Page 1

EN INSTALLATION AND USER GUIDE

ES MANUAL DE INSTALACIÓN Y UTILIZACIÓN

NL INSTALLATIE- EN GEBRUIKSGIDS

Cooking hob

Placa de cocción

Kookplaat

Page 2

2

As part of our commitment to constantly improve our products, we reserve the right to alter

their technical, functional and/or aesthetic characteristics as part of their continuous

development.

IImmppoorrttaanntt nnoottee

: Please read this Installation and User Guide carefully before installing

and using the appliance, as this will help you to quickly familiarise yourself with its

operation.

Page 3

TABLE OF CONTENTS

• Safety guidelines

___________________________________________

70

• Caring for the environment

__________________________________

71

• Description of your appliance

________________________________

72

1 / INSTALLING YOUR APPLIANCE

• Choice of location

__________________________________________

73

• Fitting

___________________________________________________

73

• Flush Fitting recommendations

_______________________________

74

• Electrical connection

_______________________________________

75

• Gas connection

____________________________________________

76

• Changing the gas supply

____________________________________

78

2 / USING YOUR APPLIANCE

• Description of the surface control panel

_______________________

83

• Switching on the gas burners

________________________________

84

• Suitable cookware for gas burners

____________________________

85

3 / REGULAR CARE OF YOUR APPLIANCE

• Caring for your appliance

____________________________________

86

4 / SPECIAL INSTRUCTIONS, TROUBLESHOOTING

• During use

________________________________________________

87

5 / COOKING CHART

• Gas cooking guide

_________________________________________

88

6 / SOME RECOMMENDATIONS

___________________________________

88

7 / AFTER-SALES SERVICE DEPARTMENT AND CUSTOMER RELATIONS

• Service calls

______________________________________________

89

3EN4

Page 4

SAFETY GUIDELINES

SAFETY GUIDELINES

— This cooking hob has been designed for

private domestic use.

— This appliance must be installed in

compliance with currently applicable

regulations and used only in a well-ventilated

location. Consult this guide before installing

and using your appliance.

— Never leave the appliance unattended when

in use.

— These cooking hobs are intended solely for

cooking food and drinks and do not contain

any asbestos-based materials.

— This appliance is not connected to a

combustion by-product disposal system. It

must be installed and connected in

compliance with all applicable laws. Special

attention should be given to applicable

ventilation regulations.

— Do not store cleaning

PRODUCTS or

FLAMMABLE PRODUCTS (aerosol cans or

pressurised containers, as well as papers,

cookbooks, etc.) in the cabinet beneath your

cooking hob.

— If you use a drawer under the hob, avoid

using it to store heat sensitive items (plastic,

papers, aerosol cans, etc.).

— Your hob must be disconnected from the

power supply (electricity and gas) before

undertaking repair work.

— If you plug electrical appliances into a plug

socket which is within close proximity of the

hob ensure that any wires do not contact the

cooking zones.

— As a safety measure, remember to shut-off

the mains gas supply tap or the

butane/propane gas cylinder tap (whichever

is applicable).

— The CE compliance mark is affixed to these

hobs.

— Installation should only be undertaken by

qualified fitters and technicians.

— Before installation, make sure that the local

distribution conditions (gas type and

pressure) and the settings on the appliance

are compatible.

— This appliance is not intended to be used

by persons (including children) with reduced

physical, sensory or mental abilities, or those

lacking experience or awareness, unless they

are supervised by someone responsible for

their safety or they have received suitable

training in its operation from the said person.

Children must be supervised to prevent them

from playing with the appliance.

— This unit is not intended to be operated

using an external timer or a separate remote

control system.

— This hob is compliant with standard

EN 60335-2-6 relating to the heating of

cabinets and the Class 3 standard with regard

to installation (as per standard EN 30-1-1).

•

Warning

The required hob settings are written

on a sticker inside the instruction guide

pouch and on the packaging.

In order to easily locate any reference

information relating to your appliance, we

recommend that it is noted on the “AfterSales Service Department and Customer

Relations” page (this page also explains

where this information can be found on your

appliance).

CAUTION: if a crack appears in the surface,

disconnect the appliance from the power

supply to prevent any risk of electric shock.

For the following references : CFI-4GLSTANAT* - CFI-3GLSTANAT*

your hob is delivered set-up for natural gas.

For the following references : CFI-4GLSTABUT* - CFI-3GLSTABUT* - 2MCF2GSAXBUT* your hob is delivered set-up for butane gas.

Page 5

CARING FOR THE ENVIRONMENT

•

— This appliance’s packing materials can be

recycled. Please recycle the packaging and

share in the protection of the environment by

depositing them in municipal containers

provided for this purpose.

— Your appliance also contains

many recyclable materials. It is

therefore marked with this logo to

indicate that used appliances must

not be mixed with other waste. The

manufacturer will organise

recycling of the appliances in

optimum conditions, in accordance with

European directive EC/2002/96 governing

electrical and electronic equipment waste.

Consult your local authority or your retailer to

find the drop-off points for used appliances

which are nearest to your home.

— Thank you for your help in protecting the

environment.

