Page 1

®

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus PHOTO 2100/2200

SEIJ01-016

Page 2

Notice

! All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical,

photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

! All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

! The contents of this manual are subject to change without notice.

! All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

! The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

EPSON disclaims any and all rights in those marks.

Copyright © 2002 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

TPCS Quality Assurance Center

TPCS Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR

OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4. DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5. ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for

servicing the product.

APPENDIX Provides the following additional information for

reference:

• Connector pin assignments

• Exploded diagram & Parts List

• Electric circuit boards components layout

• Electrical circuit boards schematics

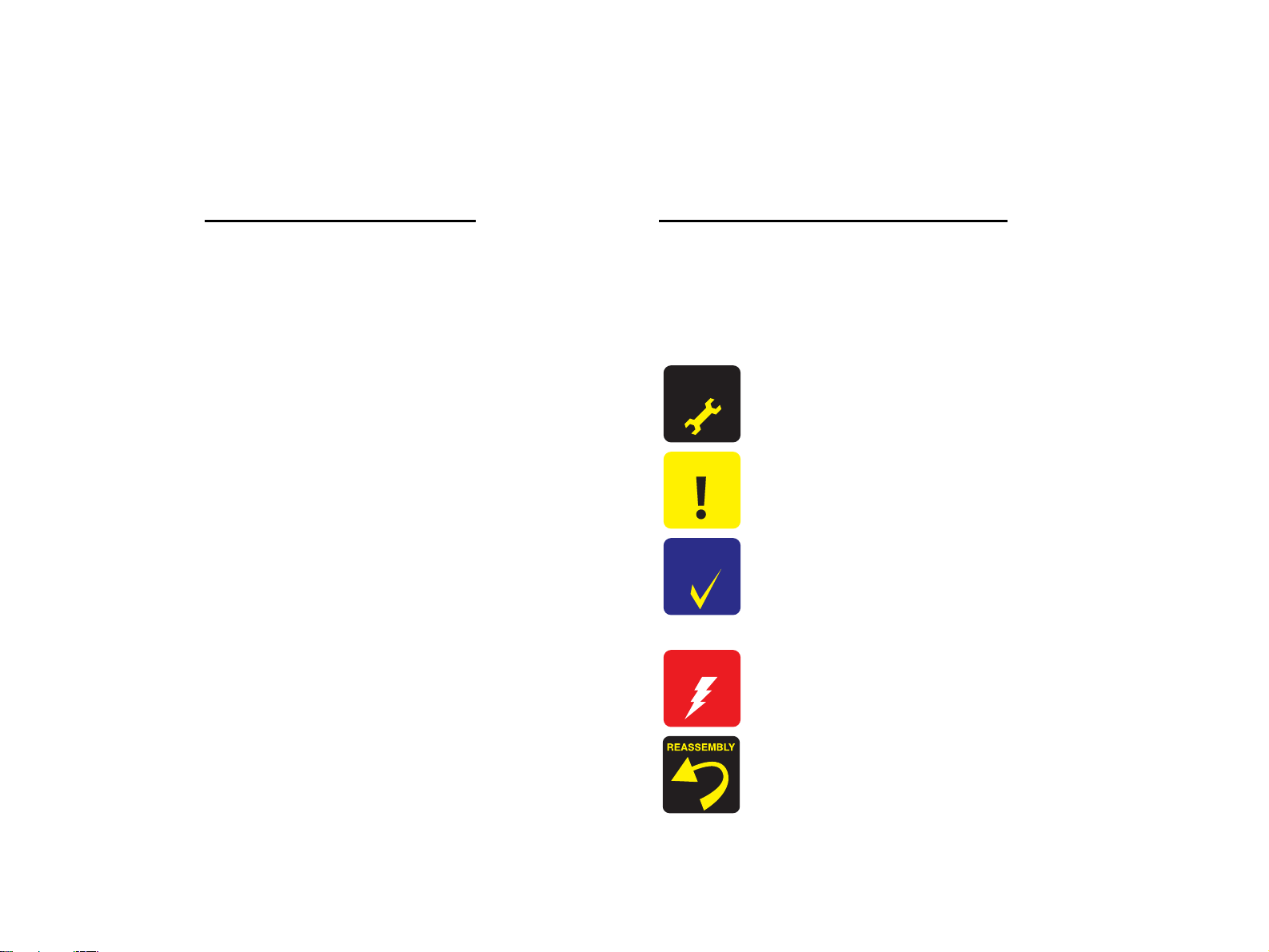

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It

may also provide additional information that is related to a

specific subject, or comment on the results achieved through a

previous action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or

loss of life.

Indicates that a particular task must be carried out according to a

certain standard after disassembly and before re-assembly,

otherwise the quality of the components in question may be

adversely affected.

Page 5

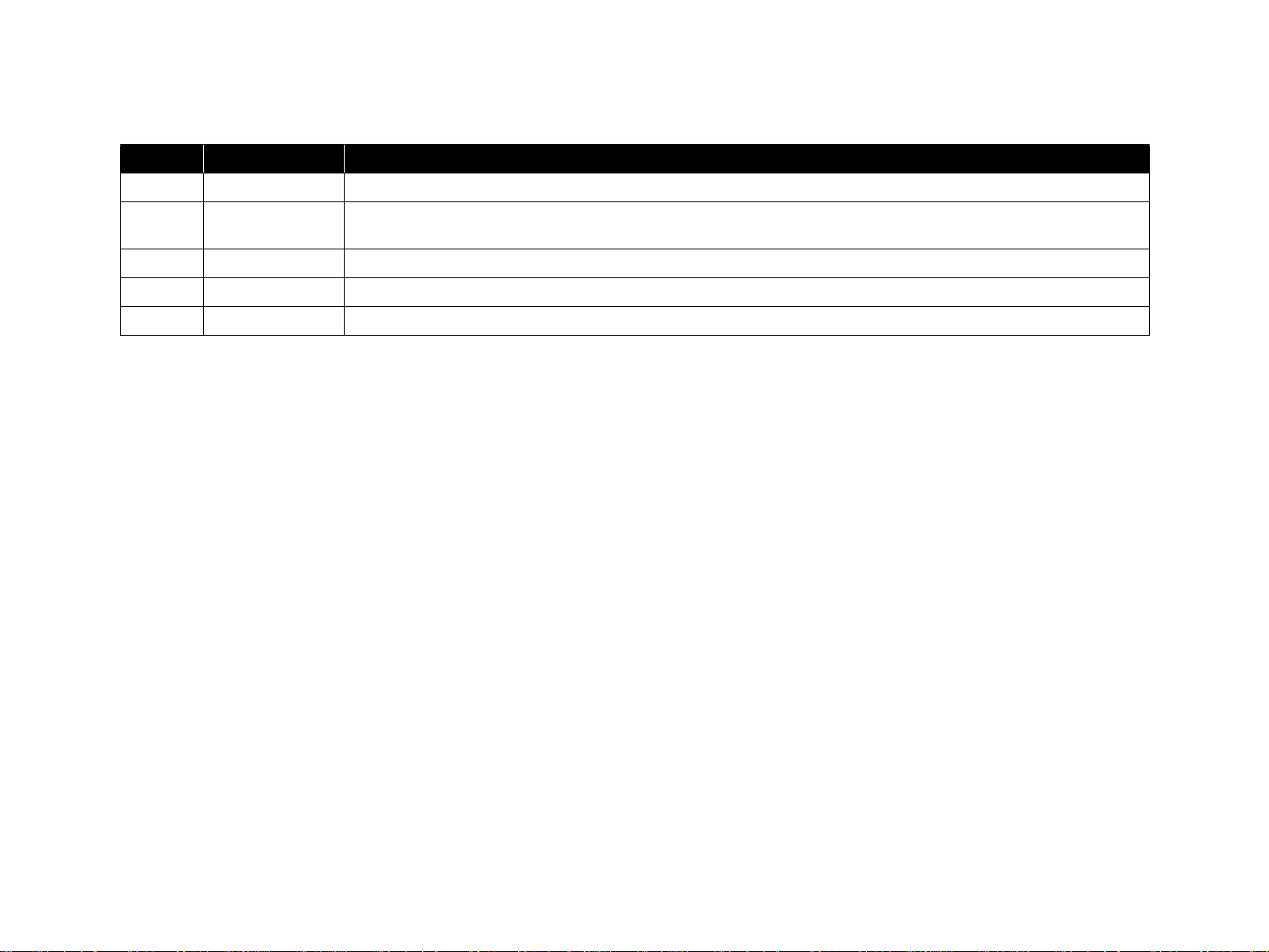

Revision Status

Revision Issued Date Description

A May 24, 2002 First Release

B August 22, 2002

Page 212 Modify the wrong description on the A3+ size Photo Quality Ink Jet Paper Check pattern (first solid pattern)

Page 213 The description for A4 size Plain Paper check point was added.

Page 6

CONTENTS

Chapter 1 PRODUCTION DESCRIPTION

1.1 Overview 9

1.2 Basic Specifications 10

1.2.1 Specification Outline Comparison ............................................................ 10

1.2.2 Paper Specification .................................................................................... 15

1.2.3 Printing Area ............................................................................................. 17

1.2.4 Ink Type-based Medium Compatibility Specifications ............................. 23

1.2.5 Release Lever .............................................. .............................................. 25

1.3 Functions 26

1.3.1 Control Panel .......................................................... ................................... 26

1.3.2 Switches ..................................................................................................... 26

1.3.3 Indicators ................................................................................................... 26

1.3.4 Switch Functions ....................................................................................... 26

1.3.5 Default Setting Selection Function ............................................................ 28

1.3.6 Special Setting Mode Function ................................................................. 29

1.3.7 Status Printing ........................................................................................... 30

1.3.8 Panel Operation for Roll Paper Printing .................................................... 31

1.3.9 Panel Operation for CD-R Printing ................... ........................................ 33

1.3.10 Panel Operation for Thick Paper Printing ............................................... 33

1.3.11 Panel Operation in Roller Cleaning Mode .............................................. 34

1.3.12 Indicator Display in Normal Mode .......................................................... 35

1.3.13 Error Status .............................................................................................. 36

1.4 Casing Specifications 37

1.5 Accessories 37

1.6 Environment Specification Items 38

Chapter 2 OPERATING PRINCIPLES

2.1 Overview 40

2.2 Printer Mechanism 40

2.2.1 Carriage Mechanism .................................................................................. 41

2.2.2 Print Mode ........................................... ...................................................... 44

2.2.3 Paper Feeding Mechanism ................................................. ....................... 48

2.2.4 Paper Loading Mechanism ........................................................................ 54

2.2.5 Ink System Mechanism ............................................................................. 58

2.2.6 Ink Sequence ............................................................................................. 60

2.2.7 Paper Cutter Mechanism ........................................................................... 63

2.2.8 Power-On Sequence .................................................................................. 65

2.3 Electrical Circuitry Operating Principles 66

2.3.1 Power Supply Circuit Operating Principle ................................................ 67

2.3.2 C387MAIN Circuit Operating Principle ................................................... 68

Chapter 3 TROUBLESHOOTING

3.1 Overview 70

3.2 Error Indications and Fault Occurrence Causes 70

3.3 Troubleshooting 78

3.3.1 Superficial Phenomenon-Based Troubleshooting ................................... 104

3.4 EEPROM Data Analysis 114

Chapter 4 disassembly and assembly

4.1 Overview 116

4.1.1 Precautions .............................................................................................. 116

4.1.2 Tools to Be Used ..................................................................................... 117

4.1.3 Screw List .............................. .................................................................. 118

4.1.4 Pre-Shipment Checks ................................ .......................................... .... 119

4.2 Disassembly 120

4.2.1 Removing the Housings .......................................................................... 121

4.2.2 Removing the Board Assembly ............................................................... 127

4.2.3 Removing the Waste Ink Pads ................................................................. 131

4.2.4 Removing the ASF Unit .......................................................................... 132

4.2.5 Removing the Paper Eject Unit ............................................................... 140

Page 7

4.2.6 Removing the Paper Eject Roller B ......................................................... 144

4.2.7 Removing the Printhead .......................................................................... 146

4.2.8 Removing the Carriage Guide Shaft B .................................................... 149

4.2.9 Removing the Carriage Guide Shaft A and Carriage Unit ...................... 152

4.2.10 Removing the Ink System Unit ............................................................. 158

4.2.11 Removing the Release Lever Shaft ....................................................... 159

4.2.12 Removing the Sensors ........................................................................... 161

4.2.13 Removing the Motors ............................................................................ 168

4.2.14 Removing the DE Unit and ASF/Pump Motor ...................................... 171

4.2.15 Removing the PF Roller ........................................................................ 175

4.2.16 Removing the Paper Eject Roller Shaft A ............................................. 179

4.2.17 Removing the PF Roller Support .......................................................... 181

4.2.18 Disassembling the Cutter Unit ............................................................... 182

4.2.19 Fitting the Protective Materials ............................................................. 186

Chapter 5 Adjustment

5.1 Adjustment Items and Overview 188

5.1.1 Servicing Adjustment Item List ............................................................... 188

5.1.2 Priority of Adjustment Items ................................................................... 193

5.1.3 Replacement Part-Based Adjustment Priorities ...................................... 194

5.1.4 Required Jigs, Tools and Like ................................................................. 196

5.2 Adjustments 197

5.2.1 Servicing Program Usage Outline ........................................................... 197

5.2.2 Head ID Input Function ........................................................................... 199

5.2.3 CR motor drive torque dispersion measurement ..................................... 199

5.2.4 PG Adjustment ........................................................................................ 200

5.2.5 Head Angular Adjustment ....................................................................... 204

5.2.6 CR Tooth Skip Prevention Mechanism Adjustment ............................... 206

5.2.7 PF Adjustment ......................................................................................... 206

5.2.8 PW Sensor Adjustment ............................................................................ 207

5.2.9 Bi-D Adjustment ..................................................................................... 208

5.2.10 Pixel Shift Adjustment .......................................................................... 209

5.2.11 Cut Position Adjustment ........................................................................ 210

5.2.12 USB ID Input ......................................................................................... 210

5.2.13 IEEE-1394 ID Input .............................................................................. 211

5.2.14 First dot position adjsutment (Left/Right Margin Adjustment) ............ 211

5.2.15 .....A3+ Pho to Quality Ink Jet Paper 2 Print Pattern Printing Function 212

5.2.16 A4 Plain Paper print check pattern ........................................................ 213

Chapter 6 Maintenance

6.1 Overview 215

6.1.1 ROM Replacement .................................................................................. 215

6.1.2 Cleaning ...................................... ............................................................. 215

6.1.3 Service Maintenance ......................................... ...................................... 216

6.1.4 Lubrication .............................................................................................. 217

Chapter 7 APPENDIX

7.1 Connector Summary 227

7.1.1 Connectors and Pin Layouts .................................................................... 227

7.1.2 EEPROM Address Map .......................................................................... 231

7.2 Exploded Diagram 236

7.3 Parts List for EPSON Stylus Photo 2100 248

7.4 Circuit Diagram 253

Page 8

PRODUCTION DESCRIPTION

CHAPTER

1

Page 9

EPSON Stylus PHOTO 2100/2200 Revision B

1.1 Overview

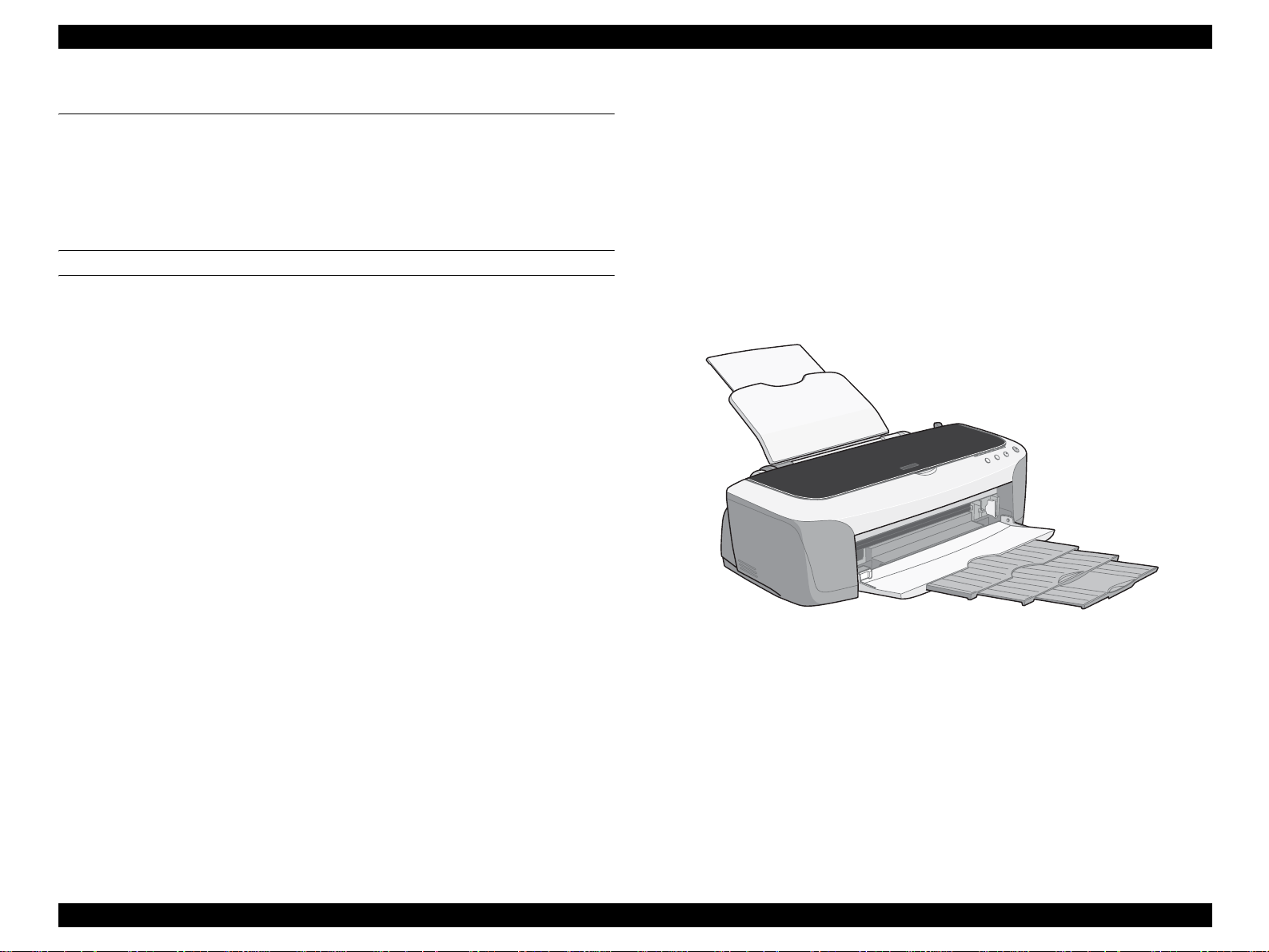

The Stylus PHOTO 2100/2200 is a photo printer designed for a wide range of users

from individual users to commercial users. As a model to replace the Stylus PHOTO

2000P, this consumer high-end model is capable of pigment-independent CSIC, CD-R

printing, and roll paper cutter functions.

