Page 1

®

SERVICE MANUAL

Stylus PHOTO 890

Color ink jet printer

EPSON Stylus PHOTO 890/1280/1290

Stylus PHOTO 1290/1280

Page 2

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2000 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

TPCS Quality Assurance Center

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR

OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of EPSON Stylus PHOTO 890/1280/

1290. The instructions and procedures included herein are intend ed for the experienced repair technicians, and attention should be given to the precautions on the

preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• EEPROM Address Map

• Connector Pin Assignments

• Component Layout

• Exploded Diagrams

• Electrical Board Circuit Diagrams

Page 5

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or to warn of possible danger present

during a procedure or an action. Be aware of all symbols when they are used, and always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed, could result in damage to, or

destruction of, equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed, could result in injury or loss of life.

Page 6

Revision Status

Revision Issued Date Description

A November 16, 2000 First Release

Revision:

• page-78: A warning message for static electricity added.

B December 27, 2000

C February 8, 2001

• page -79: Caution messages for torque and ink tube position added

• page -90& page -92: Caution messages for ink tube installation added.

• page -121: PG adjustment tool added.

Revision:

• All chapters: Stylus PHOTO 1280(for EAI) added.

• page -68: Misdescription for Maintenance Request Error corrected.

• page -128: Stylus PHOTO 1280(for EAI) added to Destination in the adjustment program.

• page -182: C393 MAIN-C Board circuit diagram added.

D June 4,2002

Revision:

• “Lubrication” on page -156: The lubrication of Oil O-12 for the Stylus Photo 1280/129 0 added.

Page 7

Table of Contents

Chapter 1 PRODUCT DESCRIPTIONS

1.1 Overview ............................................................................................................ 11

1.1.1 Features ...................................................................................................... 11

1.1.2 Accessories, Consumable Products, and Options ...................................... 12

1.2 Basic Specifications .......................................................................................... 14

1.2.1 Printing Specification ................................................................................ 14

1.2.2 Control Code ........................................................... ................................... 14

1.2.3 Paper Feeding ............................................................................................ 14

1.2.4 Input Data Buffer ....................................................................................... 14

1.2.5 Paper Specifications ................................................................................... 15

1.2.5.1 EPSON Special Media ............................................................... ....... 15

1.2.6 Printing Area .............................................................................................. 17

1.2.6.1 Cut Sheet ........................................................................................... 17

1.2.6.2 Envelopes .......................................................................................... 18

1.2.7 Adjust Lever .............................................................................................. 18

1.2.8 Ink Cartridge ................................................... ........................................... 19

1.2.9 Electric Specification ...................................... ... .................................... ... . 20

1.2.10 Reliability ................................................................................................ 20

1.2.11 Environmental Condition ......................................................................... 21

1.3 Interface ............................................................................................................. 22

1.3.1 Parallel Interface (Forward Channel) ........................................................ 22

1.3.2 Parallel Interface (Reserve Channel) ......................................................... 25

1.3.3 USB Interface ............................................................................................ 26

1.3.4 Prevention of Data Transfer Time-out ....................................................... 27

1.3.5 Interface Selection ..................................................................................... 27

1.3.6 IEEE1284.4 Protocol .......... .................................... ................................... 27

1.4 Operations ......................................................................................................... 28

1.4.1 Buttons ....................................................................................................... 28

1.4.2 Indicators ................................................................................................... 28

1.4.3 Panel Functions ....................................................... ................................... 28

1.4.4 Special Setting Mode ................................................................................. 29

1.4.5 Printer Initialization ................................................................................... 30

1.4.6 Initialization Value .................................................................................... 30

1.5 Dimension .......................................................................................................... 31

Chapter 2 OPERATING PRINCIPLES

2.1 Overview .......................................................................... .................................. 34

2.1.1 Printhead Mechanism ................................................................................ 35

2.1.2 Carriage Mechanism .................................................................................. 36

2.1.2.1 Carriage Motor (CR Motor) .............................................................. 36

2.1.2.2 Platen Gap (PG) /Parallelism Adjustment Mechanism ..................... 37

2.1.2.3 Carriage Home Position (HP) Detection ........................................... 37

2.1.3 Paper Feeding Mechanism .................................................. ....................... 37

2.1.3.1 CR Lock Mechanism ..................................................... .................... 39

2.1.4 Paper Loading Mechanism ........................................................................ 40

2.1.4.1 Drive Transmission to the ASF Unit ................................................. 40

2.1.4.2 Paper Loading Operation .................................................................. 41

2.1.4.3 Pump Mechanism .............................................................................. 42

2.1.4.4 Capping Mechanism .......................................................................... 43

2.2 Electrical Circuit Operating Principles .......................................................... 44

2.2.1 C378PSB/PSE Board ....................................................... .......................... 44

2.2.1.1 Electrical Circuit ................................................ ............................... 44

2.2.1.2 Protection Circuits ............................................................................. 46

2.2.1.3 Power Supply Control Function ............................................... ......... 46

2.2.1.4 Energy Save Mode ............................................................................ 46

2.2.2 C393MAIN Board Circuit Operation Principles ....................................... 47

2.2.2.1 Printhead Driver Circuit .................................................................... 50

2.2.2.2 RTC (Real Time Clock)/ Reset/ EEPROM Circuit ........................... 51

2.2.2.3 Motor Driver Circuit ......................................................................... 52

2.2.2.4 ASF/Pump Motor Driver Circuit ....................................................... 57

2.2.2.5 Sensor Circuit .................................................................................... 58

Chapter 3 TROUBLESHOOTING

3.1 Overview .......................................................................... .................................. 61

3.1.1 Self-Diagnostic Function ........................................................................... 62

3.1.1.1 Troubleshooting with LED Error Indicators ..................................... 62

3.1.1.2 Error Conditions ................................................................................ 62

3.1.1.3 Remedies for Paper Out Error ........................................................... 65

Page 8

3.1.1.4 Remedies for the Paper Jam Error ..................................................... 67

3.1.1.5 Remedies for No Ink Cartridge Error/Ink Cartridge Problem ........... 67

3.1.1.6 Remedies for Maintenance Request Error ......................................... 68

3.1.1.7 Remedies for Fatal Error ................................................................... 69

3.1.2 Isolating the Faulty Part on the Power Supply Board ................................ 72

3.1.3 Isolating the Faulty Part according to the Phenomenon ............................ 72

Chapter 4 DISASSEMBLY AND ASSEMBLY

4.1 Overview ............................................................................................................ 78

4.1.1 Precaution for Disassembling the Printer .................................................. 78

4.1.2 Tools .......................................................................................................... 79

4.1.3 Specifications for Screws .......................................................................... 80

4.1.4 Service Checks After Repair ..................................................................... 81

4.2 Disassembly Procedures ................................................................................... 82

4.2.1 HOUSING Removal .................................................................................. 83

4.2.2 Circuit Board Assembly Removal ............................................................. 84

4.2.3 Panel Unit Removal ................................................... ................................ 86

4.2.4 Printhead Unit Removal ............................................................................ 88

4.2.5 TRAY, ABSORBER ASSEMBLY Removal ........................................... . 89

4.2.6 Ink Unit Removal ...................................................................................... 91

4.2.7 MOTOR ASSEMBLY, CR Removal ........................................................ 94

4.2.8 MOTOR ASSEMBLY, ASF Removal ...................................................... 95

4.2.9 DE Unit Removal ...................................................................................... 96

4.2.10 ASF Unit Removal .................................................................................. 99

4.2.10.1 SHAFT, ROLLER, LD Removal .................................................. 101

4.2.10.2 ROLLER ASSEMBLY, LD, RIGHT/LEFT Removal ................. 106

4.2.11 Carriage Unit Removal .......................................................................... 107

4.2.12 BOARD ASSEMBLY, ENCODER Removal ....................................... 109

4.2.13 ROLLER, PF Removal .......................................................................... 110

4.2.13.1 SCALE, PF Installation ................................................................. 113

4.2.14 MOTOR ASSEMBLY, PF Removal ..................................................... 116

4.2.15 PE Sensor Unit Removal ....................................................................... 117

Chapter 5 ADJUSTMENT

5.1 Overview .......................................................................................................... 119

5.1.1 Adjustment Items ..................................................................................... 119

5.1.2 Adjustment Tools ..................................................................................... 120

5.2 Adjustment ...................................................................................................... 121

5.2.1 Parallelism Adjustment ............................................................................ 121

5.2.1.1 Using PG Adjustment Tool ............................................................. 121

5.2.1.2 Using Thickness Gauge ................................................................... 124

5.2.2 Backlash Adjsutment ............................................................................ 125

5.2.3 Adjustment Program Feature ................................................................... 127

5.2.3.1 How to Install the Program ............................................................. 128

5.2.3.2 How to Uninstall the Program ......................................................... 128

5.2.4 Starting the Service Program ................................................................... 128

5.2.4.1 Adjusting Program Initial Setting ................................................... 128

5.3 Individual Adjustment Program ................................................................... 130

5.3.1 Head ID ............................................. ..................................... .................. 130

5.3.1.1 Head ID Input ............................................................................... 130

5.3.1.2 Head ID Check ................................................................................ 132

5.3.2 Bi-Directional Adjustment .................................................................... 133

5.3.2.1 Input Bi-D Adjustment Value ...................................................... 135

5.3.2.2 Check Present Adjustment Data ...................................................... 136

5.3.3 Input/Check USB ID ............................................................................... 137

5.3.3.1 Input USB ID ..................................................... ............................. 138

5.3.3.2 Check USB ID ...................................................... ........................... 138

5.3.4 Maintenance ......................................... .................................................... 139

5.3.4.1 Head Cleaning Operation ................................................................ 139

5.3.5 Ink Charge Operation ............................................................................. 140

5.3.6 Refurbishment for DOA .......................................................................... 141

5.3.7 Protection Counter .................................................................................. . 143

5.3.7.1 Check the Present Counter Value ............................... ..................... 143

5.3.7.2 Clear the Protection Counter Value ................................................ 143

5.3.8 Appendix Items .......................................... .................................... .......... 145

5.3.8.1 CSIC Information ......................................................................... 145

5.3.8.2 EEPROM Data Check ................................................................... 146

5.3.8.3 Changing EEPROM Data .............................................................. 146

5.3.9 A4 Check Pattern Printing ..................................................... .................. 147

5.4 Sequential Repair Adjustment Program ...................................................... 149

5.4.1 Function ............................................................................................... .... 149

5.4.1.1 How to start the program ................................................................. 149

5.4.1.2 Printhead Removal .......................................................................... 150

5.4.1.3 Printhead Replacement .................................................................... 151

5.4.1.4 Main Board Replacement ................................................................ 152

5.4.1.5 Carriage Unit Replacement/ Removal ............................................. 152

5.4.1.6 CR Motor Replacement ................................................................... 152

5.4.1.7 Printer Mechanism Replacement .................................................... 152

Page 9

5.4.1.8 Waste Ink Pad Replacement ............................................................ 152

5.4.1.9 Clogged Nozzle Recovery ............................................................... 152

Chapter 6 MAINTENANCE

6.1 Overview .......................................................................................................... 155

6.1.1 Cleaning ................................................................................................... 155

6.1.2 Service Maintenance ................................................................................ 155

6.1.2.1 Head Cleaning ...... ........................................................................... 155

6.1.2.2 Maintenance Request Error Clear ................................................... 155

6.1.3 Lubrication ............................................................................................... 156

Chapter 7 APPENDIX

7.1 Connector Summary ...................................................................................... 166

7.1.1 Connector Alignment ............................................................................... 166

7.1.2 Connector Pin Assignment ...................................................................... 166

7.1.3 EEPROM Address Map ........................................................................... 169

7.2 Circuit Board Component Layout ................................................................ 174

7.3 Electrical Circuit Board Diagrams ............................................................... 179

7.4 Exploded Diagrams ........................................................................................ 186

7.4.1 Exploded Diagrams for Stylus PHOTO 890 ........................................... 186

7.4.2 Exploded Diagrams for Stylus PHOTO 1280/1290 ................................ 191

7.5 Parts List ......................................................................................................... 196

7.5.1 Parts List for Stylus PHOTO 890 .................................................. ... ....... 196

7.5.2 Parts List for Stylus PHOTO 1280/1290 ................................................. 201

Page 10

PRODUCT DESCRIPTIONS

CHAPTER

1

Page 11

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.1 Overview

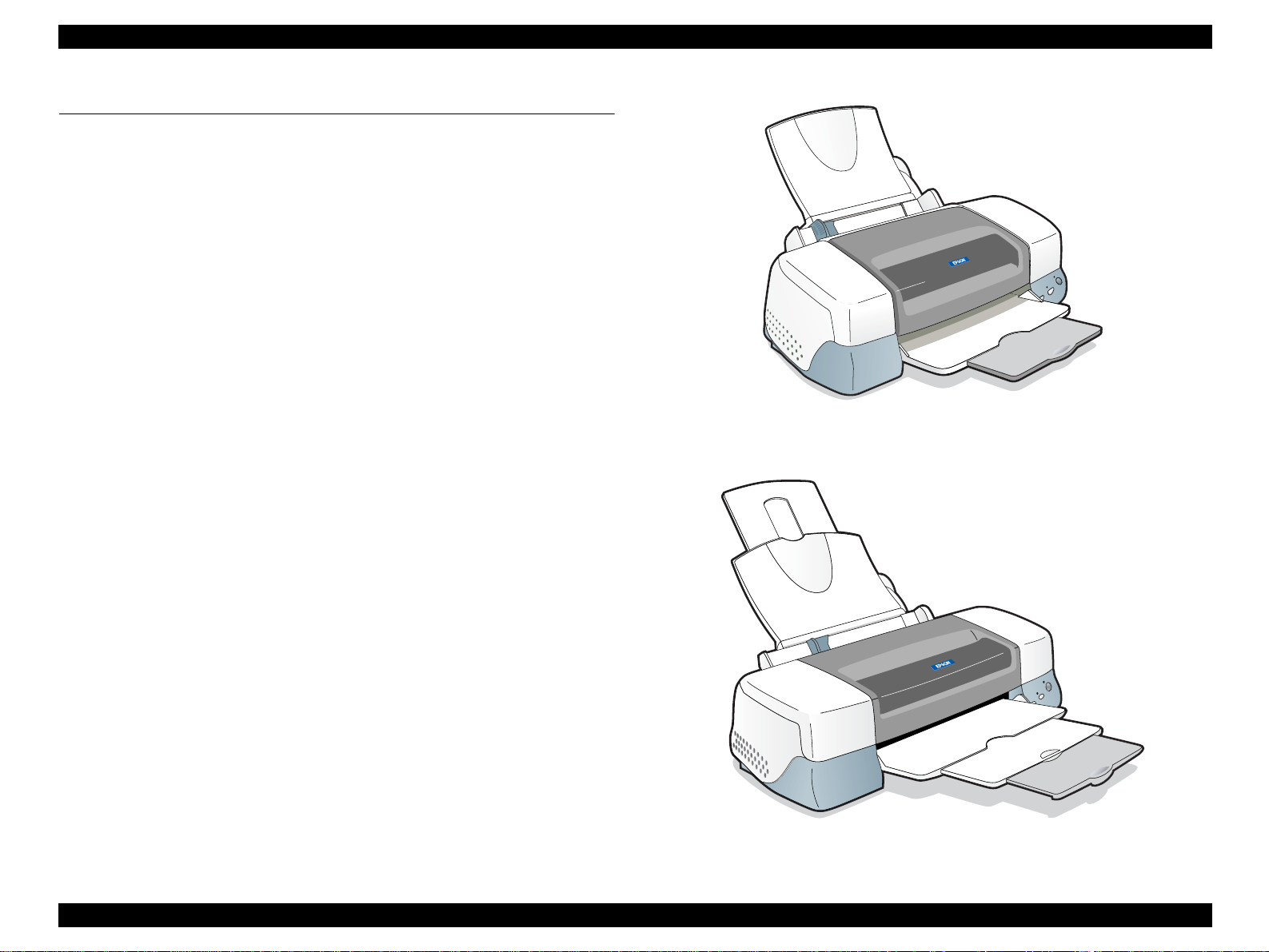

The EPSON Stylus PHOTO 890 and EPSON Stylus PHOTO 1280/1290 are designed

for both home use and office use. Stylus PHOTO 1280 is for EAI use only.