CARING FOR THE ENVIRONMENT

5EN6

Page 6

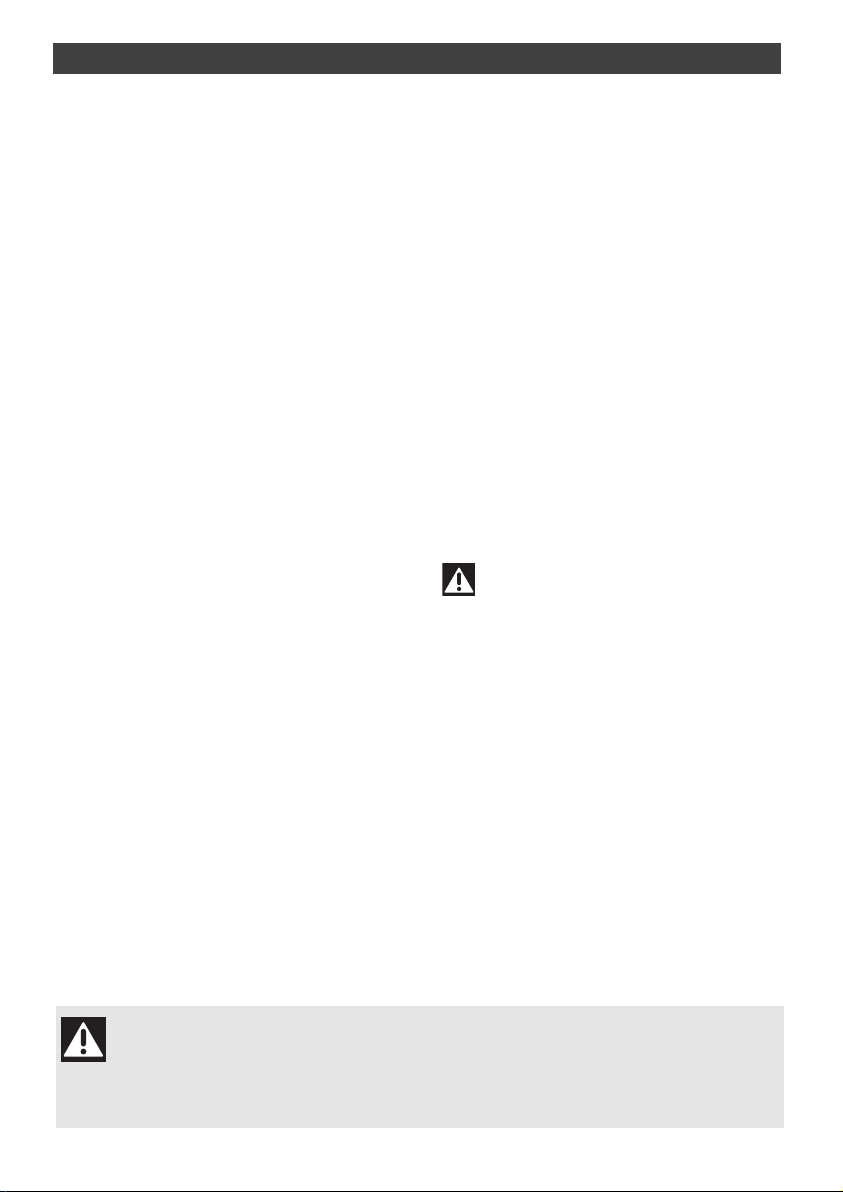

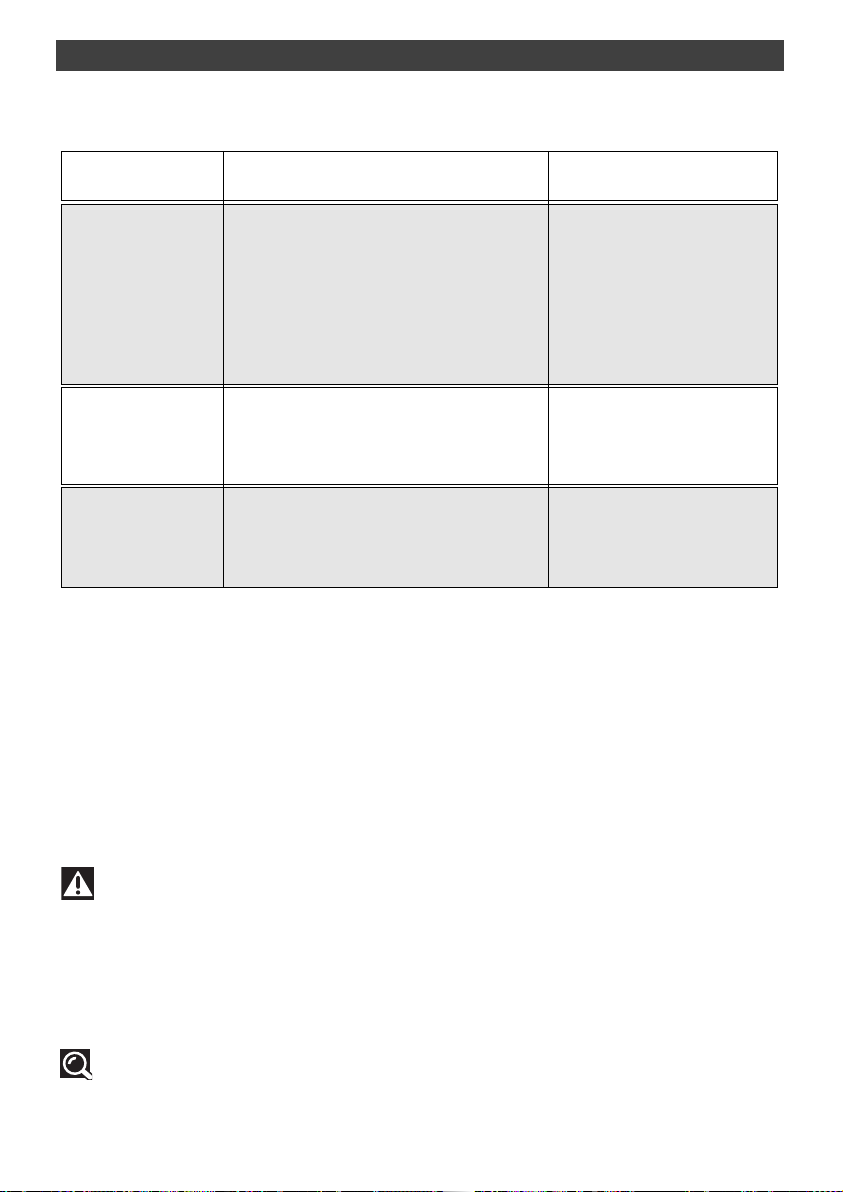

DESCRIPTION OF YOUR APPLIANCE

•

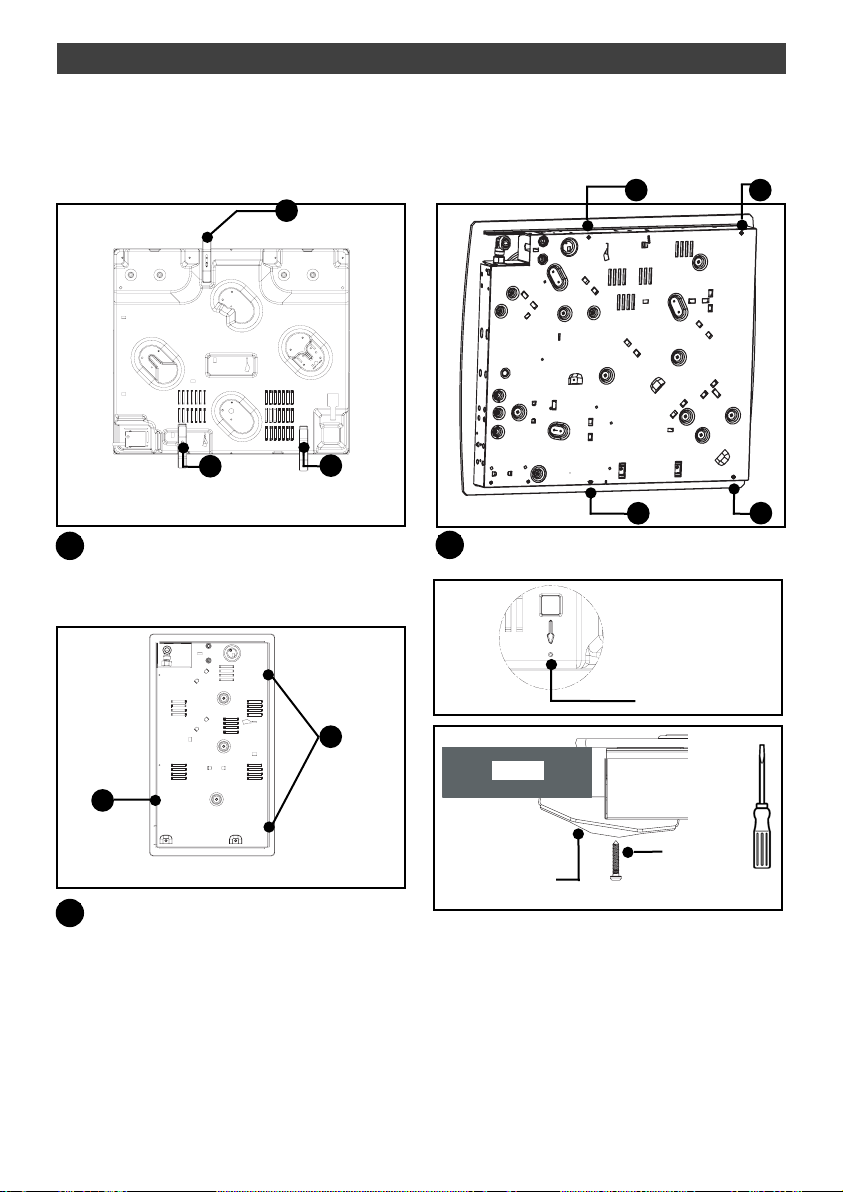

DESCRIPTION OF THE HOB

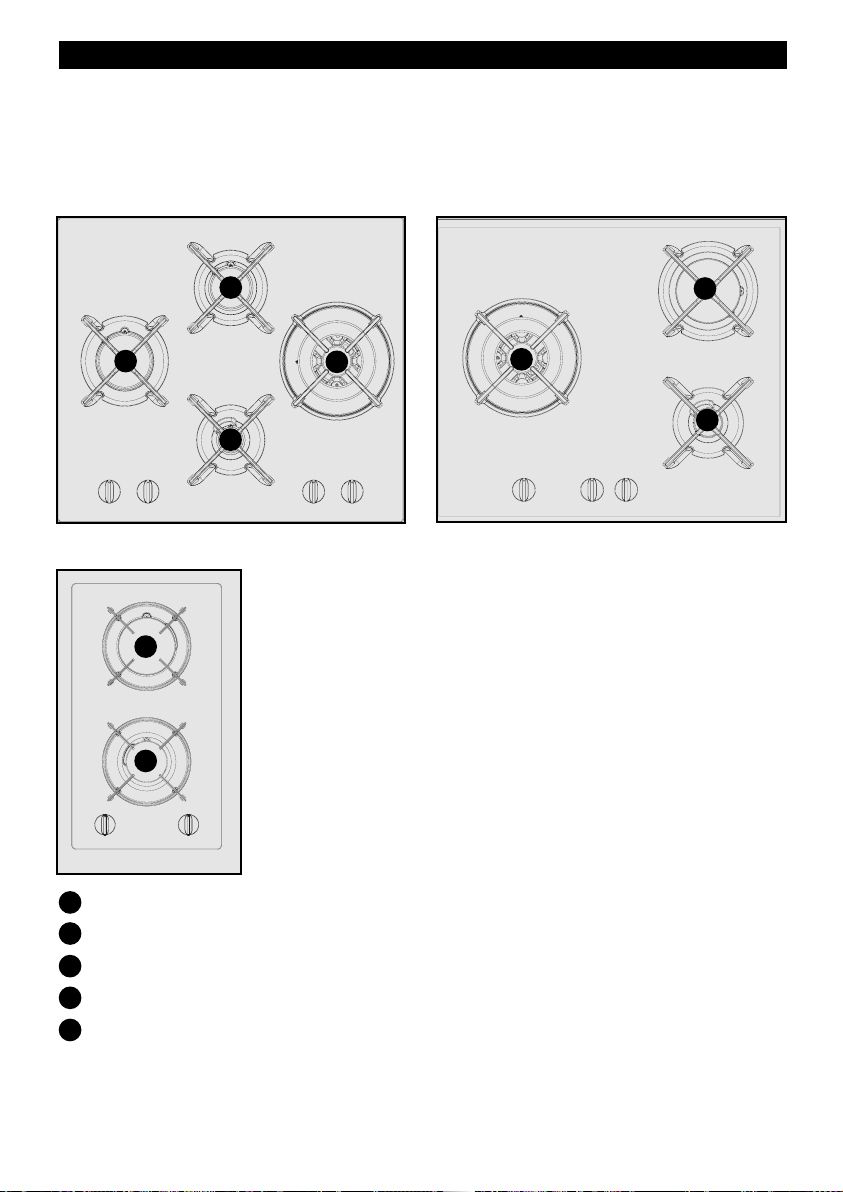

Hob model: 4 gas burners

with super fast burner

Hob model: 3 gas burners

with triple ring burner

Hob model: 2 gas burners

with super fast burner

A

B

Burner cover

Burner head

Injector

C

D

E

Spark plug

Thermocouple

Control Knob

F

G

H

Tap

Gasket

Note

This Installation and User guide covers several models. There may be minor differences

in details and fittings between your appliance and the descriptions provided.

D

E

A

B

F

H

G

C

Page 7

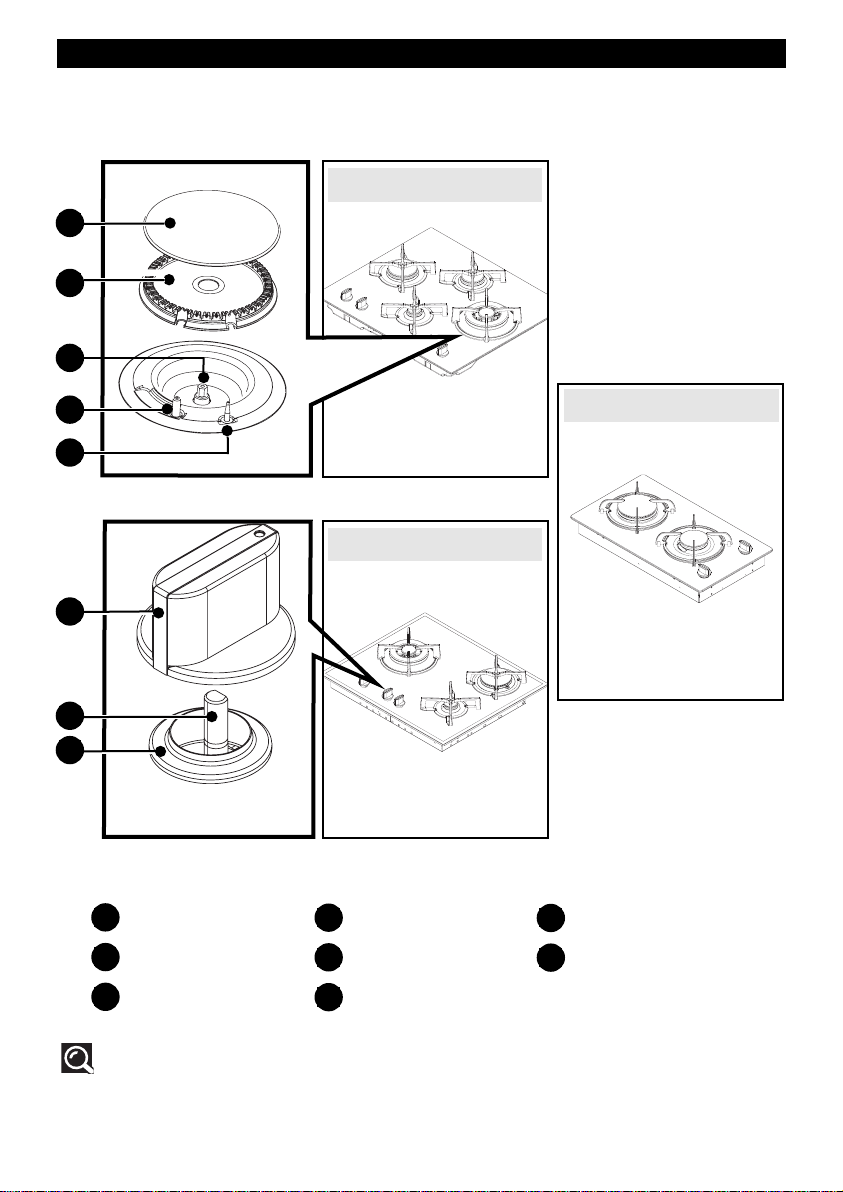

1/ INSTALLING YOUR APPLIANCE

•

CHOICE OF LOCATION

Your appliance must be flush fitted into a

support cabinet surface which is at least 3 cm

thick and is manufactured from heat resistant

material or covered in a heat resistant

coating.

A minimum distance of 30 cm either side of

the hob should be free from any obstructions

(cabinet or panel) which could hinder safe

handling of cooking utensils.

If a horizontal divider wall is positioned under

the hob, it must be located between 10 cm and

15 cm from the top of the work surface. In any

event, do not store aerosol cans or

pressurised containers in any compartments

located under the hob (refer to the

“

Safety

Recommendations”) chapter.

FITTING

In order to guarantee the seal between the

hob and the work top, the supplied seal must

be glued into the insert prior to hob

installation:

Refer to the diagram

(Fig. 01)

.

— Remove the pan supports, burner covers

and burner heads; noting their positions.

— Turn the hob over and carefully place it on

top of the opening in the cabinet to prevent

damage to the knobs and spark plugs.

— In order to guarantee the seal between the

housing and the worktop, stick the foam seal

around the edge of the frame

(Fig. 02

).

•

Fig. 01

Fig. 02

Housing

Seal

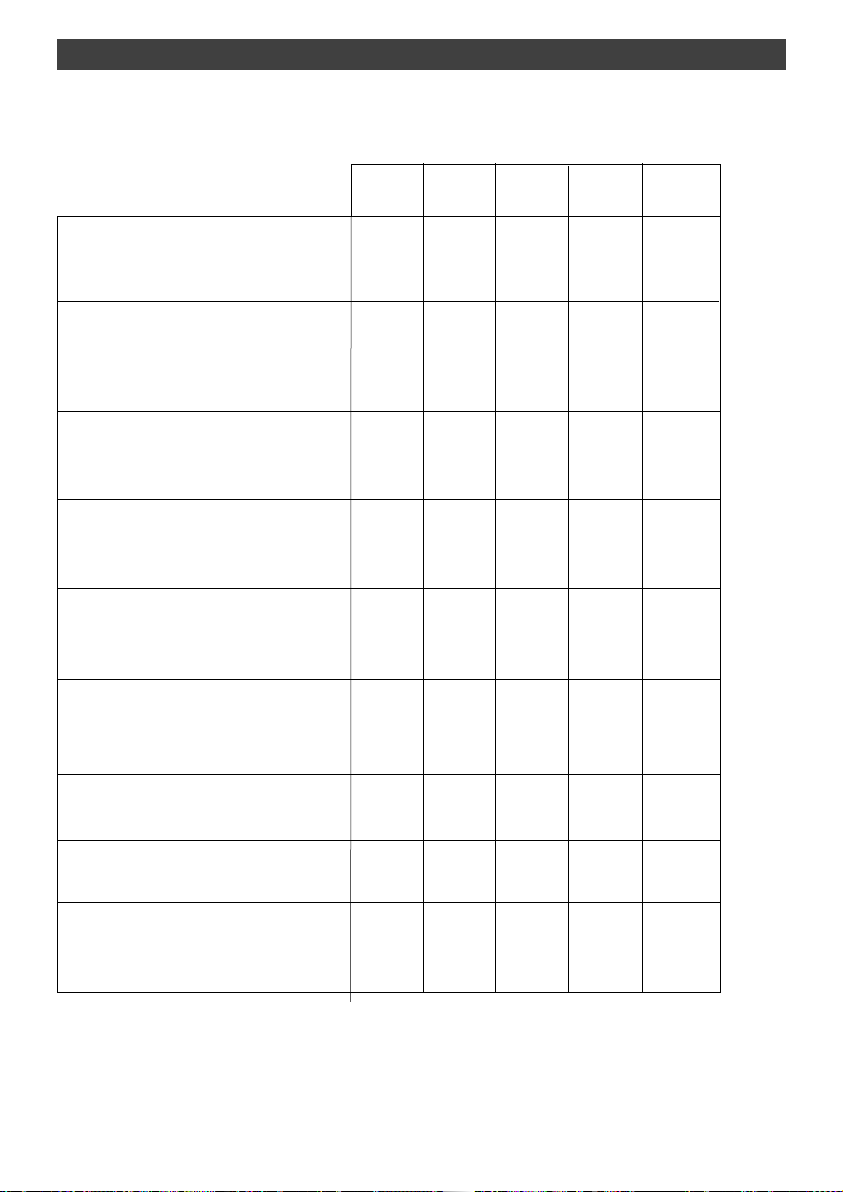

APPLIANCE (60 cm model)

Standard

cabinet

cut-out

Tot al

dimensions

above

the work

surface

Tot al

dimensions

below

the work

surface

Width

56 cm

71 cm

55.4 cm

Depth

49 cm

52.2 cm

47 cm

Thickness

depending

on

cabinet

5 cm

5.1 cm

APPLIANCE (30 cm model)

Standard

cabinet

cut-out

Tot al

dimensions

above

the work

surface

Tot al

dimensions

below

the work

surface

Width

26.5 cm

29,3 cm

26,3 cm

Depth

49 cm

52,5cm

47,9 cm

Thickness

depending

on

cabinet

5,4 cm

5.1 cm

7EN8

30 cm mini

70 cm mini

56 cm / 26,5 cm

5,8 cm mini

3 cm mini

49 cm mini

30 cm mini

Page 8

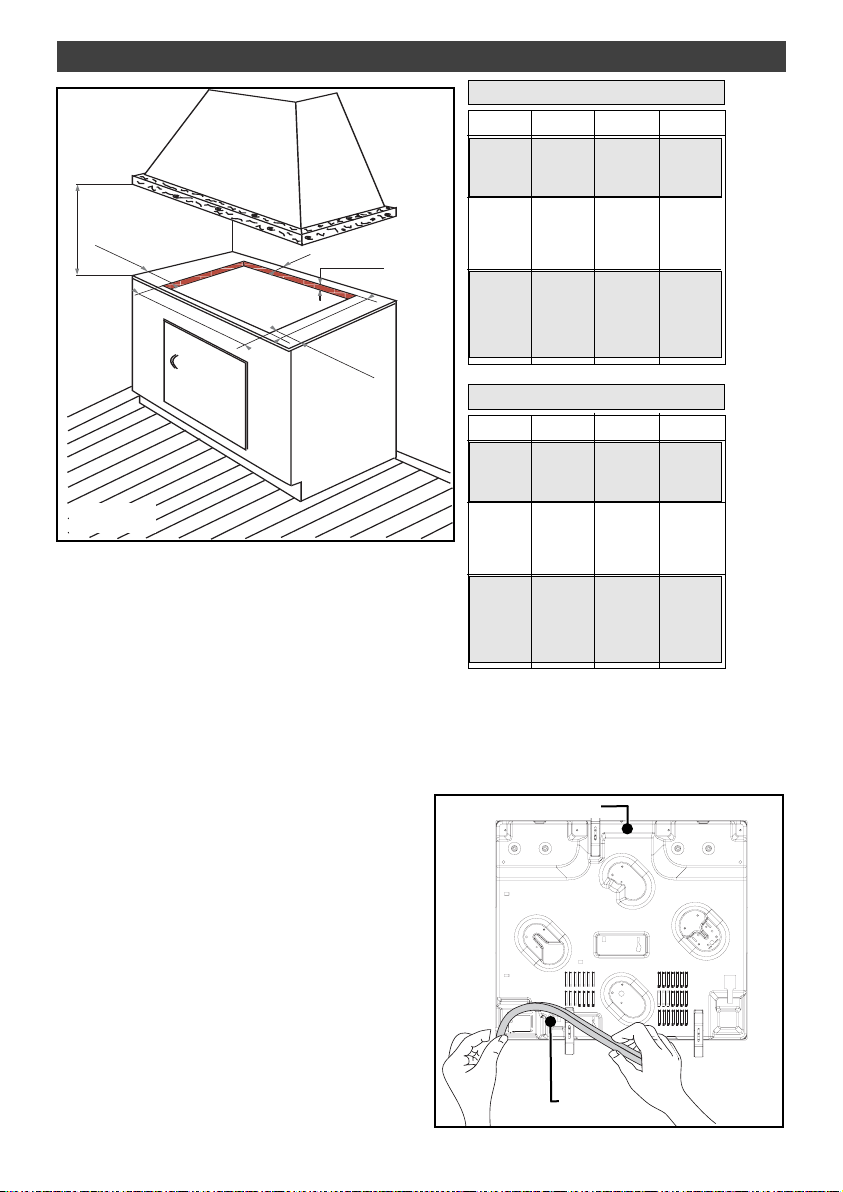

A

A

— Place your hob in the support cabinet

opening and carefully draw the hob towards

you.

— Re-position the burner heads, burner

covers and pan supports on the hob.

Connect the hob to the gas supply (See “Gas

Connection” chapter) and to the power

supply (See “Electrical Connection” chapter).

— If you wish, you can immobilise the hob

using the four mounting brackets (supplied

with screws)

(Fig. 02)

to attach them to the

four corners of the housing. You must use the

holes provided for this purpose, according

to the diagram above

(Fig. 02)

.

— Stop screwing when the mounting bracket

becomes deformed.

Do not use an electric screwdriver.

