Page 1

V7

Page 2

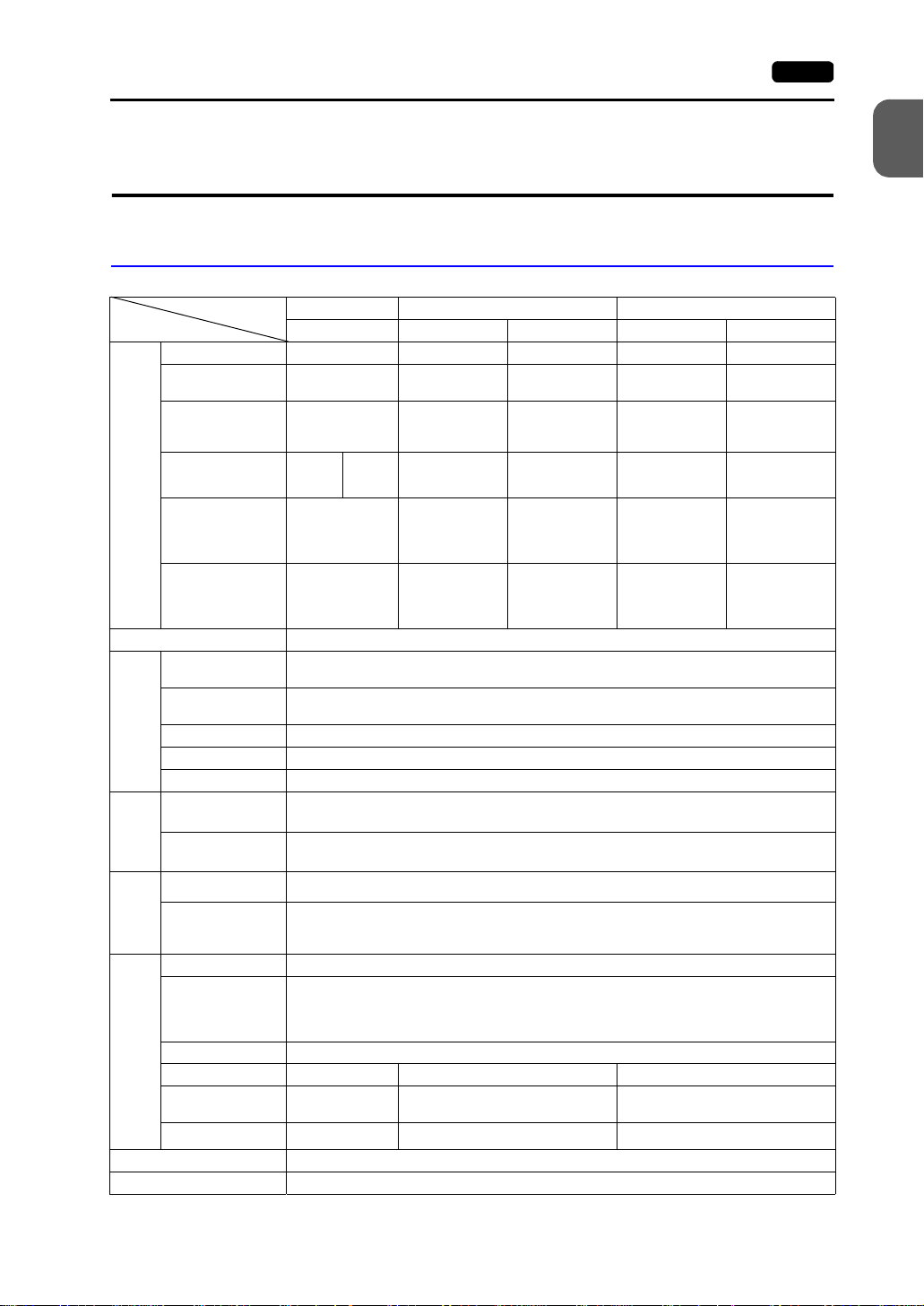

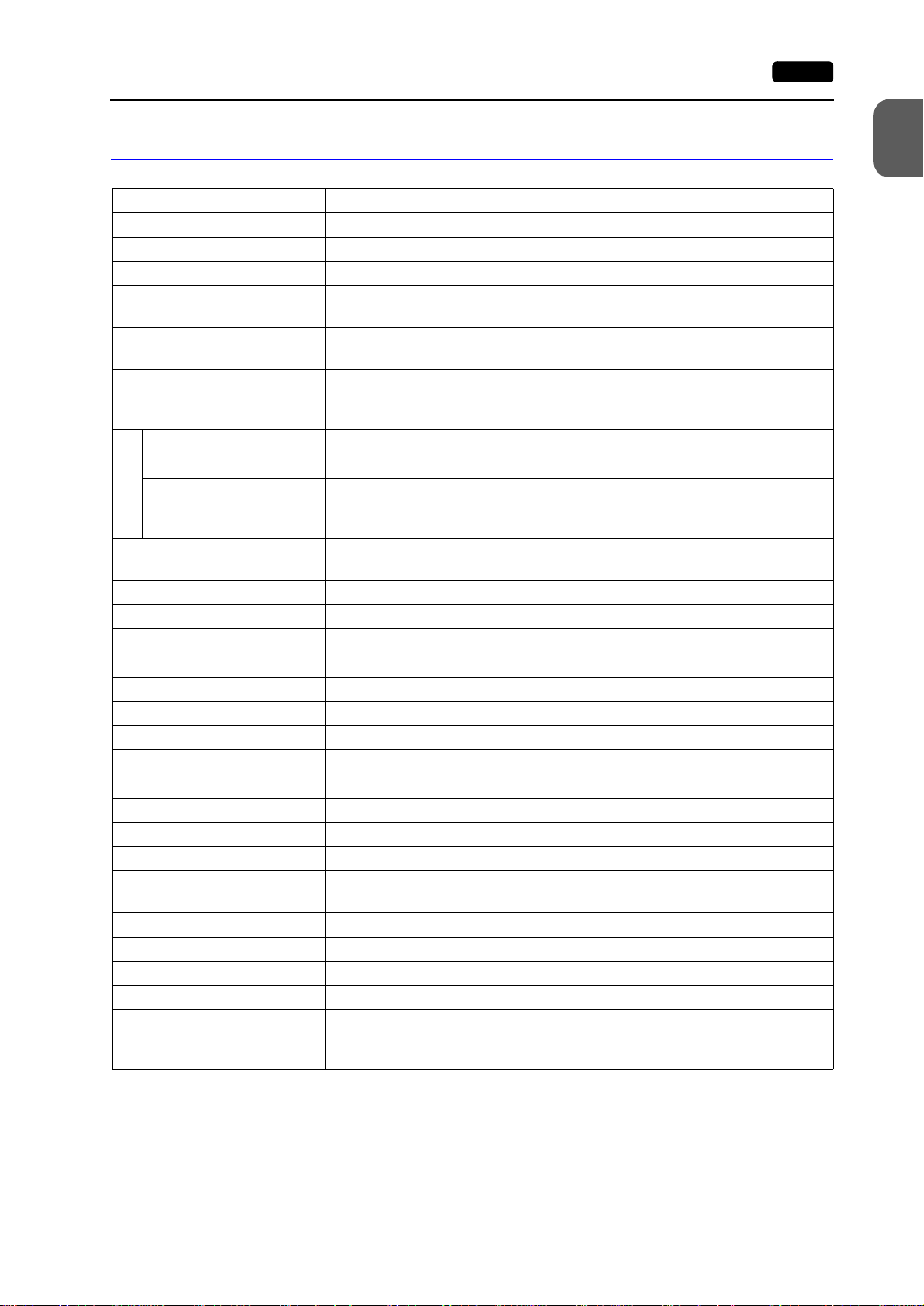

Record of Revisions

Reference numbers are shown at the bottom left corner on the back cover of each manual.

Printing Date Reference No. Revised Contents

September, 2002 2010NE0 First edition

Page 3

Page 4

Preface

Thank you for selecting the MONITOUCH V7 series.

For correct set-up of MONITOUCH, you are requested to read through this manual to understand

more about the product.

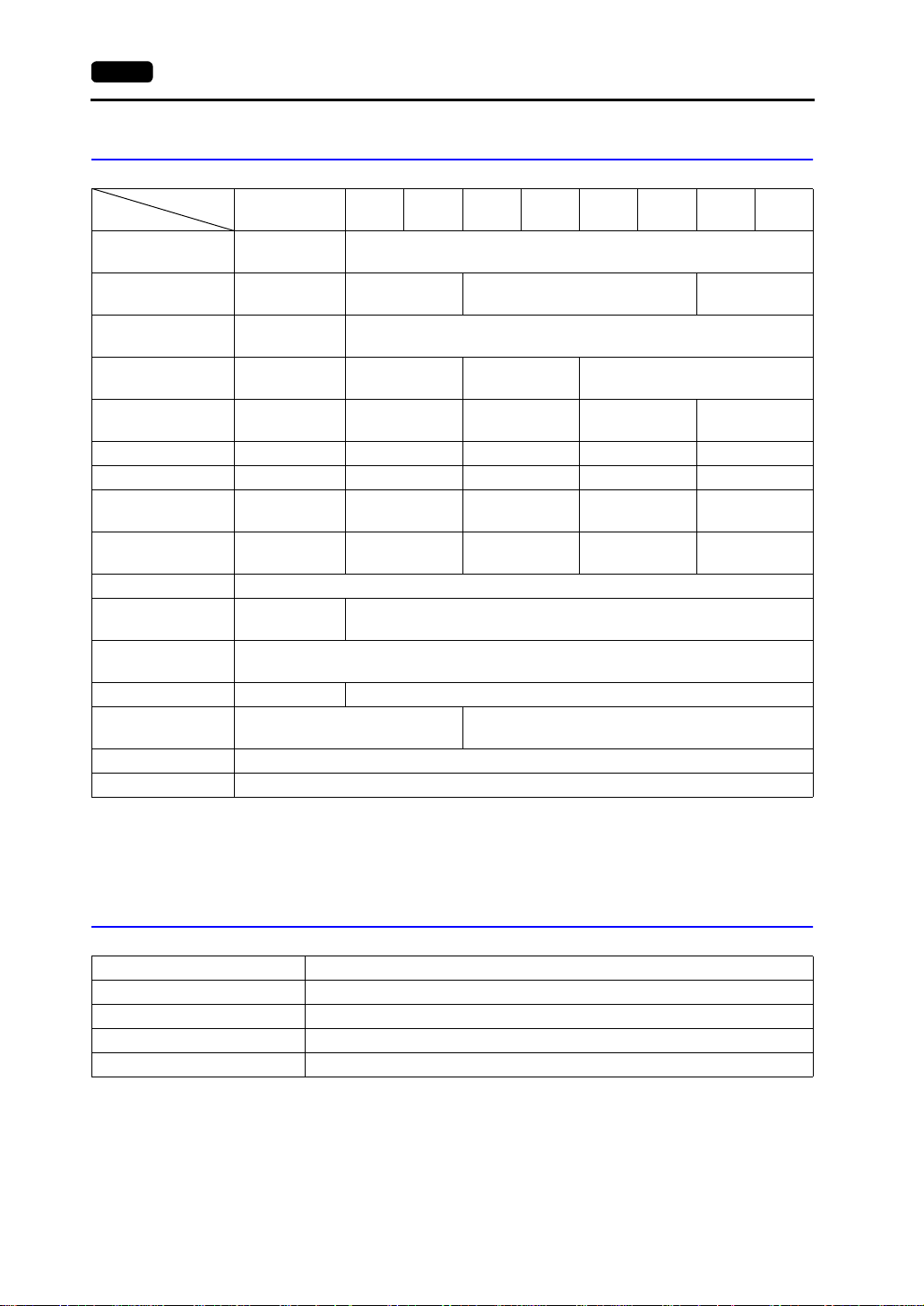

For more information about the V7 series, refer to the following related manuals.

Manual Name Contents Reference No.

Reference Manual (Operation) The V-SFT operating procedure is described. 1043NE

Reference Manual (Function) The functions and instructions of the V7/V6 series are

Universal Serial Connection Manual Universal serial specifications and commands are

Temperature Control Network The temperature control network function is explained. 1033NE

Specifications for Communication

Unit CC-LINK

Specifications for Communication

Unit PROFIBUS-DP

M-CARD SFTE Operation Manual The operating procedure of the memory card editor is

explained.

described.

Instructions for CC-LINK are contained. 1028NE

Instructions for PROFIBUS-DP are contained. 1036NE

described.

For further details about PLCs (programmable logic controllers), see the manual attached to each

PLC.

1044NE

1021NE

1023NE

Notes:

1. This manual may not, i n whole or in p art, be prin ted or reproduc ed with out the prior w ritte n

consent of Hakko Electronics Co., Ltd.

