Page 1

0

3

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

EPSONStylusPhoto72

Color Inkjet Printer

EPSON STYLUS PHOTO 720 / STYLUS PHOTO EX3

EPSONStylusPhotoEX

SEIJ00001

Page 2

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

Page 3

About This Manual

This manual describes basic functions, theory of electrical and

mechanical operations, maintenance and repair procedures of EPSON

Stylus Photo 720 / Stylus Photo EX3. The instructions and procedures

included herein are intended for the experienced repair technicians, and

attention should be given to the precautions on the preceding page.

Contents

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3.TROUBLESHOOTING

Provides the step-by-step procedures for the

troubleshooting.

CHAPTER 4.DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for

disassembling and assembling the product.

CHAPTER 5.ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

APPENDIXProvides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read WARNING, CAUTION or NOTE

messages.

W ARNING

CAUTION

CHECK

POIN T

Indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in injury

or loss of life.

Indicates an operating or maintenance procedure, practice,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the results

achieved through a previous action.

Page 4

Revision Status

Revision Issued Date Description

Rev. A April 6, 2000 First Release

Page 5

EPSON Stylus Photo 720 / EPSON Stylus Photo EX

3

A

6

Revision

Contents

Product Description

Overview ....................................................................................................... 9

Features ................................................................................................... 9

Basic Specification .................................................................................... 10

Printing Specification .............................................................................. 10

Paper Feed specification ........................................................................ 11

Input Data Buffer .................................................................................... 11

Electric Specification .............................................................................. 11

Environmental Conditions ...................................................................... 12

Reliability ................................................................................................ 12

Safety Approvals .................................................................................... 12

Acoustic Noise ........................................................................................ 12

CE Marking ............................................................................................. 12

Interface Specification .............................................................................. 13

IEEE-1284 Parallel I/F (Forward Channel) ............................................. 13

IEEE-1284 Parallel I/F (Reverse Channel) ............................................. 13

USB (Universal Serious Bus) ................................................................. 16

Miscellanea ............................................................................................ 16

Preventing Hosts from Data Transfer Time-out .................................. 16

Interface Selection .............................................................................. 16

IEEE 1284.4 protocol ......................................................................... 17

Control Specification ................................................................................ 18

Control Panel .......................................................................................... 18

Control Switches .................................................................................... 18

Code Page Selection/ Parallel I/F IEEE1284.4 Setting ...................... 19

Special Setting Mode ......................................................................... 20

LED Indications ...................................................................................... 20

Initialization ............................................................................................. 21

Errors ...................................................................................................... 21

Paper ........................................................................................................... 22

Paper handling ....................................................................................... 22

Paper Specification ................................................................................ 22

Printable Area ........................................................................................ 24

Ink Cartridge ........................................................................................... 26

Physical Specification .............................................................................. 27

Consumables and Options ....................................................................... 28

Operating Principles

Overview .................................................................................................... 30

Printer Mechanism ................................................................................. 30

Printhead ................................................................................................ 32

Printing Process ................................................................................. 33

Printing Method .................................................................................. 34

Carriage Mechanism .............................................................................. 35

Platen Gap (PG) Adjustment Mechanism .......................................... 35

Paper Feeding Mechanism .................................................................... 36

Paper Loading Mechanism (ASF Unit) ................................................... 37

Ink System Mechanism .......................................................................... 39

Pump Unit and CR Lock Mechanism ................................................. 39

Capping Mechanism .............................................................................. 40

Ink Sequence ......................................................................................... 41

Electrical Circuit Operating Principles .................................................... 42

C301PSB/PSE Board ............................................................................. 42

C301MAIN Board ................................................................................... 44

Main elements .................................................................................... 45

Printhead Driver Circuit ...................................................................... 45

PF Motor (PF/ PUMP/ ASF Motor) Driver Circuit ............................... 47

CR Motor Driver Circuit ...................................................................... 48

Reset Circuit ....................................................................................... 48

EEPROM Control Circuit .................................................................... 49

Sensor Circuit ..................................................................................... 50

Page 6

EPSON Stylus Photo 720 / EPSON Stylus Photo EX

3

A

7

Revision

Troubleshooting

Overview ..................................................................................................... 52

Unit Level Troubleshooting ...................................................................... 54

Printer does not operate at power on ..................................................... 54

Error is detected ..................................................................................... 55

Failure occurs during printing ................................................................. 55

Printer does not feed paper correctly ..................................................... 56

Control panel operation is abnormal ...................................................... 56

Unit Repair (Power Supply Board) ........................................................... 57

Unit Repair (Control Board) ...................................................................... 58

Unit Repair (Printer Mechanism) .............................................................. 60

Disassembly and Assembly

Overview ..................................................................................................... 65

Precautions ............................................................................................ 65

Tools ....................................................................................................... 65

Work Completion Check ......................................................................... 66

Disassembly ............................................................................................... 67

Housing Removal ................................................................................... 68

Circuit Board Assembly Removal ........................................................... 69

Control Panel Removal .......................................................................... 71

Ink Absorber Tray Assembly (Waste Ink Pad) Removal ........................ 72

Printer Mechanism Disassembly ............................................................ 73

Printhead Removal ............................................................................. 73

Pump Assembly / Cap Assembly Removal ........................................ 75

CR Motor Assembly Removal ............................................................ 77

PF Motor Assembly Removal ............................................................. 78

ASF Assembly Removal ..................................................................... 80

ASF LD Roller Assembly Removal ..................................................... 82

LD Roller Assembly Disassembly ....................................................... 87

CR Assembly Removal ...................................................................... 88

PE Sensor Assembly Removal .......................................................... 90

PF Roller Assembly Removal ............................................................. 91

CR HP Sensor Removal ..................................................................... 93

Adjustment

Overview .................................................................................................... 95

Required Adjustment .............................................................................. 95

Adjustment ................................................................................................. 96

PG Adjustment ....................................................................................... 96

Adjustment by Adjustment Program ....................................................... 98

Adjustment Program .............................................................................. 98

Adjustment Program Installation Procedure ........................................... 98

Adjustment Program Initial Setting Screen ............................................ 99

Market Destination Check .................................................................... 100

Head Voltage ID Input .......................................................................... 101

Head Angular Adjustment .................................................................... 103

Bi-Directional Adjustment ..................................................................... 106

USB ID Check/Input ............................................................................. 109

Head Cleaning ..................................................................................... 110

Initial Ink Charge .................................................................................. 111

Protection Counter Check/Clear .......................................................... 111

Print A4 Pattern .................................................................................... 113

Maintenance

Overview .................................................................................................. 115

Cleaning ............................................................................................... 115

Service Maintenance ............................................................................ 116

Lubrication ............................................................................................ 117

Appendix

Connector Summary ............................................................................... 122

Major Component Unit ......................................................................... 122

EEPROM Address Map ....................................................................... 125

Component Layout .................................................................................. 129

Exploded Diagram ................................................................................... 131

Parts List .................................................................................................. 139

Electric Circuit ......................................................................................... 149

Page 7

PRODUCT DESCRIPTION

CHAPTER

1

Page 8

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

9

1.1 Overview

Stylus Photo 720 and Stylus Photo EX3 is developed from Stylus Photo 700 and Stylus

Photo EX and allows a high resolution photographic high quality print enabled by

variable dot.

1.1.1 Features

Major features of this printer are as follows;

o

High color print quality

n

1440x720 (HxV) dpi printing

n

Photo-MACH technology (6 color printing. CMYKLmLc)

n

Traditional and New Microweave

o

Built-inASF(AutoSheetFeeder)

n

Holds 100 cut-sheets (64 g/m2)

n

Holds 10 envelopes

n

Holds 30 transparency films

o

Built-in 2 I/F

n

Bi-directional parallel I/F (IEEE-1284 level 1 device)

n

USB (Universal Serial Bus)

Stylus Photo 720

Stylus Photo EX3

o

Windows / Macintosh exclusive

Figure 1-1. External View

Product Descri

tion Overview

Page 9

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

1.2 Basic Specification

1.2.1 Printing Specification

PRINTING METHOD

o

On demand ink jet

NOZZLE CONFIGURATION

o

Black: 32 nozzle

o

Color: 32 nozzle x 5 colors

(Cyan, Magenta, Yellow, Light Cyan, Light Magenta)

Light

Cyan

#32

Black

Cyan

Magenta

Light

Magenta

Yellow

PRINTING SPEED AND PRINTABLE COLUMNS

o

Character mode: Refer to the table below.