Fig. 01

Fig. 03

Screw

•

FLUSH FITTING RECOMMENDATIONS

Mounting brackets

A

A

Cabinet

1/ INSTALLING YOUR APPLIANCE

Fig. 02

Mounting holes

located using

arrows

A

Fig. 01

Mounting holes

A

Mounting holes

A

A

• 4 Burner Model

(underside view of the housing)

• 3 Burner Model

(underside view

of the housing)

• 2 Burner Model

(underside view of the housing)

A

A

A A

Fig. 01

Mounting bracket

Page 9

1/ INSTALLING YOUR APPLIANCE

9

EN

•

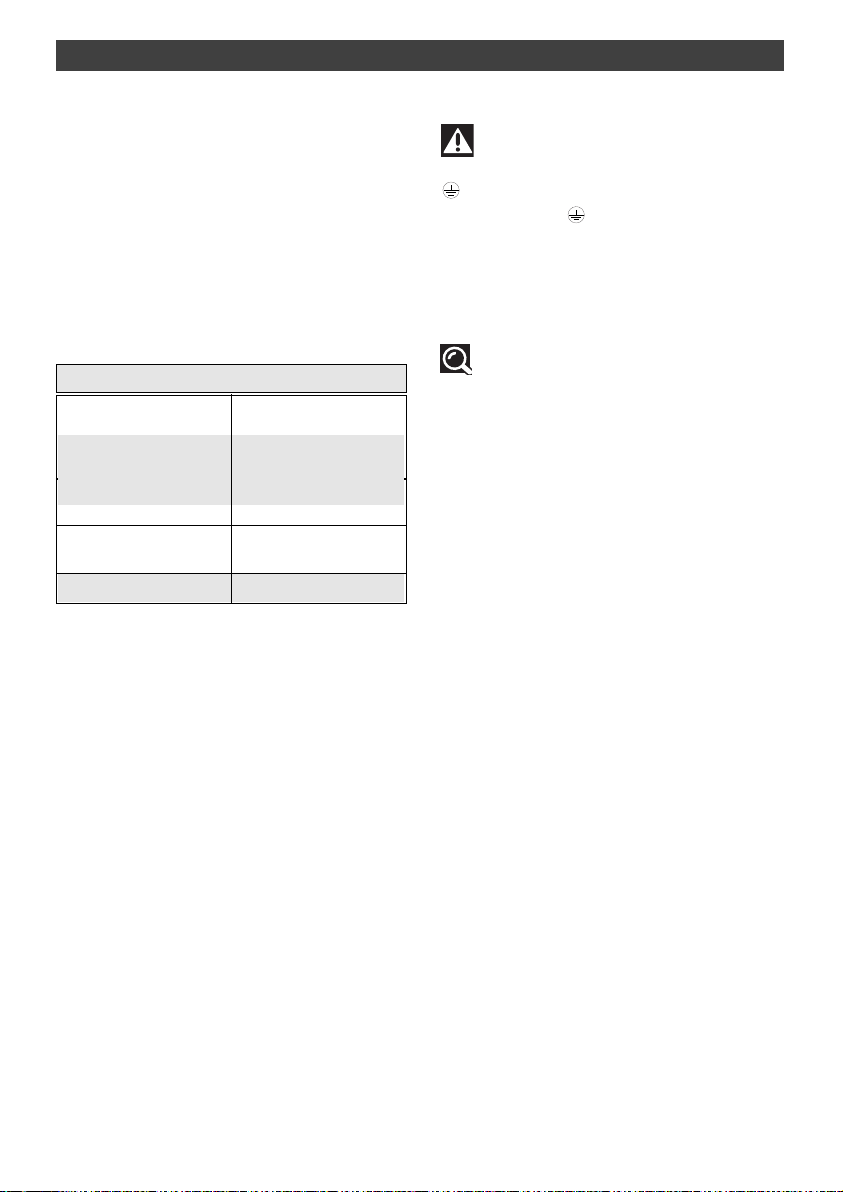

ELECTRICAL CONNECTION

Your hob (which is supplied with an H05V2V2F type wire) must be connected to the 220240 V~single phase grid via a standardised

CEI 60083 2-pole + ground electrical outlet

plug or an all-pole cut-off device, in

compliance with the current regulations.

The electrical plug socket must remain

accessible after installation.

TYPE OF CABLE SECTION TO BE USED

H05V2V2F -T90 cable

Ref. After-sales

service: 77x9060

Conductor section

in mm

2

Fuse

220-240 V~- 50 Hz

3 conductors

including

1 ground

1

10 A

Warning

The safety wire (green/yellow) is

connected to the appliance’s ground terminal

and must be connected to the installation’s

ground terminal . A 10 amperes fuse must

be used in the installation. If the power cable is

damaged, it must be replaced by a cable or a

special kit which is available from the

manufacturer or their After-Sales Service

Department.

Tip

Using a gas cooking appliance generates

heat and humidity in its local vicinity. Make sure

that your kitchen is well-ventilated: ensure

natural ventilation openings in your home are

unobstructed or install a mechanical ventilation

device (mechanical ventilation hood). Intensive,

prolonged use of the appliance may require

additional ventilation; you can, for example,

open a window or provide more effective

ventilation by increasing the setting on a

mechanical ventilation system, where installed.

(a minimum air flow of 2 m3/hr per kW of gas

power is required).

For example : 30 cm - 2 gas burners

Total power : 1.5 + 3.1 = 4.6 kW

4.6 kW x 2 = 9.2 m3/h

minimum flow.

Page 10

10

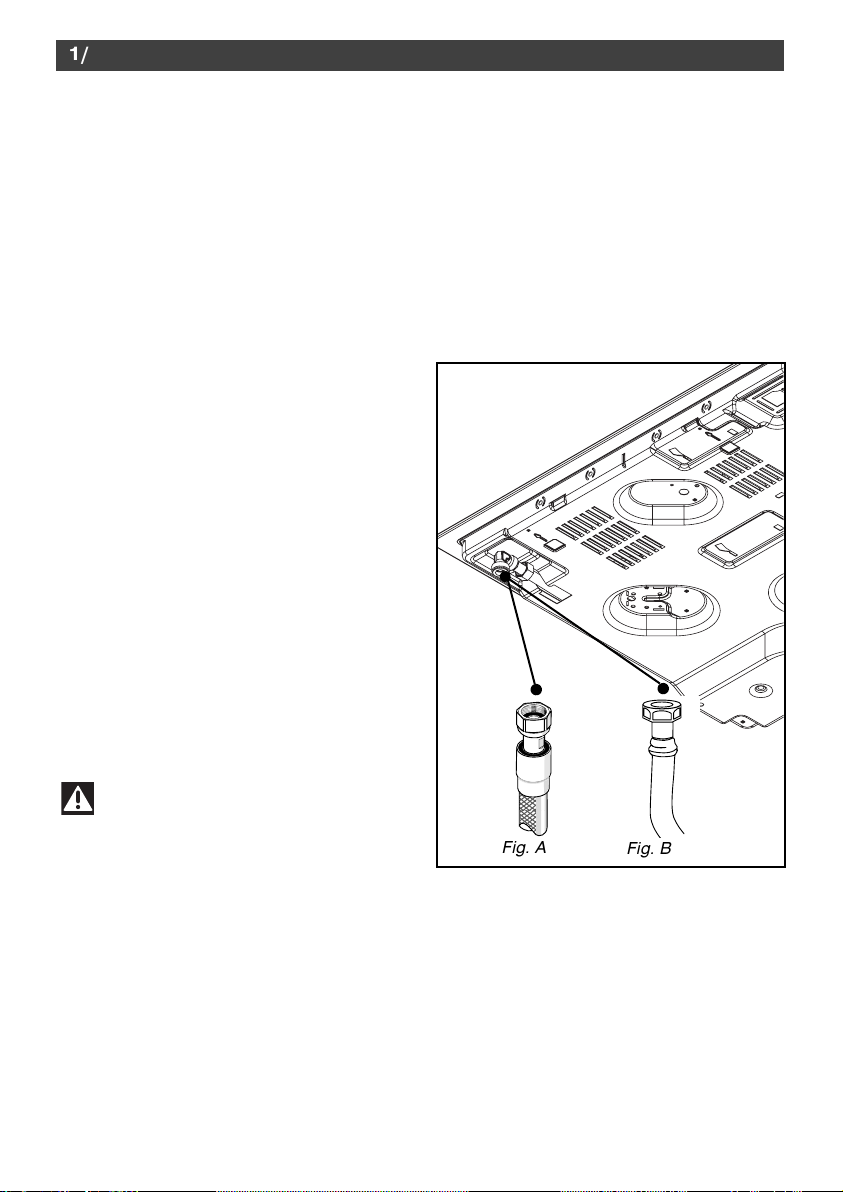

The gas connection must be installed in

compliance with applicable regulations in the

country of installation.

•

Gas distributed via natural gas

pipework

For your safety, you can only choose from the

following 3 connection options:

— Connection with a rigid copper pipe

with

screw-on mechanical connectors (G1/2 gas

standard mark). Connect directly to the end of

the elbow fitted on the appliance.

— Connection with a flexible metal hose

(stainless steel)

with screw-on mechanical

connectors

(compliant with standard NF D 36-

121) with lifetime service guarantee

(Fig. A).

— Connection with a reinforced rubber

hose

with screw-on mechanical

connectors

(compliant with the NF D 36-103 standard)

with 10 year service life guarantee

(Fig. B).

Warning

If you have to change the direction

of the elbow fitted on the appliance

when connecting your hob’s gas supply:

①①

Change the sealing washer.

②②

Tighten the elbow nut but do not

exceed 17 N.m. torque.

GAS CONNECTION

• Preliminary comments

If your hob is installed above an oven or if the proximity of other heating elements risks

overheating the connection, you must insulate the cable in a rigid pipe.

If a flexible hose or pipe (in the case of butane gas) is used, it must contact a moving part of the

cabinet or traverse a location likely to become blocked.

•

Fig. A

Fig. B

1/ INSTALLING YOUR APPLIANCE

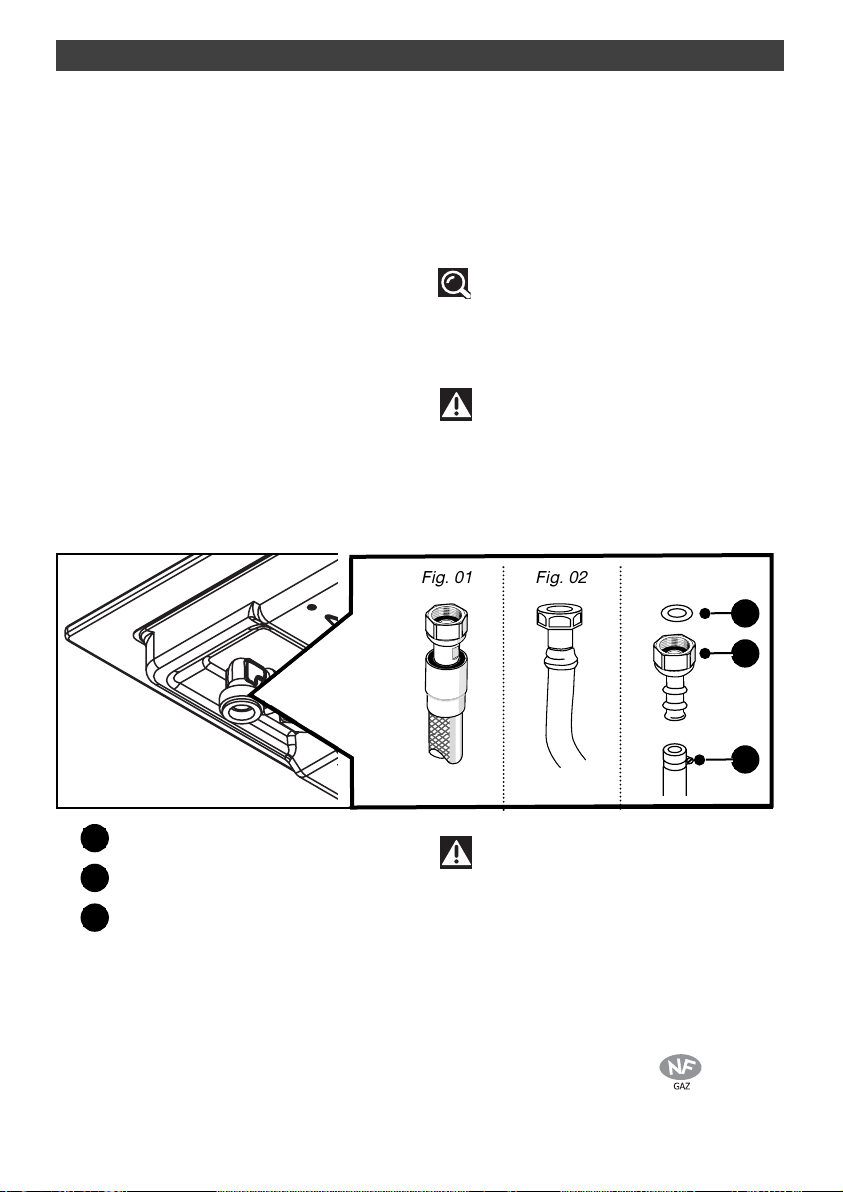

Page 11

1/ INSTALLING YOUR APPLIANCE

11

EN

•

Gas supplied by tank or

cylinder (butane/propane)

For your safety, you can only choose from the

following 3 connection options:

— Connection with a rigid copper pipe

with

screw-on mechanical connectors (G1/2 gas

standard mark). Connect directly to the end of

the elbow fitted on the appliance.

— Connection with a flexible metal hose

(stainless steel)

with screw-on mechanical

connectors (compliant with standard

NF D 36 121) with lifetime service guarantee

(Fig. 01).

— Connection with a reinforced rubber

hose

with screw-on mechanical

connectors

(compliant with the NF D 36-112 standard)

with 10 year service life guarantee (Fig. 02).

A

B

Sealing washer (not provided)

Adaptor (not provided)

Hose clip (not provided)

C

Warning

All flexible pipes and hoses with a

limited service life must have a maximum

length of 2 meters and must be accessible

along their entire length. They must be

replaced before the end of their service life

(indicated on the pipe). Regardless of the

chosen connection type, use soapy water to

ensure that the connection is leaktight once

installation is complete.

In France, you must use a hose or a pipe

bearing the “NF Gaz” stamp .

In an existing system, a flexible pipe fitted

with hose clips (compliant with the XP D 36110 standard) with a five year service life

guarantee can be used. In this case an

adaptor must be used and a sealing washer

must be inserted between the adaptor and

the hob’s elbow

(Fig. 03).

Tip

You can obtain the adaptor and the sealing

washer from your After-Sales Service

Department.

Warning

Do not exceed 25 N.m. torque when

tightening the adaptor.

Fig. 01

Fig. 02

Fig. 03

A

B

C

Page 12

12

1/ INSTALLING YOUR APPLIANCE

CHANGING THE GAS SUPPLY

Proceed as follows every time you change the

gas supply:

— Modify the gas connection

— Change the injectors

— Adjust the hob connections.

•

Modify the gas connection : refer to the

“Gas Connection” section.

•

Change the injectors, proceed as follows:

—

Remove the pan supports, heads and

covers from all burners.

For a 3-ring burner :

—

Use a 7mm type pipe spanner (not

supplied).

For other burners:

—

Use the spanner provided.

