaut de matériau et de fabrication pendant un an à compter de la date

d’achat. Festool ne donne aucune garantie

supplémentaire, implicite ou explicite, sur les

instruments portables électriques Festool.

Aucun agent, représentant commercial, distributeur, vendeur ou employé de Festool

n’est autorisé à prolonger ou à modifier les

obligations ou restrictions de la présente garantie. Les obligations de Festool sont, à son

entière discrétion, limitées à la réparation ou

à l’échange des outils portables électriques

Festool trouvés défectueux dans le présent

emballage, tels que fournis avec le présent

Guide d’utilisation.

Cette garantie exclut l’usure normale, les

dommages causés par un usage impropre,

les abus ou la négligence, ou tout dommage

autre que ceux attribuables à des défauts de

matériau et de fabrication. Cette garantie ne

s’applique pas aux accessoires tels que lames de scie circulaire, mèches de perceuse

et vilebrequin, lames de scie sauteuse, bandes abrasives et meules. Sont également ex-

clues les pièces d’usure, telles que balais de

charbon, lamelles pour outils à air comprimé,

joints et manchons de caoutchouc, disques

et patins ponceurs, ainsi que les piles.

Les outils électriques portables Festool à

remplacer ou à réparer doivent être retournés avec le reçu d’achat à Festool (appelez

au 800-554-8741 pour connaître l’adresse

d’expédition).

FESTOOL N’EST EN AUCUN CAS RESPONSABLE DES DOMMAGES DIRECTS OU INDIRECTS, IMPLICITES OU EXPLICITES,

DÉCOULANT DE LA RUPTURE DE CETTE

GARANTIE OU DE TOUTE AUTRE GARANTIE. TOUTES LES GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET

D’ADÉQUATION À UN USAGE PARTICULIER, SONT LIMITÉES À UNE PÉRIODE

DE TROIS ANS.

Certains états américains et certaines provinces canadiennes ne permettent pas la limitation des garanties implicites; il se pourrait donc que les limites indiquées ci-dessus

ne s’appliquent pas dans votre cas. À l’exception de certaines garanties implicites des

provinces ou des états indiquées ici, la présente garantie est exclusive et remplace toute autre garantie, convention et obligation similaire de Festool.

Cette garantie vous confère des droits légaux

spécifiques, et vous pouvez aussi avoir

d’autres droits pouvant varier d’un état à

l’autre, ou d’une province à l’autre au Canada.

28

Page 29

Índice

Símbolos ................................. 29

Símbolos

Indicaciones de seguridad.......... 29

Datos técnicos.......................... 32

Descripción de las funciónes....... 33

Uso conforme a lo previsto......... 33

Puesta en servicio..................... 33

Ajustes ................................... 35

Alojamiento para herramienta, acceso-

rios de prolongación.................. 35

Trabajo con la máquina ............. 37

Mantenimiento y cuidado........... 38

Accesorios ............................... 38

Reciclaje.................................. 39

Transporte............................... 39

Garantía.................................. 39

V Voltios

AAmperios

Hz Hertzios

~Rensión alterna

n

rpm Revoluciones por minuto

Revoluciones por minuto en vacio

0

Clase II Constucción

Diámetro

Indicación, consejo

Aviso ante un peligro general

Peligro de electrocución

¡Leer las instrucciones e indicaciones!

¡Usar protección para los oídos!

¡Utilizar guantes de protección!

Indicaciones de seguridad

Indicaciones de seguridad gene-

rales

¡ATENCIÓN! Lea íntegramente las

instrucciones e indicaciones de se-

guridad.

trucciones e indicaciones puede dar lugar a

descargas eléctricas, incendios o lesiones

graves.

Guardar todas las advertencias de peligro e instrucciones para futuras consultas.

El término herramienta eléctrica empleado

en las siguientes advertencias de peligro se

refiere a herramientas eléctricas de conexión

a la red (con cable de red) y a herramientas

eléctricas accionadas por acumulador (o sea,

sin cable de red).

