Page 1

Technical Reference Guide

Describes features and general specifications for the product.

Describes setup and installation of the product.

Describes how to control the printer and necessary information

when you develop applications.

Describes how to handle the product.

Describes to administrator for necessary information to administer

TM-C710 in the system such as installing new printer or

replacing the printer.

Product Overview

Setup

Application Development Information

Handling

Maintenance of the TM-C710

M00063201

Rev.B

Page 2

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained

herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating

and maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of

any options or any consumable products other than those designated as Original Epson Products or

Epson Approved Products by Seiko Epson Corporation.

Trademarks

Microsoft, Windows, and Windows Vista are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision is a registered trademark or trademark of Seiko Epson Corporation.

All other trademarks are the property of their respective owners and used for identification purpose

only.

Copyright

The Ethernet interface model of this product includes software developed by the University of California, Berkeley, and its contributors.

© Seiko Epson Corporation 2013 - 2014. All rights reserved.

2

Page 3

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read

the following carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of

data.

CAUTION

Possibility of sustaining physical injuries.

Possibility of causing physical damage.

Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

3

Page 4

Warnings

WARNING

To avoid risk of electric shock, do not set up this product or handle cables during

a thunderstorm.

Be sure to use as power cable that complies with safety standards with a PE

(power earth) terminal on the plug, and make sure to ground the product before

use.

Ignoring this may result in severe shock.

Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

Handle the power cable with care.

Improper handling may lead to fire or electric shock.

Do not modify or attempt to repair the cable.

Do not place any heavy object on top of the cable.

Avoid excessive bending, twisting, and pulling.

Do not place the cable near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the plug all the way in.

Be sure to use the specified power source.

Connection to an improper power source may cause fire or shock.

Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire.

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your

dealer or a Seiko Epson service center for advice.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact your

dealer or a Seiko Epson service center for advice.

If you open the DIP switch cover, be sure to close the cover and tighten the screw

after adjusting the DIP switch.

Using this product with the cover open may cause fire or electric shock.

Do not use aerosol sprayers containing flammable gas inside or around this

product.

Doing so may cause fire.

4

Page 5

Cautions

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

CAUTION

Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

Do not place heavy objects on top of this product. Never stand or lean on this

product.

Equipment may fall or collapse, causing breakage and possible injury.

To ensure safety, unplug this product before leaving it unused for an extended

period.

Do not remove the ink cartridge during transportation of the printer.

Restriction of Use

When this product is used for applications requiring high reliability/safety, s uch as

transportation devices related to aviation, rail, marine, automotive, etc.; disaster prevention

devices; various safety devices, etc.; or functional/precision

product only after giving consideration to including fail-safes and redundancies into your

design to maintain safety and total system reliability. B ec ause this product was not intended for

use in applications requiring extremely high reliability/safety, s uch as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment

related to direct medical care, etc., please make your own judgment on this product’s suitability

after a f

ull evaluation.

devices, etc., you should use this

5

Page 6

About this Manual

Aim of the Manual

This manual was created to provide information on development, design, and installation of

POS systems and development and design of printer applications for developers.

Manual Content

The manual is made up of the following sections:

Chapter 1 Product Overview

Chapter 2 Setup

Chapter 3 Application Development Information

Chapter 4 Handling

Chapter 5 Maintenance of the TM-C710

6

Page 7

Contents

■ For Safety .............................................................................................................................. 3

Key to Symbols........................................................................................................................................ 3

Warnings.................................................................................................................................................. 4

Cautions ..................................................................................................................................................5

■ Restriction of Use.................................................................................................................. 5

■ About this Manual................................................................................................................ 6

Aim of the Manual .................................................................................................................................6

Manual Content.....................................................................................................................................6

■ Contents................................................................................................................................ 7

Product Overview........................................................................11

■ Features............................................................................................................................... 11

■ Product Configuration........................................................................................................ 13

Interface ................................................................................................................................................13

Color ......................................................................................................................................................13

Accessories ...........................................................................................................................................13

■ Parts Name and Function.................................................................................................. 14

Front Panel.............................................................................................................................................14

Rear Panel.............................................................................................................................................15

Buttons and Indicators .........................................................................................................................16

■ Status/Error Indications...................................................................................................... 18

■ Offline .................................................................................................................................. 19

■ Paper End Detection.......................................................................................................... 19

■ Ink Replacement Request Detection............................................................................... 19

■ Paper Jam Detection......................................................................................................... 19

■ Buzzer Function................................................................................................................... 20

■ DIP Switches........................................................................................................................ 20

■ Product Specifications....................................................................................................... 21

Operating Environment .......................................................................................................................22

Printing Speed.......................................................................................................................................22

Barcodes/Two-Dimensional Symbols..................................................................................................23

Ink Cartridge .........................................................................................................................................27

Print Area and Cut Positions ................................................................................................................28

Electrical Characteristics .....................................................................................................................29

Reliability................................................................................................................................................29

Environmental Specifications ..............................................................................................................29

External Dimensions..............................................................................................................................31

■ Precautions......................................................................................................................... 32

To Handle the Ink Cartridge ................................................................................................................32

To Prevent Ink Waste.............................................................................................................................32

7

Page 8

■ Restrictions.......................................................................................................................... 33

Setup .............................................................................................35

■ Flow of Setup ...................................................................................................................... 35

■ Installing the Printer............................................................................................................ 36

Important Notes on Installation.......................................................................................................... 36

■ Connecting the USB/Ethernet Cable................................................................................ 38

■ Connecting the AC Adapter............................................................................................. 40

■ Loading the Roll Paper ...................................................................................................... 41

■ Loading the Ink Cartridge ................................................................................................. 43

■ Setting the Lane ID .............................................................................................................45

■ Setting the Printer IP Address ............................................................................................ 46

■ Adding a TCP/IP Port.......................................................................................................... 47

■ Installing the Printer Driver................................................................................................. 50

For USB Interface Model...................................................................................................................... 50

For Ethernet Interface Model ............................................................................................................. 51

■ Installing Status API ............................................................................................................ 52

■ Setting the DIP Switches..................................................................................................... 53

Application Development Information......................................55

■ Overview............................................................................................................................. 55

■ Printer Driver ....................................................................................................................... 55

■ Status API ............................................................................................................................ 56

■ Sample Program ................................................................................................................ 56

■ Software .............................................................................................................................. 58

Printer Driver.......................................................................................................................................... 58

Administering network printers ........................................................................................................... 58

Developing applications..................................................................................................................... 59

Handling .......................................................................................61

■ Replacing the Ink Cartridge ............................................................................................. 61

■ Replacing the Roll Paper................................................................................................... 62

■ Removing Jammed Paper ................................................................................................ 64

■ How to Use the Printer Driver............................................................................................. 65

How to Display the Printer Driver ........................................................................................................ 65

Registering User Defined Media ......................................................................................................... 66

8

Page 9

Favorite Setting .................................................................................................................................... 67

Information for User Definition ............................................................................................................ 70

Buzzer Setting at the Time of Errors .................................................................................................... 71

Autocutting after Printing ................................................................................................................... 72

Barcode Printing .................................................................................................................................. 73

2D Symbol Printing ............................................................................................................................... 82

Barcode and 2D Symbol Font Printing on .NET Environment .......................................................... 87

Functions of the Printer Driver............................................................................................................. 89

■ Uninstallation.......................................................................................................................93

Uninstalling the Printer Driver .............................................................................................................. 93

Uninstalling Status API.......................................................................................................................... 95

■ Self-test ................................................................................................................................98

Procedure for the Self-test .................................................................................................................. 98

■ Nozzle Check......................................................................................................................99

Nozzle Check Using the Self-test ........................................................................................................ 99

Nozzle Check Using the Printer Driver................................................................................................ 99

■ Cleaning............................................................................................................................100

Cleaning the Printer Case ................................................................................................................ 100

Head Cleaning .................................................................................................................................. 100

■ Preparing for Transport .....................................................................................................102

■ Storing Long-term .............................................................................................................103

Before Long-term Storage ................................................................................................................ 103

After Long-term Storage ................................................................................................................... 103

■ Troubleshooting ................................................................................................................105

Lighting and Flashing Error LED......................................................................................................... 105

Maintenance of the TM-C710...................................................107

■ Necessary Information for an Administrator of the Printer ...........................................108

Printer Driver Functions ...................................................................................................................... 108

Destination for the Printer Driver Setting.......................................................................................... 109

Installing Multiple Printer Drivers on One Client Computer ........................................................... 110

■ Maintenance ....................................................................................................................111

Adding a Client Computer (for the Ethernet Interface Model) ................................................... 111

Adding a Printer ................................................................................................................................. 112

Adding a Paper Type/Changing the Print Setting......................................................................... 113

Replacing the Printer......................................................................................................................... 113

9

Page 10

10

Page 11

Chapter 1 Product Overview

Product Overview

This chapter describes features and functions of the product.

Features

The TM-C710 is a 4-color ink jet printer that offers high speed, full-color printing with the ease of

operability and high reliability required for commercial applications. Its compact size fits easily

on a counter.

Printing

•High-speed printing

130 mm/s {5.12"/s} (printing width 53 mm {2.09"}, 360 dpi × 180 dpi, unidirectional)

100 mm/s {3.94"/s} (printing width 53 mm {2.09"}, 360 dpi × 360 dpi, bidirectional)

90 mm/s {3.54"/s} (printing width 53 mm {2.09"}, 360 dpi × 720 dpi, bidirectional)

•Full color printing

CMYK 4-color printing

Each color has 4 gradations

Print resolution: 360 dpi × 180 dpi, 360 dpi × 360 dpi, 720 dpi × 360 dpi

[dpi: dots per 25.4 mm (dots per inch)]

Handling

•Front operation (when replacing roll paper and ink cartridges)

•Drop-in roll paper method

•An autocutter as standard equipment

Reliability

• Uses pigment ink for excellent light-fastness and water resistance

1

•Fitted with automatic nozzle check system and automatic recovery function for missing dots

Printer driver

•Printing with a Windows printer driver.

•The printer has a built-in barcode font, which is available from .NET application.

•Supported OS

For detailed information on supported operating systems, see the release note for the printer driver.

11

Page 12

Status API

•Can transmit the printer status (such as printer and ink cartridge status, and print job informa-

tion) to your applications, and can set the buzzer to beep when an error such as a cover open

occurs.

•Dedicated sample program using Status API (program language: C + +, VB.NET, C#)

pared.

Other features

•Compact size that fits unobtrusively on a counter

Main unit footprint: W: 140 mm × D: 210 mm {5.51" × 8.27"}

•Ethernet interface and USB interface as standard equipment

•A buzzer as standard equipment

is pre-

12

Page 13

Chapter 1 Product Overview

Product Configuration

Interface

USB interface (USB 2.0 high speed) and Ethernet interface (100 Base-TX/10 Base-T)

Color

EDG (Epson Dark Gray)

Accessories

Unpacking

•Ink cartridge (Model number: SJIC25P) (STARTER CARTRIDGE)

•Ink cartridge (Model number: SJIC25P)

• Roll paper

•AC Adapter (Model: Adapter, K)

