Page 1

SC-P800 series

Large Format Color Inkjet Printer

SERVICE MANUAL

SECP14-007

SE Group Confidential (Related Staff Only)

Page 2

SE Group Confidential (Related Staff Only)

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners. EPSON

disclaims any and all rights in those marks.

Copyright © 2015 SEIKO EPSON CORPORATION.

352)(66,21$/35,17,1*23(5$7,216',9,6,21

Page 3

SE Group Confidential (Related Staff Only)

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) Damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAI

R PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASI

C SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONI

CS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTI

L

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONI

C COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURY FROM

METAL PARTS WITH

SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATI

NG

PLATE.

IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT

IT TO

THE POWER SOURCE.

3.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVI

NG OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN AIR DUSTER IS USED ON THE REPAIR AND THE MAINTENANCE WORK, THE USE OF THE AIR DUSTER PRODUCTS CONTAI

NING

THE I

NFLAMMABLE GAS IS PROHIBITED.

7. MAKE SURE AN ANTIVIRUS SOFTWARE IS INSTALLED ON THE COMPUTER USED FOR SERVICE SUPPORT. BE SURE TO H

AVE THE

LATEST

VIRUS DEFINITION FILE FOR THE SOFTWARE.

Page 4

SE Group Confidential (Related Staff Only)

About This Manual

About This Manual: This manual is made for the sole purpose of providing necessary information in order that a serviceperson qualified by Epson performs his / her appropriate

repair / maintenance for the applicable Epson’s products. You shall not use this manual out of this purpose.

This manual is Epson’s confidential information. When you use this manual, you shall hold it in strict confidence and shall not disclose to any third party without prior consent of

Epson.

The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 3.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the product.

CHAPTER 4.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 5.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved lubricants and

adhesives required for servicing the product.

CHAPTER 6.APPENDIX

Provides the following additional information for reference:

•

C

onnectors

• Panel Menu Maps

• ASP

List

•Exploded Diagrams

Page 5

SE Group Confidential (Related Staff Only)

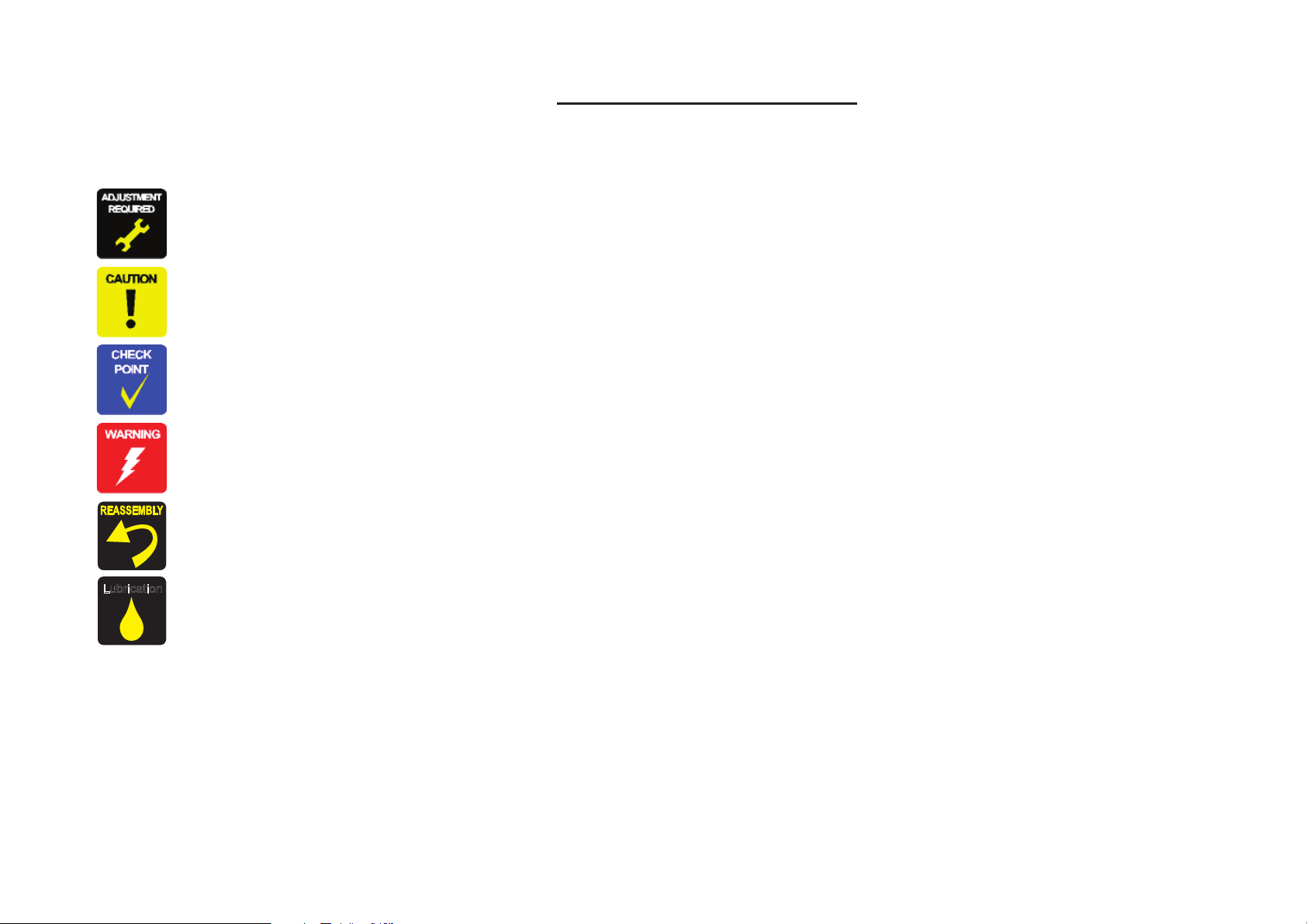

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or to warn of possible danger present during a procedure or an action.

Be aware of all symbols when they are used, and always read NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed, could result in damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to accomplish a task efficiently. It may also provide additional

information that is related to a specific subject, or comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain standard after disassembly and before re-assembly, otherwise the quality of the components

in question may be adversely affected.

Indicates that lubrication is needed for the parts after disassembly, when doing a maintenance or replacing a part with a new one.

Lubrication

Page 6

SE Group Confidential (Related Staff Only)

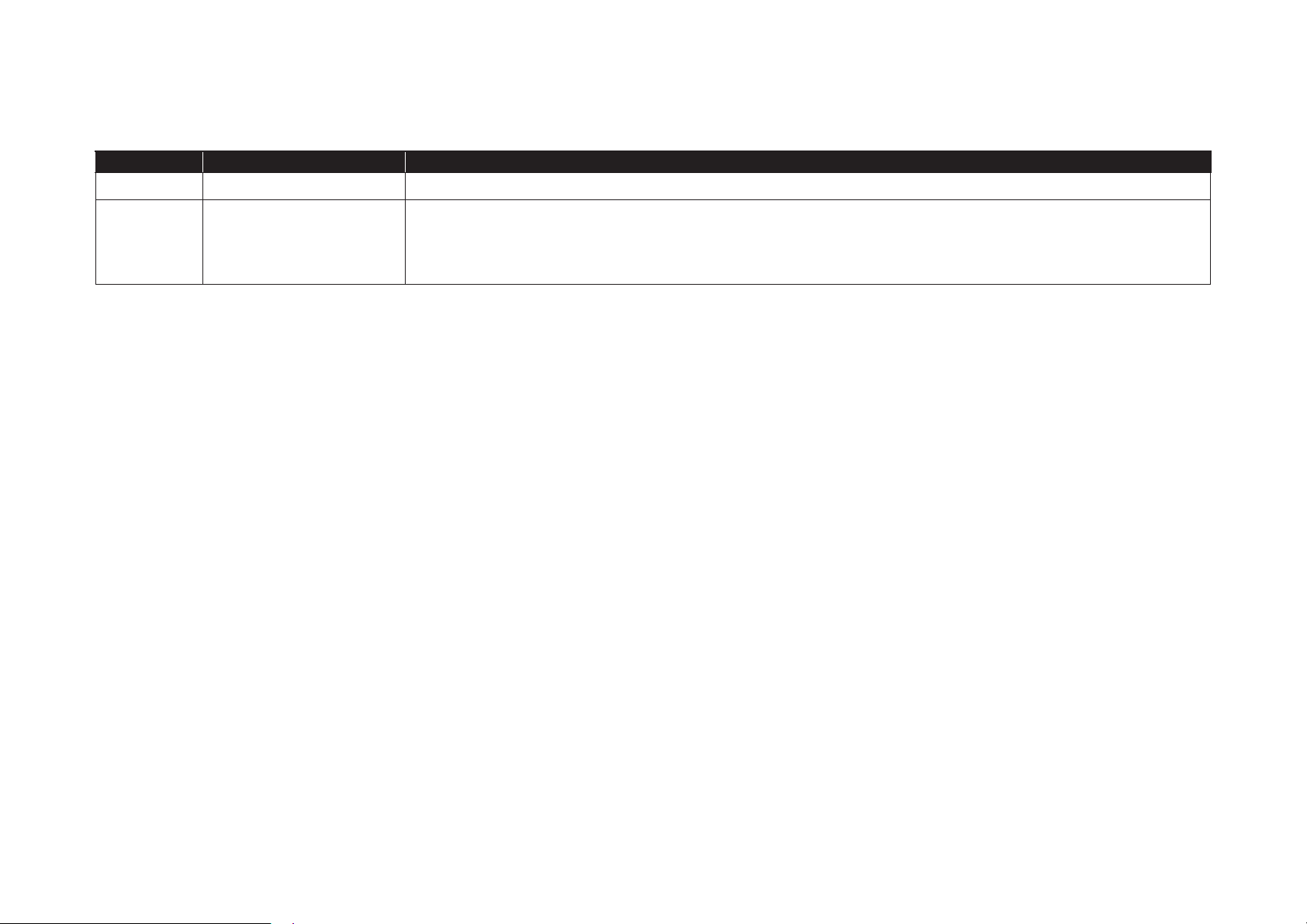

Revision Status

Revision Date of Issue Description

A March 27, 2015 First release

B

May 2,2015

• Chapter 4

Added of Figure 4-3,4 to page 211.

Changed of text to page 211.

Replacement of Figure 4-5,6,7,8 to page 212.

Page 7

SC-P800 series Revision B

7

SE Group Confidential (Related Staff Only)

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Product Description ............................................................................................ 11

1.2 Basic Specifications ............................................................................................ 12

1.2.1 Basic Specifications ................................................................................... 12

1.2.2 Electric Specifications ............................................................................... 13

1.2.3 Ink Specifications ...................................................................................... 13

1.3 Printing Specifications ........................................................................................ 14

1.3.1 Paper Feed Specifications .......................................................................... 14

1.3.2 Paper Feeder Specifications ....................................................................... 14

1.3.3 Supported Media ........................................................................................ 15

1.3.3.1 Epson Special Media Table ................................................................ 15

1.3.3.2 Usable Commercially Available Paper Size ...................................... 17

1.3.4 Printable area ............................................................................................. 20

1.3.5 Borderless Printing Specification .............................................................. 21

1.4 Hardware Specifications ..................................................................................... 22

1.4.1 Dimensions and Weight ............................................................................. 22

1.4.2 Installation Room Requirement ................................................................. 22

1.4.3 Part Names ................................................................................................. 23

1.5 Control Panel Specifications .............................................................................. 25

1.5.1 Control panel ............................................................................................. 25

1.5.2 Menu Descriptions ..................................................................................... 28

1.5.3 Inspection Mode ........................................................................................ 32

Chapter 2 TROUBLE SHOOTING

2.1 Overview ............................................................................................................ 34

2.1.1 Preliminary Check ..................................................................................... 34

2.1.1.1 Before performing troubleshooting .................................................... 34

2.1.1.2 Check for the usage environment ....................................................... 34

2.1.1.3 Recurrence check of the trouble ......................................................... 34

2.1.1.4 Check for the counter values/history .................................................. 34

2.1.1.5 Test print check .................................................................................. 34

2.1.2 Troubleshooting Procedure ........................................................................ 35

2.1.3 Procedure after troubleshooting ................................................................. 35

2.1.3.1 If the trouble has been successfully solved ........................................ 35

2.1.3.2 If necessary to escalate the trouble case ............................................. 35

2.2 Remedies for Maintenance Requests ................................................................. 36

2.3 Remedies for Service Call Error ........................................................................ 37

2.4 Remedies for Print Quality Troubles .................................................................. 44

2.5 Trouble on Paper Feeding .................................................................................. 47

2.6 Other Troubles .................................................................................................... 48

2.7 Trouble on Service Program ............................................................................... 49

2.8 Trouble on NVRAM Viewer .............................................................................. 50

Chapter 3 DISASSEMBLY & ASSEMBLY

3.1 Overview ............................................................................................................ 52

3.1.1 Precautions ................................................................................................. 52

3.1.2 Cautions after assembling .......................................................................... 54

3.1.3 Orientation Definition ................................................................................ 54

3.1.4 Recommended Tools ................................................................................. 55

3.2 Parts Diagram ..................................................................................................... 56

3.3 Disassembly Flowchart ...................................................................................... 62

3.4 Disassembly and Assembly Procedure ............................................................... 68

3.4.1 Preparation for servicing ........................................................................... 68

3.4.1.1 Unlocking the CARRIAGE, ASSY. manually ................................... 68

3.4.2 Consumable ............................................................................................... 69

3.4.2.1 Ink Cartridge ...................................................................................... 69

3.4.2.2 Maintenance Cartridge ....................................................................... 70

3.4.3 Housing ...................................................................................................... 71

3.4.3.1 COVER, IH, ASSY. ........................................................................... 71

3.4.3.2 HOUSING, REAR, ASSY. ................................................................ 72

3.4.3.3 HOUSING, FRONT, LEFT ............................................................... 74

3.4.3.4 HOUSING, FRONT, RIGHT, UPPER .............................................. 75

3.4.3.5 COVER, WB ...................................................................................... 76

3.4.3.6 COVER, PRINTER ............................................................................ 77

3.4.3.7 PAPER, SUPPORT, ASSY. ............................................................... 78

3.4.3.8 Cover, Panel ....................................................................................... 79

3.4.3.9 HOUSING, LEFT .............................................................................. 80

Page 8

SC-P800 series Revision B

8

SE Group Confidential (Related Staff Only)

