Page 1

AFTER

technical

SALES

SERVICE

TECHNICAL STUDY

PRODUCT:

RANGE:

Washing machines

Innova top-loading

Date: 15/04/2003

Document Nº: 3956

Page 2

technical

This document is for use by all persons providing technical assistance service (T .A.S.).

It is an aid for repairing the product described, and provides back-up documentation

for technical consultations.

The following safety warnings are given in this manual:

How to use this manual

Electrical Hazard: Identifies possible electrical risks

which could permanently damage the appliance.

Warning: Identifes information or circumstances which

may cause personal injury or death.

!

Important: Identifies vital information for understan-

ding the product.

I

© Copyright by Fagor Electrodomésticos S. Coop. 2002. All rights reserved. The total

or partial reproduction of this document, using any type of procedure or on any type

of support, is prohibited without previous written authorisation by the owner of the trading rights. Persons failing to comply with this reservation will be pursued under the

applicable legislation and may be prosecuted.

FAGOR ELECTRODOMÉSTICOS reserves the right to introduce any modifi cations

to the characteristics of its products, without prior notice.

Page 3

technical

1.- Warnings and precautions...................................1

2.- Features.................................................................2

3.- Description of functioning ...................................3

Contents

3.1.- General description.............................................................3

3.2.- Assembly and disassembly instructions............................ 10

3.3.- Maintenance...................................................................... 25

3.4.- Diagrams........................................................................... 27

Page 4

technical

1.- Warnings and precautions

1. This manual must NOT be considered an overall guide to the repair / maintenance

of the appliance.

2. It must only be used by duly qualifi ed persons with technical knowledge applicable

to this product and with suitable testing equipment and tools.

3. Before any electrical appliances are repaired they must be disconnected (unplugged) from the mains.

4. Before servicing the appliance, its earth connection and insulation resistance must

be checked.

5. Safety precautions must be taken for protection against accidents caused by sharp

metal or plastic edges.

Warnings and precautions

6. After servicing, the electrical safety of the appliance must be checked again. In the

case of appliances connected to a water intake (i.e. washing machines, dishwashers,

cooking centres), check for any leaks in the pipes and valves and rectify where necessary.

7. Attempting to carry out DIY maintenance and repair work on complex equipment

can be dangerous. The company recommends consulting your Service Centre in

case of any problems with these appliances.

8. Although the company has made every effort to guarantee the accuracy of the information given in this guide, they have no liability for any inconveniences or losses

arising from errors in the same.

1

Page 5

technical

2.- Features

Removable detergent drawer

Drum open button

Lever for placing on wheels

Drain pump access hatch

Cover positioner

Short wash

Hand wash

Extra rinse

Features

Anti-crease stop

Adjustable 100-1100 r.p.m. drain

2

Page 6

technical

3.- Description of functioning

3.1.- General description

Dimensions

Height: 85 cm

Length: 60 cm

Width: 40 cm

Weight: 57 Kg

Draining

Maximum height: 90 cm

Description of functioning

Minimum height: 65 cm

Length of drain hose: 1.40 maximum 2.50 m

Capacity 5Kg

Electrical Characteristics

230V

50H

10 Amp

2250W

Water Consumption according to model

59 litres

64 litres

74 litres

Temperature control

By adjustable cold thermostat to 90º

By potentiometer (10 Kohms)

By temperature thermostat to 74º which detects temperature via tub wall

A 10K potentiometer allows the temperature selection from cold to 90º by means of

the module reading the information transmitted by the sensor (NTC)

