Page 1

8040 CNC

N

EW

EATURES

F

REF. 0307

OFT

(S

(S

M: 7.XX)

OFT

M: 7.1X)

Page 2

8040 CNC

NEW F

EATURES

(S

M: 7.XX)

OFT

M: 7.1X)

(S

OFT

Page 2 of 2

Page 3

NDEX

I

Version 7.01

1 Detected errors ..................................................................................................................1

2 Sampling period .................................................................................................................2

3 The meaningless zeros will not be displayed .....................................................................2

4 Management of the new Sercos board ..............................................................................3

5 Key inhibiting codes for the monitors .................................................................................3

6 New work languages ..........................................................................................................3

7 Load version without using an external microprocessor. ...................................................3

8 WINDNC improvements .....................................................................................................4

9 Telediagnosis .....................................................................................................................4

10 Improvements to the profile editor ......................................................................................6

11 Modified variables ..............................................................................................................6

12 New variables .....................................................................................................................7

13 New range of OEM subroutines. ........................................................................................9

14 RPT instruction with program number definition ................................................................9

15 Improved non-random tool magazine management ..........................................................9

16 Improved drive parameter management ..........................................................................10

17 User and OEM arithmetic parameters ..............................................................................10

18 Exponential type of leadscrew backlash peak .................................................................10

19 Functions associated to machine safety ..........................................................................11

19.1 Limit the feedrate of the axes and the spindle speed ................................................11

19.2 Cycle Start disabled by hardware errors ...................................................................12

19.3 Maximum spindle machining speed. .........................................................................12

20 Axes (2) controlled by a drive ...........................................................................................13

21 Mandatory home search ..................................................................................................13

22 Change of active tool from the PLC .................................................................................14

23 Synchronize a PLC axis with a CNC axis ........................................................................14

24 Error register ....................................................................................................................15

25 Path JOG mode ...............................................................................................................15

26 Tool inspection .................................................................................................................17

27 New instructions in the configuration language ................................................................17

28 Improvements in tool compensation ................................................................................18

29 Improvements in high speed machining ...........................................................................19

30 New graphics option .........................................................................................................20

31 Improvement in the tool measuring cycle PROBE1 .........................................................20

31.1 Measure or calibrate the tool length. .........................................................................21

31.2 Measure or calibrate the radius of a tool. ..................................................................23

31.3 Measure or calibrate the tool radius and length. .......................................................24

32 Oscilloscope function .......................................................................................................26

32.1 Configuration .............................................................................................................27

32.2 Scale / Offsets ...........................................................................................................32

32.3 Analysis .....................................................................................................................33

32.4 Parameters ................................................................................................................33

32.5 Actions .......................................................................................................................34

32.6 Begin .........................................................................................................................34

33 MC model. Execute a part-program .................................................................................35

34 MC model. Maintain F, S y Smax on power up ................................................................35

35 MC model. Messages and warnings ................................................................................35

36 MC model. Tool calibration ..............................................................................................35

37 MC model. Cycle selection ...............................................................................................36

38 MC model. Auxiliary M functions in all the cycles ............................................................37

39 MC model. Modifications in the tapping cycle ..................................................................38

40 MC model. Modifications in the Multiple milling and positioning cycles ...........................38

41 MC model. Icon indicating the available options ..............................................................38

42 MC model. Tool measurement and calibration ................................................................39

NEW F

EATURES

Page i of ii

8040 CNC

Page 4

8040 CNC

Version 7.11

1 Detected errors ................................................................................................................43

2 New validation codes .......................................................................................................45

3 Smooth stop in probing move (G75/G76) ........................................................................45

4 Square-corner or round-corner machining when changing tool offset .............................45

5 New management of the distance-coded reference mark (I0) .........................................46

6 Improved look ahead ........................................................................................................46

7 Leadscrew error compensation in both directions ............................................................46

8 Parameters accessible from the oscilloscope or OEM subroutine ...................................47

8.1 Axis parameters that may be modified from the oscilloscope ...................................47

8.2 General parameters modifiable from the oscilloscope ..............................................47

8.3 Machine parameters modifiable from an OEM program ...........................................47

NEW F

EATURES

Page ii of ii

Page 5

ERSION

V

7.01

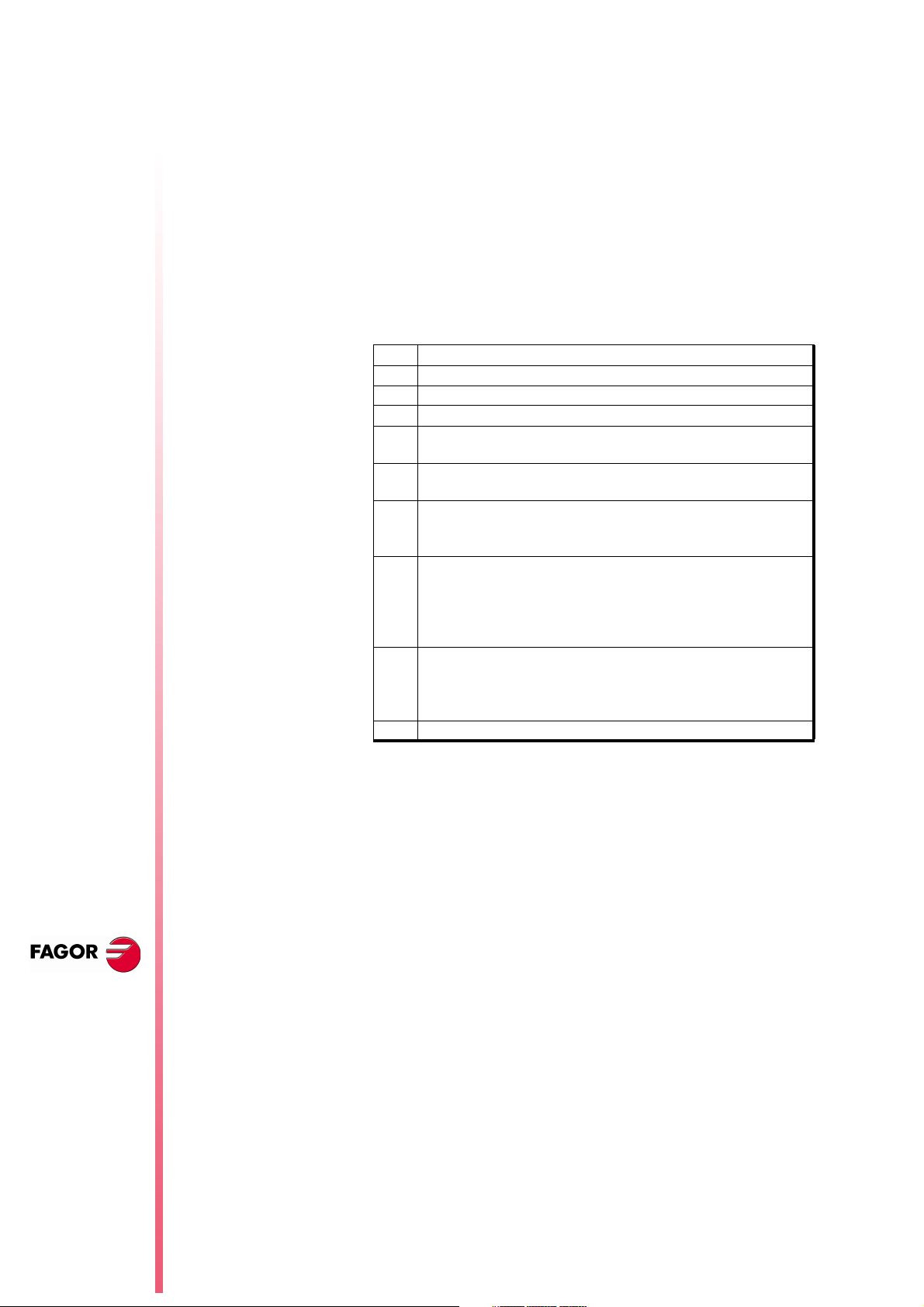

1 Detected errors

NBTOOL Variable

The installation and programming manuals indicate that this variable

is read-only from the CNC, PLC and DNC.

Actually, it is read-only from the CNC and DNC and it can only be

used inside a tool-change subroutine.

OPMODE Variable

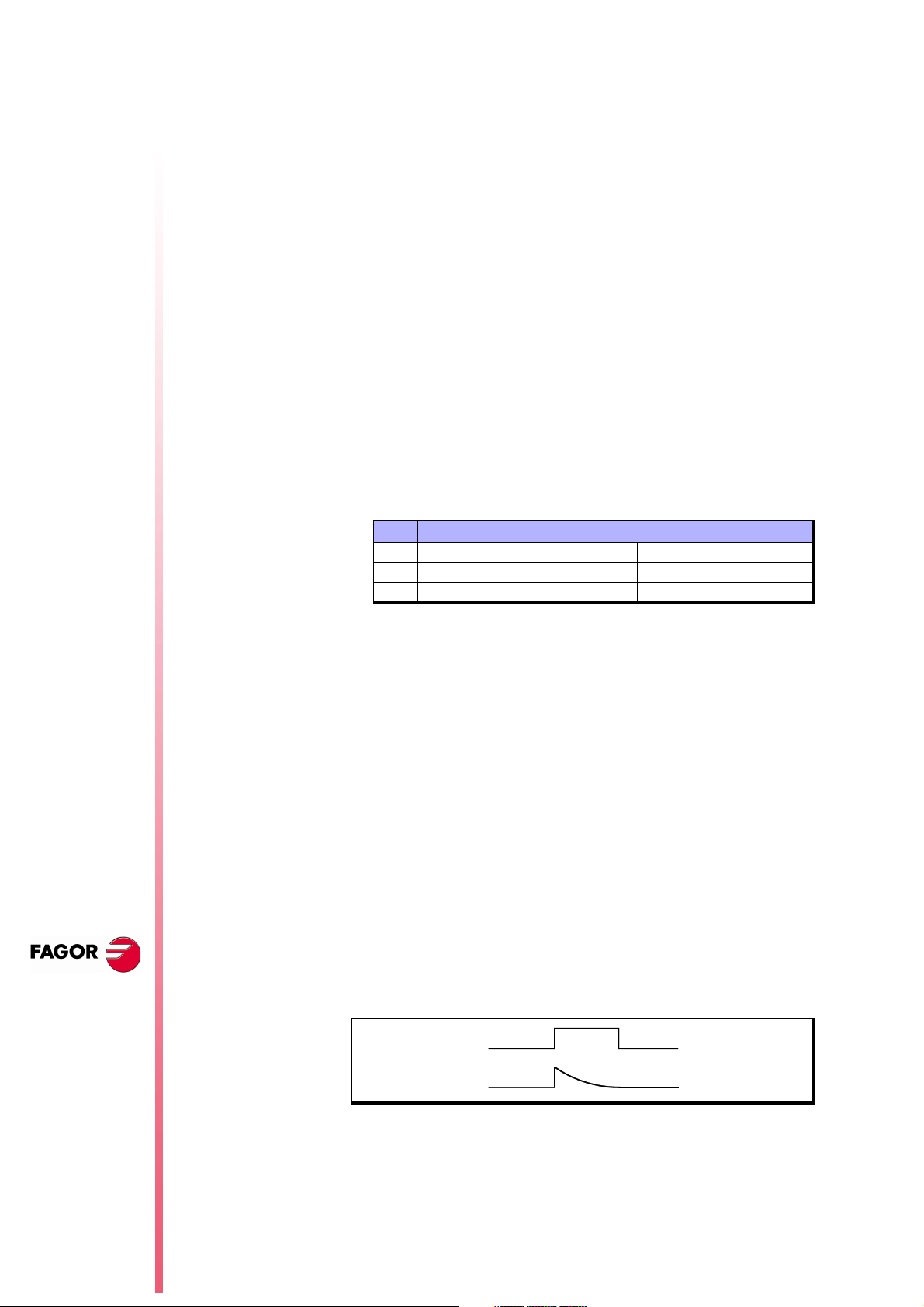

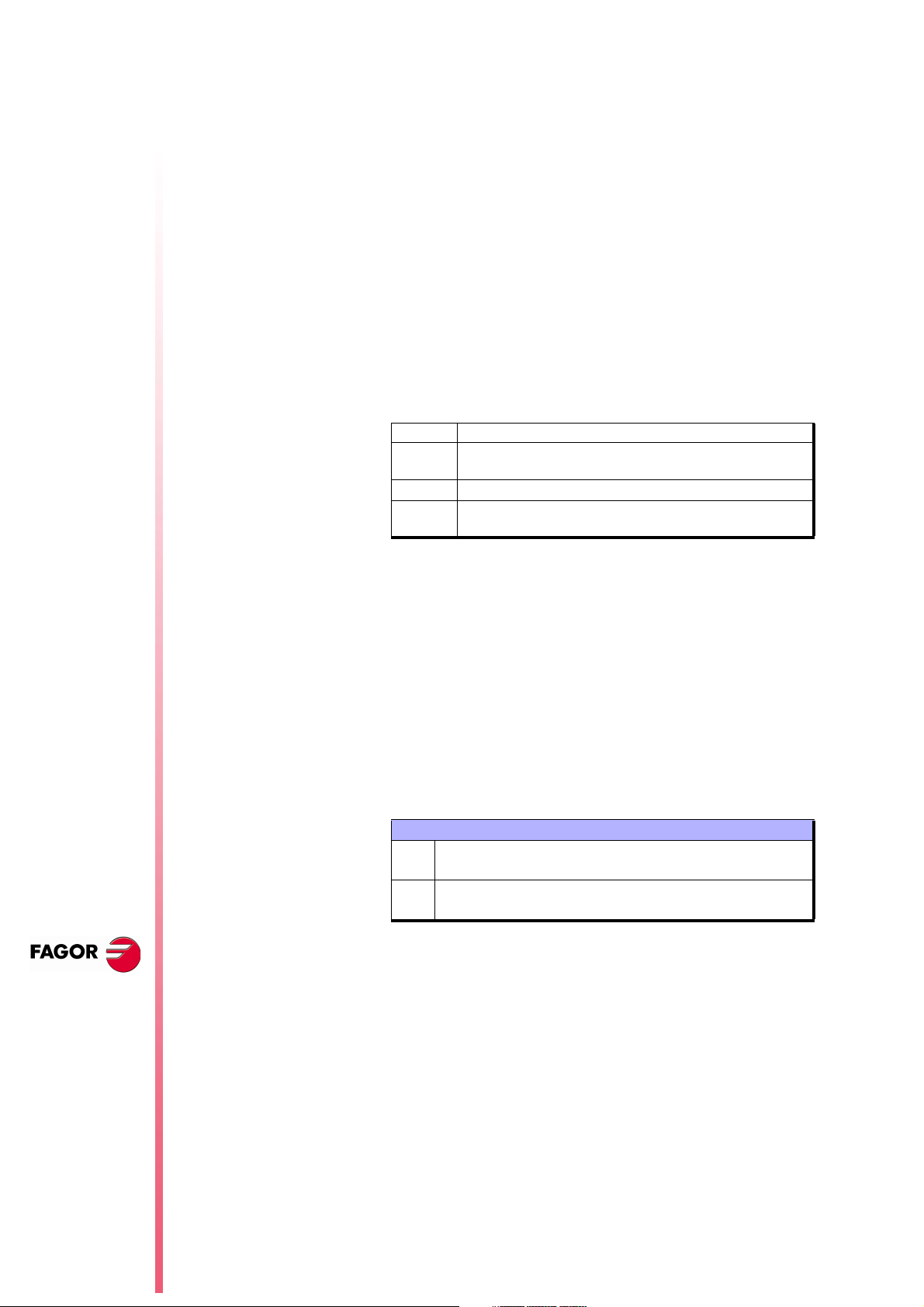

This variable also returns the following code:

