SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus Photo 1400/1410

SEIJ06009

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES BEFORE PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIES FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS

A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR OTHER

COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE WARRANTY OFFERED

BY EPSON.

6. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF SUCH PRODUCTS CONTAINING

FLAMMABLE GAS IS PROHIBITED.

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance, and repair procedures of the printer.

The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4. DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5. ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the list of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Connector summary

• Electric circuit diagrams

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, and WARNING messages.

W A R N I N G

C A U T I O N

C H E C K

P O I N T

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates a product reassembly procedure, practice or condition that

must be executed in accordance with the specified standards to maintain

the product’s quality.

A D J U S T M E N T

R E Q U I R E D

Indicates an operating or maintenance procedure, practice or condition

that must be executed in accordance with the specified standards to

maintain the product’s quality.

Revision Status

Revision Date of Issue Description

A October 20, 2006 First Release

EPSON Stylus Photo 1400/1410 Revision A

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Overview ............................................................................................................... 9

1.2 Printing Area ....................................................................................................... 10

1.2.1 Printing Area (Cut sheet, Envelope)........................................................... 11

1.3 PG Setting............................................................................................................ 16

1.4 Printer Function ................................................................................................... 17

1.4.1 Operator Controls ....................................................................................... 17

1.4.2 Buttons........................................................................................................ 17

1.4.3 LED Indicators............................................................................................ 17

1.4.4 Panel Functions........................................................................................... 17

1.4.5 Printer Condition and Panel LED Status .................................................... 18

1.4.6 Errors .......................................................................................................... 19

1.5 Size and Weight................................................................................................... 20

1.6 Accessories .......................................................................................................... 20

Chapter 2 OPERATING PRINCIPLES

2.1 Overview ............................................................................................................. 22

2.2 Printer Mechanism............................................................................................... 22

2.2.1 Carriage Mechanism................................................................................... 23

2.2.2 Printhead Specifications ............................................................................. 26

2.2.3 Paper Feeding Mechanism.......................................................................... 26

2.2.4 Paper Feeding Mechanism.......................................................................... 30

2.2.5 Ink System Mechanism............................................................................... 31

2.2.6 Ink Sequence............................................................................................... 33

2.2.7 Power-On Sequence.................................................................................... 34

2.3 Electrical Circuit Operating Principles................................................................ 35

2.3.1 Power Supply Circuit Operating Principle ................................................. 36

2.3.2 C655 MAIN Circuit Operating Principle ................................................... 37

Chapter 4 DISASSEMBLY AND ASSEMBLY

4.1 Overview ............................................................................................................. 72

4.1.1 Precautions.................................................................................................. 72

4.1.2 Tools ........................................................................................................... 73

4.1.3 Screws......................................................................................................... 73

4.1.4 Work Completion Checklist ....................................................................... 74

4.1.5 Sharp Metal Edges...................................................................................... 75

4.1.6 Method for making CSIC board removal tool............................................ 75

4.2 Disassembly/Assembly Procedures..................................................................... 76

4.2.1 Removing the Housings.............................................................................. 77

4.2.2 Waste Ink Pad............................................................................................. 83

4.2.3 Front Paper Guide Pad................................................................................ 84

4.2.4 ASF Assy.................................................................................................... 85

4.2.5 Removing the Boards ................................................................................. 89

4.2.6 Disassembling the Printer Mechanism ....................................................... 91

4.2.7 Removing the Motors ............................................................................... 121

4.2.8 Removing the Sensors .............................................................................. 123

Chapter 5 ADJUSTMENT

5.1 Adjustment Items and Overview....................................................................... 128

5.1.1 Servicing Adjustment Item List................................................................ 128

5.1.2 Replacement Part-Based Adjustment Priorities ....................................... 131

5.1.3 Required Adjustment Tools...................................................................... 133

5.2 Adjustment ........................................................................................................ 133

5.2.1 PF Belt Tension Adjustment..................................................................... 133

5.2.2 PG Adjustment ......................................................................................... 135

5.2.3 PF Roller Shaft Center Support Position Adjustment .............................. 140

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................. 40

3.1.1 Troubleshooting according to Panel Messages........................................... 40

3.1.2 Troubleshooting based on Observed Faults................................................ 62

6

EPSON Stylus Photo 1400/1410 Revision A

Chapter 6 MAINTENANCE

6.1 Overview ........................................................................................................... 145

6.1.1 ROM Replacement ................................................................................... 145

6.1.2 Cleaning.................................................................................................... 145

6.1.3 Service Maintenance................................................................................. 146

6.1.4 Lubrication................................................................................................ 147

Chapter 7 APPENDIX

7.1 Connector Summary.......................................................................................... 154

7.1.1 Connectors and Pin Layouts ..................................................................... 154

7.2 Exploded Diagrams and Parts List .................................................................... 158

7.3 Electrical Circuit Diagrams ............................................................................... 158

7

PRODUCT DESCRIPTION

CHAPTER

1

EPSON Stylus Photo 1400/1410 Revision A

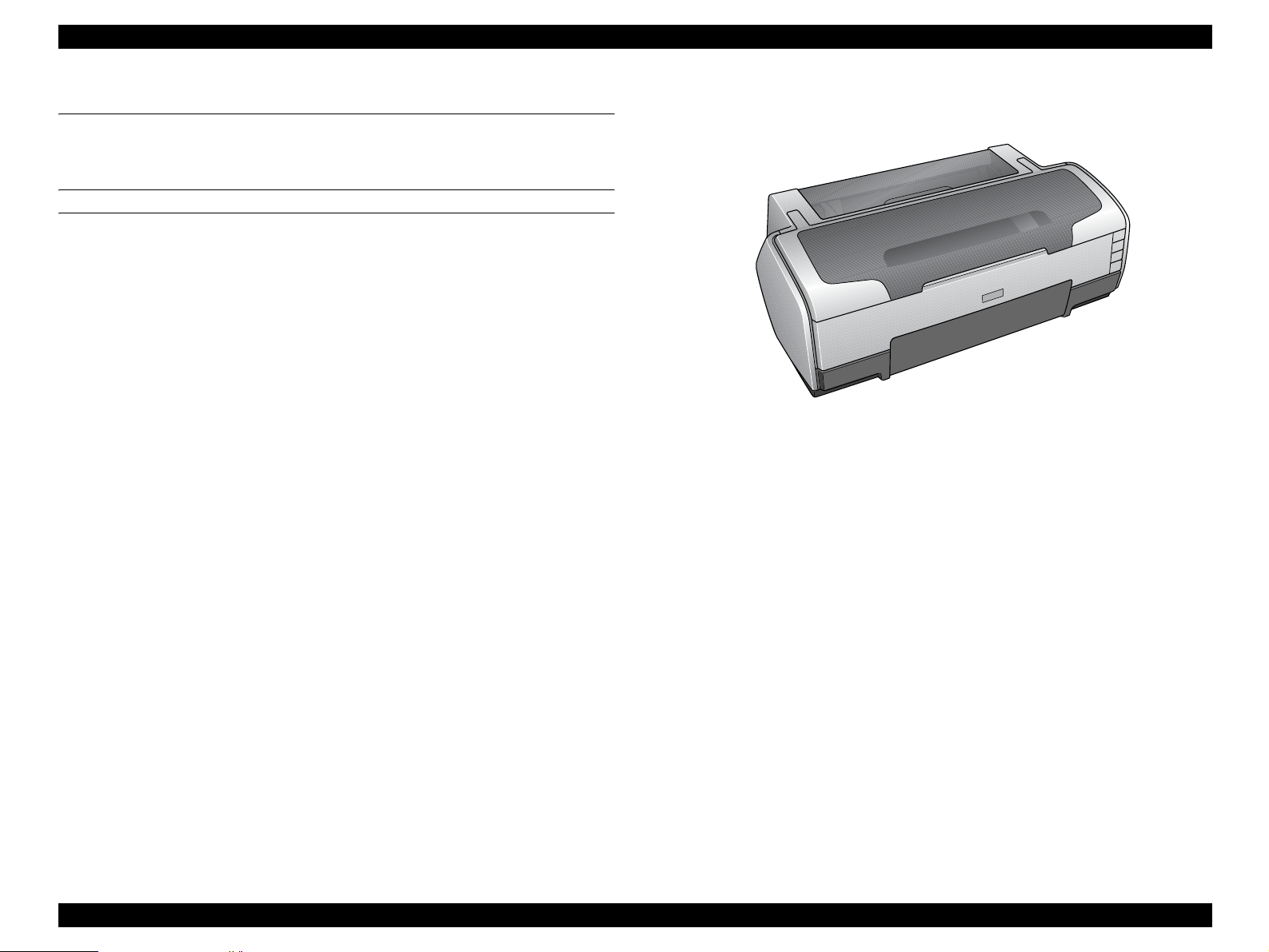

1.1 Overview

EPSON Stylus Photo 1400/1410 is a color inkjet printer designed for a wide range of

users, from home use to office use. The main features of this printer are:

Features

EPSON’s latest dye ink ensures high levels of lightfastness and gasfastness

Six individually replaceable ink cartridges let you print at up to

5760 x 1440 dpi (dots per inch).

Border-free printing up to A3+

High-quality and high-speed printing

CD-R direct printing capability using the CD/DVD tray fed into the front of the printer

ESC/P-R Level-1 command compatible

Prints RGB images transferred from the host devices

Directly prints from PictBridge and an USB Direct Print-enabled digital cameras

Clearly arranged three buttons and three LEDs offer quick, easy operation

Figure 1-1. Product’s External View

PRODUCT DESCRIPTION Overview 9

EPSON Stylus Photo 1400/1410 Revision A

L

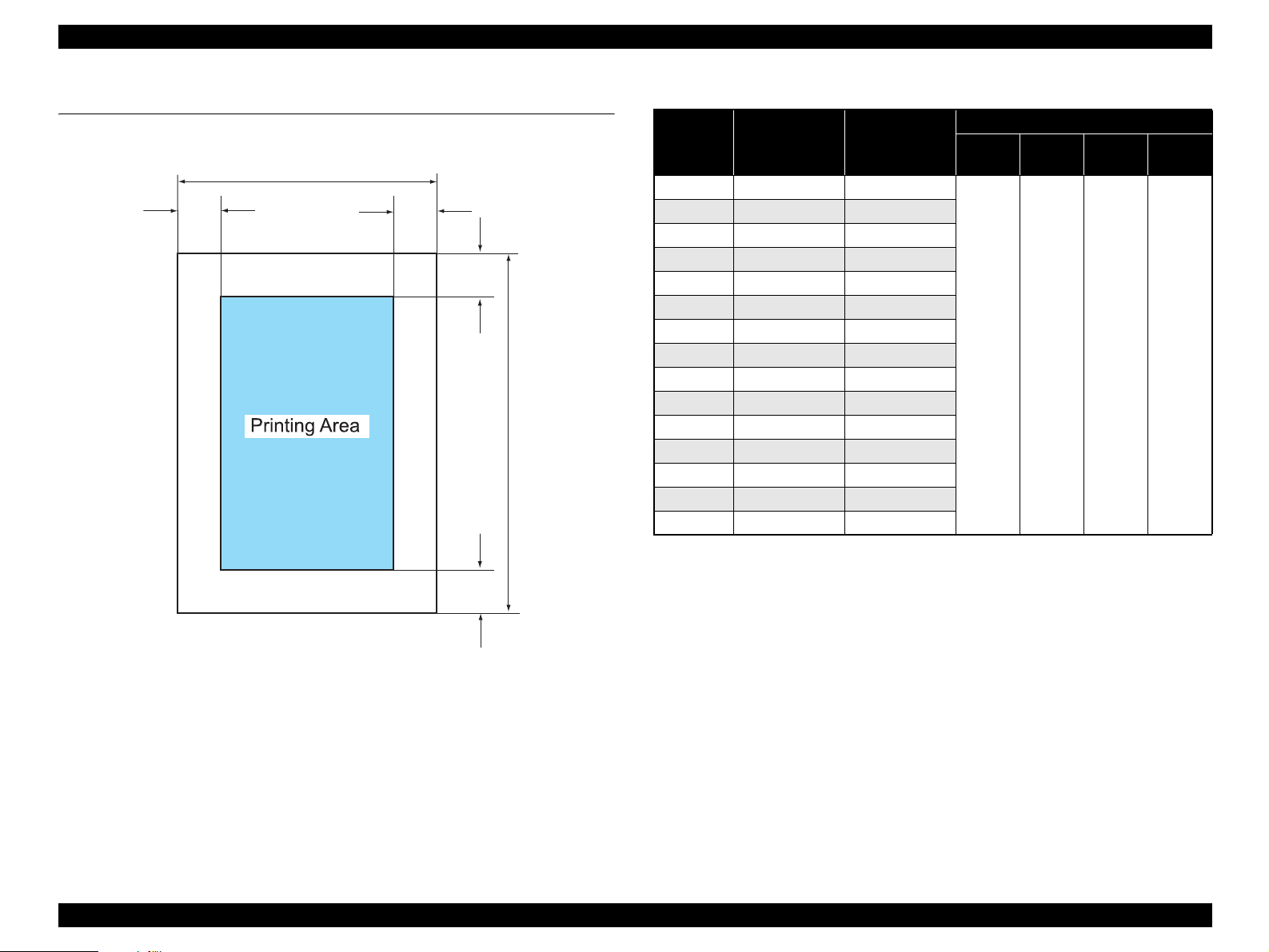

1.2 Printing Area

The printing area for this printer is shown below.