3.4.3.10 HOUSING, RIGHT .......................................................................... 81

3.4.3.11 Housing, Front, Support/Hinge, Cover, IC ...................................... 82

3.4.3.12 HOUSING, FRONT, UPPER .......................................................... 83

3.4.3.13 OPERATION, PANEL, ASSY. ....................................................... 84

3.4.3.14 HOUSING, UPPER .......................................................................... 85

3.4.3.15 COVER, HOUSING, LOWER ........................................................ 87

3.4.3.16 BASE, ENCLOSURE ...................................................................... 88

3.4.3.17 LOCK, COVER, ASSY. .................................................................. 90

3.4.3.18 MAINTENANCE CARTRIDGE SENSOR .................................... 93

3.4.4 Electric Circuit Components ...................................................................... 94

3.4.4.1 BOARD ASSY., MAIN ..................................................................... 94

3.4.4.2 BOARD ASSY., POWER SUPPLY .................................................. 97

3.4.4.3 AC INLET .......................................................................................... 99

3.4.4.4 BOARD ASSY., SUB ...................................................................... 100

3.4.4.5 WiFi, Assy ........................................................................................ 101

3.4.5 Carriage Mechanism / Ink System Mechanism ....................................... 102

3.4.5.1 COVER, CR ..................................................................................... 102

3.4.5.2 PRINT HEAD .................................................................................. 103

3.4.5.3 SCALE, CR ...................................................................................... 107

3.4.5.4 BOARD ASSY., ENCODER ........................................................... 110

3.4.5.5 BOARD ASSY., DETECTOR, PW; B ............................................ 111

3.4.5.6 BELT, CR ......................................................................................... 112

3.4.5.7 PULLEY, DRIVEN, ASSY. ............................................................ 113

3.4.5.8 MOTOR ASSY., APG ..................................................................... 114

3.4.5.9 MOTOR ASSY., CR ........................................................................ 116

3.4.5.10 APG SENSOR ................................................................................ 118

3.4.5.11 CARRIAGE, ASSY. ...................................................................... 119

3.4.5.12 PUMP, CAP ASSY. ....................................................................... 122

3.4.5.13 INK, SYSTEM, ASSY. .................................................................. 125

3.4.5.14 POROUS PAD, TRAY, INK EJECT ............................................. 132

3.4.5.15 POROUS PAD, INK WASTE BOX, RIGHT/

POROUS PAD, INK WASTE BOX, LEFT .................................... 133

3.4.5.16 PRESSURE, PUMP, ASSY. .......................................................... 135

3.4.5.17 CABLE ASSY., ASP ..................................................................... 137

3.4.6 Paper Feed Mechanism ............................................................................ 152

3.4.6.1 STACKER, ASSY. ........................................................................... 152

3.4.6.2 BOARD PAPER TRAY/FRAME, PAPER, EJECT, ASSY ............ 159

3.4.6.3 Rear Paper Guide Assy ..................................................................... 170

3.4.6.4 PAPER, GUIDE, LOWER, L / R ..................................................... 171

3.4.6.5 SCALE, PF, 180 ............................................................................... 172

3.4.6.6 ENCODER, PF, ASSY. ................................................................... 173

3.4.6.7 TIMING BELT, PF .......................................................................... 174

3.4.6.8 MOTOR, RELEASE, ASSY. ........................................................... 176

3.4.6.9 PAPER, DETECTOR, PE, ASF, ASSY .......................................... 179

3.4.6.10 ASF, ASSY. ................................................................................... 180

3.4.6.11 MOTOR ASSY., ASF .................................................................... 184

3.4.6.12 ASF SENSOR ................................................................................ 185

3.4.6.13 RELEASE SENSOR ...................................................................... 186

3.4.6.14 PAPER, DETECTOR, ASSY. ....................................................... 187

3.4.6.15 SHAFT, RELEASE, ASSY. .......................................................... 189

3.4.6.16 PAPER GUIDE, UPPER, ASSY. .................................................. 190

3.4.7 Printer Mechanism ................................................................................... 192

3.4.7.1 Replacing the PRINTER MECHANISM ......................................... 192

Chapter 4 ADJUSTMENT

4.1 Overview .......................................................................................................... 194

4.1.1 Precautions ............................................................................................... 194

4.1.2 Adjustment Items and the Order by Repaired Part .................................. 195

4.1.3 Adjustment Items ..................................................................................... 202

4.1.4 List of Tools/Software/Consumables for Adjustments ........................... 208

4.1.5 Service Program Basic Operations .......................................................... 209

4.2 NV-RAM BACKUP/NVRAM Viewer ............................................................ 210

4.2.1 NVRAM Read Procedure ........................................................................ 210

4.2.2 NVRAM Viewer Basic Operation ........................................................... 211

4.3 ADJUSTMENTS (Individual) ......................................................................... 216

4.4 ADJUSTMENTS (Sequence) ........................................................................... 217

4.5 Installing Firmware .......................................................................................... 218

4.6 Image Print ....................................................................................................... 219

4.7 Counter Reset ................................................................................................... 220

4.8 References ........................................................................................................ 221

4.9 Printer Setting Change ...................................................................................... 222

4.10 CR Related Adjustments ................................................................................ 223

4.10.1 PG Position Adjustment ........................................................................ 223

4.10.2 CR Timing Belt Tension Check ............................................................ 225

4.10.3 APG Function Check ............................................................................. 226

4.10.4 CR Scale Check ..................................................................................... 227

4.10.5 Bi-D Adjustment .................................................................................... 228

4.10.6 PW Adjustment ...................................................................................... 229

4.11 Head Related Checks and Adjustments .......................................................... 231

4.11.1 Head ID Input ........................................................................................ 231

4.11.2 Head Inclination Check & Adjustment (CR direction) ......................... 232

Page 9

SC-P800 series Revision B

9

SE Group Confidential (Related Staff Only)

4.11.3 Head Slant Check & Adjustment (PF direction) ................................... 236

4.11.4 Cleaning ................................................................................................. 238

4.11.5 Nozzle Check ......................................................................................... 239

4.11.6 Colorimetric Calibration ........................................................................ 240

4.11.6.1 Overview of the Colorimetric Calibration ...................................... 240

4.11.6.2 Adjusting Method of the Colorimetric Calibration ........................ 243

4.11.6.3 Maintenance menu ......................................................................... 253

4.12 Ink Supply Related Checks and Adjustments ................................................ 256

4.12.1 Initial ink charge .................................................................................... 256

4.12.2 Ink Selector Operation Check ................................................................ 257

4.13 Media Feed Related Checks and Adjustments ............................................... 259

4.13.1 PF Timing Belt Tension Check ............................................................. 259

4.13.2 LD Roller Position Adjustment ............................................................. 261

4.13.3 PF Scale Check ...................................................................................... 264

4.13.4 Media Feed Auto Adjustment ................................................................ 265

4.13.5 EJ Adjustment ........................................................................................ 267

4.14 Boards Related Checks and Adjustments ....................................................... 269

4.14.1 Main Board initial setting ...................................................................... 269

4.14.2 RTC Check & Input ............................................................................... 270

4.14.3 Serial Number & USB ID Input ............................................................ 271

4.14.4 MAC Address Input ............................................................................... 272

4.14.5 Initial Ink charge Flag off ...................................................................... 273

4.15 Other Printer Checks and Adjustments .......................................................... 274

4.15.1 CR Motor Measurement ........................................................................ 274

4.15.2 PF Motor Measurement & Automatic Adjustment ............................... 275

4.16 Inspection Mode ............................................................................................. 276

Chapter 5 MAINTENANCE

5.1 Overview .......................................................................................................... 279

5.2 Transportation ................................................................................................... 280

5.3 Exchange Parts ................................................................................................. 281

5.4 Cleaning ............................................................................................................ 282

5.5 Lubrication ....................................................................................................... 284

Chapter 6 APPENDIX

6.1 Block Wiring Diagram ..................................................................................... 294

6.2 Connection Diagram ......................................................................................... 295

6.3 Panel Menu Map ............................................................................................... 299

6.4 Part names used in this manual ........................................................................ 301

6.5 Exploded Diagram/Parts List ........................................................................... 303

Page 10

SE Group Confidential (Related Staff Only)

C H A P T E R

1

PRODUCT DESCRIPTION

Page 11

SC-P800 series Revision B

PRODUCT DESCRIPTION Product Description 11

SE Group Confidential (Related Staff Only)

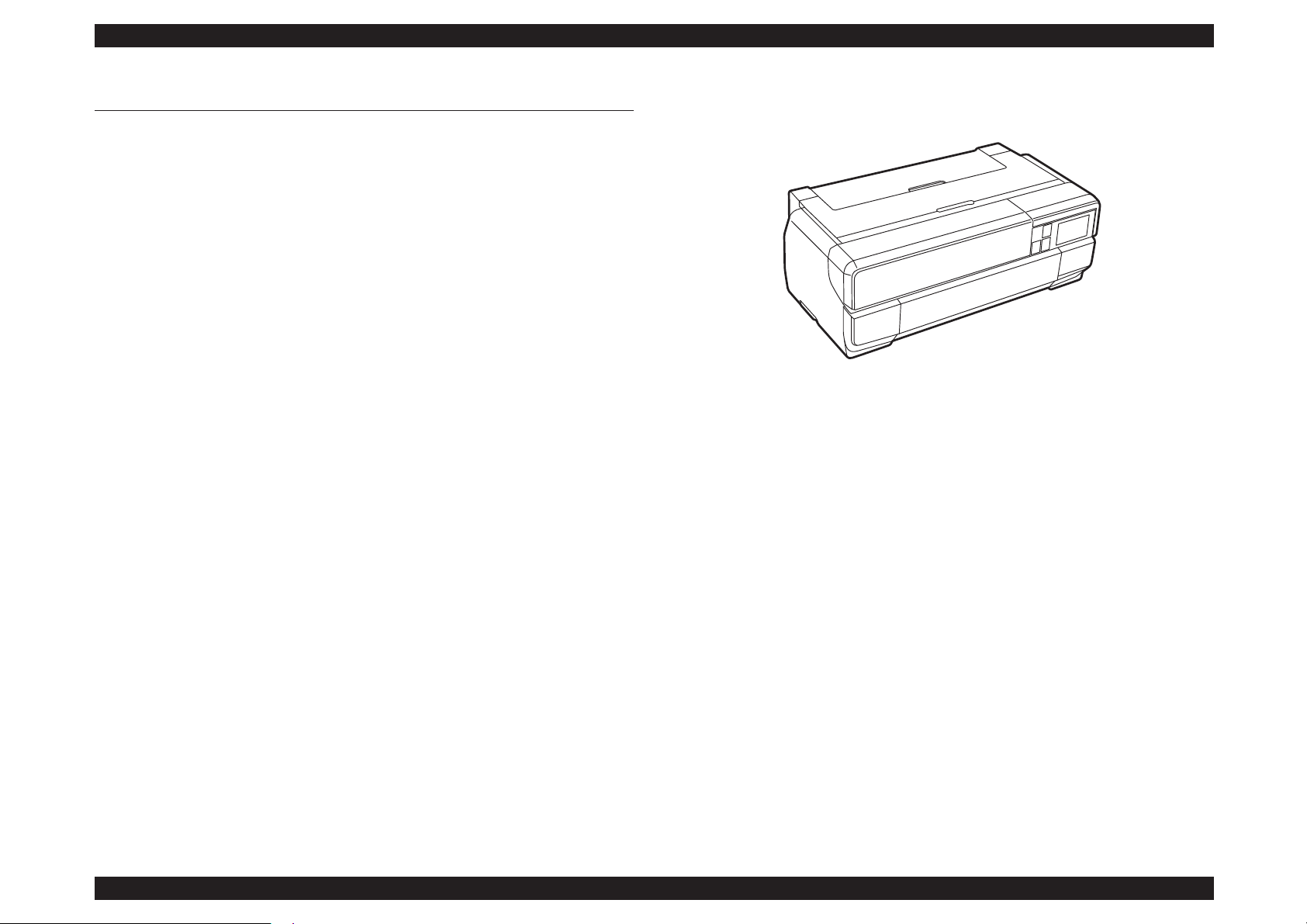

1.1 Product Description

SC-P800 series are large size color inkjet printers that support up to A2 (17”) sized cutsheet paper.

F-Mach (180N x 8-column) print head

Maximum print resolution (dpi): 2880 x 1440

Superior color and monochrome reproducibility with eight colors

UltrachromeK3 ink system, consisting of 4 basic colors (YMCK) with 2

complementary colors and 2 complementary blacks

Automatic switching between black ink modes; Photo black and Matte black.

Requires no user intervention, and ink used during the conversion is remarkably

reduced.

Two manual paper feeders are provided in addition to the ASF (Auto Sheet

Feeder)

Front manual feeder: Supports thick paper having a thickness of up to 1.5

mm.

Roll paper: Feeds paper using the roll paper unit (option).

High speed network and communication supported

100BASE-TX/10BASE-T Network Interface

USB2.0 High Speed Interface

Wireless LAN 802.11b/g/n Network Interface

Borderless printing supported

Equipped with a control panel having a 2.7-inch color touch panel, offering

excellent visibility and operability

Figure 1-1. External View

Page 12

SC-P800 series Revision B

PRODUCT DESCRIPTION Basic Specifications 12

SE Group Confidential (Related Staff Only)

1.2 Basic Specifications

1.2.1 Basic Specifications

Note "*" : The all 9 ink cartridges can be installed simultaneously. The printer automatically switches

between Photo and Matte black depending on the driver selection while utilizing the same

physical ink channel.

