Developer’s Guide

Series

Before use

Functions and Operating

Procedures of the Printer

How to Use the Printer Driver

Application Development

Information

Media Design

Printer Management

Appendix

M00107502

Rev.C

Before use

This chapter describes information you should know before using the product.

Manuals for This Product

Paper manual

Manual viewable

with PC

Manual viewable

with PC

Start Here

Describes precautions on handling the product. Be sure to read the

precautions before use in order to ensure safe and proper use, and to prevent

personal injury to you and other persons and damage to property. This also

gives instructions for unpacking and installing the product.

User's Guide

Describes details about the functions and operating procedures of the

product and software, maintenance information, and troubleshooting.

Developer's Guide (This Manual)

Provides information necessary for developing a system using the product.

It can be viewed from the supplied CD.

Downloading the Latest Version

The latest versions of the printer driver, utilities, and manuals can be downloaded from the

following URLs.

For customers in North America, go to the following web site:

<www.epson.com/support/>

For customers in other countries, go to the following web site:

<www.epson-biz.com/>

2

Symbols Used in This Guide

The following symbols are used in this guide to indicate important information.

Handling the product improperly by ignoring this symbol can lead to

CAUTION

c IMPORTANT

injury and property damage.

Indicates information with which you must comply when using the

product. Mishandling due to ignoring this information may cause the

product to fail or malfunction.

Q NOTE

U Indicates a reference page containing related information.

Indicates supplementary explanations and information you should know.

3

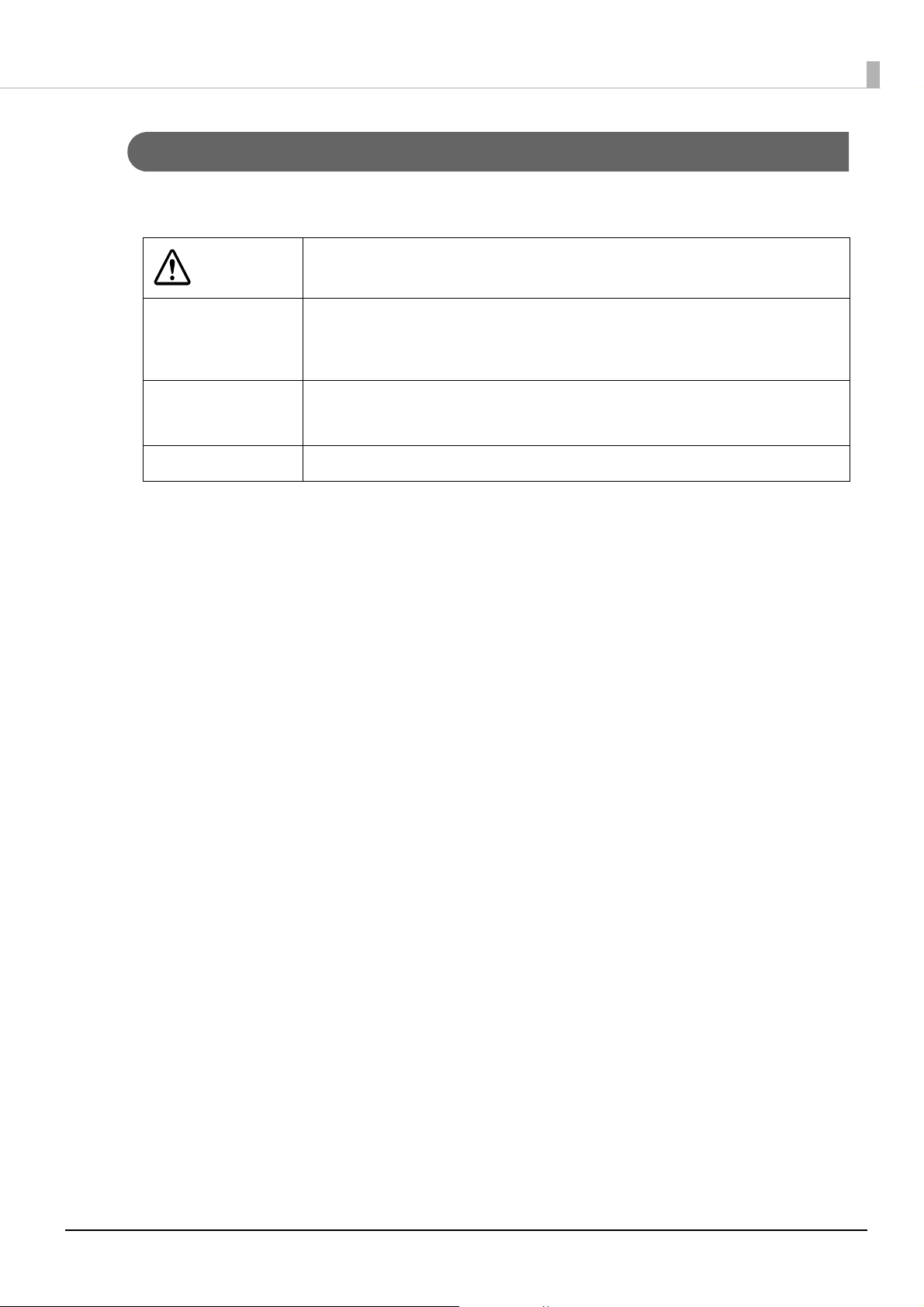

Product and Driver Versions

Firmware version

Printer driver version

Unless otherwise specified, the explanations in this manual are for the following versions.

Product firmware: WAM31000

Printer driver: Ver.2.0.0.0

How to Check the Product Version

You can check the version of the product firmware being used by performing self test printing.

Check the first line of the self test print results. For the procedure for the self-test printing, see

the User’s Guide.

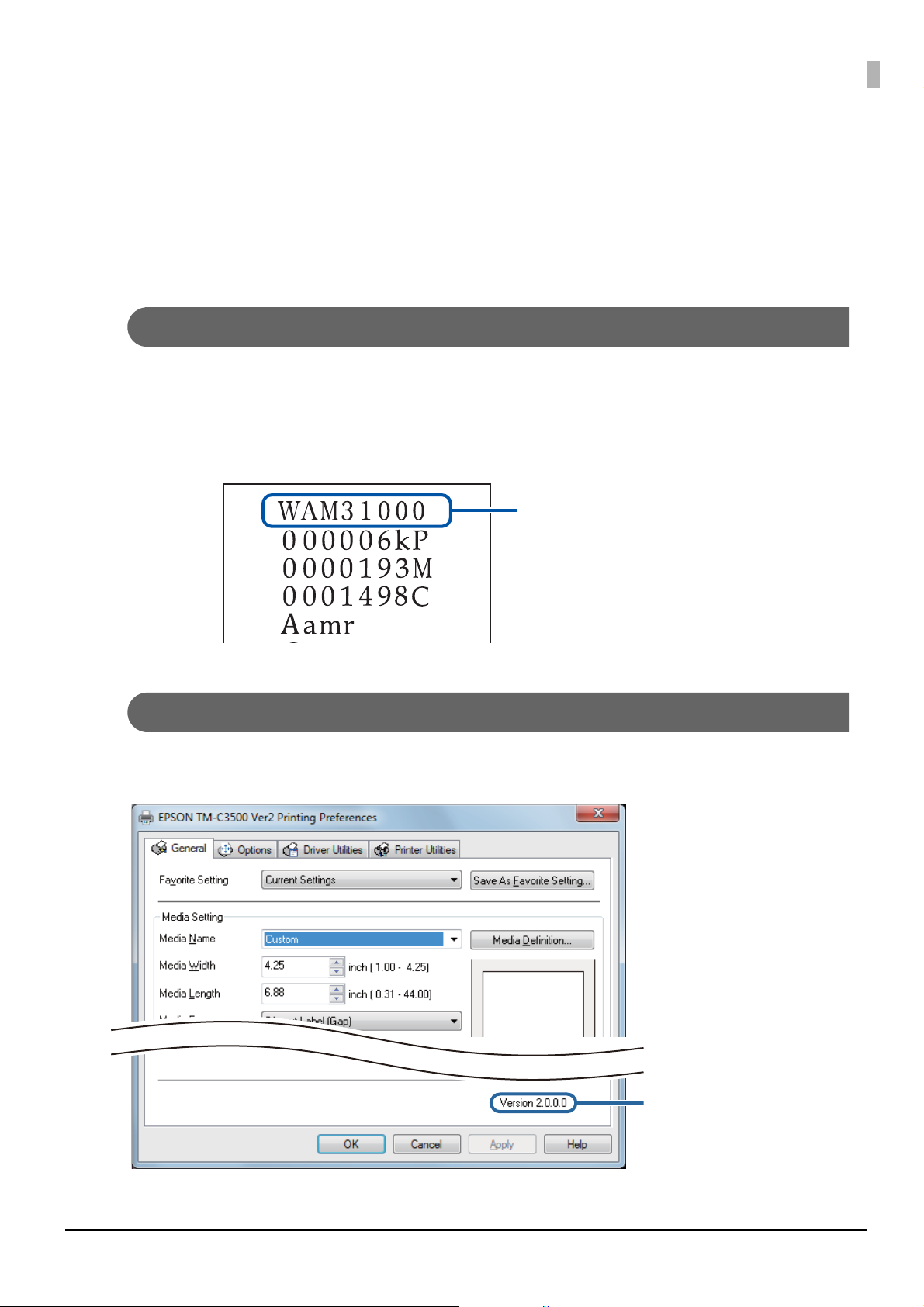

How to Check the Printer Driver Version

You can check the version in the printer driver screen.

4

Screens in This Manual

The screens in this manual and the screens actually displayed in Windows may differ depending on the

product used and operating system. Unless otherwise specified, the screens in this manual are those

when using TM-C3500 in Windows 7.

5

Contents

Before use ..................................... 2

■ Manuals for This Product ................................2

Downloading the Latest Version.........................................2

Symbols Used in This Guide .................................................3

■ Product and Driver Versions...........................4

How to Check the Product Version....................................4

How to Check the Printer Driver Version .........................4

■ Screens in This Manual ....................................5

■ Contents ...........................................................6

Functions and Operating

Procedures of the Printer............. 8

■ Preventing Mistaken Operation of the Power

Button ...............................................................8

■ Disabling the Power Button............................9

■ Saving and Restoring PrinterSetting

Settings.......................................................... 11

Saving Settings....................................................................... 12

Restoring Settings................................................................. 13

How to Use the Printer Driver....14

■ Printing Barcodes/2-Dimensional Symbols 14

Barcodes/2-Dimensional Symbol Settings................... 15

Font Replacement................................................................. 23

Printing from an Application............................................. 25

Checking the Feeding Position......................................... 35

■ Favorites........................................................ 36

Favorites Screen Configuration ........................................ 36

Registering Favorites............................................................ 37

■ Importing/Exporting Settings Files ............ 39

Settings that can be Exported to a BSF File ................. 39

Settings that cannot be Exported to a BSF File .......... 39

Exported Settings.................................................................. 40

Importing Settings................................................................ 41

Application Development

Information.................................42

■ Epson Inkjet Label Printer SDK.....................42

Media Design.............................. 43

■ Types of Media that can be Used..................43

Paper that cannot be Used................................................. 44

■ Paper Loading Detection ..............................45

Detection Methods ...............................................................45

Paper Limitations...................................................................46

■ Paper Specifications......................................48

Continuous Paper..................................................................48

Continuous Paper (Black Marks)....................................... 49

Full-page Label .......................................................................51

Die-cut label (Gap)................................................................. 52

Die-cut label (black marks).................................................54

Wristband .................................................................................58

■ Print Position and Cut Position.....................60

Continuous Paper and Roll Paper ....................................60

Continuous Paper (Black Marks) and Roll Paper......... 62

Continuous Paper (Black Marks) and Fanfold Paper..64

Full-page Label and Roll Paper..........................................66

Die-cut Label (Gaps) and Roll Paper................................ 68

Die-cut Labels (Black Marks) and Roll Paper ................70

Die-cut Labels (Black Marks) and Fanfold Paper......... 72

Wristband and Roll Paper (WB-S Series)........................74

Wristband and Roll Paper (WB-M Series) ...................... 76

Wristband and Roll Paper (WB-L Series) ........................ 79

■ Paper Handling to Prevent Unprinted

Labels .............................................................83

Printing from the First Label at Paper Loading ........... 83

Printing the Final Label........................................................ 86

6

Printer Management.................. 89

■ Software ........................................................ 89

■ Efficiently Setting Up a Printer .................... 90

Specify Printer Settings Before Ink Charging............... 90

Efficiently Setting up Multiple Printers.......................... 91

■ Efficiently Setting up the Printer Driver ..... 92

Creating an Installation Package ..................................... 92

Client Computer Procedures............................................. 92

■ Efficient System Management..................... 93

Printer Monitoring................................................................. 93

Changing Printer Settings.................................................. 95

Changing Printer Driver Settings..................................... 96

Automatically Changing a Printer Driver USB Port.... 97

Appendix ..................................101

■ Notes............................................................ 101

■ Trademarks.................................................. 101

7

Functions and Operating Procedures of the Printer

This chapter describes the functions of and how to use the printer.

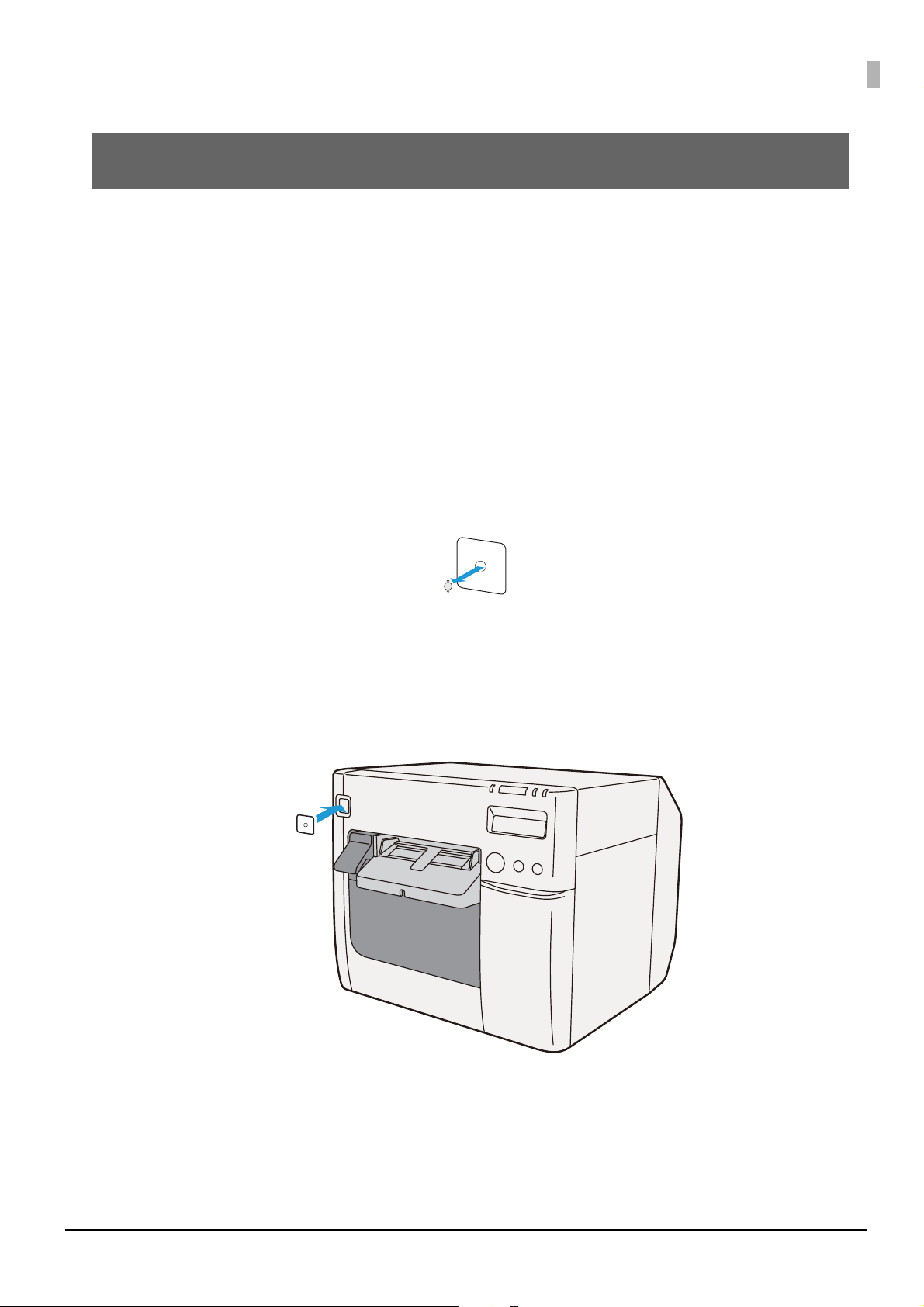

Preventing Mistaken Operation of the Power Button

Attach the supplied power switch cover to prevent users from mistakenly pressing the power button.