PW

LM RM

Figure 1-2. Printing Area

TM

BM

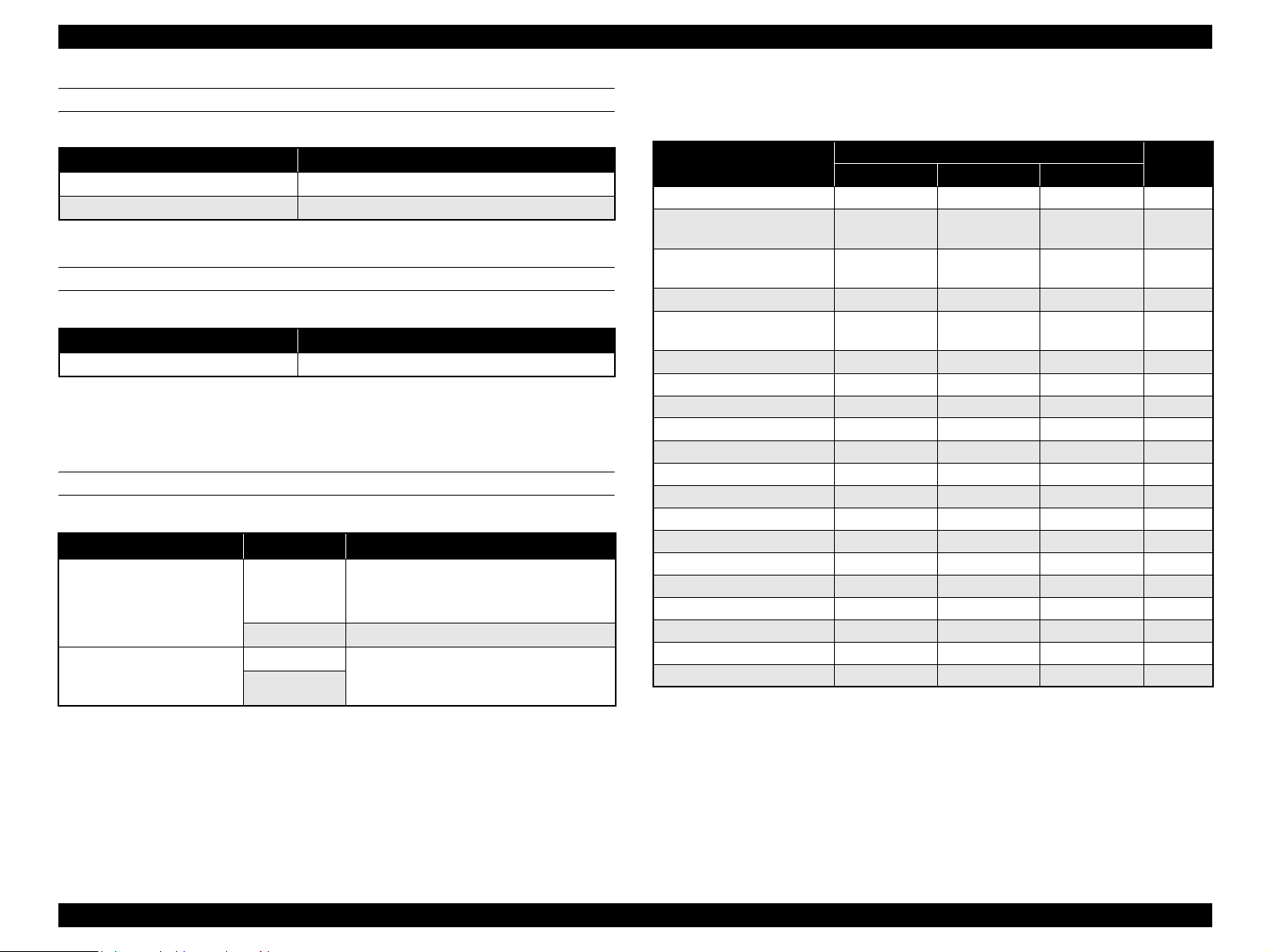

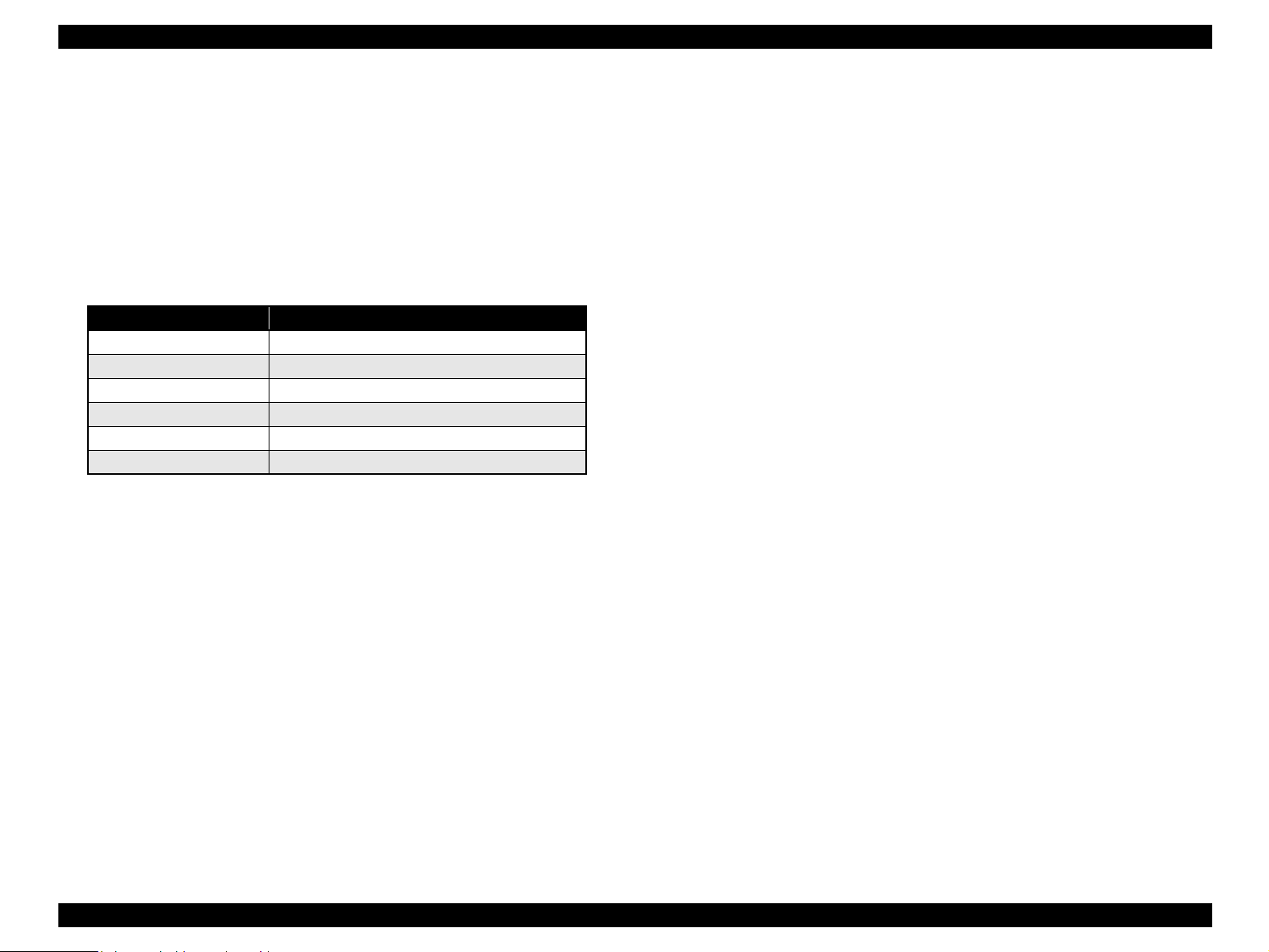

Table 1-1. Printing Area

Paper Size

Width

(PW)

Length

(PL)

Left

(LM)

Right

(RM)

Margin

Top

(TM)

Bottom

(BM)

*1

A3+ 329 mm (12.9 in.) 483 mm (19 in.)

A3 297 mm (11.7 in.) 420 mm (16.5 in.)

*2

US B

279.4 mm (11 in.) 431.8 mm (17 in.)

B4 257 mm (10.1 in.) 364 mm (14.3 in.)

US Legal 216 mm (8.5 in.) 356 mm (14 in.)

US Letter 216 mm (8.5 in.) 279 mm (10.9 in.)

A4 210 mm (8.3 in.) 297 mm (11.7 in.)

*3

B5

A5

182 mm (7.2 in.) 257 mm (10.1 in.)

*3

148 mm (5.8 in.) 210 mm (8.3 in.)

3 mm

(0.12 in.)

or more

3 mm

(0.12 in.)

or more

3 mm

(0.12 in.)

or more

3 mm

(0.12 in.)

or more

Half letter*2139.7 mm (5.5 in.) 215.9 mm (8.5 in.)

P

A6 105 mm (4.1 in.) 148 mm (5.8 in.)

*2

8x10

203.2 mm (8 in.) 254 mm (10 in.)

5x7 127 mm (5 in.) 262 mm (10.3 in.)

4x6 101.6 mm (4 in.) 152.4 mm (6 in.)

16:9 Wide 101.6 mm (4 in.)

180.6 mm (7.1 in.)

Note *1: Bottom margin can be reduced to 3 mm (minimum) by specifying the paper length

via ESC(S command, however, print quality may not be acceptable in the area 3 mm

to 43.3 mm (0.12 in. to 1.7 in.) from the bottom edge. When paper length is not

specified, the bottom margin will be 3 mm or more.

*2: EAI models only.

*3: Except for EAI models.

Note 1: Under the specific conditions, margins on all sides can be reduced to 0 mm.

2: Under the specific conditions, margins on both left and right sides can be reduced to

0 mm.

PRODUCT DESCRIPTION Printing Area 10

EPSON Stylus Photo 1400/1410 Revision A

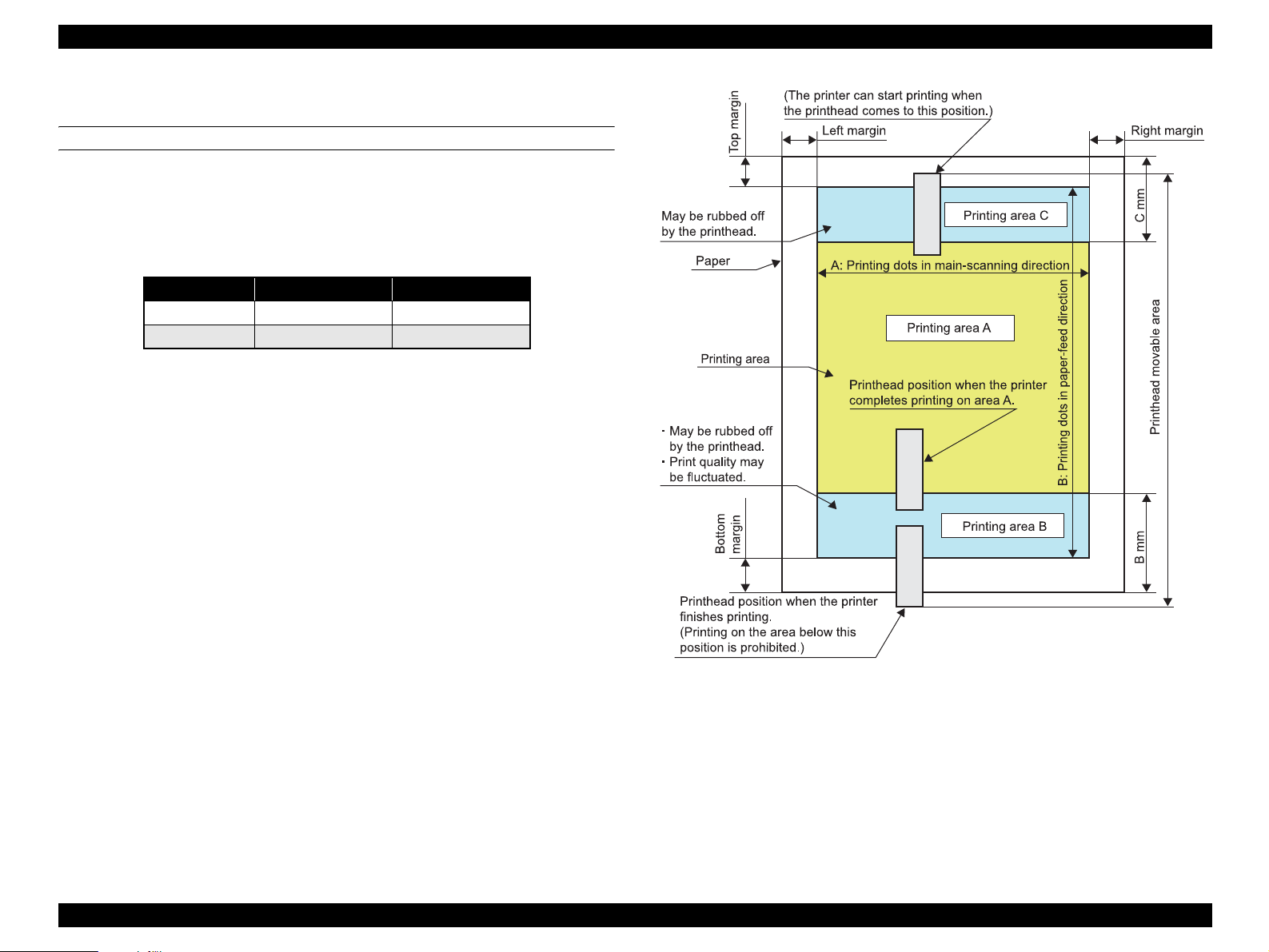

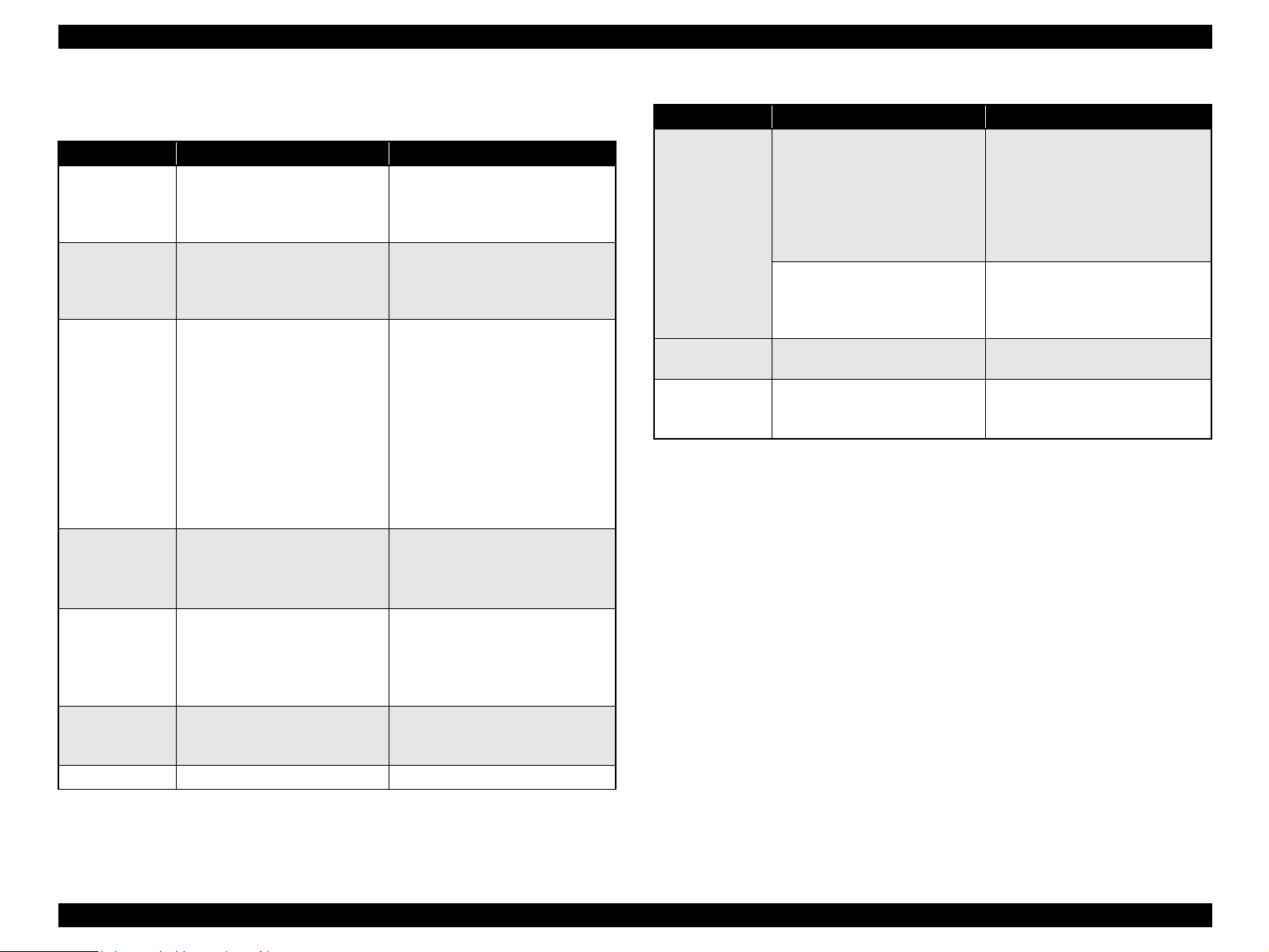

1.2.1 Printing Area (Cut sheet, Envelope)

Printing area (Print with borders)

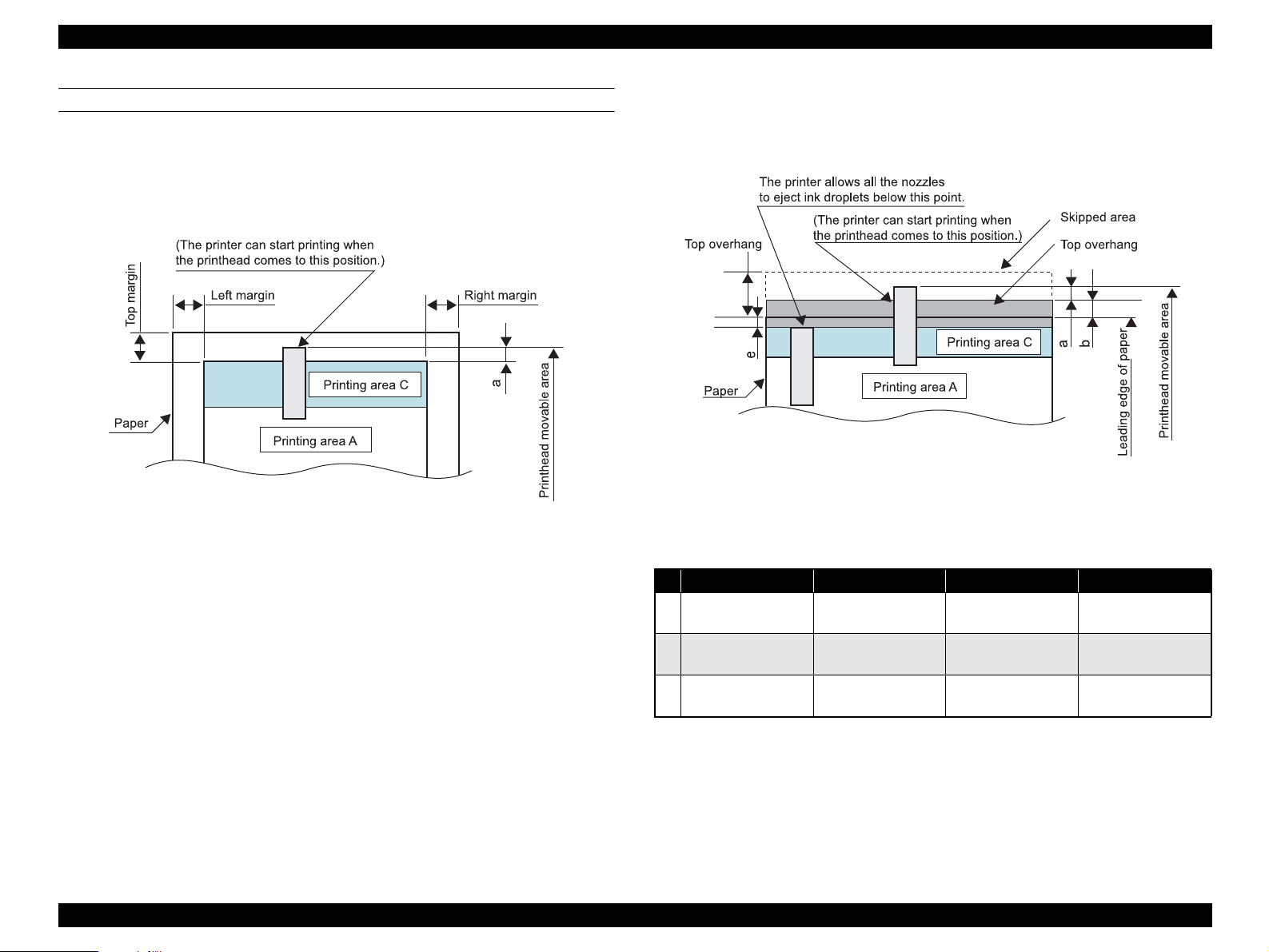

Figure 1-3 shows the printing area (A, B, and C) for cut sheet and envelope.

