Page 1

Describes how to handle the product.

Describes setup and installation of the product and peripherals.

Describes how to control the printer and necessary information

when you develop applications.

Describes general specications and character code tables.

Describes features for the product.

Technical Reference Guide

SeriesSeries

/

Product Overview

Setup

Handling

Application Development Information

Appendix

M00079112

Rev. M

Page 2

Cautions

No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson Corporation.

The contents of this document are subject to change without notice. Please contact us for the latest informa-

tion.

While every precaution has been taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those designated as Original EPSON Products or EPSON

Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/Label are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft®, Windows®, Windows Vista®, and Windows Server® are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

Zebra Technologies Corporation and ZPL II are the registered trademarks or trademarks of Zebra Technologies

Corporation.

Intel®, Celeron®, and Pentium® are trademarks of Intel Corporation in the U.S. and/or other countries.

AMD® and AMD Athlon

BarTender® is registered trademark of Seagull Scientific, Inc. in the United States and other countries.

Seagull Scientific is trademark of Seagull Scientific, Inc. in the United States and other countries.

NiceLabel® is trademarks or registered trademarks of Euro Plus d.o.o.

CODESOFT is registered trademarks or trademarks of TEKLYNX International.

All other trademarks are the property of their respective owners and used for identification purpose only.

©Seiko Epson Corporation 2014-2019. All rights reserved.

TM

are a trademark or registered trademark of Advanced Micro Devices, Inc.

2

Page 3

For Safety

This document explains the functions of and how to operate this product and the software, the setup from

installation until printing, information regarding maintenance, and solutions to various kinds of trouble. Be

sure to read this document thoroughly before use and to use this product properly.

You can easily setup this product using Install Navi.

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the following

carefully before handling the product.

Handling the product improperly by ignoring this symbol can lead to death or serious

injury.

WARNING

Handling the product improperly by ignoring this symbol can lead to injury and property damage.

CAUTION

Indicates supplementary notes and other useful information.

Cautions on Installation

Do not block the air vents of this product. Doing so can result in heat accumulated in the

product causing a fire. (

WARNING

CAUTION

Do not cover the product with a cloth or install it in a poorly-ventilated location. Make

sure to allow installation space as specified in this manual. (

Installation" on page 38

Do not install/store the product in an unstable location or in a location subject to vibration

from other devices. Equipment may fall or collapse, causing breakage and possible injury.

Do not install the product in a location exposed to oily smoke or dust, or in a humid location.

Doing so may cause electric shock or fire.

Use a natural posture when lifting this product. Lifting the product in an inappropriate pos-

ture may cause injury.

Do not carry this product alone. Two or more people are required while unpacking or moving

the product. The weight of this product is approximately 37 kg {81.57 lb}. (

Printer" on page 37

Hold the parts of the product specified in this manual when lifting up this product. Otherwise,

the product may fall or your finger may be caught when you lower the product, resulting in

injury. (

"Installing the Printer" on page 37)

While installing the printer, make sure that no cords or foreign objects are tucked under the

printer.

"Rear Side" on page 21)

"Location Appropriate for

)

"Installing the

)

3

Page 4

Cautions on Power Supply

Do not allow dust or foreign materials to adhere to the power plug. Accumulated dust or

foreign material may cause electric shock or fire.

WARNING

Insert the power plug securely into the socket. Failure to insert the plug securely may

cause electric shock or fire.

Use only the power cable supplied with this product. In addition, use the supplied power

cable only for this product. Other use may cause electric shock or fire.

Do not use a damaged power cable. Doing so may cause electric shock or fire.

Contact qualified service personnel if the power cable is damaged. Observe the following points so as not to damage the power cable:

Do not modify the power cable.

Do not place heavy objects on the power cable.

Do not forcibly bend, twist or pull the power cable.

Do not locate the power plug near a heating device.

Do not hold the power plug with a wet hand. Doing so may cause electric shock.

Do not connect too many power cables to one outlet. Doing so may cause fire.

Disconnect the power plug from the outlet on a periodical basis, and clean the areas

around and between the blades. Leaving the power plug connected to the outlet for a

long period of time may cause dust to accumulate on the blade root, resulting in a short-

circuit or fire.

Hold the plug and do not pull the cable when disconnecting the power plug from the

outlet. Pulling the cable may damage the cable or deform the plug, causing electric

shock or fire.

CAUTION

To ensure safety, unplug this product before leaving it unused for an extended period.

4

Page 5

Cautions on Handling

Do not use this product in a location with volatile substances such as alcohol or paint

thinner, or near fire. Doing so may cause electric shock or fire.

WARNING

Shut down the product immediately if it produces smoke, a strange odor, or unusual

noise. Continued use may cause electric shock or fire. Immediately unplug the product

when a fault or other problem occurs, and contact qualified service personnel.

Shut down the product immediately if water or other liquid spills into this product. Con-

tinued use may cause electric shock or fire. Immediately unplug the product and contact

qualified service personnel.

Never disassemble or repair this product. Tampering with this product may result in

injury or fire.

Do not use this product in an environment where inflammable gas or explosive gas may

exist. Do not use aerosol sprayers containing flammable gas inside or around this product. Doing so may cause fire.

Do not connect cables in ways other than those mentioned in this manual. Doing so may

cause fire. It may also damage other devices.

Do not touch the areas inside the product other than those mentioned in this manual.

Doing so may cause electric shock or burns.

Do not insert metal or flammable materials, or allow them to fall into the product. Doing

so may cause electric shock or fire.

Use a power cable that has acquired a safety standard certification and has a power sup-

ply system (PE) terminal. Make sure you earth the terminal; otherwise it may cause electric shock.

CAUTION

Do not allow anyone to stand or place heavy objects on top of this product. Equipment may

fall or collapse, causing breakage and possible injury.

Install the cables and optional products in the proper direction according to the proper proce-

dures. Failure to install correctly may cause fire or injury. Follow the instructions in this manual

to install them properly.

Before moving the product, shut down and unplug the product, and make sure that all the

cables are disconnected. Failure to do so may damage a cable, causing electric shock or fire.

Do not store or transport the product in a tilted, standing or upside-down position. Doing so

may cause the ink to leak.

Using in the presence of silicon gas (silicon adhesive, silicon oil, silicon powder, etc.) including

siloxane and of malignant gas (nitric acid, hydrosulfuric, ammonia, chlorine, etc.) may cause

contact failure at contact points in a mechanical switch and a DC motor etc. in a short time

because of adhesion or oxidization of the insulation film.

If the printer is out of use for a prolonged period, it could develop problems due to dust build-

ing up on the external supply paper or entering through it, etc. Therefore, protect the printer

with a cover or similar, or remove the paper and store it in a dust-free place.

Do not allow a solvent that is based on benzene, thinner, toluene, or ketones to adhere to the

printer surface as they may deteriorate or damage plastic.

5

Page 6

Cautions on the Ink Cartridge / Maintenance box

Do not touch IC chips on the ink cartridges or Maintenance box. Doing so may cause operat-

ing/printing malfunction.

CAUTION

This product uses ink cartridges equipped with an IC chip that monitors the amount of ink

used by each cartridge. Cartridges are usable even if they are removed and reinstalled. How-

ever, if an ink cartridge in which little amount of ink remains is removed and reinstalled, it may

not be usable. Some ink is consumed each time cartridges are installed because the product

automatically checks their reliability.

Install all ink cartridges. Printing is not possible even if only one ink cartridge is missing.

Since ink cartridges are designed to stop the operation before ink runs out completely to

maintain the quality of the print head, some ink remains in the used ink cartridge.

All the ink colors are consumed also for the maintenance operations when an ink cartridge is

replaced and for print head cleaning.

Flashing (Power) LED indicates that head cleaning, ink charging, or printing is in progress.

Do not open or close the Roll paper cover, Ink cartridge cover, or Maintenance box cover, or

turn off the power.

Do not turn off the product or open the ink cartridge cover while charging ink ( (Power)

LED is flashing). Opening the cover may cause the ink to be recharged, resulting in more ink

being consumed. Also, it may cause printing malfunction.

Even for monochrome printing (printing of monochrome image), all the ink colors are used in

an operation designed to maintain the printing and print head quality.

Do not disassemble the ink cartridges or Maintenance box, or supply or replace ink. If you dis-

assemble them, ink may get into your eyes or adhere to your skin. It may also prevent you from

printing correctly. Ink may leak and damage the printer.

Do not remodel the ink cartridge. Doing so may cause printing malfunction.

Use of an old ink cartridge may result in reduced print quality. Use it up within six months after

opening the package. The usage period for ink cartridges is printed on the packaging of indi-

vidual ink cartridges.

Do not reuse a maintenance box which has removed and detached a long period.

Store the ink cartridges or Maintenance box out of the reach of children. Do not drink ink.

If ink contacts your skin, eyes, or mouth, take the following actions.

When it gets onto your skin, immediately wash the area with soap and water.

When ink gets into your eyes, immediately flush them with water. Leaving the ink as is may

result in bloodshot eyes or mild inflammation. If something is wrong, immediately consult

with a doctor.

When ink gets into your mouth, immediately spit it and consult with a doctor.

Be careful when handling the ink cartridges or Maintenance box as if ink leaks and adheres to

clothes, it may not come off even after washing it.

There may be some ink around the ink supply port on the removed ink cartridge. Take care so

that it does not stain the desk or other surface.

Do not remove the ink cartridge or maintenance box, except when you replace it.

