Page 1

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus Photo R240/R245/R250

EPSON ME PHOTO 20

SEIJ05011

Page 2

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED

TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND

OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH

SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF

THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER

SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF

SUCH PRODUCTS CONTAINING FLAMMABLE GAS IS PROHIBITED.

Page 3

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4. DISASSEMBLY/ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5. ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for

servicing the product.

CHAPTER 7. APPENDIX

Provides the following additional information for reference:

• Connector Summary

• Exploded Diagram

• Electrical Circuits

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates that a particular task must be carried out according to a

certain standard after disassembly and before re-assembly,

otherwise the quality of the components in question may be

adversely affected.

Page 4

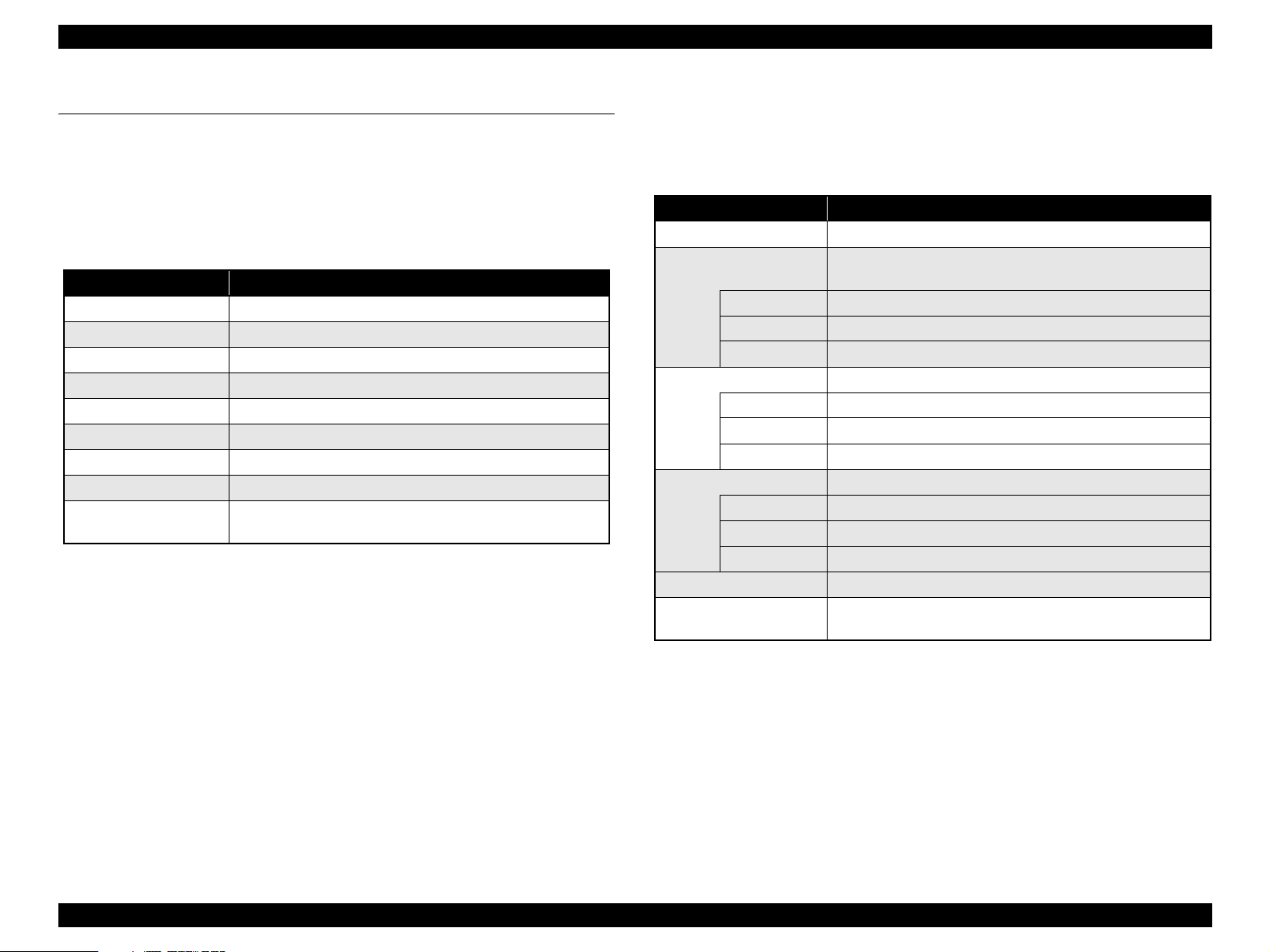

Revision Status

Revision Date Item Description

A October 7, 2005 --- First Release

B March 10, 2006 5.1.2 Adjustments Required After Part

Replacement (p.129)

C October 6, 2006 All EPSON ME PHOTO 20 is added.

1.2.1.3 Paper Support (p.11) Table 1-3 “Exclusive Papers” is modified.

1.2.1.5 Ink Cartridge Specification (p.15) EPSON ME PHOTO 20 is added.

1.6.3 Control Panel Appearance (p.31) EPSON ME PHOTO 20 is added.

5.1.2 Adjustments Required After Part

Replacement (p.129)

PW Sensor Adjustment (PW Deterioration Adjustment) added after Main

Board Replacement(Read OK)

Error correction

Page 5

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

Contents

Chapter1 PRODUCT DESCRIPTION

1.1 Overview........................................................................................................... 10

1.1.1 Features .................................................................................................... 10

1.2 Specifications.................................................................................................... 11

1.2.1 Printer specifications................................................................................ 11

1.2.1.1 Physical Specification....................................................................... 11

1.2.1.2 Printing Specification........................................................................ 11

1.2.1.3 Paper Support.................................................................................... 11

1.2.1.4 Printing Area..................................................................................... 13

1.2.1.5 Ink Cartridge Specification............................................................... 15

1.2.1.6 Electric Specification........................................................................ 15

1.2.1.7 Environmental Performance ............................................................. 16

1.2.1.8 Durability .......................................................................................... 16

1.2.1.9 Safety Standards: EMC..................................................................... 16

1.2.1.10 CE Marking....................................................................................... 16

1.3 Interface ............................................................................................................ 17

1.3.1 USB Interface........................................................................................... 17

1.3.2 Standard Card Slots.................................................................................. 18

1.3.2.1 Memory card..................................................................................... 18

1.3.2.2 Supported power supply voltage....................................................... 18

1.3.2.3 Multi-slot operations......................................................................... 19

1.4 Memory Card Print ........................................................................................... 20

1.4.1 Basic Specifications ................................................................................. 20

1.4.1.1 File system ........................................................................................ 20

1.4.1.2 Media format..................................................................................... 20

1.4.1.3 File formats ....................................................................................... 20

1.4.1.4 Valid image size................................................................................ 20

1.4.1.5 Maximum number of photo data files............................................... 21

1.4.1.6 Thumbnail image data....................................................................... 21

1.4.1.7 File sorting ........................................................................................ 21

1.4.1.8 File sorting rules ............................................................................... 21

1.4.1.9 Rules for acquisition of date/time data ............................................. 21

1.4.1.10 Number of sheets which can be printed in total................................ 21

1.4.2 Functions .................................................................................................. 22

1.4.2.1 List of functions ................................................................................ 22

1.4.2.2 Memory card printing mode ............................................................. 22

1.4.3 Layout and Paper Type, Paper Size ......................................................... 23

1.4.4 Trimming Function .................................................................................. 23

1.4.5 Assignment Rules for Photo Frame Numbers and Rotation .................... 24

1.4.6 Layout Drawings...................................................................................... 25

1.4.6.1 Border free ........................................................................................ 25

1.4.6.2 1-up with borders.............................................................................. 25

1.4.6.3 20-up ................................................................................................. 26

1.4.6.4 30-up ................................................................................................. 26

1.4.6.5 80-up ................................................................................................. 27

1.4.7 Relation between Paper Type and Quality............................................... 27

1.5 USB Direct-Print/PictBridge Functions ........................................................... 28

1.5.1 Supported Device..................................................................................... 28

1.5.2 Functions Available from DSC................................................................ 28

1.5.3 Operation.................................................................................................. 28

1.5.3.1 Preparation........................................................................................ 28

1.5.3.2 Standard Operations.......................................................................... 28

1.5.3.3 Display when DSC is Connected...................................................... 29

1.5.3.4 Cancel Print....................................................................................... 29

1.5.3.5 Operation when the Printing is Completed....................................... 29

1.5.3.6 Exclusive Control Specifications for Paper Type, Size, and Layout 29

1.5.3.7 Camera direct error executing other processing (error).................... 29

1.6 Control Panel .................................................................................................... 30

1.6.1 Buttons ..................................................................................................... 30

1.6.2 Indicators.................................................................................................. 30

1.6.3 Control Panel Appearance ....................................................................... 31

1.6.4 The method of changing mode................................................................. 32

1.6.5 Operations ................................................................................................ 33

1.6.5.1 Memory card mode/Setup mode/DSC direct mode.......................... 33

1.6.5.2 Memory Card Insertion/Ejection ...................................................... 35

1.6.5.3 Connection/Removal of DSC ........................................................... 35

1.6.5.4 Low Power Panel Mode.................................................................... 35

1.6.5.5 Paper Thickness Lever Function....................................................... 35

1.6.6 Printer Condition and Panel Status .......................................................... 36

6

Page 6

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

Chapter2 OPERATING PRINCIPLES

2.1 Overview........................................................................................................... 40

2.2 Printer Mechanism ............................................................................................ 40

2.2.1 Printer Mechanism ................................................................................... 40

2.2.2 Print Head................................................................................................. 41

2.2.2.1 Printing Process ................................................................................ 42

2.2.2.2 Printing Method ................................................................................ 42

2.2.3 Carriage Mechanism ................................................................................ 43

2.2.3.1 Carriage Mechanism ......................................................................... 43

2.2.3.2 Carriage Home Position Detection ................................................... 44

2.2.3.3 Sequence Used for PW Detection..................................................... 44

2.2.4 Paper Loading/Feeding Mechanism......................................................... 45

2.2.4.1 Paper Loading Mechanism ............................................................... 46

2.2.4.2 Paper Feeding Mechanism................................................................ 49

2.2.5 Ink System Mechanism............................................................................ 50

2.2.5.1 Capping Mechanism ......................................................................... 51

2.2.5.2 Pump Unit Mechanism ..................................................................... 52

2.2.6 Ink Sequence ............................................................................................ 53

2.3 Electrical Circuit Operating Principles ............................................................. 54

2.3.1 C610 PSB/PSE Board .............................................................................. 55

2.3.2 C606 Main Board..................................................................................... 56

2.3.2.1 Main Elements .................................................................................. 56

Chapter3 TROUBLESHOOTING

4.3.2 Stacker Assy............................................................................................. 86

4.3.3 Printer Cover ............................................................................................ 87

4.3.4 Panel Unit................................................................................................. 88

4.3.5 Upper Housing ......................................................................................... 90

4.3.6 Print Head ................................................................................................ 91

4.3.7 Main Board Unit ...................................................................................... 93

4.3.8 Head Cable Frame.................................................................................... 95

4.3.9 Printer Mechanism ................................................................................... 96

4.3.10 PS Board Unit .......................................................................................... 99

4.3.11 Waste Ink Pad ........................................................................................ 100

4.3.12 ASF Unit ................................................................................................ 101

4.3.13 CR Motor ............................................................................................... 103

4.3.14 PF Motor and PF Encoder Sensor .......................................................... 104

4.3.15 Carriage Unit, CR Encoder Board, PW Sensor Board, Head FFC ........ 106

4.3.16 Shaft Holder Unit ................................................................................... 110

4.3.17 Spur Gear 36.8, Extension Spring 0.143, Clutch ................................... 112

4.3.18 PE Sensor Board and PE Sensor Lever.................................................. 113

4.3.19 Upper Paper Guide Unit......................................................................... 114

4.3.20 CR Guide Frame .................................................................................... 115

4.3.21 Paper Eject Frame Unit .......................................................................... 116

4.3.22 Ink System Unit ..................................................................................... 118

4.3.23 Front Paper Guide Unit .......................................................................... 120

4.3.24 PF Scale/PG Sensor ............................................................................... 121

4.3.25 PF Roller Unit ........................................................................................ 123

3.1 Overview........................................................................................................... 59

3.2 Error Indications and Fault Occurrence Causes ............................................... 59

3.3 Troubleshooting ................................................................................................ 60

3.3.1 Superficial Phenomenon-Based Troubleshooting.................................... 74

Chapter4 DISASSEMBLY AND ASSEMBLY

4.1 Overview........................................................................................................... 82

4.1.1 Precautions ............................................................................................... 82

4.1.2 Tools......................................................................................................... 82

4.1.3 Work Completion Checklist..................................................................... 83

4.2 Cautions on Disassembly/Reassembly of Printer Mechanism & How to Ensure

Quality of Reassembled Printers 84

4.3 Disassembly Procedure..................................................................................... 85

4.3.1 Paper Support Assy. ................................................................................. 86

Chapter5 ADJUSTMENT

5.1 Adjustment Items Summary ........................................................................... 126

5.1.1 List of Adjustment Items........................................................................ 126

5.1.2 Adjustments Required After Part Replacement ..................................... 129

5.2 Adjustments by Adjustment Program............................................................. 131

5.2.1 Top margin adjustment .......................................................................... 131

5.2.2 Head Angular Adjustment ..................................................................... 131

5.2.3 Bi-D Adjustment .................................................................................... 132

5.2.4 First Dot Adjustment.............................................................................. 132

5.2.5 PW Sensor Adjustment .......................................................................... 133

5.2.6 PF Adjustment........................................................................................ 134

5.2.7 PF Band Adjustment .............................................................................. 135

5.3 Adjustment Except Adjustment Program ....................................................... 136

5.3.1 PG adjustment ........................................................................................ 136

7

Page 7

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

Chapter6 MAINTENANCE

6.1 Overview......................................................................................................... 141