Print quality may be fluctuated in printing area B, and both printing area B and C are

subject to being rubbed off by the Printhead. Margins on all sides are designed to

prevent the printed images from running off the paper.

Table 1-2. Printing Area

Paper Type Printing Area B Printing Area C

Cut sheet 43.3 mm (1.7 in.) 40.1 mm (1.58 in.)

Envelope 20 mm (0.79 in.) 40.1 mm (1.58 in.)

Figure 1-3. Printing Area (Print with Borders)

PRODUCT DESCRIPTION Printing Area 11

EPSON Stylus Photo 1400/1410 Revision A

Printing area (Border-free printing)

Figure 1-4 shows the printing area (A, B, C, and D) when border-free printing is

selected. Printing area D is supposed to be trimmed and may not be printed.

Border-free printing is available on the following media sizes:

Paper width

54, 55, 89, 100, 127, 210 mm

4, 5, 8, 8.5 inch

Table 1-3. Printing Area Off the Paper Edges

Margin 4x6 A4/Letter or smaller A3+ or smaller

Top 19/360” (1.34 mm) 42/360” (2.96 mm) 42/360” (2.96 mm)

Left/ Right 36/360” (2.54 mm) 36/360” (2.54 mm) 49/360” (3.46 mm)

Bottom 36/360” (2.54 mm.) 57/360” (4.02 mm) 64/360” (4.52 mm)

*: 2.96 mm (168/1440”)

Length from leading edge of paper reference point to paper feed standby position

Figure 1-4. Printing Area (Border-free Printing)

PRODUCT DESCRIPTION Printing Area 12

EPSON Stylus Photo 1400/1410 Revision A

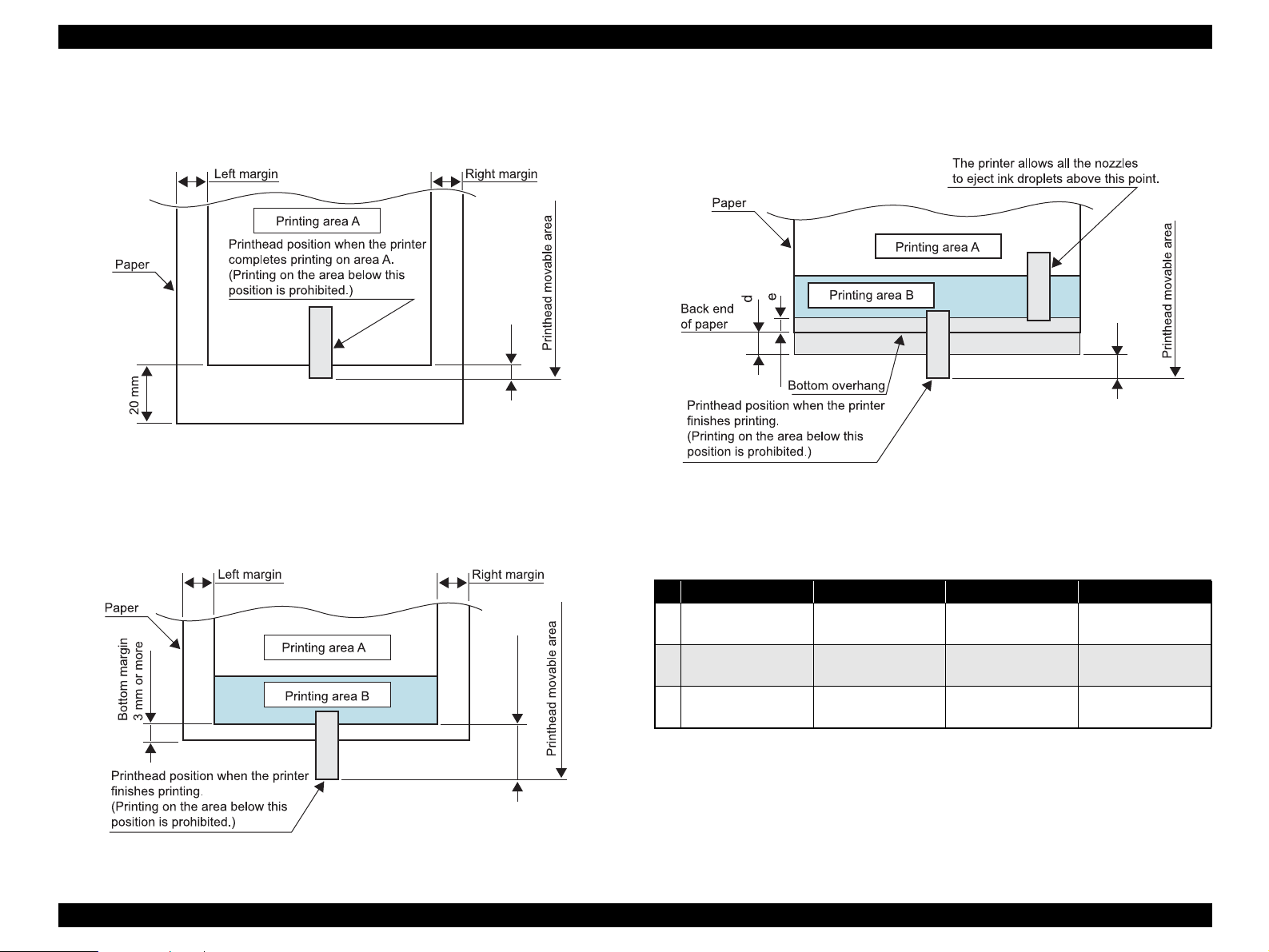

Printhead movable area

Figure 1-5 to Figure 1-9 show movable area of the printhead in relation to the printing

area in sub-scanning (paper-feed) direction.

Top edge

(1) When top margin is set to 3 mm (0.12 in.)

a = Not defined

Figure 1-5. Printhead Movable Area (3-mm Top Margin)

(2) When top margin is set to 0 mm

During printing the area indicated by the arrows a in the figure, some nozzles

are controlled not to eject ink droplets. When #1 nozzle passes through

printing area C, the control is cleared.

Figure 1-6. Printhead Movable Area (0-mm Top Margin)

Details on the length that the printhead moves off the paper edges (a), printing area off

the paper edges (b), and points where the nozzle control is cleared (e) are shown in the

table below.

4x6 (Hi-speed) 4x6

a

b

e

Note : As for e values, areas off the paper edges are indicated by negative values.

68/360”

(4.80 mm/0.19 in.)

13/360”

(0.92 mm/0.04 in.)

-55/360”

(-3.88 mm/-0.15 in.)

Nozzle positions for printing off the paper edge: #1 to #18 (18 nozzles in total)

Nozzle pitch for printing off the paper edge: 68/360 (4.80mm)

68/360”

(4.80 mm/0.19 in.)

9/360”

(0.64 mm/0.03 in.)

-50/360”

(-3.52 mm/-0.14 in.)

A4/Letter or smaller A3+ or smaller

68/360”

(4.80 mm/0.19 in.)

9/360”

(0.64 mm0.03 in.)

-46/360”

(-3.25 mm/-0.13 in.)

68/360”

(4.80 mm/0.19 in.)

9/360”

(0.64 mm0.03 in.)

-38/360”

(-2.68 mm/-0.1 in.)

PRODUCT DESCRIPTION Printing Area 13

EPSON Stylus Photo 1400/1410 Revision A

Bottom edge

(1) When bottom margin is set to 20 mm (0.79 in.)

(For envelope/when bottom margin is set automatically)

c = 33/360” (2.33 mm)

For reference: C= 20 mm - (length from upstream nozzle position to nip position + its

variations (simple addition) + variations in the bottom area accumulated from the top)

Figure 1-7. Printhead Movable Area (20-mm Bottom Margin)

(2) When bottom margin is set to 3 to 20 mm (0.12 to 0.79 in.)

(3) When bottom margin is set to 0 mm

During printing the area indicated by the arrows c in the figure, some nozzles

are controlled not to eject ink droplets.

C

Figure 1-9. Printhead Movable Area (0-mm bottom margin)

c

Details on the length that the printhead moves off the paper edges (a), printing area off

the paper edges (b), and points where the nozzle control is cleared (e) are shown in the

table below.

c

c = Not defined

Figure 1-8. Printhead Movable Area (3-mm Bottom Margin)

4x6 (Hi-speed) 4x6

a

b

e

Note : As for e values, areas off the paper edges are indicated by negative values.

68/360”

(4.80 mm/0.19 in.)

27/360”

(1.91 mm/0.07 in.)

-41/360”

(-2.89 mm/-0.11 in.)

Nozzle positions for printing off the paper edge: #73 to #90 (18 nozzles in total)

Nozzle pitch for printing off the paper edge: 68/360 (4.80mm)

68/360”

(4.80 mm/0.19 in.)

30/360”

(2.12 mm/0.08 in.)

-44/360”

(-3.10 mm/-0.12 in.)

A4/Letter or smaller A3+ or smaller

68/360”

(4.80 mm/0.19 in.)

39/360”

(2.75 mm/0.10 in.)

-38/360”

(-2.68 mm/-0.1 in.)

68/360”

(4.80 mm/0.19 in.)

55/360”

(3.88 mm/0.16 in.)

-28/360”

(-1.98 mm/-0.08 in.)

PRODUCT DESCRIPTION Printing Area 14

EPSON Stylus Photo 1400/1410 Revision A

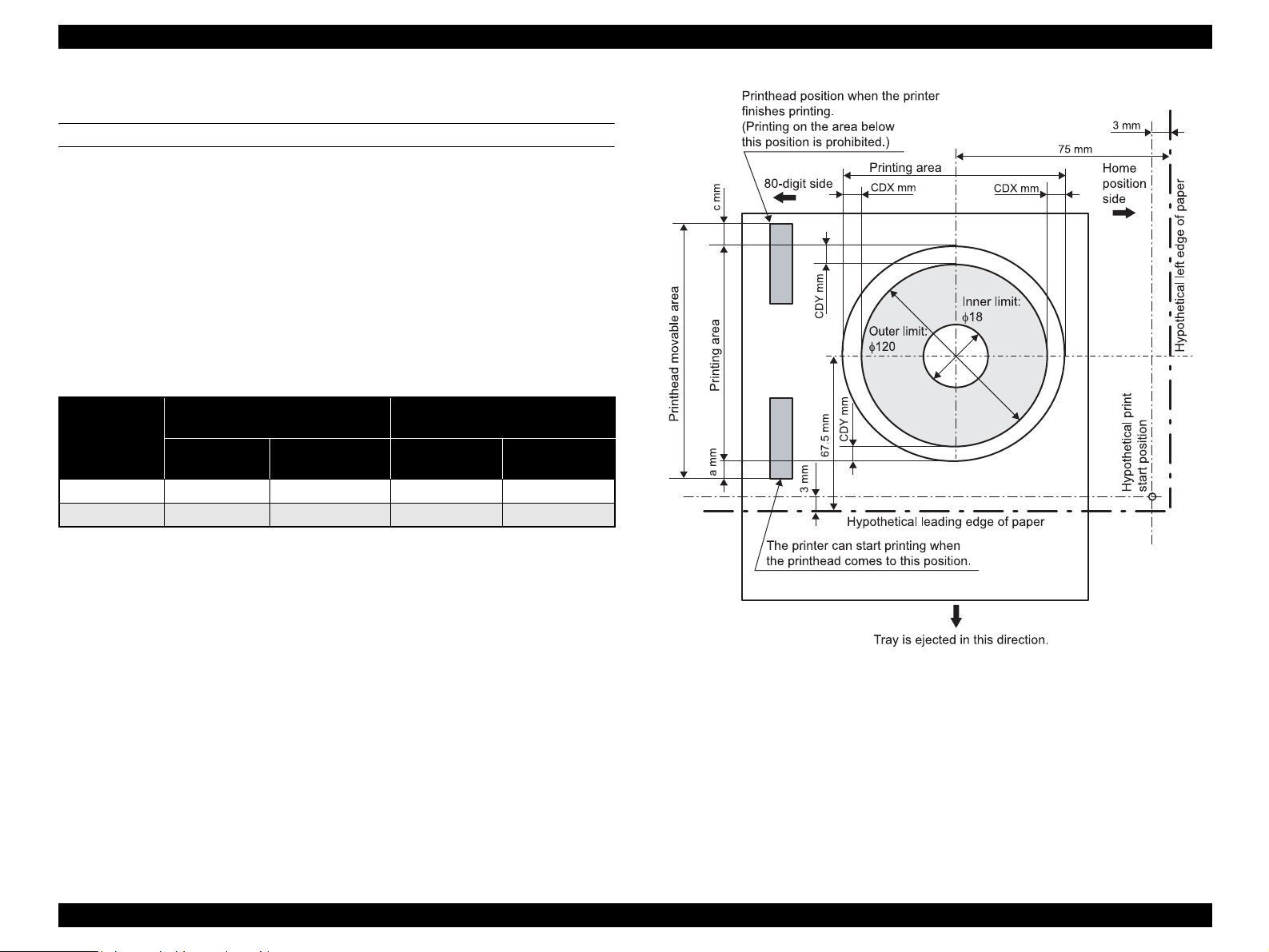

1.2.1.1 Printing Area (CD-R)

Printing Area

Figure 1-10 shows the printing area for CD-R. Outer and inner limit of printing area is

φ120 and φ18, respectively. The process of determining the reference point and

defining the printing area is described below.

(1) The reference point in main-scanning direction is 72 mm off from the center

of the CD-R (toward the home position side). The center of the CD-R is

detected automatically.

(2) The reference point in paper-feed direction is 67.5 mm off from the center of

the CD-R (toward the downstream side).

(3) User can change the center position of the CD-R in the range of ± CDX mm

(main-scanning direction) and ± CDY mm (paper-feed direction).