3

Page 7

technical

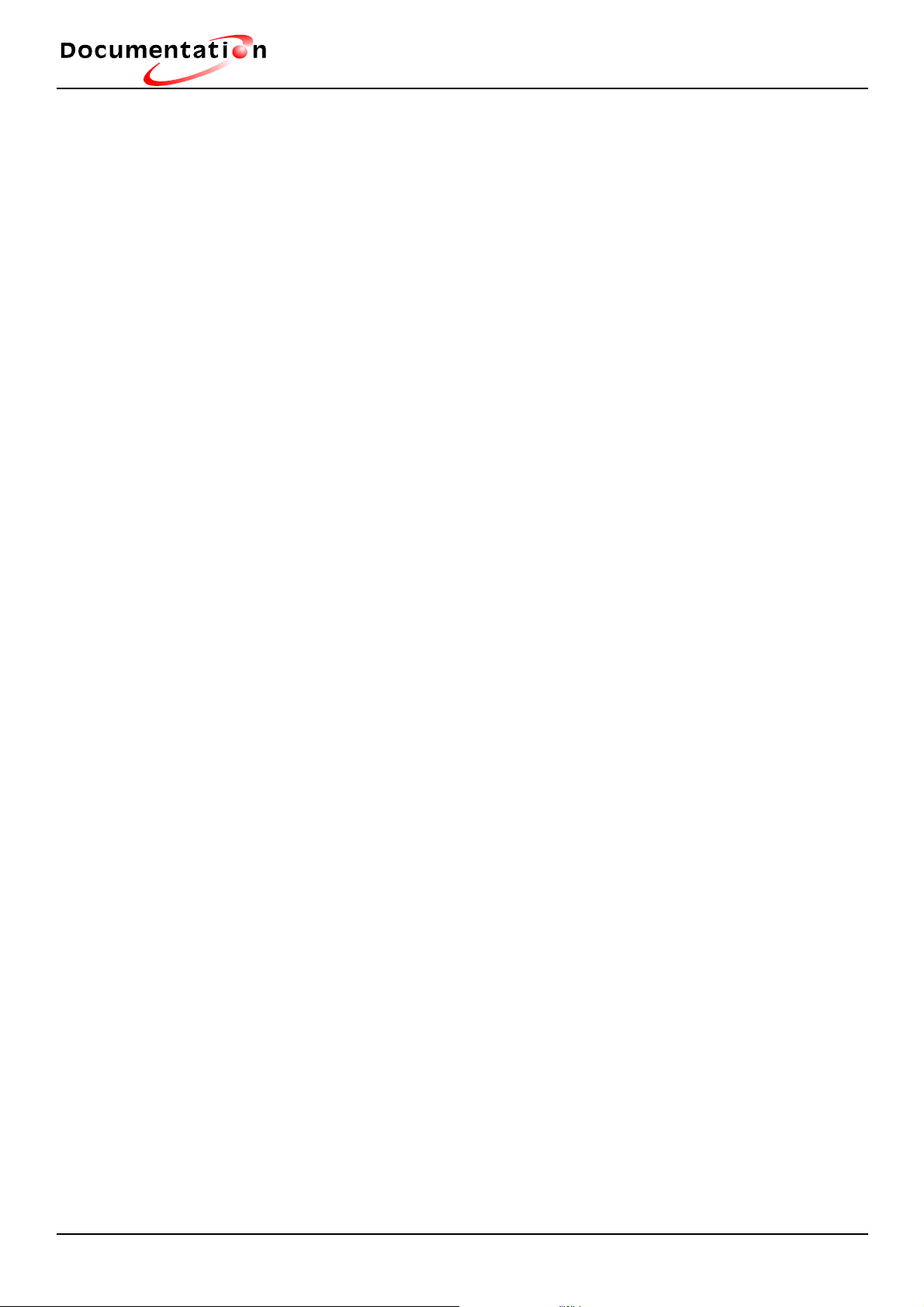

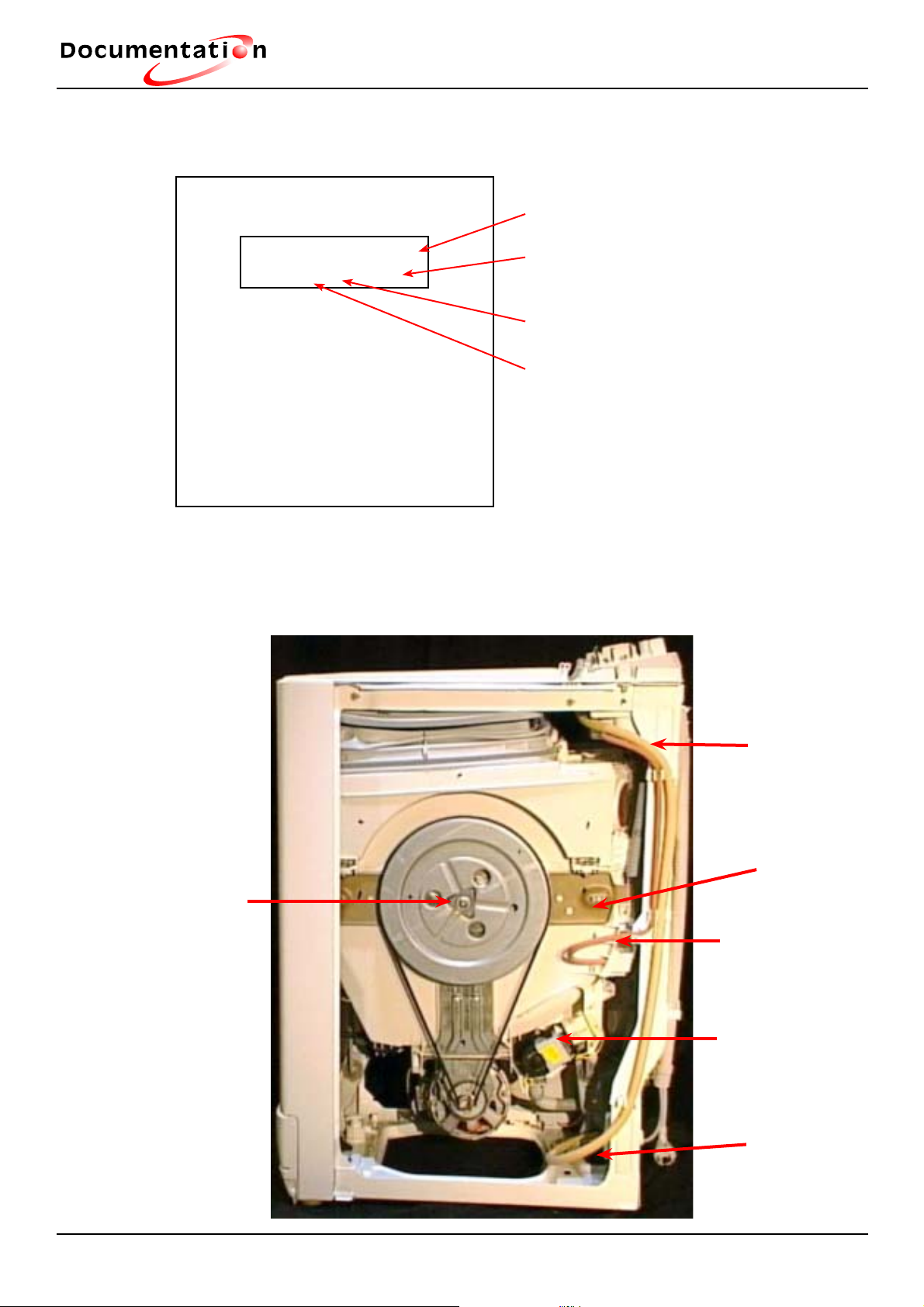

Water levels

Average wash level 72 mm (A) (11-12 Pressure switch)

Average rinse level 167 mm (B) (11-14 Pressure switch)

Average overfl ow level 287 mm (C) (11-16 Pressure switch)

Description of functioning

C

B

A

Packaging and blocking

Dibujo 1 ibujo 2.1

Dibujo 2.2

Dibujo 2.3

2

2

4

Page 8

technical

Reference plate

Description of functioning

FAGOR

MOD: 1FT-116D-DE

Nr: 02 11 00530

COD: 925010293

IPX4

Type: MAP3BNP315112

230 V - 50 Hz - 2250 W

10 Amp

Maximum clothes load 5 Kg

Revolutions: 110 r.p.m.

Inlet water pressure 0.7-10 bar

Model

Nº of washing machines

manufactured

Month of manufacture

Year of manufacture

NOTE: The reference plate is located on the rear of the washing machine. There is

another label indicating the model and and date of manufacture which can be viewed

by removing the detergent drawer.

