Page 1

EPSON

EPSON

EPSON France S.A.

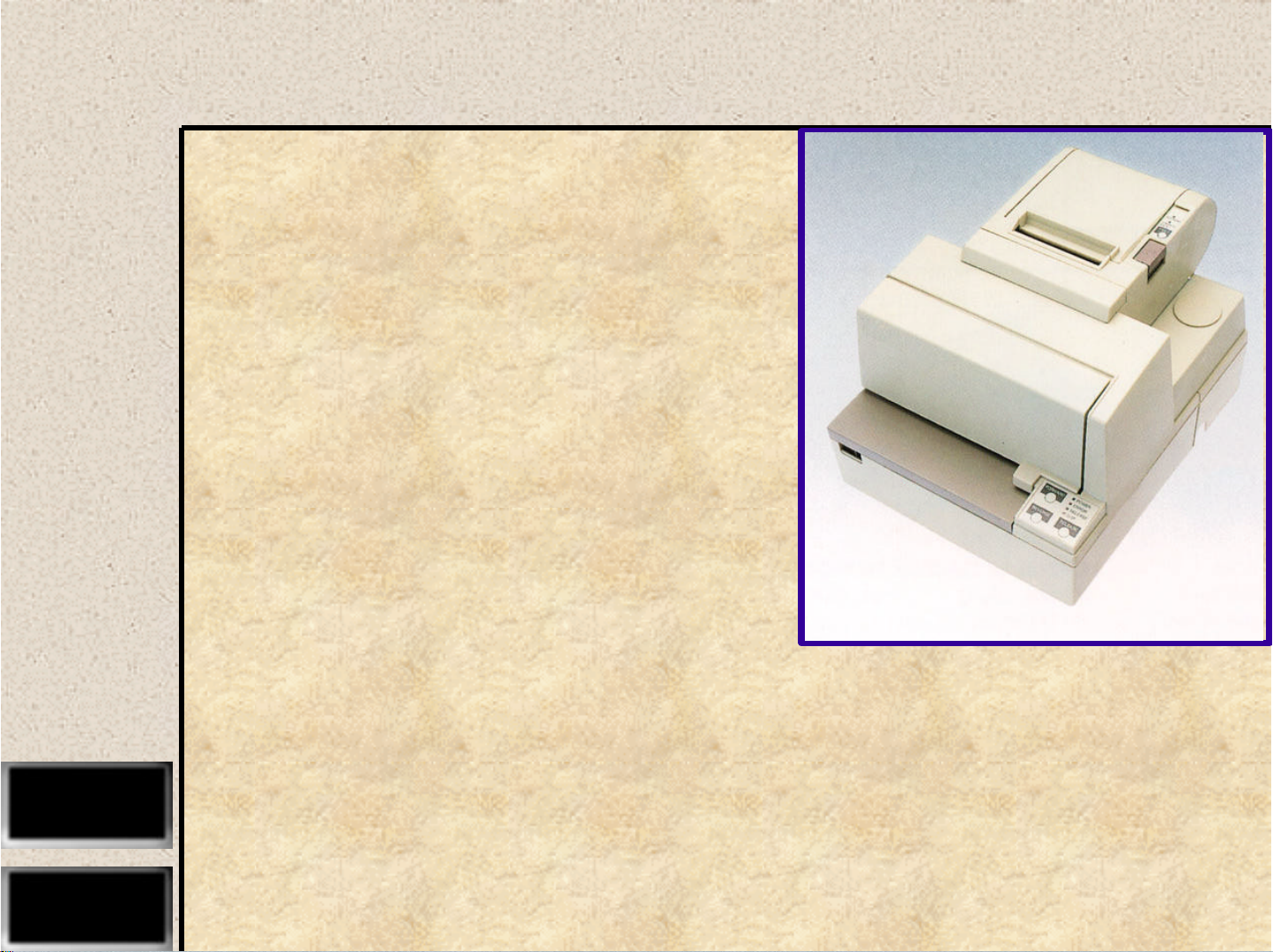

TM-H5000II

SERVICE MANUAL

Page 2

Confidential

technical manual

TM-H5000II Series

Copied Date 199 , ,

Copied by

EPSON

English

4008612

Page 3

Confidential

CONFIDENTIALITY AGREEMENT

BY USING THIS DOCUMENT, YOU AGREE TO ABIDE BY THE TERMS OF THIS

AGREEMENT. PLEASE RETURN THIS DOCUMENT IMMEDIATELY IF YOU DO NOT AGREE

TO THESE TERMS.

1. This document contains confidential, prop rietary informat ion of Seiko Epson Corporation or

its affiliates. You must keep such information confidential. If the user is a business entity or

organization, you must limit disclosure to those of your employees, agents and contractors

who have a need to know and who are also bound by obligations of confidentiality.

2. On the earlier of (a) termination of your relationship with Seiko Epson, or (b) Seiko Epson’s

request, you must stop using the confidential information. You must then return or destroy

the information, as directed by Seiko Epson.

3. If a court, arbitrator, government agency or the like orders you to disclose any confidential

information, you must immediately notify Seiko Epson. You agree to give Seiko Epson

reasonable cooperation and assistance in resisting disclosure.

4. You may use confidential information only for the purpose of operating or servicing the

products to which the document relates, unless you obtain the pr ior written consent of Seik o

Epson for some other use.

5. Seiko Epson warrants that it has the right to disclose the confidential information. SEIKO

EPSON MAKES NO OTHER WARRANTIES CONCERNING THE CONFIDENTIAL

INFORMATION OR ANY OTHER INFORMATION IN THE DOCUMENT, INCLUDING

(WITHOUT LIMITATION) ANY WARRANTY OF TITLE OR NON-INFRINGEMENT.

Seiko Epson has no liability for loss or damage arising from or relating to your use of or

reliance on the information on the document.

6. You may not reproduce, store or transmit the confidential information in any form or by any

means (electronic, mechanical, photocopying, recording, or otherwise) without the prior

written permission of Seiko Epson.

7. Your obligations under this Agreement are in addition to any other legal obligations. Seiko

Epson does not waive any right under this Agreement by failing to exercise it. The laws of

Japan apply to this Agreement.

Page 4

Confidential

TM-H5000II SeriesTechnical Manual

FCC CLASS A

FCC Compliance Statement

For American Users

This equipment has been tested an d found to comply wi th the limits for a Class A dig ital dev ice, purs uant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the FCC Verification of this

device and may cause interference levels which exceed the limits established by the FCC for this equipment.

You are cautioned that changes or modifications not expr essly approved by the party respon sible for compliance could

void your authority to operate the equipment.

FOR CANADIAN USERS

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment regulations.

Cet appareil numérique de la classe A respecte toutes les exdgences du Règlement sur le matériel brouilleur du

Canada.

GEREÄUSCHPEGEL

Gemäß der Dritten Ve rordr ung z um Ger ätesi ch erheit sgecsetz (Masc hinen lärminf orm ation s- Vero rdnun g-3. GS GV) i st

der arbeitsplatzbezogene Geräusch-Emissionswert kleiner als 70 dB(A) (basierend auf ISO 7779).

Modular type connectors

You see the following caution label near the modular type connectors on the back panel of the

product.

Caution:

The product uses a modular type connector exclusively for the DM display. Never plug a

telephone line into this connector.

Rev. A i

Page 5

Confidential

Introduction

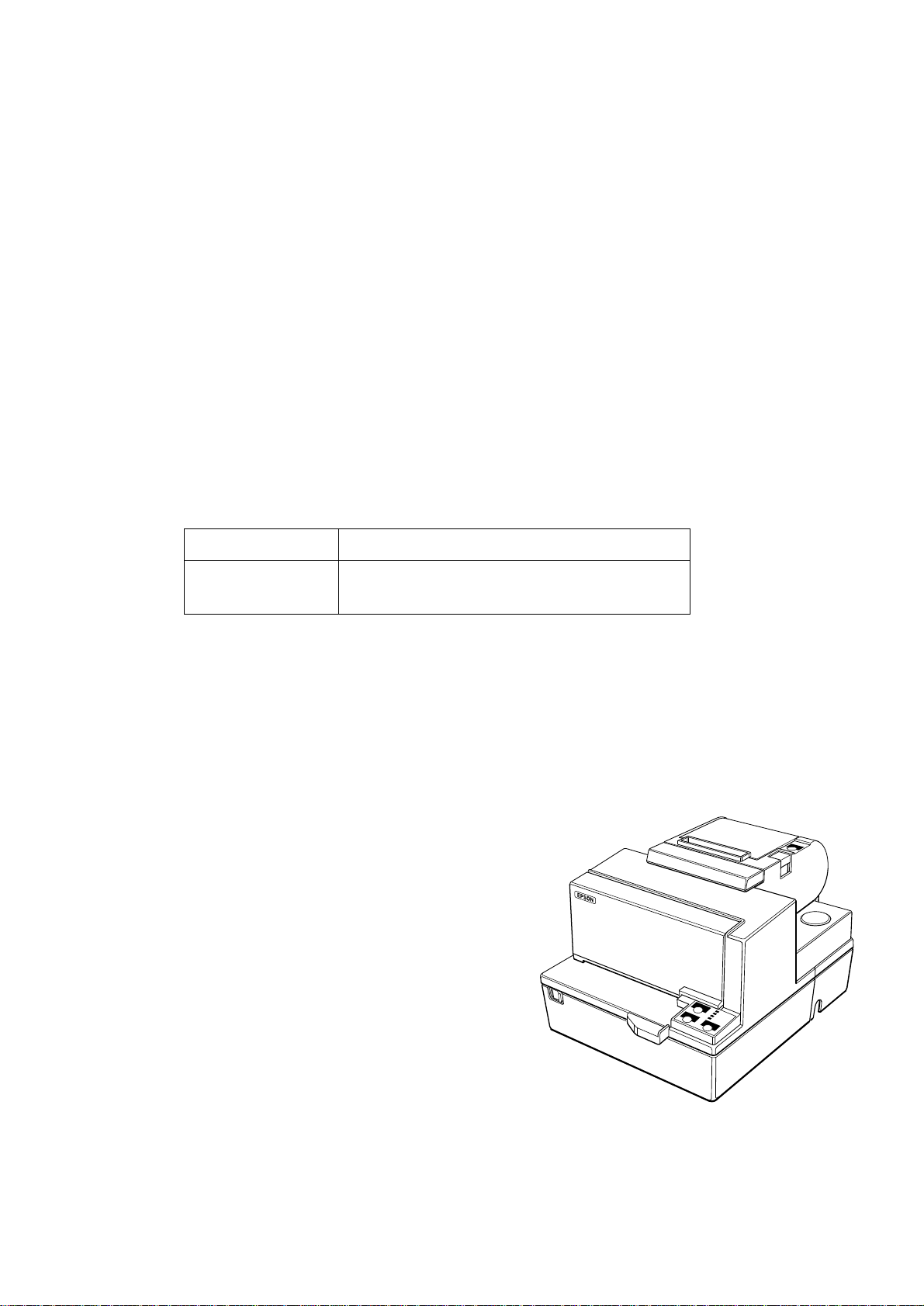

The TM-H5000II Series is a high-quality POS printer that can print on slip and receipt paper (paper roll). The printer

has the following features:

Slip Section

❏

Wide slip paper capability (maximum characters per line: 88 with 7 x 9 font).

❏

Copy printing is possible.

❏

High throughput using bidirectional, minimum distance printing.

❏

Optional Magnetic Ink Character Recognition (MICR) reader that enables the printer to

perform consecutive reading and processing of MICR characters and printing

endorsements.

Receipt Section

❏

High speed printing with collective printing.

❏

The standard auto-cutter provides easy user operation.

❏

Ladder bar code printing is possible by using a bar code command.

❏

New paper handling enables easy paper roll loading.

Both Receipt and Slip

❏

EPSON customer display series connection (DM-D102-012/DM-D203-012). (Available only

for serial interfac e model.)

❏

Selectable receive buffer size (45 bytes or 4K bytes).

❏

Command protocol based on the ESC/POS

❏

Automatic status Back (ASB) function that automatically transmits changes in the printer

status.

❏

Available non-volatile bit image buffer (384K bytes).

®

standard.

ii Rev. A

Page 6

Confidential

Warnings, Cautions and Notes

WARNING:

Warnings must be followed carefully to avoid bodily injury.

CAUTION:

Cautions must be observed to avoid damage to your equipment.

Note:

Notes have important information and useful tips on the operation of your printer.