This product has the following features.

FEATURES

High Color Print Quality

!

" High photo quality thanks to Photo Mach technology

" Achievement of higher quality using microwaves and super microwaves

" High resolution printing of 2880 x 1440dpi

! Three Different Interfaces Supported

" IEEE-1284 parallel interface

" USB 2.0

" IEEE-1394

! Windows/Macintosh Exclusive

! Multi-size Capable ASF

ASF equipped as standard supports forms ranging up to A3+.

! Roll paper compatibility

! Thick paper/CD-R printing compatibility

! Auto cutter compatibility

! Frameless printing compatibility

! Two-sided printing compatibility

By addition of the standard-equipped CD-R print kit, direct printing can be done

on a CD-R label.

! CSIC-compatible Independent Ink Cartridge

Three different ink sets, Photo-Black & Light-black, and Matte-Black & Light-

black, can be changed.

Figure 1-1. Product Appearance

! Newly Developed Pigment Ink

" As compared to the conventional pigment ink, the color reproduction area of

the new ink has increased up to about 80% of the dye ink, improving color

development.

" The concentration of YMC has been increased, and the Light-black ink

adopted improves the Light-black balance and metamerism.

PRODUCTION DESCRIPTION Overview 9

Page 10

EPSON Stylus PHOTO 2100/2200 Revision B

1.2 Basic Specifications

1.2.1 Specification Outline Comparison

The following table gives the comparison of specifications between this product and similar conventional models.

Head

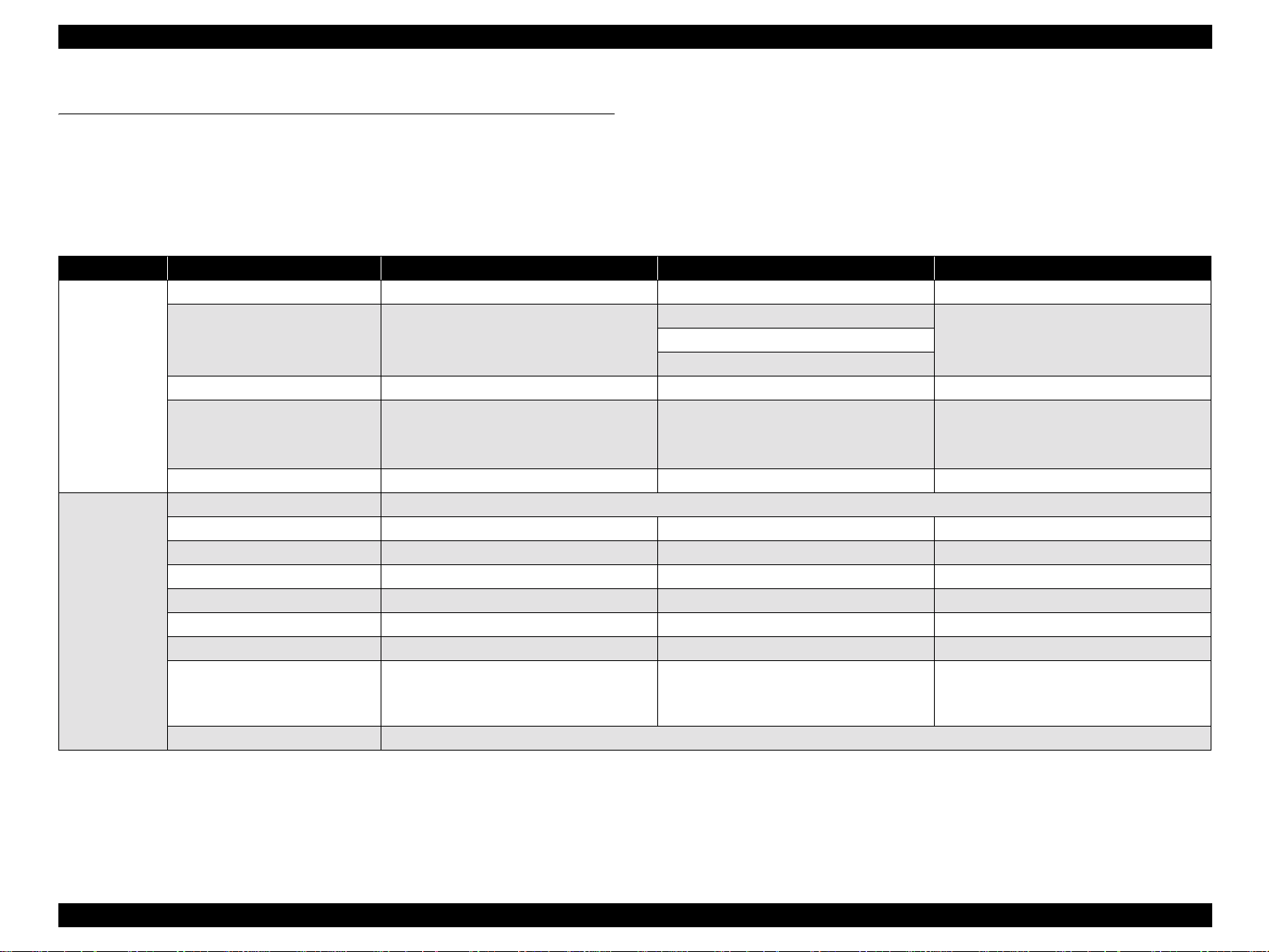

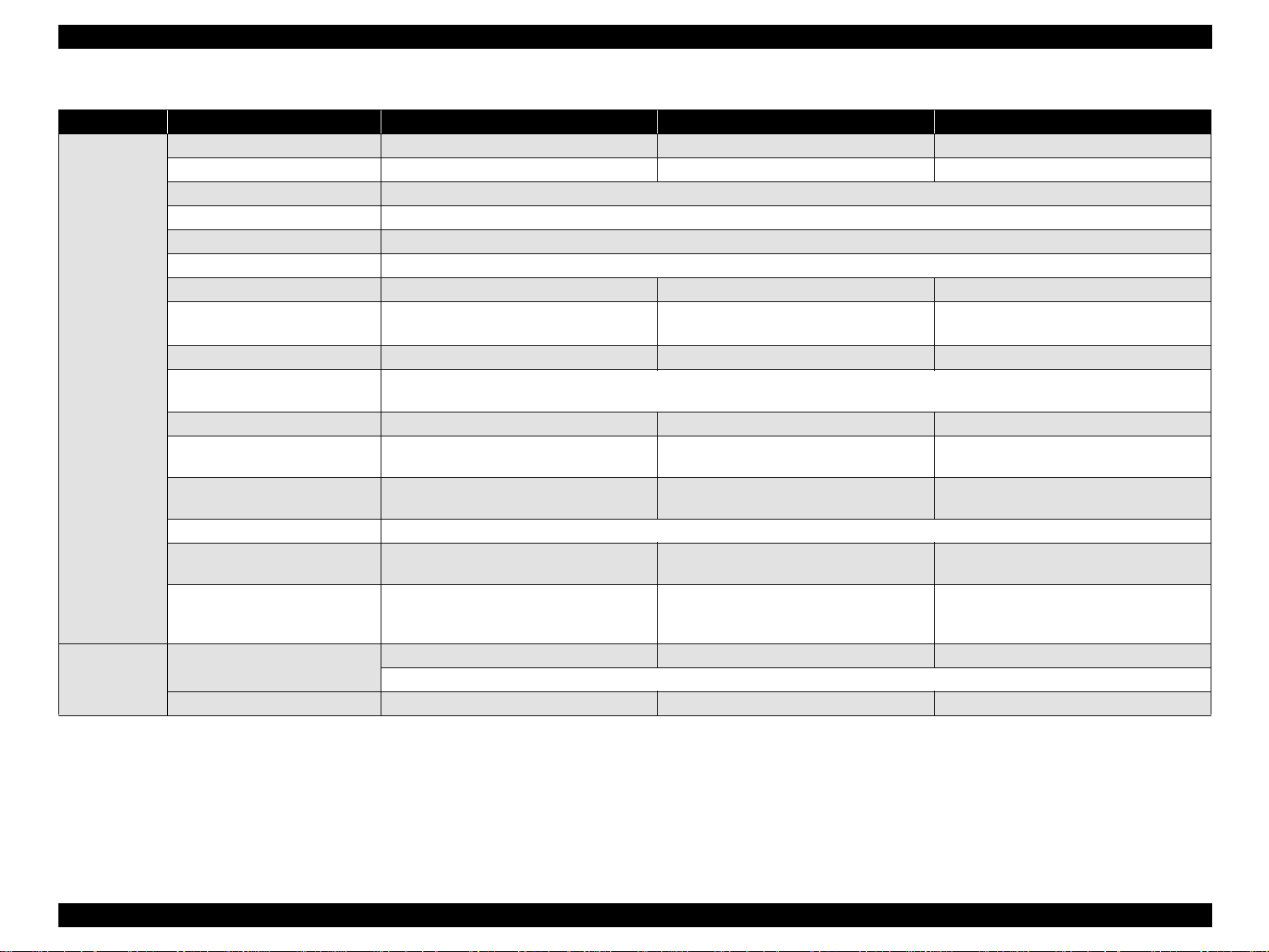

Table 1-1. Specification Outline Comparison

Item Stylus PHOTO 950 Stylus PHOTO 2100/2200 Stylus PHOTO 2000P

Location Successor to PM-920C Successor to Stylus PHOTO 2000P No corresponding model

7 colors

Number of colors

Resolution (H × V) 2880 × 1440 2880 × 1440 1440 × 720

Cut sheet size L/L2 size, A6 to A4

Roll paper compatibility 89/100/127/210mm width 89/100/210/329mm width

Number of Head Monochrome and color integrated type

Head type (black) G-Mach G-Mach E-Chips

Nozzle arrangement 96 nozzles × 1 line 96 nozzles × 2 lines 48 nozzles × 1 line

Nozzle pitch 180dpi 180dpi 120dpi

Head type (color) G-Mach G-Mach E-Chips

Nozzle arrangement 96 nozzles × 6 lines 96 nozzles × 5 lines 48 nozzles × 5 lines

Nozzle pitch 180dpi 180dpi 120dpi

Delivery (ng)

Head reliability/nozzle 3 billion shots/nozzle

(6 colors: 2 lines for BK, 1 line for each of C, LC,

M, LM, Y)

VSD1 : 13.8 + 27.6 + 41.5

VSD2 : 5.4 + 9.5 + 23.0

VSD4 : 2.5

7 colors (2 types for Bk + C, LC, M, LM, Y)

Matte-Black & Light-black

• A6 to Super A3

• Thickness : 0.08 to 0.11mm

• Envelope : #10, DL, C6

VSD1 : 13.8ng − 27.6ng − 41.5ng

VSD2 : 4.5ng − 9.5ng − 23.0ng

VSD4 : 4.5ng

6 colors (Bk, C, Lc, M, Lm, Y)Photo-Black & Matte-Black

• A6 to Super A3

• Thickness : 0.08 to 0.11mm

• Envelope : #10, DL, C6

ND :

PRODUCTION DESCRIPTION Basic Specifications 10

Page 11

EPSON Stylus PHOTO 2100/2200 Revision B

Table 1-1. Specification Outline Comparison

Item Stylus PHOTO 950 Stylus PHOTO 2100/2200 Stylus PHOTO 2000P

Ink type Dye Newly developed pigment Pigment

Ink cartridge type Color-separated CSIC Color-separated CSIC Black, color-individual CSIC type

Ink cartridges

• T0331 (Bk)

• T0332 (C)

• T0333 (LC)

I/C

(T code : Overseas)

Ink fill amount (black) 18.3g +/− 0.5g 18.3g +/− 0.5g

Effective ink amount 14.4g or more 14.4g or more

Remaining ink amount 3.4g or less 3.4g or less

Cartridge weight (black) 42g/each color 42g/each color

Number of printable sheets (black)

ISO/IEC 10561 Letter at 360dpi

Black ink end detection Dot counter (software counter)

Ink fill amount (color) 18.3g +/− 0.5g (Y/M/C/Lc/Lm) 18.3g +/− 0.5g (C/LC/M/Lm/Y)

Effective ink amount 14.4g or more (Y/M/C/Lc/Lm) 14.4g or more (C/LC/M/Lm/Y)

Remaining ink amount

*1 : Y/M/C,

*2 : Lc/Lm

Cartridge weight (color) 42g/each color 42g/each color

Number of printable sheets (black)

ECOMA ISO 10561 5% duty

Color ink end detection Dot counter (software counter)

• T0334 (M)

• T0335 (LM)

• T0336 (Y)

570 pages

(360dpi, A4)

3.4g or less (Y/M/C/Lc/Lm) 3.4g or more (C/LC/M/Lm/Y)

TBD

(360dpi, A4)

• T0341 (Photo Bk)

• T0342 (C)

• T0343 (M)

• T0344 (Y)

• T0345 (LC)

• T0346 (LM)

• T0347 (Light Black)

• T0348 (Matte Bk)

T.B.D

T.B.D

• T015 (Bk)

• T016 (Color)

PRODUCTION DESCRIPTION Basic Specifications 11

Page 12

EPSON Stylus PHOTO 2100/2200 Revision B

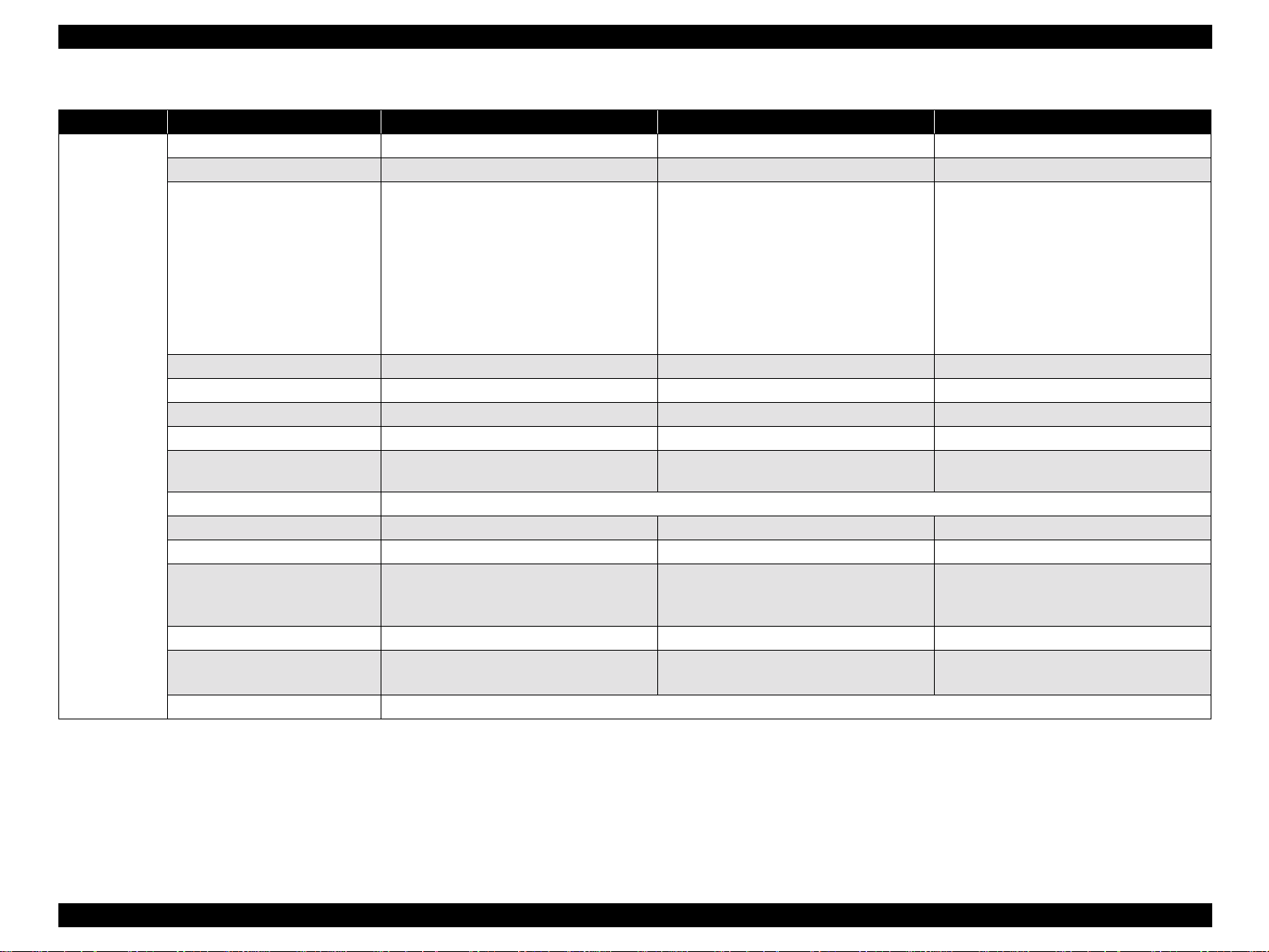

Table 1-1. Specification Outline Comparison

Item Stylus PHOTO 950 Stylus PHOTO 2100/2200 Stylus PHOTO 2000P

Mechanism

outline

Maximum number of print digits

(10CPI)