Table 1-1. Printing Speed (Character Mode)

Character Pitch Printable Columns LQ speed

Stylus Photo 720 10 CPI (Pica) 80 200 CPS**

Stylus Photo EX3 10 CPI (Pica) 114 200 CPS**

NOTE: These figures are not described in the user’s guide.

** This value is the speed of normal-dot printing.

o

Raster graphics mode: Refer to the table below.

Table 1-2. Printing Speed (Raster Graphics Mode)

Stylus Photo 720

Horizontal

Resolution

180 dpi 8.26 inch 1488 508mm/s (20 IPS)

360 dpi 8.26 inch 2976 508mm/s (20 IPS)

720 dpi 8.26 inch 5952 508mm/s (20 IPS)

180 dpi 11.46 inch 2062 508mm/s (20 IPS)

Printable

Area

Available

Dot

CR Speed

Stylus Photo EX3

4 / 360"

#1

360 dpi 11.46 inch 4125 508mm/s (20 IPS)

720 dpi 11.46 inch 8250 508mm/s (20 IPS)

CONTROL CODE

o

ESC/P Raster command

nozzle

o

EPSON Remote command

Figure 1-2. Nozzle Configuration (Seen from the Back of the Head)

PRINTING DIRECTION

o

Bi-direction with logic seeking

Product Descri

tion Basic Specification 10

Page 10

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

CHARACTER TABLES

o

2 international character sets

n

PC437 (US, Standard Europe)

n

PC850 (Multilingual)

TYPEFACE

o

Bitmap LQ font

n

EPSON Courier 10 CPI

1.2.2 Paper Feed specification

o

Feeding Method: Friction feed with ASF

o

Paper path: Cut-sheet ASF (Top entry Front out)

o

Feed speed: 10.16mm feed: 110ms

Continuous feed: 114.3mm/s

1.2.3 Input Data Buffer

o

Buffer: 256 Kbytes

1.2.4 Electric Specification

o

120V version

n

Rated voltage: AC 100V

n

Input voltage range: AC 99 -132V

n

Rated frequency range: 50 - 60Hz

n

Input frequency range: 49.5-60.5 Hz

n

Rated current: 0.4A (Max. TBD)

n

Power consumption: Approx.18W (ISO10561 Letter pattern)

n

Insulation Resistance: 10 M ohms min.

n

Dielectric: AC 1000 V rms. 1 minute or

o

220-240V version

n

Rated voltage: AC 220 - 240V

n

Input voltage range: AC 198 - 264V

n

Rated frequency range: 50 - 60Hz

Approx. 2.5W in standby mode

Energy Star compliant

(between AC line and chassis, DC 500V)

AC 1200 V rms. 1 second

(between AC line and chassis)

n

Input frequency range: 49.5-60.5 Hz

n

Rated current: 0.2A (Max. TBD)

n

Power consumption: Approx.18W (ISO10561 Letter pattern)

Approx. 2.5W in standby mode

Energy Star compliant

n

Insulation Resistance: 10 M ohms min.

(between AC line and chassis, DC 500V)

n

Dielectric: AC 1500 V rms. 1 minute

(between AC line and chassis)

Product Descri

tion Basic Specification 11

Page 11

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

1.2.5 Environmental Conditions

o

Temperature

Operating: 10 to 35

Non-operating: -20 to 40°C

1monthat40°C, 120 hours at 60°C

o

Humidity

Operating: 20 to 80% RH

Non-operating: 5 to 85% RH

o

Resistance to shock

Operating: 1G, within 1ms

Non-operating: 2G, within 2ms

o

Resistance to vibration

Operating: 0.15G

Non-operating: 0.50G

NOTE: *1: with shipment container.

*2: without condensation.

*3: The environmental condition should be within the range shown in the

figure below.

(%)

80

*3

°C

*1

*2,*3

*1,*2

*1

*1

1.2.6 Reliability

o

Total print volume: 10,000 pages (A4, Letter)

o

Print Head Life: 3 billion dots / nozzle

Or 5 years at the normal temperature

(Whichever comes first.)

1.2.7 Safety Approvals

o

120V version:

n

Safety Standards: UL1950

CSA22.2 No.950

n

EMI: FCC part15 subpart B class B

CSA C108.8 class B

o

220 - 240V version:

n

Safety Standards: EN 60950 (VDE)

n

EMI: EN 55022 (CISPR Pub. 22) class B

AS/NZS 3548 class B

1.2.8 Acoustic Noise

o

Level: Approx. 47dB (A) (According to ISO7779)

1.2.9 CE Marking

220-240V version

55

20

10 27 35

(”C)

tmphumid

Figure 1-3. Environmental Condition

Product Descri

tion Basic Specification 12

o

Low Voltage Directive 73/23/EEC: EN60950

o

EMC Directive 89/336/EEC: EN55022 class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Page 12

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

1.3 Interface Specification

This printer has IEEE-1284 parallel interface and USB interface as standard.

1.3.1 IEEE-1284 Parallel I/F (Forward Channel)

Forward channel is the mode to transfer the ordinary printing command to the printer

side from the PC side.

Table 1-3. Parallel I/F Specification (F-Channel)

Item Specification

Transmission mode 8bit parallel

Synchronization By STROBE pulse supplied from the external

Handshaking By BUSY and ACKNLG signal

Signal Level TTL level (IEEE-1284-Level 1 device)

Adaptable connector 36 pin 57-30360 (amphenol) or equivalent

NOTE: I/F cable is recommended to be in minimum length.

The connector pin assignment is described below. For these signals described in the

table, use the twist pair wire and connect the return side to the signal GND.

Table 1-4. Connector Pin Assignment and Signals (F-Channel)

Pin No.

1 19 -STROBE PC

2-9 20-27 Data0-7 PC

10 28 -ACKNLG Printer

Return

GND Pin

Signal

Name

From Function Description

The strobe pulse for the printer to read data.

Pulse width requires min. 0.5µs (500ns).

High at normal condition. Receives data after

shifting Low.

The DATA 1 through DATA8 signals

represent data bits 1-8, respectively.

A low signal indicates the printer can accept

data. Pulse width is 0.5 (default) or can be set

at 2µs.

Table 1-4. Connector Pin Assignment and Signals (F-Channel)

Pin No.

11 29 BUSY Printer

12 28 PE Printer A high signal indicates paper-out error.

13 28 SLCT Printer

14 30 -AFXT PC Not used.

31 30 -INIT PC

32 29 -ERROR PC A low signal indicates printer error condition.

36 30 -SLIN - Not used.

18 - Logic H -

35 - +5V -

17 - Chassis - Printer chassis GND.

16, 33

19-30

15, 34 - NC - Not used.

Return

GND Pin

- GND - Twist pair return GND.

Signal

Name

From Function Description

A high signal indicates that the printer cannot

receive data. The signal becomes high under

the condition below;

-Receiving data.

-Error.

-Other I/F receiving data.

Always at high level. Pulled up to +5V via

1.0KΩ resistor.

The printer is initialized by the width of min.

50µs Low pulse input.

Always at high level. Pulled up to +5V via

3.9KΩ resistor.

Always at high level. Pulled up to +5V via

1.0KΩ resistor.

1.3.2 IEEE-1284 Parallel I/F (Reverse Channel)

Reverse channel is used to transfer the information data from the printer side to the PC

side.