•AC cable

•TM-C710 Documents Disc

•Setup Guide

1

13

Page 14

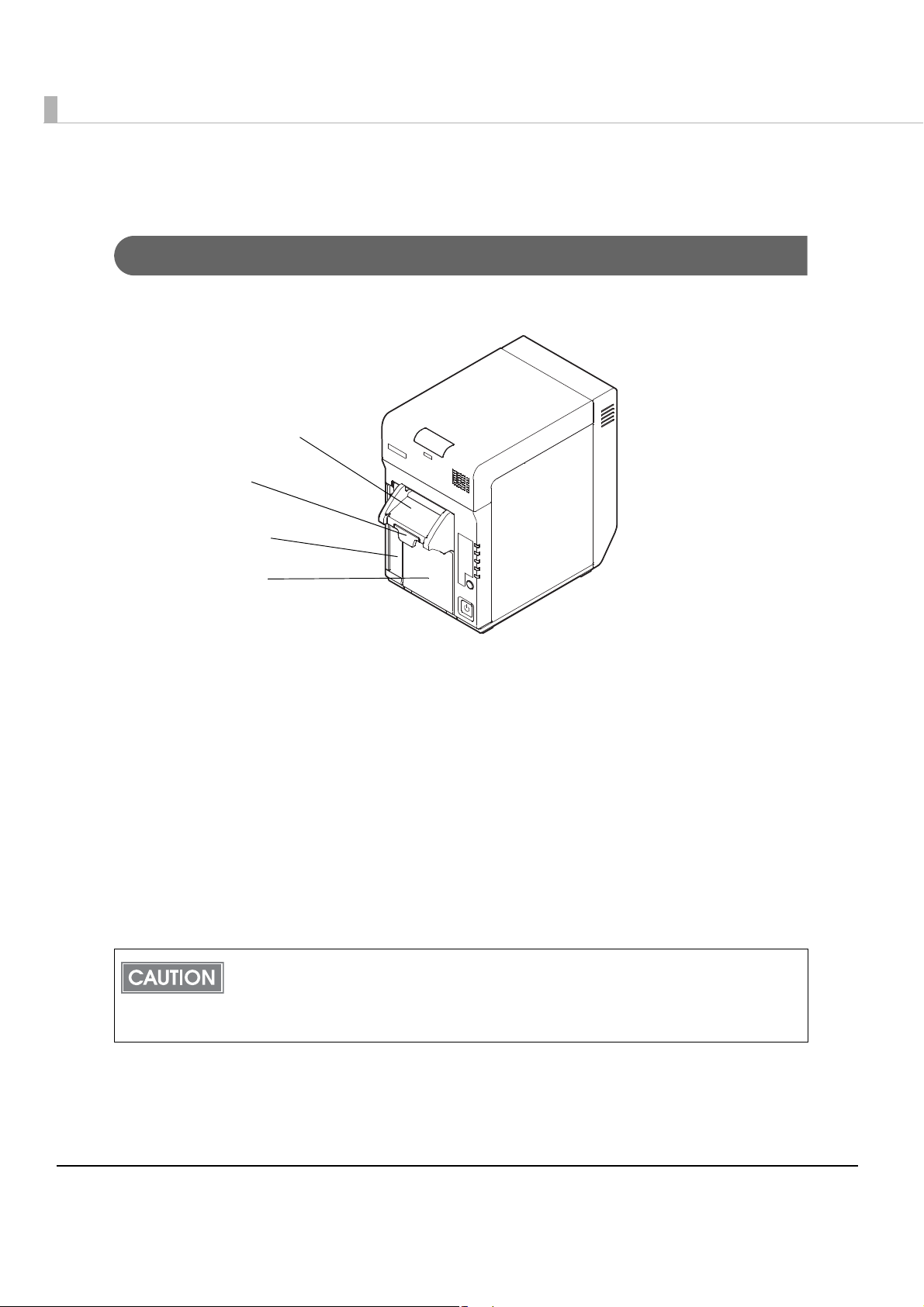

Parts Name and Function

Roll paper cover

Release lever

Paper ejection guide

Ink cartridge slot

Front Panel

Paper ejection guide:

Printed coupons are ejected along the paper ejection guide.

Release lever:

Pull the release lever to open the roll paper cover.

Ink cartridge slot:

Ink cartridge is loaded.

Roll paper cover:

Open the roll paper cover to load or replace roll paper.

Do not open the roll paper cover during printer operation. When the roll paper cover is

opened during printing, printing stops, the printer automatically goes offline, and the Error

LED lights. The data being printed is lost. When the cover is closed, the printer returns to

online and the printable state.

14

Page 15

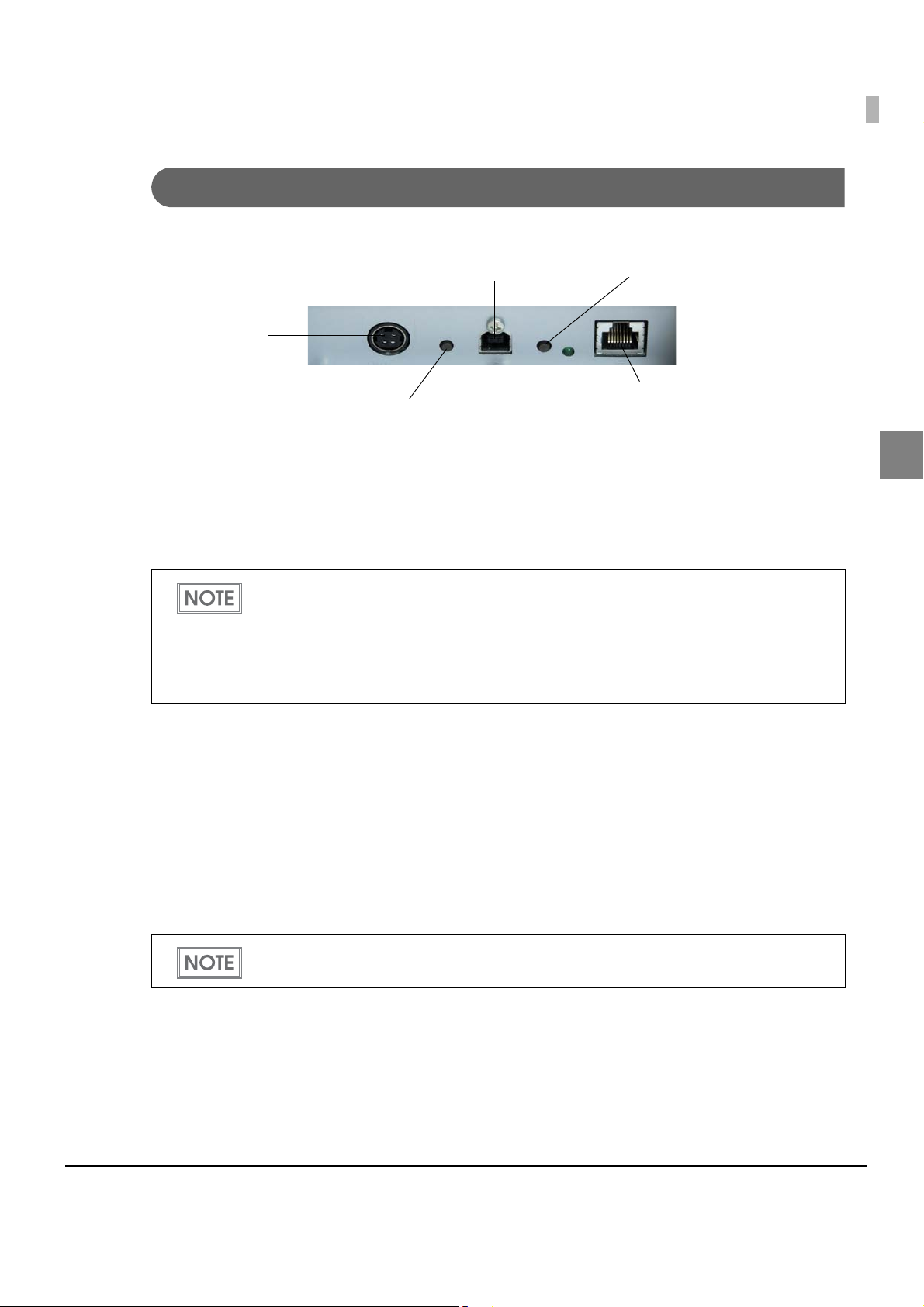

Rear Panel

Power connector

Lane setting button

Self-test button

USB interface connector

Ethernet interface connector

Power connector:

Connect a DC cable for the accessory AC adapter.

Self-test button:

Press the button to perform a self-test.

Chapter 1 Product Overview

1

You can check the printer status with the following items the self-test prints out.

Printer configuration

IP address

Firmware version

Serial number

Nozzle check pattern

USB interface connector:

Connect a USB cable when USB interface is used.

Lane setting button:

The printer executes the lane setting function after this button is held down for 5 seconds or

longer continuously.

Ethernet interface connector:

Connect a LAN cable.

For details how to connect the interface and power supply connector, see "Connecting the

USB/Ethernet Cable" on page 38 and "Connecting the AC Adapter" on page 40.

15

Page 16

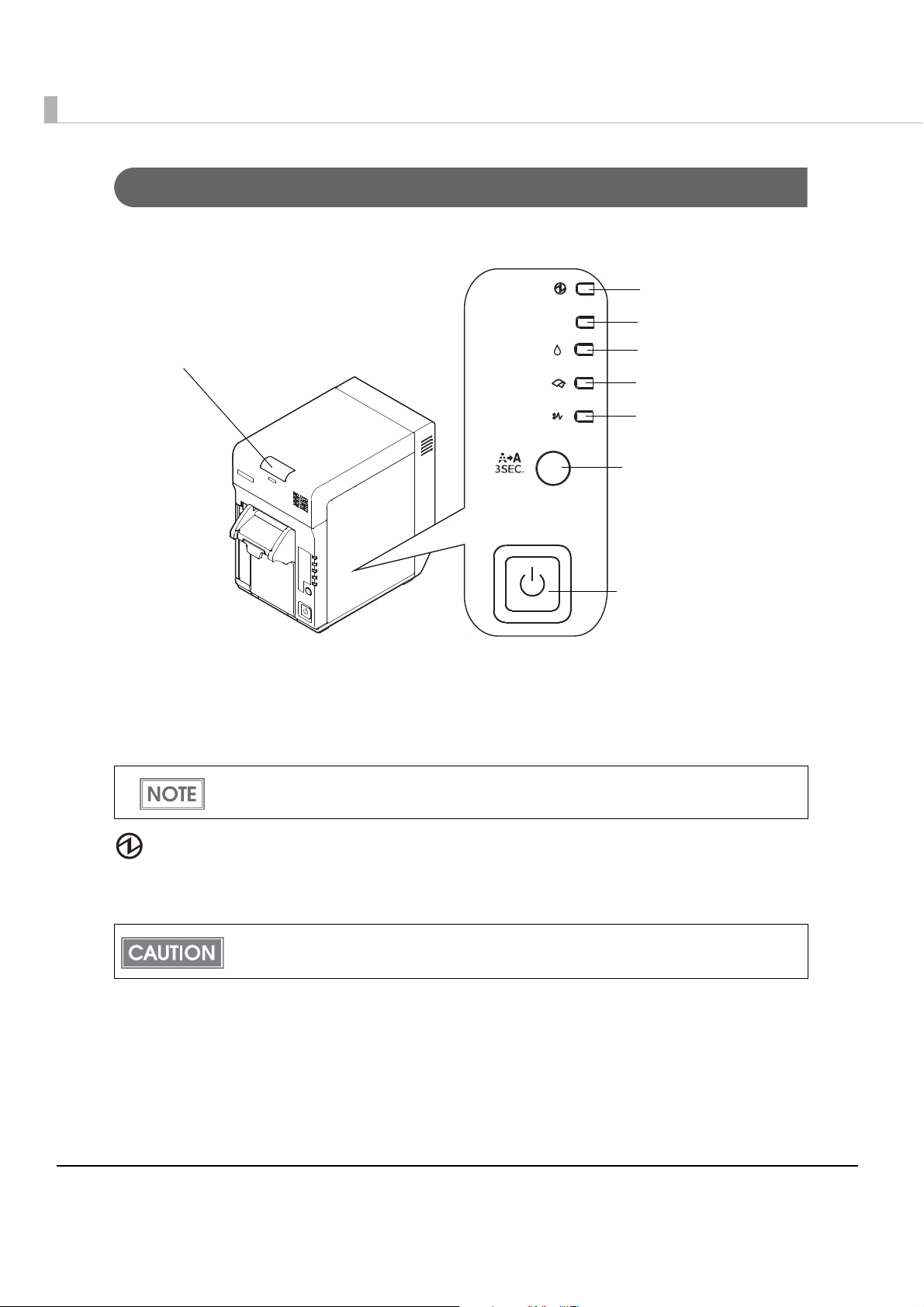

Buttons and Indicators

Error

Replace Ink

Check Paper

Paper Jam

Power LED

Cleaning button

Error LED

Replace Ink LED

Check Paper LED

Paper Jam LED

Status LED

Power button

Status LED (Green/Orange)

•The green LED lights when there is no error.

•The orange LED flashes when there is an error.

The buzzer beeps when the Status LED flashes. For details on the buzzer function, see

"Buzzer Function" on page 20.

Power LED (Green)

•Lights when the power is on.

•Flashes when the printer is initializing, cleaning, printing, or during an error state.

Before turning off the printer, wait more than 10 seconds (so that the print head cap closes)

after the printer finishes operating.

Error LED (Orange)

•Lights when the printer is in the error state.

•Flashes when a fatal error or maintenance requirement occurs.

16

Page 17

Chapter 1 Product Overview

Replace Ink LED (Orange)

•Lights when no ink cartridge has been loaded or when the printer is requesting replacement of

the ink cartridge.

Check Paper LED (Orange)

•Lights when no paper has been loaded.

Paper Jam LED (Orange)

•Lights when the paper is jammed.

The printer status is also displayed with combinations of lighting and flashing of LEDs. See

"Status/Error Indications" on page 18 for details.

Cleaning button

•When printing is faint or dots are missing, press the Cleaning button for 3 seconds or more

continuously to perform the print head cleaning.

Do not press the cleaning button unless there is a problem with print quality. Unnecessary

cleaning wastes ink.

Power button

•When DIP switch 1 is Off, the power is turned on after the Power button has been pressed

while the power is off.

•When DIP switch 1 is Off, the power is turned off after the Power button has been pressed for

3 seconds or more while the power is on.

•When DIP switch 1 is On, the printer settings are reset after the Power button has been pressed

for 3 seconds or more.

For 30 seconds after a reset, the printer and host cannot communicate.

After resetting, the printer is in the same state as when the power is turned on.