2. Information in this manual is subject to change without prior notice.

3. Windows and Excel are registered trademarks of Microsoft Corporation in the United

States and other countries.

4. All other company names or product names are trademarks or registered trademarks of

their respective holders.

5. This manual is intended to give accurate information about MONITOUCH hardware. If

you have any questions, please contact your local distributor.

Page 5

Notes on Safe Use of

MONITOUCH

In this manual, you w ill fin d va rious notes categorize d un der t he fo ll owing levels with the s ign al words

“DANGER,” and “CAUTION.”

DANGER

CAUTION

Note that there is a possibility that the item listed with may have serious

ramifications.

Indicates an imm inentl y haz ardous situat ion w hich, if not av oided , will re sult in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury and could cause property damage.

CAUTION

DANGER

• Never use the input function of MONITOUCH for operations that may threaten human life or to

damage the system, such as switches to be used in case of emergency. Please design the

system so that it can cope with malfunction of a touch switch.

• Turn off th e powe r suppl y when yo u se t up the un it, conn ect ca bles or perfo rm m ainten ance an d

inspection. Failure to do so could cause an electric shock or damage to the unit.

• Never touch any terminals while the power is on. An electric shock may occur.

• You must put a cover on the terminals on the unit when you turn the power on and operate the

unit. Without the terminal cover in place, an electric shock may occur.

• The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged,

never swallow the leaked liquid crystal. If the liquid crystal spills on your skin or clothing, use

soap and wash off thoroughly.

Page 6

CAUTION

[Notes on System Design]

• Never bundle co ntrol cabl es and inp ut/output c ables with high-vol tage an d large- current ca rrying

cables such as power supply cables. Keep these cables at least 200 mm away from the power

supply or high-voltage cables. Otherwise, malfunction may occur due to noise.

• For use in a nuclear energy facility, or other facility of such official importance, please consult

your local distributor.

[Notes on Installation]

• Operate (or store) MONITOUCH under the conditions indicated in this manual and related

manuals. Failure to do so could cause fire, malfunction, physical damage or deterioration.

• Understand the following environmental limits for use and sto r ag e of MO NITOUCH. Otherwise ,

fire or damage to the unit may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas,

solvents, grinding fluids or cutting oil can come into contact with the unit.

- Avoid high tempe rature, hi gh hu midit y, and out sid e weather co ndi tions, such as w ind, rain or

direct sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibration or physical shock may be transmitted.

• Equipment must be correctly mounted so that the main terminal of MONITOUCH will not be

touched inadvertently.

• Tighten the MONITOUCH mounting screws to the specified torque. Excessive tightening may

distort the panel surface. Loose tightening may cause MONITOUCH to come off, malfunction or

be short-circuited.

• Tighten terminal screws on the power input terminal block equally to a torque of 0.5 N•m.

• Check the appearance of MONITOUCH when it is unpacked. Do not use the unit if any damage

or deformation is found.

• MONITOUCH has a glass screen. Do not drop or give physical shock to the unit.

[Notes on Cable Connection]

• Connect the cables correctly to the terminals of MONITOUCH in accordance with the specified

voltage and wa ttag e. O ver-vol tag e, ov er-watt age or inc orrect ca ble conn ectio n cou ld cau se fi re,

malfunction or damage to the unit.

• Be sure to establish a ground of MONITOUCH. The FG terminal must be used exclusively for

the unit with the level of grounding resist an ce les s tha n 100 Ω.

• Prevent any conductive particles from entering into MONITOUCH. Failure to do so may lead to

fire, damage or malfunction.

(To be continued)

Page 7

CAUTION

[Notes on Maintenance and Operation]

• Hakko Electronics Co., Lt d. is not responsibl e for any damage s resulting from rep air, overhaul or

modification of MONITOUCH that was performed by an unauthorized person.

• Do not use thinners for cleaning because they may discolor the MONITOUCH surface. Use

alcohol or benzine commercially available.

• Do not use a sharp-pointed tool when pressing a touch switch.

• Only experts are authorized to set up the unit, connect the cables or perform maintenance and

inspection.

• MONITOUCH is equipped with a lithium battery. Lithium batteries contain combustible material

such as lithium or organic solvent. Mishandling may cause heat, explosion or ignition resulting

in fire or injury. Read this manual and related manuals carefully and handle the lithium battery

correctly as instructed.

• If a data receive error occurs when MONITOUCH and the counterpart (PLC, temperature

controller , etc.) are s tarted at the same time, read th e manual for th e counterp art unit and ha ndle

the error correctly.

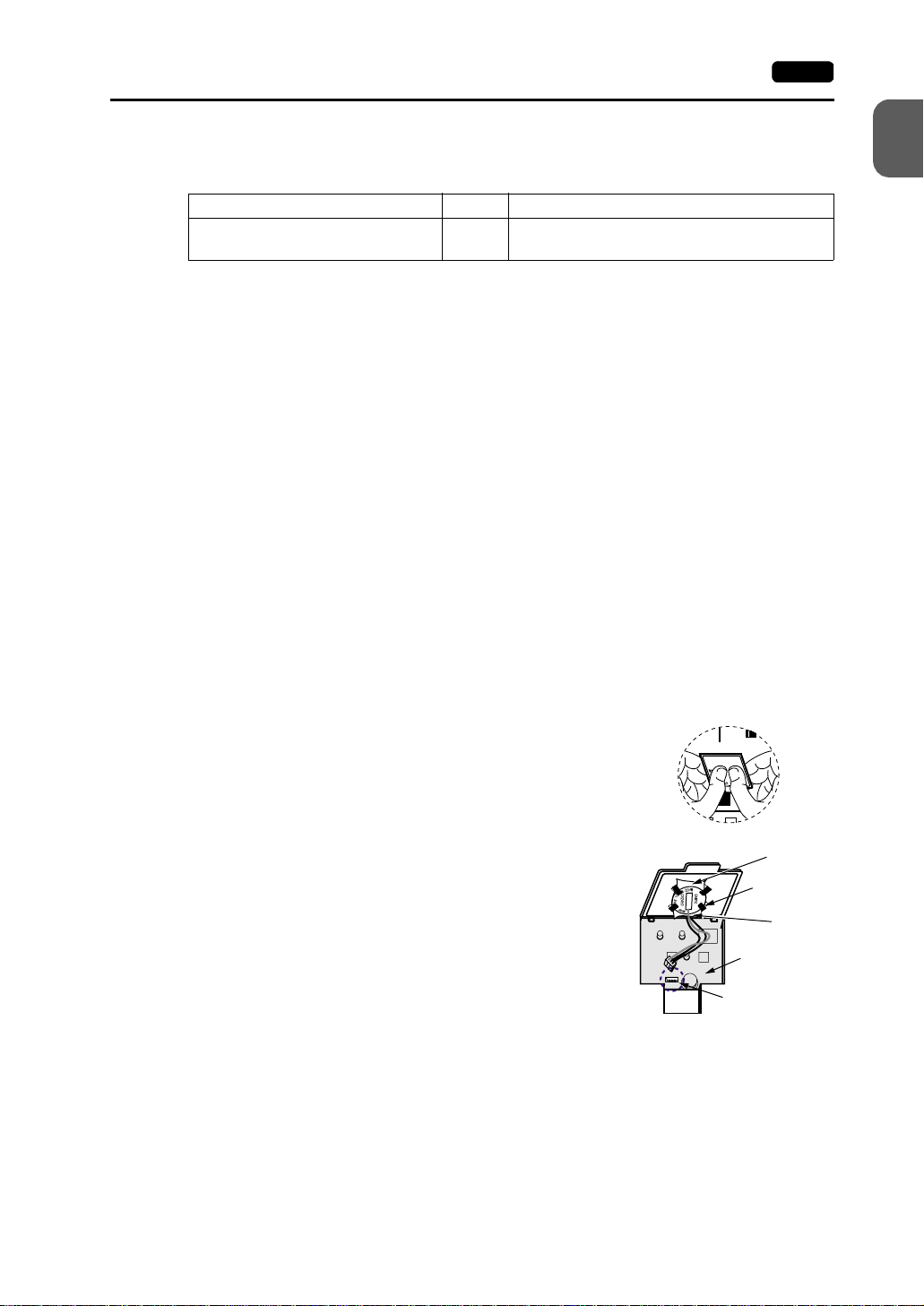

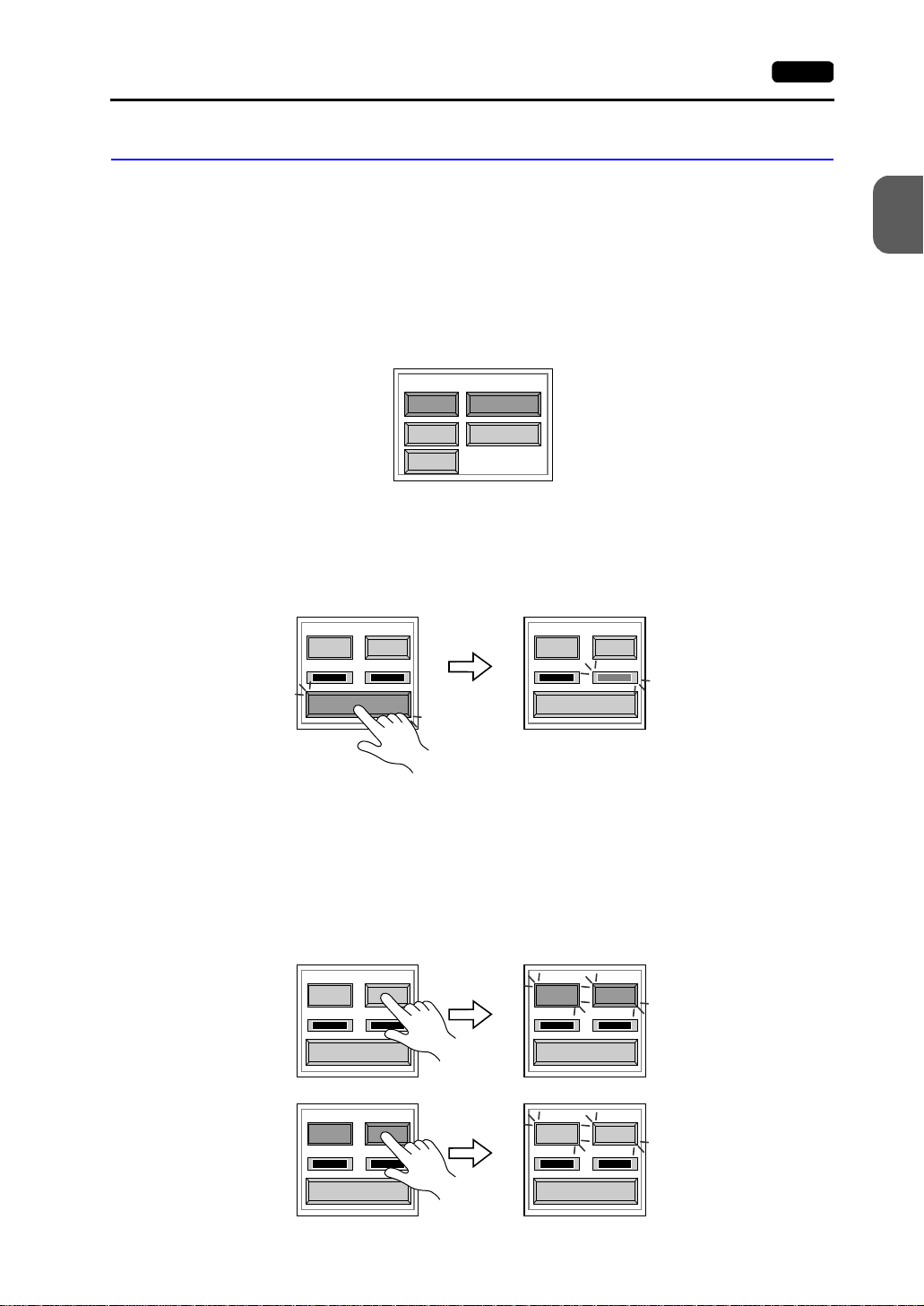

• Switch resolution of the MONITOUCH V7 series is determined by

the analog-type resistance film. Do not press two or more

positions on the screen at the same time.

If two or more positions are pressed at the same time, the switch

located between the pressed positions activates. Please take

note of this.

[Notes on Disposal]

• At the time of disposal, MONITOUCH must be treated as industrial waste.

SWITCH

POWER

Pressing two positions at the same time

activates the switch in the center.