Product Descri

tion Interface Specification 13

Page 13

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

o

Table 1-5. Parallel I/F Specification (R-Channel)

Item Specification

Transmission mode IEEE-1284 nibble mode

Synchronization Comply with the IEEE-1284 specification

Handshaking Comply with the IEEE-1284 specification

Logic Level TTL level (IEEE-1284-Level 1 device)

Data trans. timing Comply with the IEEE-1284 specification

Extensibility request data The printer responds affirmatively when the extensibility request

values are 00H or 04H;

00H: Request Nibble Mode Reverse Channel Transfer.

04H: Request Device ID;

Return Data Using Nibble Mode Reverse Channel Transfer

Device ID

n

When IEEE-1284.4 protocol is effective:

[00H] [5AH]

MFG: EPSON;

CMD: ESCPL2, BDC, D4;

MDL: Stylus[SP]Photo[SP]720;

*1

CLS: PRINTER;

DES: EPSON[SP]Stylus[SP]Photo[SP]720;

n

When IEEE1284.4 protocol is NOT effective:

*1

[00H] [57H]

MFG: EPSON;

CMD: ESCPL2, BDC;

MDL: Stylus[SP]Photo[SP]720;

*1

CLS: PRINTER;

DES: EPSON[SP]Stylus[SP]Photo[SP]720;

*1

Note: *1 For Stylus Photo EX3, MDL: Stylus[SP]Photo[SP]EX3;

DES: EPSON[SP]Stylus[SP]Photo[SP]EX3, respectively.

The connector pin assignment is described in the table below. For these signals

described in the table, use the twist pair wire and connect the return side to the signal

GND.

Table 1-6. Connector Pin Assignment and Signals (F-Channel)

Pin No.

1 19 HostClk PC Host clock signal.

2-9 20-27 Data1-8 PC

10 28 PtrClk Printer Printer clock signal.

11 29

12 28

13 28

Product Descri

tion Interface Specification 14

Return

GND Pin

Signal Name From Function Description

The DATA 1 through DATA8 signals

represent data bits 1-8 respectively.

PtrBusy/

DataBit-3,7

AckDataReq/

DataBit-2,6

Xflag/DataBit-

1,5

Printer

Printer

Printer

Printer busy signal and reverse channel

transfer data bit 3 or 7.

Acknowledge data request signal and

reverse channel transfer data bit 2 or 6.

X-flag signal and reverse channel

transfer data bit 1 or 5.

Page 14

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

Table 1-6. Connector Pin Assignment and Signals (F-Channel)

Pin No.

14 30 HostBusy PC Host busy signal.

31 30 -INIT PC Not used.

32 29

36 30 1284-Active PC 1284 active signal.

18 - Logic H Printer Pulled up to +5V via 3.9K ohm resistor.

35 - +5V Printer Pulled up to +5V via 3.3 K ohm resistor.

17 - Chassis - Printer chassis GND.

16, 33

19-30

15, 34 - NC - Not used.

Following lists “Notes” when using the parallel interface.

o

“Return GND pin” in the table means twist pair return and is connected to the

signal GND level.

For each signal, use the twist pair wire and connect the return side.

Also, these cables are shielded wires and it is effective means to connect to each

chassis GND in the center machine and printer for electrostatic noise.

Return

GND Pin

Signal Name From Function Description

-DataAvail/

DataBit-0,4

Printer

Data available signal and reverse channel

transfer data bit 0 or 4.

- GND - Twist pair return GND.

DATA

/STROBE

BUSY

/ACKNLG

Data byte n Data byte n+1

t

hold

t

t

setup

ready

t

stb

t

busy

t

reply

Figure 1-4. Timing Chart

On the above timing chart, T

Parallel I/F Mode T

High speed (default) 0.5

Normal speed 2 µs

ratedperiodisshownbelow.

act

Table 1-7. t

act

t

ack

Rated Period

Rated Period

act

µs

t

nbusy

t

next

timechart

o

Conditions for interface are all based on TTL level. Rise and fall time should be

within 0.2

o

Refer to the timing chart for transmission timing of each signals.

o

Do not perform data transmission ignoring -ACK or BUSY signals. (Perform the

µs.

data transmission after confirming that either -ACK or BUSY signal is Low)

o

It is possible to perform the printing test including interface circuit without using

external equipment when 8-bit data signal (2-9 pin) is set to appropriate character

code (against GND, Open=”1”, Short=”0”) and connect then forcefully to -ACK

and -STRB. However, to perform this, “I/F selection” of EEPROM must be set to

“Auto”. Also, IEEE-1284.4 packet mode must be set Off.

The figure below shows the timing chart of the parallel interface.

Product Descri

tion Interface Specification 15

Page 15

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

1.3.3 USB (Universal Serious Bus)

Following shows specification.

o

Standard:

n

Universal Serial Bus Specifications Revision 1.0

n

Universal Serial Bus Device Class Definition for Printing Devices version 1.1

o

Bit rate: 12Mbyte (Full Speed Device)

o

Data encoding: NRZI

o

Adaptable connector: USB Series B

o

Recommended cable length: max. 2 meters

Table 1-8. Connector Pin Assignment and Signals

Pin.

No

1VCC --

2 -Data I/O Data

3 +Data I/O Data. Pull up to +3.3V via 1.5K ohm resistor.

4 Ground -- Cable ground.

Signal Name I/Out Function Description

Cable power. Maximum power consumption

is 2mA.

1.3.4 Miscellanea

1.3.4.1 Preventing Hosts from Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when a peripheral is in busy state

for dozens of seconds continuously. To prevent hosts from acting this kind of time-out,

when the open space of input buffer becomes 1024 byte, the printer receives data per

certain period of time (1 second) and avoid BUSY state continues for a long time. The

printer will be in busy state continuously when the input buffer finally gets full. This

operation is not performed while communicating by IEEE1284.4 protocol.

1.3.4.2 Interface Selection

IEEE-1284 parallel interface and USB interface is switched by auto select function.

The following explains the conditional shift of the I/F auto select function and the

operations when specific interface is set.

AUTOMATIC SELECTION

In this automatic interface selection mode, the printer is initialized to the idle state

scanning which interface receives data when it is powered on. Then the interface that

receives data first is selected. When the host stops data transfer and the printer is in the

stand-by state for the seconds, the printer is returned to the idle state. As long as the

host sends data or the printer interface is in the busy state, the selected interface is let as

is.

Pin #1Pin #2

Pin #3 Pin #4

usb

INTERFACE STATE AND INTERFACE SELECTION

o

When the parallel interface is not selected, the interface became to the busy state.

When the printer is initialized or returned to the idle state, the parallel interface

became to the ready state. Caution that the interrupt signal such as the -INIT signal

on the parallel interface is not effective while the inter face is not selected.

Figure 1-5. USB Interface Port

Product Descri

tion Interface Specification 16

Page 16

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

1.3.4.3 IEEE 1284.4 protocol

The packet protocol described by IEEE1284.4 standard always a device to carry on

multiple exchanges or conversations which contain data and/or control information

with another device at the same time across a single point-to-point link. The protocol is

not, however, a device control language. It does provide basic transport-level flow

control and multiplexing services. The multiplexed logical channels are independent of

each other and blocking of one has no effect on the others. The protocol operate over

IEEE1284.

o

Auto

An initial state is compatible interface and starts IEEE1284.4 communication

when the magic strings (1284.4 synchronous commands) are received.

o

On

An initial state is IEEE 1284.4 communication and data that received it by the time

it is able to take synchronization by magic string (1284.4 synchronous commands)

is discarded.

o

Off

An initial state is compatible interface and never starts IEEE1284.4

communication even if the magic strings (1284.4 synchronous commands) are

received.

For parallel I/F, regardless of the factory default setting, after initial ink charge

operation, the setting of the EEPROM must be set to “AUTO”. The change in this

setting will be effective when the power is back on after the initial ink charge

operation.

Product Descri

tion Interface Specification 17

Page 17

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

1.4 Control Specification

1.4.1 Control Panel

The control panel is at the front right of the printer and has 2 non-lock type push

switches and 1 lock type switch and 4 LEDs. The appearance of the control panel

differs between Stylus Photo 720 and Stylus Photo EX3, but the number of buttons and

LEDs is the same. So, this section explains names of the buttons using the Stylus Photo

720 control panel.