—

Unscrew and remove the injectors located

in the base of each crucible

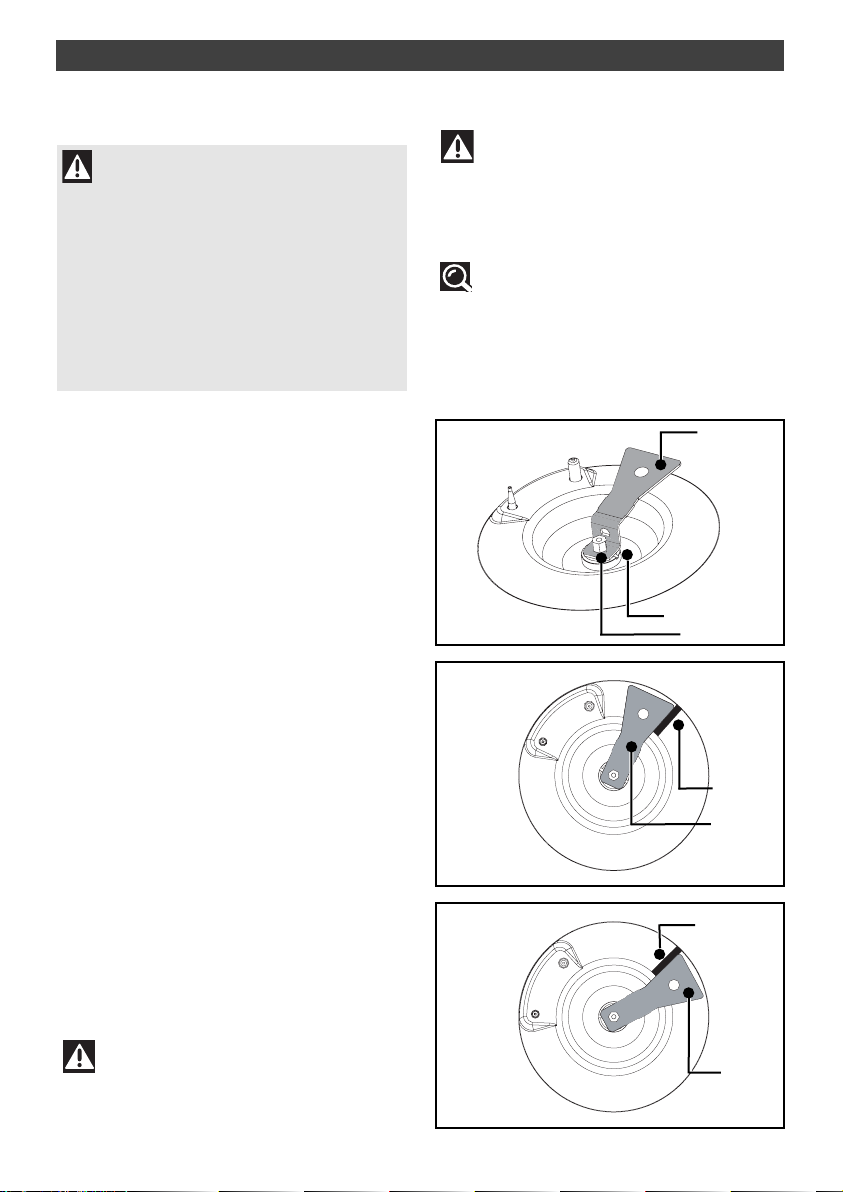

(Fig. 01).

—

Replace with the corresponding gas

injectors, in compliance with the injector

positioning markers and the gas

characteristics table at the end of this chapter;

proceed as follows:

—

First, manually tighten until the injector

locks into place.

—

Fully connect the spanner onto the injector.

—

Draw a line on the burner plate using a

pencil where shown

(Fig. 02).

—

Turn the spanner clockwise until the line

appears on the opposite side

(Fig. 03).

Warning

Exceeding this limit may damage the

product.

•

Fig. 02

Fig. 03

Line

Line

Fig. 01

Spanner

Injector

Crucible

Warning

- For the following references : CFI4GLSTANAT* - CFI-3GLSTANAT*, your hob

is delivered set-up for

nnaattuurraall ggaass

.

- For the following references : CFI4GLSTABUT* - CFI-3GLSTABUT* - 2MCF2GSAXBUT*, your hob is delivered set-up for

bbuuttaannee ggaass

.

The injectors which are needed to change

the gas can be found in the installation

guide pouch.

Warning

Exceeding this limit may damage the

product.

-

Reposition the burner heads, burner covers

and pan supports on the hob.

Tip

Each time you change the gas supply,

tick the box corresponding to the new gas

level on the label found in the instruction

guide pouch.

Refer to the corresponding “Gas

Connection” section.

Spanner

Spanner

Page 13

1/ INSTALLING YOUR APPLIANCE

13

EN

•

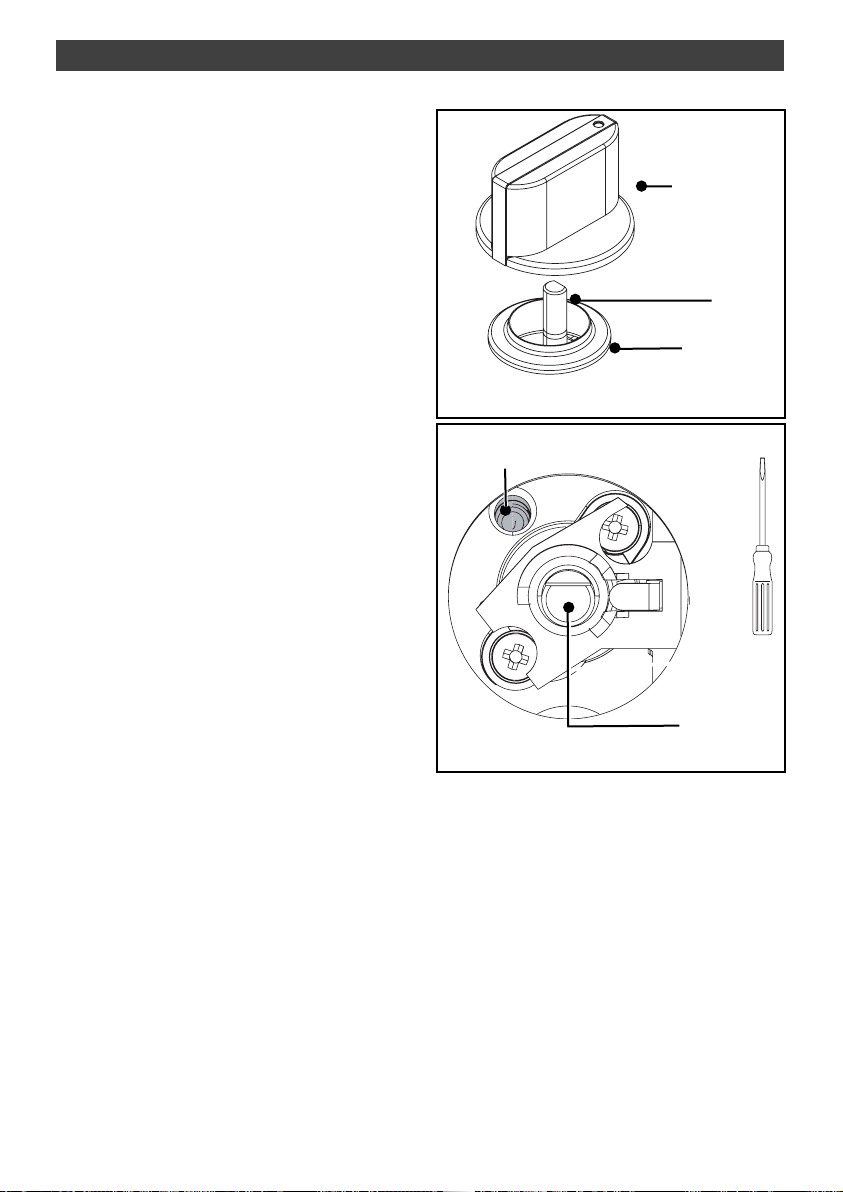

Adjust the hob connections: these are

located underneath the control knobs

(Fig. 04)

.

—

Proceed one tap at a time.

—

Remove the control knobs and the gaskets

by pulling upwards.

- Switching from natural gas to

butane/propane

-

Using a small flat-head screwdriver, fully

tighten the brass burner power screws

(yellow)

(Fig. 05),

in a clockwise direction.

-

Replace the gaskets and the control knobs,

noting their direction and ensuring that the

control knobs are fully inserted.

- Switching from butane/propane to natural

gas

-

Unscrew the brass (yellow) burner power

screws

(Fig. 05)

, using a small flat-head

screwdriver, turn twice anti-clockwise.

-

Replace the control knob.

-

Ignite the burner in maximum heat mode,

then turn down to reduced heat mode.

-

Remove the control knob again, then turn

the burner power screw clockwise until it

reaches the lowest possible setting without

extinguishing the flame.

-

Replace the gasket and control knob.

-

Repeatedly change from the maximum to

the minimum flow rate: the flame must not go

out ; if it does, unscrew the burner adjustment

screw to achieve good flame retention during

these changes.

-

Replace the burner heads, burner covers

and pan supports on the hob.

Sealing ring

Tap

Fig. 04

Fig. 05

Tap axis

Burner power

adjustment screw

Control Knob

Page 14

14

1/ INSTALLING YOUR APPLIANCE

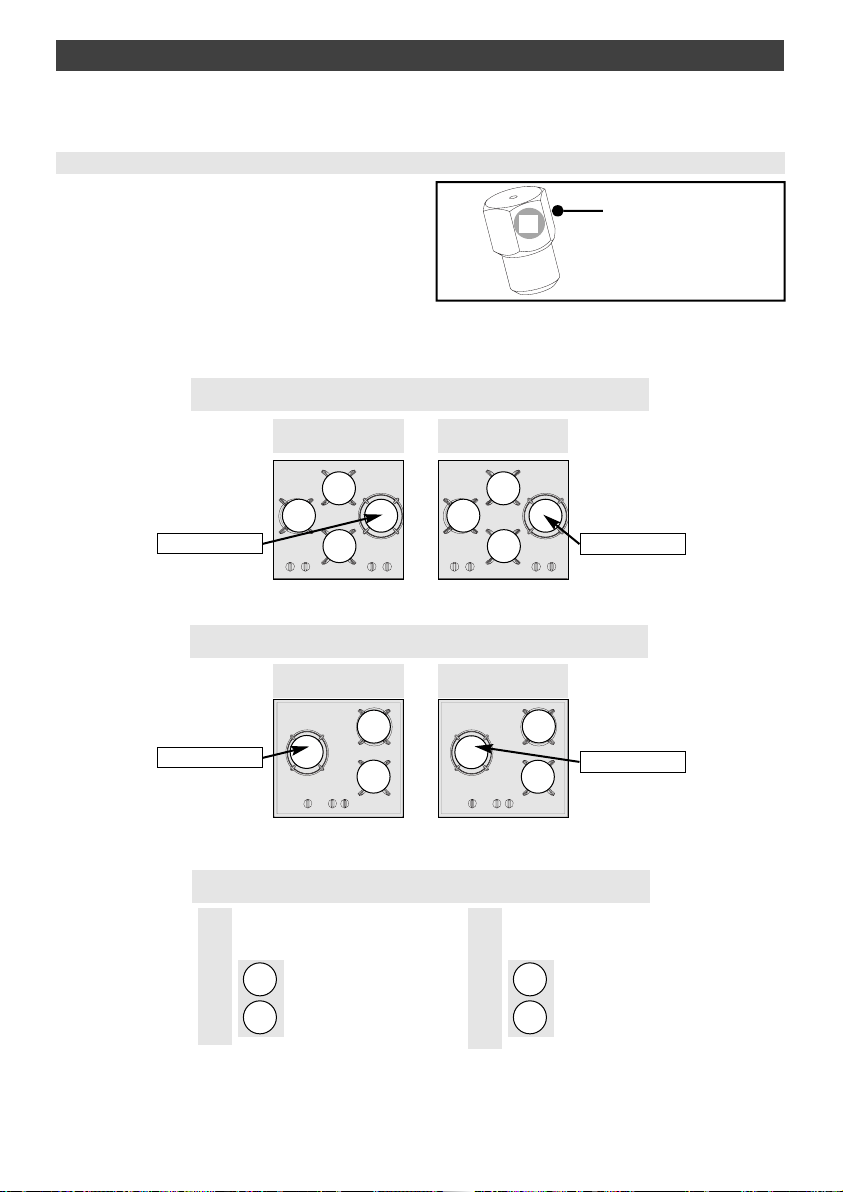

• Injector markings

The diagram opposite shows where the

injectors are positioned on your appliance

according to the type of gas used.

Each number is marked on the injector.

INJECTOR MARKINGS

4 gas burner hob with triple ring

3 gas burner hob with triple ring

62

For example:

injector marking 62

Natural Gas

Butane/Propane

Gas

2 gas burner hob

Natural Gas

Butane/Propane Gas

137

63

Natural Gas

Butane/Propane

Gas

94

1R

63

62

7R

45

88A

45

092/55B/092

092/55B/092

60/37/60

60/37/60

137

94

88A

62

Page 15

1/ INSTALLING YOUR APPLIANCE

15

EN

• Injector markings

TRIPLE RING BURNER INJECTOR MARKINGS

Natural Gas

Butane/Propane Gas

092

60

55B

37

092

60

Page 16

16

1/ INSTALLING YOUR APPLIANCE

•Gas Properties

Appliance intended to be installed for use with:

Butane Butane Propane Natural Natural

FR.......................cat : II2E+3+ gas gas

ES - PT ..............cat : II2H3+ G30 G30 G31 G20 G25

CZ - SK ..............cat : 2H3B/P 28-30 mbar 30 mbar 37 mbar 20 mbar 25 mbar

Following hourly rate at 15°C under 1013 mbar:

H

IGH-SPEED BURNER

Marking engraved on injector 7R 7R 7R 1R 1R

Nominal heat release rate (kW) 2.15 2.15 2.15 2.25 2.25

Reduced heat release rate (kW) 0.830 0.830 0.870 0.870

Hourly rate (g/hr) 156 156 154

Hourly rate (l/hr) 214 249

S

UPER-FAST BURNER

Marking engraved on injector 88A 88A 88A 137 137

Nominal heat release rate (kW) 3.15 3.15 3.15 3.10 3.10

Reduced heat release rate (with safety) (kW) 0.830 0.830 0.870 0.870

Hourly rate (g/hr) 229 229

Hourly rate (l/hr) 225 295 343

S

EMI-FAST BURNER

Marking engraved on injector 62 62 62 94 94

Nominal heat release rate (kW) 1.50 1.50 1.50 1.50 1.50

Reduced heat release rate (with safety) (kW) 0.620 0.620 0.615 0.615

Hourly rate (g/hr) 109 109

Hourly rate (l/hr) 107 143 166

A

UXILIARY BURNER

Marking engraved on injector 45 45 45 63 63

Nominal heat release rate (kW) 0.75 0.75 0.75 0.85 0.85

Reduced heat flow (kW) 0.300 0.300 0.350 0.350

Hourly rate (g/hr) 55 55

Hourly rate (l/hr) 54 81 94

T

RIPLE RING BURNER

Marking engraved on injector 60/37/60 60/37/60 60/37/60 092/055B/092 092/055B/092