SYSTEM

F1

F2

F3

F4

F5

F6

F7

Page 8

Contents

Chapter 1 Hardware Specifications

1. Features..........................................................................................................................1-1

2. Models and Peripheral Equipment..................................................................................1-2

MONITOUCH Models ............................................................................................... .... .... .. .... .. ...1-2

Peripheral Equipmen t..................... ...................................... ....................................................... 1-3

3. System Composition.......................................................................................................1-7

System Composition of V7 (Standard)......................................................................................... 1-7

System Composition of V7i (High-performance)...... .................................................................... 1-8

4. Specifications.................................................................................................................. 1-9

General Specifications.................................................................................................. .... .. ......... 1-9

Display Specifications................................................................................................................ 1-10

Touch Panel Specifications........................................................................................................ 1-10

Function Switch Specifications..................................................................................................1-11

Interface Specifications.............................................................................................................. 1-11

Clock and Backup Memory Specifications................................................................................. 1-11

Drawing Environment.................................................................................................................1-12

Display Function Specifications.................................................................................................1-12

Function Performance Specifications........................................................................................1-13

5. Dimensions and Panel Cut-out......................................................................................1-14

V708/V708i External View and Dimensions............................................................................... 1-14

V710/V710i External View and Dimensions............................................................................... 1-15

V712/V712i External View and Dimensions............................................................................... 1-16

6. Names and Functions of Components.......................................................................... 1-17

7. Mounting Procedure...................................................................................................... 1-20

Mounting Procedure. ............................................................... ................................................... 1-20

Mounting Angle....................................................................... ...................................................1-20

8. Power Supply Cable Connection................................................................................... 1-21

Power Supply Cable Connection ............................................................................................... 1-21

Notes on Usage of 100-240 VAC Specifications .......................................................... .. .... .... ...1-22

Grounding.................................................................................................................................. 1-22

9. Coin-type Lithium Battery.............................................................................................. 1-23

Battery Mounting Procedure ......................................................................................................1-23

Battery Replacement .................................................................................................................1-24

10. DIP Switch Setting......................................................................................................... 1-26

DIP Switch (DIPSW) Setting......................................................................................................1-26

11. Serial Connector (CN1).................................................................................................1-28

Serial Connector for PLC Connection........................................................................................ 1-28

Page 9

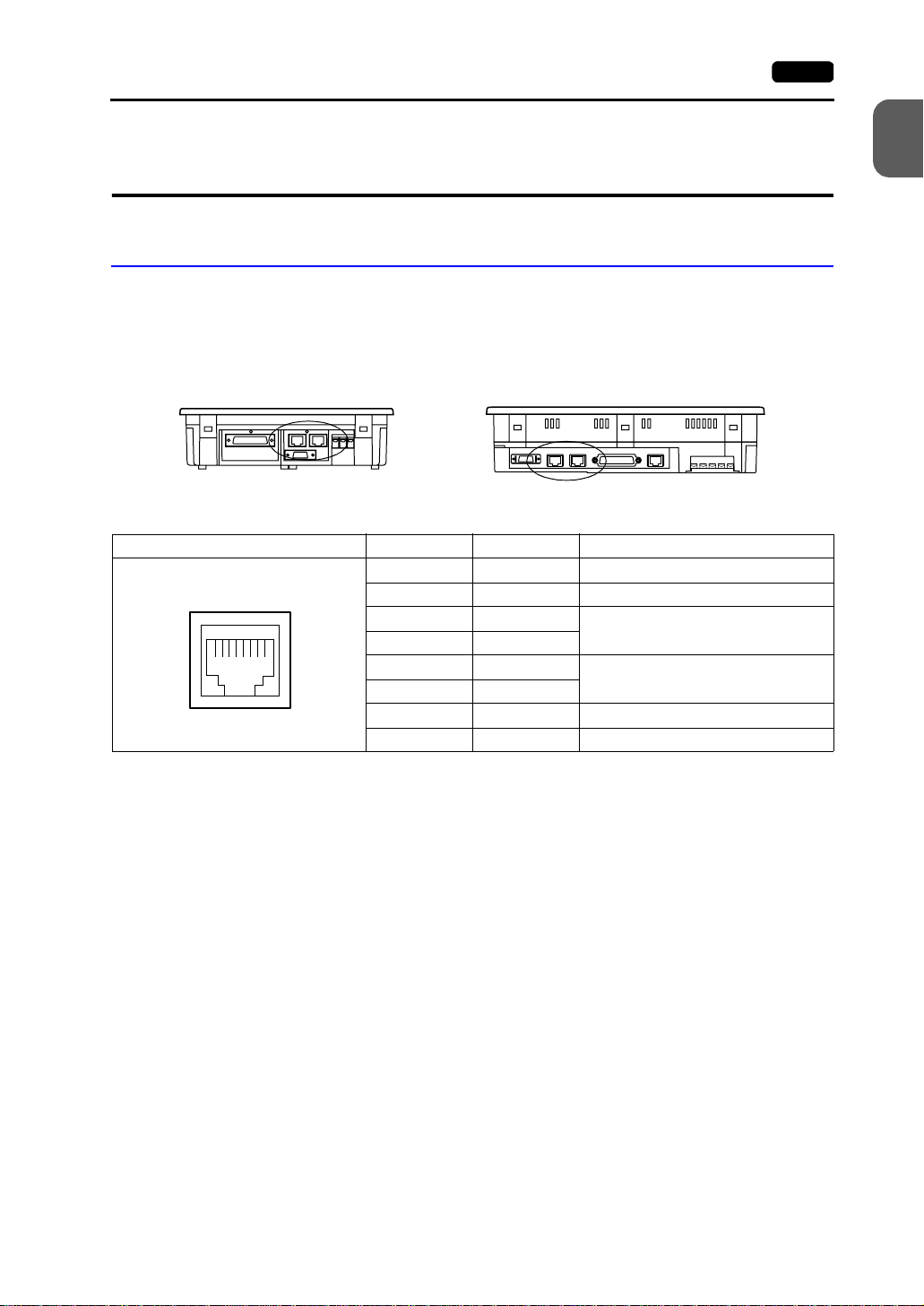

12. Modular Jack (MJ1/MJ2)................................................................................................1-29

Modular Jack 1 (MJ1)/2 (MJ2) .................................................................................. ................. 1-29

V-SFT Setting............. ......................... ................................................... ...................................1-30

Transferring Screen Data....................................................................................................... .... 1-32

Barcode Reader Connection........................................................ .. .... ....... .... .. .... .. ......... .. .... .. ....1-32

13. 10BASE-T (LAN)............................................................................................................1-33

10BASE-T Connector ................................................................................................................ 1-33

Notes on Wiring......................................................................................................................... 1-34

14. CF Card (CF).................................................................................................................1-35

Recommended CF Card............................................................................................................ 1-35

Mounting and Dismounting the CF Card....................................................................................1-35

Notes on Handling the CF Card ................................................................................................. 1-36

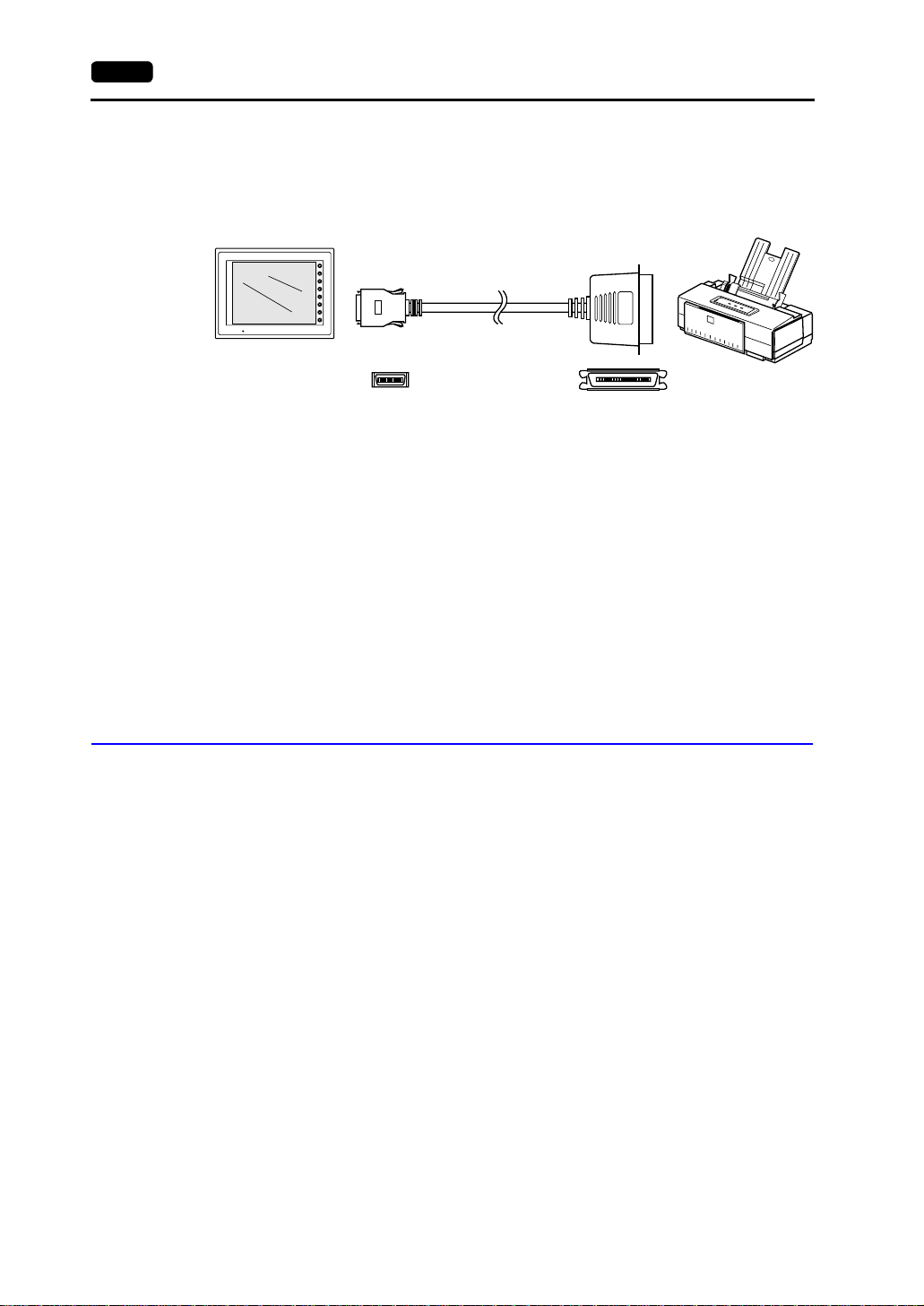

15. Printer Connection (PRINTER)..................................... ...... .................................. ..... ....1-37

Printer Connector (PRINTER).................................................. .... .. .. ......... .. .. .... .. .... ....... .... .. .. ....1-37

Connection with Printer through Serial Interface .......................................................................1-38

Chapter 2 MONITOUCH Operations

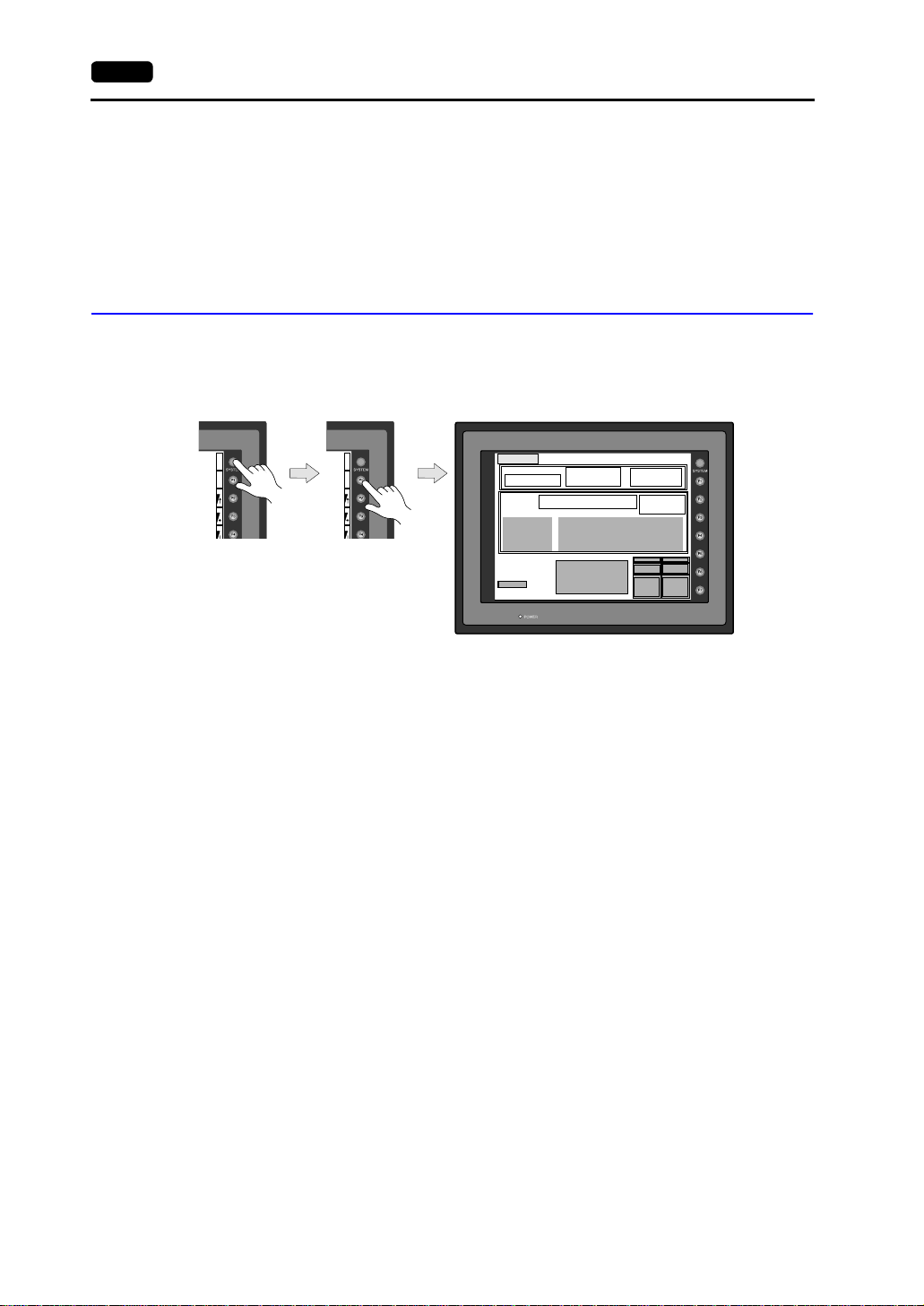

1. Operation of V7 Main Menu.............................................................................................2-1

