Page 1

CNC

8055 ·T·

Programming manual

Ref. 1310

Soft: V01.4x

Page 2

It is possible that CNC can execute more functions than those described in its

associated documentation; however, Fagor Automation does not guarantee the

validity of those applications. Therefore, except under the express permission

from Fagor Automation, any CNC application that is not described in the

documentation must be considered as "impossible". In any case, Fagor

Automation shall not be held responsible for any personal injuries or physical

All rights reserved. No part of this documentation may be transmitted,

transcribed, stored in a backup device or translated into another language

without Fagor Automation’s consent. Unauthorized copying or distributing of this

software is prohibited.

The information described in this manual may be subject to changes due to

technical modifications. Fagor Automation reserves the right to change the

contents of this manual without prior notice.

All the trade marks appearing in the manual belong to the corresponding owners.

The use of these marks by third parties for their own purpose could violate the

rights of the owners.

This product uses the following source code, subject to the terms of the GPL license. The applications busybox V0.60.2;

dosfstools V2.9; linux-ftpd V0.17; ppp V2.4.0; utelnet V0.1.1. The librarygrx V2.4.4. The linux kernel V2.4.4. The linux boot

ppcboot V1.1.3. If you would like to have a CD copy of this source code sent to you, send 10 Euros to Fagor Automation

for shipping and handling.

damage caused or suffered by the CNC if it is used in any way other than as

explained in the related documentation.

The content of this manual and its validity for the product described here has been

verified. Even so, involuntary errors are possible, hence no absolute match is

guaranteed. However, the contents of this document are regularly checked and

updated implementing the necessary corrections in a later edition. We appreciate

your suggestions for improvement.

The examples described in this manual are for learning purposes. Before using

them in industrial applications, they must be properly adapted making sure that

the safety regulations are fully met.

Page 3

Programming manual

INDEX

About the product ......................................................................................................................... 7

Declaration of conformity.............................................................................................................. 9

Version history............................................................................................................................ 11

Safety conditions ........................................................................................................................ 13

Warranty terms ........................................................................................................................... 17

Material returning terms.............................................................................................................. 19

Additional remarks ...................................................................................................................... 21

Fagor documentation.................................................................................................................. 23

CHAPTER 1 GENERAL CONCEPTS

1.1 Part programs ................................................................................................................26

1.1.1 Considerations regarding the Ethernet connection .................................................... 28

1.2 DNC connection............................................................................................................. 29

1.3 Communication protocol via DNC or peripheral device ................................................. 30

CHAPTER 2 CREATING A PROGRAM

2.1 Program structure at the CNC ....................................................................................... 32

2.1.1 Block header .............................................................................................................. 32

2.1.2 Program block............................................................................................................ 33

2.1.3 End of block ...............................................................................................................34

CHAPTER 3 AXES AND COORDINATE SYSTEMS

3.1 Axis nomenclature ......................................................................................................... 36

3.1.1 Axis selection .............................................................................................................37

3.2 Plane selection (G16, G17, G18, G19) .......................................................................... 38

3.3 Part dimensioning. Millimeters (G71) or inches (G70) ................................................... 39

3.4 Absolute/incremental programming (G90, G91) ............................................................ 40

3.5 Programming in radius or in diameters (G152, G151) ................................................... 41

3.6 Coordinate programming ............................................................................................... 42

3.6.1 Cartesian coordinates ................................................................................................ 43

3.6.2 Polar coordinates ....................................................................................................... 44

3.6.3 Angle and Cartesian coordinate................................................................................. 46

3.7 Rotary axes.................................................................................................................... 47

3.8 Work zones.................................................................................................................... 48

3.8.1 Definition of the work zones ....................................................................................... 48

3.8.2 Using the work zones................................................................................................. 49

CHAPTER 4 REFERENCE SYSTEMS

4.1 Reference points............................................................................................................ 51

4.2 Machine reference (Home) search (G74) ...................................................................... 52

4.3 Programming with respect to machine zero (G53) ........................................................ 53

4.4 Coordinate preset and zero offsets................................................................................ 54

4.4.1 Coordinate preset and S value limitation (G92) ......................................................... 55

4.4.2 Zero offsets (G54..G59 and G159) ............................................................................ 56

4.5 Polar origin preset (G93)................................................................................................ 58

CHAPTER 5 ISO CODE PROGRAMMING

5.1 Preparatory functions..................................................................................................... 60

5.2 Feedrate F ..................................................................................................................... 62

5.2.1 Feedrate in mm/min or inches/min (G94)................................................................... 63

5.2.2 Feedrate in mm/rev.or inches/rev (G95) .................................................................... 64

5.3 Spindle speed (S) .......................................................................................................... 65

5.3.1 Constant surface speed (G96) ................................................................................... 66

5.3.2 Spindle speed in rpm (G97) ....................................................................................... 67

5.4 Spindle selection (G28, G29)......................................................................................... 68

5.5 Synchronized spindles (G30, G77S, G78S) .................................................................. 69

5.6 Tool number (T) and tool offset (D)................................................................................ 70

CNC 8055

CNC 8055i

SOFT: V01.4X

·3·

Page 4

5.7 Auxiliary function (M) ..................................................................................................... 72

5.7.1 M00. Program stop .................................................................................................... 73

5.7.2 M01. Conditional program stop.................................................................................. 73

5.7.3 M02. End of program ................................................................................................. 73

5.7.4 M30. End of program with return to the first block ..................................................... 73

5.7.5 M03, M4, M5. Spindle start and stop ......................................................................... 73

5.7.6 M06. Tool change code ............................................................................................. 75

5.7.7 M19. Spindle orientation ............................................................................................ 75

5.7.8 M41, M42, M43, M44. Spindle gear change .............................................................. 76

5.7.9 M45. Auxiliary spindle / Live tool................................................................................ 77

CHAPTER 6 PATH CONTROL

6.1 Rapid traverse (G00) ..................................................................................................... 80

6.2 Linear interpolation (G01) .............................................................................................. 81

6.3 Circular interpolation (G02, G03)................................................................................... 82

6.4 Circular interpolation with absolute arc center coordinates (G06) ................................. 86

6.5 Arc tangent to previous path (G08)................................................................................ 87

6.6 Arc defined by three points (G09).................................................................................. 88

6.7 Helical interpolation ....................................................................................................... 89

6.8 Tangential entry at the beginning of a machining operation (G37) ................................ 90

6.9 Tangential exit at the end of a machining operator (G38) ............................................. 91

6.10 Automatic radius blend (G36) ........................................................................................ 92

6.11 Chamfer (G39)...............................................................................................................93

6.12 Threading (G33) ............................................................................................................ 94

6.13 Withdrawal of axes when interrupting a threading operation (G233)............................. 97

6.14 Variable pitch threads (G34).......................................................................................... 99

6.15 Activates the C axis (G15). .......................................................................................... 100

6.15.1 Machining on the side of the part............................................................................. 101

6.15.2 Machining on the face of the part............................................................................. 102

6.16 Move to hardstop (G52)............................................................................................... 103

6.17 Feedrate "F" as an inverted function of time (G32)...................................................... 104

6.18 Tangential control (G45) .............................................................................................. 105

6.18.1 Considerations about the G45 function.................................................................... 107

6.19 G145. Temporary cancellation of tangential control .................................................... 108

Programming manual

CNC 8055

CNC 8055i

SOFT: V01.4X

CHAPTER 7 ADDITIONAL PREPARATORY FUNCTIONS

7.1 Interruption of block preparation (G04)........................................................................ 109

7.1.1 G04 K0: Block preparation interruption and coordinate update ............................... 111

7.2 Dwell (G04 K) .............................................................................................................. 112

7.3 Working with square (G07) and round (G05,G50) corners.......................................... 113

7.3.1 G07 (square corner)................................................................................................. 113

7.3.2 G05 (round corner) .................................................................................................. 114

7.3.3 Controlled round corner (G50) ................................................................................. 115

7.4 Look-ahead (G51)........................................................................................................ 116

7.4.1 Advanced look-ahead algorithm (integrating Fagor filters) ...................................... 118

7.4.2 Look-ahead operation with Fagor filters active ........................................................ 119

7.5 Mirror image (G10, G11. G12, G13, G14) ................................................................... 120

7.6 Scaling factor (G72)..................................................................................................... 121

7.6.1 Scaling factor applied to all axes. ............................................................................ 122

7.6.2 Scaling factor applied to one or more axes.............................................................. 123

7.7 Electronic axis coupling/uncoupling............................................................................. 125

7.7.1 Electronic axis coupling, slaving, (G77) ................................................................... 126

7.7.2 Cancellation of the electronic axis coupling, slaving, (G78)..................................... 127

7.8 Axes toggle G28-G29 .................................................................................................. 128

CHAPTER 8 TOOL COMPENSATION

8.1 Tool length compensation............................................................................................ 129

8.2 Tool radius compensation............................................................................................ 130

8.2.1 The location code of the tool (tool type)................................................................... 131

8.2.2 Working without tool radius compensation .............................................................. 134

8.2.3 Working with tool radius compensation ................................................................... 135

8.2.4 Beginning of tool radius compensation (G41, G42) ................................................. 136

8.2.5 Sections of tool radius compensation ...................................................................... 139

8.2.6 Cancellation of tool radius compensation (G40) ...................................................... 140

8.2.7 Temporary cancellation of tool compensation with G00 .......................................... 144

8.2.8 Change of type of tool radius compensation while machining ................................. 146

8.2.9 Tool compensation in any plane .............................................................................. 147

8.3 Collision detection (G41 N, G42 N) ............................................................................. 148

·4·

Page 5

Programming manual

CHAPTER 9 CANNED CYCLES

9.1 G66. Pattern repeat cycle canned cycle ...................................................................... 150

9.1.1 Basic operation ........................................................................................................ 153

9.1.2 Profile programming syntax ..................................................................................... 155

9.2 G68. X axis roughing canned cycle ............................................................................. 156

9.2.1 Basic operation ........................................................................................................ 159

9.2.2 Profile programming syntax ..................................................................................... 162

9.3 G69. Z axis roughing canned cycle.............................................................................. 163

9.3.1 Basic operation ........................................................................................................ 166

9.3.2 Profile programming syntax ..................................................................................... 169

9.4 G81. Turning canned cycle for straight sections.......................................................... 170

9.4.1 Basic operation ........................................................................................................ 172

9.5 G82. Facing canned cycle for straight sections ........................................................... 174

9.5.1 Basic operation ........................................................................................................ 176

9.6 G83. Axial drilling and tapping canned cycle ............................................................... 178

9.6.1 Basic operation ........................................................................................................ 180

9.7 G84. Turning canned cycle for curved sections........................................................... 181

9.7.1 Basic operation ........................................................................................................ 183

9.8 G85. Facing canned cycle for curved sections ............................................................ 185

9.8.1 Basic operation ........................................................................................................ 187