1.1.1 Features

The main features of the products are:

High-quality color print (6 colors)

High-speed & image quality bidirectional printing

Photo quality print enabled by photo mach technology

Supports microweave and super microweave

Prints at high resolution (2880x 720 dpi)

Two built-in interfaces

Bi-directional parallel interface (IEEE-1284 level 1 device)

USB I/F

Small size requiring less space.

Figure 1-1. Stylus PHOTO 890

Used only in Windows or Macintosh environment.

Built-in ASF (auto sheet feeder) supports multiple sizes of paper.

Stylus PHOTO 890: From postcard size up to A4

Stylus PHOTO 1280/1290: From postcard size up to A3 (W)

CSIC keeps track of ink life information on the ink cartridge side.

Figure 1-2. Stylus PHOTO 1280/1290

PRODUCT DESCRIPTIONS Overview 11

Page 12

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.1.2 Accessories, Consumable Products, and Options

ACCESSORIES

Users Guide

Ink cartridge (Black and color)

CD-ROM (Printer driver and utilities)

CONSUMABLE PRODUCTS

NOTE: The product codes of the ink cartridges may vary by location.

NOTE: The availability of special media varies by location.

NOTE: The products with an asterisk (*)are only available for Stylus PHOTO

1280/1290.

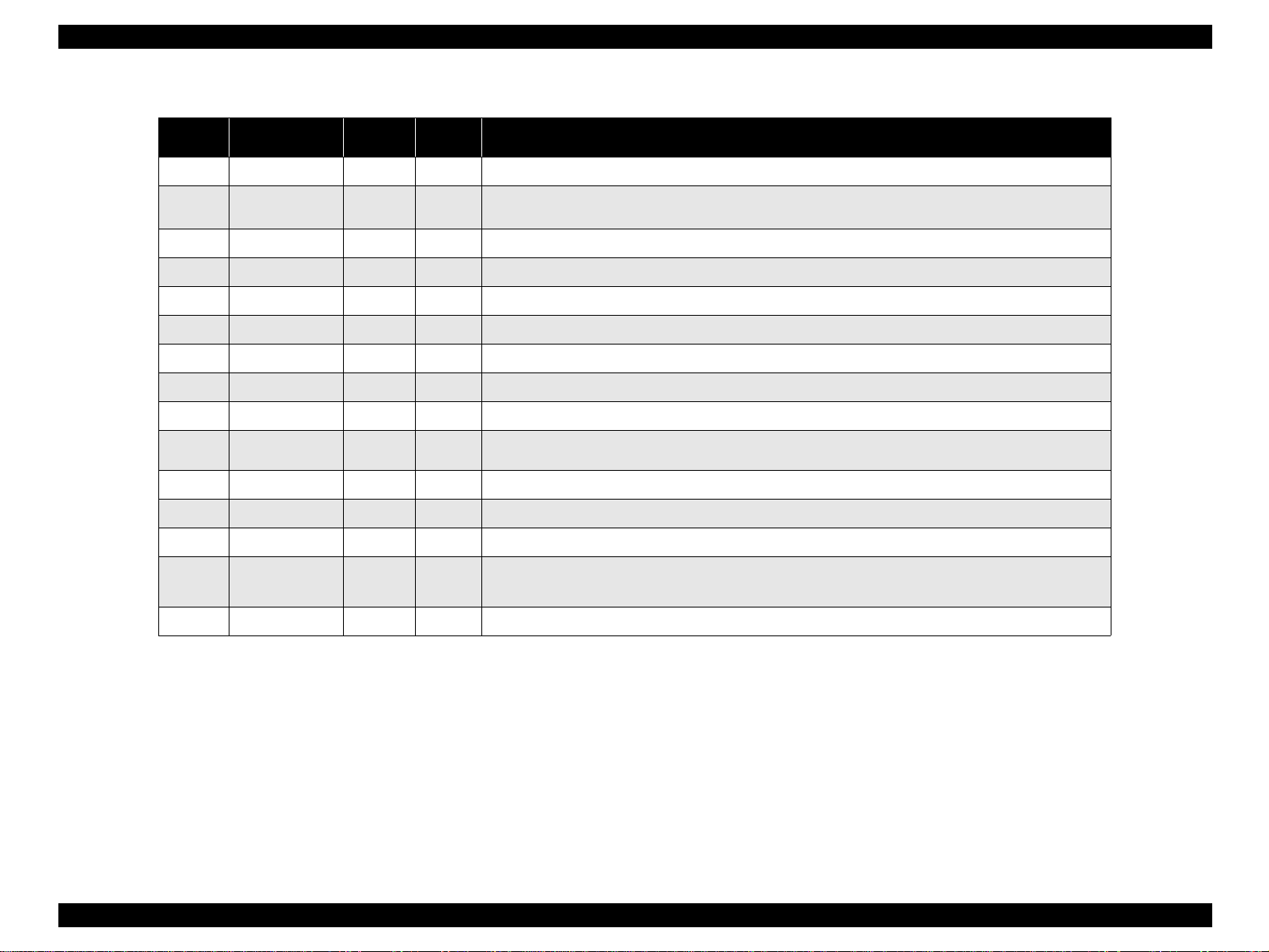

Table 1-1. Consumable Products

Product Name Code

Black ink cartridge T007

Color ink cartridge (Stylus PHOTO 890) T008

Color ink cartridge (Stylus PHOTO 1280/1290) T009

EPSON Premium Ink Jet Plain Paper (A4) S041214

EPSON 360 dpi Ink Jet Paper (A4)

EPSON 360 dpi Ink Jet Paper (Letter)

EPSON 360 dpi Ink Jet Paper (A3)*

EPSON 360 dpi Ink Jet Paper (Super A3/B)*

EPSON Iron-On Cool Peel Transfer Paper (A4)

EPSON Iron-On Cool Peel Transfer Paper (Letter)

EPSON Iron-On Cool Peel Transfer Paper (A3)*

EPSON Photo Quality Ink Jet Paper (A4)

EPSON Photo Quality Ink Jet Paper (Letter)

EPSON Photo Quality Ink Jet Paper (Legal)

EPSON Photo Quality Ink Jet Paper (A3)*

EPSON Photo Quality Ink Jet Paper (Super A3/B)*

EPSON Photo Quality Ink Jet Paper (B)*

S041059/S041025

S041060/S041028

S041065/S041046

S041066/S041047

S041154

S041153/S041155

S041238

S041061/S041026

S041062/S041029

S041067/S041048

S041068/S041045

S041069/S041043

S041070/S041044

Table 1-1. Consumable Products (continued)

Product Name Code

EPSON Photo Quality Ink Jet Cards (A6)

EPSON Photo Quality Ink Jet Cards(5x8”)

EPSON Photo Quality Ink Jet Cards(8x10”)

EPSON Photo Quality Self Adhesive Sheet (A4) S041106

EPSON Ink Jet Note Cards A6 (with envelops) S041147

EPSON Ink Jet Greeting Cards 5x8” (with envelopes)

EPSON Ink Jet Greeting Cards 8x10” (with envelopes)

EPSON Matte Paper-Heavyweight (A4)

EPSON Matte Paper-Heavyweight (Letter)

EPSON Matte Paper-Heavyweight (A3)*

EPSON Matte Paper-Heavyweight (Super A3/Super B)*

EPSON Photo Paper (A4)

EPSON Photo Paper (Letter)

EPSON Photo Paper (A3)*

EPSON Photo Paper (Super A3/Super B)*

EPSON Photo Paper (B)*

EPSON Photo Paper (4x6”)

EPSON Photo Paper (100 x 150 mm)

EPSON Photo Paper (200 x 300 mm)

EPSON Photo Paper (89 mmx 7M)

EPSON Photo Paper (100 mm x 8M)

EPSON Photo Paper (210 mm x 10M)

EPSON Photo Paper (329 mm x 10M)*

EPSON Panoramic Photo Paper (210 x 594 mm) S041145

EPSON Photo Paper Cards (A4) S041177

S041054

S041121

S041122

S041148

S041149

S041256/S041258/

S041259

S041257

S041260/S041261/

S041262

S041263/S041264/

S041265

S041140

S041141

S041142

S041143

S041156

S041134

S041255

S041254

S041281

S041279

S041280

S041233

PRODUCT DESCRIPTIONS Overview 12

Page 13

EPSON Stylus PHOTO 890/1280/1290 Revision C

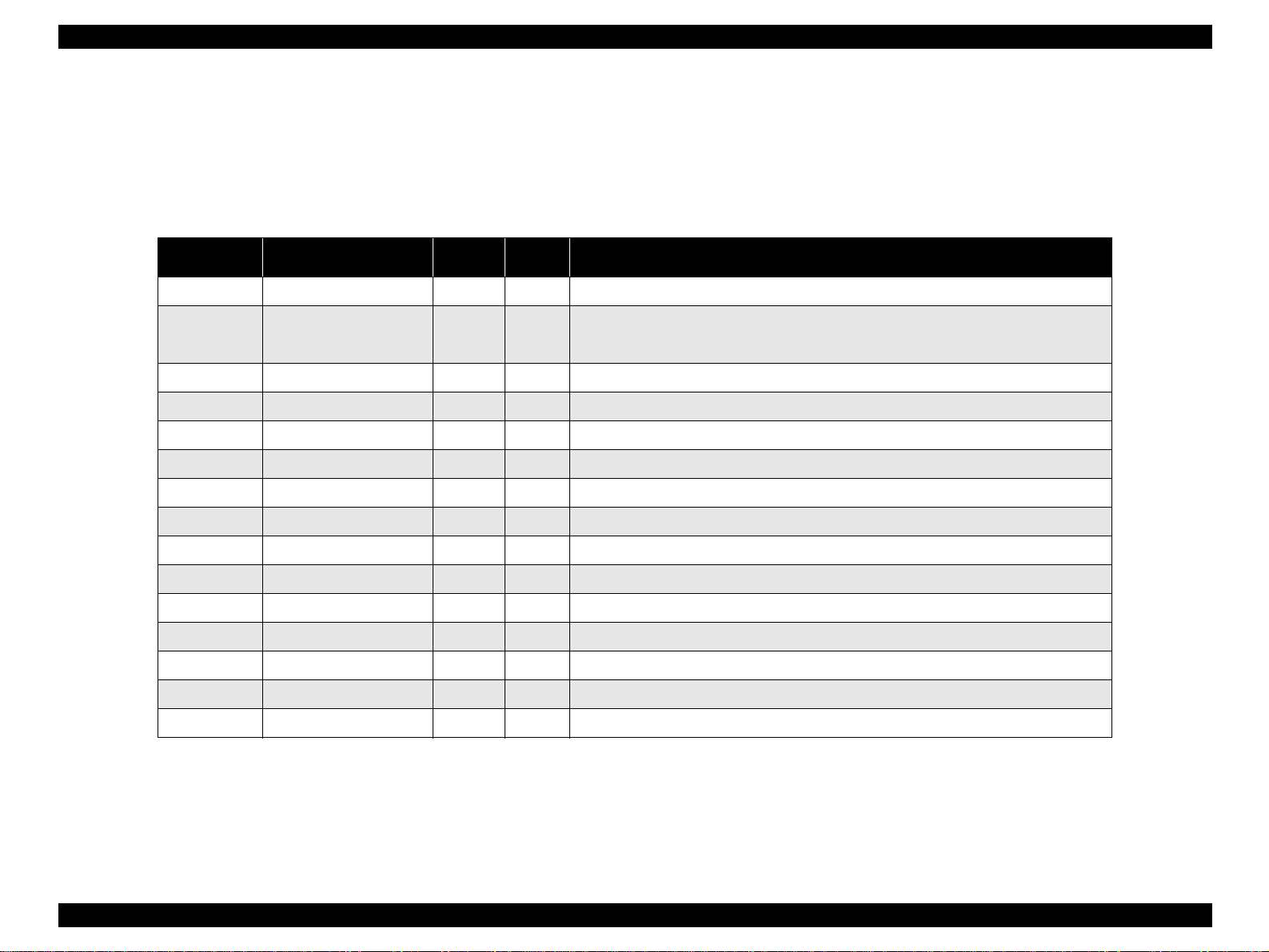

Table 1-1. Consumable Products (continued)

Product Name Code

Photo Quality Glossy Film (A4)

Photo Quality Glossy Film (Letter)

Photo Quality Glossy Film (A3)*

Photo Quality Glossy Film (Super A3/B)*

Photo Quality Glossy Film (B)*

Photo Quality Glossy Film (A6)

S041071

S041072

S041073

S041074

S041075

S041107

EPSON Photo Stickers 16 (A6)

EPSON Photo Stickers 4 (A6)

EPSON Ink Jet Transparencies (A4)

EPSON Ink Jet Transparencies (Letter)

EPSON Premium Glossy Photo Paper (A4)

EPSON Premium Glossy Photo Paper (Letter)

EPSON Premium Glossy Photo Paper (A3)*

EPSON Premium Glossy Photo Paper (B)*

EPSON Premium Glossy Photo Paper (Super A3/ SuperB)*

EPSON Ink Jet Back Light Film (A3)* S041131

S041144

S041176

S041063

S041064

S041287/S041297

S041286

S041288

S041290

S041289

OPTIONS

Table 1-2. Options

Product Name Code

Parallel Interface cable (shielded) C83602*

USB I/F Interface cable (shielded) C83623*

Roll Paper Holder C81106*

* The asterisks are substitutions for the last digits of the product name, which may vary by

country.