1 PUESTO DE TRABAJO

a)

Mantenga limpio y bien iluminado su

puesto de trabajo.

minación deficiente en las áreas de trabajo

pueden provocar accidentes.

b)

No utilice la herramienta eléctrica en

un entorno con peligro de explosión,

El incumplimiento de dichas ins-

El desorden y una ilu-

en el que se encuentren combustibles

líquidos, gases o material en polvo.

herramientas eléctricas producen chispas

que pueden llegar a inflamar los materiales

en polvo o vapores.

c)

Mantenga alejados a los niños y otras

personas de su puesto de trabajo al

emplear la herramienta eléctrica.

distracción le puede hacer perder el control

sobre el aparato.

2 SEGURIDAD ELÉCTRICA

a)

El enchufe del aparato debe corresponder a la toma de corriente utilizada. No es admisible modificar el

enchufe en forma alguna. No emplear

adaptadores en aparatos dotados con

una toma de tierra.

dificar adecuados a las respectivas tomas

de corriente reducen el riesgo de una descarga eléctrica.

b)

Evite que su cuerpo toque partes conectadas a tierra como tuberías, radiadores, cocinas y refrigeradores.

riesgo a quedar expuesto a una sacudida

Los enchufes sin mo-

Las

Una

El

29

Page 30

eléctrica es mayor si su cuerpo tiene contacto con tierra.

No exponga las herramientas eléctri-

c)

cas a la lluvia y evite que penetren líquidos en su interior.

Existe el peligro de

recibir una descarga eléctrica si penetran

ciertos líquidos en la herramienta eléctrica.

d)

No utilice el cable de red para transportar o colgar el aparato, ni tire de él

para sacar el enchufe de la toma de

corriente. Mantenga el cable de red

alejado del calor, aceite, esquinas cortantes o piezas móviles.

Los cables de

red dañados o enredados pueden provocar

una descarga eléctrica.

e)

Al trabajar con la herramienta eléctrica en la intemperie utilice solamente

cables de prolongación homologados

para su uso en exteriores.

La utilización

de un cable de prolongación adecuado para

su uso en exteriores reduce el riesgo de

una descarga eléctrica.

f)

Si fuese imprescindible utilizar la herramienta eléctrica en un entorno húmedo, es necesario conectarla a

través de un fusible diferencial.

La aplicación de un fusible diferencial reduce el

riesgo a exponerse a una descarga eléctrica.

3 SEGURIDAD DE PERSONAS

a)

Esté atento a lo que hace y emplee la

herramienta eléctrica con prudencia.

No utilice la herramienta eléctrica si

estuviese cansado, ni tampoco después de haber consumido alcohol, drogas o medicamentos.

El no estar atento

durante el uso de una herramienta eléctrica puede provocarle serias lesiones.

b)

Utilice un equipo de protección y en

todo caso unas gafas de protección.

riesgo a lesionarse se reduce considerablemente si, dependiendo del tipo y la aplicación de la herramienta eléctrica empleada,

se utiliza un equipo de protección adecuado como una mascarilla antipolvo, zapatos

de seguridad con suela antideslizante, casco, o protectores auditivos.

Evite una puesta en marcha fortuita

c)

del aparato. Cerciorarse de que el aparato esté desconectado antes conectarlo a la toma de corriente.

transporta el aparato sujetándolo por el interruptor de conexión/desconexión, o si in-

troduce el enchufe en la toma de corriente

con el aparato conectado, ello puede dar

lugar a un accidente.

Retire las herramientas de ajuste o

d)

llaves fijas antes de conectar la herramienta eléctrica.

Una herramienta o llave colocada en una pieza rotante puede

producir lesiones al ponerse a funcionar.

e)

Sea precavido. Trabaje sobre una base

firme y mantenga el equilibrio en todo

momento.

Ello le permitirá controlar mejor la herramienta eléctrica en caso de presentarse una situación inesperada.

Utilice ropa adecuada. No utilice ropa

f)

ancha ni objetos de joyería o bisutería. Mantenga el pelo y la ropa alejada

de las piezas en movimiento.

suelta o el pelo largo pueden quedar atrapados por piezas en movimiento.

Siempre que sea posible utilizar unos

g)

equipos de aspiración o captación de

polvo, asegúrese que éstos estén

montados y que sean utilizados correctamente.