You can turn the printer power on and off by inserting a ballpoint pen or similar item with a thin tip

into the hole of the power switch cover.

Attach the power switch cover by following the procedures below.

Pierce the middle of the power switch cover with a thin-tipped hard object

1

to open the hole.

Peel off the backing of the double-sided tape of the power switch cover.

2

Affix the power switch cover over the printer power button.

3

8

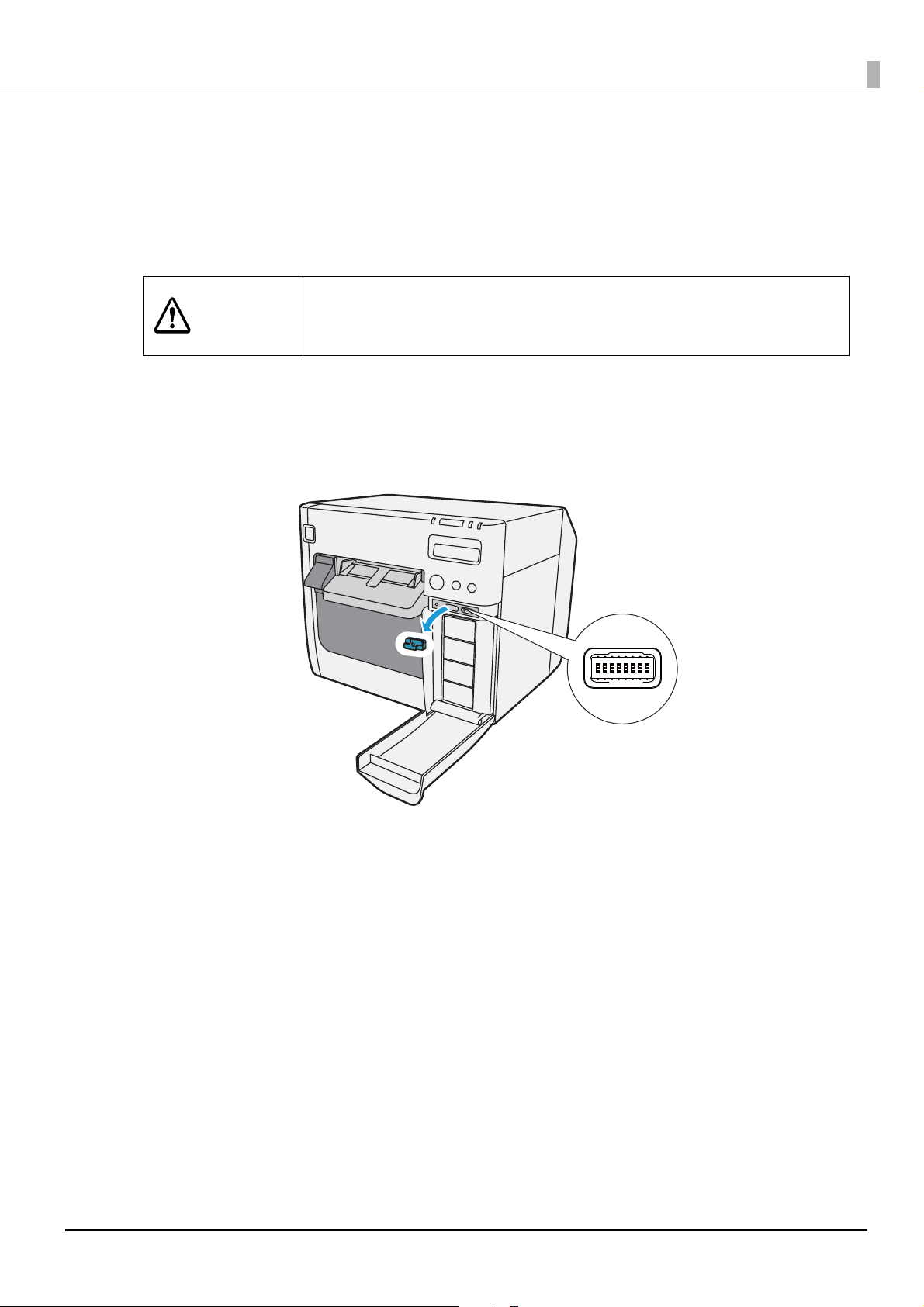

Disabling the Power Button

You can disable power button operation so that the power remains constantly on. Pressing the power

button with the power disabled does not turn the power off but rather resets the printer.

Disable the power button by following the procedures below.

Turn the printer off before removing the dip switch cover.

CAUTION

Check that the printer is powered off.

1

Open the ink cartridge cover and remove the dip switch cover.

2

Removing the cover while the power is on may cause the printer to fail

due to a short circuit.

9

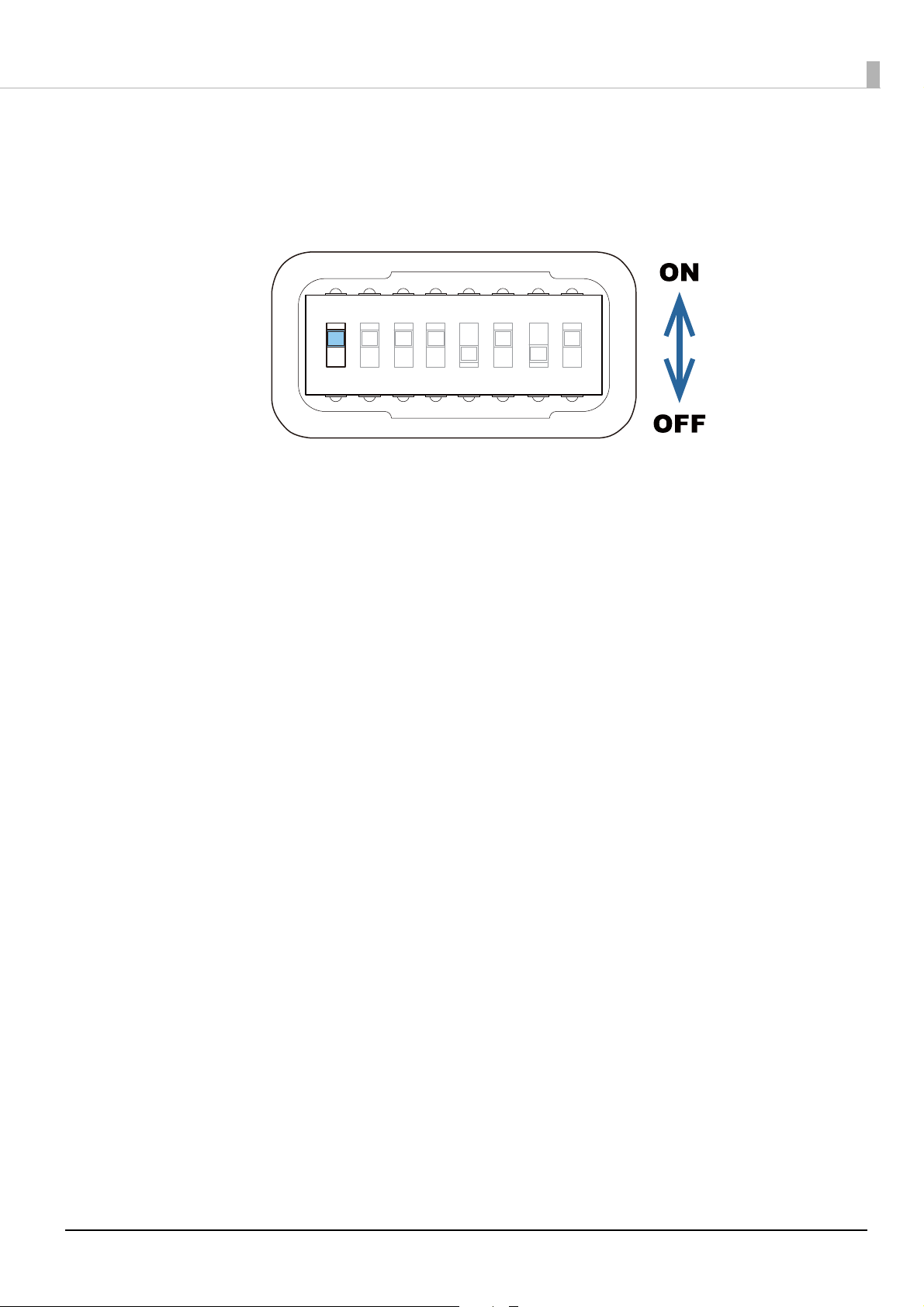

Use an object with a sharp tip to operate the dip switches.

1 23456

7

8

3

The dip switches are numbered in order from the left. Up is the ON state

and down is the OFF state. Turn on dip switch 1.

Attach the dip switch cover and close the ink cartridge cover.

4

10

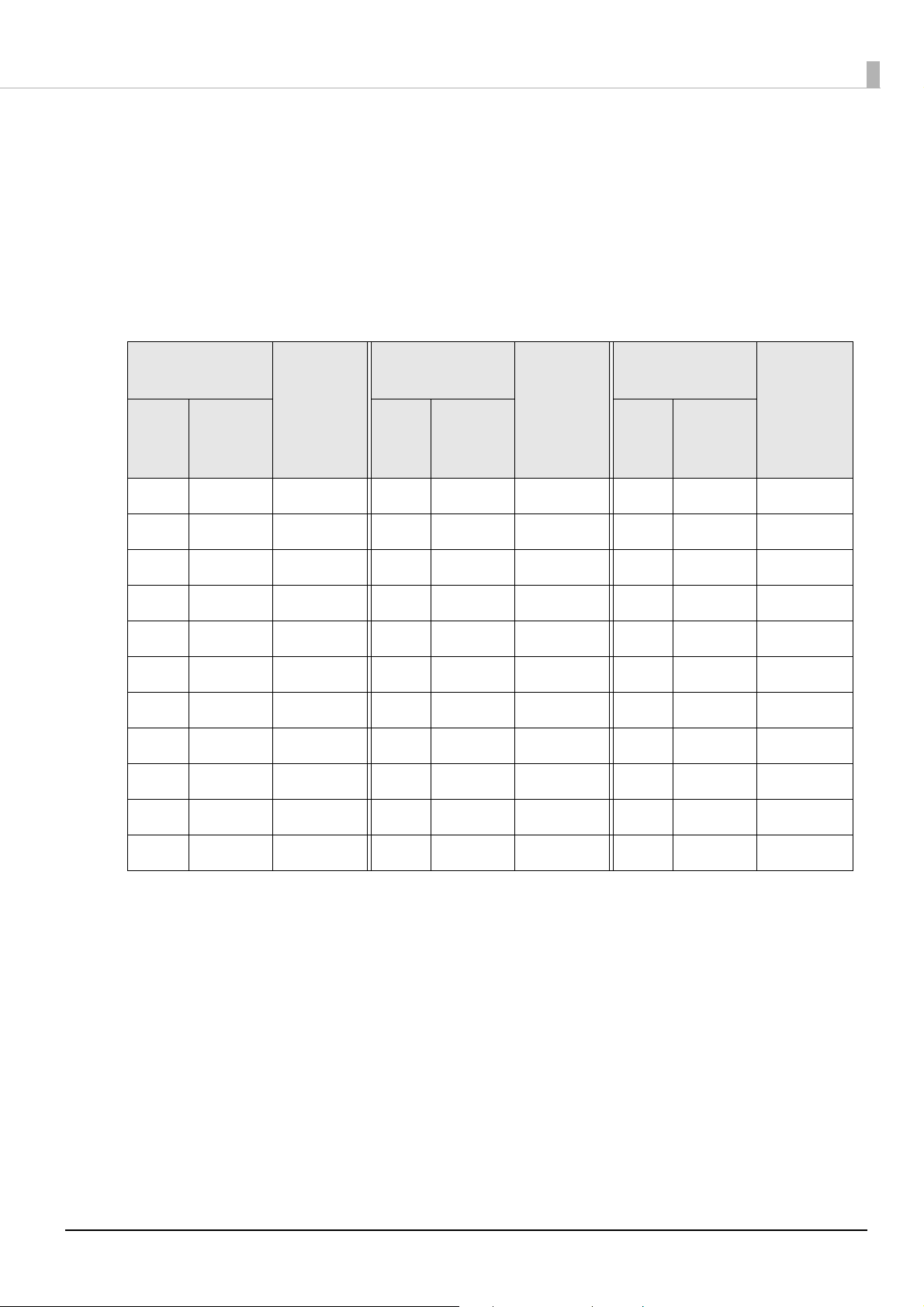

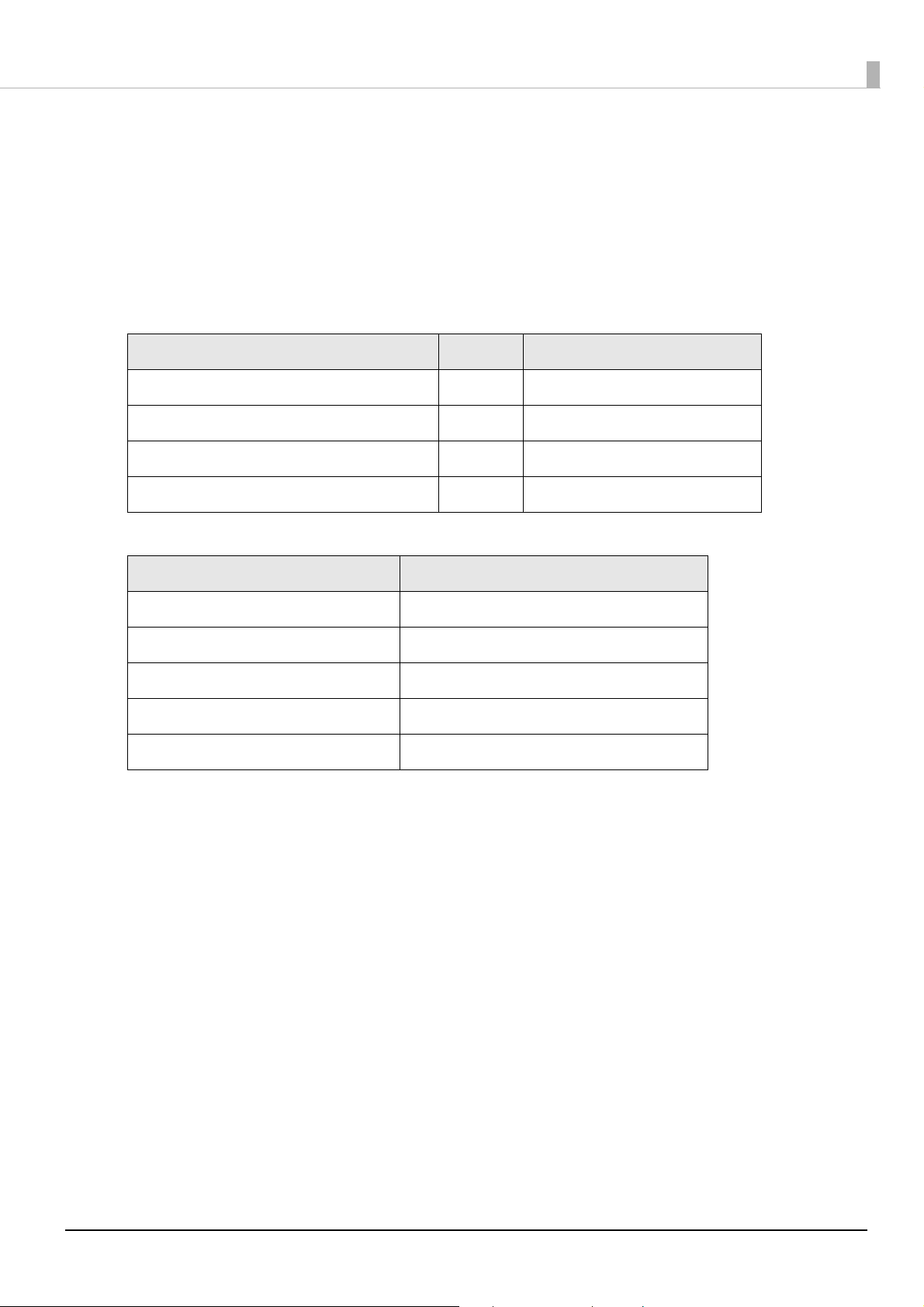

Saving and Restoring PrinterSetting Settings

PrinterSetting is a utility to set the printer from a Windows computer. You can save settings made

using PrinterSetting in a settings file. A settings file can be used as a backup file or master file when

operating multiple printers.