PRODUCT DESCRIPTIONS Overview 13

Page 14

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.2 Basic Specifications

1.2.1 Printing Specification

Print Method: On demand ink jet

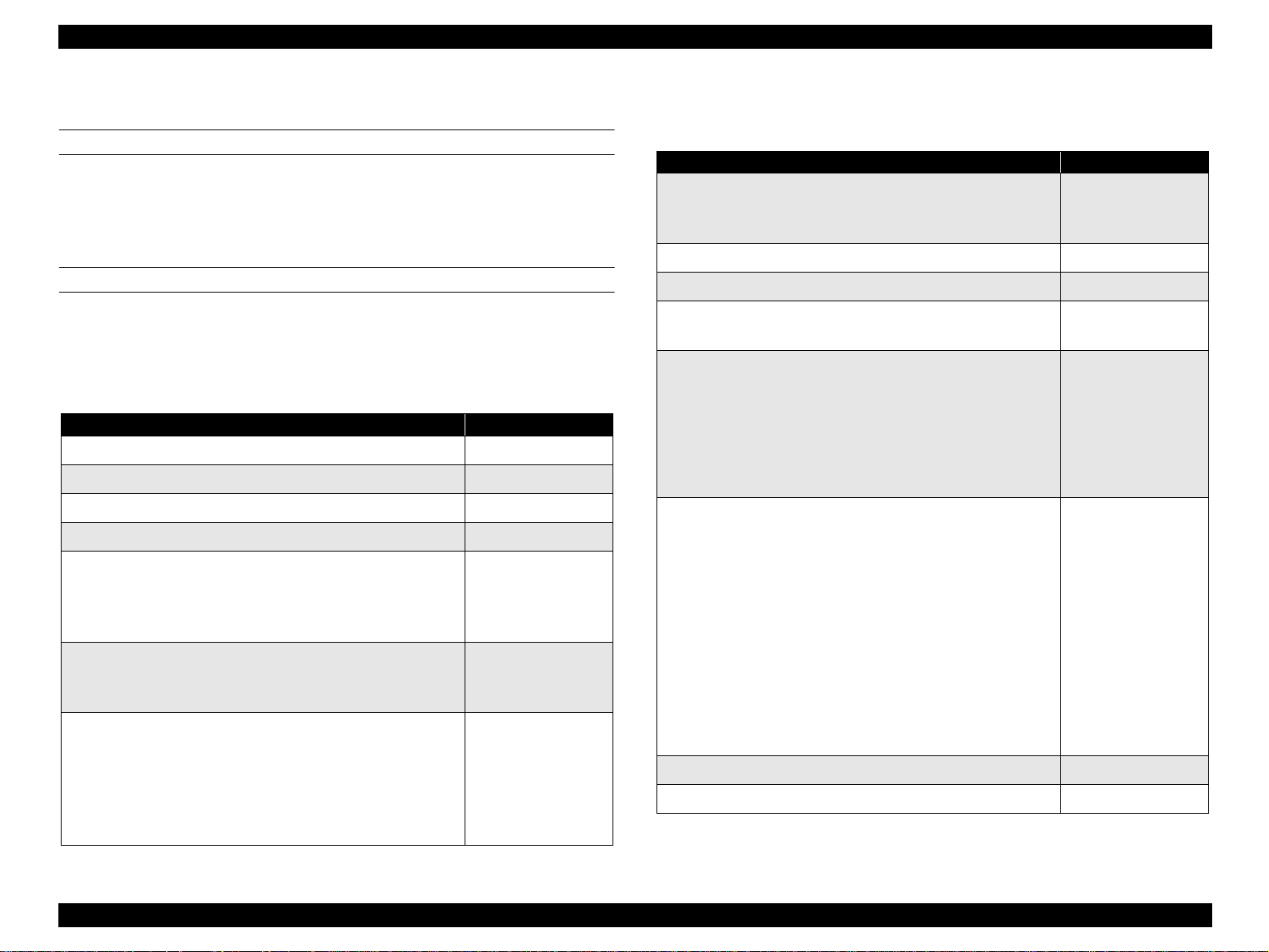

Nozzle Configuration

Monochrome: 48 nozzles (120 dpi)

Color: 48 nozzles x 5 (Cyan, Magenta, Yellow, Light cyan,

Light magenta) (120 dpi)

The following figure shows nozzle configuration viewed from the back of the

printhead:

* The value is the speed of normal-dot printing.