Number of motors

*1 : Optional cutter

CR motor armature resistance 23.0Ω +/− 25% (with DC brushes) 23.0Ω +/− 25% (with DC brushes) 31.1Ω +/− 25% (with DC brushes)

ASF/PUMP motor winding

resistance

PF motor armature resistance

(ASF)

Platen gap 1.35mm +/− 0.1mm 1.2mm +/− 0.1mm 1.14mm +/− 0.1mm

Reliability (except head) 5 years or black: 25000 pages, or color: 10000 pages

Operation noise (ISO 7779) 45dB (A)

Paper feeder

External dimensions (W × D × H)

*1 : When tucked

*2 : When used

Weight

4 motors (CR, PF, Pump, Cutter *1) 4 motors (CR, PF, Pump, Cutter *1) 3 motors (ASF, CR, PF)

10.0Ω +/− 10%: Per phase (PM stepping) 7.0Ω +/− 10%: Per phase (PM stepping) 10.4Ω +/− 10% : Per phase (PM stepping)

22.3Ω +/− 25% (with DC brushes) 23.0Ω +/− 25% (with DC brushes) 31.1Ω +/− 25% (with DC brushes)

•515 × 332.8 × 209mm *1

•515 × 526.3 × 229.4mm *2

(Cutter not included)

• 7.25kg (printer alone)

• Cutter: 950g

86.97 digits 127 digits

• ASF (Top entry front out)

• Roll paper feeder

• Matte board paper feeder

• CD-R printing tray

• 631 × 320 × 205mm *1

• 631 × 931 × 357mm *2

(Cutter not included)

• 11.7kg (printer alone)

• Cutter: 1.4kg

• 609 × 311 × 175mm *1

• 609 × 766 × 414mm *2

ASF (Top entry front out)

8.4kg

PRODUCTION DESCRIPTION Basic Specifications 12

Page 13

EPSON Stylus PHOTO 2100/2200 Revision B

Table 1-1. Specification Outline Comparison

Item Stylus PHOTO 950 Stylus PHOTO 2100/2200 Stylus PHOTO 2000P

CR encoder Linear scale + encoder sensor

PF encoder Loop scale + encoder sensor

PE detector Transparent photo interrupter

PE detector (rear) - - -

PG detector Mechanical contact (2 pcs.) -

Sensors

Main board

Power board

Panel board Panel board C456PNL C387PNL C304PNL

Paper leading edge/

paper width detector (PW sensor)

I/C detector CSIC

ASF HP detector Clutch detection Transparent photo interrupter

CDR tray detector Also us ed as PF sensor Mechanical contact -

Cutter CR position detector Transparent photo interrupter

Control code

Interface

USB (transfer speed) 12Mbps 12Mbps to 480Mbps 12Mbps

Main board C456Main−B C387Main C304Main/C298Main−B

Input buffer 256KB 112KB 256KB

PROM application Program Program & 2 Tables (PC437, PC850) Program & 2 Tables (PC437, PC850)

PROM type SOJ SOJ, 8Mbit, 3.3V DIC, 8M, 3.3V

Backup battery Installed Installed Installed

Backup battery type Capacitor Capacitor Lithium battery

Backup battery life

Power board C456PSB/PSE C387PSB/PSE C298PSB/PSE

Power switch Push switch with locking function

Output voltage 42V/5V

(electricity accumulated every power-on)

USB USB (2.0 compatibility) USB

- IEEE1394 (400Mbps) -

1 week

Transparent photo interrupter -

Transparent photo interrupter

(2 pcs.)

ESCP/2

ESCP remote

Panel (IEEE1284.4 compatibility)

1 week

(electricity accumulated every power-on)

5 years

-

PRODUCTION DESCRIPTION Basic Specifications 13

Page 14

EPSON Stylus PHOTO 2100/2200 Revision B

Table 1-1. Specification Outline Comparison

Item Stylus PHOTO 950 Stylus PHOTO 2100/2200 Stylus PHOTO 2000P

Market initial setting information EEPROM write EEPROM write EEPROM write

Head ID input 19 digits (21 digits on label) 25 digits 14 digits

Head inclination adjustment Mechanical lever inside CR

Head height adjustment No

Bi-D adjustment EEPROM write

USB ID input 18 digits (10 digits for input from adjustment program)

IEEE1394 ID input - 5 digits -

1.2mm +/− 0.1mm

No

predetermined)

O-12

1.14mm +/− 0.1mm

Yes

(within 0.1mm of standard)

Adjustment

Maintenance

Platen gap 1.27mm +/− 0.1mm

Pixel Shift Adjustment - EEPROM write -

Printout position adjustment

(CR scanning direction)

CR Measurement EEPROM automatic write EEPROM automatic write -

CR motor drive torque dispersion

measurement

PF Adjustment

(Band feed adjustment)

Top margin adjustment EEPROM (value basically fixed to all models)

PW sensor mounting position

adjustment

PF backlash adjustment

Lubricating oil/

grease

Waste ink pad 47325 points 60352 points 33900 points

(PF motor fixing screw tightening order

EEPROM write EEPROM write -

- EEPROM write -

- EEPROM write -

No

predetermined)

G-26 G26/G45/G56 G-26

Main shaft/sub shaft adjustment jig necessary

EEPROM (value basically fixed to each model)

(PF motor fixing screw tightening order

PRODUCTION DESCRIPTION Basic Specifications 14

Page 15

EPSON Stylus PHOTO 2100/2200 Revision B

1.2.2 Paper Specification

1.2.2.1 Cut Sheet (Anti-EPSON special media)

Table 1-2. Cut Sheet

Paper

Paper size

A3 297 420

A4 210 297

A5 148 210

A6 105 148

B4 257 364

B5 182 257

Letter 216 279

Half letter 139.7 215.9

Legal 216 356

width mm

(inch)

Paper

length mm

(inch)

Quality

Plain paper,

Bond paper

Thickness

mm

(inch)

0.08 to 0.11

(0.003 to

0.004)

Weight

g/m2 (lb)

64 to 90

(17 to 24,

55 to 78)

1.2.2.2 Envelope (Anti-EPSON special media)

Table 1-3. Envelope

C A U T I O N

Paper

Paper size

*a

#10

*a

DL

*a

C6

220 × 132 220 132

width mm

(inch)

241.3 104.8

220 110

162 114

*a :The longer side has a flap that has been folded.

" For use in general room temperature environment only.

" No wrinkled, scuffed, torn or folded paper be used.

" No curled paper more than 5mm be used.

" No envelops glued in the flap and others be used.

" No doubled/windowed envelops be used.

Paper

length mm

(inch)

Quality

Bond paper, PPC,

Air mail

Weight

(g/m2)

45 to 75

(12 to 20lb)

Executive 184.2 266.7

C A U T I O N

" No wrinkled, scuffed, torn or folded paper be used.

" No curled paper more than 5mm be used.

PRODUCTION DESCRIPTION Basic Specifications 15

Page 16

EPSON Stylus PHOTO 2100/2200 Revision B

1.2.2.3 EPSON Special media

Quality: EPSON specifically designed media for ink jet printers

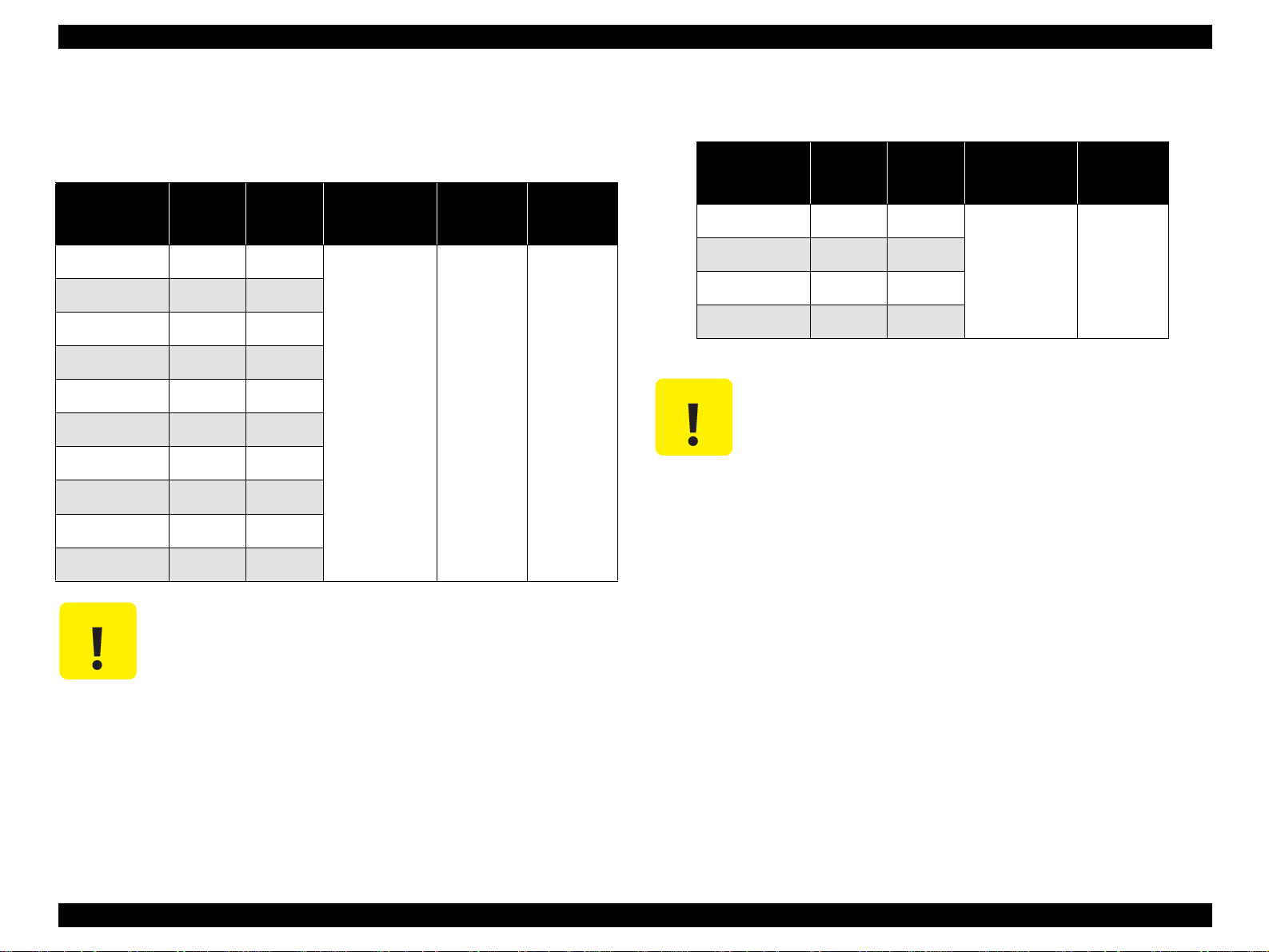

Table 1-4. EPSON Special media

EPSON

Special media

Photo Quality

Ink Jet Paper 2

Archival Matte

Paper

Paper

Paper size

Super A3 329 483

A3 297 420 65 ×

A4 210 297 65 ×

B5 182 257 65 ×

Super A3 329 483

A3 297 420 10 #

A4 210 297 20 #

Roll type

width

mm

(inch)

Paper

length

(inch)

89 7m - -

100 8m - -

Quality mmWeight

mm

g/m2 (Ib)

0.11 92(24)

0.25 189(50)

ASF

setting

65 ×

10 #

Support

sheet

EPSON

Special media

Premium Glossy

Photo paper

Glossy PaperPhoto Weight

Watercolor

Paper-Radiant

White

Table 1-4. EPSON Special media

Paper

Paper size

Super A3 329 483

A3 297 420 1 ×

A4 210 297 20 ×

Roll type

Super A3 329 483

A3 297 420 1 ×

A4 210 297 1 ×

Super A3/B 329 483 0.29 190(51) 1 ×

width

mm

(inch)

Paper

length

(inch)

89 7m - -

100 8m - -

127 8m - -

210 10m - -

329 10m - -

Quality mmWeight

mm

2

(Ib)

g/m

0.27 255(68)

0.22 217(58)

ASF

setting

1 ×

1 ×

Support

sheet

Matte Board A4 210 297 1.28 1100(293) - ×

Premium Ink

Jet Plain Paper

Bright White

Ink Jet Paper

(Bond Paper)

A4 210 297 0.11 80(21) 100 ×

A3 297 420

0.13 92.5(25)

A4 210 297 100 ×

100 ×

PRODUCTION DESCRIPTION Basic Specifications 16

Page 17

EPSON Stylus PHOTO 2100/2200 Revision B

EPSON

Special media

Matte Paper-

Heavyweight

C A U T I O N

Table 1-4. EPSON Special media

Paper

Paper size

Super A3/B 329 483

A3 297 420 10 #

A4 210 297 20 #

Roll type

width

mm

(inch)

Paper

length

(inch)

89 7m - -

100 8m - -

127 8m - -

Quality mmWeight

mm

2

(Ib)

g/m

0.23 167(44)

ASF

setting

10 #

Support

sheet

" For use in general room temperature environment only.

" No wrinkled, scuffed, torn or folded paper be used.

" No curled paper more than 5mm be used.

" Paper characteristics conform to the medium delivery

specification.

" The CD-R exclusive tray should be handled like board paper.

