Page 1

TITLE

SHEET

C

NO.

NEXT

SHEET

1

ESC/Label

Application Development Guide

for TM-C7500 series

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 2

TITLE

SHEET

C

NO.

NEXT

SHEET

2

TABLE OF CONTENTS

Introduction ................................................................................................................................... 4

1

1.1 Outline ............................................................................................................................................................................... 4

1.2 Applicable Scope ............................................................................................................................................................... 4

1.3 Reference Documents ....................................................................................................................................................... 4

2 Basic Printing Method .................................................................................................................. 5

2.1 Points for structure Print Commands ................................................................................................................................. 5

2.2 Basic Structure of Printing Commands .............................................................................................................................. 5

2.3 Example Printing Command .............................................................................................................................................. 6

3 Functions to be implemented ..................................................................................................... 10

3.1 List of Functions .............................................................................................................................................................. 10

3.2 Media Coating Type Setting ............................................................................................................................................ 11

3.3 Media Layout Setting ....................................................................................................................................................... 12

3.4 Completion Autocut Setting ............................................................................................................................................. 17

3.5 Completion Beeper Setting.............................................................................................................................................. 18

3.6 Completion Pause Setting ............................................................................................................................................... 19

3.7 Printing Color Correction Mode Setting ........................................................................................................................... 20

3.8 Ink Profile and Brightness Adjustment Setting ................................................................................................................ 21

3.9 Ratio of Black to Composite Setting ................................................................................................................................ 22

3.10 Bar Width Adjustment Setting .......................................................................................................................................... 24

3.11 Banding Reduction Setting .............................................................................................................................................. 25

3.12 Printing Speed Setting ..................................................................................................................................................... 26

3.13 Head maintenance Setting .............................................................................................................................................. 27

3.14 Label Edge Detector Setting ............................................................................................................................................ 28

3.15 Media Source Setting ...................................................................................................................................................... 29

3.16 Nozzle Verification Technology Settings ......................................................................................................................... 30

3.17 Printing Start Position Adjustment Setting ....................................................................................................................... 31

3.18 Re-print Setting ............................................................................................................................................................... 31

3.19 LED Notification Setting (Ink Cartridge Low) ................................................................................................................... 32

3.20 Paper Feed Adjustment Setting ....................................................................................................................................... 32

3.21 TrueType Font Download ................................................................................................................................................ 33

3.22 Display Consumables Information ................................................................................................................................... 34

3.23 Head Cleaning ................................................................................................................................................................. 37

3.24 Print Nozzle Clogging Check Pattern .............................................................................................................................. 37

4 Notes on Communication ........................................................................................................... 38

4.1 DeviceID .......................................................................................................................................................................... 38

4.2 String Descriptor .............................................................................................................................................................. 38

4.3 Receiving Buffer Full Control ........................................................................................................................................... 38

4.4 Notes If Using Printer Information request Command ..................................................................................................... 39

4.5 Notes if Using Commands that Request Resonse from the Printer ................................................................................. 39

4.6 Notes If Using USB and Network Interface Together ...................................................................................................... 40

4.7 Printing Cancel ................................................................................................................................................................ 40

5 How to print labels efficiently ...................................................................................................... 41

5.1 Outline ............................................................................................................................................................................. 41

5.2 Procedure ........................................................................................................................................................................ 42

6 Paper Feed Adjustment .............................................................................................................. 55

6.1 Type of the Paper Feed Adjustment ................................................................................................................................ 55

6.2 Method of Paper Feed Adjustment for EPSON Standard Label(Default Setting) ............................................................ 56

6.3 Method of Paper Feed Adjustment for EPSON Recommended Label ............................................................................ 56

6.4 Method of Paper Feed Adjustment for Other Label ......................................................................................................... 56

6.5 Detail Procedure of Each Step ........................................................................................................................................ 57

7 Control of Beeper Sounding, Cuts, and Pauses ........................................................................ 60

7.1 Outline ............................................................................................................................................................................. 60

7.2 Beeper Sounding ............................................................................................................................................................. 61

7.3 Pause .............................................................................................................................................................................. 62

7.4 Cut ................................................................................................................................................................................... 64

7.5 Example of Combining Cutting and Pausing ................................................................................................................... 65

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 3

TITLE

SHEET

C

NO.

NEXT

SHEET

3

Cautions

1. This document shall apply to the product(s) to which this document relates.

2. The examples, such as the sample codes or control methods for products described in this document are for

the purpose of designing a model only, and Seiko Epson Corporation shall not provide any sort of warranty

that the contents of the document do not infringe on any intellectual property right of a third party.

3. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

4. The contents of this document are subject to change without notice. Please contact us for the latest

information.

5. While every precaution has been taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

6. Neither is any liability assumed for damages resulting from the use of the information cont ained herein.

7. Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of the product(s) to which this document relates or unauthorized modifications,

repairs, or alterations to the product(s) to which this document relates, or (excluding the U.S. ) failure t o str ictly

comply with Seiko Epson Corporation's operating and maintenance instructions.

8. When the product(s) to which this document relates are used for applications requiring high reliability / safety,

such as transportation devices related to aviati on, rail, marine, automotive, etc.; disaster prevention devices;

various safety devices, etc.; or functional / precision devices, etc., you should use the product(s) t o which this

document relates only after giving consideration to including f ail-safes and redundancies into your design to

maintain safety and total system reliability. B ecause the product(s) to which this document relates were not

intended for use in applications requiring extremely high reliability / safety, such as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment related to direct

medical care, etc., please make your own judgment on the products' suitabil ity after a full evaluation.

9.Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those designated as Original EPSON Products or E PSON

Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/Label are registered trademarks or t r ademarks of Seiko Epson Corporation.

Zebra Technologies Corporation and ZPL II are the registered tr ademarks or trademar ks of Zebra T echnologies

Corporation.

General Notice: Other product and company names used herein are for identific ation purposes only and may be

trademarks of their respective companies.

©Seiko Epson Corporation 2014-2015. All rights reserved.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 4

TITLE

SHEET

C

NO.

NEXT

SHEET

4

1 Introduction

1.1 Outline

This document explains the necessary technical information for developing printer control

software (drivers, utilities and application) for the TM-C7500 series using the ESC/Label

command. For detailed specifications of the ESC/Label command, please refer to the

ESC/Label Command Reference Guide. They will not be described in this document.

1.2 Applicable Scope

This document applies to the development of control software for the TM-C7500 series that use

the ESC/Label command.

1.3 Reference Documents

Ø ESC/Label Command Reference Guide

Ø ESC/Label Command List

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 5

TITLE

SHEET

C

NO.

NEXT

SHEET

5

Figure 2-1 Basic Structure of Print Com m ands

2 Basic Printing Method

This section describes how commands are structured, using printing a basic label as an

example.

2.1 Points for structure Print Commands

ž If you want to change printing settings for each print, send t he set ting command for each print.

Ø The print settings can also be saved to the printer. However, we recommend that you

send the setting command for each print for settings that are likely to change for each

print. The settings for setting commands sent for each print are given priority over

settings saved to the printer.

ž To set settings for the label edge detector or paper media source, we recommend checking

that the printer is idle then sending the setting command while replacing paper.

Ø These settings are printer settings that are applied in print operations after the settings are

changed. When changing settings, if there is still unprinted print data in the printer, the

settings after the change may unintentionally be applied.

2.2 Basic Structur e of Printing Commands

The following indicates the basic structure of commands sent for printing.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 6

TITLE

SHEET

C

NO.

NEXT

SHEET

6

Table 2-1 Description of Basic St ructure of Print Commands

Item

Description

Setting commands for each print

Allocates commands that perform print settings for each print.

However, if there are other applications or drivers

Therefore, we recommend sending the

.8.1 of ESC/Label

Command Reference Guide).

Commands for saving graphics

Allocates commands for saving the graphics to be printed in the

printer.

Print commands

Allocates commands related to printing and instructions for

operation to the printer.

Rendering commands

Allocates commands for rendering print data such as text,

barcodes, and graphics.

Post-print operation commands

Allocates commands for post-print printer operations such as the

autocut, sounding the buzzer, and pause the printer.

Print termination commands

Allocates commands for cleaning up after the print.

ESC/Label Command Reference Guide) , etc..

Settings are unnecessary if printing using the setting values set in

the printer.

that use the printer, there is a possibility of the printer settings will

be overwritten.

commands for each print.

And, delete the files that remain in the printer, and might become a

potential cause of shortage of the drive space for command

executions that follow (refer to the section 2

Delete the files registered for the print (refer to the section 2.8.1 of

2.3 Example Print i ng Com m and

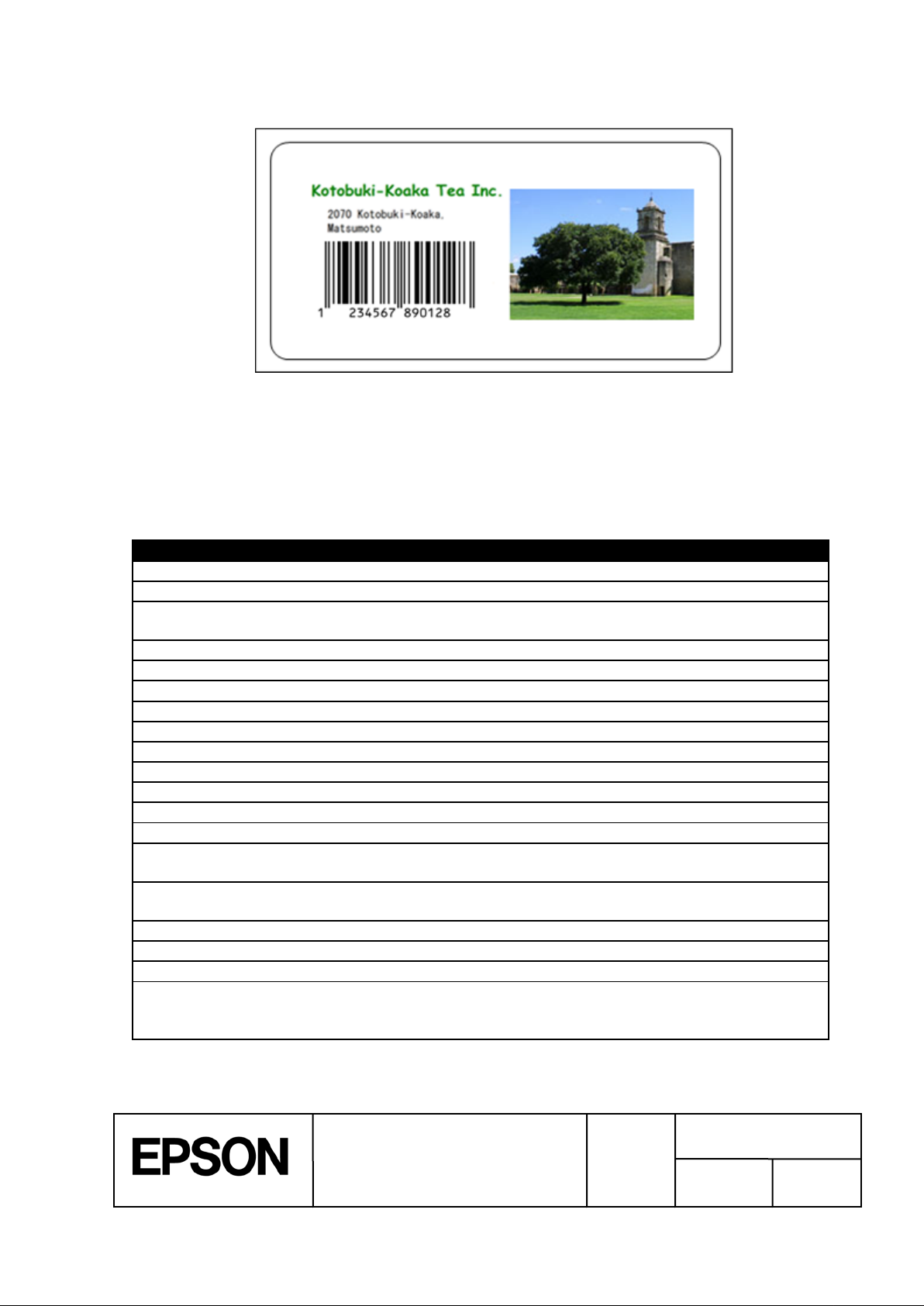

2.3.1 Description

In this example, imagine you are printing the label in Figure 2-2. The following indicates the

main structures of the label.

