Page 1

TM-C100

Technical Reference

Guide

EPSON

English

410000602

Page 2

Page 3

TM-C100 Technical Reference Guide

CAUTIONS

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

❏ The contents of this document are subject to change without notice. Please contact Seiko Epson for the latest

information.

❏ While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.)

failure to strictly comply with Seiko Epson Corporation's operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original EPSON Products or EPSON Approved

Products by Seiko Epson Corporation.

TRADEMARKS

EPSON® is a registered trademarks of Seiko Epson Corporation.

Microsoft

Other product and company names used herein are for identification purposes only and may be trademarks of their

respective companies.

®

Windows® and Windows NT® are registered trademarks of Microsoft Corporation.

Revision Information

Rev. Page Changes

Rev. A All pages Newly authorized

Rev. B All pages Single color ink cartridge added

Rev. C iv Note on restriction of use added

Rev. C i

Page 4

Important Safety Information

Key to Symbols

The following symbols are used in this document. Please check the meaning of the symbols

before using the printer.

WARNING:

Warnings must be followed carefully to avoid serious bodily injury or death.

CAUTION:

Cautions must be observed to avoid the following kinds of damage.

• Physical injury

• Damage to property

• Loss of data and the like

Note:

Notes provide useful information about maintaining the performance of your printer and its operation.

ii Rev. C

Page 5

Warnings

❏

Turn off the printer and unplug it immediately if it produces smoke, a strange odor, or

unusual noise. Continued use may lead to fire or electric shock.

❏

Do not disassemble or modify the printer. Doing so may result in injury, fire, or electric

shock.

❏

To avoid the danger of electric shock, do not set up the printer or attach cables to it

when there is lightning.

❏

Always use the specified power source. Using a different power source may result in

fire or electric shock.

❏

Do not connect or disconnect the power plug with wet hands. Doing so may result in

electric shock.

❏

Do not allow foreign objects to get into the printer. Doing so may result in fire or

electric shock.

TM-C100 Technical Reference Guide

WARNING:

❏

If water or other liquid is spilled inside the printer, turn off the POWER switch

immediately and disconnect the power cable. Continuing to use the printer may

result in fire or electric shock.

❏

Do not plug in several power cables to the same power outlet. Doing so may result in

fire. Take the power directly from a standard domestic power outlet.

❏

Handle the power cable with care. Using it improperly may result in fire or electric

shock.

• Do not modify the power cable.

• Do not place heavy objects on the power cable.

• Avoid excessive bending, twisting, and pulling.

• Do not place the power cable near heating equipment.

• Check that the power plug is clean before plugging it in.

• Push the prongs of the power plug all the way in.

Rev. C iii

Page 6

Cautions

CAUTION:

❏

Do not attach any equipment not shown in this guide. Doing so may result in failure,

fire, and the like.

❏

Do not place the printer on an unstable or tilted surface. Doing so may cause it to

fall, resulting in injury.

❏

Do not place the printer in a humid or dusty location. Doing so may result in failure,

fire or electric shock.

❏

Do not stand on the printer or place heavy objects on it. Doing so may break the

printer or cause you to fall, leading to injury.

❏

To ensure safety, always unplug the printer from the outlet when you will not be using

it for a long time.

❏

Do not use aerosol sprayers containing flammable gas inside or around this product.

Doing so may cause fire.

Restriction of Use

When this product is used for applications requiring high reliability/safety such as

transportation devices related to aviation, rail, marine, automotive etc.; disaster prevention

devices; various safety device etc; or functional/ precision device etc., you should use this

product only after giving consideration to inclusion of fail-safes and redundancies into your

design to maintain safety and total system reliability.

Modular connectors

The printer uses dedicated modular connectors for connecting the options. Do not connect these

connectors to general public lines. Some connectors look the same as telephone connectors. Be

sure not to connect a telephone line to them.

iv Rev. C

Page 7

TM-C100 Technical Reference Guide

About This Manual

Aim of the Manual

The purpose of this manual is to provide all necessary information to development engineers

who are developing, designing or installing commercial systems using the TM-C100 printer, or

who are developing or designing applications for the printer.

Contents of the Manual

Chapter 1 "Product Outline" An outline of the features and specifications

Chapter 2 "Setup" Information on such matters as DIP switches,

memory switches, error processing for using TMC100

Chapter 3 "Using the Printer" Information required for using the printer

Chapter 4 "Application Development

Information"

Appendix A "Product Specifications of

the TM-C100"

Appendix B "System Design" Introduction of control methods and

Information required for programming

Detailed specifications of the TM-C100

connection types

Rev. C v

Page 8

Related Software and Documents

Related Software and Documents

Software/document name Description

TM-C100 User's Manual This provides information allowing the operator to use the TM-

TM-C100 Technical Reference Guide This manual.*

EPSON OPOS-X ADK This is the OCX driver.

EPSON OPOS-X ADK Manual This provides information required for programming using

Epson Advanced Printer Driver This is a Windows driver.*

Epson Advanced Printer Driver Manual This provides information required for programming using the

* You can obtain these items from one of the following URLs:

For customers from North America: http://pos.epson.com/

For customers from other countries: http://www.epson-pos.com/

Select the product from the “Select any product” pull-down menu.

C100 safely and correctly. This manual is packed in the box with

the printer.*

OPOS-X. This is included in the EPSON OPOS-X ADK.*

APD (Epson Advanced Printer Driver). This is included in the

EPSON Advanced Printer Driver.*

vi Rev. C

Page 9

TM-C100 Technical Reference Guide

TM-C100 Technical Reference Guide

Chapter 1 Product Outline

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Product Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2.1 Printer types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2.2 Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.3 TM-C100 related products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 Ink cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Roll paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.3 Standard size paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2 Setup

2.1 Part Names and Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Part names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.1 Installing options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.1.1 Installing the ASF (auto sheet feeder) unit . . . . . . . . . . . . . . . . . . 2-6

2.3.1.2 Installing the roll paper holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2 Connecting the power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2.1 Connection procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.3 Installing the ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.4 Connecting the printer to the host PC / POS terminal . . . . . . . . . . . . . 2-11

2.4 Installing a Printer Driver in the Host PC / POS Terminal . . . . . . . . . . . . . . . 2-12

2.4.1 Advanced Printer Driver (APD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1.1 Install and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.2 OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.2.1 Installation and setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.2.2 Contents of the EPSON OPOS-X ADK package . . . . . . . . . . . . . . 2-15

Chapter 3 Using the Printer

3.1 How to Set, Replace, and Print on the Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 With the auto sheet feeder (ASF) specification . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1.1 How to set and replace the paper . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1.2 Printing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 With the roll paper specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2.1 How to install and replace paper . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2.2 Printing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.3 Feeding and printing paper by hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2 Replacing the Ink Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1 Ink head cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1.1 Using the switch on the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1.2 Using the maintenance utility of the driver. . . . . . . . . . . . . . . . . . 3-7

3.3.2 Cautions when transporting the printer . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4.1 Flashing LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4.2 The paper being printed does not come out . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.4.3 A paper jam occurred . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.4.4 Paper is not supplied from the ASF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.4.5 Hand fed printing is not possible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.4.6 Eliminating excessive bottom margins (roll paper specification) . . . . . 3-10

Rev. C vii

Page 10

3.4.7 The paper is not cut (roll paper specification) . . . . . . . . . . . . . . . . . . . . . 3-10

3.5 FAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.5.1 Printing on long paper (roll paper specification) . . . . . . . . . . . . . . . . . . . 3-11

3.5.2 Cutting the paper at a fixed length (roll paper specification) . . . . . . . . . 3-11

3.5.3 Making fine color adjustments such as color matching . . . . . . . . . . . . . 3-11

3.6 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.1 Self Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.1.1 With the ASF specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.1.2 With the roll paper specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.6.1.3 Feeding paper by hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Chapter 4 Application Development Information

4.1 Bar Code Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Using the Windows Advanced Printer Driver . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Using OPOS-X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Precautions When Using OPOS-X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Distinguishing between the ASF and roll paper specifications . . . . . . . 4-2

4.2.2 Selecting the feed type (ASF specification) . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 Paper size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.4 Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Appendix A Product Specifications of the TM-C100

A.1 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.3 Roll Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.3.1 Print area and cutter position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.3.1.1 Plain paper/special paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.3.1.2 Plain borderless label paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.4 ASF Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A.4.1 Print area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

A.4.1.1 For standard printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

A.5 Hand Fed Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

A.5.1 Print area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.5.1.1 For standard printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.6 Case Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.6.1 External Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.6.2 Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.6.3 Outline drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

A.6.3.1 Roll paper specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

A.6.3.2 ASF specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Appendix B System Design

B.1 Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.1.1 Windows Driver (Epson Advanced Printer Driver) . . . . . . . . . . . . . . . . B-1

B.1.1.1 Epson Advanced Printer Driver Outline . . . . . . . . . . . . . . . . . . . . B-1

B.1.1.2 Epson Advanced Printer Driver components . . . . . . . . . . . . . . . . B-1

B.1.1.3 Epson Advanced Printer Driver support environment . . . . . . . . B-2

B.1.2 EPSON OPOS ADK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.1.2.1 EPSON OPOS ADK Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.2.2 EPSON OPOS ADK components . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.2.3 EPSON OPOS ADK support environment . . . . . . . . . . . . . . . . . . B-4

B.1.3 How to Obtain the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

viii Rev. C

Page 11

TM-C100 Technical Reference Guide

Chapter 1

Product Outline

1.1 Features

The TM-C100 is a compact inkjet printer, newly designed for commercial applications. Besides

printing product photographs and POP items, the printer has the following features.

❏ Since it is small and light-weight, it can be used effectively on limited counter space.

❏ Thanks to its high reliability and durable design, it can be used every day for commercial

applications.

❏ Since an autocutter is provided as standard, the printer can be used efficiently for ticketing

applications using the roll paper.

❏ You can print on a range of print media such as label sheets, business card size paper, and so

on.

❏ Besides a Windows driver, the printer is provided with a driver for control of POS

peripheral equipment compatible with the OPOS specification established by the

UnifiedPOS Committees.

❏ The printer uses pigment ink for excellent lightfastness and water resistance.

1.2 Product Specification

1.2.1 Printer types

TM-C100 has following two model types, depending on the paper feed methods.

❏ TM-C100 Roll paper specification

❏ TM-C100 ASF (auto sheet feeder) specification

Rev. C Product Outline 1-1

Page 12

1.2.2 Standard Accessories

The printer comes with the following accessories.

❏ User's Manual

❏ Exclusive ink cartridge

❏ Power unit

❏ Power cable (not included for some models)

❏ Roll paper: 1 roll (roll paper specification only)

Note:

Since the packaged ink cartridge is for trial use, it may not last as long as a normal cartridge.