Initial Screen................................................................................................. ............................... 2-1

1. Main Menu Screen..............................................................................................................2-2

2. I/O Test............ ................................................................................................................... 2-4

2-1. Self-loop Test...................................................................................................................... 2-5

2-2. Print Check............. .............................................................................. ...............................2-8

2-3. SYSTEM & Function Switch Test......... ............................................................................... 2-8

2-4. Touch Switch Test............. .................................................................................................. 2-9

3. Card Menu Screen............................................................................................................ 2-11

3-1. CREC Menu Screen................................................................................... .... ......... .. .... ....2-12

3-2. Transferring Screen Data from a CF Card.................... ....................................................2-15

3-3. Saving Backup Copies of SRAM....................................................................................... 2-21

3-4. Messages during Data Transfer........................................................................................ 2-23

4. Ethernet.............................................................................................................................2-24

5. SRAM/Clock...................................................................................................................... 2-27

6. Extension Program Information.........................................................................................2-28

7. Extended Function Setting................................................................................................ 2-29

2. Function Switches..........................................................................................................2-30

Types......................................................................................................................................... 2-30

[SYSTEM] Switch....................................................................................................................... 2-30

3. Errors Displayed on the V7 Series.................................................................................2-32

1. Communication Erro r........................................................................................................ 2-32

2. Check ................................................................................................................................2-36

3. Warning............................................................................................................................. 2-36

4. SYSTEM ERROR.............................................................................................................2-37

5. Touch Switch is Active........................... ...........................................................................2-37

Page 10

Chapter 3 S erial Communications

1. 1 : 1 Connection.............................................................................................................. 3-1

1 : 1 Connection................................................... .... ..... .. .. .... .. .. .. .. ....... .. .. .. .... .. .. ..... .... .. .. .. ........... 3-1

Wiring........................................................................................................................................... 3-2

V-SFT Setting.............................................................................................................................. 3-4

2. 1 : n Connection (Multi-drop)........................................................................................... 3-9

1 : n Connection................................................... .... ..... .. .. .... .. .. .. .. ....... .. .. .. .... .. .. ..... .... .. .. .. ........... 3-9

Wiring (RS-422/485) ....................................................................................................................3-9

V-SFT Setting............................................................................................................................ 3-10

Notes on Communication Errors.................... ............................................................................3-10

3. n : 1 Connection (Multi-link 2)........................................................................................ 3-11

Multi-link 2..................................................................... .............................................................3-11

Wiring......................................................................................................................................... 3-12

V-SFT Setting............................................................................................................................ 3-14

Communication Error................................................................................................................. 3-15

4. n : 1 Connection (Multi-link)...........................................................................................3-16

Multi-link..................................................................................................................................... 3-16

Wiring......................................................................................................................................... 3-17

V-SFT Setting............................................................................................................................ 3-18

5. Universal Serial Communicatio ns.................................. ...... ..... ...... ..... .........................3-20

Universal Serial Communications.............. ................................................................................ 3-20

6. V-Link............................................................................................................................ 3-21

V-Link......................................................................................................................................... 3-21

Wiring......................................................................................................................................... 3-22

V-SFT Setting............................................................................................................................ 3-24

Protocol...................................................................................................................................... 3-25

NAK: Error Codes ...................................................................................................................... 3-29

1-byte Character Code List........................................................................................................3-30

7. PLC2Way......................................................................................................................3-31

PLC2Way...................................................................................................................................3-31

Limitations on Connection at the MJ Port .............................................. .... ...... ........... ...... .... .....3-32

PLCs Compatible with PLC2 W a y Connection a t MJ Port..................... .. ............. .. .............. ...... 3-32

Wiring......................................................................................................................................... 3-33

V-SFT Setting – System Setting................................................................................................3-35

V-SFT Setting – When the temperature control network/PLC2Way table is used:.................... 3-38

Indirect Memory Designation .....................................................................................................3-45

User Log Read for YOKOGAWA’s PLC..................................................................................... 3-46

Processing Cycle....................................................................................................................... 3-47

Notes on Screen Data Transfer ................................................................................................. 3-48

System Memory.........................................................................................................................3-49

8. Temperature Control Network....................................................................................... 3-52

Temperature Control Network....................................................................................................3-52

Page 11

Chapter 4 Net work Communications

1. Ethernet...........................................................................................................................4-1

Ethernet.......................................................................................................................................4-1

Notes on Ethernet Communications............................................................................................4-3

IP Address for the V7 Series................................................................... ..................................... 4-3

Communication Interface Unit CU-03.......................................................................................... 4-3

Wiring...........................................................................................................................................4-5

Transferring Screen Data....................................................................................................... ......4-8

V-SFT Setting (PLC Type/Communication Parame te r)............. ......................... .......................4-10

V-SFT Setting (Network Ta b l e Editing)....................... ...............................................................4-14

V-SFT Setting (Macro)......................................................... ...................................... ................ 4-19

System Memory......................................................................................................................... 4-22

Ethernet Access Functions (HKEtn10.DLL)............................................................................... 4-26

Server Communication Procedure............................................................................................. 4-44

Error Display..............................................................................................................................4-45

2. FL-net (OPCN-2)............................................................................................................4-48

FL-net (OPCN-2)........................................................................................................................ 4-48

3. MELSECNET/10............................................................................................................4-49

MELSECNET/10........................................................................................................................ 4-49

4. CC-Link..........................................................................................................................4-51

CC-Link......................................................................................................................................4-51

5. OPCN-1.........................................................................................................................4-52

OPCN-1 ..................................................................................................................................... 4-52

6. T-LINK............................................................................................................................ 4-53

T-LINK........................................................................................................................................ 4-53

7. PROFIBUS-DP..............................................................................................................4-54

PROFIBUS................................................................................................................................. 4-54

Page 12

Chapter 5 Connection to PLCs

1. MITSUBISHI PLC............................................................................................................5-1

Available PLCs............................................................................................................................. 5-1

Communication Setting................................................................................................................5-4

A Series Link, QnA Series Link: Switch Setting........................................................................... 5-6

Available Memory........................................................................................................................5-8

Wiring......................................................................................................................................... 5-11

A Link + Net10........................................................................................................................... 5-15

V-MDD (Dual Port Interface)......................................................................................................5-17

Ladder Transfer Function...........................................................................................................5-18

2. OMRON PLC...................................... ..... ...... ................................................................5-22

Available PLCs........................................................................................................................... 5-22

Communication Setting..............................................................................................................5-24

Available Memory......................................................................................................................5-25

Wiring......................................................................................................................................... 5-26

SYSMAC CS1 DNA...................................................................................................................5-29

3. SHARP PLC..................................................................................................................5-30

Available PLCs........................................................................................................................... 5-30

Communication Setting..............................................................................................................5-30

JW Series: Link Unit Switch Setting............................................................. .............................. 5-31

JW100/70H COM Port, JW20 COM Port: System Memory Setting........................................... 5-31

Available Memory......................................................................................................................5-32

Wiring......................................................................................................................................... 5-33

4. HITACHI PLC................................................................................................................5-35

Available PLCs........................................................................................................................... 5-35

Communication Setting..............................................................................................................5-36

HIDIC-H: Switch Setting.............................................................................................................5-37

Available Memory......................................................................................................................5-37

Wiring......................................................................................................................................... 5-39

5. MATSUSHITA PLC....................................................................................................... 5-41

Available PLCs........................................................................................................................... 5-41

Communication Setting..............................................................................................................5-41

MEWNET: Link Unit Switch Setting........................................................................................... 5-42

Available Memory......................................................................................................................5-42

Wiring......................................................................................................................................... 5-43

6. YOKOGAWA PLC......................................................................................................... 5-45

Available PLCs........................................................................................................................... 5-45

Communication Setting..............................................................................................................5-46

Available Memory......................................................................................................................5-47

Wiring......................................................................................................................................... 5-48

7. YASKAWA PLC............................................................................................................. 5-50

Available PLCs........................................................................................................................... 5-50

Communication Setting..............................................................................................................5-50

Available Memory......................................................................................................................5-51

Wiring......................................................................................................................................... 5-52

Page 13

8. Toyopuc PLC.................................................................................................................5-55

Available PLCs.................................................................................................. ......................... 5-55

Communication Setting.............................................................................................................. 5-55

Switch Setting............................................................................................................................ 5-55

Available Memory........... .................................................................................................... ....... 5-56

Screen Editing (Memory Input) ..................................................................................................5-56

Wiring.........................................................................................................................................5-57

9. FUJI PLC.......................................................................................................................5-58

Available PLCs.................................................................................................. ......................... 5-58

Communication Setting.............................................................................................................. 5-58

MICREX-F Series, FLEX-PC Series: Switch Setting................................................................. 5-59

Available Memory........... .................................................................................................... ....... 5-60

Wiring.........................................................................................................................................5-62

10. KOYO PLC.....................................................................................................................5-64

Available PLCs.................................................................................................. ......................... 5-64

Communication Setting.............................................................................................................. 5-65

Available Memory........... .................................................................................................... ....... 5-66

Switch Setting............................................................................................................................ 5-67

Wiring.........................................................................................................................................5-69

11. Allen-Bradley PLC..........................................................................................................5-72

Available PLCs.................................................................................................. ......................... 5-72

Communication Setting.............................................................................................................. 5-73

Available Memory........... .................................................................................................... ....... 5-74

PLC-5 Series: Switch Setting.....................................................................................................5-76

SLC500 Series, Micro Logix 100: Transmission Parameter Setting.......................................... 5-78

Wiring.........................................................................................................................................5-79

12. GE Fanuc PLC...............................................................................................................5-82

Available PLCs.................................................................................................. ......................... 5-82

Communication Setting.............................................................................................................. 5-82

Available Memory........... .................................................................................................... ....... 5-83

Wiring.........................................................................................................................................5-84

13. TOSHIBA PLC...............................................................................................................5-86

Available PLCs.................................................................................................. ......................... 5-86

Communication Setting.............................................................................................................. 5-86

Available Memory........... .................................................................................................... ....... 5-87

Wiring.........................................................................................................................................5-87

14. TOSHIBA MACHINE PLC..............................................................................................5-88

Available PLCs.................................................................................................. ......................... 5-88

Communication Setting.............................................................................................................. 5-88

Available Memory........... .................................................................................................... ....... 5-88

Wiring.........................................................................................................................................5-89

15. SIEMENS PLC...............................................................................................................5-90

Available PLCs.................................................................................................. ......................... 5-90

Communication Setting.............................................................................................................. 5-90

Available Memory........... .................................................................................................... ....... 5-92

Wiring.........................................................................................................................................5-95

Page 14

16. SHINKO PLC................................................. ...... ................................. ...... ...... ..... ...... ..5-98

Available PLCs........................................................................................................................... 5-98

Communication Setting..............................................................................................................5-98

Available Memory......................................................................................................................5-98

Wiring......................................................................................................................................... 5-99