8040 CNC

25 Rapid simulation with S=0

56 User parameter table

57 OEM parameter table

117 Oscilloscope.

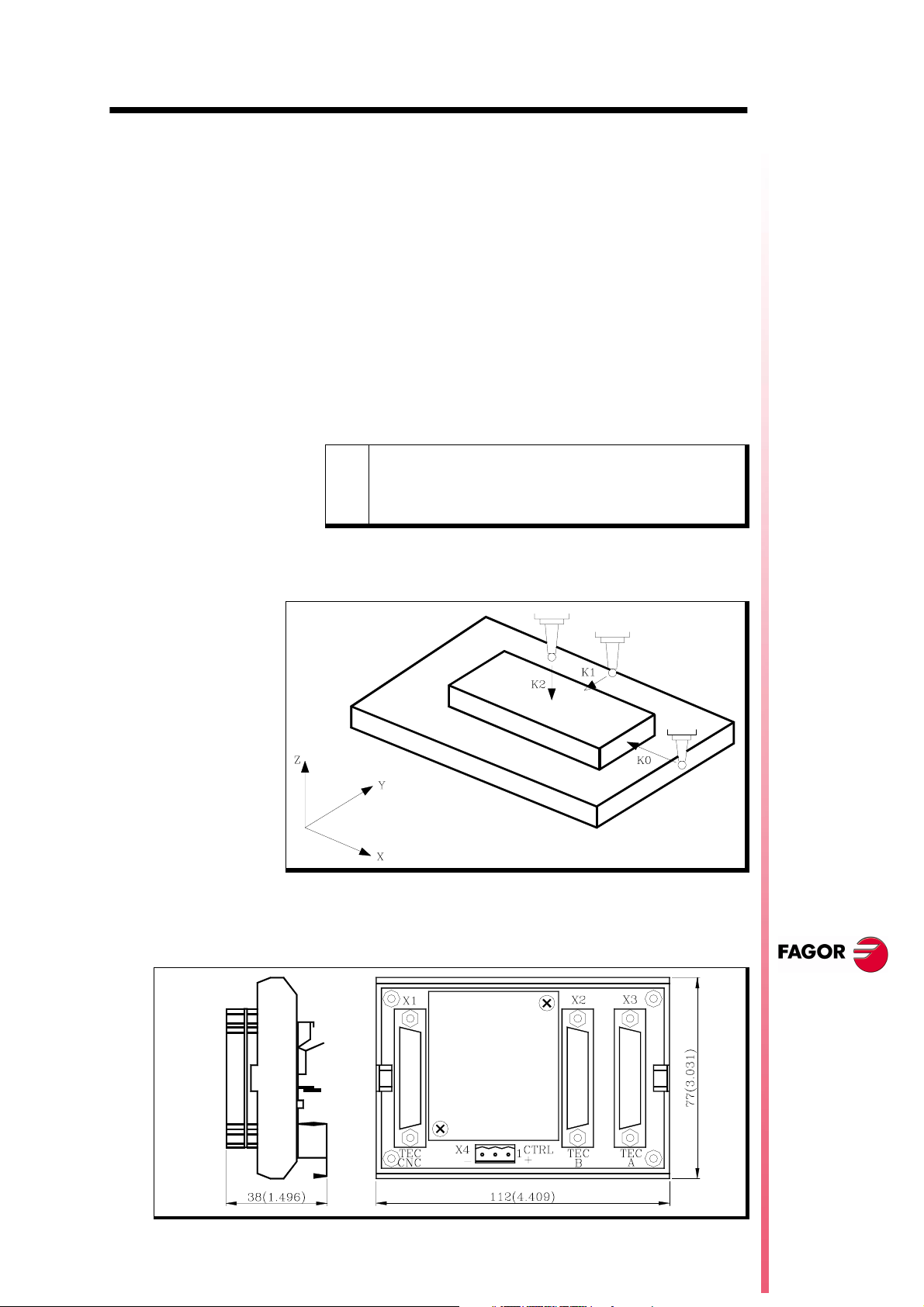

Probe canned cycle for surface measurement (PROBE 3)

The moving direction with K1 is as shown in this figure.

Connection of the KS50/55 adapter:

The installation manual describes how to use this adapter, but the

correct connection is the following:

NEW F

EATURES

(S

M: 7.XX)

OFT

Detected errors

Page 1 of 48

Page 6

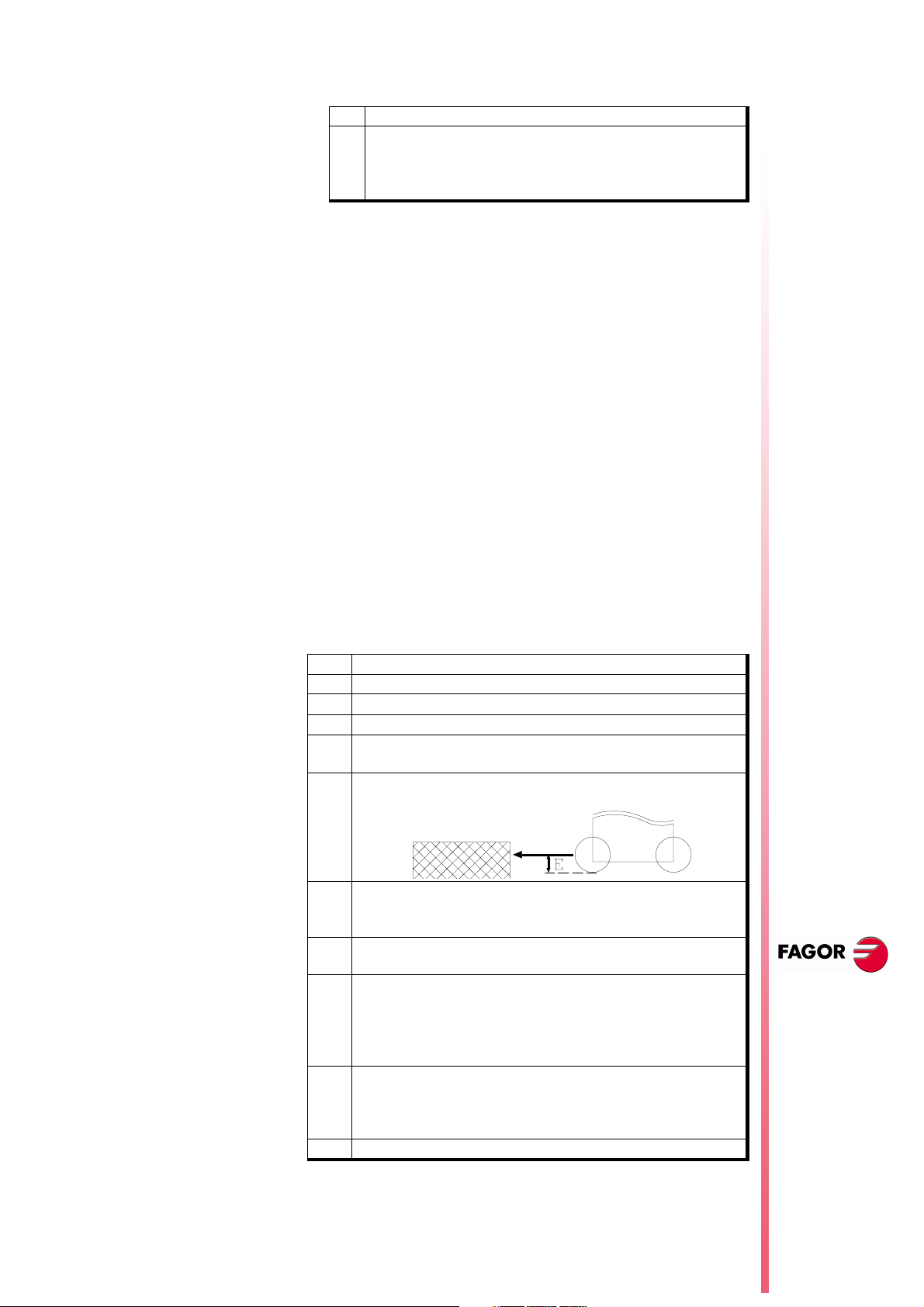

8040 CNC

Main plane simulation

25-pin female SUB-D type (normal density) connector to connect

X1

the "Central Unit + Monitor".

25-pin female SUB-D type (normal density) connector to connect

X2

the "Alphanumeric keyboard + Monitor".

25-pin female SUB-D type (normal density) connector to connect

X3

the "Operator panel".

3-pin male Phoenix connector, 7,62 mm pitch, to select the

X4

keyboard to be attended by the Central Unit.

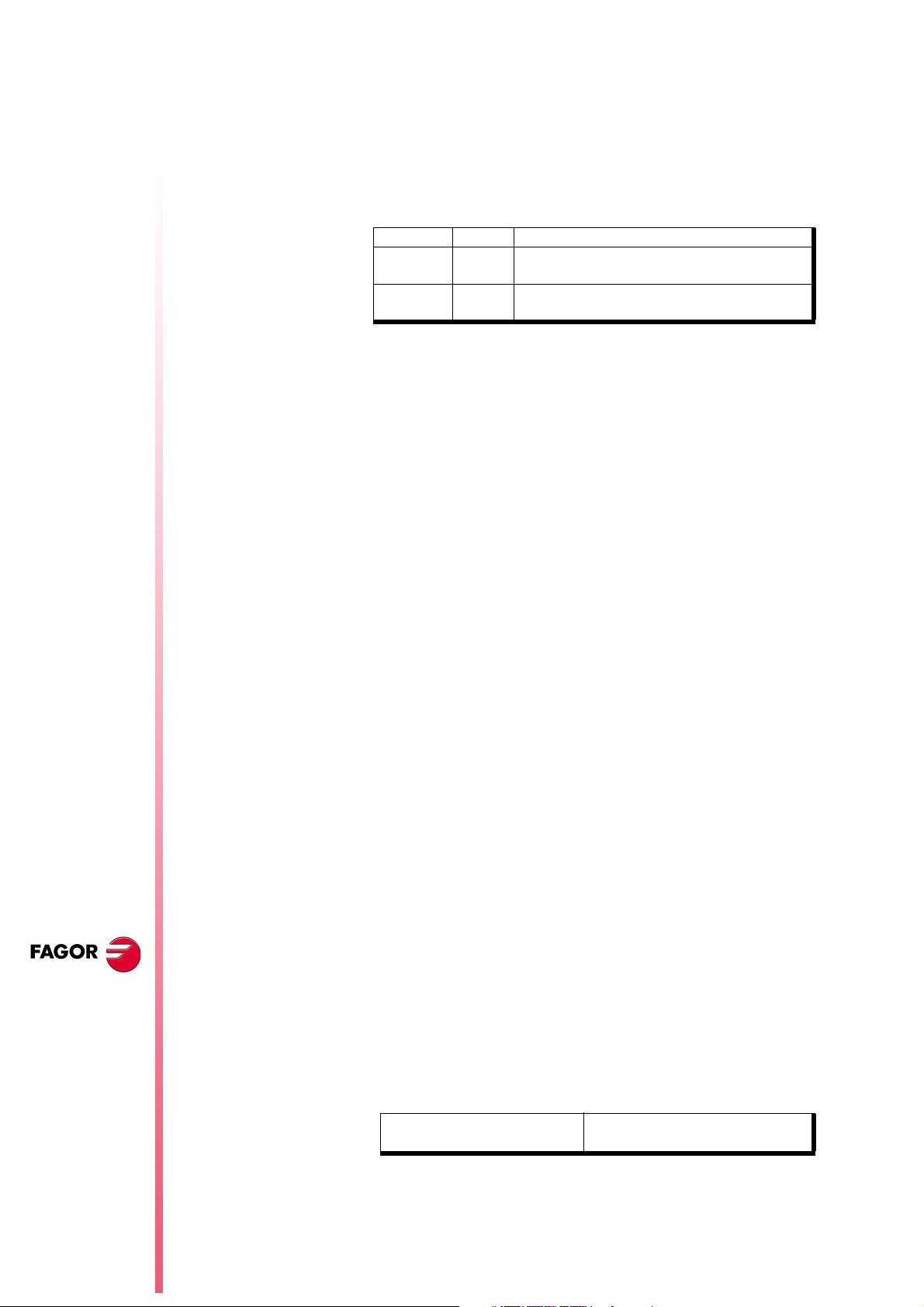

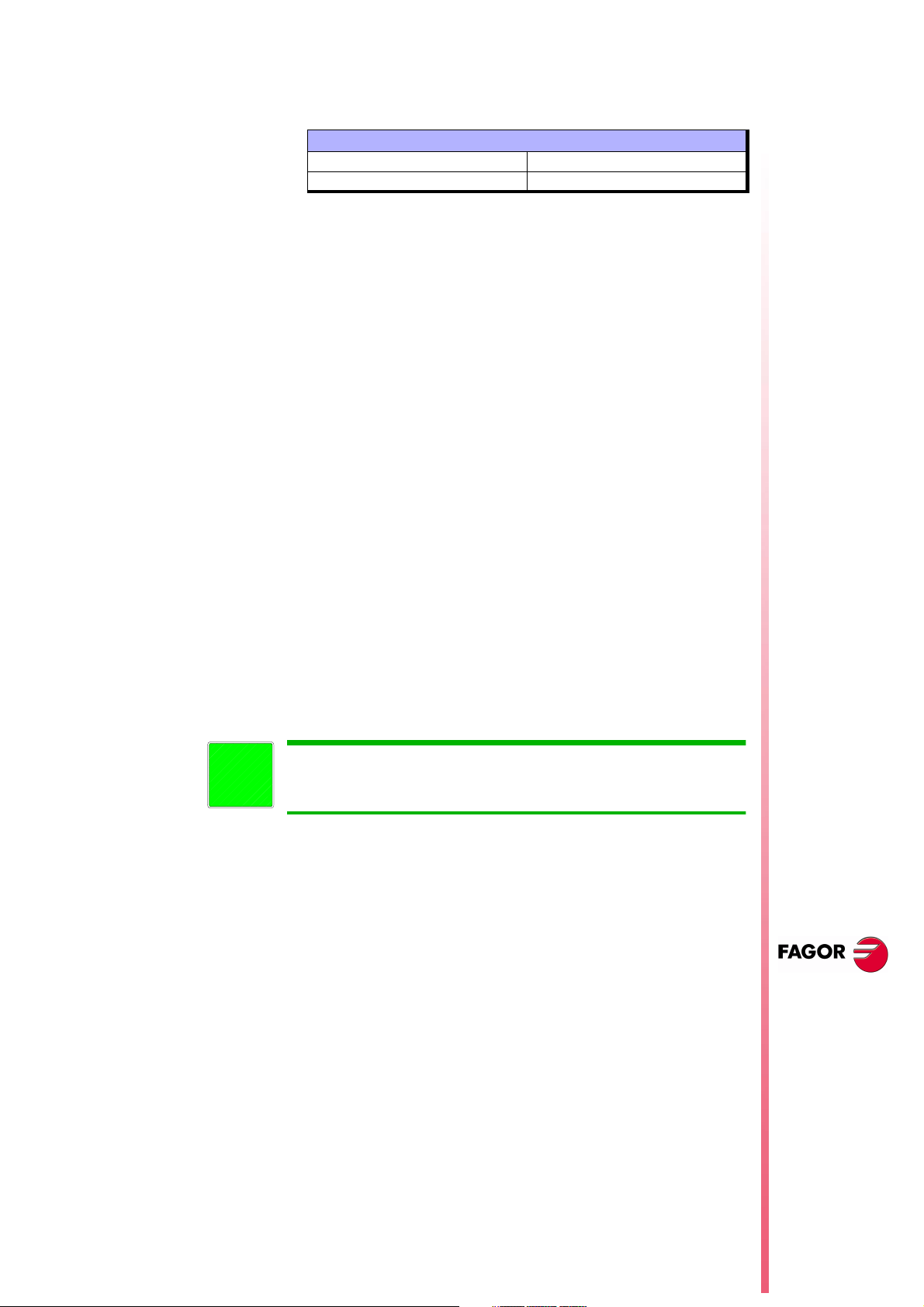

Pin Value Meaning

10V

2

3

GND

The CNC attends to the operator panel

24V

The CNC attends to the alphanumeric keyboard

----

Not being used

External power supply

If connector X4 is not supplied with voltage, the CNC attends to

the operator panel.