9.9 G86. Longitudinal threading canned cycle................................................................... 189

9.9.1 Basic operation ........................................................................................................ 194

9.10 G87. Face threading canned cycle .............................................................................. 195

9.10.1 Basic operation ........................................................................................................ 201

9.11 G88. X axis grooving canned cycle.............................................................................. 202

9.11.1 Basic operation ........................................................................................................ 203

9.12 G89. Z axis grooving canned cycle.............................................................................. 204

9.12.1 Basic operation ........................................................................................................ 205

9.13 G60. Axial drilling / tapping (on the face) ..................................................................... 206

9.13.1 Basic operation ........................................................................................................ 208

9.14 G61. Radial drilling/ tapping (on the side of the part)................................................... 210

9.14.1 Basic operation ........................................................................................................ 212

9.15 G62. Slot milling canned cycle on the side of the part ................................................. 214

9.15.1 Basic operation ........................................................................................................ 216

9.16 G63. Slot milling canned cycle on the face of the part................................................. 217

9.17 Basic operation ............................................................................................................ 219

CHAPTER 10 PROBING

10.1 Probing (G75, G76)...................................................................................................... 222

10.2 Probing canned cycles................................................................................................. 223

10.3 PROBE 1. Tool calibration canned cycle ..................................................................... 224

10.3.1 Basic operation ........................................................................................................ 227

10.4 PROBE 2. Probe calibration canned cycle. ................................................................. 230

10.4.1 Basic operation ........................................................................................................ 231

10.5 PROBE 3. Canned cycle for part measuring and tool correction on the X axis ........... 233

10.5.1 Basic operation ........................................................................................................ 234

10.6 PROBE 4. Canned cycle for part measuring and tool correction on the Z axis ........... 235

10.6.1 Basic operation ........................................................................................................ 236

CHAPTER 11 HIGH-LEVEL LANGUAGE PROGRAMMING

11.1 Lexical description ....................................................................................................... 237

11.2 Variables ...................................................................................................................... 239

11.2.1 General purpose parameters or variables................................................................ 240

11.2.2 Variables associated with tools. ............................................................................... 242

11.2.3 Variables associated with zero offsets. .................................................................... 245

11.2.4 Variables associated with machine parameters....................................................... 246

11.2.5 Variables associated with work zones ..................................................................... 247

11.2.6 Variables associated with feedrates......................................................................... 249

11.2.7 Variables associated with coordinates ..................................................................... 251

11.2.8 Variables associated with electronic handwheels .................................................... 253

11.2.9 Variables associated with feedback ......................................................................... 255

11.2.10 Variables associated with the main spindle ............................................................. 256

11.2.11 Variables associated with the second spindle.......................................................... 259

11.2.12 Variables associated with the live tool ..................................................................... 262

11.2.13 PLC related variables............................................................................................... 263

11.2.14 Variables associated with local parameters ............................................................. 265

11.2.15 Sercos variables....................................................................................................... 266

11.2.16 Software & hardware configuration variables........................................................... 267

11.2.17 Variables associated with telediagnosis................................................................... 270

11.2.18 Operating-mode related variables............................................................................ 273

11.2.19 Other variables......................................................................................................... 276

11.3 Constants..................................................................................................................... 281

CNC 8055

CNC 8055i

SOFT: V01.4X

·5·

Page 6

11.4 Operators..................................................................................................................... 282

11.5 Expressions ................................................................................................................. 284

11.5.1 Arithmetic expressions............................................................................................. 284

11.5.2 Relational expressions............................................................................................. 285

CHAPTER 12 PROGRAM CONTROL INSTRUCTIONS

12.1 Assignment instructions............................................................................................... 288

12.2 Display instructions...................................................................................................... 289

12.3 Enable-disable instructions.......................................................................................... 290

12.4 Flow control instructions .............................................................................................. 291

12.5 Subroutine instructions ................................................................................................ 293

12.6 Probe related instructions ............................................................................................ 297

12.7 Interruption-subroutine instructions ............................................................................. 298

12.8 Program instructions.................................................................................................... 299

12.9 Screen customizing instructions .................................................................................. 302

CHAPTER 13 ANGULAR TRANSFORMATION OF AN INCLINE AXIS

13.1 Turning angular transformation on and off................................................................... 309

13.2 Freezing the angular transformation............................................................................ 310

APPENDIX

A ISO code programming................................................................................................ 313

B Program control instructions ........................................................................................ 315

C Summary of internal CNC variables. ........................................................................... 319

D Key code...................................................................................................................... 327

E Programming assistance screens of the system. ........................................................ 337

F Maintenance ................................................................................................................ 341