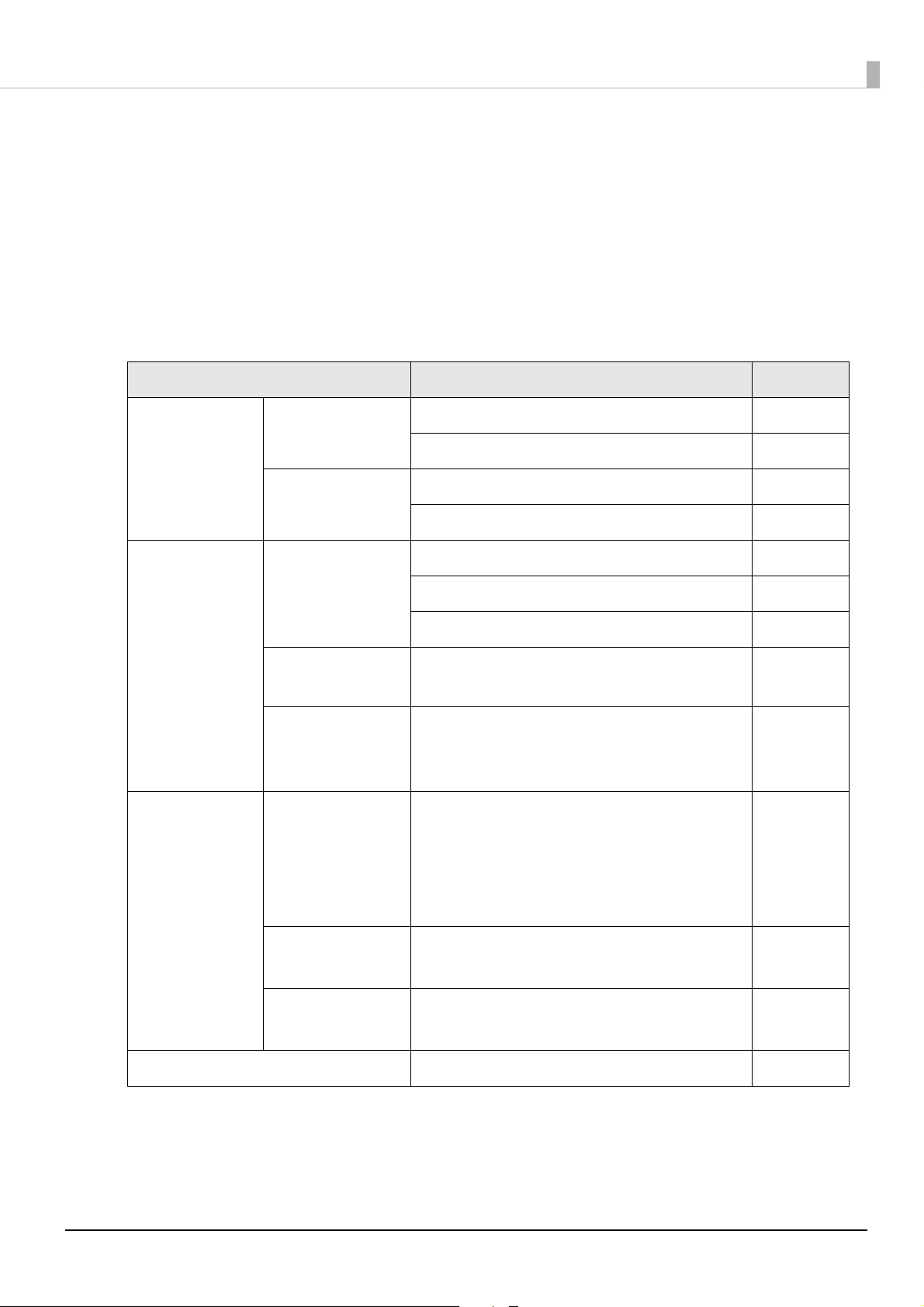

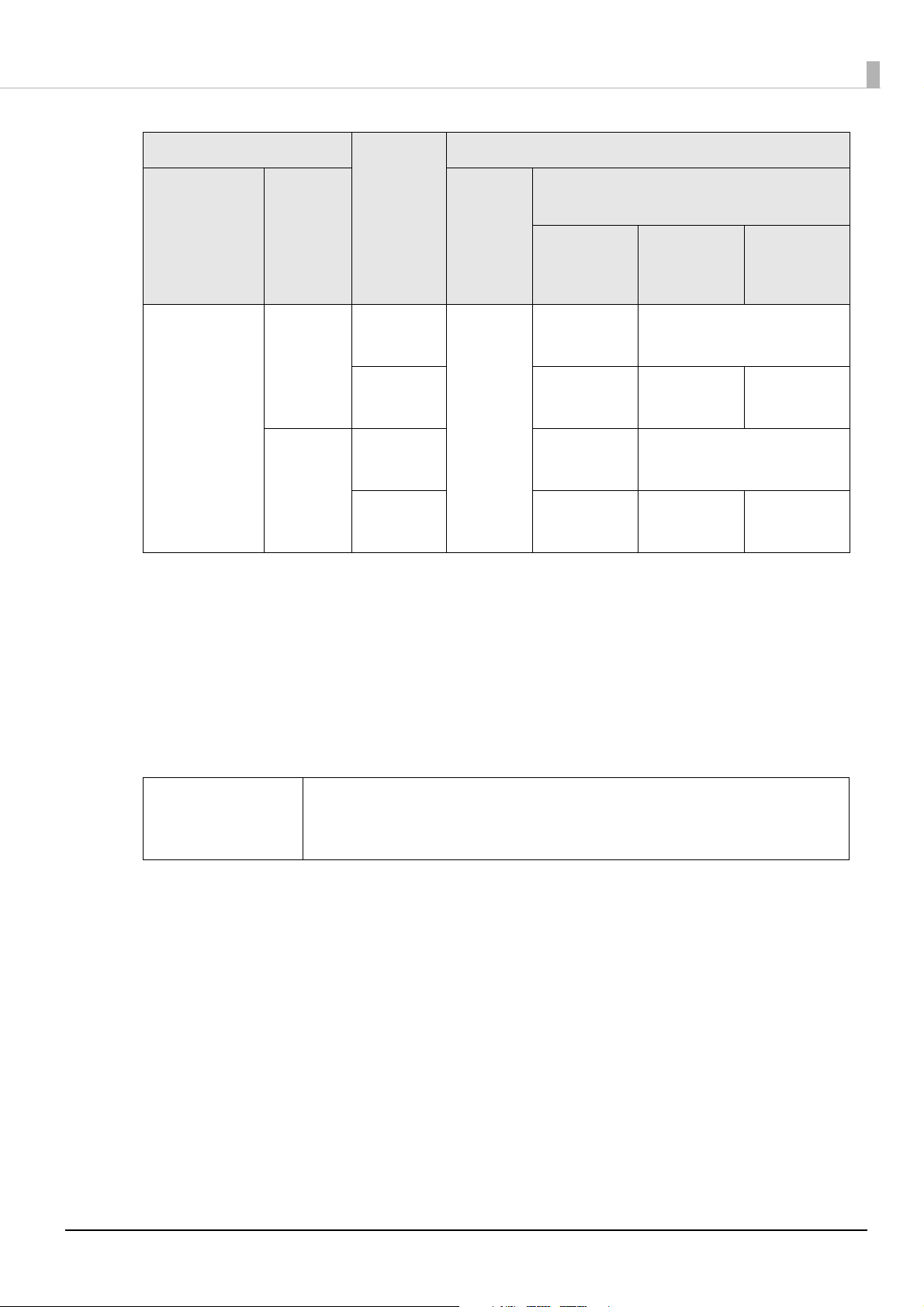

✓: Can be saved

-: Cannot be saved

Menu Setting item Savable

General Media Settings Media source settings ✓

Media detection settings ✓

Advanced

Settings

Printer

Adjustment

Printer Operation

Settings

Notification

Settings

Panel Button

Settings

Operating Time

Settings

Paper Feed

Adjustment

Nozzle Check Mode Settings ✓

Paper Loading Settings ✓

Beep Notification Setting at an Error ✓

LED Notification Setting at Ink Low ✓

Notification Setting at a Media Size Error ✓

Panel Button Settings ✓

Platen Vacuum Operation Pause Time Settings

Data Standby Time Settings

Cut Position Adjustment

Print Start Position Adjustment (Vertical

Direction)

Print Start Position Adjustment (Horizontal

Direction)

✓

✓

Sensor

Adjustment

Print Head

Alignment

Option Media Source Settings Option -

Adjust the Label Gap Detection Sensor

Adjust the Black Mark Detection Sensor

Banding Adjustment

Bi-directional Printing Adjustment

-

-

11

Saving Settings

Save settings by following the procedures below.

Display the printer driver.

1

Select the Printer Utilities tab and then click Printer Setting.

2

The TM-C3500 PrinterSetting screen appears.

Select Settings Save and Restore.

3

The Settings Save and Restore screen appears.

If set values can be acquired from this printer, the values acquired from the

4

current settings will be displayed.

Click Save Settings.

5

The Save as screen appears

Specify a file name and saving location, and then click Save.

6

The successful operation message is displayed to indicate that settings have been saved.

12

Restoring Settings

Restore settings by following the procedures below.

Display the printer driver.

1

Select the Printer Utilities tab and then click Printer Setting.

2

The TM-C3500 PrinterSetting screen appears.

Select Settings Save and Restore.

3

The Settings Save and Restore screen appears.

Click Restore Settings.

4

The Open screen appears.

Select the settings file you want to restore and click Open.

5

A confirmation screen appears.

Click OK. File restoration starts.

6

A message is displayed when restoration is completed. Click OK.

7

The successful operation message is displayed to indicate that settings have been restored.

13

How to Use the Printer Driver

This chapter describes the functions and operating procedures of the printer driver.

Printing Barcodes/2-Dimensional Symbols

This section describes how to use the fonts for barcodes/2-dimensional symbols of the printer driver,

and how to print barcodes/2-dimensional symbols. Using a font for barcodes/2-dimensional symbol

allows you to print barcodes/2-dimensional symbols with a high level of readability that is suitable for

the resolution of this printer.

The settings flow is as follows.

Barcodes/2-Dimensional Symbol Settings

Set the type and size of barcodes/2-dimensional symbols in the font for barcodes/

2-dimensional symbols of the printer driver.

Font Replacement

You can replace the printer driver fonts to replace the font for barcodes/2-dimensional symbols with a True Type font.

Printing from an Application

Use an application to create values for barcodes/2-dimensional symbols and

print accordingly.