For details on the DIP switches, see "DIP Switches" on page 20.

1

17

Page 18

Status/Error Indications

: On

: Flashing : Off

or

or

or

ororor

or

or

or

or

The printer status is displayed by a combination of lighting and flashing of LEDs.

Power Error

LED

Replace

Ink

———

——

——

Check

Paper

——

Paper

Jam

Status

Status/

Action

Roll paper cover is open.

Close the roll paper cover.

No roll paper is loaded.

Load new roll paper.

No ink cartridge is loaded or

ink cartridge needs to be

replaced.

Load new ink cartridge.

Paper jam occurred.

Remove jammed paper and

load roll paper.

Fatal error occurred.

Reset the printer. If the printer

does not recover, the printer

needs to be repaired.

Maintenance is required.

The printer needs to be

repaired.

Software updating

Wait for the updating to be

completed.

Lane setting

Complete the lane setting.

After the time-out of 30

seconds, the printer recovers

from the lane setting mode.

Concerning the “—” column, this depends on the combination with other states.

18

Page 19

Chapter 1 Product Overview

Offline

The printer does not have an online/offline switch. Offline occurs:

•Between when the power is turned on (including the printer reset through the interface) and

when the printer is ready to receive data.

•During a self-test.

•When the roll paper cover is open.

•During an error state.

•When the printer stops printing due to a paper-end.

•When the printer stops printing due to ink replacement request.

•When the printer is waiting for recovery from a high-temperature error.

The printer can transmit or receive data from/to the host PC even when the printer is offline.

Paper End Detection

When roll paper is used up, printing stops, the printer automatically goes offline, and the Check

Paper LED lights. The data being printed is lost.

When roll paper is replaced with a new roll, the printer returns to online and the printable state.

Ink Replacement Request Detection

When an ink cartridge is not loaded, the printer goes offline, and the Replace Ink LED lights.

When the ink replacement request is detected, the Replace Ink LED lights.

When the ink cartridge is replaced with a new one, the printer returns to online and

state.

the printable

1

Paper Jam Detection

When a roll paper jam occurs, the printer automatically goes offline, and the Paper Jam LED

lights.

When you remove the jammed paper, never pull out the paper forcibly. When roll paper is

replaced and roll paper cover is closed, the printer returns to online and the printable state.

19

Page 20

Buzzer Function

The printer records the buzzer sound file in the NV memory, and beeps the file when the printer

event occurs according to the table below.

Vo l ume control: 2 levels (On/Off)

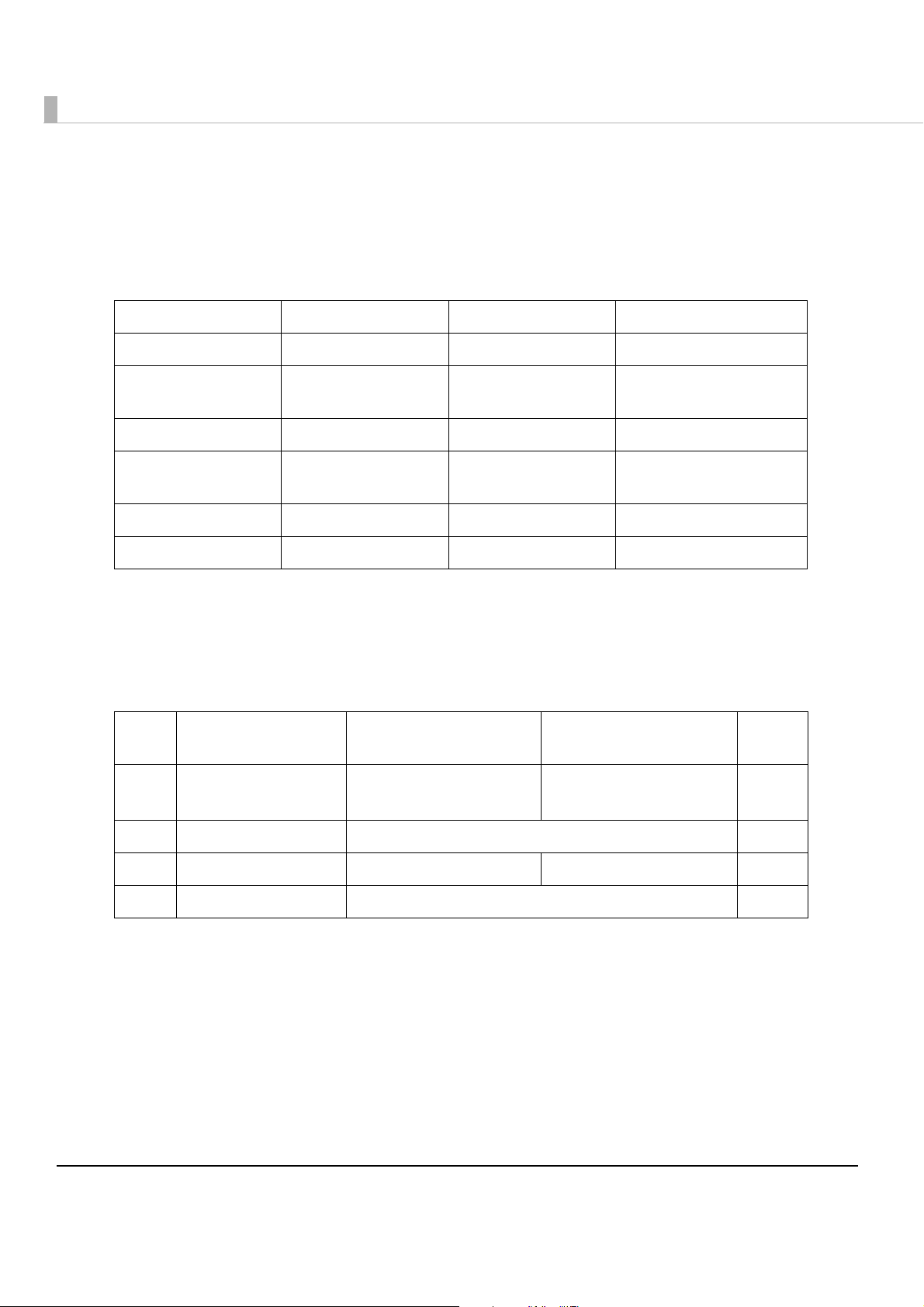

Printer event Frequency Beeping period Pattern

Fatal error 2.0 KHz Approx. 1.0 seconds 1 time

Maintenance

requirement

Cover open 3.0 KHz Approx. 1.0 seconds Continuous

Time to replace ink

cartridge

Roll paper out 3.0 KHz Approx. 1.0 seconds Continuous

Paper jam error 3.0 KHz Approx. 1.0 seconds Continuous

2.5 KHz Approx. 1.0 seconds 1 time

3.0 KHz Approx. 1.0 seconds Continuous

DIP Switches

Setting the DIP switches to On or Off switches the following functions. See "Setting the DIP

Switches" on page 53 for how to set the DIP switches.

Switch

no.

1 Operation of the

Function On Off Default

power button

Reset

(Power button is disabled)

Power On/ Off

(Power button is enabled)

Off

20

2 Internal use Do not change Off

3 Cleaning at power on Disabled Enabled Off

4 Internal use Do not change On

Page 21

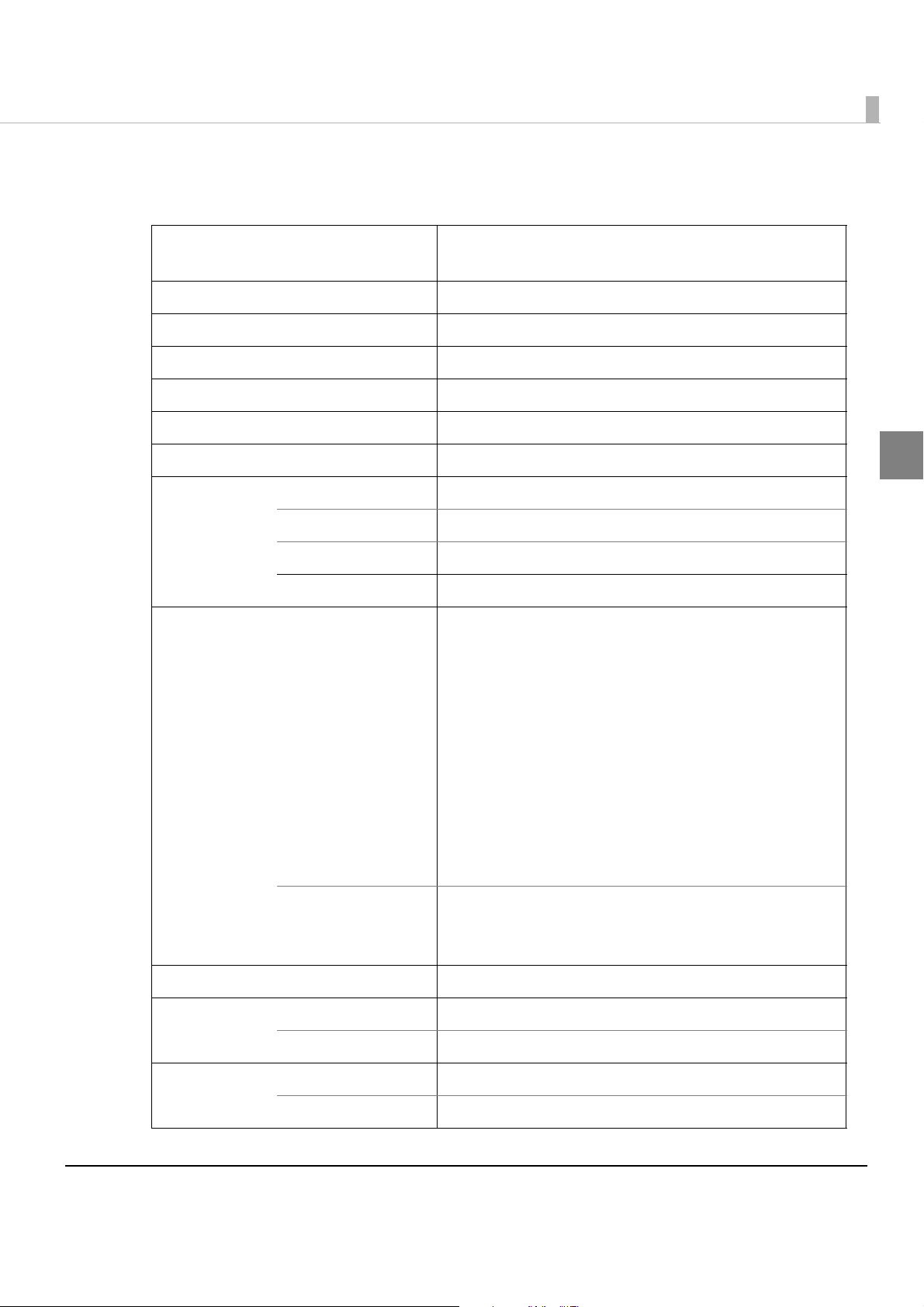

Product Specifications

Print method Serial inkjet, dot matrix

Four-color printing

Print direction Bidirectional/unidirectional printing

Paper feed Forward direction feed

Print width 53 mm {2.09"} maximum

Autocutting method By separated-blade scissors

Autocut type Partial cut (one center point uncut)

Chapter 1 Product Overview

Roll paper supply method Drop-in roll paper

Roll paper Paper width 58 mm {2.28"} (57.5 ± 0.5 mm {2.26 ± 0.02"})

Maximum diameter 90 mm {3.54"}

Paper core Outside diameter: 18 mm {0.71"} or larger

Paper type Plain paper, Light Matte Coated paper

Interface Ethernet Specification: IEEE 802.3-compliant

Communication speed: 100BASE-TX/10BASE-T

Supporting communication protocols:

ARP, ICMP, IP, UDP, TCP, HTTP, DHCP, ENPC, SNMP, Port 9100,

APIPA (Microsoft Automatic Private IP Addressing)

Factory setting:

IP address setting mode: Manual

IP address: 192.168.192.168

Lane number: 168

Host name: TM-C710-xxxxxx

(xxxxxx sets the lowest 6 digits of MAC address.)

Domain name: None

USB Specification: USB 2.0-compliant

Communication speed: High-speed

Device type: Self-powered device

1

Power supply Power supplied by accessory AC adapter

AC adapter Input voltage (rated) 100 to 240 V

Frequency (rated) 50 to 60 Hz

Power

consumption

Operating Average approximately 30 W

Idling Average approximately 3 W

21

Page 22

Main unit size (W D H) 140 210 222 mm {5.51 8.27 8.74"} (excluding the

protrusion)

Mass Approx. 5.2 kg [11.4 lb] (excluding ink cartridge and roll

paper)

Operating Environment

Computers PC/AT-compatible

System requirements CPU Computers with a processor clock speed of 1 GHz or higher

are recommended.

RAM RAM of 512 MB or more is recommended.

