Page 1

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

EVBOX1

Front mounted electrical boards for cold

rooms with single-phase compressor

Installation guide| ENGLISH

Code 144BOX1E124

page 1 of 88

Page 2

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

Important

Read th is document thoroughly before installation and before

use of the device and follow all recommendations; keep this

document with the device for future consultation.

Only use the device in the way described in this document; do

not use the same as a safety device.

Disposal

The device must be disposed of in compliance with local

standards regarding the collection of electric and electronic

equipment.

page 2 of 88

Page 3

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

Index

1 INTRODUCTION .............................................. 4

1.1 Introduction ................................................... 4

1.2 Summary table of available models, their main

characteristics and purchase codes .................... 5

2 DESCRIPTION ................................................. 8

2.1 Outward appearance description ....................... 8

2.2 Interior description ........................................ 10

3 DIMENSIONS AND INSTALLATION ................... 13

3.1 Dimensions .................................................. 13

3.2 Installation ................................................... 13

3.3 Installation warnings ..................................... 14

4 ELECTRIC CONNECTION ................................. 15

4.1 Preliminary notes .......................................... 15

4.2 Electric connection for models EVB1204N9 and

EVB1214N9 .................................................. 16

4.3 Electric connection for models EVB1206N9 and

EVB1216N9 .................................................. 17

4.4 Electric connection for models EVB1226N9 and

EVB1236N9 .................................................. 18

4.5 Electric connection for models EVB1246N9 and

EVB1256N9 .................................................. 19

4.6 Electric connection for models with magneto-

thermal switch or differential magneto-thermal

circuit breaker (example for EVB1256N9D) ....... 20

4.7 Insertion of the RS-485 MODBUS port termination

resistor ........................................................ 21

4.8 Connection of the RS-485 network cable screen to

GND ............................................................ 21

4.9 Warnings for the electric connection ................ 21

5 FIRST USE .................................................... 22

5.1 First use ....................................................... 22

6 USER INTERFACE .......................................... 24

6.1 Preliminary notes .......................................... 24

6.2 Device switch-on/off in manual mode .............. 24

6.3 The display ................................................... 24

6.4 Displaying the magnitude detected by an analogue

input ........................................................... 24

6.5 "Rapid cooling" function enabling/disabling ....... 25

6.6 Defrosting manual activation .......................... 26

6.7 Turning on/off of room lights manually (only if the

parameter u1 and/or parameter u11 is set at 0) 26

6.8 Turning the demister heating elements on/off

manually (only if the parameter u1 and/or

parameter u11 is set at 1) .............................. 26

6.9 Turning on/off of the auxiliary output manually

(only if the parameter u1 and/or parameter u11 is

set at 2) ....................................................... 27

6.10 Keyboard locking/unlocking ............................ 27

6.11 Silencing the buzzer ...................................... 28

7 OPERATION WITH LOW OR HIGH RELATIVE

HUMIDITY PERCENTAGES (ONLY IF THE F0

PARAMETER IS SET TO 5) .............................. 29

7.1 Preliminary notes .......................................... 29

7.2 Manual activation of the low and high relative

humidity percentages operating mode ............. 29

7.3 Learning the current operating mode ............... 29

8 “ENERGY SAVING” FUNCTION ......................... 30

8.1 Preliminary notes .......................................... 30

9 “CPT” FUNCTION (CALCULATED PRODUCT

TEMPERATURE) ............................................. 30

9.1 Preliminary notes .......................................... 30

10 “HACCP” FUNCTION ....................................... 30

10.1 Preliminary notes .......................................... 30

10.2 Display of HACCP alarm in formation ................. 31

10.3 Cancelling the HACCP alarm list ....................... 32

11 COMPRESSOR OPERATING HOURS COUNT ........ 33

11.1 Preliminary notes .......................................... 33

11.2 Display of Compressor Operation Hours ............ 33

11.3 Cancelling the compressor operation hours ....... 34

12 SETTINGS .................................................... 35

12.1 Setting the date, time and day of the week (only

in the models with clock) ................................ 35

12.2 Setting the working set point .......................... 36

12.3 Setting the configuration parameters ............... 36

12.4 Restoring the Manufacturer’s Settings .............. 37

12.5 List of configuration parameters ...................... 38

13 WARNING LIGHTS AND DIRECTIONS ............... 73

13.1 Signals ......................................................... 73

13.2 Signal Descriptions/Explanations ..................... 75

14 ALARMS ....................................................... 76

14.1 Alarms ......................................................... 76

15 ERRORS ....................................................... 79

15.1 Errors .......................................................... 79

16 ACCESSORIES ............................................... 81

16.1 Non opto-isolated RS-485/USB serial interface

AVIF20SUXI .................................................. 81

16.2 Data recorder EVUSBREC01 ............................ 81

16.3 USB cover for panel installation 0812000002 .... 81

16.4 0810500018/0810500020 connection cable ...... 82

17 TECHNICAL DATA .......................................... 83

17.1 Technical data ............................................... 83

page 3 of 88

Page 4

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

1 INTRODUCTION

1.1 Introduction

EVBOX1 is a line of front mounted electrical boards for the

management of cold rooms with single-phase compressor.

The user interface comprises a large custom display (with

decimal point and function icons), six keys, and has a

guaranteed IP65 protection grade front part.

The boards are equipped with two 30A res. @ 250 VAC relays

for the direct control of high power compressors and

defrosting elements, with no need for remote control switches.

They can operate in conditions of both low and high relative

humidity percentages, have an adaptive management of the

defrost function, and can implement energy-saving strategies.

Some models are also equipped with a magneto-thermal

switch or different ial magneto-thermal circuit breaker, a clock

(to save the HACCP alarms), management of defrosting

elements and have an integrated driver for unipolar stepper

electronic expansion valves.

The unit is designed to be wall mounted, with bolts and

fastening screws.

page 4 of 88

Page 5

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

1.2 Summary table of available models, their main characteristics and purchase

codes

The following table contains a description of the available models.

Available models

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

The following table shows the main characteristics of the devices.

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

Power supply

115... 230 VAC • • • • • • • •

Analogue inputs

room temperature (PTC/NTC) • • • • • • • •

evaporator temperature (PTC/NTC) • • • • • • • •

auxiliary temperature (PTC/NTC) (1) • • • • • • • •

Vapour pressure (4-20 mA) • •

evaporation temperature (PTC/NTC) • •

Digital inputs (for NA/NC contact)

door micro switch • • • • • • • •

multifunction • • • • • • • •

multifunction 2 • • • • • • • •

Digital inputs (electromechanical relays; A res. @ 250 VAC)

compressor 30 A 30 A 30 A 30 A 30 A 30 A 30 A 30 A

defrosting 30 A 30 A 30 A 30 A 30 A 30 A 30 A 30 A

evaporator fan 16 A 16 A 16 A 16 A 16 A 16 A 16 A 16 A

room light 16 A 16 A 16 A 16 A 16 A 16 A

load 4 (default to room light) (2) 8 A 8 A

page 5 of 88

Page 6

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

load 5 (default to condenser fan) (3) 8 A 8 A 8 A 8 A 8 A 8 A

load 6 (default to alarm ) (3) 8 A 8 A 8 A 8 A 8 A 8 A

Communication ports

RS-485 MODBUS for other EVCO products • • • • • • • •

Other characteristics

clock • • • •

alarm buzzer • • • • • • • •

three-phase defrost elements management • •

integrated driver for unipolar stepper electronic expansion valves. • •

operation at low and high relative humidity percentages • • • • • • • •

overheated condenser alarm management • • • • • • • •

defrosting adaptive management • • • • • • • •

"HACCP" function • • • •

"energy saving" function • • • • • • • •

"rapid cooling" function • • • • • • • •

Notes

(1)

can be set through a configuration parameter to condenser temperature, critical temperature, evaporator 2 temperature or

CPT temperature parameter.

(2)

can be set through a configuration parameter to room light, demister heating elements, auxiliary, alarms, door resistors,

neutral area operation resistors, condenser fan, compressor 2, defrosting 2 evaporator fan 2, pump down valve, on/stand-

by or man in cold room

(3) can be set through a configuration parameter to demister heating elements, auxiliary, alarms, door resistors, neutral area

operation resistors, condenser fan, compressor 2, defrosting 2 evaporator fan 2, pump down valve, on/stand-by or man in

cold room

Available options

In some models, there is a magneto-thermal switch or differential magneto-thermal circuit breaker.