6.1.1 Cleaning ................................................................................................. 141

6.1.2 Service Maintenance .............................................................................. 141

6.1.3 Lubrication ............................................................................................. 143

Chapter7 APPENDIX

7.1 Connector Summary ....................................................................................... 149

7.1.1 Major Component Unit .......................................................................... 149

7.2 Exploded Diagram .......................................................................................... 150

7.3 Electrical Circuits ........................................................................................... 151

8

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.1 Overview

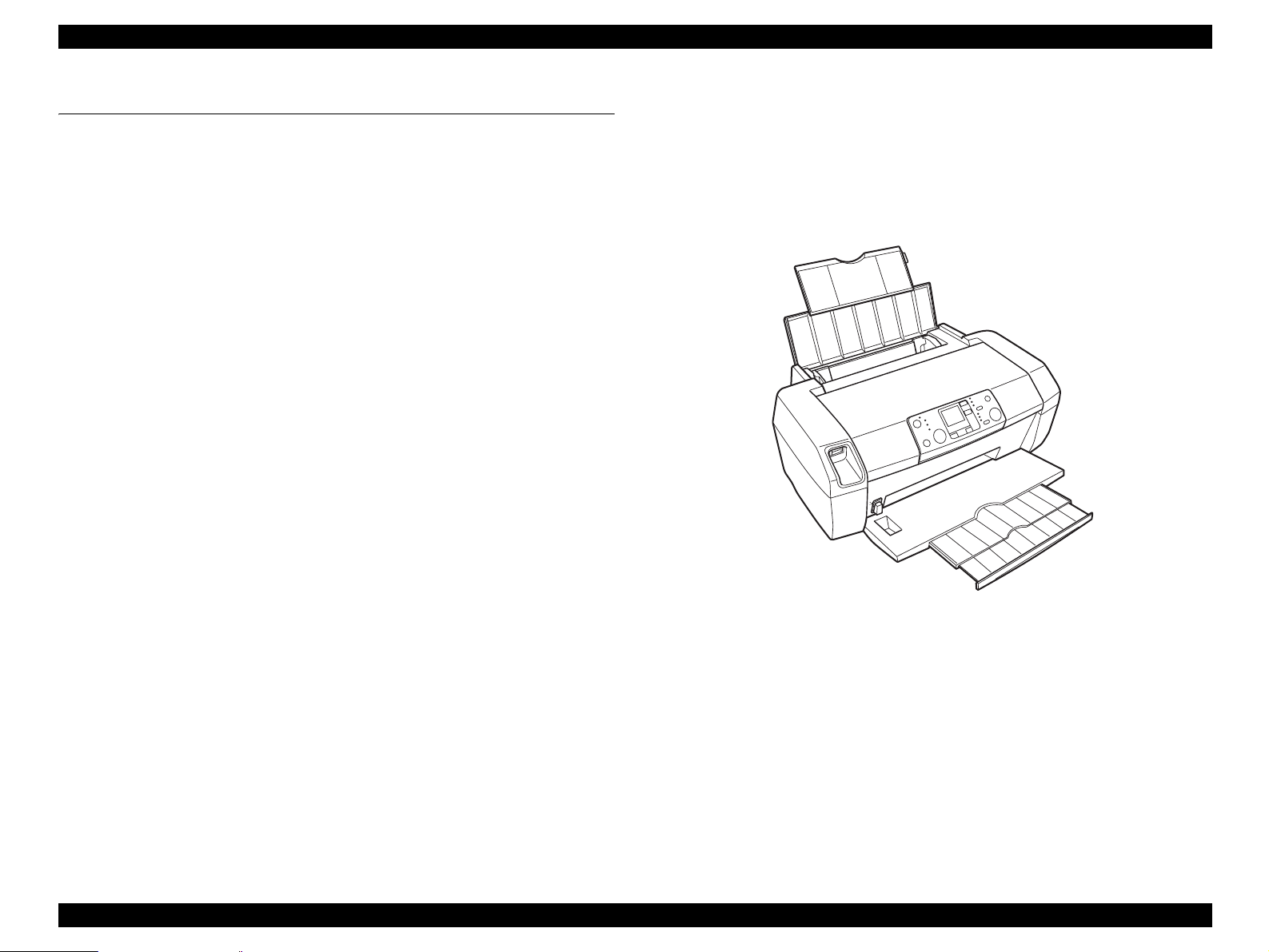

The major features of EPSON color inkjet dot matrix printer EPSON Stylus Photo

R240/R245/R250/ME PHOTO 20 are:

1.1.1 Features

Printer functions

As a printer, this unit achieves high-quality output at high speed on plain paper,

and uses new inks for improved light fastness, water fastness, gas fastness, rubbing

fastness. It includes the following features.

Maximum print resolution: 5760 (H) x 1440 (V) dpi

Separate ink cartridge for each color

ASF (Auto Sheet Feeder) holds up to 100 cut sheets (64g/m

Borderless printing

Reduced noise level

Fast and thick draft mode with the combination of real black and composite

black

Card reader functions

This unit includes memory card slots that support CompactFlash, SmartMedia,

Memory Stick, Memory Stick PRO, Microdrive, SD Memory Card,

and xD-Picture Card standards.

2

)

Easy operation panel

The unit has a simple operation panel equipped with 1.5 inch LCD and 11 buttons

including power button, 10 LEDs and provides basic functions only for easy

operation.

Exterior design

This unit has operation panel on the front side, which becomes more distinctive

but still easier to use.

Memory card print functions

This unit can print images from the memory card in memory card slots

in stand-alone mode.

USB DIRECT-PRINT/PictBridge functions

This unit can print from Digital Still Camera that is compliant with “USB

DIRECT-PRINT”/”CIPA DC-001-2003 Digital Photo Solutions for Imaging

Devices” and that is connected by USB cable.

Simultaneous use of functions

Printer functions and card reader functions are independent and can therefore be

operated simultaneously from a connected computer.

Figure 1-1. Product’s external view

PRODUCT DESCRIPTION Overview 10

Page 10

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.2 Specifications

1.2.1 Printer specifications

This section covers specifications of the printer.

1.2.1.1 Physical Specification

Weight

5.0kg (without the ink cartridges)

Dimension (Including rubber feet, not including loading tray)

435.9mm (W) x 268.2mm (D) x 171.2mm (H)

1.2.1.2 Printing Specification

Print Method

On demand ink jet

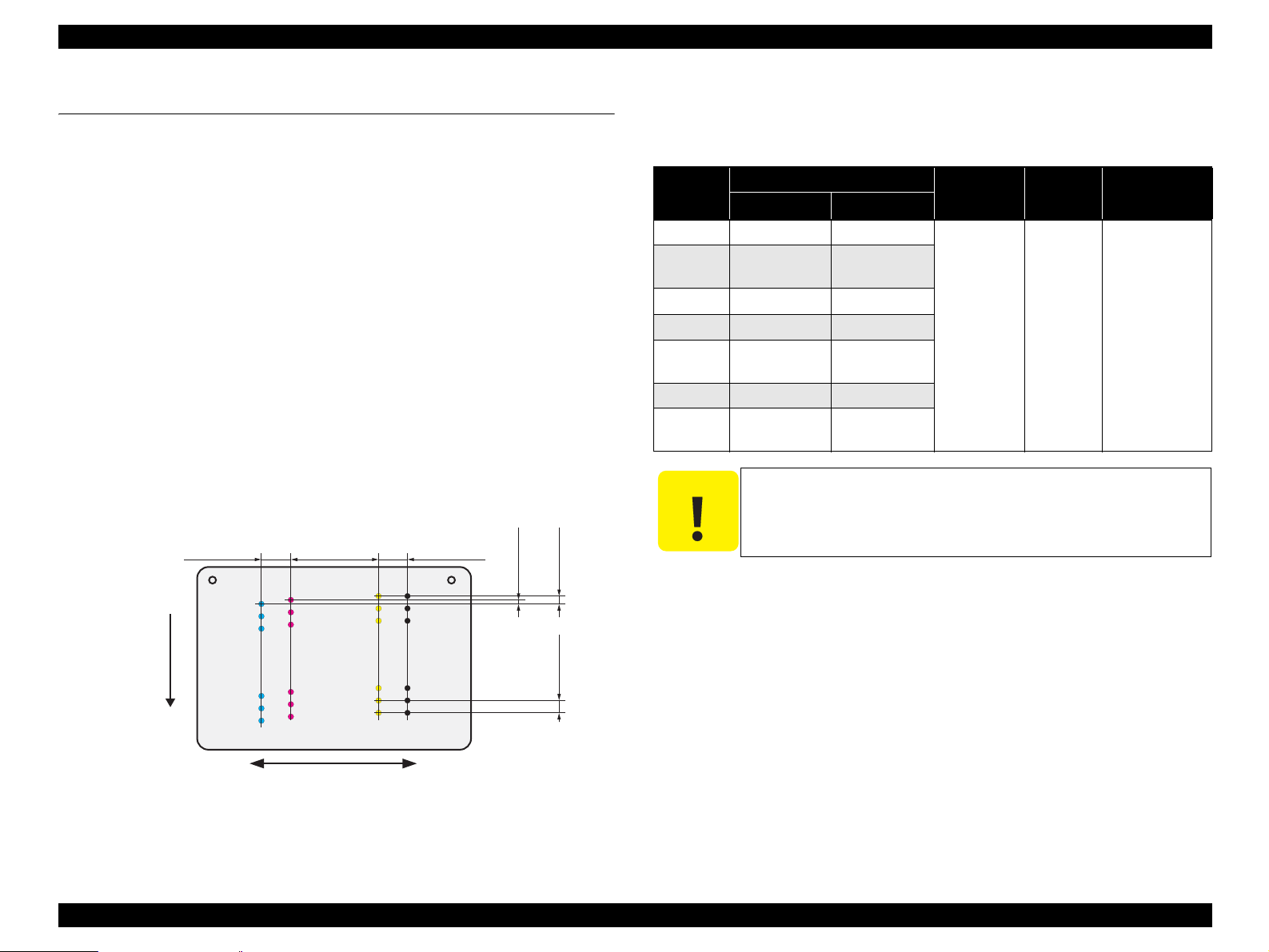

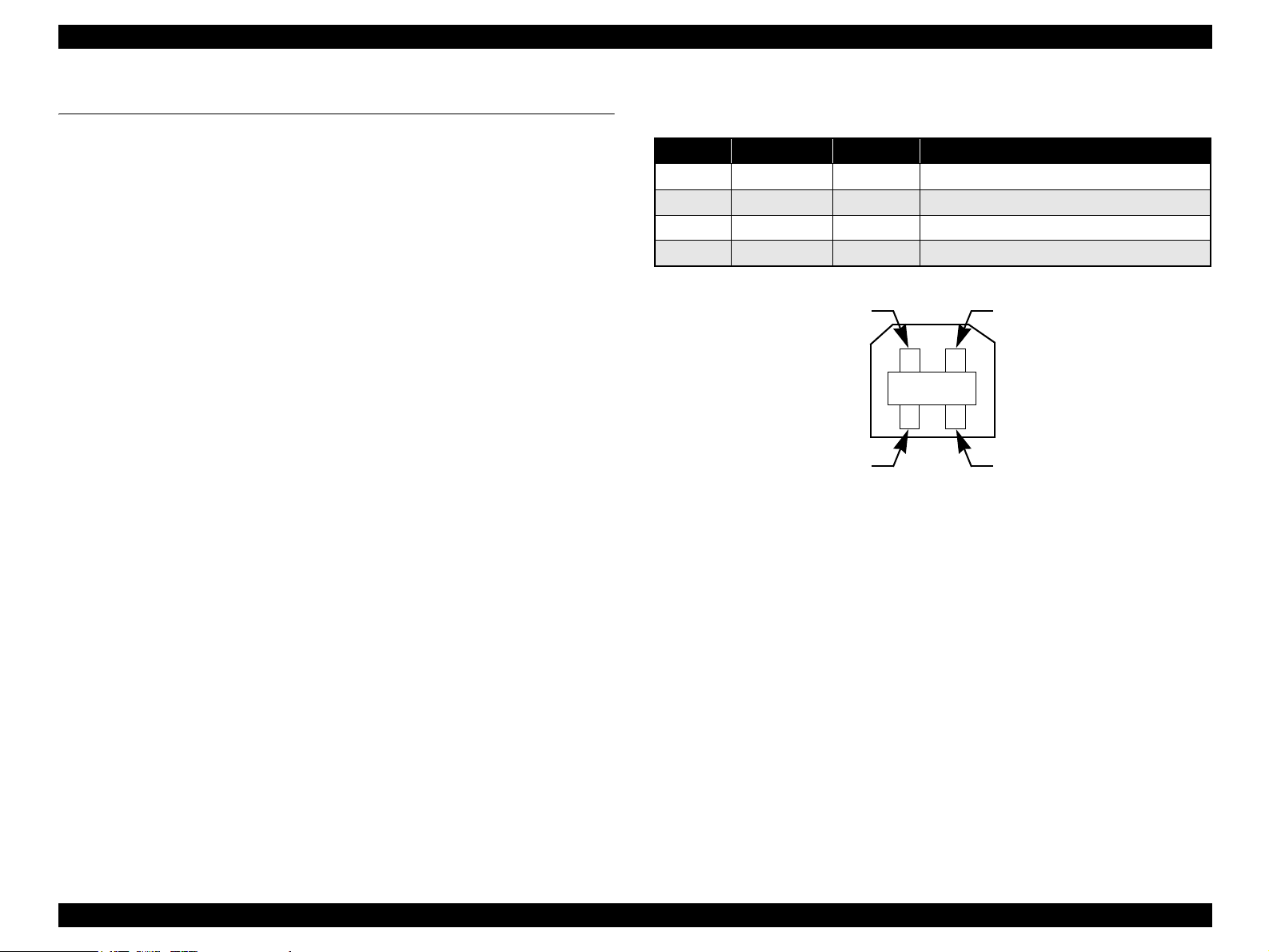

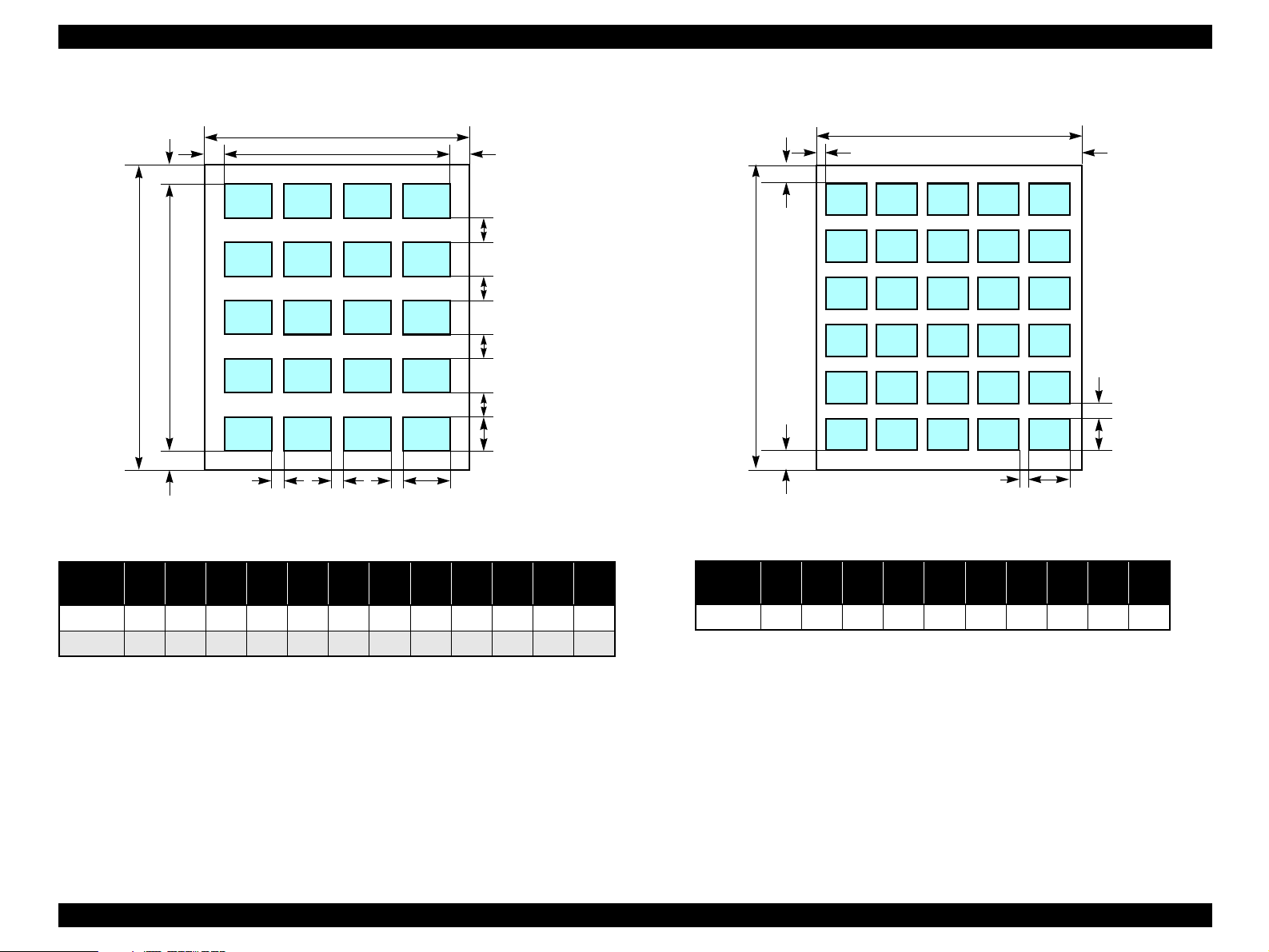

Nozzle Configuration

Black: 90 nozzles

Color: 90 nozzles x 3 (Cyan, Magenta, Yellow)