Page 2 of chapter 3 of the operating manual does not mention this

type of simulation.

It only executes the movements corresponding to the axes that form

the main plane.

It takes into account the tool radius compensation (functions G41,

G42) thus drawing the tool center path.

It sends the M, S, T functions to the PLC.

It starts the spindle, if programmed.

The axes move at maximum feedrate F0 regardless of the F that was

programmed and it may be varied with the Feedrate Override switch.

2 Sampling period

From this version on, on the 8055/C and 8055i/C models that do not

have the CPU turbo, it is possible to set a sampling period of 2

milliseconds g.m.p. “LOOPTIME (P72)”.

The following values may be allocated to plc.m.p. "CPUTIME (P26)

that sets the time the System CPU dedicates to the PLC when

programming a "LOOPTIME = 2 ms":

CPUTIME = 0 1 ms every 8 samplings, every 16 ms

CPUTIME = 1 1 ms every 4 samplings, every 8 ms

CPUTIME = 2 1 ms every 2 samplings, every 4 ms

By default 0

N

EW FEATURES

(S

M: 7.XX)

OFT

Sampling period

Page 2 of 48

3 The meaningless zeros will not be displayed

From this version on, the data displayed on the screen (positions,

feedrates, etc.) will not display the meaningless zeros to the left of

the value. Example:

From this version on Z -4.210

Previous versions Z -00004.210

Page 7

4 Management of the new Sercos board

This software version is ready to work with the new Sercos boards,

reference: 902103 and newer.

The "Hardware diagnosis" function shows these boards as

"SERCOS816" because they carry the SERCON 816 chip.

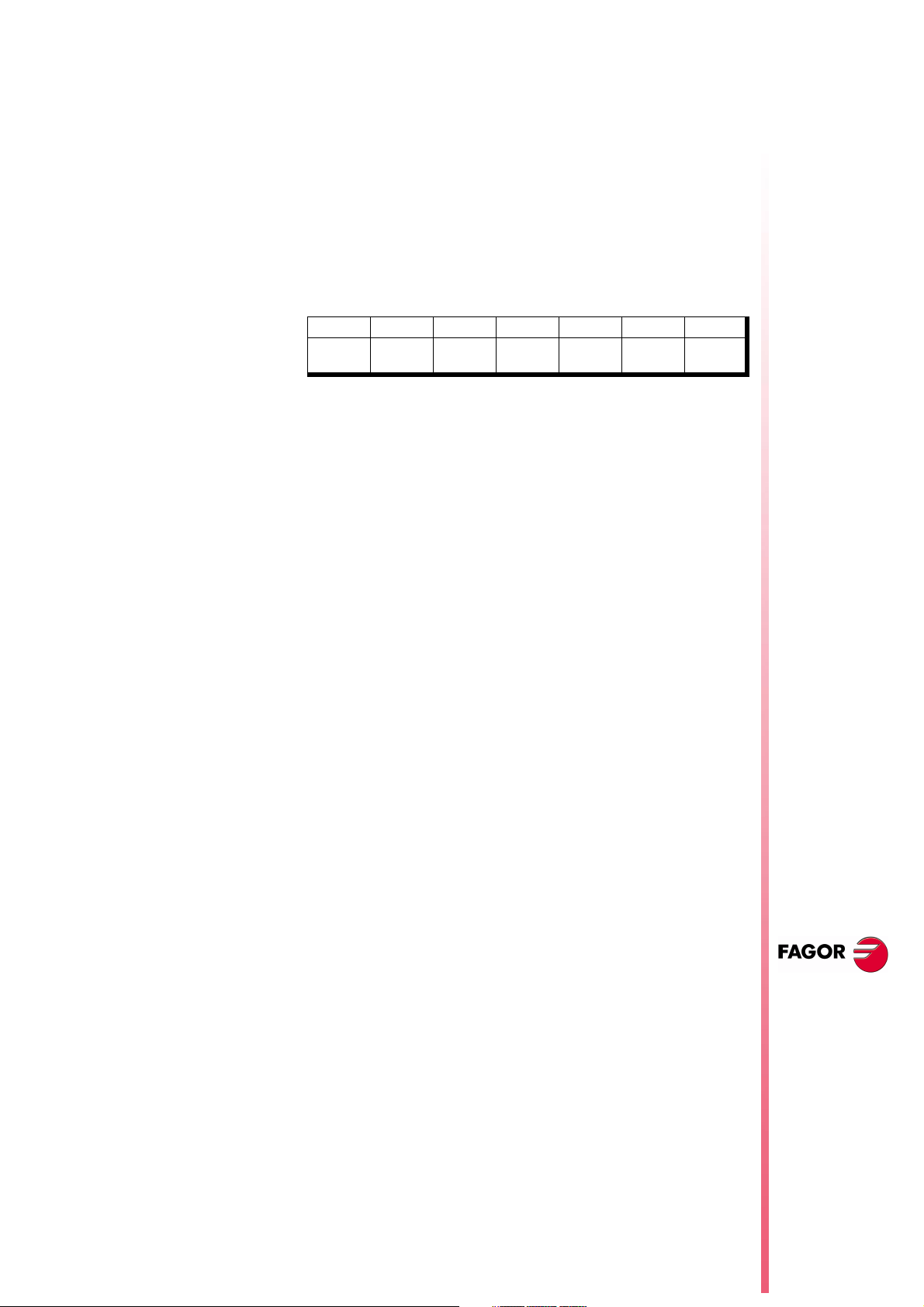

5 Key inhibiting codes for the monitors

The inhibiting codes for softkeys F1 through F7 of monitors models

such as “NMON-55-11-LCD” are:

F1 F2 F3 F4 F5 F6 F7

Bit 24

R508

Bit 25

R508

Bit 26

R508

Bit 27

R508

6 New work languages

Basque and Russian are now available from this version on.

Bit 28

R508

Bit 29

R508

8040 CNC

Bit 30

R508

LANGUAGE (P122)

Defines the work language

Possible values:

0 English 1 Spanish 2 French

3 Italian 4 German 5 Dutch

6 Portuguese 7 Czech 8 Polish

9 Mainland Chinese 10 Basque 11

Russian

By default 0

7 Load version without using an external microprocessor.

This feature is available on 8040 CNC models whose identifying

label shows "03 A" or later and whose software version is V07.01 or

later.

It is not necessary to turn the CNC off and back on or actuate the

external switch to update the software version, as indicated in

section 2.2 of the Operating Manual.

To update the CNC software, proceed as follows:

Remove the "Memkey Card" and insert the "Memory Card" that

•

contains the software version to be updated.

Access the Diagnosis mode - Software Configuration and press

•

the [Load version] softkey.

The CNC will show the software updating stages and their status.

When done updating it, remove the "Memory Card" that contains

•

the software version and insert the "Memkey Card" back.

Note:

• If the "[load version]" softkey is pressed but the Memory

Card containing the software version is missing, the CNC

will issue the relevant error message.

• The CNC cannot execute anything if it has the Memory

Card that contains the software version.

NEW F

EATURES

(S

M: 7.XX)

OFT

Management of the

new Sercos board

Page 3 of 48

Page 8

8040 CNC

(

)

Línea telefónica

8 WINDNC improvements

From this CNC version on and having WINDNC version V2.0 and the

following, it is possible:

Select the work unit for CNC files Option (a).

•

(b)

(c)

(a)

(d)

Then indicate the desired work unit: Memory (b), Hard Disk (c) or

Card A (d).

From a PC, using the WINDNC application, copy from the CNC

•

to the PC or vice versa, any file, program or table available in the

CARDA or hard disk. The available new tables are:

OEP OEM arithmetic parameters

USP USER arithmetic parameters

DRS Spindle drive table

DS2 Table of the Second Spindle drive

DPX Table for the Auxiliary spindle drive

DRX, DRY,

DRZ, DRU,

DRV, DRW,

DRA, DRB,

DRC

These tables are compatible with the tables that have been

saved from the drive to a PC via serial line using WINDDS.

Tables for axis drives

N

EW FEATURES

•

•

•

•

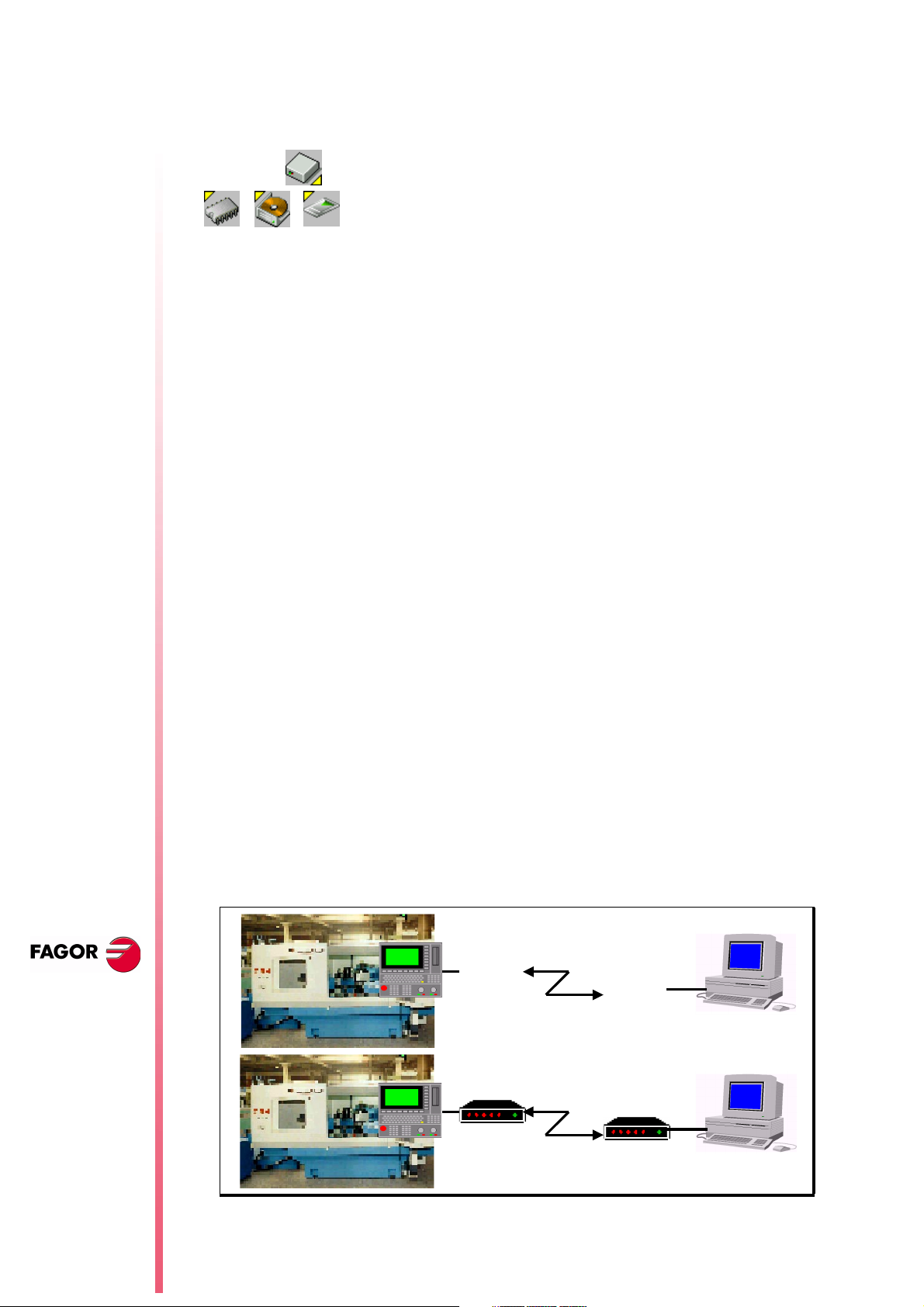

9 Telediagnosis

It may be used to govern and monitor the CNC status remotely

through the RS232 serial line or using a modem through a telephone

line.

Consult the table directory (machine parameters, zero offsets,

magazine, tools, tool offsets, geometry, user parameter, OEM

parameter, etc.).

Read global and local arithmetic parameters individually using

variables GUPn and LUP(a,b).

The installation and programming manuals describe how to use

these variables.

Having telediagnosis, display CNC screens at the PC in remote

mode via serial line or via MODEM.

Having telediagnosis, dial the telephone number associated with

the modem at the PC.

CNC PC

(RS232)

RS232

(S

improvements

Page 4 of 48

M: 7.XX)

OFT

WINDNC

CNC PC

Módem

Módem

Telephone line

Internet - RDSI

Page 9

The remote PC must have the WINDNC application version 2.00 or

later installed in it and the CNC software version must be V07.01 or

later.

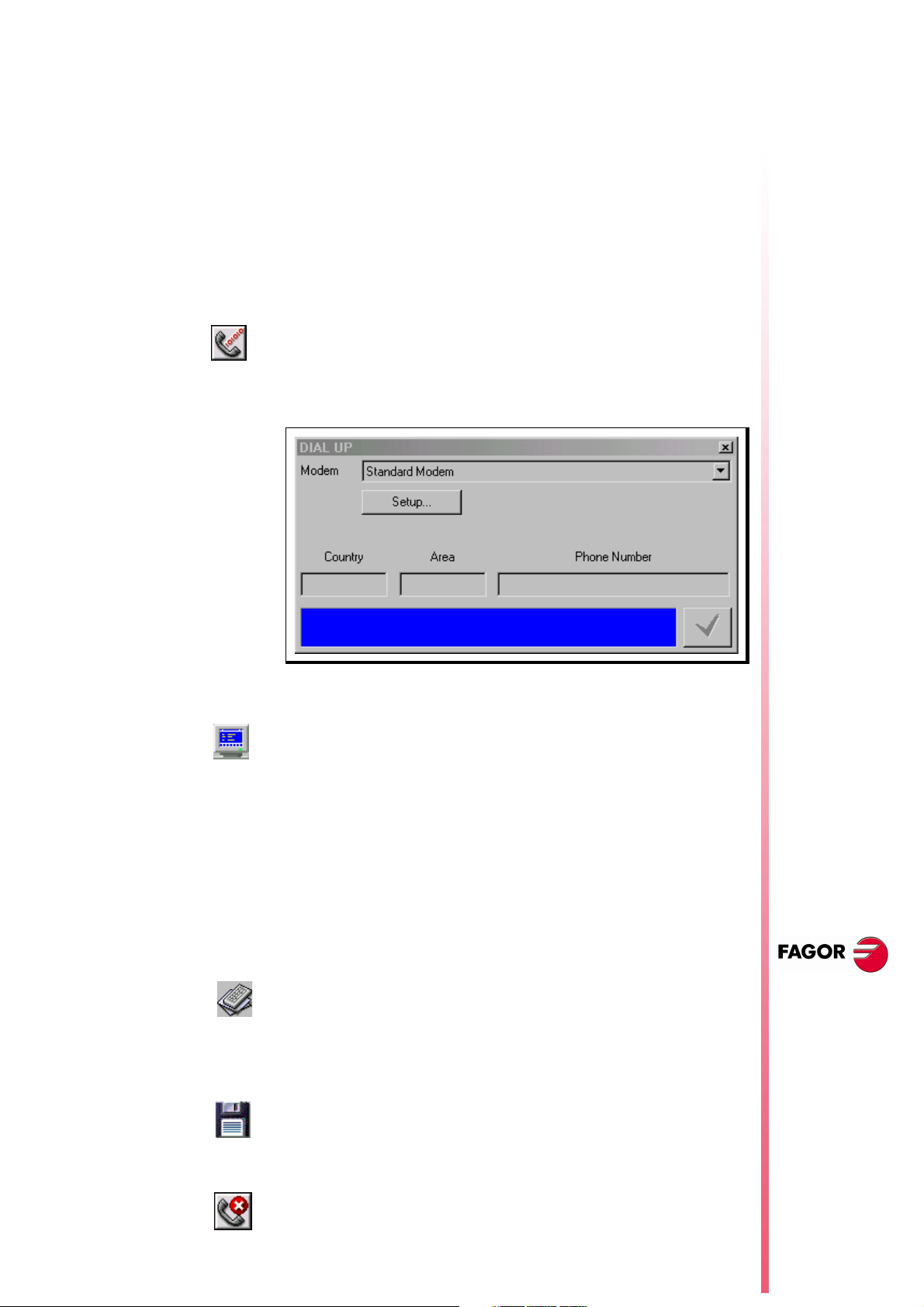

CNC connection to the telephone line

It must be done through the RS232 serial line and using a modem

that has RS232 serial line communication.