Power LED

Ink Maintenance Button

Paper Check LED

Black Ink End LED

Color Ink End LED

Power Button

Load/ Eject Button

Table 1-9. Panel Functions in Normal State

Button Function

Load/Eject

(Less than 2 seconds)

Load/ Eject

(for 3 seconds)

Ink maintenance

(for 3 seconds)

Ink maintenance

(Less than 2 seconds)

Load or eject paper

When the print head is at the ink replacement position, it returns to

the home position.

Start the ink cartridge replacement sequence.

Start cleaning the print head.

In the condition of “Ink Low”, “Ink End” or “No Ink Cartridge”,

start the ink cartridge replacement sequence.

When the print head is at the ink replacement position, it returns to

the home position.

Figure 1-6. Control Panel

1.4.2 Control Switches

Since this printer does not have so many switches, each button has several functions.

The tables below show their functions and how to enter those functions for each button.

Product Descri

tion Control Specification 18

Page 18

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

Table 1-10. Panel Function with Turning the Power On

Button Function

Load/Eject Start status-printing.*

Print “Firmware version”→ “CPU Mask version”→ “Waste

ink counter”→ “Code page setting”→ “Nozzle check pattern”.

Ink maintenance Code page.selection/ Parallel I/F IEEE 1284.4 setting (See

Section 1.4.2.1)

Load/Eject

+

Ink maintenance

Start special setting mode.

(See Table 1-13)

1

*Note

NOTE: Turning the power on = to turn on the printer power while specified

button is pressed down.

*1: Printer performs the following according to the value of 1BH in EEPROM.

Table 1-11. EEPROM 1BH Data and Function W

Bit 7, Bit 6 Action

00

11

01 Start hex-dump printing.

Print firmware version, ink counter, selected code page and nozzle

check pattern.

1.4.2.1 Code Page Selection/ Parallel I/F IEEE1284.4 Setting

On this setting mode, you can select code page table (PC437 or PC850) and parallel I/F

IEEE1284.4 mode (ON, AUTO, OFF).

o

Code Page Selection

You can select the code table PC437 or PC850 by the following panel operation.

1. Turn on the power while pressing the maintenance button.

2. Paper check LED starts blinking.

3. When you see the paper check LED starts blinking, release maintenance button.

4. After 2 seconds, the code page setting will be indicated by maintenance LED. See the

table below.

Table 1-12. Code Page Setting

Code page before this

function is performed.

PC437 PC850 Ink END (Color) ON

PC850 PC437 Ink END (Black) ON

NOTE: You can check current code page by status print.

Code page after this

function is performed.

LED Indication

10 Start self-test printing.

Product Descri

tion Control Specification 19

Page 19

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

1.4.2.2 Special Setting Mode

You can go to the special setting mode by the following operations.

1. Turn on the power while pressing the Load/ Eject button and ink maintenance button.

2. Paper check LED starts blinking. (3 seconds)

3. While the paper check LED is blinking (3 seconds), press the appropriate button. See

Table 1-13.

n

When maintenance error (protection counter over flow) is

happened, if you clear the error by this operation, be sure to

replace the waste ink absorber.

n

Whenever you replaced the waste ink counter (even when ink

maintenance error has not occurred), be sure to perform the

counter reset by this operation.

Table 1-13. Special Settings Mode

Buttons Function

Load/Eject Initialize EEPROM and reset timer IC.

This operation will reset the following items:

• Interface selection (04H)

• CL time (68/ 69H)

• Power OFF time (6C/ 6DH)

Reset the ink overflow counter.

Cleaning

(Pressed for 10 seconds)

NOTE: Hold the button pressed for 10 seconds.

This operation will reset the following items:

• Ink counter A0 (5C/ 5DH)

• Ink counter A80 (5E/ 5FH)

1.4.3 LED Indications

See the table below for more detailed LED indications. Since LED indicates the

various errors and current printer operations, LED indications enable to find out the

proper repair operation.

Table 1-14. Printer Status displayed on the control panel

Indicators

Printer Status

Power on condition On --

Ink sequence Blink -- -- -- 6

Ink cartridge exchange mode Blink -- -- -- 5

Data processing Blink -- -- -- 8

Paper check

Paper jam

No ink cartridge or Ink end

(black)

No ink cartridge or Ink end

(color)

Ink level low (black) -- -- Blink -- 7

Ink level low (color) -- -- -- Blink 7

EEPROM and Timer IC reset

Maintenance Request Blink Blink Blink Blink 2

Fatal Error

*1

*1

*1

*1

*2

*1

Power

-- On -- -- 4

-- Blink Off Off 3

-- -- On -- 7

-- -- -- On 7

--

Blink Blink On On 1

Paper

Check

*3

On

(for 1

second)

Ink End

(Black)

-- -- 9

On

(for 1

second)

Ink end

(Color)

On

(for 1

second)

Priority

--

NOTE: *1 For error condition, refer to “Fatal Error” under the “Errors” on

page 21.

*2 EEPROM clear does not mean to clear all address in

EEPROM. (See “Special Settings Mode” on page 20)

*3 -- in the table above means no change.

Product Descri

tion Control Specification

0

Page 20

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

1.4.4 Initialization

The printer have 3 types of initialization. The initialization operations executed by each

initialization method are described below.

o

Hardware Initialization

This printer initializes itself when it is turned on.

On this initialization, following actions are performed.

n

Initialize printer mechanism

n

Clear the input data buffer

n

Clear the print buffer

n

Set default values

o

Software initialization

Initialization command, “ESC@” also initializes the printer.

On this initialization, following actions are performed.

n

Clear the print buffer

n

Set default values

o

Panel initialization

This printer initializes itself when it is turned off and is turned on again within 10

seconds, or when it recognizes the -INIT signal input.

On this initialization, following actions are performed.

1.4.5 Errors

o

Ink Out

When the printer almost runs out the ink of any one color, it warns ink-low and

keeps printing. When the printer runs out the whole ink of any one color, it stops

printing and indicates ink-out error. User is requested to install a new ink-cartridge

in this state. A ink-cartridge once taken out should never used again. Reinstallation of the cartridge not filled fully upsets the ink level detection and may

cause a serious problem in the print head as a result.

o

Paper out

When the printer fails to load a sheet, it goes paper out error.

o

Paper jam

When the printer fails to eject a sheet, it goes paper jam error.

o

No ink-cartridge

When the printer detects that the ink-cartridge comes off, it goes no ink-cartridge

error.

o

Maintenance request

When the total quantity of ink wasted through the cleaning and flushing reaches to

the limit, the printer indicates this error and stops. The absorber in the printer

enclosure is needed to be replaced with new one by a service person.

o

Fatal errors

Carriage control error or CG access error.

n

Cap the print head (Mechanism initialization is not performed.)

n

Eject paper

n

Clear the input buffer

n

Clear the print buffer

n

Set default values

Product Descri

tion Control Specification

1

Page 21

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

o

1.5 Paper

1.5.1 Paper handling

Do not perform reverse feed more than 9.5mm (0.38”).

Envelope

n

Size:

No.10 (241.3 mm x 104.8 mm)

DL (220 mm x 110 mm)

C6 (162 mm x 114 mm)

n

Thickness: 0.16mm to 0.52mm(0.006 to 0.02”)

1.5.2 Paper Specification

STYLUS PHOTO 720

o

Cut Sheet

n

Paper Size:

A4 (210 x 297 mm)

Letter (216 x 279 mm)

B5 (182 x 257 mm)

Legal (216 x 356 mm)

Statement (139.7 x 215.9 mm)

Executive (184.2 x 266.7 mm)

A5 (148 x 210 mm)

A6 (105 x 148 mm)

n

Thickness: 0.08mm to 0.11mm(0.003 to 0.004”)

n

Weight: 64g/m2to 90g/m2(17lb to 24lb)

n

Paper quality: Exclusive paper, Bond paper, PPC

o

Transparency, Glossy paper

n

Size:

A4 (210 x 297 mm)

Letter (216 x 279 mm)

n

Weight: 45g/m2to 75g/m2(12lbto20lb)

n

Paper quality: Bond paper, Plain paper, Air mail

*Envelope printing is only available at normal temperature.