If the minimum configuration system requirements as shown above are not met, the printer

may not perform well.

For detailed information about supported operating systems, see the release note for

the printer driver.

Printing Speed

Input resolution

(horizontal vertical)

180 180 dpi 360 180 dpi Unidirectional printing 130 mm {5.12"/s}

360 360 dpi 360 360 dpi Bidirectional printing 100 mm {3.94"/s}

360 360 dpi 720 360 dpi Bidirectional printing 90 mm {3.54"/s}

[dpi: dots per 25.4 mm (dots per inch)]

The printer speeds above are for continuous printing except during print head cleaning,

Printing speed may be slower, depending on the data transmission speed.

Graphic resolution

(horizontal vertical)

autocutting, or starting/ending a job.

Print direction

Printing speed

(53 mm printing width)

22

Page 23

Chapter 1 Product Overview

Barcodes/Two-Dimensional Symbols

Barcodes/Two-dimensional symbols encodable by the printer

driver

Barcode/twodimensional

symbol printing

Barcodes

Identification rate:

ANSI rank D (based

on Seiko Epson

Corporation

standard)

Two-dimensional

symbols

UPC-A, UPC-E, JAN 8 (EAN 8), JAN 13 (EAN 13), CODE 39, CODE

128, GS1-128, GS1 DataBar Omnidirectional,

GS1 DataBar Truncated, GS1 DataBar Limited,

GS1 DataBar Expanded

Stack type:

PDF417, GS1 DataBar Stacked, GS1 DataBar Stacked Omni-

directional, GS1 DataBar Expanded Stacked

Matrix type:

QR Code

If you want to create graphic data for barcodes/two-dimensional symbols, create data which

meet the following conditions.

Use black as the print color of the barcode on blank paper (not pre-printed).

When creating barcode/2-dimensional symbol data as the graphic data, use the input

resolution in the table below. At other resolutions, the barcode reader may return errors.

Because of the characteristics of the ink, it may penetrate the paper, and bars of printed

barcodes may become thicker. This depends on the paper. Users can maintain the barcode recognition rate by methods such as ± 1 correction, reducing the data in a bar by

one pixel and increasing the blank space by one pixel. Be sure not to use this method for

the two-dimensional symbols.

1

Input resolution

(horizontal vertical)

180 180 dpi 360 180 dpi

360 360 dpi 360 360 dpi

360 360 dpi 720 360 dpi

Graphic resolution

(horizontal vertical)

23

Page 24

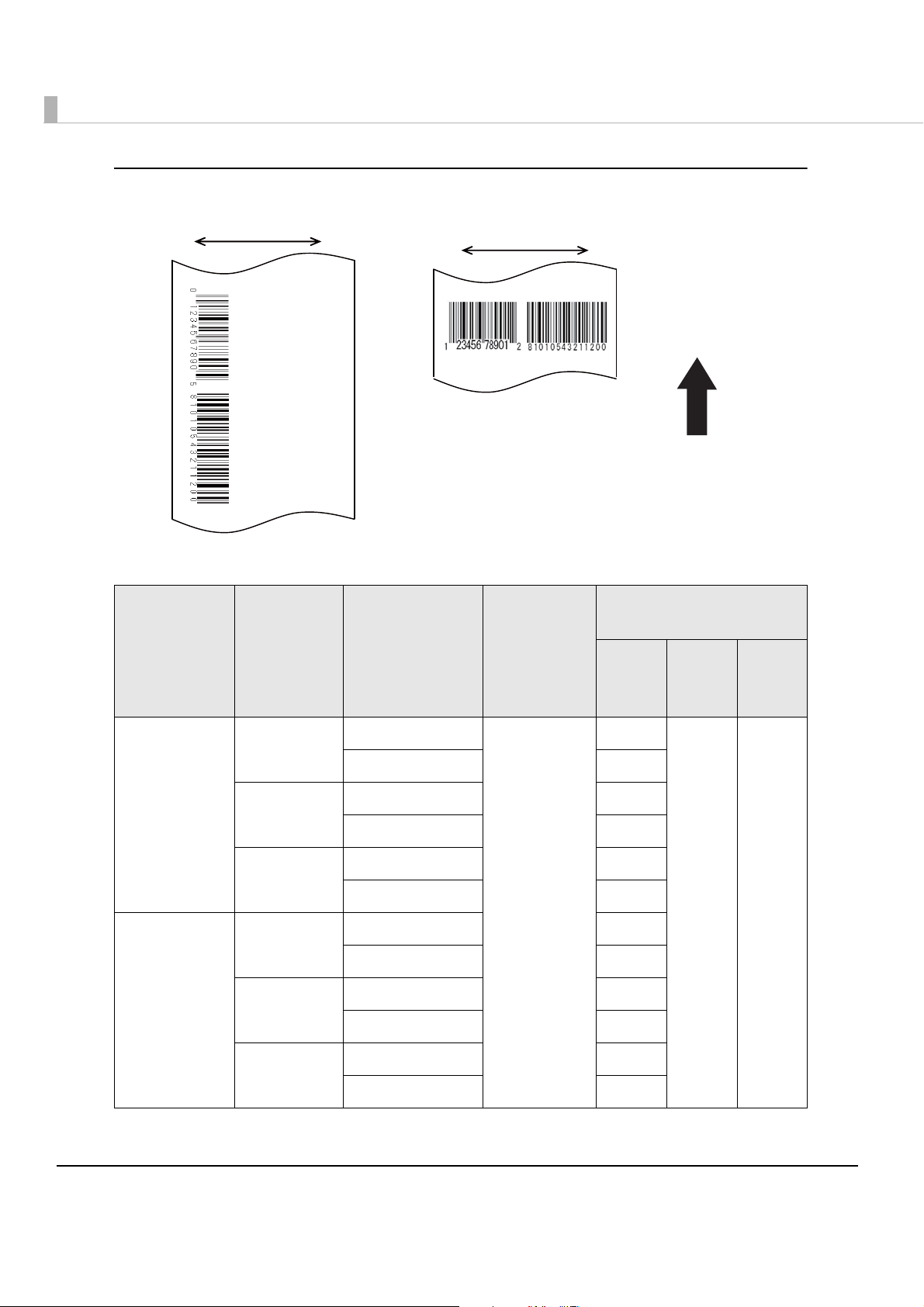

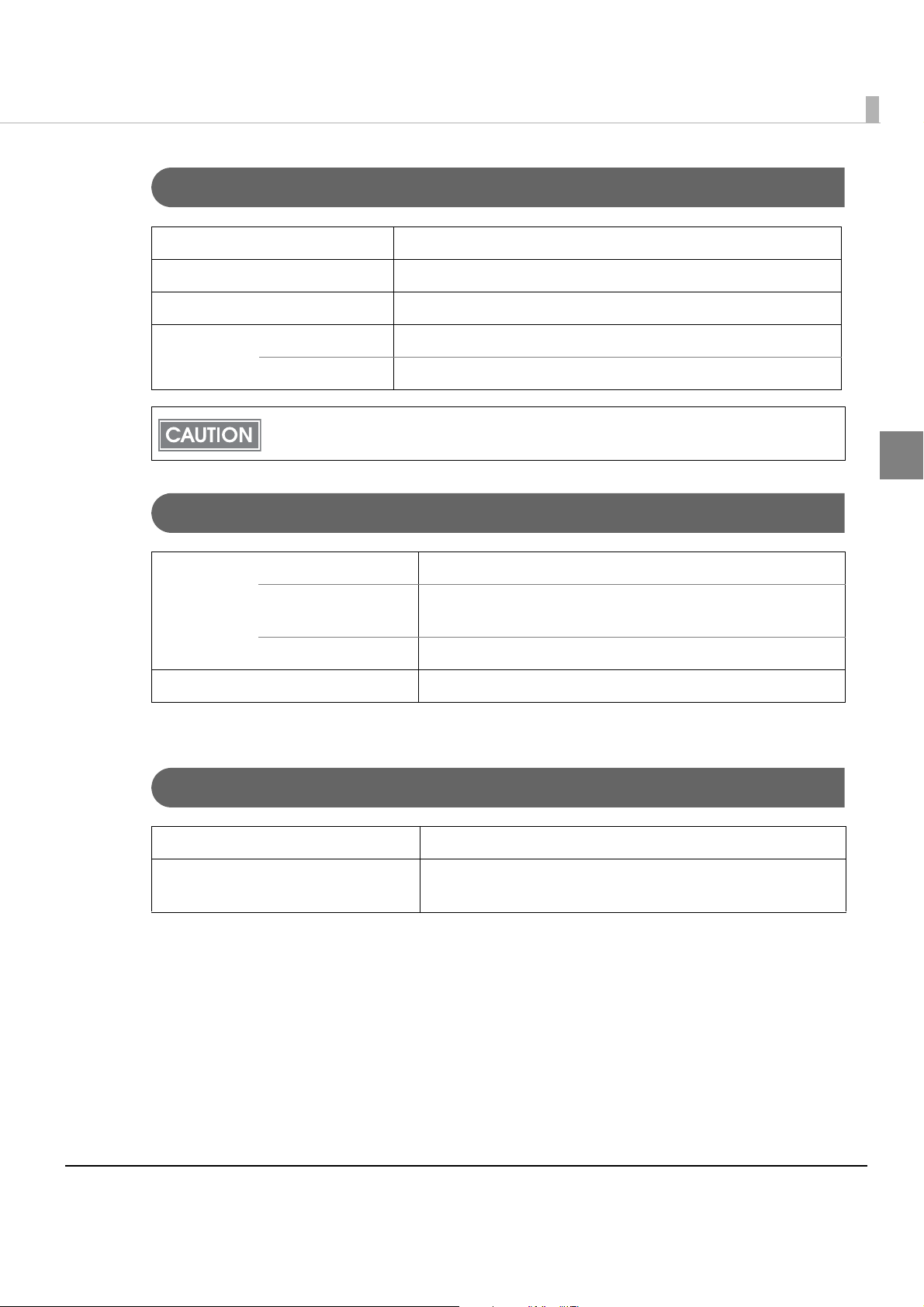

Creating the graphic data for barcode

Paper feeding direction

Carriage move directionCarriage move direction

Ladder Barcode

Fence Barcode

The following table shows the recommended value.

Paper type Resolution Barcode type

Bar width

adjustment

Minimum module

(by 360 dpi)

ANSI

Grade D

or

higher

ANSI

Grade C

or

higher

ANSI

Grade B

or

higher

Plain

Light matte

coated

-: Not supported

360 180 dpi

360 360 dpi

720 360 dpi

360 180 dpi

360 360 dpi

720 360 dpi

Fence barcode

Ladder barcode 6 dots

Fence barcode 4 dots

Ladder barcode 6 dots

Fence barcode 4 dots

Ladder barcode 6 dots

Available

Fence barcode 4 dots

Ladder barcode 6 dots

Fence barcode 4 dots

Ladder barcode 6 dots

Fence barcode 4 dots

Ladder barcode 6 dots

4 dots

--

24

Page 25

Chapter 1 Product Overview

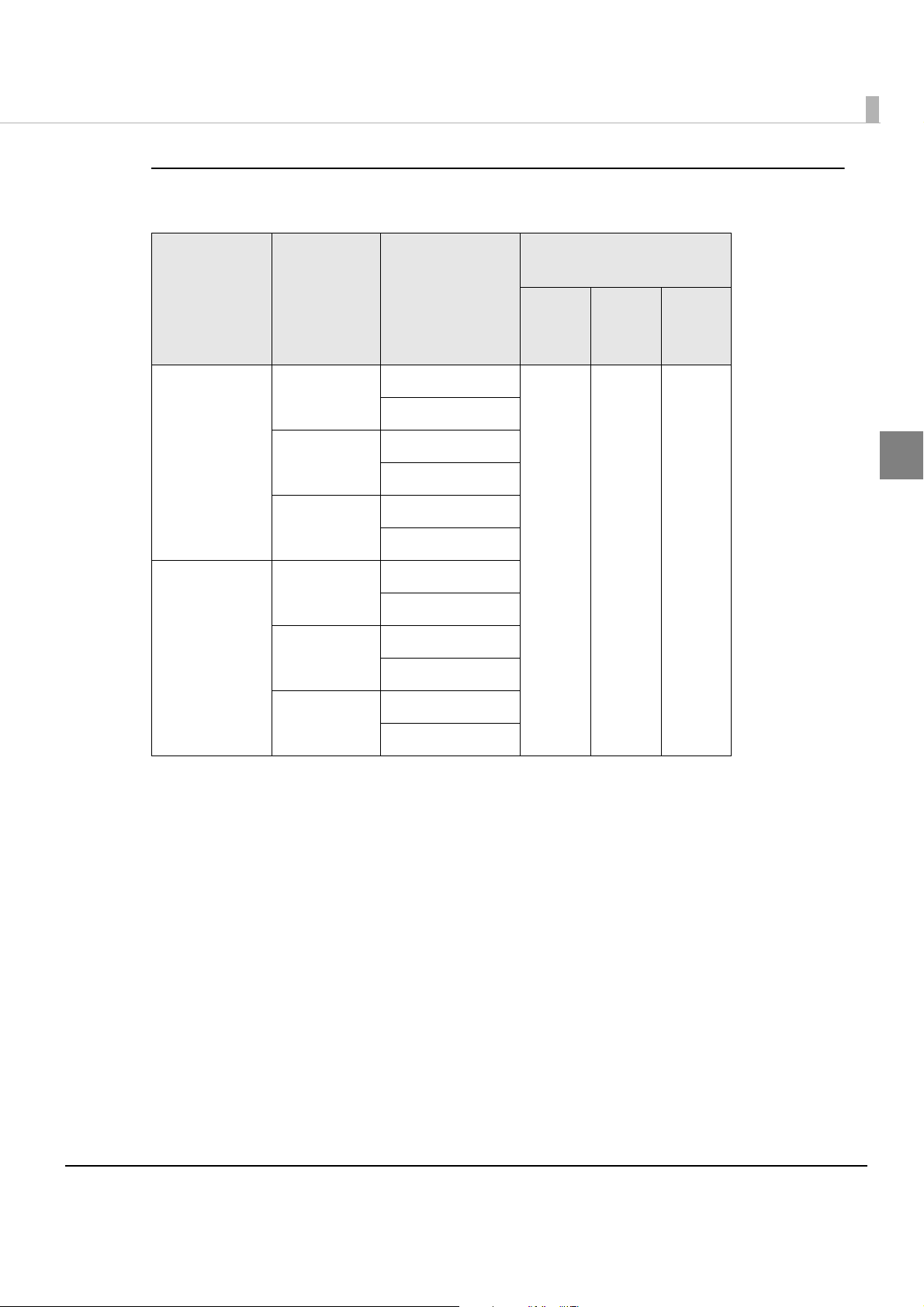

Creating the graphic data for two-dimensional symbol (stack type)