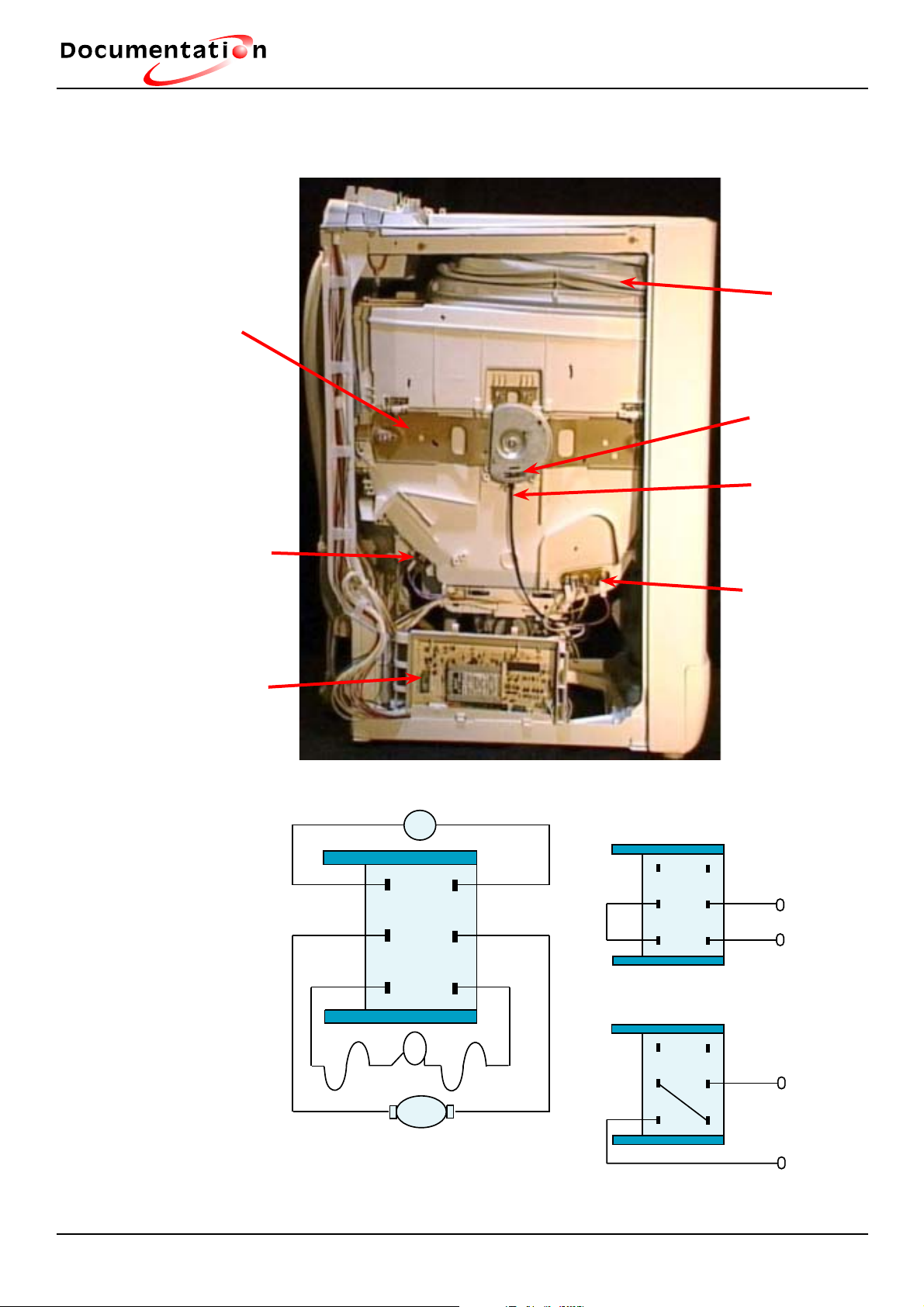

Right side view

Pulley

fixing

screw

(Torx 40)

Water supply

tube

Bearing holder

support

Pressure switch

tube

Drain pump

Electrovalve

position

5

Page 9

technical

TG

Brown

Brown

Black

Blue

Red

White

1

4

5

6

3

2

T

Rotor

1

4

5

63

2

1

4

5

63

2

230 V

230 V

Anti-clockwise

connection

Clockwise

connection

Left side view

Description of functioning

Bearing holder

support

Thermostat

Electronic

Module

Muffle

Drum position

sensor

Position sensor

wiring

Washing ele-

ment + NTC

1150 r.p.m. universal type motor connection

E1 (Stator): 1.67 ohms Rotor: 70 ohms

E2 (Stator): 0.84 ohms TG (Tacho-generator): 1.6 ohms

T: Motor heating thermostat

6

Page 10

technical

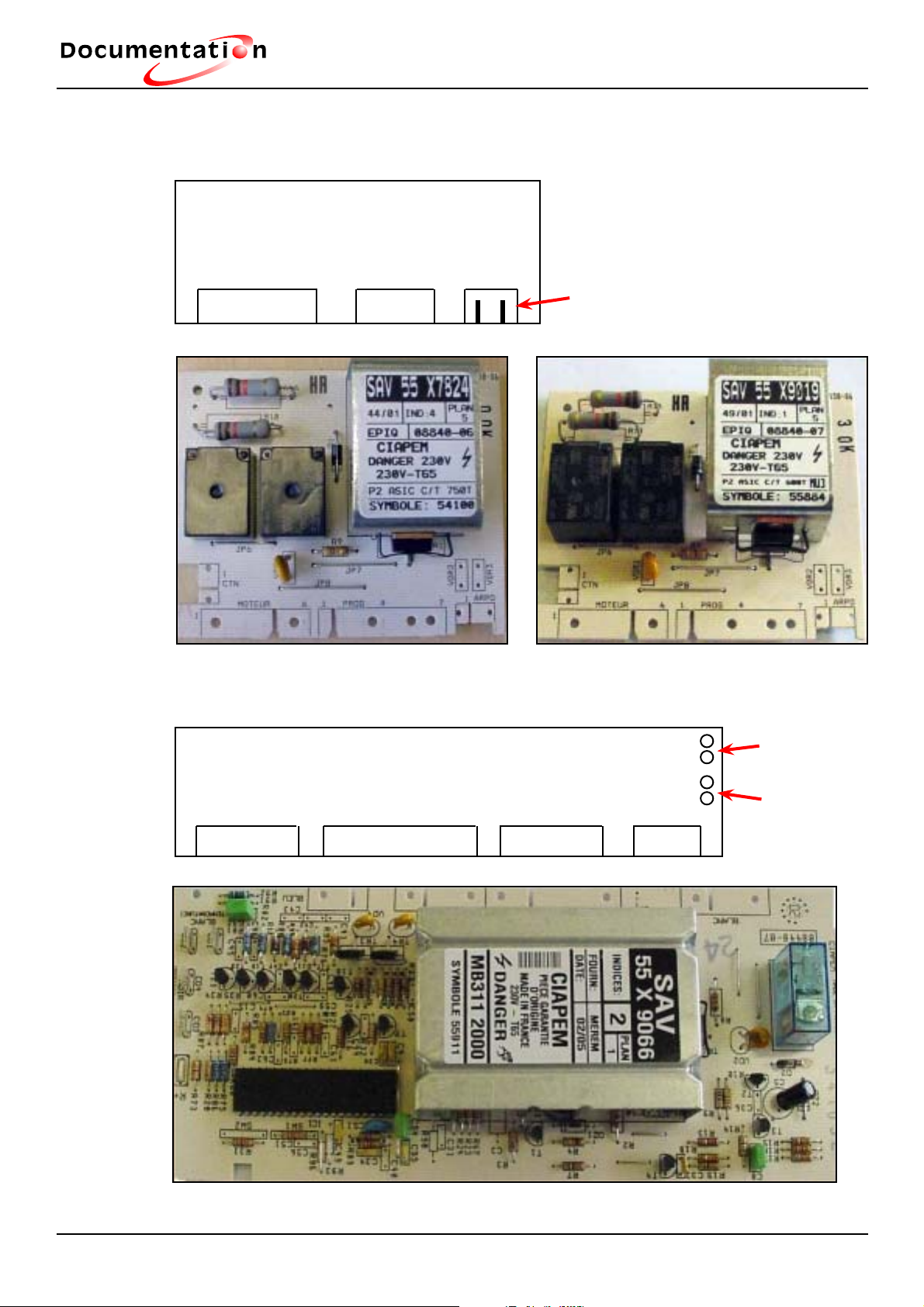

Modules

P2A Type

Electronic Module

Motor

Connection

1-2-3-4-5-6 1-2-3-4

Description of functioning

Drum Position Sensor Connection

(according to model)

P3B Type Module

P3B Type

Electronic Module

White Connctor. White Connctor. Black Connctor. Blue Conntr.