First, turn on the modem, then the CNC and then the remote PC, in

that order.

PC connection to the telephone line

Connect the PC to the telephone line through a modem and execute

the WINDNC application. Within the options for the serial line, select

(a)

option (a).

The application shows the following window. Indicate which modem

is being used and the telephone number to dial.

8040 CNC

PC-CNC communication (Telediagnosis)

Once the connection has been established (either via serial line or

via modem), select the "telediagnosis" option (b) of the WINDNC

(b)

application.

From this moment on, the CNC may be governed either from its own

keyboard or remotely from the PC keyboard.

The PC will display the same information (screens) as the CNC.

•

It is possible to access the different CNC modes, modify tables

•

and parameters when knowing the password, simulate

programs, etc.

For safety reasons, it is not possible to move the axes of the

•

machine or execute part-programs.

With the WINDNC application, it is also possible to send to the CNC

a file containing a keystroke sequence, option (c).

(c)

While in remote control mode, no other DNC command may be

executed through the same serial line (for example the execution of

an infinite program).

With option (d), it is possible to save into a BMP file a CNC screen

image that is being displayed.

(d)

NEW F

EATURES

(S

M: 7.XX)

OFT

Telediagnosis

End the communication (End telediagnosis)

To end the communication, select option (e) from those associated

to the serial line in the WINDNC application.

(e)

Page 5 of 48

Page 10

10 Improvements to the profile editor

The following improvements have been made:

It is possible to select the coordinate system of the work plane, axes

and their direction.

8040 CNC

The right window, under "Display Area", indicates whether the

autozoom is on or not and the selected coordinate system.

It includes graphic data editing. Use the up-arrow and down-arrow

keys to select the desired window and key in the desired value.

It is possible to modify rectangular and circular elements.

There are 2 new softkeys:

Save and continue

To save a profile without having to quit the session.

Undo

To undo the last modification.

On conversational models, MC and MCO, it indicates the number of

the profile being edited.

11 Modified variables

HARCON

It indicates, with bits, the CNC's hardware configuration.

The bit will be "1" when the relevant configuration is available.

From now on, bits 24, 25, 26 indicate the type of monitor and bits 27,

28 the CPU turbo board being used.

26,25,24 000

bit

001

28,27 00

01

Color LCD Monitor

Monochrome LCD monitor

Turbo board at 25 Mhz

Turbo board at 40 Mhz

N

EW FEATURES

(S

M: 7.XX)

OFT

Improvements to

the profile editor

Page 6 of 48

MPGn

MP(X-C)n

MPSn

MPSSn

MPASn

MPLCn

These variables, related to machine parameters, that until now were

read-only, from this version on, can be read and written from the

CNC in the following cases:

When they are executed inside an OEM program.

•

When they are executed inside an OEM subroutine.

•

To modify machine parameters from the PLC, an OEM subroutine

containing the relevant variables must be executed using the

CNCEX instruction.

In order for the CNC to assume the new values, one must operate

according to the indicators associated with each machine

parameter.

// It is necessary to press the keystroke sequence: "Shift -

Reset" or turn the CNC off and back on.

/ Just press Reset.

The rest of the parameters (those unmarked) will be updated

automatically, only by changing them.

Page 11

12 New variables

Feedrate related variables

FREAL(X-C)

FTEO(X-C)

Actual (real) X-C axis feedrate Is read-only from the CNC, DNC and

PLC.

Theoretical X-C axis feedrate Is read-only from the CNC, DNC and

PLC.

Coordinate related variables

DPLY(X-C)

DRPO(X-C)

GPOS(X-C)n p

"Coordinates of the selected axis" displayed on the screen Is readonly from the CNC, DNC and PLC.

Position indicated by the X-C axis Sercos drive (Sercos variable

PV51 or PV53 of the drive). Is read-only from the CNC, DNC and

PLC.

Programmed coordinate for a particular axis (X-C), in the indicated

block (n) and program (p).

(P100 = GPOSX N99 P100)

It assigns to P100 the value of the coordinated programmed for

the X axis in label N99 and located in program P100.

It Is read-only and it is only enabled at the CNC. Only programs

located in RAM memory may be consulted.

8040 CNC

If the defined program number does not exist, it issues Error 69

•

"Program does not exist".

If the defined block number does not exist, it issues error 1060

•

"undefined label".

If the requested axis is not programmed in the indicated block, it

•

returns the value: 100000.0000

Spindle related variables

DRPOS

SDRPOS

FTEOS

SFTEOS

Position indicated by the Sercos drive of the spindle. Is read-only

from the CNC, DNC and PLC.

Position indicated by the Sercos drive of the second spindle. Is readonly from the CNC, DNC and PLC.

Theoretical spindle turning speed. Is read-only from the CNC, DNC

and PLC.

Theoretical second spindle turning speed. Is read-only from the

CNC, DNC and PLC.

Speed limit related variables

NEW F

(S

OFT

EATURES

M: 7.XX)

MDISL

Maximum spindle machining speed. It is read-write from the PLC

and read-only from DNC and CNC.

This variable is also updated with the programmed S value, in the

following cases:

When programming "G92 S" in MDI mode

New variables

Page 7 of 48

Page 12

When programming "G92 S" in ISO code in MC mode.

Variables related to Probe cycles

8040 CNC

TIPPRB

TIPDIG

It indicates the PROBE cycle being executed at the CNC. Is readonly from the CNC, DNC and PLC.

It indicates the DIGIT cycle being executed at the CNC. Is read-only

from the CNC, DNC and PLC.

PLC related variables

PLCMM(n)

It permits reading modifying a single PLC mark (the PLCM variable

permits reading or modifying 32 marks at once). It is read-write and

it is only available from the CNC.

(PLCMM4 = 1)

It sets mark M4 to "1" and leaves the rest untouched

(PLCM4 = 1)

It sets mark M4 to "1" and the following 31 marks (M5, through

M35) to "0"

Feedback related variables

ASIN(X-C)

"A" signal of the CNC sinusoidal feedback for the X-C axis. Is readonly from the CNC, DNC and PLC.

N

EW FEATURES

(S

M: 7.XX)

OFT

New variables

BSIN(X-C)

ASINS

BSINS

SASINS

SBSINS

"B" signal of the CNC sinusoidal feedback for the X-C axis. Is readonly from the CNC, DNC and PLC.

"A" signal of the CNC sinusoidal feedback for the spindle. Is readonly from the CNC, DNC and PLC.

"B" signal of the CNC sinusoidal feedback for the spindle. Is readonly from the CNC, DNC and PLC.

"A" signal of the CNC sinusoidal feedback for the second spindle. Is

read-only from the CNC, DNC and PLC.

"B" signal of the CNC sinusoidal feedback for the second spindle. Is

read-only from the CNC, DNC and PLC.

Variables related to the WGDRAW application

PANEDI

DATEDI

Number of the screen created by the user or by the OEM using the

WGDRAW application for diagnosis, consultation, work cycle, etc,

that is being consulted. Is read-only from the CNC, DNC and PLC.

Number of the screen element created using the WGDRAW

application that is being consulted. Is read-only from the CNC, DNC

and PLC.

Page 8 of 48

Page 13

13 New range of OEM subroutines.

A new range of OEM subroutines has now been defined.

Available subroutine ranges:

General subroutines SUB 0001 - SUB 9999

OEM subroutines SUB 10000 - SUB 20000

Although OEM subroutines are treated like the general ones, the

have the following restrictions:

They can only be defined in OEM programs, having the [O]

•

attribute. Otherwise, it shows error 63 "Program subroutine

number between 1 and 9999.".

If the subroutine to be executed using CALL, PCALL or MCALL

•

is an OEM subroutine and it is located in a program that does not

the [O] attribute, it will issue Error 1255 "Subroutine restricted to

OEM program".

14 RPT instruction with program number definition

From this version on, the RPT instruction can execute a portion of

the same program or of the indicated program.

8040 CNC

(RPT N(expression), N(expression), P(expression))

The new parameter "P" indicates the number of the program located

in RAM memory containing the two blocks defined by the N labels.

If parameter "P" is not defined, the CNC interprets that the portion

•

to be repeated is located in the same program.

If the defined program number does not exist, it issues Error 69

•

"Program does not exist".

Warning:

Since the RPT instruction does not interrupt block preparation or tool

i

compensation, it may be used when using the EXEC instruction and

while needing to maintain tool compensation active.

15 Improved non-random tool magazine management

When the tool changer is configured as non-random, the tools must

be placed in the tool magazine table in the pre-established order (P1

T1, P2 T2, P3 T3, P4 T4, etc.).

TOOLMATY (P164)

With this improvement, it is possible to assign several tools to each

tool position.

This g.m.p. is taken into account when using a non-random tool

magazine. It indicates how many tools may be assigned to each

turret position.

0 One tool per position

1 Several tools per position.

By default 0

NEW F

EATURES

(S

M: 7.XX)

OFT

New range of OEM

subroutines.

Page 9 of 48

Page 14

16 Improved drive parameter management

From this version on, it also possible to save and load into a

peripheral device or PC the drive parameter tables via Sercos serial

line.

8040 CNC

For that, select the parameter page of the desired drive at the CNC

and press the relevant softkey.

A file saved from the CNC via WINDNC may be loaded into the drive

via DDSSETUP and vice versa.

17 User and OEM arithmetic parameters

There are now two new ranges of global arithmetic parameters.

User parameters Range: P1000 - P1255.

OEM parameters Range: P2000 - P2255

For compatibility with previous versions, global arithmetic

parameters P100-P299 are maintained and may be used by the

user, by the OEM and by the CNC cycles.

There are now 2 new tables of global arithmetic parameters.

Arithmetic parameter tables available:

GUP Global parameters P100-P299

USP User parameters P1000-P1255

OEP OEM parameters P2000 - P2255

Changing an OEM parameter requires an OEM password.

N

EW FEATURES

(S

M: 7.XX)

OFT

Improved drive

parameter

management

OEM parameters and subroutines having OEM parameters may

only be written in OEM programs having the [O] attribute.

On the MC and MCO models, when using OEM parameters in the

configuration programs, these programs must have the [O] attribute.

If they don't, an error will be issued when editing a user cycle that

refers to OEM parameters in write mode.

General machine parameters “ROPARMIN” and “ROPARMAX” may

be used to protect any global parameter (user and OEM included)

against being written.

There is no restriction to read these parameters.

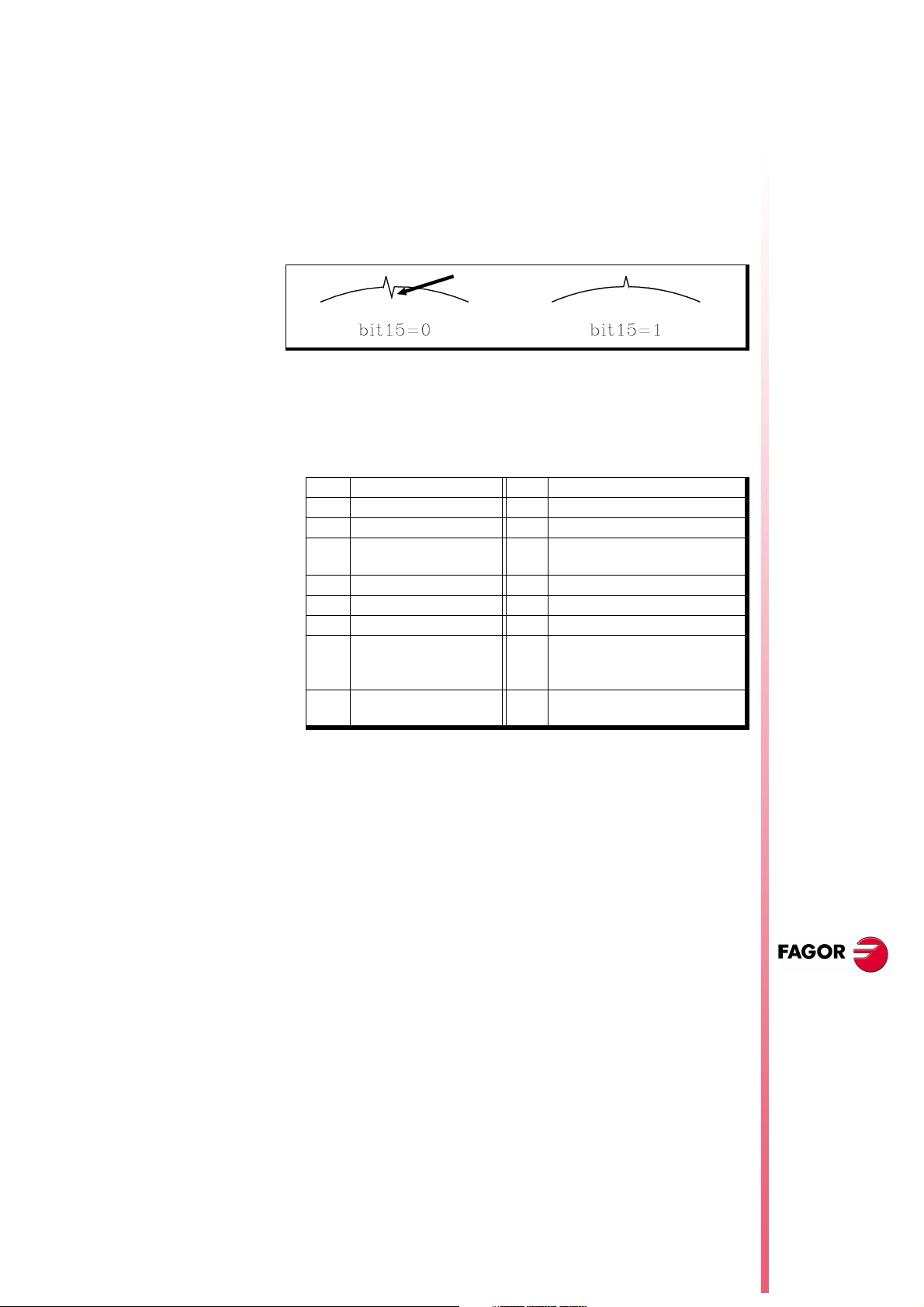

18 Exponential type of leadscrew backlash peak

The additional command pulse used to make up for the possible

leadscrew backlash in movement reversals may be rectangular or

exponential.

If the duration of the rectangular pulse is adjusted for low speed, it

could be excessive for high speed or insufficient for low speed when

adjusted for high speed.