Rev. A iii

Page 7

Confidential

Revision Sheet

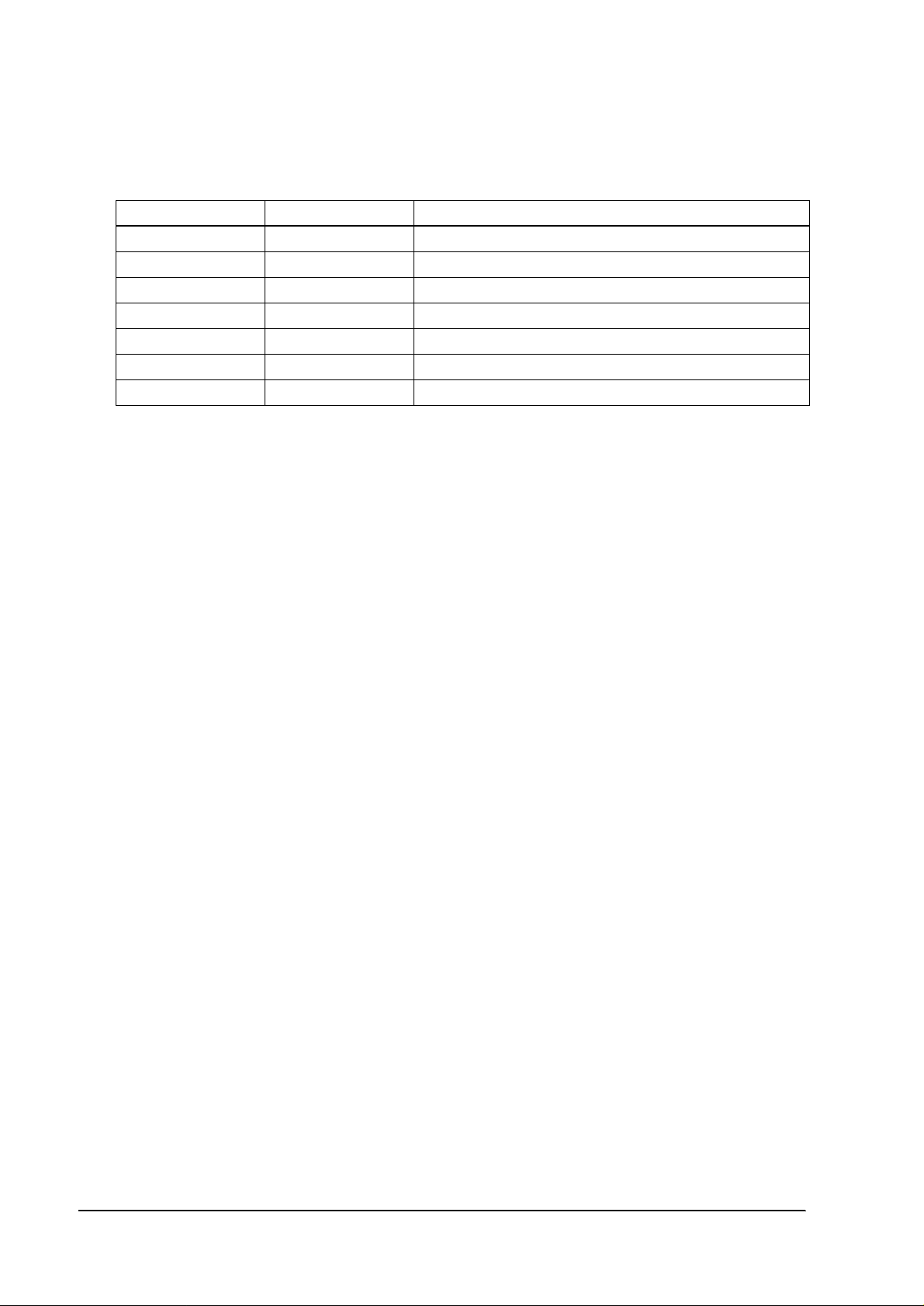

Revision Page Altered Item and Contents

Rev. A

iv Rev. A

Page 8

Confidential

Contents

Chapter 1

Printer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Slip Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Character Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Paper Feed and Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

MICR Reader (when the printer is used with the MICR reader) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Notes on using the MICR reader (only when the printer is used with MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Receipt Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Character Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Auto Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Paper Roll Supply Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 9

Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Printing and Cutting Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

General Section (for both receipt and slip) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Internal Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

EMI and Safety Standards Applied (EMC is tested using the EPSON PS-170 power supply) . . . . . . . . . . . . . . 1-13

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Major Component Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

M-U590 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

M-T88II Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Drawer Kick-out Connector (Modular Connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Customer Display Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

RS-232 serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Notes on setting DIP switch 2-1 to ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Notes on Resetting the Printer Using the Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Buttons and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Panel Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Buffer Full Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Hexadecimal Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Hexadecimal Dumping Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Performing a Hexadecimal Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Ending hexadecimal dumping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Paper Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Sensors and LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Sensors and Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Printer Cover Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

External Power Supply PS-170 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Features and General Specifications

Rev. A v

Page 9

Confidential

Chapter 2

Component Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

M-U590 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Detector Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Ribbon Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

MICR Reader Mechanism (Factory Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

M-T88II Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Paper Supply Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Cutter Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Cover Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Display Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Main Circuit Board Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

CPU and CPU Peripheral Logic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

M-U590 Control Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

M-T88II Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Control Panel Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

DIP Switch Read Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Malfunction Protection Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Customer Display Interface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Drawer Kick Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Power Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

I/F Circuit Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

I/F Circuit Board Assembly Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Interface Board Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Switchboard A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Switchboard B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

Intermit Circuit Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Mechanisms and Operation

Chapter 3

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transport Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setup Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operational Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Printing on Slip Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Check Paper Magnetic Character Recognition (MICR READER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Installing and Removing the Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Problem Solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Clearing a Receipt Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Clearing a Slip or Check Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Lubrication Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Type of Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Handling, Maintenance, and Repairs

vi Rev. A

Page 10

Confidential

Chapter 4

Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Performing the Receipt Mechanism Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Performing the Slip Mechanism Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Self-test End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Error Types and Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Error types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Chapter 5

Before starting disassembly, assembly, and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Small Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Titles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Disassembly, Assembly, and Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Names of Parts and Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

TM-H5000II Disassembly, Assembly, and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Level 1 Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Level 2 Disassembly and Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

M-U590 Printer Mechanism Disassembly, Assembly, and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Level 1 Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Level 2 Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Level 3 Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

Level 4 Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

M-T88II Printer Mechanism Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Level 1 Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Level 2 Disassembly and Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-94

Troubleshooting Guide

Disassembly, Assembly, and Adjustment

Appendix

Updating the Flash ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

The way to update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

IEEE 1284 Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

RS-485 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

XON/XOFF Transmit Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Data Format When Using RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Main Circuit Board Unit Parts Layout (parts side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Main Circuit Board Unit Parts Layout (solder side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

RS-232 Serial Interface Circuit Board Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

IEEE 1284 Parallel Interface Circuit Board Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

RS-485 Serial Interface Circuit Board Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Intermit Circuit Board Assembly Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Switch Circuit Board Assembly-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Switch Circuit Board Assembly-B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Case Unit Parts Name List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

M-U590 Printer Mechanism Parts Name List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

M-T88II Printer Mechanism Parts Name List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

Overall Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-25

Case Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-25

M-U590 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-26

M-T88II Printer Mechamism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

Lubrication Points Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

M-U590 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

M-T88II Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

Circuit Board Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

Rev. A vii

Page 11

Confidential

Main Circuit Board Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-30

I/F circuit Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-40

Intermit Circuit Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-44

Switch circuit board assembly-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-45

Switch circuit board assembly-B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-46

viii Rev. A

Page 12

Chapter 1

Confidential

Features and General Specifications

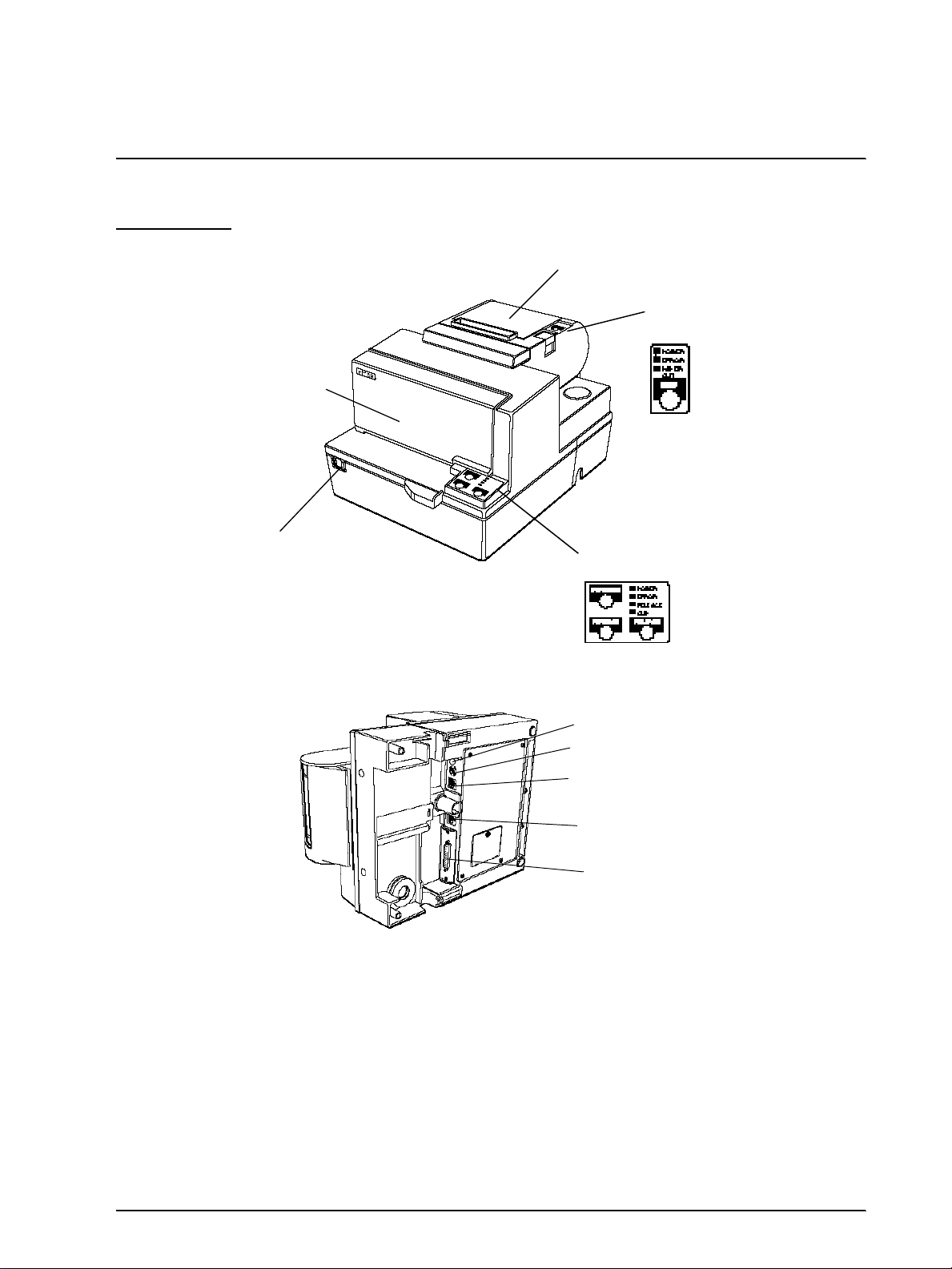

Printer Parts

Paper roll cover

Front cover

TM-H5000II Series Technical Manual

Paper roll

control panel

On/Off switch

Slip paper

control panel

Grounding screw

Power supply connector

Drawer kick-out connector

Display module connector

Interface connector

Rev. A Features and General Specifications 1-1

Page 13

Slip Section

Confidential

Printing Specifications

Printing method: Serial impact dot matrix

Head wire configuration: 9-pin vertical line, wire pitch 1/72 inch

Head wire diameter: 0.29 mm (.01")

Printing direction: Bidirectional, minimum distance printing

Character Specifications

Number of characters: Alphanumeric characters: 95

Internati onal charac ters: 32

Extended graphics: 128 × 10 pages

(including one space page)

Kanji characters: JIS Level 1, Level 2

(JIS X0208−1990)

(with two-pass printing)

Character structure: Font A: 9 × 9 3-dot spacing (in half dot units)

Font B: 7 × 9 2-dot spacing (in half dot units)

Kanji: 16× 16 Left 0-dot, Right 2-dot spacing (in half dot

units)

Larger spacing can be set by using ESC SP or FS S.

Characters per inch, characters per second, characters per line, character size

Character Structure

(Horizontal dots

×

vertical dots)

9 × 9 3 dots 12.5 233 66 1.6 × 3.1 (.06" × .12")

7 × 9 2 dots 16.7 311 88 1.3 × 3.1 (.05" × .12")

16× 16 (*) 2 dots 3.06 45 44 2.7 × 2.9 (1.06" × 1.14")

Character

Spacing

(half dots)

Characters

Per Inch

(CPI)

Characters Per Second

(CPS)

(Carriage moving speed)

Characters

Per Line

(CPL)

Characters Size

(units: mm)

Width × Height

(*) Kanji character spacing at default setting is 2 half dots. (Kanji character spacing can be

changed by FS S.) Printing speed for kanji characters shown in table above is in the case of

full column printing with two-pass printing .