The printer does not come with a USB cable. Please provide this yourself.

1.2.3 TM-C100 related products

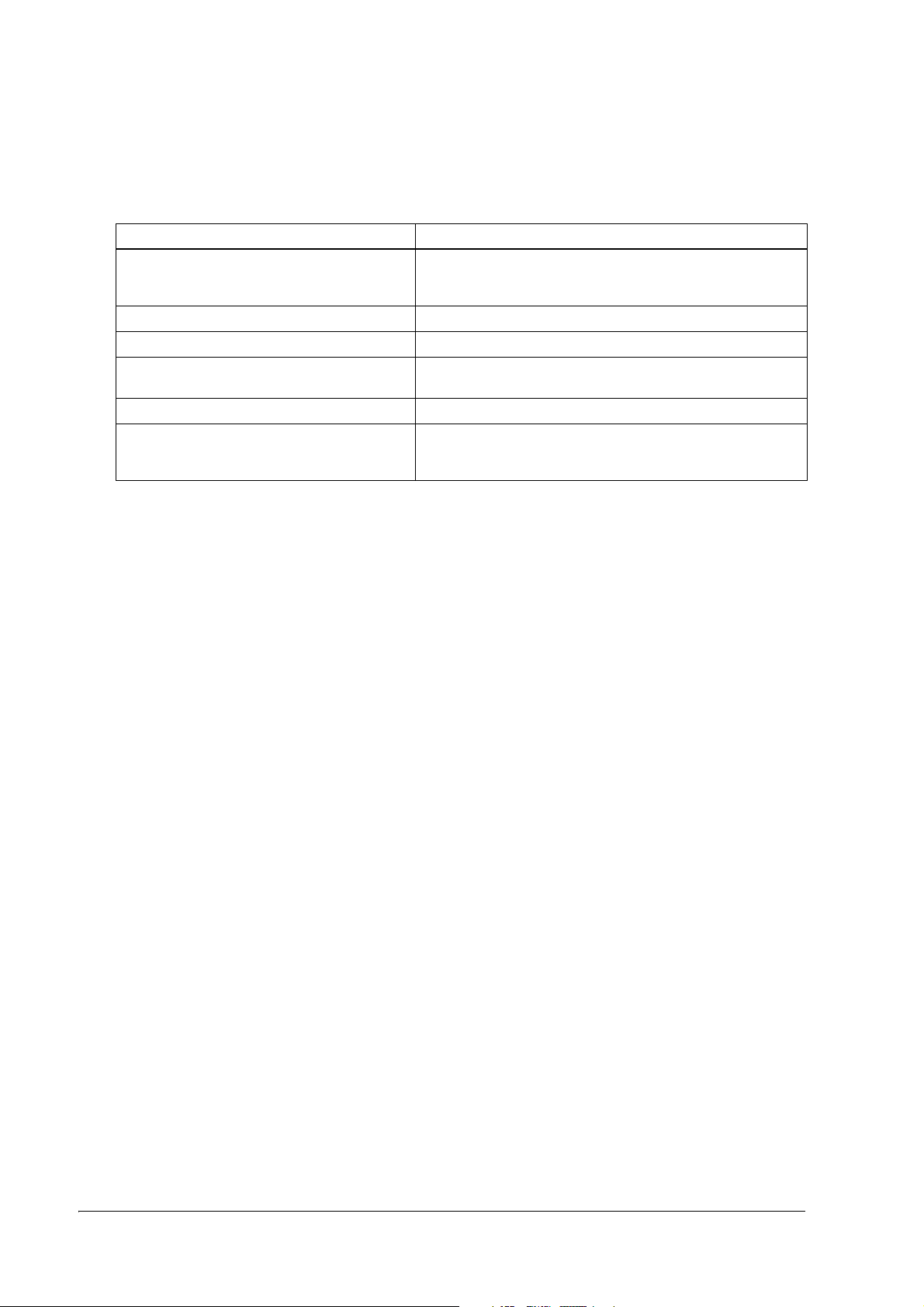

The table below shows the TM-C100 related products.

Category Name Description

Options ASF unit Similar to the unit packaged with the TM-C100 ASF

specification. By removing the roll paper holder unit from the

roll paper specification TM-C100, you can print using the ASF

unit by attaching this option.

Roll paper holder unit Similar to the unit packaged with the TM-C100 roll paper

specification. By removing the ASF unit from the ASF

specification TM-C100, you can print on roll paper by

attaching this option.

Consumables Exclusive TM-C100

ink cartridge

This is necessary for printing with the TM-C100.

(Note: The TM-C100 uses an exclusive ink cartridge. Note that

you cannot install other types of ink cartridge.)

Roll paper This is necessary for printing with the roll paper specification

TM-C100. See "Roll paper" on page 1-3.

Standard size paper This is necessary for printing with the ASF specification TM-

Manuals User's Manual This manual is packaged with the printer.

Technical Reference Guide This manual.

Drivers

(WIndows)

OPOS-X ADK An OCX driver compliant with the OPOS-X specification is

Advanced printer driver This is a Windows driver. This includes a manual on how to use

C100. See "Standard size paper" on page 1-4.

provided. A manual and sample programs are included.

the driver.

To obtain these items, please contact your dealer. For drivers and manuals, you can obtain from

one of the following URLs:

1-2 Product Outline Rev. C

Page 13

TM-C100 Technical Reference Guide

For customers from North America: http://pos.epson.com/

For customers from other countries: http://www.epson-pos.com/

Select the product from the “Select any product” pull-down menu.

1.3 Consumables

1.3.1 Ink cartridges

Ink cartridges are necessary for printing.

❏ Part number: four-color model: SJIC9P, single color model: SJIC10P(K)

Note:

The TM-C100 uses an exclusive ink cartridge. You cannot install other type of ink cartridge.

We recommend that you use genuine Epson ink cartridges to ensure that your printer gives maximum

performance.

1.3.2 Roll paper

The following types of roll paper are available for use with the TM-C100 (roll paper

specification). These can be purchased from your dealer.

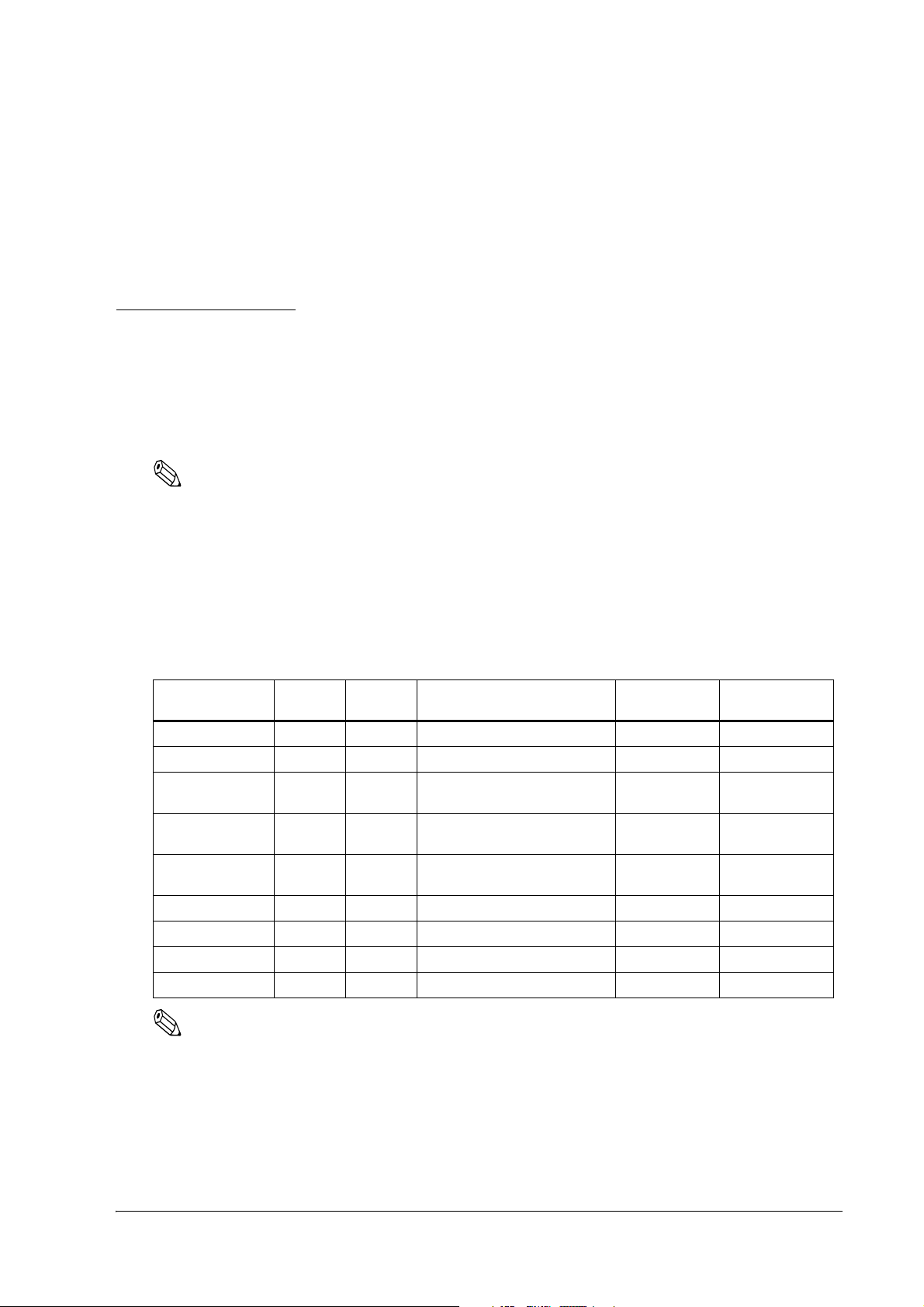

Paper

Part number

ENP105-090 105 mm 90 mm Plain paper -- 3 rolls

ENP076-090 76 mm 90 mm Plain paper -- 3 rolls

ENL105-090 105 mm 90 mm Plain label paper (borderless

ENL090-090 90 mm 90 mm Plain label paper (borderless

ENL076-090 76 mm 90 mm Plain label paper (borderless

EFP105-090 105 mm 90 mm Special fine paper -- 3 rolls

EFP076-090 76 mm 90 mm Special fine paper -- 3 rolls

EAP105-090 105 mm 90 mm Special matte paper -- 3 rolls

EAP076-090 76 mm 90 mm Special matte paper -- 3 rolls

Width

Note:

We recommend that you use genuine Epson paper to ensure that your printer gives maximum

performance.