Raster Graphic Mode

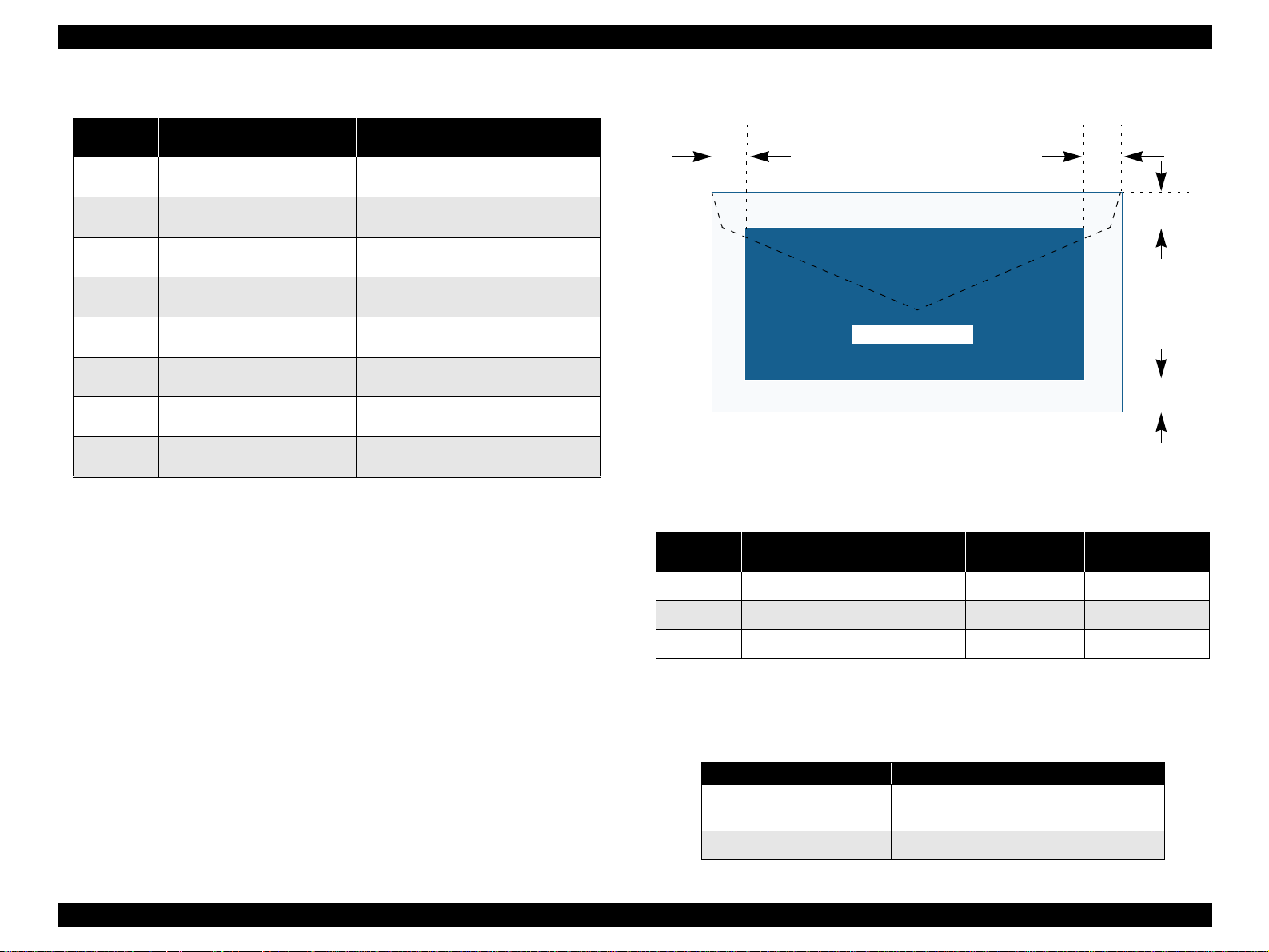

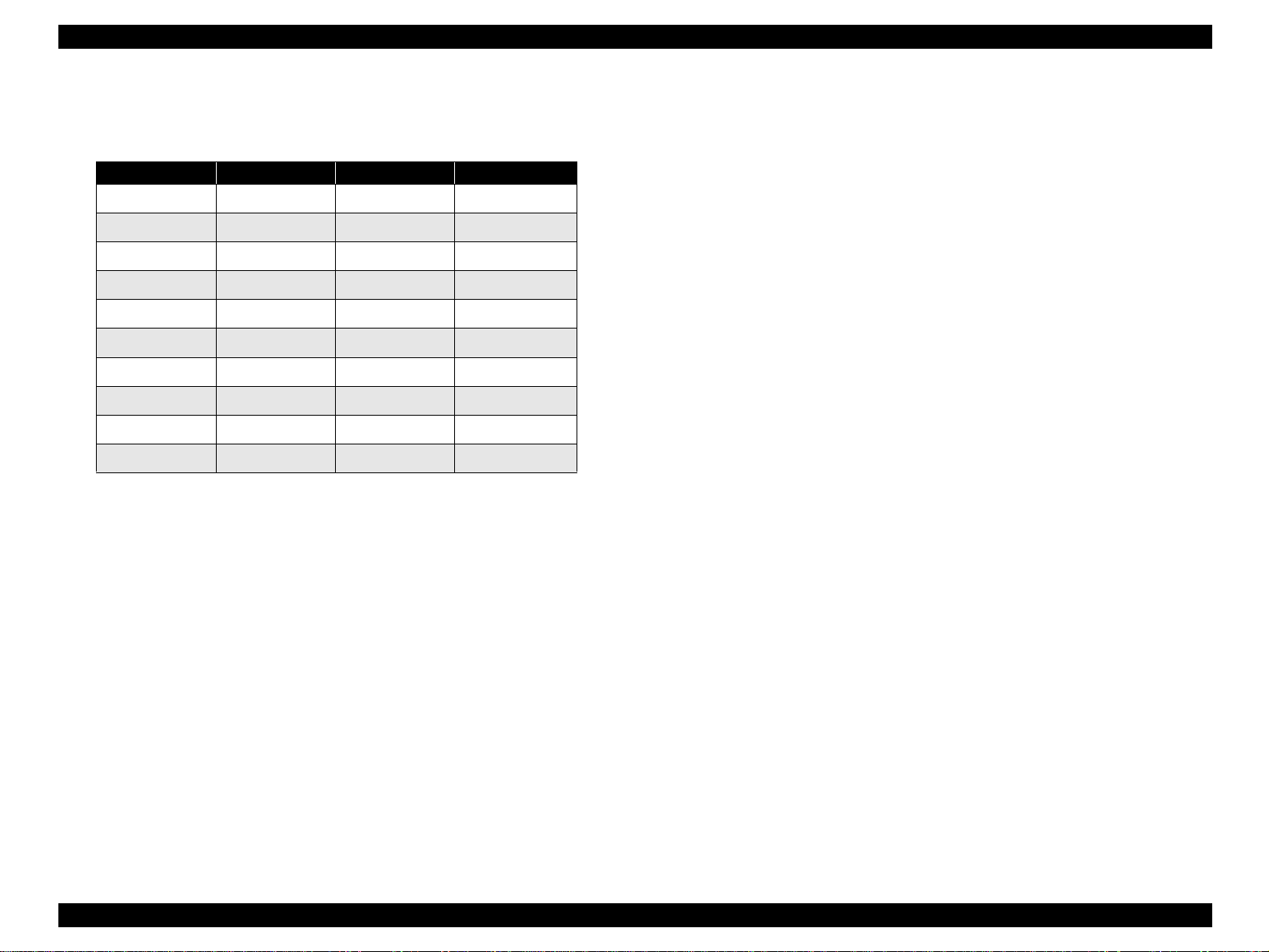

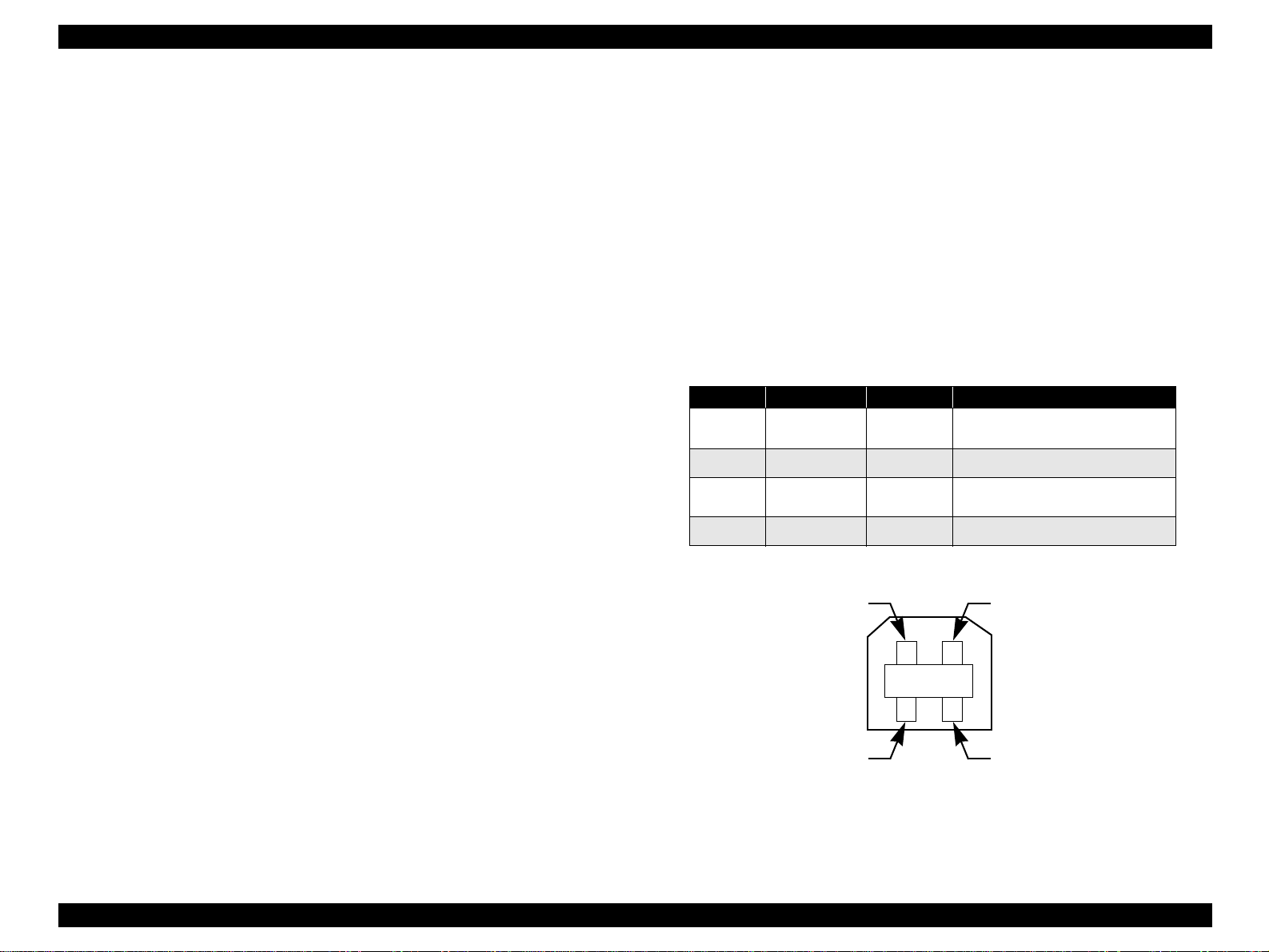

Table 1-4. Raster Graphics Mode

Model

Stylus PHOTO 890

Stylus PHOTO

1280/1290

Horizontal

Resolution

180 dpi

360 dpi

720 dpi

180 dpi

360 dpi

720 dpi

Printable

Area

209.8mm/

8.26”

209.8mm/

8.26”

209.8mm/

8.26”

322.986mm/

12.716”

322.986mm/

12.716”

322.986mm/

12.716”

1.2.2 Control Code

ESC/P Raster command

Available Dot CR Speed

1488 23.8/19 IPS

2976 23.8/19 IPS

5952 19 IPS

2289 23.8/19 IPS

4578 23.8/19 IPS

9156 19 IPS

Figure 1-3. Nozzle Configuration

Print Direction Bi-direction with logic seeking

Print Speed & Printable Columns

Character Mode

Table 1-3. Character Mode

Model Character Pitch Printable Columns LQ Speed

Stylus PHOTO 890 10 CPI (Pica) 80 238CPS*

Stylus PHOTO 1280/

1290

10 CPI (Pica) 127 238CPS*

EPSON Remote command

1.2.3 Paper Feeding

Feeding method: Friction feed with ASF

Paper Path: Cut-sheet ASF (top entry, front out)

Feed Speed: 110mm/sec (10.16mm feed)

152.4mm(6.0inch)/sec (Fast, continues feed)

1.2.4 Input Data Buffer

256 KB

PRODUCT DESCRIPTIONS Basic Specifications 14

Page 15

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.2.5 Paper Specifications

The asterisk(*) indicates Stylus PHOTO 1280/1290 use only.

CUT SHEET

Size: See the table below:

Table 1-5. Paper Specifications - Cut Sheet

Size Specifications (Width x Length)

*

A3

A4 210 mm (8.3”) x 297 mm (11.7”)

A5 148 mm x 210 mm

A6 148mm x 105 mm

*

B

Letter 216 mm (8.5”) x 279 mm (11.0”)

Half Letter 139.7 mm x 215.9 mm

Legal 216 mm (8.5”) x 356 mm (14.0”)

Executive 184.2 mm (7.25”) x 266.7 mm (10.5”)

2L 178 mm x 127 mm

L 127 mm x 127 mm

5” x 8” 127 mm x 203 mm

8” x 10” 203 mm x 254 mm

Double Side A4 210 mm x 297 mm

297mm (11.7”) x 420mm (16.5”)

279 mm x 432

ENVELOPE

Size (Width x Length):

#10 241.3mm (9 1/2”) x 104.8mm(4 1/8”)

DL 220mm (8.7”) x 110mm (4.3”)

C6 162mm (6.4”) x 114mm (4.5”)

220 x 132 220mm x 132 mm

Thickness: 0.16mm (0.006”) - 0.52mm (0.02”)

Weight: 45g/m2 (12Ib.) - 75g/m2 (20Ib.)

Quality: Bond paper, PPC, Air mail

Note1: Envelope printing is only available at normal temperature.

Note 2: Keep the longer side of the envelope horizontally at setting.

1.2.5.1 EPSON Special Media

EPSON offers specifically- designed media for ink jet printers.

PHOTO QUALITY INK JET PAPER

Size (Width x Length):

*

A3+

A3

*

329mm x 483mm

297mm x 420mm

A4 210mm x 297mm

A6 105mm x 148mm

*

B

210mm x 297mm

Letter 216mm x 279mm

Legal 216mm x 356mm

5” x 8” 127mm x 203mm

8” x 10” 203mm x 254mm

User Defined 89 to 241.3 mm x 89 to 1117.6 mm

Quality: Plain paper, Bond paper

Thickness: 0.08mm- 0.11mm (0.003”- 0.004”)

(Normal paper)

Weight: 64g/m2 - 90g/m2 (55kg-78kg, 17lb.- 24Ib.)

PRODUCT DESCRIPTIONS Basic Specifications 15

Page 16

EPSON Stylus PHOTO 890/1280/1290 Revision C

360 DPI INK JET PAPER

Size (Width x Length):

A3+

A3

*

*

A4 210mm x 297mm

A6 105mm x 148mm

Letter 216mm x 279mm

INK JET TRANSPARENCIES

Size (Width x Length):

A4 210mm x 297mm

Letter 216mm x 279mm

PHOTO QUALITY GLOSSY FILM

Size (Width x Length):

*

A3+

*

A3

A4 210mm x 297mm

A6 105mm x 148mm

*

B

Letter 216mm x 279mm

329mm x 483mm

297mm x 420mm

329mm x 483mm

297mm x 420mm

210mm x 297mm

200 x 300mm 216mm x 338mm(cut-line)

Roll Paper (89mm x 7m, 100mm x 8m,

210mm x 10m, 329mm x 10m

PHOTO QUALITY ADHESIVE SHEET

Size (Width x Length):

A4 210mm x 297mm

Letter 216mm x 279mm

IRON-ON COOL PEEL TRANSFER PAPER

Size (Width x Length):

A3

*

297mm x 420mm

A4 210mm x 297mm

Letter 216mm x 279mm

PHOTO STICKERS

Size (Width x Length):

A6 105mm x 148mm /16

A6 105mm x 148mm /4

MATTE PAPER-HEAVYWEIGHT

*

)

PHOTO PAPER

Size (width x length):

*

+A3

*

A3

A4 210mm x 297mm

*

A6

*

B

Letter 216mm x 279mm

329mm x 483mm

297mm x 420mm

105mm x 148mm

210mm x 297mm

Size (Width x Length):

*

A3+

A3

*

329mm x 483mm

297mm x 420mm

A4 210mm x 297mm

*

B

210mm x 297mm

Letter 216mm x 279mm

100mm x 150mm

Roll Paper (89mm x 7m, 100mm x 8m,

210mm x 10m, 329mm x 10m

*

)

Photo Paper Card 2 175.4mm x 113.6mm (cut-line)

Panoramic Photo Paper 210mm x 594mm

152.4mm (6“) x 101.6mm (4“)(no cut-line)

100mm x 150mm

PRODUCT DESCRIPTIONS Basic Specifications 16

Page 17

EPSON Stylus PHOTO 890/1280/1290 Revision C

PREMIUM GLOSSY PHOTO PAPER

Size (Width x Length):

+A3

A3

*

*

329mm x 483mm

297mm x 420mm

A4 210mm x 297mm

*

B

210mm x 297mm

Letter 216mm x 279mm

Roll Paper (89mm x 7m, 100mm x 8m,

127mm x 8m*,210mm x 10m,

329mm x 10m

INK JET BACK LIGHT FILM

Size (Width x Length):

A3

*

297mm x 420mm

1.2.6 Printing Area

1.2.6.1 Cut Sheet

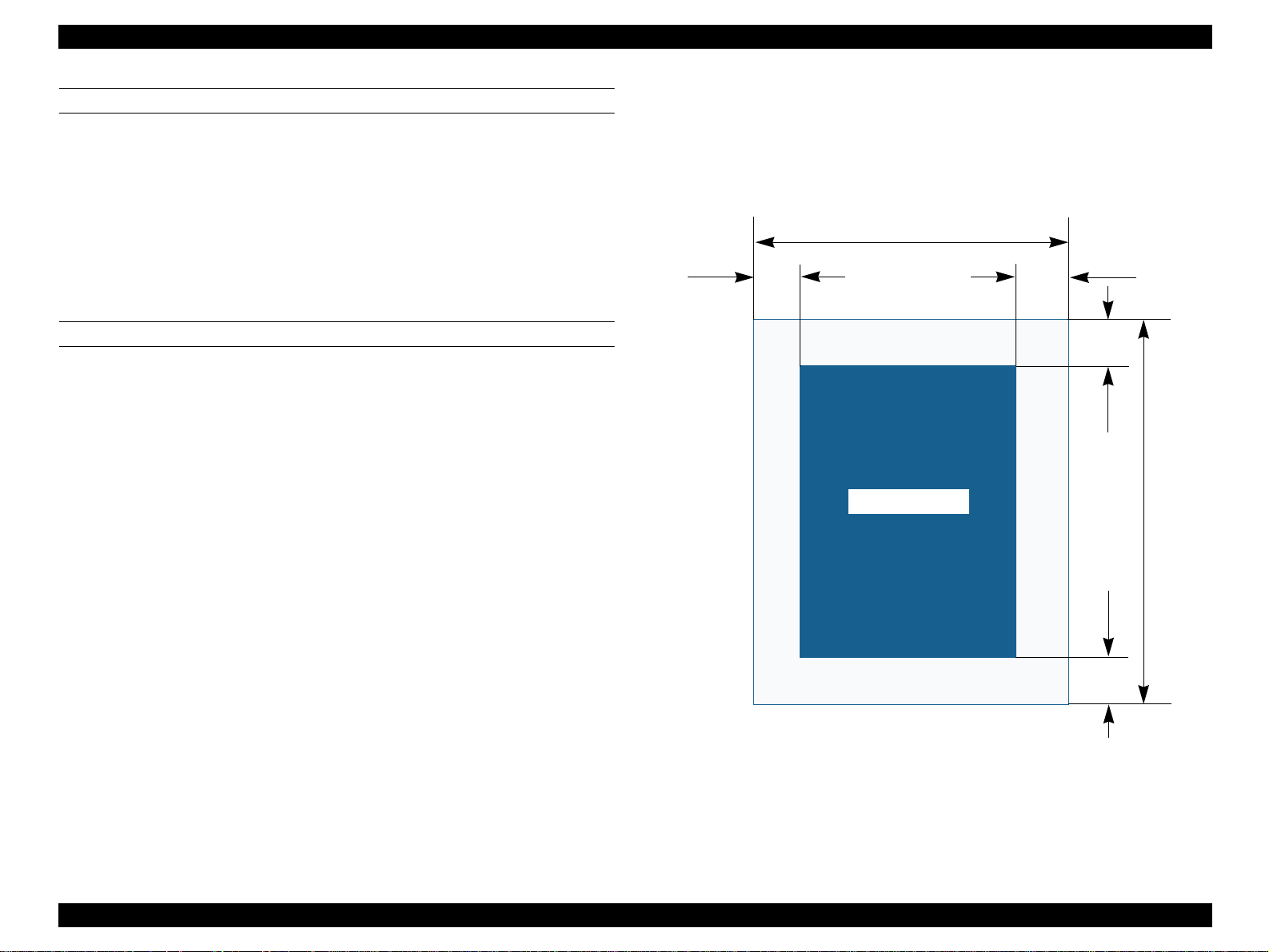

See the figure below and the following tables for the printing area for Stylus PHOTO

890/Stylus PHOTO 1280/1290.

PW

LM

*

)

Printable Area

RM

TM

PL

BM

Figure 1-4. Printable Area for Cut Sheet

PRODUCT DESCRIPTIONS Basic Specifications 17

Page 18

EPSON Stylus PHOTO 890/1280/1290 Revision C

Table 1-6. Printing Area

Left Margin

Paper Size

A3*

A3+*

A4

Letter

B5

Legal

Statement

Exclusive

*

: Stylus PHOTO 1290 only.

*1

:Bottom margin can be reduced to 3mm when paper dimension is

(min.)

3 mm

(0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

*2

*2

*2

*2

*2

*2

*2

*2

defined by using command, otherwise it remains 14mm.

As for an area between 3mm and 14mm margin, print quality may

decline.

*2

: Zero mm can be set by special command.

Right Margin

(min.)

Top Margin

(min.)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

3 mm (0.12”)*23 mm (0.12”)

*2

*2

*2

*2

*2

*2

*2

*2

Bottom Margin

(min.)

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

14 mm (0.54”) /

3mm (0.12”)

*1*2

1.2.6.2 Envelopes

LM

Printable Area

Figure 1-5. Printable Area for Envelopes

Table 1-7. Envelope Margin

Left Margin

Size

(min.)

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.55”)

DL 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.55”)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

RM

TM

BM

(min.)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.55”)

1.2.7 Adjust Lever

Set the adjust lever according to the type of paper as shown in the following table.

Table 1-8. Adjust Lever Setting Position

Paper Setting Position Gap

Cut sheet, OHP Sheet, Label,

Postcard

Envelope Rear (+) +0.9 mm

PRODUCT DESCRIPTIONS Basic Specifications 18

Front (0) 0 mm

Page 19

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.2.8 Ink Cartridge

BLACK INK CARTRIDGE

The black ink cartridge specifications for Stylus PHOTO 890 and Stylus PHOTO

1280/1290 are common.