Page 10 of 48

In this cases, it is recommended to use the exponential type that

applies a strong pulse at the beginning and decreases in time.

Page 15

Bit 16 of g.m.p. “ACTBAKAN (P144)” indicates the backlash peak

being used.

0 rectangular leadscrew backlash peak

1 exponential type of leadscrew backlash peak

By default 0

ACTBAKAN (P144)

A finer tuning of the leadscrew backlash consists in testing the circle

geometry and watch for internal peaks when changing quadrants

(left figure). In these cases, it is recommended to set bit 15 of g.m.p.

“ACTBAKAN (P144)” to "1" to eliminate the internal peaks.

Under these conditions, the CNC eliminates the leadscrew backlash

peak as soon as it detects a movement reversal. If the internal peaks

are not eliminated, adjust the leadscrew backlash compensation

better.

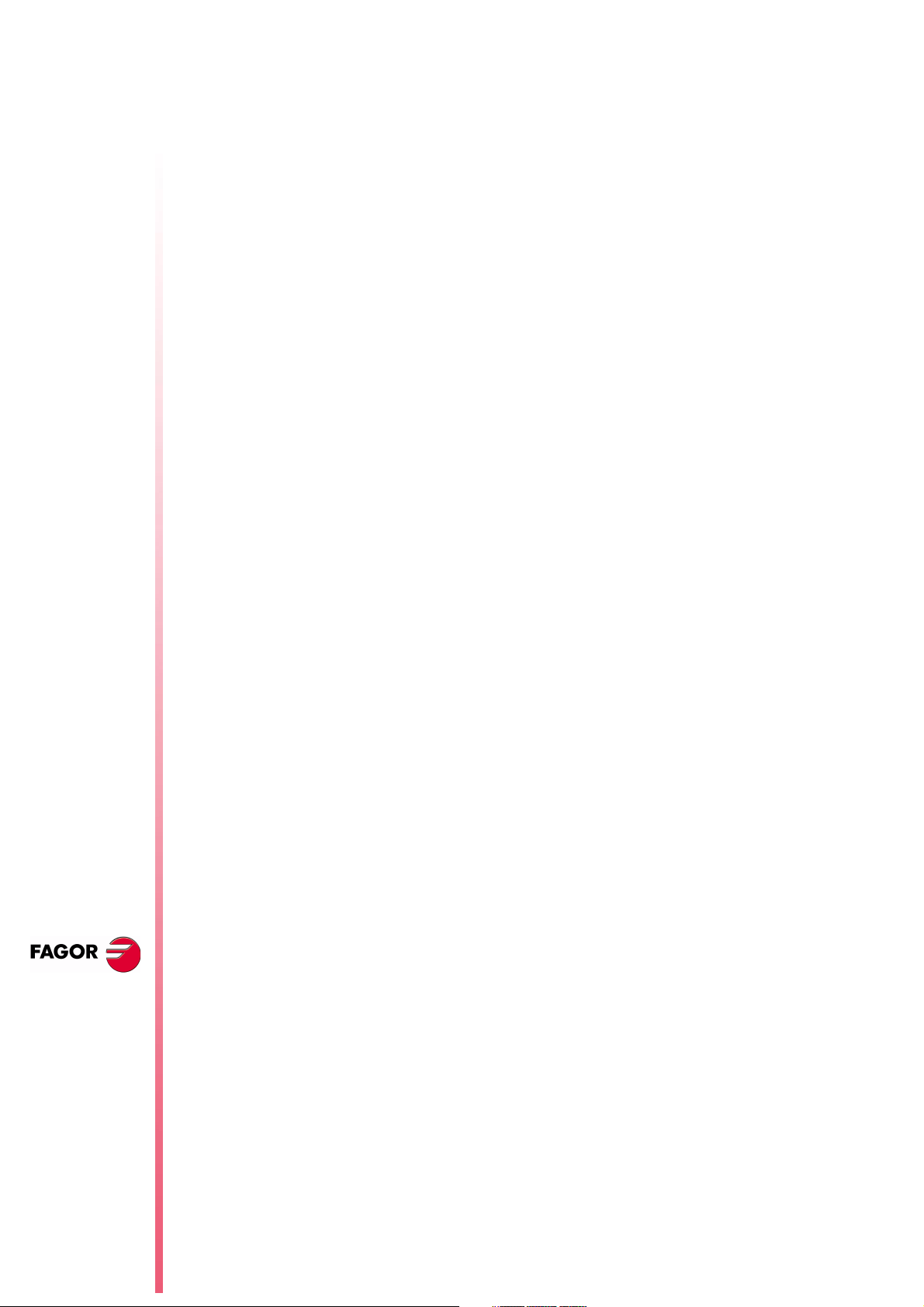

It has 16 bits counted from left to right.

bit Function bit Function

19

210

Additional pulse with G2

3

412

513

614

715

816

/ G3

11

It minimizes internal peaks

detected with the circle

geometry test

Exponential leadscrew

backlash peak

8040 CNC

By default, all bits are set to "0".

19 Functions associated to machine safety

19.1 Limit the feedrate of the axes and the spindle speed

It is possible to limit the feedrate of the axes and the spindle turning

speed.

FLIMIT (P75)

SLIMIT (P66)

FLIMITAC (M5058)

SLIMITAC (M5059)

The a.m.p. "FLIMIT" sets the maximum feedrate for each axis and

the s.m.p. "SLIMIT" sets the maximum turning speed for each

spindle.

When the PLC sets this signal high, it limits the feedrate of all the

axes. It does not let any feedrate to exceed the value set by the

corresponding a.m.p. "FLIMIT (P75)" .

When the PLC sets this signal high, it limits the speed of all the

spindles. It does not let any feedrate to exceed the value set by the

corresponding s.m.p. "SLIMIT (P66)" .

The limitation is applied in all work modes, including the PLC

channel. When the mark is high, the CNC applies the limitation and

when going low, it restores the programmed F or S.

NEW F

EATURES

(S

M: 7.XX)

OFT

Functions

associated to

machine safety

Page 11 of 48

Page 16

When the spindle moves with PLCCNTL, the spindle limitation is

ignored.

19.2 Cycle Start disabled by hardware errors

8040 CNC

If when pressing the Cycle-Start key, a hardware error is detected

(Sercos board error, CAN board error, etc.), the CNC issues the

corresponding error message and does not allow executing or

simulating the program.

19.3 Maximum spindle machining speed.

To limit the spindle speed, use the MDISL variable associated with

speed limits. It is read-write from the PLC and read-only from DNC

and CNC.

This variable is also updated with the programmed S value, in the

following cases:

When programming "G92 S" in MDI mode

•

When programming "G92 S" in ISO code in MC mode.

•

In MC mode, when a new speed limit is defined in the "SMAX"

•

field.

The speed limits entered via CNC, PLC (PLCSL) and DNC (DNCSL)

keep the same functionality and priority unaffected by the new

MDISL variable; in other words, the CNC keeps limiting the spindle

speed like until now.

In order to comply with the safety regulation, it is recommended to

manage from the PLC the variables associated with speed limits as

shown in the following example:

N

EW FEATURES

(S

M: 7.XX)

OFT

Functions

associated to

machine safety

Page 12 of 48

A new part-program cannot be executed without previously

•

entering the speed limit. Otherwise, a message will be displayed.

If the program is executed again, the limit does not have to be

entered again, it is only required when executing the program for

the first time.

While executing a program if a new limit is entered in MDI, the

•

new one will replace the previous one.

In independent MC cycles it is not required to enter the SMAX

•

because it is already defined in each cycle.

If the program being executed already has a G92S, it will be

•

validated only if it is smaller than the one programmed in MDI.

When having two main spindles, the speed limit entered will be

•

valid for both.

PRG

REA

()=CNCRD(OPMODA,R100,M1000) ; Reading of OPMODA

B0R100 AND INCYCLE = M100 ; Indicator of program in execution

;

DFU M100 ; At the beginning of the execution

= CNCRD(PRGN,R101,M1000) ; reads the program in execution

= CNCRD(MDISL,R102,M1000) ; and the S limitation from MDI

;

M100 ; During the execution

= CNCRD(PRGSL,R103,M1000) ; and the S limitation from CNC

;

M100 AND CPS R101 NE R201 ; If new program in execution

= M101 ; activates mark M101

;

M100 AND CPS R101 EQ R201 ; If same program in execution

Page 17

= M102 ; activates mark M102

;

M101 ; If new program in execution

AND CPS R102 EQ 0 ; and the "S" has not been limited from MDI

= ERR10 ; Error 10: "The S has not been limited from

MDI"

;

M101 ; If new program in execution

AND CPS R102 NE 0 ; and the "S" has been limited from MDI

= MOV R101 R201 ; it copies the number of the program in

execution

= MOV R102 R202 ; and the S limitation from MDI

;

M102 ; If same program in execution

AND CPS R102 NE 0 ; and the "S" is limited again from MDI

= MOV R102 R202 ; it copies the S limitation from MDI

;

M100 ; If program in execution

AND CPS R202 LT R103 ; and "S" limitation from MDI < "S" limitation

from CNC

= CNCWR(R202,PLCSL,M1000) ; Applies "S" limitation from the PLC with the

value set in MDI

;

M100 ; If program in execution

AND CPS R202 GT R103 ; and "S" limitation from MDI > "S" limitation

from CNC

= CNCWR(R210,PLCSL,M1000) ; It does not limit "S" from PLC (R210=0)

;

DFD M100 ; At the end of execution

= CNCWR(R210,PLCSL,M1000) ; it cancels "S" limitation from the PLC

= CNCWR(R210,MDISL,M1000) ; and it resets the MDISL variable

;

END

8040 CNC

20 Axes (2) controlled by a drive

Until this version, when having 2 axes controlled by a single drive,

the polarity of the analog output (command sign) always

corresponded to that of the main axis.

From this version on, since sometimes the turning direction of the

two axes may be different, the sign of the command for each axis will

taken into account [the one set by a.m.p “LOOPCHG (P26)”].

Warning

This new version is not compatible with previous versions.

On machines having axes controlled by a single drive the secondary

axis might run away.

Before installing the new software, make sure that the a.m.p.

"LOOPCHG (P26)" of the associated axis has the same value as that of

the main axis.

21 Mandatory home search

The CNC forces a home search on an axis by setting the relevant

REFPOIN* mark low in the following cases:

On CNC power-up

•

After executing SHIFT RESET

•

When the feedback is direct through the axes board and a

•

feedback alarm occurs.

NEW F

EATURES

(S

M: 7.XX)

OFT

Axes (2) controlled

by a drive

Page 13 of 48

Page 18

When losing feedback count via Sercos due to broken

•

communication. Difference greater than 10 microns (0.00039")

or 0.01º

When changing machine parameters that affect the memory

•

distribution, for example: number of axes.

8040 CNC

In all these cases, a home search must be carried out so the signal

is set back high.

22 Change of active tool from the PLC

If the tool change process is interrupted, the values of the tool

magazine table and active tool may not reflect the machine's reality.

To update the tool table, variables TOOL, NXTOOL, TOD and

NXTOD that until now were read-only are now read-write from the

PLC as long as a block or a part-program is not being executed or

simulated.

TOOL Number of the active tool

NXTOOL Number of the next tool that is selected, but waiting for the

execution of an M06 to become active.

TOD Number of the active tool offset

NXTOD Number of the offset of the next tool that is selected, but

waiting for the execution of an M06 to become active.

This way, it is possible to resume the tool change from the PLC and

redefine the tool table according to their positions using the TMZT

variable.

To allocate a magazine position to the tool that is considered active

by the CNC and is physically in the tool magazine, proceed as

follows:

Cancel the tool, TOOL=0 and TOD=0

1.

Assign the relevant position using the TMZT variable.

2.

N

EW FEATURES

(S

M: 7.XX)

OFT

Change of active

tool from the PLC

When trying to write in variables TOOL, NXTOOL, TOD and NXTOD

check the OPMODA variable to make sure that no block or partprogram is being executed or simulated. The following bits must be

at "0".

OPMODA

bit 0 Program in execution

bit 1 Program in simulation

bit 2 Block in execution via MDI, JOG

bit 8 Block in execution via CNCEX1

23 Synchronize a PLC axis with a CNC axis

To synchronize an axis of the PLC channel with another one of the

CNC channel (main channel), set a.m.p. SYNCHRO (P3) of the PLC

axis indicating which axis it must synchronize with.

Axis synchronization is carried out from the PLC by activating the

general input "SYNCHRO" of the axis to be coupled as slave (PLC

axis).

To assure that both axes are stopped when they are being

synchronized, we suggest:

Page 14 of 48

Page 19

To execute a special M function at the CNC so the PLC executes

•

another M function in the PLC channel and activates the general

input "SYNCHRO".

The M function of the main channel must not end until the PLC's

•

M function execution is completed and the ENABLE signal of the

slave axis is set high.

Once both axes are synchronized, it won't be possible to program

movements of the PLC axis. Otherwise, error 1099 will be issued:

"Do not program a slaved axis".

During synchronization, it does not check whether the PLC axis gets

in position or not. For this reason:

The logic output "ENABLE" of the PLC axis is activated (allowing

•

motion).

The logic output "INPOS" of the PLC axis is deactivated (the axis

•

is NOT in position).

General input "INHIBIT" of the PLC axis is ignored, thus not being

•

possible to prevent it from moving.

The execution of the movement of the synchronized slave axis

•

cannot be aborted even by activating the general input

"PLCABORT".

8040 CNC

24 Error register

If an error occurs canceling the "ENABLE" logic outputs of all the

axes, it also cancels the synchronization.

To end synchronization, cancel the "SYNCHRO" general input of the

PLC axis.

To assure that the PLC axis recovers its position after the

synchronization, it is recommended to use other 2 special M

functions, one at the CNC and another one at the PLC.

The "CNC" screen of the "STATUS" mode offers the softkey: [BB].

Pressing this softkey displays the error history indicating the error

number and when it occurred.

This information is very useful to the service technician. Pressing the

[SAVE] softkey requests the number of the CNC program to store

that information.

If the service department asks you for that program, transfer it to a

PC via DNC and send it to the corresponding address via internet.