Outside

diameter Paper type Label width

labels)

labels)

labels)

103 mm

(width)

88 mm (width) 3 rolls

76 mm (width) 3 rolls

Number of

sheets

3 rolls

Rev. C Product Outline 1-3

Page 14

1.3.3 Standard size paper

The following types of paper are available for use with the TM-C100 (ASF specification). These

can be purchased from your dealer.

Number of

Part number Paper size Paper type

ENS105-148 A6 Plain paper 500 sheets

EFS105-148 A6 Special fine paper 250 sheets

Note:

We recommend that you use genuine Epson paper to ensure that your printer gives maximum

performance.

sheets

1-4 Product Outline Rev. C

Page 15

Chapter 2

Setup

2.1 Part Names and Basic Operations

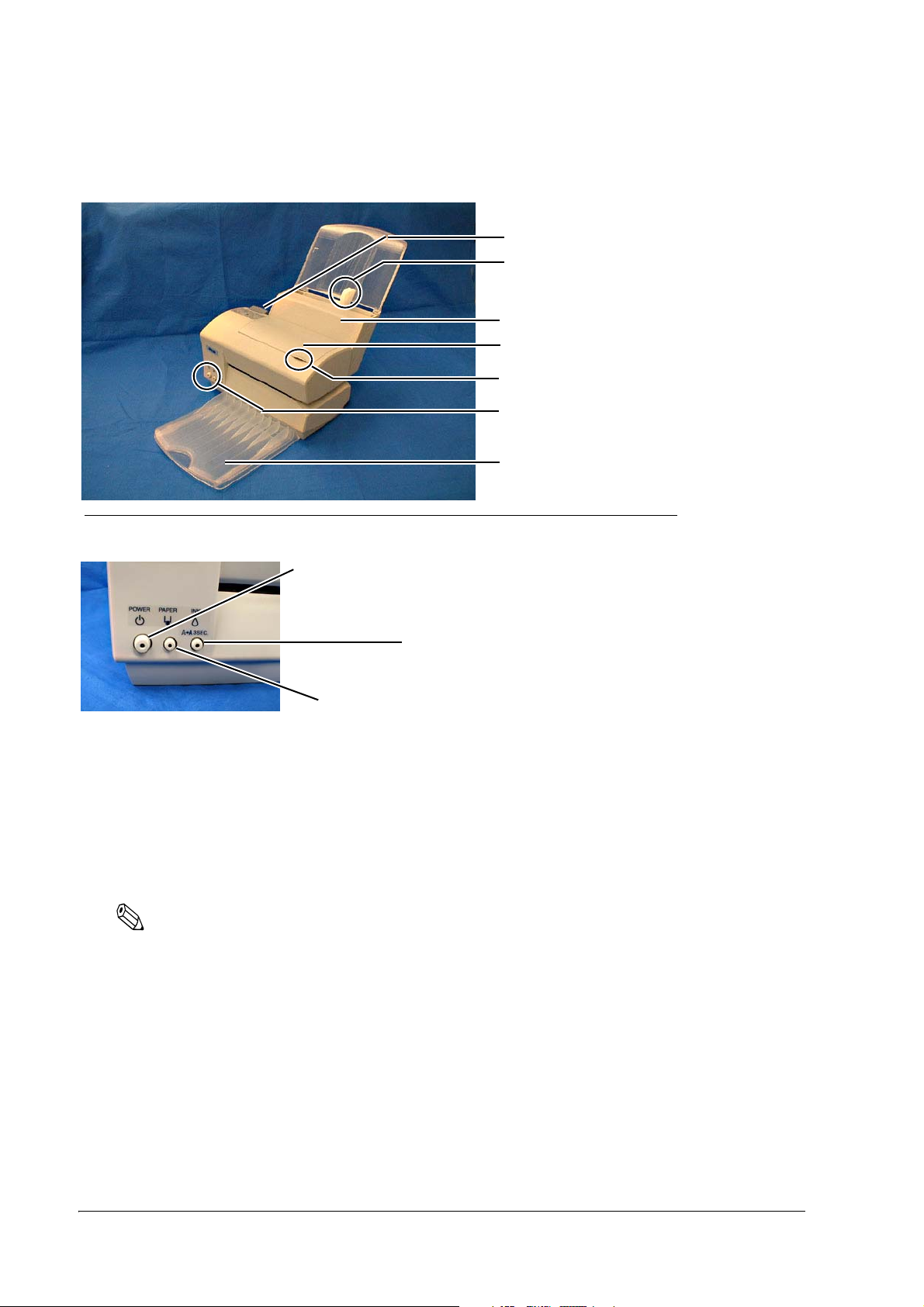

2.1.1 Part names

Roll paper specification

release lever

TM-C100 Technical Reference Guide

❏ Release lever

printer cover

tab

control panel

paper tray

roll paper holder

locking clip

roll paper

edge guide

Enlarged view of the

control panel

INK LED &

CLEANING switch

POWER LED &

POWER switch

PAPER LED &

PAPER switch

Pressing this lever switches between the paper clamp status (preparing to print) and paper

release status (ready for insertion of paper).

• Release lever raised: paper clamped status (ready to print)

• Release lever lowered: paper released status (not ready to print)

Note:

See "Control panel" on page 2-3 for how to use the control panel.

For details of how to use the products, see "How to Set, Replace, and Print on the Paper" on page 3-1.

Rev. C Setup 2-1

Page 16

ASF (auto sheet feeder) specification

Enlarged view of the control panel

POWER LED &

POWER switch

release lever

edge guide

auto sheet feeder (ASF)

printer cover

tab

control panel

paper tray

INK LED &

CLEANING switch

PAPER LED &

PAPER switch

❏ Release lever

Pressing this lever switches between the paper clamped status (preparing to print) and

paper released status (ready for insertion of paper).

• Release lever raised: paper clamped status (ready to print)

• Release lever lowered: paper released status (not ready to print)

Note:

When supplying paper from the auto sheet feeder (ASF), it is not necessary to operate the release lever. It

is only used when feeding paper by hand.

See "Control panel" on page 2-3 for how to use the control panel.

For details of how to use the products, see "How to Set, Replace, and Print on the Paper" on page 3-1.

2-2 Setup Rev. C

Page 17

2.1.2 Control panel

The following shows the functions of the control panel.

❏ POWER switch

This switches the power on and off. The POWER LED indicates whether the power is on or

off.

• POWER LED: Indicates whether the power is on or off.

On: The power is on. (power on)

Off: The power is off. (power off)

Flashing: The power is performing an operation.

(cleaning, power-on process, power-off process, voiding remaining print data and so

on.)

CAUTION:

When turning the printer off, always use the POWER switch. If the power is turned off

by unplugging the power cable instead of using the POWER switch and the printer

is left for 2 weeks or more, the ink head nozzles become blocked and no longer

work because the printer was unable to perform the power-off process.

TM-C100 Technical Reference Guide

Note:

When the POWER LED is flashing, do not open the printer cover or turn off the printer.

If the POWER LED and another LED are flashing at the same time, it indicates that an error has

occurred. For details, see "Troubleshooting" on page 3-8.

❏ PAPER switch

Pressing this feeds the paper. Normally it is not necessary to press it.

Note:

With the ASF (auto sheet feeder) specification printer, paper placed in the ASF cannot be fed.

• PAPER LED: Indicates the status of the printer.

On: The printer cover is open.

Off: Normal status.

Flashing: The power is performing paper control.

(waiting for insertion of paper, feeding, ejecting, or positioning the paper)

Note:

If the PAPER LED and another LED are flashing at the same time, it indicates that an error has

occurred. For details, see "Troubleshooting" on page 3-8.

Rev. C Setup 2-3

Page 18

❏ CLEANING switch

The printer performs head cleaning if the switch is pressed for 3 seconds or more. For

information about head cleaning, see "Ink head cleaning" on page 3-7.

Note:

Head cleaning consumes ink. Note that performing head cleaning more than necessary shortens the

product lifetime of the ink cartridge.

• INK LED: Indicates the status of ink remaining.

On: An ink cartridge is not installed, or it is out of ink. It is necessary to replace the ink

cartridge.

Off: Normal status. (An ink cartridge is installed, and it is has sufficient ink.)

Flashing: Indicates that the ink is low. Prepare to replace the ink cartridge.

Note:

If another LED is flashing at the same time, irrespective of the status of the INK LED, it indicates that

an error has occurred. For details, see "Troubleshooting" on page 3-8.

2-4 Setup Rev. C

Page 19

TM-C100 Technical Reference Guide

2.2 Setup Procedure

To get the best performance from your printer, it is necessary to make various settings before

you use it. Set up the printer as required.

The procedure for preparing the printer for use is as follows.

1. Printer setup

(See "Printer Setup" on page 2-6.)

❏ Install the options

• Roll paper unit, paper tray, roll paper

• ASF unit, paper tray, standard size paper

❏ Connect the printer to the power supply

❏ Install the ink cartridge

2. Driver settings

❏ Install the driver

❏ Set the port

❏ Set the options to use

❏ Set the paper (paper type, size, mode and so on)

❏ Set the autocutter action

3. Setup is complete

Rev. C Setup 2-5

Page 20

2.3 Printer Setup

2.3.1 Installing options

❏ When using the ASF (auto sheet feeder) specification printer, see "Installing the ASF (auto

sheet feeder) unit" on page 2-6.

❏ When using the roll paper specification printer, see "Installing the roll paper holder" on page

2-8.