Nominal heat release rate (kW) 3.25 3.25 3.25 3.60 3.60

Reduced heat flow (kW) 1.650 1.650 1.450 1.450

Hourly rate (g/hr) 236 236 232

Hourly rate (l/hr) 343 399

4

GAS BURNER HOB WITH TRIPLE RIN G

Total heat release rate (kW) 7.65 7.65 7.65 8.20 8.20

Maximum flow rate (g/hr) 556 556 547

(l/hr) 781 908

3

GAS BURNER HOB WITH TRIPLE RIN G

Total heat release rate (kW) 7.15 7.15 7.15 7.55 7.55

Maximum flow rate (g/hr) 520 520 511

(l/hr) 719 836

2

GAS BURNER HOB

WITH SUPER FAST

Total heat release rate (kW) 4.65 4.65 4.65 4.60 4.60

Maximum flow rate (g/hr) 338 338 332

(l/hr) 438 509

ES - PT -FRCZ - SK ES - PT -

FR

FR - ES PT - CZ -

SK

FR

Page 17

2 / USING YOUR APPLIANCE

17

EN

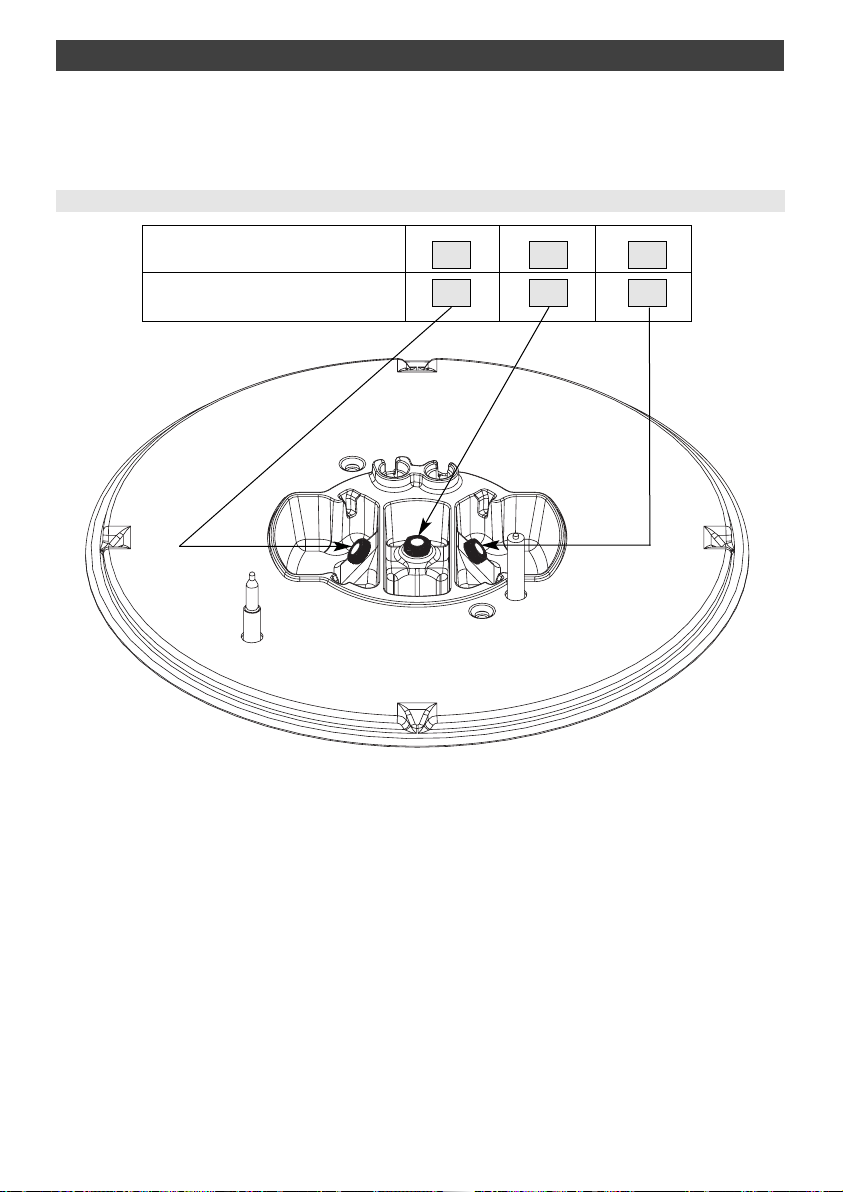

DESCRIPTION OF THE SURFACE CONTROL PANEL

•

CFI-4GLSTA*

2MCF-2GSAX*

A

B

C

D

E

C

A

E

B

D

Semi-fast burner 1.50 kW*

High-speed burner 2.25 kW

*

Super fast burner 3.10 kW*

Auxiliary burner 0.85 kW *

Triple-ring burner 3.6 kW*

* Power obtained with natural gas G20

C

A

CFI-3GLSTA*

C

E

D

Page 18

18

2 / USING YOUR APPLIANCE

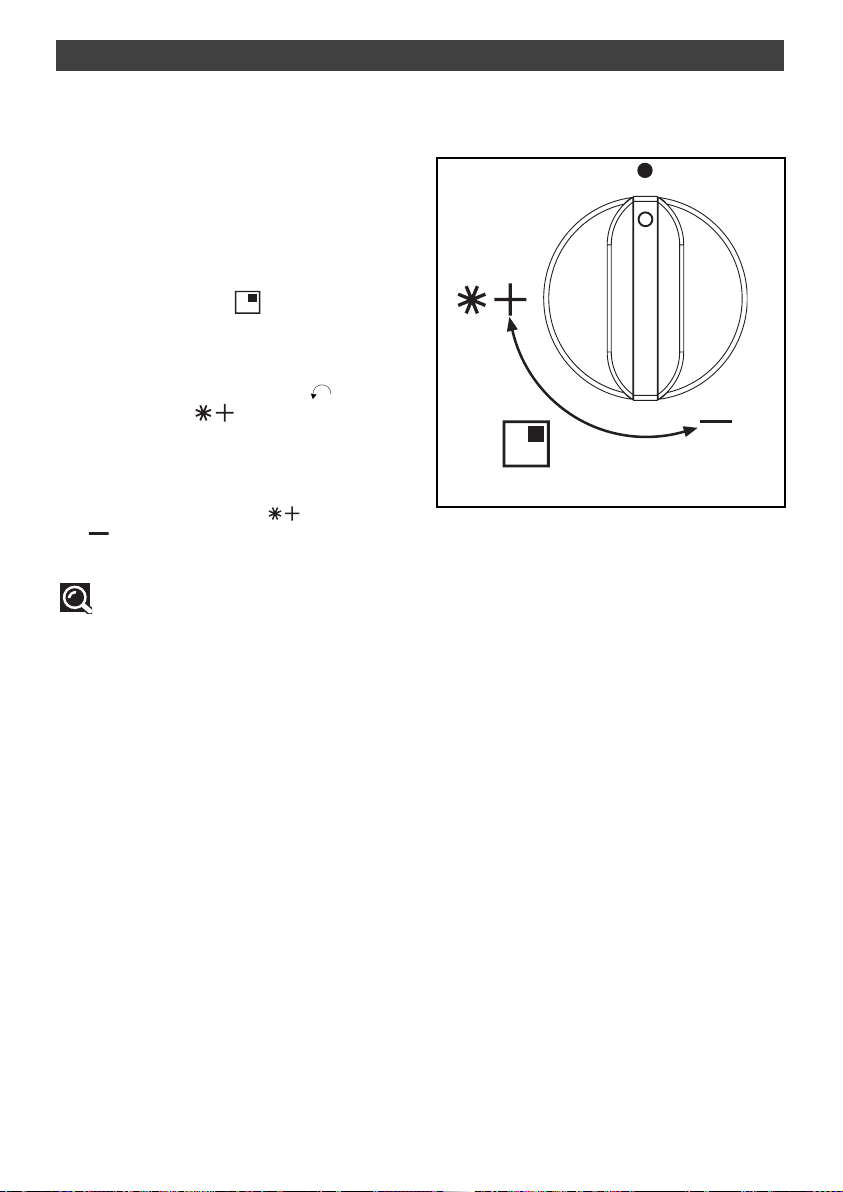

Gas is supplied to each burner via a tap which

is opened by pressing and turning the gas

control knob anti-clockwise.

The black

“

●

”

indicates the closed position.

— Choose the desired burner by using the

symbols located near the control knobs (e.g. :

right hand side burner ).

The control knobs on your hob are fitted with

an integrated burner-ignition system.

— To light a burner, press in and turn the

control knob anti-clockwise to the

maximum setting .

— Hold down the control knob to produce a

series of sparks until the burner lights.

The setting for more moderate flame

intensities is between the symbol and

the symbol.

Tip

If a control knob becomes difficult to

turn, do not force it. Call the installer for

emergency repairs.

If the flame is extinguished accidentally, reignite as normal following the burner

ignition instructions.

•

Fig. 01

SWITCHING ON THE GAS BURNERS

Page 19

2 / USING YOUR APPLIANCE

19

EN

•

CORRECT

INCORRECT

CONVEX

CONCAVE

Fig. 01

Fig. 02

Fig. 03

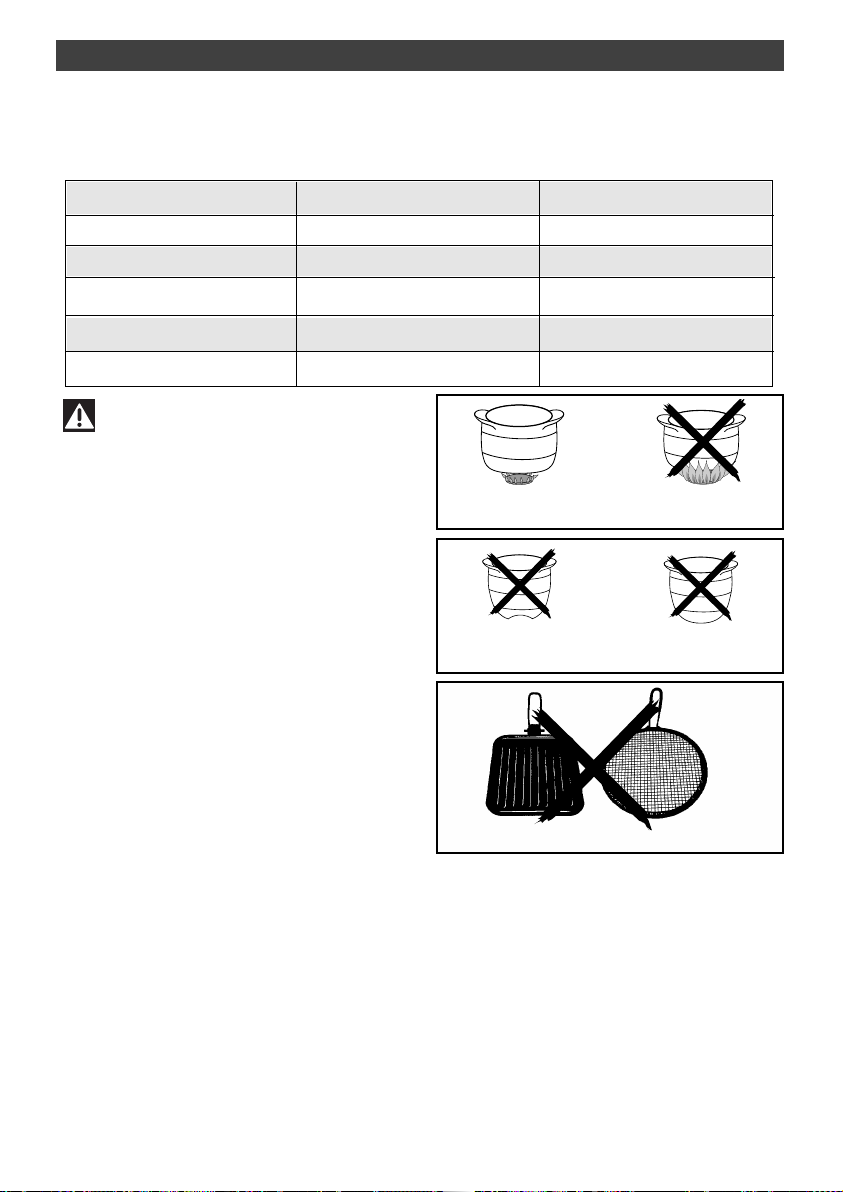

SUITABLE COOKWARE FOR GAS BURNERS

• Which burner should you use for your particular cookware?

Warning

— Adjust the burner flame so that it

does not extend beyond the edge of the

cookware (Fig. 01).

— Do not use cookware with a concave or

convex base without the appropriate supports

(Fig. 02).

— Do not use cookware that partially covers

the control knobs (Fig. 03).

— Do not leave empty cookware over an

ignited gas burner.

— Do not use heat regulators, toasters, steel

meat grills or stewpots with feet which sit on

or contact the glass worktop.

Cookware diameter

20 to 30 cm

18 to 28 cm

16 to 22 cm

12 to 20 cm

8 to 14 cm

Cookware diameter

Triple ring

Super fast

High-speed

Semi-fast

Auxiliary

Usage

Frying - Boiling

Searing

Sauces - Reheating

Gentle simmer

Page 20

20

PRODUCTS/ACCESSORIES

TO BE USED

. Small, hard-bristled brush.

. Safety pin.

. Gentle scouring cream.

. Cleaning sponge.

- Cleaning sponge.

- Special vitroceramic glass

products (e.g.: Cera-Clean).

Warning

- Never clean your appliance while it is in operation. Set all the electric and gas

controls to zero.

- WARNING: if a crack appears in the surface, disconnect the appliance from the power

supply to prevent any risk of electric shock.

Tip

—

We recommend cleaning hob fittings by hand rather than in a dishwasher.

—

Do not use an abrasive sponge to clean your hob.

—

Do not use a steam cleaner.

CARING FOR YOUR APPLIANCE

•

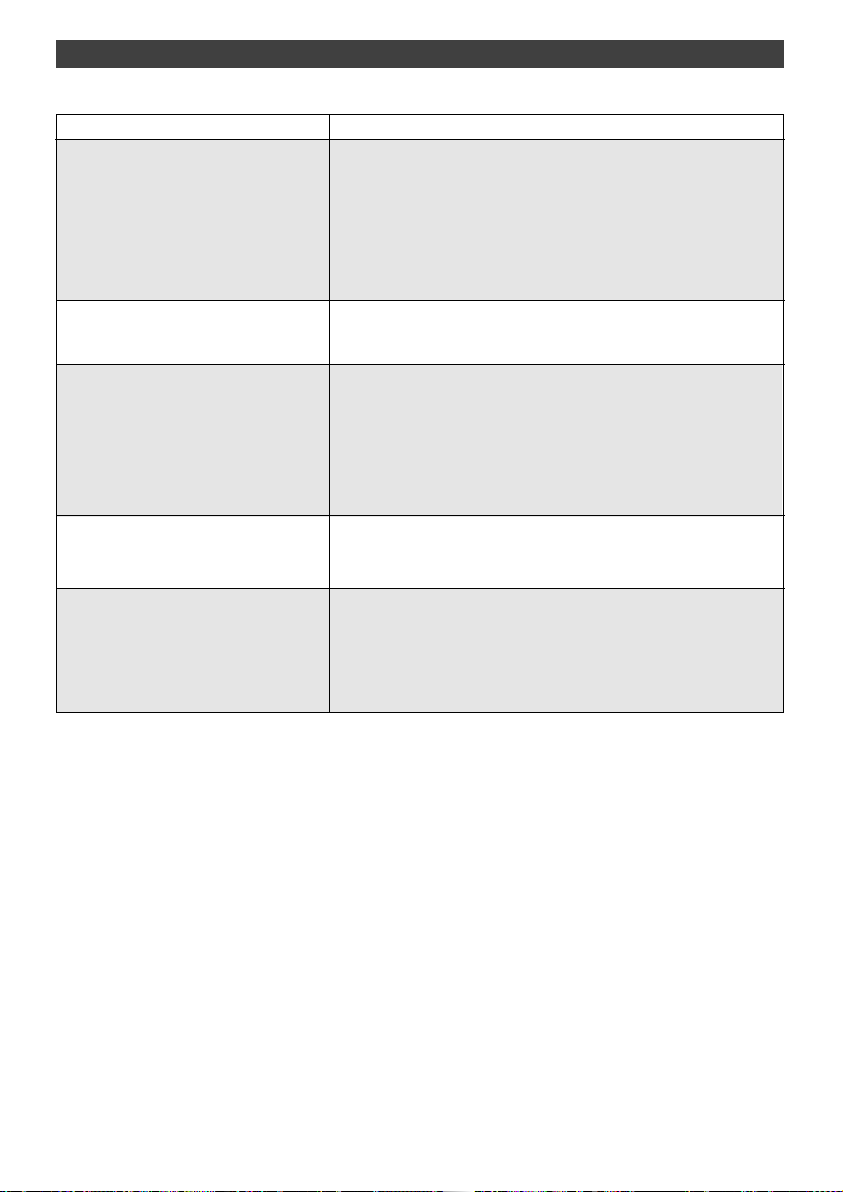

MAINTENANCE......