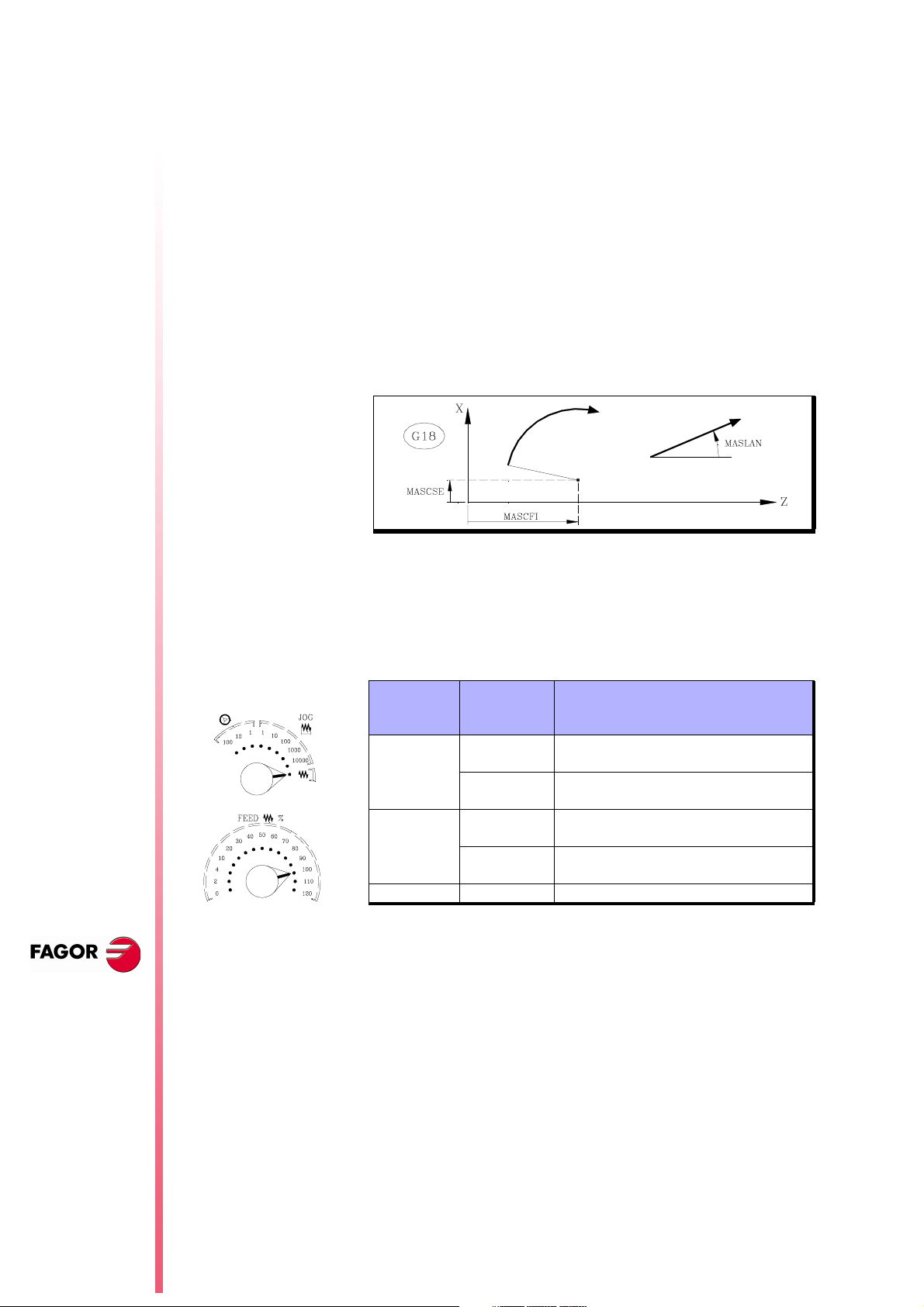

25 Path JOG mode

It is similar to the "Path Handwheel" mode.

The "Path Handwheel" mode acts at the Handwheel position of the

selector switch whereas the "Path JOG" acts at the continuous and

incremental jog positions of the selector switch.

"Path JOG" may be used to act upon the jog keys of an axis to move

both axes of the plane at the same time for chamfering (straight

sections) and rounding (curved sections).

The CNC assumes as "Path JOG" the keys associated with the X

axis.

NEW F

EATURES

(S

M: 7.XX)

OFT

Error register

Page 15 of 48

Page 20

This feature must be managed from the PLC.

To turn on or off the "Path JOG" work mode, use CNC logic input

“MASTRHND” M5054,

M5054 = 0 "Path JOG" function off.

M5054 = 1 "Path JOG" function on.

8040 CNC

To indicate the type of movement, use CNC logic input

“HNLINARC” M5053

M5053 = 0 Linear Path

M5053 = 1 Circular path.

For a linear path, indicate the path angle in the MASLAN variable

(value in degrees between the linear path and the first axis of the

plane)

For an arc, indicate the arc center coordinates in the MASCFI,

MASCSE variables (for the first and second axes of the main

plane)

Variables MASLAN, MASCFI and MASCSE may be read and

written from the CNC, DNC and PLC.

Operation

N

EW FEATURES

(S

M: 7.XX)

OFT

Considerations

When pressing one of the associated keys, X+ and X-, the CNC acts

as follows:

Selector

Switch

Position

Continuous

Incremental

Handwheel It ignores the keys.

Path JOG Type of movement

OFF

ON

OFF

ON

Only the axis and in the indicated

direction

Both axes in the indicated direction along

the indicated path

Only the axis, the selected distance and

in the indicated direction

Both axes, the indicated distance and

direction, but along the indicated path

The rest of the keys always operate the same way regardless of

whether the "Path JOG" function is on or off. It only moves the

selected axis and in the indicated direction.

It assumes as axis feedrate the one selected in JOG mode and it is

affected by the override. If F0 is selected, it assumes the one

indicated by a.m.p. “JOGFEED (P43)”. The [Rapid] key is ignored.

Path JOG mode

Page 16 of 48

The movements in "Path JOG" observe the travel limits and zone

boundaries

The movements in "Path JOG" may be aborted:

By pressing the [CYCLE STOP] key

•

By selecting one of the handwheel positions of the JOG selector

•

switch.

Page 21

•

•

26 Tool inspection

By setting the general logic input “MASTRHND (M5054)” =0.

Setting the general logic input “\STOP (M5001)”=0.

The I and K values

Warning

The tool inspection mode now offers a new option: "Modify Offsets".

This window shows (at the top) a help graphic and the tool fields that

can be edited.

When editing the active tool, it is possible:

To modify the I and K data.

Select another tool for calibration (T xx Enter).

When NOT editing the active tool, it is possible:

To modify the I, K and D data.

Select another tool for calibration (T xx Enter).

The values entered in the I, K fields are incremental, they are added

to the ones already in the table. The "I" data is given in diameter.

The new g.m.p. “MAXOFFI (P165)” and “MAXOFFK (P166)” indicate

the maximum value that may be entered in each field. When trying

to enter a greater value, the relevant message will be displayed.

To assume the new I and K values, select the tool again.

8040 CNC

27 New instructions in the configuration language

The new token "UNMODIFIED" of the configuration language

indicates that the associated element must not take the editing

focus.

;(UNMODIFIED)

It is programmed as a prefix of the instructions

;(W1=GUP100)

It may be used to associate the "W1" data with the value of a

global parameter, variable or resource of the PLC and the

"W1" element is assigned the editing focus.

;(AUTOREFRESH W6=FLWEX)

It refreshes (updates) the value of the graphic element W6

and it assigns the editing focus to it.

The resulting new instructions are:

;(UNMODIFIED W1=GUP170)

It associates the "W" data with the value of a global

parameter, variable or resource of the PLC, but the "W1"

element does not take the editing focus.

;(UNMODIFIED AUTOREFRESH W6=FLWEX)

It refreshes (updates) the value of the graphic element W6 but

it does not take the editing focus.

NEW F

EATURES

(S

M: 7.XX)

OFT

Tool inspection

Page 17 of 48

Page 22

28 Improvements in tool compensation

8040 CNC

COMPTYPE (P74)

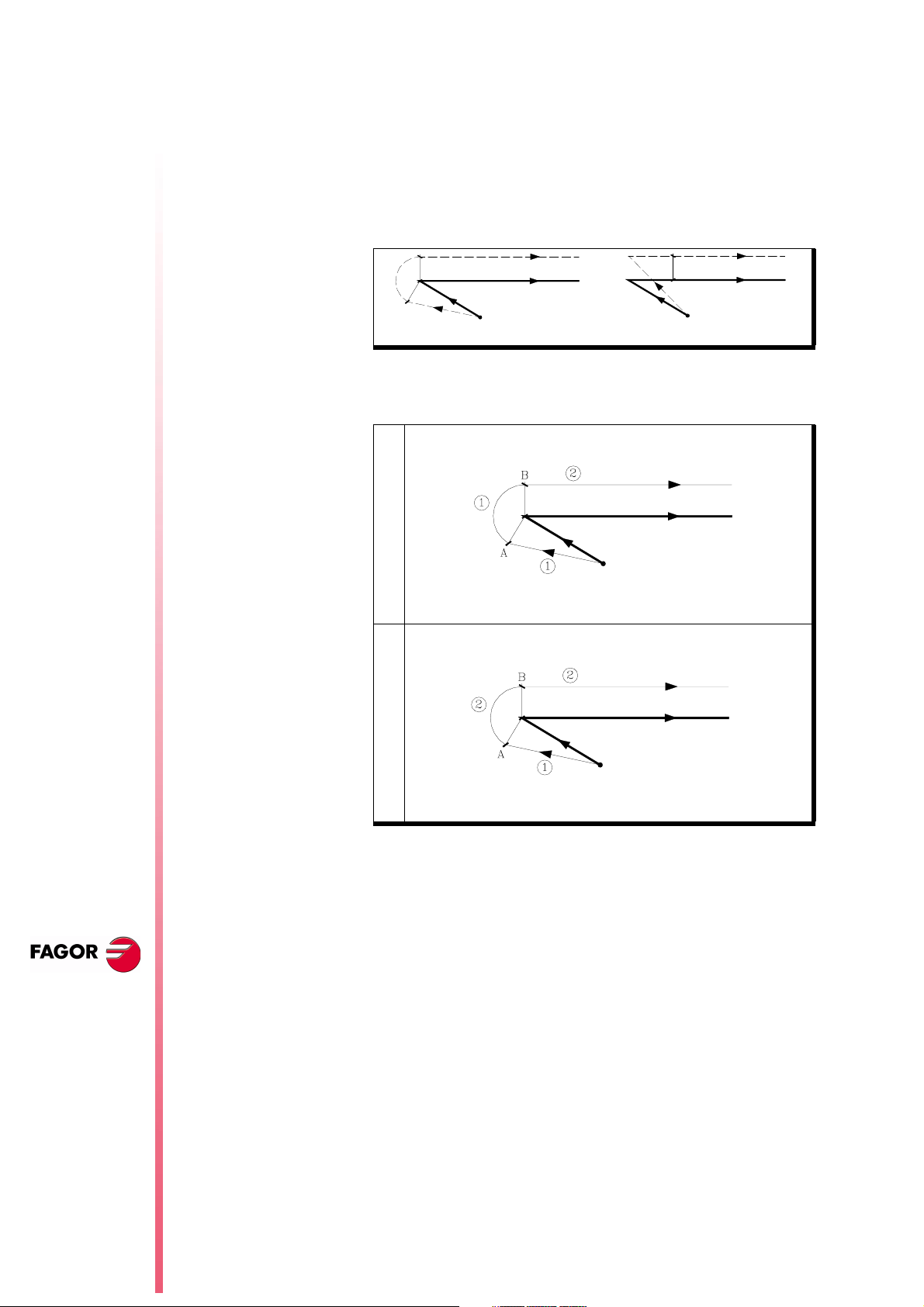

From this version on, this g.m.p. has two digits.

The units set the beginning and end of radius compensation applied

by the CNC (like it was before).

x0 It approaches the starting point going around the corner

x1 it goes directly perpendicular to the point (without going

around the corner)

COMPTYPE= x0 COMPTYPE= x1

The tens indicate whether the additional block of the compensation

is executed at the end of the current block or at the beginning of the

next block with compensation.

00 It is executed at the end of the current block (like in previous

versions).

N

EW FEATURES

(S

M: 7.XX)

OFT

Executing block by block (single block mode), the first

movement ends at point "B".

10 It is executed at the beginning of the next block with

compensation

Executing block by block (single block mode), the first

movement ends at point "A".

By default COMPTYPE=00

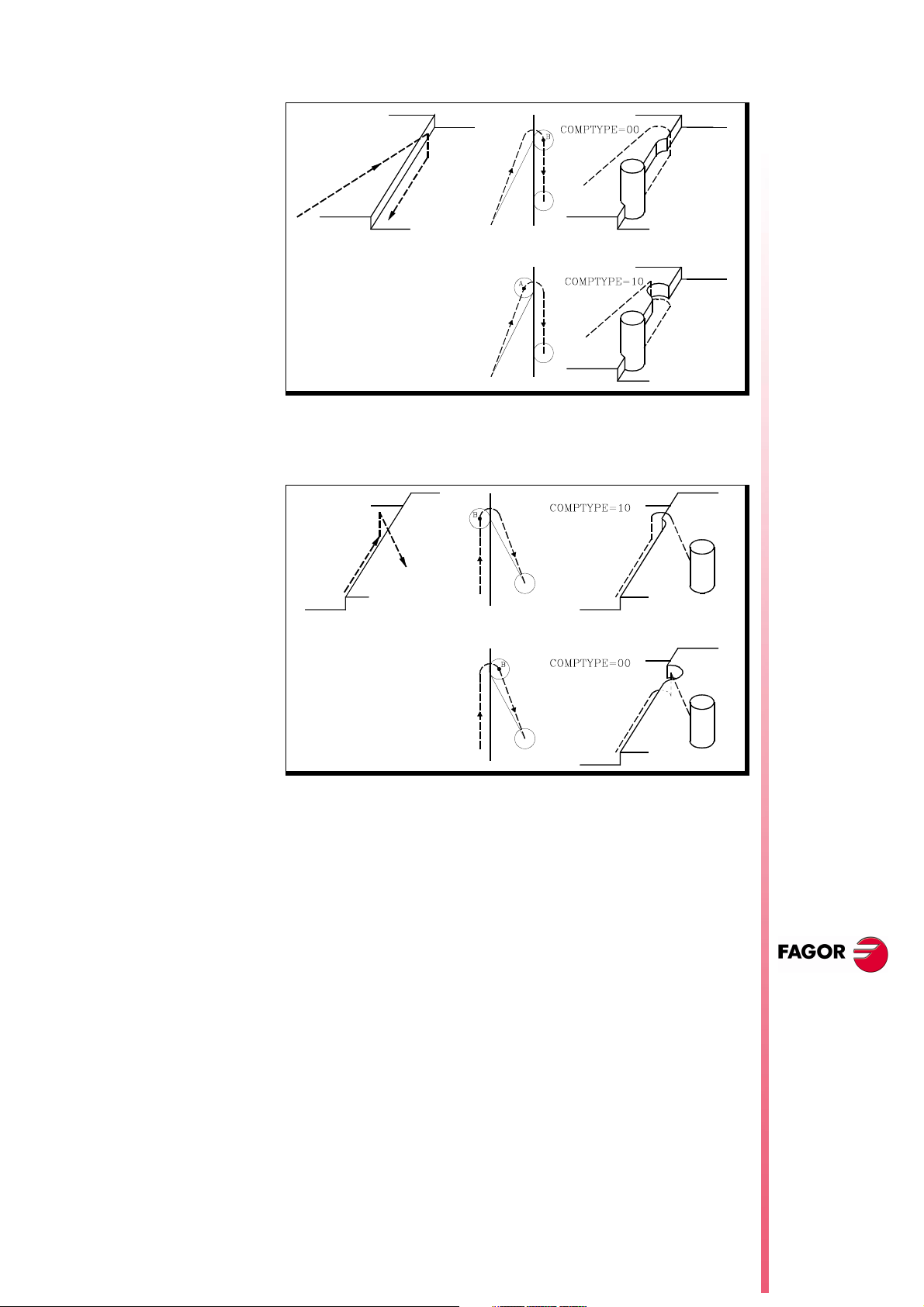

When the beginning or end of the compensation takes place to a

different plane (there is an intermediate vertical movement) and at

an angle greater than 270º it is recommended to check the CNC's

behavior as shown next:

At the beginning of the compensation, the tool should be positioned

before penetrating into the part. The additional block must be

Improvements in

tool compensation

Page 18 of 48

Page 23

executed in the upper plane and therefore together with the first

block “COMPTYPE=00”.

At the end of the compensation, the tool should withdraw from the

part without penetrating into it. The additional block must be

executed in the upper plane and therefore together with the second

block “COMPTYPE=10”.

8040 CNC

29 Improvements in high speed machining

The number of blocks analyzed in advance (look-ahead) has been

increased. From 50 blocks to 75.

The extreme cases have been improved, such as small blocks (of a

few microns) in order to machine faster and more smoothly.

Jerk control can now be applied in Look-ahead, g.m.p. “JERKACT

(P160) and TLOOK (P161)”.