*Keep the longer side of the envelope horizontally at setting.

o

Index Card

n

Size:

A6(105x148mm)

A5(148x210mm)

5x8” index card (127 x 203 mm)

10x8” index card (254 x 203mm)

n

Thickness: 0.23 mm(0.0091”)

n

Thickness: 0.075mm to 0.085mm(0.003 to 0.0033”)

*Transparency printing is only available at normal temperature.

Product Descri

tion Paper

2

Page 22

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

n

STYLUS PHOTO EX3

Additional following items to the Stylus Photo 720 specification;

o

Cut Sheet

n

Paper size:

A3 (297 x 420 mm)

Letter (216 x 279 mm)

B5 (182 x 257 mm)

Legal (216 x 356 mm)

Statement (139.7 x 215.9 mm)

Executive (184.2 x 266.7 mm)

A5 (148 x 210 mm)

A6 (105 x 148 mm)

n

Thickness: 0.08mm to 0.11mm(0.003 to 0.004”)

n

Weight: 64g/m2to 90g/m2(17lb to 24lb)

n

Paper quality: Exclusive paper, Bond paper, PPC

o

Transparency, Glossy paper

n

Size:

A3 (297 x 420 mm)

A4 (210 x 297 mm)

Letter (216 x 279 mm)

o

Paper quality: Bond paper, Plain paper, Air mail

*Envelope printing is only available at normal temperature.

*Keep the longer side of the envelope horizontally at setting.

Index Card

n

Size:

A6(105x148mm)

A5(148x210mm)

5x8” index card (127 x 203 mm)

10x8” index card (254 x 203mm)

n

Thickness: 0.23 mm(0.0091”)

n

Thickness: 0.075mm to 0.085mm(0.003 to 0.0033”)

*Transparency printing is only available at normal temperature.

o

Envelope

n

Size:

No.10 (241.3 mm x 104.8 mm)

DL (220 mm x 110 mm)

C6 (162 mm x 114 mm)

n

Thickness: 0.16mm to 0.52mm(0.006 to 0.02”)

n

Weight: 45g/m2to 75g/m2(12lb to 20lb)

Product Descri

tion Paper

3

Page 23

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

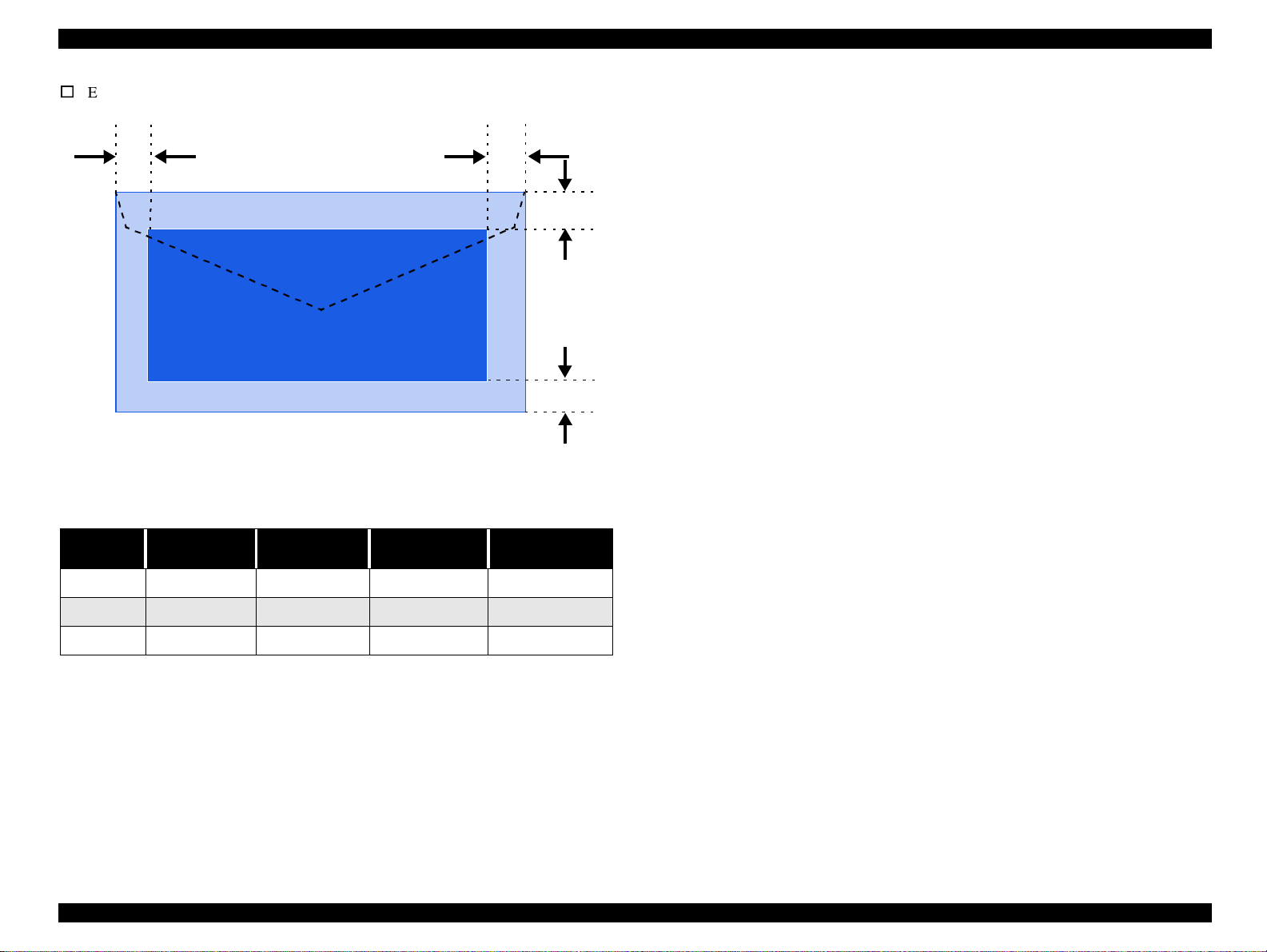

1.5.3 Printable Area

o

Cut Sheet

LM RM

PW

Printable AreaPrintable Area

TM

PL

Table 1-15. Character Mode

Paper Size

A4 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14 mm (0.54”)

Letter 3mm (0.12”) 9mm (0.35”) 3mm (0.12”) 14 mm (0.54”)

B5 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14 mm (0.54”)

Legal 3mm (0.12”) 9mm (0.35”) 3mm (0.12”) 14 mm (0.54”)

Statement 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14 mm (0.54”)

Exclusive 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14 mm (0.54”)

LM (Left

Margin) min.

RM (Right

Margin) min.

TM (Top

Margin) min.

BM (Bottom

Margin) min.

Table 1-16. Raster Graphics Mode

Paper Size

A4 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Letter 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

B5 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

LM (Left

Margin) min.

RM (Right

Margin) min.

TM (Top

Margin) min.

BM (Bottom

Margin) min.

14 mm (0.54”) /

3mm (0.12”)*

14 mm (0.54”) /

3mm (0.12”)*

14 mm (0.54”) /

3mm (0.12”)*

Legal 3mm (0.12”) 9mm (0.35”) 3mm (0.12”)

BM

Statement 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Exclusive 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

14 mm (0.54”) /

3mm (0.12”)*

14 mm (0.54”) /

3mm (0.12”)*

14 mm (0.54”) /

3mm (0.12”)*

Figure 1-7. Cut Sheet Printable Area

NOTE: * Bottom margin can be set up to 3mm at minimum when the paper length

is designated with “ESC(S” command.) However, the printing quality is

not guaranteed in the area ranging from 3mm to 14mm, from the form

lower end. When the paper length is not designated, the bottom margin

must be wider than 14 mm.