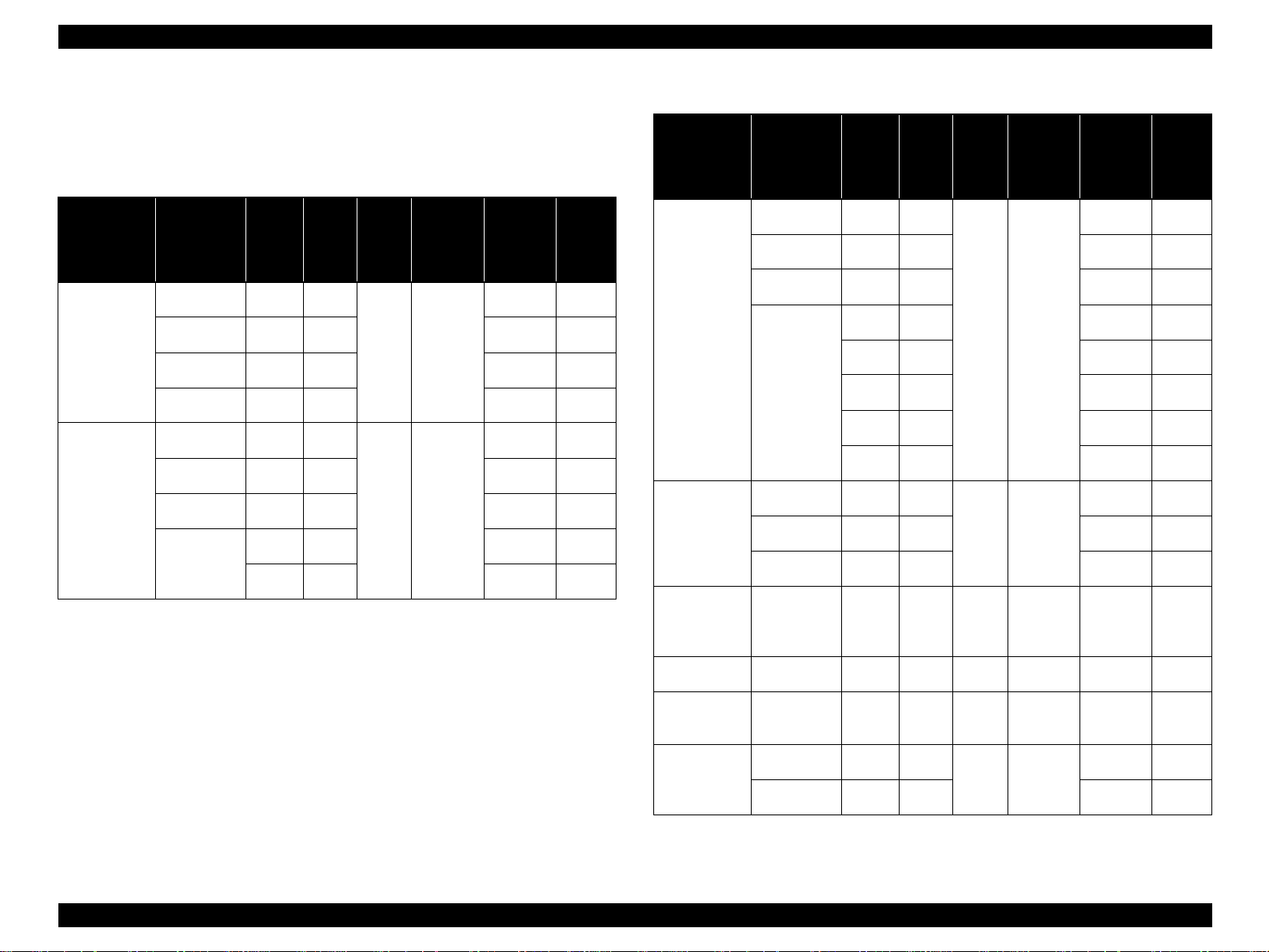

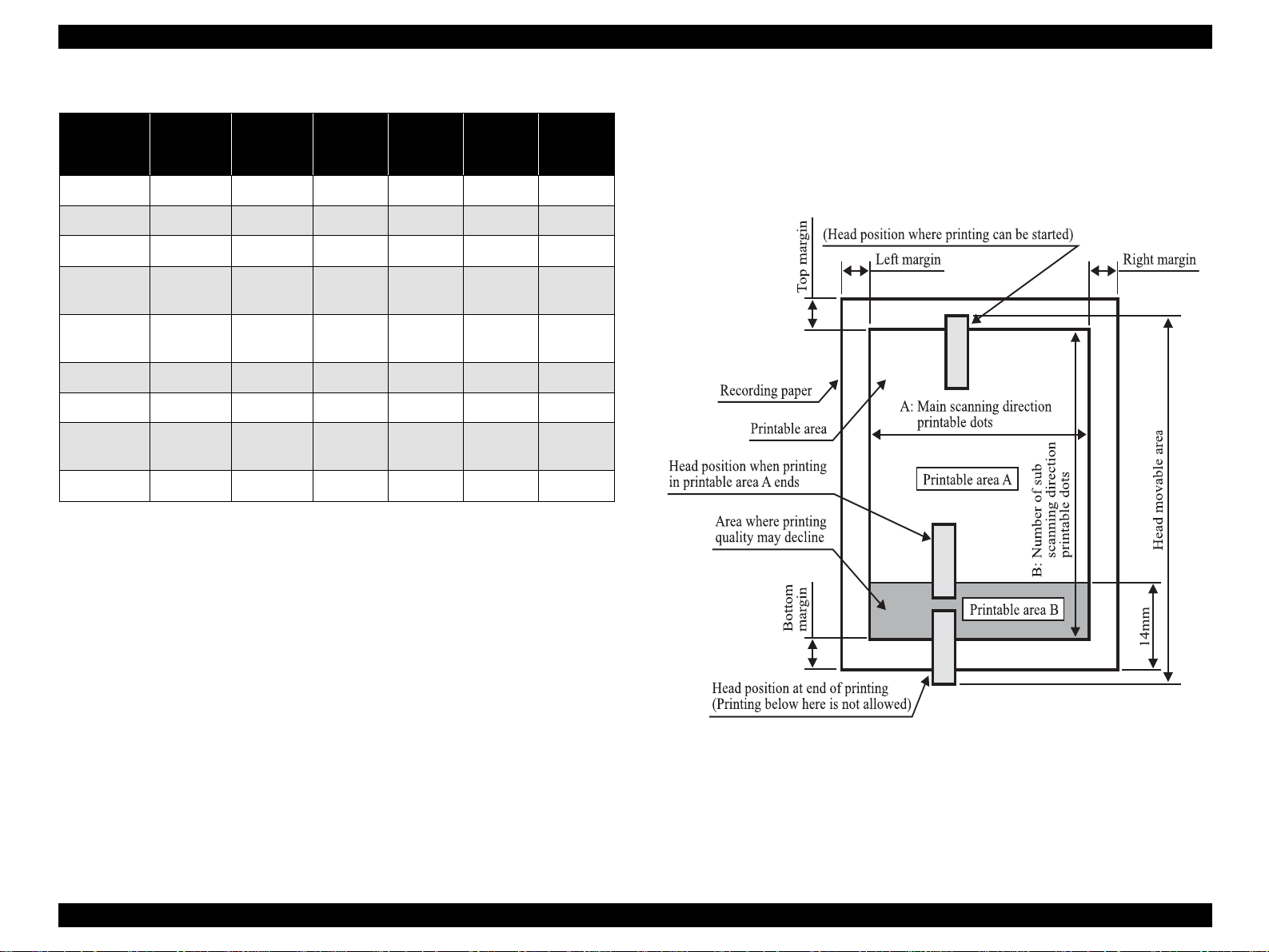

1.2.3 Printing Area

! The printing area guaranteed for this printer is shown below.

Figure 1-2. Printing Area

PRODUCTION DESCRIPTION Basic Specifications 17

Page 18

EPSON Stylus PHOTO 2100/2200 Revision B

!

Table 1-5. Printing Area (mm) of Stylus PHOTO 2100/2200

PW

Paper size

(paper

width)

A3 Wide 329 483 3

A3 297 420 3

US Legal 216 356 3

PL

(paper

length)

LM

(Left

margin)

*a

*a

*a

RM

(Right

margin)

*a

3

*a

3

*a

3

TM

(Top

margin)

*b

3

*b

3

*b

3

BM

(Bottom

margin)

*b*c

14/3

*b*c

14/3

*b*c

14/3

Printing area (Cut sheet)

" Printable area

The range made of the printable area A and printable area B shown in Figure

1-3. In the printable area B, printing quality may decline. The image quality

levels of the printing areas A, B are defined in the quality standard.

US Letter

(Landscape)

US Letter

(Portrait)

216 279 3

279 216 3

A4 210 297 3

B5 182 257 3

Photo Card

(4" x 6")

113.6 175.4 3

Roll paper - - 3

*a

*a

*a

*a

*a

*a

*a

3

*a

3

*a

3

*a

3

*a

3

*a

3

20

*b

3

*b

3

*b

3

*b

3

*b

3

*b

*a : Under specific conditions, the left and right margins can be zeroed.

*b : Under specific conditions, the top and bottom margins can be zeroed.

*c : When the paper length is specified with the ESC (S command, the bottom

margin can be reduced to the minimum of 3mm. However, printing quality

may decline in the range 3mm to 14mm from the paper bottom. When the

paper length is not specified, the bottom margin remains unchanged from

14mm or more.

14/3

14/3

14/3

14/3

14/3

*b*c

*b*c

*b*c

*b*c

*b*c

14

Figure 1-3. Printing Area

PRODUCTION DESCRIPTION Basic Specifications 18

Page 19

EPSON Stylus PHOTO 2100/2200 Revision B

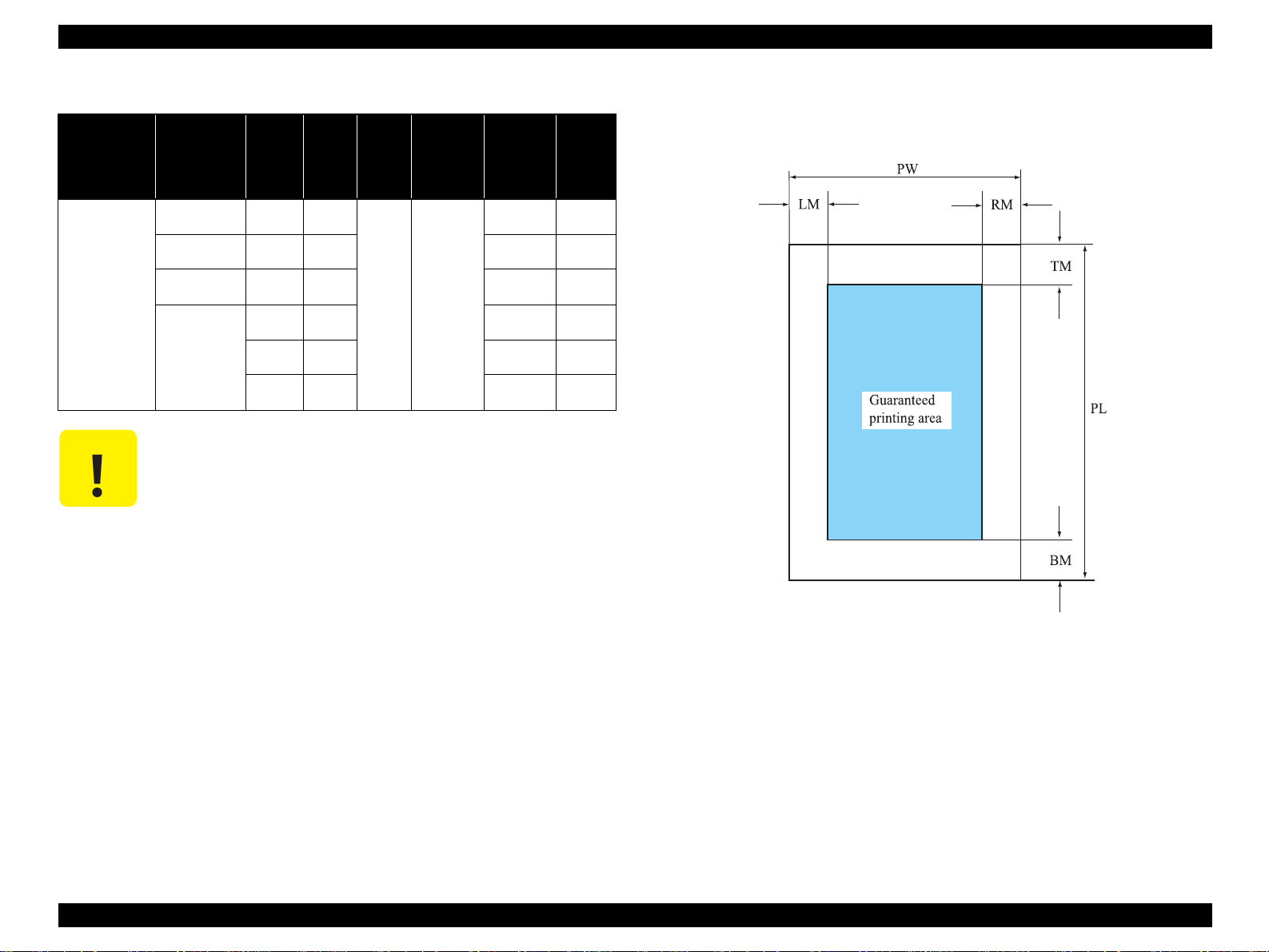

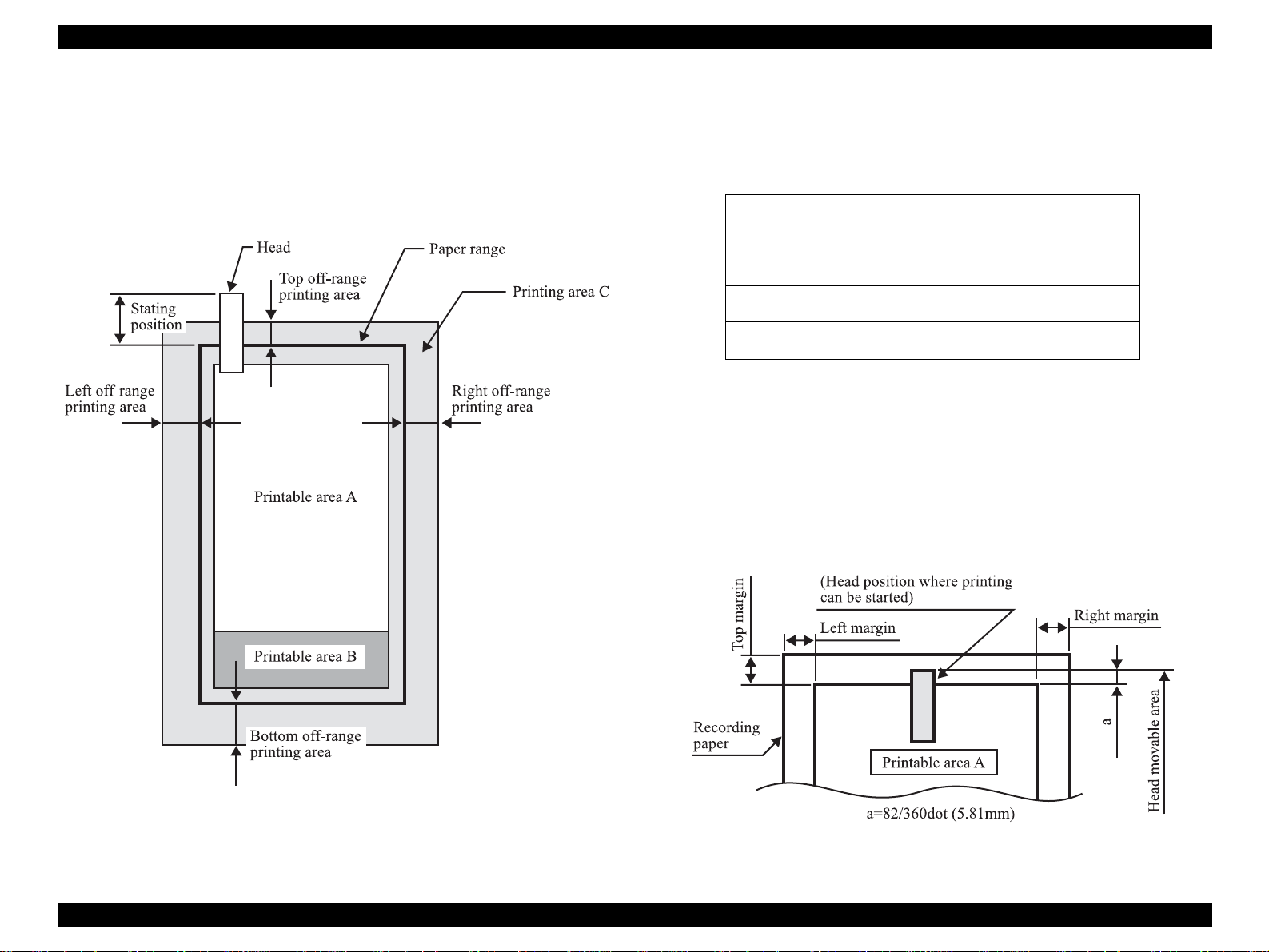

"

Printable area (Margin-less printing)

The range made of the printable areas A and B and the top, bottom, left and

right off-range printing areas C shown in Figure 1-4.The image quality levels

of the printing areas A, B are defined in the quality standard. The printing

areas C are trimmed areas, where printing may not be done. Note that the

paper width is limited to 89, 100, 127, 210 or 329mm or to 4, 5, 8, or 8.5

inches.

Starting position : 85/360 (6mm)

!

! Off-range printing areas

Table 1-6. Off-range Printing Areas

Top 42/360 (3mm) 42/360 (3mm)

Left, right 36/360 (2.5mm) 49/360 (3.5mm)

Bottom 72/360 (5mm) 72/360 (5mm)

Size Less than

in Right Field

11inch/A3/A3+

" Head movable areas

Set the head movable areas (areas where the nozzles may come out of the

printing range) relative to the printing area in the sub scanning direction

(paper feeding direction). Those areas are as shown in Figure 1-5 to Figure

1-9. The main scanning direction (carriage direction) is as shown in the A0

carriage operation area diagram.

1) Top head movable area

1. At the setting of top margin to 3mm or more

Figure 1-4. Printing Area (Margin-free Printing)

Figure 1-5. Head Movable Area for 3mm Top Margin

PRODUCTION DESCRIPTION Basic Specifications 19

Page 20

EPSON Stylus PHOTO 2100/2200 Revision B

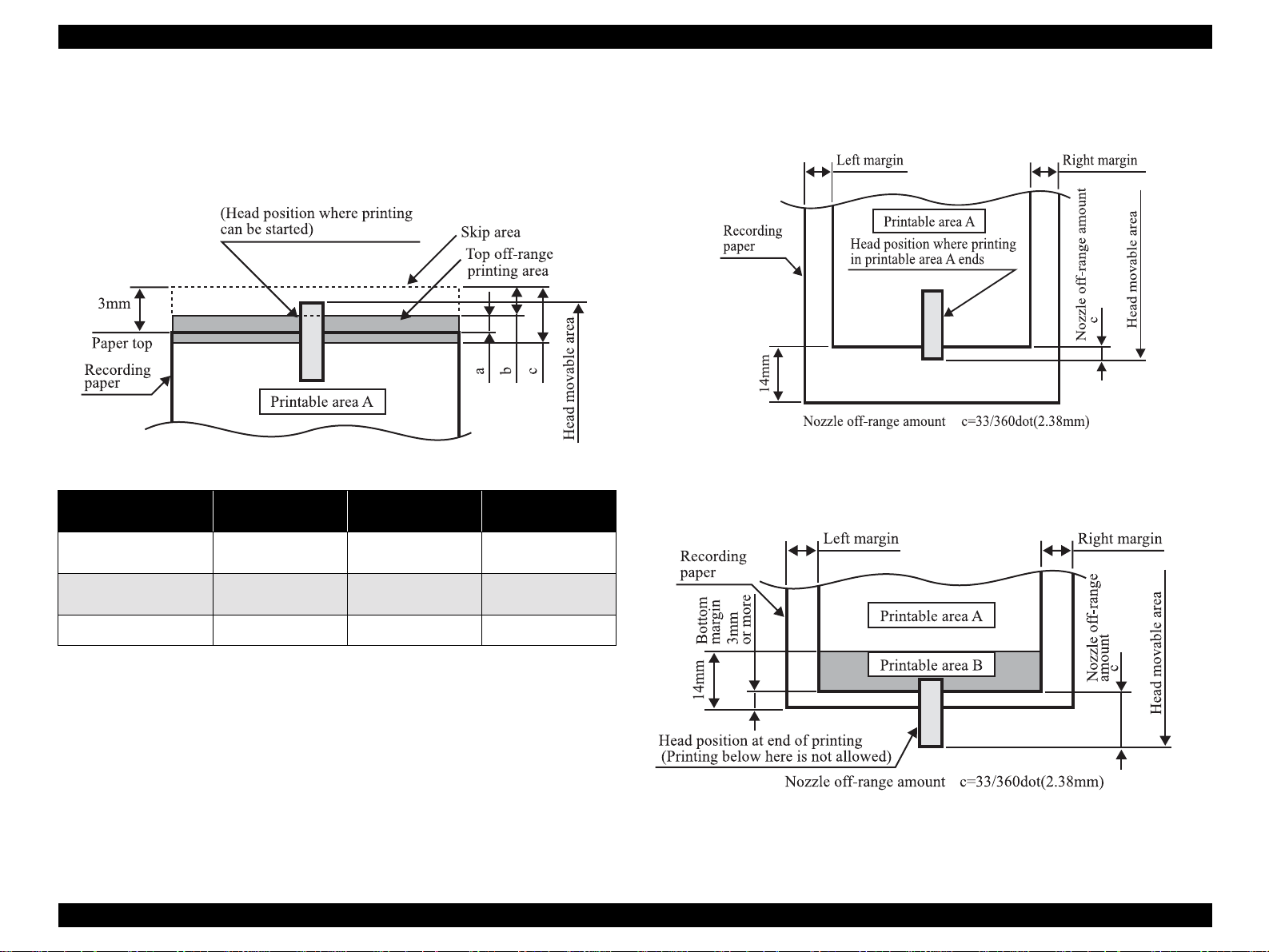

2. At the setting of top margin to 0mm

Top off-range printing prints the area a, and nozzle-restricted

printing prints the area c. After the #1 nozzle has passed through the

area c, nozzle restriction is canceled.