1-2-3-4-5-6 1-2-3-4-5-6-7-8-9 1-2-3-4-5-6 1-2-3-4

1- Positioner

Connection

2- NTC

Connection

7

Page 11

technical

Description of functioning

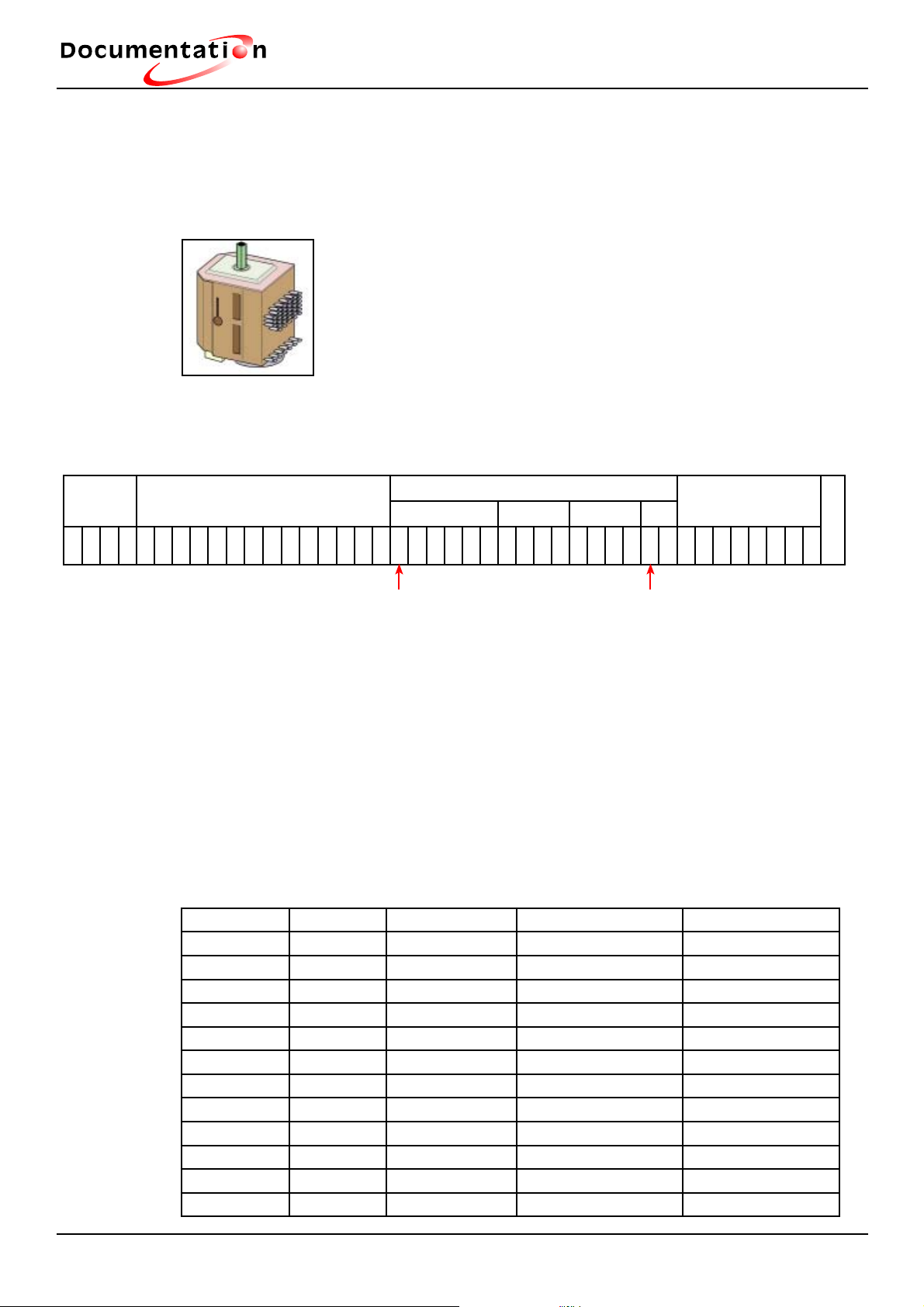

Electro-mechanical Programmer

A micro-motor displaces the cams, allowing the contacts supplying the different elements to open or close.

Electrovalve

Element

Drain pump

Door lock

Supplies and controls motor reversal (low spin speed washing

machines)

Wash Programme and duration times for a 500 r.p.m. model.

Prewash Wash

1234567891 01 11 21 31 41 51 61 71 81 92 02 12 22 32 42 52 62 72 82 93 03 13 23 33 43 53 63 73 83 94 04 14

R1 R2 R3 R4

Rinses

Spin dry

Bleach Fabric Softener

Prewash 12´- 1.5´- 7.5” - 82.5”

Wash: 3´- 12´- 6´- 6´- 6´- 12´- 3´- 3´- 6´- 12´- 12´- 1.5´- 7.5” - 82.5”

Rinse R1 6´- 1.5´- 7.5” - 37.5” - 7.5” - 37.5”

Rinse R2 6´- 1.5´- 7.5” - 82.5”

Rinse R3 6´- 1.5´- 7.5” - 82.5”

Rinse R4 6´- 7.5”

Spin 7.5”/90” - 7.5” - 37.5” - 7.5” - 37.5” - 12´- 1.5´

Programming types

Model R.P.M. Card type Programming type Reference

1FT-116 1100 MB-311 P3B LB55X9066

1FT-96 900 MB-313 P3B LB55X9067

1FT-76 700 ASIC P2A LB55X9020

1FT-53 500 NO P1B 1FT-51 500 NO P1B 1LT-86 400-800 ASIC P2A LB55X9020

1LT-63 600 ASIC P2A LB55X9019

1LT-53 500 NO CARD P1B 1LT-51 500 NO CARD P1B LA-363 600 ASIC P2 LB55X9019

LA-343 400 NO CARD P1A LA-143 400 NO CARD P1A -

S

T

O

P

2

8

Page 12

technical

Description of functioning

P1A P1B

Constant speed at 400 r.p.m. Constant speed at 500 r.p.m.

Heating chronometric or by thermostat

1/2 Load 1/2 Load

Anti-crease Anti-crease

Eco on chronometric heating Eco on chronometric heating

1 wash cycle 2 wash cycles

Spin dry Spin dry

Consumption 84 litres Consumption 74 litres

P2A

Variable speed at 750 r.p.m.