Do not open the ink cartridge package until you are ready to install it in the product.

Do not shake the ink cartridges or Maintenance box strongly. If you shake or swing them

strongly, or push the sides strongly, ink may leak from the cartridges or Maintenance box.

Do not push the supply port of the ink cartridges or Maintenance box as ink may leak.

6

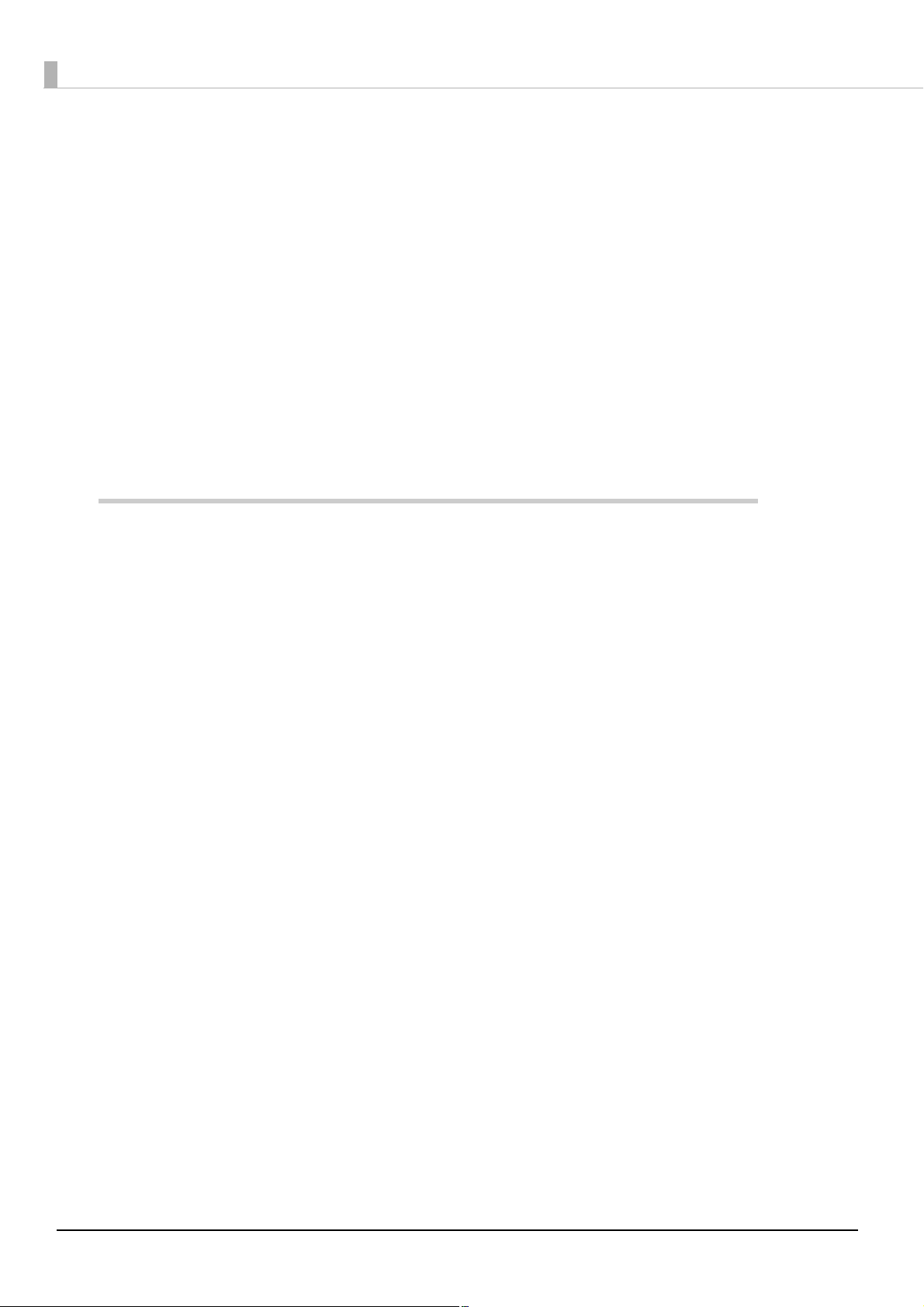

Page 7

CAUTION

autocutter blade

autocutter fixed blade

Do not allow foreign objects to fall into the cartridge installation section. Doing so may cause

printing malfunction. Remove any object that might have fallen into the installation section,

taking care not to damage the section.

Inside the ink cartridge holder that is in the printer where ink cartridges are stored has a nee-

dle for supplying ink to the printer. Do not insert your fingers and so on as it may stain.

When ink is charged for the first time (right after purchase), ink is consumed for filling the print

head nozzle (ink discharge holes) to get ready for printing. That is why the number of the

printable sheets may be fewer than for the cartridges to be installed later.

When using the printer for the first time, the replacement interval for the maintenance box is

shorter than usual as ink charging consumes the ink.

If you turn the power off the product using the power button, the print head is automatically

capped, which prevents the ink from drying. After installing the ink cartridges, be sure to turn

the power off using the power button when you are not using the product. Do not pull out the

power plug or trip the breaker while the power is on.

Printing on water-repellent paper such as art paper, which is slow-drying, may cause print

stains. Also, printing on glossy paper may cause finger prints on the paper or ink may adhere

to your fingers when you touch it. Select paper not to case print stains before use.

If you transport the printer without ink cartridges installed, ink may leak. Make sure the Ink

cartridges are installed when transporting the printer.

If you use a non-genuine Maintenance box that does not support this printer, it may affect the

printer or deteriorate the print quality and cause a non-returnable error, preventing the

printer's optimum performance. We recommend using a genuine Maintenance box.

Do not allow a solvent that is based on benzene, thinner, toluene, or ketones to adhere to the

ink cartridges or Maintenance box as it may deteriorate or damage plastic.

When disposing of the ink cartridges or Maintenance box, follow the laws, legislations, and

regulations of your country or community.

Caution Label

The caution label on the product indicates the following precaution.

Take care not to injure your fingers on the fixed blade of the autocutter.

CAUTION

7

Page 8

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices

related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc., you should use this product only after giving consideration to including failsafes and redundancies into your design to maintain safety and total system reliability. Because this product was

not intended for use in applications requiring extremely high reliability/safety, such as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment related to direct

medical care, etc., please make your own judgment on this product's suitability after a full evaluation.

8

Page 9

About this Manual

Aim of the Manual

This manual was created to provide information on development, design, and installation of systems and development and design of printer applications for developers.

Manual Content

The manual is made up of the following sections:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Appendix

Product Overview

Setup

Handling

Application Development Information

Product Specifications

9

Page 10

Contents

■ For Safety................................................................................................................................. 3

Key to Symbols ....................................................................................................................................................................3

Cautions on Installation ...................................................................................................................................................3

Cautions on Power Supply ..............................................................................................................................................4

Cautions on Handling .......................................................................................................................................................5

Cautions on the Ink Cartridge / Maintenance box .................................................................................................6

Caution Label .......................................................................................................................................................................7

■ Restriction of Use ................................................................................................................... 8

■ About this Manual.................................................................................................................. 9

Aim of the Manual ..............................................................................................................................................................9

Manual Content ..................................................................................................................................................................9

■ Contents................................................................................................................................. 10

Product Overview.......................................................................................... 15

■ Features.................................................................................................................................. 15

Printing................................................................................................................................................................................ 15

Operability ......................................................................................................................................................................... 16

Reliability ............................................................................................................................................................................ 16

Easy setup........................................................................................................................................................................... 16

How to Print....................................................................................................................................................................... 16

Other Features .................................................................................................................................................................. 17

■ Part Names and Functions.................................................................................................. 18

Front Side............................................................................................................................................................................ 18

Operation Panel ............................................................................................................................................................... 19

Rear Side ............................................................................................................................................................................. 21

■ Nozzle Verification Technology ......................................................................................... 22

Setting the Nozzle Verification Technology ........................................................................................................... 22

Dot substitution ............................................................................................................................................................... 24

■ Periodic auto cleaning......................................................................................................... 25

■ Status/Error Indications ...................................................................................................... 26

Ink Cartridge and Maintenance Box Status............................................................................................................ 30

Beeper.................................................................................................................................................................................. 31

■ Reprint.................................................................................................................................... 32

10

Page 11

Setup............................................................................................................... 33

■ Install Navi ............................................................................................................................. 34

■ Work flow to set up this product without using the Install Navi ................................ 35

■ Checking the Items Included in the Package.................................................................. 36

■ Installing the Printer............................................................................................................ 37

Location Appropriate for Installation ....................................................................................................................... 38

■ Connecting the Power Cable.............................................................................................. 39

■ Connecting the Interface Cable......................................................................................... 40

■ Turning On/Off...................................................................................................................... 41

Turning On ......................................................................................................................................................................... 41

Turning Off......................................................................................................................................................................... 41

■ Installing the Ink Cartridge ................................................................................................ 42

■ Installing the Maintenance box......................................................................................... 46

■ REWINDER.............................................................................................................................. 49

How to install the REWINDER ...................................................................................................................................... 49

Removing the rewinder................................................................................................................................................. 50

Attaching the paper leading edge to the rewinder ............................................................................................ 50

■ Setting the Paper.................................................................................................................. 52

Setting the Roll Paper .................................................................................................................................................... 52

Setting the Fanfold Paper............................................................................................................................................. 60