Check that the switch is available for the device; contact the EVCO distribution network.

For additional information, please read chapter "TECHNICAL DATA",

page 6 of 88

Page 7

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

The following table shows the purchase codes.

Available models

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

Add "M" for the magneto-thermal switch or "D" for the differential magneto-thermal circuit breaker.

For additional models, please contact the EVCO distribution network

page 7 of 88

Page 8

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

2 DESCRIPTION

2.1 Outward appearance description

The following drawing shows the outward appearance of the devices.

The following table shows the meaning of the parts of the front of the devices

PART MEANING

1 access door to the magneto-thermal switch or differential magneto-thermal circuit breaker

2 screws fastening the front shell to the back shell

3 tab fastening the front shell to the back shell

4 handle of the access door to the magneto-thermal switch or differential magneto-thermal circuit breaker

5 handle to remove the cover of the screws fastening the front shell to the back shell

6 cover of the screws fastening the front shell to the back shell

7 on/off key, hereinafter also "ON/STAND-BY" key

8 manual defrosting key, hereinafter also "DEFROSTING" key

9 auxiliary functions key, hereinafter also "AUXILIARY" key

10 display

11 increase key, hereinafter also "UP" key

page 8 of 88

Page 9

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

12 settings key, hereinafter also "SET" key

13 decrease key, hereinafter also "DOWN" key

14 seal

15 if present, magneto-thermal switch or differential magneto-thermal circuit breaker

16 front shell

17 back shell

For additional information, please refer to the following chapters.

page 9 of 88

Page 10

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

2.2 Interior description

To access the interior of the devices, proceed as follows (numbers in parentheses refer to the part number shown in the tables in

paragraph 2.1 “Outward appearance description"):

1.

Open the access door of the magneto-thermal switch or differential magneto-thermal circuit breaker (1) using the relevant

handle (4) and loosen the two screws fastening the front shell to the back shell (2) with a screwdriver.

2.

Remove the cover of the two screws fastening the front shell to the back shell (6) using the relevant handle (5) and loosen

the two screws fastening the front shell to the back shell (2) with a screwdriver.

Lift the front shell (16) using the assembly tabs fastening the front shell to the back shell (3) as a pivot.

3.

The following drawing shows the inner appearance of the devices.

page 10 of 88

Page 11

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

The following table shows the meaning of the parts inside the devices

PART MEANING

3 tab fastening the front shell to the back shell

4 handle of the access door to the magneto-thermal switch or differential magneto-thermal circuit breaker

5 handle to remove the cover of the screws fastening the front shell to the back shell

15 if present, magneto-thermal switch or differential magneto-thermal circuit breaker

18 K3 digital output (evaporator fan)

19 K2 digital output (defrosting)

20 K1 digital output (compressor)

21 device power supply

22 if present, driver for unipolar stepper electronic expansion valves connected to a removable male only screw terminal board

23 if present, driver for unipolar stepper electronic expansion valves connected with male only JST connector

24 BUS RS-485 polarisation jumper

25 RS-485 MODBUS port

26 RS-485 MODBUS port termination resistor insertion jumper

27 digital inputs (micro port, multifunction 1 and mult ifunction 2)

analogue inputs 1 and 2 (room temperature and evaporator temperature) and analogue input 3 (can be set through a

28

configuration parameter to condenser temperature, critical temperature, evaporator 2 temperature or CPT temperature)

29 if present, analogue inputs 4 and 5 (evaporation temperature and vapour pressure)

in the EVB1204N9 and EVB1214N9 models, K4 digital output (can be set through a configuration parameter to room light,

demister heating elements, auxiliary, alarms, door resistors, neutral area operation resistors, condenser fan, compressor 2,

defrosting 2, evaporator fan 2, pump down valve, on/stand-by or man in cold room; manufacturer default is room light).

30

in the remaining models, K6 digital output (can be set through a configuration parameter to de mister heating elements,

auxiliary, alarms, door resistors, neutral area operation resistors, condenser fan, compressor 2, defrosting 2, evaporator

fan 2, pump down valve, on/stand-by or man in cold room; manufacturer default is alarm).

page 11 of 88

Page 12

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

if present, K5 digital output (can be set through a configuration parameter to demister heating elements, auxiliary, alarms,

31

door resistors, neutral area operation resistors, condenser fan, compressor 2, defrosting 2, evaporator fan 2, pump down

valve, on/stand-by or man in cold room; manufacturer default is condenser fan).

32 if present, digital output 4 (room light)

33 seal

34 drilling lead for wall installation

35 ground terminal

36 raised profile

37 seal

For additional information, please refer to the following chapters.

page 12 of 88

Page 13

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

3 DIMENSIONS AND INSTALLATION

3.1 Dimensions

The following drawing shows the measurements of the devices, in mm (in).

3.2 Installation

The unit is designed to be wall mounted, with bolts and fastening screws (not supplied).

To install the devices, proceed as follows (numbers in parentheses refer to the part number shown in the tables in chapter 2

"DESCRIPTION"):

1. Open the access door of the magneto-thermal switch or differential magneto-thermal circuit breaker (1) using the relevant

handle (4) and loosen the two screws fastening the front shell to the back shell (2) with a screwdriver.

remove the cover of the two screws fastening the front shell to the back shell (6) using the relevant handle (5) and loosen

2.

the two screws fastening the front shell to the back shell (2) with a screwdriver.

3.

Lift the front shell (16) using the assembly tabs fastening the front shell to the back shell (3) as a pivot.

4. Drill a hole with a diameter of 5.0 mm (0.196 in) in each of the three drilling leads for wall installation (34).

5.

Drill three 6.0 mm (0.236 in) holes in the wall where the device is to be installed, using the three previously perforated

drilling leads (34) as template.

Insert three bolts in the three holes drilled into the wall.

6.

7.

Insert three seals (37) in three fastening screws.

If the connection wires are to be threaded from the top or the bottom, drill a hole in a flat surface of the back shell (17),

8.1

whose dimensions are adequate for a cable tray (not supplied; the cable tray dimensions must be appropriate to the

number of cables to be laid) and assemble the cable tray.

8.2 If the connection cables are to be installed from the back, drill a hole with dimensions appropriate to the number of cables

to be laid in the raised profile (36) on the back wall of the back shell (17) and apply some silicone on the whole profile.

9.

Fasten the back shell (17) with the three screws and the seals (37) previously inserted in the screws.

make the necessary electric connections; please refer to chapter "ELECTRIC CONNECTION".

10.

Place the front shell (16) on the back shell (17) using the assembly tabs fastening the front shell to the back shell (3) as a

11.

pivot.

12.

Tighten the four screws fastening the front shell to the back shell (2) with a screwdriver, put the fastening screws cover (6)

back on and close the access door to the magneto-thermal switch or differential magneto-thermal circuit breaker (1) with

the handle (4).

page 13 of 88

Page 14

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

3.3 Installation warnings

- make sure that the device work conditions (temperature of use, humidity, etc.) lie within the limits indicated; see chapter

“TECHNICAL DATA”

-

do not install the device near to any heat sources (heating elements, hot air ducts etc.), equipment containing powerful

magnets (large diffusers, etc.), areas affected by direct sunlight, rain, humidity, excessive dust, mechanical vibrations or

shocks

- in compliance with Safety Standards, the device must be installed correctly and in a way to protect against any contact with

electric parts; all parts that ensure protection must be fixed in a way that they cannot be removed without the use of tools.

page 14 of 88

Page 15

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4 ELECTRIC CONNECTION

4.1 Preliminary notes

The magnitude detected by the auxiliary sensor (terminals 5 and 8) can be set through the P4 configuration parameter as follows:

no magnitude (parameter P4 = 0)

-

condenser temperature (parameter P4 = 1)

-

-

critical temperature (parameter P4 = 2)

evaporator temperature 2 (parameter P4 = 3)

-

outgoing air temperature (parameter P4 = 4); in this case, the temperature associated with the setting shall be the CPT

-

(Calculated Product Temperature) one

In the EVB1204N9 and EVB1214N9 models the application managed by the K4 digital output (terminals 13, 14 and 15) can be set by

the u11 configuration parameter as follows:

-

room light (parameter u1 = 0, default setting)

demister heating elements (parameter u1 = 1)

-

-

auxiliary output (parameter u1 = 2)

alarm output (parameter u1 = 3)

-

- door heating elements (parameter u1 = 4)

-

neutral area operating heating elements(parameter u1 = 5)

condenser fan (parameter u1 = 6)

-

compressor 2 (parameter u1 = 7)

-

-

defrosting 2 (parameter u1 = 8)

evaporator fan 2 (parameter u1 = 9)

-

-

pump down valve (parameter u1 = 10)

on/stand-by (parameter u1 = 11)

-

man in cold room exit (parameter u1 = 12).

