Page 1

Color ink jet printer

EPSON Stylus PHOTO 2000P

®

SEIJ00003

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, el ectronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The conte nts o f this manual are sub je ct t o c hange w i t hout notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereo f.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective

owners. EPSON disclaims any and all rights in those marks.

Copyright © 2000 SEIKO EPSON CORPORATION. Printed in Japan.

2

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precaut i o n ary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO

THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

3

Page 4

PREFACE

This manua l des cri b es ba s ic fun ct i on s , theo ry of el ec t r ical and mechanical operations, maintenance and repair procedures of EPSON Stylus PHOTO 2000P. The

instructio ns and p roce dure s included herein ar e intended for the experienced repair technicians, and at ten t i o n should be given to the precautions on the preceding

page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector Summary

• EEPROM Address Map

• Circuit Board Component Layout

• Exploded Diagrams

• Parts List

• Electrical Board Circuit Diagrams

4

Page 5

Revision Status

Revision Issued Date Description

A May 11, 2000 First Release

B November 30, 2000

P.77 : Add empty cartridges for tool

P.90 : Revise the caution.

5

Page 6

Stylus PHOTO 2000P Revi si o n A

Contents

Chapter 1 Product Descriptions

1.1 General Characteristics .................................................................. 10

1.2 Printing specification ...................................................................... 11

1.2.1 Printing specification ................................................................. 11

1.2.2 Paper feeding ............................................................................ 11

1.2.3 Input data buffer ........................................................................ 12

1.2.4 Electric specification .................................................................. 12

1.2.5 Environmental condition ............................................................ 13

1.2.6 Reliability ................................................................................... 14

1.2.7 Safety Approvals ....................................................................... 14

1.2.8 Acoustic noise ........................................................................... 14

1.2.9 CE Marking ................................................................................ 14

1.3 Interface ............................................................................................ 15

1.3.1 Hardware interface .................................................................... 15

1.3.1.1 Parallel interface ................................................................. 15

1.3.1.2 Parallel Interface (Reverse Channel) ................................. 18

1.3.1.3 USB interface ..................................................................... 19

1.3.1.4 Prevention Hosts from Data Transfer Time-out .................. 20

1.3.1.5 Interface Selection .............................................................. 20

1.3.1.6 IEEE1284.4 protocol .......................................................... 20

1.4 Operator Controls ............................................................................ 21

1.4.1 Buttons ...................................................................................... 21

1.4.2 LED Indicators ........................................................................... 21

1.4.3 Panel Functions ......................................................................... 22

1.4.4 Special Setting Mode ................................................................ 22

1.4.5 Printer Condition and Panel Status ........................................... 23

1.4.6 Errors ......................................................................................... 23

1.4.7 Printer Initialization .................................................................... 24

1.5 Paper ................................................................................................. 25

1.5.1 Paper handling .......................................................................... 25

1.5.2 Paper specification .................................................................... 25

1.5.2.1 Cut Sheet ........................................................................... 25

1.5.2.2 Envelope ............................................................................ 25

1.5.2.3 EPSON special media ........................................................ 25

1.6 Printing area .................................................................................... 27

1.6.1 Cut Sheet .................................................................................. 27

1.6.1.1 Envelopes ........................................................................... 28

1.7 Ink cartridge ..................................................................................... 29

1.7.1 Black ink cartridge ..................................................................... 29

1.7.2 Color ink cartridge ..................................................................... 29

1.8 Physical specification ..................................................................... 30

Chapter 2 OPERATING PRINCIPLES

2.1 Overview .......................................................................................... 32

2.1.1 Printer Mechanism .................................................................... 32

2.1.2 Ink ............................................................................................. 33

2.1.2.1 Comparison between Pigment Ink and Dye Ink ................. 33

2.1.2.2 Drop of Pigment Ink and Dye Ink ....................................... 33

2.1.3 Printhead Mechanism ............................................................... 34

2.1.4 Carriage Mechanism ................................................................. 35

2.1.4.1 Carriage Motor (CR Motor) ................................................. 35

2.1.4.2 Platen Gap (PG) /Parallelism Adjustment Mechanism ....... 36

2.1.4.3 Carriage Home Position (HP) Detection ............................. 36

2.1.5 Paper Feeding Mechanism ....................................................... 36

2.1.5.1 CR Lock Mechanism .......................................................... 38

2.1.6 Paper Loading Mechanism ....................................................... 39

2.1.6.1 Drive Transmission to the ASF Unit ................................... 39

2.1.6.2 Paper Loading Operation ................................................... 40

2.1.6.3 Pump Mechanism ............................................................... 41

2.1.6.4 Capping Mechanism ........................................................... 42

2.2 Electrical Circuit Operating Principles .......................................... 43

2.2.1 C298PSB/PSE Board ................................................................ 43

2.2.1.1 Electrical Circuit .................................................................. 43

2.2.1.2 Protection Circuits .............................................................. 45

2.2.1.3 Power Supply Control Function .......................................... 45

6

Page 7

Stylus PHOTO 2000P Revi si o n A

2.2.1.4 Energy Save Mode ............................................................. 45

2.2.2 C304MAIN Board Circuit Operation Principles .......................... 46

2.2.2.1 Printhead Driver Circuit ...................................................... 48

2.2.2.2 Reset Circuit ....................................................................... 49

2.2.2.3 Motor Driver Circuit ............................................................ 49

2.2.2.4 ASF/Pump Motor Driver Circuit .......................................... 52

2.2.2.5 EEPROM Control Circuit .................................................... 53

2.2.2.6 Sensor Circuit ..................................................................... 53

Chapter 3 TROUBLESHOOTING

3.1 Overview ........................................................................................... 56

3.1.1 Self-Diagnostic Function ........................................................... 57

3.1.1.1 Troubleshooting with LED Error Indicators ......................... 57

3.1.1.2 Error Conditions ................................................................. 58

3.1.1.3 Remedies for Paper Out Error ............................................ 59

3.1.1.4 Remedies for the Paper Jam Error ..................................... 62

3.1.1.5 Remedies for No Ink Cartridge Error/Ink Cartridge Problem 62

3.1.1.6 Remedies for Maintenance Request Error ......................... 63

3.1.1.7 Remedies for Fatal Error .................................................... 64

3.1.2 Isolating the Faulty Part on the Power Supply Board ................ 67

3.1.3 Isolating the Faulty Part according to the Phenomenon ............ 69

3.2 FAQ ................................................................................................... 73

Chapter 4 DISASSEMBLY AND ASSEMBLY

4.1 Overview ........................................................................................... 76

4.1.1 Precaution for Disassembling the Printer .................................. 76

4.1.2 Tools .......................................................................................... 77

4.1.3 Specifications for Screws .......................................................... 78

4.1.4 Service Checks After Repair ..................................................... 79

4.2 Disassembly P rocedures ................................................................ 80

4.2.1 HOUSING Removal .................................................................. 81

4.2.2 Circuit Board Assembly Removal .............................................. 82

4.2.3 Panel Unit Removal ................................................................... 85

4.2.4 Printhead Unit Removal ............................................................ 87

4.2.5 TRAY, ABSORBER ASSEMBLY Removal ............................... 89

4.2.6 Ink Unit Removal ....................................................................... 91

4.2.7 MOTOR ASSEMBLY, CR Removal .......................................... 94

4.2.8 MOTOR ASSEMBLY, ASF Removal ........................................ 95

4.2.9 DE Unit Removal ....................................................................... 96

4.2.10 ASF Unit Removal ................................................................... 99

4.2.10.1 SHAFT, ROLLER, LD Removal ..................................... 101

4.2.10.2 ROLLER ASSEMBLY, LD, RIGHT/LEFT Removal ........ 106

4.2.11 Carriage Unit Removal .......................................................... 107

4.2.12 BOARD ASSEMBLY, ENCODER Removal .......................... 109

4.2.13 ROLLER, PF Removal .......................................................... 110

4.2.13.1 SCALE, PF Installation ................................................... 113

4.2.14 MOTOR ASSEMBLY, PF Removal ....................................... 116

4.2.15 PE Sensor Unit Removal ...................................................... 117

Chapter 5 ADJUSTMENT

5.1 Overview ........................................................................................ 119

5.1.1 Adjustment Items .................................................................... 119

5.1.2 Adjustment Tools .................................................................... 120

5.2 Adjustment ..................................................................................... 121

5.2.1 Parallelism Adjsutment ........................................................ 121

5.2.2 Backlash Adjsutment ............................................................ 123

5.2.3 Using the Adjustment Program ............................................... 125

5.2.3.1 About the Adjustment Program ........................................ 125

5.2.3.2 How to Install the Program ............................................... 125

5.2.3.3 How to Uninstall the Program ........................................... 125

5.2.3.4 Starting the Adjustment Program ..................................... 126

5.2.4 Head voltage ID input ........................................................... 126

5.2.4.1 Where to Find the Head ID ............................................... 126

5.2.4.2 Check Present Data ......................................................... 127

5.2.4.3 Change Data .................................................................... 127

5.2.5 Head angular adjsutment ..................................................... 128

5.2.6 Bi-Directional ad justment ..................................................... 130

5.2.7 USB ID check /input ............................................................... 132

5.2.7.1 Inputting/Checking the USB ID ......................................... 132

5.2.8 Head cleaning ........................................................................ 133

5.2.9 Initial ink charge .................................................................... 134

5.2.10 Protection counter check ................................................... 134

5.2.10.1 Check the Present Counter Value .................................. 134

5.2.10.2 Clear the Protection Counter Values .............................. 135

5.2.11 C SIC inf o rmat ion ................................................................. 136

7

Page 8

Stylus PHOTO 2000P Revi si o n A

5.2.12 Print A4 pattern ................................................................... 137

5.2.12.1 Recovery Routine ........................................................... 137

Chapter 6 MAINTENANCE

6.1 Overview ......................................................................................... 139

6.1.1 Cleaning .................................................................................. 139

6.1.2 Service Maintenance ............................................................... 139

6.1.2.1 Head Cleaning .................................................................. 139

6.1.2.2 Paper Eject Roller Cleaning ............................................. 140

6.1.2.3 ASF Roller Cleaning ......................................................... 141

6.1.2.4 Maintenance Request Error Clear .................................... 142

6.1.3 Lubrication ............................................................................... 142

Chapter 7 APPENDIX

7.1 Connector Summary ..................................................................... 149

7.1.1 Connector Pin Assignment ...................................................... 149

7.2 EEPROM Address Map ................................................................. 153

7.3 Circuit Board Component Layout ................................................ 157

7.4 Exploded Diagrams ....................................................................... 160

7.5 Parts List ........................................................................................ 168

7.6 Electrical Circuit Board Diagrams ............................................... 174

8

Page 9

PRODUCT DESCRIPTIONS

CHAPTER

Page 10

EPSON Stylus PHOTO 2000P Revision A

1.1 General Characteristics

High color print quality

- 2880 (H) x 720 (V) dpi printing

- 6 color printing (YMCK)

- Traditional and New Microweave

- Pigment Ink supported

Built- i n auto sheet feeder

- A3+paper supported

- Holds 100 cut-sheets (64 g/m

- Holds 10 envelopes

- Holds 30 transparency films

Built-in 2 I/F

- Bi-directional parallel I/F (IEEE-1284 level 1 device)

- USB

Windows/Macintosh exclusive

2

)

Product Descriptions General Characteristics 10

Page 11

EPSON Stylus PHOTO 2000P Revision A

Typeface : Bit map L Q font

1.2 Printing specification

- EPSON Courier 10 CPI

1.2.1 Printing specification

P rin t m e th od : O n d em a nd in k jet

Nozzle Configuration : 48 nozzles x 6 colors

(Black, Cyan, Magenta, Yellow,

Light-Cyan, Light-Magenta)