ž Use the TrueType font registered in the printer to print “Kotobuki-Koaka Tea Inc.” in green.

ž Print an EAN-13 barcode.

ž Print “IMG001.PNG”, an image of tree.

Application Development Guide

ESC/Label

for TM-C7500 series

REVISION

Page 7

TITLE

SHEET

C

NO.

NEXT

SHEET

7

Figure 2-2 Sample Label

Table 2-2 List of Sample Printing Sett i ngs

Item

Setting

Media coating type

Matte

Media form

Die-cut label

Label edge detection

method

Black mark detection

Media width

2645 [dot] (112.0 [mm])¹

Label width

2551 [dot] (108.0 [mm])¹

Label length

3600 [dot] (152.4 [mm])¹

Left gap

47 [dot] (2.0 [mm])¹

Top margin

35 [dot] (1.5 [mm])¹

Bottom margin

35 [dot] (1.5 [mm])¹

Left margin

35 [dot] (1.5 [mm])¹

Right margin

35 [dot] (1.5 [mm])¹

Feather edges

Disable

Color correction

EPSON Standard

Ink profile and

brightness adjustment

0

Ratio of black to

composite setting

0

Bar width adjustment

0

Head maintenance

Continuous

Printing speed

12 [inch/sec] (300 [mm/sec])

Post-print operations

Autocut after printing is completed

Printer pauses after printing is completed

Also, for this example, imagine you are print ing using the settings in Table 2-2.

¹The unit of the setting value can be selected from dot/mm/inch by ^S(CMP,U or ^MU command.

Buzzer does not sound after printing is completed

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 8

TITLE

SHEET

C

NO.

NEXT

SHEET

8

[Setting commands for each print]

[Commands for saving graphics]

[Print commands]

< Rendering commands >

2.3.2 Commands

^XA Begins label format.

^IDR:*.*^FS Delete the files that remain in the pri nter.

^S(CLR,R,600 Sets the format base in dots per inch to 600 [dpi].

^S(CLR,P,600 Sets the print resolution to 600 [dpi].

^S(CLM,T,M1 Sets the media coating type to Matte1.

^S(CLM,F,DL Sets the media form to Die-cut Label.

^S(CLM,P,IR Sets the media source to internal roll.

^S(CLM,S,RP Sets the media shape to roll paper.

^S(CLM,D,M Sets the detection method to Black mark detection.

^S(CLS,P,2551 Sets the label width to 2551 [dot].

^S(CLS,L,3600 Sets the label length to 3600 [dot].

^S(CLS,G,47 Sets the left gap to 47 [dot].

^S(CLW,T,35 Sets the top margin to 1.5[mm].

^S(CLW,B,35 Sets the bottom margin to 1.5[mm].

^S(CLW,L,35 Sets the left margin to 1.5[mm].

^S(CLW,R,35 Sets the right margin to 1.5[mm].

^S(CPC,E,D Sets the feather edges function to be not performed.

^S(CPC,C,N Sets the color correction mode to EPSON Preferred

Color.

^S(CPC,D,0 Sets the ink profile and brightne adjustment to 0.

^S(CPC,P,0 Sets the ratio of black to composite setting to 0.

^S(CPC,B,0 Sets the banding reduction to 0.

^S(CBW,C,0 Sets the bar width adjustment to 0.

^S(CMP,F,2 Sets the flush onto paper mode to 2.

^S(CMP,S,12 Sets the printing speed to 12 [inch/sec].

^S(CMP,M,C Sets the printer operation mode to cutter.

^S(CLE,M,10 Adjusts the label left edge position to left 10[dot].

^S(CLE,T,12 Adjusts the label leading edge position

to upper 12[dot].

^S(CLP,M,5 Sets the paper feed adjustment to 5[pixel]

^S(CMV,I,100 Sets the auto nozzle check interval to 100 labels.

^S(CMV,O,N Sets the operation at clogged nozzle detection

to notifying.

^XZ Ends label format.

~DYR:IMG001,B,P,39628,, Saves the PNG file “IMG001.PNG” in the R drive.

^XA Begins label format.

^FO216,216 Field origin: (216, 216)

^A@N,90,90,R:TT001.FNT Calls up the TrueType font registered in the printer.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 9

TITLE

SHEET

C

NO.

NEXT

SHEET

9

< Post-print operation commands >

[ Print termination commands ]

^F(C0,128,0,255,0,0,0,0,0,0 Sets the font color to green.

^FDKotobuki-Koaka Tea Inc.^FS Prints “Kotobuki-Koaka Tea Inc.”.

^FO300,348 Field origin: (300, 348)

^A0,N,32,25 Sets the font to Font0.

^FD2070 Kotobuki-Koaka^FS Prints “2070 Kotobuki-Koaka”.

^FO300,438 Field origin: (300, 438)

^A0,N,32,25 Sets the font to Font0.

^FDMatsumoto^FS Prints “Matsumoto”.

^FO300,540 Field ori gin: (300, 540)

^BY9^BEN,360,Y,N^FD123456789012^FS

Prints the EAN-13 barcode.

^PON Sets the printing direction to standard.

^FO1320,240 Field origin: (1320, 240)

^IMR:IMG001.PNG^FS Loads the image saved in the R drive,

“IMG001.PNG”.

^S(CUB,S,N Sets for the buzzer not to sound after printing is

completed.

^PQ1,1 Sets to pause printer after printing is completed.

^XZ Ends label format.

^XA Begins label format.

^IDR:*.*^FS Delete the files registered for the print.

^XZ Ends label format.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 10

TITLE

SHEET

C

NO.

NEXT

SHEET

10

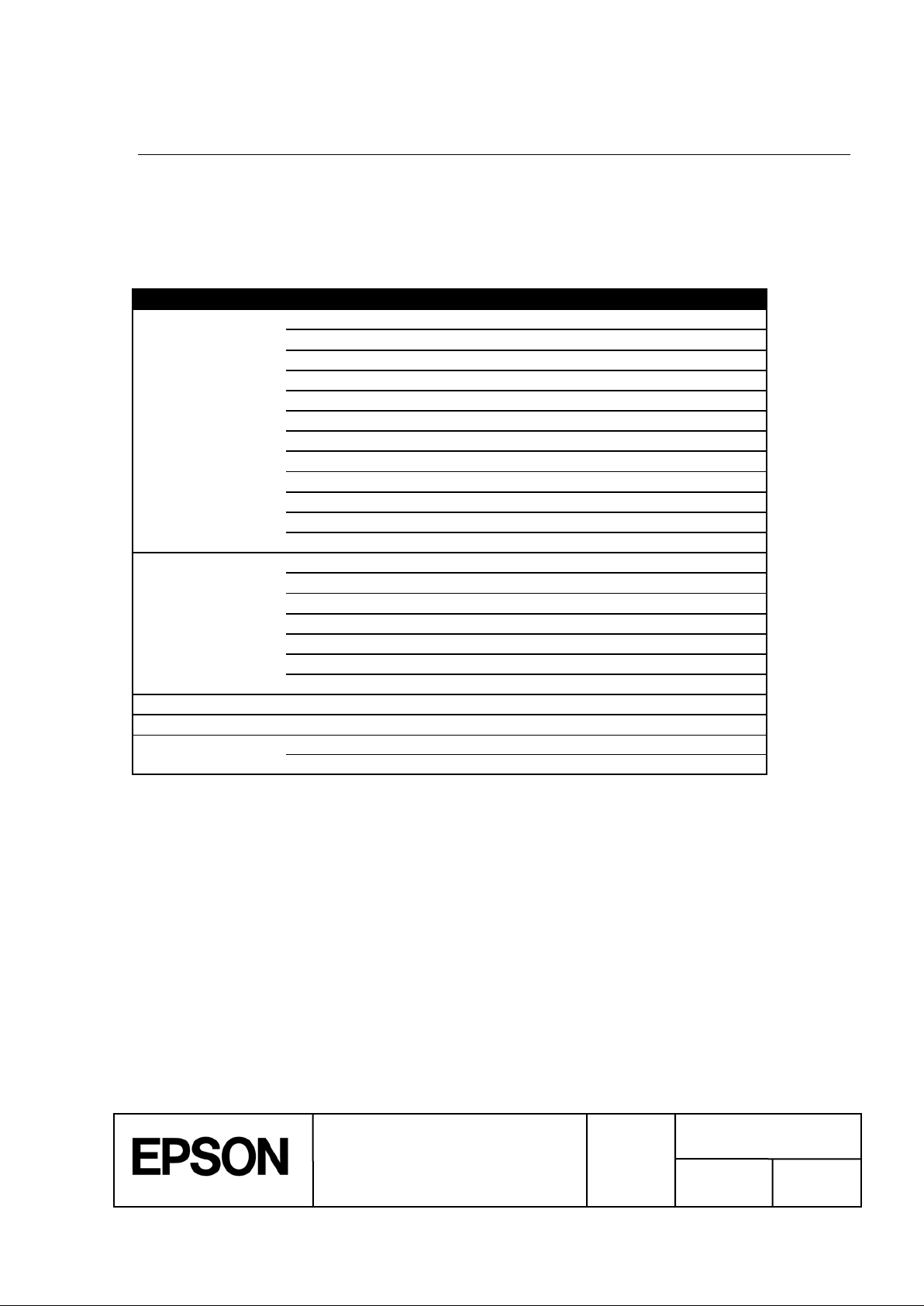

Table 3-1 List of Functions to be implemented

Category

Function name

Print setting

Media Coating Type Setting

Media Layout Setting

Completion Autocut Setting

Completion Beeper Setting

Completion Pause Setting

Printing Color Correction Mode Setting

Ink Profile and Brightness Adjustment Setting

Ratio of Black to Composite Setting

Bar Width Adjustment Setting

Banding Reduction Setting

Printing Speed Setting

Head maintenance Setting

Printer setting

Label Edge Detector Setting

Media Source Setting

Nozzle Verification Technology Settings

Printing Start Position Adjustment Setting

Re-print Setting

LED Notification Setting (Ink Cartridge Low)

Paper feed Adjustment Setting

Download

TrueType Font Download

Display status

Display Consumables Information

Utility functions

Head Cleaning

Print Nozzle Clogging Check Pattern

3 Functions to be implemented

3.1 List of Funct ions

Table 3-1 indicates a list of functions that mounted with the control software usually.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 11

TITLE

SHEET

C

NO.

NEXT

SHEET

11

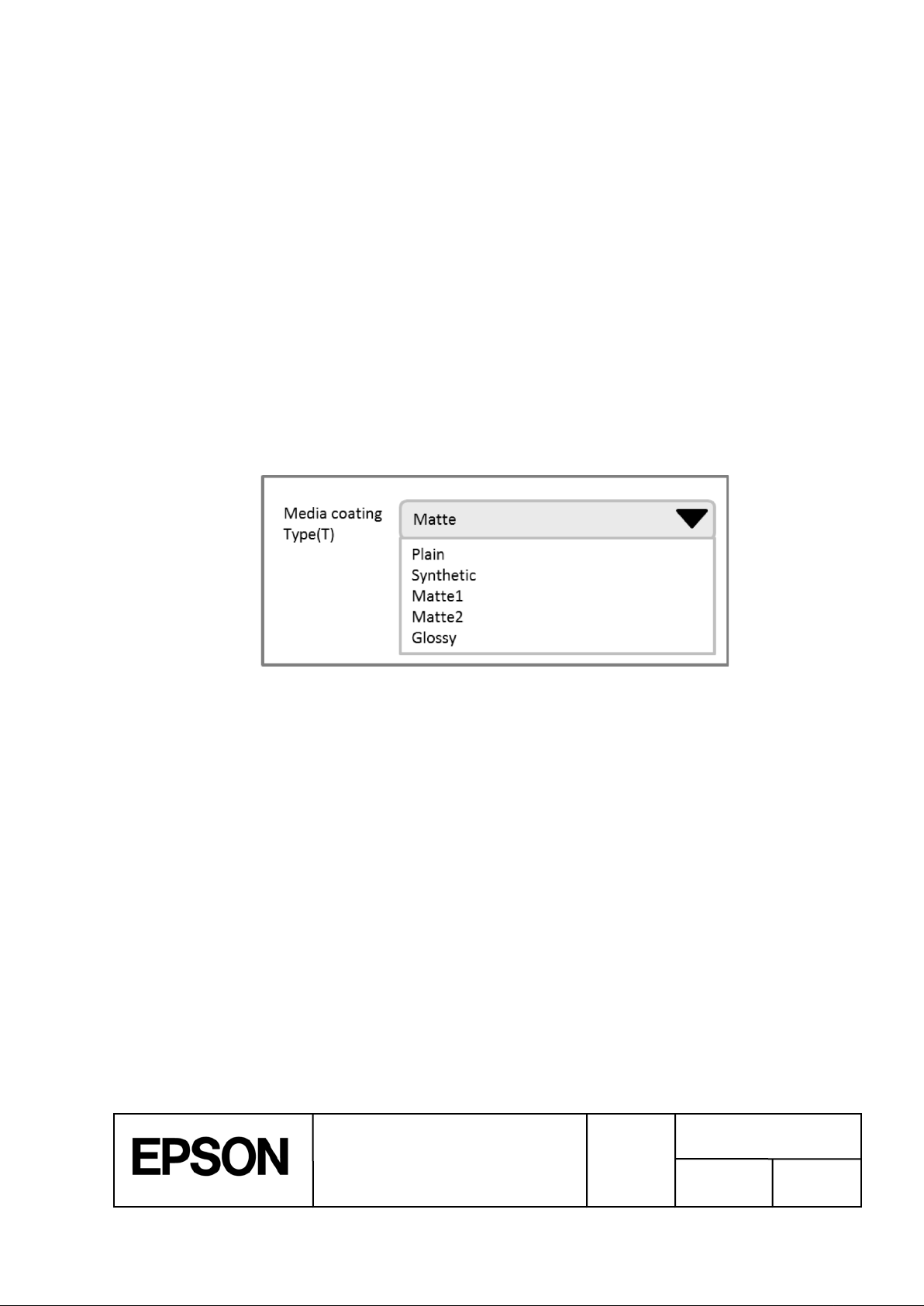

Figure 3-1 UI Sample for the Media CoatingType Setting

3.2 Media Coating Type Setting

n Function description:

Ø This function sets the media coating type to be used.