-

In the remaining models, the application managed by the K5 digital output (terminals 16 and 17) can be set through the u1

configuration parameter and that managed by the K6 digital output (terminals 13, 14 and 15) through the u11 configuration parameter

as follows:

demister heating elements (parameter u1 = 1)

-

auxiliary output (parameter u1 and/or u11 = 2)

-

-

alarm output (parameter u1 and/or u11 = 3, default setting for the K6 digital output

door heating elements (parameter u1 and/or u11 = 4)

-

neutral area operating heating elements(parameter u1 and/or u11 = 5)

-

-

condenser fan (parameter u1 and/or u11 = 6, default setting for the K5 digital output)

compressor 2 (parameter u1 and/or u11 = 7)

-

defrosting2 (parameter u1 and/or u11 = 8)

-

-

evaporator fan 2 (parameter u1 and/or u11 = 9)

pump down valve (parameter u1 and/or u11 = 10)

-

on/stand-by (parameter u1 and/or u11 = 11)

-

-

man in cold room exit (parameter u1 and/or u11 = 12).

Through the RS-485 MODBUS port it is possible to carry out on eof the following actions:

- device configuration, through the Parameters Manager set-up software system

device data recording, through the EVUSBREC01 data recording device

-

device supervision, through the CloudEvolution system monitoring and supervision (via Web) system

-

-

use of the MODBUS slave function through third party devices.

The port must not be used for more than one of these purposes at the same time.

Please see paragraph “Setting the configuration parameters” for the settings of the configuration parameters.

For additional information, please refer to the following paragraphs.

page 15 of 88

Page 16

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4.2 Electric connection for models EVB1204N9 and EVB1214N9

The following drawing shows the electric connections for the EVB1204N9 and EVB1214N9 mode ls.

page 16 of 88

Page 17

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4.3 Electric connection for models EVB1206N9 and EVB1216N9

The following drawing shows the electric connections for the EVB1206N9 and EVB1216N9 models.

page 17 of 88

Page 18

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4.4 Electric connection for models EVB1226N9 and EVB1236N9

The following drawing shows the electric connections for the EVB1226N9 and EVB1236N9 models.

page 18 of 88

Page 19

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4.5 Electric connection for models EVB1246N9 and EVB1256N9

The following drawing shows the electric connections for the EVB1246N9 and EVB1256N9 models.

page 19 of 88

Page 20

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4.6 Electric connection for models with magneto-thermal switch or differential

magneto-thermal circuit breaker (example for EVB1256N9D)

The following drawing shows the electric connections for models with magneto-thermal switch or differential magneto-thermal circuit

breaker (example EVB1256N9D).

page 20 of 88

Page 21

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

4.7 Insertion of the RS-485 MODBUS port termination resistor

To reduce reflections on the signal transmitted through the cables connecting the devices to a RS-485 network it is necessary to insert

the termination resistor of the first and last elements of the network.

To insert the termination resistor place the jumper as shown in the following drawing.

4.8 Connection of the RS-485 network cable screen to GND

To prevent external disturbances from being interpreted as signals by the RS-485 network, it might be necessary to connect the cable

screen of the RS-485 network to GND

To connect the cable screen to GND, place the jumper as shown in the following drawing.

4.9 Warnings for the electric connection

- do not use electric or pneumatic screwdrivers on the device terminal board

-

if the device has been taken from a cold to hot place, humidity could condense inside; wait about 1 hour before powering it

make sure that the power supply voltage, the frequency and the operational electric power of the device, correspond with

-

those of the local power supply; see chapter “TECHNICAL DATA”

-

disconnect the device power supply before proceeding with any type of maintenance

connect the device to a RS-485 MODBUS network using a twisted pair

-

-

position the power cables as far away as possible from the signal cables

for repairs and information regarding the device, contact the EVCO sales network.

-

page 21 of 88

Page 22

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

5 FIRST USE

5.1 First use

Operate as follows:

Install the device as described in chapter "DIMENSIONS AND INSTALLATION" , following in particular the instructions of

1.

paragraph “Installation warnings”.

2.

Make the relevant electric connections f or the device as shown in chapter "ELECTRIC CONNECTION", following in particular

the instructions of paragraph “Warning for the electric connection", without connecting the device or the loads power

supply.

3. Connect the device power supply: this shall launch an internal test.

The test typically takes a few seconds to complete; at the end of the test, the display turns off.

If, at the end of the test, the letters "rtc" flash on the screen and the buzzer sounds intermittently, it will be necessary to

4.

set the date, time and day of the week; please refer to paragraph 12.1 “Setting the date, time and day of the week (only in

the models with clock)”.

5. Configure the device using the procedure described in paragraph “Setting the configuration parameters”,

The following table shows the meaning of the main configuration parameters; the parameters are shown in the order with

which it is best to configure the device.

PARAM. MEANING DEFAULT SETTINGS

temperature probe type

P0

0 = PTC

= NTC

1

1

temperature unit of measurement

P2

P9 pressure transducer minimum setting 5

P10 pressure transducer maximum setting 80

P11

SP work set-point -18,0 °C

r0 working set-point differential 2.0 °C

d0

0 = °C

= °F

1

position of the pressure decimal point

0 = no decimal points

= on the tens digit

1

type of defrosting

0

= electric

= by hot gas

1

= via stopping of compressor

2

0

1

0

d3 maximum defrosting duration 30 min

page 22 of 88

Page 23

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

in the EVB1204N9 and EVB1214N9 models, the application is managed through

the K4 digital output

0

= man in cold room exit

= demister heating elements

1

= auxiliary output

2

3

= alarm output

= door heating elements

4

u1

u1

= neutral area operating heating elements

5

6

= condenser fan

= compressor 2

7

8 = defrosting2

9

= evaporator fan 2

= pump down valve

10

= on/stand-by

11

12

= man in cold room exit

in the remaining models, the application is managed by the K5 digital output

= reserved

0

1

= demister heating elements

= auxiliary output

2

= alarm output

3

4

= door heating elements

= neutral area operating heating elements

5

= condenser fan

6

7

= compressor 2

= defrosting2

8

= evaporator fan 2

9

10

= pump down valve

= on/stand-by

11

12

= man in cold room exit

0

5

if present, the application is managed by the K6 digital output

0

= reserved

1

= demister heating elements

= auxiliary output

2

3 = alarm output

4

= door heating elements

= neutral area operating heating elements

u11

5

= condenser fan

6

7

= compressor 2

8 = defrosting2

= evaporator fan 2

9

10

= pump down valve

= on/stand-by

11

= man in cold room exit

12

2

Then, check that the remaining settings are appropriate; refer to paragraph 12.5 “List of configuration parameters”.

Connect the loads power supply

6.

Turn the device on; refer to paragraph "Device switch-on/off in manual mode".

7.

For additional information, please refer to the following paragraphs.

page 23 of 88

Page 24

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

6 USER INTERFACE

6.1 Preliminary notes

Operating Statuses:

-

“on” state (the device is powered and is on: the

regulators can be switched on)

“stand-by” status (the device is powered but is

-

switched off via software: the regulators are

switched off; the possibility to turn the room light

or the auxiliary output on/off manually depends on

parameter u2)

-

the “off” status (the device is not powered).

Hereafter, with the word “start-up” means the passage from

“stand-by” status to “on” status; the word “shutdown” means

the passage from “on” status to “stand-by” status.

When the power is switched back on, the device displays the

status that it was in at the time it was disconnected.