Print direction: Bi-direction with logic seeking

Print speed & Printable columns

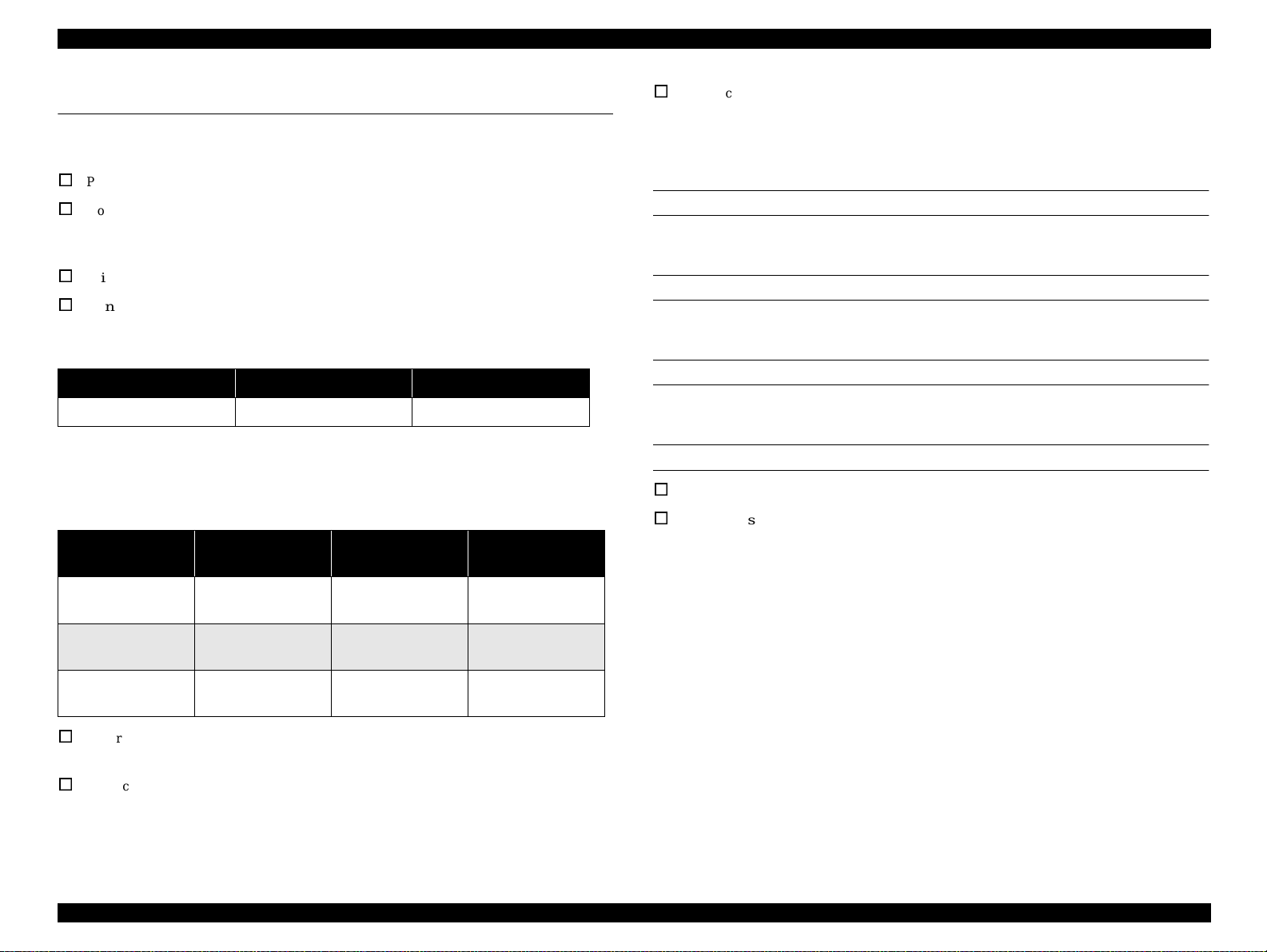

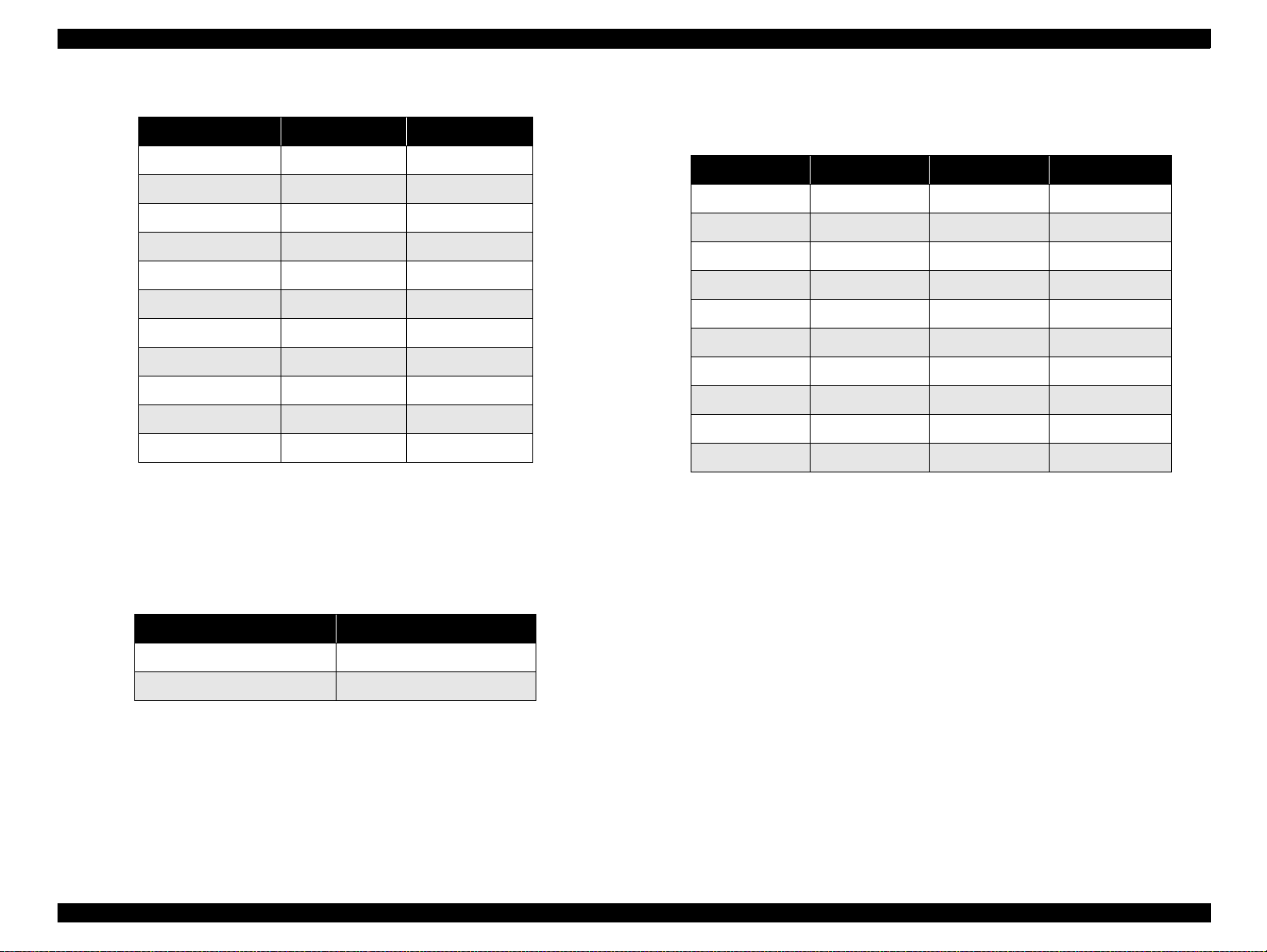

Table 1-1. Character Mode

Character pitch Printable columns LQ speed

10 CPI (Pica) 127 238 CPS**

* Do not mention in the user’s manual.

** This value i s the speed of normal-dot printing.

Table 1-2. Raster Graphic Mode

Horizontal

resolution

180 dpi 322.986mm(12.716

Printable area Available dot CR Speed

2289 60.452/48.26cm/

inch)

s(23.8/19 IPS)

1.2.2 Paper feeding

Feeding Method

Friction feed with ASF

Line Spacing

Programmable by 1/6” or 1/360” step

Paper Path

Cut-sheet ASF (Top entry Front out)

Feed Speed

110msec (10.16 mm feed)

152.4mm/sec (6.0 inch/sec) (Fast, continuous feed)

360 dpi 322.986mm(12.716

inch)

720 dpi 322.986mm(12.716

inch)

Control code : ESC/P Raster comm and

: E P S O N R e mo te c om m an d

C h ar ac ter ta b le s : 2 in te rn atio n al c ha ra cte r se ts

- PC 437 (US, Standard Europe)

- P C 85 0 (M u ltilingual)

4578 60.452/48.26cm/s

(23.8/19 IPS)

9156 48.26cm/s(19 IPS)

Product Descriptions Printing specification 11

Page 12

EPSON Stylus PHOTO 2000P Revision A

ASF Hopper Specification

Paper size

90mm x 205mm ~ A3+

Thickness

8mm or less

Number of sheets

Table 1-3. Hopper Capacity

Paper Type Size Sheets

2

Plain paper (65g/m

Envelope See “Pape r specifica ti on” on

Premium Semigloss Photo Paper A3+, A3, A4, Letter, US B 1 sheet

Glossy Paper-Photo Weight A3+, A3, A4, Letter, US B 1 sheet

Archival Matte Paper A4, Letter 1 sheet

Wat er color Paper-Radi ant Whit e A3+ 1 she et

Super Fine A3+, A3, A4 approx. 65 sheets

) A4, A3, Letter, Legal approx. 100 sheets

10 sheets

page -25

A3, A3+, US B 20 sheet

Stacker Capacity

NOTE: The figures in the table is measured in the normal room condition.

Table 1-4. Stacker Capacity

Paper Type Print Type Stacker Capacity

Plain paper Text 30 sheet or more

Graphics 20 sheet or more

Envelope Text 10 sheet or more

Archival Matte Paper Graphics 10 sheet or more

Super Fine Graphics 10 sheet or more

Other special paper Graphics 1 sheet o r m or e

1.2.3 Input data buffer

: 256KB

1.2.4 Electric specification

120 V version

Rated voltage: AC 120 V

Input voltage range: AC 99 - 132 V

Rated frequency range: 50 - 60 Hz

Input frequency range: 49.5 - 60.5 Hz

Rated current: 0.4A

Power consumption: Approx. 1815W (ISO10561 Letter Pattern)

Approx. 3.5W in standby mode

Energ y Star c o m pliant

Insulation Resistance: 10 M ohms min.

(between AC line and chassis, DC 500 V)

Product Descriptions Printing specification 12

Page 13

EPSON Stylus PHOTO 2000P Revision A

Dielectric strength: AC 1000 V rms. 1 minute or

AC 1200 V rms. 1 second

(between AC line and chassis)

220-240 V version

Rated voltage: AC 220 - 240 V

Input voltage range: AC 198 - 264 V

Rated frequency range: 50 - 60 Hz

Input frequency range: 49.5 - 60.5 Hz

Rated current: 0.2A

Power consumption: Approx. 1815W (ISO10561 Letter Pattern)

Approx. 3.5W in standby mode

Energy Star compliant

Insulation Resistan ce : 10 M ohms min.

(between AC line and chassis, DC 500 V)

Dielectric s trength : AC 1500 V rms. 1 minute

(between AC line and chassis)

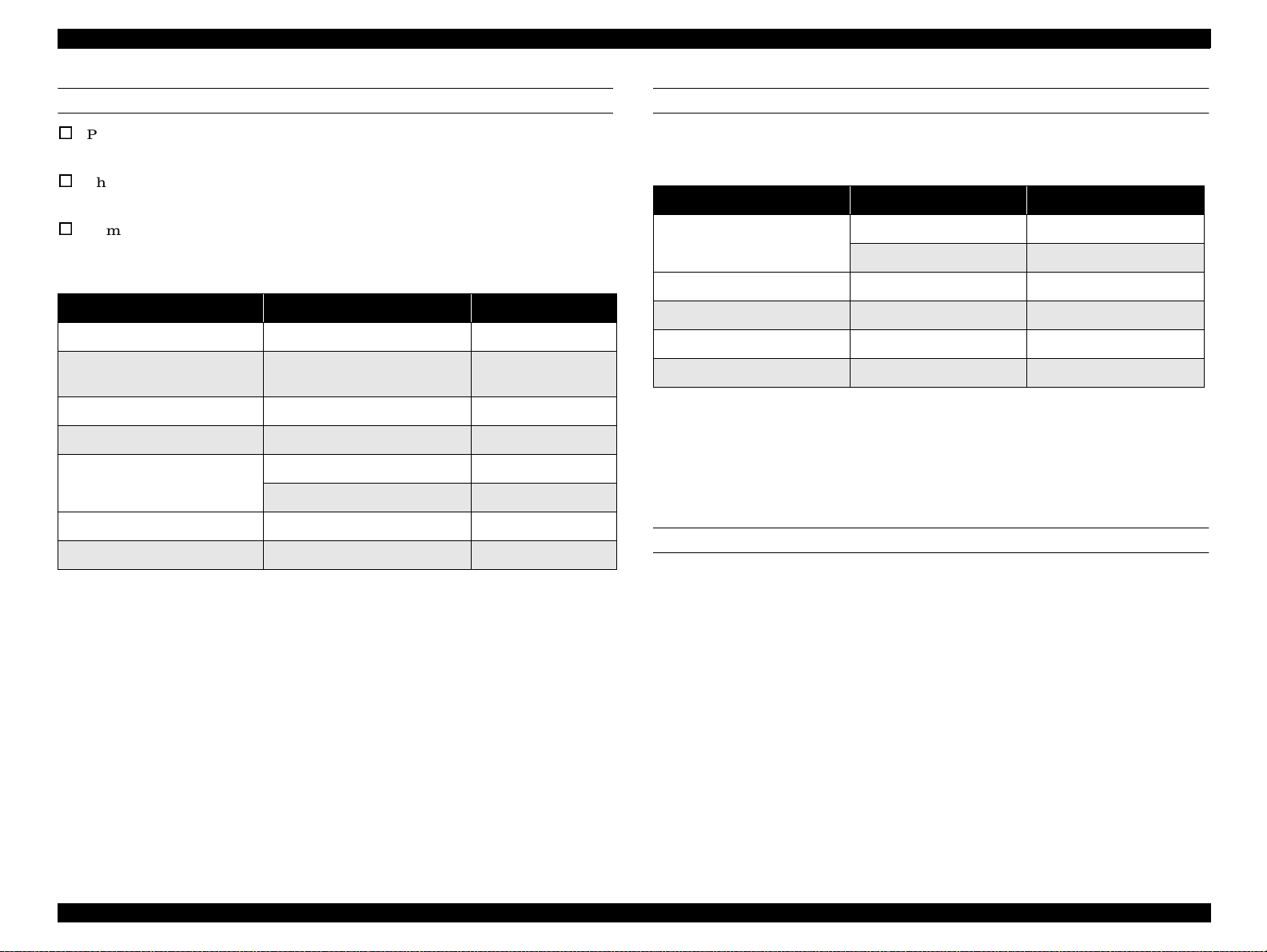

1.2.5 Environmental condition

Temperature : 10 to 35 °C (operating *3)

: -20 to 60

1 month at 40

120 hours at 60

Humidity : 20 to 80% RH (operating, *2,*3)

: 5 to 85% RH (non-operating, *1, *2)

Resistance to shock: 1 G, within 1 ms (operating)

: 2 G, within 2 ms (non-operating, *1)

Resistance to vibration: 0.15G (operating)

: 0.50G (non-operating, *1)

NOTE: *1: with shipment container

*2: without condensation

*3: Condition is as following figure.

C (non-operating, *1)

°

C

°

C

°

90

80

70

60

H u mid ity (% )

50

40

30

20

10

27

20

35

30

40

Temperature (°C)

Figure 1-1. Environmental Condition

Product Descriptions Printing specification 13

Page 14

EPSON Stylus PHOTO 2000P Revision A

1.2.6 Reliability

Total p r in t volume : 25,000 pages(Blac k) /10,000 pages(Color) (A4, Letter)

Print H ead Lif e : 3000 mil l ion dots/nozzle

1.2.7 Safety Approvals

120 V version:

Safety standards : UL1950

CSA22.2 No.950

EMI : FCC part15 subpart B class B

CSA C108.8 class B

220-240 V version:

Safety standards : EN 60950(VDE)

EMI : EN 55022(CISPR Pub.22) class B

: AS/NZS 3548 class B

1.2.8 Acoustic noise

Level : Approx. 42 dB(A) (According to ISO 7779)

1.2.9 CE Marking

220-240 V version

Low Voltage Di rective 73/23/EEC: EN60950

EMC Directive 89/336/EEC: EN55022 class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Product Descriptions Printing specification 14

Page 15

EPSON Stylus PHOTO 2000P Revision A

1.3 Interface

1.3.1 Hardware interface

This printer provides USB and parallel in terface as standard.