The following table shows the recommended value.

Minimum module

(by 360 dpi)

Paper type Resolution Print status

No paper feed

360 180 dpi

With paper feed

No paper feed

Plain

Light matte

coated

360 360 dpi

With paper feed

No paper feed

720 360 dpi

With paper feed

No paper feed

360 180 dpi

With paper feed

No paper feed

360 360 dpi

With paper feed

No paper feed

720 360 dpi

With paper feed

ANSI

Grade D

or

higher

6 dots - -

ANSI

Grade C

or

higher

ANSI

Grade B

higher

or

1

-: Not supported

25

Page 26

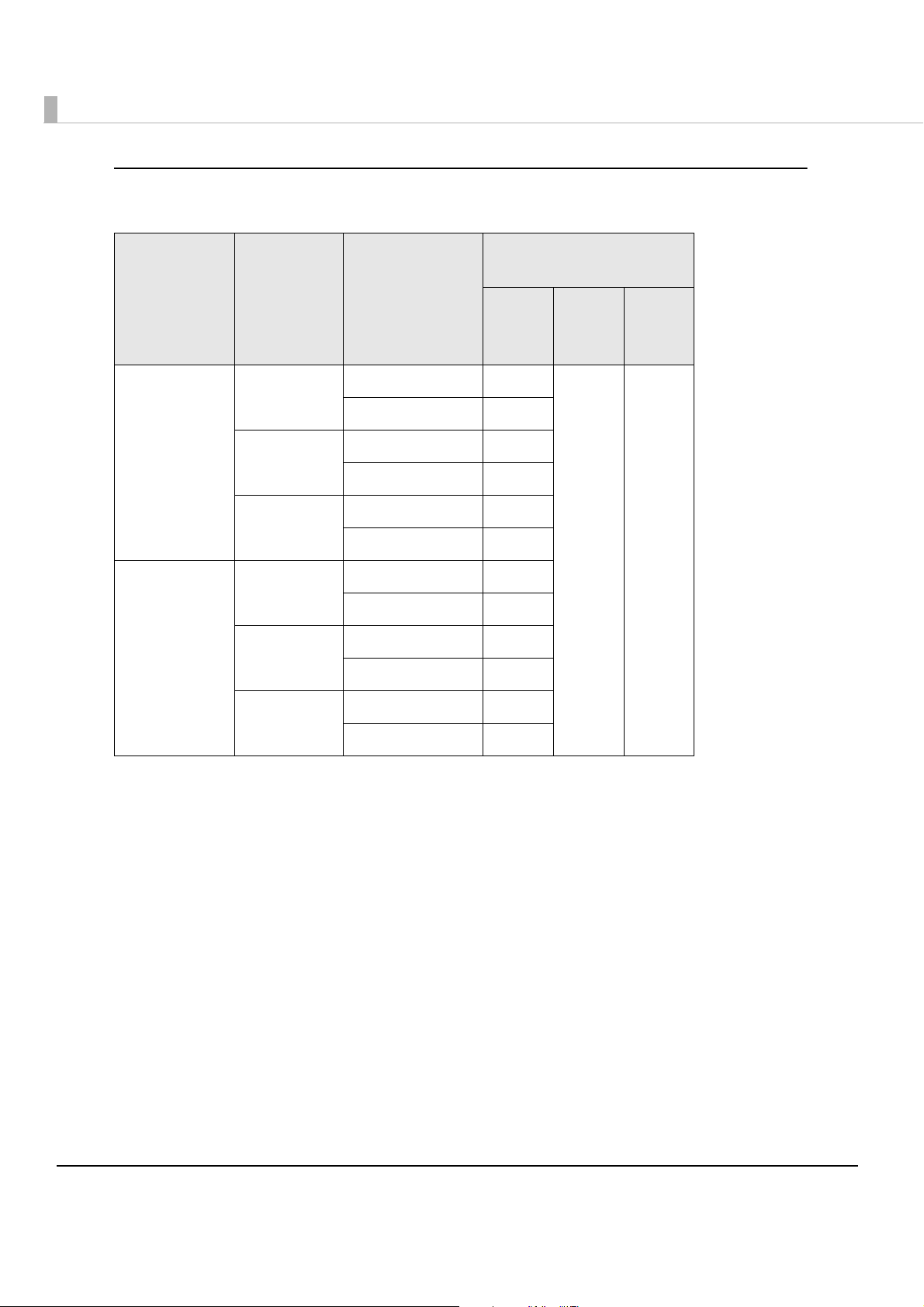

Creating the graphic data for two-dimensional symbol (matrix type)

The following table shows the recommended value.

Minimum module

(by 360 dpi)

Paper type Resolution Print status

No paper feed 6 dots

360 180 dpi

With paper feed 8 dots

No paper feed 6 dots

Plain

Light matte

coated

360 360 dpi

With paper feed 8 dots

No paper feed 6 dots

720 360 dpi

With paper feed 8 dots

No paper feed 6 dots

360 180 dpi

With paper feed 8 dots

No paper feed 6 dots

360 360 dpi

With paper feed 8 dots

No paper feed 6 dots

720 360 dpi

With paper feed 8 dots

ANSI

Grade D

or

higher

ANSI

Grade C

or

higher

--

ANSI

Grade B

or

higher

-: Not supported

26

Page 27

Chapter 1 Product Overview

203.2 mm {8.00"}

53.0 mm {2.09"}

Paper feed

direction

Ink Cartridge

Type 4-color integrated exclusive ink cartridge

Model number SJIC25P

Ink color Cyan, magenta, yellow, black

Ink type Pigment ink

Number of sheets printable 4000 coupons per cartridge

(Print area: 53.0 203.2 mm {2.09 8.00"}, total

803,000 shots, 360 dpi 180 dpi on plain paper)

Ink cartridge expiration 6 months after installation in a printer and 2 years

after the production date, including a six-month

expiration after installation in a printer.

1

Storage

temperature

Transported in the individual box -20 to 60C {-4 to 140F}

Stored in the individual box -20 to 40C {-4 to 104F}

Installed on the printer -20 to 40C {-4 to 104F}

The number of sheets printable is calculated in a case when printing an average of 52

sheets in a 12-hour day (1 sheet per approximately 14 minutes) after replacing the ink

cartridge with a new one.

The number of sheets printable depends on the environment and conditions in use

(content to print, print settings, paper type, print frequency, ambient temperature, etc.).

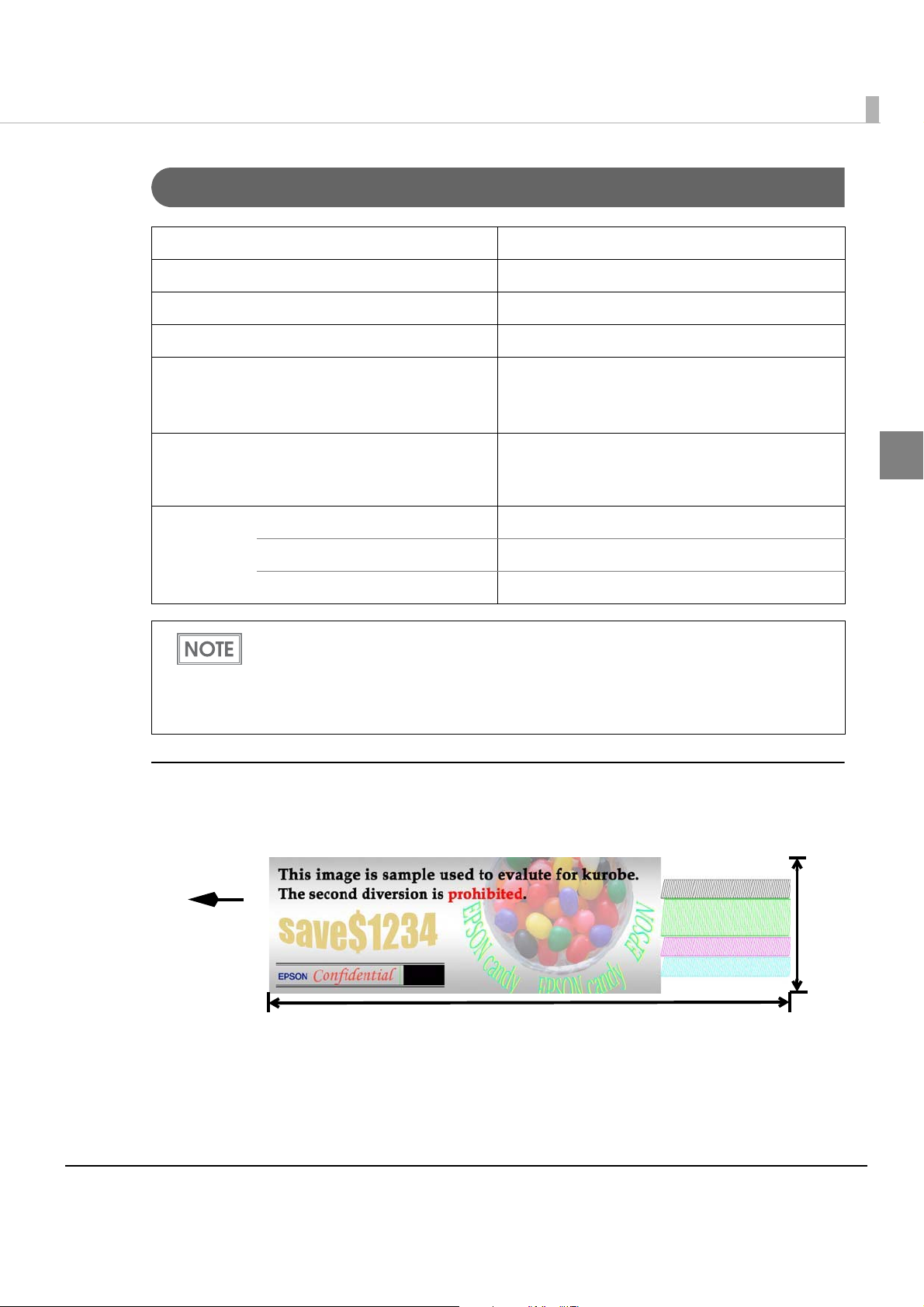

Printable area

The illustration below shows a sample coupon used to calculate the end of life for the

mechanism and the ink cartridge.