14

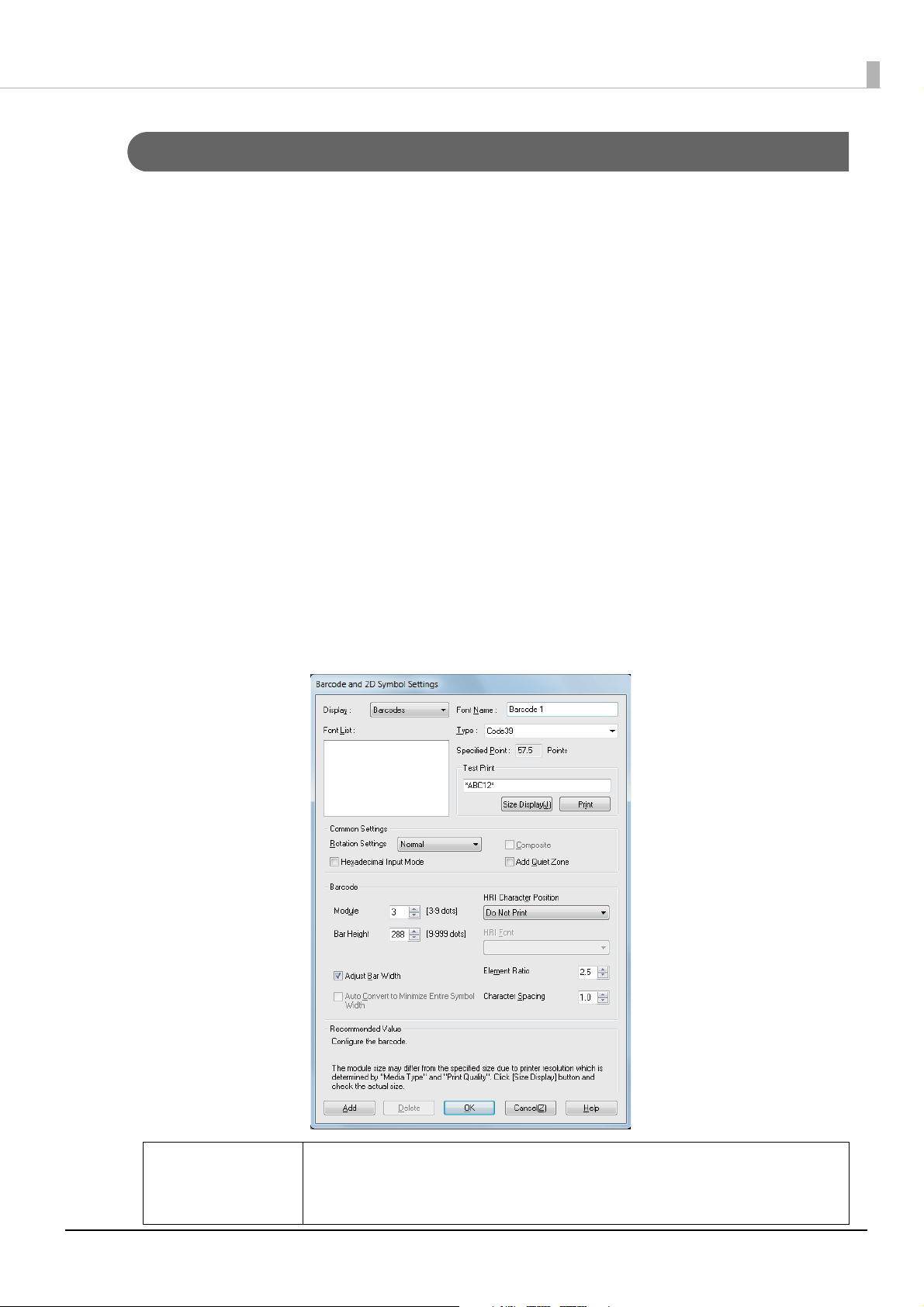

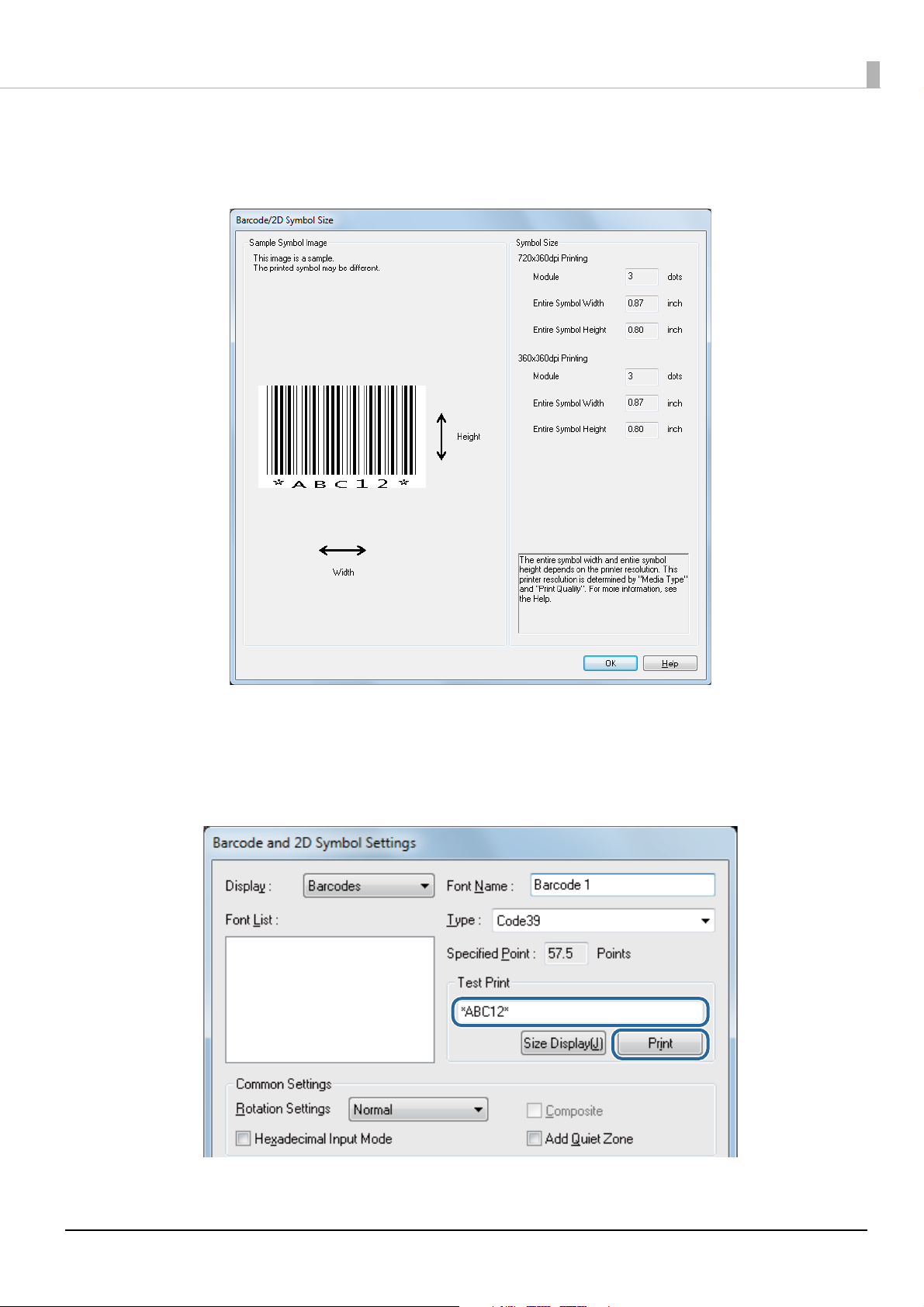

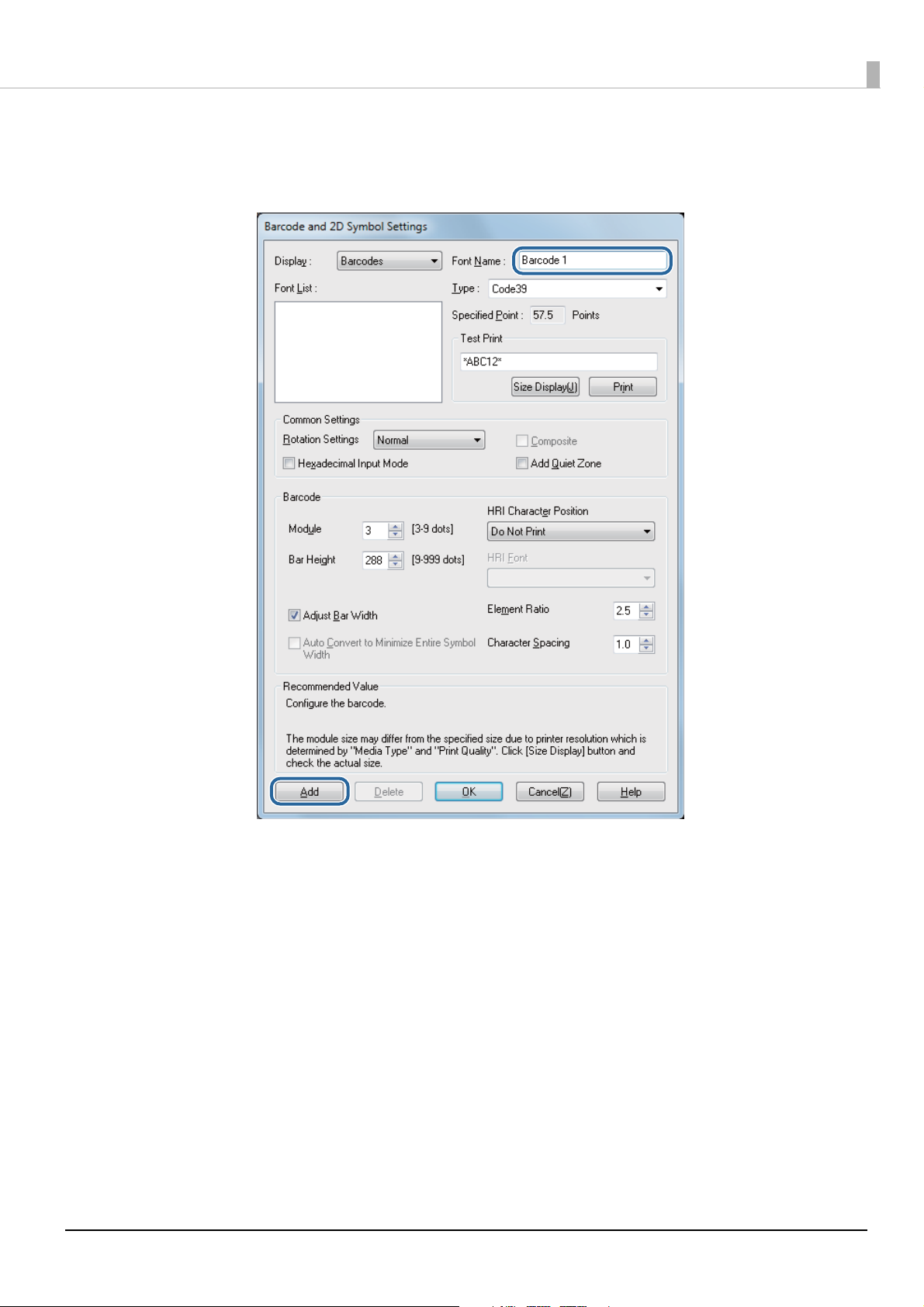

Barcodes/2-Dimensional Symbol Settings

Set items such as the type, size, and print direction of barcodes/2-dimensional symbols, and set

the font for barcodes/2-dimensional symbols.

You can specify a total of 30 items for a barcodes and 2-dimensional symbols font.

Specify settings by following the procedures below.

Display the printer driver.

1

Click Barcodes/2-Dimensional Symbols Settings on the Driver Utilities

2

tab.

The Barcode and 2D Symbol Settings screen appears.

From Type, select the barcode/2-dimensional symbol you want to specify.

3

Setting items change depending on the type.

Set the displayed items. Right-click an item and then click Help to display

4

an explanation of the setting item.

Q NOTE

Setting point displays a point value corresponding to the size of the barcodes/2-dimensional symbols. Specify this value when printing from an

application.

15

Click Size Display and check the printing size of the barcodes/2-dimen-

5

sional symbols.

Input a character string into Test print and then click Print. After printing

6

barcodes/2-dimensional symbols, use a scanner to check that they can be

read.

16

Input the name of the font for barcodes/2-dimensional symbols into Font

7

name and then click Add on the lower left.

Check that the font for barcodes/2-dimensional symbols has been added to

8

the Font list and then click OK. Close the Barcode and 2D Symbol Settings screen.

Setting of the barcodes/2-dimensional symbols is now completed.

17

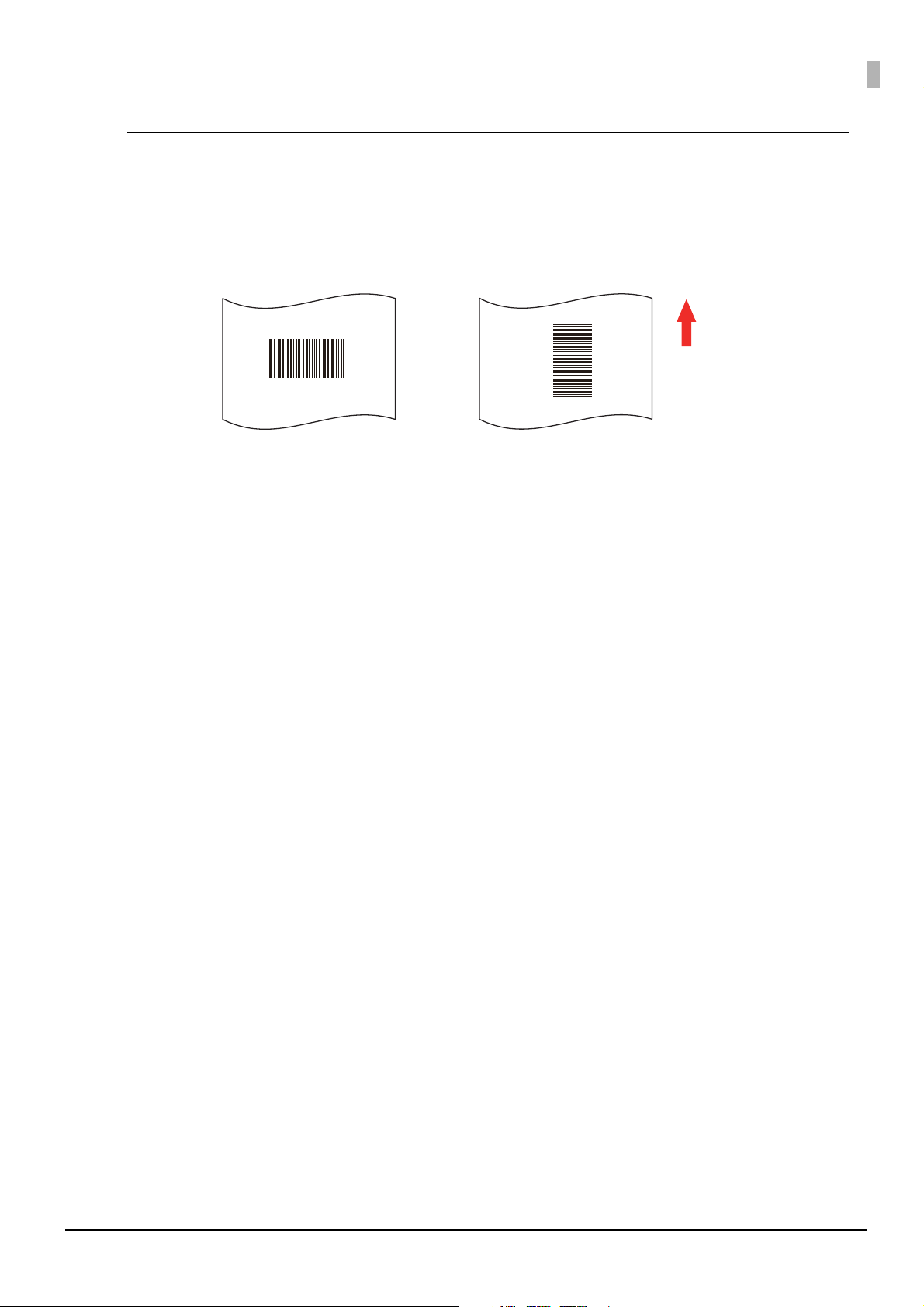

Barcode Print Direction

8 1 0 1 0 5 4 3 2 1 1 2 0 0

8 1 0 1 0 5 4 3 2 1 1 2 0 0

Paper feed direction

Fence barcode

Ladder barcode

Barcode print direction and name are as follows.

When printing ladder barcodes, it may not be possible to read the barcode with a barcode

reader if printed straddling the feeding position. (U“Checking the Feeding Position” on page

35) For this reason, it is recommended to use fence barcodes or set the Print Quality to

Quality (Mode2).

18

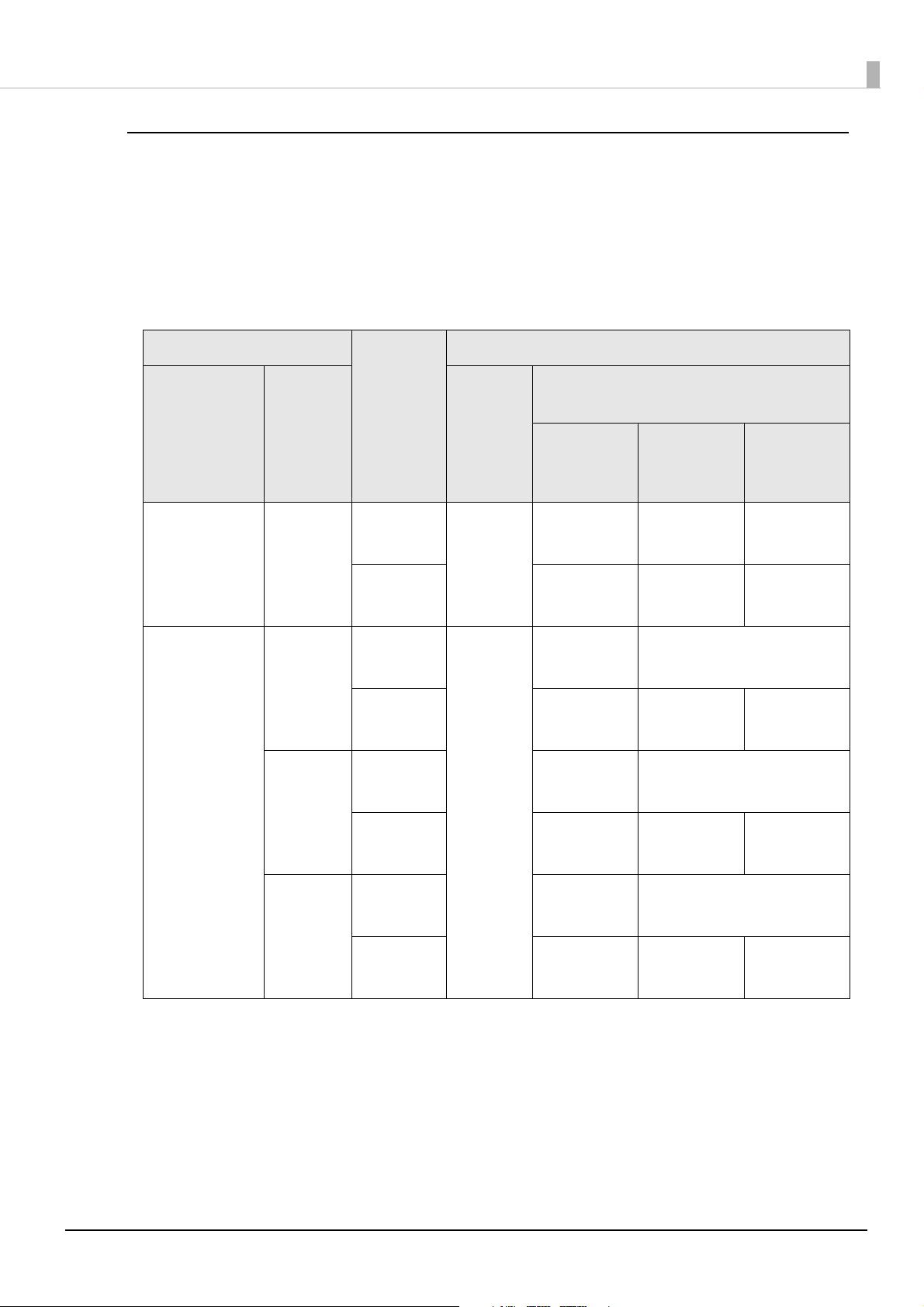

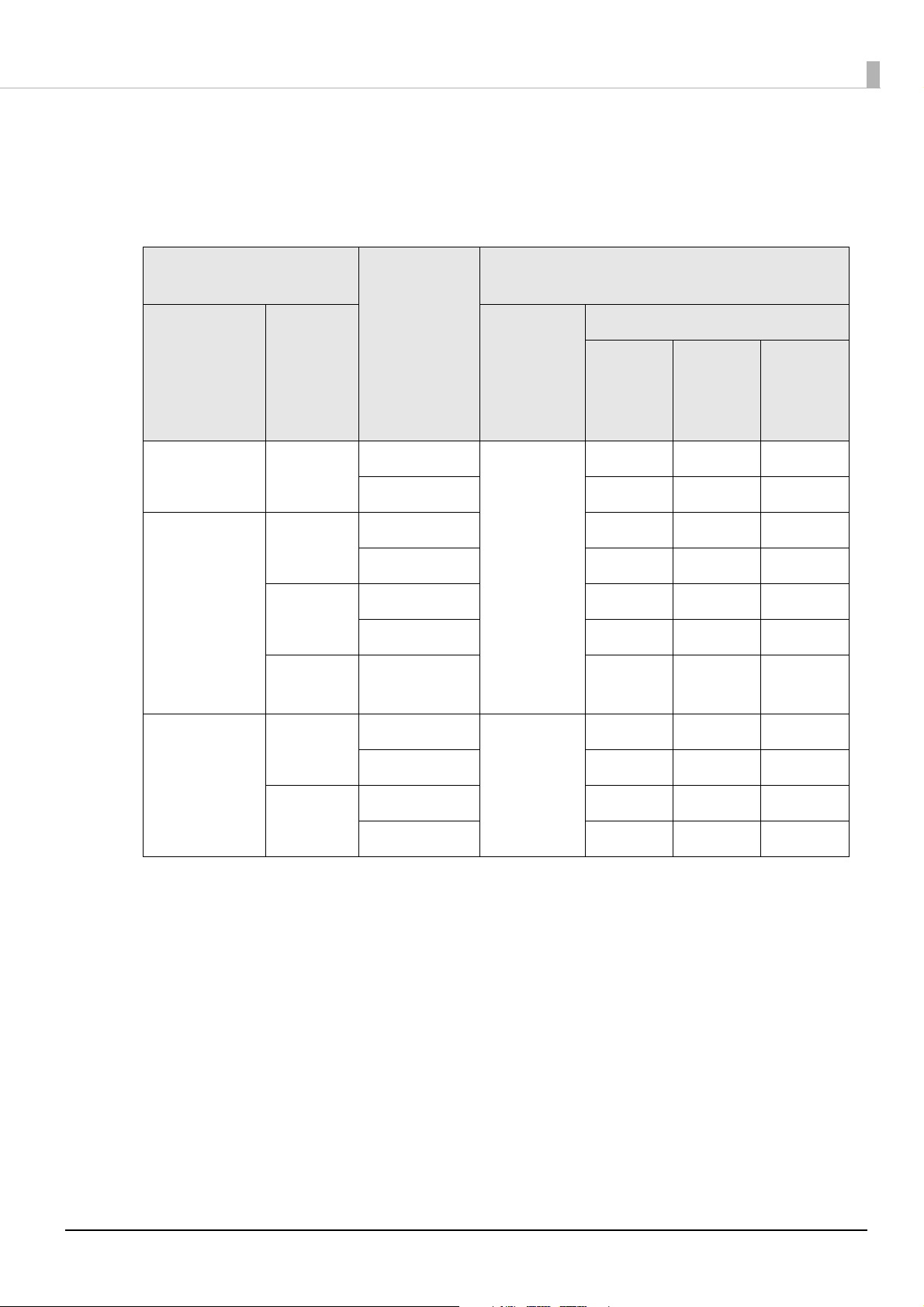

Printing with ANSI Print Quality Grade

You can print with ANSI print quality grade depending on the media type, printer driver

settings, and direction and size of barcodes/2-dimensional symbols. The setting items are as

follows.