Paper Feed Direction

2.822

(40/360inch)

#A90

#A89

#A88

A row B row C row D row

#A3

#A2

#A1

8.467

(120/360inch)

#C90

#B90

#C89

#B89

#C88

#B88

#B3

#B2

#B1

#C3

#C2

#C1

2.822

(40/360inch)

#D90

#D89

#D88

#D3

#D2

#D1

BlackCyan Magenta Yellow

0.07055

(1/360inch)

0.1411

(2/360inch)

0.2117

(3/360inch)

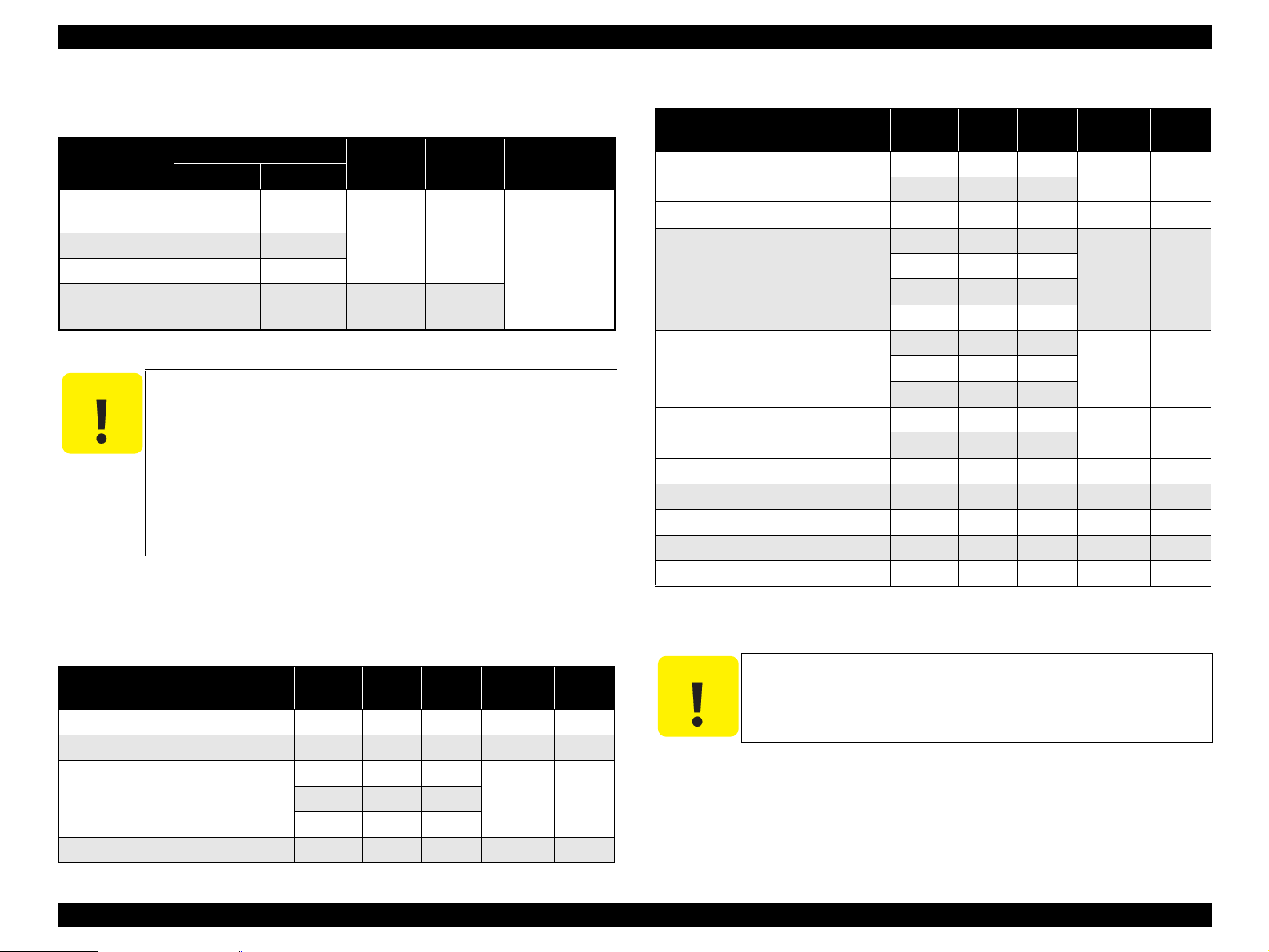

1.2.1.3 Paper Support

Cut sheets

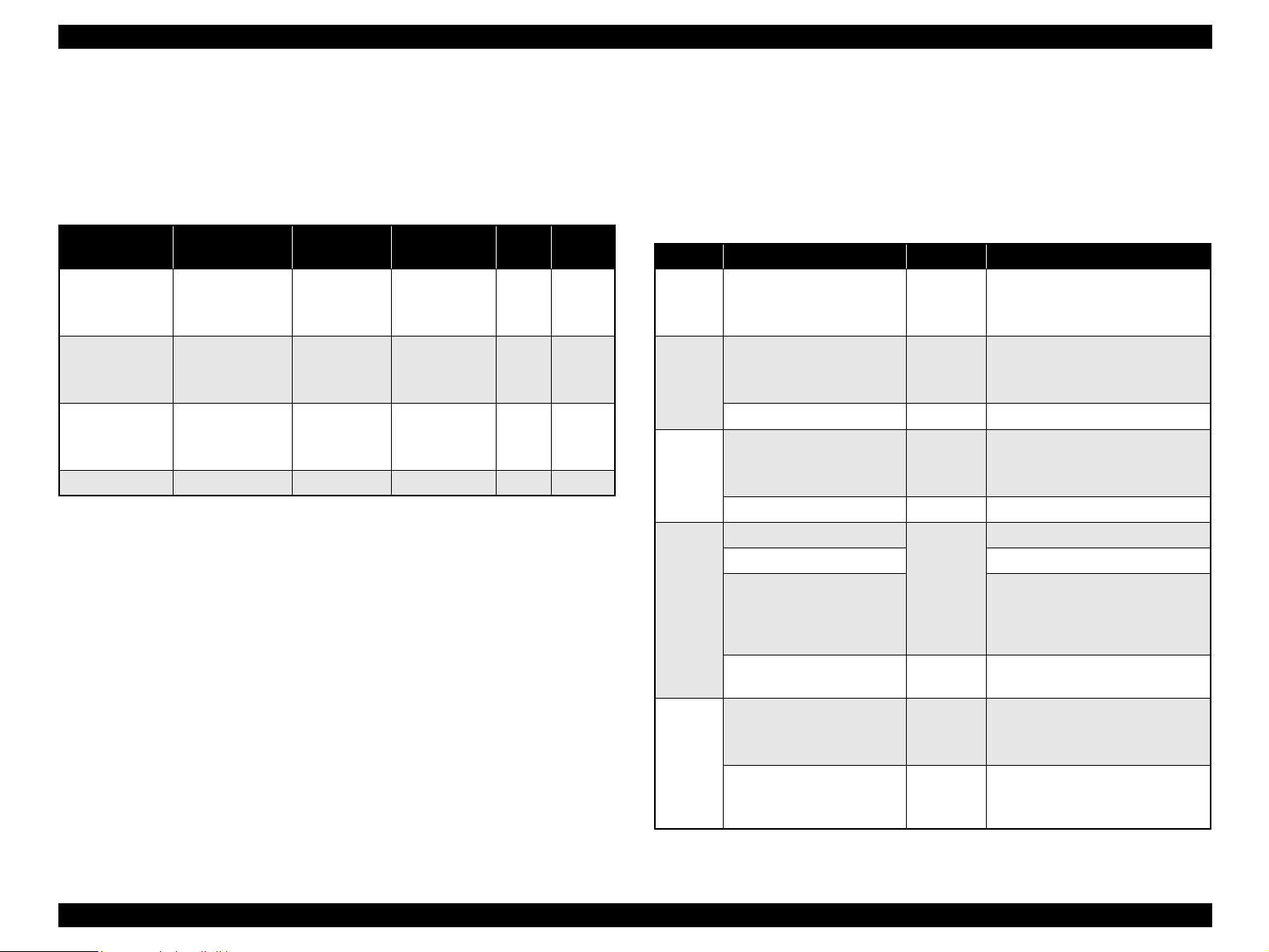

Table 1-1. Cut Sheets

(7.25")

(5.5")

the form.

Dimensions

266.7 mm

(10.5")

215.9 mm

(8.5")

Paper size

Width (PW) Length (PL)

A4 210 mm 297 mm

Executive 184.2 mm

B5 182 mm 257 mm

A5 148 mm 210 mm

Half Letter 139.7 mm

A6 105 mm 148 mm

User

50.8-329 mm 127-1117.6 mm

Defined

C A U T I O N

It is necessary that there is no wrinkle, nap, tear, fold, so on in

The curve of form must be 5mm or below.

Thickness Weight Paper type

0.08-0.11 mm

64-90 g/m

(17-24(lb))

2

Plain paper

Recycled paper

Carriage Moving Direction

Figure 1-2. Nozzle configuration

PRODUCT DESCRIPTION Specifications 11

Page 11

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

Envelopes

Table 1-2. Envelopes

Paper size

*

No.10

*

DL

*

C6

220 x 132

*

Note * : Check that the flap is on the long edge and can be folded.

C A U T I O N

Poor quality paper may reduce print quality and cause paper

Dimensions

Thickness Weight Paper type

Width (PW) Length (PL)

104.8mm

(4.125")

241.3mm

(9.5")

N/A 75-90g/m

(20-24(lb))

110mm 220mm

114mm 162mm

132mm 220mm 0.1 82g/m

(22(lb))

jams or other problems. If you encounter problems, switch to a

higher grade of paper.

It is necessary that there is no wrinkle, nap, tear, fold, so on in

the form.

Don’t use the adhesive envelopes.

Don’t use sleeve insert envelopes and cellophane window

envelopes.

The curve and swell of the form must be 3mm or below

Exclusive papers

2

2

Bond paper

Air mail

PPC

Table 1-3. Exclusive Papers

Item Size

Photo Paper A4

Width

(PW)

*1

210 297 0.23 194

4" x 6" 101.6 152.4

Photo Stickers 4/16 A6 105 148 0.19 N/A

Premium Glossy Photo Paper A4 210 297 0.27 255

*1

5" x 7"

127 178

4" x 6" 101.6 152.4

*2

3R

Glossy Photo Paper A4 210 297 0.25 258

*1

5" x 7"

127 178

4" x 6" 101.6 152.4

Premium Semigloss Photo Paper A4 210 297 0.27 250

4" x 6" 101.6 152.4

Matte Paper-Heavyweight A4 210 297 0.23 167

Double-sided Matte Paper A4 210 297 0.25 178

Economy Photo Paper

*2

A4 210 297 0.23 188

Iron-On Cool Peel Transfer Paper A4 210 297 0.14 130

Photo Quality Ink Jet paper A4 210 298 0.12 102

Length

(PL)

89 127

Thickness

(mm)

Weight

(g/m

2

)

Quality: EPSON Exclusive paper

Transparency printing is only available at normal temperature.

Note *1 : Only for Stylus Photo R240/R245.

*2: Only for Stylus Photo R250/ME PHOTO 20.

Table 1-3. Exclusive Papers

It is necessary that there is no wrinkle, nap, tear, fold, so on in

the form.

The curve of form must be 5mm or below.

Item Size

Premium Ink Jet Plain Paper

Width

(PW)

*1

A4 210 297 0.11 80

Length

(PL)

Thickness

(mm)

Weight

(g/m

Bright White Ink Jet Paper A4 210 297 0.13 92.5

Photo Quality Ink Jet Cards 8" x 10" 203.2 254 0.21 180

5" x 8" 127 203.2

A6 105 148

Photo Quality Self Adhesive Sheets A4 210 297 0.19 167

C A U T I O N

2

)

PRODUCT DESCRIPTION Specifications 12

Page 12

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

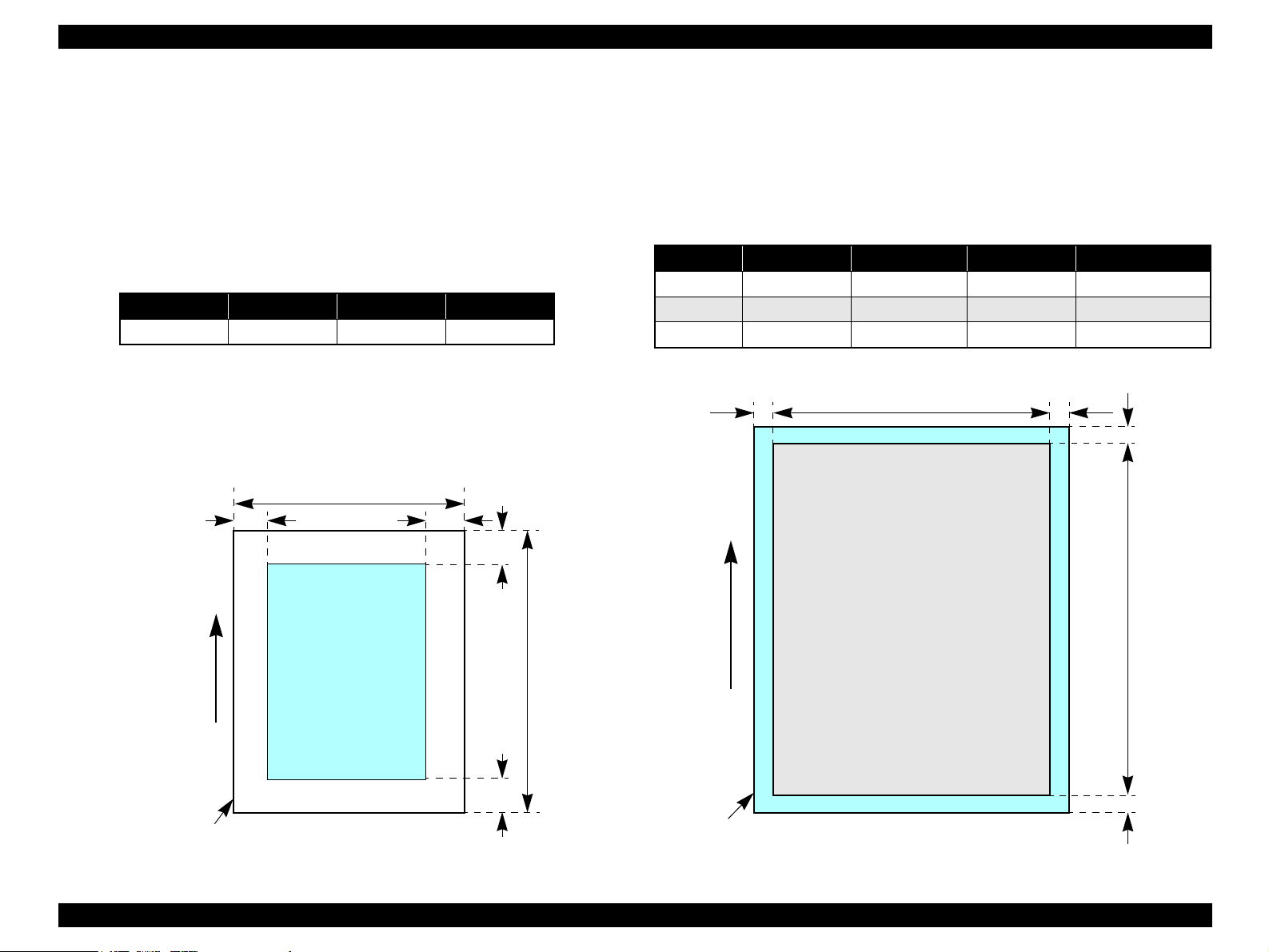

1.2.1.4 Printing Area

Cut sheet (standard printing)

Printable area

The print quality is guaranteed for the print area above the 3mm bottom

margin. For paper width (PW) and paper length (PL), refer to “1.2.1.3 Paper

Support” (p.11).