Programming manual

CNC 8055

CNC 8055i

SOFT: V01.4X

·6·

Page 7

ABOUT THE PRODUCT

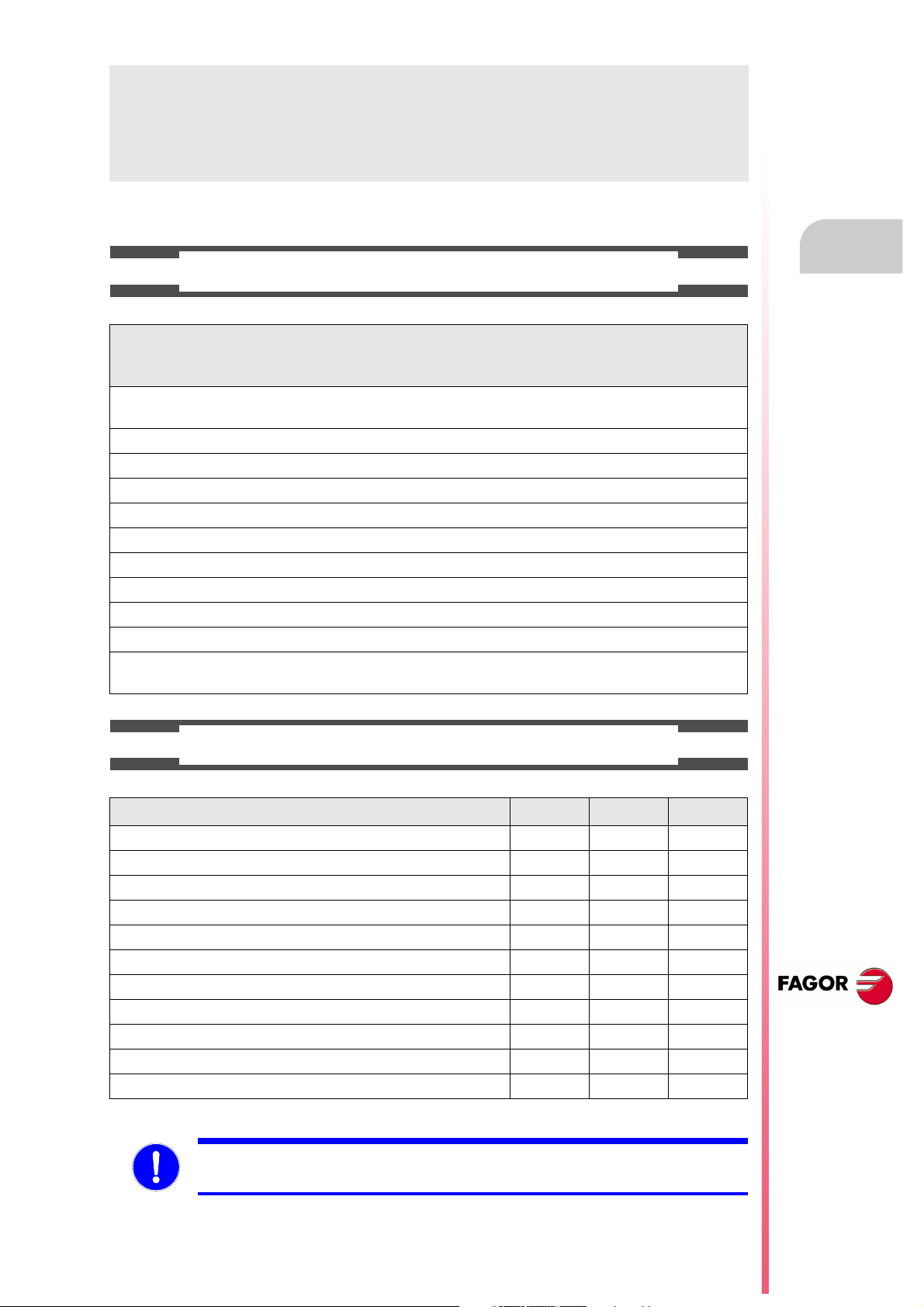

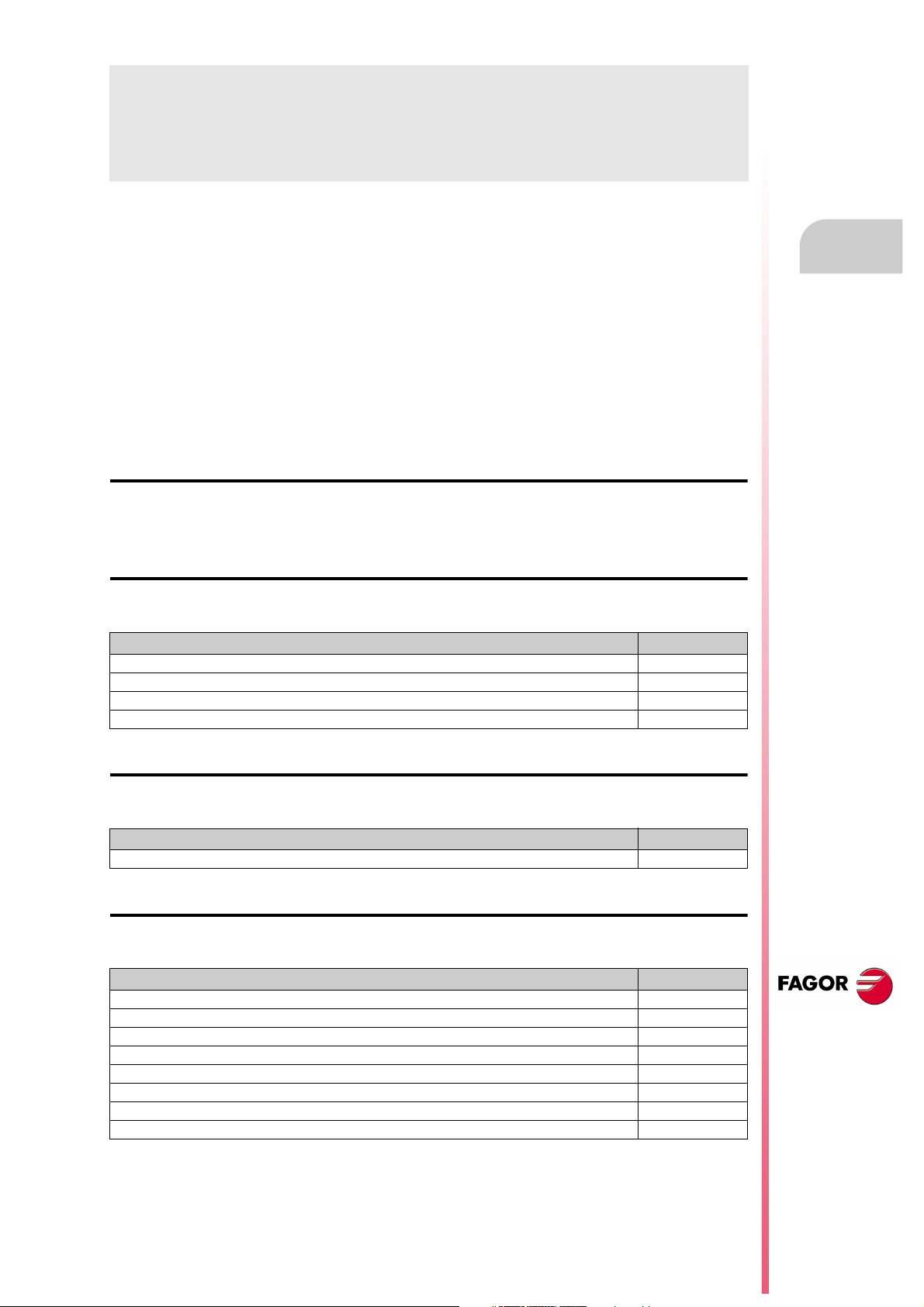

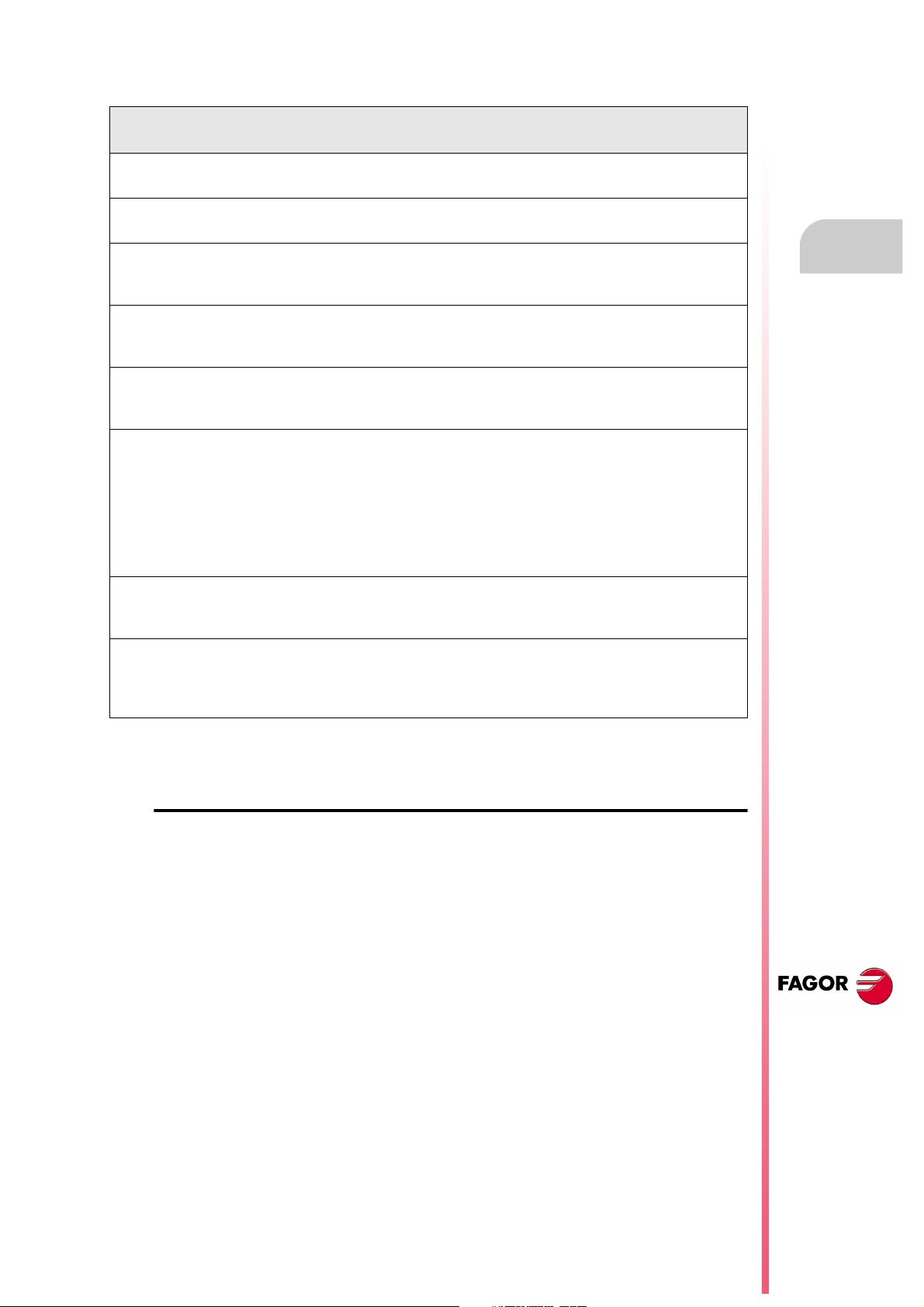

BASIC CHARACTERISTICS OF THE DIFFERENT MODELS.

8055 FL

8055i FL

8055i FL EN

Built-in 8055i FL

8055i FL EN

Enclosure 8055 FL 8055 Power

USB Standard Standard

Block processing time 3.5 ms 0.9 ms

RAM memory 1Mb 1 Mb

Software for 7 axes ----- Option

TCP transformation ----- Option

C axis (Lathe) ----- Option

Y axis (Lathe) ----- Option

Look-ahead 100 blocks 200 blocks

Flash Memory 512Mb / 2Gb Option

512Mb on the EN model

8055 Power

8055i Power

8055i Power

Option

HARDWARE OPTIONS OF THE 8055I CNC

Analog Digital Engraving

Ethernet Option Option Option

RS-232 serial line Standard Standard Standard

16 digital inputs and 8 outputs (I1 to I16 and O1 to O8) Standard Standard Standard

Another 40 digital inputs and 24 outputs (I65 to I104 and O33 to O56) Option Option Option

Probe inputs Standard Standard Standard

Spindle (feedback input and analog output) Standard Standard Standard

Electronic handwheels Standard Standard Standard

4 axes (feedback and velocity command) Option Option - - -

Remote CAN modules, for digital I/O expansion (RIO). Option Option - - -

Sercos servo drive system for Fagor servo drive connection. - - - Option - - -

CAN servo drive system for Fagor servo drive connection. - - - Option - - -

Before start-up, verify that the machine that integrates this CNC meets the 89/392/CEE Directive.