Barcodes

-: Not guaranteed

General settings

Print

Media type

Plain paper Speed Fence Yes 4 dot

Synthetic

paper

Matte paper

Glossy

Print

quality

Speed Fence Yes 3 dot

Quality

(Mode1)

direction

*1

Ladder 6 dot

Ladder 6 dot

Fence 3 dot

Font settings of barcodes/2-dimensional symbols

Upper line: Minimum module (dot)

Adjust

Bar

Width

*2

Lower line: Minimum element ratio

grade D or

higher

2.5

2.5

2.7

2.5

2.7

ANSI

ANSI

grade C or

higher

--

--

4 dot

2.5

--

4 dot

2.5

ANSI

grade B or

higher

Quality

(Mode2)

Ladder 6 dot

2.5

Fence 3 dot

2.7

Ladder 6 dot

2.5

--

4 dot

2.5

--

19

General settings

Font settings of barcodes/2-dimensional symbols

Print

Media type

Wristbands Speed Fence Yes 3 dot

*1: In some cases, missing dots and irregularity in ink shots may occur when printing ladder barcodes,

resulting in the ANSI grade being lowered to F and making barcodes unreadable. Apply an

innovative method such as printing HRI characters.

*2: Ink may penetrate the paper due to its characteristics, causing the bars of printed barcodes to

become thicker. In such cases, reduce the data in a bar by one pixel and increase the blank space

by one pixel (Adjust Bar Width).

*3: The recommended values for specified media types and barcodes are as follows.

For wristbands and Code 128: Five-dot module and ANSI grade D

For wristbands and Codabar: Four-dot module, minimum element ratio of 2.5, and ANSI grade C

Print

quality

Quality

(Mode1)

direction

*1

Ladder 6 dot

Fence 3 dot

Ladder 6 dot

Adjust

Bar

Width

*2

Upper line: Minimum module (dot)

Lower line: Minimum element ratio

ANSI

grade D or

higher

2.7

*3

2.5

2.7

*3

2.5

ANSI

grade C or

higher

4 dot

2.5

*3

-

4 dot

2.5

*3

-

grade B or

higher

-

-

ANSI

Q NOTE

If an odd number value is set for the Module, changing the Media Type

and Print Quality causes the resolution to change, resulting in a change in

the size of the printed barcode.

20

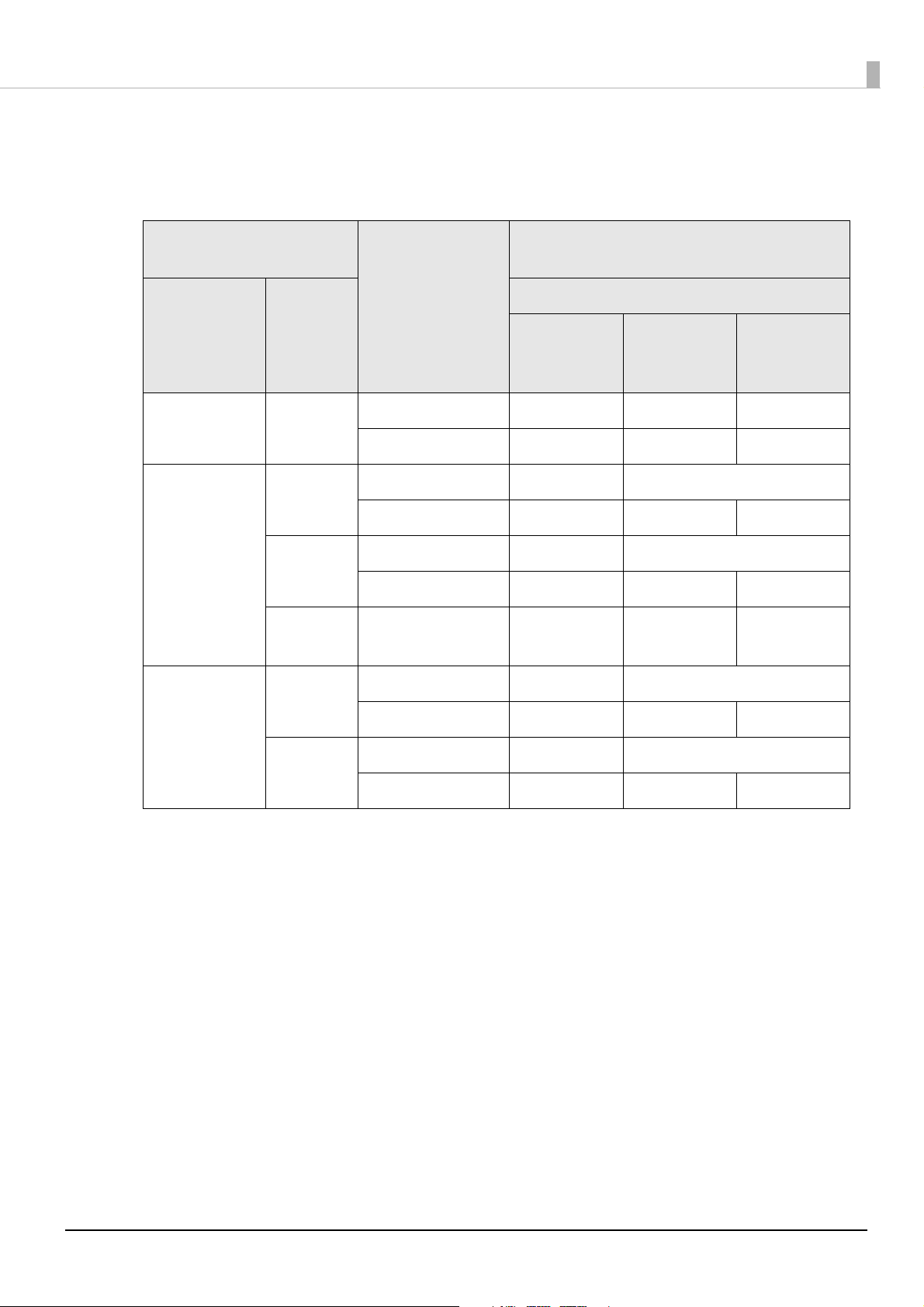

Stacked Type 2-Dimensional Symbols Fonts

Symbols: PDF417, GS1 DataBar Stacked, GS1 DataBar Stacked Omnidirectional, GS1 DataBar

Expanded Stacked

-: Not guaranteed

General settings

Straddling

Font settings of barcodes/2-dimensional sym-

bols

Minimum module (dot)

paper

Media type

Print

quality

feeding

1

*

Module

height

2

*

ANSI

grade D

or

higher

ANSI

grade C

or

higher

Plain paper Speed No 3 6 dot - -

Yes 6 do t - -

Synthetic

paper

Speed No 4 dot - -

Yes 4 do t - -

Matte paper

Glossy

Quality

No 4 dot - -

(Mode1)

Yes 4 do t - -

Quality

-4 dot--

(Mode2)

ANSI

grade B

or

higher

Wristbands Speed No 3 4 dot - -

Yes 4 do t - -

Quality

(Mode1)

No 4 dot - -

Yes 4 do t - -

*1: To check whether a 2-dimensional symbol is straddling paper feeding, use Display Media Feed

Position of the print preview function. For the print preview function, refer to "Checking the

Feeding Position" on page 35

.

*2: Recommended value when using PDF417

21

Matrix Type 2-Dimensional Symbols Fonts

Symbols: QR Code, DataMatrix

-: Not guaranteed

General settings

Media type

Print

quality

Straddling paper

feeding

*1

Font settings of barcodes/2-dimensional

symbols

Minimum cell size (unit: 360 dpi)

ANSI

grade D or

higher

ANSI

grade C or

higher

Plain paper Speed No 6 dot - -

Yes 8 dot - -

Synthetic

paper

Speed No 5 dot 6 dot

Yes 6 dot 7 dot -

*2

Matte paper

Glossy

Quality

(Mode1)

Quality

No 5 dot 6 dot

Yes 6 dot 7 dot -

- 6 dot 7 dot -

*2

(Mode2)

Wristbands Speed No 5 dot 6 dot

*2

ANSI

grade B or

higher

Yes 6 dot 7 dot -

Quality

No 5 dot 6 dot

*2

(Mode1)

Yes 6 dot 7 dot -

*1: To check whether a 2-dimensional symbol is straddling paper feeding, use Display Media Feed

Position of the print preview function. For the print preview function, refer to "Checking the

Feeding Position" on page 35

.

*2: QR Code only

22

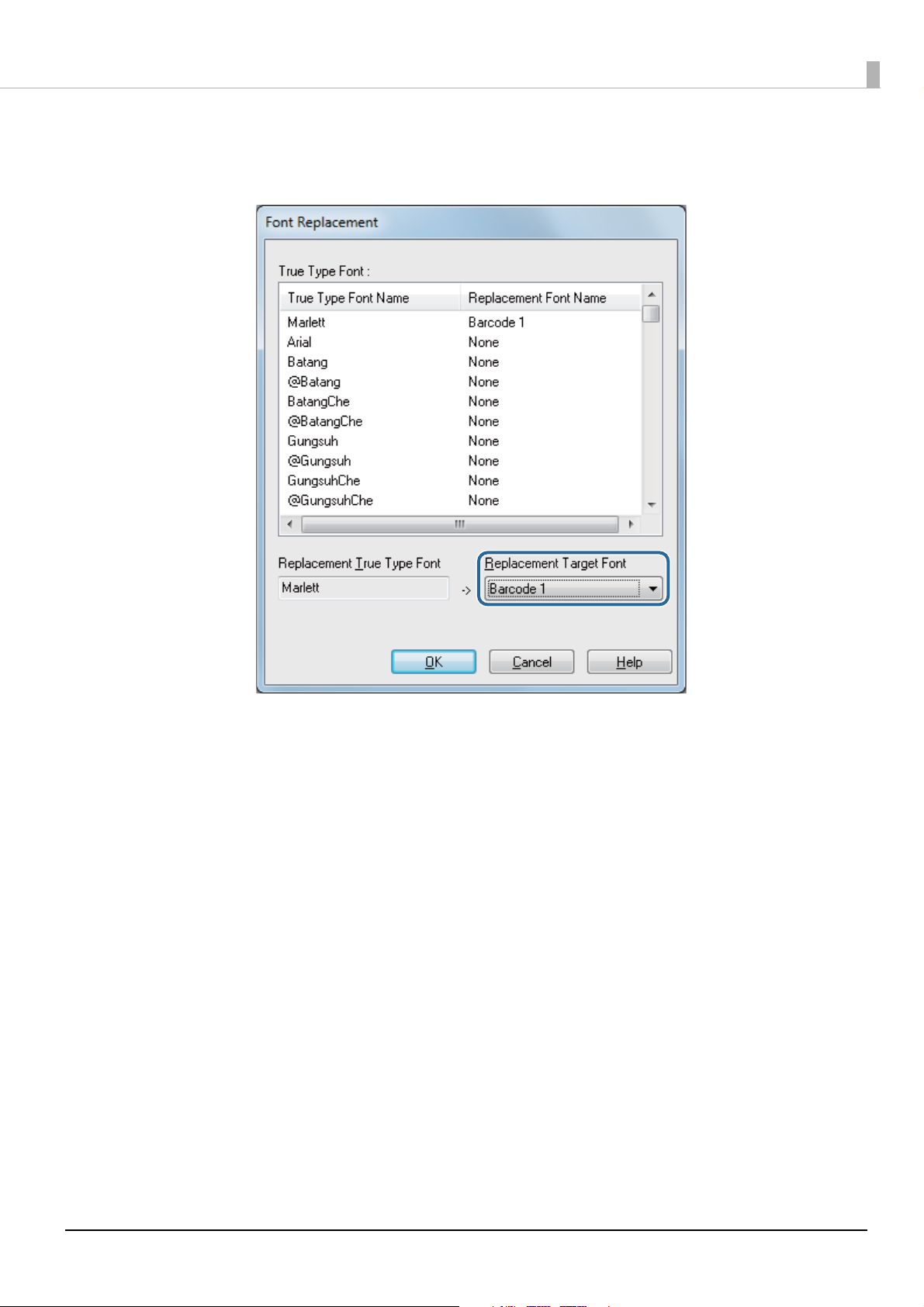

Font Replacement

The Windows .NET application cannot be used to specify printer driver fonts for barcodes/2dimensional symbols. For this reason, you must replace the font for barcodes/2-dimensional

symbols set in the previous procedure with a Windows True Type font.

For True Type fonts replacing barcode fonts, select fonts that are not being

c IMPORTANT

Replace fonts by following the procedures below.

Display the printer driver.

1

Select the Driver Utilities tab and then click Font Replacement. The Font

2

Replacement screen appears.

From the True Type Font Name, click the True Type font you want to

3

replace.

The selected font is displayed in the Replacement True Type Font.

used as print data.

23

From the Replacement Target Font, select the previously set barcodes/2-

4

dimensional symbols font.

Click OK to close the Font Replacement screen.

5

Font replacement is now completed.

24

Printing from an Application

This section describes how to create character strings of barcodes/2-dimensional symbols and

print using a specified True Type font.

Creating Character Strings of Barcodes/2-Dimensional Symbols

Refer to the following to create character strings of barcodes/2-dimensional symbols.

UPC-A

• Specify a character string of 11 to 12 digits.

• Although the first digit is the number system character, the bar code font is not checked.

• For 11 digits: The check digit is automatically added.

• For 12 digits: The 12th digit is processed as the check digit but the barcode font is not verified.

If the composite is checked, the 12th digit is ignored and the check digit is automatically added.

UPC-E

• Specify a character string of six to eight or 11 to 12 digits.

• For six digits: The check digit is automatically added.

• For seven digits: Digits two to seven are data digits and the check digit is automatically added.

• For eight digits: Digits two to seven are data digits and the eighth digit is processed as the check

digit but the barcode font is not verified.

If the composite is checked, the eighth digit is ignored and the check digit is automatically

added.

• For 11 digits: The check digit is automatically added.

• For 12 digits: The 12th digit is processed as the check digit but the barcode font is not verified.

If the composite is checked, the 12th digit is ignored and the check digit is automatically added.

• For seven digits or more: Specify 0 (zero) because the first digit is processed as the number

system digit.

JAN13(EAN)

• Specify a character string of 12 to 13 digits.

• For 12 digits: The check digit is automatically added.

• For 13 digits: The 13th digit is processed as the check digit but the barcode font is not verified.

If the composite is checked, the 13th digit is ignored and the check digit is automatically added.

25

JAN8(EAN)

• Specify a character string of 7 to 8 digits.

• For seven digits: The check digit is automatically added.

• For eight digits: The 8th digit is processed as the check digit but the barcode font is not verified.

If the composite is checked, the eighth digit is ignored and the check digit is automatically

added.

CODE39

• Specify a character string with a maximum of 256 digits.

• If one or both of the start and stop codes (“*”) are not specified, they are automatically added.

ITF

• Specify a character string with a maximum of 256 digits.

• If odd-digit data is specified, 0 (zero) is automatically added at the beginning of the string.

Codabar

• Specify a character string with a maximum of 256 digits.