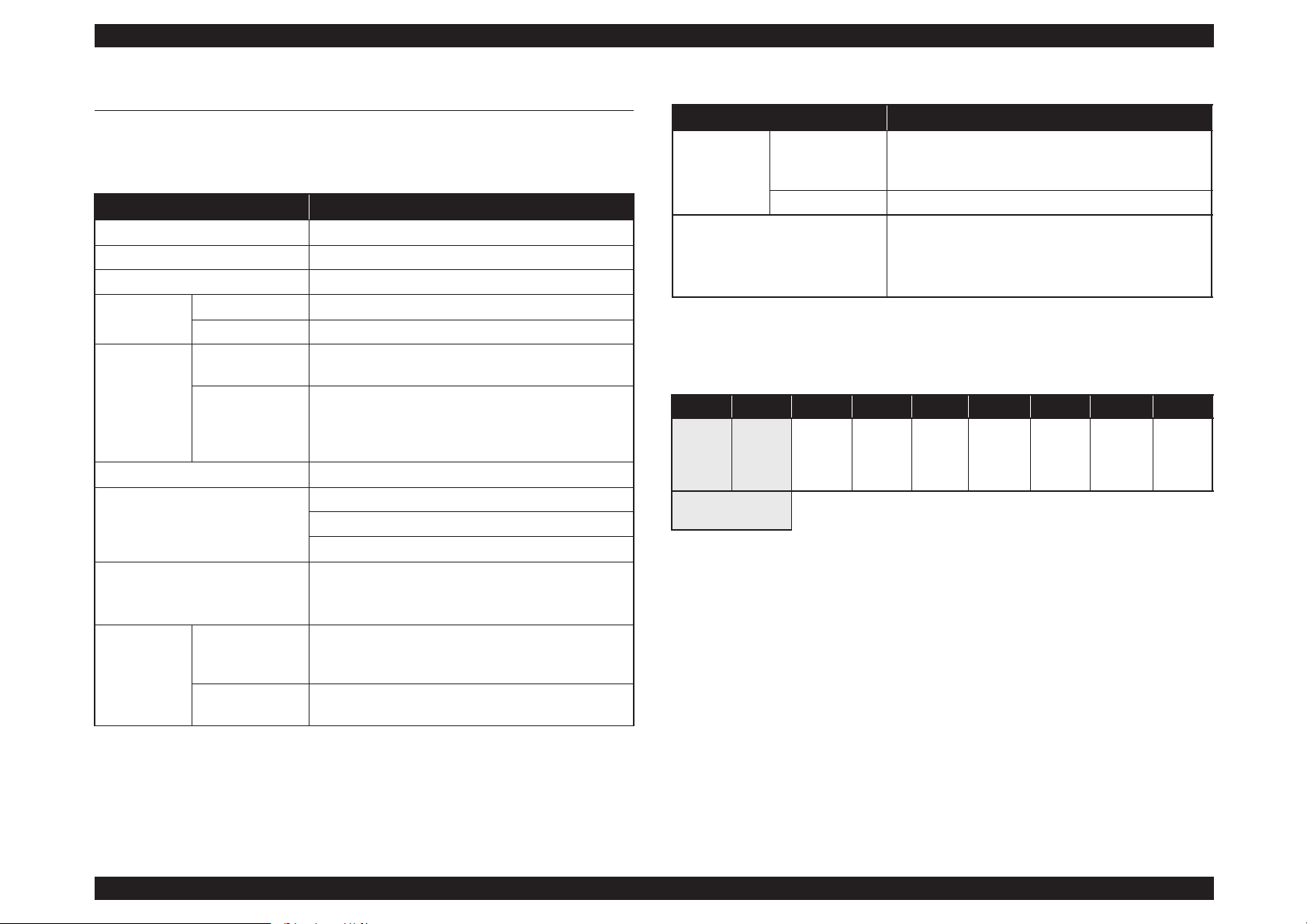

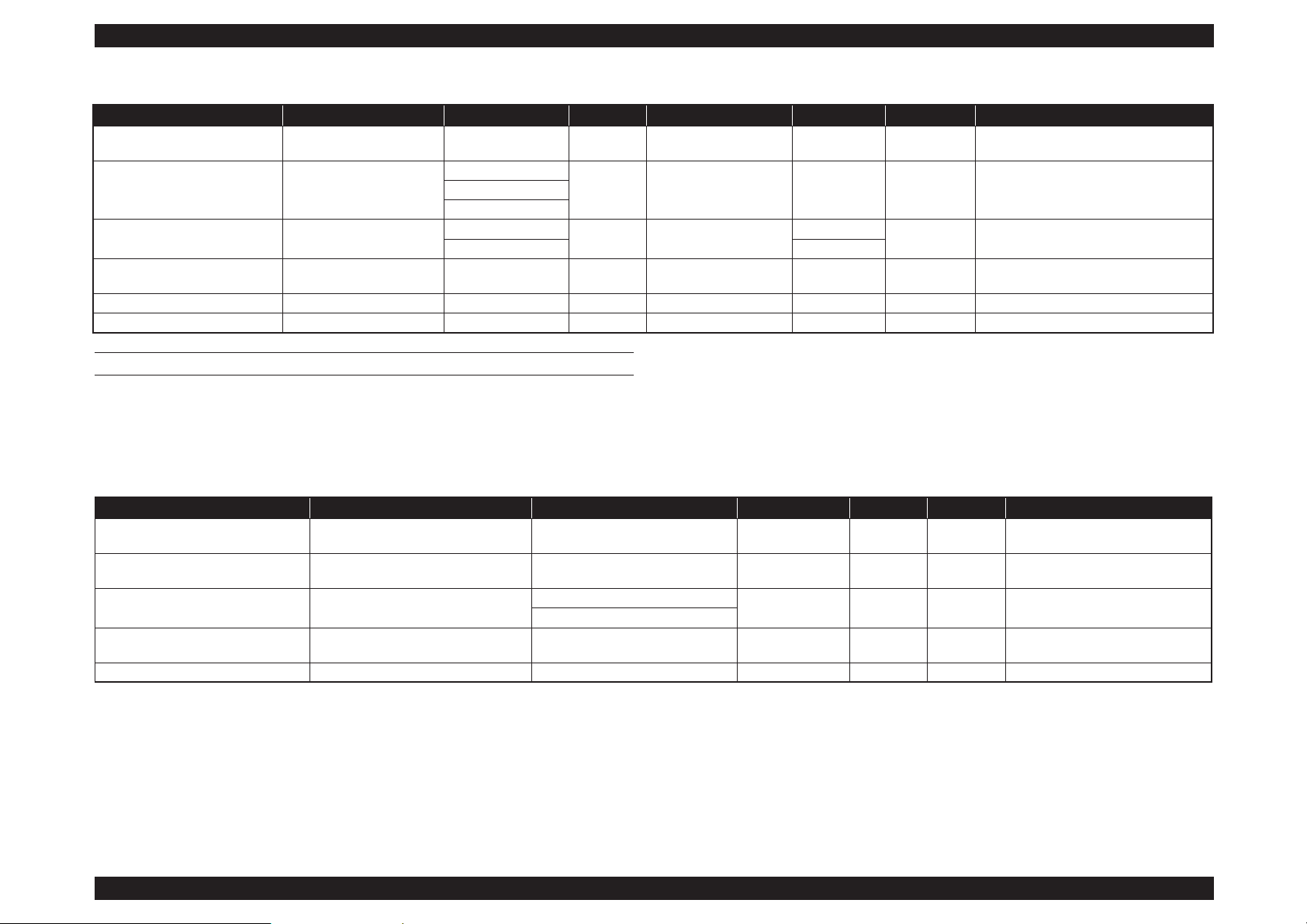

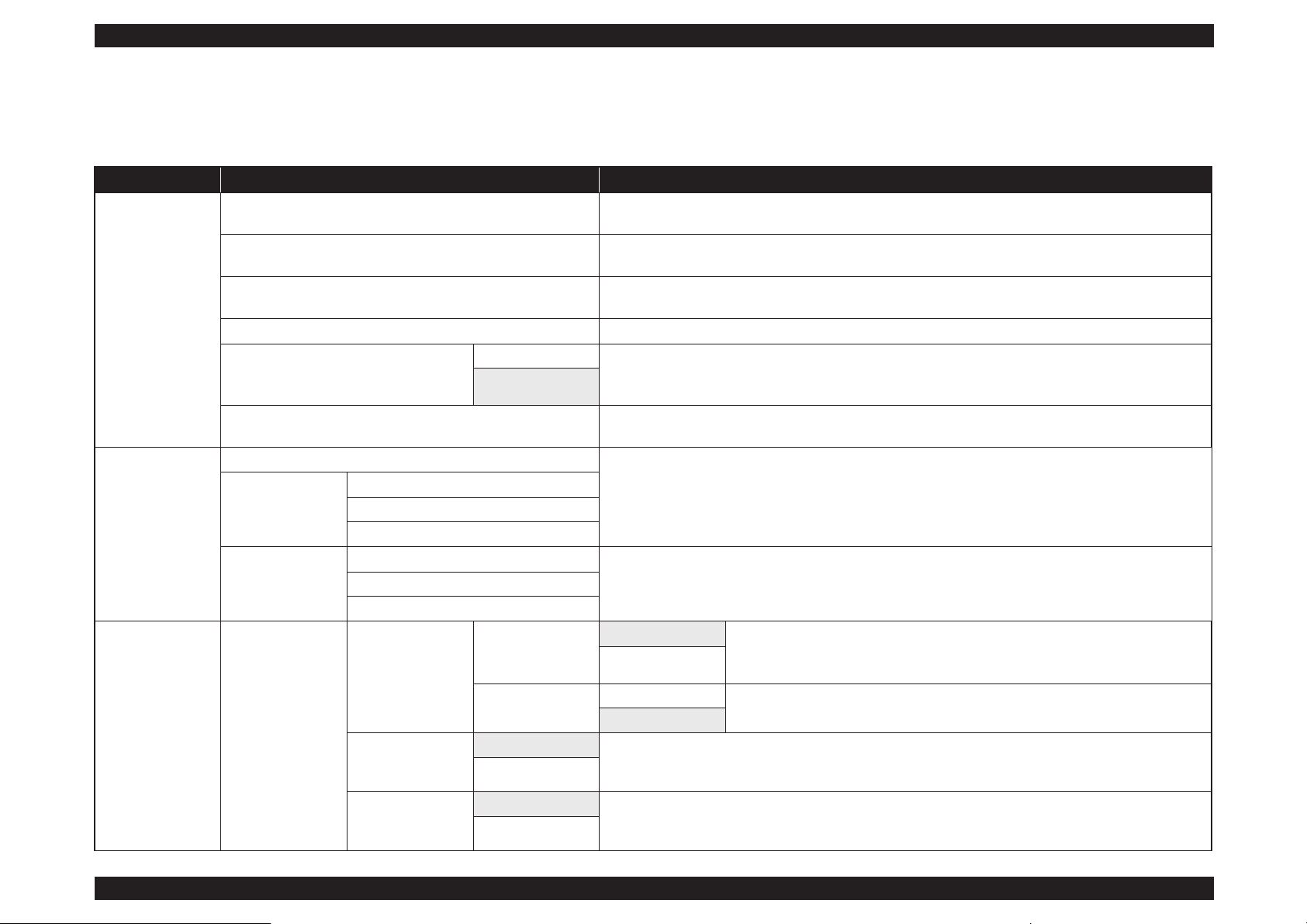

Table 1-1. Basic Specifications

Item Specifications

Maximum paper width 17 inch (43 cm)

Printing method On-demand ink jet method

Printing direction Two-way shortest distance printing with logical seeking

Print Head

Type F-Mach

Number of nozzles 180 Nozzles per color (180 Nozzles x 8 colors)*

Ink

Type

UltrachromeK3 ink system (9 independent ink

cartridges)*

Color of inks

Matte Black*, Photo Black*, Light Black, Light Light

Black, Cyan, Vivid Magenta, Yellow, Light Cyan, Vivid

Light Magenta (Refer to

table1-2 for the alignment

sequence of the cartridges)

Maximum print resolution 2880 dpi × 1440 dpi

Printing function

Borderless printing

Automatic bottom processing

L/4 x 6 Photo high-speed printing

Interface

Ethernet 100BASE-TX/10BASE-T

High-Speed USB

IEEE802.11b/g/n

Temperature

Main body

operation

environment

10 °C to 35 °C

When storing

-20 °C to 40 °C (within 120 hours under 60 °C, and

within 1 month under 40 °C)

Humidity

Main body

operation

environment

20% to 80% (Non condensing)

When storing 5% to 85% (Non condensing)

Operating life of the printer

Until any one of the following conditions is met.

12,000 pages (A2 plain paper fine mode)

1,600,000 paths (carriage movement)

5 years

Table 1-2. Cartridge Alignment Sequence

Row 1 Row 2 Row 3 Row 4 Row 5 Row 6 Row 7 Row 8 Row 9

Matte

Black

(PK)

Photo

Black

(MK)

Light

Black

(LK)

Light

Light

Black

(LLK)

Cyan

(C)

Vivid

Magenta

(VM)

Light

Cyan

(Lc)

Vivid

Light

Magenta

(VLM)

Yellow

(Y)

Switched by an Ink

Selector

Table 1-1. Basic Specifications

Item Specifications

Page 13

SC-P800 series Revision B

PRODUCT DESCRIPTION Basic Specifications 13

SE Group Confidential (Related Staff Only)

1.2.2 Electric Specifications

Note "* " : Pattern: ISO Bike, Media: plain paper, Mode:Default(720x360), Media size: A2, Printing size:

414 x 517.5mm

1.2.3 Ink Specifications

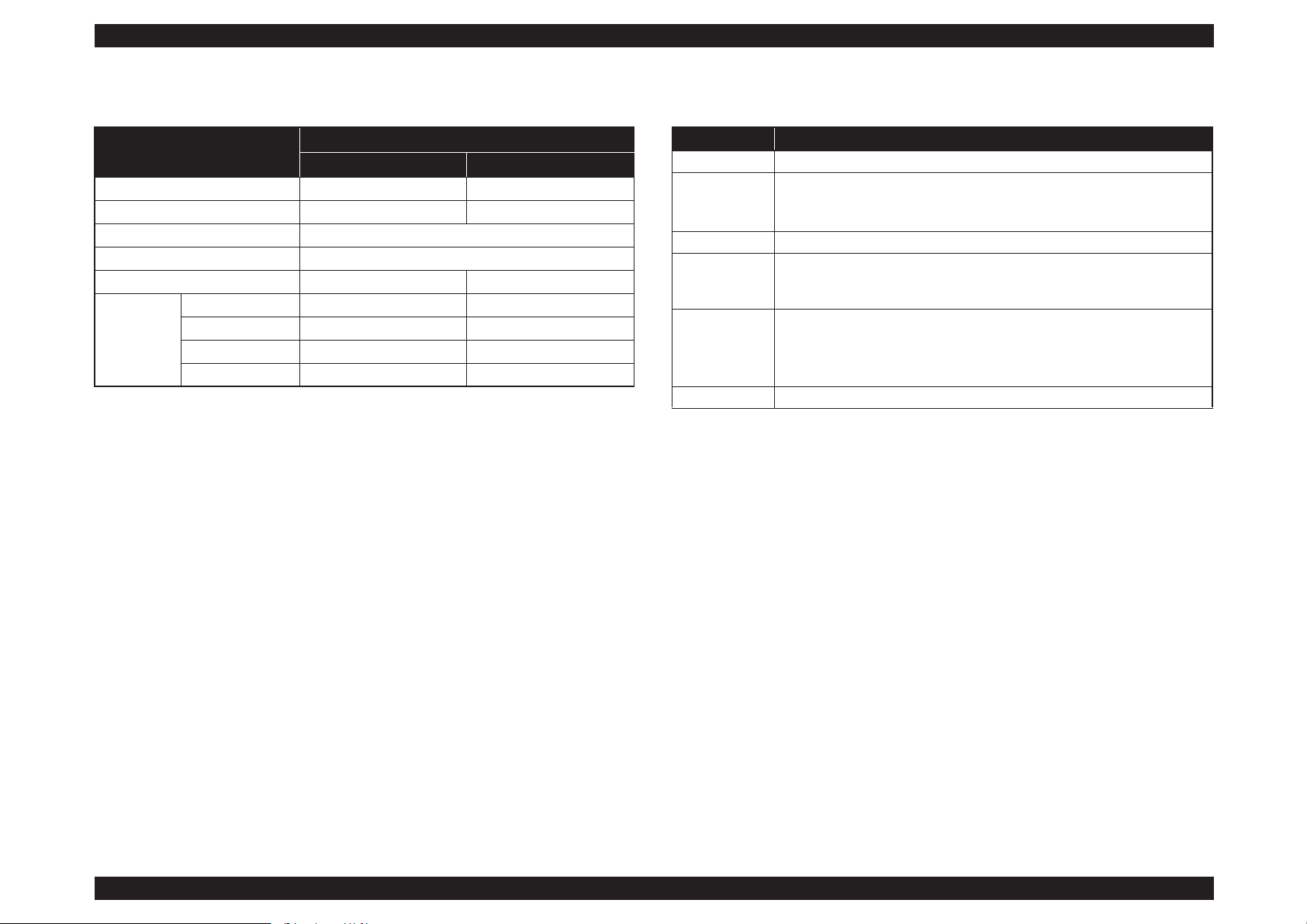

Table 1-3. Electric Specifications

Item

Specification

100/120V Model 220/240V Model

Rated voltage 120 VAC 220 to 240 VAC

Input voltage range 108 to 132 VAC 198 to 264 VAC

Rated frequency 50 to 60Hz

Input frequency range 49.5 to 60.5Hz

Rated current 0.6 A 0.3 A

Power

consumption

Operating* Approx. 21 W Approx. 21 W

Ready mode Approx. 5.8 W Approx. 5.8 W

Sleep mode Approx. 1.8 W Approx. 1.8 W

Power OFF Approx. 0.3 W Approx. 0.5 W

Table 1-4. Ink Specifications

Item Specification

Form Exclusive ink cartridge

Pigment ink

colors

Black system: Matte Black, Photo Black, Light Black, Light Light Black

Color system: Cyan, Vivid Magenta, Yellow, Light Cyan, Vivid Light

Magenta

Cartridge life See the date printed on the package (at normal temperature)

Guaranteed life

after

installation

6 month (after mounted in the printer)

Storage

Uninstalled (packed): -20 to 40 °C (within 1 month under 40 °C)

Installed: -20 to 40 °C (within 1 month under 40 °C)

Transporting (packed): -20 to 60 °C

(within 1 month under 40 °C, and within 72 hours under 60 °C)

Dimensions 700ml: W30 x L93 x H70 mm

Page 14

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 14

SE Group Confidential (Related Staff Only)

1.3 Printing Specifications

1.3.1 Paper Feed Specifications

1.3.2 Paper Feeder Specifications

SC-P800 series support three types of paper feeding methods; ASF, Front Manual

Feed, and Roll Paper Feed. The paper size and thickness for each of the methods are

shown in the table below. For paper type and feeder capacity, refer to

"1.3.3 Supported

Media" (p15).