El empleo de estos equipos

reduce los riesgos derivados del polvo.

4 TRATO Y USO CUIDADOSO DE HERRAMIENTAS ELÉCTRICAS

a)

No sobrecargue el aparato. Use la herramienta prevista para el trabajo a

realizar.

Con la herramienta adecuada podrá trabajar mejor y más seguro dentro del

margen de potencia indicado.

b)

No utilice herramientas con un interruptor defectuoso.

Las herramientas

que no se puedan conectar o desconectar

son peligrosas y deben hacerse reparar.

c)

Saque el enchufe de la red antes de

realizar un ajuste en el aparato, cambiar de accesorio o al guardar el apa-

El

rato.

Esta medida preventiva reduce el

riesgo a conectar accidentalmente el aparato.

d)

Guarde las herramientas fuera del alcance de los niños y de las personas

que no estén familiarizadas con su

uso.

Las herramientas utilizadas por per-

sonas inexpertas son peligrosas.

Cuide sus aparatos con esmero. Con-

e)

trole si funcionan correctamente, sin

atascarse, las partes móviles del apa-

Si

rato, y si existen partes rotas o deterioradas que pudieran afectar al

funcionamiento de la herramienta. Si

La ropa

30

Page 31

la herramienta eléctrica estuviese defectuosa haga repararla antes de volver a utilizarla.

se deben a aparatos con un mantenimiento

deficiente.

f)

Mantenga los útiles limpios y afilados.

Los útiles mantenidos correctamente se

dejan guiar y controlar mejor.

Utilice herramientas eléctricas, acce-

g)

sorios, útiles, etc. de acuerdo a estas

instrucciones y en la manera indicada

específicamente para este aparato.

Considere en ello las condiciones de

trabajo y la tarea a realizar.

herramientas eléctricas para trabajos diferentes de aquellos para los que han sido

concebidas puede resultar peligroso.

5 TRATO Y USO CUIDADOSO DE APARATOS ACCIONADOS POR ACUMULADOR

a)

Solamente cargar los acumuladores

con los cargadores recomendados por

el fabricante.

intentar cargar acumuladores de un tipo

diferente al previsto para el cargador.

b)

Solamente emplee los acumuladores

previstos para la herramienta eléctri-

El uso de otro tipo de acumuladores

ca.

puede provocar daños e incluso un incendio.

c)

Si no utiliza el acumulador, guárdelo

separado de clips, monedas, llaves,

clavos, tornillos o demás objetos metálicos que pudieran puentear sus

contactos.

tos del acumulador puede causar quemaduras o un incendio.

La utilización inadecuada del acumu-

d)

lador puede provocar fugas de líquido.

Evite el contacto con él. En caso de un

contacto accidental enjuagar el área

afectada con abundante agua. En caso

de un contacto con los ojos recurra

además inmediatamente a un médico.

El líquido del acumulador puede irritar la

piel o producir quemaduras.

6 SERVICIO

a)

Únicamente haga reparar su herramienta eléctrica por un profesional,

empleando exclusivamente piezas de

repuesto originales.

mantiene la seguridad de la herramienta

eléctrica.

Muchos de los accidentes

El uso de

Existe riesgo de incendio al

El cortocircuito de los contac-

Solamente así se

Indicaciones de seguridad especí-

ficas

–

Lleve puesta la protección de oídos al

usar taladros de percusión.

ruido puede causar una pérdida de la capacidad de audición.

Emplee los mangos adicionales sumi-

–

nistrados con la herramienta eléctrica.

La pérdida de control de la herramienta

eléctrica puede causar lesions físicas.

Agarre la máquina solo por las super-

–

ficies de agarre aisladas si quiere realizar trabajos en los que el tornillo

pueda dar con conducciones de corriente ocultas.

con una conducción de corriente puede poner bajo tensión también las piezas metálicas de la máquina y provocar una

descarga eléctrica.