1.3.1.1 Parallel interface

Transm ission mo de : 8 bit parallel, IEEE-1284 compat i bility m od e

Synchronization : By STROBE pulse

Handshaking : By BUSY and ACKNLG signal

Signal level : TTL compatible level

Adaptable connector : 57-30360(amphenol) or equivalent

BUSY sign al is set high before setting eit h er - E R R OR low or PE high and held high

until all these signals return to their inactive state.

BUSY signal is at hi gh level i n the follo wing cases.

-Duri ng data entry (s e e Data transmission timing)

-When input data buffer is full

-During -INIT signal is at low level or during hardware initialization

ERROR signal is at low level when the printer is in one of the following states.

-Printer hardware error (fatal error)

-Paper-out error

-Paper-jam error

-Ink-out error

PE signal is at high level during paper-out error.

Data transmission timing

DATA

-STROBE

BUSY

-

tready

setup

t

data byte n

hold

t

t

busy

treply

stb

t

tack

data byte n+1

tnext

tnbusy

-During printer error (See -ERROR signal)

-When the parallel interface is not selected

Product Descriptions Interface 15

Page 16

EPSON Stylus PHOTO 2000P Revision A

Table 1-5. Parameters

Parameter Minimum Maximum

tsetup 500ns -

thold 500ns -

tstb 500ns -

tready 0 -

tbusy - 500ns

*1

tt-out

*2

tt-in

treply 0 -

tack 500ns 10us

tnbusy 0 -

tnext 0 -

- 120ns

- 200ns

*1:Rise and fall time of every output signal.

*2:Rise and fall time of every input signal.

T yp ica l timi ng f or t a ck is s hown belo w.

Signal Level: TTL Compatible (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5V

VOL* -0.5V -

IOH* - 0.32mA VOH = 2.4V

IOL* - 12mA VOL = 0.4V

CO - 50pF

VIH - 2.0V

VIL 0.8V -

IIH - 0.32mA VIH = 2.0V

IIL - 12 m A VIL = 0.8V

CI - 50pF

* A low logic level on the Logic H signal is 2.0V or less when the printer is p o w ere d off,

and this signal is equal to or exceeding 3.0V when the printer is powered on. The

receiver shall provide an impedance equivalent to 7.5K ohm to ground.

Table 1-7.

Table 1-6. Typical Time of Tack

Parallel I/F Mode Typical Time of tack

High Speed 0.5us

Normal Speed 2us

Product Descriptions Interface 16

Page 17

EPSON Stylus PHOTO 2000P Revision A

NOTE: In/Out ref ers to the direction of signal flow seen from the printer sid e.

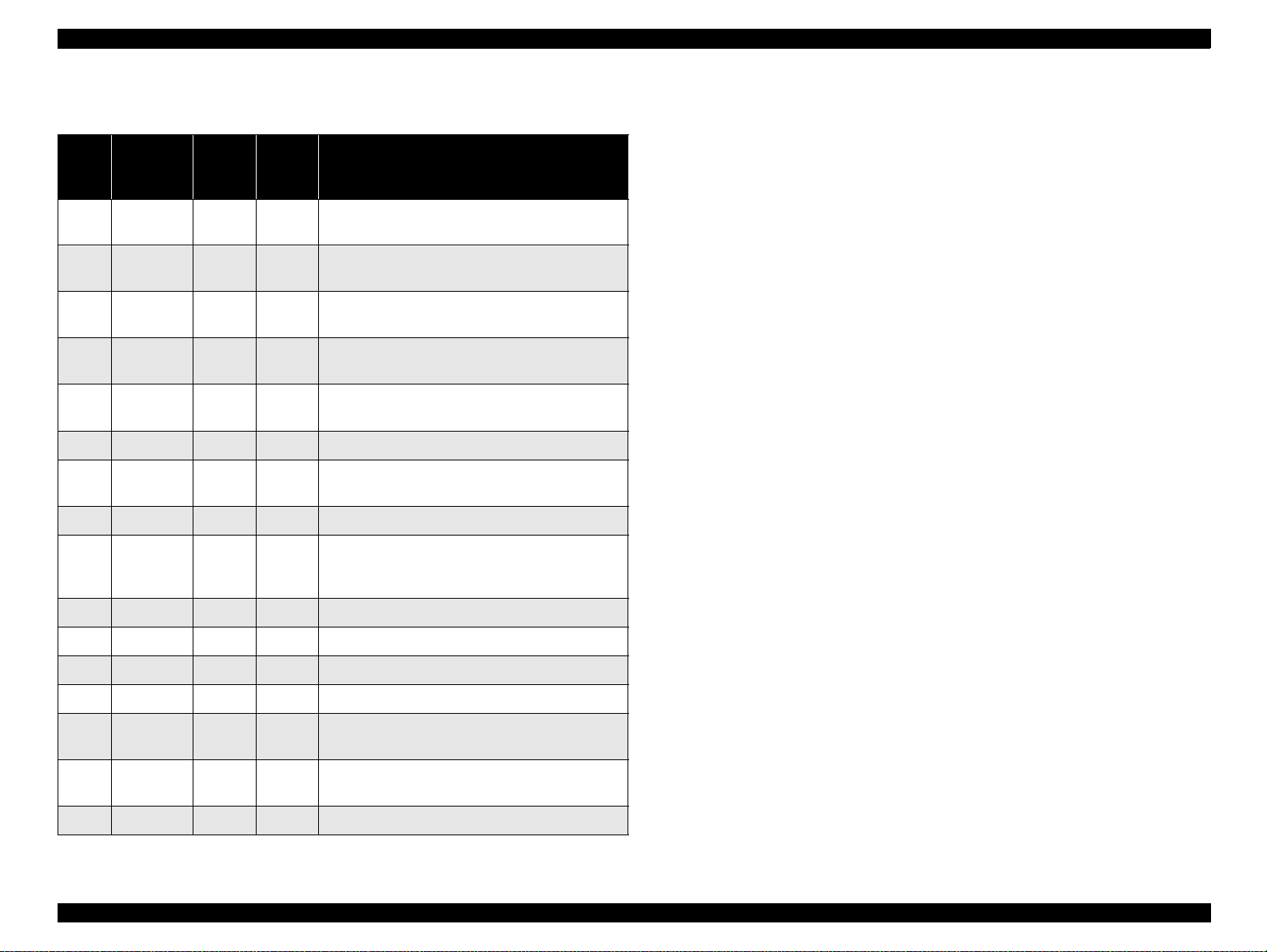

Table 1-8. Connector Pin Assignment and Signals

Pin

No.

1 -STROBE 19 In The strobe pulse. Read-in of data is performed at

2 DATA0 20 In The DATA0 through DATA7 signals represent

3 -9 DATA1-7 21-27 In Each signal is at high lev e l w hen data is lo gical 1

10 -ACKNLG 28 Out This signal is a negative pulse indicating that the

11 BUSY 29 Out A high signal indicates that the printer cannot

12 PE 28 Out A high signal indicates paper-out error.

13 SLCT 28 Out Always at high level when the printer is powered

14 -AFXT 30 In Not used.

31 -INIT 30 In The falling edge of a negative pulse or a low signal

32 -ERROR 29 Out A low signal indicates printer error condition.

Signal

Name

Return

GND

pin

In/Out Functional description

the falling edge o f this pulse.

data bi ts 0 to 7 , re sp ectively.

and low le vel when data is log ical 0.

printe r can ag ai n accept da t a .

receive data .

on.

on this line causes t he p rinter to initialize.

Minimum 50 us pulse is necessary.

36 -SLIN 30 In Not used.

18 Logic H - Out Pulled up to +5 V via 3.9 K ohm resistor.

35 +5V - Out Pulled up to +5 V via 3.3 K ohm resistor.

17 Chassis

GND

16, 33

19-30

15, 34 NC - - Not connected.

GND - - Signal GND.

- - Chassis GND.

Product Descriptions Interface 17

Page 18

EPSON Stylus PHOTO 2000P Revision A

1.3.1.2 Parallel Interface (Reverse Channel)

Transmission mode : IEEE-1284 nibble mode

Adaptable connector : See forw ard channel

Synchronization : Refer to the IEEE-1284 specification

Handshaking : Refer to the IEEE-1284 specification

Data trans. timing : R efer to the IEEE-1284 specification

Signal level : IEEE-1284 level 1 device

Se e forward ch ann el

Table 1-9. Connector pin assignment and signals

Pin

No.

Signal Name

1 HostClk 19 In Host clock signal.

2 DATA0 20 In The DATA0 through DATA7 signals

3 DATA1 21 In respectively.

4 DATA2 22 In Each signal is at high level when data is

Return

GND

Pin

In/

Out*

Functional description

represent data bits 0 to 7,

logi ca l 1 an d lo w le ve l w h en

Table 1-9. Connector pin assignment and signals

Pin

No.

12 AckDataReq /

13 Xf lag / DataB it-

14 HostBusy 30 In Host busy signal.

31 -INIT 30 In Not used.

32 -DataAva il /

36 1284-Active 30 In 1284 active signal.

18 Logic-H - Out Pulled up to +5 V via 3.9 K ohm resistor.

35 +5V - Out Pulled up to +5 V via 3.3 K ohm resistor.

17 Chassis GND - - Chassis GND.

16, 33

19-30

15, 34 NC - - Not connected.

NOTE: In/Out ref ers to the direction of signal flow seen from the printer sid e.

Signal Name

DataBit-2,6

1,5

DataBit-0,4

GND - - Signal GND.

Return

GND

Pin

28 Out Acknowledge data req ues t sign al and revers e

28 Out X-flag signal and reverse channel transfer

29 Out Data available signal and reverse channel

In/

Out*

Functional description

channe l transfe r da ta bit 2 or 6 .

data bit 1 or 5.

transfer data bit 0 or 4.

5 DA T A 3 23 In da ta is logical 0.

6 DATA4 24 In These signals are used to transfer the 1284

extens ib ility reque st values

7 DATA5 25 In to the printer.

8 DATA6 26 In

9 DATA7 27 In

10 PtrClk 28 Out Printe r clock sig na l .

11 PtrBusy /

DataBit-3,7

29 Out Prin t e r busy sign al and re v erse channe l

trans fer data bit 3 or 7 .

Product Descriptions Interface 18

Page 19

EPSON Stylus PHOTO 2000P Revision A

Extensibility Request

The printer responds affirmatively when the extensibility request values are 00H or

04H,

00H : Request Nibble Mode Reverse Channel Transfer.

04H : Request Device ID;

Return Data Using Nibble Mode Rev Channel Transfer.

Device ID

World Standard Model

The printer sends following device ID string when it is requested.

When IEEE1284.4 is enabled,

[00H] [5CH]

MFG:EPSON;

CMD:ESCPL2,BDC,D4;

MDL:Stylus[[SP]Photo[SP]2000P;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]Photo[SP]2000P;

1.3.1.3 USB interface

Standard : based on

“Universal Serial Bus Specifications Revision 1.0”

“Universal Se rial Bus Device Class Definition for

Printing Devices Version 1.0”

Bit rate : 12Mbps (Full Speed Device)

Data encoding : NRZI

Adaptable connector : USB Series B

Recommended cable length: 2 meters

Table 1-10. Connector pin assignment and signals

Pin No.

1 VCC - Cab l e power. Ma xi m u m p o w er cons umptio n is

2 -Data bi-directional data

3 +Data bi-directional data, pull up to +3.3V via 1.5K ohm resistor

4 Ground - Cable ground

Signal

name

In/Out Function description

2mA

When IEEE1284.4 is disabled,

[00H] [59H]

MFG:EPSON;

CMD:ESCPL2,BDC;

MDL:Stylus[SP]Photo[SP]2000P;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]Photo[SP]2000P;

Pin #2

Pin #3

Pin #1

Pin #4

Figure 1-2. USB Pin Assignment

Product Descriptions Interface 19

Page 20

EPSON Stylus PHOTO 2000P Revision A

1.3.1.4 Prevention Hosts from Data Transfer Time-out

Generall y, hosts a bandon data transfer to peripherals when a peripheral is in the busy

state for dozens of seconds continuously. To preve nt hosts from this kind of time-out ,

the printer receives data very s l owly, several by tes per minute , even if the printer is in

busy state. This slowdown is started when the rest of the input buffer becomes several

hundreds of bytes. Finally, the printer is in the busy state continuously when the input

buffer is full.

USB and IEEE1284.4 on the parallel interface do not require this function.

1.3.1.5 Interface Selection

The printer has 2 built-in interfaces; the USB and parallel interface.

These interfaces are selected automatically.

- Automatic selection

In this au to matic in ter fa ce se lec tio n mo d e , th e p r in ter is initia liz e d to th e idle sta te

scanning which interface receives data w hen it is po wered on. Then the interface that

receives data first is selected. When the host stops data tra n sfer and the printer is in th e

sta nd -b y sta te fo r the s ec o nd s , th e pr inte r is re tu rn ed to th e id le s ta te. As lo n g a s th e

h os t se nd s d ata o r th e p rin te r in ter fa ce is b u sy s tate , th e s ele c ted in te rfa ce is let a s it i s.

- Inte rface state and interface selection

Wh en the p arallel interface is not selected, the interface got in to th e b u sy state . W h en

th e p rin te r is initia lize d o r re tu rn ed to th e id le s ta te, th e p ara lle l inte rfa c e got into t he

ready state. Caution that the interrupt signal such as the -INIT signal on the parallel

interface is no t effective w hile that interface is not selected.

1.3.1.6 IEEE1284.4 protocol

The packet protocol described by IEEE1284.4 standard allows a device to carry on

multiple exchange s or conversations which contain data and/or control information

with another devic e at the same ti me across a singl e point-t o-point l in k. The protocol is

not, however, a device control language. It does provide basic transp ort-level flow

control and multip lexing s ervic es. The multipl exed log ic al cha nnels are inde penden t of

each other and blocking of one has no effect on the others. The protocol operate over

IEEE1284.

Automatic selection

A n initial sta te is c o m pa tib le inte rfac e a n d starts IEEE1284.4 comm unication when

m agic strings (1284.4 synchronous comm ands) are received.

On

An initial s ta te is IEE E1284.4 comm unication and data that received it by the time it is

able to take synchronization by m agic string (1284.4 synchronous com mands) is

discarded.

Off

A n initial sta te is c o m pa tible inte rfac e a n d ne ve r starts IE E E1 2 84 .4 co m m u n ica tion

even if m agic strings (1284.4 synchronous commands) are received.