17. SAMSUNG PLC..........................................................................................................5-100

Available PLCs......................................................................................................................... 5-100

Communication Setting............................................................................................................5-100

Available Memory....................................................................................................................5-100

Wiring....................................................................................................................................... 5-101

18. KEYENCE PLC...........................................................................................................5-102

Available PLCs......................................................................................................................... 5-102

Communication Setting............................................................................................................5-103

Available Memory....................................................................................................................5-104

Wiring....................................................................................................................................... 5-106

19. LG PLC........................................................................................................................5-108

Available PLCs......................................................................................................................... 5-108

Communication Setting............................................................................................................5-108

Available Memory....................................................................................................................5-109

Wiring....................................................................................................................................... 5-111

20. FANUC PLC................................................................................................................5-113

Available PLCs......................................................................................................................... 5-113

Communication Setting............................................................................................................5-113

Available Memory....................................................................................................................5-113

Wiring....................................................................................................................................... 5-114

21. FATEK AUTOMATION PLC........................................................................................5-116

Available PLCs......................................................................................................................... 5-116

Communication Setting............................................................................................................5-116

Available Memory....................................................................................................................5-116

Wiring....................................................................................................................................... 5-117

22. IDEC PLC....................................................................................................................5-118

Available PLCs......................................................................................................................... 5-118

Communication Setting............................................................................................................5-118

Available Memory....................................................................................................................5-118

Wiring....................................................................................................................................... 5-119

23. MODICON PLC...........................................................................................................5-120

Available PLCs......................................................................................................................... 5-120

Communication Setting............................................................................................................5-120

Available Memory....................................................................................................................5-120

Wiring....................................................................................................................................... 5-121

24. YAMATAKE PLC......................................................................................................... 5-122

Available PLCs......................................................................................................................... 5-122

Communication Setting............................................................................................................5-122

Available Memory....................................................................................................................5-122

Wiring....................................................................................................................................... 5-123

Page 15

25. TAIAN PLC ........................................................ ...... ..... ...... .........................................5-124

Available PLCs.................................................................................................. .......................5-124

Communication Setting............................................................................................................5-124

Available Memory........... .................................................................................................... .....5-124

Wiring....................................................................................................................................... 5-125

26. SAIA PLC........................................................... ...... ..... ...... ...... ...................................5-126

Available PLCs.................................................................................................. .......................5-126

Communication Setting............................................................................................................5-126

S-BUS Configuration................................................................................................................ 5-126

Available Memory........... .................................................................................................... .....5-126

Wiring....................................................................................................................................... 5-127

27. MOELLER PLC............................................................................................................5-128

Available PLCs.................................................................................................. .......................5-128

Communication Setting............................................................................................................5-128

Available Memory........... .................................................................................................... .....5-128

Wiring....................................................................................................................................... 5-129

28. Telemecanique PLC....................................................................................................5-130

Available PLCs.................................................................................................. .......................5-130

Communication Setting............................................................................................................5-130

Available Memory........... .................................................................................................... .....5-130

Wiring....................................................................................................................................... 5-131

29. Automationdirect PLC..................................................................................................5-132

Available PLCs.................................................................................................. .......................5-132

Communication Setting............................................................................................................5-132

Available Memory........... .................................................................................................... .....5-133

Wiring....................................................................................................................................... 5-133

Page 16

Hardware Specifications

1. Features

2. Models and Peripheral Equipment

3. System Composition

4. Specifications

5. Dimensions and Panel Cut-out

6. Names and Functions of Components

7. Mounting Procedure

8. Power Supply Cable Connection

9. Coin-type Lithium Batter y

10. DIP Switch Setting

11. Serial Connector (CN1)

12. Modular Jack (MJ1/MJ2)

13. 10BASE-T (LAN)

14. CF Card (CF)

15. Printer Connection (PRINTER)

Page 17

Page 18

1. Features 1-1

1. Features

The V7 series inherits and heightens th e features of the V6 series as described below.

1. 32k-color Display

32,768-color display makes colorful expression possible. Bitmap files are clearly

displayed in brilliant colors.

2. CF Card Interface as Standard

The CF card can be used for saving multiple screen data, sampling data, recipe data,

hard copy images, and other vario us usage s. Large-si zed vide o capture im ages, JPEG

or WAV files can be saved.

3. Connector for 10BASE-T (for high-performance type only)

This connector enables Ethernet connection with a host computer. High-speed

communications are possible via Ethernet for uploading/downloading screen data and

reading/writing data from/to the server.

4. Video Display Upgraded (for high-performance type only, optional)

The video display function is upgraded drastically to allow: saving the current video

screen, taking snapshots of multiple exposures, superimposing a semi-transparent

operation screen on a v ideo disp lay, showing four video c hannels at the same tim e, and

so on.

5. Web Server Function (for high-performance type only)

The V7i screens are converted into HTML files and displayed on the WWW browser

using the Ethernet.

1

Hardware Specifications

6. Animation Function

The animation function enables representation of the field close to the real image.

7. Play of WAV File (for high-performance type only, optional)

WAV files c an be pl ay ed with ease simp ly by c onn ec tin g th e opti on unit to the spe ak er.

It is possible to use sound for notifying the field conditions, such as an occurrence of an

error. The monitoring operator can work from a distance.

Page 19

1-2 2. Models and Peripheral Equipment

2. Models and Peripheral

Equipment

MONITOUCH Models

The model name consists of the following information.

V 7

Power supply specification

D: 24 VDC specification (in compliance with CE/UL/cUL)

None: 100-240 VAC specification

Device specification

S: TFT color LCD (SVGA)

T: TFT color LCD (VGA)

C: STN color LCD (VGA)

Functional specification

i: High-performance type

None: Standard type

Screen size

08: 8-inch

10: 10-inch

12: 12-inch

Page 20

2. Models and Peripheral Equipment 1-3

Series and

Size

V708 series

8-inch

V710 series

10-inch

V712 series

12-inch

The following models are available.

Model

Name

V708SD TFT color, 800 × 600 dots, standard, DC power supply Compliant with CE/UL/cUL

V708iSD TFT color, 800 × 600 dots, high-performance, DC power

supply

V708CD STN color, 640 × 480 dots, standard, DC power supply Compliant with CE/UL/cUL

V710T TFT color, 640 × 480 dots, standard, AC power supply

V710TD TFT color, 640 × 480 dots, standard, DC power supply Compliant with CE/UL/cUL

V710iT TFT color , 640 × 480 dots, high-performance, AC power

supply

V710iTD TFT color, 640 × 480 dots, high-performance, DC power

supply

V710S TFT col or, 800 × 600 dots, standard, AC power supply

V710SD TFT color, 800 × 600 dots, standard, DC power supply Compliant with CE/UL/cUL

V710iS TFT color, 800 × 600 dots, high-performance, AC power

supply

V710iSD TFT color, 800 × 600 dots, high-performance, DC power

supply

V712S TFT col or, 800 × 600 dots, standard, AC power supply

V712SD TFT color, 800 × 600 dots, standard, DC power supply Compliant with CE/UL/cUL

V712iS TFT color, 800 × 600 dots, high-performance, AC power

supply

V712iSD TFT color, 800 × 600 dots, high-performance, DC power

supply

Specifications Remarks

Compliant with CE/UL/cUL

Compliant with CE/UL/cUL

Compliant with CE/UL/cUL

Compliant with CE/UL/cUL

1

Hardware Specifications

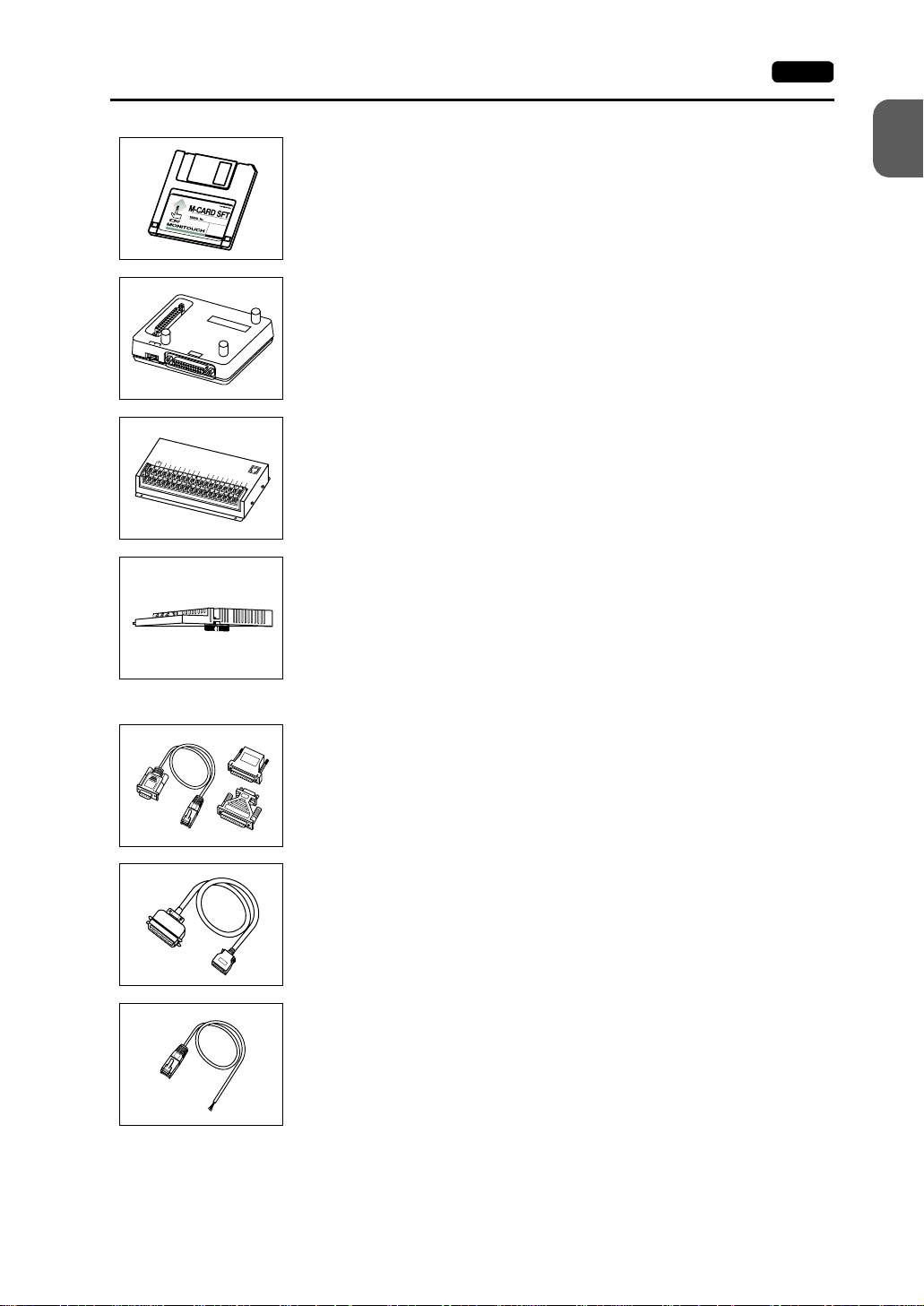

Peripheral Equipment

The following options are available for using the V7 series more effectively.

V-SFT (drawing software: English version)

Application software for editing display data for the V series.

(Windows98/NT4.0/Me/2000/XP compatible) The V7 series is

supported with ver. 2.00 and later.

Page 21

1-4 2. Models and Peripheral Equipment

EU-xx (option unit)

(* This option unit can only be mounted on the V7i model.)

xx: 00 → Video input + sound output unit

Video images can be displayed on V7i directly. WAV files can be

played at an external speaker.

xx: 01 → RGB input + sound output unit

Screen images displayed on a CRT display can be shown on V7i.

WAV files can be played at an external speaker.

xx: 02 → RGB output + sound output unit

Screen images displayed on V7i can be shown on a CRT display.

WAV files can be played at an external speaker.

xx: 03 → Sound output unit

WAV files can be played at an external speaker.

V7EM-F (FLASH memory cassette)

Extension print circuit board to extend the memory for screen data.

The capacity of FLASH memory is 8 Mbyte.

V7EM-S (SRAM cassette)

Extension print circuit board to back-up the memory for sampling data,

V7 internal memory and memo pad. The capacity of an SRAM

cassette is 512 kbyte.

CN1

SW1

TB1

TC485 (terminal converter)

Used for connection between the V7 series and a PLC at the

RS-422/485 terminal block.

CREC (card recorder)

The card recorder crea tes a ba ckup c opy of scre en dat a or works as an

external memory storage system for memory manager and data

logging functions.

REC-MCARD (memory card) compliant with JEIDA ver. 4.0

Used with the card reco rder when h aving a b ackup copy of screen data

or saving data on an external medium for memory manager and data

logging functions.