Ribbon

Type: Exclusive cassette ribbon

Ribbon cassette specifications: Part number: ERC-31 (P)

1-2 Features and General Specifications Rev. A

Color: Purple

Ribbon life (*): 7,000,000 characters

(*): when one character consists of 18 dots

Page 14

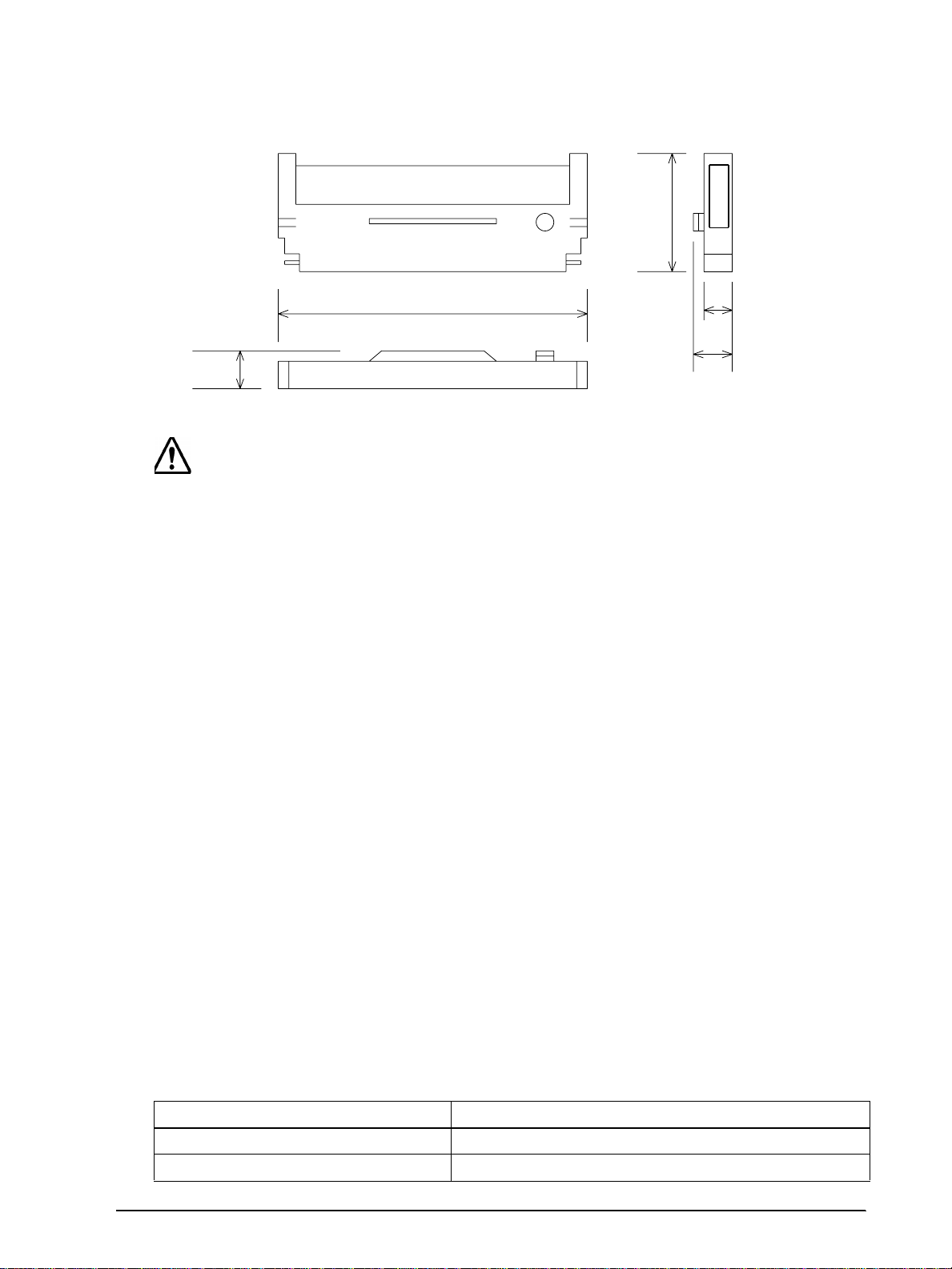

Ribbon cassette overall dimensions:

Confidential

TM-H5000II Series Technical Manual

85.5

200

28

Figure 1-1 Ribbon cassette overall dimensions

CAUTION

If you use ribbon cassettes other than t hose specifi ed, damage may occur. Seiko

Epson will not be held responsible for problems arising from the above.

Papaer Feed and Paper Specification

Paper feed method:

Paper feed pitch:

Paper feed speed:

Paper size:

Friction feed

Default 1/6 inch

Approximately 60.3 msec/line (1/6 inch feeding)

Approximately 3.4 inches/second (continuous feeding)

17

28

[ Units: mm (All the numeric values are typical.) ]

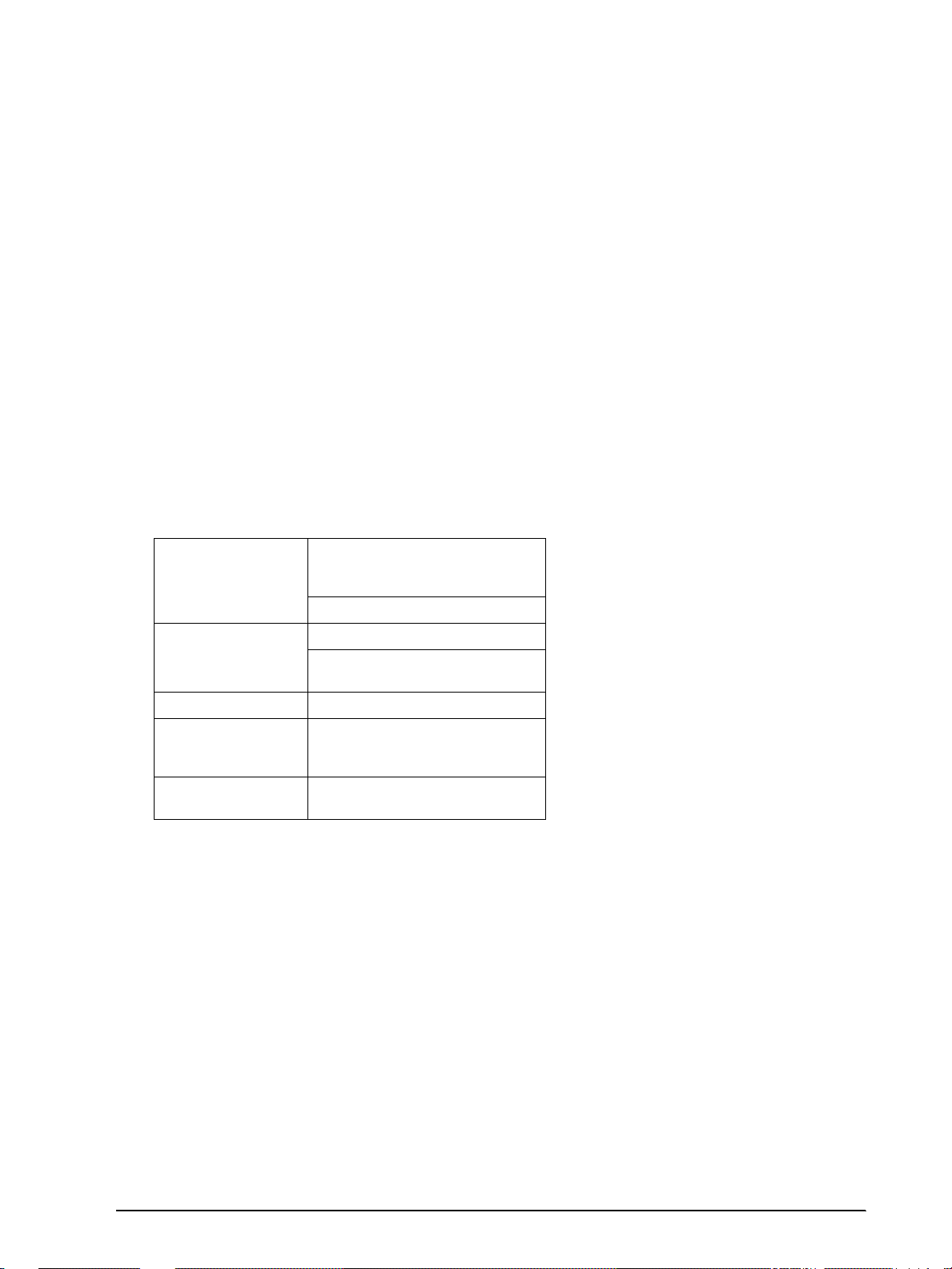

Relationship between ambient temperature and number of copies

Number of copies Ambient temperature

Original + 4 copies Approx. 20° to 45°C (68° to 113°F)

Original + 1 to 3 copies 5° to 45°C (41° to 113°F)

Rev. A Features and General Specifications 1-3

Paper type: ❏

Total thickness:

Size (W × L):

Ambient temperature and

copy capability

Normal paper

❏

Carbon copy paper

❏

Pressure sensitive paper

0.09 to 0.36 mm (.0035 to .0141")

70 mm × 70 mm to 210 mm × 297 mm (A4)

(2.76" × 2.76" to 8.27" × 11.69")

Copy capability is greatly influenced by the ambient

temperature, so printing must be performed under the

conditions described in the table below.

Page 15

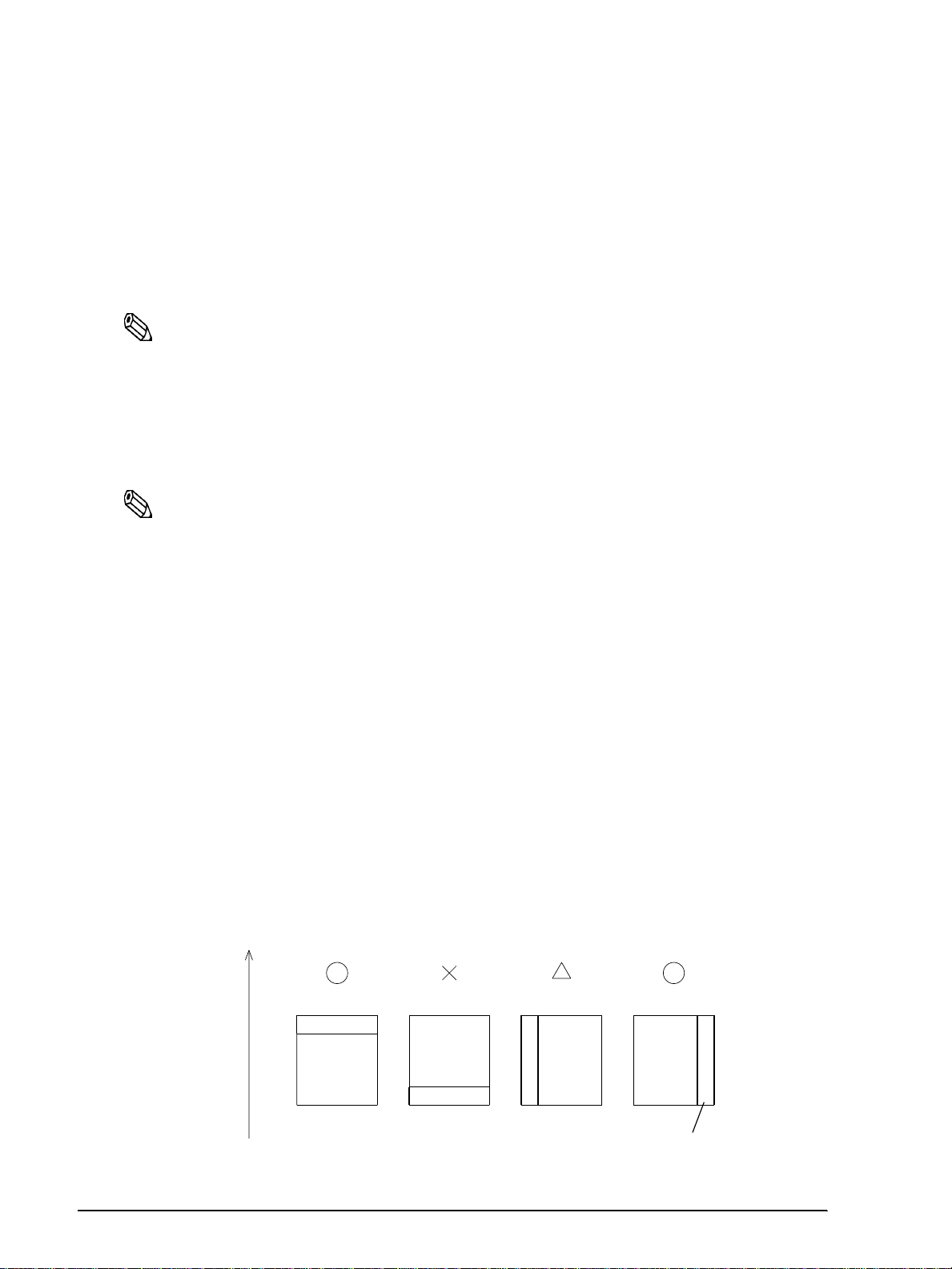

Copy capability and paper thickness:

Glued ponion

Paper feed direction

Confidential

Normal paper (single-ply): 0.09 to 0.2 mm (.0035 to .0079")

Carbon copy paper

combination:

Pressure sensitive paper: 5 sheets maximum [original + 4 copies, at 20° to 45°C

Note:

When using multi-ply paper that consists of an original and three copies, be sure to print with a 9 × 9

font. If a 7 × 9 font is used, some characters on some of the copies may not be readable.