Amount of the Nozzles Off the

Unit

inch 358/360 359/360 ±14/180 ±28/360

mm 25.26 25.33 ±2 ±2

Paper Edges

a (Top) c (Bottom)

Adjustable Range of the CD-R

Center Position

CDX

(X direction)

CDY

(Y direction)

Figure 1-10. Printing Area (CD-R)

PRODUCT DESCRIPTION Printing Area 15

EPSON Stylus Photo 1400/1410 Revision A

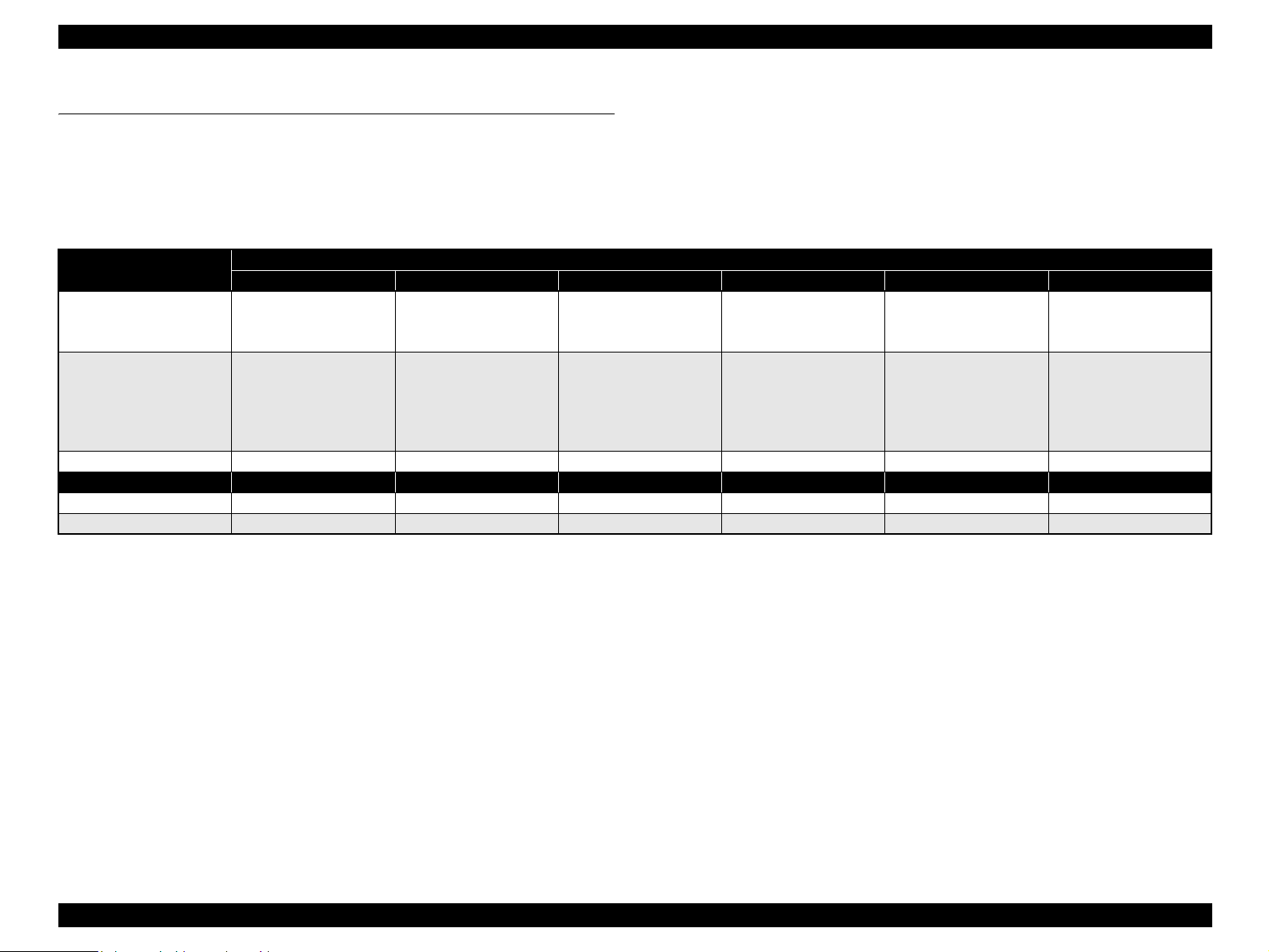

1.3 PG Setting

EPSON Stylus Photo 1400/1410 features an Auto Platen Gap (APG) adjuster that sets the platen gap to suit the type of paper being used, and this prevents paper misalignment and

jamming that can cause problems during operation.

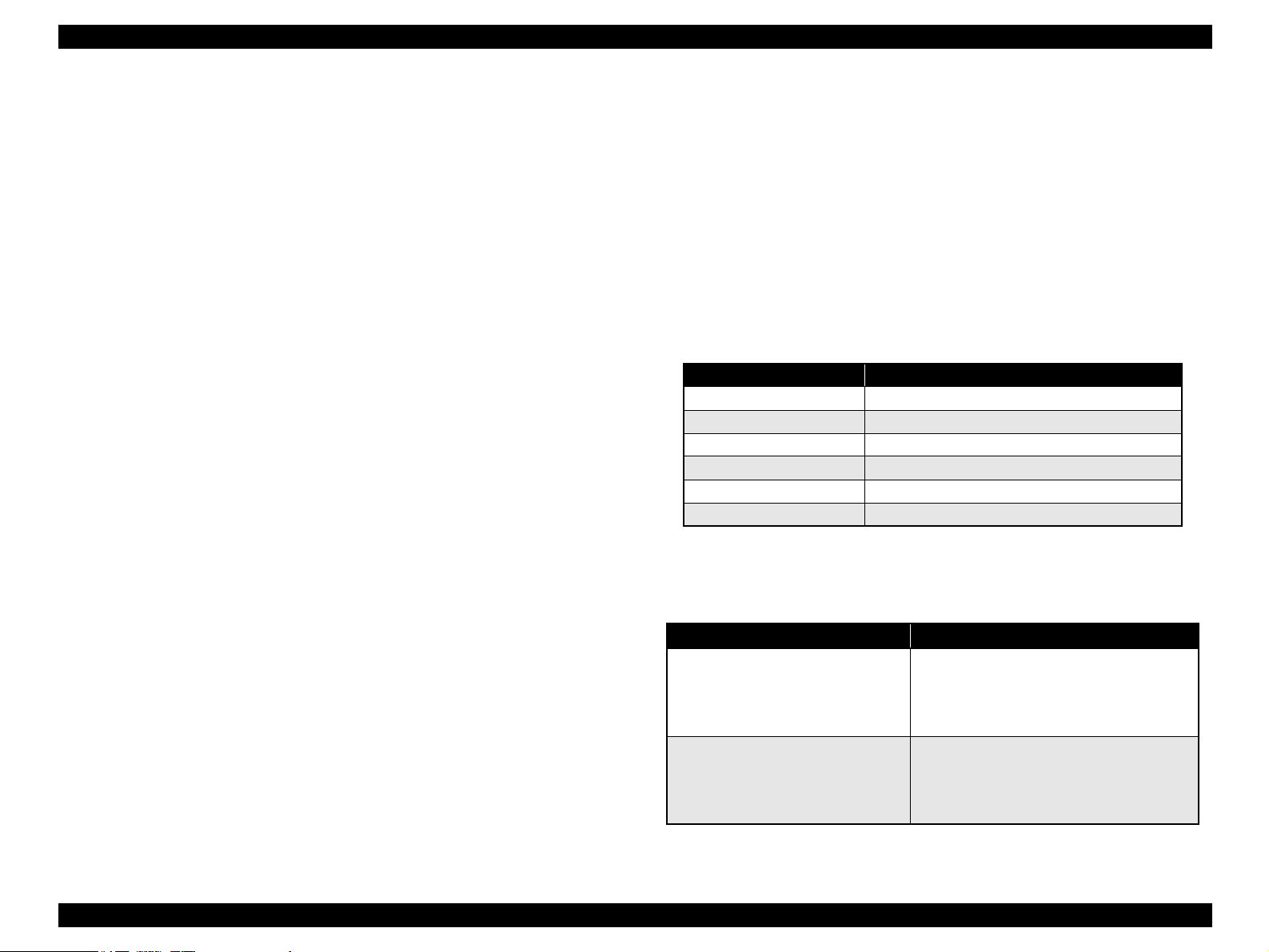

Table 1-4 shows the relationship among PG positions, media, and sensors.

Table 1-4. PG Setting

PG Position

PG (– –) PG (–) PG (Typ) PG (+) PG (++) Release

• Plain paper

Printing

Not printing

PG value 1.05 mm (0.041 inch) 1.2 mm (0.047 inch) 1.7 mm (0.06 inch) 2.1 mm (0.08 inch) 4.5 mm (0.17 inch) ---

Sensor PG (– –) PG (–) PG (Typ) PG (+) PG (++) Release

APG sensor 1

APG sensor 2 L L L L H H

*

• Some special paper • Special paper

--- ---

HHHHHH

•PG (−) rubbing

prevention

• Standing-by after

power-on

(Output tray is lowered)

• At power-off

• Envelope

• PG (Typ) rubbing

prevention

---

•CD-R

• Initialization at poweron

• Cleaning (wiping)

• Replacing ink

cartridge(s)

---

• Waiting for CD-R to be

fed

• Removing jammed

paper

Note *: APG sensor 1 outputs L between each PG position.

PRODUCT DESCRIPTION PG Setting 16

EPSON Stylus Photo 1400/1410 Revision A

1.4 Printer Function

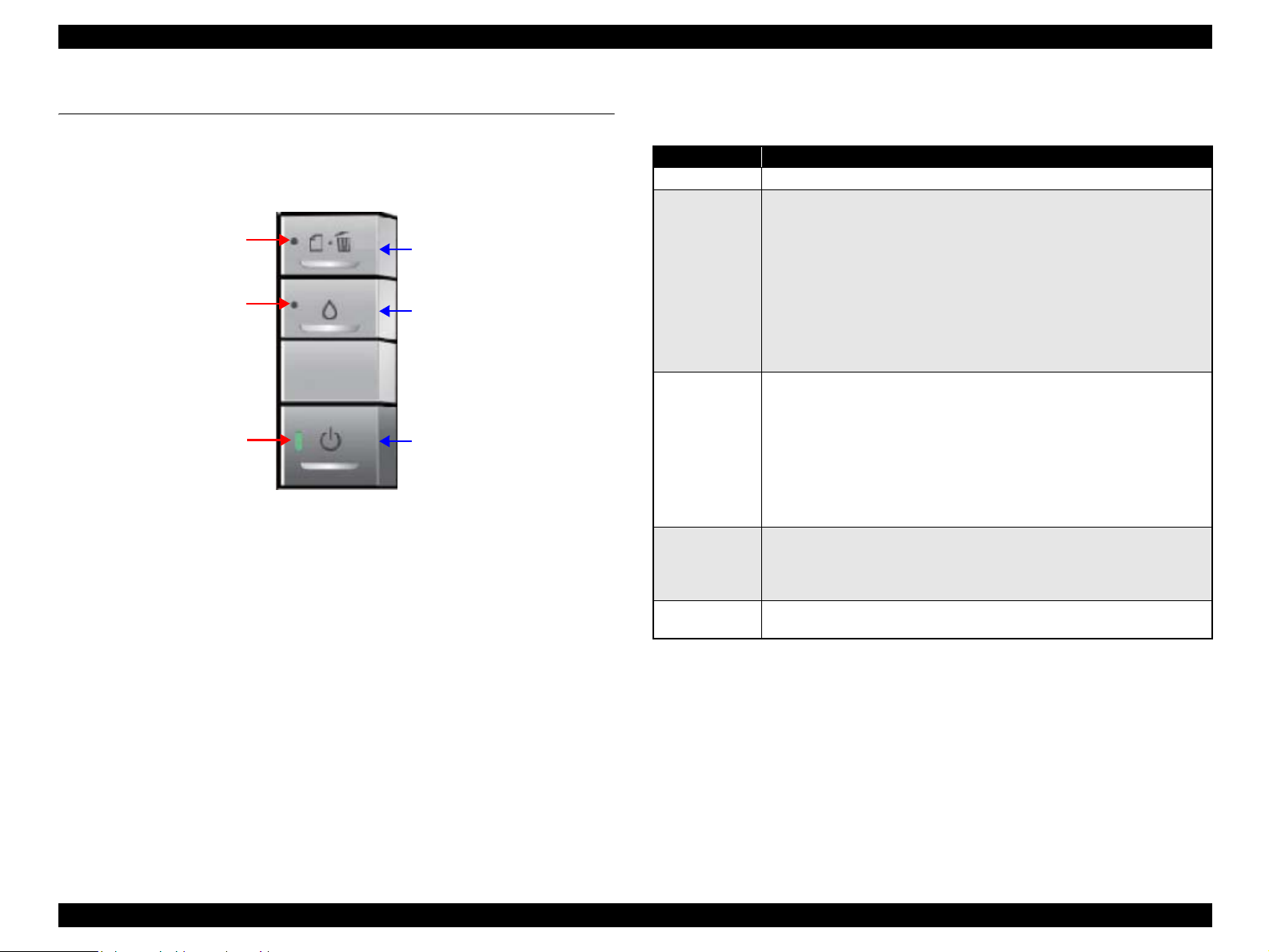

1.4.1 Operator Controls

The control panel is shown in the figure below.

Paper LED (red)

Ink LED (red)

Power LED (green)

Figure 1-11. Operator Controls

1.4.2 Buttons

Power button

Paper button

Ink button

1.4.3 LED Indicators

Paper button

Ink button

Power button

1.4.4 Panel Functions

Table 1-5. Normal Panel Functions

Button Function

Power

Paper

Ink

Ink

(When pushed

and held for 3

seconds)

CD-R guide

(When opened)

Note *: CD-R guide error occurs when the CD-R guide is opened during printing, or when

• Turns on/off the power.

• Loads or ejects the paper (Invalid when the CD-R guide is opened.)

• Clears double feed error and resumes printing.

• Cancels the current print job during printing.

• Clears paper out error and resumes printing.

• Clears paper jam error, ejects the paper, and resumes printing.

• When ink end (any cartridge) error occurs, the ink cartridge holder moves

to the ink replacement position.

• The ink cartridge holder returns to the home position from the ink

replacement position.

• The ink cartridge holder moves to the ink replacement position.

• When ink low, ink end, or no ink cartridge error occurs, the ink cartridge

holder moves to the ink check position.

• When the ink cartridge holder is in the ink check position, the holder

moves to check another cartridge of different color, or the holder moves to

the ink replacement position.

• The ink cartridge holder returns to the home position from the ink

replacement position.

• Starts printhead cleaning

• When ink low, ink end, or no ink cartridge error occurs, ink replacement

sequence starts.

• Clears CD-R guide error.

the printer receives a print job for cut-sheet with the CD-R guide opened.

*

Power LED: Green

Paper LED: Red

Ink LED: Red

PRODUCT DESCRIPTION Printer Function 17

EPSON Stylus Photo 1400/1410 Revision A

Power-on functions

Table 1-6. Panel Function during Power-on

Button Held during Power-on Function

Paper

Ink

Starts status printings.

Starts in rubbing reduction mode.

Power-off function

Table 1-7. Panel Function during Power-off

Button Held during Power-off Function

Ink Forced power-off.

Note : Press the power button first. Making sure the power button is not pressed down, push

and hold the ink button for 7 seconds.

CD-R printing

Table 1-8. Panel Function during Printing on CD-R

Button CD/DVD Tray Function

• Clears CD/DVD tray error.

Paper

Ink

Inserted

Not inserted Clears CD/DVD tray error

Inserted Same as normal panel functions (including

Not inserted

• Cancels the current print job during

printing.

the functions when the button is pushed and

held for 3 seconds).

1.4.5 Printer Condition and Panel LED Status

Table 1-9. Panel Status

Printer Status

Power ON (Ready) condition On --- --- 12

Camera being connected

(No rubbing reduction)

Camera being connected

(Rubbing reduction)

Ink low --- --- Blink 11

Unsupported device

connection error

Data processing Blink --- --- 10

Loading/Ejecting paper Blink --- --- 10

No ink cartridge or Ink end --- --- On 9

CSIC error --- --- On 9

Processing ink sequence Blink --- --- 8

Ink cartridge change mode Blink --- --- 7

CD/DVD tray error --- On --- 6

Paper out --- On --- 6

Double feed --- On --- 6

Paper (CD-R) jam --- Blink --- 5

CD-R guide error

Maintenance request Off Alt Blink Alt Blink 3

Fatal error Off Hi-speed Blink Hi-speed Blink 2

Powering OFF Hi-speed Blink Off Off 1

Reset request

Note *: All the LEDs turn on for 0.2 seconds.

Note : ---: No change to LED.

*

Blink: 0.5 seconds on, 0.5 seconds off (repeat)

Blink2: 0.2 seconds on, 0.2 seconds off, 0.2 seconds on, 0.4 seconds off (repeat)

Blink3: 0.2 seconds off, 0.2 seconds on, 0.2 seconds off, 0.4 seconds on (repeat)

Blink4: 0.8 seconds on, 0.2 seconds off

Hi-speed Blink: 0.1 seconds on, 0.1 seconds off (repeat)

Alt Blink: Continuous alternating blink of Paper and Ink LEDs.

Power Paper Ink

Blink2 --- --- 12

Blink4 --- --- 12

--- Blink2 Blink3 10

--- Blink2 Hi-speed Blink 4

On On On ---

Button LEDs

Priority

PRODUCT DESCRIPTION Printer Function 18

EPSON Stylus Photo 1400/1410 Revision A

1.4.6 Errors

Table 1-10. Errors

Error Status Occurrence Condition Remedy

Ink end

Paper out

Paper jam

Double feed error

The printer has almost run out of

ink in any cartridge.

The printer fails to load a sheet of

paper.

1. The printer cannot eject the

remaining paper at power-on

within predetermined steps.

2. The printer cannot eject the

paper by FF command or

pressing the Paper button.

3. The printer cannot eject the CD/

DVD tray.

4. The printer prints on a 58 mm

(2.3 inch) or shorter length of

paper.