How to eject paper for paper replacement............................................................................................................ 61

Ejection Angle of Printed Paper ................................................................................................................................. 62

■ Printer settings ..................................................................................................................... 63

Language Setting ............................................................................................................................................................ 63

Time Setting ...................................................................................................................................................................... 64

Network settings.............................................................................................................................................................. 65

■ Paper settings ....................................................................................................................... 67

Set using a printer driver .............................................................................................................................................. 67

Setting using the PrinterSetting ................................................................................................................................ 70

Setting with the operation panel...............................................................................................................................73

■ Test printing .......................................................................................................................... 74

Test Printing....................................................................................................................................................................... 75

■ How to Display the Printer Driver ..................................................................................... 76

Handling ........................................................................................................ 77

■ List of printer setting items ................................................................................................ 77

■ Setting panel switch ............................................................................................................80

Printing the status sheet (Network settings) ......................................................................................................... 84

Favorite................................................................................................................................................................................ 85

Cutting the Incomplete Label .....................................................................................................................................86

11

Page 12

■ PrinterSetting........................................................................................................................ 87

Starting the PrinterSetting ........................................................................................................................................... 88

Apply settings ................................................................................................................................................................... 90

Media settings .................................................................................................................................................................. 91

Layout settings ................................................................................................................................................................. 92

Position adjustment........................................................................................................................................................ 94

Print results adjustment ................................................................................................................................................ 96

Store data in the printer ................................................................................................................................................97

Background image settings ......................................................................................................................................... 98

Print head maintenance..............................................................................................................................................100

Printer settings ...............................................................................................................................................................101

Panel settings..................................................................................................................................................................102

Nozzle check settings...................................................................................................................................................103

Advanced settings.........................................................................................................................................................104

Initialize printer ..............................................................................................................................................................108

Printer information........................................................................................................................................................109

Settings save and restore............................................................................................................................................111

Option................................................................................................................................................................................112

■ Setting the Printer Driver.................................................................................................. 113

Favorite Setting ..............................................................................................................................................................113

User Defined Information ...........................................................................................................................................116

Exporting/ Importing Printer Driver Settings......................................................................................................116

Barcode Printing ............................................................................................................................................................119

2D symbol Printing .......................................................................................................................................................129

Barcode and 2D Symbol Font Printing on .NET Environment .......................................................................136

Banding Reduction .......................................................................................................................................................138

Start the PrinterSetting from the printer driver..................................................................................................139

Setting EPSON Status Monitor 3 ..............................................................................................................................140

Restricted items of printer drivers...........................................................................................................................146

■ EpsonNetConfig (Web version) ....................................................................................... 147

■ Setting the label size and paper layout for borderless printing ...............................151

Borderless Printing Concepts ....................................................................................................................................151

Label Media Design ......................................................................................................................................................152

Borderless Printing Settings ......................................................................................................................................152

■ USB Printer Class Device Replacement Service ............................................................157

Uninstallation of USB Printer Class Device Replacement Service ................................................................157

Restrictions in USB Printer Class Device Replacement Service .....................................................................158

■ Setting the Dip Switches...................................................................................................159

Setting Procedure..........................................................................................................................................................159

■ Cleaning the Printer...........................................................................................................160

Cleaning the autocutter ..............................................................................................................................................160

Cleaning the Internal Parts (Platen) ........................................................................................................................161

Cleaning the Internal Parts (Paper Path) ...............................................................................................................162

Cleaning the Printer Case ...........................................................................................................................................163

■ Long-term Storage of the Product After Ink Charging ...............................................164

Storing the product ......................................................................................................................................................164

Restart the printer after long-term storage .........................................................................................................165

12

Page 13

■ Precautions when transporting ...................................................................................... 166

■ Troubleshooting................................................................................................................. 167

Error Processing ............................................................................................................................................................. 167

Warning Processing......................................................................................................................................................171

Printer Driver................................................................................................................................................................... 172

Poor print quality ..........................................................................................................................................................173

Unclean media ...............................................................................................................................................................176

Dirt inside the printer .................................................................................................................................................. 176

Printable area.................................................................................................................................................................. 176

Detection failure............................................................................................................................................................ 177

Continuous printing cannot be performed......................................................................................................... 178

External supply .............................................................................................................................................................. 178

Paper is jammed ............................................................................................................................................................ 179

Application Development Information.................................................... 183

■ How to Control the Printer ............................................................................................... 183

Using label printing application .............................................................................................................................. 183

Using the Epson Inkjet Label Printer SDK............................................................................................................. 184

Using the ESC/Label commands ............................................................................................................................. 184

Changing Printer Settings and Replacing the Printer......................................................................................184

■ Software and Manuals ...................................................................................................... 190

■ Installing software ............................................................................................................. 192

Software installation procedures ............................................................................................................................ 192

13

Page 14

Appendix ...................................................................................................... 195

■ Product Specifications ......................................................................................................195

Operating Environment ..............................................................................................................................................197

Printing Specifications .................................................................................................................................................198

Paper Specifications .....................................................................................................................................................199

Paper detection method.............................................................................................................................................206

Print Area and Cutting Position................................................................................................................................207

Electrical Characteristics .............................................................................................................................................217

Reliability ..........................................................................................................................................................................218

Environmental Conditions .........................................................................................................................................219

External Dimensions.....................................................................................................................................................220

■ Consumable Product Specifications............................................................................... 223

Ink Cartridge....................................................................................................................................................................223

Maintenance Box ...........................................................................................................................................................223

■ Option Specifications ........................................................................................................ 224

Rewinder (TU-RC7508) ................................................................................................................................................224

■ LCD Display Specifications for the Number of Printed Copies..................................225

Display While Printing ..................................................................................................................................................225

Error Display While Printing .......................................................................................................................................225

Display When the Number of Printed Copies is Carried Up to 8 digits ......................................................225

■ Downloading Drivers, Utilities, and Manuals ............................................................... 226

■ Media detector and paper path settings when using label printing applications 227

Changing the media detector settings in BarTender .......................................................................................228

Changing the paper path settings in BarTender................................................................................................230

Changing the media detector settings in NiceLabel ........................................................................................231

Changing the paper path settings in NiceLabel.................................................................................................233

Changing the media detector settings in CODESOFT......................................................................................234

Changing the paper path settings in CODESOFT ..............................................................................................235

Changing the media detector settings in Loftware Spectrum .....................................................................236

Changing the paper path settings in Loftware Spectrum ..............................................................................237

Changing the media detector settings in Loftware Print Server..................................................................238

Changing the paper path settings in Loftware Print Server ..........................................................................240

■ For Inquiries ........................................................................................................................242

14

Page 15

Chapter 1 Product Overview

Product Overview

This chapter describes features of the product.

Features

TM-C7500/TM-C7500G is a 4-color inkjet label printer that offers high processing speed, operability and reliability required for on-demand label printing.

Printing

High speed printing

Actualizes 300 mm/s high speed printing. (600 x 1200 dpi line inkjet printing)

A large capacity ink tank was adopted to reduce time lost from ink replacement.

Able to rewind roll paper after printing with the optional rewinder (Model No.: TU-RC7508).

Printing speed varies depending on the data transfer speed.

Printing speed varies depending on such operations as a print head maintenance and autocutting

operations, start/end processing for printing jobs, and periodic flushing.

Color Printing

4-color ink printing (Black, Cyan, Magenta, Yellow)

Resolution 600 x 1200 dpi

dpi: dots per 25.4 mm (dots per inch)

Supporting diverse media types

1

Supports 8-inch diameter roll paper and fanfold paper

Supports full-page labels with black mark and die-cut labels

Supports the gap between labels and blackmark position detection

TM-C7500 Series: Supports plain labels, matte labels and synthetic labels

TM-C7500G Series: Supports the plain labels, matte labels, synthetic labels, and the glossy labels

TM-C7500G Series is designed for the glossy label printing. If using paper other than the glossy label,

printing can be done although the printing color is light.

15

Page 16

Operability

The functions of this product can be set with the operation panel and LCD display. Direct network setup (IP

address, etc.) is possible without connecting to a computer.

The status or error contents of this product are displayed on LCD. The status of this product can be checked

quickly with a beep sound or flashing of various LED.

Reliability

Uses pigment ink with superior resistance to light and water.

High reliability system equipped with the Nozzle Verification Technology makes printing with dropout noz-

zles unlikely to occur.

"Nozzle Verification Technology" on page 22

See

Easy setup

Using the CD-Rom that comes with the product, you can easily setup a printer driver, install software, or per-

form media settings and settings of this product.

How to Print

A Windows printer driver that can be used with Windows applications is available.

For the label printing applications listed below, we provide dedicated drivers for the TM-C7500/TM-C7500G

series. By installing these drivers, you can easily use all of the functions of the TM-C7500/TM-C7500G in

these label printing applications.

BarTender

NiceLabel

CODESOFT

Loftware Spectrum®

Loftware Print Server®

The printer driver has a built-in barcode font and can print high quality barcodes with superior readability.

Can be used from a .NET environment application.

Epson Inkjet Label Printer SDK (a Windows printer driver is used) that supports the customer's printing

application development is available.

The product can be directly controlled with commands (ESC/Label) from customer's application.

16

Page 17

Chapter 1 Product Overview

Other Features

You can save settings such as the media type, the media size, the media source, media detection and the pre-

set image in [Favorite setting] and register it to the device to easily apply them by selecting them on the operation panel.