Item Specification

Paper feed method Friction feed

Minimum pitch of paper feed 2.94 µm (1/8640 inch)

Paper feed

Rear ASF

Front manual feed

Rear roll paper

Paper feed speed 25.4 mm (1 inch) when line feed: 333 msec (3 inch/sec)

Paper Feed

Method

Paper Size

Thickness

(mm)

Width (mm) Length (mm)

Standard paper

(mm)

ASF 89 to 431.8 127 to 950 L/4”x6” to A2/USC 0.08 to 0.3

Front Manual Feed

(Fine art media)

203.2 to 431.8 254 to 950 A4/8”x10” to A2/USC 0.29 to 0.7

Front Manual Feed

(Board media)

203.2 to 431.8 254 to 594 A4/8”x10” to A2/USC 0.7 to 1.5

Roll paper 329 to 431.8 55 to 1117.6

A3+/8”x10” to A2/

USC

0.25 to 0.7

Page 15

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 15

SE Group Confidential (Related Staff Only)

1.3.3 Supported Media

1.3.3.1 Epson Special Media Table

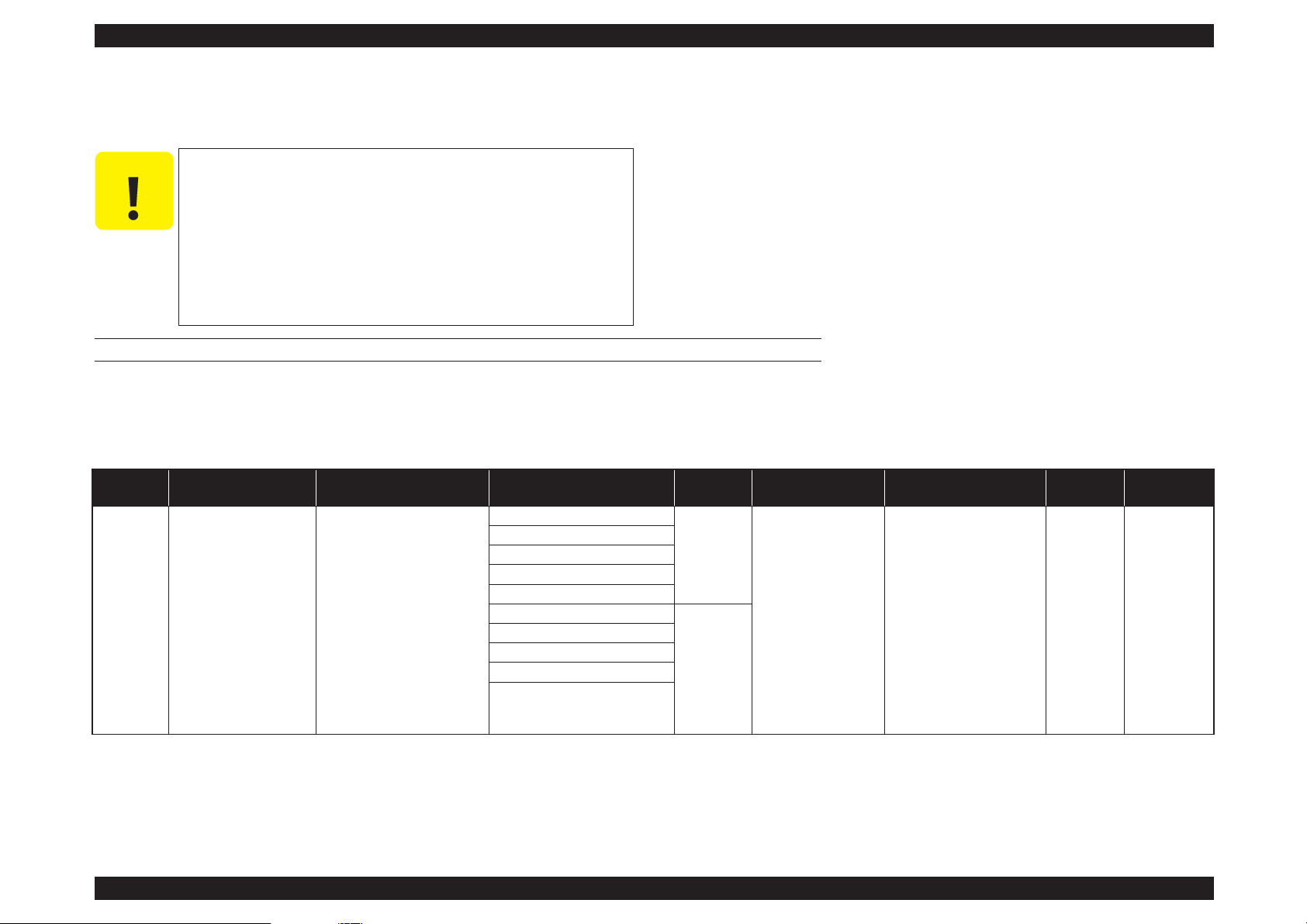

CUT SHEET

Note "*1": Borderless: Describes whether borderless printing is available.

"*2": Black ink: An abbreviation of the type of black ink supported by the media. PK: Photo Black/MK: Matte Black

"*3": May not be available depending on the area of purchase.

Table 1-5. Cut sheet Media Table

Paper Type Media Type (Printer Driver) Size Capacity Source Borderless

*1

Black ink

*2

ICC Profile

Premium Glossy Photo Paper Epson Premium Glossy

13 x 18 cm (5 x 7 in.)

30

Auto sheet feeder ✔ PK SC-P800 Series Epson Premium Glossy.icc

10 x 15 cm (4 x 6 in.)

A4

16:9 wide size

(102 x181 mm) *

3

20

A3

10

A3+

A2 1

Photo Paper Glossy Photo Paper Glossy

13 x 18 cm (5 x 7 in.)

30 Auto sheet feeder

✔ PK SC-P800 Series Photo Paper Glossy.icc10 x 15 cm (4 x 6 in.)

A4

Premium Semigloss Photo Paper Epson Premium Semigloss

10 x 15 cm (4 x 6 in.)

30

Auto sheet feeder

✔ PK

SC-P800 Series Epson Premium

Semigloss.icc

A4

A3

10

A3+

A2 1

Archival Matte Paper Epson Archival Matte

A4 30

Auto sheet feeder

✔ MK SC-P800 Series Epson Archival Matte.icc

A3

10

A3+

A2 1

Matte Paper Heavy-weight Epson Archival Matte

A4 30

Auto sheet feeder

✔ MK SC-P800 Series Epson Archival Matte.iccA3

10

A3+

Photo Quality Inkjet Paper Epson Photo Quality Ink Jet

A4 60

Auto sheet feeder --- MK SC-P800 Series Standard.icc

A3

50

A3+

A2 10

Page 16

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 16

SE Group Confidential (Related Staff Only)

ROLL PAPER

All paper loading methods are for roll paper.

Note "*1": Borderless: Describes whether borderless printing is available.

"*2": Black ink: An abbreviation of the type of black ink supported by the media. PK: Photo Black/

MK: Matte Black

Watercolor Paper - Radiant White

Watercolor Paper RadiantWhite

A3+ 1

Front manual feed

(fine art media)

✔ MK

SC-P800 Series Watercolor Paper-Radiant

White.icc

Velvet Fine Art Paper Velvet Fine Art Paper

A3

1

Front manual feed

(fine art media)

✔ MK SC-P800 Series VelvetFineArtPaper.iccA3+

A2

UltraSmooth Fine Art Paper UltraSmooth Fine Art Paper

A3+

1

Front manual feed

(fine art media)

✔

MK

SC-P800 Series UltraSmooth FineArt

Paper.icc

A2 ---

Epson Proofing Paper White

Semimatte

Epson Proofing Paper White

Semi-matte

A3+ 1 Auto sheet feeder ✔ PK

SC-P800 Series Epson Proofing Paper White

Semi-matte.icc

Premium Ink Jet Plain Paper plain papers A4 80 Auto sheet feeder ✔ PK/MK SC-P800 Series Standard.icc

Bright White Inkjet Paper plain papers A4 80 Auto sheet feeder ✔ PK/MK SC-P800 Series Standard.icc

Table 1-5. Cut sheet Media Table

Paper Type Media Type (Printer Driver) Size Capacity Source Borderless

*1

Black ink

*2

ICC Profile

Table 1-6. Roll Paper Media Table

Paper Type Media Type (Printer Driver) Size Core Borderless*1Black ink

*2

ICC Profile

Premium Glossy Photo Paper (250) Epson Premium Glossy 406 mm/16" 3 inch

✔ PK

SC-P800 Series Epson Premium

Glossy.icc

Premium Semigloss Photo Paper (250) Epson Premium Semigloss 406 mm/16" 3 inch

✔ PK

SC-P800 Series Epson Premium

Semigloss.icc

Premium Luster Photo Paper (260) Epson Premium Luster

329 mm (A3+)

3 inch

✔ PK

SC-P800 Series Epson Premium

Luster.icc

406 mm/16"

Premium Semimatte Photo Paper (260) Epson Premium Semigloss 406 mm/16" 3 inch

✔ PK

SC-P800 Series Epson Premium

Semigloss.icc

Enhanced Matte Paper Epson Archival Matte 432 mm/17" 3 inch

✔ MK SC-P800 Series Archival Matte.icc

Page 17

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 17

SE Group Confidential (Related Staff Only)

1.3.3.2 Usable Commercially Available Paper Size

This printer supports the following paper specifications for non-Epson media.

CUT SHEET

Note "*1": Borderless: Describes whether borderless printing is available.

"*2": Black ink: An abbreviation of the type of black ink supported by the media. PK: Photo Black/MK: Matte Black

"*3": The maximum length you can set in the printer driver is 15 m.

"*4": May not be available depending on the media being used. Contact the manufacturer of the media for more details.

C A U T I O N

Do not use paper that is wrinkled, scuffed, torn, or dirty.

Although plain paper and recycled paper manufactured by

other companies can be loaded and fed in the printer as long as

they meet the following specifications, Epson cannot guarantee

the print quality.

Although other paper types manufactured by other companies

can be loaded in the printer as long as they meet the following

specifications, Epson cannot guarantee the paper feeding and

print quality.

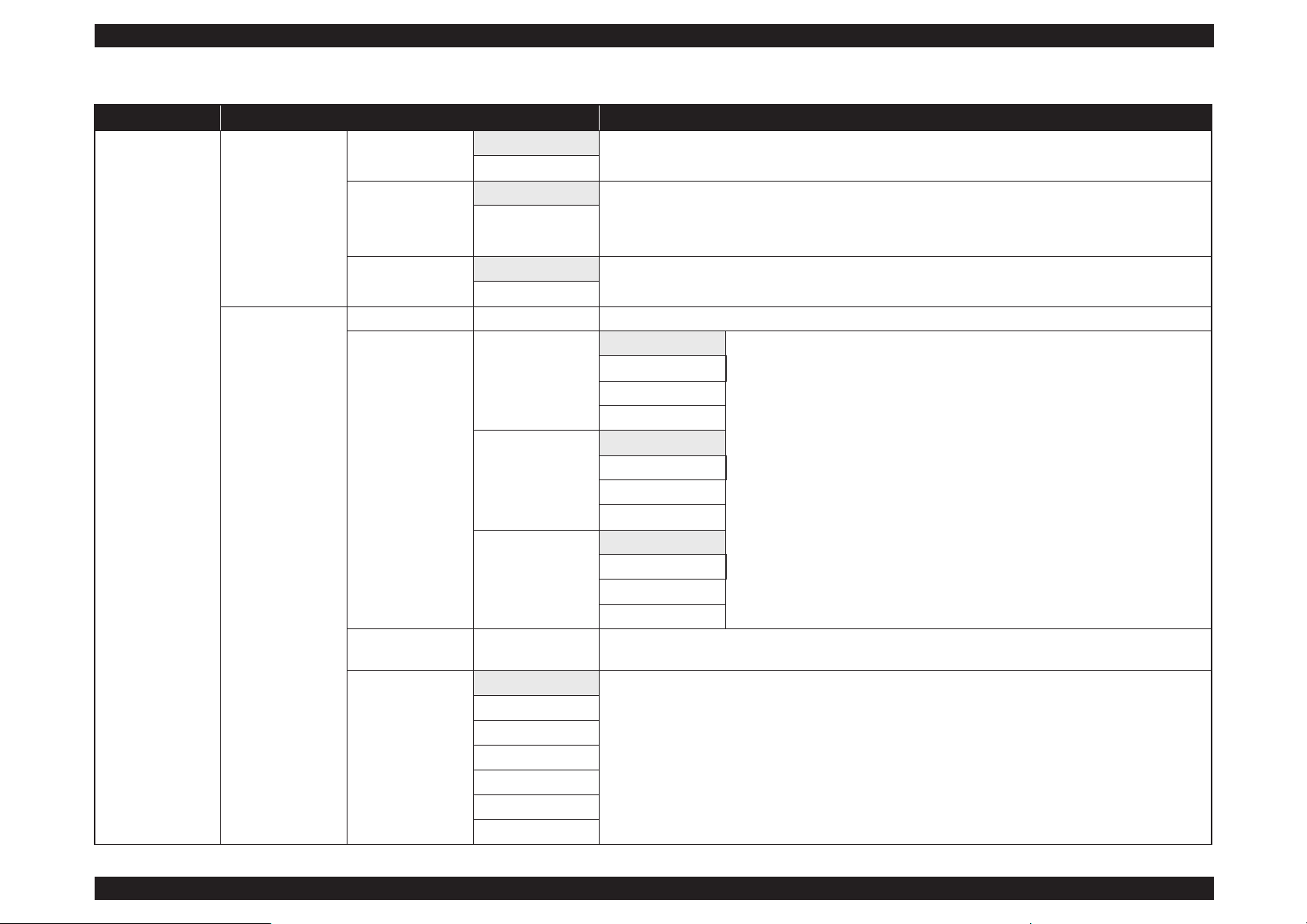

Table 1-7. Cut sheet Media Table

Item Paper Type Driver Media Types Size

Number of

Sheets

Paper thickness Loading Method Borderless

*1

Ink Type

*2

Plain Paper Cut sheets

See the manual supplied with the

paper and adjust settings as

appropriate.