Of the spark plugs

and injectors

Of the pan supports

and gas burners

Of the glass

worktop

3 / REGULAR CARE OF YOUR APPLIANCE

ACTION

If spark plugs become soiled, clean them

using a small, hard-bristled brush (nonmetallic).

The gas injector is located in the centre of

the burner in the form of a crucible. Avoid

obstructing the injector during cleaning, as

this will adversely affect hob performance.

Use a safety pin to unclog the injector if it

becomes obstructed.

For tough stains, use a non-abrasive

cream, then rinse with clean water.

Carefully wipe each part of the burner

before re-using your hob.

- Clean with warm water and then wipe.

For tough stains, use products designed

for vitroceramic glass.

Page 21

4 / SPECIAL INSTRUCTIONS, TROUBLESHOOTING

. Check the electrical connection.

. Check that the spark plugs are clean.

. Check that the burners are clean and correctly

assembled.

. If the hob is clamped to the work top, check that the

mounting brackets are not deformed.

. Check that the gaskets under the control knobs are not

coming out of their inserts.

This is normal. The ignition function is centralised and

controls all burners simultaneously.

. Ensure strong air currents are not present in the room.

. Check that the gas type being used corresponds to the

injectors installed (review the injector markings in the

“Changing the Gas Supply” chapter).

. Check that the burner power screws are correctly

adjusted (refer to the “Changing the Gas Supply”

chapter).

. Check the cleanliness of the burners and injectors

under the burners, the assembly of the burners, etc.

. Check that there is enough gas in the cylinder.

. Use small saucepans on the burners located closest to

the control knobs. Larger saucepans should be placed

on the largest burners, which are furthest from the

knobs. Saucepan must be correctly positioned in the

centre of the burner. Saucepans should not extend over

the control knobs.

21

EN

DURING USE

•

PROBLEM: RESOLUTION:

•

Burner ignition:

No sparks appear when the

control knobs are pressed.

•

When pushing in a control

knob, sparks appear on all

burners simultaneously.

•

In reduced heat mode, the

burner goes out or the flames

remain high.

•

The flames look irregular or

uneven.

•

The control knobs become hot

during cooking.

Page 22

5 / COOKING CHART

22

Tip

—

In all instances, carefully read the instructions booklet for more detailed information.

6 / SOME RECOMMENDATIONS

GAS COOKING GUIDE

•

PREPARATIONS TIMES TRIPLE SUPER FAST SEMI- AUXILIARY

RING FAST FAST

SOUPS Broths 8-10 minutes XX

Thick soups X

FISH Court-bouillon 8-10 minutes XX

Grilled food 8-10 minutes

X

SAUCES Hollandaise, Bearnaise XX

Béchamel, Aurore 10 minutes XX

VEGETABLES

Chicory, spinach XX

Cooked peas 25-30 minutes XX

Provençal tomatoes 15-20 minutes XX

Browned potatoes XX

Pasta XX

MEATS Steak XX

Blanquette, Osso-bucco 90 minutes X

Sauteed poultry breasts 10-12 minutes X

Tournedos 10 minutes XX

FRYING Chips XX

Fritters XX

DESSERTS Rice pudding 25 minutes XX

Fruit compote XX

Crêpes/Pancakes 3-4 minutes XX

Chocolate 3-4 minutes X

Custard 10 minutes X

Coffee (small percolator) X

Ignition using the gas safety

feature

. Press and hold the control knob for a few seconds

after the flame appears in order to trigger the safety

system.

. If there is a power failure, the burner can be lit by

holding a match near the burner and pushing down the

relevant control knob at the same time.

. Regularly clean the burners: this is vital to their proper

operation and to ensure a stable and regular flame.

. Check that the spark plugs are clean. Thoroughly dry

the burners and burner covers before replacing them.

. Finish cleaning by wiping the glass worktop using a

piece of absorbent paper to remove any traces of

humidity.

General maintenance

Use of cookware

. Always use stable, heat resistant cookware with a flat

base.

Tips . Once water starts to boil, reduce the burner’s heat to

prevent overflowing.

. Cover your saucepans with lids to save energy.

Page 23

Any repairs to your appliance must be carried

out by a qualified professional authorised to

work on this brand. When you call, state your

appliance’s complete reference information

(model, type, serial number). This information

appears on the manufacturer’s nameplate

which is located on the underside of the

appliance

(Fig. 01).

ORIGINAL PARTS

During any servicing, request the use of

genuine replacement parts only.

• SERVICE CALLS

We recommend the use of Clearit cleaning products to maintain your appliance.

Clearit offers professional products and solutions designed for the daily care of your

household appliances and kitchens.

They are sold by your regular retailer, along with a complete line of accessories and

consumable products.

Professional expertise serving individuals.

FagorBrandt SAS, tenant-manager – SAS with share capital of 20 000 000 euros RCS Nanterre 440 303 196.

7 / AFTER-SALES SERVICE DEPARTMENT AND CUSTOMER RELATIONS

Fig. 01

Fig. 01

23

EN

E

C

E

C

Page 24

24

Con la inquietud de mejorar constantemente nuestros productos, nos reservamos el derecho

de aportar a sus características técnicas, funcionales o estéticas todas las modificaciones

relacionadas con su evolución.

IImmppoorrttaannttee

: Antes de poner en marcha la placa, lea atentamente esta guía de instalación

y utilización para familiarizarse más rápidamente con su funcionamiento.

Page 25

SUMARIO

25

ES

• Consignas de seguridad

___________________________________

92

• Respeto del medio ambiente

_________________________________

93

• Descripción de la placa

_____________________________________

94

1 / INSTALACIÓN DE SU APARATO

• Elección del emplazamiento

_________________________________

95

• Empotramiento

____________________________________________

95

• Consejos de empotramiento

_________________________________

96

• Conexión eléctrica

_________________________________________

97

• Conexión gas

_____________________________________________

98

• Cambio de gas

____________________________________________

100

2 / UTILIZACIÓN DE SU APARATO

• Descripción de la encimera

_________________________________

105

• Puesta en marcha de los quemadores de gas

___________________

106

• Recipientes para los quemadores a gas

_______________________

107

3 / MANTENIMIENTO CORRIENTE DEL APARATO

• Limpiar el aparato

__________________________________________

108

4 / MENSAJES PARTICULARES, INCIDENTES

• Durante la utilización

_______________________________________

109

5 / CUADRO DE COCCIÓN

• Guía de cocción a gas

______________________________________

110

6 / ALGUNOS CONSEJOS

________________________________________

110

7 / SERVICIO TÉCNICO Y RELACIÓN CON EL CONSUMIDOR

• Intervenciones

_____________________________________________

111

Page 26

26

CONSIGNAS DE SEGURIDAD

CONSIGNAS DE SEGURIDAD

— Hemos diseñado esta placa para que sea

utilizada por particulares en sus hogares.

— El aparato debe ser instalado de acuerdo

con las normativas vigentes y utilizado

únicamente en un lugar bien aireado.

Consulte este manual antes de instalar o

utilizar el aparato.

— Las cocciones deberán llevarse a cabo bajo

su atenta vigilancia.

— Estas placas de cocción están destinadas

exclusivamente a la cocción de bebidas y

productos alimenticios y no contienen ningún

componente a base de amianto.

— Este aparato no va conectado a ningún

dispositivo de evacuación de los productos

de combustión. Debe ser instalado de

acuerdo con las norma vigentes. Se prestará

especial atención a las disposiciones

aplicables relativas a la ventilación.

— No guarde en el mueble situado bajo la

placa los productos de

LIMPIEZA o INFLAMABLES

(sprays o recipientes a presión, papeles,

libros de recetas...).

—Si utiliza un cajón colocado bajo la placa, le

desaconsejamos que guarde en él objetos

que no resistan altas temperaturas (plásticos,

papeles, aerosoles, etc.).

— Antes de proceder a cualquier intervención

en la placa (eléctrica o a gas) deberá

desconectarla de la toma de alimentación.

— Cuando conecte aparatos eléctricos en una

toma de corriente situada cerca de la placa,

asegúrese de que el cable de alimentación no

esté en contacto con zonas calientes.

— Por medida de seguridad, tras su uso, no

se olvide de cerrar la llave general de gas

distribuido por canalización o la llave de la

bombona de gas butano / propano.

— Estas placas están marcadas con el sello

de conformidad de la CE.

— La instalación está reservada a instaladores

y técnicos cualificados.

— Antes de la instalación, asegúrese de que

las condiciones de distribución local

(naturaleza y presión del gas) y la regulación

de la placa son compatibles.

— Este aparato no está previsto para ser

utilizado por personas (incluidos los niños)

cuyas capacidades físicas, sensoriales o

mentales sean reducidas, o por personas

privadas de experiencia o conocimiento,

salvo si han podido beneficiarse, a través de

una persona responsable de su seguridad, de

una vigilancia o de instrucciones previas

concernientes a la utilización del aparato.

Conviene vigilar a los niños para asegurarse

de que no jueguen con el aparato.

— Este aparato no es diseñado para ser

puesto en funcionamiento utilizando un

temporizador externo o de un sistema de

mando a distancia separado.

— La placa es conforme a la norma

EN60335-2-6 en lo que respecta al

calentamiento de los muebles y es de clase 3

en lo relativo a la instalación (según norma

EN30-1-1).

•

Atención

Las condiciones de regulación están

escritas en una etiqueta situada en la bolsa

y también en el embalaje.

Para que en el futuro encuentre fácilmente

las referencias del aparato, le aconsejamos

que las anote en la página “Servicio Técnico

y Atención al Consumidor” (esta página

también le explica dónde puede

encontrarlas en el aparato).

ADVERTENCIA: si la superficie está

agrietada, desconecte el aparato de

alimentación para evitar riesgos de

descargas eléctricas.

Para las ref. siguientes: CFI-4GLSTANAT* - CFI-3GLSTANAT*

su placa se entrega preinstalada para funcionar con gas natural.

Para las ref. siguientes: CFI-4GLSTABUT* - CFI-3GLSTABUT* - 2MCF-2GSAXBUT*

su placa se entrega preinstalada para funcionar con gas butano.

Page 27

RESPETO DEL MEDIO AMBIENTE

27

ES

•

— Los materiales del embalaje de este

aparato son reciclables. Participe en su

reciclaje y ayude a proteger el medio

ambiente llevándolos a los contenedores

municipales previstos para ello.

— Su aparato contiene también

numerosos materiales reciclables.

Por ello ha sido marcado con este

logotipo que indica que los

aparatos viejos no se deben

mezclar con los demás residuos.

De este modo, el reciclaje de los

aparatos que organiza el fabricante se

efectuará en óptimas condiciones, de

acuerdo con la Directiva Europea

2002/96/CE sobre los residuos de equipos

eléctricos y electrónicos. Pregunte en su

ayuntamiento o al vendedor para conocer los

puntos de recogida de aparatos viejos más

cercanos a su domicilio.

— Le agradecemos su colaboración con la

protección del medio ambiente.

RESPETO DEL MEDIO AMBIENTE

Page 28

DESCRIPCIÓN DE LA PLACA

28

•

DESCRIPCIÓN DE LA PLACA

Placa modelo 4 fuegos gas

con quemador grande rápido

Placa modelo 3 fuegos gas

con quemador de triple corona

Placa modelo 2 fuegos gas

con quemador grande rápido

A

B

Tapa de quemador

Quemador

Inyector

C

D

E

Bujía de encendido

Termopar

Mando

F

G

H

Válvula

Anillo de estanqueidad

Consejo

Este manual de instalación y utilización es válido para varios modelos. Podría haber

ligeras diferencias en detalles y equipamientos entre su aparato y las descripciones que se

presentan.

D

E

A

B

F

H

G

C

Page 29

1 / INSTALACIÓN DE SU APARATO

•

ELECCIÓN DEL EMPLAZAMIENTO

El aparato debe estar encastrado en la parte

superior de un mueble soporte con un grosor

mínimo de 3 cm, construido con un material

resistente al calor o bien recubierto de un material que cumpla esta condición.

Para no entorpecer la manipulación de los

utensilios de cocina, deberá existir, tanto a la

derecha como a la izquierda, una distancia mínima de 30 cm desde la placa al mueble o pared adyacente.

Si debajo de la placa se coloca un panel horizontal, éste deberá estar situado obligatoriamente a una distancia comprendida entre los

10 cm y los 15 cm con relación a la parte superior del plano de trabajo. En todo caso, no coloque ningún spray o envase a presión en el

compartimiento que pueda existir debajo de la

placa (ver capítulo

“

Consignas de seguridad””).

EMPOTRAMIENTO

Para garantizar la estanqueidad entre la placa

y la superficie de trabajo, pegue la junta

incluida en la bolsa antes la instalación de la

placa:

Ajústese al esquema

(Fig. 01)

.

— Retire las rejillas de soporte de las

cacerolas, las tapas y los quemadores y

marque su posición.

— Dé la vuelta a la placa y colóquela con precaución encima de la abertura del mueble para no dañar los mandos y las bujías de encendido.

— Para asegurarse de que el cajón y la

encimera queden herméticos, pegue la junta

de espuma por todo el perímetro exterior

del marco

(Fig. 02

).

•

Fig. 01

Fig. 02

Carter

Junta

APARATO (modelo 60 cm)

Recorte

mueble

estándar

Dimensiones

totales

sobre la

encimera

Dimensiones

totales

debajo de

la

encimera

Anchura

56 cm

71 cm

55,4 cm

Profundidad

49 cm

52,2 cm

47 cm

Grosor

según

mueble

5 cm

5,1 cm

APARATO (modelo 30 cm)

Recorte

mueble

estándar

Dimensiones

totales

sobre la

encimera

Dimensiones

totales

debajo de

la

encimera

Anchura

26,5 cm

29,3 cm

26,3 cm

Profundidad

49 cm

52,5cm

47,9 cm

Grosor

según

mueble

5,4 cm

5,1 cm

29

ES

30 cm mini

70 cm mini

56 cm / 26,5 cm

5,8 cm mini

3 cm mini

49 cm mini

30 cm mini

Page 30

1 / INSTALACIÓN DE SU APARATO

30

A

A

— Coloque la placa en la abertura del mueble

soporte, teniendo cuidado de tirar de la placa

hacia usted.

— Coloque las tapas, los quemadores y las

rejillas de soporte de las cacerolas.

Conecte la placa al gas (ver capítulo

“Conexión a gas”) y a la electricidad (ver

capítulo “Conexión a eléctrica”).

— Puede inmovilizar, si lo desea, la placa por

medio de patas de fijación incluidas con los

tornillos

(Fig. 01 - Fig. 03)

se fijan a las

esquinas del marco. Utilice siempre los

agujeros previstos para ello como muestra

el dibujo anterior

(Fig. 02)

.

— Deje de atornillar cuando la brida de

fijación comience a deformarse.

No utilice un destornillador eléctrico.

Fig. 01

Fig. 03

Patilla de fijación

Tornillo

•

CONSEJOS DE EMPOTRAMIENTO

Patillas de fijación

A

A

Móvel

Fig. 02

Agujeros de fijación

localizadas por las

flechas

A

Fig. 01

Orificios de fijación

A

Orificios de fijación

A

A

• Modelo de 4 fuegos

(visto por debajo del marco)

• Modelo de 3 fuegos

(visto por debajo del

marco)

• Modelo de 2 fuegos

(visto por debajo del marco)

A

A

A A

Fig. 01

Page 31

1 / INSTALACIÓN DE SU APARATO

•

CONEXIÓN ELÉCTRICA

Su placa (que incluye un cable de tipo

H05V2V2-F) debe estar conectada a la red de

220-240 V~monofásica por el conducto de

una toma de corriente de 2 polos + tierra

normalizado CEI 60083 o conectada a un

dispositivo de corte omnipolar, de

conformidad con las normas de instalación

en vigor.