Paper Type Exclusive Paper

Recording paper width

(Main scanning method)

a = Off-range printing

area

b = Skip amount 17/360 (1.20mm) 17/360 (1.20mm) 4/360 (0.28mm)

Less than 150mm Less than 150mm 150mm or more

25/360 (1.76mm) 25/360 (1.76mm) 38/360 (2.68mm)

Other than

Exclusive Paper

Any Paper Type

c = 66/360 (4.7mm) Nozzle-restricted printing area

#1 to #22 A total of 22 nozzles Nozzle restriction

2) Bottom head movable area

1. At the setting of bottom margin to 14mm

Figure 1-7. Head Movable Area for 14mm Bottom Margin

2. At the setting of bottom margin to 3mm

Figure 1-6. Head Movable Area for 0mm Top Margin

Figure 1-8. Head Movable Area for 3mm Bottom Margin

PRODUCTION DESCRIPTION Basic Specifications 20

Page 21

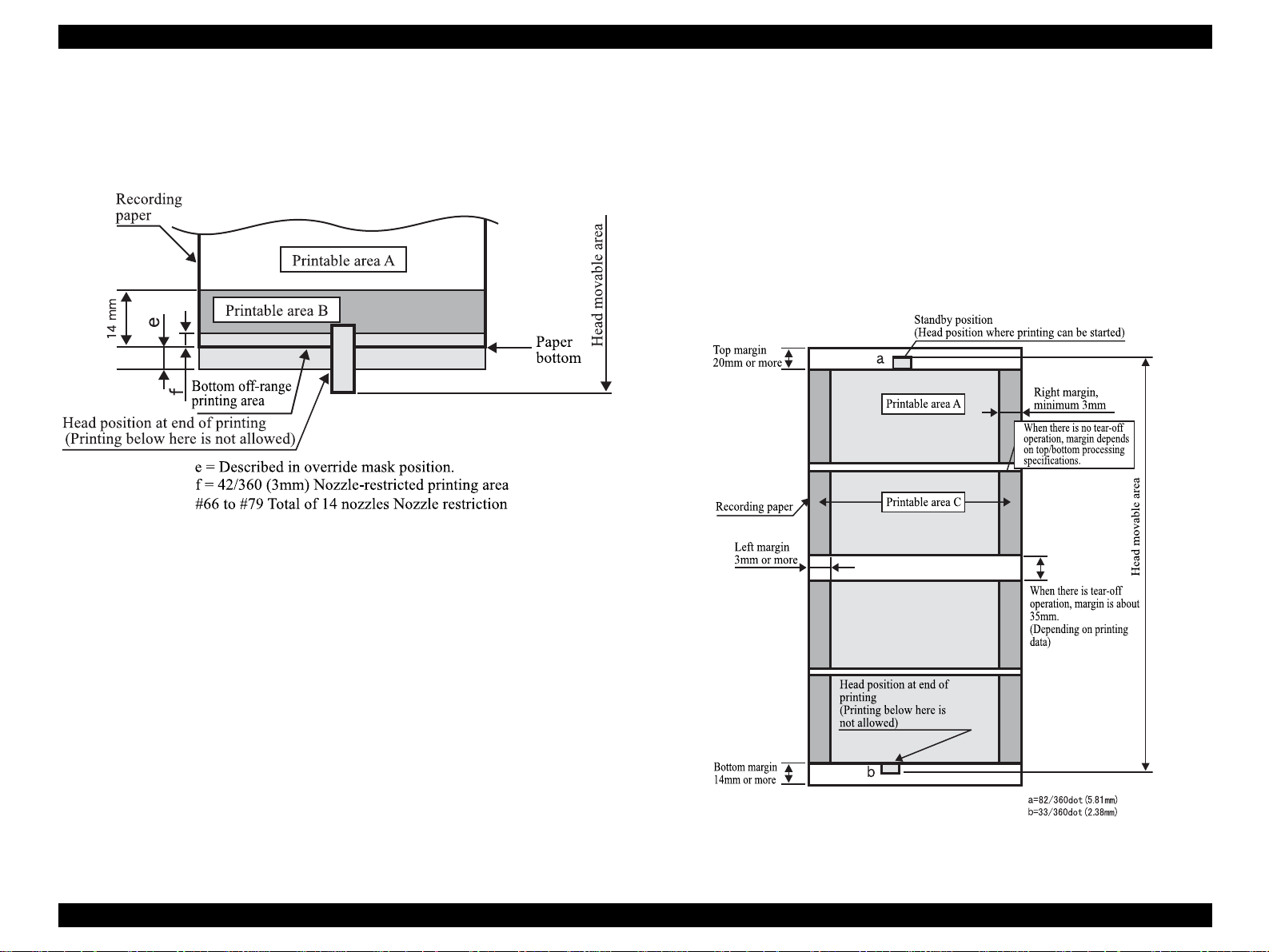

EPSON Stylus PHOTO 2100/2200 Revision B

3. At the setting of bottom marg in to 0mm

Since printing is restricted in the bottom off-range area (e) after the

distance f from the paper bottom, only a total of 14 nozzles, #66 to

#79, are used per nozzle line to perform printing.

Figure 1-9. Head Movable Area for 0mm Bottom Margin

Printing area (Roll paper)

!

" Printing area

The range made of the printable area A or printing areas A + C shown in

Figure 1-10. Note that printing in the range of printing areas A + C is limited

to the paper width 89, 100, 127, 210 or 329mm or to 4.5 inches.

" Head movable area

Set the head movable area (area where the head may come out of the printing

range) relative to the printing area in the paper feeding direction. This area is

as shown in Figure 1-10 (roll paper).

Figure 1-10. Printing Area Diagram (Roll Paper)

PRODUCTION DESCRIPTION Basic Specifications 21

Page 22

EPSON Stylus PHOTO 2100/2200 Revision B

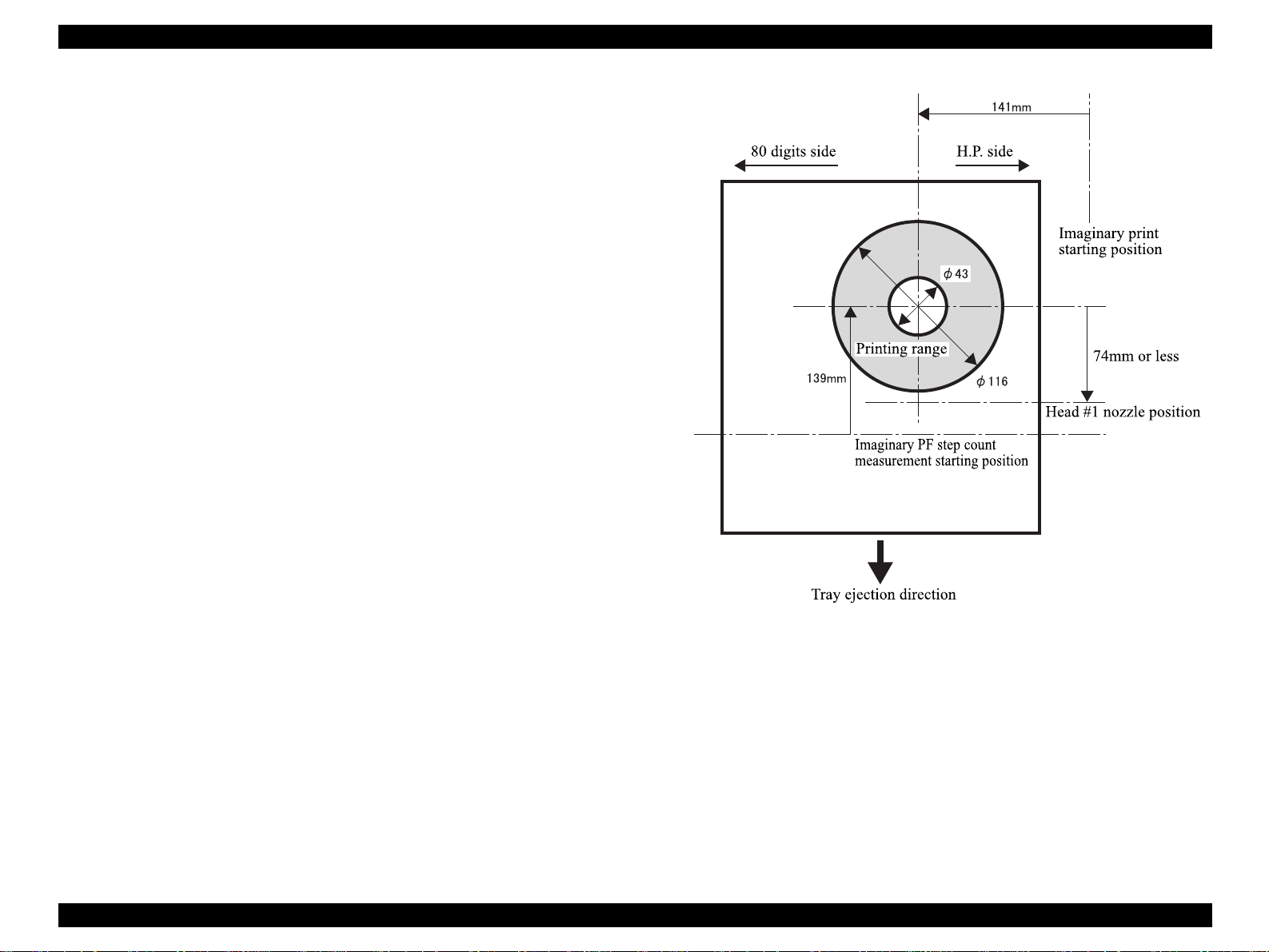

!

Printing area (CD-R)

" Printing area

Figure 1-11 shows a CD-R printing area. The printing area is in the inside of

∅116 and in the outside of ∅43.

1. The reference position of the carriage main scanning direction is 141mm

away from the center of a CD-R toward the home position. (The center of

the CD-R is identified by automatic detection.)

2. The reference position of the paper feeding direction is 139mm below the

center of the CD-R.

3. The CD-R center cannot be reversed more than 74mm from the head #1

nozzles.

Figure 1-11. Printing Area Diagram (CD-R)

PRODUCTION DESCRIPTION Basic Specifications 22

Page 23

EPSON Stylus PHOTO 2100/2200 Revision B

1.2.4 Ink Type-based Medium Compatibility

Specifications

On this product, the compatible media change depending on the black ink combination.

PIM compatibility also changes depending on the medium. The following describes the

compatible media, used LUT, and PIM compatibility that change depending on the black

ink combination.

! Photo-black + Light-black: Glossy

Standard ink combination/ink combination adequate for photo printing

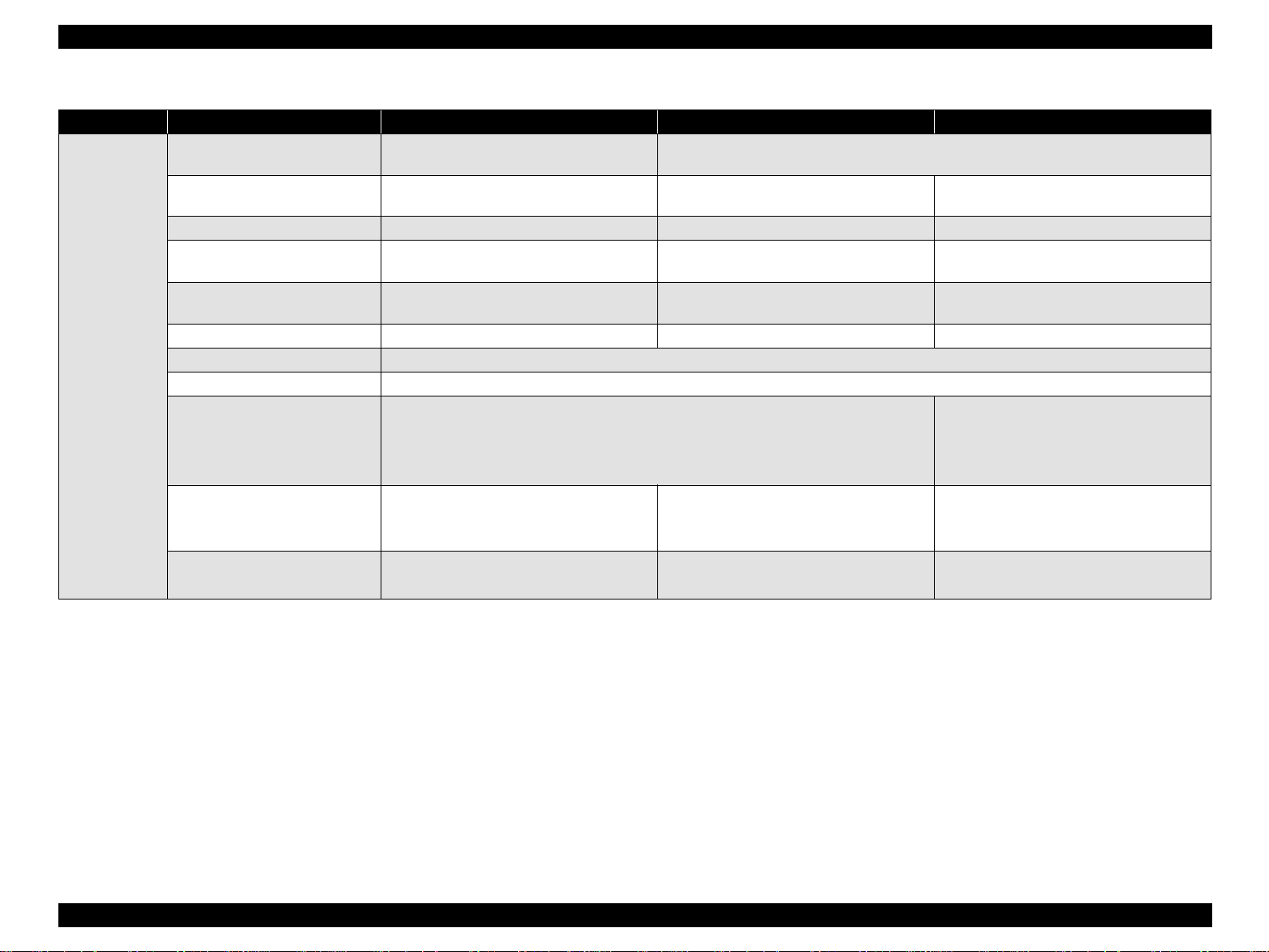

Table 1-7. Photo-black + Light-black

Paper Type Support Used LUT

Plain Paper # Plain Paper Plain Paper Plain Paper #

Premium Ink

Jet Plain Paper

Bright White

Ink Jet Paper

Premium Luster

Photo Paper

(for U.S only)

Premium

Semigloss

photo paper

Premium

Glossy Photo

Paper

(for U.S only)

Glossy Paper-

Photo Weight

(Except U.S)

# Plain Paper × × #

# Plain Paper ××#

Premium

#

#

#

#

Semigloss

photo paper

Premium

Semigloss

photo paper

Premium

Semigloss

photo paper

Glossy Paper-

Photo Weight

Driver UI Description

US Other

Premium Luster

Photo Paper

Premium

Semigloss

photo paper

Premium

Semigloss

photo paper

×

× #

Premium

Semigloss

photo paper

× #

Glossy Paper-

Photo Weight

PIM

Support

#

#

Table 1-7. Photo-black + Light-black

Paper Type Support Used LUT

Velvet Fine Art

Paper

(for U.S only)

Watercolor

Paper-Radiant

White

CD-R × ----

Photo Quality

Ink Jet Paper

Matte Paper-

Heavyweight

Photo Paper × - - - -

Photo Quality

Glossy Film

Ink Jet

Transparencies

Iron-On Cool

Peel Transfer

Paper

Ink Jet

Backlight Film

Canvas × ----

360dpi Ink Jet

Paper

#

#

Archival Matte

Paper

Watercolor

Paper-Radiant

White

× - - - -

× ----

× ----

× - - - -

× ----

× - - - -

× - - - -

Driver UI Description

US Other

Velvet Fine Art

Paper

Watercolor

Paper-Radiant

White

× #

Watercolor

Paper-Radiant

White

PIM

Support

#

Archival Matte

Paper

#

Archival Matte

Paper

Archival Matte

Paper

Archival Matte

Paper

#

PRODUCTION DESCRIPTION Basic Specifications 23

Page 24

EPSON Stylus PHOTO 2100/2200 Revision B

!

Matte-black + Light-black: Matte-black is optional.