Ø The printer performs printing that is optimal for the media coating type set in this

function.

Ø If the correct media coating type is not set, the picture quality may decrease.

Ø You can select the media coating type from the following:

Plain / Synthetic / Matte1 / Matte2 / Glossy

Default setting : Matte2

n Use case:

Ø Set when using for the first time or when you changed the paper.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

n Command to be used

Ø ^S(CLM,T

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 12

TITLE

SHEET

C

NO.

NEXT

SHEET

12

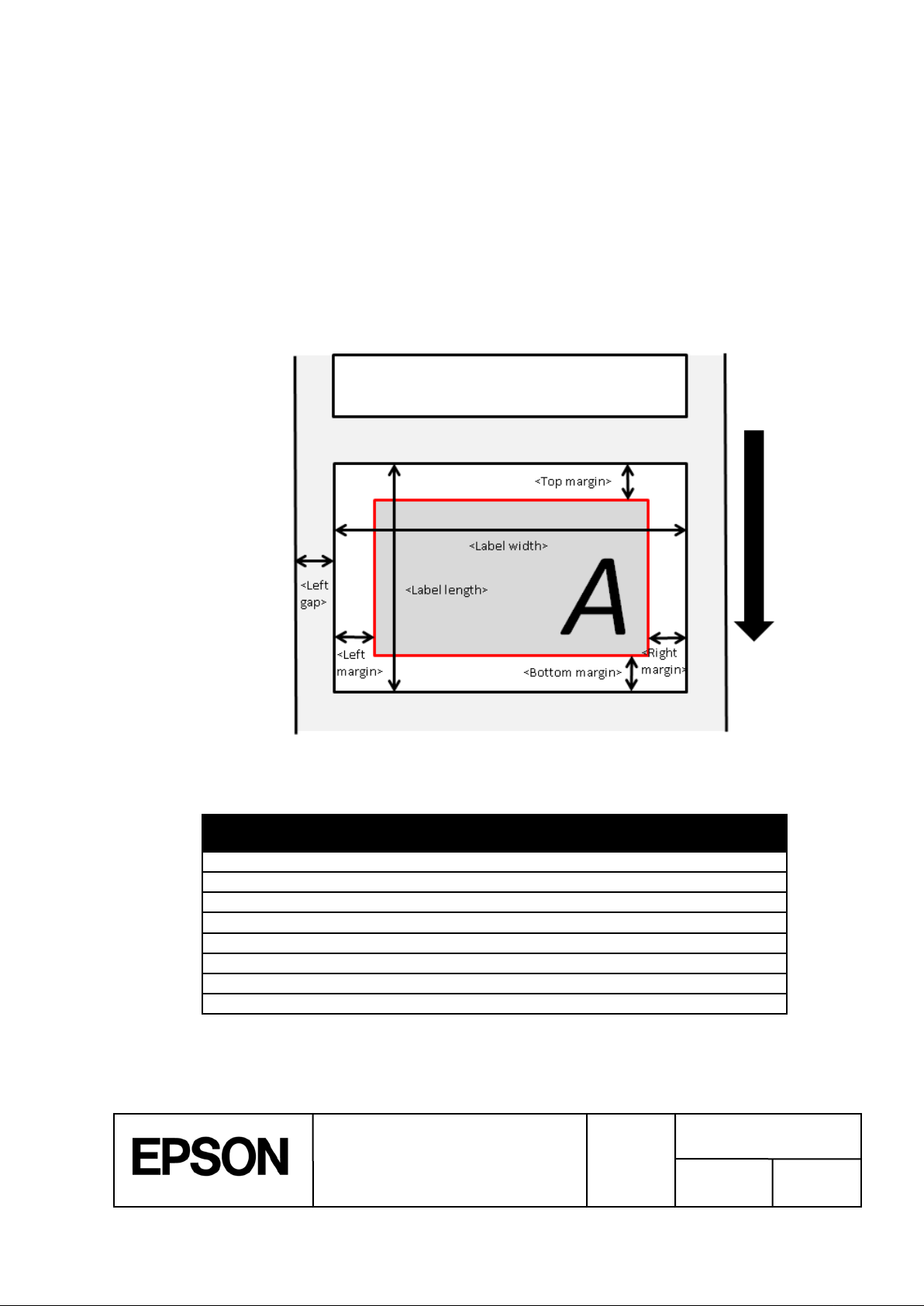

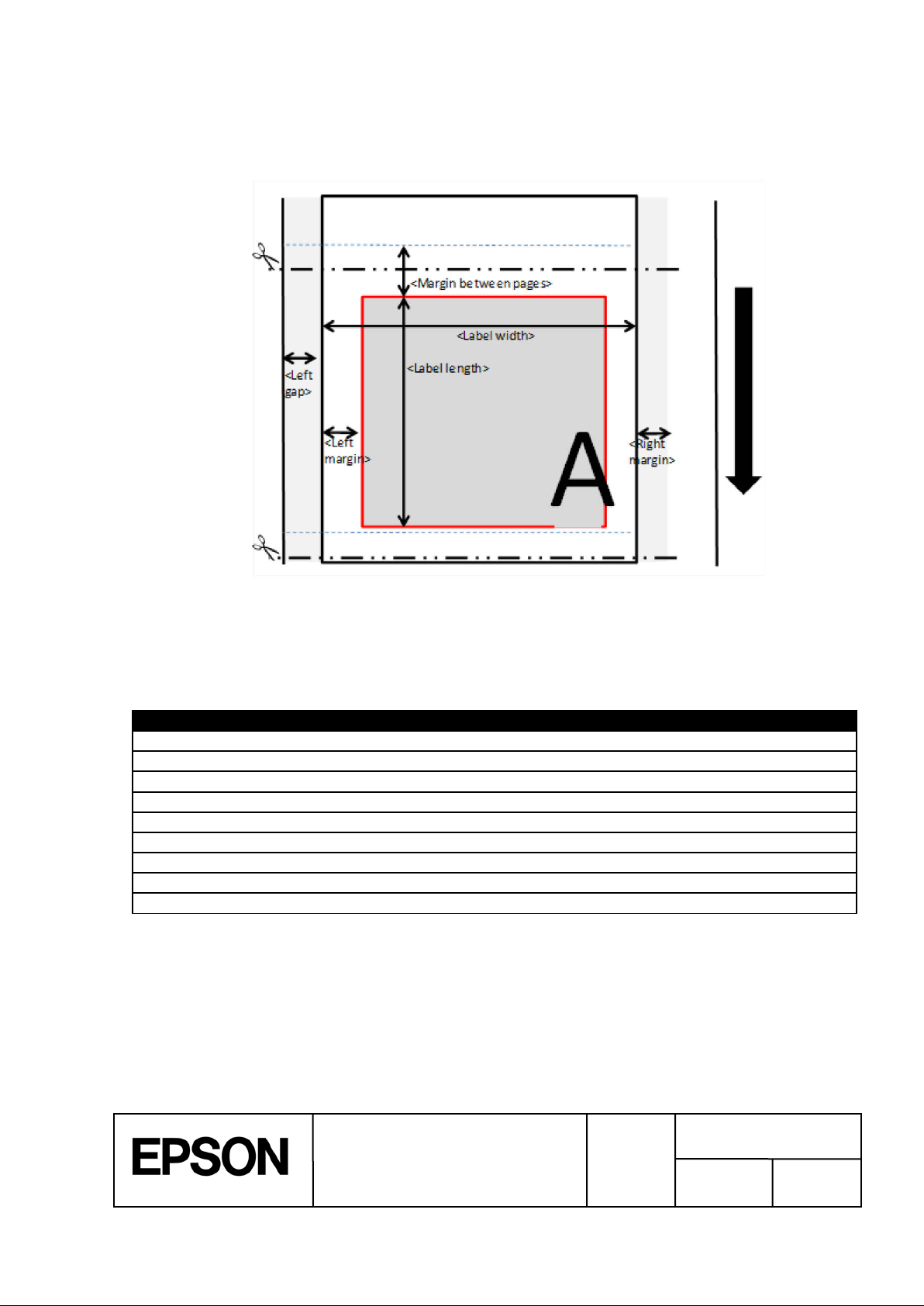

Table 3-2 Die-cut Label (Gap) Settings List

Item

Setting scope

Recommended

initial value

Command

Label width [mm]

46.0 to 108.0

108.0

^S(CLS,P

Label length [mm]

25.4 to 600.0

152.75

^S(CLS,L

Left gap [mm]

1.5 to 2.5

2.0

^S(CLS,G

Top margin [mm]*

0 / 1.5

1.5

^S(CLW,T

Bottom margin [mm]*

0 / 1.5

1.5

^S(CLW,B

Left margin [mm]*

0 / 1.5

1.5

^S(CLW,L

Right margin [mm]*

0 / 1.5

1.5

^S(CLW,R

Feather edges function*

E / D

D

^S(CPC,E

Figure 3-2 Die-cut Label (Gap) Layout

3.3 Media Layout Setting

n Function description:

Ø This function sets the layout information for the media to be used.

Ø The printer performs print processing using the media layout information set in this

function.

Ø If the correct media layout information is not set, a media size error occurs.

Ø For the media layout, set the following information for each media form and label edge

detection method.

² Die-cut label (Gap)

* The feather edges function can be set to “E”(enable), only when all of mar gins(top/bot tom/lef t/right ) are set

to 0.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 13

TITLE

SHEET

C

NO.