El enchufe debe estar accesible después de

realizar la instalación.

SECCIÓN DEL CABLE QUE SE DEBE UTILIZAR

Cable H05V2V2F -T90

Ref. Posventa:

77x9060

Sección de los

conductores en mm

2

Fusible

220-240 V~- 50 Hz

3 conductores

1 de ellos para tierra

1

10 A

Atención

El cable de protección (verde / amarillo)

está conectado a la borna de tierra del

aparato y debe estar conectado a la borna de

tierra de la instalación. El fusible de la

instalación debe ser de 10 amperios. Si el

cable de alimentación estuviera dañado,

deberá ser reemplazado por un cable o un

conjunto especial que puede adquirir en la

empresa fabricante o en el Servicio Técnico.

Consejo

El uso de hornos de gas genera una

producción de calor y de humedad en el lugar

de instalación.

AAsseeggúúrreessee ddee qquuee llaa ccoocciinnaa

tteennggaa uunnaa bbuueennaa vveennttiillaacciióónn::

mantenga

abiertos los orificios de ventilación natural de

la habitación o instale un dispositivo de

ventilación mecánica (campana de ventilación

mecánica). Una utilización intensiva y

prolongada de la placa puede hacer necesaria

una ventilación adicional, por ejemplo

abriendo una ventana o una ventilación más

eficaz , aumentando la potencia de la

ventilación mecánica, si ésta existe. (se

necesita como mínimo un caudal de aire de 2

m3/h por kW de potencia de gas).

Ejemplo : 30 cm - 2 fuegos gas

Potencia total : 1,5 + 3,1 = 4,6 kW

4,6 kW x 2 = 9,2 m3/h de

caudal mínimo.

31

ES

Page 32

1 / INSTALACIÓN DE SU APARATO

32

La conexión de gas deberá efectuarse de

acuerdo con las normas vigentes en el país

de instalación.

•

Gas distribuido por

canalización de gas natural

Para su seguridad, debe elegir únicamente

alguna de las 3 conexiones siguientes:

— Conexión con un tubo rígido

de cobre con

extremos mecánicos atornillables

(denominación norma gas G1/2). Realice la

conexión directamente en el extremo del

codo montado del aparato.

— Conexión con un tubo flexible metálico

(de

acero inoxidable)

ondulado con extremos

mecánicos

atornillables (de acuerdo con la

norma NF D 36-121) cuya vida es ilimitada

(Fig. A).

— Conexión con un tubo flexible

de goma

reforzado

con extremos mecánicos

atornillables (de acuerdo con la norma NF D

36-103) cuyo tiempo de vida es de 10 años

(Fig. B).

Atención

Al realizar la conexión de gas de

su placa, si está obligado a cambiar la

orientación del codo montado en el

aparato:

①①

Cambie la anilla de estanqueidad.

②②

Apriete la tuerca del codo sin

superar un par de fuerza de 17 N.m.

CONEXIÓN GAS

• Observaciones preliminares

Si la placa de cocción se encuentra instalada encima de un horno o si existe el riesgo de que,

debido a la proximidad de otros elementos calientes, se produzca un calentamiento de la

conexión, ésta se deberá realizar con un tubo rígido.

Si se utiliza un tubo flexible (caso del gas butano), éste no deberá estar en contacto con ninguna

parte móvil del mueble ni pasar por un lugar en el que pueda obstruirse.

•

Fig. A

Fig. B

Page 33

1 / INSTALACIÓN DE SU APARATO

•

Gas distribuido por bombona o

depósito (gas butano / propano)

Para su seguridad, debe elegir únicamente

alguna de las 3 conexiones siguientes:

— Conexión con un tubo rígido

de cobre con

extremos mecánicos atornillables

(denominación norma gas G1/2). Realice la

conexión directamente en el extremo del

codo montado del aparato.

— Conexión con un tubo flexible metálico

(de acero inoxidable)

ondulado con extremos

mecánicos

atornillables (de acuerdo con la

norma NF D 36-125) cuya vida es ilimitada

(Fig. 01).

— Conexión con un tubo flexible

de goma

reforzado

con extremos mecánicos

atornillables (de acuerdo con la norma

NF D 36-112) cuyo tiempo de vida es de

10 años

(Fig. 02).

A

B

Anilla de estanqueidad (no incluida)

Extremo (no suministrada)

Abrazadera (no incluida)

C

Atención

Todos los tubos blandos y tubos

flexibles cuya duración de vida esté

limitada deben tener una longitud máxima

de 2 metros y poder ser inspeccionados en

toda ella. Deben sustituirse antes de su

fecha límite de utilización (marcada en el

tubo). Cualquiera que sea el medio de

conexión elegido, asegúrese de su

estanqueidad, después de la instalación, con

agua con jabón suave.

En Francia, debe utilizar un tubo o tubería

con la marca NF Gaz

En una instalación existente puede utilizarse

un tubo flexible equipado con abrazaderas

para tubos (de conformidad con la norma

XP D 36-110) cuya duración de vida es de 5

años. En ese caso, es necesario utilizar un

empalme sin olvidar colocar una arandela de

estanqueidad entre el empalme y el codo de

la placa

(Fig. 03).

Consejo

El Servicio Posventa le proporcionará el

empalme y la arandela de estanqueidad.

Atención

Atornille el extremo con un par que no

supere los 25 N.m.

Fig. 01

Fig. 02

Fig. 03

A

B

C

33

ES

Page 34

1 / INSTALACIÓN DE SU APARATO

34

CAMBIO DE GAS

En cada cambio del gas, necesitará

sucesivamente:

— Adaptar la conexión de gas

— Cambiar los inyectores

— Ajustar los ralentís de las llaves

•

Adaptar la conexión de gas : consulte el

punto

“Conexión gas”.

•

Cambie los inyectores procediendo como

sigue:

—

Retire las rejillas, las tapas y los

quemadores de todos los fuegos.

Para el quemador de triple corona:

—

Por favor, utilice una llave para tubos de 7

(no incluida).

Para los demás quemadores:

—

Por favor, utilice la llave suministrada.

—

Desenrosque los inyectores situados en el

fondo de cada bote y elimínelos

(Fig. 01).

—

Monte en su lugar los inyectores de gas

correspondientes, de conformidad con lo

marcado en los inyectores y la tabla de las

características gas que se encuentra al final

del capítulo ; para ello:

—

Atorníllelos primero manualmente hasta

bloquear el inyector.

—

Apriete a fondo el inyector con ayuda de la

llave.

—

Haga una línea con un lápiz en la placa del

horno en el lugar indicado

(Fig. 02).

—

Gire la llave en el sentido de las agujas del

reloj hasta que la línea aparezca en el otro

lado

(Fig. 03).

Atención

No sobrepase esta línea ya que se

puede dañar el producto.

•

Fig. 02

Fig. 03

Línea

Línea

Llave

Llave

Fig. 01

Llave

Inyector

Hueco

Atención

- Para las ref. siguientes: CFI-4GLSTANAT* CFI-3GLSTANAT*, su placa se entrega

preinstalada para funcionar con gas natural.

- Para las ref. siguientes: CFI-4GLSTABUT* CFI-3GLSTABUT* - 2MCF-2GSAXBUT*, su

placa se entrega preinstalada para funcionar

con gas butano.

Los inyectores necesarios para el cambio de

gas están en la bolsa que contiene esta guía.

Atención

No sobrepase esta línea ya que se

puede dañar el producto.

-

Vuelva a colocar los quemadores, las tapas y

las rejillas para soporte de cacerolas

Consejo

Cada vez que cambie de gas, marque

la casilla correspondiente al nuevo gas que

figura en la etiqueta situada en la bolsa .

Consulte el párrafo correspondiente

“Conexión a gas”.

Page 35

1 / INSTALACIÓN DE SU APARATO

•

Regule los reductores de las válvulas: se

encuentran debajo de los botones

(Fig. 04)

.

—

Proceda válvula por válvula.

—

Retire los mandos y los anillos de

estanqueidad tirando de ellos hacia arriba.

- Paso del gas natural o gas butano/propano

-

Con ayuda de un pequeño destornillador

plano, atornille a fondo el tornillo de latón de

regulación de los ralentís (amarillo)

(Fig. 05),

en el sentido de las agujas del reloj

.

-

Monte de nuevo los anillos de estanqueidad

y los mandos prestando atención al sentido

de orientación que deben tener y compruebe

que los mandos están bien introducidos.

- Paso del gas natural al gas

butano/propano

-

Desatornille el tornillo de latón de regulación

de los ralentís (amarillo)

(Fig. 05)

, utilizando

un destornillador plano, dando 2 vueltas en el

sentido inverso a las agujas de un reloj.

-

Vuelva a montar los botones.

-

Encienda el fuego al máximo y ponga la

posición mínima.

-

Retire de nuevo el mando, gire el tornillo de

regulación en el sentido de las agujas del

reloj hasta la posición más baja antes de que

se extinga la llama.

-

Monte de nuevo el anillo de estanqueidad y

el mando.

-

Realice varias maniobras de abertura

máxima a abertura mínima: la llama se debe

apagar. En caso contrario, afloje el tornillo de

ajuste para obtener una buena llama durante

estas maniobras.

-

Vuelva a colocar los quemadores, las tapas

y las rejillas de soporte de cacerolas.

Botón

Anilla de

estanqueidad

Válvula

Fig. 04

Fig. 05

Eje de la válvula

Tornillo para ajuste

de los reductores

35

ES

Page 36

1 / INSTALACIÓN DE SU APARATO

36

• Señalización de los inyectores

La tabla que figura al lado indica las

ubicaciones de los inyectores de su placa de

cocción, de acuerdo con el gas que se utilice.

Cada número está marcado en el inyector.

INDICADOR DE LOS INYECTORES

Placa de 4 fuegos de gas con quemador de triple corona

Placa de 3 fuegos de gas con quemador de triple corona

62

Ejemplo:

indicación inyector 62

Gas Natural

Gas Butano /

Propano

Placa de 2 fuegos gas

Gas Natural

Gas Butano /

Propano

137

63

Gas Natural

Gas Butano /

Propano

94

1R

63

62

7R

45

88A

45

092/55B/092

092/55B/092

60/37/60

60/37/60

137

94

88A

62

Page 37

1 / INSTALACIÓN DE SU APARATO

• Señalización de los inyectores

LOCALIZACIÓN DE LOS INYECTORES DEL QUEMADOR DE TRIPLE CORONA

Gas Natural

Gas Butano / Propano

092

60

55B

37

092

60

37

ES

Page 38

1 / INSTALACIÓN DE SU APARATO

38

•Características gas

Aparato destinado a ser instalado en:

Butano Butano Propano Gas Gas

FR.......................cat : II2E+3+ natural natural

ES - PT ..............cat : II2H3+ G30 G30 G31 G20 G25

CZ - SK ..............cat : 2H3B/P

28-30 mbaras

30 mbar 37 mbar 20 mbar 25 mbaras

Caudal horario a continuación a 15°C a 1013 mbaras:

Q

UEMADOR RÁPIDO

Indicación marcada en el inyector 7R 7R 7R 1R 1R

Caudal calorífico nominal (kW) 2,15 2,15 2,15 2,25 2,25

Caudal calorífico reducido (kW) 0,830 0,830 0,870 0,870

Caudal horario (g/h) 156 156 154

Caudal horario (l/h) 214 249

Q

UEMADOR GRANDE RÁPIDO

Indicación marcada en el inyector 88A 88A 88A 137 137

Caudal calorífico nominal (kW) 3,15 3,15 3,15 3,10 3,10

Caudal calorífico reducido (con seguridad) (kW) 0,830 0,830 0,870 0,870

Caudal horario (g/h) 229 229

Caudal horario (l/h) 225 295 343

Q

UEMADOR SEMIRRÁPIDO

Indicación marcada en el inyector 62 62 62 94 94

Caudal calorífico nominal (kW) 1,50 1,50 1,50 1,50 1,50

Caudal calorífico reducido (con seguridad) (kW) 0,620 0,620 0,615 0,615

Caudal horario (g/h) 109 109

Caudal horario (l/h) 107 143 166

Q

UEMADOR AUXILIAR

Indicación marcada en el inyector 45 45 45 63 63

Caudal calorífico nominal (kW) 0,75 0,75 0,75 0,85 0,85

Caudal calorífico reducido (kW) 0,300 0,300 0,350 0,350

Caudal horario (g/h) 55 55

Caudal horario (l/h) 54 81 94

Q

UEMADOR DE TRIPLE CORONA

Indicación marcada en el inyector 60/37/60 60/37/60 60/37/60 092/055B/092 092/055B/092

Caudal calorífico nominal (kW) 3,25 3,25 3,25 3,60 3,60

Caudal calorífico reducido (kW) 1,650 1,650 1,450 1,450

Caudal horario (g/h) 236 236 232

Caudal horario (l/h) 343 399

P

LACA DE 4 FUEGOS DE GAS CON QUEMADOR DE TRIPLE CORONA

Caudal calorífico total (kW) 7,65 7,65 7,65 8,20 8,20

Caudal máximo (g/h) 556 556 547

(l/h) 781 908

P

LACA DE 3 FUEGOS DE GAS CON QUEMADOR DE TRIPLE CORONA

Caudal calorífico total (kW) 7,15 7,15 7,15 7,55 7,55

Caudal máximo (g/h) 520 520 511

(l/h) 719 836

P

LACA DE 2 FUEGOS G AS

CON GRANDE RÁPIDO

Caudal calorífico total (kW) 4,65 4,65 4,65 4,60 4,60

Caudal máximo (g/h) 338 338 332

(l/h) 438 509

ES - PT -FRCZ - SK ES - PT -

FR

FR - ES PT - CZ -

SK

FR

Page 39

2 / UTILIZACIÓN DE SU APARATO

DESCRIPCIÓN DE LA ENCIMERA

•

CFI-4GLSTA*

2MCF-2GSAX*

A

B

C

D

E

C

A

E

B

D

Quemador semirrápido 1,50 kW*

Quemador rápido 2,25 kW*

Quemador grande rápido 3,10 kW*

Quemador auxiliar 0,85 kW*

Quemador de triple corona de 3,6 kW*

* Potencias obtenidas con gas natural G20

C

A

CFI-4GLSTA*

C

E

D

39

ES

Page 40

2 / UTILIZACIÓN DE SU APARATO

40

PUESTA EN MARCHA DE LOS

QUEMADORES GAS

Cada fuego está alimentado por una válvula

cuya abertura está hecha pulsando y girando

en sentido antihorario.

El punto “

●

” se corresponde con el cierre de

la válvula.

— Seleccione el quemador deseado por usted

identificando los símbolos situados cerca de

los mandos (por ej.: quemador derecho ).

Su mesa está provista de encendido de los

quemadores integrado en los mandos.

— Para encender un fuego, pulse el botón y

gírelo en sentido antihorario hasta llegar

a la posición máxima .

— Mantenga el botón pulsado hasta que la

chispa encienda la llama.

La regulación del sistema de medida se

efectúa entre el símbolo y el símbolo

.

Consejo

Cuando tenga dificultades para girar

un botón, no lo fuerce. Pida con emergencia

la intervención de un instalador.

Si la llama se apaga accidentalmente, bastará con volver a encenderla normalmente

siguiendo las instrucciones de encendido.