In the same way, when printing Kanji characters which consist of many lines, be sure to consider that

some of characters may not be readable regardless of number of the copies.

Notes on slip paper

Notes:

❏ The slip paper must be flat, without curls or wrinkles, especially at the top edges.

Otherwise, the paper may rub against the ribbon and become dirty.

❏ There must be no glue on the bottom edge of slip paper. Choose slip paper carefully

when the glue is on the right or top edge, since paper feeding and insertion are affected

by gluing conditions (e.g., glue quality, method, and length) and glue location (refer to

the illustration below titled “Slip paper glued area”). Be especially careful when slip

paper is wide and has the glue on the left edge, since skewing may occur.

5 sheets maximum [original + 4 copies, at 20° to 45°C

(68° to 113°F)]

(68° to 113°F)]

❏ Since the slip insertion sensor uses a photo sensor, do not u se pap er that has hol es at the

sensor position, or is translucent (refer to the illustration in the next section titled “Slip

sensor position”).

❏ Since the slip ejection sensor uses a refl ective photo sensor and it detects from the back of

slip paper, do not use paper that has holes or dark portions with low reflection (less than

40% reflection) at the sensor position (refer to the illustration in the next section titled

“Paper holes and low reflection prohibited area”).

❏ Use thinner paper (N30 or equivalent) between the top and bottom sheets of multi-ply

paper. If thick paper is used, the copy capability is lowered.

Figure 1-2 Slip paper glued area

1-4 Features and General Specifications Rev. A

Page 16

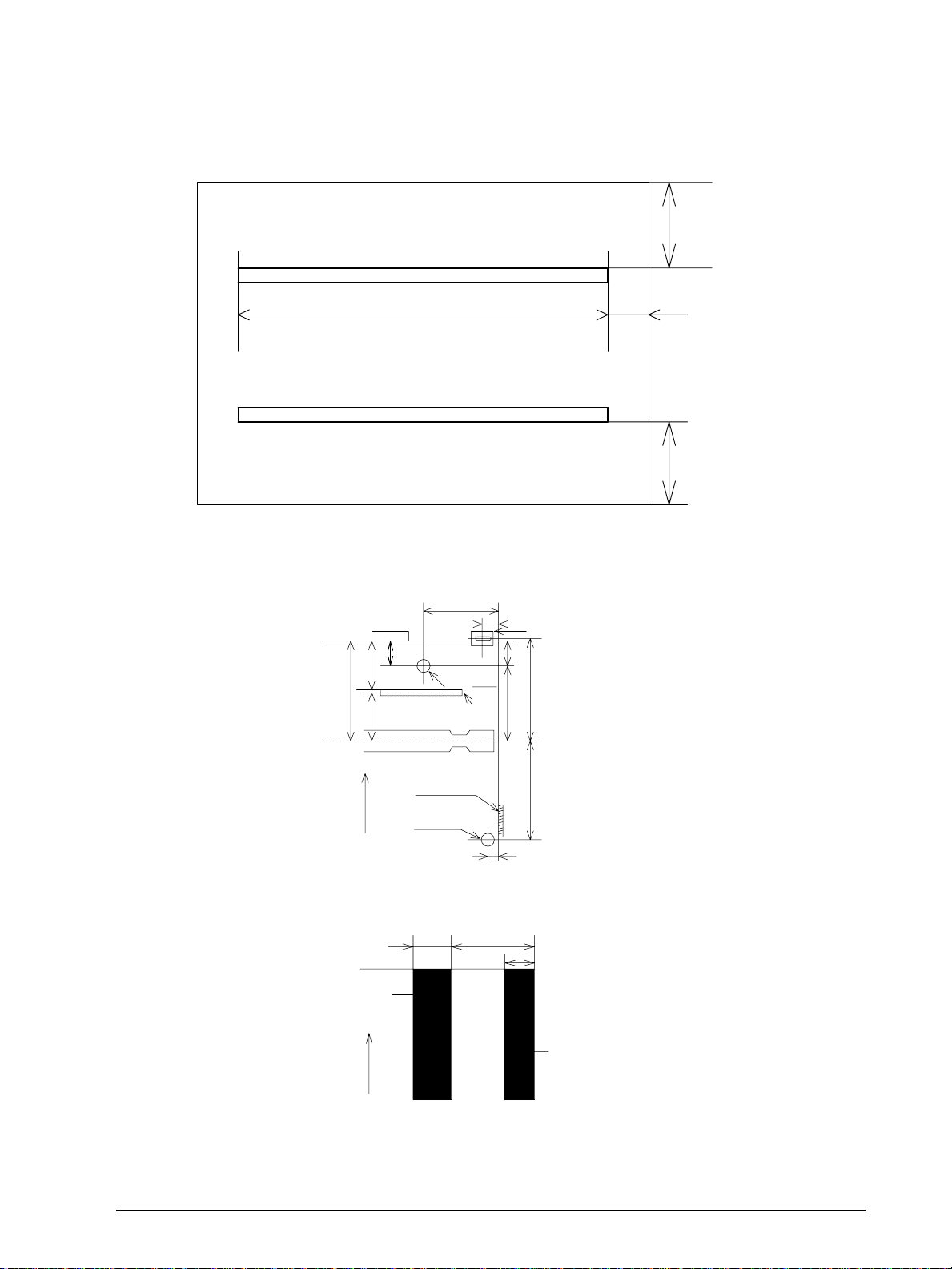

Printable Area

Confidential

ABC XYZ

TM-H5000II Series Technical Manual

Top margin

Top margin

18.9

18.9 +1/–3

135.6

abc xyz

[ Units: mm (All the numeric values are typical.)]

Figure 1-3 Slip paper printable area

30.1

31

1.3

Center of the print head

Slip side guide

BOF sensor

8

TOF sensor

position

MICR head

1.8

39

37.2

21.9

3.6

[Units: mm (All the numeric values are typical.)]

Form stopper position

38.5

Slip feeding roller

position

Paper feed direction

18.9

18

5.0

Bottom mar g in

Bottom margin

18.4 ± 2

18.4

Rev. A Features and General Specifications 1-5

Figure 1-4 Slip sensor position

Area where paper holes are prohibited

and reflection rate for the back of

paper should be 40% or more.

Paper feed direction

15 29

10

Paper holes and translucence

prohibited area.

[ Units: mm (All the numeric values are typical.) ]

Figure 1-5 Paper holes and low reflection prohibited area

Page 17

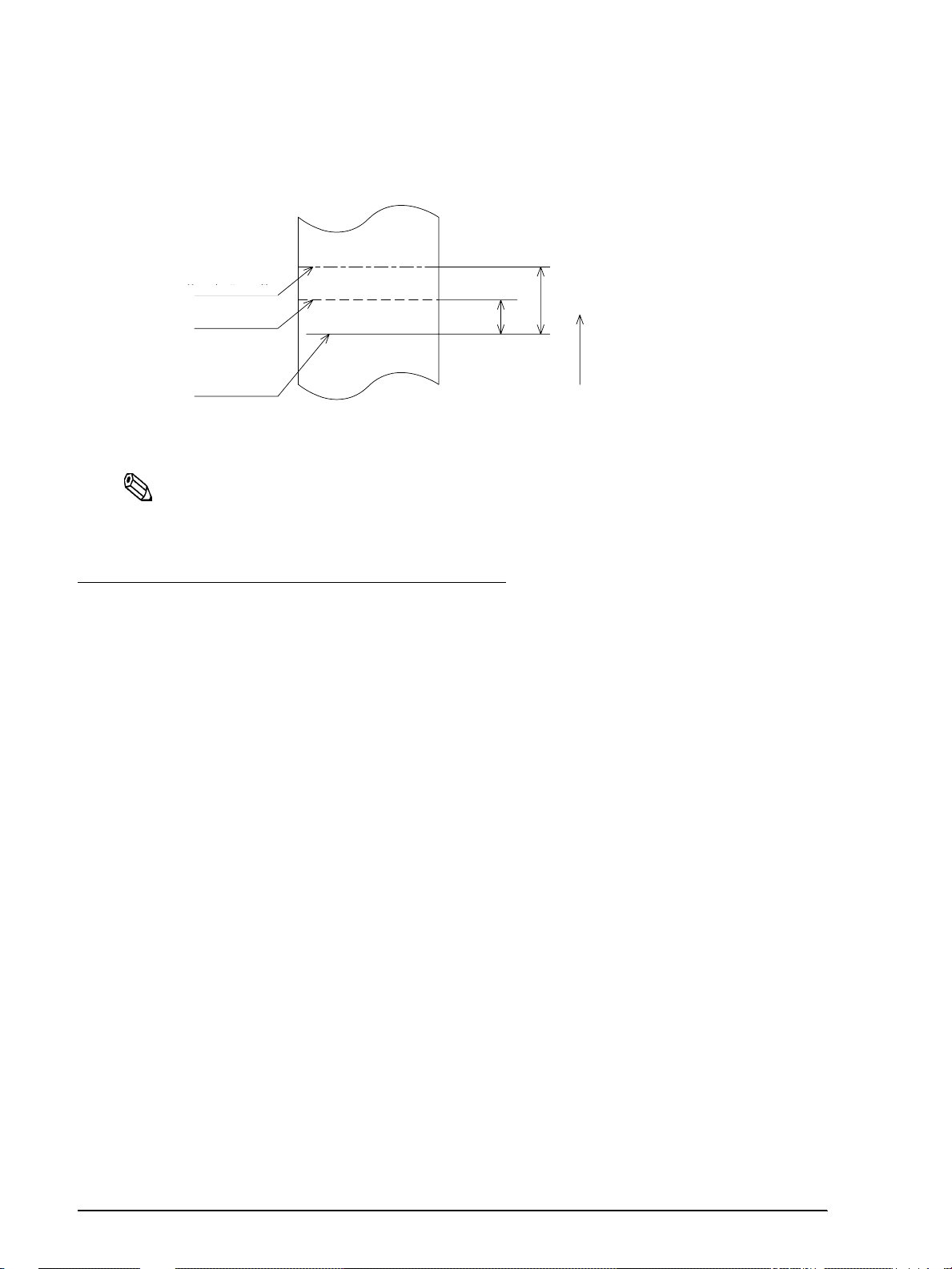

MICR Reader (when the printer is used with the MICR reader)

Confidential

Reading method: Magnetic bias

Recognition rating: 98 % or more (at 25°C [77°F])

Recognition rating is defined as follows:

Recognition rating (%) = [Total number of checks –

(number of sheets misread or not identified.)/Total

number of checks] × 100

❏ Check paper used for test is EPSON standard check

paper.

❏ Checks must be flat, without cu rl s, folds, or wri n kl es.

Inserting direction and

endorsement printing

38.1

Specified printing area

ENDORSE CHECK HERE :

"DO NOT SIGN WRITE STAMP BELOW THIS LINE

FOR FINANCIAL INSTITUTION USAGE ONLY"

Insert the check with the surface printed with the

magnetic ink downward, following the table guide.

Endorsement printing can be performed continuously

after check reading. In this case, the print starting

position is point A in the illustration below.

❏ To print endorsements in the specified area (within

38.1 mm [1.5"] from the top), set the print position for

the last line so t hat it is printed at least 3 mm (0.11 8")

above the bottom of the printable area.

8.7

A

3

1-6 Features and General Specifications Rev. A

Inserting direction

[Units: mm (All the numeric values are typical.)]

Figure 1-6 Endorsement printing

Page 18

TM-H5000II Series Technical Manual

Confidential

EPSON

TEST SAMPLE

Pay to the

order of

19

$

90-7172/132

3222

Area where recognition is impossible.

45.0

49.0 (1.9 3 ")

Dollars

9 2 5

[Units: mm ( All the numeric values are typical. )]

Figure 1-7 MICR character recognition impossible area of personal check

Notes on using the MICR reader (only when the printer is used with MICR)

Note:

The personal checks must be flat, without curls, folds, or wrinkles (especially at the edges).

Otherwise, the check may rub against the ribbon and become ink-stained.

WARNING

Do not insert checks that have clips or staples. This may cause paper jams, MICR reading errors,

and damage to the MICR head.

Note:

Let go of the check immediately as soon as the printer starts feeding it. Otherwise, the paper is not

fed straight, causing paper jams and MICR reading errors.

Rev. A Features and General Specifications 1-7

Page 19

Receipt Section

Confidential

Printing Specifications

Printing method: Thermal line printing

Dot density: 180 dpi × 180 dpi. The number of dots per 25.4 mm (1")

Printing direction: Unidirectional with friction feed

Printing width: 72 mm (2.83"), 512 dot positions

Characters per line (default): 42 (font A)

56 (font B)

Character spacing (default): 0.28 mm (.01") (2 dots) (font A)

0.28 mm (.01") (2 dots) (font B)

Programmable by control command.