NEXT

SHEET

13

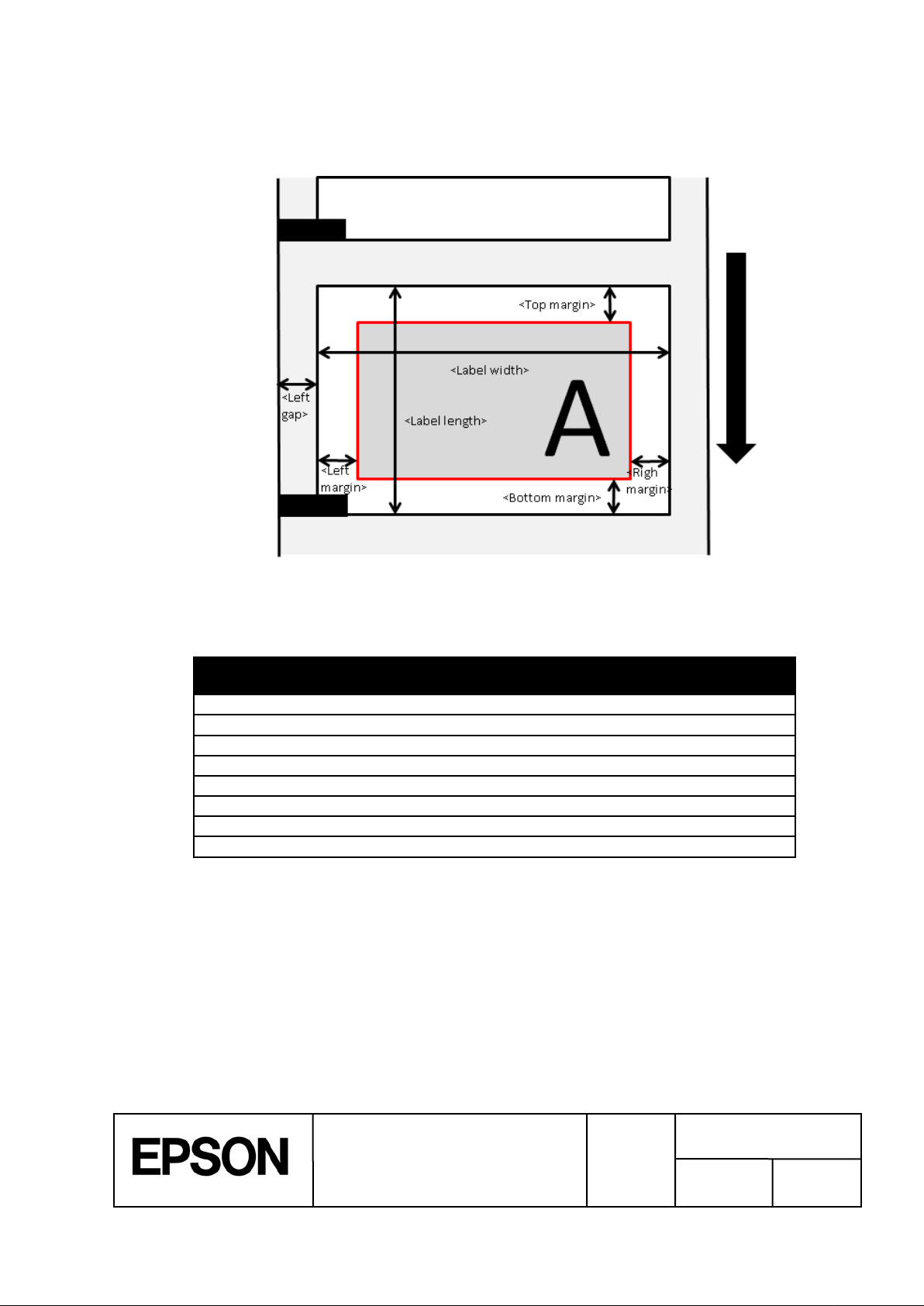

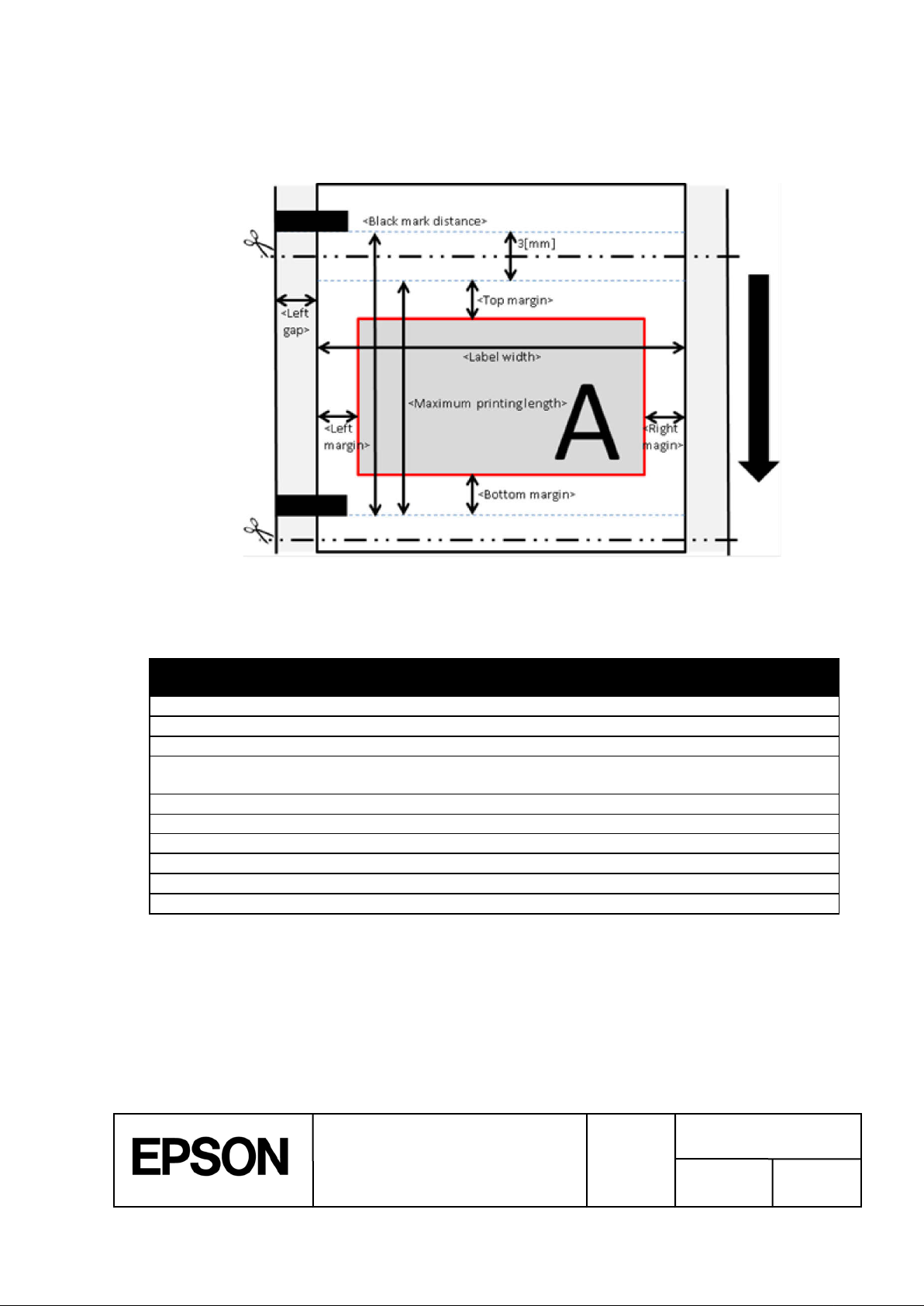

Table 3-3 Die-cut Label (BM) Setting Lis t

Item

Setting scope

Recommended

initial value

Command

Label width [mm]

46.0 to 108.0

108.0

^S(CLS,P

Label length [mm]

25.4 to 600.0

152.75

^S(CLS,L

Left gap [mm]

1.5 to 2.5

2.0

^S(CLS,G

Top margin [mm]*

0 / 1.5

1.5

^S(CLW,T

Bottom margin [mm] *

0 / 1.5

1.5

^S(CLW,B

Left margin [mm] *

0 / 1.5

1.5

^S(CLW,L

Right margin [mm] *

0 / 1.5

1.5

^S(CLW,R

Feather edges function*

E / D

D

^S(CPC,E

Figure 3-3 Die-cut Label (BM) Layout

² Die-cut label (BM)

* BM: Abbreviation for black mark.

*The feather edges function can be set to “E”(enable), only when all of margins(t op/bottom/left/ right) are set

to 0.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 14

TITLE

SHEET

C

NO.

NEXT

SHEET

14

Table 3-4 Continuous label (No detection) Setting list

Item

Setting scope

Recommended initial value

Command

Label width [mm]

46.0 to 108.0

108.0

^S(CLS,P

Label length [mm]

28.4 to 600.0

152.75

^S(CLS,L

Margin between pages [mm]

3.0 [mm] (Fixed)

- - Left gap [mm]

1.5 to 2.5

2.0

^S(CLS,G

Top margin [mm]*

0 (Fixed)

0.0

^S(CLW,T

Bottom margin [mm]*

0 (Fixed)

0.0

^S(CLW,B

Left margin [mm]*

0 / 1.5

1.5

^S(CLW,L

Right margin [mm]*

0 / 1.5

1.5

^S(CLW,R

Feather edges function*

E / D

D

^S(CPC,E

Figure 3-4 Continuous label (No detection) Layout

² Continuous label (No detection)

*The feather edges function can be set to “E”(enable), only when all of mar gins(top/bottom/ left/right) are set

to 0.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 15

TITLE

SHEET

C

NO.

NEXT

SHEET

15

Table 3-5 Continuous Label (BM) Settings Lis t

Item

Setting scope

Recommended

initial value

Command

Label width [mm]

50.0 to 108.0

108.0

^S(CLS,P

Black mark distance [mm]

28.4 to 603.0

155.75

-

Print length

25.4 to Maximum printing length

152.75

^S(CLS,L

Maximum printing length

[mm]

Black mark distance

– 3,0 [mm] (Fixed)

152.75

Left gap

1.5 to 2.5

2.0

^S(CLS,G

Top margin [mm]*

0(Fixed)

0.0

^S(CLW,T

Bottom margin [mm]*

0(Fixed)

0.0

^S(CLW,B

Left margin [mm]*

0 / 1.5

1.5

^S(CLW,L

Right margin [mm]*

0 / 1.5

1.5

^S(CLW,R

Feather edges function*

E / D

D

^S(CPC,E

Figure 3-5 Continuous Label (BM) Layout

² Continuous label (BM)

*The feather edges function can be set to “E”(enable), only when all of margins(top/ bottom/left/r ight) are set

to 0.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 16

TITLE

SHEET

C

NO.

NEXT

SHEET

16

n Use case:

Ø Set when using for the first time or when you changed the paper.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

² We recommend that the user register the media layout in advance, and select from

among the registered media layouts when printing.

Ø If the margin is set to 0 [mm], the ink may run over the edge of the label. Please

indicate to the user that when setting margin to 0 [mm], there is a risk of ink running

over.

² Example message:

“The printing may run over the edge of the label. Please ensure margins of 1.5

[mm] or larger in the print data so that the printing does not run over the edge of

the label.”

n Commands to be used:

Ø ^S(CLS,G, ^S(CLS,L ^S(CLS,P

Ø ^S(CLW,B, ^S(CLW,L, ^S(CLW,R, ^S(CLW,T

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 17

TITLE

SHEET

C

NO.

NEXT

SHEET

17

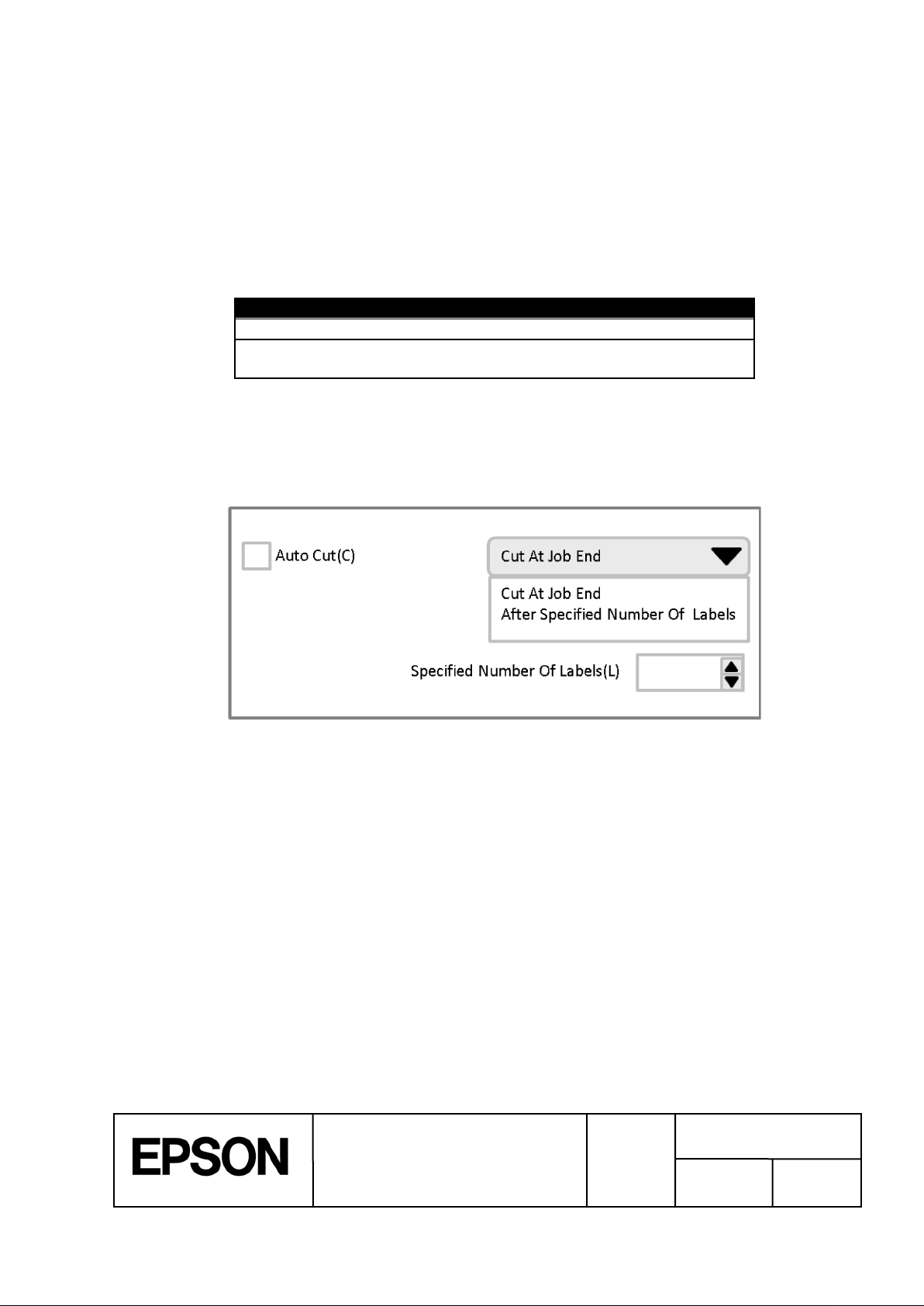

Table 3-6 Autocut Timing List

Timing

Description

Cut at job end

Cuts after printing the last printing label.