Refer to the following table.

As for each margin area, refer to Figure 1-3 (p.13).

Table 1-4. Printing Area

Left Margin Right Margin Top Margin Bottom Margin

3mm (0.12") 3mm (0.12") 3mm (0.12") 3mm (0.12")

NOTE: Printouts may get dirt with a bottom margin of less than 28.3mm or a top

margin of less than 32.1mm because of an unexpected contact of the

Printhead.

In addition, with a bottom margin of less than 28.3mm, printed image

near the bottom may be distorted.

PW

LM RM

TM

Cut sheet (border-free printing)

Printable area

For paper width (PW) and paper length (PL), refer to “1.2.1.3 Paper Support ”

(p.11).

Refer to the following table.

As for each overhang area, refer to Figure 1-4 (p.13).

Table 1-5. Printing Area

Paper size Left Overhang Right Overhang Top Overhang Bottom Overhang

Photo card 1.83 mm 1.83 mm 2.54 mm 3.53 mm

4hx6h/10x15 2.54 mm 2.54 mm 1.34 mm 2.54 mm

Other 2.54 mm 2.54 mm 2.96 mm 4.02 mm

LO RO

PW

TO

PL

Printable area

PL

Paper size

Paper Feed Direction

Paper Feed Direction

BM

Paper size

Figure 1-3. Printable area Cut sheet (standard printing)

Printable area

Figure 1-4. Printable area for Cut sheet (border-free printing)

BO

PRODUCT DESCRIPTION Specifications 13

Page 13

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

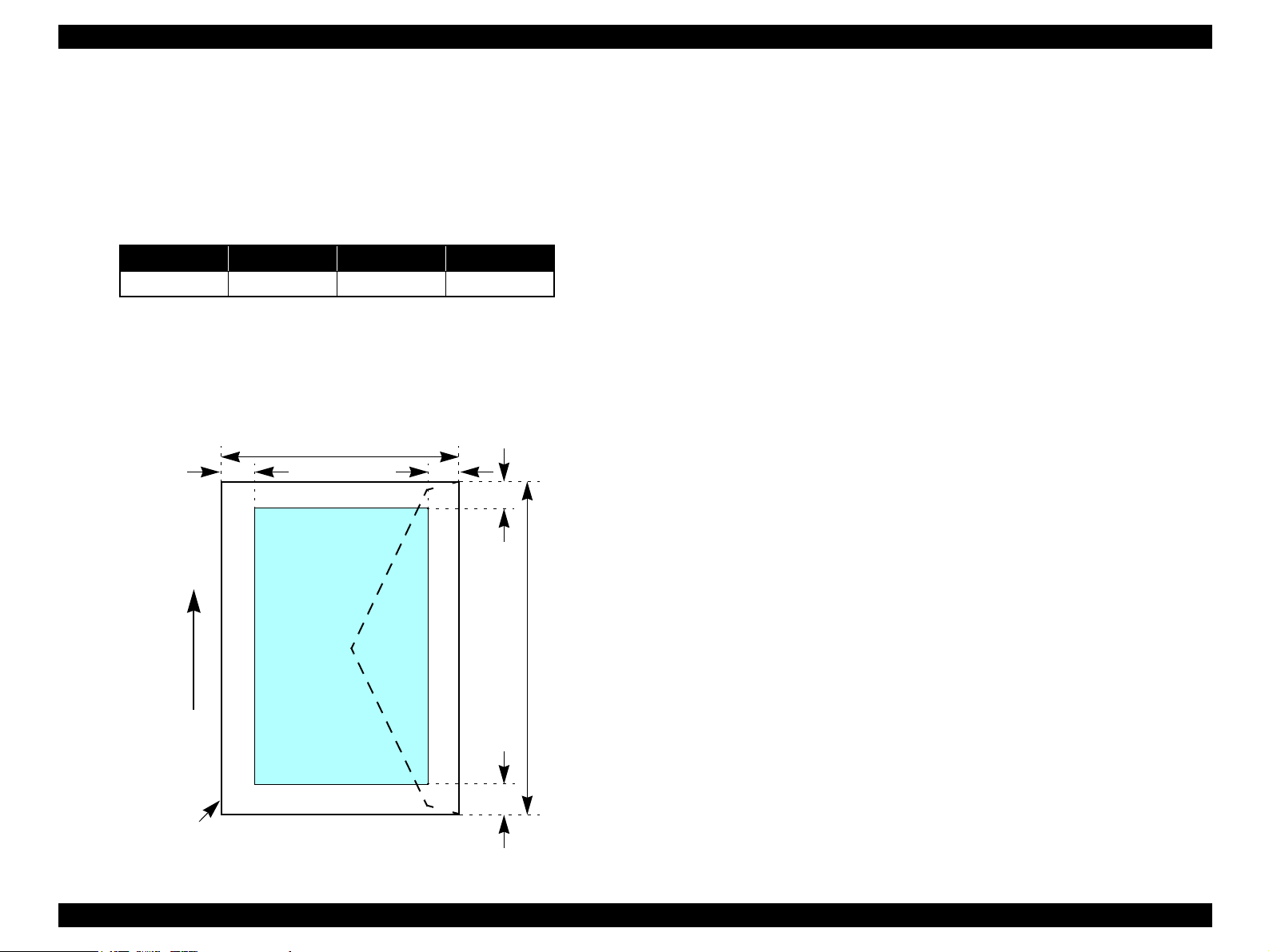

Envelopes

Printable area

For paper width (PW) and paper length (PL), refer to “ 1.2.1.3 Paper Support ”

(p.11).

Refer to the following table.

As for each margin area, refer to Figure 1-5 (p.14).

Table 1-6. Printing Area

Left Margin Right Margin Top Margin Bottom Margin

3mm (0.12") 3mm (0.12") 5mm (0.20") 20mm (0.79")

NOTE: Printouts may get dirt with a bottom margin of less than 20.0mm or a top

margin of less than 32.1mm because of an unexpected contact of the

Printhead.

In addition, with a bottom margin of less than 20.0mm, printed image

near the bottom may be distorted.

PW

LM

RM

TM

Printable area

PL

Paper Feed Direction

BM

Paper size

Figure 1-5. Printable area for envelopes

PRODUCT DESCRIPTION Specifications 14

Page 14

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

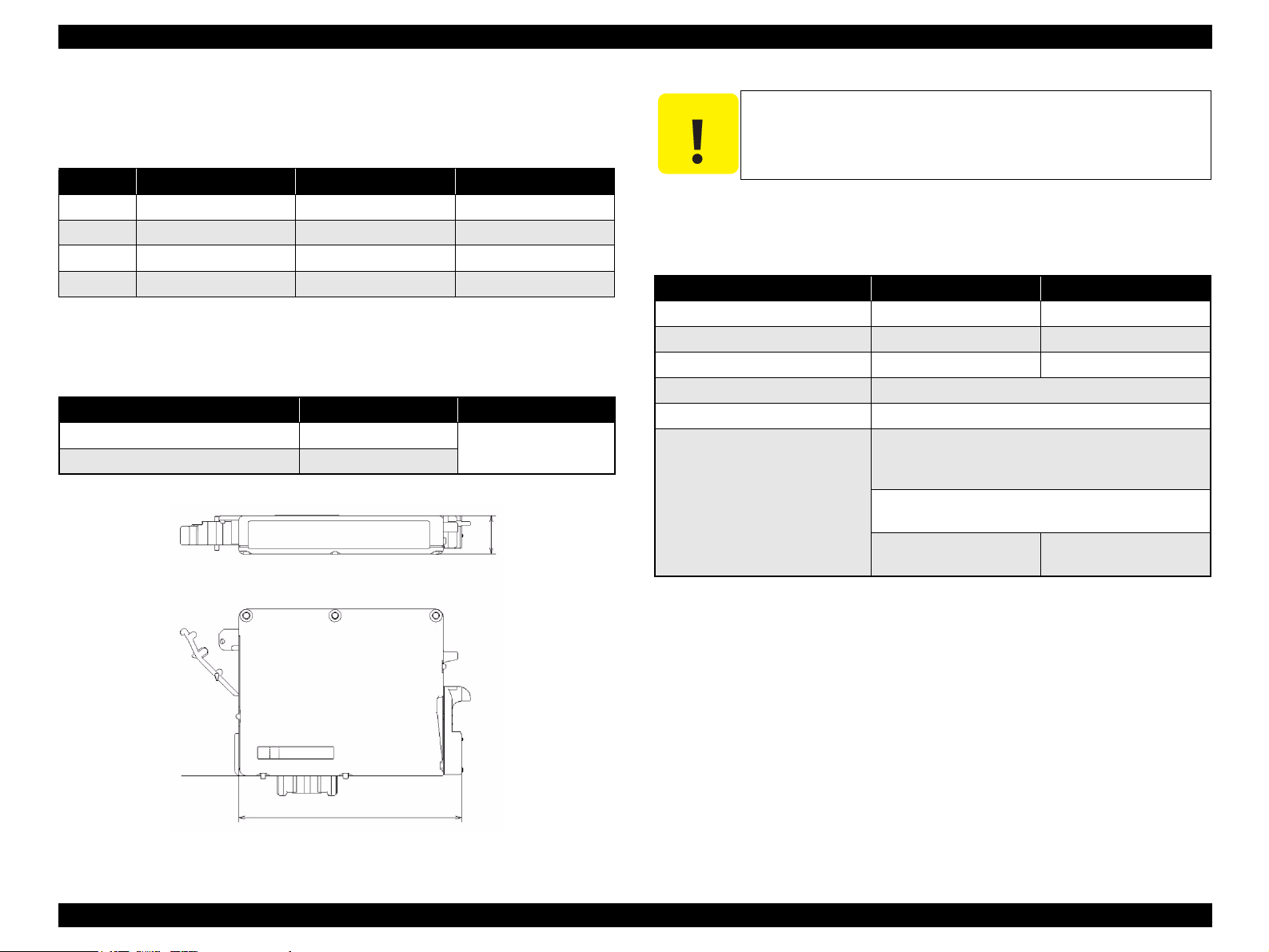

1.2.1.5 Ink Cartridge Specification

Type/color: EPSON-brand special ink cartridges

Table 1-7. Ink Cartridge

Color Stylus Photo R240/R245 Stylus Photo R250 ME PHOTO 20

Black T0551 T0561 T0841

Cyan T0552 T0562 T0842

Magenta T0553 T0563 T0843

Yellow T0554 T0564 T0844

Shelf life: After packing is opened, it is assumed 6 months, and

assumes two years including this.

Storage Temperature

Table 1-8. Storage Temperature

Situation Storage Temperature Limit

When stored in individual boxes -30 oC ~ 40 oC 1 month max. at 40 oC

When installed in main unit -20 oC ~ 40 oC

Dimension: 12.7mm (W) x 73.46mm (D) x 55.25mm (H)

12.7mm

C A U T I O N

The ink in the ink cartridge freezes when leaving it in the

environment of -16°C or under. It takes 3 hours that the frozen ink

becomes usable when moving it from the environment of -20°C to

the environment of 25°C.

1.2.1.6 Electric Specification

Primary power input

Table 1-9. Primary power input

100-120V model 220-240V model

Rated power supply voltage (VAC) 100 ~ 120 220 ~ 240

Input voltage range (VAC) 90 ~ 132 198 ~ 264

Rated current (A) 0.4 (Max. 0.7) 0.2 (Max. 0.3)

Rated frequency (Hz) 50 ~ 60

Input frequency range (Hz) 49.5 ~ 60.5

Power consumption (W) Approx. 10W

(Standalone copying, ISO10561 Letter Patter,

Plain Paper - Text)

Approx. 1.5W

(Sleep Mode)

Approx. 0.2W

(Power Off Mode)

Approx. 0.4W

(Power Off Mode)

NOTE 1: This product complies with the “Energy Star” standards.

2: If the printer is not operated at all for at least three minutes, the standby function

reduces the current to the motor to conserve power.

3: If the panel button is not operated at all for at least 13 minutes, the LCD panel is go

out.s

Base View

73.46mm

Figure 1-6. Ink cartridge

PRODUCT DESCRIPTION Specifications 15

Page 15

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

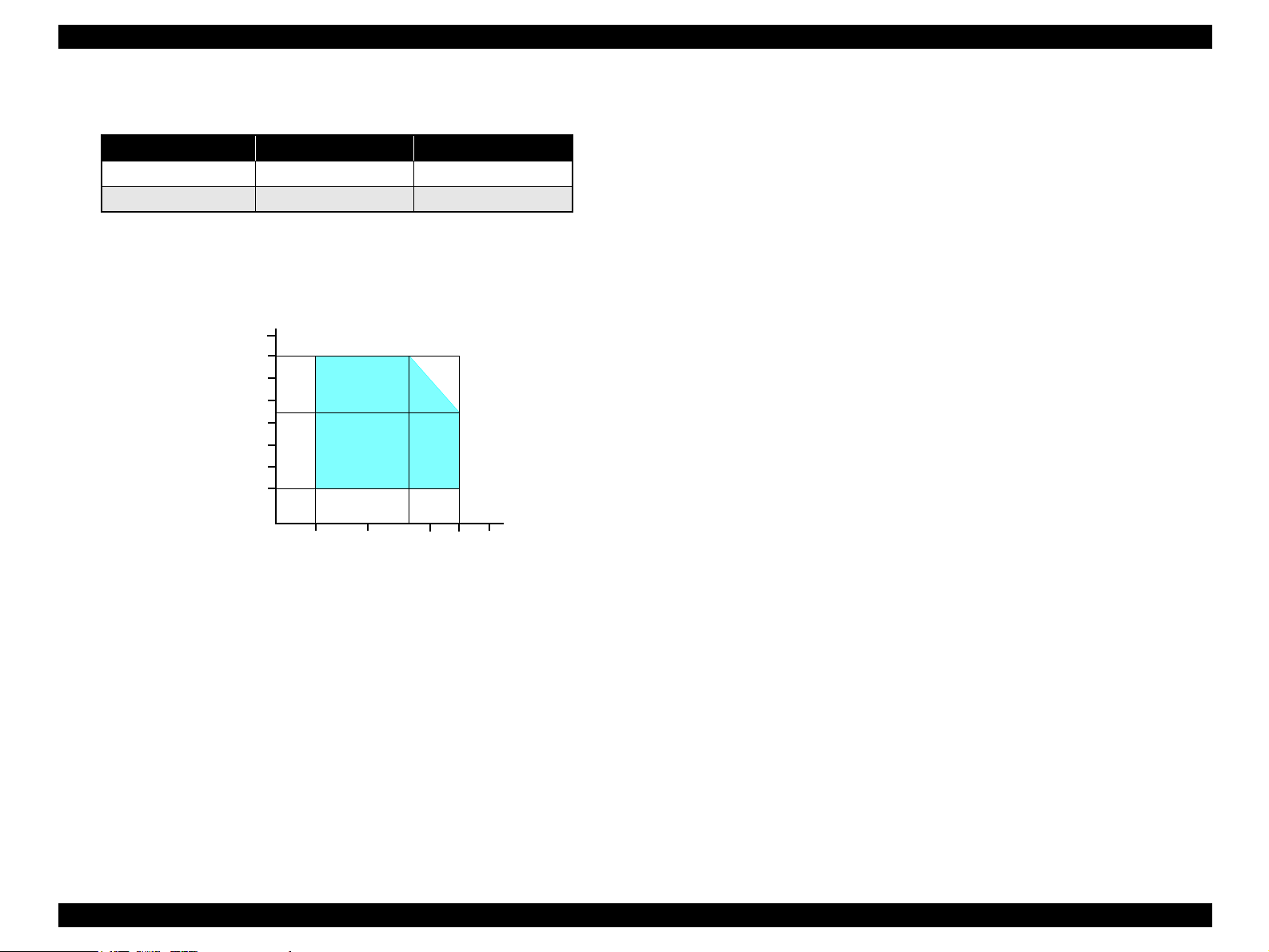

1.2.1.7 Environmental Performance

Table 1-10. Environmental Performance

Condition Temperature Humidity

Operating 10 ~ 35°C

Not operating

Note *1 : After unpacking (storage)

*2: No condensation

*3: Under the following conditions

*4: One month when at 40°C

Humidity (%)

*1

90

80

70

60

50

40

30

20

-20 ~ 40°C

10

Temperature (°C)

Figure 1-7. Temperature/Humidity range

1.2.1.8 Durability

Total print life: 10,000 pages (black only, A4), or five years

*2

*3

*4

20 ~ 80%

5 ~ 85%

*3

Print Head Life: Six billion shots (per nozzle) or five years

(whichever comes first)

(whichever comes first)

1.2.1.9 Safety Standards: EMC

220-240V model

Safety standards: EN 60950

EMI: EN 55022(CISPR Pub.22) class B

AS/NZS CISPR22 class B

1.2.1.10 CE Marking

220-240V model

Low Voltage Directive 73/23/EEC: EN60950

20

27

35

30

40

EMC Directive 89/336/EEC: EN55022 Class B

EN61000-3-2

EN61000-3-3

EN55024

PRODUCT DESCRIPTION Specifications 16

Page 16

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.3 Interface

The EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 provides the following

interface.