Heating chronometric or by thermostat

1/2 Load

Anti-crease

Eco on chronometric heating

2 wash cycles

Spin dry

Consumption 74 litres

9

Page 13

technical

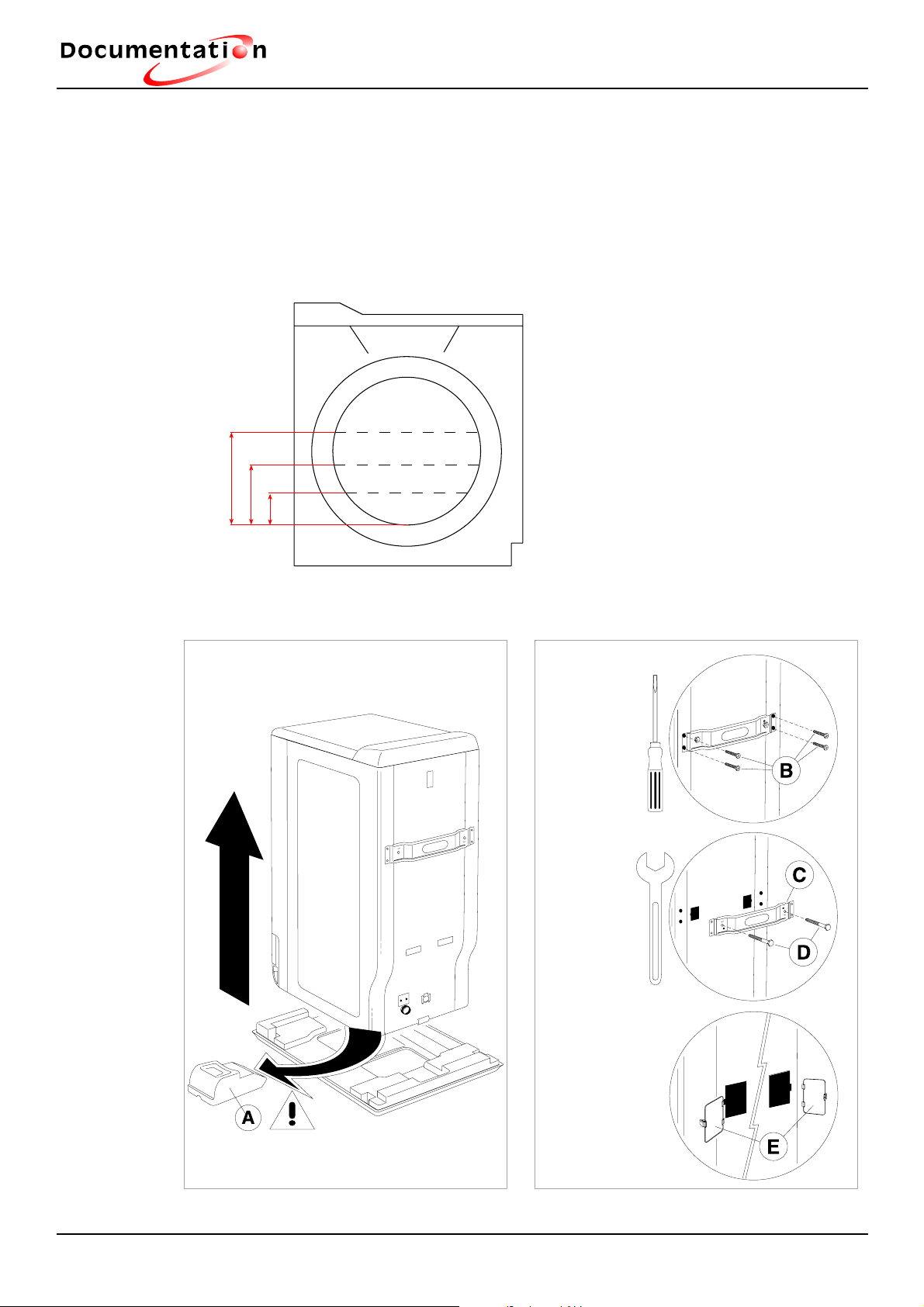

3.2.- Assembly and disassembly instructions

Removing the side panels

Tools required:

- Nº 7 hex key

Removal procedure

- Place the appliance on the wheels

- Remove the screws in the rear of the appliance (3 per panel)

- Carefully lift off the left or right panel by sliding it completely towards the rear.

To replace the panels:

Description of functioning

- Place the bottom of the panel on the support tabs and fold it towards the appliance.

- Push it towards the front and replace the fi xing screws.

Removing the control panel

Tools required:

- Medium-sized screwdriver for countersunk screws.

Removal procedure:

- Turn the programming dial and selectors to downwards position.

- Remove the rear fi xing screw ().

- Unclip the control panel cover, separating it from the rear part and tilting it

forwards.

To replace it:

- Place the largest fl at surface facing downwards

- Line up the selector indicator in downwards position.

- Place the front part fi rst and then fi x the decorative part in place.

- Check the various selectors are turning properly.

Removing the Control Panel Support

Tools required:

- Thin fl at screwdriver; Nº 7 hex key; Nº 20 torx screwdriver.

10

Page 14

technical

Removal procedure:

- Remove the control panel

- Remove the buttons

- Remove the screws (A,B,C)

- Unclip the component support and tilt it towards the rear.

- Remove all the parts in order to release the component support.

To put it back in place:

- Ensure the component support screws are not blocked preventing the side panels

from being adjusted.

Description of functioning

A B

C

Removing the door

Tools required:

- Thin fl at screwdriver

Removal procedure:

- Open the door

- Remove the hinge pins (make sure you do not scratch the top with the screwdriver

shaft)

- Pull upwards to remove the door.

To replace it again:

- Repeat the above steps in reverse order.

Pins

11

Page 15

technical

Removing the Single / Dual Pressure switch

Tools required:

- Thin fl at screwdriver, screwdriver for countersunk screws, Nº 7 hex key, Nº 20 torx

screwdriver

Removal procedure:

- Remove the control panel

- Remove the component support

- Remove the right side panel

- Remove the pressure switch connection hose. For ease of removal, carefully push

the tub unit towards the front part.

Description of functioning

- To remove the pressure switch, free it from its housing located under the component

support with the aid of a small fl at screwdriver.

- Carry out the above operation in reverse order.

To replace it again:

Carry out the above operation in reverse order.

Removing the Compression Chamber

Tools required:

- Nº 7 nut wrench, fl at screwdriver, tool for fastening

door leaves

Removal procedure:

- Remove the right side panel.

- Disconnect the compression chamber tube

- Fasten the two leaves of the drum door with the aid of the tool.

- Remove the moving omega.

- Remove the drain fi lter.

- Reach inside the opening on the left next to the moving omega and

release the compression chamber, pressing on the grooved part while using a fl at

screwdriver for leverage.

To replace it again:

- Carry out the above operation in reverse order.

12

Page 16

technical

Removing the sleeve cover

Tools required:

- Nº 20 torx screwdriver

Removal procedure:

- Remove the 5 screws located under the edge of the sleeve.

- To remove the sleeve cover, carefully detach it from the top

of the sleeve.

To replace it again:

- Carry out the above operation in reverse order.

Description of functioning

Very important: for safety reasons, the screws must be put back in the same fi xing

holes.