After specified

number of labels

Cuts after every number of labels specified by the

user.

Figure 3-6 UI Sample for the Completion Aut ocut Setting

3.4 Completion Aut ocut Setting

n Function description:

Ø This function designates the timing for the autocut.

Ø We recommend the following for the autocut ti m ing.

n Use case:

Ø Use when you want to separate each print.

Ø Use when you want to separate the print in units of multiple sheets.

n Command to be used:

Ø ^PQ

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 18

TITLE

SHEET

C

NO.

NEXT

SHEET

18

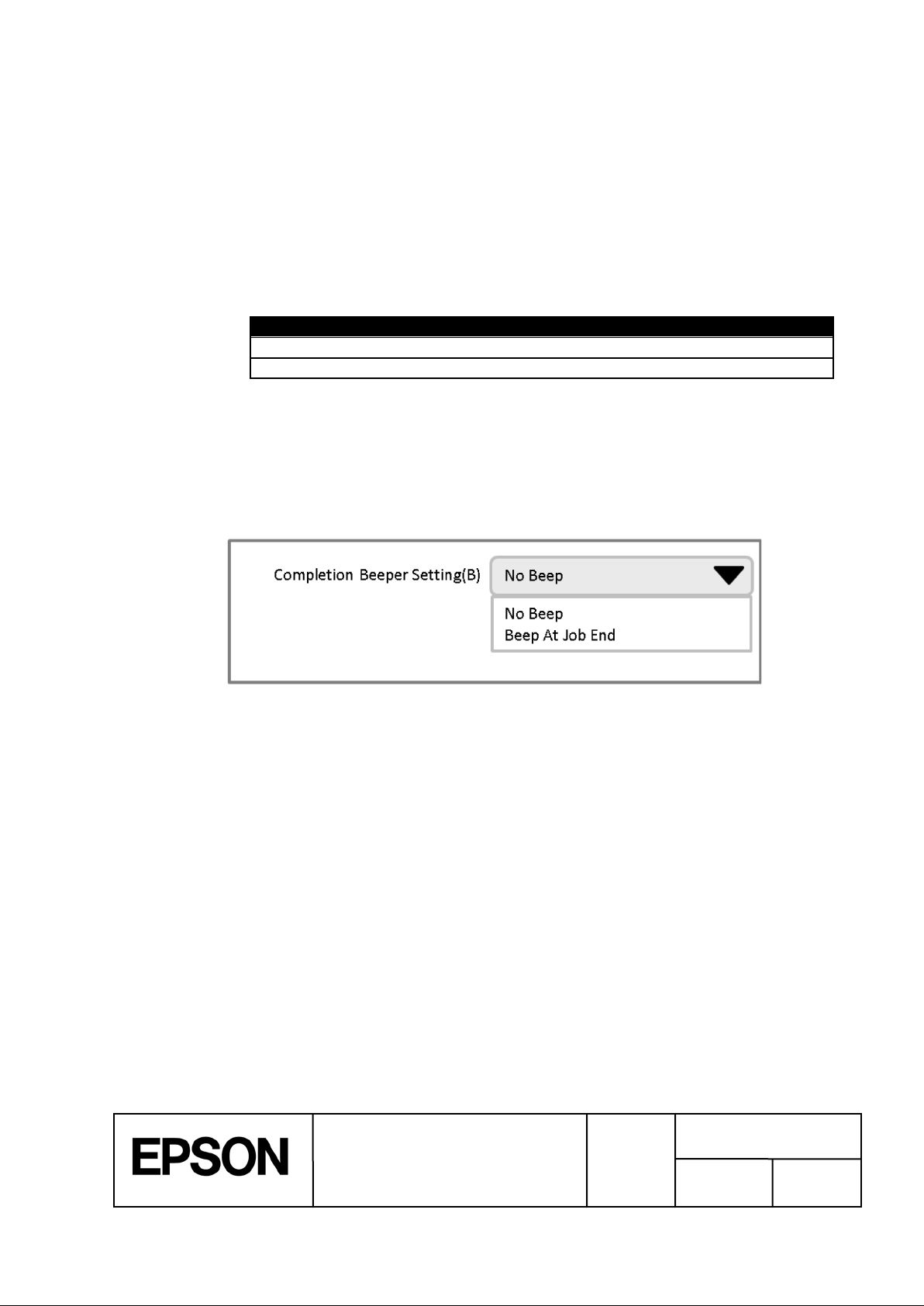

Table 3-7 Buzzer Sounding Timing List

Timing

Description

No beep

Not sounds the buzzer after printing.

Beep at job end

Sounds the buzzer after printing the last label.

Figure 3-7 UI Sample for the Completion Beeper Sett i ng

3.5 Completion Beeper Setting

n Function description:

Ø The function sounds the buzzer equipped in the printer at the print competion timing

designated by the user.

Ø We recommend the following timing to sound the buzzer.

n Use case:

Ø Use to notify by sound that printing has been completed in units specified by the user.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

n Command to be used:

Ø ^S(CUB,S

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 19

TITLE

SHEET

C

NO.

NEXT

SHEET

19

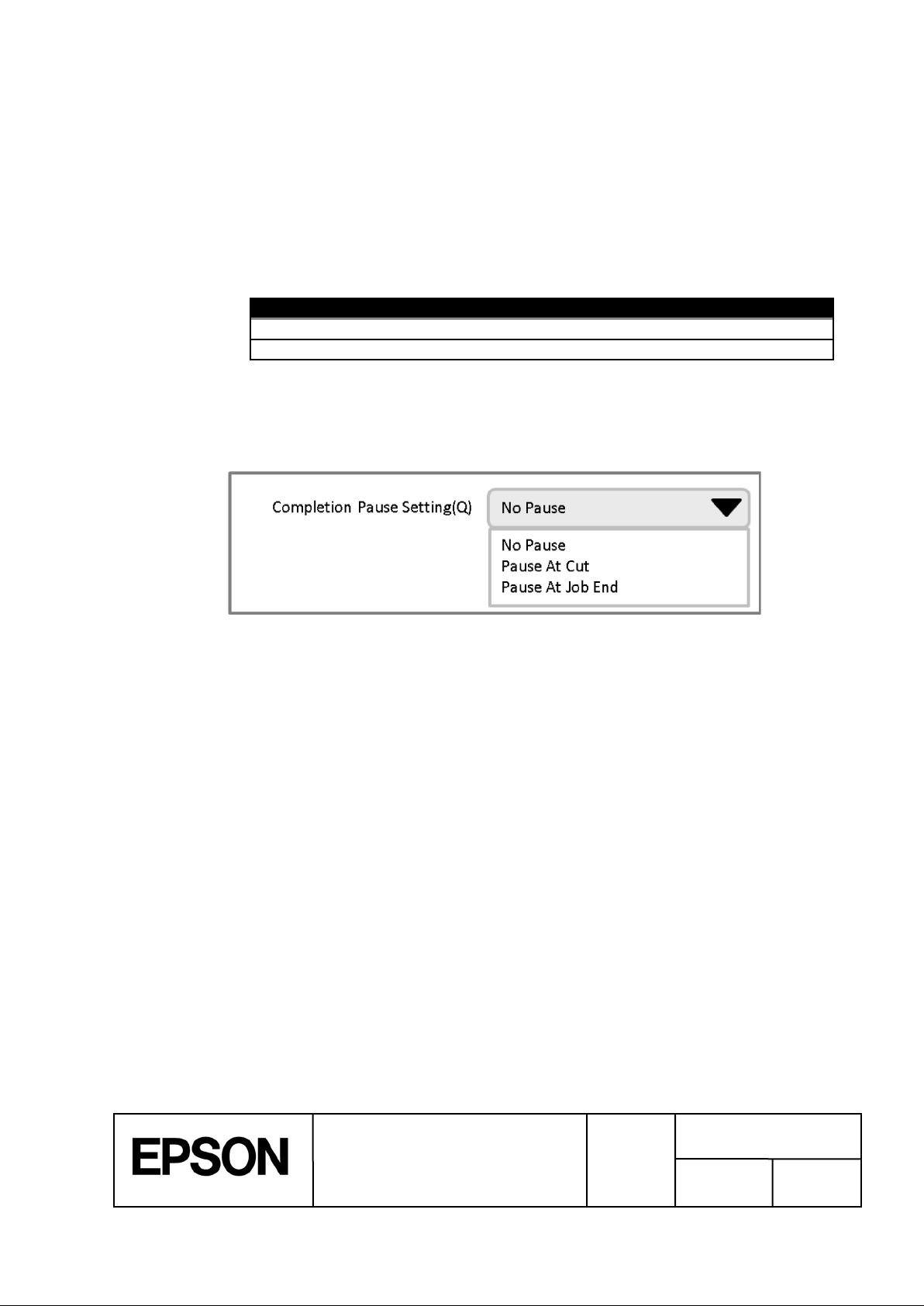

Table 3-8 Pause Printer Timing List

Timing

Description

Pause at cut

Pause the printer after performing an autocut.

Pause at job end

Pause the printer after printing the last label.

Figure 3-8 UI Sample for the Completion Pause Setting

3.6 Completion Pause Set t ing

n Function description:

Ø This function pauses the printer at the print completion timing specified by the user.

Ø We recommend the following timing to pause the printer.

n Use case:

Ø Use when the user performs procedures such as removing the paper after printing.

n Command to be used:

Ø ^PQ

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 20

TITLE

SHEET

C

NO.