Using Jerk in Look-ahead, a trapezoidal acceleration profile is

applied with a ramp slope equivalent to the maximum jerk of the axis.

The maximum jerk depends on the value assigned to a.m.p.

“JERKLIM (P67)” of that axis and of the axes involved in the

programmed path.

JERKACT (P160)

This parameter has 16 bits counted from left to right.

Bit 16 indicates whether to apply Jerk control in Look-ahead or not.

(0) Not applied.

NEW F

EATURES

(S

M: 7.XX)

OFT

Improvements in

high speed

machining

Page 19 of 48

Page 24

8040 CNC

(1) Applied.

By default 0 (not applied)

If "Jerk Control in look ahead" has been selected, the CNC analyzes

the a.m.p “JERKLIM (P67)” of each axis. During look-ahead, the

CNC assumes, for the axes with “JERKLIM (P67)=0”, the value

suggested in that parameter.

TLOOK (P161)

Real block processing time for look-ahead.

If assigned a value smaller than the real one, the machine will vibrate

and if assigned a value greater than the real one the machining

slows down.

Possible values Integers between 0 and 65535 ms

This value is calculated as follows:

Execute, in G91 and G51 E0.1, a program with many small blocks,

at least 1000. For example: “X0.01 Y0.01 Z0.01”.

Measure the program execution time, making sure that the machine

does not vibrate. Divide the execution time by 1000 (or the number

of blocks executed) and assign the resulting value, in microseconds,

to g.m.p. "TLOOK (P161)".

We recommend the use of the oscilloscope function and verify that

the internal variable VLOOKR remains constant which means that

there is no vibration.

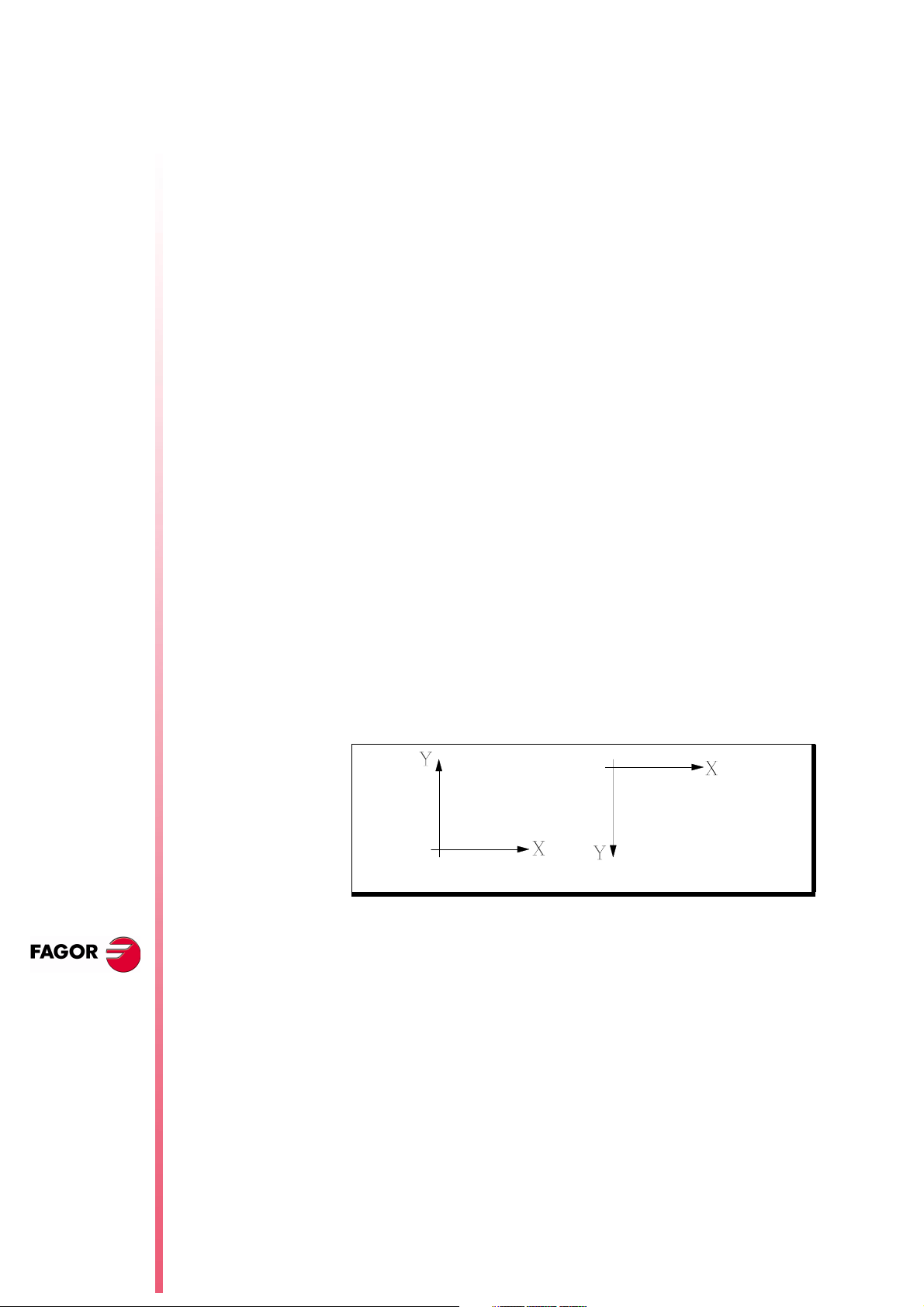

30 New graphics option

By default 0

N

EW FEATURES

(S

M: 7.XX)

OFT

New graphics

option

GRAPHICS (P16)

New value (4) for g.m.p. GRAPHICS.

It is similar to "0" value (Mill model graphics) but with different XY line

graphics.

GRAPHICS=0 GRAPHICS=4

It is available when having Power PC.

31 Improvement in the tool measuring cycle PROBE1

In previous version, this cycle only calibrated the length of the tool

(see section 12.3 of the programming manual).

From this version on, it may be used:

To calibrate the tool length.

•

To calibrate the tool radius.

•

Page 20 of 48

To calibrate the tool radius and length.

•

Measure the tool length wear.

•

Measure the tool radius wear.

•

Measure the tool radius wear and length wear.

•

Page 25

The programming cycle for the PROBE1 cycle is:

(PROBE 1, B, I, F, J, K, L, C, D, E, S, M, C, N, X, U, Y, V, Z, W)

Parameters X, U, Y, V, Z, W

They are optional parameters that are not usually necessary.

On certain machines, due to lack of mechanical positioning

repeatability of the probe's, the probe must be calibrated before

each tool calibration.

Instead of redefining machine parameters PRBXMIN, PRBXMAX,

PRBYMIN, PRBYMAX, PRBZMAX, PRBZMIN every time the probe

is calibrated, those coordinates may be indicated in variables X, U,

Y, V, Z, W, respectively.

The CNC does not modify the machine parameters and only takes

into account the coordinates indicated in X, U, Y, V, Z, W during this

calibration.

If any of the X, U, Y, V, Z is left out, the CNC takes the value

assigned to the corresponding machine parameter.

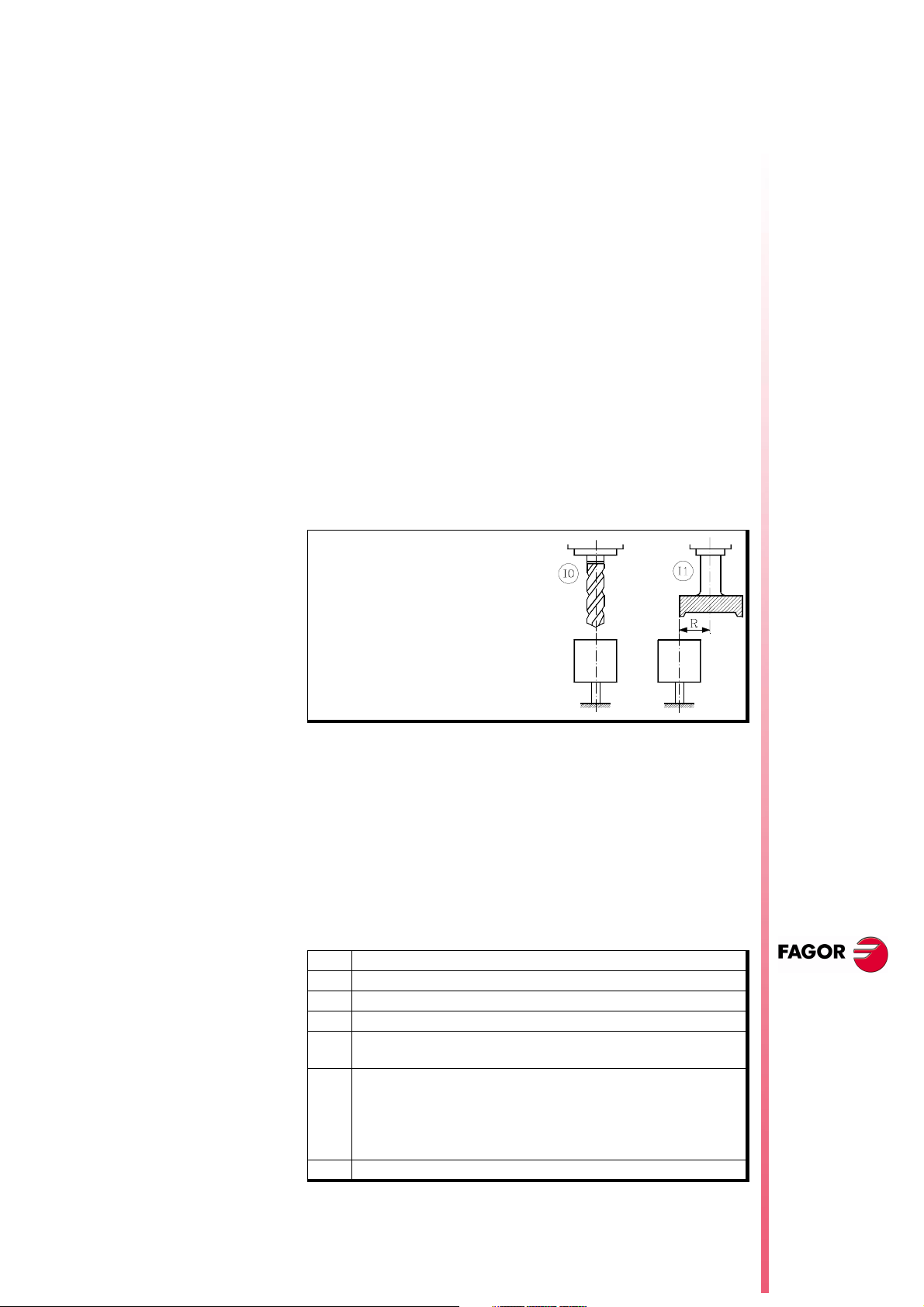

31.1 Measure or calibrate the tool length.

8040 CNC

Parameter "I" defines where the

measurement or calibration will be

carried out:

I0 On the tool shaft.

I1 On the tool tip.

If not programmed, the canned cycle

takes the value I0 (on the tool shaft).

Measure or calibrate the tool length on its shaft.

It is carried out with the spindle stopped. It is useful for drilling tools,

ball end-mills, or tools whose diameter is smaller than the probe's

probing surface.

Calibration format:

(PROBE 1, B,

Format for wear measurement:

(PROBE 1, B, I0, F, J1, L, C, X, U, Y, V, Z, W)

B Safety distance, with positive value greater than "0".

I0 Measure or calibrate the tool length on its shaft.

F Probing feedrate, in mm/min. or in inches/min.

J J0 = Calibration; J1 = Measurement

Maximum length wear permitted (with J1 and when using tool

L

life monitoring).

Behavior when exceeding the maximum wear allowed (L other

than 0).

C0 = Interrupts the execution for the user to select another tool.

C

C1 = The cycle replaces the tool with another one of the same

X...W Optional

, F, J0, X, U, Y, V, Z, W)

I0

family.

NEW F

EATURES

(S

M: 7.XX)

OFT

Improvement in the

tool measuring

cycle PROBE1

Parameters J, L, C are optional. If not programmed, the following

values are assumed:

Page 21 of 48

Page 26

8040 CNC

J0 (calibration). L0 (the tool is not rejected due to wear). C0

(interrupts the execution for the user to select another tool)

Measure or calibrate the tool length on its tip.

It may be carried out either with the spindle stopped or turning the in

the programmed direction (opposite to the cutting direction) It is

useful for calibrating tools with several cutting edges or tools whose

diameter is greater than the probe's probing surface.

Calibration format:

(PROBE 1, B, I1, F, J0, D, S, N, X, U, Y, V, Z, W)

Format for wear measurement:

(PROBE 1, B, I1, F, J1, L, D, S, C, N, X, U, Y, V, Z, W)

B Safety distance, with positive value greater than "0".

I1 Measure or calibrate the tool length on its tip.

F Probing feedrate, in mm/min. or in inches/min.

J J0 = Calibration; J1 = Measurement

Maximum length wear permitted (with J1 and when using tool

L

life monitoring).

Radius or distance referred to the tool shaft being probed. If not

D

programmed, it is done on the tip

Tool turning speed and direction. Select the opposite of the

cutting direction (positive sign if M3 and negative if M4)

S

With S0, calibration with spindle stopped.

Behavior when exceeding the maximum wear allowed (L other

than 0)

C

C0 = Interrupts the execution for the user to select another tool.

C1 = The cycle replaces the tool with another one of the same

family.

Number of cutting edges to be measured. If N0, one

measurement.

N

To measure each cutting edge when the spindle has feedback

and s.m.p. M19TYPE (P43) =1.

X...W Optional

N

EW FEATURES

(S

M: 7.XX)

OFT

Improvement in the

tool measuring

cycle PROBE1

Parameters J, L, D, S, C, N are optional. If not programmed, the

following values are assumed:

J0 (calibration). L0 (the tool is not rejected due to wear). D= tool

radius (probing is carried out on the tip). S0 (spindle stopped). C0

(interrupts the execution for the user to select another tool). N0 (the

cutting edges are not measured separately).

Once the calibration cycle has ended

It updates global arithmetic parameter P299 and assigns the

measured length to the tool offset selected in the tool offset table.

P299 = measured length - previous length (L+K)

L = measured length

K= 0

If the dimension of each cutting edge was requested, "N" parameter,

the measured values are assigned to global arithmetic parameters

P271 and on.

Once the wear measuring cycle has ended

When using tool life monitoring, it compares the measured value

with the theoretical length assigned in the table.

Page 22 of 48

Page 27

If the maximum allowed is exceeded, it issues a "tool rejected"

message and acts as follows:

C0 It interrupts the execution for the user to select another tool.

The cycle replaces the tool with another one of the same

family.

C1

It sets the "rejected tool " indicator (status = R)

It activates the general logic output PRTREJEC (M5564)

If the measuring difference does not exceed the maximum allowed

or tool life monitoring is not available:

It updates global arithmetic parameter P299 and the length wear

•

value of the tool offset selected in the tool offset table.

P299 = measured length - theoretical length (L)

L = theoretical length (it maintains the previous value).

K = measured length - theoretical length (L) [New wear value]

If the dimension of each cutting edge was requested, "N" parameter,

the measured values are assigned to global arithmetic parameters

P271 and on.

31.2 Measure or calibrate the radius of a tool.

It may be carried out either with the spindle stopped or turning the in

the programmed direction (opposite to the cutting direction)

8040 CNC

Calibration format:

(PROBE 1, B, I2, F, J0, K, E, S, N, X, U, Y, V, Z, W)

Format for wear measurement:

(PROBE 1, B, I2, F, J1, K, E, S, M, C, N, X, U, Y, V, Z, W)

B Safety distance, with positive value greater than "0".

I2 Measure or calibrate the radius of a tool.