Type: Exclusive Cartridge

Color: Black

Print Capacity: 540 pages/A4

(ISO/IEC 10561 Letter Pattern at 360 dpi)

Ink Life: 2 years from the indicated date of production

Storage Temperature

Packed (in transit): -30 to 60 oC (within a month at 40 oC, within 120

hours at 60

Packed (storage): -30 to 40 oC (within a month at 40 oC)

Installed: -20 oC to 40 oC (within a month at 40 oC)

Dimension: 20.1 mm (W) x 66.85 mm (D) x 38.5 m m (H)

o

C)

COLOR INK CARTRIDGE

Note some of the color ink specifications for the Stylus PHOTO 890 and Stylus

PHOTO 1280/1290 are different as indicated.

Type: Exclusive Cartridge

Color: Magenta, Cyan, Yellow, Light Cyan,

Light Magenta

Print Capacity:

Stylus PHOTO 890 220 pages / A4 (360 dpi, 5% duty each color)

Stylus PHOTO 1280/1290330 pages / A4 (360 dpi, 5% duty each color)

Ink Life: 2 years from the indicated date of production

Storage Temperature

Packed (in transit): -30 to 60 oC (within a month at 40 oC, within 120 hours

Packed (storage): -30 to 40 oC (within a month at 40 oC)

Installed: -20 oC to 40 oC (within a month at 40 oC)

Dimension:

Stylus PHOTO 890 49.1 mm (W) x 66.85 mm (D) x 38.5 mm (H)

Stylus PHOTO 1280/129049.1 mm (W) x 84.05 mm (D) x 41.8mm (H)

at 60

o

C)

PRODUCT DESCRIPTIONS Basic Specifications 19

Page 20

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.2.9 Electric Specification

120V VERSION

Rated Voltage: AC120V

Input Voltage Range: AC99∼132V

Rated Frequency Range: 50∼ 60Hz

Input Frequency Range: 49.5∼ 60.5Hz

Rated Current: 0.4A(Max0.7A)

Power Consumption: Approx. 15W (ISO10561 Letter Pattern)

Approx. 3W in standby mode

Energy Star compliant

Insulation Resistance: 10M ohms min.

(between AC line and chassis, DC 500V)

Dielectric Strength: AC 1000V rms. 1 minute or

AC 1200V rms. 1 second

(between AC line and chassis)

220 ∼ 240V VERSION

Rated Voltage: AC220V∼240V

1.2.10 Reliability

Total Print Volume Black: 25,000 pages (A4, Letter)

Color: 10,000 pages (A4, Letter)

Printhead Life: 3000 million dots/nozzl e

Input Voltage Range: AC198∼264V

Rated Frequency Range: 50∼60Hz

Input Frequency Range: 49.5∼60.5Hz

Rated Current: 0.2 A(Max0.35A)

Power Consumption: Approx. 15W (ISO10561 Letter Pattern)

Approx. 3W in standby mode

Energy Star compliant

Insulation Resistance: 10M ohms min.

(between AC line and chassis, DC 500V)

Dielectric Strength: AC 1500V rms. 1 minute

(between AC line and chassis)

PRODUCT DESCRIPTIONS Basic Specifications 20

Page 21

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.2.11 Environmental Condition

TEMPERATURE

Operating: 10 to 35°C

Non-Operating: -20 to 60°C

Within 1 month at 40°C /120 hours at 60°C

*1

: In a shipment container.

*2

: Refer to Figure 1-6 "Temperature/Humidity Range" for condition.

HUMIDITY

Operating: 20 to 80% RH (without condensation)

Not-Operating: 5 to 85% RH (without condensation)

90

80

70

60

Humidity (%)

50

40

30

20

*2

*1

RESISTANCE TO SHOCK

Operating: 1G, within 1 ms, X, Y, Z directions

Non-operating: 2G, within 2 ms, X, Y, Z di recti ons

*1

: In a shipment container.

*1

RESISTANCE TO VIBRATION

Operating: 0.15G

Non-operating: 0.5 0G

*1

: In a shipment container.

*2

*1

C A U T I O N

When storing the printer, make sure the printhead is capped.

When transporting the printer, ensure the ink cartridges are

installed in the printer and the printhead is capped.

If the printer power is off with the printhead left uncapped, turn

the printer on with the ink cartridges installed, cap the

printhead, and turn the printer off.

Ink freezes at below -4°C. It will be usable again after keeping it

for about three hours at 25

*1

°

C.

10

20

27

30

35

40

Temperature (°C)

Figure 1-6. Temperature/Humidity Range

*1

: In a shipment container.

*2

: Refer to Figure 1-6 "Temperature/Humidity Range" for condition.

PRODUCT DESCRIPTIONS Basic Specifications 21

Page 22

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.3 Interface

The EPSON Stylus PHOTO 890/1280/1290 provides USB and parallel interfaces as

standard.

1.3.1 Parallel Interface (Forward Channel)

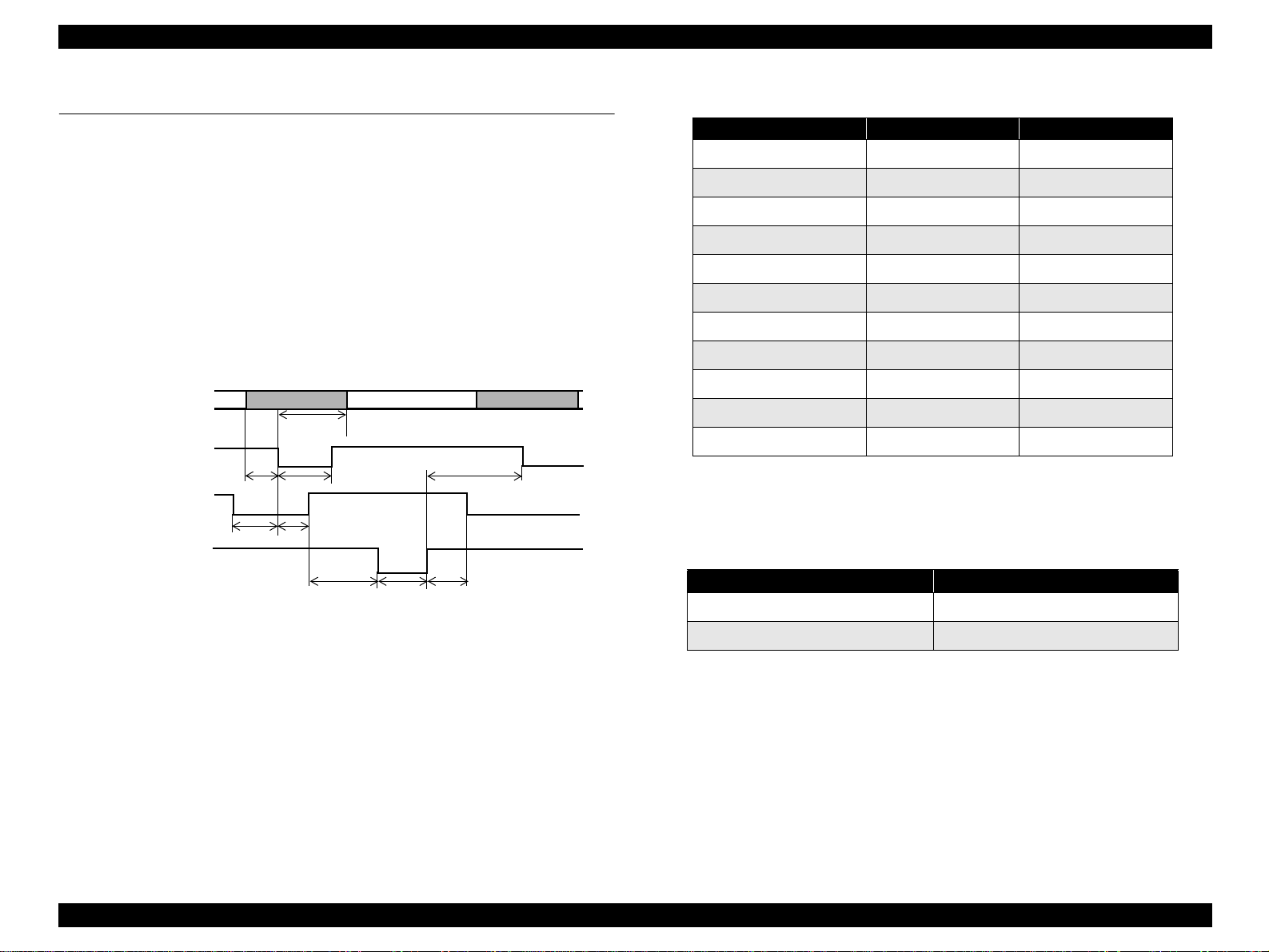

Transmission Mode: 8 bit parallel, IEEE-1284 compatibility mode

Synchronization: By STROBE pulse

Handshaking: By BUSY and ACKNLG signal

Signal Level: TTL compatible level

Adaptable Connector: 57-30360 (amphenol) or equivalent

DATA

-STROBE

BUSY

-ACKNLG

data byte n

hold

t

stb

ready

t

setup

t

t

busy

t

t

reply

ack

t

t

Figure 1-7. Data Transmission Timing

t

nbusy

data byte n+1

next

Table 1-9. Parameters

Parameter Minimum Maximum

tsetup 500ns -

thold 500ns -

tstb 500ns -

tready 0 -

tbusy - 500ns

tt-out* - 120ns

tt-in** - 200ns

treply 0 -

tack 500ns 10us

tnbusy 0 -

tnext 0 -

* Rise and fall time of every output signal.

** Rise and fall time of every input signal.

*** Typical timing for tack is shown on the following page.

Table 1-10. Typical Time of Tack

Parallel I/F Mode Typical Time of tack

High Speed 0.5us

Normal Speed 2us

PRODUCT DESCRIPTIONS Interface 22

Page 23

EPSON Stylus PHOTO 890/1280/1290 Revision C

Table 1-11.

Signal Level: TTL Compatible (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5V

VOL* -0.5V -

IOH* - 0.32mA VOH = 2.4V

IOL* - 12mA VOL = 0.4V

CO - 50pF

VIH - 2.0V

VIL 0.8V -

IIH - 0.32mA VIH = 2.0V

IIL - 12mA VIL = 0.8V

CI - 50pF

* A low logic level on the Logic H signal is 2.0V or less when the printer is turned off,

and this signal is equal to or exceeding 3.0V when the printer is turned on. The

receiver shall provide an impedance equivalent to 7.5K ohm to ground.

PRODUCT DESCRIPTIONS Interface 23

Page 24

EPSON Stylus PHOTO 890/1280/1290 Revision C

Table 1-12. Connector Pin Assignment and Signals

Pin No. Signal Name

1 -STROBE 19 In The strobe pulse. Read-in of data is performed at the falling edge of this pulse.

2-9 DATA0-DATA7 20-27 In

10 -ACKNLG 28 Out This signal is a negative pulse indicating that the printer can accept data again.

11 BUSY 29 Out A high signal indicates that the printer cannot receive data.

12 PE 28 Out A high signal indicates paper-out error.

13 SLCT 28 Out Always at high level when the printer is turned on.

14 -AFXT 30 In Not used.

17 Chassis GND - - Chassis GND

18 Logic H - Out Pulled up to +5V via 3.9K ohm resister.

31 -INIT 30 In

32 -ERROR 29 Out A low signal indicates printer error condition.

Return

GND Pin

In/Out Functional Description

The DATA0 through DATA7 signals represent data bits 0 to 7, respectively.

Each signal is at high level when data is logical 1 and low level when data is logical 0.

The falling edge of a negative pulse or a low signal on this line causes the printer to initialize. Minimum

50us pulse is necessary.

35 +5 - Out Pulled up to +5V via 3.3K ohm resister.

36 -SLIN 30 In Not used.

16,33

19-30

15,34 NC - - Not connected.

GND - - Signal GND

NOTE: In/Out refers to the direction of signal flow seen from the printer side.

PRODUCT DESCRIPTIONS Interface 24

Page 25

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.3.2 Parallel Interface (Reserve Channel)

Transmission Mode: IEEE-1284 nibble mode

Adaptable Connector See forward channel.

Synchronization: Refer to the IEEE-1284 specification

Pin No. Signal Name

1 HostClk 19 In Host clock signal.

2-9 DATA0-DATA7 20-27 In

10 PtrClk 28 Out Printer clock signal.

11 PtrBusy / DataBit-3,7 29 Out Printer busy signal and reverse channel transfer data bit 3 or 7.

12 AckDataReq / DataBit-2,6 28 Out Acknowledge data request signal and reverse channel transfer data bit 2 or 6.

13 Xflag / DataBit-1,5 28 Out X-flag signal and reverse channel transfer data bit 1 or 5.

14 HostBusy 30 In Host busy signal.

31 -INIT 30 In Not used.

32 -DataAvail / DataBit-0,4 29 Out Data available signal and reverse channel transfer data bit 0 or 4.

36 1284-Active 30 In 1284 active signal.

Handshaking: Refer to the IEEE-1284 specification

Data Trans. Timing: Refer to the IEEE-1284 specification

Signal Level: IEEE-1284 level 1 device (See forward channel.)

Table 1-13. Connector Pin Assignment and Signals

Return

GND Pin

In/Out Functional Description

The DATA0 through DATA7 signals represent data bits 0 to 7, respectively. Each signal is

at high level when data is logical 1 and low level when data is logical 0. These signals are

used to transfer the 1284 extensibility request values to the printer.

18 Logic-H - Out Pulled up to +5V via 3.9K ohm resistor.

35 +5V - Out Pulled up to +5V via 3.3K ohm resistor.

17 Chassis GND - - Chassis GND

16,33, 19-30 GND - - Signal GND

15,34 NC - - Not connected

NOTE: In/Out refers to the direction of signal flow from the printer’s point of view.

Extensibility Request:

The printer responds affirmatively when the extensibility request values are 00H

or 04H, which means:

00H: Request Nibble Mode Reverse Channel Transfer.

04H: Request Device ID;

Return Data Using Nibble Mode Rev Channel Transfer.

PRODUCT DESCRIPTIONS Interface 25

Page 26

EPSON Stylus PHOTO 890/1280/1290 Revision C

Device ID:

The printer sends the following device ID string when requested.