6.2 Device switch-on/off in manual

mode

To turn the device on/off in manual mode, proceed as follows:

Make sure that the keyboard is not locked and that

1.

no procedure is in progress.

2.

Hold the key “ON/STAND-BY” for 2 s.

Using the digital inputs it is also possible to remotely switch

on/off the device.

6.3 The display

If the device is switched on, during normal operation, the

display will show the magnitude established with P5, except

during defrosting, when the device will show the temperature

established with parameter d6.

If the device is switched off, the display will be switched off.

6.4 Displaying the magnitude

Device switch-on/off in manual mode

detected by an analogue input

To display the magnitude detected by an analogue input,

proceed as follows:

1.

Make sure that the keyboard is not locked and that

no procedure is in progress.

Hold the key “DOWN” for 1 s: the display will show

2.

the first label available.

3.

Press and release the key “UP” or “DOWN” to

select a label.

page 24 of 88

Access the procedure to display the quantity detected by an analogue

input

Page 25

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

The following table shows the correspondence between the

labels and the magn itudes disp layed.

LABEL MAGNITUDE

Pb1

Pb2 evaporator temperature

Pb3 auxiliary temperature; see also parameter P4

Pb4 CPT temperature; see also parameter P4

Pb5 if present, vapour pressure

Pb6 if present, evaporation temperature

Press and release the key “SET”.

4.

To exit the procedure:

5. Press and release the key “SET” or do not operate

6.

Press and release the “UP” or “DOWN” key until

Alternatively:

7. Press and release the “ON/STAND-BY” key.

If the evaporator temperature sensor is not present (or if the

P3 parameter is set to 0), the "Pb2" label shall not be

displayed.

If the auxiliary temperature sensor is not present (or if the P4

parameter is set to 0), the "Pb3" label shall not be displayed.

If the magnitude recorded by the auxiliary sensor is not the

outgoing air temperature (or if the P4 parameter is not set to

4) the "Pb4" label shall not be displayed.

room/inflowing air temperature; see also

parameter P4

for 60 sec.

the display shows the magnitude established with

parameter P5 or do not operate for 60 sec.

6.5 "Rapid cooling" function

Displaying the magnitude detected by an analogue input

enabling/disabling

To enable/disable the "rapid cooling" function, proceed as

follows:

1.

Check that the device is turned on, that the

keypad is not locked, that no procedures are in

progress and that there are no defrosting, dripping

or evaporator fan stop operations in progress.

Keep the "UP" key pressed for 4 s: the

2.

"temperature" LED light shall start flashing.

page 25 of 88

"Rapid cooling" function enabling/disabling

Page 26

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

During the "rapid cooling" function the work set point is

decreased by the temperature set with the r5 parameter; the

function runs for the span of time set with the r6 parameter.

During the "rapid cooling" function the defrosting function is

never activated; if the defrosting interval expires while the

rapid cooling function is in progress, the defrosting shall be

activated at the end of the cooling.

6.6 Defrosting manual activation

To activate the defrosting in manual mode, proceed as follows:

1.

Check that the device is turned on, that the

keypad is not locked, that no procedures are in

progress and that the "rapid cooling" function is

not in progress.

Keep the "DEFROSTING" key pressed for 4 s.

2.

If the evaporator temperature sensor functions as a defrosting

sensor (that is to say,if the P3 parameter is set to 1) and when

the defrosting starts the evaporator temperature exceeds the

value set with the d2 parameter, the defrosting shall not be

activated.

6.7 Turning on/off of room lights

manually (only if the parameter

Defrosting manual activation

u1 and/or parameter u11 is set at

0)

To turn the room light on/off in manual mode, proceed as

follows:

1.

Make sure no procedures are in progress.

Press and release the "AUXILIARY" key: the "room

2.

light" LED shall turn on/off.

Through the digital ports it is also possible to turn the room

light on/off from remote; see parameter u2.

If parameter u1 and/or parameter u11 are set to 2 (that is to

say, if the application managed by the K5 and/or K6 outputs is

the auxiliary output), pressing the "AUXILIARY" key for 2 s

shall make the "auxiliary 1" and/or "auxiliary 2" and the

auxiliary output LEDs turn on/off.

6.8 Turning the demister heating

elements on/off manually (only if

Turning on/off of room lights in manual mode

the parameter u1 and/or

parameter u11 is set at 1)

To turn the demister heating elements on, proceed as follows:

Check that the device is turned on and no

1.

procedures are in progress.

Demister heating elements manual activation

page 26 of 88

Page 27

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

2.

Keep the "AUXILIARY" key pressed for 2 s: the

"AUX1" and/or "AUX2" LEDs shall light up and the

heating elements be turned turned on, both for

the length of time set with the parameter u6.

The demister heating elements cannot be turned off in manual

mode (that is to say, before the time set with the parameter

u6 has expired).

6.9 Turning on/off of the auxiliary

output manually (only if the

parameter u1 and/or parameter

u11 is set at 2)

To turn the auxiliary output on/off in manual mode, proceed

as follows:

1.

Make sure that the keyboard is not locked and that

no procedure is in progress.

2.

Keep the "AUXILIARY" key pressed for 2 s: the

"AUX1" and/or "AUX2" LEDs shall turn on/off.

Through the digital ports it is also possible to turn the auxiliary

output on/off from remote; see parameter u2.

If the auxiliary output has been turned on manually, it shall be

possible to turn it off only in the same mode (similarly, if it

was turned on from renote, it shall be possible to turn it off

only from remote); see also parameter u2.

6.10 Keyboard locking/unlocking

To lock the keyboard proceed as follows:

Check that the device is turned on and no

1.

procedures are in progress.

2.

Keep the "DOWN" and "ON/STAND-BY" keys

pressed for 1 s: the word "Loc" shall be displayed

on screen for 1 s.

If the keyboard is locked, the following are not permitted:

-

device switch-on/off in manual mode

display of a magnitude recorded by an analogue

-

input (with the procedure described in paragraph

6.4 “Displaying the magn itude detected by an

analogue input”)

activation/deactivation of “rapid cooling” function

-

-

manual activation of defrosting

manual switch on/off of the auxiliary output

-

activation of the low or high relative humidity

-

percentage operation mode to learn how it works

Turning on/off of the auxiliary output manually

Keyboard locking

page 27 of 88

Page 28

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

- see information regarding the HACCP alarms

-

cancellation of HACCP alarm list

display of compressor operation hours

-

-

cancellation of compressor operation hours

set the working set point (with the procedure

-

described in paragraph “Setting the working set

point”).

The operations cause the display of the label “Loc” for 1 s.

To unlock the keyboard:

Hold the “DOWN” key and the “ON/STAND-BY” key

3.

for 1 s: the display will show the message “UnL”

for 1 s.