F Probing feedrate, in mm/min. or in inches/min.

J J0 = Calibration; J1 = Measurement

Probe side used.

K

K0 (X+ side), K1 (X- side), K2 (Y+ side), K3 (Y- side).

Distance referred to the theoretical tool tip being probed. It is

very useful with cutters whose bottom is not horizontal.

E

Tool turning speed and direction. Select the opposite of the

cutting direction (positive sign if M3 and negative if M4)

S

With S0, calibration with spindle stopped.

Maximum radius wear permitted (with J1 and when using tool

M

life monitoring).

Behavior when exceeding the maximum wear allowed (M other

than 0).

C0 = Interrupts the execution for the user to select another tool.

C

C1 = The cycle replaces the tool with another one of the same

family.

Number of cutting edges to be measured. If N0, one

measurement.

N

To measure each cutting edge when the spindle has feedback

and s.m.p. M19TYPE (P43) =1.

X...W Optional

NEW F

EATURES

(S

M: 7.XX)

OFT

Improvement in the

tool measuring

cycle PROBE1

Parameters J, E, S, M, C, N are optional. If not programmed, the

following values are assumed:

Page 23 of 48

Page 28

J0 (calibration). E0. S0 (spindle stopped). M0 (the tool is not rejected

due to wear). C0 (interrupts the execution for the user to select

another tool). N0 (the cutting edges are not measured separately).

Once the calibration cycle has ended

8040 CNC

It updates global arithmetic parameter P298 and assigns the

measured radius to the tool offset selected in the tool offset table.

P298 = measured radius - previous radius (R+I)

R = measured radius

I= 0

If the dimension of each cutting edge was requested, "N" parameter,

the measured values are assigned to global arithmetic parameters

P251 and on.

Once the wear measuring cycle has ended

When using tool life monitoring, it compares the measured value

with the theoretical radius assigned in the table.

If the maximum allowed is exceeded, it issues a "tool rejected"

message and acts as follows:

C0 It interrupts the execution for the user to select another tool.

The cycle replaces the tool with another one of the same

family.

C1

It sets the "rejected tool " indicator (status = R)

It activates the general logic output PRTREJEC (M5564)

If the measuring difference does not exceed the maximum allowed

or tool life monitoring is not available:

It updates global arithmetic parameter P298 and the radius wear

•

value of the tool offset selected in the tool offset table.

P298 = measured radius - theoretical radius (R)

R = theoretical radius (it maintains the previous value).

I = measured radius - theoretical radius (R) [New wear value]

N

EW FEATURES

(S

M: 7.XX)

OFT

Improvement in the

tool measuring

cycle PROBE1

If the dimension of each cutting edge was requested, "N" parameter,

the measured values are assigned to global arithmetic parameters

P271 and on.

31.3 Measure or calibrate the tool radius and length.

It may be carried out either with the spindle stopped or turning the in

the programmed direction (opposite to the cutting direction)

Calibration format:

(PROBE 1, B, I3, F, J0, K, D, E, S, N, X, U, Y, V, Z, W)

Format for wear measurement:

(PROBE 1, B, I3, F, J1, K, L, D, E, S, M, C, N, X, U, Y, V, Z, W)

B Safety distance, with positive value greater than "0".

I3 Measure or calibrate the tool radius and length.

F Probing feedrate, in mm/min. or in inches/min.

J J0 = Calibration; J1 = Measurement

Side of the probe used to measure or calibration the radius.

K

K0 (X+ side), K1 (X- side), K2 (Y+ side), K3 (Y- side).

Maximum length wear permitted (with J1 and when using tool

L

life monitoring).

Page 24 of 48

Page 29

Radius or distance referred to the tool shaft being for length

D

measurement or calibration. With D0 on the tool shaft and if not

programmed, on the tip.

Distance referred to the theoretical tool tip being probed. It is

very useful with cutters whose bottom is not horizontal.

E

Tool turning speed and direction. Select the opposite of the

cutting direction (positive sign if M3 and negative if M4)

S

With S0, calibration with spindle stopped.

Maximum radius wear permitted (with J1 and when using tool

M

life monitoring).

Behavior when exceeding the maximum wear allowed (if L or M

other than 0).

C

C0 = Interrupts the execution for the user to select another tool.

C1 = The cycle replaces the tool with another one of the same

family.

Number of cutting edges to be measured. If N0, one

measurement.

N

To measure each cutting edge when the spindle has feedback

and s.m.p. M19TYPE (P43) =1.

X...W Optional

Parameters J, L, D, E, S, M, C, N are optional. If not programmed,

the following values are assumed:

J0 (calibration). L0 (the tool is not rejected due to length wear). D=

tool radius (length probing is carried out on the tip). E0, S0 (spindle

stopped). M0 (the tool is not rejected due to radius wear). C0

(interrupts the execution for the user to select another tool). N0 (the

cutting edges are not measured separately).

8040 CNC

Once the calibration cycle has ended

It uses global arithmetic parameters P298, P299 and assigns the

measured length and radius to the tool offset selected in the tool

offset table.

P298 = measured radius - previous radius (R+I)

P299 = measured length - previous length (L+K)

R = measured radius

L = measured length

I= 0

K= 0

If the dimension of each cutting edge was requested, parameter "N",

the measured lengths are assigned to global arithmetic parameters

P271 and on, and the measured radii to global arithmetic parameters

P251 and on.

Once the wear measuring cycle has ended

When using tool life monitoring, it compares the measured radius

and length values with the theoretical values assigned in the table.

If the maximum allowed is exceeded in any of them, it issues a "tool

rejected" message and acts as follows:

C0 It interrupts the execution for the user to select another tool.

The cycle replaces the tool with another one of the same

family.

C1

It sets the "rejected tool " indicator (status = R)

It activates the general logic output PRTREJEC (M5564)

NEW F

EATURES

(S

M: 7.XX)

OFT

Improvement in the

tool measuring

cycle PROBE1

Page 25 of 48

Page 30

8040 CNC

If the measuring difference does not exceed the maximum allowed

or tool life monitoring is not available:

It updates global arithmetic parameter P298, P299 and the length

•

and radius wear values of the tool offset selected in the tool offset

table.

P298 = measured radius - theoretical radius (R)

P299 = measured length - theoretical length (L)

R = theoretical radius (it maintains the previous value).

I = measured radius - theoretical radius (R) [New wear value]

L = theoretical length (it maintains the previous value).

K = measured length - theoretical length (L) [New wear value]

If the dimension of each cutting edge was requested, parameter "N",

the lengths are assigned to global arithmetic parameters P271 and

on, and the radii to global arithmetic parameters P251 and on.

32 Oscilloscope function

The oscilloscope function is a help tool to adjust the CNC and the

drives.

It is possible to represent 4 previously selected variables and

manipulate CNC machine parameters and variables. When using

Fagor Sercos drives, it is also possible to set the parameters of the

drive.

N

EW FEATURES

(S

M: 7.XX)

OFT

How to operate

Suggestions

When requesting information (variable or parameter) of a drive that

is not connected via Sercos or when having an old software version,

the message "Variable does not exist" will be displayed.

Changing the machine parameters of the CNC and the drive

requires a password.

To access the Oscilloscope mode, select:

Op Mode - Diagnosis - Adjustements - Scope

Define the variables to be analyzed, the trigger conditions and the

machine parameters of the CNC or the drive to be modified.

Execute a part-program moving the axis or axes to be adjusted.

Capture data and then analyze it.

Once data capture has ended, or has been interrupted, it is possible

to analyze the signals and modify the parameters that have been

previously selected, in order to improve the machining conditions.

Capture data, analyze it and modify the parameters again until

achieving the best machining conditions.

Execute endless repetitive movements.

Oscilloscope

function

Page 26 of 48

Operation

After adjusting the axis separately, readjust the interpolating axes

together.

It is up to the user to judge what the best adjustment is, the

oscilloscope function is an assistance tool.

To enter or modify a data on the screens, it must be selected and it

must have the editing focus.

Page 31

To select another editable data or field, use the [Ï] [Ð]. It is a rotary

selection, if the first element is selected on the screen, when

pressing [Ï] the focus goes to the last one, whereas if the last

element is selected, when pressing [Ð] the focus goes to the first

one.

Softkeys

Not all the data may be edited, only the ones that may be selected,

those having the focus. There are two types of editable fields:

Editable values:

They may be assigned a value, sometimes numerical (numbers

only) and sometimes alphanumerical (numbers and letters).

Before validating the data, it is checked; if the data is incorrect, it

is rejected and a warning message is issued.

Values that may be selected:

The possible values are fixed and one of them may be selected.

Use the [Í] [Î] keys to see the possible values. On this type

values that are icons, the [White/Green] key has the same effect

as the [Î] key.

Accessing the oscilloscope mode enables the following softkeys:

Scale / Offsets

To change the amplitude of each signal, move them vertically

or adjust the time base for all of them.

Analysis

To analyze, using 2 cursors, each signal of the last data

capture.

Parameters

To assign new values to the machine parameters of the CNC

and drive that have been defined in the "Configuration" screen.

Configuration

To define the variables to be analyzed, the trigger conditions

and the machine parameters of the CNC or the drive to be

modified.

Actions

It shows various softkeys to modify the data of each field

(amplitude of the signals, vertical movement, time base

adjustment, position of the cursors, etc.).

Begin

It captures data according to the conditions set on the

"Configuration" screen to be analyzed later on.

8040 CNC

32.1 Configuration

To define the variables to be analyzed, the trigger conditions and the

machine parameters of the CNC or the drive to be modified.

It offers 2 screens, one to set the parameters and the other one to

define the variables and trigger conditions.

On the screen for defining variables and the trigger condition, it is

possible to go from block of elements to another using the [page up]

and [page down] keys.

NEW F

EATURES

(S

M: 7.XX)

OFT

Oscilloscope

function

Page 27 of 48

Page 32

8040 CNC

The parameters defining page shows the definition code on the left

column, the parameter name on the center column and the

maximum and minimum values on the right column.

To add a parameter to the list, select the row for the parameter,

enter the definition code indicated later on and press [Enter]. If it

is valid, the rest of the fields are updated and if not, it issues a

warning.

To replace a parameter from the list, select the parameter to be

replaced, enter the definition code of the new parameter and

press [Enter]. If the previous content has been deleted and no

code is entered, the line appears empty.

The [Add a parameter to the list] softkey enters a new empty line

above the currently selected line.

The [Eliminate parameter] softkey eliminates the currently

selected line and shifts all the ones below upwards.

The "Parameter editing" screen shows the parameters in the same

place where they were defined and the empty rows appear blank.

When a parameter is changed on the "Parameter Editing" screen,

the CNC machine parameter table and the drive's work parameters

are updated. The [Save Parameters] softkey is also activated on the

"Configuration - Parameters" screen.

N

EW FEATURES

Variable definition

We suggest to access that screen and press the [Save Parameters]

softkey to save the parameter tables that have been changed, those

of the CNC into the CARDA and those of the drive in its FLASH. If

only the CNC parameters have been changed, the drive tables

remain unchanged and vice versa.

Once the values saved are the same as the ones edited last, the

softkey disappears until a new modification is made.

The oscilloscope has 4 graphics channels (CH1, CH2, CH3, CH4).

The following must be defined in each channel:

The code or name of the variable to be shown. See attached

•

tables.

The color used to show them.

•

Whether it will be visible or not.

•

When defining a variable that cannot be captured, an error message

will be issued. If no variable is to be captured in a channel, just leave

the name field blank. If all 4 channels are deactivated (without

associated variable) no capture is possible.

The "hidden" channels are not shown graphically (they are not

shown on the screen after the data capture). It is useful when using

this channel to set the trigger condition.

(S

M: 7.XX)

OFT

Oscilloscope

function

Page 28 of 48

Page 33

CNC variables that may be assigned to a channel

Variable Characteristics

ANAI(1-8) Voltage of input 1-8

ANAO(1-8) Voltage to apply to output 1-8

FREAL CNC real feedrate

FREAL(X-C) Actual (real) X-C axis feedrate

FTEO(X-C) Theoretical X-C axis feedrate

FLWE(X-C) X-C axis following error

ASIN(X-C) "A" signal of the CNC sinusoidal feedback for the X-C axis

BSIN(X-C) "B" signal of the CNC sinusoidal feedback for the X-C axis

DRPO(X-C) Position indicated by the Sercos drive of the X-C axis

SREAL Real (actual) spindle turning speed.

FTEOS Theoretical spindle turning speed

FLWES Spindle following error

ASINS "A" signal of the CNC sinusoidal feedback for the spindle

BSINS "B" signal of the CNC sinusoidal feedback for the spindle

DRPOS Position indicated by the Sercos drive of the spindle

SSREAL Real (actual) second spindle turning speed.

SFTEOS Theoretical second spindle turning speed

SFLWES Second Spindle following error

SASINS "A" signal of the CNC sinusoidal feedback for the second

spindle

SBSINS "B" signal of the CNC sinusoidal feedback for the second

spindle

SDRPOS Position indicated by the Sercos drive of the second spindle

8040 CNC

Examples: ANAI1, FREAL, FLWEX, FREALZ

Fagor Sercos Drive variables that may be assigned to a channel

Indicate the desired axis and variable, separated by a period.

Examples: X.CV3, Y.SV1, S1.SV2

Variable Characteristics

CV3 CurrentFeedback

SV1 VelocityCommand

SV2 VelocityFeedback

SV7 VelocityCommandFinal

TV1 TorqueCommand

TV4 VelocityIntegralAction

RV1 FeedbackSine

RV2 FeedbackCosine

RV51 Feedback2Sine

RV52 Feedback2Cosine

Trigger conditions

Channel

Trigger

Indicates which variable or channel (CH1, CH2, CH3, CH4) is to be

used as a reference or trigger condition.

Indicates the beginning of the data capture.

NEW F

(S

OFT

EATURES

M: 7.XX)

Flank

If not selected, the data capture begins as soon as the operator

gives the go ahead. The Flank, Level and Position data are ignored.

If selected, specify the trigger condition using the Flank, Level and

Position data.

It is taken into account when Trigger has been selected. It may be

an up flank or a down flank.

Oscilloscope

function

Page 29 of 48

Page 34

8040 CNC

Level

With an up flank, the data capture begins when in a sample the data

value is lower than the level and in the next sample the value is

greater than or equal to the level.

With a down flank, the data capture begins when in a sample the

data value is greater than the level and in the next sample the value

is lower than or equal to the level.

It is taken into account when Trigger has been selected.

It sets the value that the variable must take to begin the data capture.

Position (%)

Number of

samples

Sample T

It is taken into account when Trigger has been selected. It is defined

as a percentage, between 0% and 100%.

It indicates the number of samples that are taken before the Trigger.

For example, a 10% position means that 10% of the total number of

samples programmed will be taken before the trigger and the

remaining 90% after the trigger.

The trigger condition starts evaluating after having the indicated %

of samples. If the position is defined at 50% and the trigger condition

occurs when a 10% of the samples have been taken, it will be

ignored until the 50% of the samples have been collected.

It indicates the number of sample to be captured. It is common to all

the channels. Value between 1 and 1024.

The sample will be taken at the same time in all the channels so they

are synchronized.

It indicates the sampe period or the time period between data

captures. It is given in milliseconds, integers between 1 and 1000

(between 1ms and 1s).

When analyzing CNC variables, the sample period must be a

multiple of the loop time. If it is not, a message is displayed indicating

that it has been automatically rounded off.

N

EW FEATURES

(S

M: 7.XX)

OFT

Oscilloscope

function

Mode

Superimposed

channels

The sample time may be shorter than the CNC loop time only when

analyzing 1 or 2 variables of the same drive.

When the requested number of variables forces a reconfiguration of

the CNC's Sercos ring, a warning message is issued requesting its

confirmation.