•

Fig. 01

Page 41

2 / UTILIZACIÓN DE SU APARATO

•

BIEN

MAL

CONVEXO

CÓNCAVO

Fig. 01

Fig. 02

Fig. 03

RECIPIENTES PARA LOS QUEMADORES A GAS

• ¿Qué quemador emplear según el recipiente utilizado?

Atención

— Ajuste la corona de llamas de forma

que éstas no sobrepasen el perímetro del

recipiente (Fig. 01)

— No utilice recipientes con fondo cóncavo o

convexo sin el soporte adecuado (Fig. 02)

— No utilice recipientes que cubran

parcialmente los mandos (Fig. 03).

—No deje funcionando un fuego de gas con

un recipiente vacío.

— No utilice difusores, tostadores de pan,

parrillas de acero para carne ni cacerolas

con pies que reposen o rocen la superficie

de vidrio.

Diámetro del recipiente

20 a 30 cm

18 a 28 cm

16 a 22 cm

12 a 20 cm

8 a 14 cm

Diámetro del recipiente

corona triple

Grande rápida

Rápida

Semirrápida

Auxiliar

Uso

Freír - Hervir

Alimentos a soasar

Salsas - Recalentar

Cocer a fuego suave

41

ES

Page 42

3 / MANTENIMIENTO CORRIENTE DEL APARATO

42

PRODUCTOS/ACCESORIOS

QUE SE DEBEN UTILIZAR

. Pequeño cepillo de pelo

duro.

. Imperdible

. Crema suave para fregar.

. Esponja de baño.

- Esponja de baño.

- Productos especiales para

vitrocerámica (ej.: Ceraclean).

Atención

- No limpie nunca la placa mientras esté funcionando. Ponga todos los mandos

eléctricos o de gas a cero.

- ADVERTENCIA: si la superficie está agrietada, desconecte el aparato de alimentación

para evitar riesgos de descargas eléctricas.

Consejo

—

Es mejor limpiar a mano los elementos de la placa a hacerlo en el lavavajillas.

—

No utilice esponjas abrasivas para limpiar la placa.

—

No utilice un aparato de limpieza a vapor.

LIMPIAR EL APARATO

•

MANTENIMIENTO

DE...

Las bujías y los

inyectores

Las rejillas y los

quemadores de gas

La encimera de

vidrio

¿CÓMO PROCEDER?

En caso de suciedad de las bujías de

encendido, límpielas con ayuda de un

pequeño cepillo de pelo duro (no

metálico).

El inyector de gas se encuentra en el

centro del quemador con forma de

agujero. Tenga cuidado de no obstruirlo

durante la limpieza ya que perjudicaría al

rendimiento de su placa. En caso de

obstrucción, utilice un imperdible para

desatascar el inyector.

En caso de manchas persistentes, utilice

una crema no abrasiva y después aclare

con agua limpia. Seque cuidadosamente

todas las piezas del quemador antes de

volver a utilizar la placa de cocción.

- Limpie con agua caliente y después

séquelas. Si hay manchas persistentes,

utilice productos especiales para

vitrocerámica.

Page 43

4 / MENSAJES PARTICULARES, INCIDENTES

DURANTE LA UTILIZACIÓN

•

SE DA CUENTA DE QUE: QUÉ HAY QUE HACER:

.Compruebe la conexión eléctrica de la placa

. Compruebe la limpieza de las bujías de encendido.

. Compruebe la limpieza y el correcto montaje de los

quemadores.

. Si la placa está sujeta al plano de trabajo, compruebe

que las bridas de fijación no se han deformado.

. Compruebe que los anillos de estanqueidad que se

encuentran bajo los mandos no salen de su alojamiento.

Es normal. La función de encendido está centralizada y

manda sobre todos los fuegos de manera simultánea.

. Evite que se produzcan corrientes de aire violentas en

la habitación.

. Compruebe que el gas utilizado se corresponde con los

inyectores instalados (ver la indicación de los inyectores

en el capítulo “Cambio de gas”).

. Compruebe que los tornillos están bien regulados al

ralentí (ver párrafo “Cambio de gas”).

. Compruebe la limpieza de los quemadores y los

inyectores situados bajo los quemadores, el montaje de

los quemadores, etc.

. Compruebe que queda suficiente gas en la bombona.

. Utilice cacerolas pequeñas en los quemadores que se

encuentran cerca de los mandos. Los recipientes

grandes se deben colocar en los quemadores grandes,

los más alejados de los mandos. Coloque la cacerola en

el centro del quemador. No debe sobrepasar sobre los

mandos.

•

Encendido de los

quemadores:

No se producen chispas cuando

pulsa los mandos.

•

Cuando pulsa los botones,

aparecen chispas en todos los

fuegos.

•

En modo ralentí, el quemador

se apaga o las llamas son

demasiado grandes.

•

Las llamas tienen un aspecto

irregular.

•

Durante la cocción, los

mandos se calientan.

43

ES

Page 44

5 / CUADRO DE COCCIÓN

44

Consejo

—

En cualquier caso, para más información, lea atentamente todas las páginas del

manual.

6 / ALGUNOS CONSEJOS

GUÍA DE COCCIÓN A GAS

•

PREPARACIONES TIEMPO TRIPLE GRANDE RÁPIDO SEMI- AUXILIAR

CORONA RÁPIDO RÁPIDO

SOPAS Caldos 8-10 minutos XX

Cremas espesas X

PESCADOS Caldo corto 8-10 minutos XX

Parrilas 8-10 minutos

X

SALSAS Holandesa, bearnesa XX

Bechamel, aurora 10 minutos XX

VERDURAS Endibias, espinacas XX

Guisantes 25-30 minutos XX

Tomates provenzales 15-20 minutos XX

Patatas doradas XX

Patés XX

CARNES Filete XX

Guisado de vitela, Osso-bucco

90 minutos X

Escalope 10-12 minutos X

Solomillos 10 minutos XX

FRITOS Patatas fritas XX

Rissóis XX

POSTRES Arroz con leche 25 minutos XX

Compotas de fruta XX

Crepes 3-4 minutos XX

Chocolate 3-4 minutos X

Natillas 10 minutos X

Café (cafetera pequeña) X

Encendido con seguridad gas

Para activar el sistema de seguridad, mantenga el

mando completamente presionado durante unos

segundos después de que haya aparecido la llama.

. Si se produce un corte de corriente, se puede

encender el quemador acercando una cerilla y

manteniendo al mismo tiempo pulsado el mando

correspondiente.

. Limpie periódicamente los quemadores: es esencial

para que funcionen correctamente y para que la llama

sea estable y regular.

. No se olvide de las bujías de encendido. Antes de

volverlos a colocar, seque bien los quemadores y las

tapas de los quemadores.

. Termine la limpieza pasando un papel absorbente por

encima del vidrio para eliminar restos de humedad.

Mantenimiento general

Utilización de los recipientes

. Utilice siempre recipientes estables, con fondo plano

y resistentes al calor.

Trucos . Cuando el agua comience a hervir, reduzca la fuerza

del quemador para limitar el riesgo de salpicaduras.

. Ponga la tapa en las cacerolas: es un ahorro.

Page 45

7 / SERVICIO TÉCNICO Y RELACIÓN CON EL CONSUMIDOR

Las posibles intervenciones en su aparato

deberán ser realizadas por un profesional

cualificado depositario de la marca. Cuando

realice su llamada, mencione la referencia

completa del aparato (modelo, tipo y número

de serie). Esta información figura en la placa

de características pegada bajo el aparato

(Fig. 01).

PIEZAS ORIGINALES

Siempre que realice cualquier intervención de

mantenimiento, pida que se utilicen exclusivamente

piezas de recambio certificadas origi-

nales.

•INTERVENCIONES

Para mantener en buen estado su aparato, le1 recomendamos que utilice los productos de

limpieza Clearit.

Clearit le propone productos profesionales y soluciones adecuadas para el mantenimiento

cotidiano de sus aparatos electrodomésticos y su cocina.

Los podrá encontrar a la venta en su distribuidor habitual, junto con toda una línea de

productos accesorios y consumibles.

La experiencia de profesionales al servicio de los particulares.

FagorBrandt SAS, locataire-gérant – SAS con capital social de 20. 000. 000 euros RCS Nanterre 440 303 196.

Fig. 01

Fig. 01

45

ES

E

C

E

C

Page 46

46

Uit een voortdurend streven naar het verbeteren van onze producten behouden we ons het

recht voor om wijzigingen aan te brengen aan de technische, functionele of esthetische

eigenschappen ervan, om de technische evolutie op de voet te volgen.

BBeellaanngg rriijjkk

: voordat u uw apparaat start, dient u deze installatie- en gebruiksgids

aandachtig te lezen om er sneller mee te leren werken.

Page 47

INHOUD

47

NL

• Veiligheidsaanwijzingen

_____________________________________

114

• Respect voor het milieu

_____________________________________

115

• Beschrijving van uw apparaat

________________________________

116

1 / INSTALLATIE VAN HET APPARAAT

• Keuze van de plaats

________________________________________

117

• Inbouw

___________________________________________________

117

• Inbouwtips

________________________________________________

118

• Elektrische aansluiting

______________________________________

119

• Gasaansluiting

_____________________________________________

120

• Vervanging van het gas

_____________________________________

122

2 / GEBRUIK VAN HET APPARAAT

• Beschrijving van de bovenzijde

_______________________________

127

• In werking stellen van de gasbranders

________________________

128

• Recipiënten voor de gasbranders

_____________________________

129

3 / GEWOON ONDERHOUD VAN UW APPARAAT

• Onderhoud van uw apparaat

_________________________________

130

4 / SPECIALE MEDEDELINGEN EN INCIDENTEN

• Tijdens het gebruik ________________________________________ 131

5 / KOOKTABEL

• Handleiding voor koken met gas

______________________________

132

6 / ENKELE TIPS

________________________________________________

132

7 / SERVICEDIENST EN KLANTENRELATIE

• Ingrepen

__________________________________________________

24

Page 48

48

VEILIGHEIDSAANWIJZINGEN

VEILIGHEIDSAANWIJZINGEN

— Deze kookplaat is bestemd voor particulier

gebruik in een huishoudelijke omgeving.

— Dit apparaat dient overeenkomstig de

geldende voorschriften te worden

geïnstalleerd en in een goed geventileerde

ruimte te worden gebruikt. Raadpleeg deze

gids alvorens het apparaat te installeren en te

gebruiken.

— Het gebruik ervan moet onder toezicht

gebeuren.

— Deze kookplaten zijn uitsluitend bestemd

voor het koken van vaste of vloeibare

levensmiddelen en bevatten geen

asbesthoudende onderdelen.

— Dit apparaat is niet aangesloten op een

afvoerkanaal voor rookgassen. Het dient

volgens de geldende voorschriften te worden

geïnstalleerd en aangesloten. Met speciale

aandacht voor de ventilatievoorschriften.

— Berg in het meubel onder de kookplaat

geen

REINIGINGSPRODUCTEN of BRANDBARE

PRODUCTEN

op (spuitbussen of recipiënten

onder druk, papier, receptenboeken, ...).

— Als u een schuiflade gebruikt onder de

kookplaat, adviseren wij u hier geen

hittegevoelige voorwerpen in te bewaren

(plastic, papier, spuitbussen enz.).

— Uw kookplaat moet losgekoppeld zijn van

het elektriciteits- of gasnet vóór elke ingreep.

— Wanneer elektrische apparaten

aangesloten worden op een stopcontact,

dient u na te gaan of de voedingskabel niet in

contact komt met de warme zones.

— Uit veiligheidsoverwegingen moet men na

gebruik de hoofdkraan van de gasleiding of

de kraan van de butaan- of propaanfles

dichtdraaien.

— Het conformiteitsmerk CE is op deze platen

aangebracht.

— De installatie dient door erkende

installateurs en vaklieden te worden

uitgevoerd.

— Zorg er vóór de installatie voor dat de

lokale distributievoorwaarden (aard en druk

van gas) overeenkomen met de afstelling van

het apparaat.

— Dit apparaat is niet bestemd voor gebruik

door personen (kinderen inbegrepen)

waarvan de lichamelijke, sensoriële of

mentale capaciteiten beperkt zijn, of

personen zonder ervaring of kennis, behalve

onder toezicht van een persoon die instaat

voor hun veiligheid of na voorafgaande

instructies over het gebruik van het apparaat.

Laat kinderen nooit onbewaakt, om te

vermijden dat ze met het apparaat zouden

spelen.

— Dit apparaat is niet bestemd om in werking

te worden gesteld door middel van een

externe schakelklok of een apart

afstandsbedieningssysteem.

— Deze plaat is overeenkomstig de norm

EN 60335-2-6 wat betreft het warm worden

van meubels en klasse 3 wat betreft de

installatie (volgens de norm EN 30-1-1).

•

Let op

De afstelvoorwaarden worden

aangegeven op een label in het plastic zakje

en op de verpakking.

Om de referenties van het apparaat in de

toekomst makkelijk terug te vinden, raden

wij u aan deze op de pagina “Servicedienst

en Klantenrelaties” te schrijven (op deze

pagina wordt tevens de plaats op het

apparaat beschreven waar u de referenties

kunt vinden).

WAARSCHUWING: wanneer het oppervlak

gebarsten is, dient u het apparaat van de

voeding los te koppelen om het risico op

elektrische schokken te vermijden.

Voor de volgende ref.: CFI-4GLSTANAT* - CFI-3GLSTANAT*

werkt uw kookplaat standaard met aardgas.

Voor de volgende ref.: CFI-4GLSTABUT* - CFI-3GLSTABUT* - 2MCF-2GSAXBUT*

werkt uw kookplaat standaard met butagas.

Page 49

RESPECT VOOR HET MILIEU

49

NL

•

—Het verpakkingsmateriaal van dit apparaat is

recycleerbaar. Doe mee aan de recycling en

draag bij tot de bescherming van het milieu

door dit materiaal in de hiervoor bestemde

gemeentecontainers te deponeren.

— Uw apparaat bevat tevens vele

recycleerbare materialen. Daarom

is het voorzien van dit logo dat

aangeeft dat de gebruikte

apparaten van ander afval dienen

te worden gescheiden. Zo kan uw

fabrikant de apparaten optimaal en

overeenkomstig de Europese richtlijn

2002/96/EG betreffende elektrisch en

elektronisch afval recyclen. Informeer bij uw

gemeente of bij uw verkoper naar de

dichtstbijzijnde inzamelplaats voor uw oude

apparaten.

— Wij danken u voor uw bijdrage aan de

bescherming van het milieu.

RESPECT VOOR HET MILIEU

Page 50

BESCHRIJVING VAN UW APPARAAT

50

•

BESCHRIJVING VAN UW KOOKPLAAT

Kookplaat model 4 gasbranders

met ultrasnelle brander

Kookplaat model 3 gasbranders

met brander met drievoudige krans

Kookplaat model 2 gasbranders

met ultrasnelle brander

A

B

Branderkapje

Branderkop

Injector

C

D

E

Elektrische ontsteking

Thermokoppel

Bedieningsknop

F

G

H

Kraan

Dichtingsring

Advies

Deze installatie- en gebruiksgids is voor meerdere modellen geldig. Er kunnen kleine

verschillen bestaan tussen uw apparaat en de beschrijvingen in deze gids.

D

E

A

B

F

H

G

C

Page 51

1 / INSTALLATIE VAN HET APPARAAT

•

KEUZE VAN DE PLAATS

Het apparaat moet worden ingebouwd in het

blad van een draagmeubel van minimaal 3 cm

dik, van hittebestendig materiaal of ermee

bekleed zijn.

Om het keukengerei vrij te kunnen gebruiken,

mag zich links en rechts van de kookplaat, op

minder dan 30 cm afstand, geen meubel of