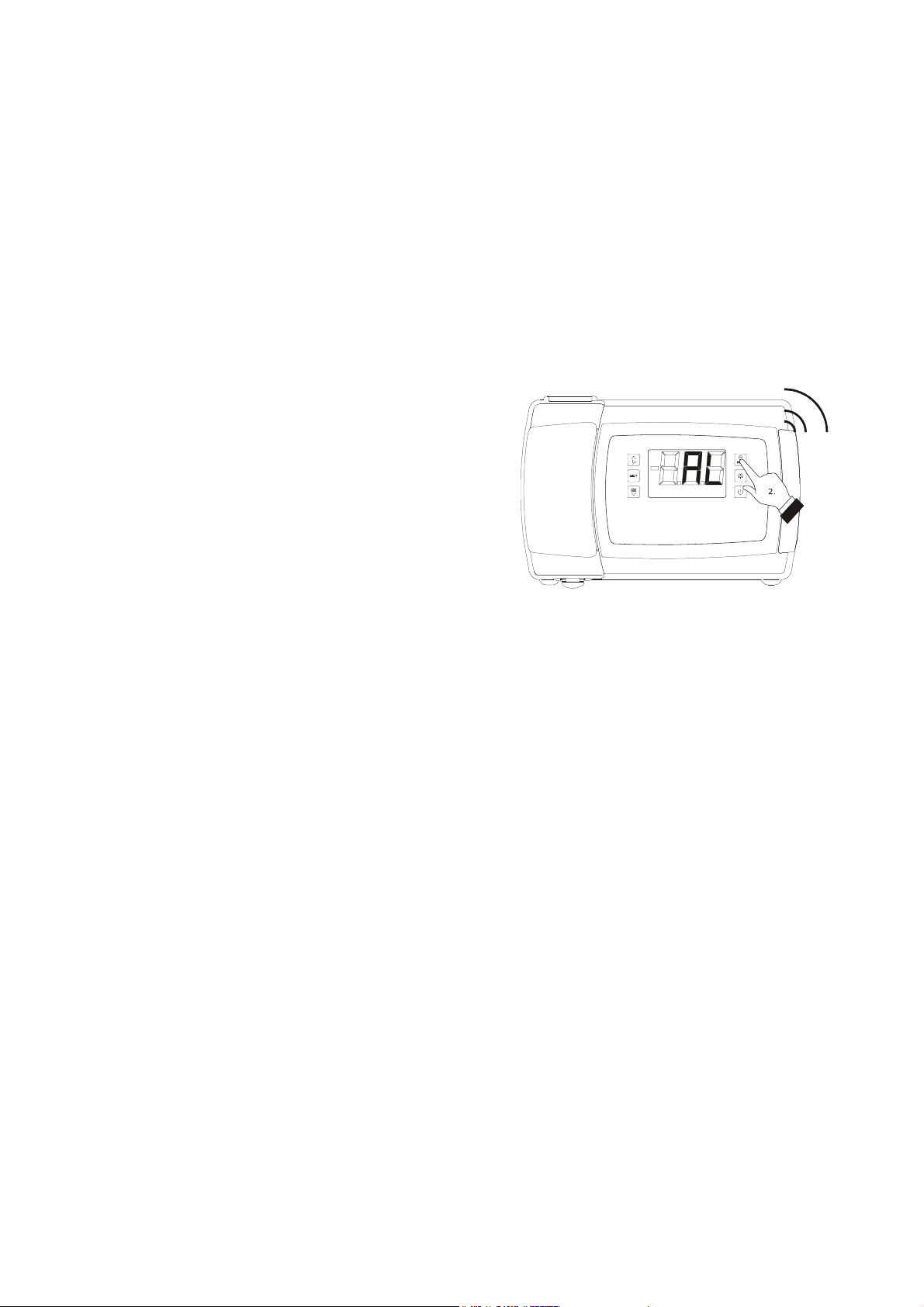

6.11 Silencing the buzzer

To silence the buzzer, proceed as follows:

Make sure no procedures are in progress.

1.

Press a key (the first pressing of the key will not

2.

cause the effect associated with that key).

If the parameter u1 and/or the parameter u11 is set at 3 (i.e.

the utility managed by the digital output K5 and/or K6 is the

alarm output) and parameter u4 is set at 1, pressing the key

will also cause the deactivation of the output.

If parameter u9 is set at 0, the buzzer will not be activated.

Silencing the buzzer

page 28 of 88

Page 29

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

7 OPERATION WITH LOW OR

HIGH RELATIVE HUMIDITY

PERCENTAGES (ONLY IF THE F0

PARAMETER IS SET TO 5)

7.1 Preliminary notes

During operation with a low relative humidity percentage, the

evaporator fan shall be turned on if the compressor is on, and

shall turn on cyclically if the compressor is off (the F4

parameter determines the duration of the off phase of the fan

and the F5 parameter determines the on phase).

During operation with a high relative humidity percentage, the

evaporator fan is always on.

7.2 Manual activation of the low

and high relative humidity

percentages operating mode

To activate the the low or high relative humidity percentages

operating mode manually, proceed as follows:

1.

Ensure that the device is on, the keypad is not

locked and that no procedure is in progress.

2.

Keep the "SET" and "UP" keys pressed for

4 s: the letters "rhL" (operation with low relative

humidity percentage) or "rhH" (operation with

high relative humidity percentage) shall be

displayed on screen for 10 s.

To restore the normal display before time:

Press any key.

3.

It is also possible to activate the low or high relative humidity

percentage operation mode with the F6 parameter.

If the F0 parameter is not set to 5, pressing the keys shall

make the message "- - -" appear on display for 1 s.

7.3 Learning the current operating

Manual activation of the low and high relative humidity percentages

operating mode

mode

To learn which operating mode is in progress proceed as

follows:

1.

Check that the device is turned on and no

procedures are in progress.

2.

Press and release the "SET" and "UP" keys: the

letters "rhL" (operat ion with low relative humidity

percentage) or "rhH" (operation with high relative

humidity percentage) sha ll be displayed on screen

for 10 s.

page 29 of 88

Learning the current operating mode

Page 30

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

8 “ENERGY SAVING” FUNCTION

8.1 Preliminary notes

Once the time you have set with parameter i10 has passed,

without activations of the door micro switch input (after the

room temperature has reached the work set point) the

“energy saving” function is activated (until the input is

activated again).

During the “energy saving” function, the work set point is

increased by the temperature established with parameter r4

and the evaporator fan is turned on cyclically, provided that

the F0 parameter is set to 1, 2, 3 or 4 (parameter F13

establishes the duration of fan switch off and parameter F14

that of switch on).

It is also possible to activate the “energy saving” function in

remote mode through the digital inputs (with effect only on

the compressor).

9 “CPT” FUNCTION

(CALCULATED PRODUCT

TEMPERATURE)

9.1 Preliminary notes

If parameter P4 is set at 4, the temperature associated to the

regulation will mainly depend on the temperature detected by

the inlet air probe and that detected by the air outlet probe,

herein called CPT temperature (Calculated Product

Temperature); the room temperature probe shall operate as

an air inlet temperature probe and the auxiliary temperature

probe as an air outlet temperature probe.

The formula for the calculation of the CPT temperature is:

CPT temperature = {[(value established with parameter P7) x

(temperature detected by the inlet air probe)] : 100} +

{[(100 - value established with parameter P7) x (temperature

detected by the outlet air probe)] : 100}.

10 “HACCP” FUNCTION

10.1 Preliminary notes

The device can memorise the following HACCP alarms:

-

minimum temperature alarm (code “AL”)

maximum temperature alarm (code “AH”)

-

door micro switch input alarm (code “id”)

-

-

power supply cut-off alarm (code “PF”; only in the

models with clock).

The device can memorise up to 9 alarms, after which the

oldest alarm is overwritten.

The device supplies the following information for every alarm:

- the crit ical value

the date and time at which the alarm occurs (only

-

in the models with clock)

-

the duration of the alarm (from 1 min to 99 hours

and 59 min, partial if the alarm is in progress).

The following table shows the correspondence between the

alarm codes and the relevant critical values.

CODE CRITICAL VALUE

AL

AH

id

PF

Models without clock update the information regarding the

alarms provided the critical value of the new alarm is more

critical than that stored or provided the informat ion has

already been displayed.

If the device is switched off, no alarms will be stored.

The “HACCP” LED provides information regarding the storage

status of the alarms; see paragraph “Signals”.

the minimum room temperature or the minimum

CPT temperature during the alarm

the maximum room temperature or the

maximum CPT temperature during the alarm

the maximum room temperature or maximum

CPT temperature during any alarm of this type;

see also parameter i4

the room temperature or the CPT temperature

when power supply is restored; see also

parameters A10 and A12

page 30 of 88

Page 31

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

10.2 Display of HACCP alarm

information

To begin the procedure:

1.

Make sure that the keyboard is not locked and that

no procedure is in progress.

Hold the key “DOWN” for 1 s: the display will show

2.

the first label available.

3.

Press and release the "UP" or "DOWN" key to

select “LS”.

4.

Press and release the “SET” key:

in the models without a clock the

4.1

display will show one of the codes

included in the table in paragraph

“Preliminary notes”

in the models with a clock the display

4.2

will show one of the codes included in

the table in paragraph “Preliminary

notes” followed by a number; the

higher the number, the less current

the alarm.

If the device does not have any alarms stored, the label “LS”

will not be displayed.

To select an alarm:

5.

Press and release the “UP” key or the “DOWN”

key.