When IEEE1284.4 is enabled,

<00H><5AH>

*1

/ <00H><5CH>

*2

MFG: EPSON

CMD: ESCPL2,BDC,D4

MDL: Stylus[SP]Photo[SP]890

/Stylus[SP]Photo[SP]1290

CLS: PRINTER

DES: EPSONStylus[SP]Photo[SP]890

/EPSONStylus[SP]Photo[SP]1290

When IEEE1284.4 is enabled,

<00H><57H>

*1

/ <00H> <59H>

*2

MFG: EPSON

CMD: ESCPL2,BDC,D4

MDL: Stylus[SP]Photo[SP]890

/Stylus[SP]Photo[SP]1290

CLS: PRINTER

DES: EPSONStylus[SP]Photo[SP]890

/EPSONStylus[SP]Photo[SP]1290

*1

: Stylus PHOTO 890 only

*2

: Stylus PHOTO 1280/1290 only

1.3.3 USB Interface

Standard: Based on:

“Universal Serial Bus Specifications Rev. 1.1”

“Universal Serial Bus Device Class Definition for

Printing Devices Version 1.1”

Bit rate: 12Mbps (Full Speed Device)

Data encoding: NRZI

Adaptable connector: USB Series B

Recommended cable length:2 meters

Table 1-14. Connector Pin Assignment and Signals

Pin No. Signal Name I/O Function Description

1VCC -

2 -Data Bi-D Data

3+DataBi-D

4 Ground - Cable ground

Pin #2

Cable power. Max. power

consumption is 2mA.

Data, pull up to +3.3 V via 1.5K

ohm resistor.

Pin #1

NOTE 1:[00H] denotes a hexadecimal value of zero.

NOTE 2:MDL value depends on the EEPROM setting.

NOTE 3:CMD value depends on the IEEE1284.4 setting.

Pin #3

Pin #4

Figure 1-8. USB Pin Assignment

PRODUCT DESCRIPTIONS Interface 26

Page 27

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.3.4 Prevention of Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when the peripheral is in the busy

state for dozens of seconds continuously. To prevent this kind of time-out, the printer

receives data very slowly, several bytes per minute, even if the printer is in the busy

state. The slowdown starts when the remaining input buffer becomes several hundreds

of bytes, and the printer finally gets into the busy state continuously when the input

buffer is full.

USB and IEEE1284.4 on the parallel interface do not require such function.

On

An initial state is IEEE1284.4 communication and data that received it by the time

it is able to take synchronization by magic string (1284.4 synchronous commands)

is discarded.

Off

An initial state is compatible interface and never starts IEEE1284.4

communication even if magic strings (1284.4 synchronous commands) are

received.

1.3.5 Interface Selection

The printer has two built-in interfaces: the USB and parallel interface.

These interfaces are selected automatically.

Automatic Selection

In this automatic interface selection mode, the printer is initialized to the idle state

while scanning which interface receives data when it is powered on. Then the

interface which received data first is selected. When the host stops data transfer

and the printer is in the stand-by state for seconds, the printer is returned to the idle

state. As long as the host sends data or the printer interface is in the busy state, the

selected interface is let as it is.

Interface State and Interface Selection

When the parallel interface is not selected, the interface gets into the busy state.

When the printer is initialized or returned to the idle state, the parallel interface

gets into the ready state. Note that the interrupt signal such as the -INIT signal on

the parallel interface is not effective while that interface is not selected.

1.3.6 IEEE1284.4 Protocol

The packet protocol described by IEEE1284.4 standard allows a device to carry on

multiple exchanges or conversations which contain data and/or control information

with another device at the same time across a single point-to-point link. The protocol is

not, however, a device control language. It does provide basic transport-level flow

control and multiplexing services. The multiplexed logical channels are independent of

each other and blocking of one has no effect on the others. The protocol operates over

IEEE1284.

Automatic Selection

An initial state is compatible interface and starts IEEE1284.4 communication

when magic strings (1284.4 synchronous commands) are received.

PRODUCT DESCRIPTIONS Interface 27

Page 28

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.4 Operations

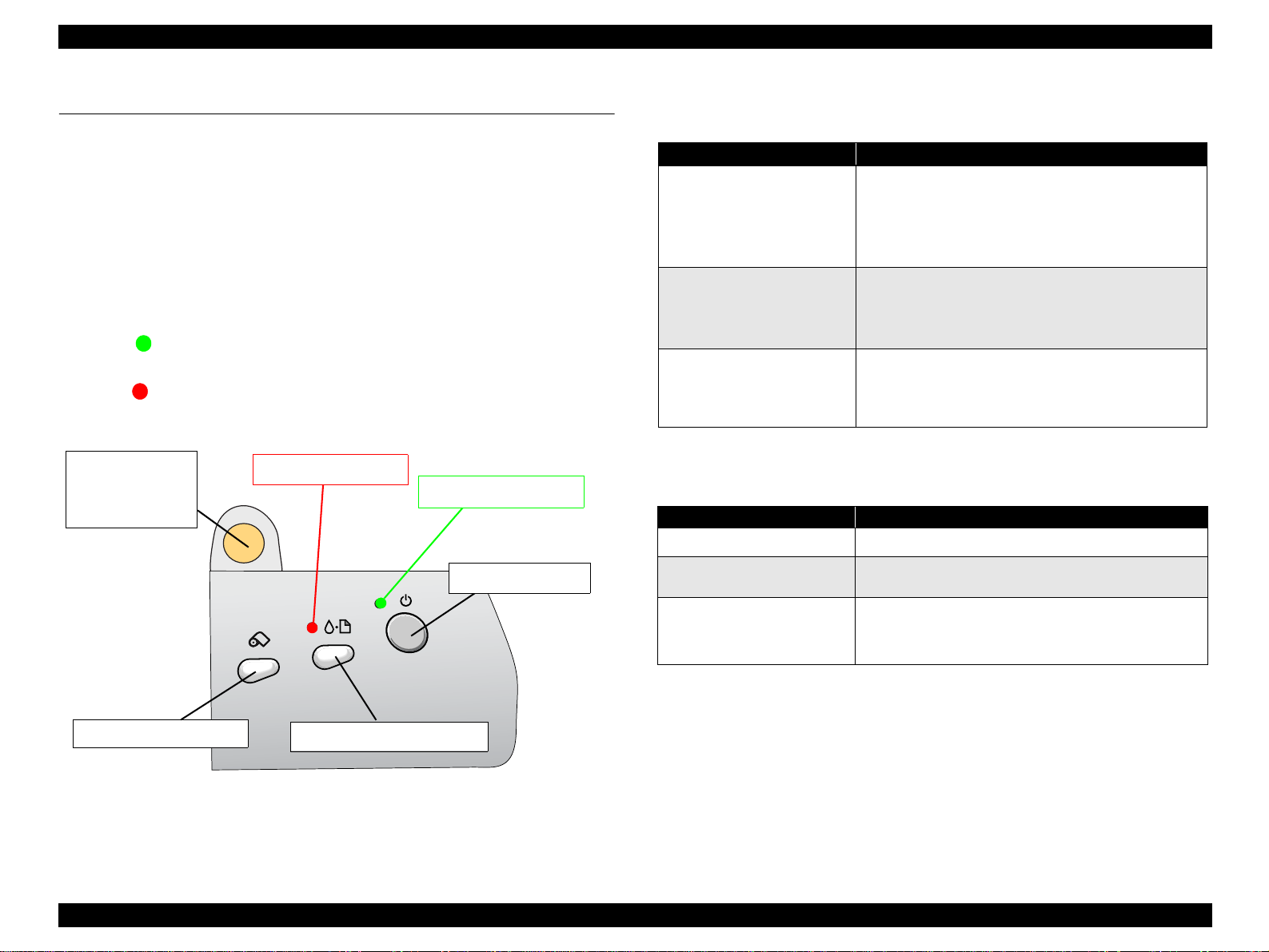

1.4.1 Buttons

Roll Paper button

Maintenance button

Ink Cartridge replacement button

Power button

1.4.2 Indicators

Power

Lights when the operating switch is “ON” and AC power is supplied.

Error

Lights during the error condition, and blinks during the ink low condition.

Ink Cartridge

replacement

button

Error indicator

Power indicator

Power button

1.4.3 Panel Functions

Table 1-15. Panel Functions

Buttons Function

Maintenance

Roll Paper

Ink Cartridge Replacement

*1

: Press the button for 3 seconds.

Table 1-16. Power On Panel Functions

Buttons Pressing with Power On Function

Maintenance • Starts status printing

Roll Paper

Maintenance

+

Roll Paper

• Loads or ejects paper.

• Returns a carriage to the home position when the

carriage is at the ink cartridge replacement position.

*1

• Starts the head cleaning

• Returns from an error condition.

• Loads or ejects Roll Paper. (Back Out feed*1)

• Feeds and returns from the Tear-Off operation.

• Returns a carriage to the home position when the

carriage is at the ink cartridge replacement position.

• Starts the Ink Cartridge change sequence.

Moves the carriage to the carriage change position.

• Returns a carriage to the home position when the

carriage is at the ink cartridge replacement position.

• Changes code pages /select IEEE1284.4 mode for

parallel I/F*3.

• Enters the special settings mode. (Factory use only).

.

*2

.

*2

: According to the content of 1BH of the EEPROM, one of the following

actions needs to be carried out. (See Table 1-17 on page 29)

Roll Paper button

Maintenance button

*3

: Do not mention the information to the users.

Figure 1-9. Control Panel

PRODUCT DESCRIPTIONS Operations 28

Page 29

EPSON Stylus PHOTO 890/1280/1290 Revision C

Table 1-17. Content of 1BH of EEPROM

[bit7] [bit6] Actions

00

11

01 Starts the hex-dump mode.

10 Starts the self test mode.

*4: Factory default setting.

Prints firmware version, ink counter, selected code

page and nozzle check pattern.

1.4.4 Special Setting Mode

To enter the special setting mode, press the Maintenance button and the Roll Paper

button while turning on the printer until the Power indicator blinks. While it is blinking

(for 3 seconds), press the specified button to activate the desirable setting mode.

NOTE: The special setting mode is not described in the user’s manual.

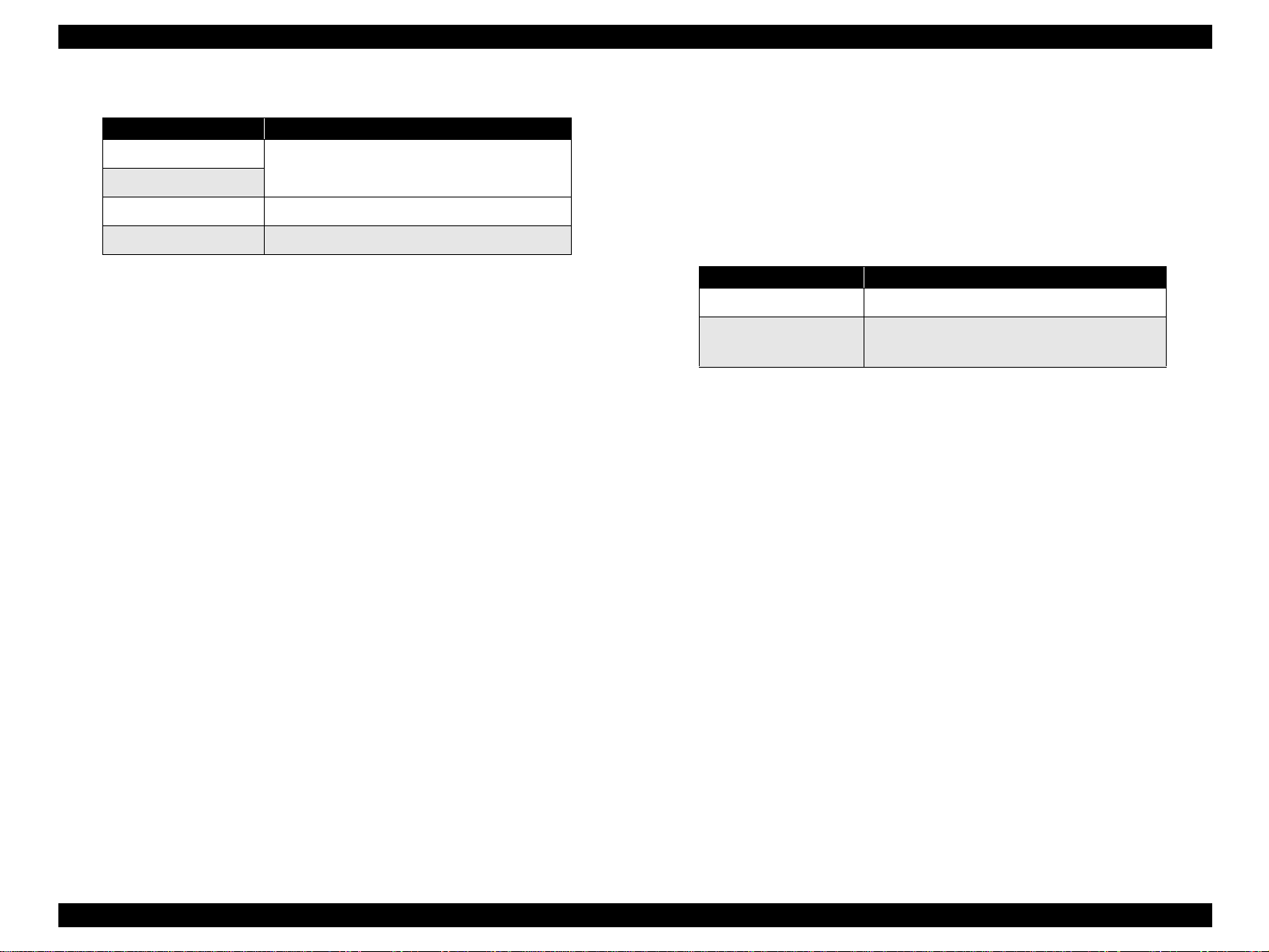

Table 1-18. Special Setting Mode

Buttons Functions

Maintenance • Initializes the EEPROM and Timer IC.

Roll Paper

*1

: Pressing the button for 10 seconds.

EEPROM/Timer IC Reset

The following will be reset when this operation is executed.

Interface selection (04H)

CL Time (68H, 69H)

Power Off timer (6AH, 6BH)

Waste Ink Counter Reset

The following will be reset when this operation is executed.

*1

• Resets the ink overflow counter (Protection

Counter) in the EEPROM.

Ink counter A0 (6CH, 6DH)

Ink counter A80 (6EH, 6FH)

PRODUCT DESCRIPTIONS Operations 29

Page 30

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.4.5 Printer Initialization

EPSON Stylus PHOTO 890/1280/1290 executes initialization by using 3 methods

mentioned below.

1. Hard Initialization

The Hard Unitization will be performed when the printer is turned on or

recognizes the cold reset command. (remote RS command)

The following will be performed during initialization.

Initializes printer mechanism.

Clears input data buffer.

Clears print buffer.

Sets default values.