27

Page 28

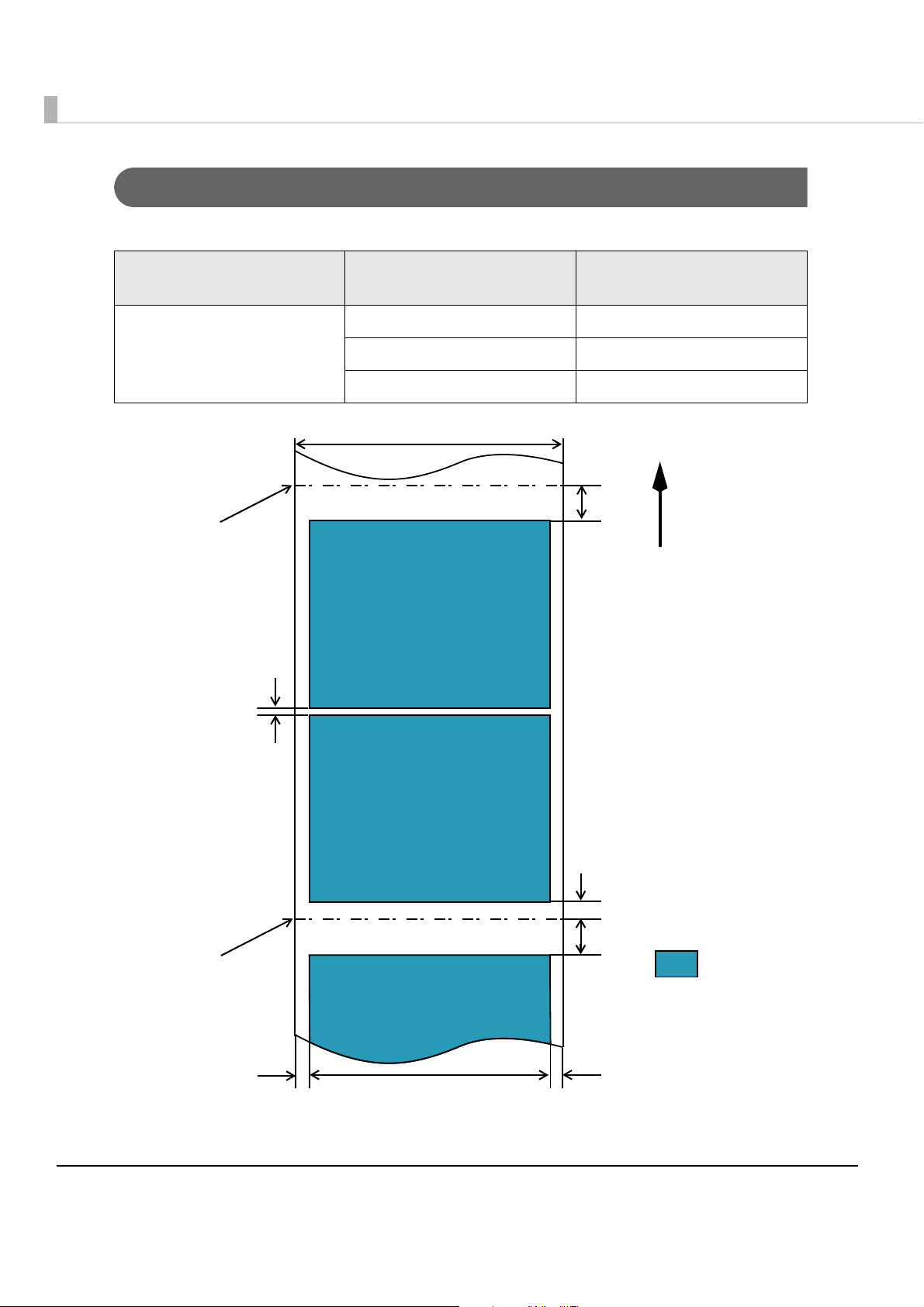

Print Area and Cut Positions

Paper width: 57.5

14

A

14

2

2.25532.25

Feed direction

Coupon 1

Coupon 2

Coupon 3

Autocutting position

Autocutting position

Print area

[The values given are typical values. Units: mm]

The length of each coupon must be 66.8 mm or longer.

The print area and cut positions are shown below.

the previous printing

360 dpi 180 dpi

360 dpi 360 dpi

720 dpi 360 dpi

Resolution of

Resolution of

the next printing

360 dpi 180 dpi 0 mm

360 dpi 360 dpi 0.21 mm {0.0083"}

720 dpi 360 dpi 0.21 mm {0.0083"}

Minimum top margin A

28

Page 29

Chapter 1 Product Overview

Electrical Characteristics

Power supply Power supplied by dedicated AC adapter

Input voltage (rated) AC 100 to 240V

Frequency (rated) 50/60 Hz

Power

consumption

Operating Approximately 30 W

Stand-by Approximately 3 W

Be sure to use the dedicated AC adapter included in the product package.

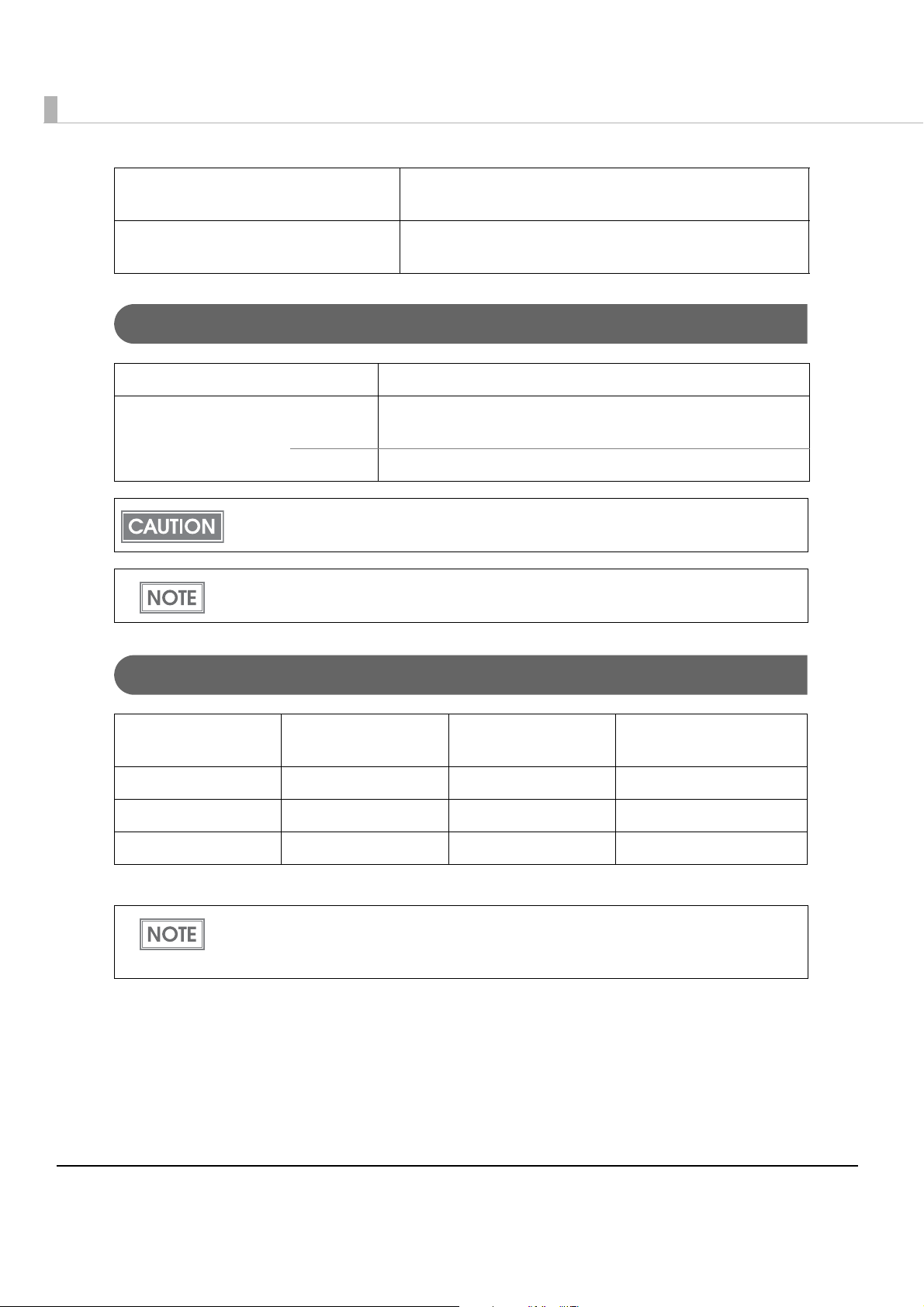

Reliability

Life Mechanism 4 million passes (Corresponds to 500,000 coupons issued*

Print head 6,000 million shots/nozzle (Corresponds to 10,760,000

coupons issued*

Autocutter 500,000 cuts

MTBF Approximately 180,000 hours

*1: When printing the coupon shown on page 27.

1

)

Environmental Specifications

1

1

)

Absolute maximum rated 70C {150F}*

Pressure (Operating/not operating) 700 to 1060 hPa (Corresponds to 0 to 2500 m {approximately

0 to 8202’} above sea level)

1

29

Page 30

Temperature/

10

20

55

80

27

35

Temperature (C)

Humidity ()

humidity

Printing 10 to 35C {50 to 95F}, 20 to 80% RH (no condensation)

Barcode printing 15 to 35C {59 to 95F}, 20 to 80% RH (no condensation)

Storage When packed: -20 to 60C {-4 to 140F}, 5 to 85% RH (no

condensation, ink not loaded) (At -20C or 60C {-4F or

140F}: up to 120 hours)

Ink loaded: -20 to 40C {-4 to 104F}

(At -20C {-4F}: up to 120 hours)

(At 0 to 30C {32 to 86F}: up to 6 months)

(At 40C {104F}: up to 1 month)

*1: This temperature must NOT be exceeded during operation or storage.

30

Page 31

External Dimensions

210

140

222

[Units: mm]

•Height: 222 mm {8.74"}

•Width: 140 mm {5.51“}

•Depth: 210 mm {8.27”}

Chapter 1 Product Overview

1

31

Page 32

Precautions

To Handle the Ink Cartridge

•Keep ink cartridges out of the reach of children.

•Do not disassemble or refill the ink cartridge. Spills can result, and tampering with the

cartridge may cause a malfunction of the printer.

•Ink can permanently stain clothing.

•Do not strike the ink supply opening. Doing so may cause ink to leak from the cartridge.

•Once you begin using an ink cartridge, there will be a residue of ink around the ink supply

opening. Avoid touching the ink supply opening, and be careful where you put the cartridge

to avoid g

•Do not touch the green circuit board at the upper side of the ink cartridge. Doing so may affect

the normal operation of the ink cartridge.

•Do not remove the ink cartridge from the printer, except when replacing it.

•Aft

er installing an ink cartridge, use it up within 6 months. Leaving the same ink cartridge in

the printer too long may affect the normal operation of that ink cartridge.

etting ink on yourself or something else.

•Use the ink cartridge by the expiration date, which is indi

cartridge and on the ink cartridge itself.

•The ink in the cartridge may freeze if stored at temperatures under -20C{-4F}, but once

thawed at temperatures over 10C{50F}, it can be used normally.

•Do not subject the ink cartridge to strong shocks or vibration.

•Ink life differs, depending on printer conditions, such as printing.

•Do not apply benzene, paint thinner, toluene, or ketone-based solvents to the ink cartridge.

These solvents may damage the plastic.

•Disposal of the ink car

and regulations.

•Do not transport a partially used ink cartridge. Doing so could result in leaking of ink.

tridge must comply with all relevant national or local laws, ordinances,

cated on the box containing the ink

To Prevent Ink Waste

Observe the following precautions to prevent ink waste.

•Do not plug in/pull out the power cable or push the Power button unnecessarily.

•Do not press the Cleaning button unless there is a problem with print quality.

32

Page 33

Chapter 1 Product Overview

Restrictions

Printer environment

•Drivers for TM printers (APD, OPS/JavaPOS) of Seiko Epson Corporation cannot be used for

this printer.

The TM-C710 printer driver can be installed and used on a computer with the APD and OPS/

JavaPOS installed.

Installation environment for the printer driver

•When the printer driver is installed using point and print, printing can be performed but the

printer status cannot be obtained.

•When setting the printer driver using point and print, setting may be made by accessing the

server via a network. Be sure to make the setting with the printer connected.

•Whe

•When using this printer in the same environment as a version of the APD earlier than APD

n using a shared printer and a local printer on one client computer, install the printer

driver for the local printer before installing the printer driver for the shared printer.

4.03, Install the APD first, a

nd then install the printer driver for this printer.

Install package of the printer driver

• The following settings are not reflected in the install package.

- [Select the folder] in [Driver Preferences] in the [Driver Utilities] tab.

- All information in [EPSON Log File Settings] in the [Driver Utilities]

- Whether or not [Always show current settings.] in the [Current settings] screen is checked

1

33

Page 34

Printing

•For the USB interface model, it takes time for the next printing if you turn the printer off and

on after printing.

•The ink cartridge contains 4 colors of ink. Even when one particular color is specified, all 4 col-

ors of ink are used for printing and for keeping the print head in good condition. When the in

level of even one color reaches the lowest limit, the printer stops printing.

•The colors of printouts may become abnormal if you tilt this printer or subject the printer to

any shocks. When you move this printer after ink charging, check the colors by performing a

test print.

If the colors of printouts are not normal, perform head cleaning. See "Head Cleaning" o

100 for how to perform head cleaning.