NEXT

SHEET

20

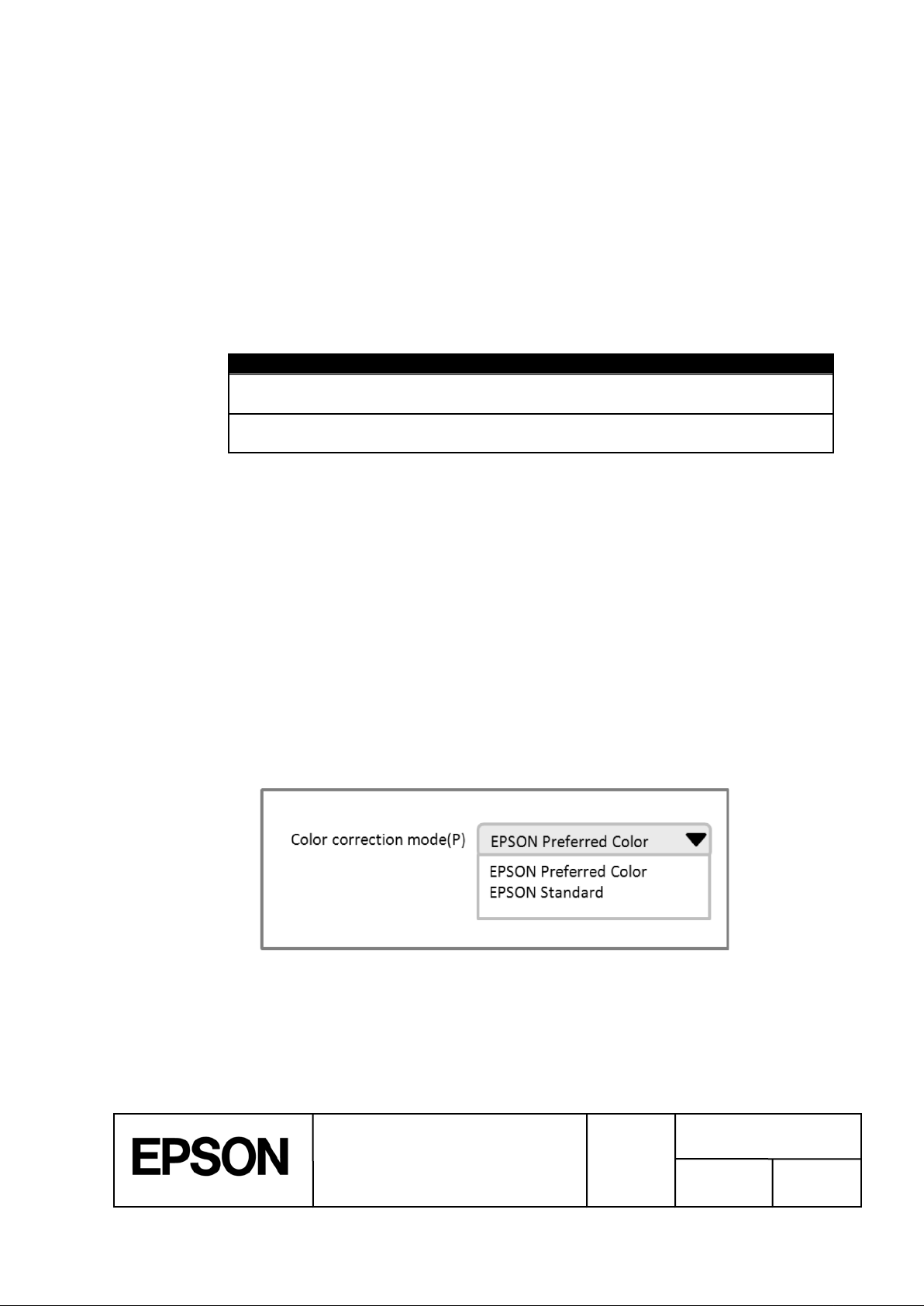

Table 3-9 Color Correction Mode List

Item

Description

EPSON Preferred Color

Prints using optimal color correction to selected media

coating type.

EPSON Standard

Prints with matching to sRGB color space, does not use

color correction to the image.

Figure 3-9 UI Sample for the Color Correction Mode Setting

3.7 Printing Color Correction Mode Setting

n Function description:

Ø This function sets the correction mode for the printing color to match the printed

contents.

Ø The printer uses the color correction mode set in this function to correct the color so

that the printing result is optimal .

Ø Select the correction mode from the following.

n Use case:

Ø Set the optimal color correction mode for the printed contents.

n Recommendation in achievement:

Ø Please allow the user to simply change settings for each print.

² With this setting, the user needs to select a color adjustment setting to match the

printed contents. Therefore, please guide users so that they can select a choice

based on the printing contents.

² Example: Include a message below in the Help menu.

l “EPSON Preferred Color” is suitable for usual case.

l When you want to arrange color, please select “EPSON Standard”.

l Even if which item is selected, the print result does not match necessarily to

the color displayed.

n Command to be used:

Ø ^S(CPC,C

n UI sample:

Application Development Guide

for TM-C7500 series

ESC/Label

REVISION

Page 21

TITLE

SHEET

C

NO.

NEXT

SHEET

21

Figure 3-10 Image of Ink Profile Amounts

Figure 3-11 UI Sample of the Ink Profile and Bright ness Adjustment Setting

3.8 Ink Profile and Brightness Adjustment Setting

n Function description:

Ø This function sets the adjustment values from the standard values of the ink profile and

brightness.

Ø If you change the settings, the ink profile (amount of ink used) duri ng printing changes.

Ø Default is the standard. You can set 6 stages for “light” and 4 stages for “dark” (for a

total of 11 stages). If Matte2 is specified as media coating type, you can set only 6

stages for “light”.

n Use case:

Ø Use to make the printed result lighter or darker depending on the media coating type

and the printed contents.

n Recommendation in achievement:

Ø Please allow the user to simply change settings for each print.

Ø If you set the ink profile and brightness towards light, it may decrease the scan quality

of barcodes. Please indicate to users that if they change the ink profile and

brightness, there is a risk the scan quality will decrease for barcodes.

n Command to be used:

Ø ^S(CPC,D

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 22

TITLE

SHEET

C

NO.

NEXT

SHEET

22

Figure 3-12 Image for the Ratio of Black Ink

3.9 Ratio of Black to Composite Setting

n Function description:

Ø This function sets the adjustment value for t he ratio of ink constituting black.

Ø Change this setting to change the ratio of ink used when pri nting black.

Ø Default is the standard. When the media coating type is Matte1/Matte2/ Glossy, you

can set 6 stages to “CMY” and 4 stages to “K” (for a total of 11 stages).

Ø When the media coating type is Plain/ Synthet ic, you can set 6 stages to “CMY”.

Ø Setting the adjustment towards “CMY” reduces the ratio of black ink. Setting the

adjustment towards“K” increases the ratio of black ink. If the ratio of black ink is

high, the ink becomes more likely to be scraped off.

n Use case:

Ø Check the printed material. If the ink is scraped off easily, set towards “CMY”.

² Depending on the quality of the paper, if you print using the default ratio of black to

composite setting, the black ink may be scraped off easily. If this phenomenon

occurs, set towards “CMY”.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

Ø If you change the ratio of black to composite setting, it may decrease the scanning

quality of barcodes. Please indicate to users that if they change the ratio of black

to composite setting, there is a risk the scan qualit y will decrease for barcodes.

n Command to be used:

Ø ^S(CPC,P

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 23

TITLE

SHEET

C

NO.

NEXT

SHEET

23

Figure 3-13 UI Sample for the Ratio of Black t o Composite Setting

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 24

TITLE

SHEET

C

NO.

NEXT

SHEET

24

Figure 3-14 UI Sample for the Bar Width Adjustment S etting

3.10 Bar Width Adjustment Setting

n Function description:

Ø This function sets the adjustment value for t he bar width.

Ø If you change this setting, the bar width adjustment value for printing barcodes is

changed.

Ø What is bar width adjustment?

² Bar width adjustment is a function to prevent a decrease in barcode scanning

quality from ink running by adjusting the bar widt h of the barcode.

² Applicable barcodes:

UPC-A, UPC-E, JAN13(EAN), JAN8(EAN), Code39, ITF, Codabar, Code93,

Code128, GS1-128, GS1 DataBar Truncated, GS1 DataBar Expanded, GS1

DataBar Limited

² The bar width changes by 1 dot, when the bar width adjustment value is changed

by 1 step.

² When the bar width adjustment value is default(0), the bar width is narrowed by 2

dots more than the width calculated by the standard of each symbol.

Ø Note:

² Bar width adjustment is performed even in default settings to increase barcode

scanning quality.

n Use case:

Ø Set when you scan a barcode printed on the paper actually used, and the scan quality

was insufficient.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

Ø If you change the bar width adjustment value, the barcode scan quality may decrease.

Please indicate to users that if they change the bar width adjustment value, there is

a risk that the barcode scan quality may decrease.

n Command to be used:

Ø ^S(CBW,C

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 25

TITLE

SHEET

C

NO.

NEXT

SHEET

25

Figure 3-15 UI Sample for the Bading Reduction Sett i ng

Banding Reduction

Light

Dark

3.11 Banding Reduction Setting

n Function description:

Ø This function sets the adjustment values to reduce vertical banding in the print result.

Ø Default is the standard. You can set 2 stages for “light” and 2 stages for “dark” (for a

total of 5 stages).

Ø Set the adjustment for “light” when the band darker than surroundings is printed, set

the adjustment for “dark” when the band lighter than surroundings is printed.

n Use case:

Ø Set when vertical banding (Light color band or dark color band) occur in the print result

depending on the media coating type.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

n Command to be used:

Ø ^S(PC,B

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 26

TITLE

SHEET

C

NO.

NEXT

SHEET

26

Figure 3-16 UI Sample for Printing Speed Setting

Printing Speed (S)

3.12 Printing Speed Setting

n Function description:

Ø This function sets the printing speed.

n Use case:

Ø Make the printing speed slower if printing is stopped midway and the paper is fed in

reverse to continue printing.

² This happens when the data transfer speed may not be fast enough depend on the

printed contents.

² This happens when the take-up speeds of re-winder made by 3

than printing speed.

n Recommendation in achievement:

Ø Please allow the user to simply change settings for each print.

n Command to be used:

Ø ^S(CMP,S

n UI sample:

rd

party are slower

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 27

TITLE

SHEET

C

NO.

NEXT

SHEET

27

Table 3-10 Head Maintenance Setting

Head maintenance

Print settings

Continuous printing(fast)

Flush onto paper mode: Level 2

Pause for maintenance(fine)

Flush onto paper mode: Level 1

Figure 3-17 UI Sample for Head maintenance Setting

3.13 Head maintenance Setting

n Function description:

Ø This function sets whether to prioritize through-put or printing quality when printing.

Ø You can switch between the following print sett ings using this setting.

Ø When “Continuous printing” is set, print quality is decreased, so the through-put is

increased when printing multiple labels.

Ø When “Continuous printing” is set, extra ink is discharged on the printed surface, and

may stand out.

Ø What is flush onto paper mode?

² For the higher level of the flush onto paper mode, the printing quality will decrease

because more ink is discharged. On the other hand, the improvement of

throughput when printing multiple labels is expected, because the period between

regular flushing that discharges ink with the head moving away is increased.

n Use case:

Ø Set when you want to prioritize print quality over through-put.

n Recommendation in achievement:

Ø Please allow the user to simply change settings f or each print.

n Command to be used:

Ø ^S(CMP,F

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 28

TITLE

SHEET

C

NO.

NEXT

SHEET

28

Table 3-11 List of Detector Settings for each Media

Media

Detector setting

Die-cut label with Gap

Gap detection

Die-cut label with black

mark, continuous paper

Black mark detection

Continuous label without

black marks

No detection

3.14 Label Edge Detector Setting

n Function description:

Ø This function sets the label edge detection method (black mark detection, gap

detection or no detection).

Ø The detection method needs to be set based on the media set in the printer.

Ø This is a printer setting, and we recommend being able to change this setting

separately from print settings.

Ø Check that the printer is idle before notifying the printer of the setting change.

Ø If it is not set properly, the printer will not detect the label edge.

Ø If the printer does not detect the label edge, an error will occur once a certain amount

of paper is fed.

Ø You can select the label edge detector from the following:

Gap detection / Black mark detection / No detection

Default setting : Gap detection

Ø The following is a list of settings for the detector for each media.

n Use case:

Ø Set the label edge detector after changing to a media with a different detection method.

n Command to be used:

Ø ^S(CLM,D

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 29

TITLE

SHEET

C

NO.

NEXT

SHEET

29

Table 3-12 List of Media Sources

Item

Description

Internal roll

Select when using roll paper set inside the printer.

Roll paper is supported as media shape.

External feed

Select when using paper set from the rear of the printer.

Fanfold paper is supported as media shape.

Table 3-13 List of combination

Media source

Media shape

Media form

Support

Internal roll

Roll paper

Die-cut label

ü

Contiuous label

ü

External feed

Fanfold paper

Die-cut label

ü

3.15 Media Source Setting

n Function description:

Ø This function sets the media source for the paper used in printing.

This is a printer setting, and we recommend being able to change this setting

Ø

separately from print settings.

Check that the printer is idle before notifying the printer of the setting change.

Ø

Select the media source from below.

Ø

n Use case:

Ø Set when you changed the media source.

² Example: Changed from the internal roll to the external feed.

n Command to be used:

Ø ^S(CLM,P ^S(CLM,S ^S(CLM,F

n Supported combination of media shape and media form:

Ø Depending on media source, the supported combination of media shape and media

form is listed in Table 3-13 List of combination.

Application Development Guide

for TM-C7500 series

ESC/Label

REVISION

Page 30

TITLE

SHEET

C

NO.