Product Descriptions Interface 20

Page 21

EPSON Stylus PHOTO 2000P Revision A

1.4 Operator Controls

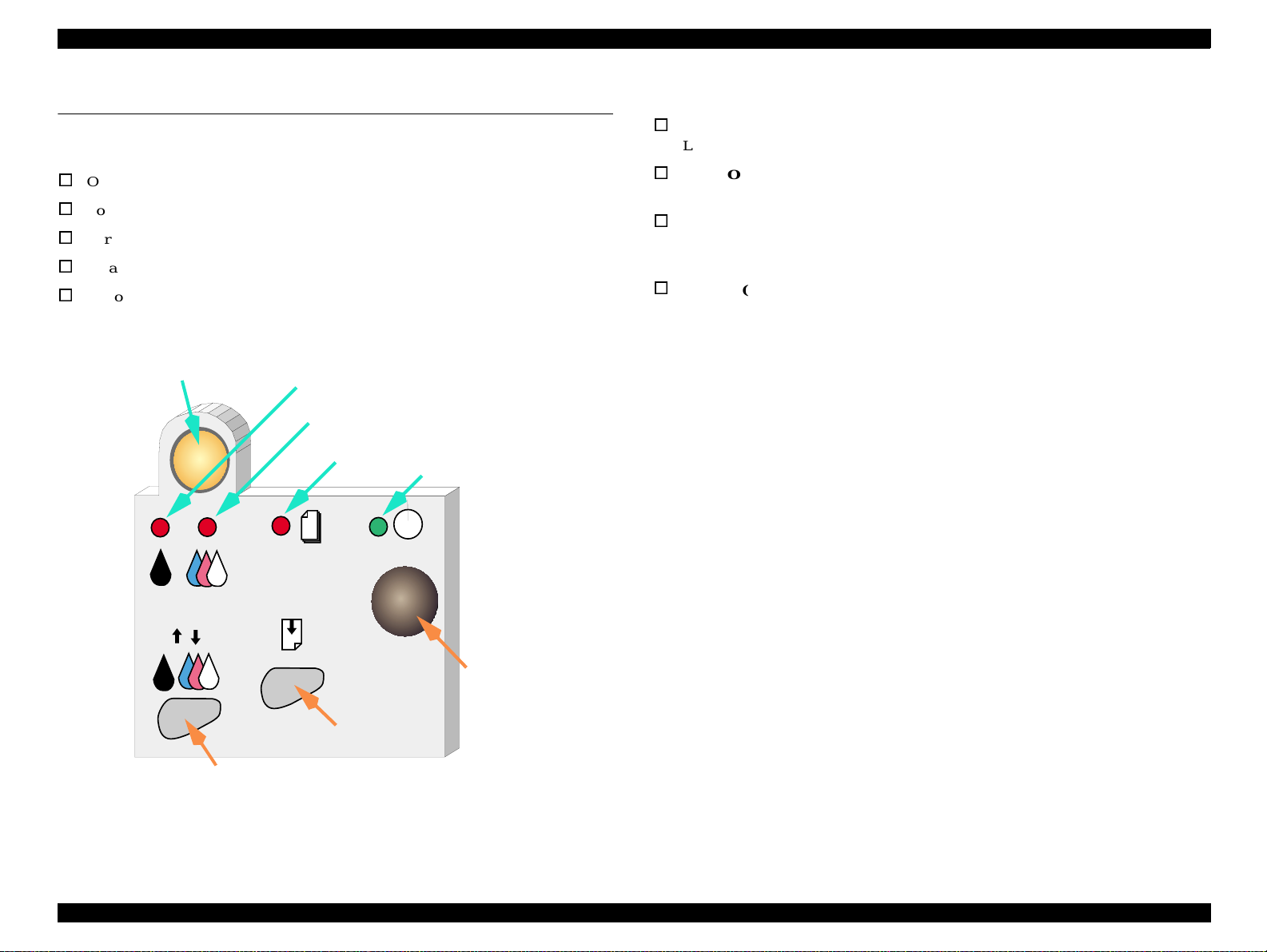

1.4.1 Buttons

Oper a ting butto n

Load/Eject button

Cartridge repl acement button

Cleaning

Button

Ink Cartridge Replacement Button

Ink Out (Black) LED

Ink Out (Color)LED

Paper Out L ED

Power LED

1.4.2 LED Indicators

Power

Lights when the power switch is “ON” and AC power is supplied.

Paper Out

Lights during the pape r out condition, and blink s during the paper jam condition.

Ink Out (Black)

Lights during no black ink condition, and blinks during the black

ink low condition.

Ink Out (Color)

Lights during no color ink condition, and blinks during the color ink low

condition.

Power Button

Load/Eject Button

Cleaning Butt o n

Product Descriptions Operator Controls 21

Page 22

EPSON Stylus PHOTO 2000P Revision A

1.4.3 Panel Functions

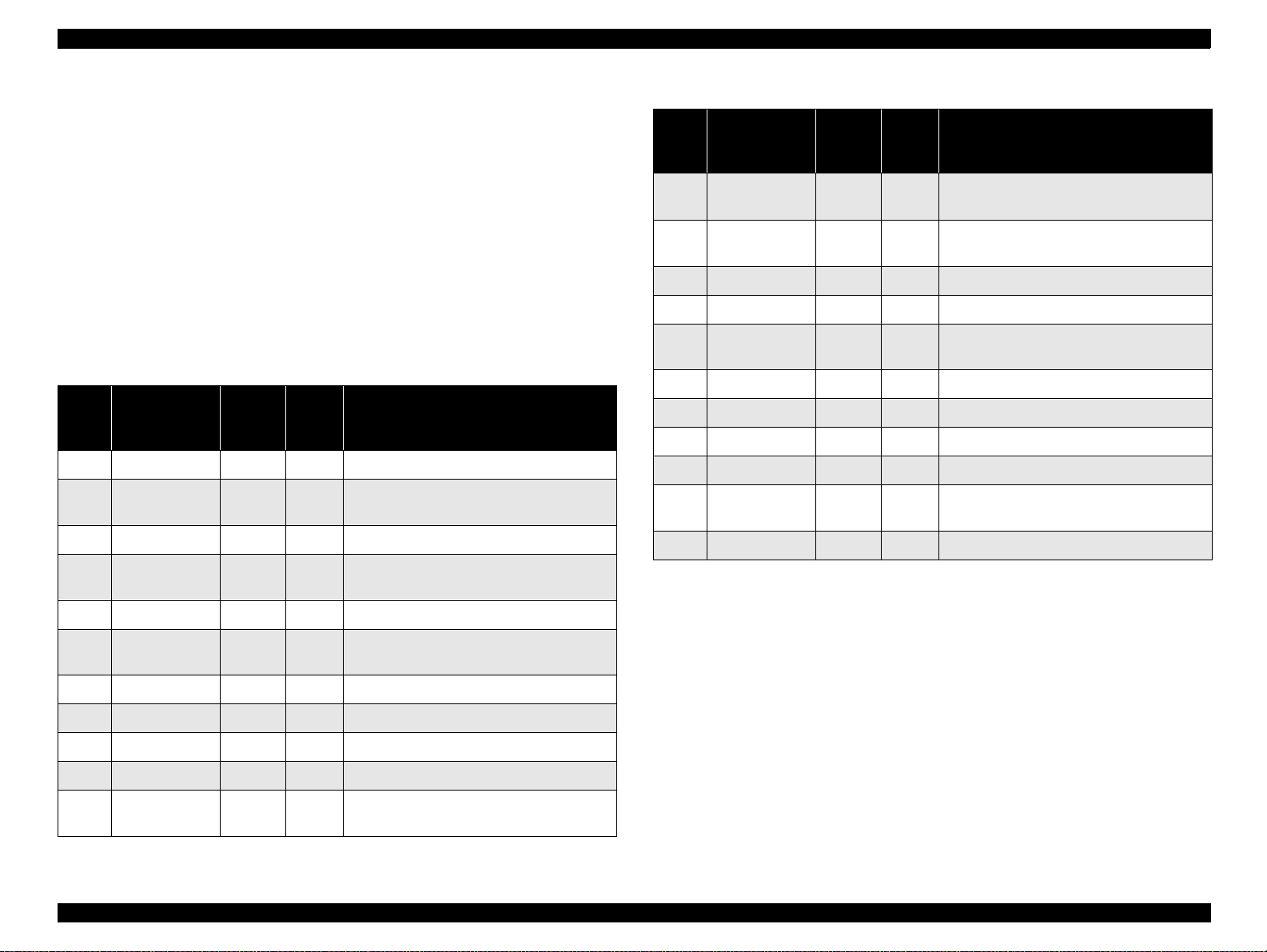

Table 1-11. Panel Functions

Buttons Function

Load / Eject

Ink Cartridge

Replacement

Cleaning

(Push for 3 secon d s)

Table 1-12. Power-on Panel Functions

Switch Pressing with Power On Function

Load / Eject • Starts status printing.

Cleaning

Load/Eject + Cleaning • Enters the special settings mode. (Factory use only).

• Loads or ejects paper.

• Return s th e pr inthead f rom the ink c ar t r id ge

replacement position to the capping position.

• Starts the ink cartridge replacement sequence.

• Moves the carriage to the cartridge replacement

position.

• Returns the car ri age from the ink cart ri dge repl ace ment

position.

• Starts a head cleaning.

• In the condition of “Ink Low”, “Ink Out”, or “N o Ink

Cartridge”, start s t he ink ca rtridge replacement

sequence.

• Returns the car ri age from the ink cart ri dge repl ace ment

position.

*1

• Changes code pages / Selects IEEE1284.4 mode for

parallel I/F.

*2

Table 1-13. Content of 1BH of EEPROM

[bit7] [bit6] Actions

00

*1

11

01

10

Print firmware version, ink counter, selected code

page an d nozzle chec k pattern.

Hex-dump mode

Self test mode

*1:Factory default setting

1.4.4 Special Setting Mode

To enter the special setting mode, press Load/Eject button and Cleaning button while

turning on the printer. The Paper Out L ED starts blinking. While it is blinking (for

three seconds), press the s pecified butt on to activate the desirable set ting mode.

NOTE: Special setting modes are not intended for users.

Table 1-14. Special Setting Modes

Switch Function

Load / Eject • Resets EEPROM and timer IC.

Cleaning

(Push for 10 seconds)

EEPROM/Timer IC reset

*3

T he follo win g is r eset w ith this op era tio n:

• Resets the ink overflow counter in EEPROM.

Interface sele cti on (04H)

*1:One of the actio ns in Table 1-13 is carr ied out accord ing to the content of

1BH of EEPRO M.

Power off timer (6CH, 6DH)

*2:Not in ten ded for users.

Waste ink counter reset

*3:See Section 1.4.4. (Not intended for users.)

T he follo win g is r eset w ith this op era tio n:

Ink counter A0 (50H, 5DH)

Ink counter A80 (5EH, 5FH)

Product Descriptions Operator Controls 22

Page 23

EPSON Stylus PHOTO 2000P Revision A

1.4.5 Printer Condition and Panel Status

Table 1-15 shows various errors and printer status.

Table 1-15. Printer Condition and Panel Status

Indicators

Printer Status

Power on condition On -- -- -- 9

Ink sequence Blinks -- -- -- 6

Ink cartridge replacement mode Blinks -- -- -- 5

Data proces sing Blinks -- -- -- 8

Paper out -- -- -- On 4

Paper jam condition -- Of f Off Blinks 3

No ink cartridge or ink end

(black)

Ink leve l low (b la ck ) -- Blinks -- -- 7

No ink cartridge or ink end

(color)

Power

-- On -- -- 7

-- -- On -- 7

Ink Out

(Black)

Ink Out

(Color)

Paper

Out

Priority

1.4.6 Errors

Ink out

When the printer runs out most of the ink of any co lor, it warns of an ink low condition

and keeps printing. When the ink cartridge is completely empty, t he printer stops

printing and generates I nk out error. In this condition , the ink cartridge must be

replaced with a new one. Not e an ink cartridge that is once taken out must not be used

again. Reinstalling of ink cartridges whose ink level is not full upsets the ink level

detection and may cause serious problems in the printheads.

Paper out

When the printer fails to load a sh eet of paper, it goes int o the Paper Out error

condition.

Paper jam

When the printer fails to eject a sheet of paper, it goes into the Paper Jam error

condition.

No ink cartridge

Ink le vel lo w ( c olor) -- -- Blinks -- 7

Enter EEPROM and Timer IC

reset

Maintenance request Blinks Blinks Blinks Blinks 2

Fatal error Blinks On On Blinks 1

-- On (for one second only) -

When the printer detects that an ink cartridge is missing, it goes into the No Ink

Cartridge error condition.

Maintenance request

When the total quantity of waste ink collected during cleanings and flushing reaches

the limit, printer indicates the Maintenance Request error and stops printing. The

NOTE: “--” means “no effect”.

absorber must be replaced by a service person.

Fatal errors

When the printer detects a carriage control error or CG access error, it goes into a fatal

error condition.

Product Descriptions Operator Controls 23

Page 24

EPSON Stylus PHOTO 2000P Revision A

1.4.7 Printer Initialization

There are three kinds of initialization methods as explained below:

1. Power on initialization

It perfor ms the foll ow ing wh en the printer is turned on or the pri nt er recogni zes

the cold res et command (re mote RS comman d):

(a) Initia liz es p rin ter m e c ha n ism .

(b) C lears inp u t d ata b uff er.

(c) C le ars prin t bu ffe r.

(d ) S ets de fau lt va lu es.

2. Panel initialization

Performed if the printer is turned off and back on within 10 seconds or /INIT

signal is input. It performs the following:

(a) C ap th e p rin te r h e ad .

(b) E jec t a p ap er.

(c) Clears input data buffer.

(d) C le ars print b uffe r.

(e) S ets de fa u lt v alu e s.

3. Software initia lization

The ESC@ command also initializes the printer. It performs the following:

(a) C le ars prin t bu ffe r.

(b ) S ets de fau lt va lu es.

Product Descriptions Operator Controls 24

Page 25

EPSON Stylus PHOTO 2000P Revision A

1.5 Paper

1.5.1 Paper handling

Do not perform reverse feed more than 9.5 mm(0.38”).