A6

Up to 12 mm

total

thickness

0.08 mm to 0.11 mm

(64 to 90 g/m

2

)

Auto sheet feeder --- PK/MK

A5

B5

A4

Letter

Legal

Up to 5 mm

total

thickness

B4

A3

A2

Non-standard sizes

W: 89 mm to 431.8mm

L: 127 mm to 950mm*

3

Page 18

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 18

SE Group Confidential (Related Staff Only)

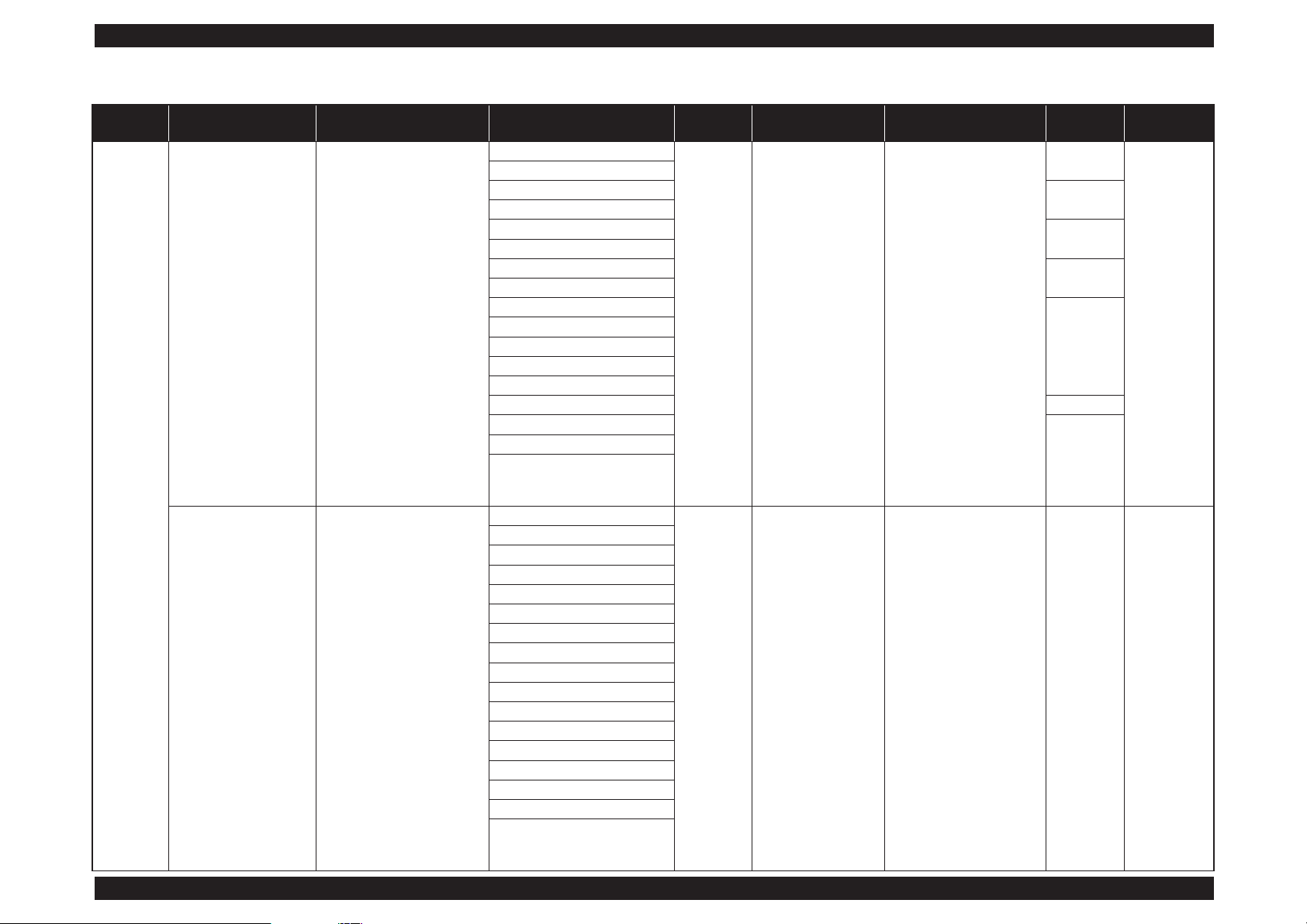

Thick paper

Cut sheets

See the manual supplied with the

paper and adjust settings as

appropriate.

A4

1 0.29 mm to 0.7 mm

Front manual feed tray (fine

art media

✔

*4

PK/MK

Letter

Legal

---

Half Letter

28 to 43 cm (11 to 17 in.)

✔

*4

43 to 56 cm (17 to 2 in.)

JIS B4

---

JIS B3

254 to 305 mm (10 to 12 in.)

✔

*4

A3

A3+

279 to 356 mm (11 to 14 in.)

30 to 30 cm (12 to 12 in.)

36 to 43 cm (14 to 17 in.) ---

41 to 51 cm (16 to 20 in.)

✔

*4

A2

Non-standard sizes

W: 89 mm to 431.8mm

L: 127 mm to 950mm*

3

Cut sheets

See the manual supplied with the

paper and adjust settings as

appropriate.

A4

1 1.2 mm to 1.5 mm

Front manual feed tray (poster

board)

--- PK/MK

Letter

Legal

Half Letter

28 to 43 cm (11 to 17 in.)

43 to 56 cm (17 to 22 in.)

JIS B4

JIS B3

254 to 305 mm (10 to 12 in.)

A3

A3+

279 to 356 mm (11 to 14 in.)

30 to 30 cm (12 to 12 in.)

36 to 43 cm (14 to 17 in.)

41 to 51 cm (16 to 20 in.)

A2

Non-standard sizes

W: 89 mm to 431.8mm

L: 127 mm to 950mm*

3

Table 1-7. Cut sheet Media Table

Item Paper Type Driver Media Types Size

Number of

Sheets

Paper thickness Loading Method Borderless

*1

Ink Type

*2

Page 19

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 19

SE Group Confidential (Related Staff Only)

ROLL PAPER

Note "*1": Borderless: Describes whether borderless printing is available.

"*2": Black ink: An abbreviation of the type of black ink supported by the media. PK: Photo Black/MK: Matte Black

"*3": You can specify and perform borderless printing; however, the print quality may decline or margins may appear due to the paper expanding or contracting.

"*4": The maximum length you can set in the printer driver is 15000 mm.

Table 1-8. Roll paper Media Table

Item Driver Media Types Size Paper thickness Roll Core Size Borderless*

1

Ink Type*

2

Roll paper

See the manual supplied with the paper

and adjust settings as appropriate.

13 to 17 inches wide

W: 329 to 431.8 mm

L: 55 to 1117.6 mm*

4

0.25 mm to 0.7 mm 2 inches/3 inches ✔*

3

PK/MK

Page 20

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 20

SE Group Confidential (Related Staff Only)