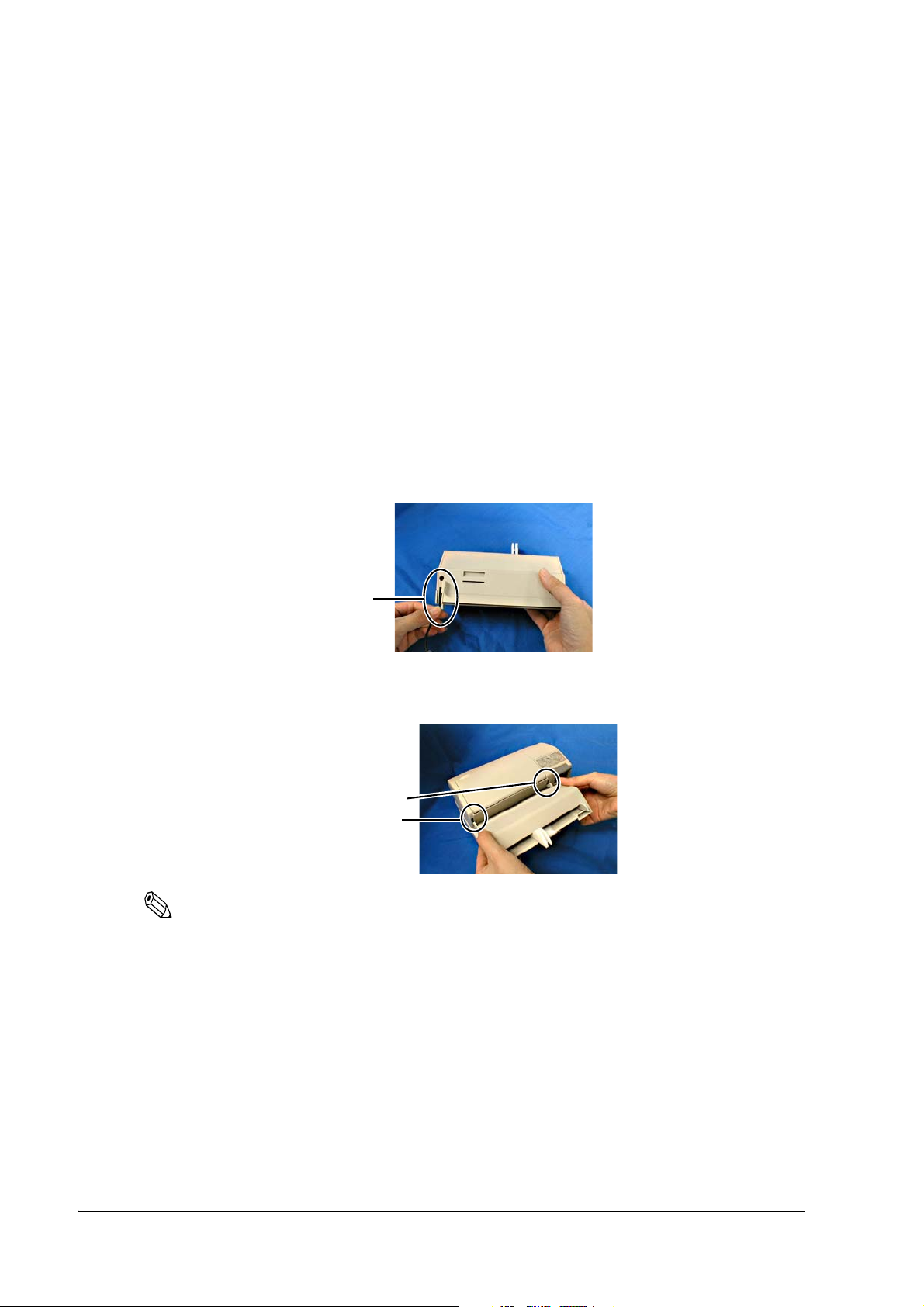

2.3.1.1 Installing the ASF (auto sheet feeder) unit

1. Check that the printer is not connected to the AC adapter. If the printer is on, turn it off and

remove the AC adapter.

2. Pass the cable of the auto sheet feeder through the groove in the auto sheet feeder.

groove

3. Insert the hooks of the auto sheet feeder into the slots in the top of the printer at the back.

insert the hook

in the slot

Note:

Take care not to catch the cable of the auto sheet feeder between the printer and the auto sheet feeder.

2-6 Setup Rev. C

Page 21

TM-C100 Technical Reference Guide

4. Push down the auto sheet feeder until the triangle marks on the printer and the auto sheet

feeder are aligned.

5. Insert the connector of the auto sheet feeder cable into the option socket at the bottom of the

back of the printer.

option socket

6. Attach the paper support.

paper support

7. Attach the paper tray to complete installation of the ASF unit.

Note:

If you use the printer without attaching the paper tray, the printed pages that are output may cause a

paper jam.

Rev. C Setup 2-7

Page 22

2.3.1.2 Installing the roll paper holder

1. Check that the printer is not connected to the AC adapter. If the printer is on, turn it off and

remove the AC adapter.

2. Insert the hooks of the roll paper holder into the slots at the back of the printer while placing

the printer on the base of the roll paper holder.

slot

hook

slot

hook

roll paper holder

3. Attach the paper tray. Insert the hooks of the paper tray into the 2 slots in the bottom of the

printer at the front. This completes installation of the roll paper unit.

Note:

If you use the printer without attaching the paper tray, the printed pages that are output may cause a

paper jam.

2.3.2 Connecting the power unit

WARNING:

Always use the Seiko Epson power unit provided.

Using an incorrect power supply may result in fire or electrical shock.

2.3.2.1 Connection procedure

1. With the POWER switch of the printer turned off, check that the cable of the power unit is

not connected to the electrical outlet.

2. Check the label on the power supply to make sure the voltage required by the power supply

matches that of the electrical outlet.

3. Connect the power unit to the electrical outlet.

2-8 Setup Rev. C

Page 23

TM-C100 Technical Reference Guide

4. Plug the power cable into the power connector.

power connector

Note:

To unplug the power connector, grip the part with the arrow mark and pull it straight out.

5. Turn on the printer. When the printer is turned on, it recognizes the ASF unit or roll paper

holder, enabling it for use.

Note:

In order to use the ASF unit or roll paper holder, it is necessary to set the driver accordingly. For

details, see the manual of the relevant driver.

2.3.3 Installing the ink cartridge

Note:

See the ink cartridge Instruction manual for precautions when using the ink cartridge.

See "Replacing the Ink Cartridge" on page 3-5 for how to replace the ink cartridge.

There is one ink cartridge for the single color model and a different one for the four-color model. If the

printer model does not match the ink cartridge type, the printer will not operate.

1. Check that the printer is turned on.

2. Open the printer cover, using the tab.

3. Remove the new ink cartridge from its box and open the transparent plastic bag.

Note:

Install the ink cartridge in the printer promptly after opening the plastic bag.

If an opened cartridge is left out of its plastic bag for an extended period of time, print quality may be

adversely affected.

4. Insert the ink cartridge into the top of the ink cartridge holder in the printer. Make sure the

ink cartridge is facing the right way.

Note:

Also see the label on the underside of the printer cover.

Rev. C Setup 2-9

Page 24

5. Push down the ink cartridge until it clicks firmly into place.

Note:

Do not use excessive force.

6. Close the printer cover (the INK LED goes off).

Note:

If the INK LED stays on, the ink cartridge is not installed properly. Check it again.

When the printer is used for the first time, it automatically performs the ink charging sequence for about 1

minute. During the ink charging sequence the POWER LED flashes. When the ink charging sequence is

finished, the POWER LED stops flashing, and the printer is ready for printing.

Do not turn off the printer or open the printer cover during the ink charging sequence (while the POWER

LED is flashing). If you do so, the printer must perform the ink charging sequence again from the start.

This will waste ink.

2-10 Setup Rev. C

Page 25

TM-C100 Technical Reference Guide

2.3.4 Connecting the printer to the host PC / POS terminal

Note:

To connect the printer to your computer you need a USB interface cable. The printer does not come with a

cable. Please provide this yourself.

1. If the printer is turned on, turn it off with the POWER switch.

2. Attach the provided cable hook to the back of the printer.

3. Hook the USB cable through the cable hook, as shown in the figure below.

cable hook

Note:

Hooking the USB cable through the cable hook, as shown in the figure above, will prevent the cable

from coming unplugged.

4. Connect the host computer and printer with the USB cable to complete the connection.

Rev. C Setup 2-11

Page 26

2.4 Installing a Printer Driver in the Host PC / POS Terminal

Epson provides 2 kinds of printer drivers for the TM-C100. The drivers are the Advanced Printer

Driver (APD) and OPOS-X for Windows

®

.

2.4.1 Advanced Printer Driver (APD)

The Epson Advanced Printer Driver (APD) is a Windows printer driver provided by Epson. For

details and information about obtaining the drivers, see "Windows Driver (Epson Advanced

Printer Driver)" on page B-1.

2.4.1.1 Install and Setup

The procedure required for using the APD is shown below. For detailed procedures, see the

"Epson Advanced Printer Driver Manual." You can obtain the manual with the driver. For

details, see "How to Obtain the Driver" on page B-4.

1. Installation

2. Setting the port

3. Setting the option to use

4. Test printing

2.4.2 OPOS

For details and information about obtaining the EPSON OPOS-X ADK, see "EPSON OPOS

ADK" on page B-2.

2.4.2.1 Installation and setup

See the installation manual for installation and setup. The installation manual is included in

Disk 1 of the OPOS-X ADK package.

2-12 Setup Rev. C

Page 27

The procedure for installation and setup is as follows.