• If a start code is not specified, ‘A’ is automatically added as the start code.

• If a stop code is not specified, a stop code that is the same as the start code is automatically

added.

• If the start or stop code is input with lower-case characters, they are automatically converted to

upper-case characters.

26

CODE93

• Specify a character string of 1 to 255 digits. awd

• A start code, two check digits, and a stop code are automatically added.

• Print characters indicating a start code (n) at the beginning of the HRI characters.

• Print characters indicating a stop code (n) at the end of the HRI characters.

• Print a combination of ■ and one alphabet character for the HRI control characters (00h to

1Fh, and 7Fh).

Control

characters

HRI char-

Hexa-

ASCII

NULL 00 ■U VT 0B ■K SYN 16 ■V

SOH 01 ■A FF 0C ■L ETB 17 ■W

STX 02 ■B CR 0D ■M CAN 18 ■X

ETX 03 ■C SO 0E ■N EM 19 ■Y

EOT 04 ■D SI 0F ■O SUB 1A ■ Z

ENQ 05 ■E DLE 10 ■P ESC 1B ■A

ACK 06 ■F DC1 11 ■Q FS 1C ■B

BEL 07 ■G DC2 12 ■R GS 1D ■C

BS 08 ■H DC3 13 ■S RS 1E ■D

decimal

number

acters

Control

characters

ASCII

Hexa-

decimal

number

HRI char-

acters

Control

characters

ASCII

HRI char-

Hexadecimal

number

acters

HT 09 ■I DC4 14 ■T US 1F ■E

LF 0A ■J NAK 15 ■U DEL 7F ■F

27

CODE128

• Specify a character string of 2 to 255 digits.

• Specify either a start code or code selection characters (CODE A, CODE B, or CODE C) for the

first two digits.

• Indicate special characters with a combination of ‘{’ followed immediately by a single character.

• Adding a check mark to Automatically Convert Symbol Overall Width to Minimum results

in the overall width of the Code 128 symbol being automatically converted to the minimum.

Use this function when it is not necessary to specify a code set and you want to print barcodes

by only inputting data for a desired symbol.

Manually specify the code set if not checked.

If code set C is specified, consider the two created digits as ASCII decimal numbers and specify

the corresponding ASCII character(s).

Example) “37”: Specify as “%”.

“65”: Specify as “A”.

“979899”: Specify as “abc”.

• An error occurs if the data immediately following ‘{’ is not as indicated below.

Control characters ASCII Control characters ASCII Control characters ASCII

SHIFT {S CODE C {C FNC3 {3

CODE A {A FNC1 {1 FNC4 {4

CODE B {B FNC2 {2 '{' {{

• Special HRI characters are expressed as follows.

Control characters HRI characters

SHIFT Not printed

CODE A/B/C Not printed

FNC1-4 Space is printed

Control characters (00h to 1Fh, and 7Fh) Space is printed

28

GS1-128

• Specify a character string of 2 to 255 digits.

• The delimiter of the application identifier is separated by “()” (parenthesis). (Although printed

as HRI characters, they are not encoded.)

• A start code (CODE A, CODE B, or CODE C) and stop code are automatically added.

• Symbol characters FNC1 are automatically added following the start code.

• Specifying ‘*’ results in the check digit being automatically calculated and converted to ‘*’.

• Specify two consecutive digits for the application identifier. An error occurs if not correctly

specified.

• If the application identifier is (01), the 14th digit of data is made the check digit but if the check

digit is specified, the barcode font is not verified. The check digit being automatically calculated

and converted to ‘*’ if the 14th digit is “*”.

• Indicate special characters with a combination of ‘{’ followed immediately by a single character.

• An error occurs if the data immediately following ‘{’ is not as indicated below.

Control characters ASCII HRI characters

Control characters (00h to 1Fh, and 7Fh) Space is printed

FNC1 {1 Space is printed

FNC3 {3 Space is printed

'{' {{ { is printed

'(' {( ( is printed

')' {) ) is printed

'*' {* * is printed

Left parenthesis of application identifier ( ( is printed

Right parenthesis of application identifier ) ) is printed

Check digit position * Check digit is printed

GS1-128M

• Specify a character string of 38 to 66 digits.

• The delimiter of the application identifier is separated by “()” (parenthesis). (Although printed

as HRI characters, they are not encoded.)

• A start code (CODE A, CODE B, or CODE C) and stop code are automatically added.

• Symbol characters FNC1 are automatically added following the start code.

• FNC1 is automatically added if FNC1 is not present at the end of the data following application

identifier (30).

29

• An error occurs if FNC1 is present at the end of the data following application identifier (10) or

(21) because FNC1 is not necessary.

• If the application identifier is (01), the 14th digit of the data section is made the check digit but

if the check digit is specified, the barcode font is not verified. The check digit is automatically

calculated and converted to ‘*’ if the 14th digit is “*”.

• An error occurs if the data immediately following the { is not a 1.

• Specify special characters according to the following formats.

Control characters ASCII HRI characters

FNC1 {1 Space is printed

Left parenthesis of application identifier ( ( is printed

Right parenthesis of application identifier ) ) is printed

Check digit position * Check digit is printed

• An error occurs if not according to the following formats.

Application identifier Format

01 14-digit number

10 1 to 20 alphanumeric characters

17 6-digit number (YYMMDD)

21 1 to 20 alphanumeric characters

30 1 to 8 digit number

GS1 DataBar Omnidirectional/GS1 DataBar truncated

/GS1 DataBar Limited

• Leading application identifier 01 is not included in the character string.

• When printing HRI characters, leading application identifier 01 is printed as “(01)” before the

packing identification code.

• Do not add a check digit to the bar code data.

• When printing HRI characters, the check digit is printed after the product code.

• Specify ‘0’ or ‘1’ as the first digit if using GS1 DataBar Limited.

30

GS1 DataBar Expanded M

• Specify a character string of 38 to 66 digits (numbers not including ‘*’).

• The delimiter of the application identifier is separated by “()” (parenthesis). (Although printed

as HRI characters, they are not encoded.)

• FNC1 is automatically added if FNC1 is not present before application identifier (10) or (21).

• FNC1 is automatically added if FNC1 is not present at the end of the data following application

identifier (30).

• An error occurs if FNC1 is present at the end of the data following application identifier (10) or

(21) because FNC1 is not necessary.

• If the application identifier is (01), the 14th digit of the data section is made the check digit. If

the check digit is not correct, an error occurs.

(Different than the case of GS1-128 in that the check digit is not automatically calculated and

added due to ‘*’.)

• ‘*’ is skipped.

• An error occurs if the data immediately following the character string { is not a 1.

• Specify special characters according to the following formats.

Control characters ASCII HRI characters

FNC1 {1 Not printed

'(' {( ( is printed

')' {) ) is printed

Left parenthesis of application identifier ( ( is printed

Right parenthesis of application identifier ) ) is printed

'*' {* * is printed

Skipped character * Not printed

31

GS1 DataBar Expanded

• Specify a character string of 2 to 255 digits.

• The delimiter of the application identifier is separated by “()” (parenthesis). (Although printed

as HRI characters, they are not encoded.)

• Be sure to include all application identifiers in the character string.

• If the first data is 01 after deleting the application identifier, left and right parenthesis, and ‘*’

from the specified data, checking is performed using the 14th digit counting from the digit

following 01 as the check digit. An error occurs if not correct.

• If the data counting the digit following 01 is less than 14 digits, the check digit is not checked.

(Different than the case of GS1-128 in that the check digit is not automatically calculated and

added due to ‘*’. If ‘*’ is specified, ‘*’ is ignored and the following data is shifted by one digit

each.)

• Specify special characters according to the following formats.

Control characters ASCII HRI characters

FNC1 {1 Not printed

Left parenthesis of application identifier ( ( is printed

Right parenthesis of application identifier ) ) is printed

'*' {* Error

Skipped character * Not printed

PDF417

• Automatic calculation is performed if the number of digits and rows is 0 (zero).

• If anything other than 0 (zero) is specified, specify so that the product of the number of digits

and rows is 928 or less.

QRCode

• The size is determined according to the specified version. If not embedded in the specified

version, it is automatically changed to the embedded version.

32

MaxiCode

• The header and secondary message can be omitted if using Mode 2 or 3.

• Specify special characters according to the following formats.

Control characters Hexadecimal number notation

SHIFT 0x7B,0x53

CODE B 0x7B,0x42

CODE C 0x7B,0x43

FNC1 0x7B,0x31

FNC2 0x7B,0x32

FNC3 0x7B,0x33

FNC4 0x7B,0x34

GS1 DataBar Stacked / GS1 DataBar Stacked Omnidirectional

• You can specify a character string up to 13 digits.

• Do not include application identifier 01 at the beginning of the character string.

• Do not add a check digit to the character string.

GS1 DataBar Expanded Stacked

• It is a multi-row symbol version of GS1 DataBar Expanded. Data specification procedures are

the same as that for GS1 DataBar Expanded.

AztecCode

• Both full-range and compact modes are supported.

DataMatrix

• Both square and rectangular shapes of version ECC200 are supported.

33

Specifying and Printing True Type Font

Specify the following in character strings of barcodes/2-dimensional symbols and print.

True Type Font

Use Font Replacement to specify the selected True Type font.

Point

Separately specify the point for each font for barcodes/2-dimensional symbols. Check the

specified points of the fonts for barcodes/2-dimensional symbols.

(U“Barcodes/2-Dimensional Symbol Settings” on page 15)

34

Checking the Feeding Position

Feeding position

Feeding is

straddled

If Speed or Quality (Mode1) is specified for the Print Quality, it may not be possible to read

the barcodes/2-dimensional symbols if they are printed straddling the feeding position. Adjust

the print data so that they are not straddling the feeding position. It is not necessary to check

the feeding position or adjust it if Quality (Mode2) is specified for the Print Quality because

the feeding position does not affect the reading accuracy of barcodes/2-dimensional symbols.

You can use Print Preview of the General tab to check an image of the print results before

printing. The feeding position is not displayed if Quality (Mode2) is specified for the Print

Quality.

35

Favorites

1

234

You can use the favorites functions to register basic and extended settings of the printer driver together

in one location.

Favorites Screen Configuration

Right-click an item and then click Help to display an explanation of the setting item.

1 List

This is a list of your favorites.

The initial settings are those specified when the printer driver is installed.

The first setting at the top of the list is the default setting when the printer driver is started.

Click Up/Down to switch the order of the list.

36

2Item

The favorites setting items.

3Current Settings

Set value when you click Save As Favorite Setting.

4 Registered Settings

Favorite set value selected from the list.

Registering Favorites

Register favorites by following the procedures below

Set the printer driver to match the paper being used for printing.

1

Click Save As Favorite Setting of the General or Options tab.

2

The Save/Delete Favorite Setting screen appears.

The contents of the General and Options tabs are displayed under Current Settings.

Input the settings name into Name and then click Add.

3

The Save/Delete Favorite Setting screen closes.

37

The added settings name is Favorite Setting of the General or Options

4

tab.

Registering favorites is now completed.

38

Importing/Exporting Settings Files

Printer driver settings can be exported to a BSF file. A BSF file can be used as a backup file or master

file.

If the printer driver of another computer is specified by using a BSF file, the file

Q NOTE

Settings that can be Exported to a BSF File

• Media definition

• Favorites

• Fonts of barcodes/2-dimensional symbols

• Font replacement

• Driver operation settings

• Epson log file settings

• Fatal error notification settings/Monitoring function settings

cannot be imported if the printer driver version is not the same.

Settings that cannot be Exported to a BSF File

• Items set for this printer by using PrinterSetting

• Printer driver port settings (printer IP address and computer port)

39

Exported Settings

Exported settings by following the procedures below.

Display the printer driver.

1

Register favorites. (U“Registering Favorites” on page 37)

2

If no favorites are registered, only the initial settings when the printer driver

was installed are registered.

Click Import/Export Settings on the Driver Utilities tab.

3

The Import/Export Settings screen appears.

Click Export Settings.

4

The Save As screen appears.

Name and save the BSF file.

5

When the file has been saved, Processing Completed is displayed.

Click OK.

6

Exporting of settings is now complete.

40

Importing Settings

You can import settings from a BSF file to overwrite printer driver settings

Q NOTE

Import settings by following the procedures below.

Display the printer driver.

1

Click Import/Export Settings on the Driver Utilities tab.

2

The Import/Export Settings screen appears.

Click Import Settings.

3

The Overwrite confirmation screen appears.

Click OK.

4

The Open screen appears.

Select the file to be imported.

5

Processing Completed is displayed.

and save them.

Click OK.

6

Importing of settings is now complete.

41

Application Development Information

This chapter provides information required for application development using this printer.

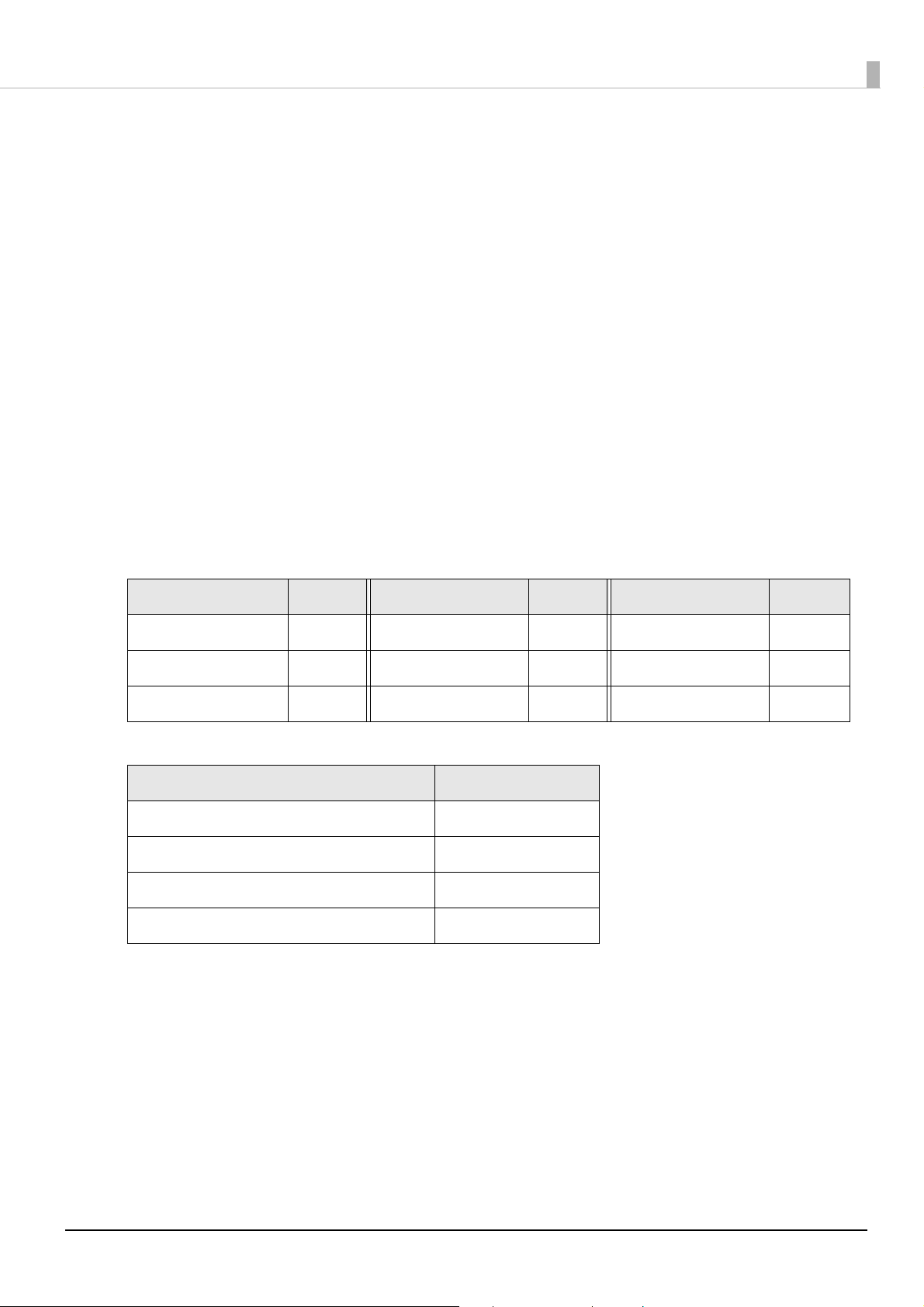

Epson Inkjet Label Printer SDK

The Epson Inkjet Label Printer SDK is a software development kit (SDK) for developing TMC3500 applications.

The Epson Inkjet Label Printer SDK contains the following tools. For use procedures, refer to

the Epson Inkjet Label Printer SDK User’s Guide.