Printing speed:

High speed mode: 28.4 lines/second maximum (1/6 inch feed)

(at 24V, 20°C, Density level 2)

120 mm/second maximum (approximately

4.72 inches/second)

Speeds are switched automatically depending on the

voltage applied to the printer and the head temperature.

Low power consumption

mode:

Paper feed speed: Approximately 120 mm/second (approximately 4.72

Line spacing (default): 4.23 mm (1/6 inch)

Approximately 16.5 lines/second (1/6 inch feed)

Approximately 70 mm/second (approximately 2.76

inches/second)

Approximately 42 mm/second (approximately 1.7

inches/second) when a ladder bar code is printed.

NOTE: Printing speed may be slower depending on the data

transmission speed and the combination of control

commands.

inches/second) (continuous printing)

Programmable by control command

1-8 Features and General Specifications Rev. A

Page 20

TM-H5000II Series Technical Manual

Confidential

Character Specifications

Number of characters:

Alphanumeric characters: 95

Extended graphics: 128 × 7 pages (including one space page)

Internati onal charac ters: 32

Kanji characters: JIS-Level 1, Level 2

( JIS X0208-1990)

Character structure: 12 × 24 (font A) (including 2-dot spacing in horizontal)

9 × 17(font B) (including 2-dot spacing in horizontal)

24 × 24 (Kanji)

Font A is selected as the default

Character size:

Character size

21

28

10

Double-width/

Double-height

2.82

× 6.77

× .27")

(.11"

1.98

× 4.80

× .19")

(.08"

6.77

× 6.77

× .27")

(.27"

Standard Double-height Double-width

× H (mm) CPL W × H (mm) CPL W × H (mm) CPL W × H (mm) CPL

W

Font A

12

× 24

Font B

9

× 17

Kanji

24

× 24

Space between characters is not included.

Characters can be scaled up to 64 times as large as the standard sizes.

CPL = Characters per line

1.41

(.06"

0.99

(.04"

3.39

(.13"

× 3.39

× .13")

× 2.40

× .09")

× 3.39

× .13")

42

56

21

1.41

(.06"

0.99

(.04"

3.39

(.13"

× 6.77

× .27")

× 4.80

× .19")

× 6.77

× .27")

42

56

21

2.82

(.11"

1.98

(.08"

6.77

(.27"

× 3.39

× .13")

×2.40

× .09")

×3.39

× .13")

Auto Cutter

Partial cut: Cutting with one point left uncut (selectable by GS V)

Note:

To prevent dot displacement, after cutting, paper must be fed approximately 1 mm (14/360

inches) or more before printing.

21

28

10

Paper Roll Supply Device

Supply method: Drop-in paper roll

Near-end sensor

Rev. A Features and General Specifications 1-9

Page 21

Detection method: Microswitch

Confidential

Paper roll spool diameter: Inside: 12 mm (.47")

Outside: 18 mm (.71")

Near-end adjustment: Adjusting screw

Remaining amount: Fixed position #1 (approximately 23 mm (0.9”))

#2 (approximately 27 mm (1.06”)

(The adjusting screw has two positions.)

Note:

You can use a command to stop printing upon detection of a paper near-end.

Paper Specification

Paper type: Specified thermal roll paper, NTP080-80

In Japan: Nakagawa, Seisakujo

In U.S.A.: Nakagawa Mfg. (USA) Inc.

In Europe: Nakagawa Mfg. (Europe) GmbH

In Southeast Asia: N.A.K. Mfg. (Malaysia) SDN BHD

Original paper: TF50KS E Nippon Paper Industries

Co.,Ltd.

The following paper can be used instead of the specified

paper above:

Original paper: PD 160R New Oji Paper Mfg. Co. Ltd.

Original paper: AF50KS-E Jujo Thermal Oy (Finland)

Original paper: P350 (F380) Kanzaki Specialty Papers,

Inc. (U.S.A.)

Form: Paper roll

Paper width: 79.5 ±0.5 mm (3.13" ± 0.02")

Paper roll size:

Roll diameter: Maximum 83 mm

Take-up paper roll width: 80 + 0.5/-1.0 mm (3.15" + 0.02"/-0.04")

Paper roll spool diameter: Inside: 12 mm (.47")

1-10 Features and General Specifications Rev. A

Outside: 18 mm (.71")

Page 22

TM-H5000II Series Technical Manual

a

b

c

de

Approximately 0.07mm (0.0028")

1 256

257 512

Confidential

CAUTION

Paper must not be pasted to the paper roll spool.

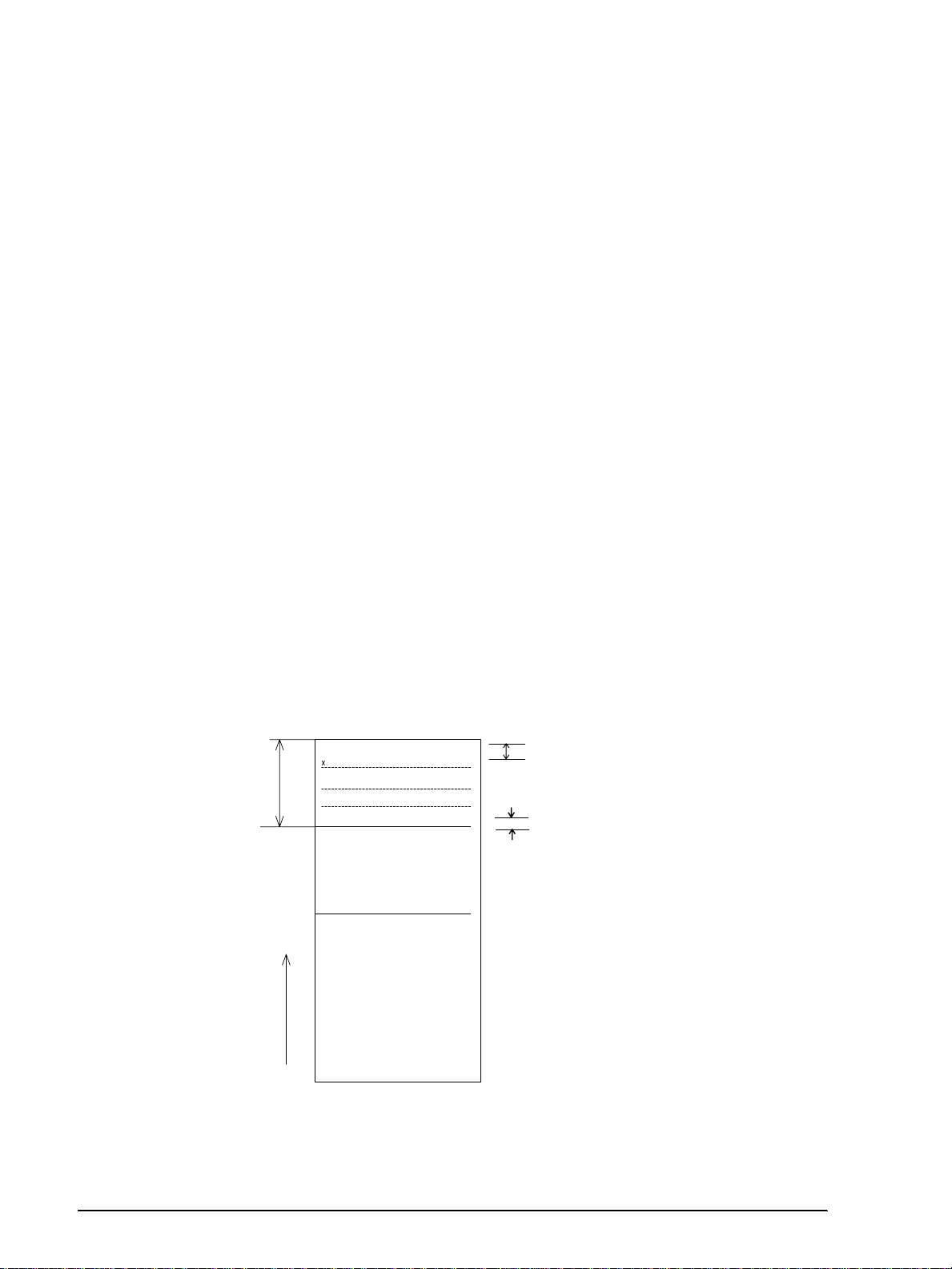

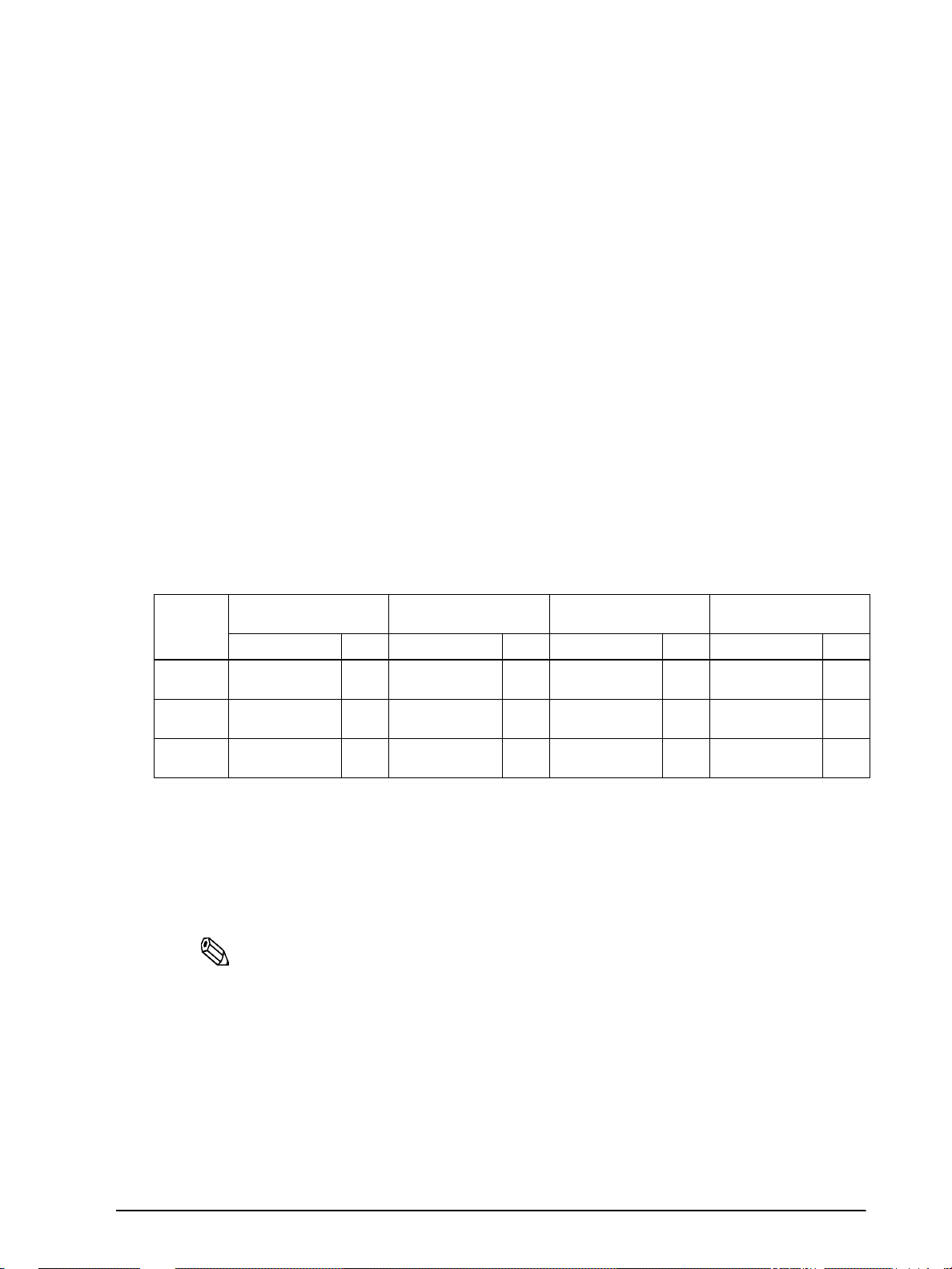

Printable Area

Paper roll The printable area of a paper wi th width of 79.5 ± 0.5 mm

(3.13" ± 0.02") is 72.2 ± 0.2 mm (2.84" ± 0.008") (512 dots)

and the space on the right and left sides are

approximately 3.7 ±2 mm (0.15" ± 0.079”).

a = 79.5 ± 0.5 mm (3.13" ± 0.02")

b = 1. 41 mm ± 0.05 mm (.056" ± .002")

c = 72.2 mm ± 0.2 mm (2.84 ± .008")

d = 3.7 ±2 mm (0.15" ± 0.079”)

e = 3.7 ±2 mm (0.15" ± 0.079”)

[All the numeric values are typical.]