1.3.1 USB Interface

Standards

“Universal Serial Bus Specifications Revision 2.0”

“Universal Serial Bus Device Class Definition for Printing Devices Version

1.1” (printer unit)

“Universal Serial Bus Mass Storage Class Bulk-Only Transport Revision 1.0”

(storage unit)

Transfer rate: 480 Mbps (High Speed Device)

Data format: NRZI

Compatible connector: USB Series B

Recommended cable length: 2 [m] or less

Connector signal layout

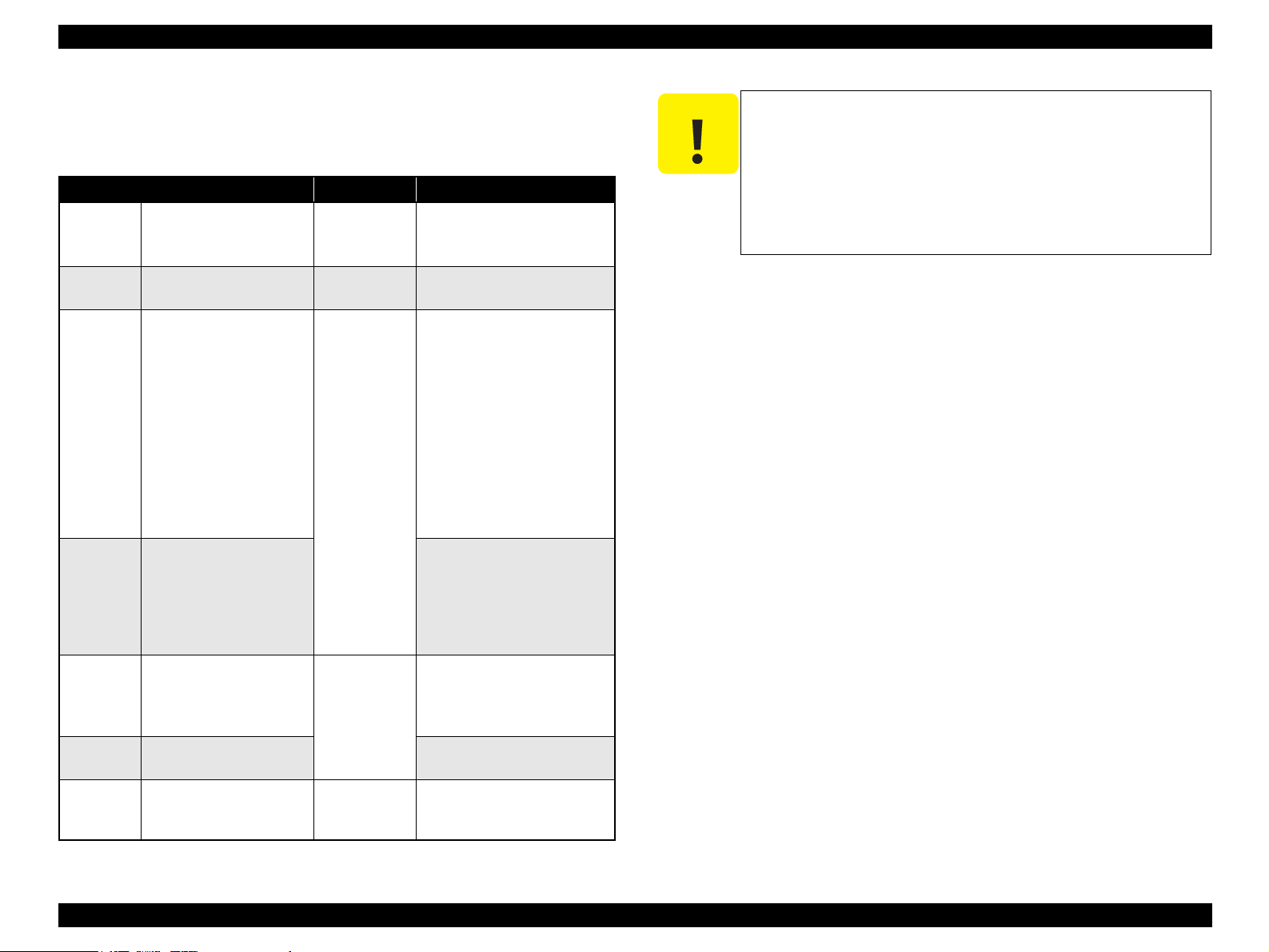

Table 1-11. Connector pin assignment and signals

Pin No. Signal name I/O Function description

1 VCC --- Cable power. Max. power consumption is 2mA.

2 -Data Bi-D Data

3 +Data Bi-D Data, pull up to +3.3V via 1.5K ohm resistor.

4 Ground --- Cable ground

Pin #2

Pin #3

Figure 1-8. USB pin Assignment

Pin #1

Pin #4

PRODUCT DESCRIPTION Interface 17

Page 17

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.3.2 Standard Card Slots

1.3.2.1 Memory card

Table 1-12. Memory card

Memory card standards Slots Supported memory cards

Compact

Flash

SmartMedia SmartMedia Standard 2003

Memory

Stick

Memory

Stick PRO

SD SD Memory Card

MultiMedia

Card

xD-Picture

Card

CF+ and CompactFlash

Specification Revision 1.4

compliant

compliant

Memory Stick Standard

version 1.3 compliant

MemoryStick Standard

Memory Stick PRO Format

Specifications version 1.0

compliant

Specifications/PART1.

Physical Layer Specification

Version 1.0 compliant

MultiMediaCard Standard

compliant

xD-Picture CardTM Card

Specification Version 1.20

Type M compliant

CF Type II slot • CompactFlash

(memory card only)

• Microdrive

SmartMedia slot •SmartMedia

(maximum capacity: 128 MB)

Memory Stick/

Memory Stick

PRO slot

SD/MMC slot • SD (Secure Digital) memory

xD-Picture Card

slot

• Memory Stick

(maximum capacity: 128 MB,

including versions with

memory select function)

• MagicGate Memory Stick

(maximum capacity: 128 MB,

copy protection function is not

supported)

• Memory Stick Duo

(requires Memory Stick Duo

adapter)

• MagicGate Memory Stick Duo

• Memory Stick PRO

(copy protection function is not

supported)

• Memory Stick PRO Duo

(requires Memory Stick Duo

adapter)

card

•miniSD card

(requires SD adapter)

MultiMediaCard

• xD-Picture Card

• xD-Picture Card Type M

C A U T I O N

Note the following caution points when handling the memory card.

Since the SD card and Memory Stick share the same slot, only

one can be inserted at a time.

Since the SmartMedia and xD-Picture Card share the same

slot, only one can be inserted at a time.

When a memory card is being accessed, be sure to keep the

memory card slot’s cover closed and do not touch the memory

card.

1.3.2.2 Supported power supply voltage

3.3V/5V (both)

3.3V (only)

NOTE 1: 3.3V power is supplied to media that support both 3.3V and 5V.

2: Maximum current to memory card is 500mA.

3: 5V type memory cards are not supported.

PRODUCT DESCRIPTION Interface 18

Page 18

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.3.2.3 Multi-slot operations

Overview

There is only one type of card that can be used to simultaneously access both

a connected computer and the direct printing function.

The slots have assigned priority to determine which slot will be accessed first

when cards are inserted in several slots at once.

To select a card that has been inserted in a non-active slot, the card in the

active slot must first be removed.

• Direct printing

Only the image files in the active slot are valid and have assigned frame

numbers. The number of images will not change if a card is also inserted in

a non-selected slot.

• Connection to computer (Windows)

Only one drive is displayed at a time as a “removable disk” and only the

card that is in the active slot can be accessed via the removable disk. A card

that has been inserted into a non-selected slot cannot be accessed.

• Connection to computer (Macintosh)

Only the card in the active slot can be mounted on the desktop. A card that

has been inserted into a non-selected slot cannot be mounted on the desktop.

Details

Access priority

The access priority among slots is assigned as:

1: CF (Microdrive)

2: SmartMedia/xD-Picture Card

3: Memory Stick (Memory Stick PRO)/SD (MMC)

Slot selection when power is turned on

If cards are inserted in several slots when the power is turned on, the active

slot is determined by the priority ranks listed above.

Example: If Smart Media and Memory Stick are both inserted at power-on,

the SmartMedia slot becomes the active slot.

Slot selection after power is turned on

When a card is removed from the active slot, the slot with the next-highest

priority becomes the active slot (if a card has been inserted into it). There is no

need to re-insert any card before accessing it. If no slots contain any cards, the

highest-priority slot (CF Microdrive) again becomes the active slot.

Cards can be removed from non-selected slots in any order.

Example: If a memory stick and CF card are inserted while SmartMedia is

selected, CF becomes selected (active) once SmartMedia is

removed.

PRODUCT DESCRIPTION Interface 19

Page 19

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.4 Memory Card Print

1.4.1 Basic Specifications

1.4.1.1 File system

DCF Version 1.0 or 2.0 is the file system that can be used with this unit’s stand-alone

printing functions. Operation is not guaranteed when any other file system is used.

The file system used by the card reader function depends on the host’s specifications.

For a detailed description of the DCF specifications, see the “Design Rule for Camera

File System Standard, DCF Version 2.0, JEIDA-CP-3461”.

1.4.1.2 Media format

Media must be formatted according to the DCF Version 1.0 or 2.0 standard.

DOS FAT formats (FAT12, FAT16) and single partition (basic partition)

1.4.1.3 File formats

The file formats supported by this unit are described below.

JPEG files (*.JPG)

These are photo data files that comply with the Exif Version 2.21 standard. (Exif

version 1.0/2.0/2.1/2.2/2.21)

Camera specification files (*.MRK)

These are definition files used when in camera specification mode. An

“AUTOPRINT.MRK” file whose full path name is no longer than 32 characters is

valid.

PRINT Image Framer (P.I.F.) definition file (*.USD)

File to define the layout in accordance with the PRINT Image Framer

specifications. Files only in the “¥EPUDL¥” directory are available. Compatible

with Print Image Framer Rev.2.1.

PRINT Image Framer (P.I.F.) definition file (*.FD2)

File to define the layout in accordance with the PRINT Image Framer

specifications. All files in the memory card are targeted for search.

Compatible with Print Image Framer Rev 3.1.

File contents are divided into complete type and template type.

Template type: The frame only on which image data is printed is specified.

Provides nearly identical functions as those supported with

the current P.I.F. Rev.3.1.

Complete type: Print layout information, image data and frame data is

contained in one package. Printing is performed using this file

only without specifying photos.

Note: As a general rule, this unit will support up to level 1 of P.I.F. Rev.3.1

Note, however, any file that is saved in the following directories or their sub-directories

cannot be included as files to be printed.

Directories containing system properties or hidden properties

“RECYCLED”

Windows directory for deleted files

“PREVIEW”

Directories containing CASIO’s DSC thumbnail images

“SCENE”

Directories containing data for CASIO’s DSC Best Shot function

“MSSONY”

Directories containing SONY’s DSC e-mail image data, voice memos, video files,

or non-compressed images

“DCIM¥ALBUM¥IMAGE”

CASIO DSC album data save directory

1.4.1.4 Valid image size

The maximum image size handled by this unit is:

Horizontal: 80 ≤ X ≤ 9200 (pixels)

Vertical: 80 ≤ Y ≤ 9200 (pixels)

PRODUCT DESCRIPTION Memory Card Print 20

Page 20

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.4.1.5 Maximum number of photo data files

This unit can handle up to 999 photo data files. If the amount of photo data to be

recorded exceeds the capacity of one memory card, this unit uses file sorting rules to

sort the photo data into valid photo data in frames numbered from 1 to 999. Although it

is possible to print photo data files with frame numbers over 999 that have been

specified for printing by camera specification files, the maximum number of frames

that can be specified is 999 frames.

If you insert a memory card that contains over 999 photo data files, only files up to 999

will be printed by the “Print All” or “Print index sheet” functions.

1.4.1.6 Thumbnail image data

This unit handles thumbnail image data in the DCF Version 1.0 or 2.0 format (Exif

format, 160 x 120 pixels).

During this unit’s Index sheet and memory card printing modes, the layout is 80

thumbnails per sheet (when using plain paper or special paper in high-speed print

mode).

1.4.1.7 File sorting

This unit stores all photo data files in the memory, using the photo data files’ full-path

file names (for example, “¥DCIM¥100EPSON¥EPSN0000.JPG”), and assigned photo

frame numbers. Since photo frame numbers are assigned based on this unit’s own

proprietary file sorting rules, the assigned frame numbers do not necessarily match

those indicated by digital cameras.

1.4.1.9 Rules for acquisition of date/time data

The following priorities are used to fetch date and time information from photo data

files.

1. Date/time data that complies with the standard format (Exif) for digital

cameras

2. Date/time data that complies with the DOS standard file system (file time

stamps)

3. Fixed values (01/01/1980, 00:00:00)

Note that the date/time data assigned to individual photo data files does not necessarily

match the date/time when the photo was actually taken. The photo date/time may be

modified due to the digital camera’s calendar settings (presence/absence of functions,

incorrect date/time settings, etc.), processing of the photo data after the photo was

taken, or subsequent saving of data. In such cases, this unit performs the relevant

processing based on the most recently modified date/time data.

1.4.1.10 Number of sheets which can be printed in total

Printing sum total number of sheets presupposes that it is possible to 999 sheets.

Moreover, the printing sum total number of sheets per sheet is possible to 99 sheets.

1.4.1.8 File sorting rules

This unit sorts photo data files based on the following prioritization rule.

File name is sorted in ASCII order as full path name.

Note: Sorting results are not guaranteed if two files have matching full-

path file names. (Matching full-path file names are not allowed

under the DOS specification.)

PRODUCT DESCRIPTION Memory Card Print 21

Page 21

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.4.2 Functions

1.4.2.1 List of functions

The memory card print menu and its settings are listed in the following table. The

values shown in this table indicate the total number of options and the number of pages

or copies that can be printed consecutively.

Table 1-13. List of functions

Memory card

printing

Print selected

*1

image

Print all images Print All/

*2

DPOF

Print index sheet Print Index Sheet None Plain Paper 1 1

Note *1 : “Print selected image” will be selected as default function of Memory Card Print.

*2: It is available only “DPOF” file exists in the memory card.