2. Software Initialization

The ESC@ command also initializes the printer.

The following will be performed during initialization.

Clears print buffer.

Sets default values.

3. Panel Initialization

The Panel Initialization will be performed if the printer is turned off and back on

within 10 seconds, or *INIT signal (negative pulse) is input.

The following will be performed during initialization.

1.4.6 Initialization Value

When the printer is initialized, it clears the following settings to their initialization

values. However, panel setting values, default setting values, and values set by the

remote command remain as they are.

Top of page Current TOP

Line feed 4.23mm(1/6 inch)

Right margin 80 columns (Stylus PHOTO 890)

127 columns (Stylus PHOTO 1280/1290)

Left margin 1st column

Character pitch 10 cpi

Print mode Text mode (Non graphics mode)

Caps the printer head.

Ejects paper.

Clears input data buffer.

Clears print buffer.

Sets default values.

PRODUCT DESCRIPTIONS Operations 30

Page 31

EPSON Stylus PHOTO 890/1280/1290 Revision C

1.5 Dimension

EXTERNAL DIMENSION

Stylus PHOTO 890

When stored(mm): 471 (W) x 290 (D) x 175 (H)

For use(mm): 471 (W) x 613 (D) x 302(H)

Stylus PHOTO 1280/1290

When stored(mm): 609(W) x 311(D) x 175 mm (H)

For use(mm): 609(W) x 766(D) x 414mm (H)

WEIGHT

Stylus PHOTO 890

Stylus PHOTO 1280/1290

: 6.0 kg

:8.4 kg

Figure 1-10. Stylus PHOTO 890 in Use

Figure 1-11. Stylus PHOTO 1280/1290 in Use

PRODUCT DESCRIPTIONS Dimension 31

Page 32

EPSON Stylus PHOTO 890/1280/1290 Revision C

PRODUCT DESCRIPTIONS Dimension 32

Page 33

OPERATING PRINCIPLES

CHAPTER

2

Page 34

EPSON Stylus Photo 890/1280/1290 Revision C

2.1 Overview

This section describes the operating principles of the printer mechanism and electrical

circuit boards. The major components of the EPSON Stylus Photo 890/1280/1290 are:

Printer mechanism: Stylus Photo 890: M4T12

Stylus Photo 1290: M4S61

Main board:

Stylus Photo 890 : C393MAIN-C/C393MAIN-B

Stylus Photo 1290: C393MAIN/C393MAIN-B

Power supply board: C378PSB/PSE Board

PRINTER MECHANISM

Unlike other EPSON ink jet printers, the

motor as power source. The DC motor enables the printer to lower noise during

printing. Table 2-1 shows various motor types used in the printer and their applications.

Table 2-1. Motor Types and Corresponding Applications

Motor Name Type Application / Feature

CR motor

DC motor with

brush

EPSON Stylus Photo 890/1280/1290

uses a DC

Table 2-2.

Drives the carriage making little noise. Works with

a linear scale to monitor motor’s operating

condition.

The basic structure of the printer mechanism is mostly common to the Stylus COLOR

400, except that the Stylus Photo 890/1290 uses a Pump/ASF motor. With this motor

equipped, the paper loading mechanism and the pumping mechanisms are

independently driven, which allows the printer to offer higher throughput.

Figure 2-1 shows the printer mechanism block diagram for the Stylus Photo 890/1290.

Rotary Encoder

Intermittent Gear

PF Motor Pinion

PF Motor

Flashing Window

(at 80th or 136th column)

Photo Interrupter (Encoder)

Notched Roller

Carriage Unit

Printhead

Timing Belt

Cap Unit

(without a valve)

PF Drive Gear (high precision)

Photo Interrupter (Encoder)

Detector Wheel

ASF Sensor

LD Roller Shaft

Loading Rollers

PE Sensor

Pump/ASF Motor

Supplies power to drive paper feeding rollers used to

PF motor

Pump/ASF

motor

DC motor with

brush

4-Phase / 48-pole

stepping motor

send paper at specified speeds and load/eject paper.

To monitor paper feeding pitch, a loop scale is

attached beside the high-precision gear.

Sends drive for pump operation and paper feeding

from ASF. Since this is a stepping motor, it has no

scales or photo sensors that are used to monitor

motor’s operating condition.

Pump Unit

CR Guide Shaft

PF Roller

Liner Scale

CR Motor

PG Lever

ASF/Pump Disengage

Gear Train

Figure 2-1. Printer Mechanism Block Diagram

OPERATING PRINCIPLES Overview 34

Page 35

EPSON Stylus Photo 890/1280/1290 Revision C

2.1.1 Printhead Mechanism

The printhead mechanism operating principles of the Stylus Photo 890/1290 are

basically the same as for the previous EPSON ink jet printers. This printer, however,

employs a newly developed ink and improved printhead driving method to provide a

higher print quality and faster printing speed than ever. Also, an IC called CSIC that

stores ink-life data is attached to each ink cartridge. With this IC, ink life of each

cartridge can be individually monitored. Note, like for other models, a head voltage

must be written with a PC.

The printhead mechanism consists of ink cartridges and printheads. Each printhead is

composed of PZT (Piezo Electric Element), nozzle surface, ink supply needle, nozzle

selection circuit board, cartridge sensor, CSIC, and CSIC connection circuit. Figure 2-2

shows its component layout.

CSIC

Ink Cartridge

Nozzle Selector

Circuit Board

CSIC Connection

Circuit

Ink Supply Needle

Ink Cartridge

An ink cartridge stores ink to be supplied to the printhead.

CSIC:

CSIC is a non-volatile memory EEPROM attached to each black and color ink

cartridge. It keeps the following information:

1) Ink remaining level

2) Number of cleanings performed

3) Number of installation of the ink cartridge

4) Accumulated installation time of the cartr idge

5) Model name of the printer in use

6) Ink cartridge production information

Printhead

PZT

Driven by the print signal from the control circuit board, it ejects ink from the

nozzle plate.

Nozzle plate

Ink pressured by the PZT is ejected from this plate.

Ink supply needle

Connects the ink cartridge and printhead to run ink to the printhead.

CSIC connection circuit

Connects the control circuit board and CSIC attached on the ink cartridge.

One end of the harness is connected to the control board together with the

printhead cable.

Nozzle selection circuit board

This circuit, controlled by ASIC on the control circuit board, selects nozzles

Nozzle Plate

PZT

to be driven for printing. On the other hand, head drive voltage is produced on

the controller circuit side.

Figure 2-2. Printhead Mechanism

OPERATING PRINCIPLES Overview 35

Page 36

EPSON Stylus Photo 890/1280/1290 Revision C

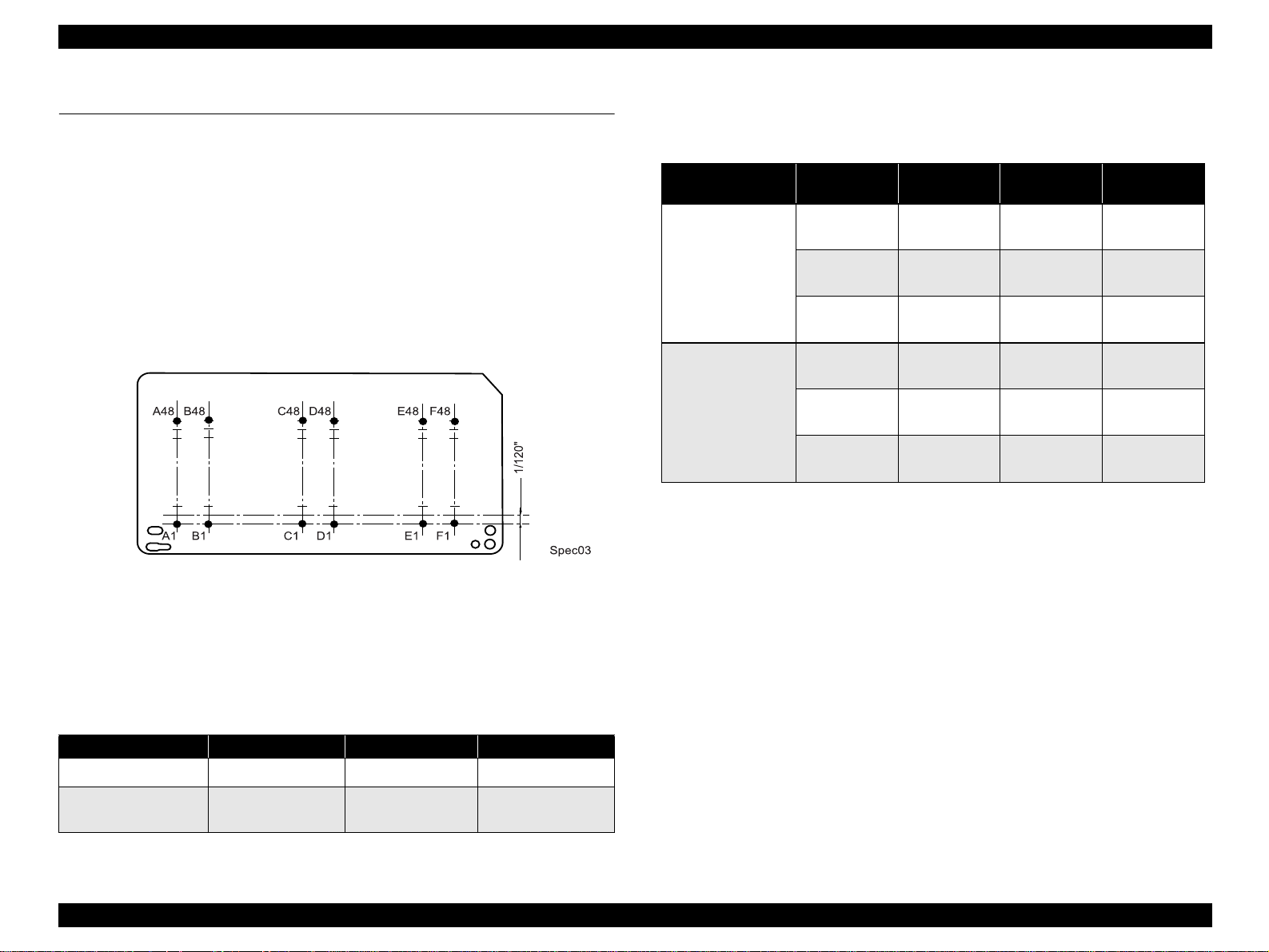

2.1.2 Carriage Mechanism

The carriage mechanism of the Stylus Photo 890/1290 is composed of the carriage

motor (CR motor), carriage guide shaft, platen gap adjustment/parallelism adjust ment

mechanism, carriage lock mechanism, and so on.

2.1.2.1 Carriage Motor (CR Motor)

The carriage mechanism of this printer is mostly the same as for other ink jet printers’

except it uses a DC motor as power source. See the table below for the carriage motor

specifications.

Table 2-3. Carriage Motor Specifications

Table 2-4.

Items Specifications

Type DC Motor with brush

Drive Voltage +42 V +/- 5% (Applied to the driver)

Coil resistance 29.2 ohms +/- 25%

Inductance 30.0 mH +/- 25%

Photo Coupler

Carriage Unit

Linear Encoder

Adjust Lever

Platen Surface

Eccentric Shaft

CR Motor

Parallelism Adjustment

Bushing

Carriage Guide

Shaft

Drive Method Constant Current Chopping

Driver IC LB1947

Op03

Figure 2-3. Carriage Mechanism (Top view)

In previous ink jet printers, since a stepping motor is used as a CR motor, the CR motor

controls the carriage position under the open loop system. This printer, however,

controls carriage speed and position with the closed loop system enabled by a DC

motor and encoder. This system, also used in the Stylus COLOR 900, is applied to

maintain a constant print quality. The CR motor also produces the print timing signal

(PTS signal) used for an accurate ink ejection timing. (Refer to Section 2.2.2.3 for

further information on the CR motor control circuit.)

For printing, the CR motor moves the carriage unit in the printing area along the CR

guide shaft.

OPERATING PRINCIPLES Overview 36

Page 37

EPSON Stylus Photo 890/1280/1290 Revision C

2.1.2.2 Platen Gap (PG) /Parallelism Adjustment Mechanism

The PG adjust lever is attached to the left end of the carriage guide shaft. When the

carriage guide shaft, which has an eccentricity, rotates as the adjustment lever moves, it

narrows or widens the distance (=PG: from 1.2 mm to 2.1 mm). This mechanism

enables the user to print with a correct PG according to print result or other conditions

such as paper curl.

Also, the parallelism adjustment bushings are attached to the right and left ends of the

carriage guide shaft. They are used to set the carriage guide shaft parallel with a platen.

Table 2-5. Platen Gap Adjust Lever Setting

Table 2-6.

Lever Position PG adjustment value

Front (0) 0 mm (=PG is 1.2 mm)

Rear (+) + 0.9 mm (=PG is 2.1 mm)

2.1.2.3 Carriage Home Position (HP) Detection

Unlike previous Epson ink jet printers, the carriage home position is detected with the

drive current from the CR motor and speed/position signal from the linear encoder.