Figure 1-8 Paper roll printable area

Note:

The print position within the printable area of the thermal elements for dots 257 to 512 is shifted

approximately 0.07 mm (.003") in the paper feed direction from the position for dots 1 to 256. Be

sure not to print a ladder bar code across both printable areas, as this can cause variations in

printing which are difficult to read. However, when the ladder bar code is printed with level 2 of

print density, the difference is only approximately 0.04 ~ 0.05mm (.0015 ~ .0019").

Approximately 0.07 mm (0.0028")

Figure 1-9 Shifting of the print position

Rev. A Features and General Specifications 1-11

Page 23

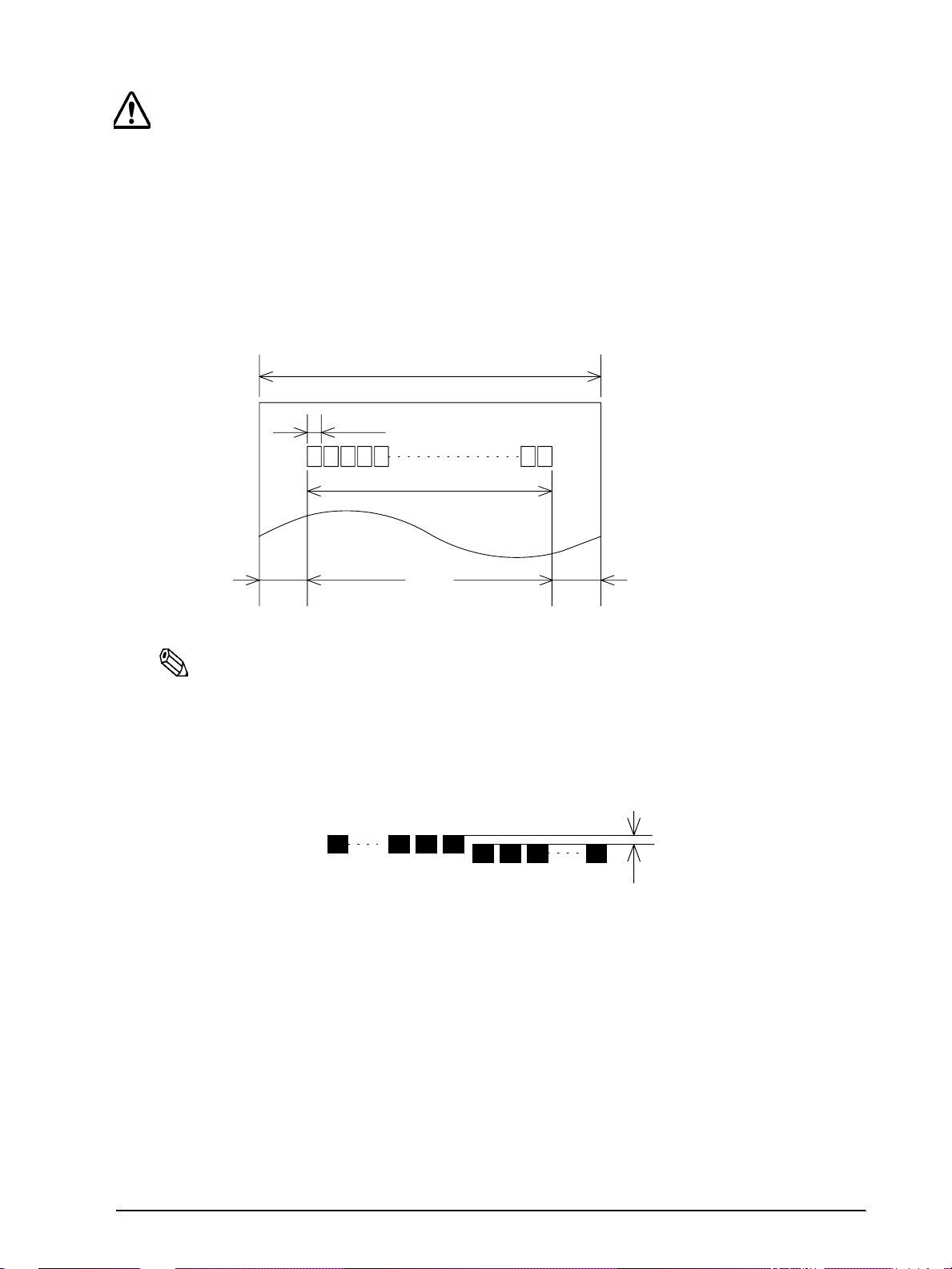

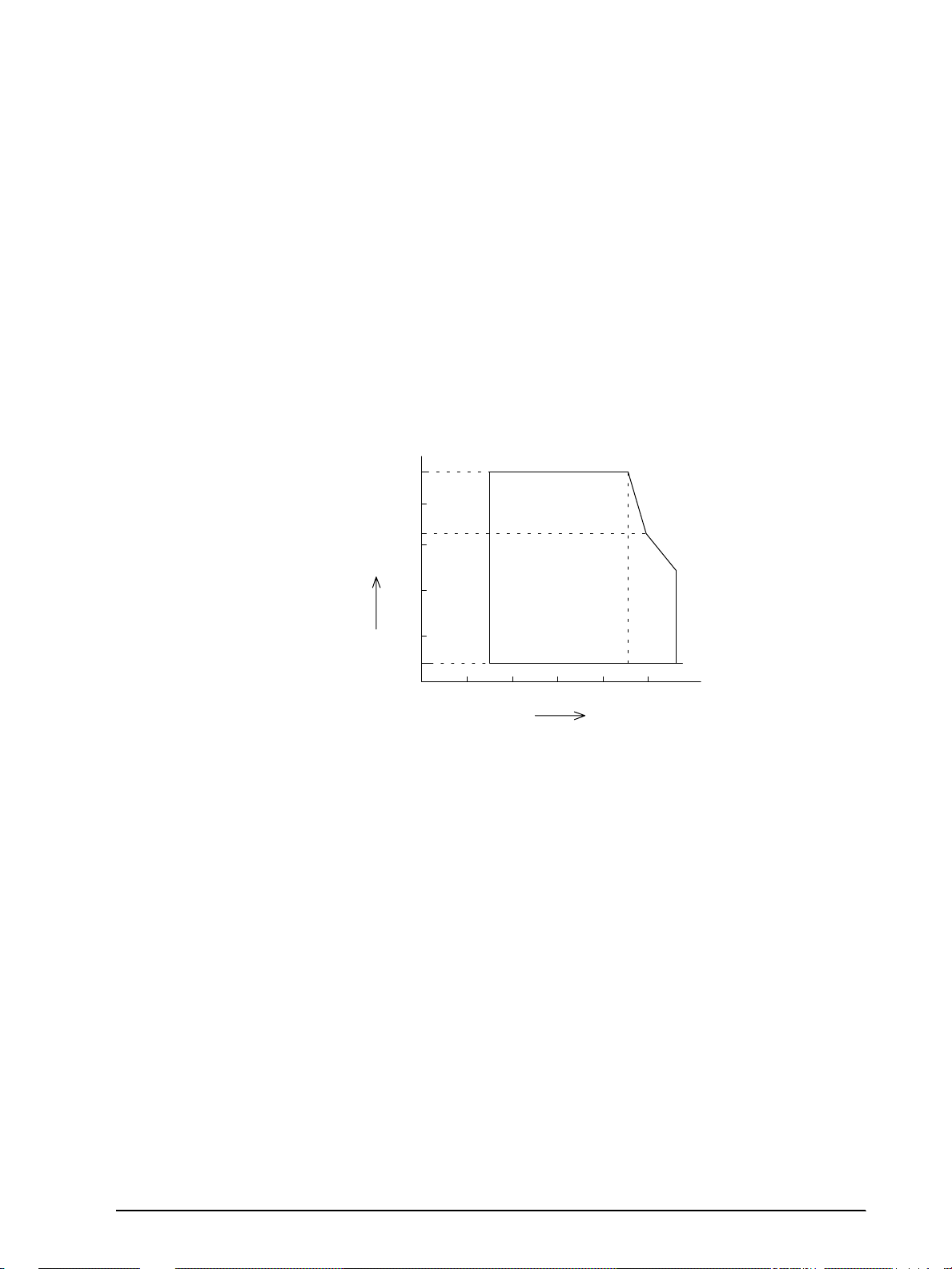

Printing and Cutting Positions

Paper feed direction

[ Units: mm (All the numeric values are typical.) ]

Center of the print dotline

Auto-cutter blade position

Manual-cutter position

14.8

26.3

Confidential

Manual-cutter position

Approx. 15

Approx.

29

Figure 1-10 Printing and cutting positions

Note:

Numeric values used here are typical values; the values may vary slightly as a result of paper slack

or variations in the paper.

General Section (for both receipt and slip)

Internal Buffer

Receive buffer selectable as 45 or 4K bytes using the DIP switch.

User-defined buffer (both for user-defined characters and user-defined bit images)

Receipt: 12K bytes Slip: 5K bytes

Macro buffer: 2K bytes

Non-volatile bit image buffer 384K bytes

Electrical Specifications

Supply voltage: +24 VDC ± 10% (optional power supply: EPSON PS-170)

Current consumption (at 24V except for drawer kickout driving)

Operating: Slip Mean:

1-12 Features and General Specifications Rev. A

Ripple voltage: 300 mVpp or less (only when the printer

is used with t he MICR read er)

Approximately 1.9A

(Character font A α-N all columns prin ting)

Peak:

Approximately 8.0A (20 msec)

When the print platen is released: 2.0A (200 msec)

Page 24

Operating: Receipt Mean:

Confidential

Approximately 1.7A

(Character font A α-N all columns prin ting)

Peak:

Approximately 7.7A (20 msec)

TM-H5000II Series Technical Manual

Low power consumption

mode:

Mean:

Approximately 1.2A

(Character font A α-N all columns prin ting)

Peak:

Approximately 6.6A

Standby: Mean:

Approximately 0.3A

EMI and Safety Standards Applied

(EMC is tested using the EPSON PS-170 power supply)

Europe: CE marking: EN55022

Safety Standard: TÜV (EN60950)

North America: EMI: FCC Class A

Safety standards: UL1950-2TH-D3

Japan: EMI: VCCI Class 1

China

(The people’s

Republic of China):

Oceania: EMI: AS/NZS 3548

Safety standards: GB4943-1995

EN50082-1

EN45501

C-UL

Class B

Reliability

Slip

Rev. A Features and General Specifications 1-13

Life (when printing alphanumeric characters)

Mechanism: 12,000,000 lines

Print head: 200 million characters

(when printing with font B)

MICR reader mechanism (only when the printer is used with the MICR reader):

240,000 passes

The MICR reader is defin ed to have r eached the end of it s

life when it reaches the beginning of the Wearout Period.

MTBF: 180,000 hours

Failure is defined as Random Failure occurring at the

time of the Random Failure Period.

Page 25

MCBF 29,000 ,000 li nes

Confidential

Receipt:

Life:

Mechanism: 15 ,000 ,000 li nes

Thermal head: 100 million pulses, 100 Km

Auto cutter: 1,500,000 cuts

MTBF 180,000 hours

MCBF 37,000 ,000 li nes

Acoustic noise:

This is an average failure interval based on failures

relating to wearout and r andom failures up to the life of

12 million lines.

Operating: Receipt: Approximately 52 dB

(Bystander position) (including

Auto-cutter operation)

Approximately 45 dB

(Bystander position) (not

including Auto-cutter operation)

External Dimensions and Weight

Height: 201 mm (7.91")

Width: 252 mm (9.92") (except for the protrusi on)

Depth: 331 mm (13.03")

Weight: Approximately 6.5 kg (14.3 lbs)

(All the numeric values are typical.)