These settings can be applied when using applications developed by users or applications that support the

ZPL II command.

USB interface and Ethernet interface are standard. Can be used as a local printer of a computer or network

printer.

Includes an autocutter. Paper can be cut by a command from applications or panel switch operations.

Includes a beeper. Notifications are available for no media or low ink, error, end of printing, etc.

If printing is cancelled due to a no paper error, the incomplete label is cut by the auto-cutter during printing

to prevent the paper of the incomplete label from accidentally being used. For

detail, refer to

In case of a USB printer, because new print cues are generated when the damaged printer is replaced with

other printer, the settings of an application or printer driver become necessary.

This product provides the function (USB Printer Class Device Replacement Service) to replace a printer

without changing the settings of a computer or printer driver.

* This function can be set with product's firmware Ver.WAI32000 or later.

"Cutting the Incomplete Label" on page 86.

1

17

Page 18

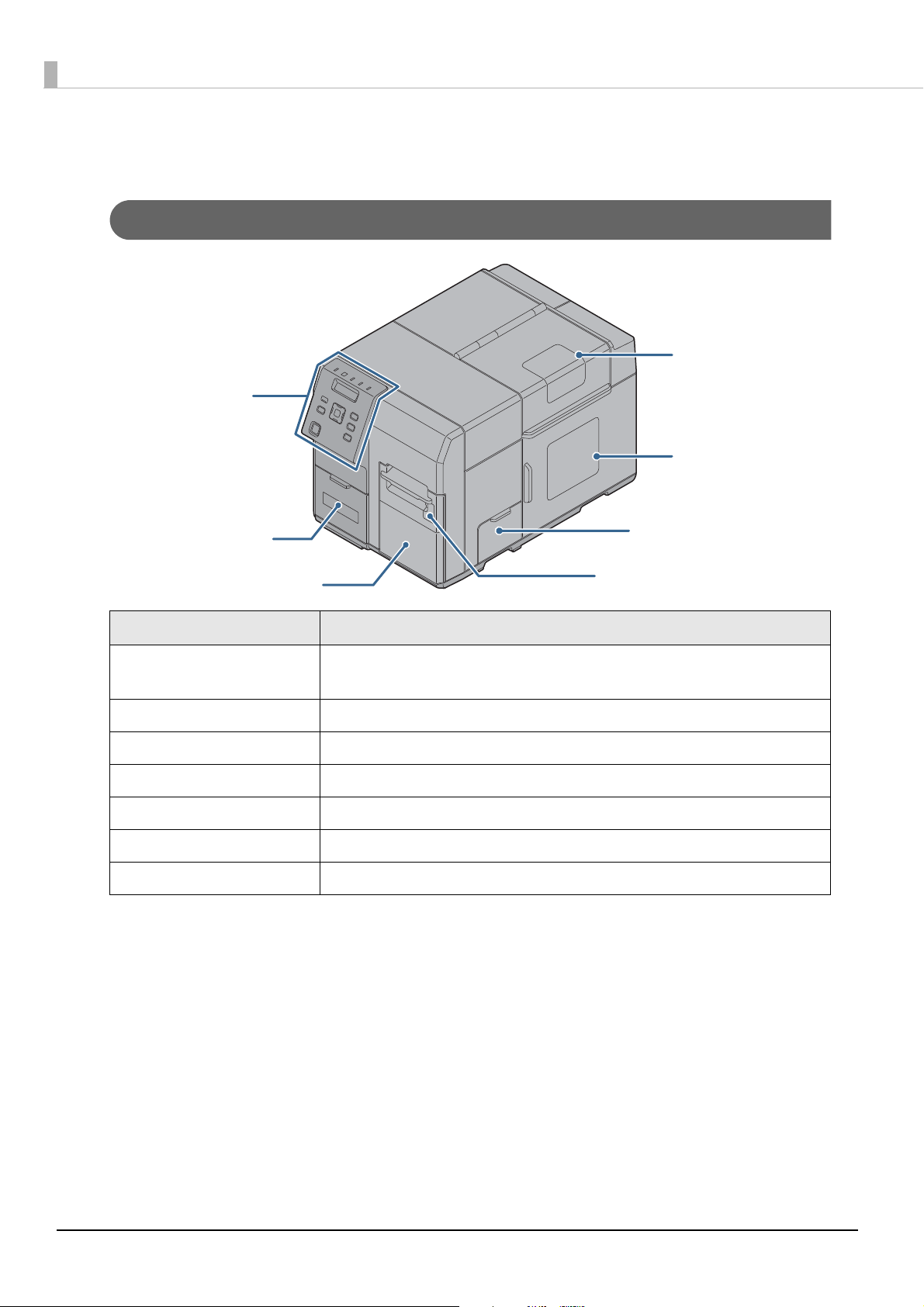

Part Names and Functions

Ink Cartridge Cover

Operation Panel

Front Cover

Rewinder Connection Cover

Maintenance Box Cover

Roll Paper Cover

Paper Set Cover

Front Side

Name Description

Operation Panel Perform various settings of this product.

For detail, see

Ink Cartridge Cover Open this cover to install/replace the ink cartridge.

Front Cover Open this cover to remove jammed paper.

Rewinder Connection Cover Open this cover to install the rewinder (option).

Maintenance Box Cover Open this cover to install/replace the maintenance box.

Roll Paper Cover Open this cover to set roll paper.

Paper Set Cover Open this cover to set roll paper or fanfold paper.

"Operation Panel" on page 19 .

18

Page 19

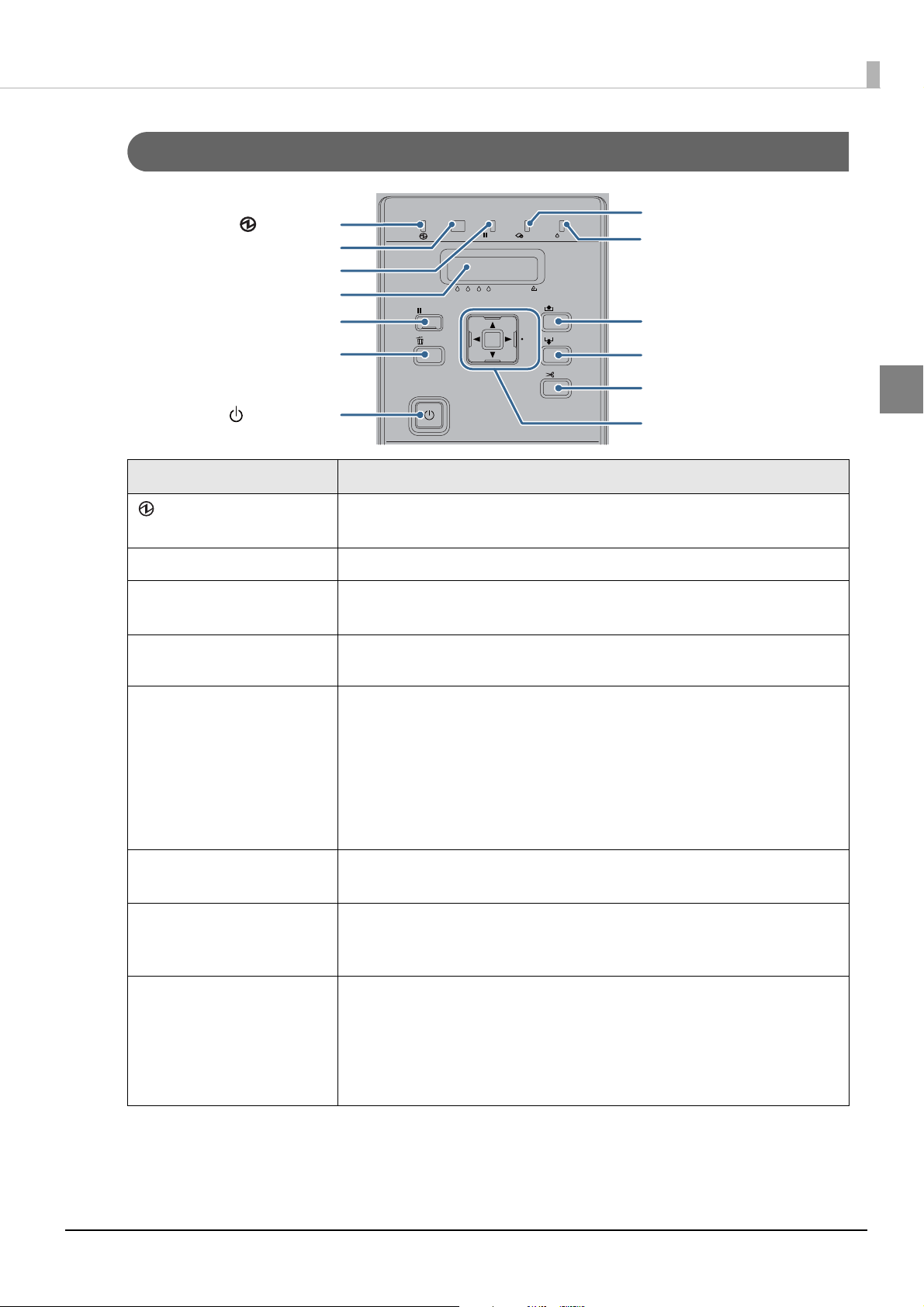

Operation Panel

Status

Pause

Pause

Cancel

Menu

OK

Paper

Ink

KC YM M/B

Back Feed

Feed

Cut

Back Feed Button

Ink LED

Paper LED

Feed Button

Cut Button

Selection/Setting Button

Cancel Button

Pause Button

LCD

Status LED

(Power) Button

Pause LED

(Power) LED

Name Description

(Power) LED Lights when the printer is powered on.