Product Descri

tion Paper

4

Page 24

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

o

Envelope

LM

RM

TM

Printable AreaPrintable Area

BM

Figure 1-8. Printable Area for Envelopes

Table 1-17. Envelope Margin

Left Margin

Size

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.55”)

(minimum)

Right Margin

(minimum)

Top Margin

(minimum)

Bottom Margin

(minimum)

DL 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.55”)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.55”)

Product Descri

tion Paper

5

Page 25

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

1.5.4 Ink Cartridge

INK CARTRIDGE (BLACK)

o

Type: Exclusive cartridge

o

Color: Black

o

Print capacity: 540 pages / A4 (ISO/IEC10561 Letter pattern at 360 dpi)

o

Ink life: 2 years from production date

o

Storage temperature:

n

-20°Cto40°C

Storage, within a month at 40

n

-30°Cto40°C

Packing storage, within a month at 40

n

-30°Cto60°C

Transit, within a month at 60

o

Dimension: 19.8mm (W) x 52.7 mm (D) x 38.5mm (H)

°

C

°

C

°

C

COLOR INK CARTRIDGE

o

Type: Exclusive cartridge

o

Color: Magenta, Cyan, Yellow

o

Print capacity: 300 pages/A4 (360 dpi, 5% duty each color)

o

Ink life: 2 years from production date

o

Storage temperature:

n

-20°Cto40°C

Storage, within a month at 40

n

-30°Cto40°C

Packing storage, within a month at 40

n

-30°Cto60°C

Transit, within a month at 60

o

Dimension: 42.9mm (W) x 52.7 mm (D) x 38.5mm (H)

°

C

°

C

°

C

Figure 1-10. Color Ink Cartridge

NOTE: Ink cartridges cannot be refilled, properly dispose of after use. Do not

Figure 1-9. Black Ink Cartridge

Product Descri

tion Paper

use the ink cartridge which is beyond its production date plus two years.

Ink will be frozen under -4

placing it more than 3 hours at room temperature.

°

C environment, however it will be usable after

6

Page 26

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

1.6 Physical Specification

o

Dimensions

n

Stylus Photo 720: 429 x 268 x 168 mm (WxDxH)

n

Stylus Photo EX3: 546 x 275 x 172 mm (WxDxH)

760.73

406

307.66

545.53

Figure 1-12. Stylus Photo EX3 Dimensions

o

Weight

n

Stylus Photo 720: approximately

Figure 1-11. Stylus Photo 720 Dimensions

Product Descri

tion Physical Specification

n

Stylus Photo EX3: approximately 7.0kg

5.2kg

7

Page 27

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

2

1.7 Consumables and Options

The consumables for this printer are following;

Table 1-18. Consumables

Classification No. Name

Consumables

S020187 Ink Cartridge (black)

S020193 Ink Cartridge (color)

Product Descri

tion Consumables and Options

8

Page 28

OPERATING PRINCIPLES

CHAPTER

2

Page 29

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1 Overview

This section describes the operating principles of the printer mechanism and electrical

circuit boards. The Stylus Photo 720 / Stylus Photo EX3 has the following boards:

o

Main board: C301MAIN

o

Power supply board: C301PSB/PSE

o

Panel board: C209PNL Board (Stylus Photo 720)

C366PNL Board (Stylus Photo EX3)

2.1.1 Printer Mechanism

Stylus Photo 720 / Stylus Photo EX3 is based on Stylus Photo 700 / Stylus Photo EX

and the basic specifications for its mechanism are almost same as Stylus Photo 700 /

Stylus Photo EX.

This printer consists of Print Head, Carriage Mechanism, Paper Feeding Mechanism,

Paper Loading Mechanism, Ink System (Pump Mechanism, Cap Mechanism, and

Carriage Lock Mechanism).

Like other EPSON ink jet printers, the Stylus Photo 720 / Stylus Photo EX3 is

equipped with two stepping motors; one for ASF/ paper feeding/ pump mechanism,

and one for CR mechanism. ASF unit uses rear entry front eject system; this design is

the same as Stylus Photo 750 / Stylus Photo 1200.

The table below shows the compatibility of the mechanical units among Stylus Photo

700, Stylus Photo 750 and Stylus Photo 720.

Table 2-1. Mechanical Unit Compatibility

Stylus Photo 700 /

Stylus Photo EX

Printhead E-Chips U-Chips E-Chips +

CR motor

(coil resistance)

PF moto

(coil resistance)

ASF unit --- Quiet noise type Quiet noise type

Paper feeding

mechanism

Pump unit Type A Type B Type A

Capping unit Valve A Valve B Valveless

Frame parts Stylus Photo 700 type Stylus Photo 750 type Stylus Photo 750 type

Main board C233MAIN C259MAIN C301MAIN

PSB/PSE board C206PSB C257PSB C301PSB/PSE

7.8Ω 7.8Ω 7.8Ω

7.8Ω 8.8Ω 8.8Ω

Bottom edge: 14mm

Stylus Photo 750 /

Stylus Photo 1200

Bottom edge: 3mm

enabled

Stylus Photo 720 /

Stylus Photo EX3

Bottom edge: 3mm

enabled

For cap assembly, Stylus Photo 720 / Stylus Photo EX3 uses valveless mechanism;

new design for this model.

Figure 2-1 on page 31 shows the outline of the printer mechanism.

eratingPrinciples Overview

O

0

Page 30

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

Paper Loading

Mechanism

CR Unit

CR Mechanism

(Printhead)

CR Motor

PF Motor

Paper Feed

Trigger Lever

Position

Paper Feeding

Mechanism

Figure 2-1. Printer Mechanism Block Diagram

Capping Position

Ink System

Cap

Mechanism

CR Lock Mechanism

Pump

Mechanism

eratingPrinciples Overview

O

1

Page 31

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.2 Printhead

The printhead uses a new developed E-CHIPS+1 head method and Stylus Photo 720 /

Stylus Photo EX3 can perform multiple shot printing and variable printing. Printhead

nozzle configuration is as follows.

n

32 nozzles x 6 rows (nozzle pitch of each row: 1/90 inch)

n

Ink configuration: black, cyan, light cyan, magenta, light magenta, yellow

(aligned in this order)

The basic operating principles of the printhead, which plays a major role in printing,

are the same as previous models; on-demand method which uses PZT (Piezo Electric

Element). In order to uniform the amount of ejecting ink, each printhead has its own

head ID (10 figures for Stylus Photo 720 / Stylus Photo EX3) which adjust PZT

voltage drive features. The printhead stores the head ID to EEPROM and generates

appropriate PZT drive voltage to prevent amount of ink from varying by printheads.

Following explains printhead basic components.

o

PZT

PZT is an abbreviation of Piezo Electric Element. Certain amount of voltage

expands and contracts PTZ. The drive wave generated on MAIN board drives PZT

and PZT pushes the top cavity which has ink stored to discharge the ink from each

nozzle on the nozzle plate.

o

Ink Cavity

The ink absorbed from the ink cartridge goes through the filter and then is stored

temporarily in this tank called “cavity” until PZT is driven.

I/C Sensor Lever

Nozzle Plate

PZT

Ink Cartridge

Needle

Cavity

Nozzle Selector Board

Filter

Figure 2-2. Printhead Sectional Drawing

o

Nozzle Plate

The board with nozzle holes on the printhead surface is called Nozzle Plate.

o

Filter

When the ink cartridge is installed, if any dirt or dust around the cartridge needle is

absorbed into the head, there is a great possibility of causing nozzle clog and

disturbance of ink flow, and finally causing alignment failure and dot missing. To

prevent this problem, a filter is set below the cartridge needle, where ink is filtered.

eratingPrinciples Overview

O

2

Page 32

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.2.1 Printing Process

This section explains the process in which the printheads of On-Demand inkjet printers

eject ink from each nozzle.

1. Normal State:

When no printing signal is sent from PC, or no PZT drive voltage is applied, PZT

does not change shape, therefore PZT does not squeeze the cavity. Ink pressure

inside the cavity is kept normal.