Slip: App ro xi m ately 65 dB

(Bystander position)

1-14 Features and General Specifications Rev. A

Page 26

Environmental Conditions

Ambient

temperature

[˚C]

[% RH]

Relative humidity

Operating environment

range

34 ˚C, 90 %

40 ˚C, 65 %

45 ˚C, 50 %

90

80

60

20

40

10

0

0 10 20 30 40 50

Confidential

Temperature:

Operating: 5° to 45°C (41° to 113°F)

Storage: –10° to 50°C (14° to 122°F) (except for paper)

Humidity:

Operating: 10 to 90% RH

Storage: 10 to 90% RH (except for paper)

TM-H5000II Series Technical Manual

Rev. A Features and General Specifications 1-15

Figure 1-11 Operating temperature and humidity range

Page 27

Major Component Specifications

Confidential

M-U590 Printer Mechanism

Paper Feed Motor

Type: 4-phase, 48-polarity, PM type stepping motor

Drive voltage: 24V DC ± 10%

Winding resistance: 35 Ω ± 5% at 25° C (77° F), per phase

Carriage Mo tor

Type: 4-phase, 48-polarity, PM type stepping motor

Drive voltage: 24V DC ± 10%

Winding resistance: 9 Ω ± 5% at 25° C (77° F), per phase

Print Head Unit

Solenoid number: 9

Drive voltage: 24V DC ± 10%

Resistance 6.65 Ω ± 4% at 25° C (77° F)

T.O.F. Sensor/B.O.F Sensor

Type: Photo sensor

Voltage: 5V DC ± 5%

Home Position Sensor

Type: Photo sensor

Voltage: 5V DC ± 5%

Carriage Sensor

Type: Photo sensor

Voltage: 5V DC ± 5%

Cover Open Sensor

Type: Photo sensor

Voltage: 5V DC ± 5%

1-16 Features and General Specifications Rev. A

Page 28

TM-H5000II Series Technical Manual

Confidential

M-T88II Printer Mechanism

Paper Feed Motor

Type: 4-phase, 48-polarity, PM type stepping motor

Drive Voltage: 24 V DC ± 10%

Winding resistance: 11.5 Ω ± 10% at 25° C (77° F), per phase

Print Head Unit

Dot number: 512 dots

Dot density: 0.141 mm/dot (180 DPI)

Resistance: 657 Ω ± 4.6%

Paper-end Sensor

Type: Reflection type photo sensor

Paper Roll Near-end Sensor

Type: Microswitch

Auto-cutter Unit

Type: DC brush moto r

Cutter motor voltage: 24 V DC ± 7%

Current consumption: 700 mA peak (at starting, low temperature)

70 mA average (room temperature)

Rev. A Features and General Specifications 1-17

Page 29

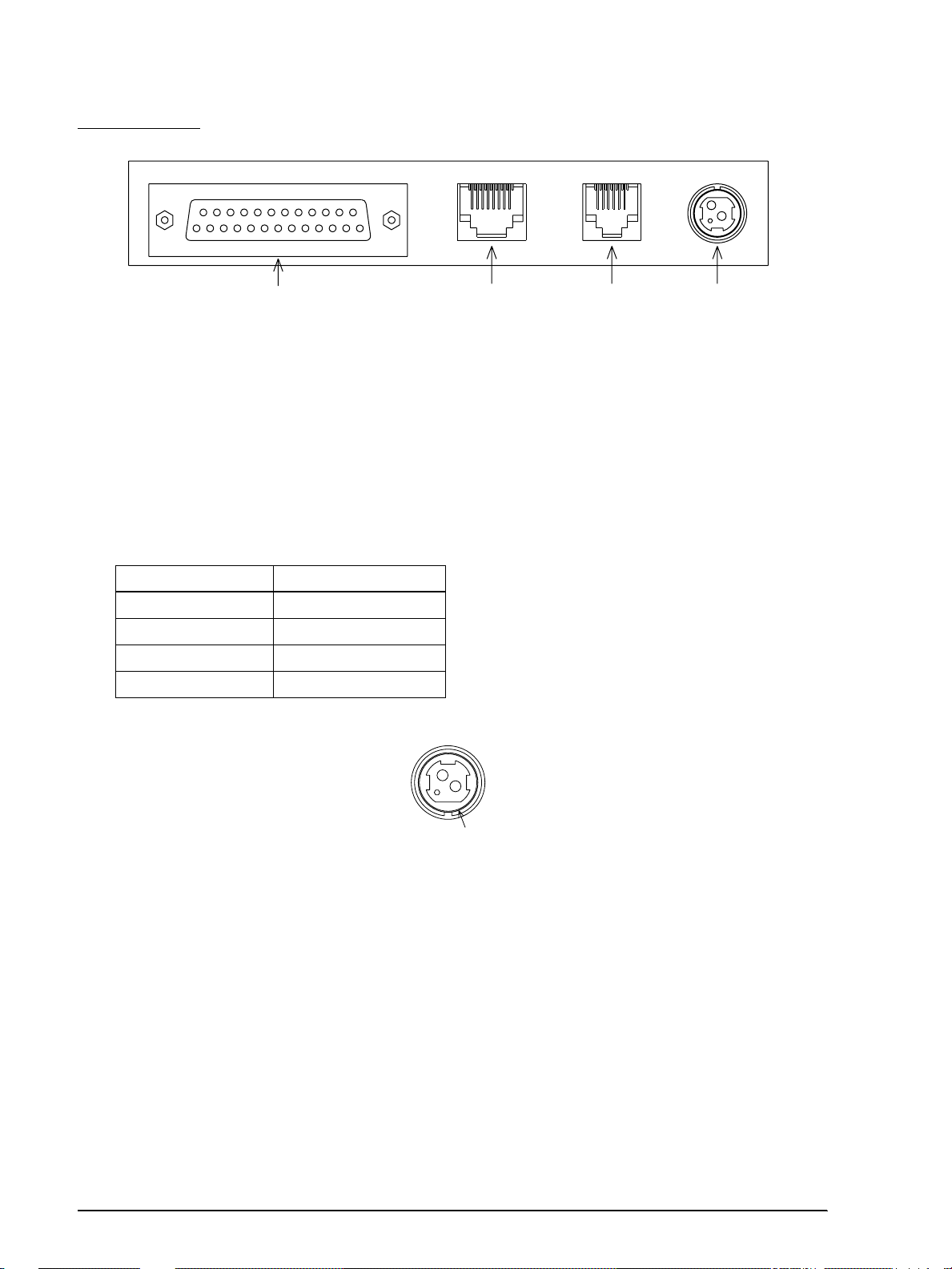

Connectors

Shell

2

31

Confidential

14 25

113

Interface connector Customer display(DM-D)

(*)The shape of the interface connector is different from the illustration above if the printer has a parallel interface.

18 16

Customer display (DM-D)

connector

connector

Drawer kick-out

connector

2

31

Power supply connector

Figure 1-12 Connector panel external appearance

Power Supply Connector

This connector is used to connect the printer to an external power source.

Model: Hosiden TCS7960-532010 or equivalent

Power supply connector pin assignments

Pin number Signal name

1 +24 VDC

2GND

3NC

Shell Frame GND

Drawer Kick-out Connector (Modular Connector)

The pulse specified by ESC p is output to this connector. The host can confirm the status of the

input signal by using the DLE EOT, GS r, or GS a (ASB) commands.

Connector model:

Printer side: MOLEX 52065-6615 or equivalent

User side: 6-position 6-contact (RJ12 telephone jack)

1-18 Features and General Specifications Rev. A

Figure 1-13 Power supply connector

Page 30

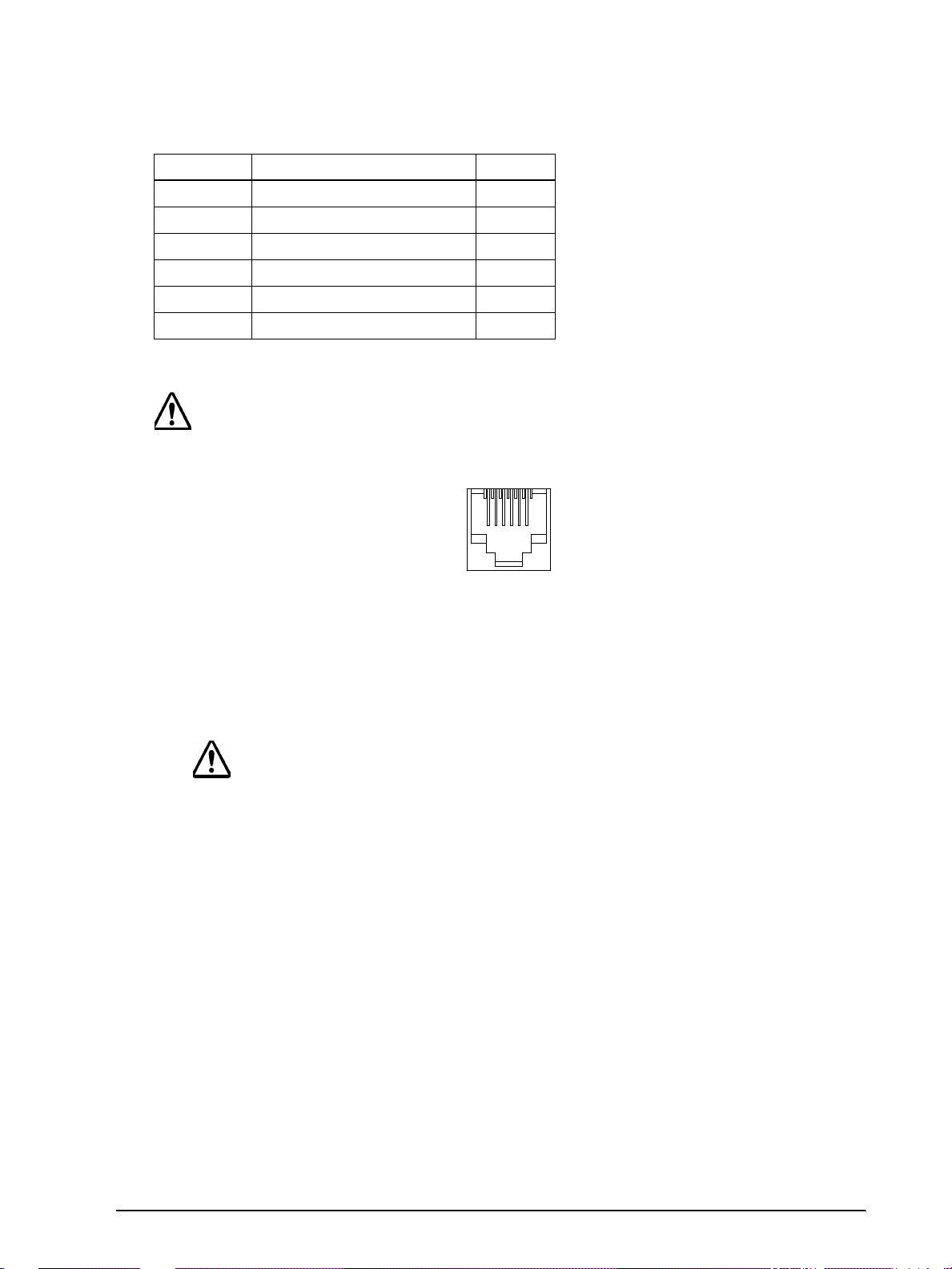

Drawer kick-out connector pin assignments

16

Confidential

Pin Number Signal Name Direction

1Frame GND —

2 Drawer Kick-out drive signal 1 Output

3 Drawer open/close signal Input

4+24 V —

5 Drawer Kick-out drive signal 2 Output

6Signal GND —

+24 V is always output through pin 4.

CAUTION

Pin 4 must be used only for the drawer

.

TM-H5000II Series Technical Manual

Figure 1-14 Drawer kick-out connector

Drawer kick-out drive signal

Output signal: Output voltage: Approximately 24 V

Output current: 1A or less

CAUTION:

To avoid an overcurrent, the r esistance of the drawe r kick-out solenoid must be

24

Ω

or more

Output waveform: Outputs the waveforms in Figure 1-16 to the points A

.

and B in Figure 1-17.

t1 (ON time) and t2 (OFF time) are specified by ESC p.

Rev. A Features and General Specifications 1-19

Page 31

Figure 1-15 Drawer kick-out drive signal output waveform

t 1x 2 msec

t 1x 2 msec

Confidential

Drawer open/close signal

t 1x2 m sec t 2x2 m sec

Input signal level

(connector pin 3):

F. G

A

P-GND

B

P-GND

"L" = 0 to 0.8 V

"H" = 2 to 5 V

Drawer kick-out connector

+24V

1

2

3

4

5

6

With shielded

Drawer kick-out solenoid

Drawer open/close switch

Notes:

Two driver transistors cannot be energized simultaneously.

The driver must not be energized continuously.

1-20 Features and General Specifications Rev. A

Printer side User side (Drawer kick-out side)

Figure 1-16 Drawer circuitry

Page 32

18

Confidential

CAUTIONS:

Do not connect a telephone line to the drawer kick-out connector, otherwise the

printer and the telephone line may be damaged.

Be sure to use the printer power supply (connector pin 4) for th e drawer power source.

The resistance of the drawer kick-out solenoid must not be less than the specified

(24

Ω

). Otherwise, an overcurrent could damage the solenoid.

Customer Display Connector

CAUTION:

Be sure not to use customer displays other than Seiko Epson DM-DXX

Model:

Receptacle: MOLEX 52065-8845 or equivalent

TM-H5000II Series Technical Manual

.

Pin assignments:

Customer display connector pin assignments

+24 V is alway s output through pin 7. The driving capability is 350 mA or less.

Pin Number Signal Name Direction

1FG—

2N.C.—

3TXDOutput

4 DTR Output

5 DSR Input

6SG—

7+24—

8PG—

Rev. A Features and General Specifications 1-21

Figure 1-17 DM-D connector

Page 33

Interface

Confidential

Note:

See the appendix for the information about the IEEE 1284 parallel interface and the RS-485 serial

interface.

RS-232 serial interface

Specifications

Data transmission: Serial

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control

Signal levels: MARK = –3 to –15 V: Logic "1"

Stop bits: 1 or more

Connector (printer side): Female DSUB-25 pin connector

The data word length, baud rate, and parity depend on the DIP switch settings.