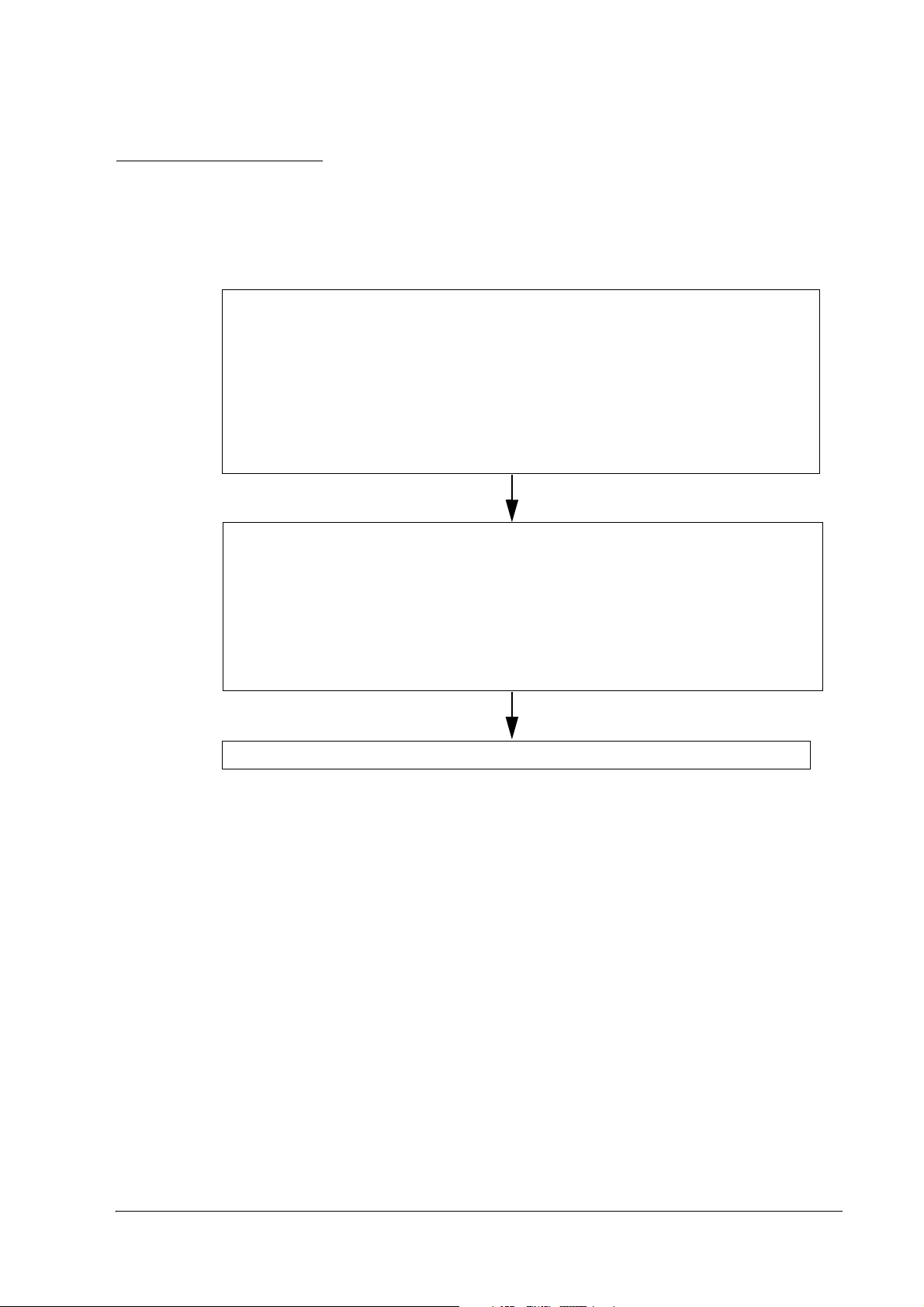

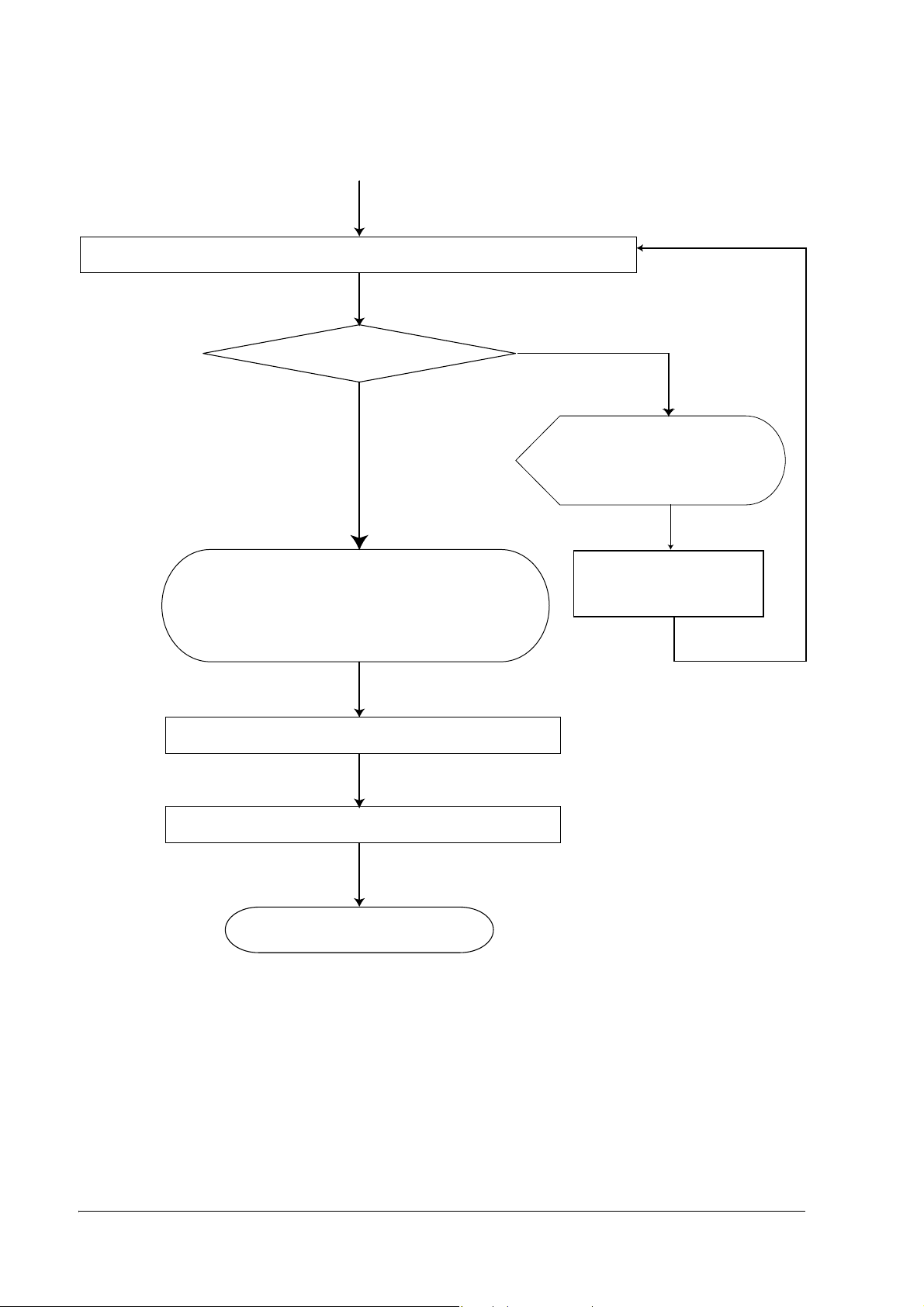

Start

1. Installing OPOS-X ADK

( Run Setup.exe on DISK1, then follow the steps in the wizard.)

TM-C100 Technical Reference Guide

Installation completed?

Completed

2. Using the SetupPOS-X utility to setup

OPOS-X and devices

You can use SetupPOS-X to setup OPOS-X and devices.

2.1 OPOS-X and device setup

❏ Select the device and I/F settings

❏ Device-specific settings

• Paper type and size setting

• Font setting and so on

Error

For details,

refer to the

[Installation

Manual].

Rev. C Setup 2-13

Page 28

2.2. Run CheckHealth and perform the device communication test.

Result code

Succeeded

OPOS-X and device setup normal.

&

Installation and setup completed.

3. Check with the sample program

Error

An error has been detected

with the CheckHealth method

call

Check the error status.

Refer to the [Application

Development Guide].

4. Create an OPOS-X compliant program

Finish

2-14 Setup Rev. C

Page 29

TM-C100 Technical Reference Guide

1. Installation

Run Setup.exe in Disk 1, and continue the installation with the wizard.

2. Perform the OPOS-X and device settings

1. Set the device setting by using SetupPOS-X utility.

• Select the device and I/F settings.

• Device-specific settings (perform settings specific to the device).

2. Run CheckHealth.

Device communication test

• If the result is "SUCCESS," the device is set correctly.

• If the result code is an error, re-check the device connection settings with reference to

the Application Development Guide.

After performing the above procedure, use an OPOS-X compliant program.

Note:

When creating your own program, see the sample program.

The OPOS-X ADK includes a sample program as reference for application development. The main device

functions and properties are introduced in the Visual Basic and Visual C++ programming languages.

2.4.2.2 Contents of the EPSON OPOS-X ADK package

❏ Installer

❏ SetupPOS-X utility

❏ OPOS Controls

❏ USB device driver (TMUSB)

• This must be installed in order to use OPOS-X with the printer. See the installation

manual for details.

❏ EPSON TM Maintenance Utility

• This is a utility with functions for adjusting the positions for head cleaning, positioning

and so on. Apart from the printer status monitoring function, it has functions equivalent

to the various utilities incorporated in the Advanced Printer Driver.

Rev. C Setup 2-15

Page 30

❏ Manuals

• Installer Manual: Explains installation and setup of the EPSON OPOS ADK

• Application Development Guide (ADG): Detailed information on development support

devices

General Development: General information on development.

General Functions: Common information to all the devices.

POS Printer: General information on the device class.

Operation Manual Sample

Programs:

Extension Function Reference

Manual:

EPSON TM Maintenance Utility

Operation Manual:

Information on the sample programs.

Information on Epson's proprietary extended functions.

Information on the bundled Epson Maintenance Utility.

❏ Sample program

VB/VC sample program for (for each device class)

2-16 Setup Rev. C

Page 31

TM-C100 Technical Reference Guide

Chapter 3

Using the Printer

This chapter describes typical usage of the printer and troubleshooting.

3.1 How to Set, Replace, and Print on the Paper

3.1.1 With the auto sheet feeder (ASF) specification

3.1.1.1 How to set and replace the paper

Note:

Use paper that is flat, without curls, folds or wrinkles.

Do not print envelopes with a closure in the middle of the back.

During positioning performed by the printer before printing, the paper is moved toward the back of the

printer. If there is any obstruction behind the printer, it may impede normal positioning. Ensure that there

is sufficient space behind the printer.

1. Check that the printer is turned on. If it is turned off, turn it on.

2. Separate the sheets of paper, and line up the edges. Ensure that the paper lies flat.

3. With the print surface facing up, place the paper vertically in the auto sheet feeder aligned

against the left side.

4. Move the edge guide left or right to align the it with the edge of the paper.

edge guide

Rev. C Using the Printer 3-1

Page 32

5. If the release lever is lowered, press it again and raise the release lever.

Note:

If you insert paper that is too small (shorter than 85 mm) by mistake, you may not be able to remove it

from the top of the auto sheet feeder, so use paper of the right size. If you cannot remove paper that you

inserted, see "A paper jam occurred" on page 3-9.

3.1.1.2 Printing method

1. Check the following 3 points before printing.

• The printer is turned on

• The release lever is up

• Paper is set in the auto sheet feeder

2. When a print command is sent from an application, the printer prints the data.

Note:

As a preliminary operation before printing, the printer feeds the paper and retracts it again. Do not

pull the paper during this operation.

During printing, do not press the release lever. If you press the release lever to release it during

printing, printing stops and all the print data is lost.

If you open the printer cover during printing, printing is paused. When the printer cover is closed,

printing restarts.

3.1.2 With the roll paper specification

3.1.2.1 How to install and replace paper

CAUTION:

Use Epson roll paper. Using the wrong paper may result in inferior prints and paper jams.

Note:

For part names, see "Part names" on page 2-1. Also see the label on the outside of the roll paper holder for

instructions on setting the roll paper.

1. Be sure that the printer power is turned on. If the power is turned off, turn it on.

2. Press the release lever to open the paper entrance.

3. If the roll paper edge guide is attached to the roll paper holder, squeeze the locking clip of

the roll paper edge guide and remove the edge guide. Be sure not to lose the removed roll

paper edge guide.

3-2 Using the Printer Rev. C

Page 33

TM-C100 Technical Reference Guide

CAUTION:

Attempting to remove the roll paper edge guide without squeezing the locking clip

may damage the components. Always squeeze the clip when removing the guide.