Removing the muffl e / load door rubber

Tools required:

- Nº 20 torx screwdriver, Nº 6 tightening wrench

Removal procedure:

- Remove the side panels.

- Remove the sleeve cover

- Remove the collar of the spring holding the seal around

the distributor in place.

- Unscrew the sleeve fi xing collar from the upper half of the

tub (A).

- Remove the sleeve

To replace it again:

- Carry out the above operation in reverse order.

Removing the tub lining cover

Tools required:

- Nº 7 hex key, fl at screwdriver, Nº 20 torx screwdri-

ver

Removal procedure:

- Remove the side panels.

- Remove the control panel

13

Page 17

technical

- Remove the control cable from the cam pin.

- Remove the door.

- Release the pressure switch.

- Tilt the component support towards the rear.

- Remove the sleeve cover.

- Remove the sleeve from around the distributor.

- Remove the distributor fi xing screw.

- Remove the fi xing screws from the upper part.

- Remove the door safety device.

- Remove the upper part.

Description of functioning

To replace it again:

- Carry out the above operation in reverse order.

Important: For ease of handling, fi rst place the sleeve around the distributor. Do not

block the fi xing screws of the sleeve cover. Remember to pass the cable through the

component support.

Removing the distributor

Tools required:

- Nº 20 torx screwdriver, medium fl at screwdriver

Removal procedure:

- Remove the control panel

- Remove the left side panel

- Remove the detergent drawer and support.

- Release the distributor control cable.

- Tilt the component support.

- Remove the sleeve cover.

- To remove the upper part of the distributor sleeve:

- Remove the spring.

- Remove the 2 distributor fi xing screws.

- To release the distributor, free it by pulling it out towards the front and lifting it up.

- To release the distributor, cut the fi xing collar of the water intake.

14

Page 18

technical

To replace it again:

- Carry out the above operation in reverse order.

Important: The collar must be replaced by another one of identical characteristics.

Adjusting the Distributor

Thread the cable under the cam and then insert the end in the distributor housing.

Place the distributor pin in the widest part of the cam (corresponding to prewash)

Description of functioning

Cam Distributor

Stop position of sheath

1- Prewash position

2- Wash position

3- Fabric softener position

15

4- Bleach position

Page 19

technical

Door lock and Omega

Tools required:

- Nº 20 torx screwdriver

Removal procedure:

- To release the door locking device, press bracket and slide unit out to the right.

- Remove the sleeve cover.

- Remove the upper part of the sleeve.

- Remove the cabling in order to release the door lock.

To replace it again:

- Carry out the above operation in reverse order.

Description of functioning

4.4 Kohms

Omega

Depending on the model, the omega may be fi xed to the drum in one of two ways,

with a screw or with a swing-out device

Screw

fixing

Press swing-out device to move omega

16

Page 20

technical

Removing the drain pump

Tools required:

- Nº 7 hex key, Nº 20 torx screwdriver

Removal procedure

- Drain the remaining water out through the drain arch (use a bowl).

- Tilt the machine to the left (remember to protect it).

- Remove the right side panel.

- Disconnect the cabling.

- To remove the drain pump, remove the three fi xing screws.

To replace it again:

Description of functioning

- Carry out the above operation in reverse order.

- Connect the cabling again before re-adjusting the pump.

155 Ohms

30 W

16 Litres

Synchronous

Removing the belt or pulley

Tools required:

- Nº 7 hex key, Nº 40 torx screwdriver for countersunk screws

Removal procedure:

- Remove the right side panel

- If necessary, remove:

- the belt, releasing it from the drum control pulley,

- the pulley, removing screw A

To replace again:

- Carry out the above operation in reverse

order.

Important: Clean the threaded hole and remove all thread brake remains. The fi xing

screw must always be replaced when the pulley is removed.

17

Page 21

technical

Removing the element with or without thermistor (depending on model)

Tools required:

- Nº 7 and 10 nut wrench

- Tool for holding drum door leaves in place.

Removal procedure:

- Remove the left side panel

Either:

- Disconnect element cabling

- Remove element fi xing nut

- Remove immersion heater.

Description of functioning

or:

- Disconnect connection cables leading from thermistor to power card

-Remove element fi xing nut

- To remove the thermistor, pull it carefully forwards.

To replace it again:

- Carry out the above operation in reverse order.

Important: - The earth connection tab must be facing upwards.

- It must be ensured that the element is correctly inserted in the bracket

located inside the tub. To do this, remove the moving omega and then immobilise the

drum door leaves.

- Check the correct position of the element in the bracket located in the

lower part of the tub. If the bracket is loose, there is a hole for fi xing it with a 3.5 x 12

stainless steel screw.

- The cabling route must be correctly followed.

2000 W - 25 Ohms

Internal thermofuse

NTC

12 Kohms at 20ºC

18

Page 22

technical

Removing the Motor

Tools required:

- Nº 7 nut wrench, Nº 20 bent torx wrench, fl at screwdriver

Removal procedure:

- Remove side panels.

- Remove belt.

- Disconnect motor cabling.

- Remove the motor, releasing the two fl anges with a fl at screwdriver.

To replace again:

- Carry out the above operation in reverse order.

Description of functioning

Adjusting pulley alignment:

- Loosen the four motor support screws.

- Adjust the alignment so that the belt has a play of 1 - 2 mm.

- Tighten the four screws.

Removing the Electrovalve

Tools required:

- Nº 7 hex key, fl at screwdriver

Removal procedure:

- Remove the right side panel.

- Unscrew the water inlet hose located at the electrovalve inlet. Ensure the water inlet

valve is closed.

- Unclip and remove the cover.

- Remove the plastic guard from the electrovalve.

- Disconnect the electrovalve cabling.

- Pull the solenoid valve upwards to release it.

- Cut the collar to remove the solenoid valve.

To replace it:

Carry out the above operation in reverse order.

19

Page 23

technical

Removing the Upper Tub

Tools required:

- Nº 7 nut wrench, Nº 20 torx screwdriver, wide fl at screwdriver, heat-resistant putty,

after sales service reference: 55X2935

Removal procedure:

- Remove decorative cover.

- Remove sleeve cover

- Release sleeve from upper half of tub.

- Remove screws from cross-piece.

- Tilt the upper part with the component support and sleeve.

Description of functioning

- Remove the belt and control pulley from the drum.

- Remove the reed switch sensor (depending on model).

- Remove the screws located on each side of the tub half.

- Separate the two tub halves, making leverage on the four fi xing points.

Note: It may appear diffi cult to separate the two halves of the tub due to the sealing

cord sticking.

Washing machines of over 1000 r.p.m have a 20Kg injected tub and those of under

1000 r.p.m. a 16Kg injected tub.

Making leverage

- Lift off the upper half of the tub.

To replace it again:

- Carry out the above operation in reverse order.

Very important: To ensure water-tightness:

- The bottom half of the tub must be cleaned.

- A sealing cord must be evenly applied in the groove of the lower half of the tub.