SRAM 256 k, 512 k, 1 M, 2 M, 4 Mbyte

FLASH ROM 256 k, 512 k, 1 M, 2 M, 4 M, 16 Mbyte

Page 22

2. Models and Peripheral Equipment 1-5

1 2 3

D

C

2

4

F

GI

M-CARD SFTE (memory card editor)

1

Application software for editing data stored on a memory card.

(Windows98/NT4.0/Me/2000/XP compatible)

Hardware Specifications

V-MDD (ACPU/QnACPU/FXCPU dual port interface)

P

P

V

-

M

G

D

D

GD

Add-on connector with two ports, specifically designed for the

connector on the MITSU BISHI’s ACPU/QnAC PU/FXCPU programm er.

Operability can be improved when directly connecting the V7 series to

the ACPU/QnACPU/FXCPU programmer.

V-I/O (serial extension I/O)

V

I

N

1

I

N

3

I

N

5

N

0

I

N

7

I

N

I

2

N

9

I

N

I

4

N

1

1

IN

I

N

6

1

3

IN

I

8

N

I

N

1

0

I

N

1

2

I

N

1

4

C

O

M

J

1

5

M

+

O

U

1

O

U

T

1

O

U

T

3

O

U

T

5

O

T

U

0

T

7

O

U

O

T

U

2

T

8

O

U

O

T

U

4

T

1

0

O

U

O

T

U

6

T

1

2

C

O

O

M

U

1

T

1

4

O

U

C

T

O

9

M

2

O

U

T

1

1

O

U

T

1

3

O

U

T

1

5

Used as an external I/O unit for PLC. It has 16 inputs and 16 outputs.

CU-xx [xx: 00 → OPCN-1, 01 → T-LINK, 02 → CC-Link,

03 → Ethernet/FL-net (OPCN-2), 04 → PROFIBUS-DP,

05 → MELSECNET/10] (communication interface unit)

Used for communications with each network. This unit enables

connection of multiple V7 series to a single PLC. Since other devices

on the same network can be connecte d, it brings abou t the reduction in

costs of the whole system.

V6-CP (screen data transfer cable) 3 m

Used for connection between the V7 series and a personal computer,

or a personal computer and the card recorder (CREC).

V7-PT (printer cable) 2.5 m

Used for connection between the V7 series and a printer.

V6-BCD (barcode reader connection cable) 3 m

Used for connection between the V7 series and a barcode reader.

Page 23

1-6 2. Models and Peripheral Equipment

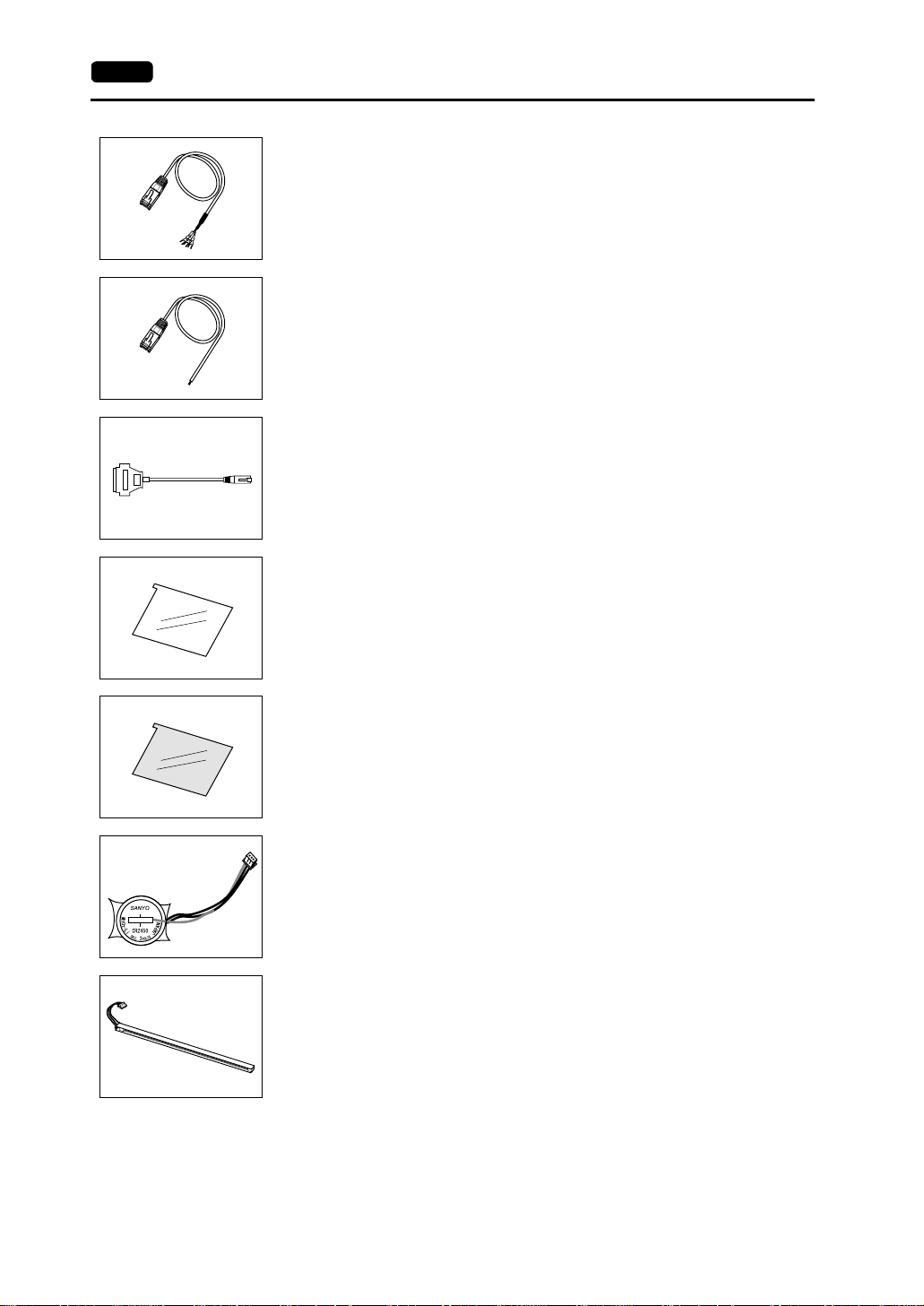

V6-MLT (multi-link 2 master cable) 3 m

Used for Multi-Link 2 connection between the V7 master station and

the V7slave station.

V6-TMP (temperature controller connection cable) 3 m

Used for connection between the V7 series and a temperature

controller or a PLC via PLC2Way.

MJ-D25 (MJ-to-D-sub conversion cable) 0.3 m under development

Used for connection between the V7 series and a PLC via PLC2Way.

V7xx-GS [xx: 08 → V708/V708i, 10 → V710/V710i, 12 → V712/V712i]

(protective sheet)

This sheet protects the operation panel surface. (5 sheets/set)

V7xx-GSN10 [xx: 08 → V708/V708i, 10 → V710/V710i,

12 → V712/V712i] (protective sheet)

This anti-glare sheet protects the operation panel surface.

(5 sheets/set)

V7-BT (battery for replacement)

Replacement lithium battery for the V7 series.

V708S-FL → V708S/V708iS

V6xxx-FL [xxx: 08C → V708C, 10T → V710T/V710iT,

10S → V710S/V710iS, 12S → V712S/V712iS]

(backlight for replacement)

Replacement backlight parts for the V7 series.

Page 24

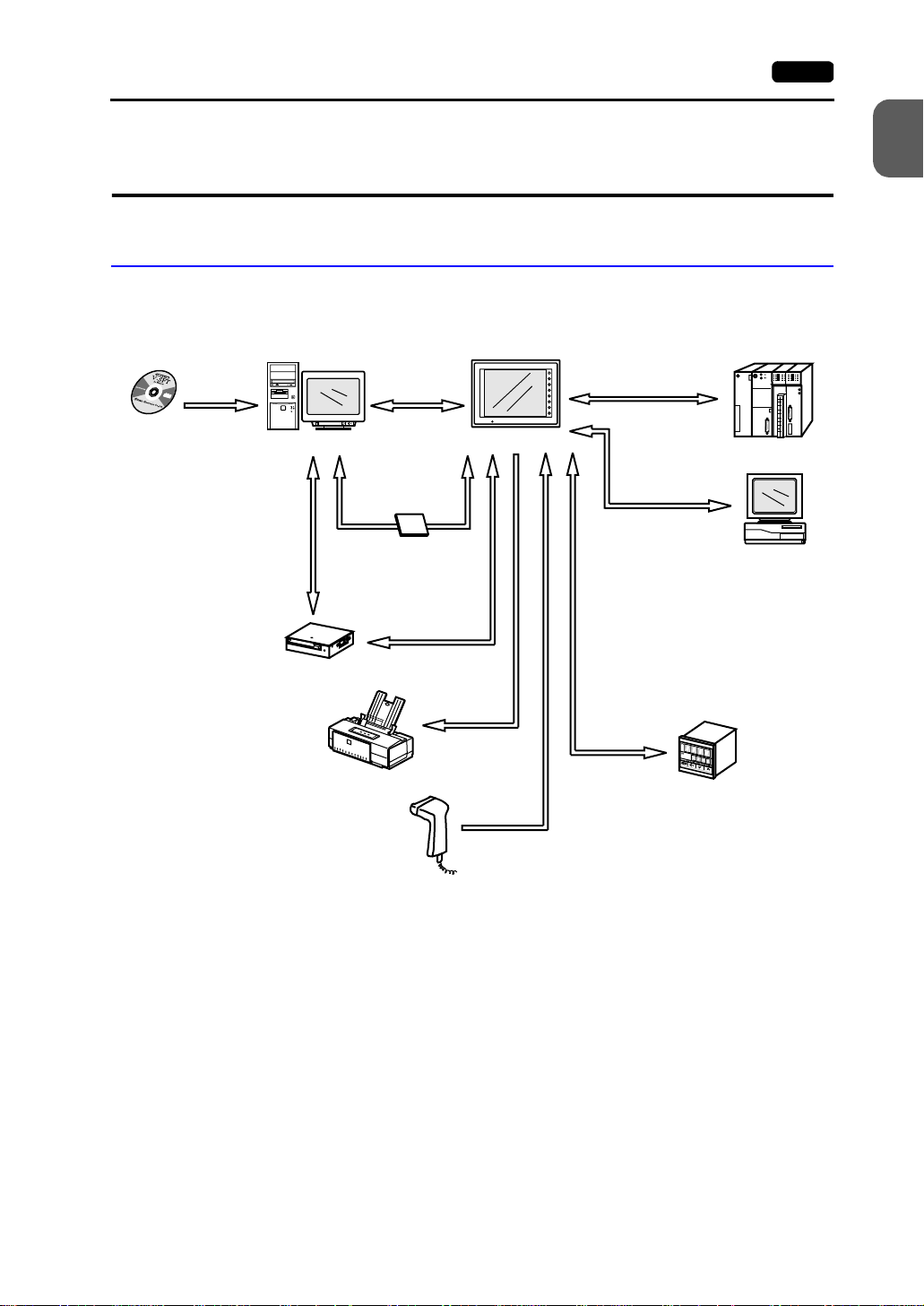

3. System Composition 1-7

3. System Composition

System Composition of V7 (Standard)

The following illustration shows possible system configurations using the V7 series

(standard).

V series

Panel Editor

V-SFT

Creating screens

disc

Personal computer (PC)

Transferring screen data

Transferring other data

V6-CP

Card recorder

CREC

Transferring

screen data

V6-CP

RESET

POWER

V7 (standard)

Transferring screen da ta

Transferring recipe data

Saving sampling data

etc.