El contacto del tornillo

El efecto del

Riesgos para la salud producidos

por el polvo

ADVERTENCIA!

dos por lijadoras motorizadas, aserra-

deros, trituradores, perforadoras y

otras actividades de construcción contienen

sustancias químicas que se sabe (en el Estado de California) causan cáncer, defectos de

nacimiento u otros daños al sistema reproductivo. Algunos ejemplos de estas sustancias químicas son:

• Plomo de las pinturas con base de plomo

• Sílice cristalino de los ladrillos y cemento y

otros productos de mampostería, y

• Arsénico y cromo de madera tratada con

sustancias químicas

El riesgo de exposición a

estas sustancias varía, dependiendo de cuantas veces se hace este tipo de

trabajo. Para reducir el

contacto con estas sustancias químicas: trabaje en un área con buena

ventilación y trabaje con equipo de seguridad

aprobado, como mascarillas para el polvo diseñadas específicamente para filtrar partículas microscópicas.

Algunos polvos crea-

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIÓN,

EL USUARIO DEBE LEER EL MANUAL DE

INSTRUCCIÓN.

31

Page 32

Datos técnicos

Taladro atornillador Akku C12 Li C15 Li

Tensión del motor 10,8-12 V 14,4-15,6 V

Número de revoluciones en vacío * 1.ª velocidad 0 - 450 rpm

2.a velocidad 0 - 1500 rpm

Par de giro máx. Atornillado suave

20 Nm 25 Nm

(madera)

Atornillado duro

34 Nm 40 Nm

(metal)

Par de giro regulable ** 1.ª velocidad 0,5 - 8 Nm

2.a velocidad 0.5 - 6 Nm

Margen de sujeción del portabrocas 1,5 - 13 mm

Diámetro máx. de perforación Madera 25 mm 35 mm

Metal 14 mm 16 mm

Alojamiento para herramienta en el husillo de taladrar 1/4 ’’ 1/4 ’’

Peso sin batería con Centrotec 0,9 kg 1,0 kg

Cargador TRC 3

Tensiójn de la red (entrada) 120 V ~

Frecuencia de la red 60 Hz

Tensión de carga (salida) 7,2 - 18 V (DC)

Carga rápida Max. 3 A

Corriente de conservación por impulsos Aprox. 0.06 A

Tiempos de recarga para LiIon 1.3 Ah/ 2.6 Ah, 80 % Aprox. 22/ 45 min

LiIon 1.3 Ah/ 2.6 Ah, 100 % Aprox. 35/ 70 min

Rango de temperatura de carga permitido -5 °C a +45 °C

Control de temperatura Mediante resistencia NTC

Batería BPC 12 Li BPC 15 Li

Número de pedido 497019 497020

Ten si ón 10,8 V 14,4 V

Capacidad 1,3 Ah 2,6 Ah

Peso 0,3 kg 0,6 kg

* Número de revoluciones con la batería totalmente cargada.

** En los niveles del par de giro inferiores, el

número de revoluciones máximo disminuye.

32

Page 33

Descripción de las funciónes

Las imágenes con la dotación de suministro

se encuentran en una hoja desplegable al comienzo de este manual de instrucciones.

Cuando lea este manual, le recomendamos

que despliegue esta página para disponer fácilmente de una vista general de la máquina.

[1-1] Rueda de ajuste de par de giro

[1-2] Compartimento para puntas de des-

tornillador

[1-3] Lámpara LED

[1-4] Interruptor de velocidades

Uso conforme a lo previsto

Los taladros atornilladores Akku son apropiados para taladrar en metal, madera, plástico

y materiales similares, así como, para atornillar y enroscar tornillos.

El cargador TRC 3 debe utilizarse únicamente

con las baterías mencionadas.

[1-5] Símbolo Taladrar

[1-6] Símbolo Atornillar

[1-7] Conmutador Taladrar/Atornillar

[1-8] Interruptor de giro derecha/

izquierda

[1-9] Interruptor de conexión y desco-

nexión

[1-10] Clip de cinturón

[1-11] Teclas para soltar el acumulador

ADVERTENCIA

El usuario es responsable de los daños

y accidentes producidos por un uso contrario a lo previsto, incluyendo también

daños y perjuicios derivados de un uso

continuo industrial.

Puesta en servicio

Cambiar la batería [2]

Extraer la batería

X

Mantenga presionadas ambas teclas [2-

1].

X

Retire la batería empujando hacia adelante.

Insertar la batería

X