The printer detects that two sheets

have stuck together during paper

feed.

Carry out the ink cartridge

replacement operation. Remove the

CD/DVD tray before pressing the Ink

button.

Load a paper in the ASF, and press

the Paper button to feed the paper. Set

the CD-R guide lever to the ASF

position before pressing the button.

1. ASF mode

Remove the jammed paper and

press the Paper button. Set the CDR guide lever to the ASF position

before pressing the button.

2. CD-R mode

Remove the jammed CD/DVD tray

and press the Paper button.

Press the Paper button to eject the

paper. Set the CD-R guide lever to the

ASF position before pressing the

button.

Table 1-10. Errors

Error Status Occurrence Condition Remedy

CD-R guide error

CD/DVD tray

error

Unsupported

device

connection error

1. The printer receives a print job

for cut-sheet when the CD-R

guide lever is set to the CD-R

position.

2. The CD-R guide lever is set to

the CD-R position during ASF

printing.

1. The printer receives a print job

for CD-R media when the CD-R

guide lever is set to the ASF

position.

CD/DVD tray is not inserted. Insert a CD/DVD tray and press the

Unsupported device is connected. Disconnect the device from the USB

Set the CD-R guide lever to the ASF

position.

Set the CD-R guide lever to the CD-R

position.

Paper button.

connector.

No ink cartridge

Ink cartridge error

Maintenance

request

Fatal error

1. The printer detects at least one

ink cartridge is missing.

2. The printer cannot communicate

with the CSIC chip on one of the

cartridges.

When the total quantity of wasted

ink used for cleaning and flushing

reaches the calculated limit.

The printer cannot control error.

Make sure genuine EPSON ink

cartridges are inserted and press the

Ink button. Remove the CD/DVD tray

before pressing the button.

Replace the waste ink pad and reset

the Waste Ink Counter.

Turn the power off and on again.

PRODUCT DESCRIPTION Printer Function 19

EPSON Stylus Photo 1400/1410 Revision A

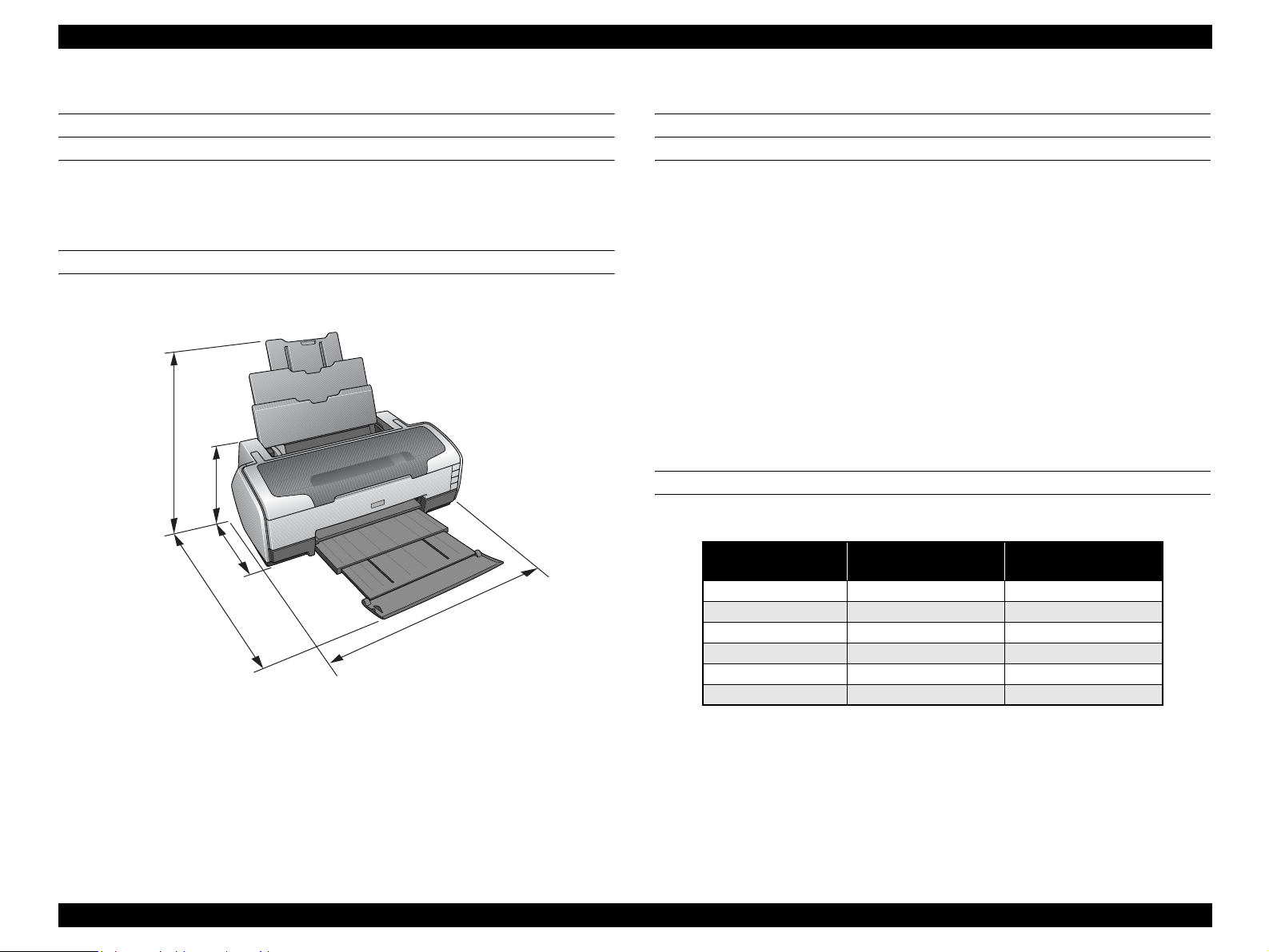

1.5 Size and Weight

Dimensions

Storage: 615 mm (24.2 in.) W x 314 mm (12.4 in.) D x 223 mm (8.8 in.) H

Printing: 615mm (24.2 in.) W x 803 mm (31.6 in.) D x 413 mm (16.3 in.) H

Weight

11.5 Kg (25.4 lbs.)

413

223

314

803

615

Figure 1-12. Physical Dimensions, in mm

1.6 Accessories

Standard accessories

User’s guide

Ink cartridge (one for each of the six colors)

Software CD-ROM

Setup sheet

On-line questionnaire sheet

Customer Satisfaction Card (information card)

Guarantee card

CD/DVD print kit

CD/DVD tray

Small CD insert

Consumable and optional supplies

Ink cartridge

Color EAI/EUR

Black T0791 T0811

Cyan T0792 T0812

Magenta T0793 T0813

Yellow T0794 T0814

Light Cyan T0795 T0815

Light Magenta T0796 T0816

Network Print Server

Latin / CIS / EAL

Middle East / Africa

PRODUCT DESCRIPTION Size and Weight 20

OPERATING PRINCIPLES

CHAPTER

2

EPSON Stylus Photo 1400/1410 Revision A

2.1 Overview

This chapter explains the operating principles of the mechanical sections and electrical

circuits in this product. The main components of this product are as follows.

Control Circuit Board : C655 MAIN

Power Supply Circuit Board : C589 PSB

Control Panel Board : C589 PNL

Head Circuit Board : C653 HEAD

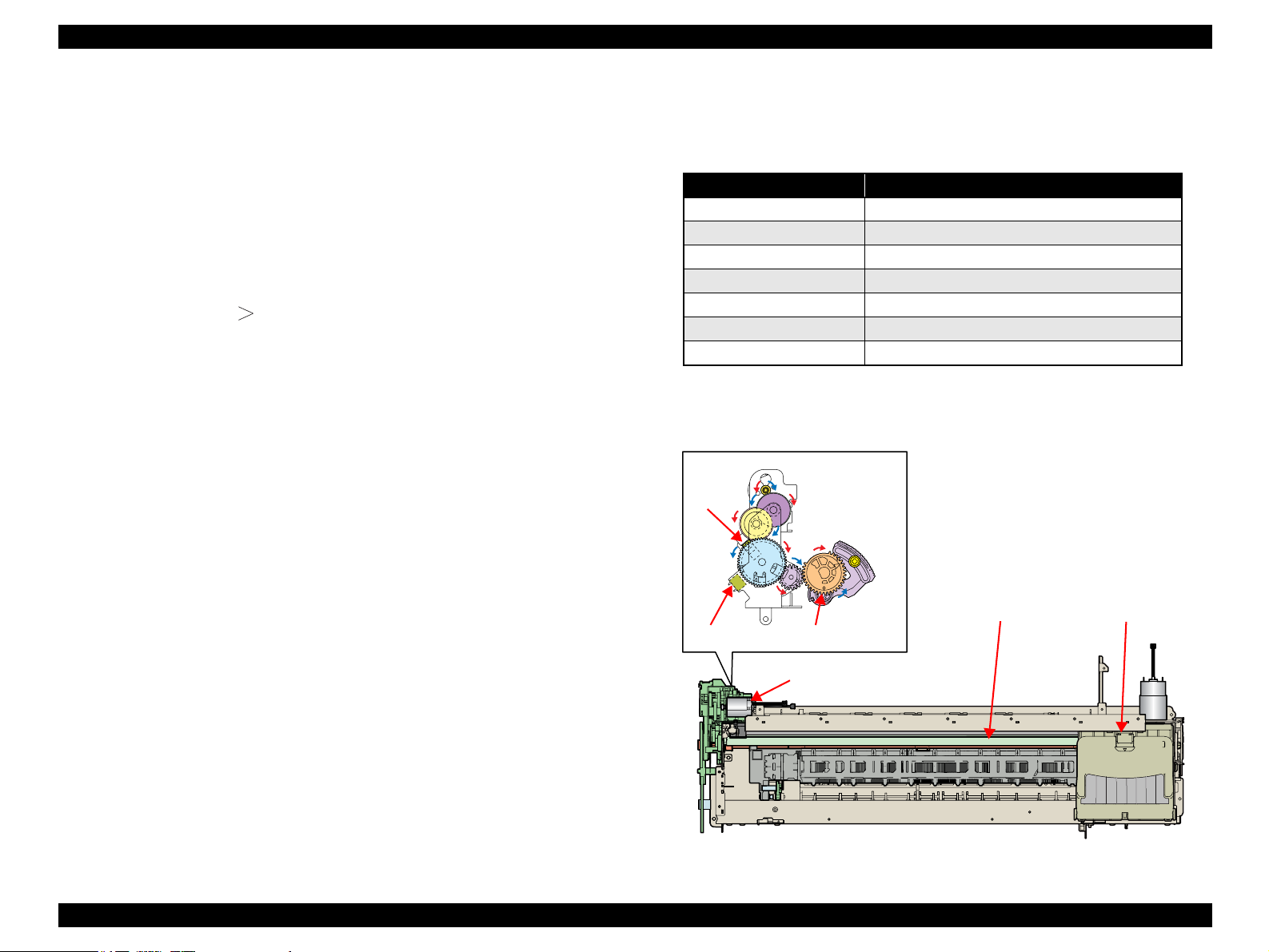

2.2 Printer Mechanism

In common with previous model, this printer uses DC motors and stepping motors as

power source. The following table describes the motor types and their applications.

Table 2-1. Motors

Motor Name Type Applications/Functions

Drives the Carriage. Makes very little driving

CR Motor DC motor with brushes

PF Motor DC motor with brushes

APG Motor DC motor with brushes

ASF Motor

Pump Motor

4-phase, 48-pole PM type

stepping motor

4-phase, 48-pole PM type

stepping motor

noise. Controlled by the CR linear scale and CR

encoder sensor.

Drives the paper feed roller for the fixed-value

paper loading or the paper feed/eject operation. To

grasp the paper feed pitch, the precision gear

surface is fitted with the PF Scale and the PF

Encoder Sensor is used to control the motor.

Drives the Carriage Unit at the time of PG setting.

The two APG Sensors and Carriage Shaft are

driven vertically to control the motor.

Drives the paper feed operation of the ASF. Since

this is a stepping motor, no scales or photo sensors

are required to grasp the driving conditions.

Drives the pump, wiper, etc. of the Ink System.

Since this is a stepping motor, no scales or photo

sensors are required to grasp the driving

conditions.

The basic mechanism is the same as the Stylus Photo R1800.

PF Encoder

Sensor

Front Paper

Eject Roller

Rear Paper

Eject Roller

PF Roller

CR Scale

PW Sensor

Carriage

Unit

Ink System

Unit

Pump Motor

CD-R Sensor

Carriage

Shaft

PF Scale

PF Motor

Figure 2-1. Printer Mechanism Outline

APG Sensors

APG Motor

APF Sensor

Timing Belt

CR Encoder

Sensor

LD Roller

Retard

Roller

PE Sensor

ASF Motor

CR Motor

OPERATING PRINCIPLES Overview 22

EPSON Stylus Photo 1400/1410 Revision A

2.2.1 Carriage Mechanism

The Carriage mechanism consists of parts/units such as the Carriage Motor (CR

Motor), Carriage Shafts, Platen Gap Adjustment Mechanism and Carriage Lock

Mechanism.

2.2.1.1 Carriage Mechanism

The following indicates the specifications of the CR motor (DC motor) that drives the

Carriage.

Table 2-2. CR Motor Specifications

Item Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Armature resistance 23.6Ω ± 10%

Inductance 17.5mH ± 25%

Drive method PWM, constant-current chopping

Drive IC A6628

Closed loop control based on the CR Motor (DC Motor) and CR Encoder Sensor has

advantages in stabilized print quality and silent operation.

Heat Generation Control

The printer has a mechanism to reduce the variations in the torque constant and

coil resistance of the DC motors, and variations in output voltage of the Power

Supply Board to obtain a designated heating value.

CR Measurement Sequence

To set the appropriate drive current value according to the CR mechanical load,

the mechanical load is measured in a CR measurement sequence and saved into

the EEPROM at power-on or after replacing the Ink Cartridge(s).

The above control and sequences correct the drive current value of the CR Motor

according to not only the mechanical load but also the variations of the motors. In

addition, the resultant CR drive current value is used to calculate a heating value, and

when the specified heating value is reached, wait time is provided per CR path for

printing.

CR Variation Measurement Sequence

The variations mentioned above are measured in a CR variation measurement

sequence when the CR mechanical load is in the initial status and saved into the

EEPROM. According to the saved information, the printer controls the drive

voltage to obtain a designated driving current. This minimizes the unit-to-unit

variation.

OPERATING PRINCIPLES Printer Mechanism 23

EPSON Stylus Photo 1400/1410 Revision A

2.2.1.2 Carriage Home Position Detection

As in the previous model, the Carriage Home Position is detected using the drive

current of the CR Motor and the speed/position signal of the CR Linear Encoder.

The basic home position detection sequence is described below.

1. The CR linear encoder pulse counter in the CPU is reset by the initialization

operation performed at power-on.

2. When the CR Motor rotates counterclockwise, the Carriage Unit moves from left

to right. When the following conditions are satisfied, the CPU assumes that the

Carriage Unit made contact with the right frame.

The ASIC detects 935/1500 counts or more in the PWM output under CR

Motor load positioning control.

P1 (number of output pulses from when the power is switched on till the

Carriage Unit makes contact with the right frame) is 19 steps or less.

3. When the CR Motor rotates clockwise, the Carriage Unit moves from right to left.

When the following conditions are satisfied, the CPU assumes that the Carriage

Unit reached the CR lock confirmation position.

The ASIC detects 600/1500 counts or more in the PWM output under CR

Motor load positioning control.

A difference between P1 and P2 (number of output pulses from when the

Carriage Unit made contact with the right frame until it reaches the Carriage

lock confirmation position) is 19 steps or less.

2.2.1.3 Sequence Used for PW Detection

The PW (paper width) Sensor installed on the bottom of the Carriage Unit is used to

control the printer according to various sequences.

The following briefly describes the operating principle of the PW Sensor.

A dark voltage is measured by the PW Sensor in three places at the right flat area (area

without the absorber) on the Front Paper Guide every time the printer is turned on, and

the measurement values are saved into the EEPROM as threshold values.

Threshold value detection voltage: Paper present

Threshold value detection voltage: Paper absent

The following sequences are performed.

Detection of Left and Right Edges of Paper Control

Before Printing

The printer sets the print range according to the paper-size information from

the Driver and the actual paper-size detected by the PW sensor.

During Printing

When executing a borderless printing, the printer sets the off-range margins

by detecting the paper edges with the PW Sensor. When the resolution is 1440

x 1440 (VSD3) or 2880 x 1440 (VSD3) dpi, the printer performs the OffRange Thinning Out Control to make a further correction to the off-range

margins.