NEXT

SHEET

30

Figure 3-18 UI Sample for the Nozzle Verifi c ation Technology

3.16 Nozzle Verification Technology Settings

n Function description:

Ø This function sets the timing of nozzle verification and the operation at clogged nozzle

detection.

Ø What is the nozzle verification technology?

² If the clogged nozzle is detected in nozzle verification, auto cleaning is executed.

l If the nozzle clogging is not recovered from by the cleaning, it reduces

deterioration of printing result by dot subsit uation.

² The nozzle verification can be set while printing multiple labels.

l The printer automatically detects the print beginning point.

sheets of the print from the print beginning point to the nozzle verification can

be specified.

l The user can correspond (confirm print result / continue print / cancel , etc) by

notification when the clogged nozzle is detected.

² Note:

l The nozzle verification is executed before start printing in “None” setting.

n Use case:

Ø Set when you want to minimize the possibility of printing defective labels by clogged

nozzle.

n Command to be used:

Ø ^S(CMV,I ^S(CMV,O

n UI sample:

The number of

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 31

TITLE

SHEET

C

NO.

NEXT

SHEET

31

Re-print at an error(R)

Printing Start Position Adjustment(P)

Figure 3-20 UI Sample for the Reprint Setting

Figure 3-19 UI Sample for the Printing Start Pos i t i on A djustment Setting

3.17 Printing Start Position Adjustment Setting

n Function description:

Ø This function adjusts the printing start position for the printer.

Ø If the printing start position is changed, printing is started in a position shifted the

adjustment amount from the position set for the pri nt data.

n Use case:

Ø Use when you want to adjust the printing position without changing the application

settings.

n Commands to be used:

Ø ^S(CLE,M, ^S(CLE,T or ^LT

n UI sample:

3.18 Re-print Setting

n Function description:

Ø This function sets whether to perform re-printing when an error, such as paper out,

occurs during printing.

n Use case:

Ø Use when you want to change the re-print settings.

n Command to be used:

Ø ^S(CWR,P, ^JZ

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 32

TITLE

SHEET

C

NO.

NEXT

SHEET

32

Figure 3-22 UI Sample for the Paper Feed Adjustment S etting

LED notification setting

at Ink cartridge low(N)

Figure 3-21 UI Sample for the LED Notificati on S et t i ng (I nk Cartridge Low)

3.19 LED Notification Setting (Ink Cartridge Low)

n Function description:

Ø This function sets whether to notify the user through the LED that the printer’s ink

cartridge is low.

n Use case:

Ø Use when you want to change the LED notification method when the ink cartridge is

low.

n Command to be used:

Ø ^S(CSL,N

n UI sample:

3.20 Paper Feed Adjustment Setting

n Function description:

Ø This function adjust CMYK ink position alignment shot onto label.

n Use case:

Ø Use when you want to change label type.

n Recommendation in achievement:

Ø A set result of the paper feed adjustment is confirmed by printing the paper feed

adjustment pattern. Not only the paper feed adjustment but also it is necessary to set

media coating type, media shape, media form and media setting(label width and left

gap) to print the paper feed adjustment pattern. When these settings are changed, it

is preferable to execute each set command.

Ø Please refer to the section 6 for detail procedure of the paper feed adjustment.

n Command to be used:

Ø ^S(CLP,M

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 33

TITLE

SHEET

C

NO.

NEXT

SHEET

33

Table 3-14 The List of Combinations of a Character Code Set and a Charac t er Code

Convesion table

Character code set

^CI command

Character code conversion table

d:o.x for ^SE command

KS X 1001(KS C 5601-1987)

^CI14

Z:EUCKR2K6.CNV

Shift-JIS

^CI15

Z:SJIS2K3.CNV

EUC-JP

^CI16

Z:EUCJPK7.CNV

EUC-CN

^CI16

Z:EUCCN199.CNV

BIG5

^CI26

Z:BIG52K7.CNV

GB18030

^CI26

Z:GB18030.CNV

UTF-8

^CI28

unnecessary

(deprecated) UTF-8

^CI17^F8

unnecessary

(deprecated, restricted) UTF-16

^CI17

unnecessary

(unusable) UTF-16

^CI29 or ^CI30

-

3.21 TrueType Font Download

n Function description:

Ø This function downloads TrueType fonts (TTF files) to the printer.

Ø You can download a TrueType font to the printer and can print in the same way as the

fonts loaded in the device using the TrueType font printing function.

n This function is necessary because:

Ø By downloading a TrueType font to the printer, you can print using the same amount of

data as the fonts loaded in the device.

n Use case:

Ø Use when you want to print using a TrueType font.

n Recommendation in achievement:

Ø Please indicate to users that they must obtain the permission of the copyright owner of

the font before they download the font to the printer.

n Command to be used:

Ø ~DY (We recommend it than ~DU.)

n Supplementation:

Ø You should take care of the combination of a download command and a extension of a

file stored as a destination of a download. The reasons are described in the

following.

A extension of a font file which is stored in a printer is decided by a download

command you use.

If you w ill use ~DY command, a extension wil be TTF(when x=T) or TTE(when

x=E),

If you will use ~DU command, a extension wil be FNT.

Even if you designate a extension by a parameter of a download command, the

extension will be set to the mentioned extension in the previous.

When you will access to a font file stored in a printer, you should designate a actual

extension of a font file of a printer.

The corresponding commans: ^A@, ^CW, ^ID, ^H(Y, ^HW, ^WD

Ø When you use a downloaded font,you should set a character code set as needed. In

addition, some of character code sets will need a character code conversion table.

The Table 3-14 shows combinations of a character code set and a character code

conversion table.

Our request : Your driver doesn’t support UTF-16.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 34

TITLE

SHEET

C

NO.

NEXT

SHEET

34

Maintenance Box level

Figure 3-23 UI Sample for the Display Consumables I nformation

3.22 Display Consumables Information

n Function description:

Ø This function displays information for t he consumables equipped in the printer.

² Consumables: Ink cartridges, maintenance box

Ø Displays the latest information for t he consumables.

n Use case:

Ø The user checks if there are enough consumables before starting printing.

n Recommendation in achievement:

Ø Display the remaining amount of the ink catridges. (Refer to the UI sample.)

Ø Display the available space of the maint enance box. (Refer to the UI sample.)

n Commands to be used:

Ø ~H(QIQ, ~H(QMN

n UI sample:

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 35

TITLE

SHEET

C

NO.

NEXT

SHEET

35

Table 3-15 Ink Cartridge Display List

Ink status

Example display

Note

Enough ink in cartridge.:RH

Moderate ink in cartridge.:RM

Small ink in cartridge.:RL

- It must display the image

Ink cartridge low.:RN

Replace ink cartridge.:RR

- It must display the image

Ink cartridge not installed.:NA

Ink cartridge installed.:CI

-It means not to be able to

Ø The amount of remaining ink is shown for the cartridges of each color. Depending on

the situation, they may be displayed in the following ways.

that remain a detected

amount of ink.

that remain a small amount

of ink.

detect the remaining ink

though the ink cartridge

installing has been detected.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 36

TITLE

SHEET

C

NO.

NEXT

SHEET

36

Table 3-16 Maintenance Box Display List

Ink status

Example display

Note

Enough space in maintenance

box.:RH

Moderate space in

maintenance box.:RM

Small space in maintenance

box.:RL

- It must display the image

Maintenance box near full.:RN

Replace maintenance box.:RR

- It must display the image

No maintenance box.:NA

Maintenance box installed.:CI

-It means not to be able to

Ø The available space in the maintenance box is displayed in black. The black area

decreases as the available space decreases. Depending on the situation, it may be

displayed in the following ways.

that remain a detected

amount of space in the

maintenance box.

that remain a small amount

of space in the maintenance

box.

n Note:

Ø What is the maintenance box?

² The maintenance box collect s waste ink.

detect the space in the

maintenance box though the

maintenance box installing

has been detected.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 37

TITLE

SHEET

C

NO.

NEXT

SHEET

37

3.23 Head Cleaning

n Function description:

Ø This function cleans the head.

Ø This automatically checks nozzle clogs and performs head cleaning.

Confirm the cleaning result by printing the nozzl e check patt ern.

Ø

n This function is necessary because:

Ø Nozzle clogs will occur.

n Use case:

Ø Use when there are missing dots in the printing result.

n Command to be used:

Ø ~J(C

3.24 Print Nozzle Clogging Check Pattern

n Function description:

Ø The function prints the pattern for checking nozzle clogs

n This function is necessary because:

Ø To check if there is no nozle clogs by printing the patt ern for checking nozzle clogs.

n Use case:

Ø Check that nozzle clogs are not occuring before printing labels.

n Command to be used:

Ø ~W(PNC

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 38

TITLE

SHEET

C

NO.

NEXT

SHEET

38

4 Notes on Communication

4.1 DeviceID

n Description:

Ø The DeviceID is as follows.

MFG:EPSON;

MDL:TM-C7500

CLS:PRINTER;

4.2 String Descri pt or

n Description:

Ø The String Descriptor is as follows.

idVendor = 04B8H

idProduct = 0E19H

iManufacturer ="EPSON“

iProduct ="TM-C7500"

1

2

4.3 Receiving Buffer Full Control

n Description:

Ø Due to color printing, the amount of data that the printer receives increases, and the

receiving buffer is likely to become full.

Ø When the receiving buffer is full, the printer cannot receive data.

Ø Because the printer cannot receive data when the receiving buffer is full, the status

cannot be got with the status command.

Ø The printer receives data even during an error.

Ø The receiving buffer may become full if the printer continues to receive data during an

error.

n Recommended control:

Ø When registering a graphic in the printer, get the available space on the drive using

the printer information request command (get available space information on the

drive).

Ø If there is enough available space for the size of the graphic you want to register, send

the data.

Ø Get the receiving buffer full status using the printer information request command (get

buffer full status information).

Ø If the buffer full status is not receiving buffer full, send dat a that is 4096 bytes or less.

n Commands to be used:

Ø ~H(SDS,R, ~H(SPB,F

1

The characters since "TM-C75" is different depending on the model of the TM-C7500 series.

2

The characters since "TM-C75" is different depending on the model of the TM-C7500 series.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 39

TITLE

SHEET

C

NO.

NEXT

SHEET

39

4.4 Notes If Using Pr i nter Information request Command

n Description:

Ø When getting two or more printer information, you can send the printer information

request commands together as one command group.

n Recommended control:

Ø When sending commands together as one command group, after all the received

printer information is confirmed, then send the next command group.

Ø If the time out is necessary, set 10 sec or more per one command.

n Command to be used:

Ø ~H(C,~H(I,~H(Q,~H(S

4.5 Notes if Using Com m ands t hat Request Resonse from the Printer

n Description:

Ø If you continue to send “Commands that request status” or “Commands that request

printer information” after you sent “Command that request response from the

printer”, the response might not be able to be received.

n Recommended control:

Ø After the response to “Command that request response from the printer” is confirmed ,

then send the next “Command that requests status” or “Commands that request

printer information”.

n Commands that request response from the printer:

Ø ^HF,^HG ^HH,^HW,^HY

n Commands that request status:

Ø ~HI,~HM,~HS

n Commands that request printer iformation:

Ø ~H(C,~H(I,~H(Q,~H(S

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 40

TITLE

SHEET

C

NO.

NEXT

SHEET

40

Figure 4-1 Selection of interface

4.6 Notes If Usi ng USB and Network Interface Together

n Description:

Ø The printer processes data from the interface that received the data fi rst .

Ø When the printer is processing data received via USB, it will only receive data from the

USB. (USB is selected.)

Ø When the printer is processing data received via the network, it will only receive data

from the network. (Network is selected.)

Ø When USB is selected, once the printer completes processing the data received via

the USB, after 10 seconds have passed, the printer becomes able to receive data

from the network.

Ø When network is selected, once the printer completes processing the data received via

the network, the printer immediately becomes able t o receive dat a from the USB.

4.7 Printing Cancel

n Description:

Ø If a spooler cancel is performed or the network cable was pulled to cancel printing,

unnecessary data is left in the printer, and the user may not be able to send any

further data.

Ø To delete unnecessary data, the user must perform a full format cancel using the

printer’s cancel button.

n Recommended control:

Ø Please suggest users performing a full format cancel using the printer’s cancel button if

they want to cancel printing.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 41

TITLE

SHEET

C

NO.

NEXT

SHEET

41

Label format

Field

Fixed-Field, Variable-Ffield

Drawing canvas

5 How to print labels efficiently

5.1 Outline

This section describes how to print labels efficient ly.