CompactFlash

Card

CF card

Transferring screen data

Memory manager

Data logging function

CREC cable

Printer cable

V7-PT

Printer

Cable

V6-BCD

SYSTEM

F1

F2

F3

F4

F5

F6

F7

During operation

(Link communication)

RS-232C/RS-422

During operation

(Universal serial

communication)

RS-232C/RS-422

Cable

V6-TMP

Temperature controller,

inverter

Link unit

General-purpose

computer

1

Hardware Specifications

Barcode reader

Page 25

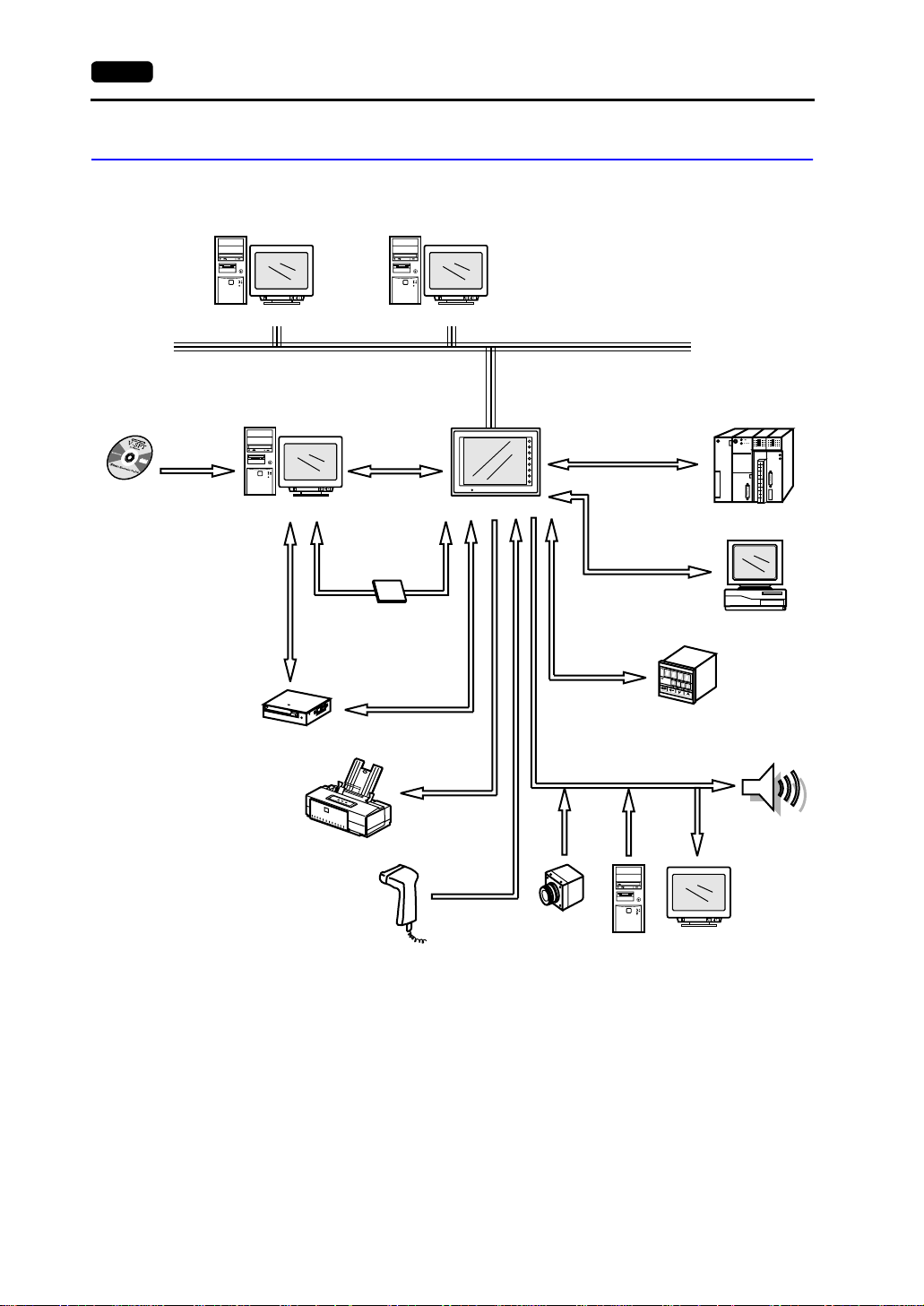

1-8 3. System Composition

System Composition of V7i (High-performance)

The following illustration shows possible system configurations using the V7i series

(high-performance).

V series

Panel Editor

V-SFT

disc

RESET

Personal computer (PC) Personal computer (PC)

Creating screens

disc

Personal computer (PC)

Transferring screen data

Transferring other data

V6-CP

Card recorder

CREC

disc

RESET

Ethernet

Transferring

screen data

RESET

V6-CP

POWER

V7i (high-performance)

Transferring screen data

Transferring recipe da ta

Saving sampling data

etc.

CompactFlash

Card

CF card

Transferring screen data

Memory manager

Data logging function

CREC cable

Printer cable

V7-PT

SYSTEM

F1

F2

F3

F4

F5

F6

F7

*1

During operation

(Link communication)

RS-232C/RS-422

During operation

(Universal serial

communication)

RS-232C/RS-422

Cable

V6-TMP

T emperature controller,

inverter

Link unit

General-purpose

computer

Printer

Barcode reader

*1 The option unit (EU-xx) is required.

Cable

V6-BCD

Video camera

(Video input)

Personal

computer

(RGB input)

Display

(RGB output)

Speaker

(Sound output)

Page 26

4. Specifications 1-9

4. Specifications

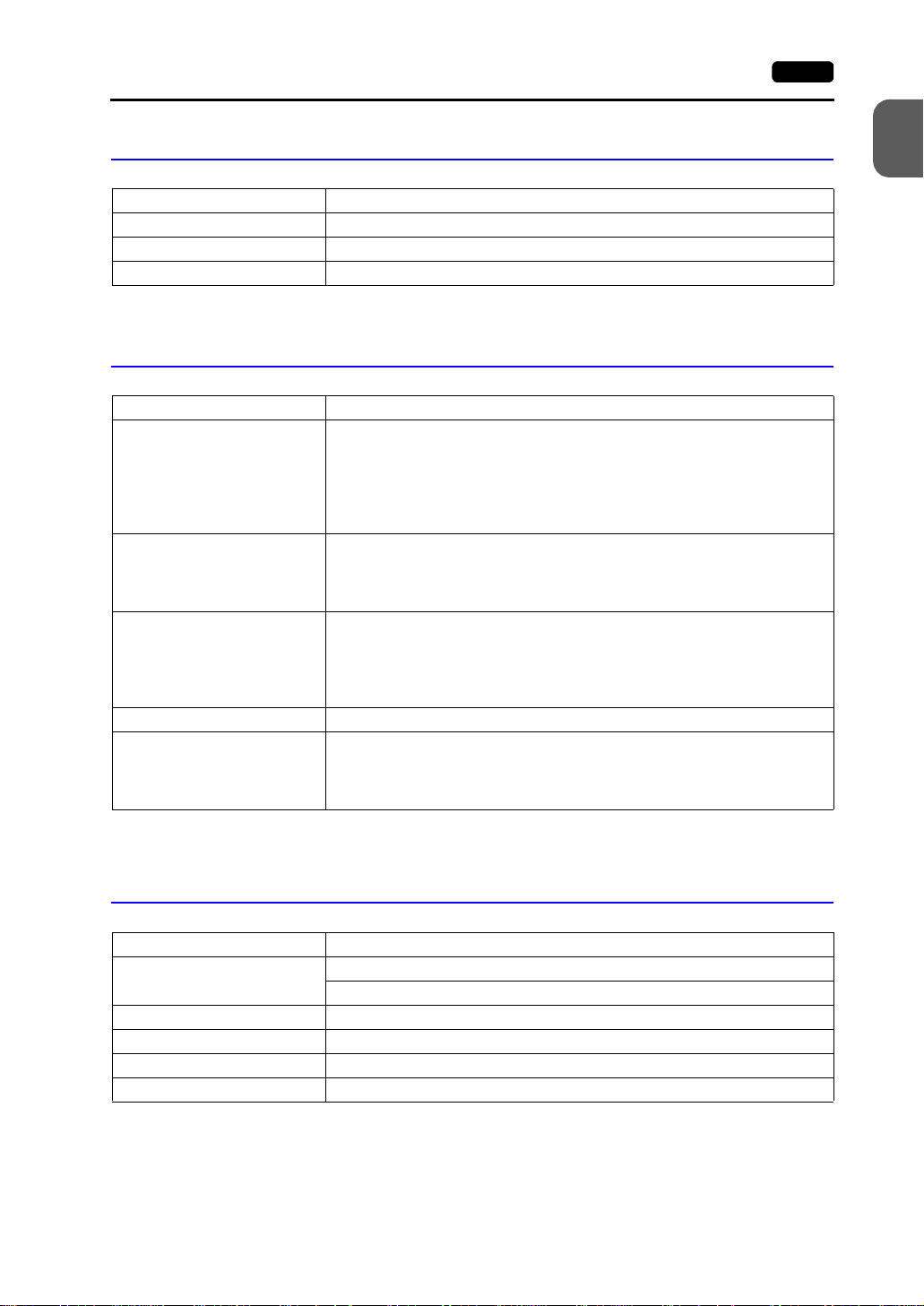

General Specifications

Model V708 V710 V712

Item DC power supply AC power supply DC power supply AC power supply DC power supply

Rated Voltage 24 VDC 100 - 240 VAC 24 VDC 100 - 240 VAC 24 VDC

Permissible Range

of Voltage

24 VDC ±10%

Permissible

Momentary Power

Failure

Power Consumption

(Maximum Rating)

Power Supply

Rush Current 25 A, 0.7 ms

Within 1 ms Within 20 ms Within 1 ms Within 20 ms Within 1 ms

V708C

V708S/iS

15 W or

less

22 W or

DC external

Withstand Voltage

terminals to FG:

500 VAC,

1 minute

Insulation Resistance 500 VDC, 10 MΩ or above

Ambient

Temperature

Storage Ambient

Temperature

Ambient Humidity 85%RH or less (without dew condensation)

Solvent Resistance No cutting oil or organic solvent attached to the unit

Physical Environment

Atmosphere No corrosive gas or conductive dust

Vibration Resistance

Working

Shock Resistance

Conditions

Mechanical

Vibration frequency: 10 to 150 Hz, Acceleration: 9.8 m/s

Single amplitude: 0.075 mm, X, Y, Z: 3 directions for one hour

Pulse shape: Sine half wave

Peak acceleration: 147 m/s

Noise Resistance 1500Vp-p (pulse width 1 µs, rising time: 1 ns)

Static Electricity

Discharge

Working

Electrical

Conditions

Resistance

Grounding Grounding resistance: less than 100 Ω

Protection structure: front panel compliant with IP65 (when using gasket)

Structure

Form: in a body

Mounting procedure: inserted in a mounting panel

Cooling System Cooling naturally

Weight (kg) Unit: approx. 1.5 Unit: approx. 2.4 Unit: approx. 2.7

Dimensions

Mounting Conditions

W × H × D (mm)

Panel Cut-out (mm)

233 × 178 × 66.1 303.8 × 231.0 × 72.0 326.4 × 259.6 × 72.0

+0.5

220.5 ×

165.5

−0

Case Color Black (Munsell N2.0)

Material PC/PS resin (Tarflon)

less

+0.5

−0

100 - 240 VAC

±10%

24 VDC ±10%

100 - 240 VAC

±10%

24 VDC ±10%

60 VA or less 30 W or less 60 VA or less 30 W or less

For 100 VAC:

16 A, 6 ms

For 200 VAC:

32 A, 7 ms

AC external

terminals to FG:

1500 VAC,

1 minute

30A, 1 ms

DC external

terminals to FG:

500 VAC,

1 minute

For 100 VAC:

16 A, 6 ms

For 200 VAC:

32A, 7 ms

AC external

terminals to FG:

1500 VAC,

1 minute

30 A, 1 ms

DC external

terminals to FG:

500 VAC,

1 minute

0°C to +50°C

−10°C to +60°C

2

(1.0G)