Flashes during printing or ink charging.

Chapter 1 Product Overview

1

Pause LED Lights/Flashes while the printer is paused.

Status LED Lights/Flashes in blue when the printer is operating properly.

Lights/Flashes in amber when the printer has an error.

Paper LED Lights when the printer has no paper or jammed paper, or when the Paper Set Cover,

the Roll Paper Cover, or the Front Cover is open.

Ink LED Flashes in the following conditions:

Ink is low.

The maintenance box is nearly full.

Lights in the following conditions:

The ink cartridge cover/maintenance box cover is open.

No ink cartridge/maintenance box is set.

It is time to replace the ink cartridge/maintenance box.

LCD Displays the menus and messages.

See

"Ink Cartridge and Maintenance Box Status" on page 30

Pause Button Press this button during printing to pause printing after one page of data is printed.

Press this button while the printer is paused (while the Pause LED is on) to resume

printer operation and have the printer return to the print standby status.

Cancel Button Press this button for less than two seconds while the printer is paused (while the

Pause LED is on) to cancel the first print job. Press this button for two seconds or more

to cancel all the print jobs. However, any data that is transmitted shortly after job cancelation may fail to be canceled, and may be printed unintentionally.

The printer returns to the print standby status if the button is pressed while a menu is

being executed.

19

Page 20

Name Description

(Power) Button Turns on/off the printer.

When the Dip switch 1 is ON, this product can be reset.

See "Setting the Dip Switches" on page 159

Selection/Setting Button Use this button to select/set the menus and items displayed on the LCD.

(Menu) Button: Displays the menu screen.

Button: Displays the previous menu.

/ Button: Use this button to select menus and items.

OK Button: Executes the selected menu and item.

Cut Button Cuts the paper.

Feed Button Press this button for less than three seconds to feed one page of paper.

Press this button for three seconds or more to feed the paper continuously.

Back Feed Button Press this button only when replacing paper.

After cutting the printed paper using the Cut button, hold down the Back Feed button to feed the paper backward so that you can pull out the paper.

However, to prevent paper jams, after you perform a back feed once, you cannot execute a back feed until the paper is set again.

When handling roll paper like setting it to the rewinder, do so after pausing printer operations tem-

porarily by pushing the Pause button.

When separating perforations of fanfold paper, do so after pausing printer operations temporarily

by pushing the Pause button or cutting the fanfold paper with the Cut button.

20

Page 21

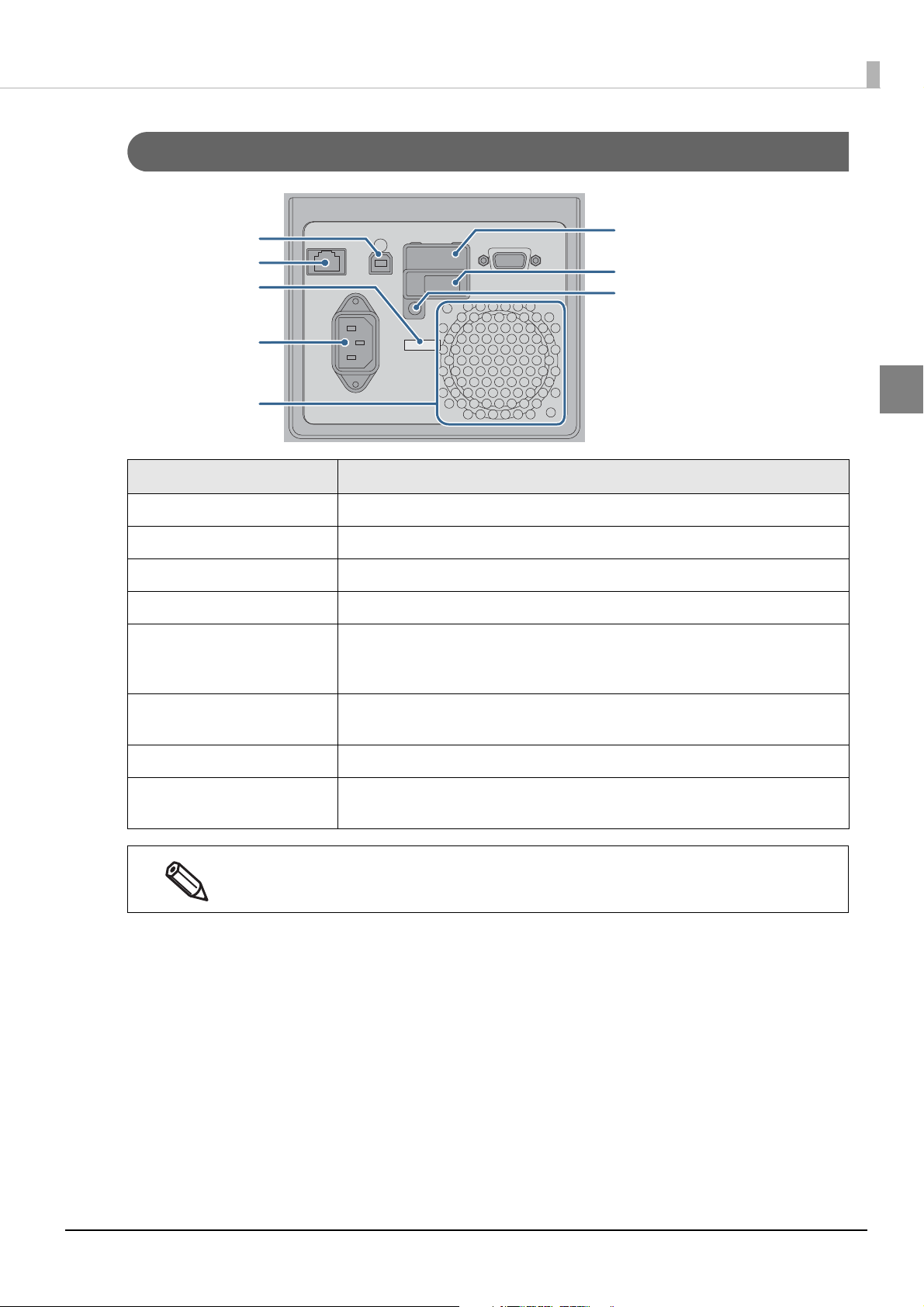

Rear Side

USB Connector

Ethernet Connector

Wire Saddle

AC Inlet

Air Vent

Dip Switch Cover

Dip Switch

Dip Switch Cover mounting screw

Name Description

USB Connector For connecting a USB cable.

Chapter 1 Product Overview

1

Ethernet Connector For connecting a LAN cable.

Wire Saddle Pass the USB cable through this saddle to prevent disconnection of the USB cable.

AC Inlet For connecting a power cable.

Air Vent Exhausts heat generated in the product to prevent an internal temperature rise. Allow

a clearance of 10 cm {3.94”} or more from the air vent to ensure ventilation when

installing the product.

Dip Switch Cover mounting

screw

Dip Switch Used when changing the function of the Power button.

Dip Switch Cover When operating the Dip Switch, remove the Dip Switch Cover Mounting Screw and

When setting the Power button operation to “Power switch disabled (Reset operation)”, make sure the

printer is not operating when turning the power OFF.

Remove the screw to open the Dip Switch Cover.

open the cover.

21

Page 22

Nozzle Verification Technology

This product has an “Nozzle Verification Technology” that detects missing dots. You can select the “Nozzle Verification Technology Enable / Disable”, “Nozzle check interval” and/or “Threshold of clogged nozzles”, depending on level of requirement for missing dots.

And when unrecoverable clogging occurs, this printer is able to carry out supplemental printing using a nearby

nozzle.

If you set “Enable” for the nozzle clog auto supplement system, it will be possible to remedy a marked fall in

print quality and barcode quality due to an irrecoverably clogged nozzle.

Setting the Nozzle Verification Technology

If you set “Enable” for the Nozzle Verification Technology, in the cases described below or every time the number of printed copies in “Setting Nozzle check interval” has been reached, an auto nozzle check will be performed.

Starting a printing job or per printed sheets specified in the interval of Nozzle check interval

Power is turned ON

The maintenance box cover is closed

The roll paper cover or paper set cover is closed after a paper jam.

If the number of nozzle dropouts that is detected exceeds the “Threshold of clogged nozzles” that you have set,

auto head cleaning will be executed to eliminate dot dropout.

Perform a nozzle check even after auto cleaning, and if the number of dropouts does not fall below the set

“Threshold of clogged nozzles“, perform auto cleaning again.

CAUTION

This Nozzle Verification Technology cannot detect 100% of dot missing cases. It cannot detect 100%

of missing dots and ink droplet curvature.

Print head maintenance is executed for all heads simultaneously. It is not executed only for the

heads and ink in which nozzle clogging was detected.

The Nozzle Verification Technology uses a small amount of ink.

After detecting a missing dot, cleaning is performed automatically and ink is also used in the clean-

ing.

22

Page 23

Setting the Nozzle Verification Technology Enable / Disable

Enable / Disable of Nozzle Verification Technology is set.

The factory setting is “Enable”.

Settings

It can be set from the setting menu of the product and PrinterSetting.