Mode selection Layout Paper type

Print Select • Standard

• Border free

• Border free

• Standard

PictBridge

Print Select • Standard

• Border free

• Border free

• Border free

• Border free

• Plain Paper

• Photo Paper

• Matte Paper

• Plain Paper

• Photo Paper

• Matte Paper

• Plain Paper

• Photo Paper

• Matte Paper

1.4.2.2 Memory card printing mode

Print selected image

This function prints selected image file stored in the memory card. As shown

below, the number of printed pages depends on the number of copies to be printed.

Print all images

This function prints all of the image files stored in the memory card. As shown

below, the number of printed pages depends on the number of copies to be printed.

DPOF printing

In this mode, the photo frame numbers previously specified via the camera are

printed in the number of pages specified via the camera. Only the paper type and

layout are specified on the printer side. If the layout assigned multiple photos per

output sheet, photos that have different frame sizes are automatically assigned in

the specified number of pages in numerical order (of the specified photo frame

Paper

size

3 1

3 1

3 1 to 99

Page/

copies

numbers). If index print mode was set via the camera, this unit will print in DPOF

index layout. (When in DPOF print mode, the mode cannot be switched by writing

the print file specification from the host after inserting the memory card.)

Print index sheet printing

This function prints thumbnail images (stored in the memory card) onto an order

sheet (form) that is marked for selecting images.

Table 1-14. Memory card printing mode

Setting Memory card printing mode Description Option, setting range, etc.

Layout

(no menu)

Paper type • Print selected image

Paper size • Print selected image

Pages/

copies

Quality • Print selected image

• Print selected image

• Print all images

• DPOF printing

• Print all images

• DPOF printing

Print index sheet printing Fixed Plain Paper

• Print all images

• DPOF printing

Print index sheet printing Fixed A4

Print selected image Sets number

Print all images 1

DPOF printing The number of copies specified via

Print index sheet printing Fixed Fixed as 1 page (can vary according

• Print all images

• DPOF printing

Print index sheet printing Fixed Prints it by the quality of Plain Paper.

Sets print

layout

Sets paper

type

Sets paper

size

of printout

Sets print

quality

Fixed in combination with paper type

and paper size (refer to “1.4.3 Layout

and Paper Type, Paper Size” (p.23))

Plain Paper, Photo Paper or Matte

paper

A4, 10x15/4”x6” or 13x18/5”x7”

1 to 99 copies (default is 1 copy).

the camera is used.

The setting range is 1 to 99 copies

(default is 1 copy).

to the number of image files)

Fixed according to paper type (refer

to “1.4.7 Relation between Paper

Type and Quality” (p.27))

Only the Color print is

supported.

PRODUCT DESCRIPTION Memory Card Print 22

Page 22

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.4.3 Layout and Paper Type, Paper Size

The layout/paper type and size combinations that can be selected are listed below.

Table 1-15. Layout and Paper Type, Paper Size

Layout Paper type Paper size Description

Border free Photo Paper A4

10x15

13x18

1-up with

borders

20-up --- 10x15

30-up --- 13x18 Prints 30 frames per page, laid out in 5 columns and

80-up --- 10x15

Plain Paper A4

10x15

13x18

13x18

13x18

Prints with no margins along top, bottom and both

sides

Prints with 3mm margins along top, bottom and

both sides

Prints 20 frames per page, laid out in 5 columns and

4 rows (For DPOF index print only)

4 rows (For DPOF index print only)

Prints 80 frames per page, laid out in 10 columns

and 8 rows (For DPOF index print only)

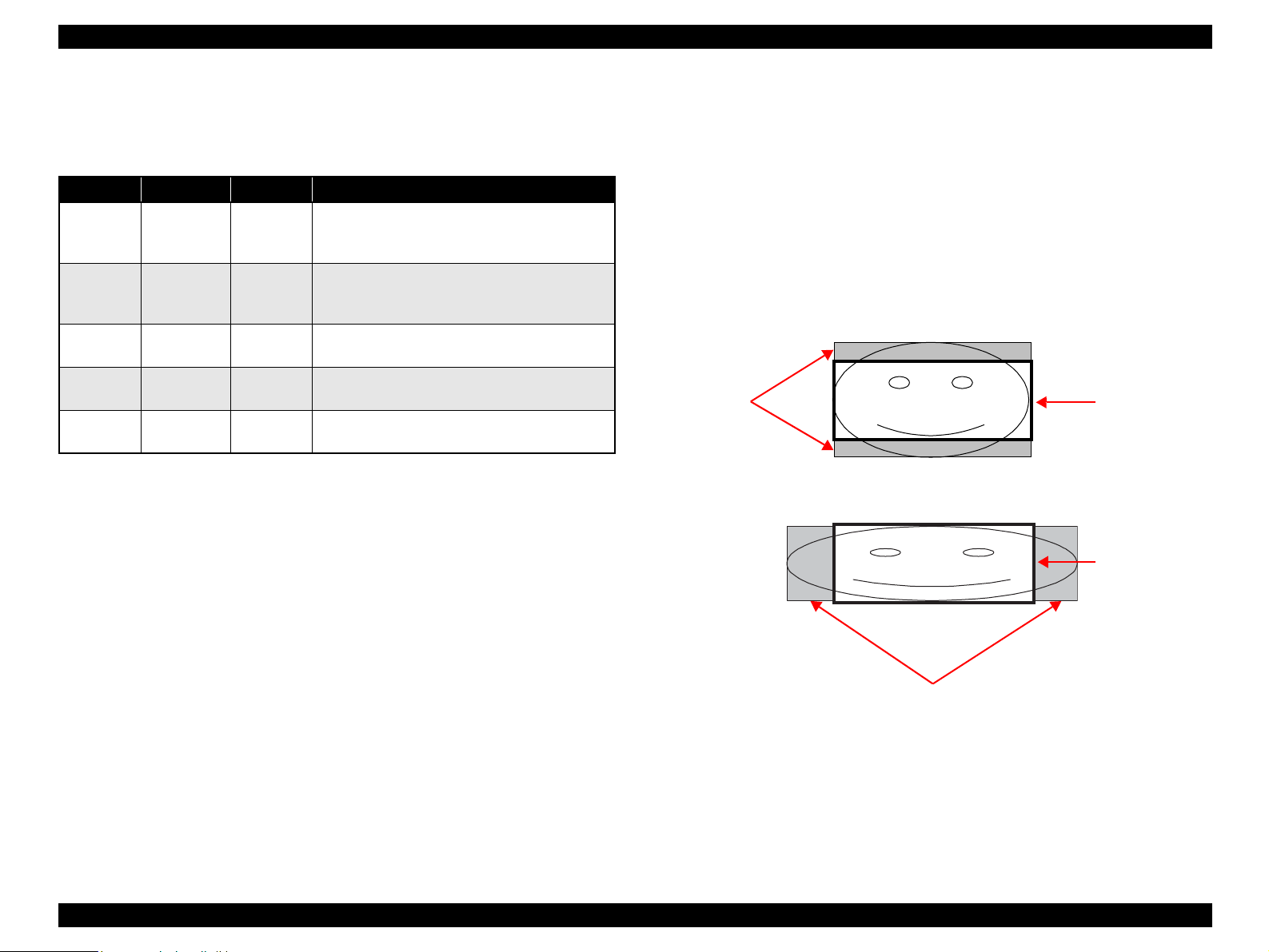

1.4.4 Trimming Function

A trimming function is provided as a means of coordinating photo data with the types

of photo frames handled by this unit. This function is always activated so that printing

photo data is in shapes that fit these photo frames.

This function is described briefly below.

The printed photo frame and the photo to be printed are matched in length along one

side and the photo is resized along the perpendicular side to fit the frame on that side.

Any part of the photo that does not fit within the photo frame is trimmed away (not

printed).

The image below shows an example in which the photo data is aligned vertically

with the photo frame.

These parts are

trimmed.

The image below shows an example in which the photo data is aligned

horizontally with the photo frame.

Photo frame

(print area)

Photo frame

(print area)

These parts are trimmed.

Figure 1-9. Trimming Function

PRODUCT DESCRIPTION Memory Card Print 23

Page 23

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

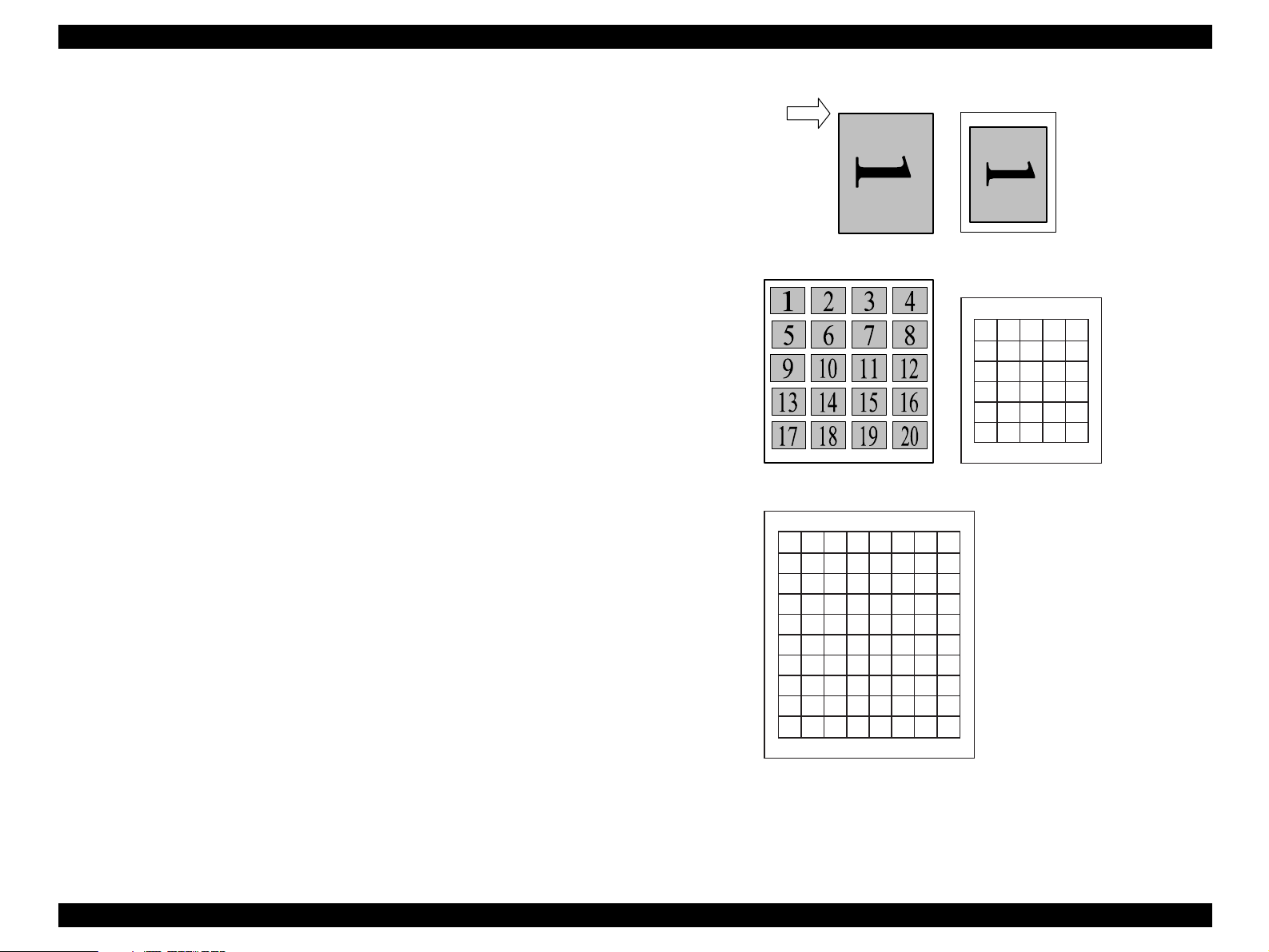

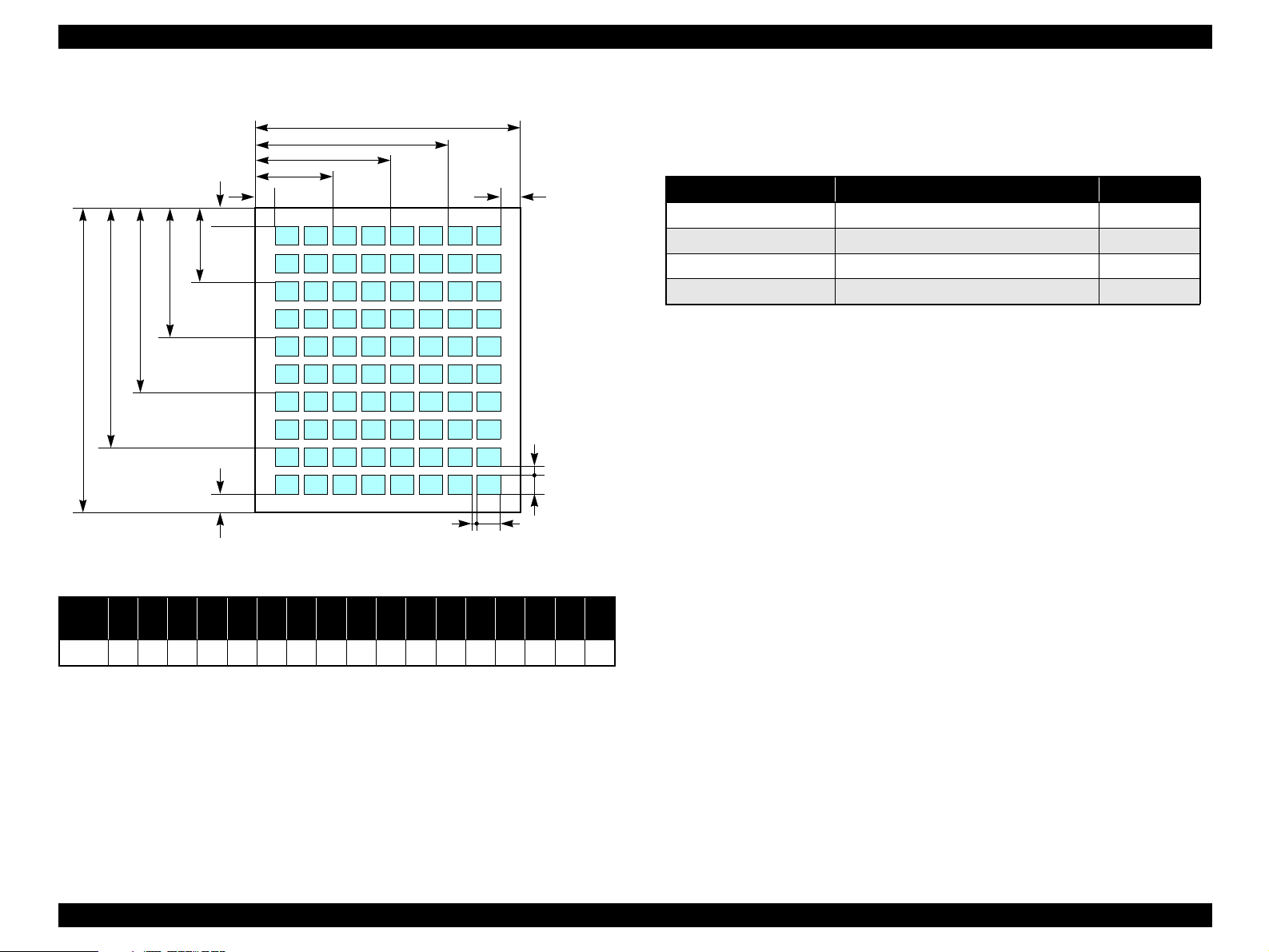

1.4.5 Assignment Rules for Photo Frame Numbers and Rotation

Top edge

The rules concerning photo frame numbers that are referenced when assigning photos

are described below. The numbers shown in each diagram and photo frame below

indicate the photo frame numbers used for various types of layout.