1.5.2 Paper specification

1.5.2.1 Cut Sheet

Size: A3 (297mm x 420mm)

A4 (210mm x 297mm)

A5 (148mm x 210mm)

A6 (105mm x 148mm)

B (2 79 mm x 432 mm)

B4 (257mm x 364mm)

B5 (182mm x 257mm)

Letter (216mm x 279mm)

1.5.2.2 Envelope

Size: #10 (241.3mm x 104.8mm)

DL (220mm x 110mm)

C6 (162mm x 114mm)

220x132 (220mm x 132mm)

Quality: Bond paper, PPC, Air mail

Weight: 45g/m

NOTE: Envelope printing is only available at normal temperature.

NOTE: Keep the longer side of the envelope horizontally at setting.

2

~ 75g/m2 (12 lb ~ 20 lb)

1.5.2.3 EPSON special media

Quality: EPSON specifically designed media for pigment

ink jet printers

(1) Glossy Paper - Photo Weight

Size: A3+ (329mm x 483mm)

A3 (297mm x 420m m)

Half letter (139.7mm x 215.9mm)

Legal (216mm x 356mm)

Executive (184.2mm x 266.7mm)

Quality: Plain paper, Bond paper

Thickness: 0.08mm ~ 0.11mm (0.003 ~ 0.004 inch)

2

Weight: 64g/m

~ 90g/m2 (17 lb ~ 24 lb, 55kg ~ 78kg)

(2) Premium Semigloss Photo

Size: A3+ (329mm x 483mm)

A4 (210mm x 297m m)

A3 (297mm x 420m m)

A4 (210mm x 297m m)

Letter (216mm x 279mm) (only for EAI)

B (only for EAI)

Roll paper

width: 89mm, 100mm, 210mm, 329mm

Product Descriptions Paper 25

Page 26

EPSON Stylus PHOTO 2000P Revision A

(3)Archival Matte Paper

Size: A3+ (329mm x 483mm)

A3 (297mm x 420mm)

A4 (210mm x 297mm)

Letter (216mm x 279mm)

B

Roll paper

width: 89mm, 100mm

(4)Water Paper - Radiant White

Size: A3+ (329mm x 483mm)

(5) Ink Jet Transparencies

Size: A4 (210mm x 297mm)

Letter (216mm x 279mm)

(6) Photo Quality Glossy Film

Size: A4 (210mm x 297mm)

Letter (216mm x 279mm)