Name Overview

EPDI

(EPSON Printer Driver Interface)

EpsonNet SDK The EpsonNet SDK provides the API used for acquiring the status of Epson

Sample programs These are sample programs for label printing. They also include sample

The Epson Driver Printer Interface (EPDI) provides the Application Programming Interface (API) for Epson printer drivers. Use the EPDI to directly

control the printer driver settings from your own developed applications.

inkjet label printers.

Use the EpsonNet SDK to acquire the status of network printers from your

own developed applications.

programs using the EPDI and EpsonNet SDK. Application execution files

and program source files are also provided.

42

Media Design

This chapter describes the required procedures for designing and arranging media (paper) that can be

used with this printer.

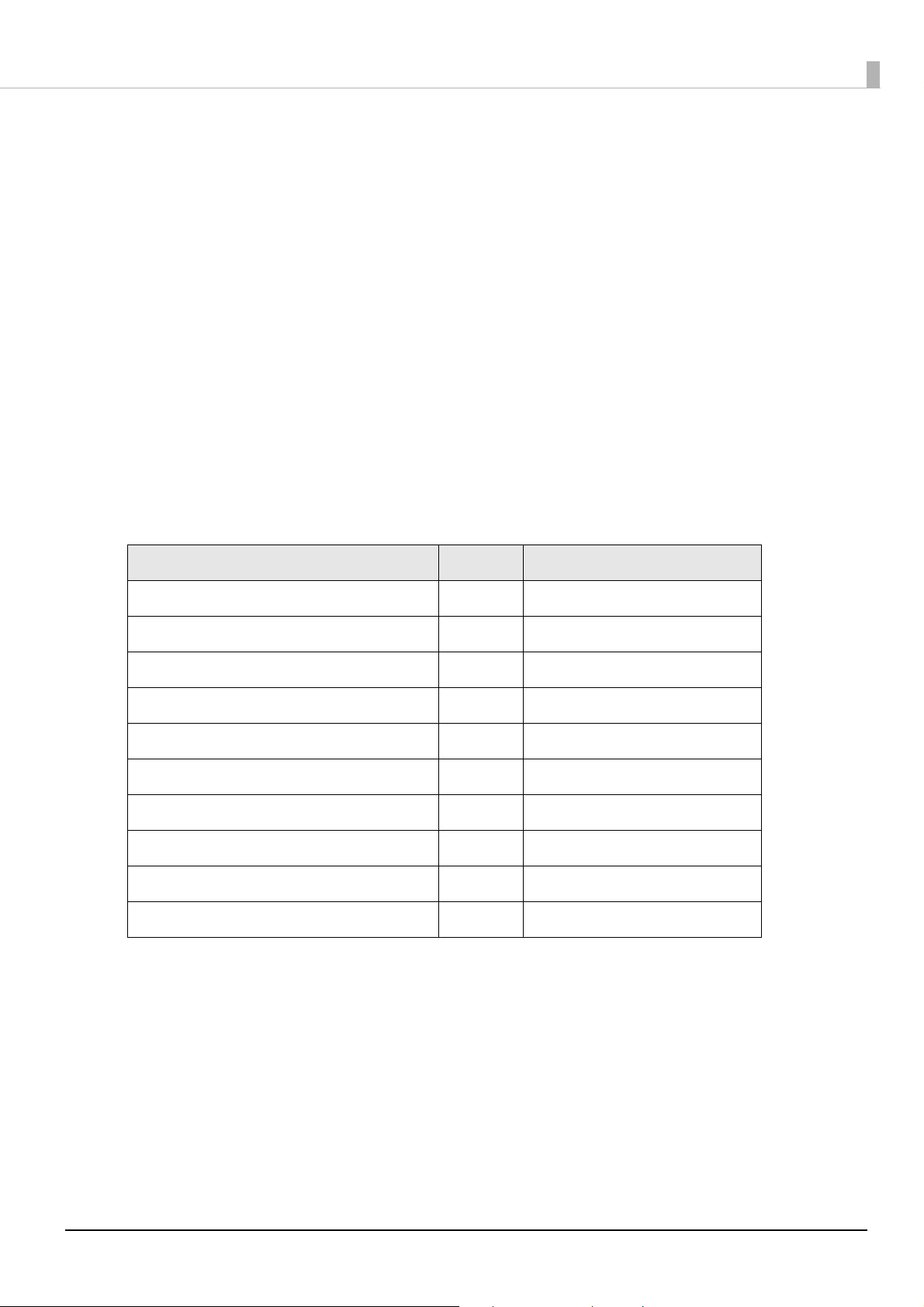

Types of Media that can be Used

The types of media that can be used with this printer are as follows.

For detailed specifications, refer to “Paper Specifications” on page 48.

Adhesive Typ e Category

Roll paper

Fanfold paper

c IMPORTANT

Full-page labels

Ye s

No

Yes Die-cut labels (with black marks)

No Continuous paper (with black marks)

Depending on the shape of die-cut labels, the labels may peel off their

backing paper inside the printer. When you want to use die-cut labels that

do not meet the specifications, contact qualified service personnel for

advice.

Die-cut labels (with black marks)

Die-cut labels (with gaps)

Continuous paper

Continuous paper (with black marks)

Plain paper

Matte paper

Synthetic paper

Glossy

Plain paper

Matte paper

Wristbands

Plain paper

Matte paper

43

Paper that cannot be Used

Thermal paper

Paper joined together or

lengthened by tape, etc.

Paper joined to the core by tape,

etc.

Paper of A size, B size, etc.

Do not load paper like the following. Such paper will cause paper jams and print stains.

44

Paper Loading Detection

This printer is equipped with a paper loading detection function. This section describes detection

methods and paper limitations.

Detection Methods

Black Mark Detection

Sensors are positioned facing the backside of the paper to detect paper loading from the optical

reflectance of the paper.

(The black mark reflectance rate must be 10% or lower, and the white reflectance rate must be

70% or higher.)

In order to accurately detect black marks, use paper having black marks printed at the positions

indicated for each black mark of the paper specifications.

Gap Detection

Transmission-type sensors are positioned along the paper path to detect paper loading from

differences in the light transmission rates between the backing paper and labels.

(The light transmission rate of the backing label must be 40% or more and that of the label

must be 23% or less.)

Light transmission rate: Light transmission rate (%) = Light transmission amount/Amount of

irradiation light x 100

45

Paper Limitations

Paper width center

13 mm

Preprinting prohibited area

Paper feed direction

Back side

8.5 mm

Preprinting Prohibited Area of Paper

Do not use paper preprinted in the following area if using paper preprinted on the back because

it negatively affects detection. (Excluding black marks.)

46

Holes Prohibited Areas of Paper

Paper width center

Holes prohibited areas

Paper feed direction

Print side

8.5 mm

6.0 mm

Do not use make holes in the following areas if it is necessary to use paper with holes such as

wristbands because it negatively affects detection.

47

Paper Specifications

The specifications of paper that can be used with this printer are as follows.

Continuous Paper

Paper type Plain paper / matte paper

Form Roll paper

Paper width 30 to 108 mm

Paper thickness 0.084 to 0.124 mm

Roll paper core Outer diameter: 44.1 mm or more

Outer diameter Max. 101.6 mm

Winding direction Printing surface must be facing outside.

c IMPORTANT

Paper with holes or cutouts cannot be used.

48

Continuous Paper (Black Marks)

Mark width

Mark center position

Mark length

Mark interval

Paper width center

Perforation position

0.5 mm or more

Fanfold paper

<Back side> <Print side>

Paper width center

Paper feed

direction

Paper

Paper type Plain paper / matte paper

Form Roll paper

Paper width 30 to 108 mm

Black mark width 13 mm or more

Label length 15 to 1117.6 mm

Black mark length 4 mm or more (margin part 4 mm or more)

Black mark center position 8.5 ± 1 mm

Black mark interval 8 to 1117.6 mm

Paper thickness 0.084 to 0.124 mm

Roll paper core Outer diameter: 44.1 mm or more

Outer diameter Max. 101.6 mm

Winding direction Printing surface must be facing outside.

c IMPORTANT

Paper with holes or cutouts cannot be used.

49

Paper type Plain paper / matte paper

Form Fanfold paper

Paper width 50 to 108 mm

Black mark width 13 mm or more

Black mark length 4 mm or more (margin part 4 mm or more)

Black mark center position 8.5 ± 1 mm

Black mark interval 8 to 304.8 mm

Paper thickness 0.124 to 0.128 mm

Perforated line interval 203.2 to 304.8 mm

Perforated line form Plain paper label: 1 mm uncut, 5 mm cut

Matte paper: 1 mm uncut, 5 mm cut

Number of folds 500 or less

• Paper with holes or cutouts cannot be used.

• When fanfold paper is used, the black marks must be at least 0.5 mm away

from the perforated lines.

• Set the auto cut position of fanfold paper to a position 0.5 to 1 mm away

behind the perforated line.

c IMPORTANT

• Use uncut perforations on both sides of the paper.

• Make sure the position of the black marks is kept the same in relation to

the perforated lines (position in which can be detection by the black mark

sensor) when inserting paper from either direction to ensure paper can be

used even if inserted in the reverse direction.

50

Full-page Label

Backing paper width

Label width

Waste part

Waste part

Backing paper

Label

Paper type Plain paper label / matte paper label / synthetic paper label /

glossy paper label

Form Roll paper

Backing paper width 30 to 112 mm

Label width 25.4 to 108 mm

Waste part on the left and right 2 ± 0.5 mm

Paper thickness Plain paper label / matte paper label / synthetic paper label:

0.129 to 0.195 mm

Glossy paper label:

0.184 mm

Roll paper core Plain paper label / matte paper label / synthetic paper label:

Outer diameter: 44.1 mm or more

Outer diameter Max. 101.6 mm

Winding direction Printing surface must be facing outside.

Glossy paper label:

Outer diameter: 56.8 mm or more

c IMPORTANT

• Paper with holes or cutouts cannot be used.

• To prevent adhesive from adhering to the roll paper supply unit, use label

paper from which the left and right wasted parts are removed.

51

Die-cut label (Gap)

Label width

Backing paper width

Gap between labels

Corner R

Label length

Backing paper

Label

Waste part

Waste part

Paper type Plain paper label / matte paper label / synthetic paper label /

glossy paper label

Form Roll paper

Backing paper width 30 to 112 mm

Label width 25.4 to 108 mm

Label length 8 to 1117.6 mm

Gap between labels 3 to 6 mm

Waste part on the left and right 2 ± 0.5 mm

Label corner R 1.5 mm or less

Paper thickness Plain paper label / matte paper label / synthetic paper label:

0.129 to 0.195 mm

Glossy paper label:

0.184 mm

Roll paper core Plain paper label / synthetic paper label:

Outer diameter: 44.1 mm or more

Matte paper label / glossy paper label:

Outer diameter: 56.8 mm or more

Outer diameter Max. 101.6 mm

Winding direction Printing surface must be facing outside.

52

c IMPORTANT

Q Note

• Paper with holes or cutouts cannot be used.

• If the backing is synthetic paper or film, cutting by hand will be difficult

even if there are perforated lines, so do not use perforated lines.

Depending on the shape of die-cut labels, the labels may peel off their

backing paper inside the printer. When you want to use die-cut labels that do

not meet the specifications, contact qualified service personnel for advice.

53

Die-cut label (black marks)

Label width

Waste part

Backing paper width

Label length

Gap between labels

Corner R

Paper without waste part

Waste part

Paper without the left and right waste parts

Waste part

Waste part

Waste width

Waste width

Label length

Gap between

labels

Corner R

Backing paper width

Label part

Label width

Backing paper

Label

Waste part

Mark width

Mark center position

Mark length

Mark interval

Paper width center

Perforation position

2 mm or more

Fanfold paper

<Back side> <Print side>

Paper width center

Paper feed

direction

Backing paper

Label

54

Paper type Plain paper label / matte paper label / glossy paper label:

Form Roll paper

Backing paper width 30 to 112 mm

Label width 25.4 to 108 mm

Label length 8 to 1117.6 mm

Gap between labels 3 to 6 mm

Waste part on the left and right 2 ± 0.5 mm

Waste width 1.5 mm or more

Label corner R 1.5 mm or less

Black mark width 13 mm or more

Black mark length 4 mm or more (margin part 4 mm or more)

Black mark center position 8.5 ± 1 mm

Black mark interval 11 to 1123.6 mm

Paper thickness Plain paper label / matte paper label:

0.129 to 0.143 mm

Glossy paper label:

0.184 mm

Roll paper core Plain paper label:

Outer diameter: 44.1 mm or more

Matte paper label / glossy paper label:

Outer diameter: 56.8 mm or more

Outer diameter Max. 101.6 mm

Winding direction Printing surface must be facing outside.

• Paper with holes or cutouts cannot be used.

• For the black mark position of the die-cut label paper, match the label

c IMPORTANT

leading edge to the black mark leading edge.

• Both types, paper without waste part and paper without the left and right

waste parts, can be used.

Q Note

Depending on the shape of die-cut labels, the labels may peel off their

backing paper inside the printer. When you want to use die-cut labels that do

not meet the specifications, contact qualified service personnel for advice.

55

Paper type Plain paper label / matte paper label:

Form Fanfold paper

Backing paper width 50 to 112 mm

Label width 46 to 108 mm

Label length 8 to 301.8 mm

Gap between labels 3 to 6 mm

Waste part on the left and right 2 ± 0.5 mm

Waste width 1.5 mm or more

Label corner R 1.5 mm or less

Black mark width 13 mm or more

Black mark length 4 mm or more (margin part 4 mm or more)

Black mark center position 8.5 ± 1 mm

Black mark interval 11 to 304.8 mm

Paper thickness 0.161 to 0.164 mm

Perforated line interval 203.2 to 304.8 mm

Perforated line form Plain paper label: 1 mm uncut, 5 mm cut

Matte paper label: 1 mm uncut, 5 mm cut

Number of folds 500 or less

56

c IMPORTANT

Mark width

Mark center position

Mark length

Mark interval

Paper width center

Per foratio n

position

2 mm or

more

Fan fold

paper

<Back side> <Print side>

Paper width

center

Paper feed

direction

Normal black

mark position

Black mark

position

when

inserted in

reverse

direction

Backing paper

Label

• Paper with holes or cutouts cannot be used.

• Auto cutting on the perforated lines will generate scraps of paper that may

cause problems. Also, auto cutting ahead of the perforated line may cause

problems when feeding paper. Therefore, perform auto cutting 0.5 to

1 mm behind the perforated line.

• Set the black mark position 2 mm or more from the perforated line.

• For the black mark position of the die-cut label paper, match the label

leading edge to the black mark leading edge.

• Use uncut perforations on both sides of the paper.

• Both types, paper without waste part and paper without the left and right

waste parts, can be used.

• Providing a black mark on both sides enables the paper to be used even

when inserted from either side.

Depending on the shape of die-cut labels, the labels may peel off their

Q Note

backing paper inside the printer. When you want to use die-cut labels that do

not meet the specifications, contact qualified service personnel for advice.

57

Wristband

Mark width

Mark center position

Mark length

Mark interval

Paper width

center

<Back side> <Print side>

Paper feed

direction

Paper width

center

Paper

58

Paper type Wristband

Specified dedicated paper WB-S series, WB-M series, WB-L series

Form Roll paper

Paper width 36 mm

Black mark width 13 mm or more

Black mark length 4 mm or more (margin part 4 mm or more)

Black mark center position 8.5 ± 1 mm

Black mark

interval

Paper thickness 0.225 mm

Roll paper core Outer diameter: 56.8 mm or more

Outer diameter Max. 101.6 mm

Winding direction Printing surface must be facing outside.

Holes and cutouts Hole diameter: 2.5 mm or more

c IMPORTANT

WB-S series 184.1 mm

WB-M series 292.1 mm

WB-L series 292.1 mm

When printing a barcode, check that the barcode can be read in actual

operation, including the quiet zone.

59

Print Position and Cut Position

Paper width

15.0 mm or more

(When not auto cutting,

8.0 mm or more)

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

Paper width

center

Paper

Continuous Paper and Roll Paper

When Borderless Printing Enabled

Margins at top, bottom, right, and left: 0 mm (typical value)

Q Note

The maximum value of the print area width is 104 mm.

60

When Borderless Printing Disabled

Paper width

1.5 mm

12.0 mm or more *1

15.0 mm or more *2

1.5 mm

1.5 mm

1.5 mm

Auto cut position

Auto cut position

Paper feed

direction

Print areaPrint area width

Paper width

center

Paper

*1: When not auto cutting,

5.0 mm or more

*2: When not auto cutting,

8.0 mm or more

Margins at top, bottom, right, and left: 1.5 mm (typical value)

61

Continuous Paper (Black Marks) and Roll Paper

Paper width

15.0 mm or more

(When not auto cutting, 8.0 mm

or more)

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

Paper width

center

Paper

Black mark position

(back side)

When Borderless Printing Enabled

Margins at top, bottom, right, and left: 0 mm (typical value)

Q Note

The maximum value of the print area width is 104 mm.