See

"Setting panel switch" on page 80 or "PrinterSetting" on page 87

Setting Nozzle check interval

Chapter 1 Product Overview

Every time the number of printed copies has been reached, the printing operation will be stopped temporarily

and the device will perform an auto nozzle check.

Settings

It can be set from the setting menu of the product and PrinterSetting.

Able to set in the unit of pages from 1 to 500

See

"Setting panel switch" on page 80 or "PrinterSetting" on page 87

Setting Threshold of clogged nozzles

Set the allowable number of nozzle dropouts when executing a Nozzle Verification Technology. When the number of nozzle dropouts exceeds the value, a head cleaning is executed.

If the number of clogged nozzles does not reach this value, the dot substitution function is activated instead of

performing head cleaning.

Settings

It can be set from the setting menu of the product and PrinterSetting.

Can be set between 0 to 10 nozzles

See

"Setting panel switch" on page 80 or "PrinterSetting" on page 87

1

The allowable number of nozzle dropouts is the total for the nozzles

for all four colors (CMYK).

The value initially set for the allowable number of nozzle dropouts is "6".

23

Page 24

Dot substitution

The dot substitution is a function that performs complementary printing using the nearby nozzles when nozzles

are clogged.

The maximum number of clogged nozzles that can be automatically supplemented is 16. However, supplementation cannot be performed adequately in the case of clogging of an adjacent nozzle.

Note that in the case of more than 16 clogged nozzles, supplementation for 16 nozzles will be implemented.

After that, printing can continue.

This function does not become enabled even when setting the dot substitution to enable if the Nozzle Verification Technology is disabled.

This function does not completely remedy falls in print quality, barcode quality and so forth.

This system carries out supplementation according to nozzle dropout information known at the

start of printing, and therefore is not able to supplement nozzle dropout that occurs during printing.

Settings

It can be set from the setting menu of this product and PrinterSetting.

The factory setting is “On”.

See

"Setting panel switch" on page 80 or "PrinterSetting" on page 87

24

Page 25

Chapter 1 Product Overview

Periodic auto cleaning

A periodic auto cleaning can be executed to maintain the printer heads in good condition.

A periodic auto cleaning takes 2 to 30 minutes. No printing can be performed during the cleaning.

You can set the time for implementation of periodic auto cleaning.

If periodic auto cleaning implementation time setting is disabled, periodic auto cleaning will be implemented at

a time that the printer judges necessary, for example when a fixed time has elapsed since the previous periodic

auto cleaning.

If the power is off at the time you set, the periodic auto cleaning will be implemented the next time

the power is turned on.

Periodic auto cleaning may sometimes be implemented when the power is turned on after having

been off for an extended period.

1

25

Page 26

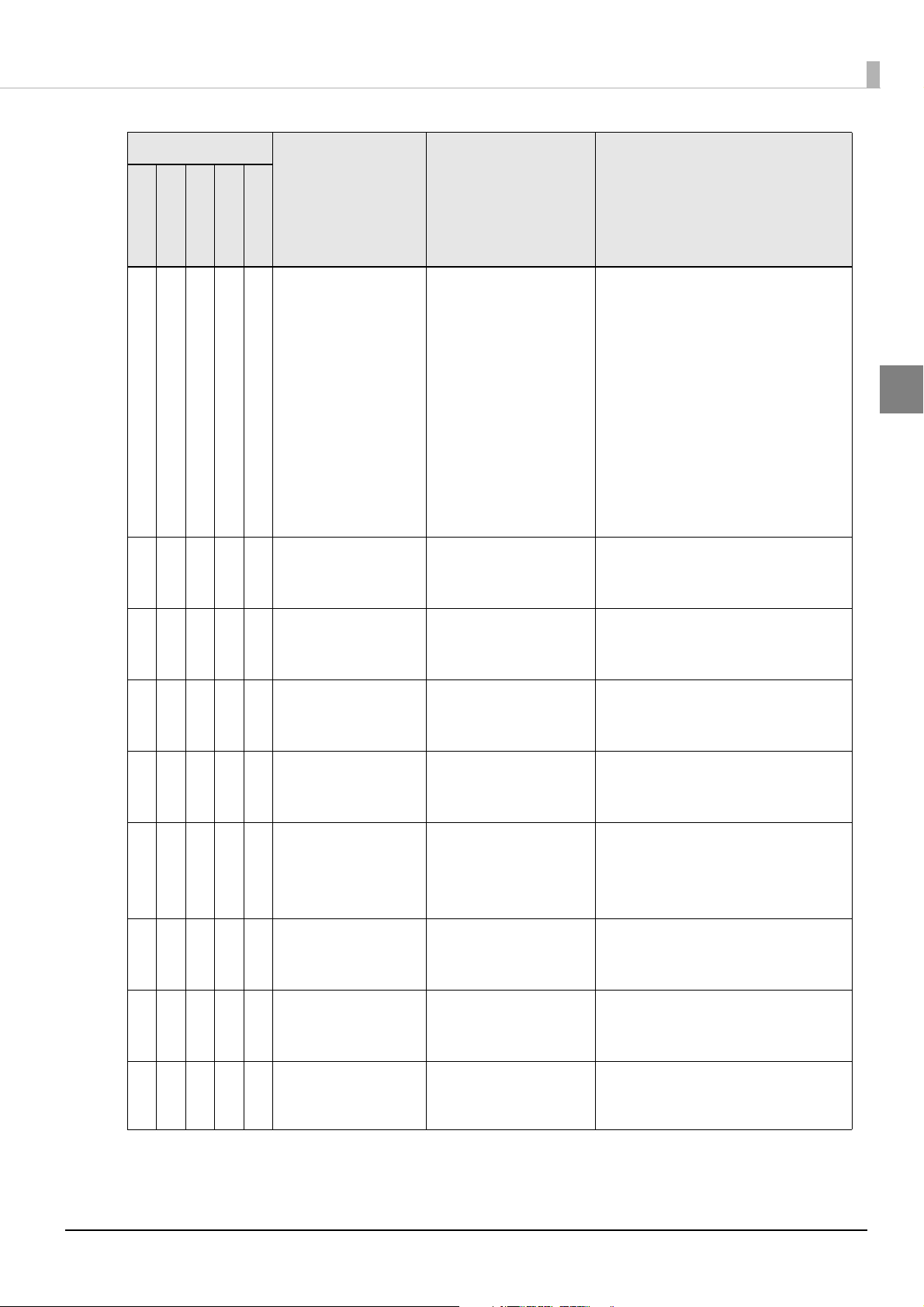

Status/Error Indications

The printer status is indicated by a combination of LED lighting/flashing and LCD indication.

When an error occurs, you can find out the cause and the remedy from the LED & LCD indication for the error.

The color of marks in the Table represents the LED color of the product.

The marks in the Table indicate the following status respectively.

●:Lit up

✓:Off

▼: Flashing (Normal)

▲:Flashing (Fast)

- : No change

LED

LCD Printer Status Description

Ink LED

Paper LED

Pause LED

Status LED

(Power) LED

▼● ✓✓✓

▼● ✓✓✓

▼● ---

▲● ---

●●---

●●---

■■■■■■■■■■■■■■■■

■■■■■■■■■■■■■■■■

EPSON

TM-C****

INITIALIZING

* * * * *

POWER OFF

* * * * *

READY

* * * * *

POWER SAVING

* * * * *

For 2 seconds after the

power is turned ON

For 2 to 4 seconds after

the power is turned ON

4 seconds after the power

is turned ON and until the

printer switches to the

idling status

Performing the powering

off process

Idling The state in which printing is possible.

Idling (with power saving) If the product does not operate for 30

-

The model name is displayed on LCD.

The LCD displays the remaining level of

ink and the available amount of space in

the maintenance box.

During this time, do not forcibly turn the

power OFF, such as by pulling out the AC

power Doing so can cause ink nozzle

dropouts.

During the time, the following operations can be done.

Turn off the product

Transition to pause status

Transition to setting mode

Feed, Back feed, or Auto cut the paper

minutes or more while the power is ON,

it moves to the power saving mode.

▼● ---

▼● ---

26

PRINTING

* * * * *

WORKING

* * * * *

Printing A beep sounds when printing is done.

After printing is done, the

printer moves to idling

Page 27

(Power) LED

Status LED

LED

Chapter 1 Product Overview

LCD Printer Status Description

Ink LED

Paper LED

Pause LED

● - ● --

●✓---

● - ● --

● ● ---

● ● ---

● ●●--

PAU S E

* * * * *

MENU

* * * * *

CANCELING JOB

* * * * *

PRINTING-NOZZLE

CHECK DISABLED

* * * * *

NOZZLE CLOGGED

* * * * *

NOZZLE CLOGGED

CHECK THE PRINT

PRESS PAUSE

TO CONTINUE

Pause When the Pause button is pushed during

printing, the printer becomes this status.

It is possible to go to the setting mode

from this state.

Menu When the Menu button is pushed, the

printer becomes this status.

Canceling the jobs When the Cancel button is pushed

during printing, print jobs are canceled,

printing is interrupted and print data

inside the printer are deleted.

Nozzle Verification Technology is disable (*1)

Unrecoverable nozzle

dropouts happen (*1)

Nozzle clogged (*1) Printing is paused temporarily, since noz-

When dot dropouts cannot be detected

due to low environmental temperature,

the LCD display shows a message. Printing continues.

This display is shown when unrecoverable nozzle dropouts happen. Printing

continues.

zle dropouts happened during printing.