The direction of the number shown in each photo frame matches the direction of the

printed photo to which the horizontal photo data was allocated. When there are more

pixels vertically than horizontally, the vertical photo data is allocated instead, and the

number shown in the figure below is then rotated 90° before being printed. In Index

printing mode, the numbers are printed as they are shown below, regardless of the

shape of the photo data.

However, when the photo data has an equal number of pixels vertically and

horizontally the photos are printed without rotation, regardless of the layout.

NOTE: The vertical photo data refers to when the photo data file itself is set for a

vertical (portrait) orientation. Photo data is defined as the vertical photo

data if it is taken by a digital camera with a portrait position detecting

function.)

<Border-free> <1 sheet with borders>

12345

678910

11 12 13 14 15

16 17 18 19 20

21 22 23 24 25

25 26 27 28 30

<20-up>

12345678

9 10 111213141516

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64

65 66 67 68 69 70 71 72

73 74 75 76 77 78 79 80

<80-up>

<30-up>

Figure 1-10. Assignment Rules for Photo Frame Numbers and Rotation

PRODUCT DESCRIPTION Memory Card Print 24

Page 24

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

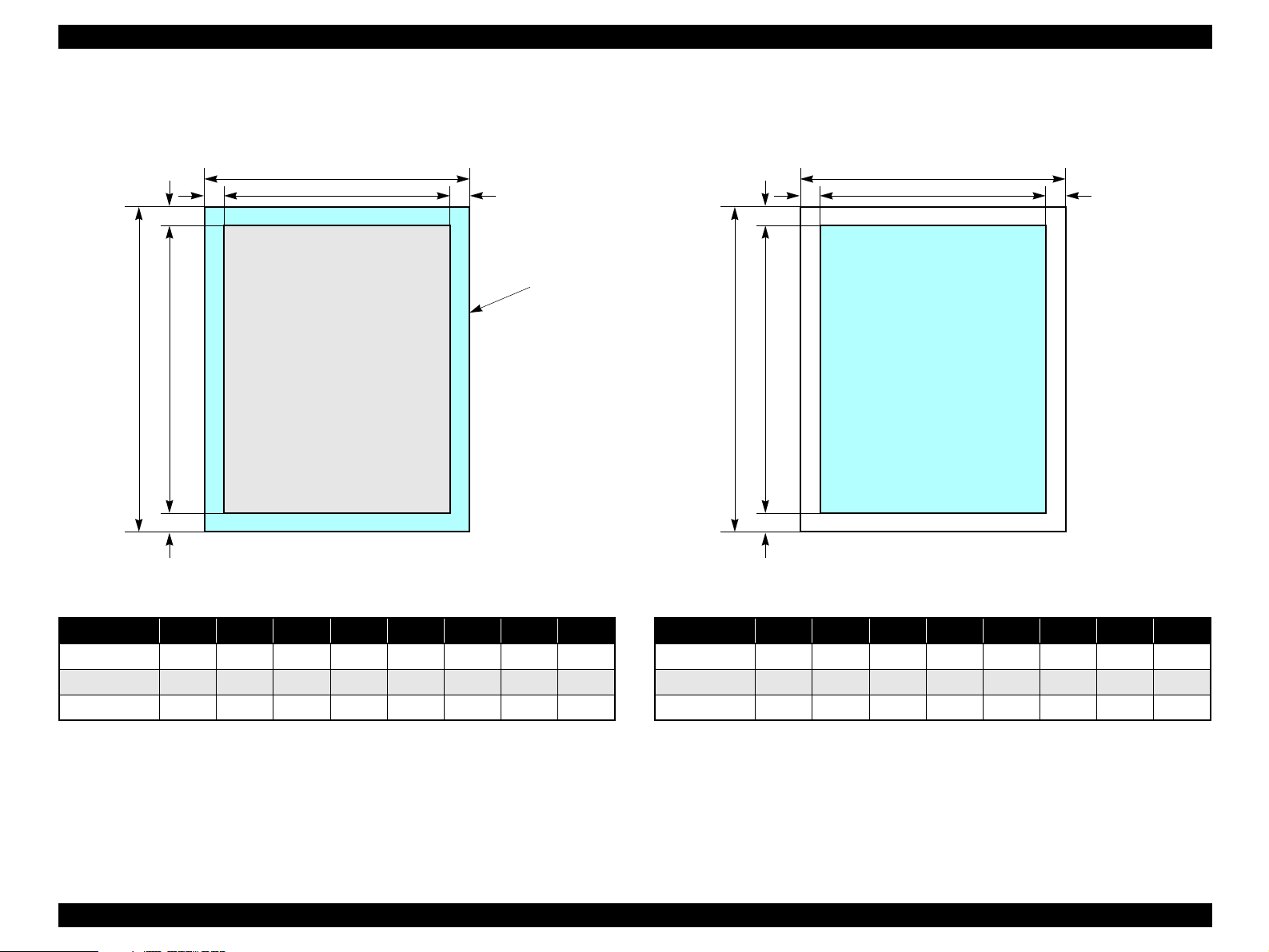

1.4.6 Layout Drawings

1.4.6.1 Border free

BD

H

C

A

Paper

Figure 1-11. Border free

Table 1-16. Border free (unit: mm)

FEG

Printable

area

1.4.6.2 1-up with borders

DB

H

Figure 1-12. 1-up with borders

Table 1-17. 1-up with borders (unit: mm)

A

C

Printable area

FEG

Paper type A B C D E F G H

A4 210 297 215.08 305.04 2.54 2.54 2.96 4.02

10x15 101.6 152.4 106.68 160.53 2.54 2.54 2.82 3.6

13x18 127 178 132.08 186.04 2.54 2.54 2.96 4.02

Paper type A B C D E F G H

A4 210 297 204 291 3 3 3 3

10x15 101.6 152.4 95.6 146.4 3 3 3 3

13x18 127 178 121 172 3 3 3 3

PRODUCT DESCRIPTION Memory Card Print 25

Page 25

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

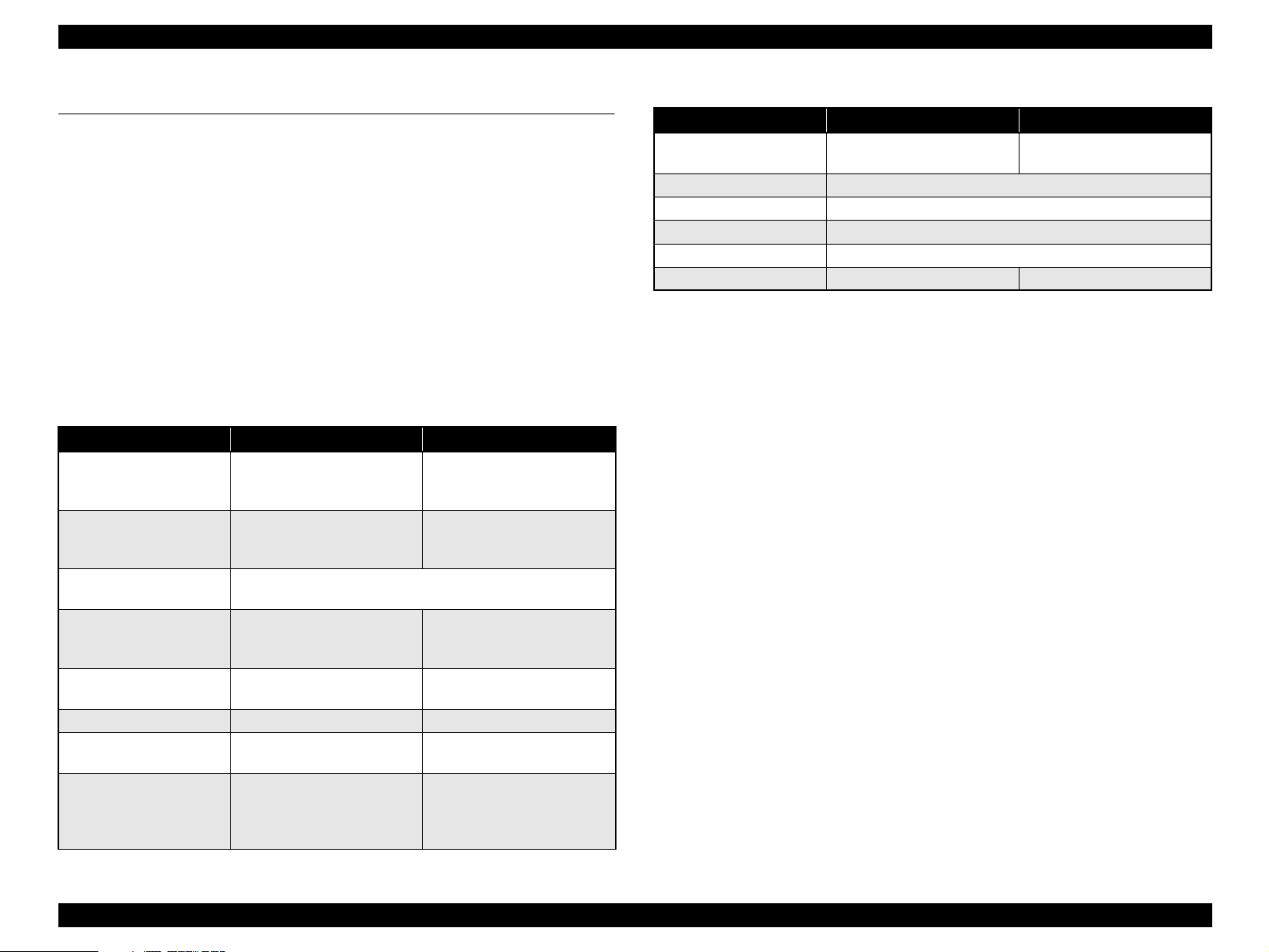

1.4.6.3 20-up

A

K

LB

H

IIIC

Figure 1-13. 20-up

Table 1-18. 20-up (unit: mm)

Paper

type

10x15 101.6 152.4 20 20 6.1 6.3 19.8 20.3 3 3 89.3 112.3

13x18 127 178 29 24.6 3 3 5 10 1.7 10 121 163

A B C D E F G H I J K L

FEG

J

J

J

J

D

1.4.6.4 30-up

A

B

H

Figure 1-14. 30-up

Table 1-19. 30-up (unit: mm)

Paper

type

13x18 127 178 20 20 4.5 4.5 14 14 4.5 6

A B C D E F G H I J

IC

FEG

J

D

PRODUCT DESCRIPTION Memory Card Print 26

Page 26

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.4.6.5 80-up

N

O

P

B

1.4.7 Relation between Paper Type and Quality

A

J

I

H

KGL

M

F

D

Q

EC

Figure 1-15. 80-up

Table 1-20. 80-up (unit: mm)

In this mode, printing is always in color (CMYK), not black ink only.

Table 1-21. Relation between Paper Type and Quality

Paper type Print resolution (H x V dpi) Dot size

Plain Paper 720 x 720 VSD3

Photo Paper 1440 x 720 VSD3

Matte Paper 1440 x 720 VSD3

Index sheet (Plain Paper) 360 x 360 VSD1

Paper

A4 210 297 20 20 2 5 18 62 106 150 18 26 76 126 176 226 26

A B C D E F G H I J K L M N O P Q

type

PRODUCT DESCRIPTION Memory Card Print 27

Page 27

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.5 USB Direct-Print/PictBridge Functions

The printer can print from Digital Still Camera that is compliant with the following

specifications.

1.5.1 Supported Device

USB DIRECT-PRINT

The device that is compliant with “USB DIRECT-PRINT” specification.

CIPA DC-001-2003 Digital Photo Solutions for Imaging Device

The device that is compliant with “CIPA DC-001-2003 Digital Photo Solutions for

Imaging Devices” specification.

1.5.2 Functions Available from DSC

Following functions are available.

Implementation of each function depends on the DSC.

Table 1-22. Functions Available from DSC

Function USB Direct-Print Functions PictBridge Functions

Specify picture OK

(single picture or DPOF)OK(single picture, multiple pictures

or DPOF)

Specify paper type OK

(Plain paper, Photo paper,

Glossy paper and Matte paper)

Specify paper size OK

(A4, 5x7in., 4x6in., 8x10in. and Letter)

Specify layout OK

(borderless, Single. 2up, 4up,

8up are available for DPOF)

Specify date print OK

(Enable or Disable)

Specify print quality NG OK

Automatic correction OK

(Enable or Disable)

Cropping OK

(Any area of rectangle. This

function is available for Single

picture print only)

(Plain paper and Glossy paper)

(borderless, Single, 2up, 4up,

8up, 20up and Index)

(Any area of rectangle)

OK

OK

OK

NG

OK

Table 1-22. Functions Available from DSC

Function USB Direct-Print Functions PictBridge Functions

PRINT Image Framer OK

(Enable or Disable)

Status acquisition OK

Start print OK

Stop print immediately OK

Stop print at the end of page OK

Reset printer OK ---

---

1.5.3 Operation

1.5.3.1 Preparation

Conditions described below are required before starting printing.

The printer is not printing from the PC.

The printer is not printing from the memory card slot.

The printer is not performing the backup of the memory card.

The error (paper empty, ink end, etc.) is cleared.

Note *: PictBridge only.

1.5.3.2 Standard Operations

Standard operations are described below. These operations depends on the DSC.

1. Preparation at the printer

Some settings are required before connecting with the DSC. If your DSC can set

these settings, preparation at the printer is not required.

1-1. Choose the Paper Type, Paper Size and Layout to the desired setting.

1-2. Change More Options if necessary (e.g. Automatic Correction, Filter and

Date print)

2. Preparation at the DSC

Some operations are necessary before connecting to the printer.

2-1. Set the DPOF (or select pictures*) if printing multiple picture.

*

PRODUCT DESCRIPTION USB Direct-Print/PictBridge Functions 28

Page 28

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

2-2. Choose the picture when Single picture print and set area to crop if

necessary.

2-3. Choose the Paper Type, Paper Size, Quality and Layout if these settings can

be specified from DSC.

Note *: PictBridge only.

3. Start printing

3-1. Connect the DSC to the printer with a USB cable. The cable that works well

with the DSC is recommended.

3-2. Start print by operating form the DSC.

3-3. The Printer print by printing conditions from DSC, if the DSC dose not

designate the printing parameter, the printer prints it by using the printing

condition that is registered to the printer.

When this unit is connected to a DSC that supports the USB DIRECT-PRINT protocol

(Revision 1.0), print settings, image selection, status monitoring, and print start/stop

commands can be controlled from the DSC.

Note *1: USB Direct-Print only.

*2: PictBridge only.

*1

*2

1.5.3.3 Display when DSC is Connected

When DSC is connected with the above conditions, “Camera Connected” icon will be

displayed on the LCD and the “Print All” LED will be turned on.

1.5.3.6 Exclusive Control Specifications for Paper Type, Size, and

Layout

Depending upon the DSC and printer settings, there may be some combinations of

paper type, size, and layout settings that are not supported by this printer.

In such a case, the paper type is given priority; paper size and layout are changed to

settings that will allow printing (the initial settings made on the printer’s operation

panel for the paper type given priority) and the document is printed.

1.5.3.7 Camera direct error executing other processing (error)

When unsupport equipment are connected during the other processing is executed

(error), the camera direct error is displayed after other processing execution (error).

When the unsupport equipment is connected and other processing ends, it doesn't

become a camera direct mode and the camera direct error is not displayed.

1.5.3.4 Cancel Print

This unit can be canceled from the DSC. The “Stop” button of the printer is also

available.

1.5.3.5 Operation when the Printing is Completed

Disconnect the USB cable after the printing is completed if you’d like to print from the

memory card

PRODUCT DESCRIPTION USB Direct-Print/PictBridge Functions 29

Page 29

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.6 Control Panel

1.6.1 Buttons

The control panel contains following 11 buttons, which are used to set and execute

various operations.