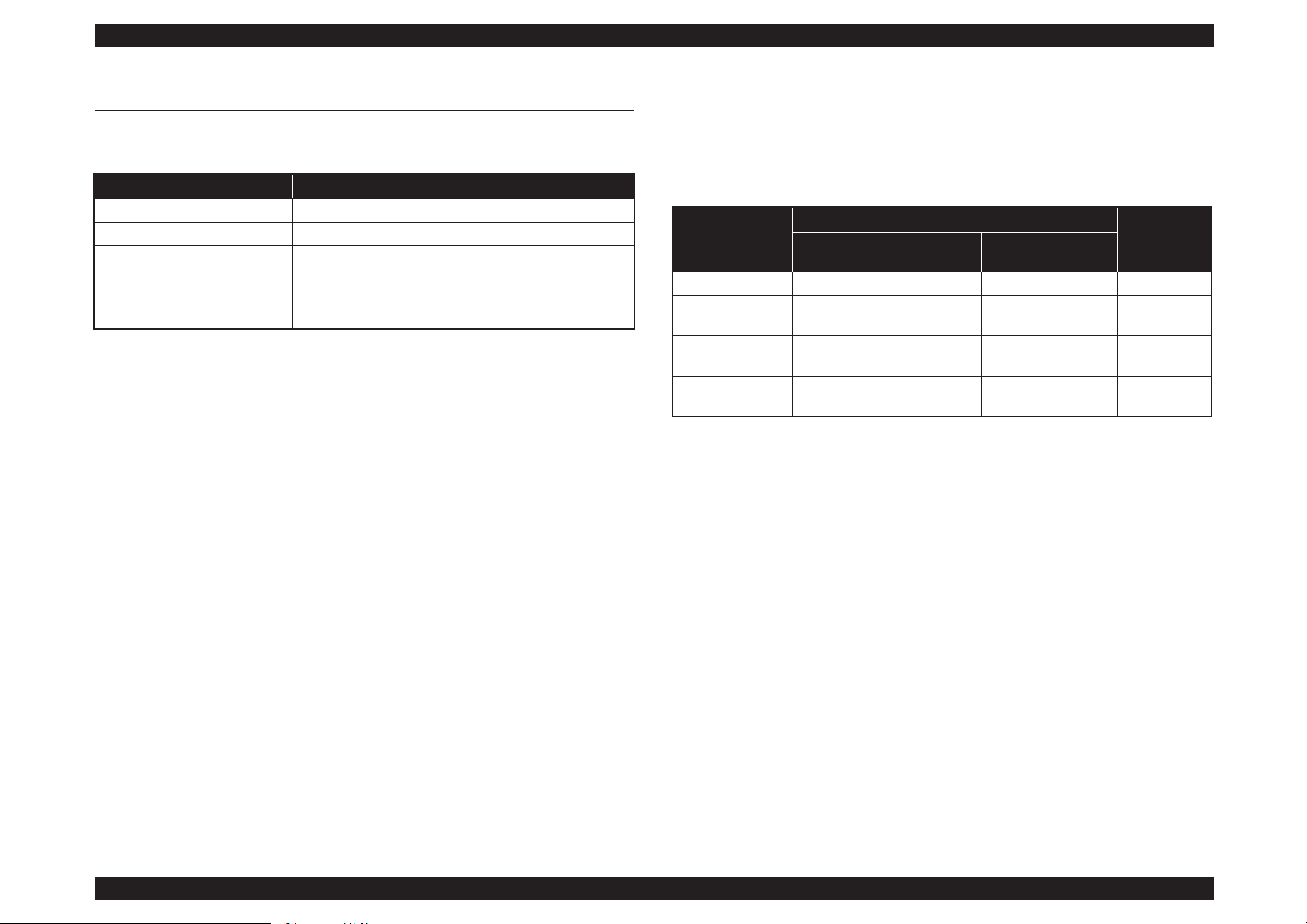

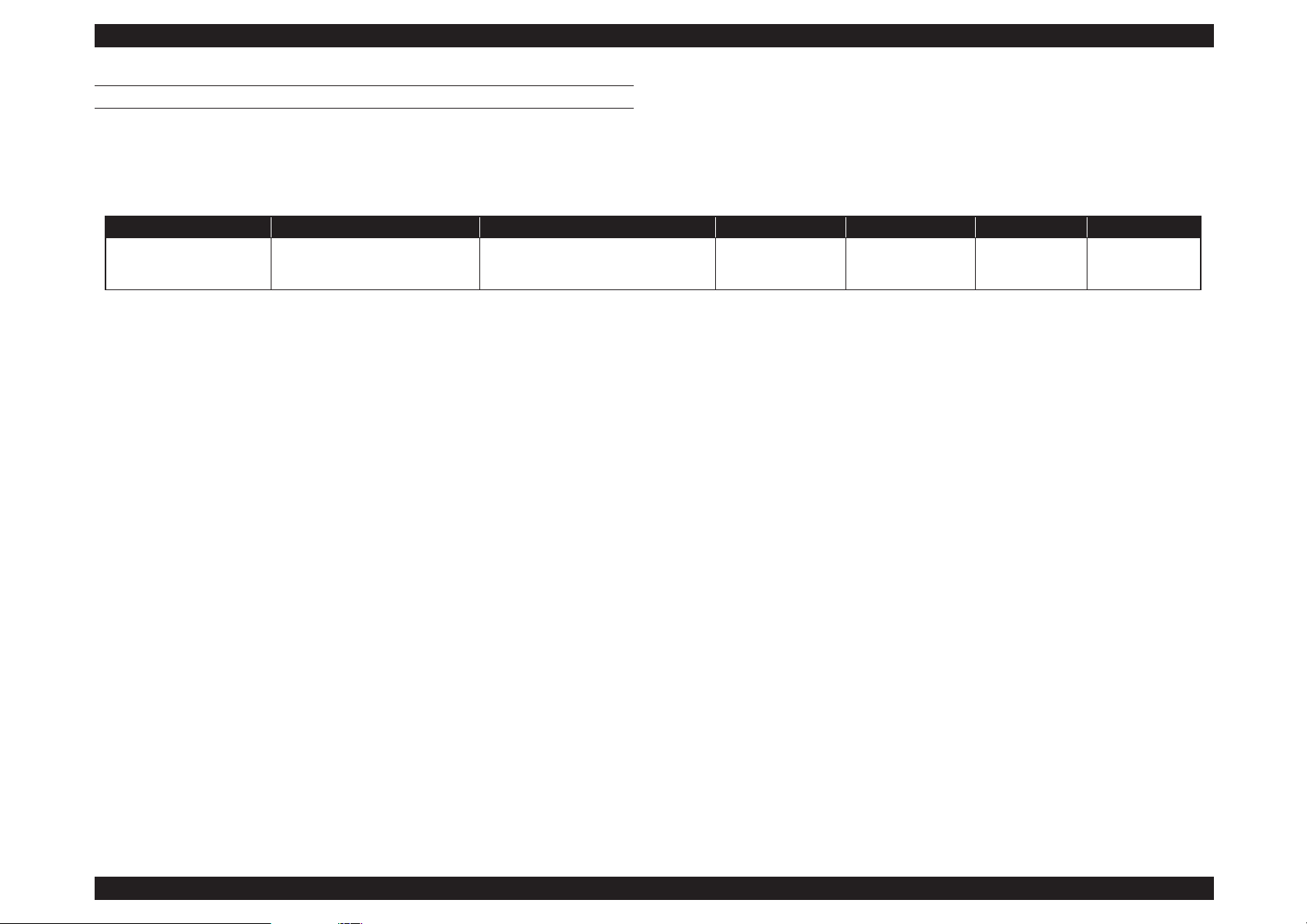

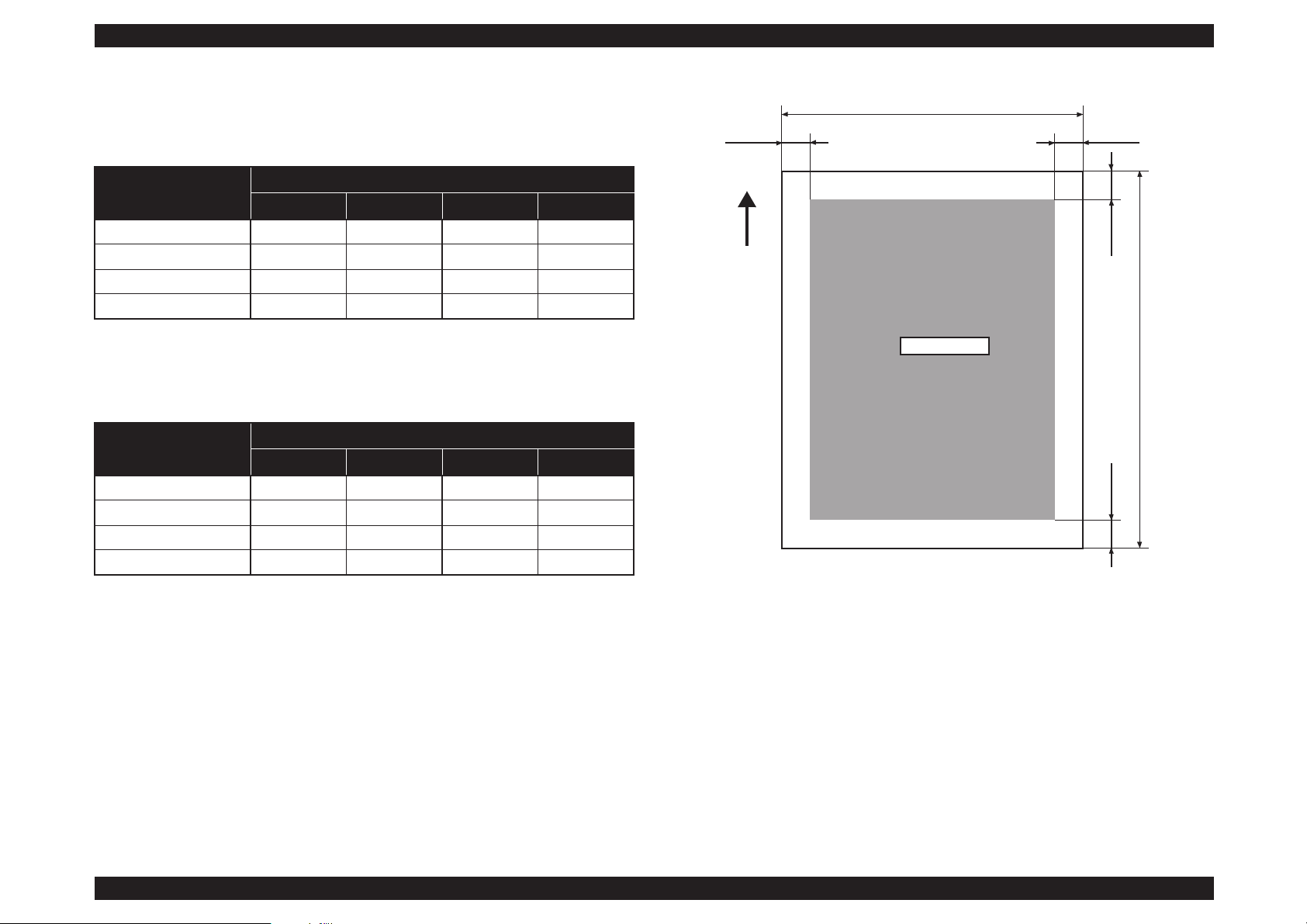

1.3.4 Printable area

Normal print

Note "*1": 0 mm for continuous print jobs.

"*2": 14 mm when Print Page Line on the control panel is set to On.

Borderless print

Note "* " : 0 mm for continuous print jobs.

Figure 1-2. Printable area

Table 1-9. Printable area (normal print)

Item

Dimension

Cut sheet Board paper Fine art paper Roll paper

TM (top margin) 3 mm 20 mm 3 mm 50 mm*

1

BM (bottom margin) 3 mm 20 mm 15 mm 19 mm*

2

LM (left margin) 3 mm 3 mm 3 mm 3 mm

RM (right margin) 3 mm 3 mm 3 mm 3 mm

Table 1-10. Printable area (borderless print)

Item

Dimension

Cut sheet Board paper Fine art paper Roll paper

TM (top margin) 0 mm 0 mm 0 mm 50 mm*

BM (bottom margin) 0 mm 0 mm 0 mm 14 mm

LM (left margin) 0 mm 0 mm 0 mm 0 mm

RM (right margin) 0 mm 0 mm 0 mm 0 mm

PW

LM RM

TM

BM

PL

Printable area

Paper feed direction

Page 21

SC-P800 series Revision B

PRODUCT DESCRIPTION Printing Specifications 21

SE Group Confidential (Related Staff Only)

1.3.5 Borderless Printing Specification

The following media sizes are supported for borderless printing. For paper type and

feeder capacity, refer to

"1.3.3 Supported Media" (p15).

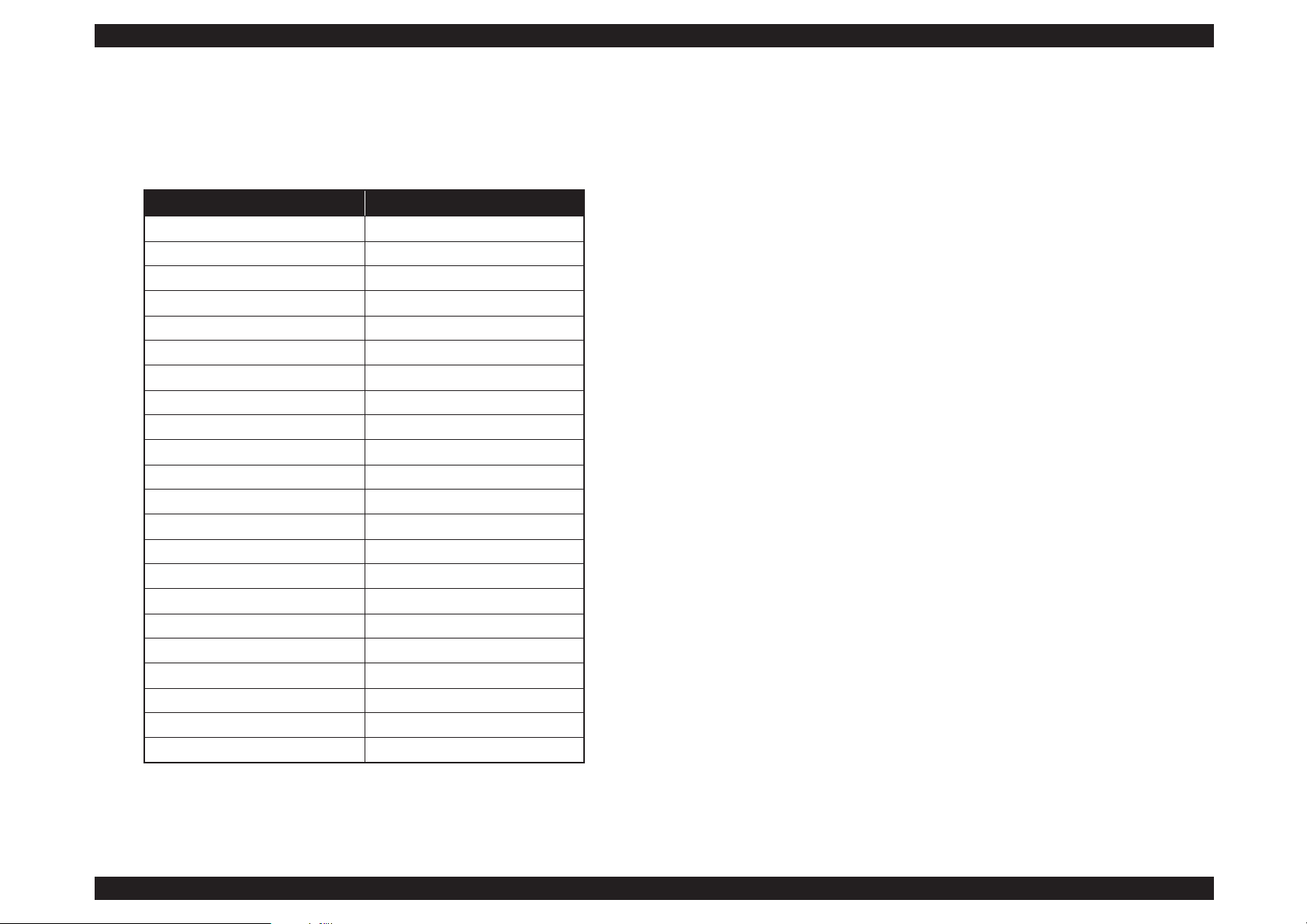

Table 1-11. Borderless Printing Specification

Paper Type Size

A4 210 mm × 297 mm

A3 297 mm × 420 mm

A3+ 329 mm × 483 mm

A2 420 mm × 594 mm

Letter 8.5 inch × 11 inch

28 × 43 cm 11 inch × 17 inch

43 × 56 cm 17 inch × 22 inch

100 × 148 mm 100 mm × 148 mm

9 × 13 cm 3.5 inch × 5 inch

10 × 15 cm 4 inch × 6 inch

13 × 18 cm 5 inch × 7 inch

13 × 20 cm 5 inch × 8 inch

16:9 wide size 102 mm × 181 mm

20 × 25 cm 8 inch × 10 inch

254 × 305 mm 10 inch × 12 inch

279 × 356 mm 11 inch × 14 inch

30 × 30 cm 12 inch × 12 inch

41 × 51 cm 16 inch × 20 inch

13 inch (329 mm) roll paper 329 mm

16 inch roll paper 406 mm

16.5 inch (42 cm) roll paper 420 mm

17 inch roll paper 432 mm

Page 22

SC-P800 series Revision B

PRODUCT DESCRIPTION Hardware Specifications 22

SE Group Confidential (Related Staff Only)

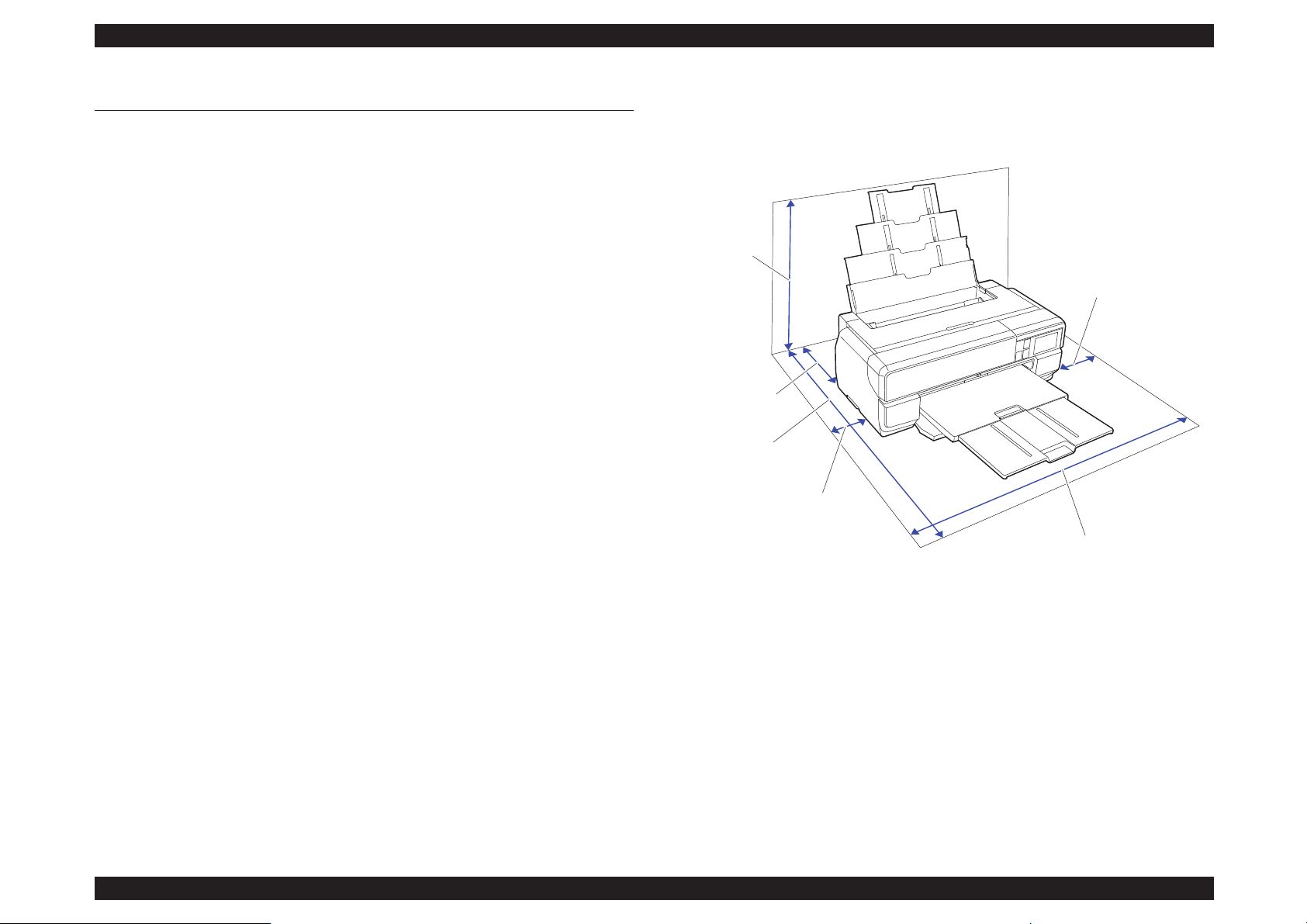

1.4 Hardware Specifications

This section provides the printer dimensions and shows the main components.

1.4.1 Dimensions and Weight

Dimensions

Storage dimensions

(W) 684 mm × (D) 376 mm × (H) 250 mm

(W) 684 mm × (D) 586 mm × (H) 286 mm

*

Normal dimensions

(W) 684 mm × (D) 963 mm × (H) 550 mm

(W) 684 mm × (D) 769 mm × (H) 286 mm

*

Note"*":When optional items are attached

Weight

Approx. 19.5kg (without ink cartridges)

1.4.2 Installation Room Requirement

Figure 1-3. Installation space

NOTE: When printing on poster board, leave a space of at least 430 mm in behind

the printer.