CNC 8055

CNC 8055i

·7·

Page 8

About the product

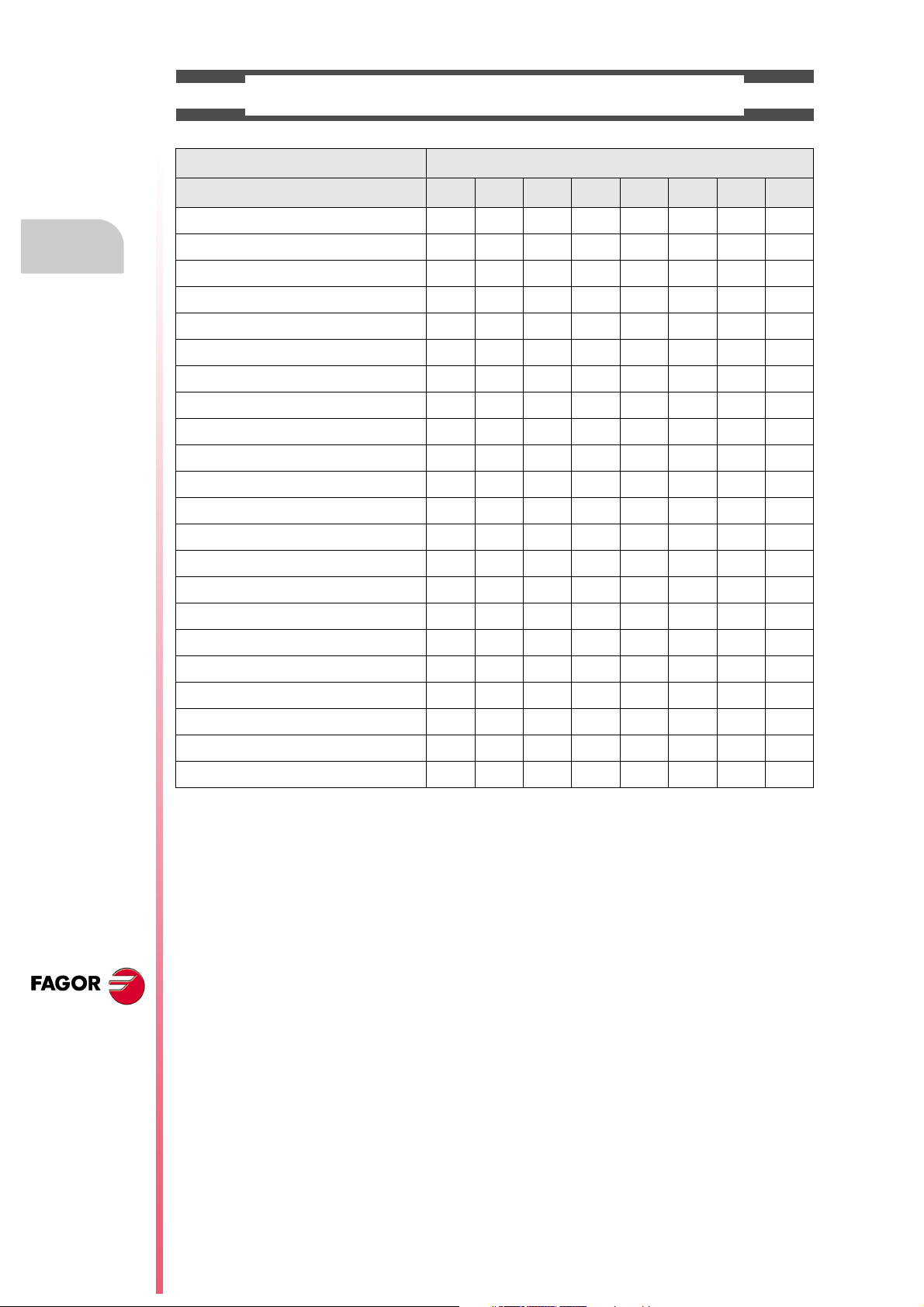

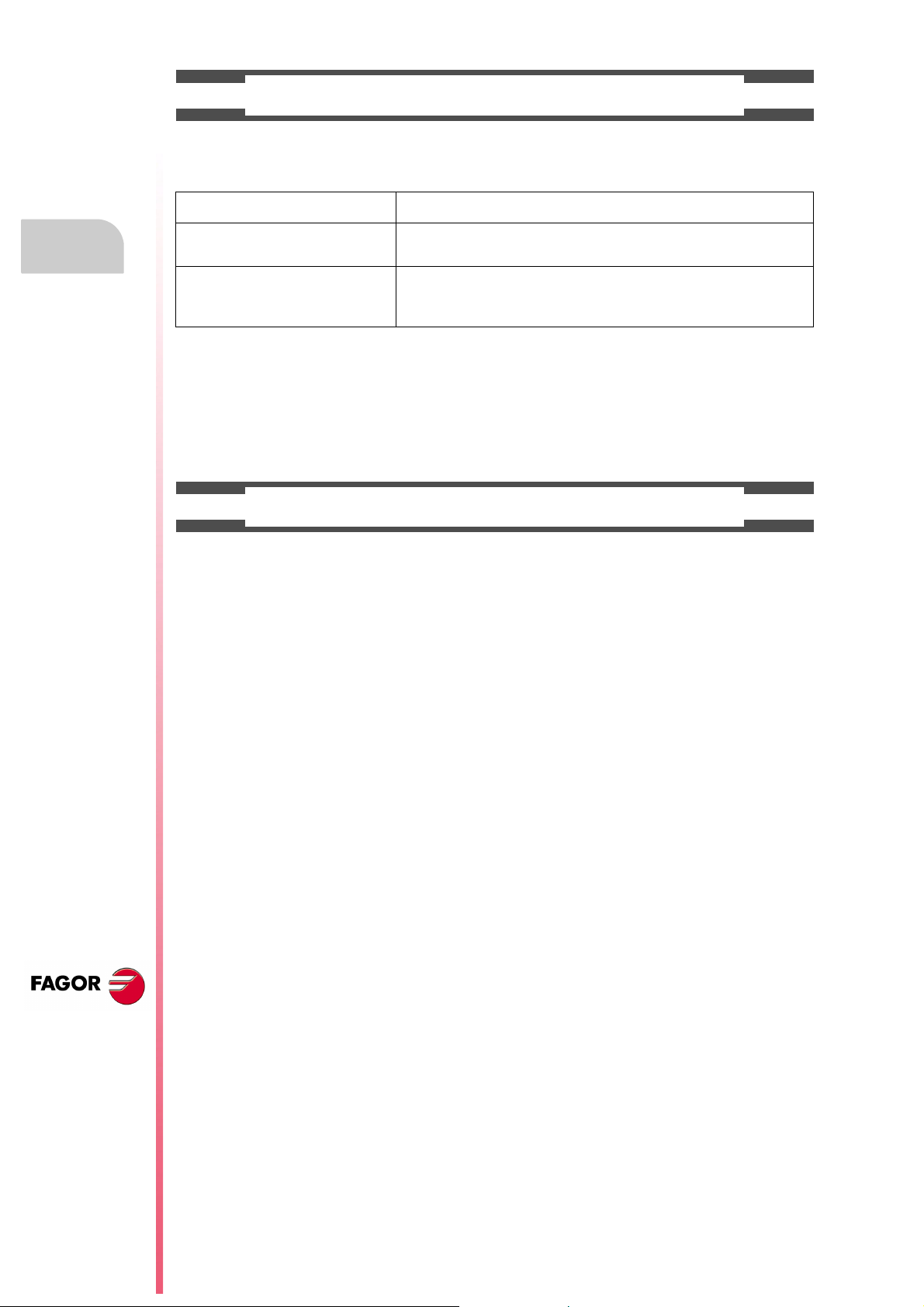

SOFTWARE OPTIONS OF THE 8055 AND 8055I CNCS.

Model

GP M MC MCO EN T TC TCO

Number of axes with standard software 4 4 4 4 3 2 2 2

Number of axes with optional software 7 7 7 7 ----- 4 or 7 4 or 7 4 or 7

Electronic threading ----- Stand. Stand. Stand. Stand. Stand. Stand. Stand.

Tool magazine management: ----- Stand. Stand. Stand. ----- Stand. Stand. Stand.

Machining canned cycles ----- Stand. Stand. ----- Stand. Stand. Stand. -----

Multiple machining ----- Stand. Stand. ----- Stand. ----- ----- -----

Solid graphics ----- Stand. Stand. Stand. ----- Stand. Stand. Stand.

Rigid tapping ----- Stand. Stand. Stand. Stand. Stand. Stand. Stand.

Tool live monitoring ----- Opt. Opt. Opt. Stand. Opt. Opt. Opt.

Probing canned cycles ----- Opt. Opt. Opt. Stand. Opt. Opt. Opt.

DNC Stand. Stand. Stand. Stand. Stand. Stand. Stand. Stand.

COCOM version Opt. Opt. Opt. Opt. ----- Opt. Opt. Opt.

Profile editor Stand. Stand. Stand. Stand. ----- Stand. Stand. Stand.

Tool radius compensation Stand. Stand. Stand. Stand. Stand. Stand. Stand. Stand.

CNC 8055

CNC 8055i

Tangential control Opt. Opt. Opt. Opt. ----- Opt. Opt. Opt.

Retracing ----- Opt. Opt. Opt. Stand. Opt. Opt. Opt.

Setup assistance Stand. Stand. Stand. Stand. Stand. Stand. Stand. Stand.

Irregular pockets with islands ----- Stand. Stand. Stand. ----- ----- ----- -----

TCP transformation ----- Opt. Opt. Opt. ----- ----- ----- -----

C axis (on Lathe) ----- ----- ----- ----- ----- Opt. Opt. Opt.

Y axis (on Lathe) ----- ----- ----- ----- ----- Opt. Opt. Opt.

Telediagnosis Opt. Opt. Opt. Opt. Stand. Opt. Opt. Opt.

·8·

Page 9

DECLARATION OF CONFORMITY

The manufacturer:

Fagor Automation S. Coop.

Barrio de San Andrés Nº 19, C.P. 20500, Mondragón -Guipúzcoa- (SPAIN).

Declares:

Under their responsibility that the product:

8055 / 8055i CNC

Consisting of the following modules and accessories:

MONITOR-8055, MONITOR-55-11-USB

OP-8055

KS 50/55, KB-40/55-ALFA, DVD AMPLI 8055

PSB-8055

CPU-KEY CF 8055 FL LARGE, CPU-KEY CF 8055 Power LARGE

AXES 8055 VPP

I/O 8055, COVER 8055, SERCOS 8055

Remote modules RIO

CNC 8055i FL, CNC 8055i Power

ANALOG 8055i-B, 40I/24O-8055i-B, ANALOG+40I/24O-B, COVER ANA+I/O-8055i-B

ETHERNET-CAN-SERCOS, ETHERNET-CAN-CAN AXES, ETHERNET-CAN AXES

Note.

Some additional characters may follow the references mentioned above. They all comply with the directives

listed. However, check that that's the case by checking the label of the unit itself.

Referred to by this declaration with following directives:

Low voltage regulations.

EN 60204-1: 2006 Electrical equipment on machines — Part 1. General requirements.

Regulation on electromagnetic compatibility.

EN 61131-2: 2007 PLC — Part 2. Requirements and equipment tests.

As instructed by the European Community Directives 2006/95/EEC on Low Voltage and

2004/108/EC on Electromagnetic Compatibility and its updates.

In Mondragón, July 27th, 2010.

CNC 8055

CNC 8055i

·9·

Page 10

Page 11

VERSION HISTORY

Here is a list of the features added in each software version and the manuals that describe them.

The version history uses the following abbreviations:

INST Installation manual

PRG Programming manual

OPT Operating manual

OPT-MC Operating manual for the MC option.

OPT-TC Operating manual for the TC option.

OPT-CO Manual of the CO manual

Software V01.00 October 2010

First version.

Software V01.20 April 2011

List of features Manual

Open communication. INST

Improvements to Look Ahead machining. INST

Blocks with helical interpolation in G51. PRG

G84. Tapping with relief. PRG

Software V01.08 August 2011

List of features Manual

S.m.p. OPLDECTI (P86). INST

Software V01.30 September 2011

List of features Manual

Gear ratio management on Sercos spindles INST

Improved feedrate limit management (FLIMIT). INST

New type of penetration in lathe type threading cycles. PRG

Improved lathe type thread repair. Partial repair. PRG

MC option: Rigid tapping with relief. OPT-MC

TC option: New type of penetration in threading cycles. OPT-TC

TC option: Improved thread repair. Partial and multi-entry (start) thread repair. OPT-TC

TC option: Zig-zag entry to the groove at the starting point of the groove. OPT-TC

CNC 8055

CNC 8055i

·11·

Page 12

Version history

Software V01.31 October 2011

List of features Manual

CNC 8055 FL Engraving model INST / OPT/ PRG

Software V01.40 January 2012

List of features Manual

Execution of M3, M4 and M5 using PLC marks INST / PRG

Values 12 and 43 of variable OPMODE in conversational work mode. INST

CNC 8055

CNC 8055i

·12·

Page 13

SAFETY CONDITIONS

Read the following safety measures in order to prevent harming people or damage to this product and those

products connected to it.

This unit may only be repaired by authorized personnel at Fagor Automation.

Fagor Automation shall not be held responsible of any physical damage or defective unit resulting from not

complying with these basic safety regulations.

PRECAUTIONS AGAINST PERSONAL DAMAGE

• Interconnection of modules.

Use the connection cables provided with the unit.

• Use proper Mains AC power cables

To avoid risks, use only the Mains AC cables recommended for this unit.

• Avoid electrical overloads.

In order to avoid electrical discharges and fire hazards, do not apply electrical voltage outside the range

selected on the rear panel of the central unit.

• Ground connection.

In order to avoid electrical discharges, connect the ground terminals of all the modules to the main

ground terminal. Before connecting the inputs and outputs of this unit, make sure that all the grounding

connections are properly made.

• Before powering the unit up, make sure that it is connected to ground.

In order to avoid electrical discharges, make sure that all the grounding connections are properly made.

• Do not work in humid environments.

In order to avoid electrical discharges, always work under 90% of relative humidity (non-condensing)

and 45 ºC (113º F).

• Do not work in explosive environments.

In order to avoid risks or damages, do no work in explosive environments.

CNC 8055

CNC 8055i

·13·

Page 14

CNC 8055

CNC 8055i

• Working environment.

This unit is ready to be used in industrial environments complying with the directives and regulations

effective in the European Community.

Fagor Automation shall not be held responsible for any damage suffered or caused when installed in

other environments (residential or homes).

• Install this unit in the proper place.