(Refer to Figure 2-3.)

2) Ejecting State:

When the print signal is output from the C301MAIN board, IC (Nozzle Selector)

located on the printhead unit latches data once by 1-byte unit. An appropriate PZT

latched by the nozzle selector is pushed into the cavity by the common voltage

applied from the main board. By this operation, ink stored in the cavity spurts out

from nozzles.

(Refer to Figure 2-3.)

Ink Path Ink Cavity

PZT

Nozzle

PZT drive voltage

Nozzle Plate

Figure 2-3. Print Head

eratingPrinciples Overview

O

3

Page 33

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.2.2 Printing Method

For print dot system, Stylus Photo 720 / Stylus Photo EX3 has the following two types

of printing modes.

n

Multiple shot printing

n

Variable dot printing

The above two printing modes are automatically selected depending on the media and

the resolution setting. The following explains each printing mode.

o

Multiple shot printing

This printing mode is developed to improve the print quality on plain paper or

transparencies in low resolution. The multiple shot printing mode uses normal dot

and the number of dot shots varies from 1 shot to maximum 3 shots depending on

the print data to enable sharp image output even in a low resolution.

o

Variable dot printing

This printing mode is developed to improve the print quality on exclusive paper.

This mode is basically the same as variable dot printing mode used by Stylus

Photo 750 / Stylus Photo 1200; micro dot, middle dot, and large dot compose this

mode. Print dot size varies according to print data and this mode enables even

sharper image output on exclusive paper.

eratingPrinciples Overview

O

4

Page 34

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.3 Carriage Mechanism

The carriage mechanism consists of carriage motor (CR motor), carriage unit

(including printhead), CR timing belt, CR guide shaft, CR guide frame, CR home

detector (HP sensor) etc.

The carriage mechanism moves the carriage back and forth according to the drive from

the carriage motor. (See Figure 2-4)

The following stepping motor is mounted to drive CR mechanism. (See the table

below.)

Table 2-2. Carriage Motor Specification

Items Specifications

Type 4-Phase/ 200-Pole HB Stepping motor

Drive Voltage +42 V +/ - 5% (DRV IC voltage)

Coil Resistance 7.8 Ω +/ - 105 (per phase)

Inductance 14 m H +/ - 20%

Drive Method Bi-Polar drive

Driver IC LB11847

The drive from CR motor is transferred to the CR unit via CR timing belt.

2.1.3.1 Platen Gap (PG) Adjustment Mechanism

The PG adjustment mechanism is designed to keep the platen gap correct for the paper

thickness to prevent ink from smearing.

The PG support lever joins the CR guide shaft, which has an eccentricity toward PG

support lever. Switching the lever from “0” to “+” rotates the CR shaft and changes the

platen gap from narrow to wide (within the range of 1.14mm to 2.04mm).

Table 2-3. Platen Gap Adjust Lever Setting

Paper Lever Position PG adjustment value

All Media Front (0) 1.14mm between head and platen

If you find any print

problems or you use

thick paper.

Rear (+) 2.04mm between head and platen

Driven Pulley

PF Roller

Timing Belt

CR motor

Right

Parallel

Adjust

Bushing

PG Adjust

Lever

CR unit

Figure 2-4. Carriage Mechanism (Top view)

eratingPrinciples Overview

O

5

Page 35

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.4 Paper Feeding Mechanism

The paper feeding mechanism consists of paper feed motor (PF motor), PF roller, paper

eject roller, paper guide, and so on.

The paper feeding mechanism feeds paper loaded from ASF using the PF roller and

paper eject roller.

Combination

Gear 12.4, 28

Spur Gear 36

Spur Gear 73.6

Combination

Gear 16, 21.6

Pinion

Gear

PF motor

Figure 2-5. Paper Feeding Mechanism (Top View)

The following stepping motors are used to drive the paper feeding mechanism.

PF Roller

Paper Eject Roller

Front Paper Guide

When DE (disengage) lever is at normal position, torque from the PF motor is sent to

the PF roller and paper eject roller as described below.

o

To the PF roller:

PF motor pinion gear

→ Combination gear (16, 21.6) → Spur gear (73.6) → PF

roller

o

To the paper eject roller:

PF motor pinion gear

→ Combination gear (12.4, 28) → Spur gear (36) → Paper

eject roller

Stylus Photo 720 / Stylus Photo EX3 allows printing up to the last 3mm like Stylus

Photo 750 / Stylus Photo 1200. The star-wheel roller assembly has been shifted 5

degrees from directly on the top of the eject roller towards the paper feed roller. This

suppresses the tailing edge of the paper so that the old minimum margin of 14mm (ex.

for Stylus Photo 700 / Stylus Photo EX) has been reduced to only 3mm.

[Stylus Photo 700 / Stylus Photo EX]

Support Roller

Bottom margin 3 mm touches

the printhead surface.

PF Roller

Paper

Printhead

Star Wheel Assy.

Eject Roller

Platen

Table 2-4. PF Motor Specifications

Item Description

Motor type 4-Phase/ 200-Pole HB Stepping motor

Drive voltage +42 V +/ - 5% (DRV IC voltage)

Coil Resistance 7.8 Ω +/ - 105 (per phase)

Inductance 14 mH +/ - 20%

Driving method Bi-Polar drive

Driver IC LB11847

[Stylus Photo 720 / Stylus Photo EX3]

Five Degrees

Steady

Figure 2-6. Paper Transportation (Right side view)

eratingPrinciples Overview

O

6

Page 36

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.5 Paper Loading Mechanism (ASF Unit)

The paper loading mechanism is positioned at the printer rear and consists of paper

load roller, paper return lever, hopper, and so on. The paper loading mechanism loads

paper at the ASF unit and feeds paper to the PF roller. The ASF unit uses a PF motor.

Drive sent from this motor is switched between the ASF unit side and Pump/PF roller

side by the disengage mechanism when the CR unit moves to the left end of the CR

guide shaft.

Drive from the PF motor is transmitted to the ASF as described below:

o

Drive sent from PF motor is switched to ASF unit

The CR unit moves to the left end of the CR shaft

left end

→ the Spur gear 26.4 moves to the left side → the Spur gear 26.4 revolves

PF motor CCW (counterclockwise).

o

Drive transmission to the ASF unit

PF Motor pinion gear

→ Combination gear (16, 21.6) →

Spur gear (73.6) → Spur gear (26.4) → Combination gear (16,40.8) → Spur gear

(23.2)

→ Spur gear (34) → ASF paper load roller shaft

Figure 2-7 shows the disengage mechanism and the parts involved.

Spur Gear 34

→ the DE lever is pushed to the

Spur Gear 23.2

When the PF motor torque is switched to the ASF unit side by the disengage

mechanism, the function of the ASF mechanism varies depending on the rotational

direction of the PF motor, as shown in the table below.

Table 2-5. ASF unit function & PF Motor rotational direction

Directions Corresponding Functions

Clockwise (*1)

Counterclockwise (*1)

(*1): The PF Motor rotational direction = seen from the PF motor pinion gear.

ASF unit stops the paper loading operation when the PE sensor detects that the paper is

loaded to the PF roller.

• Picks up and loads paper

• Resets paper to the correct paper set position using

the Return Lever.

Combination Gear

16,40.8

Spur Gear 73.6

Spur Gear 26.4

PF Roller

DE lever

Figure 2-7. Disengage Mechanism (Top view)

eratingPrinciples Overview

O

7

Page 37

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

Torque sent from the ASF/Pump motor to the ASF unit via the disengage mechanism.

ASF paper loading sequence is described below.

o

Paper loading operation

Like Stylus Photo 750 / Stylus Photo 1200, ASF of this printer has the multiple paper

loading prevention mechanism to provide steady paper loading. This mechanism

prevents a sheet of paper from falling from the paper set position into the paper path.

After and before loading paper, by revolving the PF motor CCW, a paper return lever

in the mechanism pushes paper that may have fallen off back onto the hopper. After

this motion is completed, the LD roller starts loading paper. The paper loading

mechanism, including the multiple paper loading prevention mechanism, is described

in the following steps.