Product Descriptions Paper 26

Page 27

EPSON Stylus PHOTO 2000P Revision A

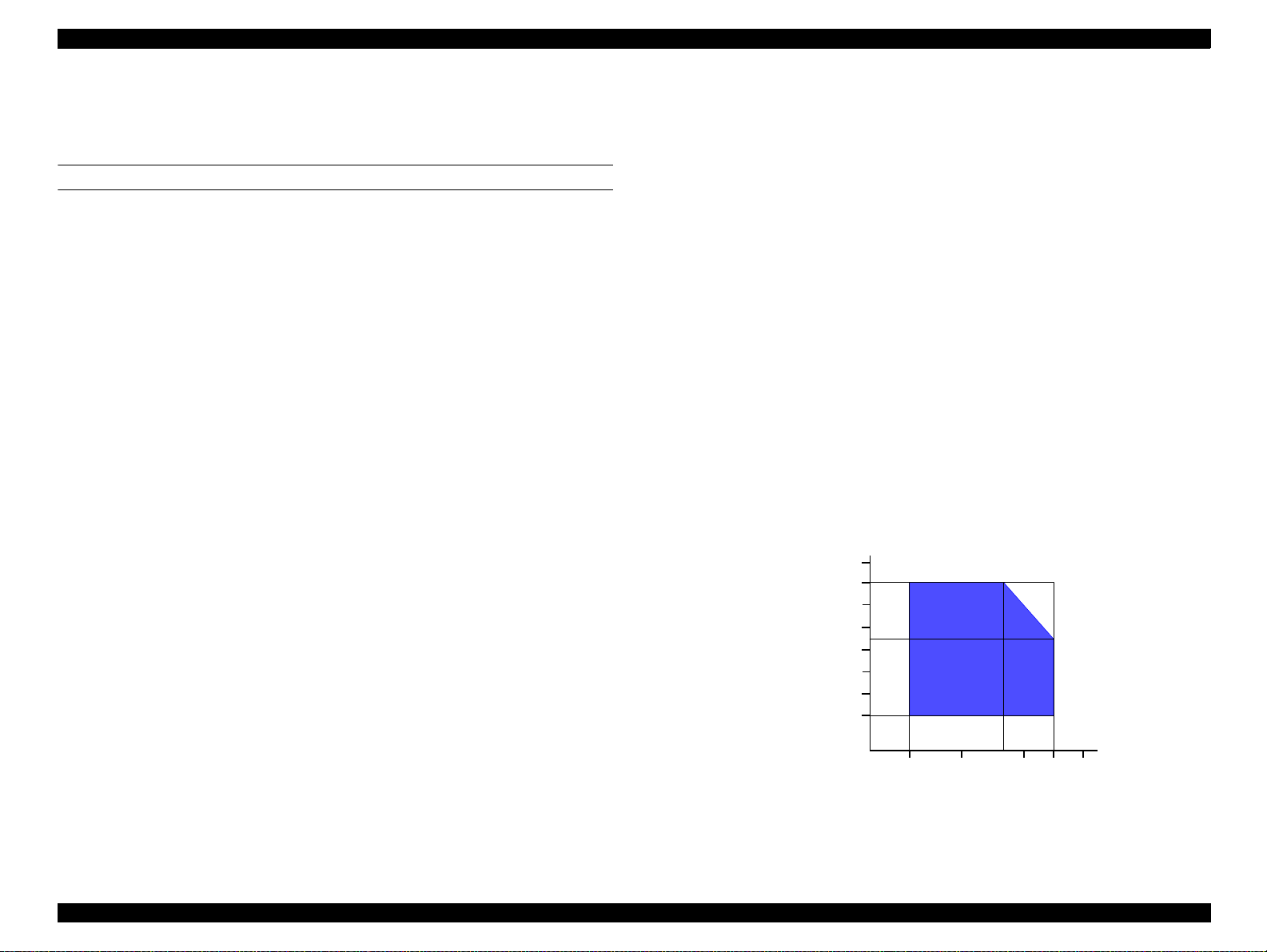

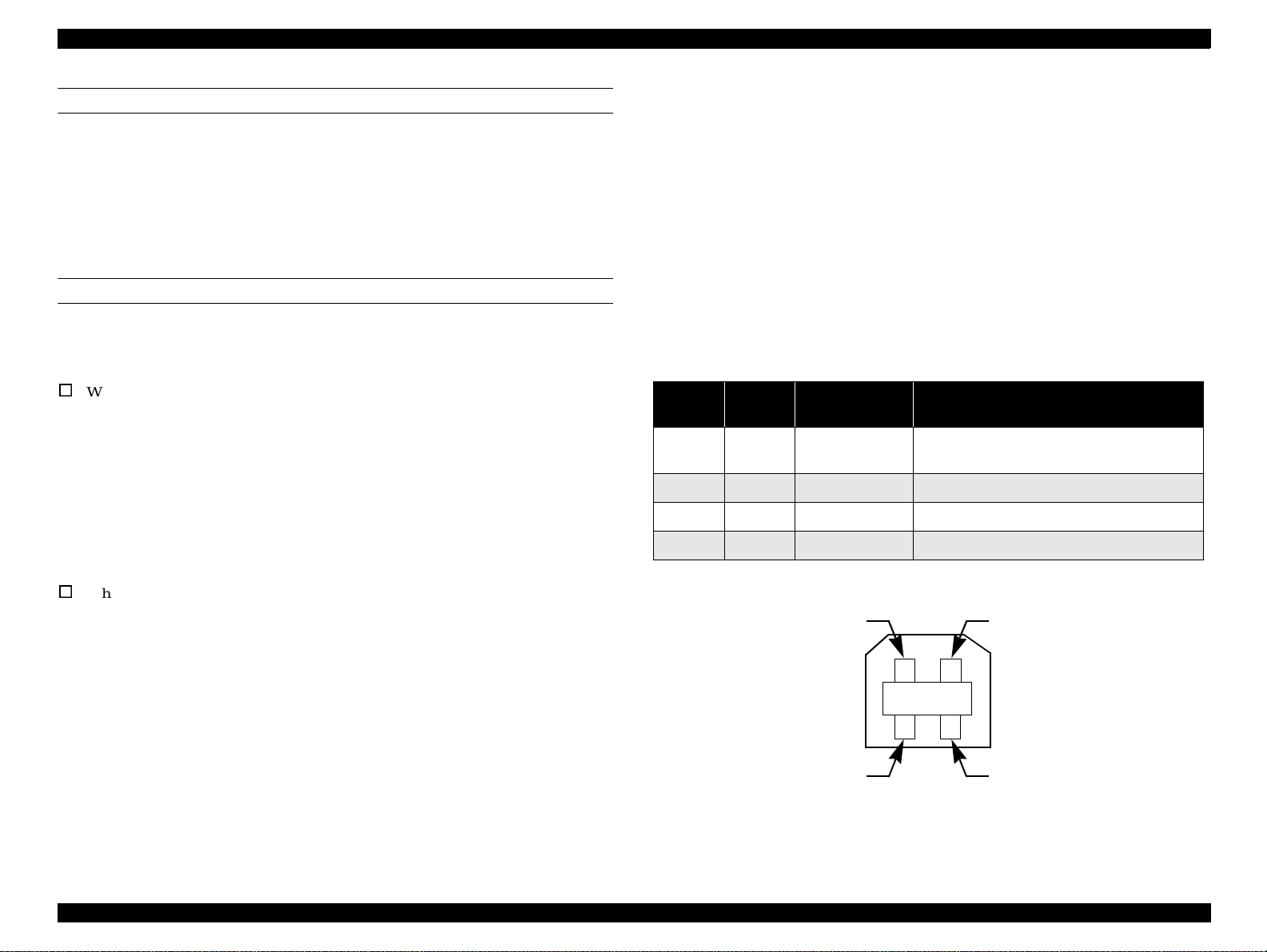

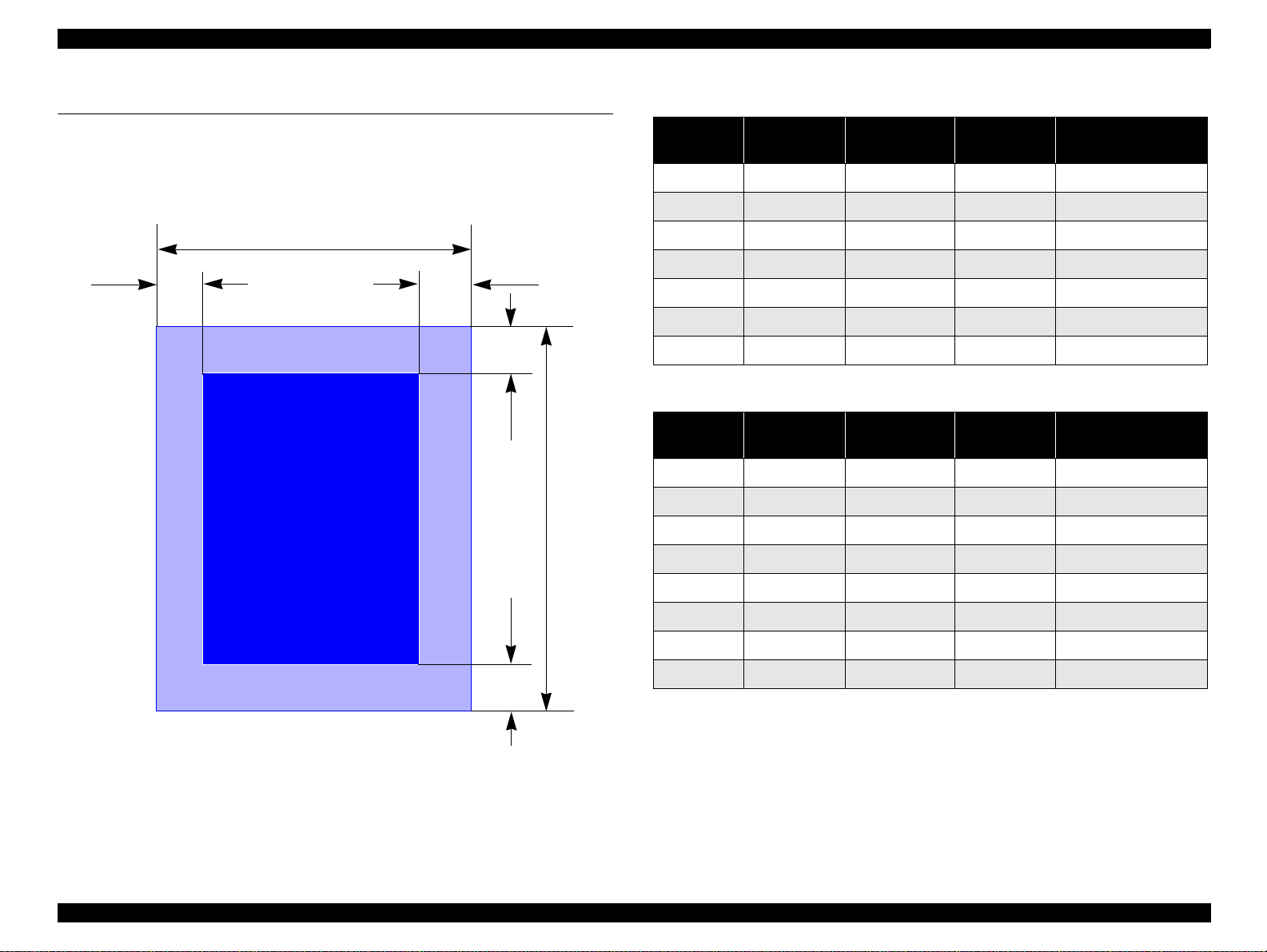

1.6 Printing area

1.6.1 Cut Sheet

LM RM

PW

Printable AreaPrintable Ar ea

TM

BM

PL

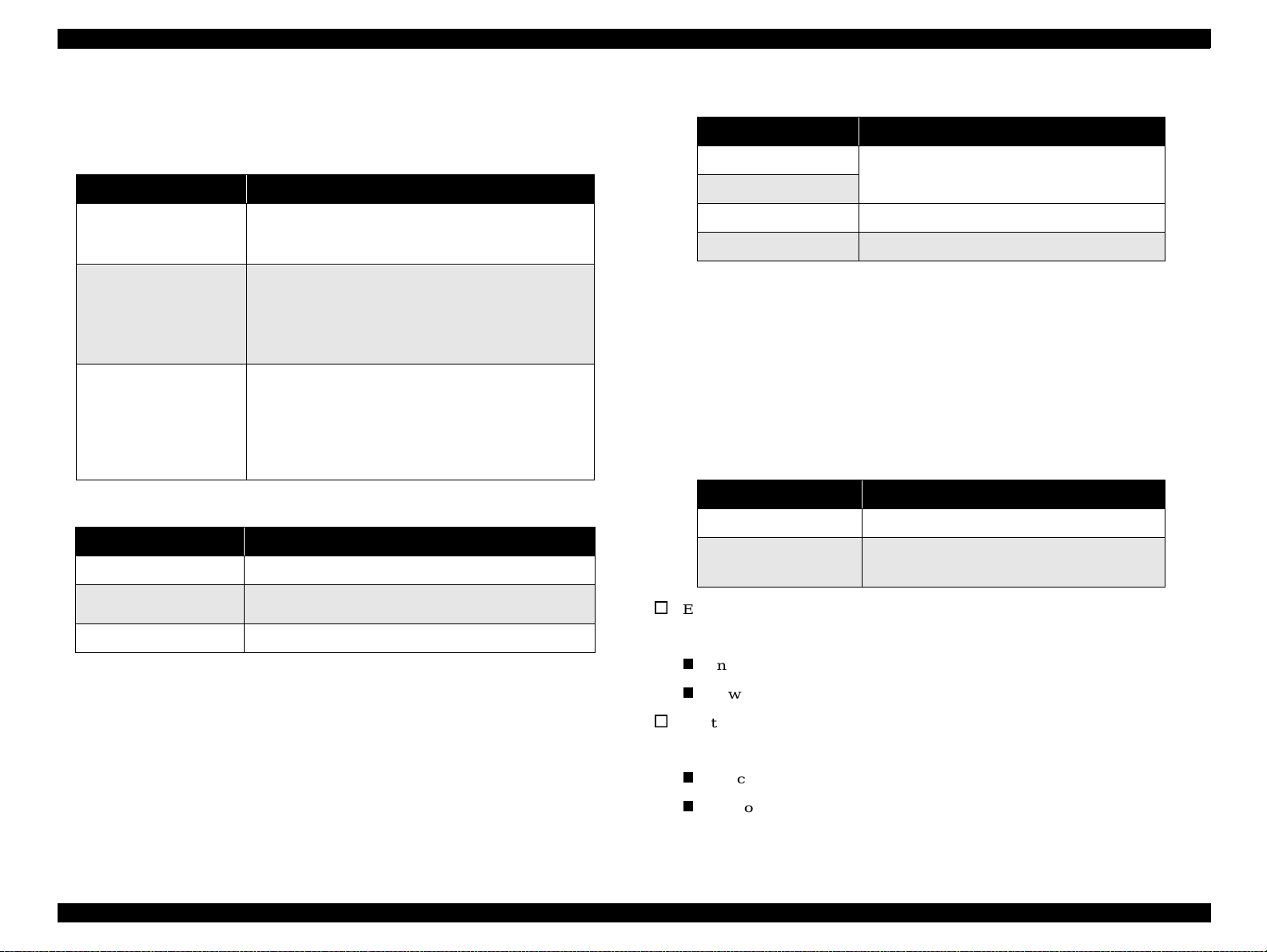

Table 1-16. Printi ng Area - Character Mode

Paper Size

A3

A4

Letter

B5

Legal

Statement

Executive

Left Margin

(minimum)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 9 mm (0.35”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 9 mm (0.35”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

Right Margin

(minimum)

Top Margin

(minimum)

Bottom Margin

(minimum)

Table 1-17. Printing Area - Raster Graphics Mode

Paper Size

A3+

A3

A4

Letter

B5

Legal

Statement

Executive

Left Margin

(minimum)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

*1:Bottom margin can be reduced to 3mm when paper dimension is defined by

using command, otherwise it remains 14mm. As for an area between 3mm

and 14mm margin, print quality may decline.

Right Margin

(minimum)

Top Margin

(minimum)

Bottom Margin

(minimum)

*1

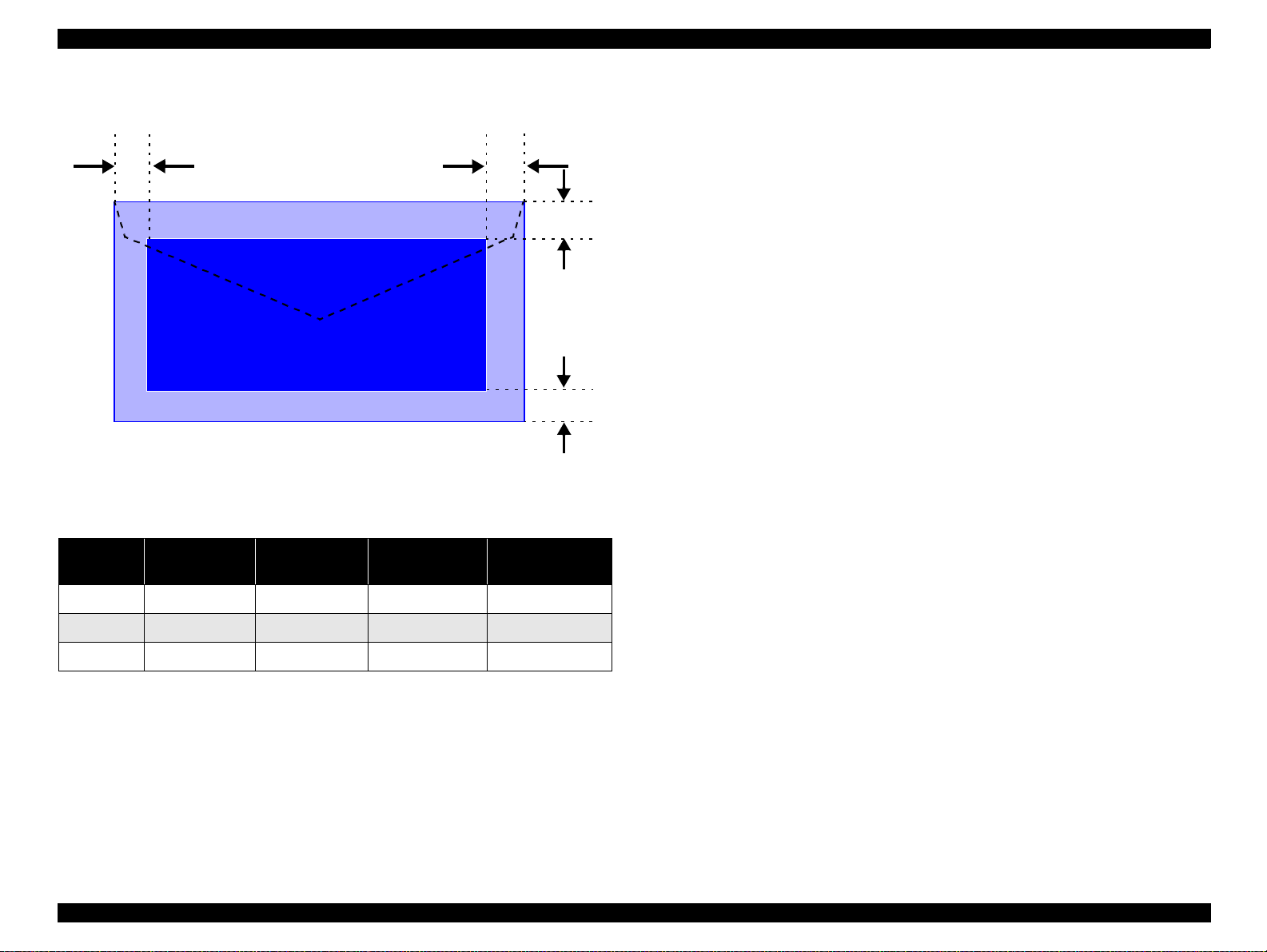

Figure 1-3. Printable Area for Cut Sheet

Product Descriptions Printing area 27

Page 28

EPSON Stylus PHOTO 2000P Revision A

1.6.1.1 Envelopes

LM

RM

TM

Printable AreaPrintable Area

BM

Figure 1-4. Printable Area for Envelopes

Table 1-18. Envelope Margin

Left Margin

Size

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.55”)

(minimum)

Right Margin

(minimum)

Top Margin

(minimum)

Bottom Margi n

(minimum)

DL 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.55”)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.55”)

Product Descriptions Printing area 28

Page 29

EPSON Stylus PHOTO 2000P Revision A

1.7 Ink cartridge

1.7.1 Black ink cartridge

Type : Exclusive cartridge

Color : Black

Print capac i ty : TBD

Ink life : 2 years from production date

Storage temperature

C - 40 °C (Storage, within a month at 40 °C)

: -20

°

: -30

C - 40 °C (Packing storage, within a month at 40 °C)

°

: -30

C - 60 °C (Transit, within 120 hours at 60 °C

°

and within a month at 40

Dimension : 20.1 mm(W) x 66.85 mm(D) x 38.5 mm(H)

1.7.2 Color ink cartridge

C)

°

Type : Exclusive cartridge

Color : Magenta, Cyan, Yellow, Light Cyan, Light Magenta

Print capac i ty : TBD

Ink life : 2 years from production date

Storage temperature

C - 40 °C (Storage, within a month at 40 °C)

: -20

°

: -30

C - 40 °C (Packing storage, within a month at 40 °C)

°

: -30

C - 60 °C (Transit, within 120 hours at 60 °C

°

and within a month at 40

Dimension : 49.1 mm(W) x 84.05 mm(D) x 41.8 mm(H)

NOTE: Do not refill the ink cartridge. The ink cartridge is a consumable item.

Do not use a cartridge whose ink life has expired.

Ink freezes below -4

than 3 hours at room temperature.

C; however it will be usable again after keeping it for more

°

C)

°

Product Descriptions Ink cartridge 29

Page 30

EPSON Stylus PHOTO 2000P Revision A

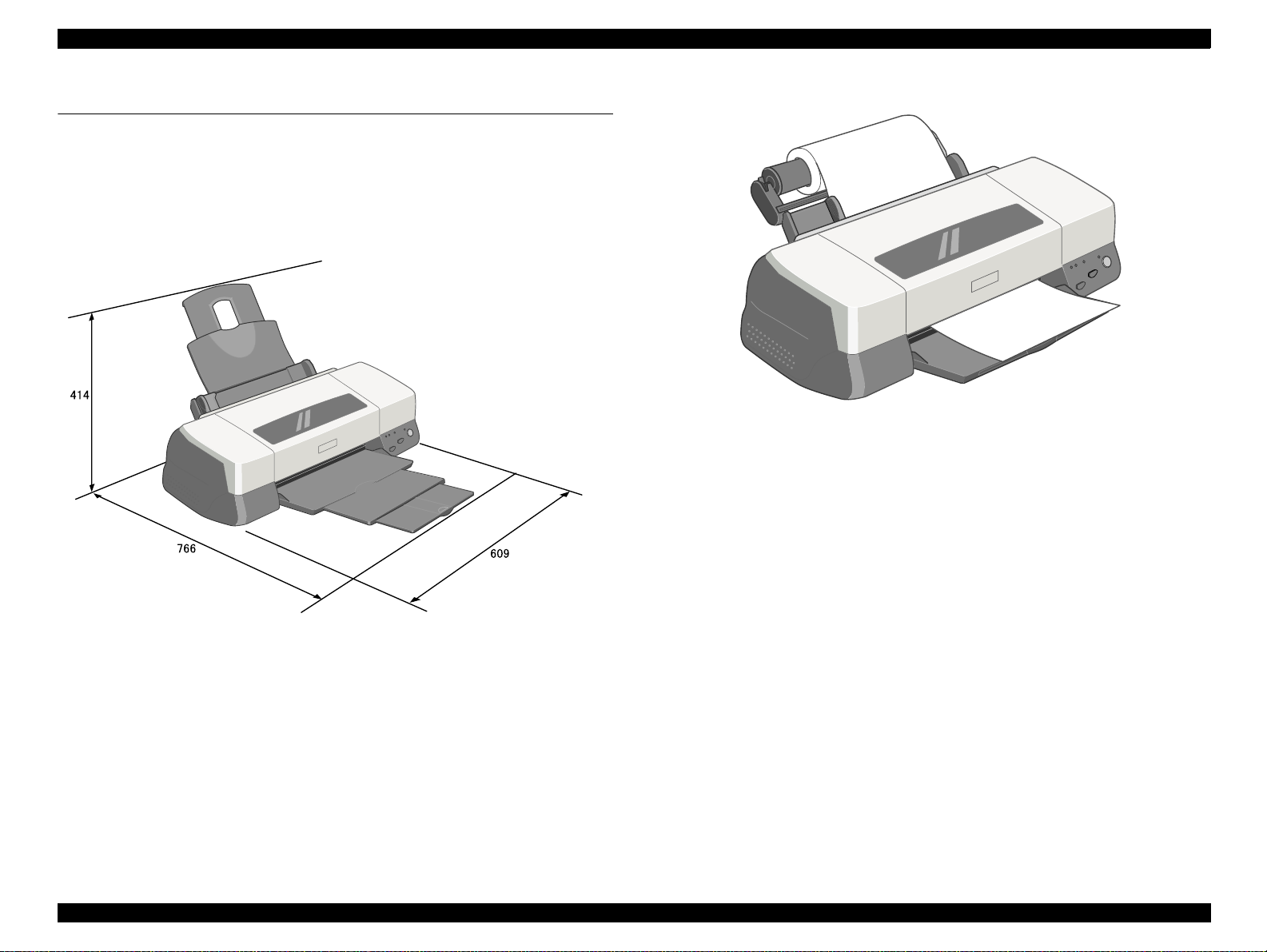

1.8 Physical specification

Weight : 8.4kg (without the ink cartridges)

Dimension : 609 mm(W) x 311 mm (D) x 175 mm (H) ( Stor age)

: 609 mm(W) x 766 mm (D) x 414 mm (H) (Printing)

Figure 1-6. With Roll Holder

Figure 1-5. Dimension -- Printing

Product Descriptions Physical specification 30

Page 31

OPERATING PRINCIPLES

CHAPTER

Page 32

EPSON Stylus PHOTO 2000P Revision A

2.1 Overview

This section describes the operating principles of the printer mechanism and electrical

circuit boards. The major components of the EPSON Stylus PHOTO 2000P are:

P rin ter mec ha n ism : M4 W 60

M ain board: C 304M A IN Board

Power supply board: C 298PSB/PSE B oard

2.1.1 Printer Mechanism

Unlike other EPSON ink jet printers, the

motor as power source. The DC motor enables the printer to lower noise during

printing. Table 2-1 shows variou s motor t ypes used in the pri nter and t heir applic ations.