It is recommended, whenever possible, to install the CNC away from coolants, chemical product, blows,

etc. that could damage it.

This unit complies with the European directives on electromagnetic compatibility. Nevertheless, it is

recommended to keep it away from sources of electromagnetic disturbance such as:

Powerful loads connected to the same AC power line as this equipment.

Safety conditions

Nearby portable transmitters (Radio-telephones, Ham radio transmitters).

Nearby radio/TV transmitters.

Nearby arc welding machines.

Nearby High Voltage power lines.

Etc.

•Enclosures.

The manufacturer is responsible of assuring that the enclosure involving the equipment meets all the

currently effective directives of the European Community.

• Avoid disturbances coming from the machine tool.

The machine-tool must have all the interference generating elements (relay coils, contactors, motors,

etc.) uncoupled.

DC relay coils. Diode type 1N4000.

AC relay coils. RC connected as close to the coils as possible with approximate values of R=220

AC motors. RC connected between phases, with values of R=300 / 6 W y C=0,47 µF / 600 V.

• Use the proper power supply.

Use an external regulated 24 Vdc power supply for the inputs and outputs.

• Grounding of the power supply.

The zero volt point of the external power supply must be connected to the main ground point of the

machine.

• Analog inputs and outputs connection.

It is recommended to connect them using shielded cables and connecting their shields (mesh) to the

corresponding pin.

• Ambient conditions.

The working temperature must be between +5 ºC and +40 ºC (41ºF and 104º F)

The storage temperature must be between -25 ºC and +70 ºC. (-13 ºF and 158 ºF)

• Monitor enclosure (CNC 8055) or central unit ( CNC 8055i)

Guarantee the required gaps between the monitor or the central unit and each wall of the enclosure.

Use a DC fan to improve enclosure ventilation.

• Power switch.

This power switch must be mounted in such a way that it is easily accessed and at a distance between

0.7 meters (27.5 inches) and 1.7 meters (5.5ft) off the floor.

PRECAUTIONS AGAINST PRODUCT DAMAGE

1 W y C=0,2 µF / 600 V.

·14·

Page 15

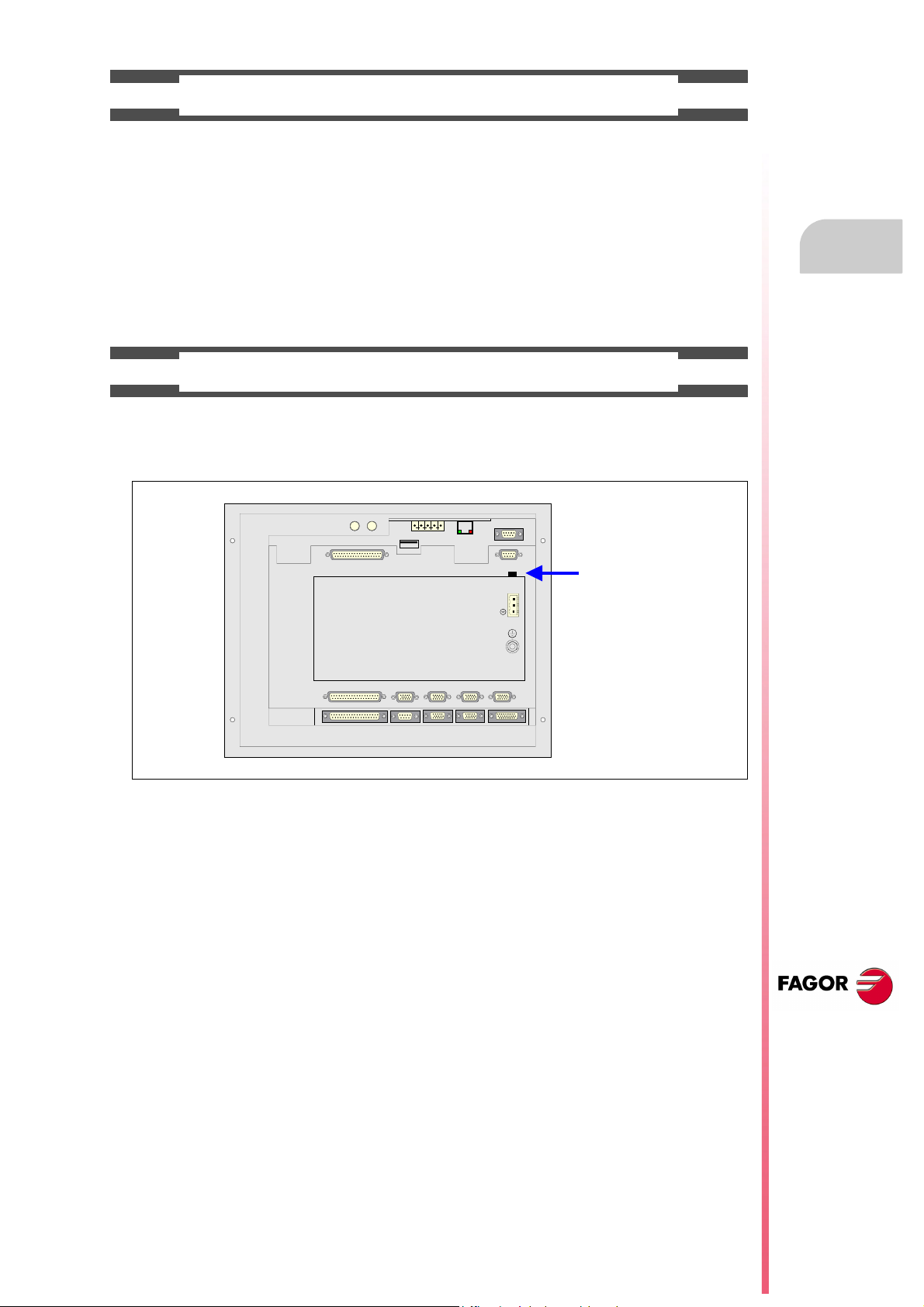

PROTECTIONS OF THE UNIT ITSELF (8055)

OUT

IN

X7

X1

X8

X9

X2

X10

X3

X11X4X12

X5

X13

X6

+24V

0V

FUSIBLE

FUSE

• "Axes" and "Inputs-Outputs" modules.

All the digital inputs and outputs have galvanic isolation via optocouplers between the CNC circuitry

and the outside.

They are protected by an external fast fuse (F) of 3.15 A 250V against overvoltage of the external power

supply (over 33 Vdc) and against reverse connection of the power supply.

• Monitor.

The type of protection fuse depends on the type of monitor. See identification label of the unit itself.

PROTECTIONS OF THE UNIT ITSELF (8055I)

• Central Unit.

It has a 4 A 250V external fast fuse (F).

• Inputs-Outputs.

All the digital inputs and outputs have galvanic isolation via optocouplers between the CNC circuitry

and the outside.

Safety conditions

CNC 8055

CNC 8055i

·15·

Page 16

PRECAUTIONS DURING REPAIR

i

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate

the inside of this unit.

Do not handle the connectors with the unit connected to main AC power. Before manipulating the

connectors (inputs/outputs, feedback, etc.) make sure that the unit is not connected to AC power.

SAFETY SYMBOLS

Safety conditions

• Symbols which may appear on the manual.

Symbol for danger or prohibition.

It indicates actions or operations that may cause damage to people or to units.

Warning symbol.

It indicates situations that may be caused by certain operations and the actions to be taken to prevent

them.

Obligation symbol.

It indicates actions and operations that must be carried out.

Information symbol.

It indicates notes, warnings and advises.

CNC 8055

CNC 8055i

·16·

Page 17

WARRANTY TERMS

INITIAL WARRANTY

All products manufactured or marketed by FAGOR carry a 12-month warranty for the end user which could

be controlled by the our service network by means of the warranty control system established by FAGOR

for this purpose.

In order to prevent the possibility of having the time period from the time a product leaves our warehouse

until the end user actually receives it run against this 12-month warranty, FAGOR has set up a warranty

control system based on having the manufacturer or agent inform FAGOR of the destination, identification

and on-machine installation date, by filling out the document accompanying each FAGOR product in the

warranty envelope. This system, besides assuring a full year of warranty to the end user, enables our service

network to know about FAGOR equipment coming from other countries into their area of responsibility.

The warranty starting date will be the one appearing as the installation date on the above mentioned

document. FAGOR offers the manufacturer or agent 12 months to sell and install the product. This means

that the warranty starting date may be up to one year after the product has left our warehouse so long as

the warranty control sheet has been sent back to us. This translates into the extension of warranty period

to two years since the product left our warehouse. If this sheet has not been sent to us, the warranty period

ends 15 months from when the product left our warehouse.

This warranty covers all costs of material and labour involved in repairs at FAGOR carried out to correct

malfunctions in the equipment. FAGOR under takes to repair or replace their products within the period from

the moment manufacture begins until 8 years after the date on which it disappears from the catalog.

FAGOR has exclusive competence in deciding whether the repair enters within the term defined as the

warranty period.

EXCLUDING CLAUSES

Repairs will be carried out on our premises. Therefore, all expenses incurred as a result of trips made by

technical personnel to carry out equipment repairs, despite these being within the above-mentioned period

of warranty, are not covered by the warranty.

Said warranty will be applied whenever the equipment has been installed in accordance with instructions,

has not be mistreated, has not been damaged by accident or by negligence and has not been tampered

with by personnel not authorized by FAGOR. If, once servicing or repairs have been made, the cause of

the malfunction cannot be attributed to said elements, the customer is obliged to cover the expenses

incurred, in accordance with the tariffs in force.

Other warranties, implicit or explicit, are not covered and FAGOR AUTOMATION cannot be held responsible

for other damages which may occur.