4. When the CR Motor rotates counterclockwise to move the Carriage from left to

right and the CPU detects 935/1500 counts or more in the PWM output under CR

Motor load positioning control, the printer judges that the Carriage has moved to

the far right position (in contact with the right frame).

5. When a difference between P1 and P3 (number of output pulses from when the

Carriage Unit reached the Carriage lock confirmation position until it makes

contact with the right frame) is 4 steps or less, the printer judges that the Carriage

Unit is in the home position.

IC9 (CPU-ASIC) sets the drive current value adequate for the Carriage Unit motion

and outputs it to the motor driver.

Based on the signal output from IC9 (CPU-ASIC), IC11 (Motor Driver) outputs the CR

Motor drive current to the CR Motor.

Detection of Top Edge of Paper Control

Before starting a print job, the printer detects the top edge of a loaded single sheet

of paper to set the off-range top margin. (Only when not detecting the top edge of

paper with the PW Sensor.)

Detection of Bottom Edge of Paper Control

After starting a borderless printing, the printer sets the off-range bottom margin.

Detection of Edges of CD-R Control

Before starting to print, the PW Sensor detects top, bottom, left and right edges of

the CD-R. See Section 2.2.3.3 CD-R Printing Mechanism on page 29.

OPERATING PRINCIPLES Printer Mechanism 24

EPSON Stylus Photo 1400/1410 Revision A

Detection of CD/DVD Tray Control

Before starting to print, determines the type of media.

PW sensor dark voltage (VH) measurement

PW sensor dark voltage (VH) measurement is performed at the following timings

and locations and used to calculate the threshold value of whether paper is present

or not.

CD/DVD Tray

When printing on a CD-R, the dark voltage is measured on the CD/DVD tray,

and the threshold value (VS) is then calculated and saved in the EEPROM

area as a PW detection level.

• Threshold value detection voltage: CD-R present

(tray home position detected)

The measurement voltage in the presence of the CD-R is saved into the

EEPROM as a white level. The white level value is used to check the sensor

deterioration condition on occasions such as servicing.

• If the measurement value of the white level is close to that of the PW

detection level, it means that the sensor is dirty or deteriorated.

2.2.1.4 APG (Auto Platen Gap) Adjustment Mechanism

The following indicates the specification of the DC motor that drives the APG adjuster.

Table 2-3. APG Motor Specifications

Item Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Armature resistance 64.7Ω ± 15%

Inductance 37.6mH ± 25%

Rotor Inertia 3.94gcm

Drive method PWM, constant-current chopping

Drive IC A6628

The APG Motor (DC Motor) and two APG Sensors drive the PG Cam to automatically

adjust the PG amount according to the paper.

APG

Sensor

2

Carriage Shaft

PG CamAPG Sensor

APG Motor

Carriage Unit

Figure 2-2. APG Mechanism

OPERATING PRINCIPLES Printer Mechanism 25

EPSON Stylus Photo 1400/1410 Revision A

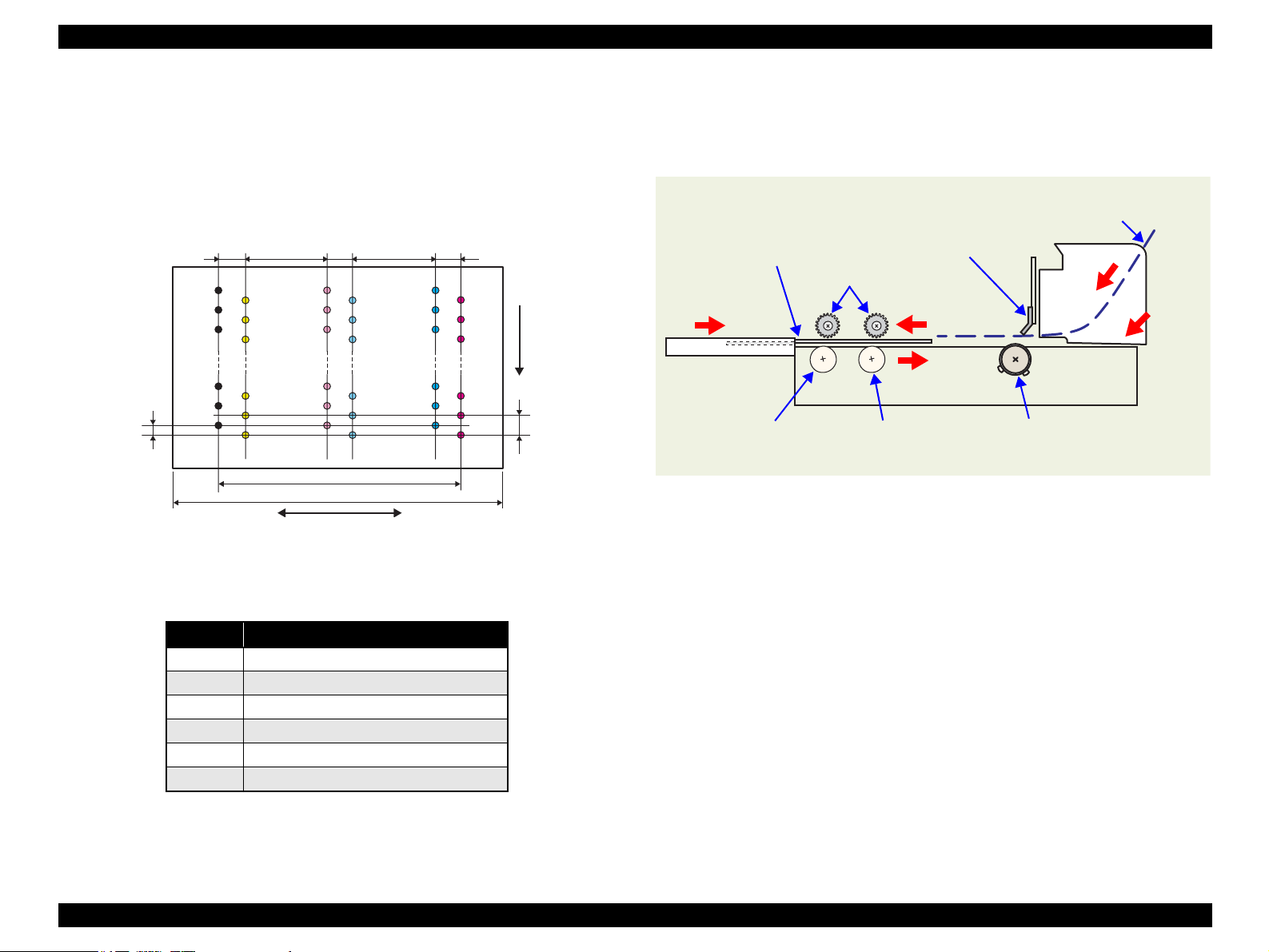

2.2.2 Printhead Specifications

The Printhead of this product is a F3-Mach head.

The following shows the arrangement of the nozzles and the color arrangement of each

nozzle line when viewing the Printhead from behind.

0.141mm

(1/180inch)

(24/720inch)

Line A

(176/720inch)

0.846mm

6.209mm

0.846mm

(24/720inch)

Line C

Line B

14.95mm

22.81mm

Carriage moving direction

6.209mm

(216/720inch)

Line E

Line D

0.846mm

(24/720inch)

Paper feeding

direction

Line F

0.282mm

(1/90inch)

2.2.3 Paper Feeding Mechanism

The paper feeding mechanism is a mechanism that feeds paper or CD/DVD tray to the

PF Roller Shaft.

Cut sheet

CD/DVD Tray

Star Wheel Rollers

Front Paper Eject Roller

Figure 2-4. Paper Feeding Mechanism

Rear Paper Eject Roller

PE Sensor

PF Roller

Figure 2-3. Nozzle Arrangement

Table 2-4. Nozzle Lines and the Corresponding Ink Color

Line Ink

ABlack

B Yellow

C Light-Magenta

D Light-Cyan

ECyan

F Magenta

OPERATING PRINCIPLES Printer Mechanism 26

EPSON Stylus Photo 1400/1410 Revision A

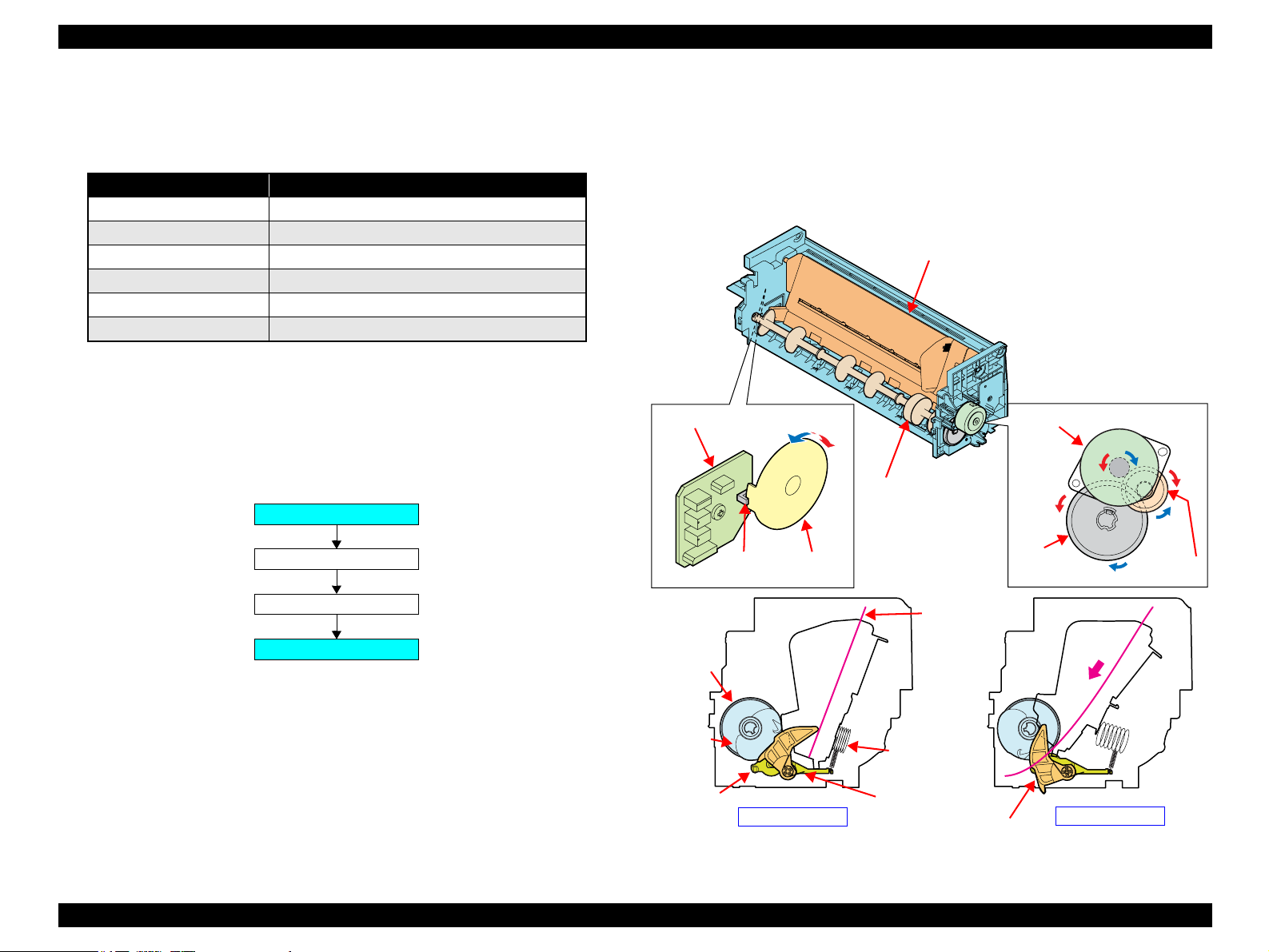

2.2.3.1 ASF Paper Feeding Mechanism

The following shows the specifications of the stepping motor that drives the ASF Assy.

Table 2-5. ASF Motor Specifications

Item Specifications

Type

Drive voltage

Winding resistance

Inductance

Drive method

Drive IC

Driven by the ASF Motor, the ASF Assy performs the following feeding operation.

1. When a paper feeding command is issued from the PC or the Paper button of the

panel is pressed after power-on, the driving force of the ASF Motor begins to be

transmitted to the LD Roller following the route shown below.

4-phase, 48-pole PM type stepping motor

+42V ± 5% (voltage applied to driver)

7.0Ω ± 10% (per phase at 25°C)

10.2mH ± 20% (1kH, 1Vrms, at 25°C)

Bipolar drive/constant-current drive

A6628

ASF Motor

Combination Gear 29, 11

4. When the next sheet of paper is fed by the LD Roller and the Retard Roller, the

Hopper is pressed against the Frame again by the Hopper Cams, and the Paper

Holder of the Paper Back Lever rises by the Cams on the left and right ends of the

LD Roller to prevent the next sheet from being fed with the previous sheet.

5. The LD Roller stops to rotate when it makes one revolution and the flag of the

ASF Sensor Wheel returns to the ASF Sensor.

Hopper

Relay Board

ASF

Sensor

LD Roller

ASF Sensor

Wheel

ASF Motor

LD Shaft

Spur Gear

Combination

Gear 29.11

LD Shaft Spur Gear

LD Roller

LD

Roller

Paper

2. When the LD Roller starts rotating, the flag of the ASF Sensor Wheel comes free

from the notch on the ASF Sensor. At the same time, the Paper Back Lever

becomes free from the Cams located at the left and right ends of the LD Roller,

then the Paper Holder on the Paper Back Lever inclines downward by tensile force

of the Paper Back Lever Torsion Spring.

3. By the LD Roller's rotation, the Hopper is released from the Hopper Cams located

on the left and right ends of the LD Roller, and the Hopper pops up by tensile force

of the Hopper Compression Spring.

Cam

Retard

Roller

Standby State

Figure 2-5. ASF Paper Feeding Mechanism

Hopper

Compression

Spring

Paper Back Lever

Torsion Spring

Paper Back Lever

Feeding Paper

OPERATING PRINCIPLES Printer Mechanism 27

EPSON Stylus Photo 1400/1410 Revision A

2.2.3.2 CD/DVD Tray Base Lock Mechanism

To prevent the Printhead from being damaged by mistake, the printer is designed to

lock the CD/DVD Tray Base when the Carriage Unit is out of its home position.

The following explains the lock mechanism of the CD/DVD Tray Base.

Lock Release Sequence

1. When the Carriage Unit returns to its home position, the Pump Motor drive is

transmitted to the Paper EJ Lock Release Cam.

2. The salient of the Cam presses down the Paper EJ Transmission Lock Lever

to release the tab of the Paper EJ Lock Lever from the Paper EJ Transmission

Lock Lever.

3. The CD-R Release Lever comes free from the Paper EJ Lock Lever and

comes down to enable the CD/DVD Tray Base to open.

When the Carriage Unit is out of its home position, the salient of the Paper EJ Lock

Release Cam does not press down the Paper EJ Transmission Lock Lever, and the tab

of the Paper EJ Lock Lever is not released. Therefore, the CD/DVD Tray Base cannot

be opened.

CD/DVD Tray Base

Paper EJ Lock

Lever

Paper EJ

Transmission

Lock Lever

Paper EJ Lock

Release Cam

CD-R Release Lever

Jointed PositionTab

Salient

Figure 2-6. CD/DVD Tray Base Lock Mechanism

OPERATING PRINCIPLES Printer Mechanism 28

EPSON Stylus Photo 1400/1410 Revision A

2.2.3.3 CD-R Printing Mechanism

CD/DVD Tray Home Position Detection Sequence

The following sequence is performed after opening the Front Cover (CD-R

Sensor: closed), inserting the CD/DVD Tray to the specified position, and pressing

the Paper button.

When the close signal of the CD-R Sensor is detected, no paper is fed from the

ASF even if the Paper button is pressed. In this case, pressing the Paper button

executes a CD/DVD Tray home position detection sequence.

1. When the APG Assy is driven, the PG position is set to “++” and the Driven

Roller of the Upper Paper Guide presses onto the CD/DVD Tray.

2. When the Carriage Unit moves to the left and the PW Sensor detects the CD-

R, the Carriage Unit returns to its home position (HP).

3. After waiting for about 5 seconds at the HP, the Carriage Unit moves to the

CD/DVD Tray HP detectable position (right end of the CD/DVD Tray).

4. The CD/DVD Tray is pulled towards the ASF, the PW Sensor detects the CD/

DVD Tray HP, and then the Carriage Unit moves to the center of the CD/

DVD Tray.

5. When the PW Sensor detects the white marking in the center of the CD/DVD

Tray, the CD/DVD Tray is fed in the paper ejection direction.