Good-looking ink combination for plain paper/matte-Light-black media

Table 1-8. Matte-black + Light-black

Paper Type Support Used LUT

Plain Paper # Plain Paper Plain Paper Plain Paper #

Premium Ink

Jet Plain Paper

Bright White

Ink Jet Paper

Premium Luster

Photo Paper

(for U.S only)

Premium

Semigloss

photo paper

Premium

Glossy Photo

Paper

(for U.S only)

Glossy Paper-

Photo Weight

(Except U.S)

Archival Matte

Paper

# Plain Paper × × #

# Plain Paper ××#

× - - - -

× ----

× - - - -

× ----

#

Archival Matte

Paper

Driver UI Description

US Other

Archival Matte

Paper

Archival Matte

Paper

PIM

Support

#

Paper Type Support Used LUT

Photo Quality

Ink Jet Paper

Matte Paper-

Heavyweight

Photo Paper × - - - -

Photo Quality

Glossy Film

Ink Jet

Transparencies

Iron-On Cool

Peel Transfer

Paper

Ink Jet

Backlight Film

Canvas × ----

360dpi Ink Jet

Paper

NOTE: When the PIM incompatible me diu m is selected, the "some PRINT

IMAGE Matching functions are not applied" message appears on bottom

right of the paper selection screen.

Table 1-8. Matte-black + Light-black

Driver UI Description

US Other

× - - - -

× ----

× ----

× - - - -

× ----

× - - - -

× - - - -

PIM

Support

Velvet Fine Art

Paper

(for U.S only)

Watercolor

Paper-Radiant

White

CD-R × ----

#

#

Archival Matte

Paper

Watercolor

Paper-Radiant

White

Velvet Fine Art

Paper

Watercolor

Paper-Radiant

White

××

Watercolor

Paper-Radiant

White

#

PRODUCTION DESCRIPTION Basic Specifications 24

Page 25

EPSON Stylus PHOTO 2100/2200 Revision B

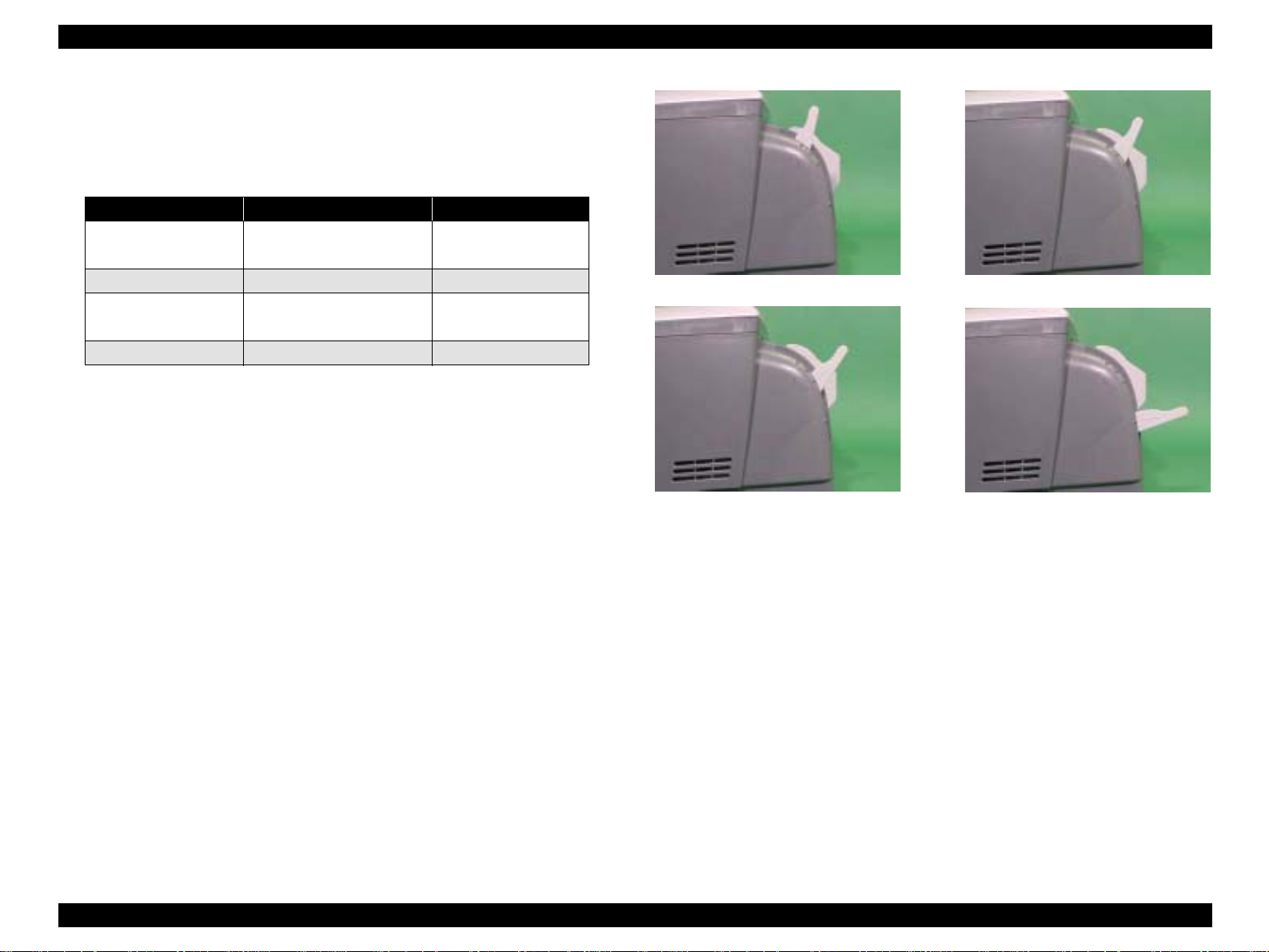

1.2.5 Release Lever

On this printer, set the Release lever as indicated in the following table depending on

the used paper type.

Table 1-9. Release lever Setting

Paper Release lever Position Gap Correction

Cut sheet, OHP, Label,

Roll paper

Envelope, Board paper First step from front position +1.3mm

CD-R tray

*a

- Far side position

*a : When the CD-R tray is loaded, any position other than the second

step from the front position will result in a release lever error.

*b : The far side position of the Release lever is used when placing

thick paper (board paper) or CD-R tray. After placing thick paper

or CD-R tray, move the release lever to the appropriate position.

Front side position 0mm

Second step from front

position

*b

+2.7mm

<Front side position>

-

<First step from front position>

<Second step from front position>

<Far side position>

Figure 1-12. Release Lever Positions

PRODUCTION DESCRIPTION Basic Specifications 25

Page 26

EPSON Stylus PHOTO 2100/2200 Revision B

1.3 Functions

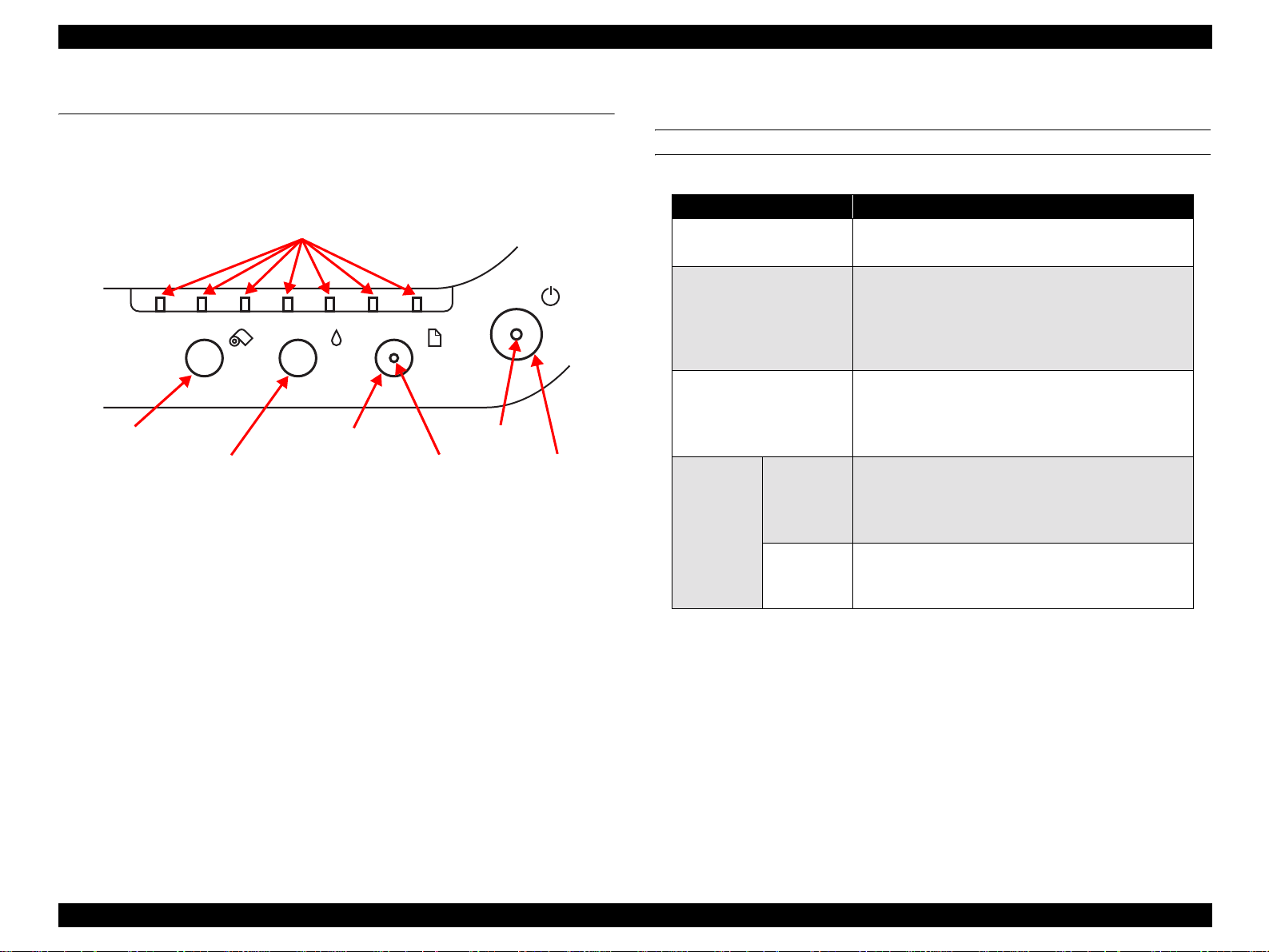

1.3.1 Control Panel

The appearance of the control panel is shown below.

Ink LEDs 1 to 7

Roll paper switch

Ink switch

Figure 1-13. Control Panel Appearance

1.3.2 Switches

! Power switch

! Paper switch

! Ink switch

! Roll paper switch

Paper switch

Power LED

Paper LED

Power switch

1.3.4 Switch Functions

FUNCTIONS IN NORMAL STATUS

Table 1-10. Normal-status Functions

Switch Function

Power switch

Paper switch

Ink switch

Without

cutter

Roll paper

switch

With cutter

*a : Turn on the power switch within 10 seconds.

*b : Hold down the switch for 3 seconds.

• Power on/off

•Panel reset

• Paper feed (Error is reset when paper is fed

successfully)

• Paper ejection

• Movement from cartridge replacement position to

home position

• Cleaning

• Movement to cartridge replacement position

• Movement from cartridge replacement position to

home position

• Tear Off execution/return from Tear Off

• Roll paper ejection (back-out)

• Movement from cartridge replacement position to

home position

• Roll paper ejection (back-out)

• Movement from cartridge replacement position to

home position

*a

*b

*b

*b

1.3.3 Indicators

! Power LED : Green

! Paper LED : Red

! Ink LEDs (1 to 7) : Red

PRODUCTION DESCRIPTION Functions 26

Page 27

EPSON Stylus PHOTO 2100/2200 Revision B

FUNCTIONS AT POWER-ON SPECIAL SETTING MODE

Table 1-11. Power-on Functions

Switch Function

Paper switch Status printing

Ink switch Roller cleaning mode

Roll paper switch

Paper switch

+

Roll paper switch

Code Page/parallel interface 1284.4

operation mode selection

Special setting mode

*a : Any of the following operations is performed according to the

value written to 5BH of the EEPROM. For details, refer to"Status

Printing" on Page 30.

00h

01h Hexadecimal dump mode

Firmware version, selected Code Page, Waste ink counter

and nozzle test pattern are printed.

*b : For details, refer to "Panel Operation in Roller Cleaning Mode" on

Page 34.

*c : For details, refer to "Default Setting Selection Function" on Page

28.

*d : For details, refer to "Special setting mode" on Page 27.

*a

*b

*c

*d

To select the special setting mode, hold down the Paper switch and Roll paper switch

and switch power on, and then press the following switches within the time when the

Paper error indicator is blinking (for about 3 seconds).

Table 1-12. Special Setting Mode

Switch Function

Paper switch EEPROM and Timer IC reset

Roll paper switch

(10 seconds)

Waste ink counter reset

*a

*b

*c

*a : This operation resets the following data at the corresponding

addresses of the EEPROM.

• 26<H>-27<H> Last cleaning time: 00<H>, 00<H>

• 28<H>-29<H> Power off time: 00<H>, 00<H>

• 44<H> Interface selection: 00<H> (Auto)

*b : For the initialized items, refer to "EEPROM Address Map" on

Page 231.

*c : The corresponding addresses of the EEPROM are 20<H>-21<H>.

PRODUCTION DESCRIPTION Functions 27

Page 28

EPSON Stylus PHOTO 2100/2200 Revision B

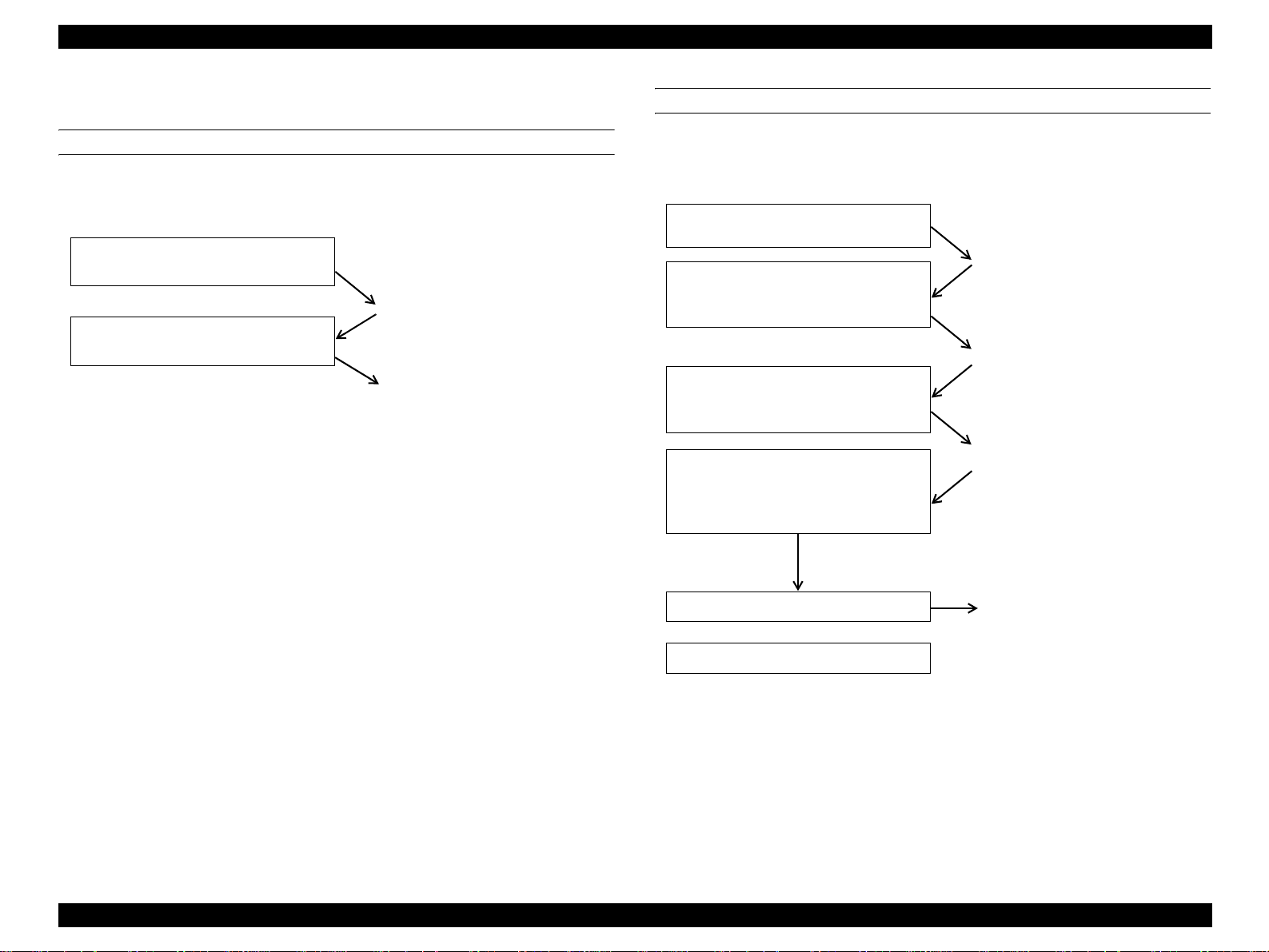

1.3.5 Default Setting Selection Function

CODE PAGE SELECTION FUNCTION

By operating the panel at power-on, you can select the default character code table.

Operating procedure

Hold down the Roll paper switch and

switch power on or reset the panel.

The Paper LED blinks.

When the blink of the Paper LED has

started, release the Roll paper switch.

Code Page is changed (changed

from PC437 to PC850 or from PC

850 to PC437 automatically) and

all LEDs are then lit for about 2

seconds.

Confirmation of the current Code Page

The currently selected Code Page can be confirmed by performing status printing.

PARALLEL INTERFACE 1284.4 OPERATION MODE SELECTION

By operating the panel at power-on, you can select the operation mode (On/Off/Auto)

of the IEEE1284.4 protocol in the parallel interface.

Operating procedure

Hold down the Roll paper switch and

switch power on.

When the blink of the Paper LED has

started, release the Roll paper switch

but keep pressing the Paper switch.

When the Power LED, Paper LED and

all Ink LEDs are lit, release the Paper

switch.