CNC 8055

CNC 8055i

·17·

Page 18

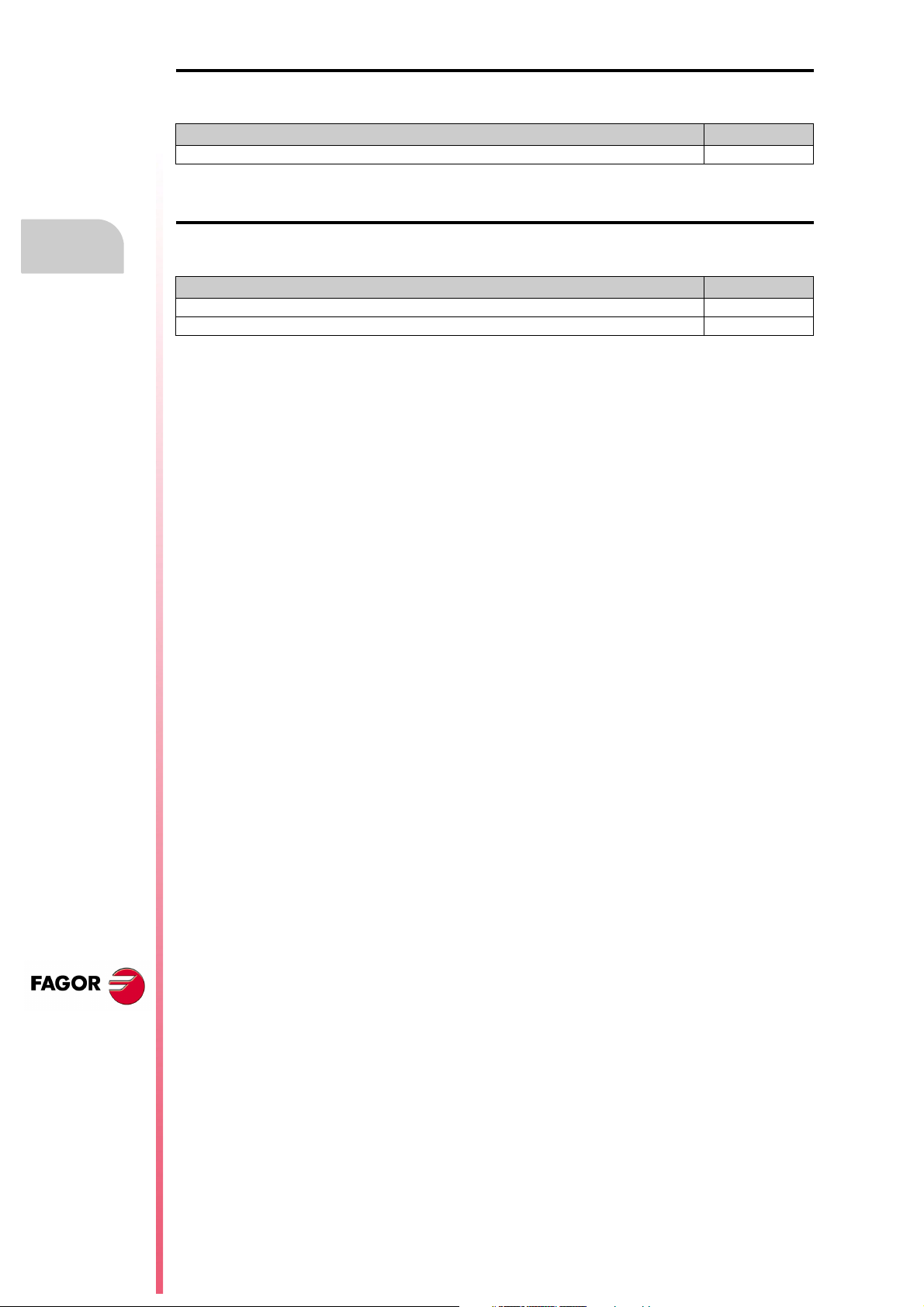

WARRANTY ON REPAIRS

In a similar way to the initial warranty, FAGOR offers a warranty on standard repairs according to the

following conditions:

PERIOD

CONCEPT

EXCLUDING CLAUSES

When the customer does not choose the standard repair and just the faulty material has been replaced,

Warranty terms

the warranty will cover just the replaced parts or components within 12 months.

For sold parts the warranty is 12 moths length.

The SERVICE CONTRACT is available for the distributor or manufacturer who buys and installs our CNC

systems.

12 months.

Covers parts and labor for repairs (or replacements) at the network's own

facilities.

The same as those applied regarding the chapter on initial warranty.

If the repair is carried out within the warranty period, the warranty extension

has no effect.

MAINTENANCE CONTRACTS

CNC 8055

CNC 8055i

·18·

Page 19

MATERIAL RETURNING TERMS

When sending the central nit or the remote modules, pack them in its original package and packaging

material. If the original packaging material is not available, pack it as follows:

1. Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger than those

of the unit. The cardboard being used to make the box must have a resistance of 170 kg. (375 pounds).

2. Attach a label indicating the owner of the unit, person to contact, type of unit and serial number.

3. In case of failure, also indicate the symptom and a short description.

4. Wrap the unit in a polyethylene roll or similar material to protect it.

5. When sending the central unit, protect especially the screen.

6. Pad the unit inside the cardboard box with polyurethane foam on all sides.

7. Seal the cardboard box with packing tape or industrial staples.

CNC 8055

CNC 8055i

·19·

Page 20

Material returning terms

CNC 8055

CNC 8055i

·20·

Page 21

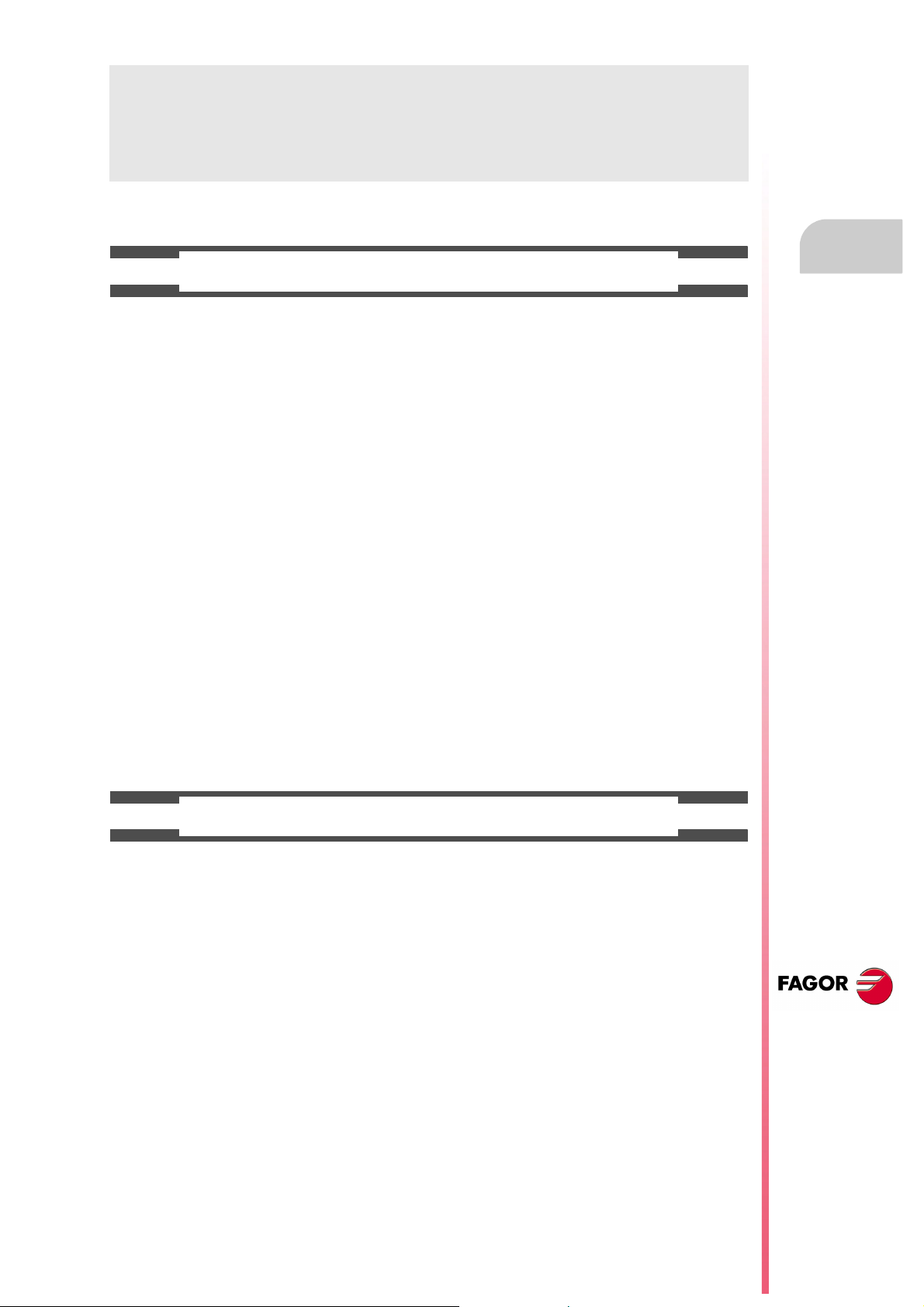

ADDITIONAL REMARKS

FAGOR

I/O

X1

X2

X3

AXES

X1 X2

X3 X4

X5 X6

X7 X8

X9

X10

CPU

X1 X2

CMPCT

FLASH

ETH

COM1

X3

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

IN

OUT

NODE

USB

(A)

(B)

X1

W1

Mount the CNC away from coolants, chemical products, blows, etc. which could damage it. Before turning

the unit on, verify that the ground connections have been properly made.

To prevent electrical shock at the central unit of the 8055 CNC, use the proper mains AC connector at the

power supply module. Use 3-wire power cables (one for ground connection).

To prevent electrical shock at the monitor of the 8055 CNC, use the proper mains AC connector (A) with

3-wire power cables (one of them for ground connection).

Before turning on the monitor of the 8055 CNC and verifying that the external AC line (B) fuse of each unit

is the right one. See identification label of the unit itself.

In case of a malfunction or failure, disconnect it and call the technical service. Do not get into the inside

of the unit.

CNC 8055

CNC 8055i

·21·

Page 22

Additional remarks

CNC 8055

CNC 8055i

·22·

Page 23

FAGOR DOCUMENTATION

OEM manual

It is directed to the machine builder or person in charge of installing and starting-up the CNC.

USER-M manual

Directed to the end user.

It describes how to operate and program in M mode.

USER-T manual

Directed to the end user.

It describes how to operate and program in T mode.

MC Manual

Directed to the end user.

It describes how to operate and program in MC mode.

It contains a self-teaching manual.

TC Manual

Directed to the end user.

It describes how to operate and program in TC mode.

It contains a self-teaching manual.

MCO/TCO model

Directed to the end user.

It describes how to operate and program in MCO and TCO mode.

Examples-M manual

Directed to the end user.

It contains programming examples for the M mode.

Examples-T manual

Directed to the end user.

It contains programming examples for the T mode.

WINDNC Manual

It is directed to people using the optional DNC communications software.

It is supplied in a floppy disk with the application.

WINDRAW55 Manual

Directed to people who use the WINDRAW55 to create screens.

It is supplied in a floppy disk with the application.

CNC 8055

CNC 8055i

·23·

Page 24

Fagor documentation

CNC 8055

CNC 8055i

·24·

Page 25

GENERAL CONCEPTS

1

The CNC may be programmed at the machine (from the front panel) and from a peripheral

(computer). Memory available to the user for carrying out the part programs is 1 Mbyte.

The part programs and the values in the tables which the CNC has can be entered from the front

panel, from a pc (DNC) or from a peripheral.

Entering programs and tables from the front panel.

Once the editing mode or desired table has been selected, the CNC allows you to enter data from

the keyboard.

Entering programs and tables from a Computer (DNC) or peripheral device.