To see information regarding the alarm:

Press and release the “SET” key: the HACCP LED

6.

will stop flashing and remain on permanently and

the display will show, for example, the following

information in succession:

Access the procedure to display information on the HACCP alarms

Selection of information on the HACCP alarms

INFORM. MEANING

8.0 the critical value is 8.0 °C/8 °F

the display is about to show the date and time

StA

y14 the alarm occurred in 2014 (continue...)

n03

d26

h16 the alarm occurred at 16:00 (continue...)

n30 the alarm occurred at 16:30

at which the alarm occurs (only in the models

with clock)

the alarm occurred in the month of March

(continue...)

the alarm occurred on 26 March 2014

(continue...)

Display of information on the HACCP alarms

page 31 of 88

Page 32

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

dur the display is about to show the alarm duration

h01 the alarm lasted for 1 hour (continue...)

n15 the alarm lasted 1 hour and 15 min

code the alarm selected

the displays each piece of information for 1 s.

To exit the information sequence:

7. Press and release the “ON/STAND-BY”: the display

will show the alarm selected.

To exit the procedure:

8.

Exit the informat ion sequence.

Press and release the “UP” or “DOWN” key until

9.

the display shows the magnitude established with

parameter P5 or do not operate for 60 sec.

Alternatively:

10.

Press and release the “ON/STAND-BY” key.

10.3 Cancelling the HACCP alarm list

To cancel the HACCP alarm list proceed as follows:

1.

Make sure that the keyboard is not locked and that

no procedure is in progress.

Hold the key “DOWN” for 1 s: the display will show

2.

the first label available.

3.

Press and release the "UP" or "DOWN" key to

select “rLS”.

4. Press and release the “SET” key.

5. Press and release the “UP” or “DOWN” key within

15 s to set “149”.

6.

Press and release the “SET” or do not operate for

15 sec: the display will show a flashing “- - -” for 4

sec and the “HACCP” LED switches off, after which

the device will exit the procedure.

If the device does not have any alarms stored, the label “rLS”

will not be displayed.

Access the procedure to cancel information on the HACCP alarms

Cancelling information on the HACCP alarms

page 32 of 88

Page 33

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

11 COMPRESSOR OPERATING

HOURS COUNT

11.1 Preliminary notes

The device can memorise up to 999 comp. operating hours.

The parameter C10 establishes the number of operating hours

is higher than the limit at which the need for maintenance is

signalled.

11.2 Display of Compressor

Operation Hours

To display the compressor operation hours, proceed as

follows:

Make sure that the keyboard is not locked and that

1.

no procedure is in progress.

2. Hold the key “DOWN” for 1 s: the display will show

the first label available.

3.

Press and release the "UP" or "DOWN" key to

select a label.

The following table shows the correspondence between the

labels and the relevant meaning.

Access the procedure to display the compressor operation hours

LABEL MEANING

CH1 Compressor operation Hours

CH2 Compressor 2 operation Hours

Press and release the “SET” key.

4.

To exit the procedure:

Press and release the “SET” key or do not operate

5.

for 60 sec.

6.

Press and release the “UP” or “DOWN” key until

the display shows the magnitude established with

parameter P5 or do not operate for 60 sec.

Alternatively:

Press and release the “ON/STAND-BY” key.

7.

If the compressor 2 is not present (or if the u1 and/or u11

parameter is not set to 7), the "CH2" labe l shall not be

displayed.

Display the compressor operation hours

page 33 of 88

Page 34

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

11.3 Cancelling the compressor

operation hours

To cancel the compressor operation hours, proceed as follows:

1.

Make sure that the keyboard is not locked and that

no procedure is in progress.

Hold the key “DOWN” for 1 s: the display will show

2.

the first label available.

3.

Press and release the "UP" or "DOWN" key to

select “rCH”.

4.

Press and release the “SET” key.

Press and release the “UP” or “DOWN” key within

5.

15 s to set “149”.

6.

Press and release the “SET” or do not operate for

15 sec: the display will show a flashing “- - -” for 4

sec and the “alarm” LED switches off, after which

the device will exit the procedure.

If the device does not have any alarms stored, the label “rCH”

will not be displayed.

Access the procedure to cancel the compressor operation hours

Cancelling the compressor operation hours

page 34 of 88

Page 35

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

12 SETTINGS

12.1 Setting the date, time and day

of the week (only in the models

with clock)

The date can be set in the day-month-year format; the time in

the hours-minutes format (24 h).

To access the procedure:

1. Make sure that the keyboard is not locked and that

no procedure is in progress.

2.

Hold the key “DOWN” for 1 s: the display will show

the first label available.

3.

Press and release the "UP" or "DOWN" key to

select “rtc”.

To set the year:

Press and release the “SET” key: the display will

4.

show “y” followed by the last two numbers of the

year and the “clock” LED light shall flash.

5. Press and release the “UP” or “DOWN” key within

15 sec.

To set the month:

Press and release the “SET” key when setting the

6.

year: the display will show “n” followed by the

number of the month.

7. Press and release the “UP” or “DOWN” key within

15 sec.

To set the day:

8.

Press and release the “SET” key when setting the

month: the display will show “d” followed by the

number of the day.

9. Press and release the “UP” or “DOWN” key within

15 sec.

To set the hour:

Press and release the “SET” key when setting the

10.

day: the display will show “h” followed by the

number of the hour.

Press and release the “UP” or “DOWN” key within

11.

15 sec.

To set the minute:

12. Press and release the “SET” key when setting the

hour: the display will show “n” followed by the

number of the minute.

13.

Press and release the “UP” or “DOWN” key within

15 sec.

To set the day of the week:

Press and release the “SET” key when setting the

14.

minute: the display will show the first label

available.

Access the procedure for setting the date, time and day of the week

Setting the year

Setting the day

Setting the minute

page 35 of 88

Page 36

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

15. Press and release the key or the key within

15 sec to set:

- “Mon” (Monday)

- “tuE” (Tuesday)

- “UEd” (Wednesday)

- “thu” (Thursday)

- “Fri” (Friday)

- “SAt” (Saturday)

- “Sun” (Sunday).

16.

Press and release the “SET”: the "clock" LED shall

turn off, and then the device shall exit the

procedure.

To exit the procedure before the operation is complete:

17.

Do not operate for 60 sec (any changes will be

saved).

12.2 Setting the working set point

To set the working set point, proceed as follows:

1. Make sure that the keyboard is not locked and that

no procedure is in progress.

2.

Press and release the “SET” key: the “compressor”

LED will flash.

Press and release the “UP” or “DOWN” key within

3.

15 sec; see also parameters r1, r2 and r3.

4.

Press and release the “SET” key or do not operate

for 15 sec: the “compressor” LED will switch off

after which, the device will exit the procedure.

To exit the procedure before the operation is complete:

5.

Do not operate for 15 sec (any changes will be

saved).

The working set point can also be set via parameter SP.

12.3 Setting the configuration

Setting the working set point

parameters

To access the procedure:

1.

Make sure no procedures are in progress.

Hold the “UP” and “DOWN” key for 4 s: the display

2.

will show “PA”.

3.

Press and release the “SET” key.

Press and release the “UP” or “DOWN” key within

4.

15 s to set “-19”.

5.

Press and release the “SET” key and do not

operate for 15 s.

Hold the “UP” and “DOWN” key for 4 s: the display

6.

will show “SP”.

Access the procedure to set the configuration parameters

page 36 of 88

Page 37

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

To select a parameter:

7.

Press and release the “UP” key or the “DOWN”

key.

To set a parameter:

Press and release the “SET” key.

8.

9.

Press and release the “UP” or “DOWN” key within

15 sec.

Press and release the “SET” key and do not

10.

operate for 15 s.

To exit the procedure:

11.

Press and release the “UP” and “DOWN” key for 4

s or do not operate for 60 s (any changes will be

saved).

After setting the parameters, suspend power supply flow to

the device.

Access the procedure to set the configuration parameters

12.4 Restoring the Manufacturer’s

Settings

To restore the manufacturer's settings, proceed as follows:

Make sure no procedures are in progress.

1.

2.

Hold the “UP” and “DOWN” key for 4 s: the display

will show “PA”.

Press and release the “SET” key.

3.

4.

Press and release the “UP” or “DOWN” key within

15 s to set “149”.

Press and release the “SET” key and do not

5.

operate for 15 s.

6.

Hold the “UP” and “DOWN” key for 4 s: the display

will show “dEF”.

7.

Press and release the “SET” key.

Press and release the “UP” or “DOWN” key within

8.