All of them are non-lock type buttons.

Table 1-23. Buttons

Button Function

Power Button Execute turning on/off this unit.

Mode Button Selects one of memory card print mode.

Setup/Utilities Button Make transition from “Memory Card mode” to “Setup mode”.

Up/Down Button sets number of copies.

Left/Right Button Select print image.

Paper Type Button Select paper type.

Paper Size Button Select paper size.

Start Button Start card print.

Stop/Clear Button Stop job of printing or sometimes work at the printing.

Clear the setting value at the non-printing

Refer to “1.6.5.1 Memory card mode/Setup mode/DSC direct mode ” (p.33) for details

about each button.

1.6.2 Indicators

The control panel contains 1.5” LCD and 10 LEDs, and one LED is located near the

card slot, which are used to indicate various status.

Table 1-24.

LED Function

Power LED [Green] Light at stand-by. Blink while some operation is proceeding.

Mode LED 1-3 Light one of them while some memory card print function

showing below is ready or proceeding.

1st [Green] Print Select

2nd [Green] Print All/PictBridge

3rd [Green] Print Index Sheet

Paper Type LED 1-3 Light one of them showing which paper type below is selected.

1st [Green] Plain Paper

2nd [Green] Photo Paper

3rd [Green] Matte paper

Paper Size LED 1-3 Light one of them showing which paper size below is selected.

1st [Green] A4

2nd [Green] 10x15/4"x6"

3rd [Green] 13x18/5"x7"

1.5inch LCD Display photo, print number, error, setting, etc.

Card Access LED [Green]* Light when available memory card is in a slot. Blink when

accessing to the card.

Note * : An another LED is located near the memory card slot and the printer status is

indicated with the LED.

PRODUCT DESCRIPTION Control Panel 30

Page 30

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

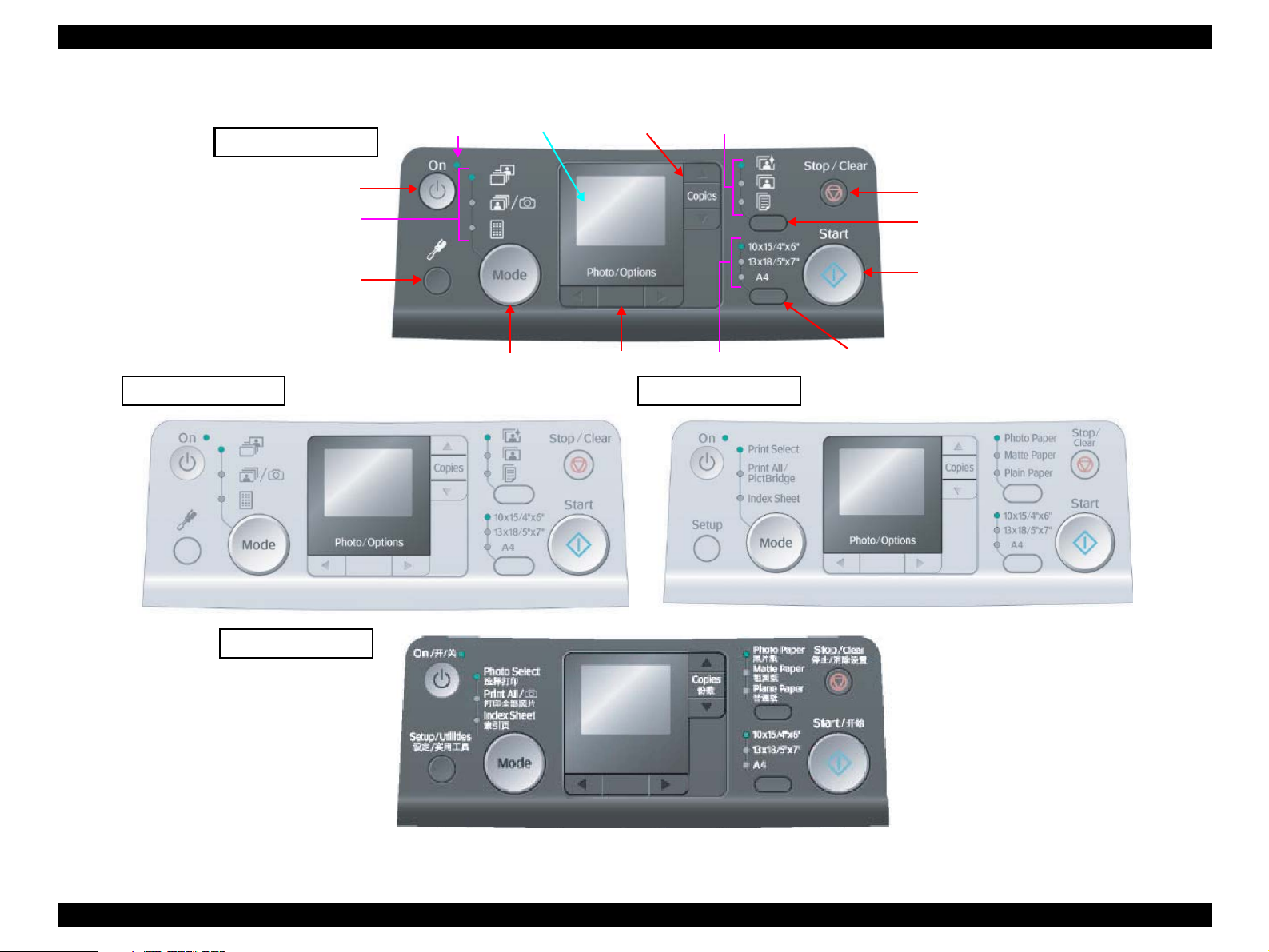

1.6.3 Control Panel Appearance

Paper Type LED 1-3

Standard version

Power LED

1.5inch LCD

Up/Down Button

Setup/Utilities Button

Premium version

ME PHOTO 20

Power Button

Mode LED 1-3

Mode Button

Left/Right Button

Paper Size LED 1-3

Asia version

Stop/Clear Button

Paper Type Button

Start Button

Paper Size Button

Figure 1-16. Control panel

PRODUCT DESCRIPTION Control Panel 31

Page 31

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.6.4 The method of changing mode

This printer has the following four modes:

Memory card mode

Setup mode

*1

DSC direct mode

If a memory card is not inserted at power-on, Memory card mode is selected in default

configuration.

Note *1: It is possible to enter respective modes by pressing the button with the same

name as each mode.

*2: This unit moves to a DSC direct mode after a device is confirmed for DSC direct,

when a device is connected to EXT. I/F (USB Host).

Factory settings of each mode are shown below.

Paper Type Photo paper Plain paper

Paper Size 4"x6" or 10x15/4"x6" A4

Sheet 1 ---

*1

*2

Table 1-25. Factory Settings of Each Mode

Item Memory card mode Setup mode

Refer to “1.6.5.1 Memory card mode/Setup mode/DSC direct mode ” (p.33) for details

about DSC direct mode.

PRODUCT DESCRIPTION Control Panel 32

Page 32

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.6.5 Operations

1.6.5.1 Memory card mode/Setup mode/DSC direct mode

The functions of this unit caused by each button in stand-alone copy mode or memory card print mode are described in the following table.

Table 1-26. Operations

Button

Power Button • Turn off this unit.

Memory Card

Button

Setup/Utilities

Button

Left/Right Button • Select print image. • Select setup menu. • Invalid.

Up/Down Button • Set number of copies incrementally/decrementally. • Select adjustment value or setting value. • Invalid.

Paper Type

Button

Paper Size Button • Alternate paper size of “A4”, “4x6/10x15” and “5x7/13x18”, which

• Change to next “Memory card print” function.

Case

• [Print Select]

Change to “Print All/PictBridge”.

• [Print All/PictBridge]

Change to “Print Index Sheet”, and change paper type and paper size

to “Plain Paper” and “A4”.

• [Print Index Sheet]

Change to “Print Select”, and change paper type and paper size to the

one last set in “Print All/PictBridge” or “Print Select”.

• Invalid while printing, cleaning head, stopping printing, exchanging I/C, or in error status except for memory card error, PG error.

• Make transition from “Memory card print” mode to “Setup” mode and

light off all mode LEDs.

• Invalid while printing, cleaning head, stopping printing, exchanging I/C, or in error status except for memory card error, PG error.

• Invalid while printing, cleaning head, stopping printing, exchanging I/C, or in error status.

• Invalid while printing, cleaning head, stopping printing, exchanging I/C, or in error status.

• Alternate paper type of “Plain Paper”, “Photo Paper” and “Matte

Paper”, which will be used in “Print All/PictBridge” or “Print Select”.

• Invalid in “Print Index Sheet”, and then it is fixed to “Plain Paper”.

• Invalid while printing, cleaning head, stopping printing, exchanging I/

C, or in error status.”

will be used in “Print All/PictBridge” or “Print Select”.

• Invalid in “Print Index Sheet”, and then it is fixed to “A4”.

• Invalid while printing, cleaning head, stopping printing, exchanging I/

C, or in error status.

Memory Card Print Setup mode DSC direct mode

• Make transition from “Setup” mode to “Memory card print”

mode and select and light “Print Select”.

• Select paper type and paper size those are memorized.

• Return to the original mode selected before “setup” mode. • Make transition to “Setup” mode and

• Invalid. • Same as “Paper Type Button” of Memory

• Invalid. • Same as “Paper Size Button” of Memory

Function

• Invalid.

light off all mode LEDs.

Card Print.

Card Print.

*1, 2

PRODUCT DESCRIPTION Control Panel 33

Page 33

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

Table 1-26. Operations

Button

Memory Card Print Setup mode DSC direct mode

Start Button • Start memory card print.

• Invalid with no card in slots.

• Move to memory card error status when incompatible memory card is

inserted or no images found in the card.

• Invalid while printing, cleaning head, stopping printing, exchanging I/C, or in ink out error.

• Load paper in paper out error or double feed error and eject paper in paper jam error.

• Move to PG error status when platen gap is large. But when this button is pressed again in that status, that print will start.

Stop/Clear

Button

Not printing situation

• Reset the setting value (paper size, paper type, number of copies).

• Light all paper type and paper size LEDs for 1 second.

Printing situation

• Stop job of printing.

• Eject paper when paper exists or may exist in the paper path.

• Invalid while cleaning head and exchanging I/C.

• Clear some of error status.

Note *1 : Start print by operating form the DSC

• Start job of printing by conditions from DSC, if the DSC dose not designate the

printing parameter, the printer prints it by using the printing condition that is

registered to the printer.

• Invalid while printing, cleaning head, stopping printing, exchanging I/C, or in ink

out error, or without “A4” is selected.

• Move to PG error status when platen gap is large.

*2: Start print by operating form the DSC

Not copying or printing situation

• Invalid.

Copying or printing situation

• Stop job of printing.

• Eject paper when paper exists or may exist in the paper path.

• Invalid while cleaning head and exchanging I/C.

• Clear some of error status.

Function

*1, 2

• Execute procedure or Start print. Invalid but for cleaning some error

status.

(See below)

• Load paper in paper out error or double

feed error and eject paper in paper jam

error.

• Move to PG error status when platen gap

is large. But when this button is pressed

again in that status, that print will start.

Not printing situation

• Reset the setting value when the setup menu is “Auto

• Same as “Stop/Clear Button” of Memory

Card Print.

Correct” or “Borderless setting”.

• Light all paper type and paper size LEDs for 1 second and

return to “Check Ink Levels” screen.

Printing situation

• Stop job of printing.

• Eject paper when paper exists or may exist in the paper path.

• Invalid while cleaning head and exchanging I/C.

• Clear some of error status.

PRODUCT DESCRIPTION Control Panel 34

Page 34

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.6.5.2 Memory Card Insertion/Ejection

The functions of this unit caused by memory card insertion or ejection are described in

the following table.

Table 1-27. Memory Card Insertion/Ejection

Action Function

Card Insertion • Recognize the card and light Card Access LED if it is right.

• The LED blinks while memory access occurs to the memory card.

• The Power LED blinks during the card recognition.

• Return from the low power panel mode.

Card Ejection • Turn off Card Access LED.

• Stop print job while memory card print is in process and eject paper.

• Clear memory card error if memory card is wrong.

1.6.5.3 Connection/Removal of DSC

Table 1-28. Connection/Removal of DSC

Action Function

Connect the

DSC to this unit

by USB cable

Remove the

DSC from this

unit

• This unit moves to a DSC direct mode after a device is confirmed for DSC

direct, when a device is connected to EXT. I/F (USB Host). It won’t move to

DSC direct mode when it shows general printing mode or error. It moves to

DSC direct mode when it finished printing or error status has been resolved.

(Errors that is related with memory card, order sheet or PG will be

automatically canceled and it moves to DSC direct mode. Ink-low status will

be also ignored.).

• “Camera Connected” icon will be displayed with LCD and Change to “Print

Select” when connection was confirmed, not when it moves to DSC direct

mode. If the DSC direct device was connected to EXT I/F and any error has

occurred on confirmation, it shows DSC direct error.

• If this unit was on power save mode and DSC direct device was connected,

this unit will be back to usual status and then it confirms connection.

• This unit moves to “Memory card print” mode and select and light “Print

Select” when condition where device recognition was carried out normally

for DSC direct.

• During the printing from a device for DSC direct, this unit stops a printing

and moves to “Memory card print” mode and select and light “Print Select”.

• When this unit is displaying “DSC direct error”, this unit cancel it error. And

this unit returns it in condition of before connection.”

1.6.5.4 Low Power Panel Mode

Without any panel operation for 3 minutes while the printer unit is in standby status,

this unit moves into the low power panel mode in which power consumption for the

panel decreases.

This unit recovers from that mode by pushing any button but Power Button or printing

by PC.

This unit is turned off by pushing Power Button in that mode.

Table 1-29. Low Power Panel Mode

Action Function

Transition to low

power mode

Recovery from low

power mode

• Turn off all LEDs except for Power LED and Card Access LED.

• No move in error status except for memory card error and PG error.

• Inserting or ejecting of memory card or accessing it by PC has no effect

on low power mode.

• Recall the panel status as that before moving to low power panel mode.

• Inserting or ejecting of memory card or accessing it by PC has no effect

on low power mode.

1.6.5.5 Paper Thickness Lever Function

Paper thickness lever is wrong position, the printer displays “PG position” warning.

Table 1-30. Paper Thickness Lever Function

Paper thickness

lever status

PG open

(“H” to “L”)

PG close

(“L” to “H”)

• “Paper thickness lever was changed” or this image icon will be

displayed with LCD.

• “Paper thickness lever was changed” or this image icon will be

displayed with LCD.

• Clear the PG error and print job suspended by PG error when the Paper

thickness lever is changed to “L: Cut sheet position” in the PG error

status.

Function

PRODUCT DESCRIPTION Control Panel 35

Page 35

EPSON Stylus Photo R240/R245/R250/ME PHOTO 20 Revision C

1.6.6 Printer Condition and Panel Status

Note : “–”: Don’t care

Fast blink: 0.2sec. On + 0.2sec. Off repetition

Blink: 0.5sec. On + 0.5sec. Off repetition

Blink 2: Blink on and off along with access to a memory card.

Indicators (Normal ready mode)

Printer status Power LED

Power on (Initializing operation) Blink --- --- --- --- --- --- --- --- --- ---

Power on (Data Processing) Blink --- --- --- --- --- --- --- --- --- ---

Power off (Power-off in progress) Fast blink Off Off Off Off Off Off Off Off Off ---

Memory card mode (Print All/DPOF) --- Blink --- --- Selected type is On Selected type is On ---

Memory card mode (Print select) --- --- Blink --- Selected type is On Selected type is On ---

Memory card mode (Print index sheet) --- --- --- Blink Blink --- --- Blink --- --- ---

Setup mode --- Off Off Off Blink --- --- Blink --- --- ---