Press the Roll paper switch to select the

operation mode (every time you press

the switch, the operation mode changes

from Auto to On to Off to Auto ...).

*a

The Paper LED blinks.

*b

(About 10 seconds)

The Power LED, Paper LED and

all Ink LEDs are lit.

The operation mode currently

selected is indicated by the

corresponding Ink LED.

On : Ink LED 7 is lit.

Off : Ink LED 6 is lit.

Auto : Ink LED 5 is lit.

Switch power off.

or

Press the Paper switch.

*a : By initializing the panel, you cannot select the 1284.4 operation m ode. To

avoid panel initialization, the power must be left off for more than about 10

seconds or the power plug must be disconnected from the receptacle once

with power off.

*b : Note that if you do not press any switch for 2 or more seconds after you

released the Roll paper switch, Code Page selection will be executed.

The selected operation mode is

stored and power is switched off.

The selected operation mode is

stored and the printer starts.

PRODUCTION DESCRIPTION Functions 28

Page 29

EPSON Stylus PHOTO 2100/2200 Revision B

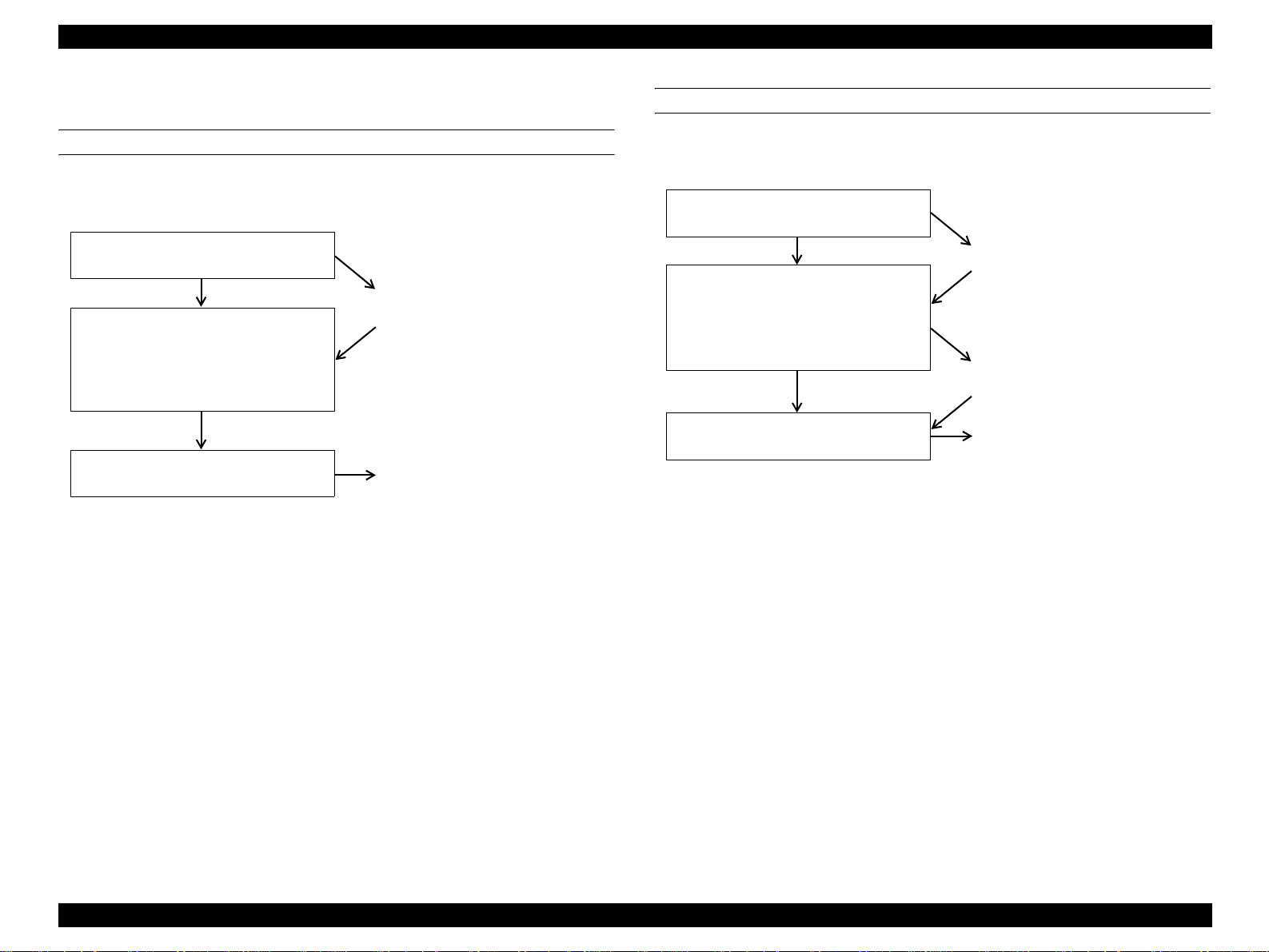

1.3.6 Special Setting Mode Function

EEPROM AND TIMER IC RESET

By operating the panel at power-on, you can reset the EEPROM and Timer IC.

Operating procedure

Hold down the Roll paper switch and

Paper switch, and switch power on.

The Power and Paper LEDs

When the blink 2 of the Power and

Paper LEDs and the blink of all Ink

LEDs have started, release the Roll

paper switch and Paper switch and

press the Paper switch.

The Power, Paper and all Ink LEDs are

lit for 1 second.

*a : If the switch is not pressed within the time when the Error LED is blinking

(for 3 seconds), the printer starts normally.

*a

blink 2 and all Ink LEDs blink.

EEPROM and Timer IC reset

ends and the printer starts.

WASTE INK COUNTER RESET

By operating the panel at power-on, reset the counter for waste ink.

Operating procedure

Hold down the Roll paper switch and

Paper switch, and switch power on.

The Power and Paper LEDs

When the blink 2 of the Power and

Paper LEDs and the blink of all Ink

LEDs have started, release the Roll

paper switch and Paper switch and

press the Roll paper switch.

The Power, Paper and all Ink LEDs are

lit for 2 seconds.

blink 2 and all Ink LEDs blink.

(About 10 seconds)

The Power LED, Paper LED and

all Ink LEDs are lit.

Waste ink counter reset ends and

the printer starts.

PRODUCTION DESCRIPTION Functions 29

Page 30

EPSON Stylus PHOTO 2100/2200 Revision B

1.3.7 Status Printing

PRINTING METHOD

Printing using remote command

!

Use the NC command of the remote commands.

! Status printing

Hold down the Paper switch and switch power on.

! Printing using D4 control command

On the D4 command channel, send the "nc" command.

PRINTING RESULT DETAILS

NOTE: Differences between the character strings printed in panel Nozzle Check

pattern and driver Nozzle Check pattern (For the driver, the firmware

version and CPU mask version are also printed at top left of the print

result paper.)

EL071C IO301A 0490

Waste counter

value

PC437

Firmware version

Code table

CPU mask version

Figure 1-14. Printed Character Strings

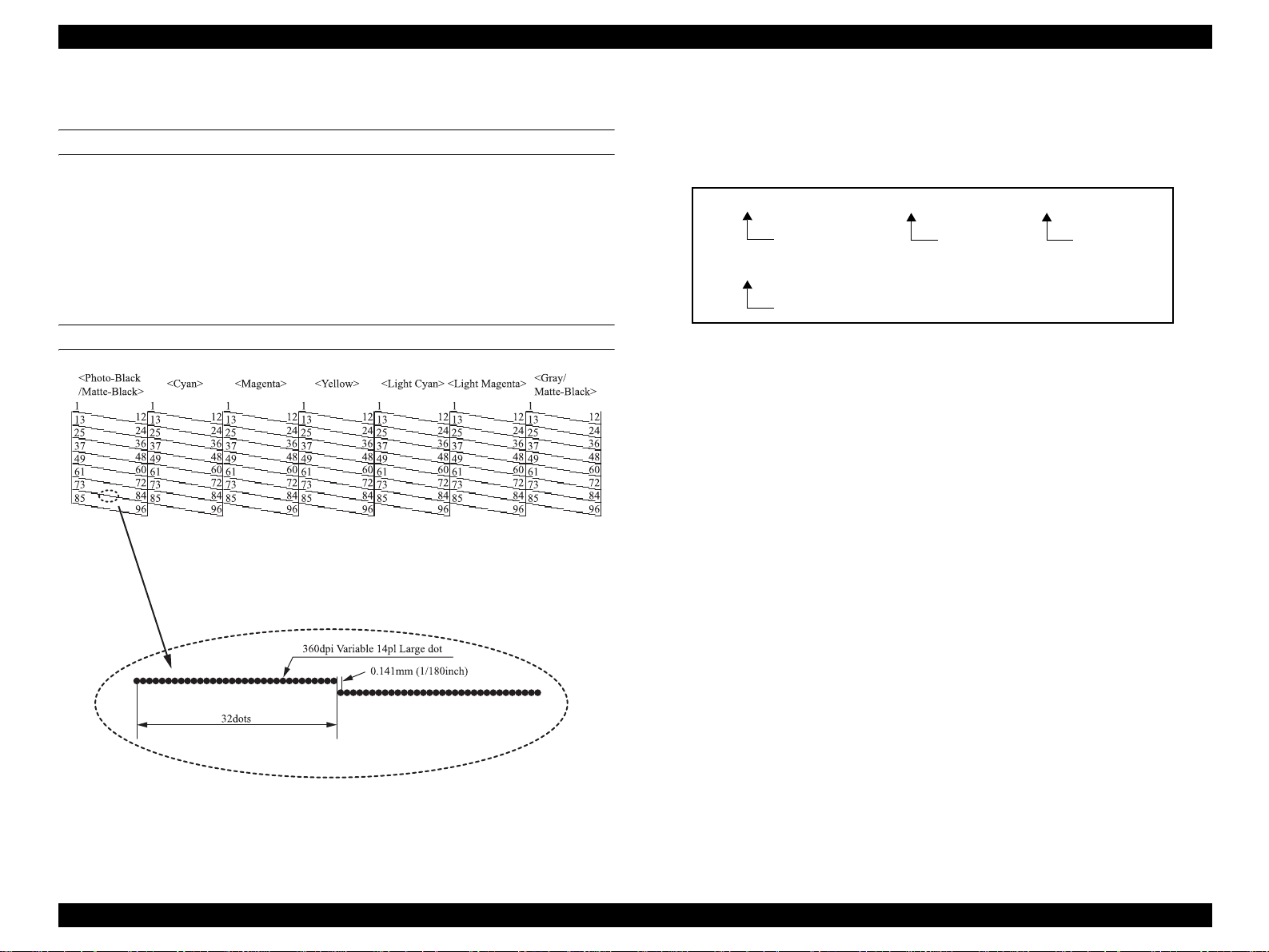

NOTE: The values above the lines indicate nozzle numbers and are not pri nted

actually.

PRODUCTION DESCRIPTION Functions 30

Page 31

EPSON Stylus PHOTO 2100/2200 Revision B

1.3.8 Panel Operation for Roll Paper Printing

PANEL OPERATION IN ROLL PAPER MODE

(WITHOUT CUTTER, TEAR-OFF LINE PRINTING)

To shift to the paper roll mode, use the roll paper mode selection command of the

remote commands.

The following indicates the basic panel operating procedure for printing on roll paper.

Operating procedure

1. Insert roll paper from the roll paper

guide.

*

a

2. Receive the roll paper data and

perform printing until the end of the

job. After the printing is over, the

printer does not eject paper and

enters the switch waiting status.

*

b

3. Press the Roll paper switch to

execute Tear Off (with tear-off

line).

*

c

4. Cut off the paper along the tear-off

line.

5. Press the Roll paper switch to

execute return from Tear Off.

*

c

6. Press the Roll paper switch for 3

seconds to back out the paper.

*

Continued to the

d

right field.

With the Paper detection sensor on

for 2 seconds, the roll paper is fed

automatically. After the roll paper

is fed, the operation with the Paper

switch is masked.

If consecutive print jobs come, the

CR stops at the end of the last job,

and the printer does not eject the

paper and enters the switch

waiting status. At this time there

are no print margins between the

jobs.

If the next print jog comes at this

point, the printer does not print and

waits for return from Tear Off.

If there is a next print job, the

printer prints and Steps 2. to 5. are

repeated.

Continued to the right

field.

Continued from the

left field

After back-out, the Paper LED

blinks. The masked Paper switch is

Continued from the left field

de-masked. If the roll paper cannot

be removed after one back-out,

press the Roll paper switch or

7. When the roll paper cannot back out

any more, remove the roll paper

Paper switch for 3 seconds to

execute back-out again.

with your hands.

*

d

8. Press the Roll paper switch or Paper

switch to clear a paper jam. The

The Paper LED goes off.

printer returns to the normal mode.

*a : If power is switched off at this point, the panel feeding status is stored onto

the EEPROM. When power is switched on again, the printer does not eject

paper. The operation in Step 2. and later can be performed.

*b : If power is switched off at this point, the roll paper mode status is stored onto

the EEPROM. When power is switched on again, the printer does not eject

paper. The operation in Step 3. and later can be performed.

*c : If power is switched off at this point, the roll paper mode status is stored onto

the EEPROM. When power is switched on again, the printer does not eject

paper. The operation that follows can be performed.

*d : If power is switched off at this point, the roll paper mode is canceled and the

panel feeding cancel is stored. When power is switched on again next, the

printer enters the normal mode.

PRODUCTION DESCRIPTION Functions 31

Page 32

EPSON Stylus PHOTO 2100/2200 Revision B

PANEL OPERATION IN ROLL PAPER MODE (WITH CUTTER)

To shift to the paper roll mode, use the roll paper mode selection command of the

remote commands.

Specify the cutting position of the roll paper using the cutting po sition specifying

command of the remote commands. When the specified position comes to the cutting

position, the paper is cut automatically.

If the cutting position specifying command is not available for the roll paper, perform

the "Panel operation in roll paper mode (Without cutter, tear-off line printing)" on Page

31.

Operating procedure

1. Insert roll paper from the roll paper

guide.

*

a

2. Receive the roll paper data and

perform printing until the end of the

job. If the cutting specified position

reaches the cutter blade position

during printing, the roll paper is cut.

*

b

3. Press the Roll paper switch to

execute Tear Off cutting. Return

from Tear Off is then performed

automatically.

*

c

Continued to the right

field.

With the Paper detection sensor on

for 2 seconds, the roll paper is fed

automatically. After the roll paper

is fed, the operation with the Paper

switch is masked.

If consecutive print jobs come, the

CR stops at the end of the last job

and the printer does not eject nor

cut the paper and enters the switch

waiting status. At this time, there

are no print margins between the

jobs.

If there is a next print jog, the

printer prints and Steps 2. and 3.

are repeated.

Continued from the left field

4. Press the Roll paper switch for 3

seconds to back out the paper.

*

d

5. When the roll paper cannot back out

any more, remove the roll paper

with your hands.

*

d

After back-out, the Paper LED

blinks. The masked Paper switch is

de-masked. If the roll paper cannot

be removed after one back-out,

press the Roll paper switch or

Paper switch for 3 seconds to

execute back-out again.

6. Press the Roll paper switch or Paper

switch to clear a paper jam. The

The Paper LED goes off.

printer returns to the normal mode.

*a : If power is switched off at this point, the panel feeding status is stored onto

the EEPROM. When power is switched on again, the printer does not eject

paper. The operation in Step 2. and later can be performed.

*b : If power is switched off at this point, Tear Off is executed automatically to cut

the roll paper, and the roll paper mode status is stored onto the EEPROM.

When power is switched on again, the printer does not eject paper. The

operation in Step 3. and later can be performed.

*c : If power is switched off at this point, the roll paper mode status is stored onto

the EEPROM. When power is switched on again, the printer does not eject

paper. The operation in Step 3. and later can be performed.

*d : If power is switched off at this point, the roll paper mode is canceled and the

panel feeding cancel is stored. When power is switched on again next, the

printer enters the normal mode if the Paper detection sensor is off.

PRODUCTION DESCRIPTION Functions 32

Page 33

EPSON Stylus PHOTO 2100/2200 Revision B

1.3.9 Panel Operation for CD-R Printing

The following indicates the basic panel operating procedure for printing on CD-R.

Operating procedure

1. Move the Release lever to the

farthest position.

2. Along the paper feed guide, put the

CD-R tray folder into the printer

front and push the CD-R tray into

the specified position toward the

printer rear.

*

a

3. Return the Release lever to the

original position.

*

a

4. Press the Paper switch.

*

b

5. Send the print data.

*a : If power is switched off and then on again at this point, the CD-R tray is not

ejected and a paper jam error occurs. When you further press the Paper

switch, the CD-R tray is ejected to the front and the printer returns to the

normal mode.

*b : If power is switched off and then on again at this point, the CD-R tray is

ejected to the front and the printer returns to the normal mode.

The Paper LED blinks fast.

If the print data has already been

sent, print operation is stopped

temporarily.

The Paper LED stops blinking fast.

The CD-R tray is fed

automatically. If it is not fed

properly, the CD-R tray is ejected

to the front and a paper feed error

occurs.

After printing is over, the CD-R

tray is ejected.

1.3.10 Panel Operation for Thick Paper Printing

The following indicates the basic panel operating procedure for printing on thick paper.

Operating procedure

1. Move the Release lever to the

farthest position.

2. Along the paper feed guide, insert

the thick paper into the printer rear.

3. Return the Release lever to the

original position.

*

a

4. Press the Paper switch.

*

b

5. Send the print data.

*a : If power is switched off and then on again at this point, the thick paper is not

ejected and a paper jam error occurs. When you further press the Paper

switch, the thick paper is ejected and the printer then returns to the normal

mode.

*b : If power is switched off and then on again at this point, the thick paper is

ejected and the printer returns to the normal mode.

The Paper LED blinks fast.