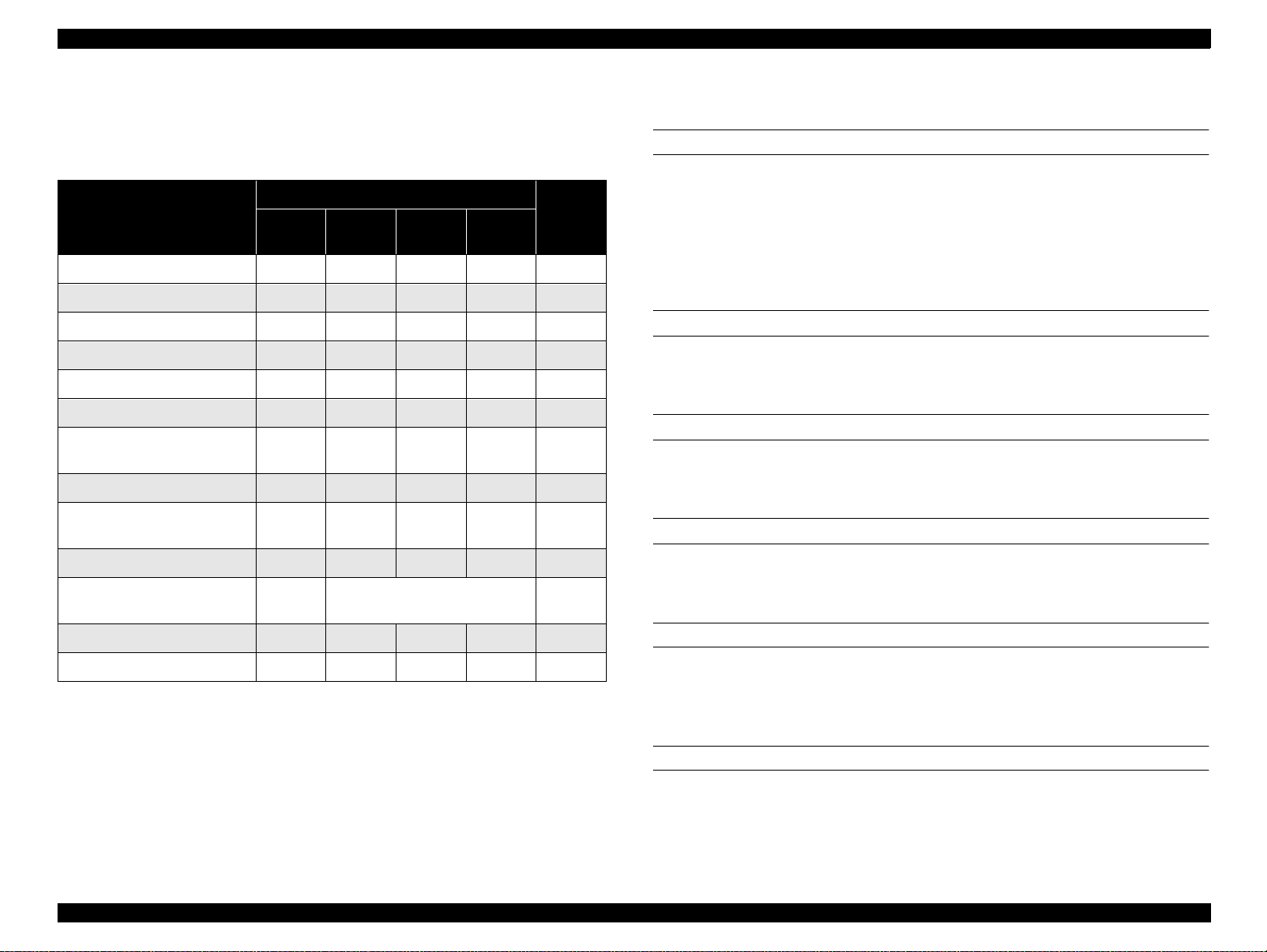

Table 2-1. Motor Types and Correspondin g Applications

Motor Name Type Application / Feature

CR motor

PF motor

DC motor with

brush

DC motor with

brush

EPSO N S tylus PHO TO 2000P

uses a DC

Table 2-2.

Drives the carriage making little noise. Works with

a linear scale to monitor motor’s operating

condition.

Supplies power t o drive paper feeding roller s used to

send paper at specified speeds and load/eject paper.

To monitor paper feeding pitch, a loop scale is

attached beside the high-precision gear.

Figure 2-1 shows the printer mechanism block diagram for the Stylus PHOTO 2000P.

Rotary Encoder

Intermittent Gear

PF Motor Pinion

PF Motor

Flashing Window

Photo Interrupter (Encoder)

Notched Roller

Carriage Unit

Printhead

Timing Belt

Cap Unit

(without a valve)

Pump Unit

PF Drive Gear (high precision)

Photo Interrupter (Encoder)

Detector Wheel

ASF Sensor

LD Roller Shaft

Loading Rollers

PE Sensor

Pump/ASF Motor

Sends drive for pump operation and paper feeding

Pump/ASF

motor

4-Phase / 48-pole

stepping motor

from ASF. Since this is a stepping motor, it has no

scales or photo sensors that are used to monitor

motor’s operating condition.

The basic structure of the printer mechanism is most ly common to the Stylus COLOR

CR Guide Shaft

PF Roller

Liner Scale

CR Motor

PG Lever

Figure 2-1. Printer Mechanism Block Diagram

ASF/Pump Disengage

Gear Train

400, except that the Stylus PHOTO 2000P uses a Pump/ASF motor. With this motor

equipped, the paper loading mechanism and the pumping mechanisms are

independently driven, which allows the printer to offer higher throughput.

OPERATING PRINCIPLES Overview 32

Page 33

EPSON Stylus PHOTO 2000P Revision A

2.1.2 Ink

2.1.2.1 Comparison between Pigment Ink and Dye Ink

The main component of Stylus PHOTO 2000P is almost the same as of Stylus Photo

1270. The most signi ficant difference is its pigment ink use.

The difference between the pigment ink and dye ink is shown in the table below.

Table 2-3. Physical Differences

Dye Ink Pigment Ink

Single element that has a specific chemical

structure.

Element minimum unit: 1 ~ 2 nm Element minimum unit: 50 ~ 200nm

Ink is only composed of liquid phase (solvent

and elemen t).

Solvable to solvent (water, glycol, etc.) Not solvable. Only disperse.

Table 2-4. Features of Pigment Ink

Advantage Disadvantage

It can make h igh density color. Have to keep equally dispersed c o nditio n .

Better dura b ility against climate.

Not easy to blur.

No limit on its solubility.

Chem ic ally sta b le: Not e as y to chang e into

pois o n: High s afety.

Aggreg ate ma te rial of el em e nts.

Ink is composed of 2 phases: liquid phase

(solve nt) and solid ph ase (elemen t).

Long time storage may cause pigment

sediment.

Table 2-5. Features of Dye Ink -- Reference

Advantage Disadvantage

Solvable to solvent (water, glycol, etc.) Easy to blur.

Homogeneity is kept. When impurities are interfuse, chemical

High brightness.

change occurs and the element may be

deteriorated.

2.1.2.2 Drop of Pigment Ink and Dye Ink

The figure below shows how pigment ink and dye ink goes onto paper.

Figure 2-2. Pigment Ink an d Dye Ink

Dye ink infiltrates paper and the element disperses, then the thickness of color

decreases.

Table 2-5. Features of Dye Ink -- Reference

Advantage Disadvantage

Have been used for ink jet for long time. Restriction on its solubility.

Easy to express the gradation. Less durability against climate.

membranes. Thereby, it keeps the printing sharp and with high density.

OPERATING PRINCIPLES Overview 33

For pigment ink, the solvent infiltrates paper but the pigment goes onto paper and

Page 34

EPSON Stylus PHOTO 2000P Revision A

Ink Cartridge

2.1.3 Printhead Mechanism

The printhead mechanism operating principles of the Stylus PHOTO 2000P are

basically the same as for the previous EPSON ink jet printers. This printer, however,

employs a newly developed ink and improved printhead driving method to provide a

higher print quality and faster printing speed than ever. Also, an IC called CSIC that

stores ink-life data is attached to each ink cartridge. With this IC, ink life of each

cartridge can be individually monitored. Note, like for other models, a head voltage

must be written with a PC.

The printhead mechanism consists of ink cart ridges and printheads. Each printhead is

composed of PZT (Piezo Electric Element), nozzle surface, ink supply needle, nozzle

selection cir cuit board, cartri dge sensor, CSIC, and CSIC connection circuit. Figure 2-3

shows its component layout.

CSIC

Ink Cartridge

Nozzle Selector

Circuit Board

CSIC Connection

Circuit

Ink Supply Needle

An ink cartridge stores ink to be supplied to the printhead.

CSIC:

CSIC is a non-v ola tile memory E EPROM attache d t o eac h bl ack and c olo r in k

cartridge. It keeps the following information:

1) Ink remaini n g level

2) Number of cleanings performed

3) Number of installation of the ink cartridge

4) Accumulated installation time of the cartridge

5) Model name of the printer in use

6) Ink cartridge production information

7) Ink cartridge code

8) Number of times that the ink cartridge is recycled

Printhead

PZT

Driven by the print signal from the control circuit board, it ejects ink from the

nozzle plate.

Nozzle plate

Ink pressured by the PZT is ejected from this plate.

Ink supply needle

Connects the ink cartridge and printhead to run ink to the printhead.

CSIC connection circuit

Connects the control circuit board and CSIC attached on the ink cartridge.

One end of the harness is connected to the control board together with the

printhead cable.

Nozzle Plate

Figure 2-3. Printhead Mechanism

PZT

Nozzle se lection circuit boar d

This circuit, controlled by ASIC on the control circuit board, selects nozzles

to be driven for printi ng. On t he othe r hand, head drive volta ge is pr oduced on

the con t roller circuit side.

OPERATING PRINCIPLES Overview 34

Page 35

EPSON Stylus PHOTO 2000P Revision A

2.1.4 Carriage Mechanism

The carriage mechanism of the Stylus PHOTO 20 00P is composed of the carriage

motor (CR motor), carriage guide shaft, platen gap adjustment/parallelism adjustment

mechan i sm , c ar r i ag e loc k mechanis m , an d s o on.

2.1.4.1 Carriage Motor (CR Motor)

The carriage mechanism this printer is mostly the same as for other ink jet printers’

except it uses a DC motor as power source. See the table below for the carriage motor

specifications.

Table 2-6. Carriage Motor Specifications

Table 2-7.

Items Specifications

Type DC Motor with brush

Drive Voltage +42 V +/- 5% (Applied to the driver)

Coil resistance 29.2 ohms +/- 25%

Inductance 30.8 mH +/- 25%

Photo Coupler

Carriage Unit

Linear Encoder

Adjust Lever

Platen Surface

Eccentric Shaft

CR Motor

Parallelism Adjustment

Bushing

Carriage Guide

Shaft

Drive Method Constant Current Chopping

Driver IC LB1947

Op03

Figure 2-4. Carriage Mechanism (Top view)

In previous ink jet printers, since a stepping motor is used as a CR motor , the CR motor

controls the car ri age p o sition under the open loop system. This printer, however,

controls carriage speed and position with the closed loop system enabled by a DC

motor and encoder. This system, also used in the Stylus COLOR 900, is applied to

maintain a constant print quality. The CR motor also produces the print timing signal

(PTS signal) used for an accurate ink ejection timing. (Refer to Section 2.2.2.3 for

further information on the CR motor control circuit.)

For printing, the CR motor moves the carriage unit in the printing area along the CR

guide shaft.

OPERATING PRINCIPLES Overview 35

Page 36

EPSON Stylus PHOTO 2000P Revision A

2.1.4.2 Platen Gap (PG) /Parallelism Adjustment Mechanism

The PG adjust lever is attached to the left end of the carriage guid e sha ft . When the

carriag e g uide shaf t, which ha s an ecce ntr ici ty, r o tates as th e a dju stment le ver mov es, it

narrows or widens the distance (=PG: from 1.2 mm to 2.1 mm). This mecha ni sm

enables the user to print with a correct PG according to print result or other conditions

such as pap er curl.

Also, the parallelism adjustment bushings are attached to the right and left ends of the

carriag e g ui de shaf t . They a re us ed to set the ca rria ge g ui de shaf t pa ral lel with a pl aten .

Table 2-8.

Platen Gap Adjust Lever Setting

Table 2-9.

Lever Position PG adjustment value

Front (0) 0 mm (=PG is 1.2 mm)

Rear (+) + 0.9 mm (=PG is 2.1 mm)

2.1.4.3 Carriage Home Position (HP) Detection

Unlike previous Epson ink jet print ers, the carriage hom e pos ition is detected with the

drive cur rent from the CR motor and speed/po sition signal from the linear encoder.

2.1.5 Paper Feeding Mechanism

The paper feeding mechanism transports paper loaded from ASF usi ng the PF rollers

and paper eject rollers. A new type of DC motor is used as the PF motor. See the table

below for the PF motor specifications.

Table 2-10.

Item Description

Motor t yp e DC Moto r w ith B rush

Drive voltage +42V +/- 5% (Applied to the driver)

Coil Resistance 31.1 ohm +/- 25%

Inductance 26.6mH +/- 25%

Control method Constant current chopping drive

Stepping motor that is used in other printers as the PF motor controls paper feed by the

open loop system. On the other hand, this printer controls paper feeding mechanism

with the closed loop system by employing the DC motor and rotary encoder for more

accurate paper feeding. Therefore, a rotary encoder attached to the left end of the PR

roller shaft controls paper feed amount. For detailed information, see Section "PF

motor driver circui t".

PF Motor Specifications

Table 2-11.

Drive from th e PF motor is sent to the PF rollers and paper eject rollers as described

below.

Driv e transmis s io n to the PF rollers :

PF motor pinion gear

Driv e tran smission to th e eje ct rollers :

PF motor pinion gear

gear (28)

Paper ejec t r o ll er s

→

Spur gear (76) → PF rollers

→

Spur gear (76) → Combination gear (13.5, 308) → Spur

→

OPERATING PRINCIPLES Overview 36

Page 37

EPSON Stylus PHOTO 2000P Revision A

Figure 2-5 gives the paper feeding mechanism block diagram, showing the parts along

the PF motor drive transmissi on path s.