100 mm

100 mm

1030 mm

550 mm

270 mm

884 mm

※

Page 23

SC-P800 series Revision B

PRODUCT DESCRIPTION Hardware Specifications 23

SE Group Confidential (Related Staff Only)

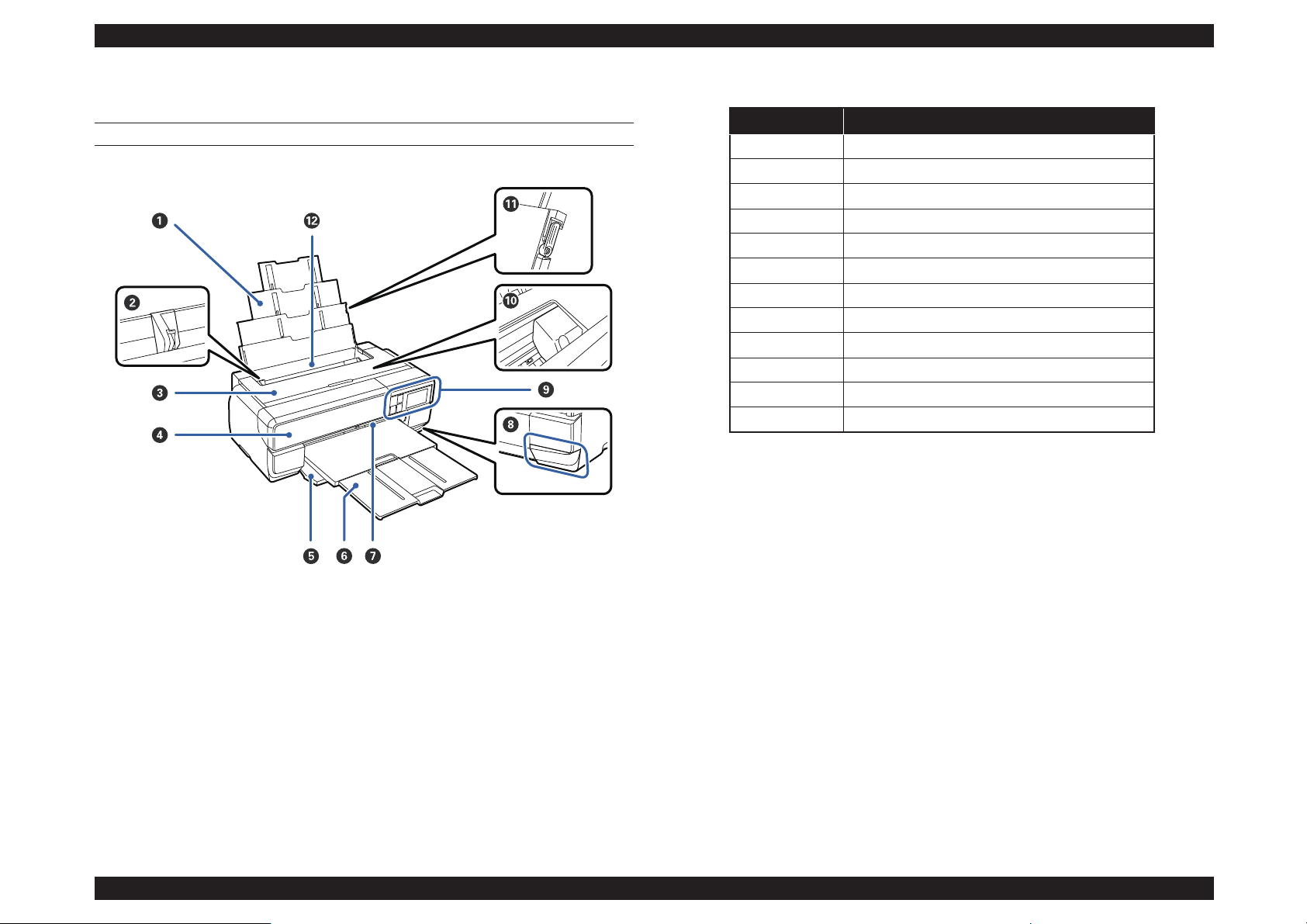

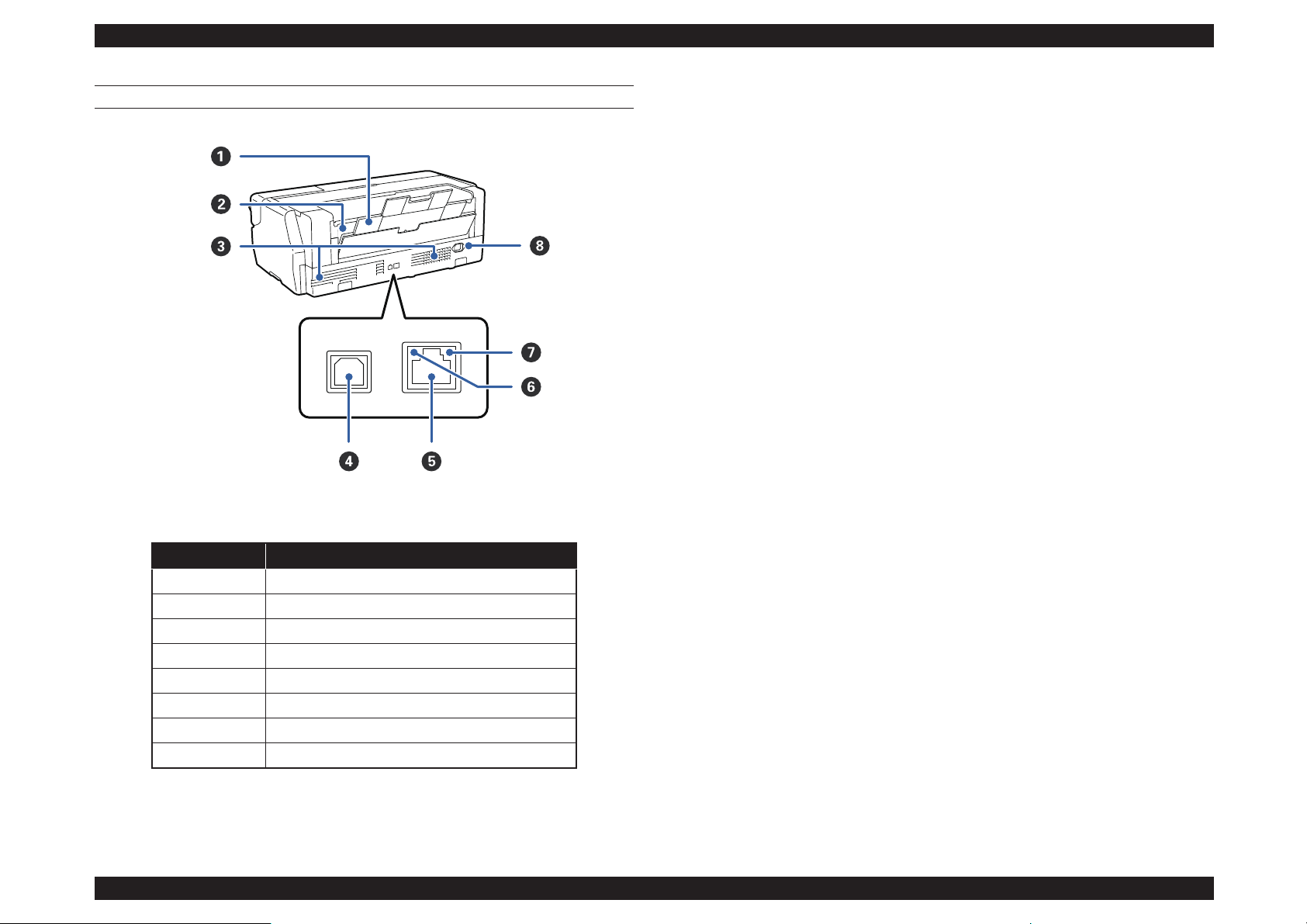

1.4.3 Part Names

FRONT SIDE

Figure 1-4. Front side

Table 1-12. Front side

No. Name

1 Paper support

2 Edge guide

3 Printer cover

4 Ink cartridge cover

5 Front cover

6 Output tray

7 Front manual feed tray

8 Maintenance cartridge cover

9 Control panel

10 Print head

11 Paper support edge guide

12 Auto sheet feeder

Page 24

SC-P800 series Revision B

PRODUCT DESCRIPTION Hardware Specifications 24

SE Group Confidential (Related Staff Only)

BACK SIDE

.

Figure 1-5. Back side

Table 1-13. Back side

No. Name

1 Rear support

2 Roll paper feeder

3 Airflow vents

4 USB port

5 LAN port

6 Status light

7 Data light

8 AC inlet

Page 25

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 25

SE Group Confidential (Related Staff Only)

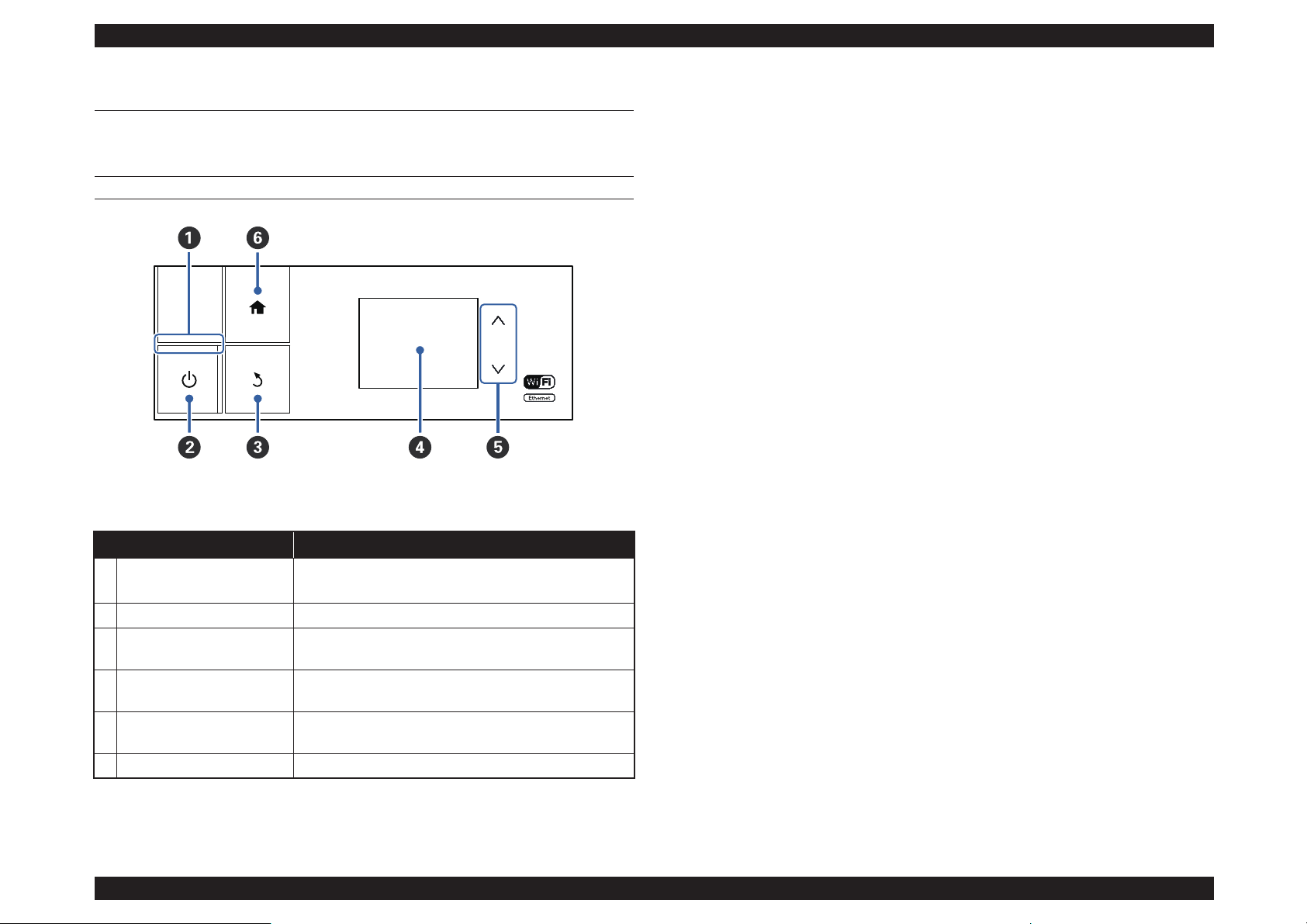

1.5 Control Panel Specifications

1.5.1 Control panel

OPERATION PANEL

Figure 1-6. Operation panel

Table 1-14. Operation panel

Name Function

1 Power light

On: The power is on.

Off: The power is off.

2 Power button Turns the power on and off.

3 Back button

Press to return to the previous screen while the Menu is

displayed.

4 Screen

Displays the printer's status, menus, error messages, and so

on.

5 up and down buttons

Press to select menu items and setting values when a menu

is displayed.

6 Home button Display the home screen.

Page 26

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 26

SE Group Confidential (Related Staff Only)

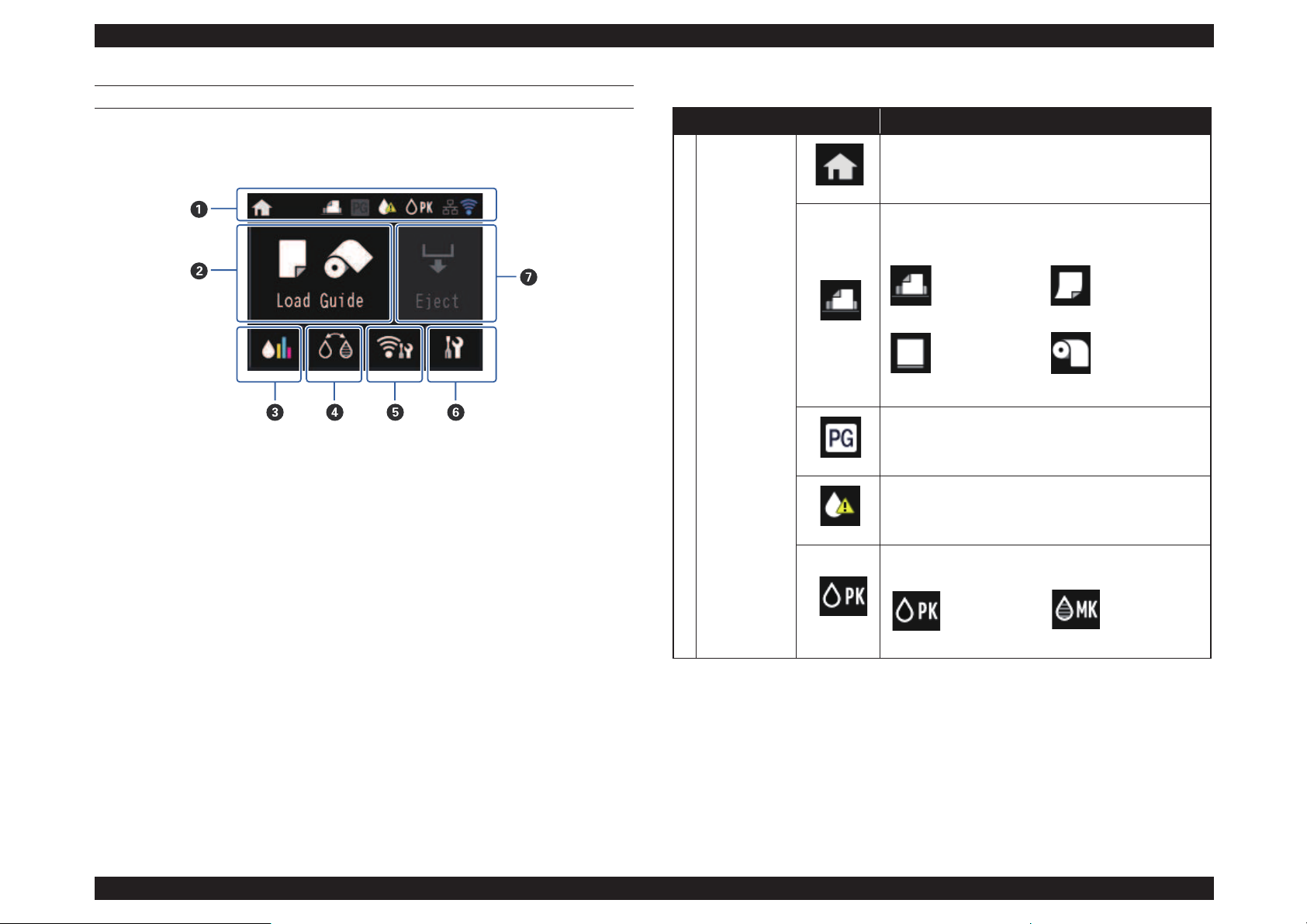

HOME SCREEN

Home Screen View

Figure 1-7. Home screen

Table 1-15. LCD

Name Function

1 Status icon

Indicates that the home screen is displayed.