20

Page 24

technical

Removing the Drum

Tools required:

- Nº 7 hex key

- Wide fl at screwdriver

- Nº 20 torx screwdriver

- Nº 40 torx screwdriver

- Screwdriver for countersunk screws

- If possible, a nº 6 ratchet wrench

Removal procedure:

- Remove decorative cover

Description of functioning

- Remove sleeve cover

- Tilt the upper part with the component support.

- Remove the sleeve from the upper part of the tub

- Remove the belt and control pulley from the drum.

- Remove the reed switch sensor (depending on the model).

- Remove the upper half of the drum.

- Remove the two bearing support cross-pieces.

- Remove the drum, separating the lower half of the tub in the drum axis holes.

To replace it again:

- Carry out the above operation in reverse order.

- Before putting the drum in place, the right and left drum lids must be bent inwards.

Important: to ensure water-tightness, the two tub halves must be cleaned before

applying a new sealing cord.

Capacity 42 litres

Right lid position

21

Page 25

technical

Removing the lower tub

Tools required:

- Nº 7 hex key

- Wide fl at screwdriver

- Nº 20 torx screwdriver

- Nº 40 torx screwdriver

- Screwdriver for countersunk screws

- If possible, a nº 6 ratchet wrench

Removal procedure:

- Remove control panel.

Description of functioning

- Remove sleeve cover.

- Tilt the upper part with the component support.

- Remove the sleeve from the upper part of the tub

- Remove the belt and control pulley from the drum.

- Remove the reed switch sensor (depending on model).

- Remove the upper half of the drum.

- Remove the two bearing support cross-pieces.

- Remove the drum.

- Disconnect the motor cabling and the drain pump.

- Remove the thermostat bulb.

- Remove the unit consisting of the lower half of the tub, the motor and the drain pump

by lifting it up and releasing the springs.

- Remove all the parts.

To replace it again:

- Carry out the above operation in reverse order.

Important: to ensure water-tightness, the two tub halves must fi rst be cleaned.

22

Page 26

technical

Removing the bearing from the pulley side

REMOVE THE BEARINGS SEPARATELY

Tools required:

- nº 7 hex key

- Nº 20 torx screwdriver for countersunk screws

- Nº 40 bent wrench for countersunk screws

- Torch

Removal procedure

Description of functioning

- Remove the right side panel.

- Remove the belt and control pulley.

- To remove the reinforcement plate, loosen the 3 screws around the drum shaft

- Remove the fi xing screws from the cross-piece.

- Remove the interface and then the V ring restrictor

- Remove the cross-piece and the roller bearing

To replace them again:

- Carry out the above operation in reverse order.

- Important: the pulley fi xing screw must be changed.

- Clean the drum shaft before applying the detergent.

- Clean the V ring restrictor, being careful not to damage the edges.

- Check with the torch.

- Place the reinforcement plate, with the lower part fi rst.

Bearing holder support

Motor support

- Tighten the screws in the order shown.

Screw tightening order:

- 4 screws around the shaft (cross-tighten them).

- 2 screws on the ends of the cross piece.

- 2 fi xing screws for tub halves.

Important: Do not forget the washers. Screw them back in using the holes which

have not yet been used.

23

Page 27

technical

Removing bearing from side opposite pulley

REMOVE THE BEARINGS SEPARATELY

Tools required:

- nº 7 nut wrench

- Nº 20 torx screwdriver for countersunk screws

- Nº 40 bent wrench for countersunk screws

- Torch

Removal procedure:

- Remove the left side panel.

- Remove the bearing support fi xing screws.

Description of functioning

- Remove the interface and then the V ring restrictor

- Remove the bearing support and the ball bearing

To replace it again: Bearing holder support

- Carry out the above operation in reverse order.

- Clean the drum shaft.

- Cover the V ring restrictor, taking care not to damage the edges. Check with the

torch.

- Tighten the screws in the order shown.

Order for tightening screws:

- Central nº 40 torx screw

- 4 screws around shaft (cross-tighten them).

- 2 screws on the ends of the bearing support

- 2 fi xing screws for tub halves.

Important: Do not forget the washers. Screw them back in using the holes which

have not yet been used.

24

Page 28

technical

2

Dibujo 13

1

3.3.- Maintenance

Cleaning the pump fi lter

This fi lter traps any small objects which may have been left in the clothes and pre-

vents pump malfunctioning as a result.

The fi lter is cleaned as follows:

- Open the fl ap doors to the drum. At the bottom of the drum you will see a plastic part,

“A” (Picture 12)

Description of functioning

Dibujo 12

A

- Unblock this plastic part. (Picture 13).

To do this: -Insert a rod-shaped object (a pencil or bolt, for example) in the hole in the

top of part “A”.

- Press this rod down vertically, pushing part “A” towards the right at the

same time until it comes out of its housing.

- Remove part “A”.

- Turn the drum slightly with the fl ap doors open towards the front of the machine

(Picture 14).

When part “A” is removed the openings are freed allowing access to the pump fi lter

“B”.

- Remove the fi lter (Picture 14)

Dibujo 14

B

25

Page 29

technical

CLANG

2

1

Dibujo 16

- Remove the objects trapped inside it.

- Rinse it under the tap (Picture 15).

- Ensure the fi lter housing is clean and then replace the fi lter, pressing it into the

housing.

Description of functioning

Dibujo 15

- Put part “A” back in place, ensuring it is correctly positioned in the openings at the

bottom of the drum, and pressing it towards the left until it is perfectly fi tted in place

(Picture 16).

26

Page 30

technical

C4

22

B3

G5

G4

B

23

A

B

4

A

3

A

450

A

F2

A3

V

B

A

B

F

F3

B4

B

B2

C3

B

A

A2

B

A

2

A

B5

C5

AP

A5

A4

4

5

GV

C

C2

2

PV

3

E2

12

D4

D5

D3

BA

7

1

N

14

13/

P

F4

F5

THERMOSTAT

DOOR BLOCK

MAINS BLOCK

START/STOP

DOOR LOCK

CONTACT

SWITCH

SAFETY

ELEMENT

COLD

PROGRAMMER

ELECTROVALVE

DRAIN PUMP

1/2 LOAD

PRESSURE SWITCH

MOTOR

3.4.- Diagrams

500 r.p.m

Description of functioning

27

Page 31

technical

Description of functioning

Mod. 1LT-51 Y 1LT-53

TPO

S

SPIN

R3

R2

R1

WASH

STO

SPIN

R4

R3

R2

RINSES

R1

WASH

PL

P

Level

PAC

2

1/

CH

ACP

cl

Drain

PREWASH

WASH

RUNNING

BLEACH

CAM

DISTRIBUTION

MMES

PROG

S

PART

DE

SEC

ENJ.

Fr

40

SEC

ENJ.