4. Remove the used roll paper core if there is one. If there is roll paper inside the printer,

remove it also.

5. Pull up the edge of the new roll paper approximately 10 cm {4 in}. Check the label

instructions for the proper direction for the paper to come off of the roll.

6. Slide the roll paper onto the shaft of the roll paper holder while inserting the end of the roll

paper into the slot in the middle of the printer, as shown below.

7. Insert the roll paper as far as it will go.

8. Insert the roll paper edge guide onto the roll paper holder while squeezing the locking clip

of the edge guide.

Note:

Adjust the edge guide so that there is no space at either edge of the roll paper.

9. Check that the installed roll paper is straight.

10. Press the release lever again to close the paper entrance.

11. The paper is cut and fed to the print starting position.

Note:

If the printer is not turned on when the release lever is pressed down, the paper will not be positioned.

In this case, operate the release lever with the power turned on, and clamp it again.

Rev. C Using the Printer 3-3

Page 34

3.1.2.2 Printing method

1. Check the following 3 points before printing.

• The printer is turned on

• The release lever is up

• Paper is set in the roll paper holder

2. When a print command is sent from an application, the printer prints the data.

Note:

During printing, do not press the release lever. If you press the release lever to release it during

printing, printing stops and all the print data is lost.

Settings for cutting the roll paper, margins and so on are all made in the driver. See the driver manual

for details.

If you open the printer cover during printing, printing is paused. When the printer cover is closed,

printing restarts.

3.1.3 Feeding and printing paper by hand

Note:

You cannot hand feed paper for printing with the roll paper specification printer when the roll paper

holder is installed. Turn the power off, and remove the roll paper holder first.

For information on how to set the driver, see the driver manual.

1. Set paper feed in the driver to "Hand feed."

2. A print command is sent from the driver.

Note:

With the ASF (auto sheet feeder) specification printer, paper that is hand-fed without a print

command from the printer is ejected. Always send a print command from the driver first.

3. Check that the printer is waiting for paper (the PAPER LED is flashing), and lower the

release lever to release it.

4. Insert the paper into the slot on the right side of the printer, and align the edge of the paper

with the leftmost side.

3-4 Using the Printer Rev. C

Page 35

TM-C100 Technical Reference Guide

5. Check that the paper is placed straight.

6. Press the release lever again, so that the release lever is in the raised position (clamped).

7. Positioning and printing of the cut sheet is performed automatically.

Note:

During printing, do not press the release lever. If you press the release lever to release it during printing,

printing stops and all the print data is lost.

During positioning, the paper is moved toward the back of the printer. If there is any obstruction behind

the printer, it may impede normal positioning. Ensure that there is sufficient space behind the printer.

3.2 Replacing the Ink Cartridge

Note:

See the ink cartridge instruction manual for precautions when using the ink cartridge.

There is one ink cartridge for the single color model and a different one for the four-color model. If the

printer model does not match the ink cartridge type, the printer will not operate.

1. Check that the printer is turned on.

2. Grip the tab and open the printer cover.

3. Pull on the tab of the currently installed ink cartridge and pull out the ink cartridge.

CAUTION:

The plastic projection inside the ink cartridge holder that supplies ink to the printer is

covered with ink. To avoid getting your fingers dirty, do not touch it.

Do not touch or apply pressure to the plastic projection. Doing so may impair the

functioning of the printer.

Since ink may still remain in the ink supply part at the bottom of the ink cartridge

when removing it, do not touch that part. Also, be careful where you put it down.

Note:

Since inserting a cartridge uses ink, do not take out the ink cartridge except when replacing it.

Rev. C Using the Printer 3-5

Page 36

4. Remove the new ink cartridge from its box and open the transparent plastic bag.

Note:

Install the ink cartridge in the printer promptly after opening the plastic bag.

If an opened cartridge is left out of its plastic bag for an extended period of time, print quality may be

adversely affected.

5. Insert the ink cartridge into the top of the ink cartridge holder in the printer. Make sure the

ink cartridge is facing the right way.

Note:

Also see the label on the underside of the printer cover.

6. Push the ink cartridge down gently until it clicks firmly into place.

7. Close the printer cover (the INK LED goes off).

Note:

The printer starts the ink replacement sequence automatically for about 1 minute. During the ink

replacement sequence the POWER LED flashes. When the ink replacement sequence is finished, the

POWER LED stops flashing, and the printer is ready for printing.

Do not turn off the printer or open the printer cover during the ink replacement sequence (the POWER

LED is flashing). If you do so, the printer must perform the ink replacement sequence again from the start.

This will waste ink.

3-6 Using the Printer Rev. C

Page 37

TM-C100 Technical Reference Guide

3.3 Maintenance

3.3.1 Ink head cleaning

If the print appears blurred, the ink head nozzles may be blocked. In this case you can return the

printer to its normal performance with ink head cleaning.

Note:

Since cleaning uses ink, avoid ink head cleaning if there is no problem with the print results.

3.3.1.1 Using the switch on the printer

Cleaning starts if the CLEANING switch on the printer is pressed for 3 seconds or more. The

POWER LED flashes during cleaning. Wait until it finishes flashing (1 minute maximum).

Note:

When the POWER LED is flashing (during cleaning), do not open the printer cover or turn off the

printer. When the printer cover is next closed, or when the power is next turned on, cleaning starts again

which wastes ink.

Since cleaning uses ink, avoid ink head cleaning if there is no problem with the print results.

3.3.1.2 Using the maintenance utility of the driver

The Windows driver and OPOS-X come with a utility for maintenance. See the relevant manual

for information on how to use them.

3.3.2 Cautions when transporting the printer

To prevent ink leaking when transporting the printer, take the following precautions.

❏ Remove the ink cartridge before transporting the printer.

❏ Ensure that the printer is kept horizontal. Do not transport it upside down.

❏ Do not transport half-used ink cartridges.

❏ Be sure not to transport any ink cartridge that has been removed from its packing.

Rev. C Using the Printer 3-7

Page 38

3.4 Troubleshooting

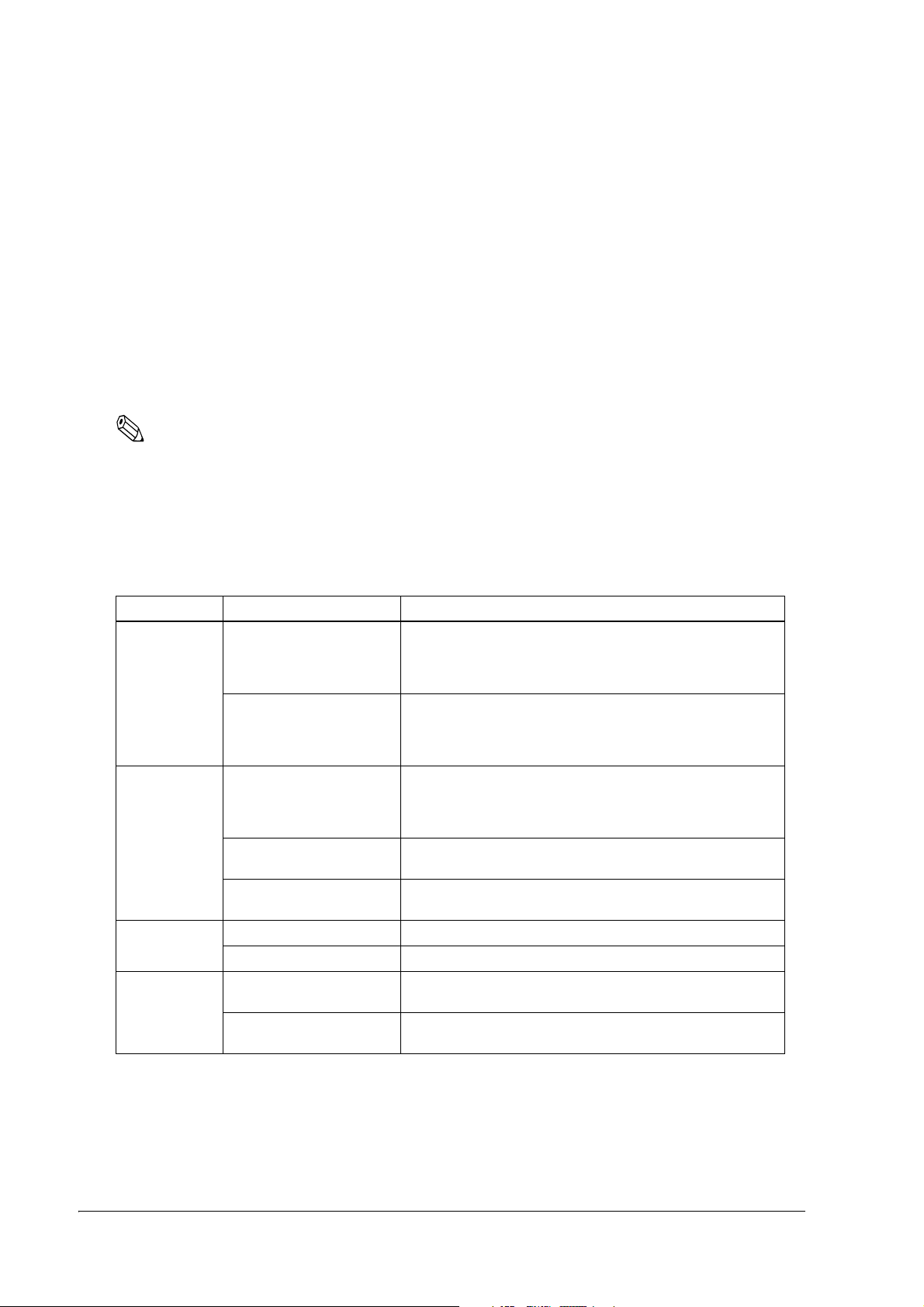

3.4.1 Flashing LEDs

When only 1 of the 3 LEDs on the control panel is on, the printer is running normally.

When more than 1 LED is on or flashing, an error has occurred. See the table below.

LED status

Status MeasuresPOWER PAPER INK

On Off Off Normal status The printer is not printing, and its status is

On On Off Printer cover open Close the printer cover.

On Flashing Off/

Flashing

LED status is

maintained

when an

error

occurred.

LED status is

maintained

when an

error

occurred.

On Out of ink, or

Paper control Try the following measures.

the cartridge is not installed

Note: If the printer power is

turned on with the cartridge

not installed and the

cartridge cover closed, the

LED status will be as follows:

POWER: Flashing

PAPER: Off

INK: On

normal. No measures are necessary.