15 s to set “1”.

9.

Press and release the “SET” or do not operate for

15 sec: the display will show a flashing “dEF” for 4

sec, after which the device will exit the procedure

10. Cut the device power supply off.

To exit the procedure in advance:

11. Hold the “UP” and “DOWN” key for 4 s during the

procedure (i.e. before setting “1”: Restore will not

be performed).

Make sure that the manufacturer’s settings are appropriate

(see paragraph 12.5 “List of configuration parameters”.

Setting a parameter

Restoring the Manufacturer’s Settings

page 37 of 88

Page 38

P0 0 1 - - - - 1 1 1 1 1 1 1 1

CA5 -25.0 25.0 °C/°F (1)

CA4 -250 250

points/10

(4)

CA3 -25.0 25.0 °C/°F (1) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 auxiliary temperature offset (see P4)

CA2 -25.0 25.0 °C/°F (1) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 evaporator temperature offset

CA1 -25.0 25.0 °C/°F (1) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

PARAM. MIN. MAX. M.U.

SP r1 r2 °C/°F (1) -18.0 -18.0 -18.0 -18.0 -18.0 -18.0 -18.0 -18.0 Working set-point; see also r0

PARAM. MIN. MAX. M.U.

The following table shows the meaning of the configuration parameters of the devices.

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

12.5 List of configuration parameters

avail.

not

avail.

not

avail.

not

avail.

not

page 38 of 88

avail.

not

avail.

not

0.0 0.0 evaporation temperature offset

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

0 0 vapour pressure offset

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

temperature probe type

0 = PTC

1

= NTC

if P4 = 0, 1, 2 o 3, room temperature offset

if P4 = 4, inlet air temperature offset

MEASUREMENT INPUTS

EVB1256N9

WORKING SETPOINT

Page 39

P5 0 4 - - - - 0 0 0 0 0 0 0 0

P4 0 4 - - - - 3 3 3 3 3 3 3 3

P3 0 2 - - - - 1 1 1 1 1 1 1 1

P2 0 1 - - - - 0 0 0 0 0 0 0 0

P1 0 1 - - - - 1 1 1 1 1 1 1 1

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

page 39 of 88

degree Celsius decimal point

temperature unit of measurement (2)

evaporator temperature probe function

magnitude displayed during normal operation

4

= temperature recorded by the auxiliary probe (see

= inlet air temperature (only if P4 = 4 )

P4)

= working set-point 2 = evaporator temperature

if P4 = 4, CPT temperature

= if P4 = 0, 1, 2 or 3, room temperature

the CPT (Calculated Product Temperature) one;

see also P7

0

1

3

3

4

= evaporator 2 temperature

= outlet air temperature; in this case the

temperature associated with the setting shall be

2

= critical temperature

1

= condenser temperature

0 = probe absent

2

= probe for evaporator fan thermostating

magnitude recorded by the auxiliary temperature probe

0

= probe absent 1 = defrosting probe and probe for evaporator fan

thermostating

0 = degree Celsius

1

= degree Fahrenheit

1

= YES

Page 40

r2 r1 99.0 °C/°F (1) 50.0 50.0 50.0 50.0 50.0 50.0 50.0 50.0 maximum working set-point

r1 -99.0 r2 °C/°F (1) -50.0 -50.0 -50.0 -50.0 -50.0 -50.0 -50.0 -50.0 minimum working set-point

r0 0,1 (5) 15.0 °C/°F (1) 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

PARAM. MIN. MAX. M.U.

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

P11 0 1 - - - -

P10 P9 999

P9 -999 P10

P8 0 250 s/10 5 5 5 5 5 5 5 5 delay displaying temperature variation

P7 0 100 % 50 50 50 50 50 50 50 50

points/10

(4)

avail.

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

page 40 of 88

EVB1226N9

EVB1236N9

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

points/10

(4)

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

avail.

not

EVB1246N9

EVB1256N9

if u1 and/or u11 7, working set-point differential; see

also r12 (6)

if u1 and/or u11 = 7, proportional band; see also r12 (7)

MAIN REGULATOR

1 1

position of the pressure decimal point

0 = no decimal points

1

= on the tens digit

80 80 pressure transducer maximum setting

5 5 pressure transducer minimum setting

percentage of the temperature detected by the inlet air

for the calculation of the CPT temperature (only ifP4 = 4)

(3)

Page 41

C2 0 240 min 3 3 3 3 3 3 3 3 minimum compressor switch-off duration (9)

C1 0 240 min 5 5 5 5 5 5 5 5

C0 0 240 min 0 0 0 0 0 0 0 0

PARAM. MIN. MAX. M.U.

EVB1204N9

EVB1214N9

EVB1206N9

r12 0 1 - - - - 1 1 1 1 1 1 1 1

r6 0 240 min 30 30 30 30 30 30 30 30 duration of “rapid cooling” function; see also r5

r5 0.0 99.0 °C/°F (1) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

r4 0.0 99.0 °C/°F (1) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

r3 0 1 - - - - 0 0 0 0 0 0 0 0

EVB1216N9

page 41 of 88

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

locking of working set-point setting (using the procedure

described in paragraph”Setting the working set point”)

working set point increase during the “energy saving"

working set-point decrease during the “rapid cooling”

1

type of r0

delay in switching on of compressor after the device

minimum time between two consecutive compressor

start-ups; also delay in compressor start-up after

conclusion of room temperature/inlet air probe error

(code “Pr1”) (9) (10)

switches on (8)

COMPRESSOR PROTECTION SYSTEM

0 = asymmetric

= symmetric

function; see also r6

function; see also i5, i10, i15, H01... H14

1

= YES

Page 42

C11 0 240 s 3 3 3 3 3 3 3 3

C10 0 999 hx10 0 0 0 0 0 0 0 0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

C8 0 15 min 1 1 1 1 1 1 1 1 blocked compressor alarm delay (code “CSd”) (12)

C7 0.0 199 °C/°F (1) 90.0 90.0 90.0 90.0 90.0 90.0 90.0 90.0

C6 0.0 199 °C/°F (1) 80.0 80.0 80.0 80.0 80.0 80.0 80.0 80.0

C5 0 240 min 10 10 10 10 10 10 10 10

C4 0 240 min 10 10 10 10 10 10 10 10

C3 0 240 s 0 0 0 0 0 0 0 0 minimum duration of compressor switch on time

page 42 of 88

(11)

condenser temperature is higher than that at which the

condenser temperature above which the blocked

number of operating hours is higher than the limit at

which the need for maintenance is signalled

minimum time interval between the switching on of two

different compressors (only if u1 and/or u11 = 7)

0

= function absent

compressor alarm is activated (code “CSd”)

condenser overheating alarm is activated (code “COH”)

duration of compressor switch on time during a room

temperature/inlet air probe error (code “Pr1”); see also

C6

duration of compressor switch off time during a room

temperature/inlet air probe error (code “Pr1”); see also

C5

Page 43

C14 0 1 - - - - 0 0 0 0 0 0 0 0

C13 0 10 - - - - 1 1 1 1 1 1 1 1

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

C12 0 10 - - - - 2 2 2 2 2 2 2 2

page 43 of 88

1 = FROM DIGITAL INPUT - the compressor and the

pump down valve shall be switched on at the

same time due to the setting; the pump down

valve shall be turned off due to the setting and

the compressor afterwards and as a consequence

of the activation of the multifunction or

multifunction 2 input (only if i5 or

i15 = 6); see also u3

the valve switch-off

to the setting; the pump down valve shall be

turned off due to the setting and the compressor

after the expiration of the u3 time interval from

type of pump down (only if u1 and/or u11 = 10)

0 = TIMED - the compressor and the pump down

valve shall be switched on at the same time due

the number of switch-ons of the two compressors ; see

also C12 (only if u1 and/or u11 = 7)

incidence of the switch-ons of the compressor on the

choice of compressor to be switched on/off when

attempting to balance the number of operation hours and

the number of switch-ons of the two compressors ; see

also C13 (only if u1 and/or u11 = 7)

incidence of the number of compressor operation hours

on the choice of compressor to be switched on/off when

attempting to balance the number of operation hours and

Page 44

d3 0 99 min 30 30 30 30 30 30 30 30

d2 -99 99.0

°C/°F

(1)

d1 0 2 - - - - 0 0 0 0 0 0 0 0

d0 0 99 h 8 8 8 8 8 8 8 8

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

PARAM. MIN. MAX. M.U.