SPACE = +3 to +15 V: Logic "0"

Switching between on -line and off-line

The printer does not have an on-line/off-line switch. The

printer goes off-line:

❏ Between when the power is turned on (including

reset using the interface) and when the printer is

ready to receive data

❏ During the self-test

❏ When the cover is open (the cover for the p aper sheet

selected by ESC c 0)

❏ During paper feeding using the paper feed switch

❏ When the printer stops printing due to a paper-end

(only when the paper roll is not present)

❏ When an error has occurred

Interface connector terminal assignments and signal functions are described in the table

below.

1-22 Features and General Specifications Rev. A

Page 34

TM-H5000II Series Technical Manual

Confidential

Printer status and signals

Pin number Signal name Signal direction Function

1FG— Frame ground

2 TXD Output Transmit data

3 RXD Input Receive data

4 RTS Output DIP SW 2-2 OFF: Same as DTR signal (Pin 20)

DIP SW 2-2 ON: Logical product of DTR signals of DM-D and TM

(If both are SPACE, the printer can receive data

(SPACE).)

6 DSR Input This signal indicates whether the host computer can receive data.

SPACE indicates that the host computer can receive data, and

MARK indicates that the host comput er can not receiv e da t a.

When DTR/DSR control is selected, the printer transmits data after

confirming this si g nal (except when transmitting da ta by DLE EOT

and GS a).

When XON/XOFF control is selected, the printer does not check this

signal.

Changing the DIP switch setti ng enables this signal to be used as a

reset signal for the printer.

The printer is reset when the signal remains MARK for 1 ms or more.

7 SG — Signal ground

,

Rev. A Features and General Specifications 1-23

Page 35

Printer status and signals

Confidential

Pin number Signal name Signal direction Function

20 D TR Output 1) When DTR/DSR control is se lect ed , this signal indicat es whether

the printer is busy. SPACE indicates that the printer is ready to

receive data, and MARK indicates that the printer is busy. The busy

condition can be changed by using DIP SW 2-1 as follows:

DIP SW 2-1 sta tus

Printer

1. During the period from when the

power is turned on (including

resetting using the inter face) to when

the printer is read y to receive data.

2. During the self-test. BUSY BUSY

Off-line

3. When the cover is open. - BUSY

4. During paper feeding usin g the

paper feed switch.

5.When the pri nte r stop s prin ting due t o

a paper-end.

6. When an error has occurred. - BUSY

7. When the receive buffer becomes

full.

ON OFF

BUSY BUSY

-BUSY

-BUSY

BUSY BUSY

2) When XON/XOFF control is selected:

The signal indicates whether the printer is correctly connected and

is ready to receive d ata. S PACE indicat es th at the p rinter is rea dy to

receive data. The s ignal is always SPACE except in the following

cases:

• During the period from when the power is turned on to when

the printer is read y to receive data

• During the self-test

25 INIT Input Changing the DIP switch settin g enables this signal to be used as a

reset signal for the printer.

The printer is reset when the signal remains SPACE for 1 ms or more.

Notes:

When the remaining space in the receive buffer drops to 16 bytes, the printer status becomes "buffer

full" and it remains "buffer full" until the space in the receive buffer increases to 26 bytes.

The printer ignores the data received when the remaining space in the receive buffer is 0 bytes.

XON/XOFF transmit timing When XON/XOFF control is selected, the printer

transmits XON or XOFF signals as follows. Transmit

timing differs depending on the DIP SW1-3 setting.

1-24 Features and General Specifications Rev. A

Page 36

TM-H5000II Series Technical Manual

Confidential

XON/XOFF transmit timing

Printer status

XON transmission 1) When the printer goes on-line after turning on the power (or

reset using interface)

2) When the receive buffer is released from the buffer full state Transmit Transmit

3) When the printer switches from off-line to on-line — Transmit

4) When the printer recovers from an error using the DLE ENQ 1 or

DLE ENQ 2 commands

XOFF Transmission 5) When the receive buffer becomes full Transmit Transmit

6) When the printer switches from on-line to off-line — Transmit

DIP SW 1-3 status

ON OFF

Transmit Transmit

—Transmit

Notes:

• The XON code is <11>H and the XOFF code is <13>H.

• In case 3, XON is not transmitted when the receive buffer is full.

• In case 6, XOFF is not transmitted when the receive buffer is full.

• When the DIP SW2-1 is set to OFF, XON is not transmitted if the printer is in off-line state in

case 6.

Notes on setting DIP switch 2-1 to ON

The printer mechanism stops but does not become busy when: an error has occurred, the cover

is open, printing stops due to a paper-end, or paper is fed using the paper feed switch.

When setting DIP switch 2-1 to ON to enable handshaking with the printer , be sure to check t he

printer status using the GS a command and the ASB function. In this setting, the default value

of n for GS a is 2. The printer automatically transmits the printer status, depending on on-line/

off-line changes.

When using DLE EOT and DLE ENQ, be sure that the receive buffer does not become full.

❏ When using a host that cannot transmit data when the printer is busy:

If an error has occurred, DLE EOT and DLE ENQ cannot be used when the printer is busy

due to a receive buffer-full state.

❏ When using a host that can transmit data when the printer is busy:

When the receive buffer becomes full while transmitting bit-image data, DLE EOT or

DLE ENQ used while sending the bit-image data is processed as bit-image data. The data

transmitted when the receive buffer is full may be lost.

Example: Check the printer status using GS I or GS r after transmitting each line of data

Rev. A Features and General Specifications 1-25

and use the 4K byte receive buffer. Transmit one line of data so that the receive

buffer does not become full.

Page 37

Notes on Resetting the Printer Using the Interface

Confidential

The printer can be reset using interface pins 6 and 25 by changing the DIP switch setting.

Reset switching

Signal Line DIP Switch Reset Condition

Pin 6 (DSR) DSW 2-7: ON MARK level input

Pin 25 (INIT) DSW 2-8: ON SPACE or TTL-HIGH level input

To reset the printer, the following requirements must be satisfied.

❏ DC characteristics:

Reset DC characteristics

Pin 6 (DSR) Pin 25 (INIT)

Input HIGH voltage V

Input LOW v oltage V

Input HIGH current: I

Input LOW c urrent: I

Input impedance: R

+3 to +15 V +2 to +15 V

IH

-15 to + -3 V -15 to + 0.8 V

IL

5 mA (maximum) 1 mA (maximum)

IH

-5.3 mA (maximum) -2 mA (maximum)

IL

3 KΩ (minimum)

IN

❏ AC characteristics:

Minimum reset pulse width: TRS 1 msec (minimum)

❏ When using pin 6 (DSR) (DIP switch 2-7 is ON):

TRS

H

L

Figure 1-18 Minimum reset pulse width (pin 6)

❏ When using pin 25 (INIT) (DIP switch 2-8 is ON):

TRS

H

L

Figure 1-19 Minimum reset pulse width (pin 25)

1-26 Features and General Specifications Rev. A

Page 38

Notes:

Confidential

When a signal that does not satisfy the requirements above is input, printer operation is not

guaranteed. When a signal is input to pin 25 (INIT) at the TTL level, the requirements above

must also be satisfied. Although a signal is input to pin 6 (DSR) at the TTL level, according to the

DC characteristics described above, the operation is not guaranteed and pin 6 cannot be controlled.

When pin 6 (DSR) and pin 25 (INIT) are open, the printer is operating.

Buttons and Switches

Power Switch

Type: Rocker switch

Function: The power switch turns the power on or off.

Note:

Turn on the power only after connecting the power supply.

TM-H5000II Series Technical Manual

Panel Button

There are panel buttons on both the slip and receipt sections. All the panel buttons are disabled

by ESC c 5.

Slip

Release button (non-locking push button)

[Function] Release paper

Reverse button (non-locking push button)

[Function] Reverse paper feeding for the line spacing set by ESC 2 and ESC 3

Forward button (non-locking pu sh button)

[Function] Feed paper for the line spacing set by ESC 2 and ESC 3

Paper feed is not executed without paper.

Note:

When the printer cover is open, the printer will not operate.

Rev. A Features and General Specifications 1-27

Page 39

Receipt

Confidential

Feed (FEED) button: Non-locking push button

[Function] If you push this button once and release it, the printer

feeds paper for one line based on the line spacing set by

ESC 2 and ESC 3. If you hold down the button, the

printer will feed paper continuously.

Paper feeding using the FEED button cannot be

performed under the following conditions:

1. The paper roll end sensor detects a paper end

2. When the printer cover is open.

If you push this button when the printer is in the

macro execution standby state, the defined macro is

executed.

During self-test printing, you can stop the self test

temporarily by pressing this button and restart it by

pressing the button again.

DIP Switches

For the serial interface model

The DIP switches are located at the bottom of the case.

DIP switch 1

DIP Switch Function ON OFF

1 Data reception error Ignored Prints “?”

2 Receive buffer capacity Data buffer 45 bytes Data buffer 4 KB

3 Handshaking XON/XOFF DTR/DSR

4 Data word le ngth 7 bits 8 bits

5 Parity check Yes No

6 Parity selec ti on Ev en Odd

7

8

Transmission speed selection

Refer to Transmission Speed Table

1-28 Features and General Specifications Rev. A

Page 40

TM-H5000II Series Technical Manual

Confidential

Transmission Speed

Transmission Speed (BPS) SW 1-7 SW 1-8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OF F

BPS: Bits Per Second

DIP switch 2

SW 2 Function ON OFF

1 Handshaking (BUSY condition) Receive buffer full

2 Customer display (DM-D) connection Connected Not connected

3

Selects print density Refer to Print Density Selection Table

4

5 Internal use Fixed to Off

6 Internal use Fixed to Off

7 I/F pin 6 reset signal Enabled Disabled

8 I/F pin 25 reset signal Enabled Disabled

Off line or receive

buffer full

Print Density Selection

Function SW 2-3 SW 2-4

Receipt low power consump t ion mode ON ON

1 Print density (Normal) OFF OFF

2ONOFF

3 Print density (Dark) OFF ON

Notes:

❏ When pin 6 of the interface connector is used for the reset signal, the printer is reset at MARK on

the RS-232 level.

❏ When pin 25 of the interface connector is used for the reset signal, the printer is reset at SPACE

on the RS-232 level or at HIGH on the TTL level.

❏ Changes in DIP switch settings (excluding switches 2-7 and 2-8 interface reset signals) are

recognized only when the printer power is turned on or when the printer is reset by using the

interface. If the DIP switch setting is changed after the printer power is turned on, the change

does not take effect until the printer is turned on again or is reset.

❏ If you turn on DIP switch 2-7 or 2-8 while the printer power is turned on, the printer may be

reset, depending on the signal state. DIP switches should not be changed while the printer

power is on.

❏ If the print density is set to level 2 or 3, printing speed is inclined to be low speed.

❏ In low power consumption, printing speed is fixed to 70 mm/sec.

Rev. A Features and General Specifications 1-29

Page 41

For parallel interface model

Confidential

DIP switch 1

DIP Switch Function ON OFF

1 Auto line feed Always enabled Always disabled

2 Receive buffer capacity Data buffer 45 bytes Data buffer 4kB

3-8 Not defined — —

DIP switch 2

DIP Switch Function ON OFF

1 Handshaking (BUSY condition)

2

3 Selects print density Refer to print density selection table

4

5-7

8

Reserved (do not change the

setting)

Reserved (do not change the

setting)

I/F pin 31 reset signal (do not

change the setting)

• Receive buffer full

• Data reading

Fixed to ON

• Off-line

• Receive buffer full

• Data reading

Fixed to OFF

Fixed to OFF

Print Density Selection

Function SW 2-3 SW 2-4

Receipt low power consumption mo de ON ON

1 Print density (Normal) OFF OFF

2ONOFF

3 Print density (Dark) OFF ON

Notes:

❏ Changes in DIP switch setting (excluding 2-8, interface reset signal) are recognized only when the

printer power is turned on or when the printer is reset by using the interface. If the DIP switch

setting is changed after the printer power is turned on, the change does not take effect until the

printer is turned on again or is reset.

❏ If you turn on DIP switch 2-8 while the printer power is turned on, the printer may be reset,

depending on the signal state. DIP switches should not be changed while the printer power is on.

❏ If the print density is set to level 2 or 3, printing speed is inclined to be low speed.

❏ In low power consumption, printing speed is fixed to 70 mm/sec.

1-30 Features and General Specifications Rev. A

Page 42

Panel LEDs

POWER

FORWARD

ERROR

RELEASE

SLIP

REVERSE RELEASE

Confidential

Slip

Figure 1-20 Panel Switches and Indicators

Power supply

(POWER) LED:

Off: Power is not stable.

Error (ERROR) LED: Red

Green

On: Power is stable.

On: Off-line (except during paper feeding using the

FORWARD and the REVERSE buttons and during

self test printing)

TM-H5000II Series Technical Manual

Off: Normal condition.

Blinking: Error

RELEASE LED: Green

On: The print platen and paper feed roller are released.

Off: The print platen and paper feed roller are clamped

Blinking: Waiting for con tinuous self test printing or macro

Slip LED: Green

On: When slip paper is selected.

Off: When slip paper is not selected. (Receipt is

Blinking Slip in sertion waiting state, slip remo val waiting

together. (During printing on slip paper.)

execution standby state

selected.)