The print performance can be improved by applying the method that mentioned here.

5.1.1 Definition of Term

Label format means a unit of commands for label printing and a image drawn by the unit of

commands. The unit of commands is began by ^XA,and completed by ^XZ.

At least one field is included i n a label format involving printing.

Field means a command unit which places a object( such as text, graphic, bar code(symbol),

and drawing-diagram) and a image of each object drawn by the command unit.

When plural labels are printed by batch, fields which a label format include can be divided

into fields which become different print result in the labels and fields which become same print

result in the labels.

The former is called a fixed-field and the latter is called a variable-field.

At least of a field is included in a label format involving printing.The including fields are either

fixed-field or variable-field, or both of them.

Drawing canvas means memory that image of label format for print is drawn to. This

memory is gotten inside the printer.

This memory is gotten at each label format. Fields of each label format is drawn to it.

5.1.2 Points for Efficient Label Printing

The points of efficient label printing is the following.

Ø Using the method of saving and loading a image of the drawing canvas

Command to be used ^C(D, ^C(L, ^C(S (Refer to ESC/Label Command Reference

Guide.)

Ø Drawing a label format in order of a fixed-field, a variable-field.

At first, you should save a image of the drawing canvas that only fixed-fields have been

drawn to.

When drawing a image of each format, you should load the saved image, and then draw

variable-fields to a format.

Ø Drawing to the drawing canvas the largest graphic first.

The printer processes transparent color of image by its own drawing process. However,

in case of first graphic of a format, the printer can reduce a process of transparent color.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 42

TITLE

SHEET

C

NO.

NEXT

SHEET

42

Step1.

Step2.

Step3.

Step4.

Step5.

5.2 Procedure

This section explains the procedure of implementation of the point with practical example.

The outline of the procedure is shown here.

The following sections explain detail s of each step.

Divide the Fields of the Label Format into Fixed-Fields and Variable-Fields.

Delete the Image of the Drawing Canvas in the Setting Comm ands f or Each Print

Save Graphics of Fixed Grapic Fields in the Commands for Savi ng G raphics

Print commands

Save the image of the drawing-canvas which Includes only fixed-field.

Draw and print first label format.

Draw and print label formats since the second.

Commands

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 43

TITLE

SHEET

C

NO.

NEXT

SHEET

43

Figure 5-1 Sample Label

5.2.1 Example of Label to Print

The Figure 5-1 shows the label printing by this practical example.

The label has fixed-fields and variable-fields.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 44

TITLE

SHEET

C

NO.

NEXT

SHEET

44

Figure 5-2 Divided Result of the Sample Label into Fixed-Fields and Variable-Fields

5.2.2 Divide the Fields of the Label Format into Fixed-Fields and Variable-Fields.

Divide the fields of the label format into fixed-fields and variable-fields.

The Figure 5-2 and Table 5-1show devided result of the practical example.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 45

TITLE

SHEET

C

NO.

NEXT

SHEET

45

Table 5-1 Divided Result of the Sample Label into Fixed-Fields and Variable-Fields

Name of Field

Category of

Field

Type of Field

Number of Figure 5-2

FXGR**

Fixed

Fixed-Graphic

01 to 04

FXTX**

Fixed

Fixed-Text(printer font)

01 to 11

FXBC**

Fixed

Fixed-Barcode(Symbol)

none

FXDR**

Fixed

Fixed-Drawing -Diagram

none

VRGR**

Variable

Variable-Graphic

01

VRTX**

Variable

Variable-Text(printer font)

01 to 02

VRBC**

Variable

Variable-Barcode(Symbol)

01

VRDR**

Variable

Variable-Drawing-Diagram

none

In this practical example, you can use drawing-diagram instead of graphic to FXGR03 and

FXGR04.

Text field means that printer font (include downloaded font) is used. If text is sent to printer

by graphic commands, it is a graphic field.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 46

TITLE

SHEET

C

NO.

NEXT

SHEET

46

^C(D

[Setting commands for each print]

^C(D Dletes the image of the drawing canvas.

5.2.3 Delete the Image of the Drawing Canvas in the Setting Commands for Each

Print

Add the command (deleting the saved image of the drawing canvas) to the setting

commands for each print mentioned at the section 2.3.2.

Coomand to be used

Delete the image of the drawing canvas saved temporarily

-Example comands

^XA Begins label format.

^IDR:*.*^FS Delete the files that remain in the printer.

^S(CLR,R,600 Sets the format base in dots per inch to 600 [dpi].

^S(CLR,P,600 Sets the print resolution to 600 [dpi].

^S(CLM,T,M1 Sets the media coating type to Matte1.

^S(CLM,F,DL Sets the media form to Die-cut Label.

^S(CLM,P,IR Sets the media source to internal roll.

^S(CLM,S,RP Sets the media shape to roll paper.

^S(CLM,D,M Sets the detection method to Black mark detection.

^S(CLS,P,2551 Sets the label width to 2551 [dot].

^S(CLS,L,3600 Sets the label length to 3600 [dot].

^S(CLS,G,47 Sets the left gap to 47 [dot].

^S(CLW,T,35 Sets the top margin to 1.5[mm].

^S(CLW,B,35 Sets the bottom margin to 1.5[mm].

^S(CLW,L,35 Sets the left margin to 1.5[mm].

^S(CLW,R,35 Sets the right margin to 1.5[mm].

^S(CPC,E,D Sets the feather edges function to be not performed.

^S(CPC,C,N Sets the color correction mode to EPSON Preferred

Color.

^S(CPC,D,0 Sets the ink profile and brightne adjustment to 0.

^S(CPC,P,0 Sets the ratio of black to composite setting to 0.

^S(CPC,B,0 Sets the banding reduction to 0.

^S(CBW,C,0 Sets the bar width adjustment to 0.

^S(CMP,F,2 Sets the flush onto paper mode to 2.

^S(CMP,S,12 Sets the printing speed to 12 [inch/sec].

^S(CMP,M,C Sets the printer operation mode to cutter.

^S(CLE,M,10 Adjusts the label left edge position to left 10[dot].

^S(CLE,T,12 Adjusts the label leading edge position

to upper 12[dot].

^XZ Ends label format.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 47

TITLE

SHEET

C

NO.

NEXT

SHEET

47

[Commands for saving graphics]

5.2.4 Save Graphics of Fixed Grapic Fields in the Commands for Saving Graphics

Save graphics as shown by the section 2.3.2.

At here, you should download graphics data of fixed graphic fields.

And at here or between the print commands of each label, you can download graphic data of

variable-graphic fields. In this example, graphic data of variable-graphic-field is downloaded

between the print commands of each label.

-Example comands

~DYR:FXGR01,B,P,...... Saves FXGR01.PNG in the R drive.

~DYR:FXGR02,B,P,...... Saves FXGR02.PNG in the R drive.

~DYR:FXGR03,B,P,...... Saves FXGR03.PNG in the R drive.

~DYR:FXGR04,B,P,...... Saves FXGR04.PNG in the R drive.

Note:The notation of the above-mentioned commands has omitted to specify the number of

graphic data and the data.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 48

TITLE

SHEET

C

NO.

NEXT

SHEET

48

5.2.5.1 Save the Image of the Drawing-Canvas which Includes Only Fixed-Field

^C(Sp Save image of drawing canvas temporarily

Figure 5-3 Label Format which Include Only Fix ed-Field

5.2.5 Print commands

You should make a label format which include only fixed-fields, and should temporarily

save a image of the drawing-canvas.

The image temporarily saved is used as the fixed image at t he following.

-Procedure

At beginning of the label format, draw FXGR02 which is the largest fixed-graphic-field,

and after that, draw other fixed-field.

Draw all fixed-fields , and save temporarily the image of the drawing-canvas using ^C(S

command.

Specify the parameter "p"(print image after saving) of ^C(S command to "N"(No).

-Command to be used

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 49

TITLE

SHEET

C

NO.

NEXT

SHEET

49

[Print commands]

< Rendering commands >

<Fixed-field>

^C(SN Save the image of the drawing canvas.

(without pirnting)

-Example comands

^XA Begins label format.

^FT107,1842

^IMR:FXGR02.PNG^FS Draw FXGR02.PNG.

^FT1174,280 (the largest graphic of fixed-graphic-field)

^IMR:FXGR01.PNG^FS Draw FXGR01.PNG.

^FT376,2324

^IMR:FXGR03.PNG^FS Draw FXGR03.PNG.

^FT2062,3437

^IMR:FXGR04.PNG^FS Draw FXGR04.PNG.

^FT1410,237^A0N,183,187 Draw FXTX01.

^F(C0,0,255,255,D,255,255,255,0,D^FH¥

^FDKotobuki^FS

^FT1430,470^A0N,183,187

^F(C0,0,255,255,D,255,255,255,0,D^FH¥

^FDFood^FS

^FT1181,932^A0N,150,153 Draw FXTX02.

^F(C0,0,0,255,D,255,255,255,0,D^FH¥

^FDABCDEFGHIJK^FS

Drawing FXTX03 to FXTX08 is omitted.

^FT1630,1982^A0N,100,101 Draw FXTX09.

^F(C0,0,0,255,D,255,255,255,0,D^FH¥

^FDFlavor : Tomato^FS

^FT285,3257^A0N,92,94 Draw FXTX10.

^F(C0,0,0,255,D,255,255,255,0,D^FH¥

^FD2070 Kotobuki-Koaka, Matsumoto,^FS

^FT285,3374^A0N,92,94

^F(C0,0,0,255,D,255,255,255,0,D^FH¥

^FDNagano, 399-8702, JAPAN^FS

^XZ Ends label format.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 50

TITLE

SHEET

C

NO.

NEXT

SHEET

50

Figure 5-4 The Fixed Image Saved Temporarily

The image of Figure 5-4 is temporarily saved by the above-mentioned commands.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 51

TITLE

SHEET

C

NO.

NEXT

SHEET

51

5.2.5.2 Draw and Print first label format

^C(L

[Commands for saving graphics]

[Print commands(continued)]

<Fixed-field>

^C(L

<Variabl-field>

< Post-print operation commands >

Draw and print first label format by the following procedure.

-Procedure

Download variable-graphic-field.

At beginning of the label format, l oad(draw) the fixed image saved temporarily.

And then, draw variable-fields.

-Command to be used

Load temporary saved image of drawing canvas

-Example comands

~DYR:VRGR01,B,P,...... Saves VRGR01.PNG(for 1st label) in the R drive.

^XA Begins label format.

Loads fixed image

^FT81,545

^IMR:VRGR01.PNG^FS Draws VRGR01.PNG(for 1st label)

^FT741,1784^A0N,100,101

^F(C0,0,0,255,D,255,255,255,0,D^FH¥

^FDABC-0001-DEF^FS Draws VRTX01(for 1st label)

^FT441,2406^A0N,233,236

^F(C0,0,0,255,D,255,255,255,0,D^FH¥

^FDABC-0001-DEF^FS Draws VRTX02(for 1st label)

^FT651,3073^BY9,3,403^BCN,,Y,N

^F(C0,0,0,255,D,255,255,255,0,D

^FD>:ABC>50001>6DEF^FS Draws VRBC01(for 1st label)

^S(CUB,S,N Sets for the buzzer not to sound after printing is

completed.

^PQ1,1 Sets to pause printer after printing is completed.

^XZ Ends label format.

The image of Figure 5-5 is printed by the above-mentioned commands.

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 52

TITLE

SHEET

C

NO.

NEXT

SHEET

52

Figure 5-5 Drawing Image of Label Format

ESC/Label

Application Development Guide

for TM-C7500 series

REVISION

Page 53

TITLE

SHEET

C

NO.

NEXT

SHEET

53

5.2.5.1 Draw and Print Label Formats Since the Second

^C(L

[Commands for saving graphics]

[Print commands(continued)]

<Fixed-field>

^C(L

<Variabl-field>

< Post-print operation commands >

Draw and print label formats since the second.

Repeat this procedure for necessary number of labels.

-Procedure

Download variable-graphic-field.

At beginning of the label format, l oad(draw) the fixed image saved temporarily.

And then, draw variable-fields.

-Command to be used

Load temporary saved image of drawing canvas

-Example comands

~DYR:VRGR01,B,P,...... Saves VRGR01.PNG(for 2nd label) in the R drive.

VRGR01.PNG is overwritten to graphic of 2nd label.

^XA Begins label format.

Loads fixed image

^FT81,545

^IMR:VRGR01.PNG^FS Draws VRGR01.PNG(for 2nd label)