Printing restarts when the Pause button

is pushed. When canceling printing, push

and hold the CANCEL button for two seconds or more before pushing the Pause

button.

button and button switch the

LCD display.

1

● ▼● --

● ▼● --

● ▼● --

● ▼● - ●

● ▼● - ●

● ▼● ● -

ROLL COVER OPEN

* * * * *

FRONT COVER OPEN

* * * * *

PAPER COVER OPEN

* * * * *

MAINTENANCE BOX

COVER OPEN

* * * * *

INK CARTRIDGE COVER

OPEN

* * * * *

MEDIA DETECTION

ERROR

* * * * *

Roll paper cover open (*1) The Roll paper cover is open.

Front cover open (*1) The Front cover is open.

Paper cover open (*1) The Paper set cover is open.

Maintenance box cover

open error (*1)

Ink cartridge cover open

error (*1)

Media detection error (*1) The printer media detector's setting and

The Maintenance box cover is open.

The Ink cartridge cover is open.

the media in the printer are different.

button can be used to move to the

setting mode and set the media detector.

27

Page 28

(Power) LED

Status LED

LED

LCD Printer Status Description

Ink LED

Paper LED

Pause LED

● ▼● ● -

● --● -

● ▼● ● -

● ▼● ● -

● ▼● ● -

● ▼● ● -

● ----

MEDIA DETECTION

ERROR

* * * * *

NO PAPER

* * * * *

MEDIA SIZE ERROR

* * * * ## *

NO PAPER ERROR

* * * * *

PAPER JAM ERROR

* * * * ## *

PAPER REMOVAL

ERROR

* * * * *

CUT UNAVAILABLE

* * * * *

Media detection error (*1) The media type settings of the printer

and the media in the printer are different.

button can be used to move to the

setting mode and set the media type.

No paper (*1) No paper is available.

Media size error (*1) The media size settings of the printer and

the size of the media in the printer are

different.

No paper error (*1) No paper is available.

Paper jam error (*1) The paper is jammed.

Paper removal error (*1) Printing ended when the last edge is

removed from the core during printing.

Jobs still printing end and then the paper

removal error occurs.

In cutter unavailable state

(*1)

Autocutting is being performed 2 or

more times with the paper in the same

position.

● ▼● - ●

▼● ---

▼● ---

● ---▼

● ▼● - ●

● ▼● - ●

NO INK CARTRIDGE

* * * * *

INK CHARGING

* * * * *

HEAD MAINTENANCE

* * * * *

INK LOW (*2)

* * * * *

REPLACE INK (*3)

* * * * *

INK CARTRIDGE READ

ERROR

* * * * *

No ink cartridge (*1) An ink cartridge is not loaded.

Ink charging Performing ink charging (initial charge).

Caution: Do not turn this product's

power OFF until it is finished.

Executing ink sequence Printer head maintenance is being exe-

cuted.

Caution: Do not turn this product's

power OFF until it is finished.

Ink is running low (*1) The level of ink indicated in the LCD dis-

play is low and ink cartridges need to be

changed soon. Printing is possible.

Ink cartridge is expended

(*1)

Ink cartridge reading

error (*1)

The ink cartridges indicated in the LCD

display need to be changed. Check the

target ink on the LCD screen.

The ink cartridge information could not

be read.

28

Page 29

(Power) LED

Status LED

LED

Chapter 1 Product Overview

LCD Printer Status Description

Ink LED

Paper LED

Pause LED

● ---●

● ▼● - ●

● ▼● - ●

● ---▼

NON-GENUINE

CARTRIDGE MAY

NOT PERFORM AT

OPTIMUM LEVEL

CONTINUE?

YES

CONTINUE?

NO

PLEASE USE

GENUINE EPSON

INK CARTRIDGE

* * * * *

NO MAINTENANCE

BOX

* * * * *

MAINTENANCE BOX

ERROR

* * * * *

MAINTENANCE BOX

NEAR FULL

* * * * *

Non-genuine cartridge

(*1)

Maintenance box not

loaded (*1)

Maintenance box reading

error (*1)

Maintenance box near full

(*1)

Non-genuine ink cartridge is used.

1

The maintenance box is not loaded

The maintenance box error occurred.

The maintenance box has almost no free

space left.

Maintenance box full (*1) The maintenance box has no free space

left.

Memory over-capacity This occurs when creating a file that

exceeds the available size of this product's built-in storage (SD, built-in RAM).

The product is near the

end of its service life (*1)

The product is beyond its

service life.

Malfunction (*1)

Fatal error (*1) A fatal error occurred in the printer. No

The maintenance service of the printer is

due soon. Printing is possible.

Printer maintenance is necessary. No

printing can be performed.

printing can be performed. Repairs are

required.

● ▼● - ●

● ●●--

● ----

▼ ▼▼▼▼

▼ ▼▼▼▼

REPLACE MAINTENANCE BOX

* * * * *

MEMORY FULL

WRITE FAILURE

PRESS PAUSE

TO CONTINUE

SERVICE REQUIRED

SOON

* * * * ## *

SERVICE REQUIRED

* * * * ## *

PRINTER ERROR

* * * * ## *

*1: Recovery method: See "Troubleshooting" on page 167

*2: When the firmware version is WAI32500 or earlier, "INK CARTRIDGE NEAR EMPTY" is displayed.

*3: When the firmware version is WAI32500 or earlier, "INK CARTRIDGE EMPTY" is displayed.

29

Page 30

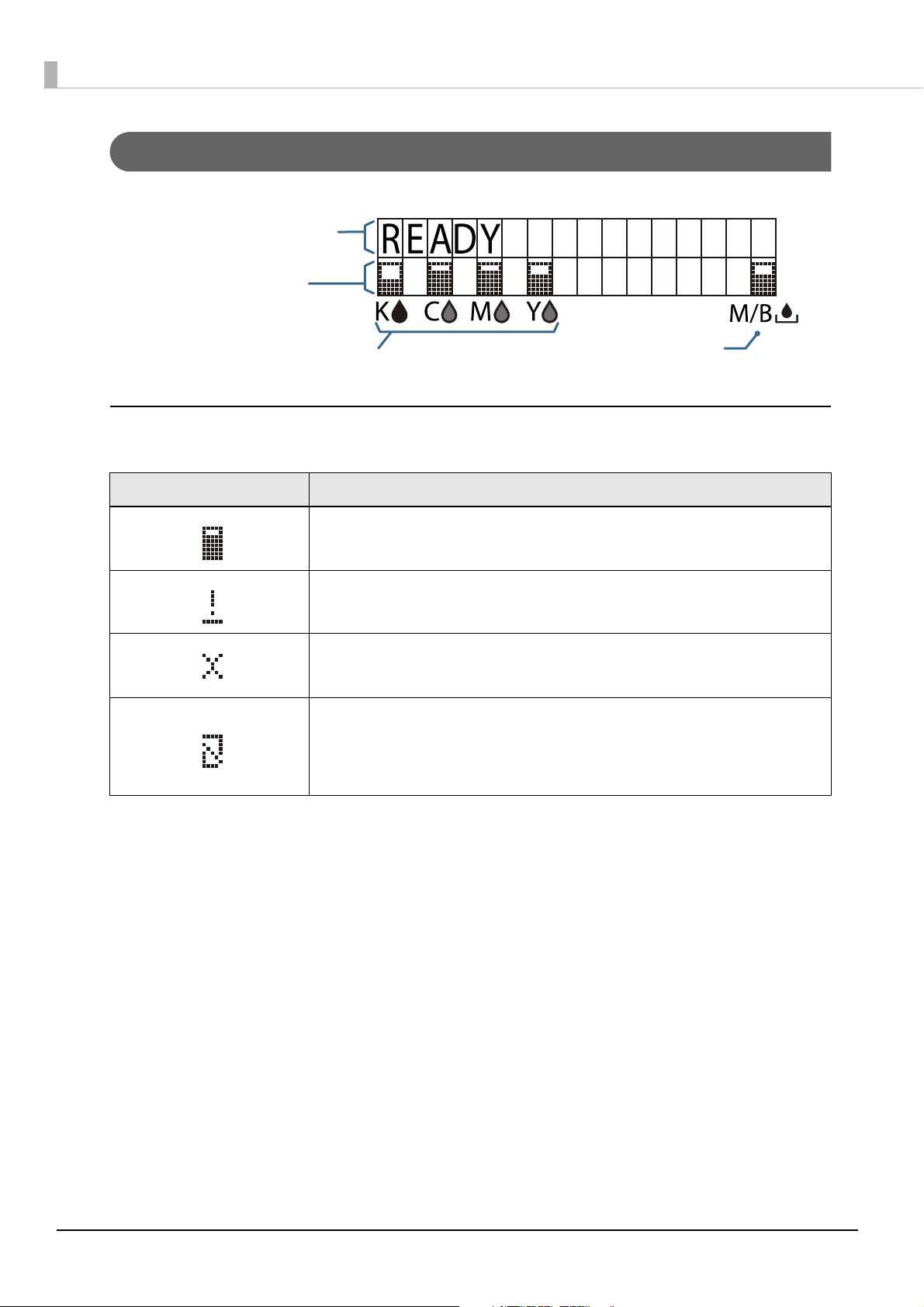

Ink Cartridge and Maintenance Box Status

Amount used for the maintenance box

Amount remaining for the ink cartridge

(black ink, cyan ink, magenta ink, yellow ink)

displays the status of the

ink cartridges and maintenance box

Row 2:

displays the

printer’s status

Row 1:

You can check the status of the printer, the ink cartridges, and the maintenance box from the LCD.