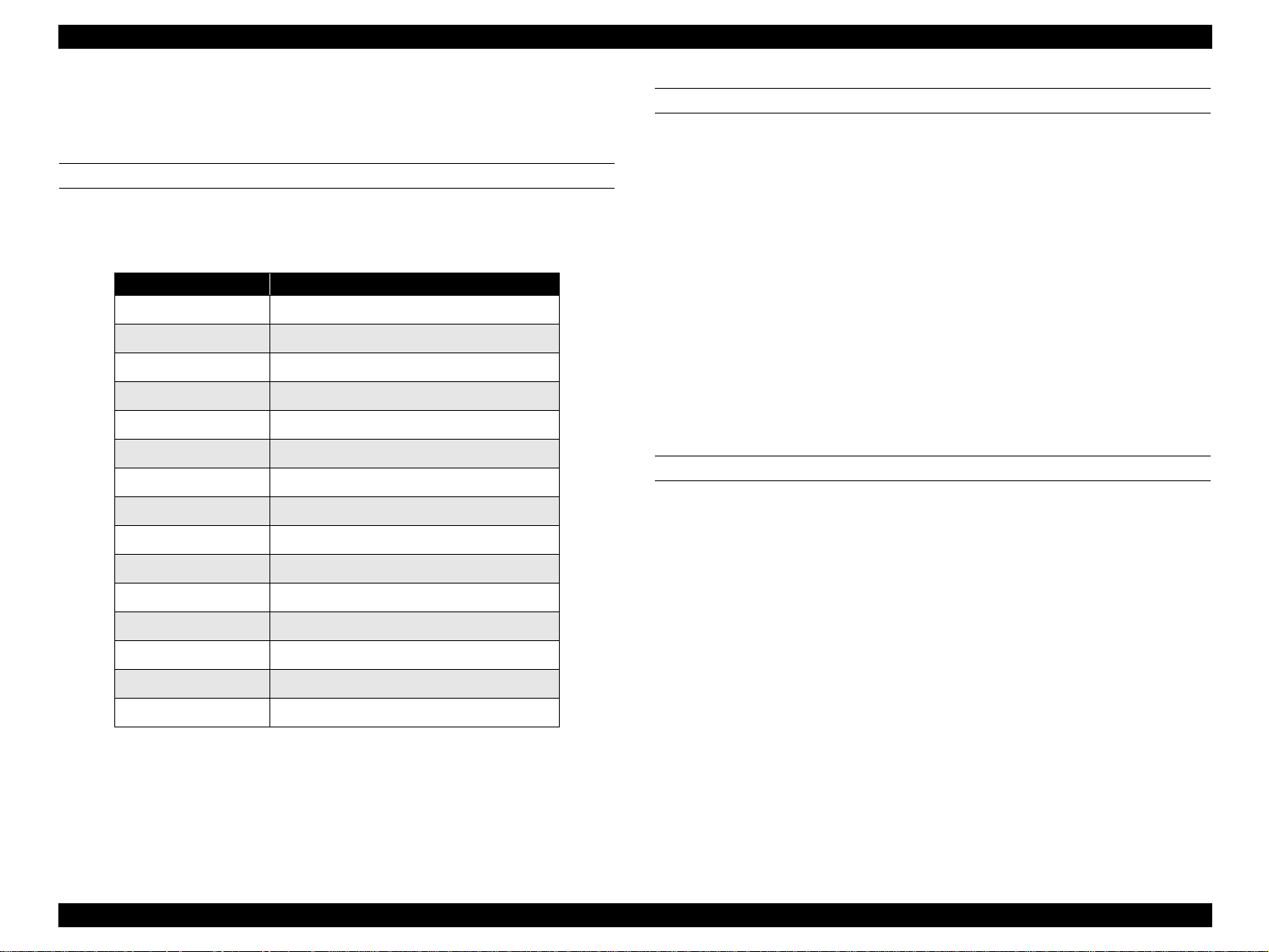

2.1.3 Paper Feeding Mechanism

The paper feeding mechanism transports paper loaded from ASF using the PF rollers

and paper eject rollers. A new type of DC motor is used as the PF motor. See the table

below for the PF motor specifications.

Table 2-7. PF Motor Specifications

Table 2-8.

Item Description

Motor type DC Motor with Brush

Drive voltage +42V +/- 5% (Applied to the driver)

Coil Resistance 29.2ohm +/- 25%

Inductance 30.0mH +/- 25%

Control method Constant current chopping drive

Stepping motor that is used in other printers as the PF motor controls paper feed by the

open loop system. On the other hand, this printer controls paper feeding mechanism

with the closed loop system by employing the DC motor and rotary encoder for more

accurate paper feeding. Therefore, a rotary encoder attached to the left end of the PR

roller shaft controls paper feed amount. For detailed information, see Section "PF

motor driver circuit".

Drive from the PF motor is sent to the PF rollers and paper eject rollers as described

below.

Drive transmission to the PF rollers:

PF motor pinion gear

Drive transmission to the eject rollers:

PF motor pinion gear

gear (28)

→

Paper eject rollers

→

Spur gear (76) → PF rollers

→

Spur gear (76) → Combination gear (13.5, 308) → Spur

OPERATING PRINCIPLES Overview 37

Page 38

EPSON Stylus Photo 890/1280/1290 Revision C

Figure 2-4 gives the paper feeding mechanism block diagram, showing the parts along

the PF motor drive transmission paths.

Combination Gear

(13.5, 308)

Spur Gear (76)

PF Motor Pinion Gear

Paper Eject Roller

PF Roller

PF Motor

Front Paper Guide

Paper Eject Roller

Figure 2-4. Paper Feeding Mechanism

The printer loads paper at the ASF, which is detected by the PE sensor attached to the

right side of the top frame, and advances it to send the paper’s leading edge to the

halfway of the front paper guide. Then, to correct paper deflection, the printer feeds the

paper back specified steps toward ASF, and advances the paper again toward the front

paper guide and stops it at the specified TOF (Top Of Form) position. Once printing

starts, the paper is fed by the PF rollers and sub rollers. For printing or transporting the

tailing edge area (14 mm), a notched roller and drive from the paper eject roller are

used. Like the Stylus Photo 870/1270, this printer also provides this extra printable

range of 14 mm from the bottom edge, excluding the bottom margin of 3mm, by

changing the position of the star wheel gear; it has been shifted by 5

the eject roller toward the front paper guide. Due to this change, the tailing edge of

paper is suppressed, and the printer can advance paper steadily. See Figure 2-5 next

page that shows how paper is transported and parts involved.

°

from the top of

[Previous Models]

Platen Surface

Notched Roller

Paper

Paper Eject Roller

[Stylus Photo 890/1290]

Figure 2-5. Paper Transportation

Printhead

Bottom Margin (3 mm)

5

°

Steady Feeding

Support Roller

PF Roller

OPERATING PRINCIPLES Overview 38

Page 39

EPSON Stylus Photo 890/1280/1290 Revision C

2.1.3.1 CR Lock Mechanism

The carriage lock mechanism prevents the carriage from being left uncapped for a long

time, which is usually caused by vibration during printer transportation, user’s

mishandling of the printer, and so on. If the carriage unit is left uncapped for a long

time, ink on the printhead surface dries gradually and, eventually, ink can not flow to

nozzles. In addition to that, there is a possibility that the nozzles clogged with dried ink

can not be recovered by a head cleaning. To avoid this problem, the printer locks the

carriage unit under the circumstances below:

After Power-Off

If the printer power is turned off in the middle of printing or other operations, the

printer completes the initialization sequence and then performs a carriage lock.

After Power-On

When the printer is turned on, the printer automatically begins a power-on cleaning

and then performs a carriage lock.

[Power-on cleaning]

The printer runs a power-on cleaning automatically when its power is turned on. Since

the timer IC on the main control circuit board is powered by a lithium battery that is

also mounted on the board, it keeps counting the printer’s power off time. According to

the power of time counted, the printer selects the cleaning level to perform.

After paper ejection

If the printer does not receive any print data after Load/Eject button is pressed, it

performs a carriage lock and enters a standby status. But if paper is fed into the printer,

the printer does not perform it.

Top View

Bushing

Paper Eject Roller

CR Lock Lever

Middle Frame

Figure 2-6. CR Lock Mechanism

Right Side View

OPERATING PRINCIPLES Overview 39

Page 40

EPSON Stylus Photo 890/1280/1290 Revision C

2.1.4 Paper Loading Mechanism

The paper loading mechanism loads paper at the ASF unit and feeds paper to the PF

rollers. The ASF unit is the same as in previous models. A 4-phase 48-pole PM type

stepping motor is used as the ASF/Pump motor to drive ASF. Drive sent from this

motor is transmitted to the ASF side and Pump side via the disengage mechanism (DE

mechanism). See Figure for the ASF/Pump motor specifications.

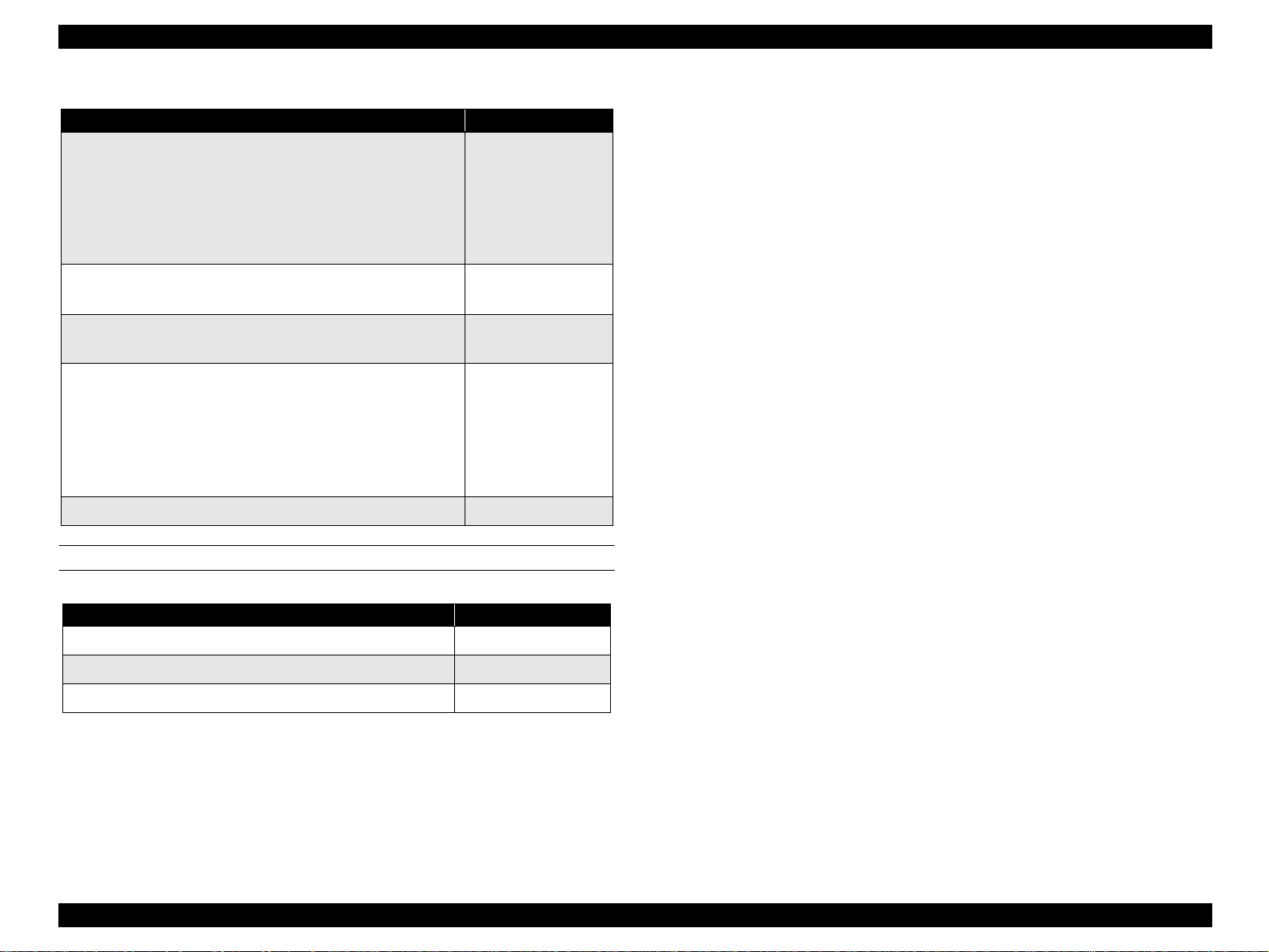

Table 2-9. ASF/Pump Motor Specifications

Items Description

Motor type 4 Phase/ 48-pole /PM type pulse motor

Drive method Bipolar constant current drive

Drive voltage

Coil Resistance 10.4 ohm +/- 10%

Inductance 15.0 ohm +/- 10%

The rotation directions in order to drive ASF unit/ Pump mechanism are as shown

below.

Table 2-10. Directions of ASF Unit/Pump Mechanism Rotation

Rotation Direction

*2

CW

*3

CCW

ASF Paper Loading Roller

Rotation Direction

+42V +/- 5% (applied to the driver)

Pump Rotation Direction

Reverse Rotation Normal Rotation

Normal Rotation Reverse Rotation

*1

2.1.4.1 Drive Transmission to the ASF Unit

1) The CR unit moves to the right end of the CR shaft, which then pushes the DE

lock lever to the right end.

2) The ASF/Pump motor rotates counterclockwise specified steps (viewed from the

motor pinion gear side).

3) With the ASF-Pump motor’s rotation of step 2), the planetary gear set in the DE

unit shifts toward the combination gear (12, 22.4).

4) The carriage unit moves from the right end of the CR shaft specified steps, which

causes the DE lock lever to fix the planetary gear unit.

5) Torque from the ASF/Pump motor is transmitted as described below.

Motor pinion gear

Combination gear (14, 28)

Figure 2-7 shows the disengage mechanism and its parts.

Combination Gear

14, 28

→

Planetary gear (15.2) → Combination gear (12, 22.4) →

→

Spur gear (32) in ASF

Combination Gear 12, 22.4

Planetary Gear 15.2 Unit

DE Lock Lever

A

*1

: Refer to “Drive Transmission to the ASF Unit” on page -40

*2

: CW refers to clockwise from ASF/Pump Motor Pinion side

*3

: CCW refers to counterclockwise from ASF/Pump Motor Pinion side

Drive from the ASF/Pump motor is sent to the ASF unit by the switching operation of

ASF-Pump Motor Pinion Gear

Figure 2-7. Disengage Mechanism

Combination Gear 17.19, 25.6

the carriage unit and the DE mechanism described in the following section.

The ASF unit loads paper by the torque sent from the ASF/Pump motor via the DE

mechanism as described in the following section.

OPERATING PRINCIPLES Overview 40

Page 41

EPSON Stylus Photo 890/1280/1290 Revision C

2.1.4.2 Paper Loading Operation

Multiple paper loading prevention mechanism is included in the ASF unit to ensure

steady paper loading. To prevent any paper from falling from the paper set position

into the paper path, the paper return lever pushes paper that may have fallen off back

onto the hopper. After this motion is completed, the LD roller starts loading paper. The

paper loading mechanism, including the multiple paper loading prevention mechanism,

is described in the following steps.

1) When the printer power is turned on, the ASF/Pump motor rotates

counterclockwise to detect ASF home position. Then it rotates clockwise specified

steps to set the LD roller and paper return lever in their standby status. (See

“Standby State” in Figure 2-1.)

2) When the paper loading signal is sent from the PC and the Load/Eject button is

pressed, the ASF/Pump motor turns counterclockwise to let the LD roller start

loading paper. (See “Paper Pick Up State” in Figure 2-1.)

3) When the paper is transported to the PF roller, the LD roller stops where it loses

friction. (See “PF Roller Paper Feed State” in Figure 2-1.)

4) When the next print signal is sent and Load/Eject button is pressed*, the ASF/

Pump motor rotates clockwise specified steps to set the LD roller and the paper