6. The Carriage Unit moves to the left, the PW Sensor detects the white marking

on the left, then the Carriage Unit moves to the right, and the PW Sensor

detects the white marking on the right.

7. The Carriage Unit moves to the center of the CD/DVD Tray, and the PW

Sensor starts detection of the front and back direction of the CD-R. After the

front end of the CD-R is detected, the CD/DVD Tray is fed towards the paper

ejection direction, and the back end of the CD-R is detected. After that, the

CD/DVD Tray is fed to the center of the CD-R in the paper ejection direction.

8. The Carriage Unit moves to the left, and the PW Sensor starts detection in the

horizontal direction of the CD-R. After the left end of the CD-R is detected,

the Carriage Unit moves to the right, and the right end of the CD-R is

detected.

9. The Carriage Unit stops after moving to the CD/DVD Tray HP detectable

position, then the CD/DVD Tray is fed towards the ASF.

10. When the CD/DVD Tray stops operating, the Carriage Unit moves to the

carriage HP and stands by.

If the CD/DVD Tray HP, the white marking, or the CD-R cannot be detected within the

steps predetermined for the CD/DVD Tray HP detection sequence, the CD/DVD Tray

is ejected and Paper Out Error is displayed.

PW Sensor

CD/DVD Tray

Carriage Unit

CD-R Home Position

Figure 2-7. CD-R Printing Mechanism

OPERATING PRINCIPLES Printer Mechanism 29

EPSON Stylus Photo 1400/1410 Revision A

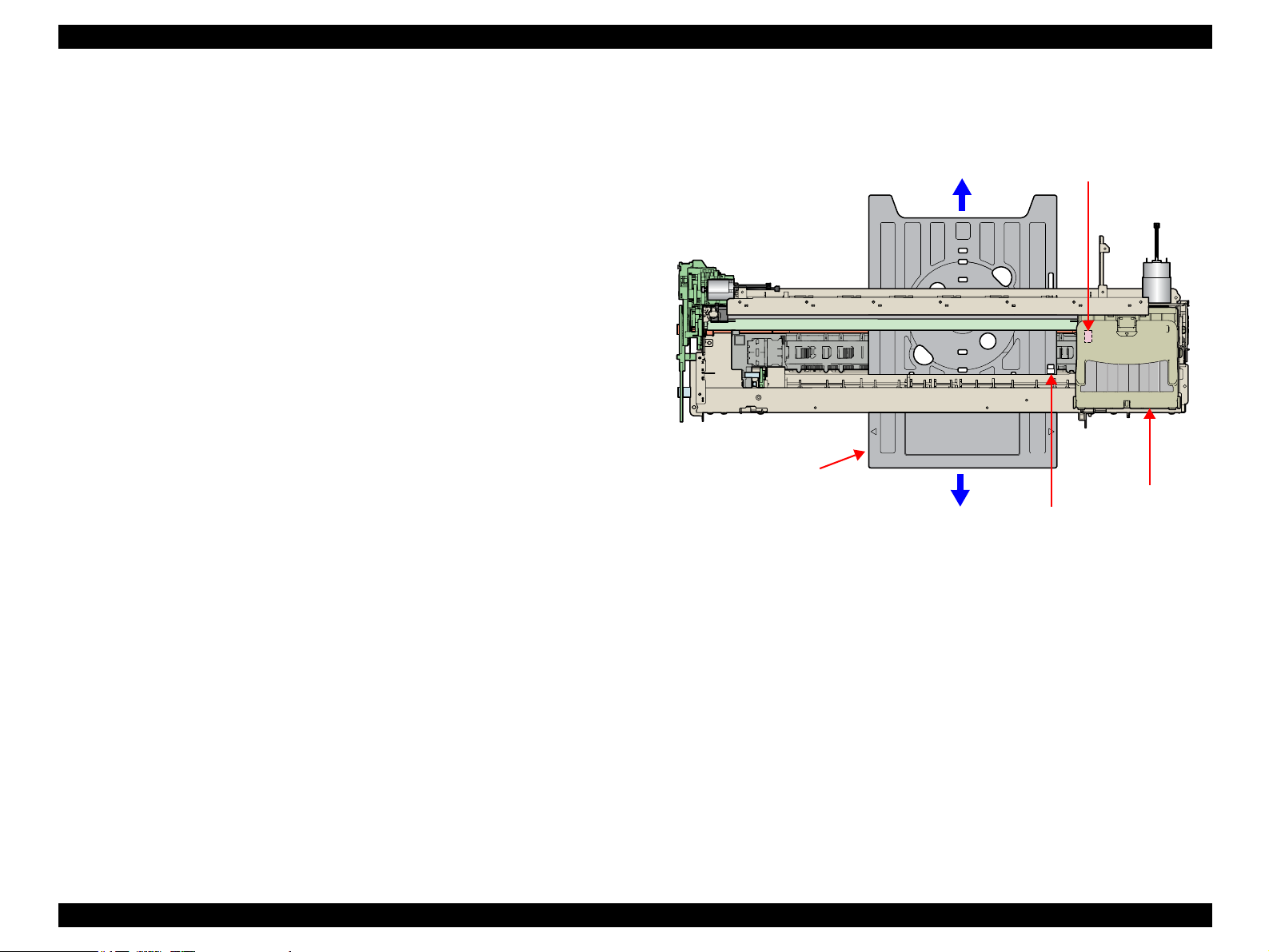

2.2.4 Paper Feeding Mechanism

The Paper Feeding Mechanism is designed to transfer the paper fed from the ASF, or

the CD-R fed from the CD/DVD Tray according to the print data.

2.2.4.1 Paper Feeding Mechanism

The following shows the specifications of the DC motor that drives the Paper Feeding

Mechanism.

Table 2-6. PF Motor Specifications

Item Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Armature resistance 21.2Ω ± 10%

Inductance 17.2mH (1kHz)

Rotor Inertia 18.8gcm2

Drive method PWM

Drive IC A6628

Like the CR Motor, a DC motor is used as the PF Motor in this product.

Closed loop control based on the DC Motor and Rotary Encoder has the following

advantages.

Improved paper feed accuracy

PF Motor

PF Timing Belt

Combination Gear

36.294, 55

PF Roller

Spur Gear 31.5

Spur Gear 68

Front Paper Eject Roller

Spur Gear 16; B (front)

Spur Gear 15.5

Spur Gear 16; B (rear)

Rear Paper Eject Roller

The following shows the part names and outline of the drive transmission path.

Combination Gear

36.294, 55

PF Timing Belt

PF Motor

Spur Gear 16; B (rear)

Spur Gear 68

Spur Gear 16;

B (front)

Spur Gear 15.5

Paper feed amount control

Spur Gear 31.5

Front Paper Guide

The PF Motor drive is transmitted to the PF Roller and the Paper EJ Roller following

the route shown below.

PF Roller

Front Paper Eject Roller

Rear Paper Eject Roller

Figure 2-8. Paper Feeding Mechanism

OPERATING PRINCIPLES Printer Mechanism 30

EPSON Stylus Photo 1400/1410 Revision A

The fed paper is detected by the PE Sensor, and its front end is then transferred to the

front of the Front Paper Guide.

To eliminate the deflection of the paper, the paper is then returned toward the ASF

Assy by the specified number of steps according to the paper feeding mode.

The paper is re-transferred to the specified paper locating position of the Front Paper

Guide.

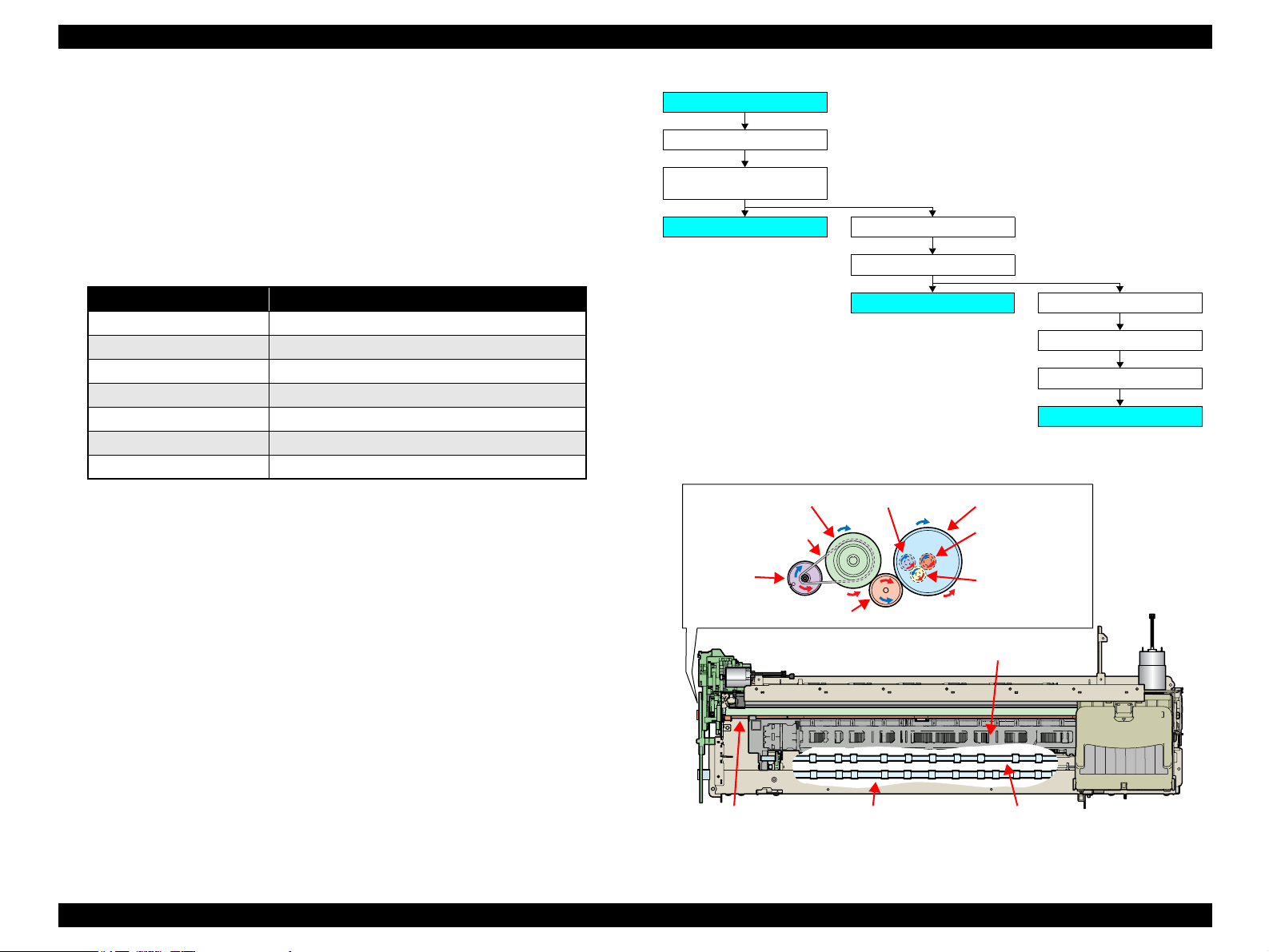

2.2.4.2 PF Measurement Sequence

The mechanical load in the paper feeding path is measured in the following cases

to perform control so that an adequate current value is set according to the

mechanical load.

When power is switched on

When the Ink Cartridge is replaced

When the mechanical load in the paper feeding path reaches the specified value,

Fatal Error is displayed.

2.2.5 Ink System Mechanism

The Ink System Mechanism consists of the following units.

Pump Unit (including the CR Lock Lever)

Cap Unit

2.2.5.1 Pump Unit

The Pump Unit is designed to suck ink from the Printhead or Cap Unit. The Cap Unit

has a built-in Head Cleaning Wiper.

The following shows the specifications of the stepping motor that drives the Pump

Unit.

Table 2-7. Pump Motor Specifications

Item Specifications

Type 4-phase, 48-pole PM type stepping motor

Drive voltage +42V ± 5% (voltage applied to driver)

Winding resistance 10.3Ω ± 10% (per phase at 25°C)

Inductance 13.4mH ± 20% (1kH,1Vrms)

Drive method Bipolar drive/constant-current drive

Drive IC A6628

The following operations are performed when the drive of the Pump Motor is

transmitted to the Pump Unit.

Table 2-8. Pump Motor Rotation Directions and Functions

Pump Motor Rotation Direction* Functions

• Cap closing

CW direction

CCW direction

Note * : The direction (CW or CCW) was determined by viewing the motor from the output

shaft of the motor mounting plate.

• Ink suction

• Wiper resetting

• CR Lock setting

• Cap opening

• Pump release

• Wiper setting

• CR Lock resetting

OPERATING PRINCIPLES Printer Mechanism 31

EPSON Stylus Photo 1400/1410 Revision A

2.2.5.2 Drive Transmission Path to Pump Unit

The drive of the Pump Motor is transmitted to the Pump Unit in the following path.

Pump Motor

Combination Gear 10.2, 21.2 IS

Spur Gear 20.4 IS

Pump Unit

The following shows the internal part names and operation outline of the Pump Unit.

<Pump Unit inside>

Combination Gear 10.2, 21.2 IS

Spur Gear

20.4 IS

The following shows the Pump Unit operating principle.

Cap Unit Side

To Waste ink pad

Figure 2-10. Pump Unit Operating Principle

Ink Suction

1. The Pinion Gear of the Pump Motor rotates in the CW direction.

2. The Roller turns and simultaneously presses the tube.

3. Ink is fed from the Cap Unit toward the Waste Ink Pad.

Pump Release

1. The Pinion Gear of the Pump Motor rotates in the CCW direction.

Pump Motor and Motor Pinion Gear

Figure 2-9. Outline of Pump Unit Inside

2. The Roller moves away from the tube and releases the tube.

3. Ink is not sucked.

OPERATING PRINCIPLES Printer Mechanism 32

EPSON Stylus Photo 1400/1410 Revision A

2.2.5.3 Cap Unit

The Cap Unit is designed to keep inside of the Cap airtight by the Cap sticking to the

Printhead surface with the driving force of the Pump Motor when ink is sucked.

When the printer is in a standby status or its power is OFF, the Cap Unit prevents the

ink from thickening.

The following figures shows the Cap Unit operation.

Carriage Unit

Cap

Printhead

Figure 2-11. Capping Mechanism

Slider cap rises to perform

capping.

2.2.6 Ink Sequence

The following ink sequence is executed according to various timer, counter, flag and

other information saved on the EEPROM.

Initial Ink Filling

When the printer is powered on for the first time after purchase, the printer

executes the initial ink filling operation to fill the ink cavities of the Head with ink.

When the initial ink filling operation is performed properly, the printer clears the

flag in the EEPROM so that initial ink filling operation will not be performed

when it is powered on the next time. The Stylus Photo 1400/1410 requires about

170 seconds to perform the initial ink filling operation.

If the sequence does not end normally during initial filling, the initial filling flag is

not cleared and the CL operating flag is set. Because of these flags, when powered

on the next time, the printer assumes that it was powered off for some reason

during initial filling and executes CL3 instead of the initial filling sequence. (On

the previous model, initial filling was executed again. However, when this

operation was performed, ink was wasted and therefore CL3 is executed to cover

for the ink filling performance.)

When the initial filling flag is set and the CL operating flag is not set, the printer

judges that the initial filling was not executed at all (power was switched on but

the cartridges were not installed), and when the printer is powered on the next

time, it executes initial filling.

Replacement Cleaning

Replacement cleaning is executed when an Ink Cartridge(s) is replaced.

OPERATING PRINCIPLES Printer Mechanism 33

EPSON Stylus Photo 1400/1410 Revision A

Manual Cleaning

This printer provides three different manual cleanings to remove ink coagulated by

air bubbles, viscous material, or foreign matter. Perform the following manual CL

operations by operating the panel or using the utility included in the printer driver.

Independently of the printing path after the previous CL, perform manual CL from

CL1 to CL3 in order if the cumulative printing timer counter is less than 9 minutes.

When the cumulative printing timer counter is more than 9 minutes, only CL1 is

executed.

Wiping Operation

Clean the nozzle surface, with the right-half of the rubber part on the wiper.

Flushing Operation

Prevent color mixture. Stabilize the ink surface inside the nozzles.

In addition, the printer determines which CL to perform according to the

remaining amount of ink in the Cartridge. When the printer detects the amount is

low, it automatically choose the CL that uses ink less than the other CLs. If the

remaining amount of ink is extremely low (Ink Low or Ink End status), the printer

disables the all the manual cleanings and indicates the status on the STM3.

2.2.7 Power-On Sequence

The following describes the printer operation after it is powered on.

When the Carriage Unit is in the Home Position with the CR Locked

1. After power-on, the drive of the APG Motor is transmitted to the Carriage Shaft,

and the PG position changes from PG Typ. to PG++.