Display of the ink cartridge, maintenance box status

Displays the status of ink cartridges and maintenance box with icons.

Icon Status

Display of amount remaining for the ink cartridge

Display of free space in the maintenance box

Display for “Ink cartridge low”

Display for “Maintenance box near full”

Display for “Replace ink cartridge”

Display for “Replace maintenance box”

Display for “No ink cartridge”

Display for “Ink cartridge read error”

Display for “No maintenance box”

Display for “Maintenance box read area”

30

Page 31

Chapter 1 Product Overview

Beeper

The pattern of beeper sound is shown in the below table. The beeper continues to beep until all the causes of

error are removed.

Frequency: Fixed to approximately 2.5 kHz

Volume control: 5 levels on the software (you can turn the sound off)

Number

Sounding

period

Silent

period

of the pat-

tern

repeated

Overall

time

Number of

times repeated

Printer event

500 ms 200 ms 5 6 seconds

100 ms 100 ms 5 1 second 1

Until the error fac-

tor is removed.

Service required

Printer error

Replace ink cartridge

Replace maintenance box

Media detection error

Media size error

Paper jam error

Paper removal error

No paper error

Ink cartridge cover open

Maintenance box cover open

Paper set cover open

Roll paper cover open

Front cover open

Auto loading failure

Storage capacity over

No ink cartridge

No maintenance box

Ink cartridge read error

Maintenance box read error

1

1 second - None - 1 Printing finished

Operation panel sound volume

100 ms - None - 1

change

Auto loading successes

31

Page 32

Reprint

Paper feed direction

Printer

Not included

in reprinting

Included

in reprinting

Included

in reprinting

Yellow head

Magenta head

Cyan head

Black head

Reprinting is carried out when an error other than a fatal error or maintenance error occurs during printing.

“During printing” means the time from paper loading up until the yellow head’s printing operation

ends.

This printer employs the 4-color line printing method, and so the reprinting will print one or more

(depending on the length of the labels used) unfinished pages in which printing by some of the

heads only is completed.

Reprinting is carried out in units of pages.

If an error that is the cause of reprint is cleared by canceling the job, printer reset, or power on/off,

the printer does not perform reprint.

32

Page 33

Chapter 2 Setup

Setup

This chapter describes the installation and setup of the product and peripherals necessary before using this

product.

This product can be set up using the following methods.

Perform setup following the Install Navi on the included CD-ROM. (

Use the computer to start the Install Navi on the included CD-ROM and follow the procedure to set up this

product.

Setup this product without using the Install Navi. (

page 35)

page 34)

2

33

Page 34

Install Navi

By using the Install Navi, this product can be set following the steps shown on the screen.

Unpacking and Installing the this product in advance. See the following for details.

Checking the Items Included in the Package (page 36)

Installing the Printer (page 37)

The setup procedure is as follows.

Turn on the computer.

1

Check that the product's power is OFF.

2

Make sure the printer's power is OFF.

Insert the CD-ROM in your computer and the Launcher automatically starts.

3

Click [Printer Setup] to start the Install Navi.

When the Install Navi is executed, the following screen is displayed. Agree to the

4

SOFTWARE LICENSE AGREEMENT and click [Next]. Follow the instructions on the

screen from here on to setup this product.

One of the setup steps of Install Navi is "Software installation" in which printer drivers, PrinterSetting and other

software can be installed.

The product can be setup without installation. Also, the software can be installed later.

See the following if you are installing the rewinder.

How to install the REWINDER (page 49)

Attaching the paper leading edge to the rewinder (page 50)

This completes the setup of the product.

34

Page 35

Chapter 2 Setup

3. Connecting the Power Cable (page 39)

2. Installing the Printer (page 37)

1. Checking the Items Included in the Package (page 36)

4. Connecting the Interface Cable (page 40)

5. Installing the Ink Cartridge (page 42)

8. Attaching the paper leading edge to the rewinder (page 50)

7. Setting the Paper (page 52)

9. Printer settings (page 63)

10. Paper settings (page 67)

11. Test printing (page 74)

Completing Setup

6. How to install the REWINDER (page 49)

Work flow to set up this product without using the Install Navi

This chapter explains the installation and settings for this product and the peripherals necessary before using

this product.

2

Please check the printing result depending on the environment after setup, you want to use.

35

Page 36

Checking the Items Included in the Package

When using the printer for the first time, check the items included in the package.

The items included in the package are as follows:

ABCD

EF

G

A TM-C7500 Series B Ink cartridge(C, M, Y, K) *

D USB cable E Roll paper F AC cable

G Cushioning material *

*1 It can be used for initial ink charging.

*2 This is required when re-shipping the product. Keep it in a safe place.

2

1

CCD-ROM

36

Page 37

Installing the Printer

Secure sufficient space in a location appropriate for installation.

Two people are required to lift up this product.

CAUTION

Chapter 2 Setup

The weight of this product is approximately 37 kg {81.57 lb}. When lifting up this product, place the

product between two people as shown in the figure below and hold the recessed areas on both

sides of the product. Carrying the product by holding other areas may damage the product. When

placing the product on the floor, be careful not to get your fingers caught between the product

and the installation surface.

Lift up this product in a natural posture, for example, bending your knees a sufficient amount.

Lifting the product in an inappropriate posture may cause injury to the worker or damage to the

product.

Do not tilt the product more than 10 degrees in any direction while carrying it. Doing so may cause

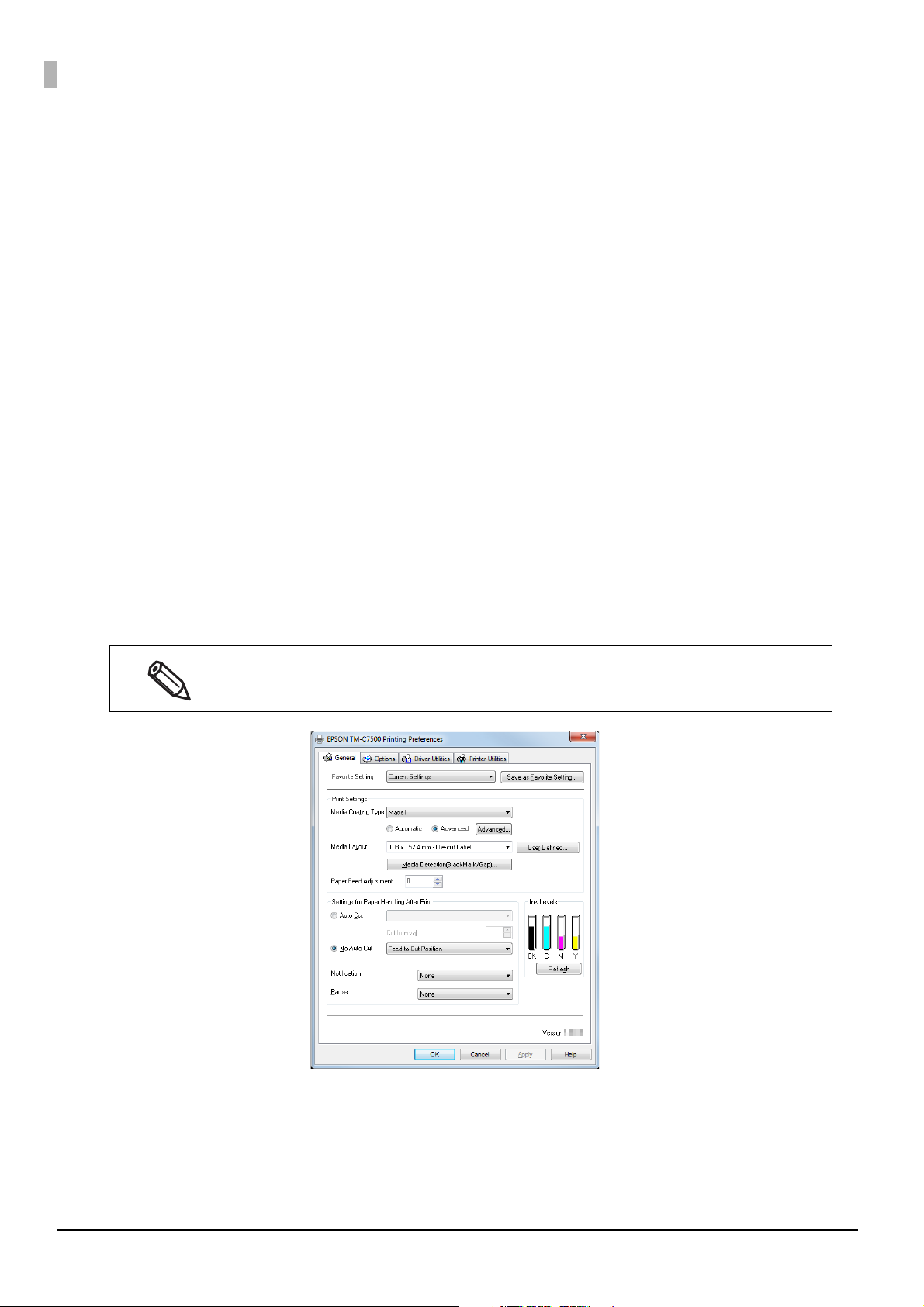

an accident.