2

(15G), X, Y, Z: 3 directions six times each

Compliant with IEC1000-4-2, contact: 6 kV, air: 8 kV

rear case: compliant with IP20

+0.5 +0.5

289.0 × 216.2 313.0 × 246.2

−0

+0.5

−0

+0.5

−0

1

Hardware Specifications

Page 27

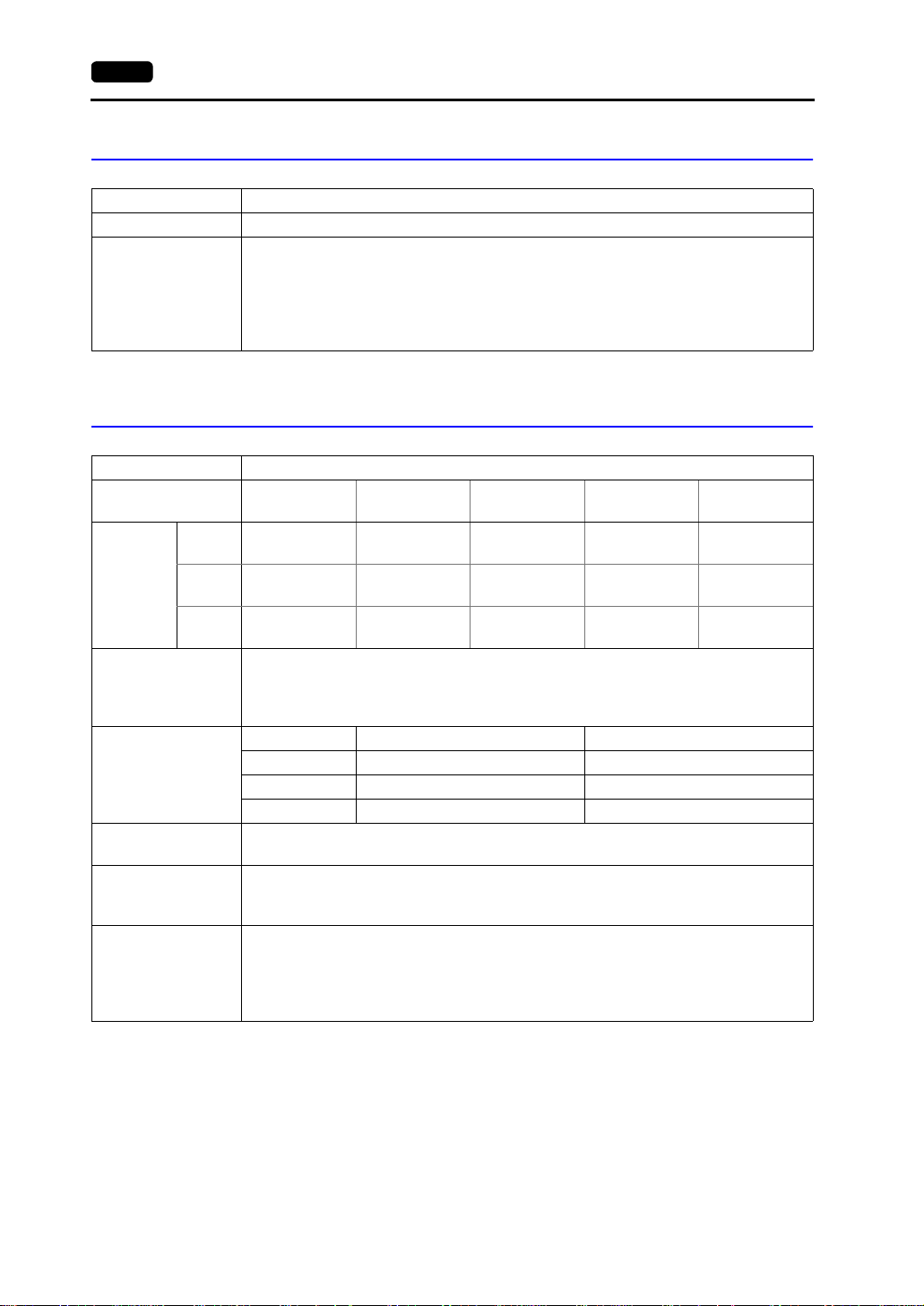

1-10 4. Specifications

Display Specificati ons

Model

Item

Display Device

Effective Display

Area

Colors

Resolution

W × H (dots)

Dot Pitch

W × H (mm)

Brightness (cd/m

Contrast Ratio 25 : 1 250 : 1 300 : 1 300 : 1 350 : 1

Angle of Vertical

Visibility (°)

Angle of Horizontal

Visibility (°)

Backlight Cold cathode rectifier (exchangeable by users)

Backlight Average

*1

Life

Backlight

Auto OFF Function

Contrast Adjustment P rovided

Brightness

Adjustment

Surface Sheet Material: Polycarbonate, 0.3 mm thick

POWER Lamp ON when the power is supplied

2

) 200 350 350 280 350

V708C V708S V708iS V710T V710iT V710S V710iS V712S V712iS

STN

color LCD

7.7-inch 8.4-inch 10.4-inch 12.1-inch

128 colors

+16-color blinks

640 × 480 800 × 600 640 × 480 800 × 600

0.246 × 0.246 0.213 × 0.213 0.33 × 0.33 0.264 × 0.264 0.3075 × 0.3075

+40, −30 +35, −55 +45, −55 +35, −45 +40, −45

±50 ±50 ±70 ±50 ±55

Approx.

40,000 h

Always ON, random setting

*2

Not provided 3 levels

TFT color LCD

32,768 colors

+16-color blinks

Approx. 50,000 h

Not provided

*2

*1 When the normal temperature is 25°C, and the surface luminance of the display is 50% of the

initial s e tting.

*2 Adjustable with function switches

Touch Panel Specifications

Item Specifications

Method Analog resistance film type

Switch Resolution 1024 (W) × 1024 (H)

Mechanical Life One million activations or more

Surface Treatment Hard-coated, anti-glare treatment 5%

Page 28

4. Specifications 1-11

Function Switch Specifications

Item Specifications

Number of Switches 8

Method Pressure sensitive

Mechanical Life One million activations or more

Interface Specifications

Item Specifications

Serial Interface for PLC

Connection

(D-sub 25-pin, female)

Serial Interface 1, 2 for Screen

Data Transfer/External

Connection

(Modular jack, 8-pin)

Printer Interface for Printer

Connection

CF Card Interface Compliant with CompactFlash

10BASE-T for Ethernet

Connection

(Standard with V7i)

RS-232C, RS-422/485

Asynchronous type

Data length: 7, 8 bits

Parity: even, odd, none

Stop bit: 1, 2 bits

Baud rate: 4800, 9600, 19200, 38400, 57600, 76800, 115 kbps

RS-232C, RS-422/485 (2-wire connection)

CREC, Barcode, V-I/O, Multi-link 2,

Temperature control network/PLC2Way, V-link, etc.

Compliant with Centronics, half-pitch 36-pin

NEC: PR201

EPSON: ESC/P-J84, ESC/ P super func ti on, ESC / P24-J 84

CBM292/293 printer

Barcode printer MR400

Compliant with IEEE802.3

Baud rate: 10 Mbps

Cables: 100 Ω unshielded twist-pair,

Category 5, maximum length = 100 m

*1

1

Hardware Specifications

, HP PCL Level 3

TM

*1 The CBM292/293 printer cannot print screen hard copies.

Clock and Backup Memory Specifications

Item Specifications

Battery Specification Coin-type lithium primary cell

Battery type: Sanyo CR2450-CN21

Backup Memory SRAM 64 kbyte

Backup Time Period 5 years (ambient temperature at 25°C)

Battery Voltage Drop Detection Provided (internal memory allocated)

Calendar Accuracy Monthly deviation ±90 sec (ambient temperature at 25°C)

Page 29

1-12 4. Specifications

Drawing Environment

Item Specifications

Drawing Method Exclusive drawing software

Drawing Tool Name of exclusive drawing software: V -SFT (Ver. 2.00 and later)

Personal computer: Pentium II 450 MHz or above recommended

OS: Windows98/Me/NT Ver. 4.0/2000/XP

Capacity of hard disk required: Free space of approx. 460 Mbyte or more

Display: Resolution 800 × 600 or above recommended

(For minimum installation: approx. 105 Mbyte)

Display Function Specifications

Item Specifications

Display Language* Japanese English/

Characters 1/4-size

1-byte

2-byte

16-dot

2-byte

32-dot

Character Size 1/4-size: 8 × 8 dots

Number of

Displayable

Characters

Characters

Properties

Graphics Lines: Line, continuous line, box, parallelogram, polygon

Graphic Properties Line types: 6 (thin, thick, dot, chain, broken, two-dot chain)

ANK code Latin 1 ASCII code ASCII code ASCII code

JIS #1, #2 level −−−− Chinese

JIS #1 level −−−− −−−− −−−− −−−−

1-byte: 8 × 16 dots

2-byte: 16 × 16 dots or 32 × 32 dots

Enlarge: W: 1 to 8 times, H: 1 to 8 times

Resolution 640 × 480 800 × 600

1/4-size 80 columns × 60 lines 100 columns × 75 lines

1-byte 80 columns × 30 lines 100 columns × 37 lines

2-byte 40 columns × 30 lines 50 columns × 37 lines

Display properties: Normal, reverse, blink, bold, shadow

Colors: 32,768 colors + blink 16 colors (V708C: 128 colors + blink 16 colors)

Circles: Circle, arc, sector, ellipse, elliptical arc

Others: Tile patterns

Tile patterns: 16 (incl. user-definable 8 patterns)

Display properties: Normal, reverse, blink

Colors: 32,768 colors + blink 16 colors (V708C: 128 colors + blink 16 colors)

Color selection: Foreground, background, boundary (line)

European

Chinese Chinese

(Simplified)

Chinese

(simplified)

Korean

Hangul

(without Kanji)

* Refer to the Reference Manual (Operation) for HK fonts.

Page 30

4. Specifications 1-13

Function Performance Specifications

Item Specifications

Screens Max. 1024

Screen Memory Flash memory: Appox. 4,992 kbyte (varies depending on the font)

Switches 768 per screen

Switch Actions Set, reset, momentary, alternate, to light

(Possible to press a function switch and a display switch at the same time)

Lamps Reverse, blink, exchange of graphics

Graphs Pie, bar, panel meter and closed area graph: No limitation within 256 kbyte

Numerical Data Display No limitation within 256 kbyte per screen *

Character Display No limitation within 256 kbyte per screen *

Message Display Resolution: 640 × 480, max. 80 characters (1-byte)

Data Setting

Sampling Sampling display of buffer data

Graphic Library Max. 1024

Multi-Overlaps Max. 1024

Data Blocks Max. 2560

Messages Max. 6144 lines

Patterns Max. 1024

Macro Blocks Max. 1024

Page Blocks Max. 1024

Direct Blocks Max. 1024

Screen Blocks Max. 1024

Data Sheets Max. 1024

Screen Library Max. 1024

Animation (Frames) Max. 1023

Temperature Control Network/

PLC2Way Table

Time Display Time display function: provided

Hard Copy Screen hard copy function: provided

Buzzer Buzzer: provided, 2 sounds (short beep, long beep)

Auto OFF Function Always ON, random setting

Self-diagnostic Function Switch self-test function

768 per screen

per screen *

Statistics and trend graphs: Max. 256 per layer *

1

1

800 × 600, max. 100 characters (1-byte)

No limitation within 256 kbyte per screen *

(Constant sample, bit synchronize, bit sample, relay sample, alarm function)

Max. 32

Communication parameter setting check function

Communication check function

1

1

2

1

Hardware Specifications

*1 The number of setting memory locations is limited to 1024 per screen.

*2 Layer: 4 per screen (base + 3 overlaps)

Page 31

1-14 5. Dimensions and Panel Cut-out

5. Dimensions and

Panel Cut-out

V708/V708i External View and Dimensions

(Unit: mm)

• Side View • Front View

66.1

233

165

POWER

6.6

• Rear View • Bottom View

220

165

CN6

See operating or maintenance

instruction for type of battery

to be used.

Battery replacement.

24VDC

- +

MJ1

PRINTER

CN5

CN1

MJ2

MEMORY

LAN

CF

220

24.3

SYSTEM

F1

F2

F3

F4

F5

F6

F7

178

• Panel Cut-out Dimensions

+0.5

220.5

-0

+0.5

-0

165.5

Page 32

5. Dimensions and Panel Cut-out 1-15

V710/V710i External View and Dimensions

(Unit: mm)

• Side View • Front View

72

8

215.2

POWER

• Rear View • Bottom View

288.0

303.8

SYSTEM

1

Hardware Specifications

F1

F2

F3

F4

F5

F6

F7

231

215.2

100-240VAC

L N

CN6

CN5

LAN

MEMORY

See operating or maintenance

instruction for type of battery

to be used.

Battery replacement.

MJ1 MJ2

CN1

CF

PRINTER

288.0

35.2

• Panel Cut-out Dimensions

+0.5

289

-0

+0.5

-0

216.2

Page 33

1-16 5. Dimensions and Panel Cut-out

V712/V712i External View and Dimensions

(Unit: mm)

• Side View • Front View

72

8

326.4

245.2

259.6

SYSTEM

• Rear View • Bottom View

312

CN6

CN5

MEMORY

See operating or maintenance

instruction for type of battery

to be used.

Battery replacement.

CF

245.2

PRINTERMJ2MJ1

100-240VAC

L N

CN1

LAN

63.8

F1

F2 F3

POWER

F4

F5 F6 F7

312

• Panel Cut-out Dimensions

+0.5

313

-0

+0.5

-0

246.2

Page 34

6. Names and Functions of Components 1-17

6. Names and Functions of

Components

V708/V708i

13

LAN

MEMORY

CF

14

1

8

4

POWER

2

10

SYSTEM

3

F1

F2

F3

F4

F5

F6

F7

12

15

11

CN6

See operating or maintenance

instruction for type of battery

to be used.

Battery replacement.

24VDC

- +

CN5

PRINTER

MJ1

CN1

MJ2

1

Hardware Specifications

V710/V710i

4

6

7

5

13

POWER

2

10

56 789

SYSTEM

9

11 12 13

CN6

F1

F2

F3

F4

F5

F6