The CNC allows data to be exchanged with a computer or peripheral device, using the RS232C serial

line.

If this is controlled from the CNC, it is necessary to preset the corresponding table or part program

directory (utilities) you want to communicate with.

Depending on the type of communication required, the ser ial port machine parameter "PROTOCOL"

should be set.

"PROTOCOL" = 0 If the communication is with a peripheral device.

"PROTOCOL" = 1 If the communication is via DNC.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·25·

Page 26

1.

1.1 Part programs

Part programs

Programming manual

The operating manual describes the different operating modes. Refer to that manual for further

information.

Editing a part-program

To create a part-program, access the –Edit– mode.

The new part-program edited is stored in the CNC's RAM memory. A copy of the part-programs may

be stored in the hard disk (KeyCF) at a PC connected through the serial line or in the USB disk.

To transmit a program to a PC through the serial, proceed as follows:

1. Execute the "WinDNC.exe" application program at the PC.

2. Activate DNC communications at the CNC.

3. Select the work directory at the CNC. It is selected from the –Utilities– mode, option Directory

\Serial L \Change directory

GENERAL CONCEPTS

In –Edit– mode, it is possible to modify part-programs residing in the CNC's RAM memory. To modify

a program stored in the hard disk (KeyCF), in a PC or in the USB disk, it must be previously copied

into RAM memory.

Executing and editing a part-program

Part-programs stored anywhere may be executed or simulated. Simulation is carried out in the

–Simulation– mode, whereas the execution is done in the –Automatic– mode

When executing or simulating a part-program, bear in mind the following points:

• Only subroutines stored in the CNC's RAM memory can be executed. Therefore, to execute a

subroutine stored in the hard disk (KeyCF), in a PC or in the USB disk, it must be first copied

into the CNC's RAM memory.

• The GOTO and RPT instructions cannot be used in programs that are executed from a PC

connected through the serial line.

• From a program in execution, it is possible to execute another program located in RAM memory,

in the hard disk (KeyCF) or in a PC using the EXEC instruction.

The user customizing programs must be in RAM memory so the CNC can execute them.

–Utilities– operating mode.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·26·

The –Utilities– mode, lets display the part-program directory of all the devices, make copies, delete,

rename and even set the protections for any of them.

Page 27

Programming manual

Operations that may be carried out with part-programs.

See the program directory of ...

See the subroutine directory of ...

Create the work directory from ...

Change the work directory from ...

Edit a program from ...

Modify a program from ...

Delete a program from ...

Copy from/to RAM memory to/from ...

Copy from/to HD to/from ...

Copy from/to DNC to/from ...

Rename a program from ...

Change the comment of a program from ...

Change the protections of a program from ...

Execute a part-program from ...

Execute a user program from ...

Execute a PLC program from ...

Execute programs with GOTO or RPT instructions from ...

Execute subroutines residing in ...

Execute programs with the EXEC instruction, in RAM from ...

Execute programs with the EXEC instruction, in HD from ...

Execute programs with the EXEC instruction, in DNC from ...

RAM

memory

Ye s

Ye s

No

No

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Hard

disk

Ye s

No

No

No

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

No

Ye s

No

Ye s

Ye s

Ye s

DNC

Ye s

No

No

Ye s

No

No

Ye s

Ye s

Ye s

Ye s

No

No

No

Ye s

No

No

No

No

Ye s

Ye s

No

1.

Part programs

GENERAL CONCEPTS

Open programs with the OPEN instruction, in RAM from ...

Open programs with the OPEN instruction, in HD from ...

Open programs with the OPEN instruction, in DNC from ...

Via Ethernet:

See from a PC the program directory of ...

See from a PC the subroutine directory of ...

See from a PC, a directory in ...

Ye s

Ye s

Ye s

No

No

No

Ye s

Ye s

Ye s

Ye s

No

No

(*) If it is not in RAM memory, it generates the executable code in RAM and it executes it.

Ethernet

When having the Ethernet option and if the CNC is configured as another node within the computer

network, the following operations are possible from any PC of the network:

• Access the part-program directory of the hard disk (KeyCF).

• Edit, modify, delete, rename, etc. the programs stored on the hard disk.

• Copy programs from the hard disk to the PC and vice versa.

To configure the CNC as another node within the computer network, see the installation manual.

Ye s

Ye s

No

No

No

No

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·27·

Page 28

1.

Part programs

GENERAL CONCEPTS

Programming manual

1.1.1 Considerations regarding the Ethernet connection

When configuring the CNC as another node in the computer network, the programs stored in the

hard disk (KeyCF) may be edited and modified from any PC.

Instructions for setting up a PC to access CNC directories

To set up the PC to access the CNC directories, we recommend to proceed as follows.

1. Open the "Windows Explorer"

2. On the "Tools" menu, select the "Connect to Network Drives" option.

3. Select the drive, for example "D".

4. Indicate the path. The path will be the CNC name followed by the name of the shared directory.

For example: \\FAGORCNC\CNCHD

5. When selecting the option: "Connect again when initiating the session", the selected CNC will

appear on each power-up as another path of the "Windows Explorer" without having to define

it again.

Data format

This connection is established through Ethernet and, therefore, the CNC does not control the syntax

of the programs while they are received or modified. However, whenever accessing the program

directory of the Hard Disk (HD), the following verification takes place:

File name.

The file number must always have 6 digits and the extension PIM (for milling) or PIT (for lathe).

Examples: 001204.PIM 000100.PIM 123456.PIT 020150.PIT

If the file has been given the wrong name, for example: 1204.PIM or 100.PIT, the CNC will not change

it, but it will display it with the comment "****************". The file name cannot be modified

at the CNC; it must be edited from the PC to correct the error.

File size.

If the file is empty (size = 0) the CNC will display it with the comment "********************".

The file can be edited or deleted either from the CNC or from the PC.

First line of the program.

The first line of the program must have the % character, the comment associated with the file (up

to 20 characters) and between the two commas (,) the program attributes O (OEM), H (hidden), M

(modifiable), X (executable).

Examples: %Comment ,MX,

% ,OMX,

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·28·

If the first line does not exist, the CNC will display the program with an empty comment and with

the modifiable (M) and executable (X) attributes.

When the format of the first line is wrong, the CNC does not modify it, but it displays it with the

comment "****************". The file can be edited or deleted either from the CNC or from the

PC.

The format is incorrect when the comment has more than 20 characters, a comma (,) is missing

to group the attributes or there is a strange character in the attributes.

Page 29

Programming manual

1.2 DNC connection

The CNC offers as optional feature the possibility of working in DNC (Distributed Numerical Control),

enabling communication between the CNC and a computer to carry out the following functions:

• Directory and delete commands.

• Transfer of programs and tables between the CNC and a computer.

• Remote control of the machine.

• The ability to supervise the status of advanced DNC systems.

1.

DNC connection

GENERAL CONCEPTS

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·29·

Page 30

1.

GENERAL CONCEPTS

Communication protocol via DNC or peripheral device

Programming manual

1.3 Communication protocol via DNC or peripheral device

This type of communication enables program-and-table transfer commands, plus the organization

of CNC directories such as the computer directory, for copying/deleting programs, etc. to be done

either from the CNC or the computer.

When you want to transfer files, it is necessary to follow this protocol:

• The "%" symbol will be used to start the file, followed by the program comment (optional), of up

to 20 characters.

Then, and separated by a comma ",", comes the protection of each file, read, write, etc. These

protections are optional and need not be programmed.

To end the file header, RT (RETURN ) or LF (LINE FEED) characters should be sent separated

by a comma (",").

Example: %Fagor Automation, MX, RT

• Following the header, the file blocks should be programmed. These will all be programmed

according to the programming rules indicated in this manual. After each block, to separate it from

the others, the RT (RETURN ) or LF (LINE FEED) characters should be used.

Example: N20 G90 G01 X100 Y200 F2000 LF

(RPT N10, N20) N3 LF

If communication is made with a peripheral device, you will need to send the ‘end of file’ command.

This command is selected via the machine parameter for the serial port: "EOFCHR", and can be

one of the following characters :

ESC ESCAPE

EOT END OF TRANSMISSION

SUB SUBSTITUTE

EXT END OF TRANSMISSION

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·30·

Page 31

CREATING A PROGRAM

2

A CNC program consists of a series of blocks or instructions. These blocks or instructions are made

of words composed of capital letters and numerical format.

The CNC’s numerical format consists of :

• The signs . (decimal points, + (plus), - (minus).

• Digits 0 1 2 3 4 5 6 7 8 9.

Programming allows spaces between letters, numbers and symbols, in addition to ignoring the

numerical format if it has zero value, or a symbol if it is positive.

The numeric format of a word may be replaced by an arithmetic parameter when programming. Later

on, during execution, the CNC will replace the arithmetic parameter by its value. For example, if XP3

has been programmed, during execution the CNC will replace P3 by its numerical value, obtaining

results such as X20, X20.567, X-0.003, etc.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·31·

Page 32

2.

Programming manual

2.1 Program structure at the CNC

All the blocks which make up the program have the following structure:

Block header + program block + end of block

2.1.1 Block header

The block header is optional, and may consist of one or more block skip conditions and by the block

number or label. Both must be programmed in this order.

Block skip condition. "/", "/1", "/2", "/3".

These three block skip conditions, given that "/" and "/1" are the same, they are governed by the

marks BLKSKIP1, BLKSKIP2 and BLKSKIP3 of the PLC. If any of these marks is active, the CNC

will not execute the block or blocks in which it has been programmed; the execution takes place in

the following block.

CREATING A PROGRAM

Program structure at the CNC

Up to 3 skip conditions can be programmed in one block; they will be evaluated one by one,

respecting the order in which they have been programmed.

The control reads 200 blocks ahead of the one being executed in order to calculate in advance the

path to be run. The condition for block skip will be analyzed at the time when the block is read i.e.

200 blocks before execution.

If the block skip needs to be analyzed at the time of execution, it is necessary to interrupt the block

preparation, by programming G4 in the previous block.

Label or block number. N(0-99999999).

This is used to identify the block, and is only used when block references or jumps are made. They

are represented by the letter N followed by up to 8 digits (0-99999999).

No particular order is required and the numbers need not be sequential. If two or more blocks with

the same label number are present in the same program, the CNC will always give priority to the

first number.

Although it is not necessary to program it, by using a softkey the CNC allows the automatic

programming of labels. The programmer can select the initial number and the step between labels.

Restrictions:

• Displaying the number of the active block in the top window of the screen:

When executing a program in ISO mode, when the label number is higher than 9999, it

displays N**** .

On the "DISPLAY / SUBROUTINES" window, when displaying an RPT that has a label higher

than 9999, it displays it with ****.

• Canned cycles G66, G68 and G69 can only be edited using 4-digit labels.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·32·

Page 33

Programming manual

2.1.2 Program block

This is written with commands in ISO and high level languages. To prepare a program, blocks written

in both languages will be used, although each one should be edited with commands in just one

language.