Fr

Fr

30

4060

0

PL

NORO

MO

ER

THRACH

MM

RA ES

OG

PR

STOP

0

6

3'

9

82,5"

8

7,5"

7

75"/90"

6

ACP7,5"

5

7,5"

4

6'

3

3'

2

N+3'

1

3'

5

0

N+3'

9

82,5"

8

7,5"

7

1,5'

6

N+3'

5

N+12'

4

STOP

3

1,5'

2

Va40co

30

40

E69060

12'

1

37,5"

4

0

7,5"

9

37,5"

8

7,5"

7

75"/90"

6

ACP7,5"

5

7,5"

4

6'

3

82,5"

2

7,5"

1

1,5'

3

0

6'

9

82,5"

8

7,5"

7

1,5'

6

6'

5

37,5"

4

7,5"

3

37,5"

2

7,5"

1

1,5'

2

0

6'

9

82,5"

8

7,5"

7

1,5'

6

N+12'

5

N+12'

4

N+6'

3

N+3'

2

N+3'

1

N+12'

0

1

N+6'

9

N+6'

8

N+6'

7

N+12'

6

N+3'

5

82,5"

4

7,5"

3

1,5'

2

N+12'

1

DURATION

INT/250 V.

MOTIVE CONT.

FIXED CONT.

CAM Nº

ELEMENT

MICROMOTOR DETECT

D4

D5

CONDENSER PV

C2

DRYING

RHYTHM+/-

D3

A

BBABABA

8

7

C3

6

CONDENSER GV

C1

1/2 LOAD

NORMAL RHYTHM

B1

B2

B3

4

PUMP

E.V.

B4

B5

A

B

3

GENERAL

A2

ABA

2

CONDENSER PV

A4

0

6

9

8

7

6

5

4

3

2

1

5

00

9

8

7

6

5

4

3

2

1

4

0

9

8

7

6

5

4

3

2

1

3

0

9

8

7

6

5

4

3

2

1

2

9

8

7

6

5

4

3

2

1

0

1

9

8

7

6

5

4

3

2

1

7,5"

45"3'1.5'6'12'

P

SLOW RHYTHM

CONDENSER GV

TC

TB/2

TB/24TBTBx4

A5

B

1

TBx8

AC

G4

A

G3

G5

B

23

2"6" 7" 6" 3"

2"3" 3"

3"6" 6" 6" 6" 6"

3"3" 6" 34"

6" 18"

4"3"

0, 14,

3" 5" 8" 5" 6" 6"

+

PV

F1

F2

F3

A

BPV

22

28

Page 32

technical

700 r.p.m.

SELECTOR 230V

Description of functioning

START/STOP

SWITCH

SUPPRESSION

FILTER

2B

2

2A

ANTI-CREASE

ADJUSTABLE

THERMOSTAT

1B

1A

1

ELECTROVALVE

2A

PUMP

HEATING ELEMENT

4

4B

PROGRAMMER

DOOR LOCK

4A

DOOR LOCK

CONTACT

5

5A

RINSE +

PRESSURE SWITCH N1

13/14

1

12

P

6B

F2

F3

F

55

5

54

47K

6A

12

13

S

1

4

12345

T

R

3

5

2

61234

T

S

S

R

CARD

R

PH

CAD

ESSO

RC

POTENTIOMETER

DRAIN

100K

WOOL

5B

53

52

29

Page 33

technical

Description of functioning

ONTI

POSI

S.PO

0

56

55 050454

03

53

02520151

ML 52149L

S

TE

3

3

3

3

3

3

3

3

3

6/3

3

3

3

3

3

3

6/3

3

6/3

6

3

3

3

3

6

3

3

6/3

3

6

6

6

6

6/3

3

3

3

3

6/3

6

6/3

3

3

6

6

6

6

6/3

3

3

6/3

STOP

7.5"

STOP

PCL/3

7.5"

2'52.5"

2'52.5"

PCL/7.5"

2'52.5"

MINU

OP

C

OP

C

R5

R1

ST

DRAIN

ES

R4

R3

R2

R1

PREWASH

ST

DRAIN

ES

R4

R3

R2

BLEACH

0L9

PREWASH

**

****

SOFTENER

**

**

** *

**

3

2

1

)(T

4BLEACH

5

HEATING

STOP WITH LOAD

1B

1A

1

B

A

1C

T.P.

C.

2A

A

LIGHT

2B

1

VE

AL

TROVEC

EL

DRAIN

4B

4A

4

B

A2CB

4

30

PUMP

1/2 LOAD

6B

6A

5

A

SLOW CAD.

8A

6

A5B

6

NORMAL CAD.

8B

B

WASH

PREWASH

PROGRAM SELECTOR

SOFTENER

Page 34

technical

1100 r.p.m.

Description of functioning

E3

F3

TEMP. POWER

4

3

2

42

THERMOSTAT

A

B

F2

10

B

F

G5

G3

G4

1

2

E4

E5

E

23/

22

P

SENSOR

SELECTOR 230V BLOCK

SUPPRESSION

FILTER

G

24

N2

SPEED POWER

HEATING ELEMENT

ELECTROVALVE

EV

PRESSURE SWITCH

START/STOP

SWITCH

PROGRAMMER

DOOR LOCK

13/

12

PUMP

14

P

DOOR LOCK

CONTACT

1

N

A3

A

C

A4

D

C3

C2

D2

DRUM POSIT.

RINSE

5

4

62

3

2

D5

D4

B2

B

7

A

B

5

8

7

5

CARD

4

3

9

2

R

5

S

4

R

6

3

S

2

T

T

F5

3

2

R

5

S

4

Ta ch

y

WOOL

SHORT

C4

A

B

A

B5

3

B

2

B

B4

D3

31

Page 35

technical

Description of functioning

0

6

9

8

7

6

5

4

3

2

1

0

5

9

8

7

6

5

4

3

2

1

0

4

9

8

7

6

5

4

3

2

1

POSITION

0

3

9

8

7

6

5

4

3

2

1

2

0

9

8

7

6

5

4

3

2

1

0

1

9

8

7

6

5

4

3

2

1

s

15

mn

1

TIME

A4

A3A1A3

16

(A)

OR

CTSE

B

A

1C

001

(0. A)

C

DECO

BAA

B5C4*

*

A)

001

(0.

E

CODE

B

3C 2C

C3

A)

001

001

(0. A)

(0.

A

B

CODEBCODE

A

5C

D4

A)

001

(0.

CODE B

A

D3

7C

E4D5E5

E3

A)

A)

.1

(0

001

(0.

D

LOCK LIGHT

CODEBCTP

A

B

9C

.1

A)

(0

E1

E3

A)

510.

(

HEATING

B

A

10C

OPST

R3

R2

R+

R1

OPR3ST

R2

R+

R1

OP

ST

DRAIN DRAIN DRAIN

R3

R2

R+

R1

WASH WASH WASH

PREWAS PREWAS

PROGRAMME SELECTOR

** ** ** ** * **

1

(T)

PREWASH

3

2

4

WASH

BLEACH

SOFTENER

5

32

Page 36

© FAGOR ELECTRODOMESTICOS, S.COOP. 2003

Bº San Andrés, s/n

20500 Mondragón (Gipuzkoa)

España (Spain)

Loading...

Loading...