LD Roller

Hopper Hopper Spring

Cam

1. When the printer is powered on, the CR unit moves to the DE lever switching position

and switches DE position to the ASF side. PF motor revolves CW and ASF home

position is detected by ASF HP sensor. Then PF motor revolves CCW, drives paper

return lever and return the paper to the stand-by position.

2. When the print signal is sent from the PC or the Load/Eject button is pressed, CR unit

moves to the DE lever switching position and switches DE position to the ASF side. PF

motor revolves CW to let the LD roller load paper.

3. When PE sensor detects paper loaded from ASF is transported to the PF roller, the ASF

unit stops loading paper. LD roller of ASF stops at ASF HP when ASF HP sensor

detects ASF HP. CR unit switches from DE switching position to CR HP side and

disengages PD roller drive from ASF unit.

4. When the PF roller ejects paper, CR unit moves to the DE switching position and

switches DE lever to the ASF side. PF motor revolves CCW to drive paper return lever

and returns paper to the stand-by position.

2

Pinch Roller

3

Paper Return

Lever

[Stand-by State]

Pad

Pad Spring

[Paper Pickup State]

[PF Roller Paper Load State]

Figure 2-8. Multiple Paper Loading Prevention Mechanism (right side view)

eratingPrinciples Overview

O

8

Page 38

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

3

2.1.6 Ink System Mechanism

Ink system mechanism consists of pump unit (including CR lock mechanism) and

capping mechanism.

Ink system mechanism drives the pump unit that presses cap to the printhead and ejects

ink from ink cartridge, head cavity and cap to the waste ink pad.

CR lock mechanism assembled in the pump unit locks the printhead to prevent the head

from slipping off the capping position so that the printhead nozzle surface is kept clean

and wet.

2.1.6.1 Pump Unit and CR Lock Mechanism

The pump unit is driven by PF motor. PF motor drive is always transmitted to the paper

feeding mechanism and pump unit, and therefore pump unit and CR lock mechanism

drives according to the PF motor rotational direction, as shown in the table below.

Table 2-6. PF motor rotational direction & Ink System Mechanism

Directions Corresponding ASF Functions

Clockwise (*1)

Counterclockwise (*1)

• Retracts the wiper.

• Releases the CR lock lever.

• Absorbs ink by the pump unit

•Setsthewiper.

• Sets CR lock lever

Figure 2-9 shows the operating principles of the pump mechanism.

Counterclockwise

Tube squeezed

Clockwise

Tube released

Figure 2-9. Pump Mechanism

(*1): The PF Motor rotational direction = seen from the PF motor pinion gear.

eratingPrinciples Overview

O

9

Page 39

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

4

2.1.7 Capping Mechanism

The capping mechanism covers the printheads with the cap holder to prevent the ink

around the nozzles from increasing viscosity when the printer is in stand-by mode or

when the printer is off.

Capping mechanism moves up when the CR unit moves to the right end of the CR

guide shaft and covers the printhead nozzle plate.

Stylus Photo 750 / Stylus Photo 1200

Flag for Carri age

Negative pressure

Ink Eject Valve

Valve

Stylus Photo 750 / Stylus Photo 1200 has built-in air valves in the capping unit but

Stylus Photo 720 / Stylus Photo EX3 uses valveless system.

Air valve function used for the previous models pumps and ejects ink only inside the

cap by sucking ink with the valve open. Valveless system is developed by changing the

ink sequence.

When sucking ink only inside the cap (false absorption), Stylus Photo 720 / Stylus

Photo EX3 moves printhead to the left from the cap unit (out of the cap) and drives

pump to perform false absorption.

Stylus Photo 720 and Stylus Photo EX3

Flag for Carri age

Ink Eject Valve

Negative pressure

Released state

Closed state

The absorbing

power is low.

Flags for

Frame

Air valve is not assembled

in this portion.

Figure 2-10. Valveless Capping Mechanism

eratingPrinciples Overview

O

0

Page 40

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

4

n

2.1.8 Ink Sequence

o

Initial ink charge

After the product is purchased and the printer is turned on for the first time, the

printer performs the initial ink charge and charges ink inside the head cavity.

When the initial ink charge is completed properly, the printer releases the flag

inside the EEPROM and no initial ink charge will be performed next time the

power is turned on. Stylus Photo 720 / Stylus Photo EX3 takes 85 seconds to

complete initial ink charge sequence.

o

Manual cleaning

When the dot missing by printhead is occurred, Stylus Photo 720 / Stylus Photo

EX3 provides three types of manual CL to clean air bubbled or clogged ink with

viscosity or foreign substances.

The following manual CL sequences can be executed by panel operation or from

the printer driver utility.

n

CL1

- Ink absorption (Black Ink: 0.096ml, Color Ink: 0.48ml)

-Wiping operation (Wipes nozzle plate by the rubber part on the right half of the

wiper.)

-Flashing operation (Prevents color from mixing. Stabilizes ink surface inside the

nozzle)

The above mentioned manual CL is executed by performing nozzle check pattern and

manual CL alternately. The cleaning order is CL1

print is executed between each manual CL, only CL1 is to be performed. Like previous

models, when the power is turned ON, the printer executes power on CL automatically

according to power OFF period and the counter value of the cleaning timer. Power on

CL sequence is designed to prevent the ink viscosity and dot missing caused by foreign

substances. According to each counter value, certain amount of ink (Black: max.

0.12ml, Color: max. 0.58ml) is consumed by power on CL when the power is applied.

CL2

- Ink absorption (Black Ink: 0.21ml, Color Ink: 1.059ml)

-Wiping operation (Wipes nozzle plate by the rubber part on the right half of the

wiper.)

-Rubbing operation (Wipes nozzle plate by the felt part on the left half of the

wiper.)

-Flashing operation (Prevents color from mixing. Stabilizes ink surface inside the

nozzle)

→ CL1’→ CL2→ CL1. If no test

n

CL1’

- Ink absorption (Black Ink: 0.24ml, Color Ink: 1.19ml)

-Wiping operation (Wipes nozzle plate by the rubber part on the right half of the

wiper.)

-Flashing operation (Prevents color from mixing. Stabilizes ink surface inside the

nozzle)

eratingPrinciples Overview

O

1

Page 41

E

PSON Stylus Photo 720 / EPSON Stylus Photo EX3 Revision A

p

E

4

2.2 Electrical Circuit Operating Principles

The electric circuit of the Stylus Photo 720 / Stylus Photo EX3 consists of the

following boards.

o

Main board: C301MAIN Board

o

Power supply board: C301PSB/PSE Board

o

Panel board: C209PNL Board (Stylus Photo 720)

C366PNL Board (Stylus Photo EX3)

This section provides operating principles of C301PSB/PSE Board and C301MAIN

Board. Refer to Figure 2-11 for the major connection of the three boards and their

roles.

C209PNL Board (Stylus Photo 720)

C366PNL Board (Stylus Photo EX3)

C301MAIN Board

3.3V Driver IC 5V Driver IC

3.3V Regulator

Power Off

+5V DC

C301 PSB/PSE

Board

+42V DC

Printer Mechanism

CR Motor

PF Motor

Head Driver Board

Several Sensors

2.2.1 C301PSB/PSE Board

The power supply boards of Stylus Photo 720 / Stylus Photo EX3 use a RCC (Ringing

Chalk Converter) circuit, which generates +42VDC for drive line and +5VDC for logic

line to drive the printer. The application of the output voltage is described below.

Table 2-7. Application of the DC Voltages

Voltage Application

• Motors (CR Motor, ASF/Pump Motor, PF Motor)

+42VDC

+5VDC

Stylus Photo 720 / Stylus Photo EX3 uses the delay circuit (secondary side power

switch). Use of the secondary switch enables the circuit to keep supplying voltage to 5

V line and 24 V line for approximately 30 seconds if the printer power is turned off

through the panel switch. Even if the printer is turned off through the panel switch

while it is in operation, the printer turns the power supply off after performing the