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

page 44 of 88

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

if P3 = 0 o 2, defrosting duration

se P3 = 1, maximum defrosting duration; see also d2

0

= defrosting will not be activated

d3

temperature at end of defrosting (only if P3 = 1); see also

evaporator fan activity will depend on parameter

F2

2

= VIA STOPPING OF COMPRESSOR - during

defrosting the compressor will remain switched off

and the defrosting output will remain deactivated;

on parameter F2

1

= BY HOT GAS - during defrosting the compressor

will be switched on and the defrosting output will

be activated; evaporator fan activity will depend

activated; evaporator fan activity will depend on

parameter F2

type of defrosting

0

= ELECTRIC - during defrosting the compressor will

remain off and the defrosting output will be

d8 = 3, maximum defrost interval

if d8 = 0, 1 or 2, defrosting interval (13)

0 = interval defrosting will never be activated

DEFROSTING

Page 45

d7 0 15 min 2 2 2 2 2 2 2 2

d6 0 2 - - - - 1 1 1 1 1 1 1 1

d5 0 99 min 0 0 0 0 0 0 0 0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

d4 0 1 - - - - 0 0 0 0 0 0 0 0

page 45 of 88

during dripping the compressor will remain switched off

and the defrosting output will remain deactivated; if d16

= 0, evaporator fan activity will depend on parameter F2;

if d16 0, the evaporator fan will remain switched off)

2 = indication “dEF” (16)

+ t”; if on activation of defrosting, the room

temperature or CPT temperature is above “work

set point + t”, at maximum the room temperature

or CPT temperature on activation of defrosting

(14) (15)

1

temperature displayed during defrosting (only if P5 = 0)

0

= room temperature or CPT temperature

= if on activation of defrosting, the room

temperature or CPT temperature is below the

“work set point + t”, at maximum “ work set point

switched on (8)

if d4 = 0, minimum time between switching on of device

and activation of defrosting (8)

if d4 = 1, delay in activation of defrosting after device is

1

= YES

defrosting when device is switched on (only if d8 = 0, 1, 2

or 3) (8)

Page 46

d11 0 1 - - - - 0 0 0 0 0 0 0 0

d9 -99 99.0

°C/°F

(1)

0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

d8 0 4 - - - - 0 0 0 0 0 0 0 0

page 46 of 88

temperature has remained below the temperature

2 = AT INTERVALS - FOR EVAPORATOR TEMPERATURE

- defrosting will be activated when the evaporator

1 = AT INTERVALS - FOR COMPRESSOR SWITCH-ON -

defrosting will be activated once the compressor

has altogether been switched on for time d0

d0

defrosting activation methods

0

= AT INTERVALS - defrosting will be activated once

the device has altogether been running for time

1

= YES

absence of an evaporator temperature probe (code “Pr2”)

visible in models EVB1204N9, EVB1206N9,

4

= IN REAL TIME - defrosting will be activated at the

times established in parameters Hd1... Hd6 (not

evaporator temperature; see also d18, d19, d20

and d22 (17)

defrosting alarm switches off once maximum time limit

has been reached (code “dFd”; only if P3 = 1 and in

evaporator temperature is higher than that at which the

defrost interval counter is suspended (only if d8 = 2)

EVB1226N9 and EVB1246N9)

3

= ADAPTABLE - defrosting will be activated at

intervals, whose duration will each time depend

on the duration of compressor switch-ons and the

d9 for a total time of d0 (17)

Page 47

d20 0 500 min 180 180 180 180 180 180 180 180

d19 0.0 40.0

°C/°F

(1)

3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0

d18 0 999 min 40 40 40 40 40 40 40 40

d16 0 99 min 0 0 0 0 0 0 0 0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

d15 0 99 min 0 0 0 0 0 0 0 0

page 47 of 88

minimum time that the compressor must be switched on

predripping duration (during predripping the compressor

will remain switched off, the defrosting output will be

minimum consecutive time the compressor must be

switched on such as to provoke the defrost activation

0

= defrosting will never be activated due to the effect

of this condition

(only if d8 = 3)

average, or “evaporator temperatures average - d19”)

activated (relative to the evaporator temperatures

evaporator temperature above which the defrost is

0

= defrosting will never be activated due to the effect

of this condition

defrosting interval (only if d8 = 3; defrosting will be

activated when the compressor has been on totally, with

the evaporator temperature below that of d22, for time

d18)

activated and the evaporator fan will remain switched off)

before defrosting can be activated (only if d1 = 1) (18)

Page 48

d26 0 99 h 6 6 6 6 6 6 6 6

d25 0 1 - - - - 0 0 0 0 0 0 0 0

d22 0.0 10.0

°C/°F

(1)

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

d21 0 500 min 200 200 200 200 200 200 200 200

page 48 of 88

minimum consecutive time the compressor must be

switched on after the insturment switches on (on

condition that the difference “cell temperature - working

setpoint” is higher than 10 °C/20 °F) and after function

Overcooling is activated such as to provoke the defrost

activation

enabling of the outlet air temperature probe as defrosting

probe during the evaporator temperature probe error

defrosting interval for effect of enabling of outlet air

temperature probe like defrosting probe during evaporator

temperature probe error (code “Pr2”; only if P4 = 4), if

d25 = 1 (13)

0

= defrosting will never be activated due to the effect

of this condition

(code “Pr2”; only if P4 = 4); see also d26 (19)

average + d22”) (only if d8 = 3)

evaporator temperature above which the time d18 count

is paused (relating to the average of evaporator

temperatures, that is to say, "evaporator temperatures

0

= the defrost will never be activated because the

compressor has been switched on

Page 49

A6 0 240 min 120 120 120 120 120 120 120 120

A5 0 2 - - - - 1 1 1 1 1 1 1 1

A4 -99.0 99.0

A2 0 2 - - - - 1 1 1 1 1 1 1 1

A1 -99.0 99.0

A0 0 1 - - - - 0 0 0 0 0 0 0 0

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

PARAM. MIN. MAX. M.U.

°C/°F

(1)

10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

page 49 of 88

(1)

-10.0 -10.0 -10.0 -10.0 -10.0 -10.0 -10.0 -10.0

°C/°F

EVB1204N9

EVB1214N9

EVB1206N9

EVB1216N9

EVB1226N9

EVB1236N9

EVB1246N9

EVB1256N9

delay in maximum temperature alarm (code “AH”) after

the device is switched on (8)

2

= absolute (that is A4)

point + A4”; consider A1 without sign)

type of maximum temperature alarm (code “AH”)

0

= alarm absent 1 = relative to working set-p oint (that is “working set-

temperature higher than that at which the maximum

temperature alarm is activated (code “AH”); see also A5

and A11

2

= absolute (that is A1)

point - A1”; consider A1 without sign)

type of minimum temperature alarm (code “AL”)

0

= alarm absent 1 = relative to working set-p oint (that is “working set-

temperature below that at which the minimum

temperature alarm is activated (code “AL”); see also A0,

A2 and A11

1

= evaporator temperature (20)

0

= room temperature or CPT temperature

temperature associated with the minimum temperature

alarm (code “AL”)

TEMPERATURE ALARMS

Page 50

avail.

A12 0 2 - - - -

not

1

A11 0.1 (5) 15.0

°C/°F

(1)

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 differential of parameters A1 and A4

EVCO S.p.A. EVBOX1 | Installation guide ver. 1.2 | Code 144BOX1E124

A10 0 240 min 1

A9 0 240 min 15 15 15 15 15 15 15 15

A8 0 240 min 15 15 15 15 15 15 15 15

A7 0 240 min 15 15 15 15 15 15 15 15 temperature alarm delay (code “AL” and code “AH”)

avail.

not

1

page 50 of 88

and by the “HACCP” LED

avail.

not

1

avail.

not

1

1

2

= alarm will be signalled by the “PF” code, buzzer

(as long as cut-off duration exceeds time A10)

buzzer and the “HACCP” LED

type of power supply cut-off alarm signal (code “PF”)

0

= alarm will be signalled by the “HACCP” LED