• A print command was sent from the

application, but the printer is out of

paper. If there is no paper on the paper

feeder, place paper in the roll paper

holder or the ASF (see page 3-1 and

page 3-2).

• A print command was sent from the

application, and the printer is waiting

for paper to be hand-fed. Hand feed

paper (see page 3-4)

• The printer is preparing to print or is

printing. When the operation finishes,

the PAPER LED will go off automatically.

Wait a while.

Cannot print because there is no ink.

Install a new ink cartridge (page 2-9).

On Off Flashing Ink near end Although there is little ink remaining,

normal printing is possible. Have a new

ink cartridge ready.

Flashing On Off/On/

Flashing

Flashing Flashing Off Printer operating

Printer operating

(Such as cleaning,

initialization)

(Such as adjusting head

temperature)

Internal printer operation. Wait a while

and the printer will return to normal

status

Internal printer operation. Wait for a

maximum of 1 minute and the printer

will return to normal status

3-8 Using the Printer Rev. C

Page 39

LED status

TM-C100 Technical Reference Guide

Status MeasuresPOWER PAPER INK

Flashing Flashing On Autocutter error,

or

failure status 1

Flashing Flashing Flashing Failure status 2 The head or motor have reached the

• Turn off the printer promptly, and if

there is a paper jam, remove the paper.

Then turn the printer on again.

• If these measures do not return the

printer to normal, have the printer

serviced.

end of their product lifetime. Have the

printer serviced.

3.4.2 The paper being printed does not come out

❏ If you set paper larger than the size that can be printed, it many not print, or it may jam and

you will not be able to remove it. For information on the size of the paper that can be used,

see "Roll Paper Specification" on page A-4 and "ASF Specification" on page A-7.

❏ If you set paper smaller than the size that can be printed, you may not be able to remove it

easily. In this case, remove the option (ASF or roll paper holder), and remove the paper.

❏ If you cannot remove jammed paper, do not use excessive force. Have the printer serviced.

3.4.3 A paper jam occurred

Resolve it with the following procedure.

1. Turn off the printer.

2. Lower the release lever so that it is released.

3. Remove the jammed paper carefully.

4. Open the printer cover and check that there are no remaining paper scraps or foreign objects

inside the printer.

Note:

If there are foreign objects or paper scraps in the printer that are difficult to remove, have the printer

serviced.

5. Turn on the printer. (The printer will be initialized automatically.)

3.4.4 Paper is not supplied from the ASF

Try the following measures. (For information on how to set the driver, see the driver manual.)

❏ Change the driver "Option setting" to "ASF."

Rev. C Using the Printer 3-9

Page 40

Note:

When using OPOS-X, the option setting is set automatically. Change only the feed setting. (Use the

"SlpPaperBinNumber" properties.)

❏ Change the driver "Feed setting" to "ASF."

❏ Turn off the printer, and reconnect the cable of the ASF unit to the printer. Then turn on the

printer again.

❏ Check with "ASF Specification" on page A-7 that the size of the paper you are using is

appropriate for the product specification.

3.4.5 Hand fed printing is not possible

If after following "Feeding and printing paper by hand" on page 3-4 hand fed printing is not

possible, try the following measures again. (For information on how to set the driver, see the

driver manual.)

❏ Set paper feed in the driver to "Hand feed."

❏ If the roll paper holder is attached, remove it.

❏ After checking that the PAPER LED flashes after the print command was sent from the

driver, set the paper.

❏ Check with "Hand Fed Paper Specifications" on page A-9 that the size of the paper you are

using is appropriate for the product specification.

3.4.6 Eliminating excessive bottom margins (roll paper specification)

When using the APD, if you set the "Roll paper saving mode" in the driver, the printer cuts the

paper when printing finishes, irrespective of the paper size settings, so that the bottom margin is

not excessive. (For information on how to set the driver, see the driver manual.)

Note:

When using OPOS-X, any cut position can be programmed. Note that there is no "Roll paper saving

mode."

3.4.7 The paper is not cut (roll paper specification)

❏ You can use a self-test (see "Self Test Procedure" on page 3-11) to check the operation of the

printer. If the paper is not cut after self-testing, the printer may not be working properly.

Have it serviced.

❏ In the long print mode, the paper is not cut at a new page. Check the driver settings. (For

information on how to set the driver, see the driver manual.)

Note:

When using OPOS-X, any cut position can be programmed. Note that there is no "Long print mode."

3-10 Using the Printer Rev. C

Page 41

TM-C100 Technical Reference Guide

3.5 FAQ

3.5.1 Printing on long paper (roll paper specification)

By turning on "Long print mode" in the driver settings, you can print long pages without

changing the paper size. See the driver manual for details.

Note:

When using OPOS-X, any cut position can be programmed. Note that there is no "Long print mode."

3.5.2 Cutting the paper at a fixed length (roll paper specification)

By turning off "Roll paper saving mode" and "Long print mode" in the driver settings, you can

cut the paper at a fixed size. See the driver manual for details.

Note:

When using OPOS-X, it is necessary to program the desired cut position. Note that there is no "Roll

paper saving mode" or "Long print mode."

3.5.3 Making fine color adjustments such as color matching

Unfortunately neither APD nor OPOS-X support these functions currently. Please adjust the

data for printing yourself.

3.6 Self Test

With the self test you can check if the printer is operating properly. It checks the control circuits,

printer mechanism, head nozzles status, and firmware version.

This test is independent of any other equipment or software, so it is a good idea to run it when

you first set up the printer and if you have any trouble. If the self tests work correctly, the

problem is in the other equipment or the software, not the printer.

3.6.1 Self Test Procedure

3.6.1.1 With the ASF specification

1. Check that the printer is turned off, the printer cover is closed, and the ASF is installed

properly.

2. Place paper in the ASF.

3. While pressing FEED, turn on the printer.

Rev. C Using the Printer 3-11

Page 42

4. Printing is performed and paper is output.

Self test print example

5. The printer is ready to receive data as soon as it completes the self test. Normal printing is

now possible.

Note:

If this self test is not possible, try a self test by hand feeding paper ("Feeding paper by hand" on page 3-

13).

3.6.1.2 With the roll paper specification

Note:

You can check the operation of the autocutter with the self test when the roll paper holder is installed.

1. Check that the printer is turned off, the printer cover is closed, and the roll paper holder is

installed properly.

2. Install roll paper.

3. While pressing FEED, turn on the printer.

4. Printing is performed and the paper is cut.

Self test print example

5. The printer is ready to receive data as soon as it completes the self test. Normal printing is

now possible.

Note:

If this self test is not possible, try a self test by hand feeding paper ("Feeding paper by hand" on page 3-

13).

3-12 Using the Printer Rev. C

Page 43

TM-C100 Technical Reference Guide

3.6.1.3 Feeding paper by hand

1. Check that the printer is turned off, the printer cover is properly closed, and no option (ASF,

roll paper holder) is installed.

2. While pressing FEED, turn on the printer.

3. Lower the release lever so that it is released, and set the paper.

4. Press the release lever again, so that the release lever is in the raised position (clamped).

5. Printing is performed and paper is output.

Self test print example

6. The printer is ready to receive data as soon as it completes the self test. Normal printing is

now possible.

Rev. C Using the Printer 3-13

Page 44

3-14 Using the Printer Rev. C

Page 45

TM-C100 Technical Reference Guide

Chapter 4

Application Development Information

This chapter contains useful information for developing POS systems using the printer.

4.1 Bar Code Printing

4.1.1 Using the Windows Advanced Printer Driver

When using the Windows Advanced Printer Driver, you need to create the necessary bar code

image data yourself. Create the data with commercial bar code creation software or the like.

Create the bar code data at the resolution appropriate to the paper settings used when printing.

(See the table below.)

Driver paper settings Bar code resolution

Plain paper 180 × 180 dpi

Special fine paper 360 × 360 dpi

Matte paper 360 × 360 dpi

4.1.2 Using OPOS-X

When using OPOS-X, you can print with the PrintBarCode method. OPOS-X supports the

following bar code formats.

Bar codes supported by OPOS-X

UPCA

UPCE

JAN13

EAN13

JAN 8

EAN8

CODE39

ITF

CODABAR

CODE93

CODE128

PDF417

Rev. C Application Development Information 4-1

Page 46

4.2 Precautions When Using OPOS-X

This section explains the precautions necessary when using OPOS-X. For details of the

functions, see the OPOS-X manual.

4.2.1 Distinguishing between the ASF and roll paper specifications

OPOS-X automatically determines from the connected TM-C100 whether it is the ASF or roll

paper specification, so no settings are necessary.

4.2.2 Selecting the feed type (ASF specification)

With the ASF specification of the TM-C100, use the "SlpPaperBinNumber" property to select

ASF or hand feeding as the feed type.

4.2.3 Paper size

In addition to the original OPOS functions, you can select a paper size to use. In this way you do

not have to take into account the line feed position, and you can eliminate wasteful movement of

the print head. To select a paper size, it is necessary to set it in either the SetupPOS-X utility or

the DirectIO method.

4.2.4 Fonts

Unlike traditional printers, you can use Windows fonts to print with the TM-C100. You can use

the SetupPOS-X utility to set the fonts used.

4-2 Application Development Information Rev. C

Page 47

TM-C100 Technical Reference Guide

Appendix A

Product Specifications of the TM-C100

A.1 Product Specifications

Item Specification

Interface (compatible) USB

Power supply Power supply with a dedicated AC adapter

Input voltage (rated) Input voltage (rated) 90 (100 - 10%) to 264 (230 + 15%) VAC

Frequency (rated) 47 to 63 Hz

Power consumption Operating

Idling

Applicable standards Europe: CE marking EMC Directive: 89/336/EEC

North

America:

Oceania: EMC: AS/NZS 3548/CISPR22 Class B

Japan: EMI: VCCI Class A

Reliability Product

lifetime:

MTBF 180,000 hours (Failure is defined as a random failure occurring during the random

failure period.)

MCBF 30,000,000 passes

Temperature and humidity Printing:

Absolute maximum rated

temperature

Pressure (elevation) Printing:

This is an average failure interval based on failures relating to wearout and random

failures up to the life of 12,000,000 passes.

Storage:

70ºC (This temperature must NOT be exceeded whenever it is operating or in

storage.)