62

When Borderless Printing Disabled

Paper width

1.5 mm

12.0 mm or more*1

15.0 mm or more*2

1.5 mm

1.5 mm

1.5 mm

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

Paper width

center

Paper

Black mark position

(back side)

*1: When not auto cutting,

5.0 mm or more

*2: When not auto cutting,

8.0 mm or more

Margins at top, bottom, right, and left: 1.5 mm (typical value)

63

Continuous Paper (Black Marks) and Fanfold Paper

Paper width

0.5 to 1.0 mm

Issuing interval (Ph)

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

Perforated line interval (Pm)

Perforated line

Auto cut position

Perforated line

Paper width

center

Black mark position

(back side)

15.0 mm or more

(When not auto cutting, 8.0

mm or more)

When Borderless Printing Enabled

Margins at top, bottom, right, and left: 0 mm (typical value)

c IMPORTANT

Q Note

Set the perforated line interval so that it becomes an integral multiple of the

issuing interval.

The maximum value of the print area width is 104 mm.

64

When Borderless Printing Disabled

Paper width

0.5 to 1.0 mm

12.0 mm or more*1

Issuing interval (Ph)

1.5 mm

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

1.5 mm

1.5 mm

1.5 mm

1.5 mm

Perforated line interval (Pm)

Perforated line

Auto cut position

Perforated line

Paper width

center

1.5 mm

Paper

Black mark position

(back side)

*1: When not auto cutting, 5.0 mm or more

*2: When not auto cutting, 8.0 mm or more

15.0 mm or more*2

Margins at top, bottom, right, and left: 1.5 mm (typical value)

c IMPORTANT

Adjust the issuing interval (Pm) and perforated line interval so that the

relationship becomes as shown below.

Pm = Ph x integral multiple

65

Full-page Label and Roll Paper

Backing paper width

15.0 mm or more

(When not auto cutting, 8.0 mm

or more)

Auto cut position

Paper feed

direction

Print area

Print area width

2.0 mm

2.0 mm

Label

Paper width center

Backing paper

Waste part

Waste part

Paper width center

When Borderless Printing Enabled

Margins at top, bottom, right, and left (inside label): 0 mm (typical value)

Q Note

The maximum value of the print area width is 104 mm.

66

When Borderless Printing Disabled

Backing paper width

1.5 mm

12.0 mm or more*1

15.0 mm or more*2

1.5 mm

1.5 mm

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

1.5 mm

Label

Paper width

center

Backing paper

Waste part

2.0 mm

Waste part

2.0 mm

*1: When not auto cutting,

5.0 mm or more

*2: When not auto cutting,

8.0 mm or more

Margins at top, bottom, right, and left (inside label): 1.5 mm (typical value)

67

Die-cut Label (Gaps) and Roll Paper

Backing paper width

0.5 to 1.0 mm

15.0 mm or more*1

1.5 mm

Waste part

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

2.0 mm

2.0 mm

Waste part

Label

1.5 mm

3.0 mm

Paper width

center

Backing paper

18.0 mm or more*2

Perforation position

*1: When not auto cutting,

8.0 mm or more

*2: When not auto cutting,

11.0 mm or more

When Borderless Printing Enabled

Margins at top, bottom, right, and left (inside label): 0 mm (typical value)

Q Note

The maximum value of the print area width is 104 mm.

68

When Borderless Printing Disabled

Backing paper width

0.5 to 1.0 mm

12.0 mm or more*1

15.0 mm or more*2

1.5 mm

1.5 mm

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

2.0 mm

2.0 mm

1.5 mm

Label

1.5 mm

1.5 mm

3.0 mm

Paper width

center

Backing paper

18.0 mm or more*3

Perforation position

Waste part Waste part

Between

labels

1.5 mm

*1: When not auto cutting,

5.0 mm or more

*2: When not auto cutting,

8.0 mm or more

*3: When not auto cutting,

11.0 mm or more

Margins at top, bottom, right, and left (inside label): 1.5 mm (typical value)

69

Die-cut Labels (Black Marks) and Roll Paper

Backing paper width

0.5 to 1.0 mm

15.0 mm or more*1

18.0 mm or more*2

1.5 mm

Auto cut position

Paper feed

direction

Print area

Print area width

Label

1.5 mm

Paper width

center

Waste part

2.0 mm

1.5 mm

Auto cut position

Backing paper

Waste part 2.0 mm

Auto cut position

Perforation position

Black mark position

(back side)

*1: When not auto cutting,

8.0 mm or more

*2: When not auto cutting,

11.0 mm or more

When Borderless Printing Enabled

Margins at top, bottom, right, and left (inside label): 0 mm (typical value)

Q Note

The maximum value of the print area width is 104 mm.

70

When Borderless Printing Disabled

Backing paper width

0.5 to 1.0 mm

15.0 mm or more*2

18.0 mm or more*3

1.5 mm

Auto cut position

Paper feed

direction

Print area

Print area width

1.5 mm

Label

1.5 mm

1.5 mm

Paper width

center

Waste part 2.0 mm

1.5 mm

Auto cut position

Backing paper

1.5 mm

Waste part 2.0 mm

12.0 mm or more*1

Auto cut position

Perforation position

Black mark position

(back side)

1.5 mm

*1: When not auto cutting,

5.0 mm or more

*2: When not auto cutting,

8.0 mm or more

*3: When not auto cutting,

11.0 mm or more

Margins at top, bottom, right, and left (inside label): 1.5 mm (typical value)

71

Die-cut Labels (Black Marks) and Fanfold Paper

Backing paper width

15.0 mm or more*1

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

Label

1.5 to 3.0 mm

0.5 to 1.0 mm

1.5 to 3.0 mm

Perforated line interval (Pm)

Perforated line

Auto cut position

Perforated line

Paper width

center

1.5 to 3.0 mm

Backing paper

Waste part 2.0 mm

Waste part 2.0 mm

18.0 mm or more*2

Issuing interval (Ph)

Black mark position

(back side)

*1: When not auto cutting, 8.0 mm or more

*2: When not auto cutting, 11.0 mm or more

When Borderless Printing Enabled

Margins at top, bottom, right, and left (inside label): 0 mm (typical value)

c IMPORTANT

• Set the perforated line interval so that it becomes an integral multiple of

the issuing interval.

• To prevent unstable printing due to the perforated line and print area

overlapping or shortening of the cutter life due to the perforated line and

auto cut line positions overlapping, use paper with black marks on the

back to align the paper position.

Q Note

The maximum value of the print area width is 104 mm.

72

When Borderless Printing Disabled

1.5 mm

15.0 mm or more*2

1.5 mm

Auto cut position

Auto cut position

Paper feed

direction

Print area

Print area width

Label

1.5 to 3.0 mm

0.5 to 1.0 mm

1.5 to 3.0 mm

Perforated line interval (Pm)

Perforated line

Auto cut position

Perforated line

Paper width

center

1.5 to 3.0 mm

Backing paper

1.5 mm

Waste part 2.0 mm

1.5 mm

Waste part 2.0 mm

12.0 mm or more*1

18.0 mm or more*3

Issuing interval (Ph)

Black mark position

(back side)

Backing paper width

*1: When not auto cutting, 5.0 mm or more

*2: When not auto cutting, 8.0 mm or more

*3: When not auto cutting, 11.0 mm or more

Margins at top, bottom, right, and left (inside label): 1.5 mm (typical value)

c IMPORTANT

• Set the perforated line interval so that it becomes an integral multiple of

the issuing interval.

• To prevent unstable printing due to the perforated line and print area

overlapping or shortening of the cutter life due to the perforated line and

auto cut line positions overlapping, use paper with black marks on the

back to align the paper position.

73

Wristband and Roll Paper (WB-S Series)

Paper width

Auto cut position

Paper feed

direction

Printable area

Paper

Auto cut position

Paper width center

5.5 mm

184.2 mm

11.0 mm

14.6 mm

81.5 mm

157.2 mm

105.9 mm

Recommended print

area for text or barcode

72.5 mm

15.0 mm

12.4 mm

30.2 mm

70.4 mm

7.9 mm

Black mark position

(back side)

36 mm

When Borderless Printing Enabled

Margins at top, bottom, right, and left: 0 mm (typical value)

c IMPORTANT

• Do not print over holes for attaching snaps and within a distance of 2 mm

from the holes.

• When using the WB-S/M/L series, use an attachment (OT-WA34).

74

When Borderless Printing Disabled

Paper width

1.5 mm

Auto cut position

Paper feed

direction

Paper

1.5 mm

1.5 mm

Printable area

Paper width center

5.5 mm

184.2 mm

11.0 mm

14.6 mm

81.5 mm

157.2 mm

105.9 mm

Recommended print area

for text or barcode

72.5 mm

15.0 mm

12.4 mm

1.5 mm

30.2 mm

70.4 mm

7.9 mm

Black mark position

(back side)

Black mark position

(back side)

Auto cut position

36 mm

Margins at top, bottom, right, and left: 1.5 mm (typical value)

c IMPORTANT

• Do not print over holes for attaching snaps and within a distance of 2 mm

from the holes.

• When using the WB-S/M/L series, use an attachment (OT-WA34).

75

Wristband and Roll Paper (WB-M Series)

Paper width

Auto cut position

Paper feed

direction

Printable area

Paper

Paper width center

5.5 mm

11.0 mm

Recommended print area

for text or barcode

30.6 mm

292.1 mm

156.5 mm105.0 mm

15.0 mm

265.0 mm

14.6 mm

12.5 mm

138.9 mm

142.4 mm

Auto cut position

10.8 mm

36 mm

Black mark position

(back side)

When Borderless Printing Enabled

Margins at top, bottom, right, and left: 0 mm (typical value)

76

c IMPORTANT

• Do not print over holes for attaching snaps and within a distance of 2 mm

from the holes.

• When using the WB-S/M/L series, use an attachment (OT-WA34).

77

When Borderless Printing Disabled

Paper width

1.5 mm

Auto cut position

Paper feed

direction

Printable area

1.5 mm

Paper

Paper width center

5.5 mm

11.0 mm

1.5 mm

Recommended print area

for text or barcode

1.5 mm

30.6 mm

292.1 mm

156.5 mm105.0 mm

15.0 mm

265.0 mm

14.6 mm

12.5 mm

138.9 mm

142.4 mm

Auto cut position

10.8 mm

36 mm

Black mark position

(back side)

Margins at top, bottom, right, and left: 1.5 mm (typical value)

c IMPORTANT

• Do not print over holes for attaching snaps and within a distance of 2 mm

from the holes.

• When using the WB-S/M/L series, use an attachment (OT-WA34).

78

Wristband and Roll Paper (WB-L Series)

Paper width

Auto cut position

Paper feed

direction

Printable area

Paper

Auto cut position

Paper width center

5.5 mm

183.0 mm

15.0 mm

71.0 mm

265.0 mm

158.4 mm

122.9 mm

Recommended print area

for text or barcode

38.1 mm

292.1 mm

28.0 mm

24.0 mm

14.6 mm

12.5 mm

10.8 mm

36 mm

Black mark position (back side)

When Borderless Printing Enabled

Margins at top, bottom, right, and left: 0 mm (typical value)

79

c IMPORTANT

• Do not print over holes for attaching snaps and within a distance of 2 mm

from the holes.

• When using the WB-S/M/L series, use an attachment (OT-WA34).

80

When Borderless Printing Disabled

Paper width

1.5 mm

Auto cut position

Paper feed

direction

Printable area

2.0 mm

Paper

Auto cut position

Paper width center

5.5 mm

183.0 mm

15.0 mm

1.5 mm

71.0 mm

265.0 mm

158.4 mm

122.9 mm

Recommended print area

for text or barcode

38.1 mm

292.1 mm

28.0 mm

24.0 mm

14.6 mm

12.5 mm

1.5 mm

10.8 mm

36 mm

Black mark position

(back side)

Margins at top, bottom, right, and left: 1.5 mm (typical value)

81

c IMPORTANT

• Do not print over holes for attaching snaps and within a distance of 2 mm

from the holes.

• When using the WB-S/M/L series, use an attachment (OT-WA34).

82

Paper Handling to Prevent Unprinted Labels

Auto cut position

Paper leading edge position

Leading edge of roll

paper cover

Paper leading edge position area

If using die-cut or continuous paper (black marks), the first label of paper may not be printed when fed

or printable label may still remain when paper out is detected. This section explains paper handling

and setting to prevent such types of paper from causing these problems.

Printing from the First Label at Paper Loading

As this printer can detect the leading edge of a page, fixed-quantity feeding is performed after

the paper is loaded. As a result, it may not be possible to print the first sheet of labels. This

section describes the paper loading methods and paper handling in order to prevent this

problem and print from the first labels.

Loading Paper

When loading paper, check that the leading edge of roll paper is between the auto cut position

and leading edge of the discharge table, and then close the roll paper cover.

83

Roll Paper

Black mark width leading edge

172.5 to 200 mm

Paper feed direction

Black mark width leading edge

172.5 to 200 mm

Paper feed direction

Compatible paper formats are as follows.

• Continuous paper (black marks)

• Die-cut labels (black marks)

• Die-cut labels (gaps)

• Die-cut labels with transparent backing paper

Paper Handling Method

• Continuous paper (black marks)

Set the leading edge of the first black mark so that it is located at 172.5 to 200 mm from the

leading edge of the paper.

Do not set the black mark so that it is located at less than 172.5 mm from the leading edge of the

paper.

• Die-cut labels (black marks and gaps) and die-cut labels (gaps) with transparent backing paper

Set the leading edge of the first label so that it is located at 172.5 to 200 mm from the leading

edge of the paper.

Do not set the label or black mark so that it is located at less than 172.5 mm from the leading

edge of the paper. This area must only consist of backing paper.

84

Fanfold Paper

Black mark width leading edge

25 mm or more

Paper feed direction

Black mark width leading edge

25 mm or more

Paper feed direction

Compatible paper formats are as follows.

• Continuous paper (black marks)

• Die-cut labels (black marks)

Paper Handling Method

• Continuous paper (black marks)

Set the leading edge of the first black mark so that it is located at 25 mm or more away from the

leading edge of the paper.

Do not set the black mark so that it is located at less than 25 mm from the leading edge of the

paper.

• Die-cut labels (black marks)

Set the leading edge of the first label so that it is located at 25 mm or more from the leading

edge of the paper.

Do not set the label or black mark so that it is located at less than 25 mm from the leading edge

of the paper. This area must only consist of backing paper.

85

Printing the Final Label

Printable label may still remain when paper out is detected. This section describes the printer

driver and this printer’s settings, and paper handling in order to print on the last label of loaded

paper.

Check Printer Driver Settings

Check that No Auto Cut (Feed to Peel Off Position) is not selected for the printer driver.

Check the printer driver settings by following the procedures below.

Display the printer driver.

1

Select the General tab and select Media Definition.

2

Select the media definition you want to use and then click Edit.

3

Check that No Auto Cut (Feed to Peel Off Position) is not selected in

4

Settings for Paper Handling After Print.

Printer Settings

Use PrinterSetting to enable notification settings at a Media Size Error Settings. Specify the

printer settings by following the procedures below.

Display the printer driver.

1

Select the Printer Utilities tab and then click Printer Settings.

2

The TM-C3500 PrinterSetting screen appears.

Select Advanced Settings - Notification Settings.

3

The Notification Settings screen appears.

From the Notification Settings at a Media Size Error Settings pull-down

4

menu, select Error Notification.

Click Apply Settings.

5

Enabling of this setting is now complete.

86

Roll Paper Handling

Max. 11 mm

5 ±0.5 mm

Max. 11 mm

5 ±0.5 mm

107.5 mm or more

107.5 mm or more

Roll paper core

Roll paper core

End edge of last label

End edge of last label

Paper feed direction

Paper feed direction

Continuous paper (black marks)

Die-cut labels (black marks)

Paper formats that can be handled are as follows.

• Continuous paper (black marks)

• Die-cut labels (black marks)

• Die-cut labels (gaps)

• Die-cut labels with transparent backing paper

Paper Handling Procedures

• Continuous paper (black marks) and die-cut labels (black marks)

Set a margin of 107.5 mm or more between the end edge of the paper and the end edge of the

final ticket or label printed. Do not set the label so that it is located less than 107.5 mm from the

end edge of the paper. This area must only consist of backing paper. Affix two black marks

behind the final ticket or label printed.

If new print data is sent to this printer after print processing (including auto

Q NOTE

cut) of the final ticket or label has completed normally, a Media Size Error

will occur, and the printer will stop with the print data retained.

87

• Die-cut labels (gaps) and die-cut label with transparent backing paper

Paper feed