ISO language

This language is specially designed to control axis movement, as it gives information and movement

conditions, in addition to data on feedrate. It offers the following types of functions.

• Preparatory functions for movement, used to determine geometry and working conditions, such

as linear and circular interpolations, threading, etc.

• Control functions for axis feedrate and spindle speeds.

• Tool control functions.

• Complementary functions, with technological instructions.

High level language

This enables access to general purpose variables and to system tables and variables.

2.

It gives the user a number of control sentences which are similar to the terminology used in other

languages, such as IF, GOTO, CALL, etc. It also allows the use of any type of expression (arithmetic,

referential, or logical).

It also has instructions for the construction of loops, plus subroutines with local variables. A local

variable is one that is only recognized by the subroutine in which it has been defined.

It is also possible to create libraries, grouping subroutines with useful and tested functions, which

can be accessed from any program.

CREATING A PROGRAM

Program structure at the CNC

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·33·

Page 34

Programming manual

2.1.3 End of block

The end of block is optional and may consist of the indication of number of repetitions of the block

and of the block comment. Both must be programmed in this order.

Number of block repetitions. N(0-9999)

This indicates the number of times the block will be executed. The number of repetitions is

represented by the letter N followed by up to 4 digits (0-9999). The active machining operation does

not take place if N0 is programmed; only the movement programmed within the block takes place.

2.

CREATING A PROGRAM

Program structure at the CNC

Movement blocks can only be repeated which, at the time of their execution, are under the influence

of a modal subroutine. In these cases, the CNC executes the programmed move and the active

machining operation (canned cycle or modal subroutine) the indicated number of times.

Block comment

The CNC allows you to incorporate any kind of information into all blocks in the form of a comment.

The comment is programmed at the end of the block, and should begin with the character ";"

(semicolon).

If a block begins with ";" all its contents will be considered as a comment, and it will not be executed.

Empty blocks are not permitted. They should contain at least one comment.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·34·

Page 35

AXES AND COORDINATE SYSTEMS

3

Given that the purpose of the CNC is to control the movement and positioning of axes, it is necessary

to determine the position of the point to be reached through its coordinates.

The CNC allows you to use absolute, relative or incremental coordinates throughout the same

program.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·35·

Page 36

3.

Programming manual

3.1 Axis nomenclature

The axes are named according to DIN 66217.

Axis nomenclature

AXES AND COORDINATE SYSTEMS

Characteristics of the system of axes:

X and Y main movements on the main work plane of the machine.

Z parallel to the main axis of the machine, perpendicular to the main XY plane.

U, V, W auxiliary axes parallel to X, Y, Z respectively.

A B C Rotary axes on each axis X, Y, Z.

The drawing below shows an example of the nomenclature of the axes on a parallel lathe.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·36·

Page 37

Programming manual

3.1.1 Axis selection

Of the 9 possible axes that may exist, the CNC allows the manufacturer to select up to 7 of them.

Moreover, all the axes should be suitably defined as linear/rotary, etc. through the axis machine

parameters which appear in the Installation and Start-up Manual.

There is no limitation to the programming of the axes, and up to 7 axes may be interpolated at the

same time.

3.

Axis nomenclature

AXES AND COORDINATE SYSTEMS

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·37·

Page 38

3.

Programming manual

3.2 Plane selection (G16, G17, G18, G19)

Plane selection should be made when the following are carried out :

• Circular interpolations.

• Controlled corner rounding.

• Tangential entry and exit.

•Chamfer.

• Coordinate programming in Polar coordinates.

• Pattern rotation.

• Tool radius Compensation.

• Tool length compensation.

The "G" functions which enable selection of work planes are as follows :

G16 axis1 axis2. Enables selection of the desired work plane, plus the direction of G02 G03

(circular interpolation), axis1 being programmed as the abscissa axis and

axis2 as the ordinate axis.

Plane selection (G16, G17, G18, G19)

AXES AND COORDINATE SYSTEMS

G17. Selects the XY plane.

G18. Selects the ZX plane.

G19. Selects the YZ plane.

The G16, G17, G18 and G19 functions are modal and incompatible among themselves. The G16

function should be programmed on its own within a block.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·38·

On power-up, after executing M02, M30 or after EMERGENCY or RESET, the CNC will assume that

the plane defined by the general machine parameter as "IPLANE" is the work plane.

Page 39

Programming manual

3.3 Part dimensioning. Millimeters (G71) or inches (G70)

The CNC allows you to enter units of measurement with the programming, either in millimeters or

inches.

It has a general machine parameter "INCHES" to define the unit of measurement of the CNC.

However, these units of measurement can be changed at any time in the program. Two functions

are supplied for this purpose :

• G70. Programming in inches.

• G71. Programming in millimeters.

Depending on whether G70 or G71 has been programmed, the CNC assumes the corresponding

set of units for all the blocks programmed from that moment on.

The G70 and G71 functions are modal and are incompatible.

The CNC allows you to program figures from 0.00001 to 99999.9999 with or without sign, working

in millimeters (G71), called format +/-5.4, or either from 0.00001 to 3937.00787 with or without sign

if the programming is done in inches (G70), called format +/-4.5.

However, and to simplify the instructions, we can say that the CNC admits +/- 5.5 format, thereby

admitting +/- 5.4 in millimeters and +/- 4.5 in inches.

On power-up, after executing M02, M30 or after EMERGENCY or RESET, the CNC will assume that

the system of units of measurement is the one defined by the general machine parameter "INCHES".

3.

AXES AND COORDINATE SYSTEMS

Part dimensioning. Millimeters (G71) or inches (G70)

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·39·

Page 40

3.

Absolute coordinates:

G90 X200 Z60 ; Point P0

X160 Z60 ; Point P1

X80 Z100 ; Point P2

X80 Z120 ; Point P3

Incremental coordinates:

G90 X200 Z60 ; Point P0

G91 X-40 ; Point P1

X-80 Z40 ; Point P2

Z20 ; Point P3

Example programming the X axis in diameter.

Programming manual

3.4 Absolute/incremental programming (G90, G91)

The CNC allows the programming of the coordinates of one point either with absolute G90 or

incremental G91 values.

When working with absolute coordinates (G90), the point coordinates refer to a point of origin of

established coordinates, often the part zero (datum).

When working in incremental coordinates (G91), the numerical value programmed corresponds to

the movement information for the distance to be traveled from the point where the tool is situated

at that time. The sign in front shows the direction of movement.

The G90/G91 functions are modal and incompatible with each other.

AXES AND COORDINATE SYSTEMS

Absolute/incremental programming (G90, G91)

On power-up, after executing M02, M30 or after an EMERGENCY or RESET, the CNC will assume

G90 or G91 according to the definition by the general machine parameter "ISYSTEM".

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·40·

Page 41

Programming manual

3.5 Programming in radius or in diameters (G152, G151)

The X axis coordinates may be programmed in radius or diameter. The following functions may be

used for that.

• G151. Programming the X axis in diameter.

• G152. Programming the X axis in radius.

It is carried out by interpolating the main spindle (that is turning) with the Z axis. After the execution

of one of these functions, the CNC assumes the relevant programming mode for the blocks

programmed afterwards.

The change of units is also taken into account in the following cases.

• Displaying the real X value of in the part's coordinate system.

• Reading of the variable PPOSX (programmed coordinate).

Functions G151 and G152 are modal and incompatible with each other.

On power-up, after executing an M02, M30 or after an emergency or reset, the CNC assumes G151

or G152 depending on the setting of X axis machine parameter "DFORMAT".

3.

AXES AND COORDINATE SYSTEMS

Programming in radius or in diameters (G152, G151)

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·41·

Page 42

3.

Programming manual

3.6 Coordinate programming

The CNC allows the selection of up to 7 of the 9 possible axes X, Y, Z, U, V, W, A, B, C.

Each of these may be linear, linear to position only, normal rotary, rotary to position only or rotary

with hirth toothing (positioning in complete degrees), according to the specification in the machine

parameter of each "AXISTYPE" axis.

With the aim of always selecting the most suitable coordinate programming system, the CNC has

the following types :

• Cartesian coordinates

• Polar coordinates

• Angle and Cartesian coordinate

Coordinate programming

AXES AND COORDINATE SYSTEMS

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·42·

Page 43

Programming manual

3.6.1 Cartesian coordinates

The Cartesian Coordinate System is defined by two axes on the plane, and by three or more axes

in space.

The origin of all these, which in the case of the axes X Y Z coincides with the point of intersection,

is called Cartesian Origin or Zero Point of the Coordinate System.

The position of the different points of the machine is expressed in terms of the coordinates of the

axes, with two, three, four, or five coordinates.

The coordinates of the axes are programmed via the letter o f t h e a x is ( X, Y, Z , U, V, W , A , B, C, a lw ay s

in this order) followed by the coordinate value.

The values of the coordinates are absolute or incremental, depending on whether it is working in

G90 or G91, and its programming format is ±5.5.

3.

Coordinate programming

AXES AND COORDINATE SYSTEMS

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·43·

Page 44

3.

Programming manual

3.6.2 Polar coordinates

In the event of the presence of circular elements or angular dimensions, the coordinates of the

different points on the plane (2 axes at the same time), it may be easier to express them in polar

coordinates.

The reference point is called Polar Origin, and this will be the origin of the Polar Coordinate System.

A point on this system would be defined by :

Coordinate programming

• The RADIUS (R), the distance between the polar origin and the point.

• The ANGLE (Q), formed by the abscissa axis and the line which joins the polar origin with the

point. (In degrees).

AXES AND COORDINATE SYSTEMS

The values R and Q are absolute or incremental depending on whether you are working with G90

or G91, and their programming format will be R5.5 Q±5.5. The radius value must always be positive.

The values R and Q are incremental and their programming format will be R±5.5 Q±5.5.

The R values may be negative when programming in incremental coordinates; but the resulting value

assigned to the radius must always be positive.

When programming a "Q" value greater than 360º, the module will be assumed after dividing it by

360. Thus, Q420 is the same as Q60 and Q-420 is the same as Q-60.

Programming example assuming that the Polar Origin is located at the Coordinate Origin.

CNC 8055

CNC 8055i

·T· MODEL

SOFT: V01.4X

·44·

Page 45

Programming manual

Absolute coordinates:

G90 R430 Q0 ; Point P0

G03 Q33.7 ; Point P1, in an arc (G03)

G01 R340 Q45 ; Point P2, in a straight line (G01)

G01 R290 Q33.7 ; Point P3, in a straight line (G01)

G01 R230 Q45 ; Point P4, in a straight line (G01)

G01 R360 Q63.4 ; Point P5, in a straight line (G01)

G03 Q90 ; Point P6, in an arc (G03).

Incremental coordinates:

G90 R430 Q0 ; Point 0