Operating:

Average: Approximately 11 W

Peak: Approximately 13 W

Average: Approximately 1 W

EN55022 Class B

EN55024

IEC61000-4-2

IEC61000-4-3

IEC61000-4-4

IEC61000-4-5

IEC61000-4-6

IEC61000-4-11

Safety standard: TÜV (EN 60950)

EMI: FCC/ICES-003 Class A

Safety Standard: UL 60950/CSA C22.2 No. 60950

Mechanism 12,000,000 passes (6,000,000 carriage returns)

Print head 1,600,000,000 shots/nozzle

(Shots are the numbers of pulses energized for the print

Autocutter Plain paper, special fine paper 350,000 cuts

ASF 200,000 sheets

10 to 35ºC, 20 to 80% RH no condensation

Packaged for shipping

Ink loaded

775 to 1,050 hPa (corresponding to 0 to 2,000 m above sea level)

700 to 1,060 hPa (corresponding to 0 to 2,500 m above sea level)

head.)

Special matte paper, plain borderless label paper

200,000 cuts

(The end of product lifetime is when the printer reaches

the start of the wear-out failure period.)

–20 to 60ºC, 5 to 85% RH no condensation

(Ink not loaded)

(within 120 hours at

–20ºC or 60ºC)

–20 to 40ºC, 20 to 85% RH

Rev. C Product Specifications of the TM-C100 A-1

Page 48

Item Specification

Vibration resistance test

specifications:

Shock resistance test

specifications

Noise Operating approximately 51 dB (ANSI bystander position)

Packaged: Frequency 5 to 55 Hz

Acceleration approximately 19.6 m/s

Sweep 10 minutes (half cycle)

Time 1 hour

Orientation XYZ

No external or internal damage was observed and no problems

occurred in operation after vibration under the above conditions.

Packaged:

Unpacked:

(including using the autocutter in normal mode printing)

Packaging specification Epson standard package

Height 60 cm

Orientation 1 corner, 3 edges, and 6 surfaces

Height 5 cm

Orientation Lift one edge and release it (for all 4 edges).

No external or internal damage was observed and no problems

occurred in operation after dropping.

2

{2 G}

A-2 Product Specifications of the TM-C100 Rev. C

Page 49

A.2 Printing Specifications

Item Specification

Printing Method Serial ink-jet dot matrix

Print direction Bidirectional, logic seeking

Paper feed Forward and reverse friction feed

Printing width 116 mm Max.

Printing speed See table "Approximate printing speed" on page A-3

Ink cartridges Type:

Color printing

Ink color:

Number of sheets

printable:

Expiration date:

Type:

Ink color:

Number of sheets

printable:

Expiration date:

4-color integrated ink cartridge

Cyan, magenta, yellow, black

660 pages

(Print area: 100 × 280 mm, occupancy of each color on the page: 8.5%,

when printing at 180 dpi)

*This number is with a newly replaced ink cartridge and continuous

printing.

Half a year after opening the transparent plastic bag (at ordinary

temperature)

However, 2 years from the date of manufacture (at ordinary

temperature, this 2 years includes the half a year after opening the

transparent plastic bag.)

The expiration date 2 years from the date of manufacture is printed on

the individual box containing the ink cartridge and on the ink cartridge

itself.

Single color ink cartridge

Black

2500 pages

(Print area: 100 × 150 mm, occupancy of the color on the page: 6.0%,

when printing at 180 dpi)

*This number is with a newly replaced ink cartridge and continuous

printing.

Half a year after opening the transparent plastic bag (at ordinary

temperature)

However, 2 years from the date of manufacture (at ordinary

temperature, this 2 years includes the half a year after opening the

transparent plastic bag.)

The expiration date 2 years from the date of manufacture is printed on

the individual box containing the ink cartridge and on the ink cartridge

itself.

TM-C100 Technical Reference Guide

Approximate printing speed

Image resolution

(horizontal ×

Printing mode Driver setting

High speed Plain paper, fast 180 × 180 dpi Bi 35 mm/s 111 mm

Normal Plain paper, fine 360 × 180 dpi Bi 20 mm/s 116 mm

Fine 1 Special paper,

fast

Fine 2 Special paper,

fine

[dpi: dots per 25.4 mm (dots per inch)]

vertical) Print direction

360 × 360 dpi Uni 6.3 mm/s 116 mm

360 × 360 dpi Uni 3.2 mm/s 116 mm

Printing width

Speed at 60 mm

Maximum

printable area

Rev. C Product Specifications of the TM-C100 A-3

Page 50

[Bi: bidirectional printing]

[Uni: unidirectional printing]

Note:

1. Printing speed is with continuous printing without cleaning, auto-cutting, or paper feed or ejection.

2. Printing speed may be slower, depending on the data transmission speed, status receiving and so on.

A.3 Roll Paper Specification

Item Specification

Autocutter Cutting method: Circular cutter

Cutting type: Full cut

Minimum cut length: 15 mm

Roll paper holder Supply method: Axial

Paper feed specifications Paper feed type: Friction feed

Paper specifications Paper type: Plain paper/special paper (special fine paper, special matte

Mass Roll paper specification: Approximately 2.0 kg

Roll paper detection: TOF/BOF sensor

Paper near-end detection: No

Paper width selection: Selectable from 45 mm to 105 mm

Paper width detection: No

Roll paper holder detection: Yes

Continuous paper feed speed: approximately53 mm/s

paper)/plain borderless label paper (scraps on both sides:

width 1 mm)

Form: Roll paper

Paper width: 45 to 105 mm

Paper thickness: 0.06 to 0.23 mm

Basic weight: 52.3 to 200 g/m

(45 to 173 kg / 1,000 sheets / 788 × 1,091 mm)

Outside diameter: Maximum φ90 ± 1 mm

Core: Inside diameter 38 mm, outside diameter 44 mm (cannot be

pasted with paper)

Roll length: Plain paper approximately 61 m

Borderless label paper approximately 37 m

Special fine paper approximately 40 m

Special matte paper approximately 20 m

Roll direction: Top-side roll

Holes and cutouts: No holes or cutouts in the roll paper are permitted.

ASF specification: Approximately 1.9 kg

2

(JIS P8124)

Note:

Print quality may fall when printing immediately after installing the roll paper.

A-4 Product Specifications of the TM-C100 Rev. C

Page 51

A.3.1 Print area and cutter position

A.3.1.1 Plain paper/special paper

TM-C100 Technical Reference Guide

autocut

position

overall size

autocut

position

2

paper width 45 mm to 105 mm

feed direction

2

hand fed

paper guide

print area

auto-cutting

15 mm or more when

roll paper guide

2

0.42

2

[Unit: mm]

Print area and cutter position (plain paper/special paper)

Rev. C Product Specifications of the TM-C100 A-5

Page 52

A.3.1.2 Plain borderless label paper

autocut

position

overall size

autocut

position

paper width 45 mm to 105

2

hand fed

paper

15 mm or more

when auto-cutting

roll paper guide

2

2

2

0.42

1 (scrap)1 (scrap)

Print area and cutter position (borderless label sheets)

feed direction

print area

[Unit: mm]

Note:

Borderless label paper must have scraps on both sides (a portion of installing only).

Do not print on the scrap parts (the portion of installing only).

The values given are typical values. Since there is variation in the slack and thickness of the paper, take

this into account when setting the postion of the cutter and the printing position.

A-6 Product Specifications of the TM-C100 Rev. C

Page 53

TM-C100 Technical Reference Guide

p

A.4 ASF Specification

Item Specification

Cut sheet feeder specifications Paper feed type: Friction feed

Paper specifications Paper type: Plain paper/special paper (special fine paper, special matte

Feed specifications Number of sheets set: Combined paper thickness 5.5 mm or less (including

Mass Approximately 1.9 kg

Note:

The paper must be flat, without curls or wrinkles (especially at the top edges). Otherwise, the paper may

rub against the nozzles and be soiled.

ASF unit detection: Detection by an optional connector

Cut sheet detection: Detection by the TOF/BOF sensor

Paper size: 55 to 135 mm (width) × 85 to 210 mm (length)

Paper thickness: 0.08 to 0.25 mm

Basic weight: 64 to 218 g/m

paper)/plain borderless label paper

2

(JIS P8124)

(55 to 188 kg / 1,000 sheets / 788 × 1,091 mm)

unevenness in the paper)

20 sheets or less (with paper thickness of 0.25 mm)

50 sheets or less (with paper thickness of 0.10 mm)

When printing envelopes, curls or wrinkles may occur because of the sealing method, shape, material and

so on, causing feed and printing errors; therefore prior evaluation is necessary.

In order for cut sheet detection to work properly, do not use paper that has cutouts or holes. However, as

shown in the following figure, holes and cutouts of the "permissible hole and cutout size" in the "hole and

cutout permissible area" are permissible.

feed direction

hole and cutout

permissible area

hole and cutout

ermissible size

11 or less

* Hole and cutout outside the "hole and cutout permissible area" are not

10 or more

3 or more

[Unit: mm, all values are typical]

8 or less

Cut sheet hole permissible area

Rev. C Product Specifications of the TM-C100 A-7

Page 54

A.4.1 Print area

A.4.1.1 For standard printing

overall size

area that is

printable but where

print quality is

reduced

2 or more

17

paper width

maximum print area

109 (high speed)

114 (normal, fine)

feed direction

2

hand fed

paper guide

2

2

2

[Unit: mm]

Print area (cut sheet)

print area

A-8 Product Specifications of the TM-C100 Rev. C

Page 55

TM-C100 Technical Reference Guide

A.5 Hand Fed Paper Specifications

Item Specification

Paper specifications Paper type: Plain paper/special paper (special fine paper, special matte

Paper size: 49 to 210 mm (width) × 120 to 297 mm (length)

Paper thickness: 0.06 to 0.25 mm

Basic weight (reference value):

(45 to 188 kg / 1,000 sheets / 788 × 1,091 mm)

Note:

The paper must be flat, without curls or wrinkles (especially at the top edges). Otherwise, the paper may

rub against the nozzles and be soiled.

When printing envelopes, curls or wrinkles may occur because of the sealing method, shape, material and

so on, causing feed and printing errors; therefore prior evaluation is necessary.

In order for cut sheet detection to work properly, do not use paper that has cutouts or holes. However, as

shown in the following figure, holes and cutouts of the "permissible hole and cutout size" in the "hole and

cutout permissible area" are permissible.

paper)/plain borderless label paper

52.3 to 218 g/m

2

(JIS P8124)

hole and cutout

permissible area

10 or more

hole and cutout perm issible

3 or more

11 or less

[Unit: mm, all values are typical]

* Hole and cutout outside the "hole and cutout permissible area" are not

8 or less

Cut sheet hole permissible area

feed direction

Rev. C Product Specifications of the TM-C100 A-9

Page 56

A.5.1 Print area

A.5.1.1 For standard printing

overall size

area that is printable

but where print quality

is reduced

2 or more

17

paper width

maximum print area

111 (high speed)

116 (normal, fine)

feed direction

2

hand fed

paper guide

2

2

2

[Unit: mm]

print area

Print area (cut sheet)

A.6 Case Specifications