•When printing image data, white lines (lines shown in white) or black lines (overlapping of

image parts) may appear at about 1 inch intervals in the print result. By setting [Print Head

Alignment] - [Media Feed Adjustment] in [Maintenance And Utilities] tab, this can be

reduced but cannot be removed completely.

k

n page

•When printing image dat

result.

a, change of color tone may appear at 1 inch intervals in the print

34

Page 35

Setup

3. Connecting the AC Adapter (page 40)

4. Loading the Roll Paper (page 41)

5. Loading the Ink Cartridge (page 43)

2. Connecting the USB/Ethernet Cable (page 38)

1. Installing the Printer (page 36)

6. Setting the Lane ID (page 45)

7. Setting the Printer IP Address (page 46)

This step is not necessary for the USB interface model.

8. Adding a TCP/IP Port (page 47)

This step is not necessary for the USB interface model.

9. Installing the Printer Driver (page 50)

10. Installing Status API (page 52)

This step is not necessary if you do not use Status API.

11. Setting the DIP Switches (page 53)

This step is not necessary if you do not need to change the settings.

This chapter describes setup and installation of the product.

Flow of Setup

This chapter consists of the following sections along with the setup flow of the product.

Follow the flow of setup in order to prevent ink leakage.

Chapter 2 Setup

2

35

Page 36

Installing the Printer

Install the printer in an appropriate location with sufficient space around it.

Important Notes on Installation

Do not place the printer in a dusty place.

Make sure no cables or other objects are caught under the printer.

Do not put objects heavier than 700 g {1.5 lb} (two paper rolls) on the printer.

Do not put beverages or vases on the printer.

Do not tilt the printer during initial ink filling, printing, or head cleaning. Otherwise, ink

may leak out of the printer.

•You must place the printer horizontally (back to front: ±10, right to left: ±10).

•Place the printer where the roll paper cover can open fully and the ink cartridge can be ejected,

and be careful not to place an obstacle in front of the printer, especially when you install the

printer on a mounting

table.

•Be sure to avoid bumping the printer so that it is not exposed to strong impact during

operation.

36

Page 37

Chapter 2 Setup

Bracket

Screw M4

Rubber foot

15 to 20 mm

Bracket

1 mm or more

To pre vent the printer from falling, use a bracket as shown below to secure the printer.

2

37

Page 38

Connecting the USB/Ethernet Cable

USB interface model

Ethernet interface model

Ethernet interface model

USB interface model

For the USB interface model, connect the USB cable, for the Ethernet interface model, connect the

Ethernet cable to the printer.

Direct connection to an aerial LAN cable located outside may cause induced lightning to

damage devices. When you use such cables, connect via devices that protect against

surges.

Do not plug an ordinary telephone line into the Ethernet connector.

Make sure the power is turned off for both the printer and the host

1

computer.

For the USB interface model, connect the USB cable to the connector.

2

For the Ethernet interface model, connect the Ethernet cable to the

connector until it clicks.

Secure the cable with the hook.

3

38

Page 39

Chapter 2 Setup

For the USB interface model, connect the other side of the USB cable to

4

a host computer. For the Ethernet interface model, connect the other

side of the Ethernet cable to a network hub.

2

39

Page 40

Connecting the AC Adapter

Always use the included AC adapter.

Using a nonstandard power supply can result in electric shock or fire.

WARNING

Follow the steps below to connect the AC adapter.

Plug the accessory AC cable into the accessory AC adapter.

1

Should a fault ever occur in the AC adapter, immediately turn off the power to the

printer and remove the AC cable from the outlet.

Unplug the power cable of the AC adapter from the outlet before you plug/unplug

the AC adapter into the printer.

Make sure the wall socket power supply satisfies the rated voltage requirements

of the AC adapter. Never insert the AC cable into a socket that does not meet the

rated voltage requirements of the AC adapter.

Doing so may result in damage to both the AC adapter and the printer.

40

Plug the DC cable of the AC adapter into the printer’s power connector

2

(stamped “42V”).

Plug the AC cable into the outlet.

3

Page 41

Loading the Roll Paper

Follow the steps below to load the roll paper.

Do not touch the autocutter blade when you open the roll paper cover.

Otherwise, you may be injured.

Turn the power on.

1

Make sure the Power LED is on.

Pull the release lever to the front to open the roll paper cover.

2

Do not touch the release lever during printing, paper feeding, or cleaning.

Do not touch the gears on the roll paper cover when you open it.

Chapter 2 Setup

Load the roll paper in the orientation shown below.

3

2

41

Page 42

Pull out the paper end to the paper exit, and then close the roll paper

4

cover.

When the roll paper cover is closed, roll paper is automatically fed about

5

10 cm {3.9"}, and then autocutting is performed.

42

After loading the roll paper, head cleaning may start automatically. Wait for cleaning to be

completed.

Page 43

Loading the Ink Cartridge

Green circuit board

Follow the steps below to load the ink cartridge.

When you start to use the printer, it takes about 4 minutes for initial ink filling. Never

open the covers, press the Power button, or turn the printer off during initial ink filling

(while the Power LED is flashing). Otherwise, initial ink filling will be performed again

from the beginning. This wastes ink.

Do not tilt the printer during initial ink filling. Otherwise, ink may leak out of the printer.

Do not touch the inside of the ink cartridge slot. Doing so may cause ink adhesion or

printer malfunction.

Use only the ink cartridge specified by Seiko Epson, SJIC25P. Operation with another

ink cartridge is not guaranteed.

Do not touch the green circuit board at the side of the ink cartridge. Doing so may affect

the normal operation of the ink cartridge.

Chapter 2 Setup

When install the ink cartridge for the first time, use the STARTER CARTRIDGE included

with the printer.

When using the product for the first time, ink filling also uses up some ink to make the

product ready for printing.

An ink cartridge has 4 different colors. Even when one specific color is specified for

printing, ink of all colors is spent in printing and operations to maintain the print head in a

good condition. If remaining ink of any of the ink cartridge reaches its lower limit amount,

the printer stops printing.

Since ink cartridges are designed to stop the operation before ink runs out completely to

maintain the quality of the print head, some ink remains in the used ink cartridge.

The used cartridge has a red line drawn through its label on the top.

2

43

Page 44

Turn the power on.

1

Make sure that the Power LED is on.

Insert the ink cartridge arrow-side-up into the ink cartridge slot until it

2

stops.

When the ink cartridge is installed for the first time, the (Power) LED starts flashing,

and ink charging starts. When ink charging finishes, the (Power) LED stays on (not

flashing).

44

Page 45

Chapter 2 Setup

500 ms 1.5 s

Repeats flashing as many times as the set value

Setting the Lane ID

Yo u can set the printer lane ID manually or through the printer driver.

Follow the steps below to set the lane ID manually. When the lane ID is set manually, the value of

the bottom byte in the IP address is automatically set to the same as the value of the set lane ID.

Push the Lane setting button for at least 5 seconds when the printer is in

1

the idle mode.

The printer prints the following message and enters the lane ID setting mode.

Lane ID Mode Started

Current ID: xxx

Set the third digit of the lane ID assuming decimal expression by pushing

2

the Self-test button.

Assuming the in itial setting value to be 0, the value increases by 1 in the following

progression each time the Self-test button is pushed.

0 1 2 3 4 5 6 7 8 9 0

The following Paper Jam LED pattern enables you to confirm the selected value.

2

Push the Lane setting button to fix the setting.

3

The printer moves on to the setting mode for the next digit.

Repeat steps 2 and 3 for the second and then the first digit.

4

After the first digit is set, the printer prints the following message.

Lane ID is xxx

Press the Lane button to confirm

Press the SelfTest button to cancel

If the set lane ID is out of the range of 1-254, the following message is printed. The printer

discards the set value and ends the lane ID setting mode.

Lane ID Mode Cancel

ID Range error

ID xxx

45

Page 46

If the printed lane ID is correct, push the Lane setting button.

5

The printer stores the set lane ID and the IP address and ends the lane ID setting mode.

Push the Self-test button to cancel the set lane ID. Then the printer ends the lane ID

mode.

If 30 seconds or more elapses without any operations while the printer waits for user

operation in the lane ID setting mode, the printer discards the set value and ends the

lane ID setting mode.

Setting the Printer IP Address

This setting is necessary only for the Ethernet interface model.

Connect the printer to the network via a hub using the Ethernet cable.

Set an IP address to the printer with EpsonNet Config.

Yo u can download EpsonNet Config from the following URL.

CAUTION

http://download.epson-b

When Ethernet cables are installed outdoors, make sure devices without proper

surge protection are cushioned by being connected through devices that do have

surge protection. Otherwise, the devices can be damaged by lightning.

Do not plug an ordinary telephone line into the Ethernet connector.

Make sure the Ethernet cable is connected to the printer, and the printer is turned on.

iz.com/?service=pos

46

Page 47

Adding a TCP/IP Port

This procedure is necessary only for Ethernet model, and unnecessary for the USB interface

model.

Follow the steps below to add a TCP/IP Port.

Make sure the Ethernet cable is connected to the printer, and the printer is turned on.

Select [Start] - [Control Panel] - [Printer] on the computer.

1

Menus to select are different for each OS.

Select [File] - [Add Printer] from the menu.

2

Select [Add a local printer].

3

Chapter 2 Setup

2

47

Page 48

Select [Create a new port:], select [Standard TCP/IP Port] in “Type of

4

port,” and click [Next].

Set the items by referring to the table below, and click [Next].

5

48

Item Setting value

Device type TCP/IP Device

Hostname or IP address

Por t nam e

Query the printer and automatically

select the driver to use

IP address set for the printer

Setting values in “Hostname or IP address” are

automatically input.

Uncheck the checkbox.

Page 49

Chapter 2 Setup

Select [Standard], and [Generic Network Card] in “Device Type.” Then

6

click [Next].

Click [Cancel].

7

Do not install the printer driver in this step.

The addition of the TCP/IP port is completed.

2

49

Page 50

Installing the Printer Driver

Yo u can download Printer Driver for TM-C710 from the following URL.

http://download.epson-biz.com/?service=pos

The installation procedure is different between the USB interface model and the Ethernet

interface model.

Make sure to log on as an administrator to install the printer driver.

Before installing, check the hardware requirements. (See "Operating Environment" on

page 22.)

For USB Interface Model

Follow the steps below to install the printer driver.

Connect the printer to the computer.

1

Turn off the printer before installing. You need to turn it on during installation by following

the instructions.

For a 32bit OS, double-click the icon “c71d32_xxxx.exe.”

2

For a 64bit OS, double-click the icon “c71d64_xxxx.exe.”

If the “User Account Control” screen is displayed, click [OK].

3

Select [EPSON TM-C710], and click [OK].

4

Complete the installation by following the instructions displayed.

5

To display the printer driver, follow the steps below.

1. Click [Start] - [Control Panel] - [Printer] (or [Printers or Faxes]).

2. Right-click on [EPSON TM-C710] and click [Printing Preferences].

For details on how to use the printer driver, see the printer driver help or "How to Use the

Printer Driver" on page 65.

50

Page 51

Chapter 2 Setup

For Ethernet Interface Model

Before installing the printer driver, set an IP address to the printer, and add a TCP/IP port.

(See "Setting the Printer IP Address" on page 46 and "Adding a TCP/IP Port" on page 47.)

The printer driver for the Ethernet interface model cannot be installed with a USB inter-

face model printer connected. In this case, turn off the USB interface model printer

before installing the printer driver for the Ethernet interface model.

Make sure the Ethernet cable is connected to the printer, and the printer is turned on.

Follow the steps below to install the printer driver.

For a 32bit OS, double-click the icon “c71d32_xxxx.exe.”

1

For a 64bit OS, double-click the icon “c71d64_xxxx.exe.”

If the “User Account Control” screen is displayed, click [OK].

2

Select [EPSON TM-C710], and click [OK].

3

2

Complete the installation by following the instructions displayed.

4

To display the printer driver, follow the steps below.

1. Click [Start] - [Control Panel] - [Printer] (or [Printers or Faxes]).

2. Right-click on [EPSON TM-C710] and click [Printing Preferences].

For details on how to use the printer driver, see the printer driver help or "How to Use the

Printer Driver" on page 65.

51

Page 52

Installing Status API

If you want to use Status API, install Status API after installing the printer driver.

Programming Status API enables you to acquire the printer status with your application.

The Status API and the sample programs are provided as the Epson TM-C710 SDK.

Yo u can download it from the following URL.

ttp://download.epson-biz.com/?service=pos

h

Install the printer driver before installing Status API. ("Installing the Printer Driver" on page

50.)

To install it without displaying the window, add the command (/s /v"/qn") to the install file

name for Status API.

e.g: c71sapi_xx.exe /s /v"/qn"

Follow the steps below to install Status API.

Double-click the icon “c71sapi_xx.exe.”

1

The "EPSON TM-C710 StatusAPI - InstallShield Wizard“ screen is displayed.

2

Click [Next].

Complete the installation by following the instructions displayed.