Combination Gear

(13.5, 308)

Spur Gear (76)

Paper Eject Roller

PF Roller

[Previous Models]

Notched Roller

Paper

Platen Surf ace

Printhead

Support Roller

Front Paper Guide

PF Motor Pinion Gear

PF Motor

Paper Eject Roller

Figure 2-5. Paper Feeding Mechanism

The printer loads paper at the ASF, which is detected by the PE sensor attached to the

right side of the top frame, and advances it to send the paper’s leading edge to the

halfway of the front paper guide . Then, to correct paper deflection, the printer feeds the

paper back specified steps toward ASF, and advances the paper again toward the front

paper guide and stops it at the specified TOF (Top Of Form) position. Once printing

starts, the paper is fed by the PF rollers and sub rollers. For printing or transporting the

tailing ed g e ar ea (14 mm), a notched roller and drive from the paper eject roller are

used. Like the Stylus Photo 750/1200, this printer also provides this extra printable

range of 14 mm from the bottom edge, excluding the bottom margin of 3mm, by

changing the position of the star wheel gear; it has been shifted by 5

the eject roller toward the front paper guide. Due to this change, the tailing edge of

paper is suppressed, and the printer can advance paper steadily. See Figure 2-6 next

page that shows how paper is t r ansported and parts involved.

from the top of

°

Paper Eject Rolle r

Bottom Margi n (3 mm)

PF Roller

[Stylus PHOTO 2000P]

°

Paper Eject Roller (round)

5

Steady Feeding

Figure 2-6. Paper Transportation

Notched roller is used for previous models as a paper eject roller. Stylus PHOTO

2000P adopts a round roller to prevent a paper from notched roller trace. When the

paper setting on the prin ter and the actu al paper ty pe differ s and i f the paper ejec t roller

is tainted with ink because the printer eject s pa per before the printed surface would b e

dried, you have to clean the roller by the roller cleaning function by the panel

operation. (See “Special Sett in g M o d e ” on pag e-22.)

OPERATING PRINCIPLES Overview 37

Page 38

EPSON Stylus PHOTO 2000P Revision A

2.1.5.1 CR Lock Mechanism

The carriage lock mechanism prevents th e carriage from being left unc apped for a long

time, which is usually caused by vibration during printer transportation, user’s

mishandling of the printer, and so on. If the carriage unit is left uncapped for a long

time, ink on the printhead surface dries gradually and, eventually, ink can not flow to

nozzles. In additi on to th at, ther e is a poss ib ili ty that the no zzles clogged wi t h drie d ink

can not be recovered by a head cleaning. To avoid this problem, the printer locks the

carriage unit under t he circumstance below:

After Power-Off

If th e p rin ter po w e r is tu rn ed of f in th e m id d le o f p rin ting o r o the r o p era tio ns , the

p rinte r c o mple tes th e initia liz atio n se q u en c e a n d th e n p e rfo rm s a c a rria g e loc k .

After Power-On

Wh en th e p rin te r is tu r n ed o n, th e p rin te r a u to ma tic ally b eg in s a po wer-o n c le an in g

and then p erform s a carriage lock .

[Power-on cleaning]

The printer runs a power-on cleaning automatically when its po wer is turned on. Since

th e tim er IC o n th e m a in co n tro l c irc uit b o ar d is p o we re d by a lithiu m b atte ry th a t is

als o moun ted o n the board , it kee p s co un ting the p r in ter’s power off time. According to

the power of time counted, the printer selects the cleaning level to perform.

Top view

Bushing 6

Paper Ejec t Roller

Figure 2-7. CR Lock Mechanism

CR Lock Lever

Middle Frame

Right side view

CR unit

CR unit

After paper ejection

If th e p rin ter do e s n o t re c eiv e a n y p rin t d ata a fter L o a d/Ejec t bu tto n is p re ss ed , it

p erf o r ms a carr ia ge lo c k a n d e nte rs a s ta nd b y s ta tus. But if pa p er is fe d into the printer,

th e p rin te r d o es no t p e rfo rm it.

OPERATING PRINCIPLES Overview 38

Page 39

EPSON Stylus PHOTO 2000P Revision A

2.1.6 Paper Loading Mechanism

The paper loading mechanism loads paper at the ASF unit and feeds paper to the PF

rollers. The ASF unit is the same as in previous models. A 4-phase 48-pole PM type

stepping motor is used as the ASF/Pump motor to drive ASF. Drive sent from this

motor is t r ansmitted to the ASF side and Pump side via the disengage m echanism (DE

mechanism). See Figure 2-12 for the ASF/Pump motor specifications.

Table 2-12. ASF/Pump Motor Specifications

Table 2-13.

Items Description

Motor type 4 Phase/ 48-pole /PM type pulse motor

Drive method Bipolar constant current drive

Drive voltage +42V +/- 5% (applied to the driver)

Coil Resistance 10.4 ohm +/- 10%

Inductance 15.0 ohm +/- 10%

Drive from the ASF/Pump motor is sent to the ASF unit by the switching operation of

the carriage unit and the DE mechanism described in the following section.

2.1.6.1 Drive Transmission to the ASF Unit

1) The CR unit moves to the right end of the CR shaft, which then pushe s the DE

lock lever to the right end.

2) The ASF/Pump motor rotates co unterclockwise specified steps (viewed from the

motor pinion gear side).

3) With the ASF-Pump motor’s rotation of step 2), the planetary gear set in the DE

unit shifts toward the combination gear (12, 22.4).

4) The carriage unit moves from the right end of the CR shaft specified steps, which

causes the DE lock lever to fix the planetary gear unit.

5) Torque from the ASF/Pump motor is transmitted as described below.

Motor pinion gear

Combination gear (14, 28)

Figure 2-8 shows the disengage mechani sm and its parts.

Combinat ion G e a r

14, 28

Planetary gear (15.2) → Combination gear (12, 22.4) →

→

Spur gear (32) in ASF

→

Comb ination G e ar 12, 22.4

Planetary Gear 15.2 Unit

DE Lock Lever

A

ASF-Pum p Moto r Pin io n Gear

Comb ination Gear 17.19, 25. 6

Figure 2-8. Disengage Mechanism

The ASF unit loads paper by the torque sent from the ASF/Pump motor v ia the DE

mechanism as described in the following section.

OPERATING PRINCIPLES Overview 39

Page 40

EPSON Stylus PHOTO 2000P Revision A

2.1.6.2 Paper Loading Operation

Multiple paper loading prevention mechanism is included in the ASF unit to ensure

steady paper loading. To prevent any paper from falli n g from the pap er se t posit io n

into the paper path, the paper return lever pushes paper that may have fallen off back

onto the hopper. Afte r this moti on is comple te d, the LD roller s tarts loadin g paper. The

paper loadi ng mecha nism , inc ludi ng the multi ple pape r lo ading p reve ntion mecha nism,

is described in the following steps.

1) When the printer power is turned on, the ASF/Pump motor rotates

countercloc kwise to det ect AS F home posi tio n. The n it rotates cl ockwis e spe cifie d

steps to set the LD roller and paper return lever in their standby status. (See

“Standby State” in Figure 2-1. )

2) When th e paper loading signal is sent from the PC and the Load/Eject butt on is

pressed, the AS F/Pump motor turns counterclockwise to let the LD roller st art

loading paper. (See “Paper Pick Up State” in Figure 2-1.)

3) When the paper is tr ans ported to the PF roller, the LD rol ler stops where it loses

friction. (See “PF Roller Pa per Feed State” in Figure 2-1.)

4) When the next print signal is sent and Load/Eject button is pressed*, the ASF/

Pump motor r otates clockwise specified steps to set the LD roller and the paper

return lever in standby status. (See “Standby State” in Figure 2-1.)

LD Roller

Paper Return

Lever

Hopper

Cam

Standby State

Hopper Spring

Pad Spri ng

Pad

2

Paper Load State

Pinch Roller

3

PF Roller Paper

Feeding State

* If t he print er do es not r ecei v e any print signal for TBD seconds in step 4, the LD

roller and the paper return leve r automatically return to the standby state.

Flowchart 2-1. Multip le Paper Loading Prevention Mechanism

OPERATING PRINCIPLES Overview 40

Page 41

EPSON Stylus PHOTO 2000P Revision A

Torque transmis sion to the pump unit

2.1.6.3 Pump Mechanism

The pump mechanism absorbs ink from the printhead and the cap assembly. The wiper

for head cleaning is included in the cap assembly.

The pump mechanism is driven by the ASF/Pump motor, a 4phase 48-pole PM type

stepping motor. See Table 2-12 for the ASF/Pump motor specifications. When the

torque from the ASF/Pump motor is switched to the pump unit side, the pump

mechanism act s di ffere ntly according to the directi ons of the ASF/Pump motor

rotation, as shown in the table below:

Table 2-14. ASF/Pump Motor Functions

Table 2-15.

Directions Corresponding Functions

Counterclockwise

Clockwise

• Absorbs ink.

• Sets the wiper.

• Releases tube.

• Resets the wiper.

T h e tor qu e fro m the ASF /Pu m p mo to r is tra n sm itted to th e pu m p m e c ha n is m a s

described below:

1) The CR unit moves to the right end of the CR shaft, which then pushes the DE

lock lever to the right end.

2) The ASF-Pump motor rotates clockwise (viewed from the motor pinion gear

side) specified steps.

3) With the rota tion of s tep 2), the planet ary gea r set in the DE unit moves toward

the combination gear (17.19, 25.6).

4) The CR unit moves specified steps from the right end of the CR shaft to the

left. With this motion, the DE lock lever fixes the planetary gear set.

5) Torque from the ASF/Pump motor is transmitted as described below.

Motor pinion gear

Tension belt → Pum p unit g e a r → Pump unit

→

Planetary gear (15.2) → Combination gear (17.19, 25.6)

→

Combination Gear 14, 28

Combination Gear 12, 22.4

Planetary Gear 15.2

A

DE Lock Lever

Tension Belt

ASF/Pump Motor Pinion Gear

Combination Gea r 17.19, 25.6

Pump Unit Gear

Figure 2-9. Torque to the Pump Mechanism

OPERATING PRINCIPLES Overview 41

Page 42

EPSON Stylus PHOTO 2000P Revision A

2.1.6.4 Capping Mechanism

The capping mechanism, which is driven by the pump unit, caps the printhead closely

to maintain air tightness inside the cap. This operation is required to vacuum ink from

the ink cartrid ges , printhead, and cap. Also, to moiste n t he inside of the cap while the

printer power is off, this mechanism works to keep the cap and the printhea d surface in

a tight contac t. This function prevents ink fr om clogging while the printer is not in use.

Previous Models

Negative

pressure is

released here.

Closed state

Ink Ejection

Hole

Valve

Released st at e

The capping mechanism of this printer is a newly designed valveless capping

mechanism. So, unlike previous printers, it does not integrates an air valve. The air

valve is usually equipped to remove bubbles created inside the cap by releasing the

negative pressure. However, due to change in the ink sequence, the new valveless

capping mechanism enables the printer to maintain the initial ink charge and cleaning

effects at the same level as before. Figure 2-10 outlines the valveless capping

mechanism.

Stylus PHOTO 2000P

Ink Ejection

Hole

There is no air valve

assembled.

Figure 2-10. Valveless Capping Mechanism

OPERATING PRINCIPLES Overview 42

Page 43

EPSON Stylus PHOTO 2000P Revision A

2.2 Electri ca l Circ u it Ope rat in g Prin c ipl es

The electric circuit of the Stylus PHOTO 2000P consists of the following:

Control circuit board: C 304M AIN

Power supply board: C 298PSB/PSE

Panel board: C304PN L

Refer to Figure 2-11 for the major connection of the boards and their roles.

C304PN L P anel Board

C304PNL Panel Board

Printer MechanismPrinter Mechanism

CR Motor

C304M A IN or C298MA IN-B

C304M A IN or C298MA IN-B

Control Board

Control Board

PF Motor

ASF/Pump Motor

3.3V Regulator3.3V Regulator

Head Driver Circuit

Sensors

Power OFF

+5VDC

+42VDC

2.2.1 C298PSB/PSE Board

The power supply boa rd for th e Stylus PHOTO 2000P is C298PSB/ PSE. It uses a RCC

switching regulator system, and supplies +42VDC and +5VDC to the printer

mechanism and control board.

2.2.1.1 Electrical Circuit

The table below shows the voltage s produced in this circuit and their applications.

Table 2-16. Application of the DC Voltages

Table 2-17.

Voltage Application

+42VDC ± 2VDC

Rated output current: 0.5 A

Maximum curr ent: 1.4 A

+5VDC ± 0.25VDC

Rated output current: 0.5 A

Maximum curr ent: 0.6 A

NOTE: The 5VDC is only applied to the parts and locations shown in the table above.

The C304MAIN use s 3.3V dri ve chips for mo st of the logi c-line chip s (CPU ,

ASIC, ROM, DRAM). For this reason, those chips are not driven by the +5VDC

produced by the but power supply board but the 3.3V DC that is reduced by the

3.3VDC regulator on the C298PSB/PSE.

• CR Motor

• ASF/Pump Motor

• PF Mot or

• Head driving power supply

• Logic sensor circuit

• Panel LED

• Nozzle selection circuit (on the printhead)

• I/F control circuit

• Slave CPU for DC motor control

C298PSB /PSE P ow er

C298PSB/PSE Power

Supply Board

Supply Board

Figure 2-11. Electric Circuit of Stylus PHOTO 2000P

OPERATING PRINCIPLES Electrical Circuit Operating Principles 43

Page 44

EPSON Stylus PHOTO 2000P Revision A

Figure 2-1 2 shows the block diagram for the C298 PSB/PSE board.

The C298PSB/PSE Board produces the +42VDC and +5VDC using AC power as

described below:

1. Regardless of the power swi tch’s on/off condi ti on, volt age is always app lie d to the

primary side of the power supply board from the moment or at the state that ACplug is plugged in. F 1, a fuse, prevents AC100V from flowing into the circuit. A

power thermistor TH1 also protects the circuit from rush current after power-on.

The filter circuit composed of L1, C1, and C2 prevents high harmonic wave noise

generated in the switching circuit from going out, and eliminates the noise from

outside.

2) The AC voltage is full-wave rectified by the diode bridge DB1 and smoothed by

C11.