If the print data has already been

sent, print operation is stopped

temporarily.

Insert the thick paper along the

right end of the paper feed guide.

The Paper LED stops blinking fast.

The thick paper is fed

automatically. If it is not fed

properly, a paper feed error occurs,

or if the CR interferes with the

thick paper, a paper thickness error

occurs.

After printing is over, the thick

paper is ejected.

PRODUCTION DESCRIPTION Functions 33

Page 34

EPSON Stylus PHOTO 2100/2200 Revision B

1.3.11 Panel Operation in Roller Cleaning Mode

If the ink concentration is increased within the printer driver detail setting, the ink

printed on the medium may be transferred to the rollers. In this case, the ink may be

transferred from the rollers to the print medium, making the print image dirty. If this

phenomenon has occurred, start this mode to clean the rollers. If ink is transferred to

the rollers heavily, start this mode and apply the cleaning pad packed with this product

to the rubber rollers to clean the rollers.

The following describes how to start and end the roller cleaning mode and operate the

panel during the roller cleaning mode.

OPERATING PROCEDURE

!

Roller cleaning mode starting procedure

1. Initial status: Power off

2. Hold down the Ink switch

and switch power on. → The Power LED is lit.

The Paper LED and all Ink LEDs blink 2.

3. Release the Ink switch. → The mechanism starts.

The Power LED blinks.

The Paper LED and all Ink LEDs go off.

↓

After the mechanism has ended starting,

the roller cleaning mode starts.

(Roller cleaning mode initial status)

The Power LED blinks 2.

The Paper LED blinks 2 and all Ink LEDs go off.

! Operating procedure in roller cleaning mode

1. Roller cleaning mode init ial status

Power LED : Blink 2

Paper LED : Blink 2

All Ink LEDs : Off

Pressing the Paper switch starts roller

cleaning.

If there is no paper on

the paper feed tray

NOTE: During the roller cleanin g mode, the In k switch and Roll paper switch

are invalid.

During roller cleaning execution, the Paper switch, Ink switch and Roll

paper switch are invalid.

2. Roller cleaning (paper feed) start

Power LED : Blink 2

Paper LED : Blink 2

All Ink LEDs : Off

If there is paper on the paper

feed tray

3. Roller cleaning execution

Power LED : Blink 2

Paper LED : Blink 2

All Ink LEDs : Off

Roller cleaning end

4. Roller cleaning end

Power LED : On

Paper LED : On

All Ink LEDs : Off

Pressing the Paper

switch restarts roller

cleaning.

! End of roller cleaning mode

" When you press the Power switch during the roller cleaning mode, the roller

cleaning mode ends and power switches off.

" When you press the Power switch during roller cleaning execution, the printer

ejects the roller cleaning paper, and then the roller cleaning mode ends and

power switches off.

PRODUCTION DESCRIPTION Functions 34

Page 35

EPSON Stylus PHOTO 2100/2200 Revision B

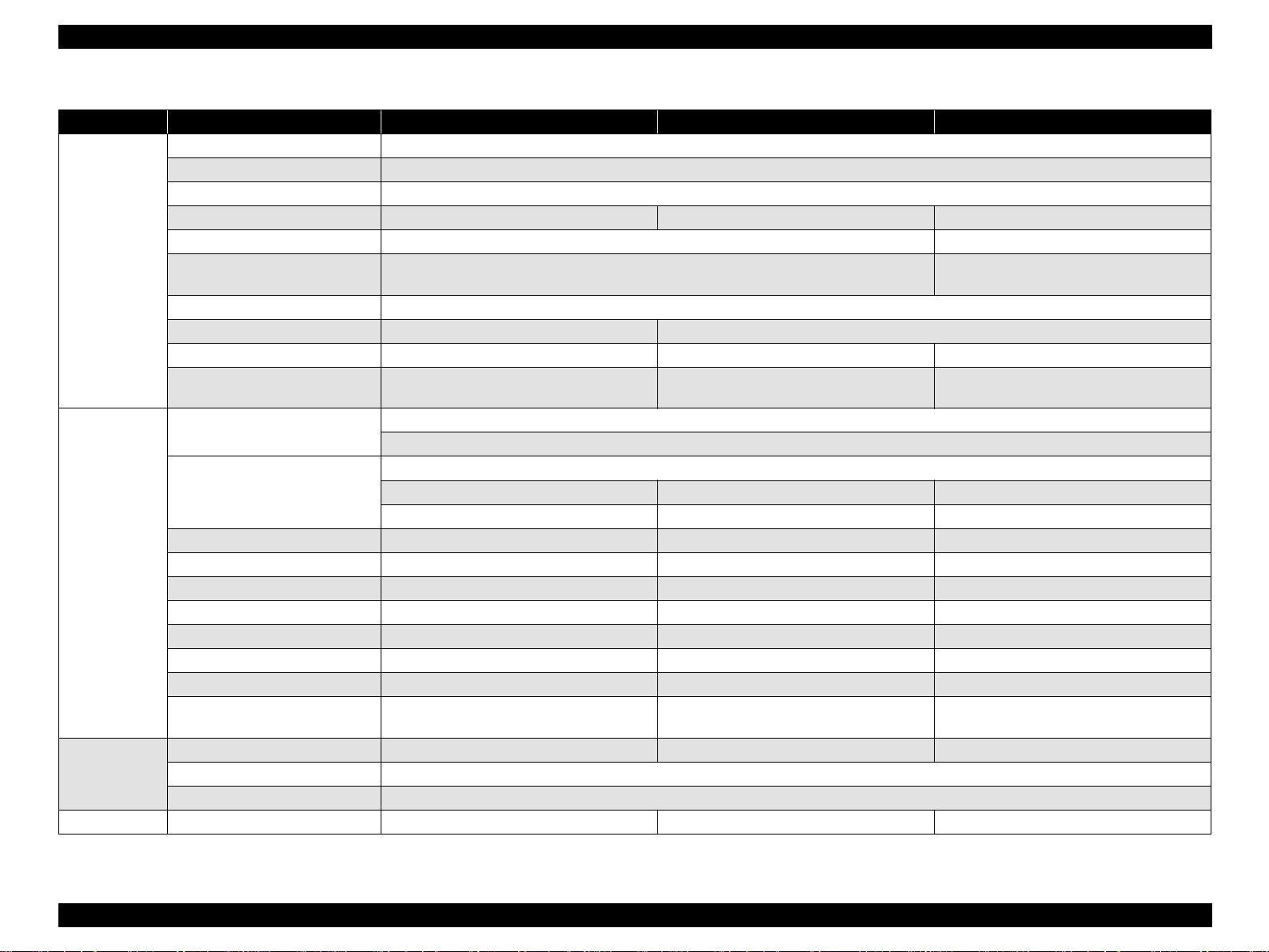

1.3.12 Indicator Display in Normal Mode

Table 1-13. Printer Condition and LED Status

blink

Blink

blink

Indicators

High speed

High speed

alternately 2

High speed

*a

*b

*b

*b

blink

*b

blink

*b

-4

Blink

blink

Printer status

Power on condition On - - 18

Data processing Blink - - 17

Ink sequence Blink - Special blink

Ink cartridge change mode Blink - - 15

Ink level low - - Blink

Paper out - On - 13

Ink end - - On

Ink color error - -

Ink combination error - -

No ink cartridge or

Ink cartridge error

Double feed error - On - 8

Paper jam condition - Blink - 7

Paper gap error - On - 6

Cutter jam error - Blink2 - 5

Release lever position error -

Cutter position error Off Blink2 Blink2 3

Maintenance request Off

Main board RAM Error On Slow blink Slow blink Slow blink

Fatal error Off

Power Paper Ink 1 - 7 priority

- - On

High speed

alternately 1

High speed

16

14

12

11

10

! "-" indicates no change.

! Blink : Repetition of On 0.5 sec + Off 0.5 sec

! Blink 2 : Repetition of On 0.2 sec + Off 0.2 sec + On 0.2 sec +

Off 0.4 sec

! High speed blink : Repetition of On 0.1 sec + Off 0.1 sec

! Blink alternately 1 : Same as blink

! Blink alternately 2 : Repetition of Off 0.5 sec + On 0.5 sec

! Special blink : TBD

9

2

1

*a : Indicated by all Ink LEDs.

*b : The Ink LEDs corresponding to the cartridge lines A, B, C, D, E, F, G turn

on or blink individually. When viewed from the printer front, the places of

inserting the ink cartridges are lines A, B, C, D, E, F, G from left to right

and correspond to LED1, LED2, LED3, LED4, LED5, LED6, and LED7.

PRODUCTION DESCRIPTION Functions 35

Page 36

EPSON Stylus PHOTO 2100/2200 Revision B

1.3.13 Error Status

If any of the following states is detected, this printer is put in an error status and turns

the interface signal -ERROR "Low" and BUSY "High" to inhibit data input. At this

time, the printer is automatically disabled from printing. However, when

communication is being made using the IEEE1284.4 protocol, communication with the

printer is enabled.

! Ink end

" Ink end detection is performed for the monochrome and color inks.

" When the ink is getting low, Ink Low is displayed. When the specified amount

is consumed, the printer displays Ink End and stops. For the color cartridges,

an Ink End error occurs if any one color ink ends.

! Paper Out

" This error occurs if paper is not fed by paper feeding operation.

! Paper jam

" When the residual paper cannot be ejected by the paper feeding operation of

the specified step count at power-on or when paper cannot be ejected using

the FF command or Paper feed/eject switch, it is regarded as a paper jam and

an error occurs.

! No Ink cartridge or Ink cartridge error

" The printer detected that any ink cartridge was not fitted or had come off.

" The printer cannot read or write the CSIC information of any ink cartridge

properly.

! Maintenance request

" When the waste ink reaches the specified level, the printer displays this error

and stops. The ink pad should be replaced by the service personnel, and this

error should not be reset until the necessary area of the nonvolatile memory is

rewritten.

! Fatal error

" When detecting a fatal error such as a carriage control error, the printer is

placed in an error status.

! Release lever position Error

" This error occurs if the Release lever is in the release position.

" This error occurs if the print mode is not adequate for the platen gap.

" When this error occurs, the panel is made invalid and printing stops.

! Paper Gap Error

" This error occurs if the printer judges that the gap between the head and paper

is narrow when thick paper is fed.

" When this error occurs, printing stops.

! Double feed error

" This error occurs if two or more pieces of paper are fed and printed together or

a paper feed displacement is detected in the double-sided printing mode.

" When this error occurs, printing stops.

! Cutter Position Error

" This error occurs if the printer detects that the cutter could not return to the

home position after cutter operation or mechanism initialization.

! Cutter Jam Error

" This error occurs if the printer detects that paper could not be cut properly

after cutter operation.

! Ink Color Error

" This error occurs if the printer detects that the new ink cartridge inserted

during printing differs from the old one in color/type.

" When this error occurs, printing stops.

! Ink Combination Error

" This error occurs if the printer detects that the color/type combination of the

ink cartridges inserted during ink replacement does not exist in the

specifications.

" When this error occurs, printing stops.

PRODUCTION DESCRIPTION Functions 36

Page 37

EPSON Stylus PHOTO 2100/2200 Revision B

1.4 Casing Specifications

EXTERNAL DIMENSIONS

When tucked : 631 (width) × 320 (depth) × 205 mm (height)

When used : 631 (width) × 864 (depth) × 409 mm (height)

WEIGHT

11.7kg

EXTERNAL DIMENSION DIAGRAM

1.5 Accessories

STANDARD ACCESSORIES

Instruction manual : 1 set

!

! Ink cartridge : 1 set

! CD-ROM (Printer driver utility) : 1 set

! Roll paper holder : 1 set

! Sheet : 1 pc.

! Customer information card : 1 pc.

! Warranty: : 1 pc.

! Free exclusive paper pack : 1 set

! CD-R tray guide : 1 pc.

! CD-R tray : 1 pc.

! Cleaning kit : 1 set

CONSUMABLES AND OPTIONS

!

Ink cartridges

Photo-black : T0341

Cyan : T0342

Magenta : T034 3

Yellow : T0344

Light cyan : T0345

Light magenta : T0346

Light-black : T0347

Matte-black : T0348

! Roll paper auto cutter

(Cutter, paper support basket, instruction manual): PMA3NRAC1

Figure 1-15. External Dimension Diagram

! Ink cartridge storage box : PMICBOX1

! USB cable : USBCB2

PRODUCTION DESCRIPTION Casing Specifications 37

Page 38

EPSON Stylus PHOTO 2100/2200 Revision B

1.6 Environment Specification Items

Table 1-14. Environment Specification Items

Class Details Results

Main unit

Resource

usage

reduction

Energy

saving

Recyclable

design and

use of

recycled

materials

Safety and

environment

al protection

Total amount of power consumption 52.2Wh

Compliance with the International Energy

Marking of materials to plastic parts Indicated

Percentage of parts using recycled material 20%

Prohibition of the use of substances banned

in EQS (EPSON Quality Standard) in the

Prohibition of the use of cadmium, lead,

Prohibition of the use of ozone-depleting

Reduction of release of harmful substances:

for laser printers (Dust, Ozone, Styrene)

Product Capacity 0.04m

Product weight 11kg

Turn-off power consumption 0.3W

Star program

Percentage of recyclable parts 85%

Total number of parts 624parts

Disassemblability of major units

(Ease of disassembly)

Disassembly index of parts

(Ease of disassembly)

product

and mercury in batteries

substances

3

Compliant

110

628

Confirmed

Confirmed

Confirmed

Dust:0.15mg/m3

or less

Ozone:0.02mg/

m3 or less

Styrene:0.07mg/

m3 or less

Main unit

Packaging

and Packing

Materials

Consumables

Table 1-14. Environment Specification Items

Class Details Results

Expandability of memory :for laser printers Implemented

Longevity

Others

Resource

usage

reduction

Recyclable

design and

use of

recycled

materials

Safety and

environment

al protection

Recyclable

design and

use of

recycled

materials

Safety and

environment

al protection

Five-year guarantee of spare parts from the

termination of production

Print capability on recycled paper

Operating noise : Sound Pressure level 43dB (A) or less

Capacity 0.16m

Weight 16kg

Percentage of marking of materials to

plastic parts

Percentage of parts using recycled material 25%

Percentage of recyclable material by weight 75%

Percentage of material unification 85%

Percentage of recycled paper used 60%

Percentage of waste paper in recycled paper 50%

Use of non-bleached paper or paper

bleached without chlorine

Prohibition of the use of substances banned

in EQS (EPSON Quality Standard) In the

product

Total contents of heavy metals (lead,

mercury, cadmium, sexivalent chromium)

Marking of materials to plastic parts

Prohibition of the use of substances banned

in EQS (EPSON Quality Standard) In the

product

Guaranteed

Able to print on

recycled paper

made from 100%

waste paper

(Using non-

bleached paper)

100ppm or less

Marking to all

parts not less

than 5g or more

3

87%

Confirmed

Confirmed

Confirmed

PRODUCTION DESCRIPTION Environment Specification Items 38

Page 39

OPERATING PRINCIPLES

CHAPTER

2

Page 40

EPSON Stylus PHOTO 2100/2200 Revision B

2.1 Overview

This chapter explains the operating principles of the mechanical sections and electrical

circuits in this product. The main components of this product are as follows.

! Control circuit board : C387 MAIN

! Power supply circuit board : C387 PSB/PSE

! Control panel board : C387 PNL

2.2 Printer Mechanism

Like the Stylus PHOTO 2000P, this product uses DC motors as power sources. The

following table describes the motor types and their applications.

Table 2-1. Various Motors

Motor Name Type Applications/Functions

CR motor

PF motor

ASF/Pump motor

DC motor with

brushes

DC motor with

brushes

4-phase, 48-pole

PM type

stepping motor

Though the Stylus PHOTO 2100/2200 is similar in basic structure of the mechanism to

the Stylus PHOTO 2000P, it has the following features.

• For compatibility with CD-R label direct printing, the CD-R tray adaptor and

exclusive sensor are loaded. (Only for Stylus PHOTO 2100)

• To feed board paper and roll paper, the exclusive paper feed guide is fitted.

• For compatibility with the CD-R tray and correction of ink transfer to the roller, the

newly designed paper eject unit is provided.

Used for carriage driving. Makes little noise during

driving. The CR linear scale and CR encoder sensor

are used to control the motor.

Power source to drive the Paper loading rollers a t the

time of fixed-value paper loading or paper feed/eject

operation. To grasp the paper feed pitch, the

precision gear surface is fitted with the PF scale and

the PF encoder sensor is used to control the motor.

Drives the pump and performs paper feed operation

from the ASF. Because of a stepping motor, this

motor does not require a scale, photo sensor and like

to be fitted to grasp the driving conditions.

The following shows the outline of the printer mechanism.

Loop scale

PF motor

Cutter adapter

Paper eject roller A

Paper eject roller B

PW sensor

Printhead

CR unit

CD-R sensor

CR shaft B

CR lock lever

Pump unit

Cap unit

Timing belt

PF roller

CR shaft A

PF encoder sensor

CR encoder

Figure 2-1. Printer Mechanism Outline

sensor

ASF/Pump

motor

linear

scale

ASF sensor

ASF sensor

wheel

LD roller shaft

LD roller

PE sensor

ASF/Pump

switching ring line

CR motor

Release lever

OPERATING PRINCIPLES Overview 40

Page 41

EPSON Stylus PHOTO 2100/2200 Revision B

2.2.1 Carriage Mechanism

The Carriage mechanism consists of the Carriage motor (CR motor), Carriage guide

shafts A (main shaft), B (sub shaft), Platen gap adjustment mechanism, Carriage lock

mechanism, and others.

2.2.1.1 Carriage Motor (CR Motor)

Like the one of the conventional Stylus PHOTO 2000P, the Carriage mechanism of

this product uses a DC motor as a drive source. The following indicates the Carriage

driving DC motor specifications.