3

52

Page 53

Setting the DIP Switches

Screw

Screw

Rear cover

Follow the steps below to change the DIP switch settings.

Turn the power off before removing the cover.

Otherwise, a short-circuit may cause the printer to malfunction.

CAUTION

DIP switch setting becomes enabled after turning the power on or completing reset by the

interface.

Make sure that the printer is turned off.

1

Unscrew the screws to remove the rear cover.

2

The DIP switches are on the right side of the printer.

Chapter 2 Setup

Set the DIP switches, using the tip of a tool, such as a small screwdriver.

3

Attach the rear cover.

4

For the DIP switch settings, see "DIP Switches" on page 20.

2

53

Page 54

54

Page 55

Chapter 3 Application Development Information

Application Development Information

This chapter describes how to control the printer and gives information useful for printer

application development.

Overview

The following is provided for use of this printer.

❏ A dedicated printer driver for Windows is available. For details on how to use the printer

driver, see the printer driver help or "How to Use the Printer Driver" on page 65.

❏ A Status API that can be used with your applications is available.

❏ Va ri

❏ Dedicated sample programs for the TM-C710 are available.

ous utilities and user’s manuals are available.

Use them as a reference for developing applications.

This printer cannot use the APD or OPOS/JavaPOS provided by Epson.

Printer Driver

The printer driver has the following functions, so it is not necessary to implement them in

applications.

❏ Barcode and 2D symbol fonts are implemented. The barcode and 2D symbol fonts can be

printed using the font replacement function for .NET environment.

The barcode and 2D symbol font must be set in advance

tion. (See "Barcode Printing" on page 73 and "2D Symbol Printing" on page 82 for details of

how to make the setting.)

In the .NET environment, a TrueType font is specified to be replaced by barcode and 2D sym-

bol fonts. The barcodes and 2D symbols can be printed by specifying a replaced TrueType font

from the applica

page 87 for details about the font replacement function.)

tion. (See "Barcode and 2D Symbol Font Printing on .NET Environment" on

in the printer driver to use this func-

3

55

Page 56

Status API

With Status API, you can transmit the printer status (such as printer and ink cartridge status and

print job information) to your applications, and can set the buzzer to beep when an error such as

a cover open occurs.

(Header files and assembly files for .Net are included

in the sample programs.)

Sample Program

Refer to the TM-C710 sample programs to develop the application using this printer.

❏ Features of TM-C710 sample programs

•Programs are provided in the step-up method from the basic ones to the advanced ones.

This helps you to learn how to control the printer.

•Program files are provided in the exe format and the source format.

•Header files and assembly files for .Net are provided.

(The assembly files for .Net are necessary to build a Status API-based application in the .Net

environment.)

• Development environment: Visual Studio 2005/Visual Studio 6.0

• Development language: C++, VB.NET, C# (C# is not provided for some programs.)

❏ Structure of TM-C710 sample programs

The following is the structure and language used for TM-C710 sample program.

Language

Level Program name Specification

C++

Step 1.

Printing characters

Step 2.

Printing barcodes

Basic

Step 3.

Printing graphics

Step 4. Confirming the

printer status

Basic print program

Sets barcode font in advance to use

for print program.

The program to print graphics

Checks the printer condition before

printing and executes error handling.

C#

VB.NET

—

—

—

56

Page 57

Chapter 3 Application Development Information

Level Program name Specification

Language

C++

C#

VB.NET

Basic

Advanced

Step 5.

Call-back process

Complete basic

features

Monitoring the printer

status and controlling

print jobs

DEVMODE Executes a 90-degree rotation or

Obtaining the print completion

When the condition of the printer

changes, the printer can cause

actions to occur in the application,

and executes error handling.

The program from Step 1 to 5

Cancels a print job when a paper

end is detected.

changes the number of copies in the

application.

Changes the number of copies in

the application.

Acquires the print completion.

—

—

—

—

3

57

Page 58

Software

Var ious utilities are provided to system administrators and application developers.

Printer Driver

Software Package Explanation

Printer driver for

Windows

Printer Driver for TMC710

32 bit version and 64 bit version are available.

Administering network printers

Software Package Explanation

The user can set/check the network printer.

Settings can be applied simultaneously to

multiple printers.

The user can set/check the network information

of the printer by entering IP address of the printer

to the address bar of the Web browser.

One printer can be set/checked.

This cannot be used for a printer in the default

condition since the IP address is not available.

EpsonNet Config

EpsonNet Config

(Web version)

EpsonNet Config

(for Windows OS)

N/A (included in the

printer firmware)

58

Page 59

Chapter 3 Application Development Information

Developing applications

Software Package Explanation

Transmits the printer information (such as status

of the printer and the ink cartridge, and print job

Status API

information), and sets the buzzer to beep when

an error occurs.

Status API Reference Guide is included in the

package.

Epson TM-C710 SDK

Sample Program

Yo u can download the above software from the following URL.

http://download.epson-biz.com/?service=pos

Sample programs for using the TM-C710.

(VB.NET and C++ for all programs. C# for some

programs.)

Header files and assembly files for .Net are

included in the sample programs. (The assembly

files for .Net are necessary to build a Status API

based application in the .Net environment.)

3

59

Page 60

60

Page 61

Chapter 4 Handling

Green circuit board

Handling

This chapter describes basic handling of the printer.

Replacing the Ink Cartridge

Printing is not possible if any of the four color inks needs replacement.

When the Replace Ink LED lights, the ink cartridge needs to be replaced. Follow the steps below

to replace the ink cartridge.

Do not touch the inside of the ink cartridge slot. Doing so may cause ink adhesion or

printer malfunction.

Use only the ink cartridge specified by Seiko Epson, SJIC25P. Operation with another

ink cartridge is not guaranteed.

Do not touch the green circuit board at the side of the ink cartridge. Doing so may affect

the normal operation of the ink cartridge.

When the time to replace the ink cartridge has come, the ink cartridge is automatically

ejected.

An ink cartridge has 4 different colors. Even when one specific color is specified for

printing, ink of all colors is spent in printing and operations to maintain the print head in a

good condition. If remaining ink of any of the ink cartridge reaches its lower limit amount,

the printer stops printing.

Since ink cartridges are designed to stop the operation before ink runs out completely to

maintain the quality of the print head, some ink remains in the used ink cartridge.

The used cartridge has a red line drawn through its label on the top.

61

4

Page 62

Turn the power on.

1

Make sure the Power LED is on.

Pull out the used ink cartridge to remove it.

2

Insert the new ink cartridge arrow-side-up into the ink cartridge slot until

3

it stops.

When the ink replacement is finished, the Replace Ink LED goes out and the printer is

ready for normal printing.

Replacing the Roll Paper

When the roll paper is out, the Check Paper LED and the Error LED light.

Follow the steps below to replace the roll paper.

Do not touch the autocutter blade when you open the roll paper cover.

Otherwise, you may be injured.

Turn the power on.

1

Make sure the Power LED is on.

Pull the release lever to the front to open the roll paper cover.

2

Do not touch the release lever during printing, paper feeding, or cleaning.

Do not touch the gears on the roll paper cover when you open it.

62

Page 63

Remove the used roll paper core, if any.

3

Load the roll paper in the orientation shown below.

4

Chapter 4 Handling

Pull out the paper end to the paper exit, and then close the roll paper

5

cover.

4

63

Page 64

When the roll paper cover is closed, roll paper is automatically fed about

6

10 cm {3.9"}, and then autocutting is performed.

After loading the roll paper, head cleaning may start automatically. Wait for cleaning to be

completed.

Removing Jammed Paper

When a roll paper jam occurs, the printer automatically goes offline, and the Paper Jam LED

lights. Open the roll paper cover, and remove the jammed paper. When you remove the jammed

paper, never pull out the paper forcibly.

When roll paper is reloaded and roll paper cover is closed, the printer returns to online and the

printable state. For loading the roll paper, see "Loading the Roll Paper" on page 41.

64

Page 65

Chapter 4 Handling

How to Use the Printer Driver

The printer driver allows you to change the print settings and also provides some utilities such

as checking the printer status and cleaning the print head.

How to Display the Printer Driver

Select [Start] - [Control Panel] - [Printer] on the computer.

1

Menus to select are different in each OS.

Right-click [EPSON TM-C710], and click [Printing References].

2

The printer driver screen is displayed.

The above icon name is displayed when the printer’s name registered as [EPSON

TM-C710].

65

4

Page 66

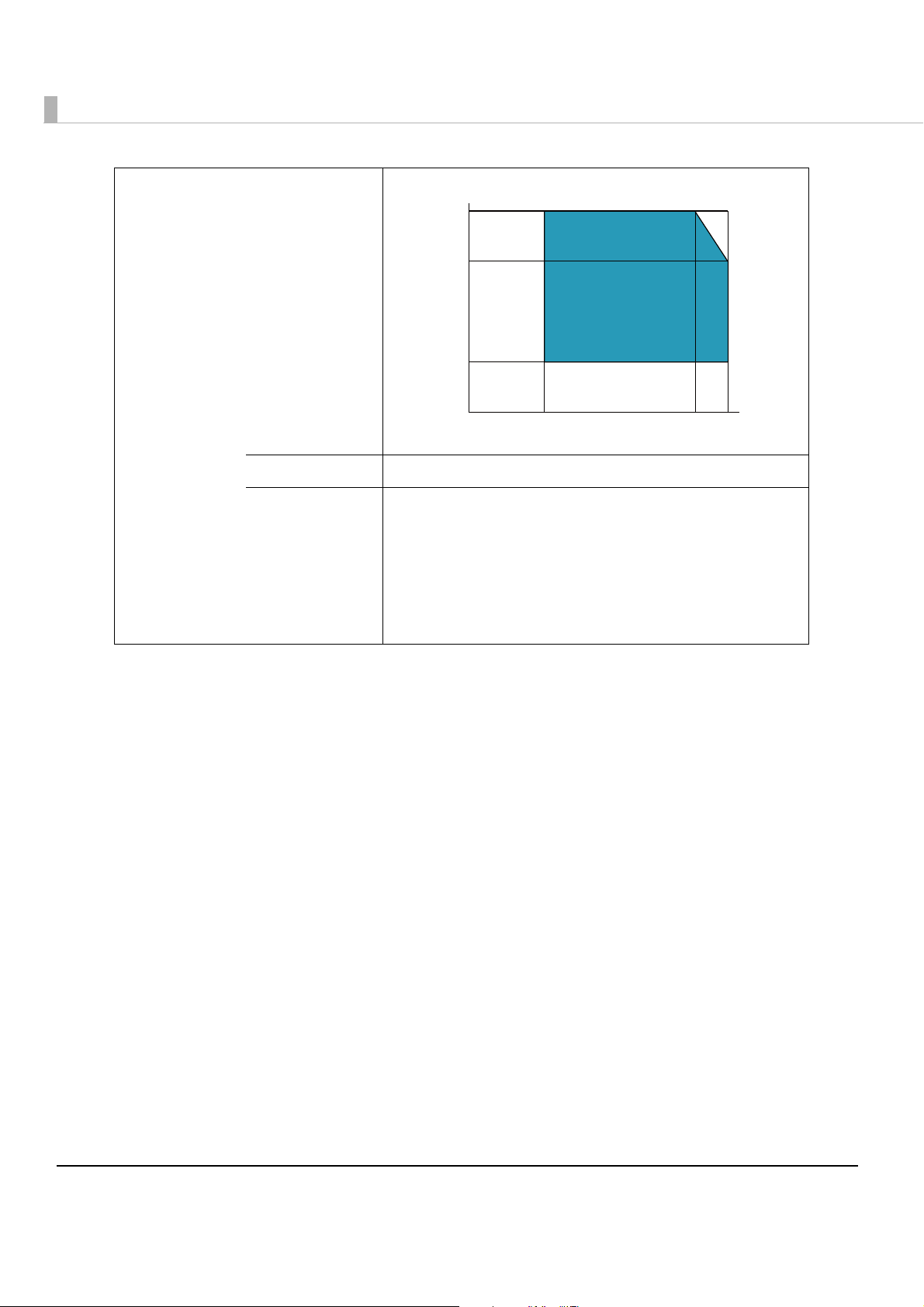

Registering User Defined Media

Registered

paper

➁

➂

➃

If the paper size to use is not in [Media Layout], register user defined media.

The registered layout will be stored in [Favorite Setting] to use from user applications.

Registering User Defined Media

Click [Add/Del] of [Media Size] on the [General] tab.

1

Enter [Media Size Name] on the displayed [User Defined Media Size]

2

screen.

This is registered as a user defined media name.

Enter the size of the paper.

3

Click [Add]. The user defined media will be registered and displayed in

4

the list of [Media Size].

66

Page 67

Chapter 4 Handling

[General] tab Favorite setting

[Page Layout] tab

Favorite Setting

[Favorite Setting] is the function to administer several printer driver settings into one.

The settings from the [General] and [Page Layout] tabs such as Media Type, Media Layout

(including User Defined Media) are included.

4

67

Page 68