2. The drive of the CR Motor is transmitted to the Carriage Unit, and the Carriage

Unit performs HP detection operation in the following path.

Home position ⇒ Right frame ⇒ CR Lock confirmation position

⇒ Right frame ⇒ Home position

3. The drive of the Pump Motor is transmitted to the Cap Unit, the Cap opens

(lowers), and the CR Lock is released.

4. After the Carriage Unit has moved to the left by the specified number of steps, the

Wiper, driven by the Pump Motor, performs the following.

Timer Cleaning

Ink is consumed depending on the combination of the cumulative printing timer,

cumulative cleaning count and cleaning timer.

Flushing

There are two types of flushing.

Flushing before printing

This is performed to reduce the viscosity of ink in the Printhead nozzles

before starting to print.

Scheduled Flushing

This is performed to prevent ink in the Printhead nozzles from increasing its

viscosity during printing.

Wiper setting ⇒ Wiper resetting

5. The Carriage Unit returns to the home position, and the PG position returns from

PG++ to PG Typ.

6. The drive of the PF Motor is transmitted to the PF Roller and Paper Eject Rollers

(front and rear) to rotate them for predetermined steps.

7. After moving between the left and right frames twice, the Carriage Unit moves to

the right end of the Front Paper Guide.

8. The PF Roller and Paper Eject Rollers (front and rear) rotates.

9. The Carriage Unit returns to the home position and is secured by the CR Lock.

OPERATING PRINCIPLES Printer Mechanism 34

EPSON Stylus Photo 1400/1410 Revision A

When the Carriage Unit is Out of the Home Position

1. When the PG position is other than PG++ after power-on, the drive of the APG

Motor is transmitted to the Carriage Shaft, and the PG position changes to PG++.

2. The drive of the CR Motor is transmitted to the Carriage Unit, and the Carriage

Unit returns to the home position at slow speed.

3. The drive of the PF Motor is transmitted to the PF Roller and Paper Eject Rollers

(front and rear), which then rotate for about 2 seconds.

4. After the Carriage Unit has moved to the left by the specified number of steps, the

Wiper is set by the drive of the Pump.

5. After the Carriage Unit has returned to the home position, it moves to the left again

by the specified number of steps. Then driven by the Pump Motor, ink is sucked in

for about 4 seconds, then the Wiper is set, and the CR Lock is locked.

6. The Carriage Unit performs HP detection operation in the following path.

Home position ⇒ Right frame ⇒ CR Lock confirmation position

⇒ Right frame ⇒ Home position

7. The drive of the Pump Motor is transmitted to the Cap Unit, the Cap opens

(lowers), and the CR Lock is released.

8. The Carriage Unit returns to the home position, and the PG position returns from

PG++ to PG Typ.

9. The PF Motor drive is transmitted to the PF Roller and the Paper EJ Rollers (front

and rear) to rotate them for predetermined steps.

10. Steps 7 to 9 of “When the Carriage Unit is in the Home Position with the CR

Locked (p34)” is carried out, and the Carriage Unit is locked.

2.3 Electrical Circuit Operating Principles

The electrical circuit of Stylus Photo 1400/1410 consists of the following circuits.

Control circuit board: C655 MAIN

Power supply circuit board: C589 PSB

Control panel board: C589 PNL

Head circuit board: C653 HEAD

The following shows how the four circuit boards are connected.

PNL Board

MAIN Board

Printer

Mechanism

CR Motor

PF Motor

APG Motor

ASF Motor

Pump Motor

Head drive circuit

Sensors

Power OFF +3.3VDC +42VDC

PSB/PSE Power

Supply Board

Figure 2-12. Electrical Circuit Block Diagram

OPERATING PRINCIPLES Electrical Circuit Operating Principles 35

EPSON Stylus Photo 1400/1410 Revision A

2.3.1 Power Supply Circuit Operating Principle

The power supply circuit board of this product is the C589 PSB.

Basic circuit structure

Flyback switching system

+42VDC and +3.3VDC are supplied to the Printer Mechanism and Control

Board

The following indicates the applications of the voltages generated in this power supply

circuit.

Table 2-9. Supplied Power

Voltage Applications

+42VDC

Rated output current: 0.45A

+3.3VDC

Rated output current: 0.5A

• CR Motor

•PF Motor

•PG Motor

•ASF Motor

• Pump Motor

• Head drive voltage

• Logic sensor circuit

• Sensor circuit

• Nozzle selection circuit (on the Printhead)

• Interface control circuit

The following is a block diagram of the power supply circuit.

Separate-excited

Simulated Resonance

Flyback Converter

Over Current Limitation

F51

Fuse for LPS

Over Voltage Limitation

Secondary Power

Supply SW function

Low Power mode

C51, C52

Smoothing

Circuit

D51

IC51

+3.3V Chopper

Circuit

TRANS: T1

QF1

Main Switching

Circuit

+42VDC

+3.3VDC

+5VDC

PSC Signal

ESAVE

AC Input

Over Current

Protection

Filter Circuit

C1, FL1F1, TH1

Full Wave

Rectifier

Circuit

D11, D12,

D13, D14

Smoothing

Circuit

C11

Figure 2-13. Power Supply Circuit Block Diagram

OPERATING PRINCIPLES Electrical Circuit Operating Principles 36

EPSON Stylus Photo 1400/1410 Revision A

2.3.2 C655 MAIN Circuit Operating Principle

The C655 MAIN Board consists of the following circuits and sensors.

Logic Circuits (CPU-ASIC 2 in 1, PROM, SDRAM)

Circuits for controlling and driving Motors

(CR Motor, PF Motor, APG Motor, ASF Motor, Pump Motor)

Circuits for controlling and driving the Head

Interface Circuits (USB 2.0)

Sensor Circuits

RTC Circuit

DAC Converter Circuit

Regulator Circuit

Complex Circuit (IC8)

The Complex Circuit (IC8) that consists of EEPROM, RTC, and Reset circuit is

installed in the printer. Employing a large-capacity condenser for the Timer allows

to backup the time recorded at power-off for about a week after the power-off.

OPERATING PRINCIPLES Electrical Circuit Operating Principles 37

EPSON Stylus Photo 1400/1410 Revision A

The following is the block diagram of the C655 MAIN control board.

CR Encoder Sensor

PROM

(IC6)

SDRAM

(IC7)

USB2.0

CN1

USB Host

CN2

RTC

(IC8)

CN14

Data

Address

CPU-ASIC

2 in 1

(IC9)

DAC

(IC4)

CN3

Motor

Driver

(IC11)

Motor

Driver

(IC12)

Relay Board

CN6

CN7

CN8

CN9

CN13

PF Encoder Sensor

PE Sensor

ASF Sensor

APG Sensor 1

APG Sensor 2

CR Motor

PF Motor

Pump Motor

APG Motor

ASF Motor

PW Sensor

C589 PSB/PSE Board

C653 Head Board

C589 Panel Board

CD-R Sensor

CN4

CN15

CN5

Head

Driver

(IC10)

Q6, Q9,

Q10, Q11

CN10

CN11

CN12

Printhead

Figure 2-14. C655 MAIN Control Board Block Diagram

OPERATING PRINCIPLES Electrical Circuit Operating Principles 38

TROUBLESHOOTING

CHAPTER

3

EPSON Stylus Photo 1400/1410 Revision A

3.1 Overview

This chapter describes unit-level troubleshooting.

3.1.1 Troubleshooting according to Panel Messages

After checking the printer LED and STM3 error indications, you can grasp the fault location using the check list in this section. When you find the fault location, refer to Chapter 4

“Disassembly and Reassembly” and change the corresponding part and/or unit. The following table indicates the check point reference tables corresponding to the error states (LED

and STM3).

Table 3-1. Reference Tables of Error States

Error State Reference Table

Communication Error Refer to Table 3-2 "Troubleshooting of Communication Error" on page 41

Model Difference Refer to Table 3-2 "Troubleshooting of Communication Error" on page 41

Cover Open (Tray) Error Refer to Table 3-3 "Troubleshooting of Cover Error" on page 44

Paper Out Error Refer to Table 3-4 "Troubleshooting of Paper Out Error" on page 44

Paper Jam Error Refer to Table 3-5 "Troubleshooting of Paper Jam Error" on page 48

Paper Mismatch Error Refer to Table 3-6 "Troubleshooting of Paper Mismatch Error" on page 49

Ink Low Refer to Table 3-7 "Troubleshooting of Ink Low" on page 49

Ink End Error Refer to Table 3-8 "Troubleshooting of Ink End Error" on page 49

No Ink Cartridge/CSIC Error Refer to Table 3-9 "Troubleshooting of No Ink Cartridge/CSIC Error" on page 50

Maintenance Request Error Refer to Table 3-10 "Troubleshooting of Maintenance Request" on page 52

Fatal Error Refer to Table 3-11 "Troubleshooting of Fatal Error" on page 53

TROUBLESHOOTING Overview 40

EPSON Stylus Photo 1400/1410 Revision A

Table 3-2. Troubleshooting of Communication Error

Occurrence

Timing

Phenomenon Detail

At power-on The printer does not operate at

all.

Faulty Part/

Part Name

Panel FFC 1. Check that the Panel FFC is connected to the Panel Board

Connector and Main Board Connector CN5.

Panel FFC

Panel Board

connector

Check Point Remedy

1. Connect the Panel FFC to the Panel Board and

Main Board connector CN5.

Panel FFC

CN5

2. Check the Panel FFC for damages. 2. Replace the Panel FFC with a new one.

Panel Board 1. Check the Panel Board for damages. 1. Replace the Panel Board with a new one.

TROUBLESHOOTING Overview 41

EPSON Stylus Photo 1400/1410 Revision A

Table 3-2. Troubleshooting of Communication Error

Occurrence

Timing

Phenomenon Detail

At power-on The printer does not operate at

all.

Faulty Part/

Part Name

Power Supply

Board

Check Point Remedy

1. Check that the Connector Cable of the Power Supply Board is

connected to the Main Board Connector CN4.

Power Supply Board

connector cable

CN4

Blue line

Pin 1 side

2. Make sure that the Power Supply Board connector cable is

inserted into the Main Board Connector CN4 with the blue line

on the cable facing the Pin 1 side of the connector as shown in

the picture above.

3. Check that the Fuse F1 on the Power Supply Board has not

blown.

1. Connect the Connector Cable of the Power

Supply Board to the Main Board Connector

CN4.

2. Reconnect the Power Supply Board Connector

cable so that the blue line is inserted into the

Pin 1.

3. Replace the Power Supply Board with a new

one.

Fuse F1

4. Check the components on the Power Supply Board for damage. 4. Replace the Power Supply Board with a new

one.

TROUBLESHOOTING Overview 42

EPSON Stylus Photo 1400/1410 Revision A

Table 3-2. Troubleshooting of Communication Error

Occurrence

Timing

At power-on After the power-on sequence has

At operation Operation at power-on is normal,

Phenomenon Detail

started, the LED turns off and the

printer does not operate.

but an error appears when the

print job is sent to the printer.

Faulty Part/

Part Name

Main Board 1. Check that the Relay connector of the ASF Motor and the Relay

connector of the Pump Motor are not connected to the wrong

connectors causing a short circuit.

Relay Connector of

the Pump Motor

Interface cable 1. Check that the Interface cable is connected between the PC and

the printer.

2. Check the Interface cable for breaking. 2. Replace the Interface cable with a new one.

EPSON

USB driver

USB 1. Check that the PC and printer are connected via the USB hub. 1. Enter the USB serial No. indicated on the

Printer Driver 1. Check that the printer driver for Stylus Photo 1400/1410 has

Main Board 1. Check that a wrong model name has not been input to the

1. When using USB, check that the EPSON USB driver has been

installed on the PC.

already been installed.

2. Check that the connected printer is Stylus Photo 1400/1410. 2. Connect the Stylus Photo 1400/1410 printer.

EEPROM address on the Main Board.

Check Point Remedy

1. Connect the Relay Connector of the ASF

Motor and the Relay Connector of the Pump

Motor correctly, and replace the Main Board

with a new one.

Relay Connector of

the ASF Motor

1. Connect the Interface cable to the PC and the

printer.

1. Install the EPSON USB driver.

product nameplate.

Refer to Chapter 5 "ADJUSTMENT".

1. Install the printer driver for Stylus Photo 1400/

1410.

1. Using the Adjustment Program, enter the

correct model name.

Refer to Chapter 5"ADJUSTMENT".

TROUBLESHOOTING Overview 43

EPSON Stylus Photo 1400/1410 Revision A

Table 3-3. Troubleshooting of Cover Error

Occurrence

Timing

Phenomenon Detail

During printing A Cover Open (Tray) Error is

indicated during printing.

Occurrence

Timing

Phenomenon Detail

At operation When the Paper button is

pressed, the LD Roller attempt to

feed paper but the paper is not

fed.

Faulty Part/

Part Name

Check Point Remedy

Printer Cover 1. Check that the CD-R Unit is not open. 1. Close the CD-R Unit.

Table 3-4. Troubleshooting of Paper Out Error

Faulty Part/

Part Name

ASF Assy. 1. Check the LD Roller or Retard Roller of the ASF Assy for paper

dust and foreign matter.

Check Point Remedy

1. Using a cleaning sheet (part code:1262115),

clean the LD Roller and Retard Roller.

The procedure is as follows.

(1) Place the cleaning sheet upside down and

put it into the ASF Assy.

(2) Press the Paper button to start paper feed.

(3) Repeat the above steps several times.

* To remove persistent contamination,

staple an alcohol-dampened cloth to a

postcard and clean the rollers in the

following method.

Cleaning sheet Postcard used

Non-adhesive part

as mount

Adhesive part

This side down

Stapling

Cloth damped

with alcohol

(1) Place the alcohol-dampened cloth facing

to the LD Roller surface of the ASF Assy.

(2) Hold the mount top end securely and

press the Paper button.

(3) Repeat the paper feed sequence several

times to clean the LD Roller surface of

the ASF Assy.

TROUBLESHOOTING Overview 44

EPSON Stylus Photo 1400/1410 Revision A

Table 3-4. Troubleshooting of Paper Out Error

Occurrence

Timing

Phenomenon Detail

At operation Though paper is fed from the

ASF Assy, it stops near the PE

Sensor Lever.

Faulty Part/

Part Name

Check Point Remedy

PE Sensor 1. Check that the Connector cable of the PE Sensor is securely

connected to the PE Sensor and Relay Board Connector CN2.

PW Sensor Connector

CN2

2. Check that the Sensor Holder is mounted to the Mechanical

frame correctly.

Sensor Holder

Detection Lever

Torsion Spring

1. Connect the Connector cable of the PE Sensor

to the PE Sensor and Relay Board Connector

CN2.

2. Install the Sensor Holder correctly.

3. Move the Detection Lever manually as when the paper passes,

and check that the Detection Lever returns to the original

3. Replace the PE Sensor Holder Unit with a new

one.

position automatically by the Torsion Spring when released.

Refer to the above photo.

4. Using a tester, check that the PE Sensor is normal.

⋅ Paper absent: 2.4V or more

4. Replace the PE Sensor Holder Unit with a new

one.

⋅ Paper present: 0.4V or less

TROUBLESHOOTING Overview 45

EPSON Stylus Photo 1400/1410 Revision A

Table 3-4. Troubleshooting of Paper Out Error

Occurrence

Timing

The Paper button

was pressed at the

setting of the CD/

DVD Tray.

Phenomenon Detail

The CD/DVD Tray HP detection

sequence stops and the Tray is

ejected.

The CD/DVD Tray is fed toward

the ASF Assy, but is ejected

immediately.

Faulty Part/

Part Name

Check Point Remedy

CD/DVD Tray 1. Check the HP detection position or white markings of the CD/

DVD Tray for paper dust and foreign matter.

White Markings

HP detection

position

2. Check the Driven Roller surface for contamination such as paper

dust and CD-R coating material.

3. Check that the HP detection position or white markings of the

CD/DVD Tray are not chipped.

PW sensor 1. Check the PW Sensor for contamination such as paper dust,

ink, etc.

1. Remove paper dust and/or foreign matter from

the detection position.

2. Feed A4-size sheets of plain paper from the

ASF Assy several times to remove the

contamination.

3. Replace the CD/DVD Tray with a new one.

1. Clean the PW Sensor surface.

PW sensor

Carriage Unit Bottom

2. Compare the EEPROM values in two places and check that they

2. Replace the PW Sensor with a new one.

are not approximated to each other.

TROUBLESHOOTING Overview 46

EPSON Stylus Photo 1400/1410 Revision A

Table 3-4. Troubleshooting of Paper Out Error

Occurrence

Timing

The Paper button

was pressed at the

setting of the CD/