Indicates the selected Load Guide using the following

icons.

Turns on when Thick Paper is set to On.

Indicates that the ink is running low or the maintenance

cartridge is running out of space. Prepare a new cartridge.

Indicates the selected black ink using the following icons.

Auto sheet

feeder

Fine art media

Poster board Roll paper

Photo black

ink

Matte black

ink

Page 27

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 27

SE Group Confidential (Related Staff Only)

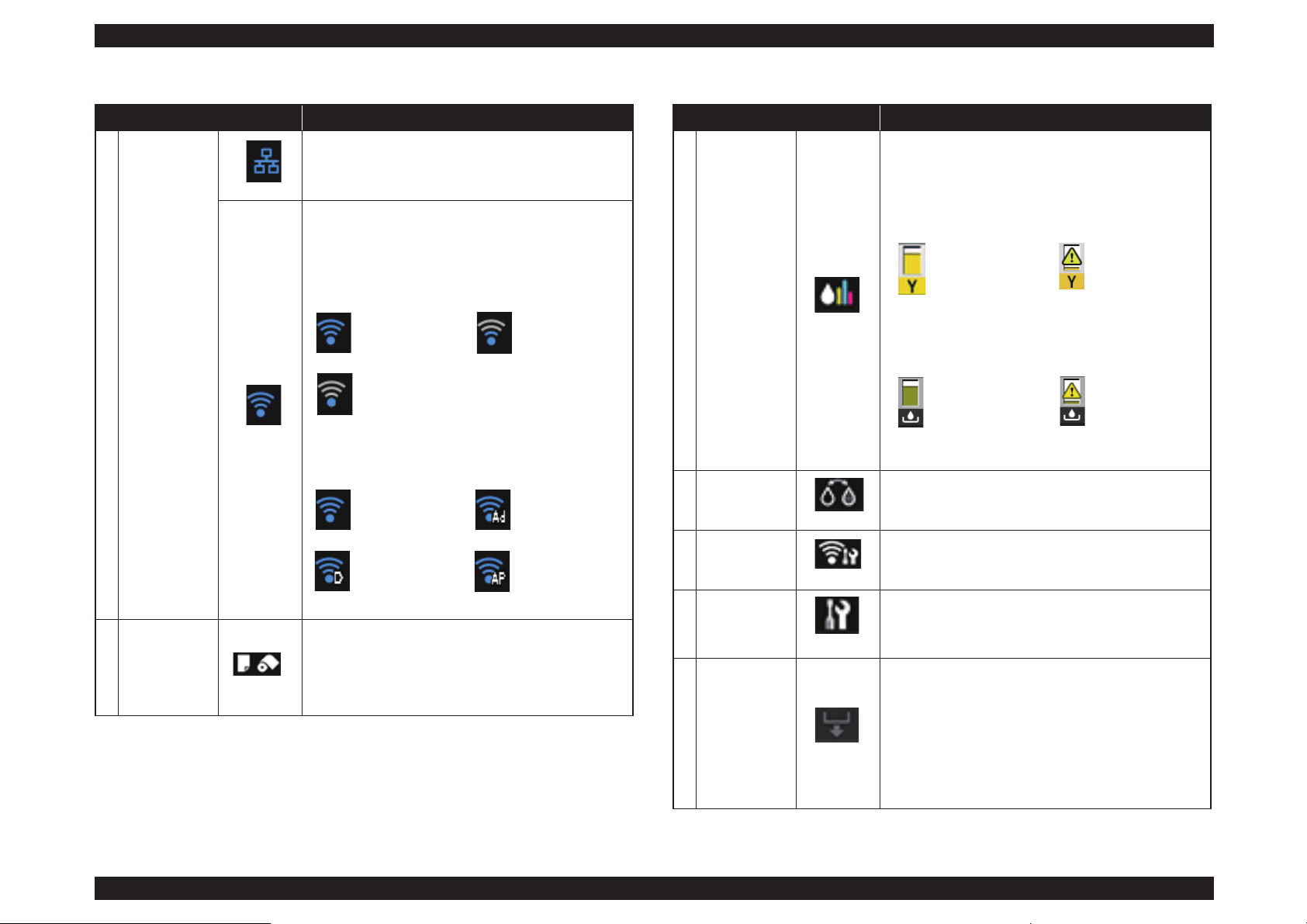

1 Status icon

Displayed when connected to a wired LAN.

Displays the operation mode, radio wave status, and

connection status for the wireless LAN.

The icon is not displayed when the wireless LAN is

disconnected.

The number of lines indicates the radio wave strength.

The icon changes as shown below depending on the

operation mode.

2

(Load Guide/

Media Setup)

button

Load Guide is displayed when paper is not loaded. You

can continue by checking the selected Load Guide

procedure on the screen.

Media Setup is displayed when paper is loaded. You can

set the Media Size and Media Type.

Table 1-15. LCD

Name Function

Strong Weak

Searching or

unavailable

Infrastructure

mode

Ad hoc mode

Wi-If Direct

mode

Simple AP mode

3

(Ink Remaining

Display) button

Displays the approximate amount of ink remaining and

free space in the maintenance cartridge.

Depending on the status of each cartridge, the icons

change as shown below.

Ink cartridge

Maintenance cartridge

4

(BK Ink

Change) button

You can change from one type of black ink to another.

5

(Network

Summary

Display) button

Displays the status of the printer's connection to the

computer. You can also display Wi-Fi/Network Settings

and so on directly from the Menu.

6 (Setup) button

You can perform printer maintenance and adjust printer

settings.

7

(Cut/Eject)

button

You can eject paper that has been loaded.

The following can be performed when roll paper is

loaded.

Move the end of the printed section to the cutting

position

Eject roll paper after moving the end of the printed

section to the cutting position

Eject roll paper

Table 1-15. LCD

Name Function

No error Ink low

No error The

Maintenance

Box is nearing

the end of its

service life.

Page 28

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 28

SE Group Confidential (Related Staff Only)

1.5.2 Menu Descriptions

Set up menu

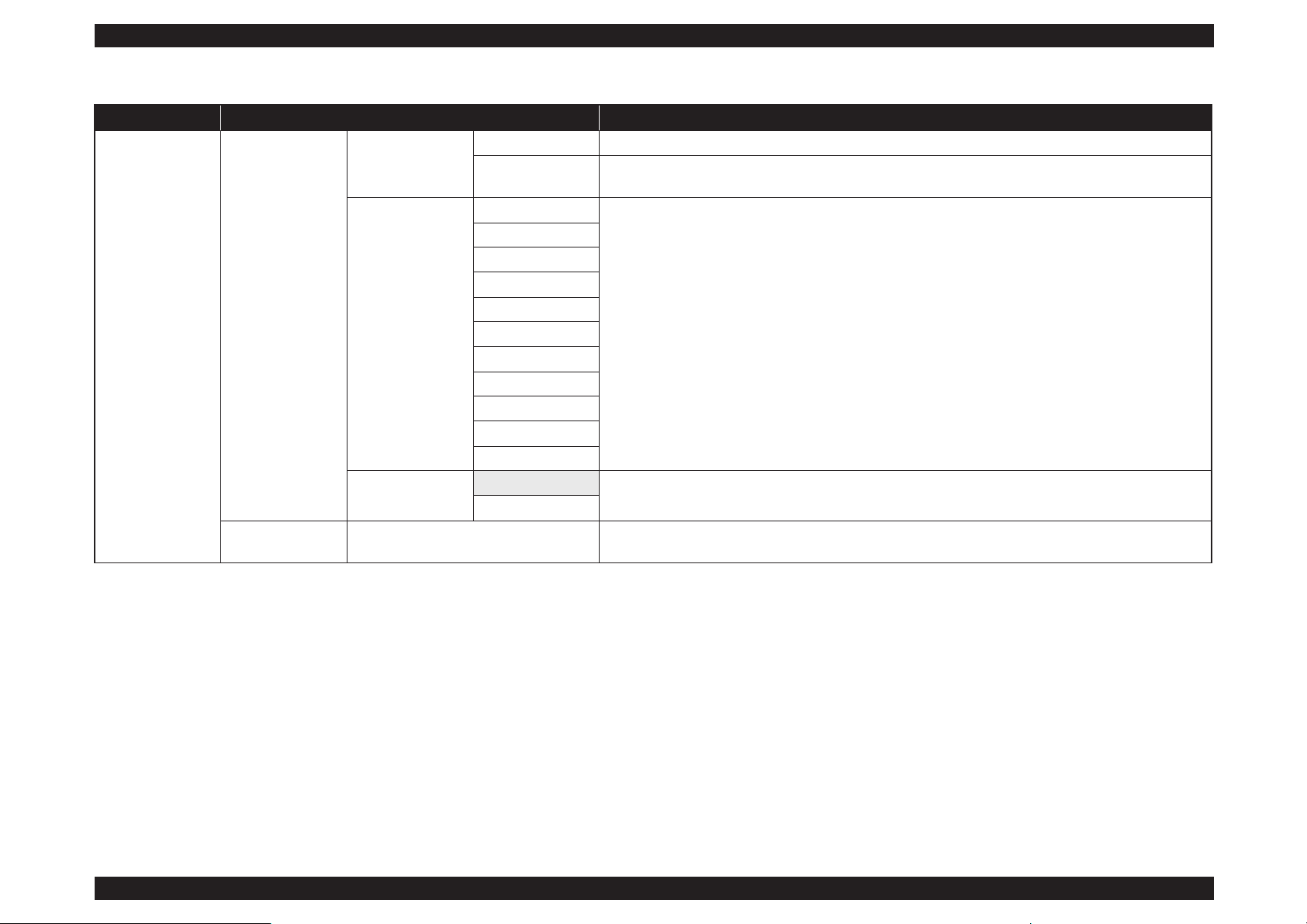

Table 1-16. Set up menu

Menu Menu Item / Setting Value (Shaded one is the default) Explanation

Maintenance

Print Head Nozzle Check

Check whether the print head nozzles are clogged. Visually confirm the printed check pattern, and perform

head cleaning if there are any blurred or missing sections.

Print Head Cleaning

Perform head cleaning if you notice banding or gaps in the print results. Cleans the print head to improve the

print quality.

Heavy Head Cleaning

Use this if nozzles are clogged even after performing Print Head Cleaning several times. Note that this

consumes more ink than Print Head Cleaning.

Paper Guide Cleaning Select this option to pass (feed and eject) plain paper through the printer and clean the rollers.

Thick Paper

On This option is only available when printing from a smart device.

Set this if print results are scuffed or smeared. When this is set to On, print speed may slow down. Only use

this if scuffing occurs. When the printer is turned off, this setting returns to Off.

Off

Print Head Alignment

If print results appear grainy or out of focus, perform Print Head Alignment to correct the print

misalignment.

System

Administration

Check network information.

Network Status

Wi-Fi/Network Status

Wi-Fi Direct Status

Google Cloud Print Status

Print Status Sheet

Configuration Status Sheet

Prints an information sheet for the current status and settings.Supply Status Sheet

Usage History Sheet

System

Administration

Printer Settings

Paper Source

Settings

Paper Setup Display

On Automatically displays the media setup screen when paper is loaded.

When this is Off, AirPrint is unavailable. Also, Error Notice from Paper Source

Settings becomes Off.

Off

Error Notice

On

Set whether or not to display an error if the paper size or type differ from the printer

settings.

Off

Paper Skew Check

On This option only takes effect with fine art media and poster board. Select On to display an error in the control

panel’s screen when the paper is fed in at a slant. On is recommended, as feeding the paper at a slant can

cause the paper to jam.

Off

Horizontal Centered

On When this is set to On, even if the print position moves on the loaded paper due to a cutting error or paper

feed error, the printer detects the width of the paper and the image is adjusted and printed in the center. Even

if there is a paper cutting error or print position error, the margins are still set evenly on the left and right.

Off

Page 29

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 29

SE Group Confidential (Related Staff Only)

System

Administration

Printer Settings

Print Page Line

On

When this is set to On, a dotted line is printed on the roll paper.

Off

Paper Size Check

On Select whether or not (On/Off) to detect the paper width. When this is set to Off, printing may be performed

beyond the edges of the paper. If printing is performed beyond the edges of the paper, the inside of the printer

will be soiled with ink. We recommend setting this to On. When selecting Off, borderless printing can not be

performed.

Off

BK Ink Auto Change

On

When this is set to On, the black ink is changed automatically using the Media Type selected in the printer

driver.

Off

Common Settings

LCD Brightness 1 to 9 You can adjust the brightness of the screen in nine stages.

Sound

Button Press

High

Set whether or not to play a sound and the volume for operation sounds, error sounds,

and done sounds.

Medium

Low

Off

Error Notice

High

Medium

Low

Off

CompletionNotice

High

Medium

Low

Off

Sleep Timer 1 to 240 mins.

Set the time to switch to sleep mode (energy saving mode) when the printer is not operated for a continuous

period.

Power Off Timer

Off

Set whether or not to turn off the printer automatically, as well as setting the time until the printer

automatically turns off when no printer operations are performed for a continuous period. The default setting

varies depending on the area of use.

30minutes

1h

2 h

4 h

8h

12h

Table 1-16. Set up menu

Menu Menu Item / Setting Value (Shaded one is the default) Explanation

Page 30

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 30

SE Group Confidential (Related Staff Only)

System

Administration

Common Settings

Date/Time Settings

Date/Time Set the date and time.

Time Difference

Set the time difference from Coordinated Universal Time (UTC). Default: Since this is set to ±0:00, it does

not normally need to be changed.

Language

English

Select the language for the screen display. The default setting varies depending on the area of use.

French

Italian

German

Spanish

Portuguese

Dutch

Russian

Simplified Chinese

Traditional Chinese

Korean

Operation Timer Out

On

You are returned to the Home screen if no operations are performed for three minutes on each menu.

Off

Wi-Fi/Network

Settings

Wi-Fi/Network Status Print a network status sheet. View network settings and connection status.

Table 1-16. Set up menu

Menu Menu Item / Setting Value (Shaded one is the default) Explanation

Page 31

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 31

SE Group Confidential (Related Staff Only)

Network Summary Display

System

Administration

Wi-Fi/Network

Settings

Wi-Fi Setup

Manual

---

Push Button Setup

(WPS)

PIN Code Setup

(WPS)

Wi-Fi Auto Connect

Disable Wi-Fi

Wi-Fi Direct Setup

Connection Check

Advanced Setup

Printer Name

TCP/IP Address

DNS Server

Proxy Server

Wi-Fi Direct

Google Cloud Print

Services

How to

Select How to display an explanation of the function. Visit the portal for more information on registering and

usage. You can stop/restart service usage and restore content to the default settings from Settings.

Settings

Restore Default

Settings

Wi-Fi/Network Settings Restore network settings to the default settings.

All except Network Settings Restore all control panel settings except network settings to the default settings.

All Settings Restore all settings to the default settings.

Table 1-16. Set up menu

Menu Menu Item / Setting Value (Shaded one is the default) Explanation

Table 1-17. Network Summary Display

Menu Menu Item Explanation

Menu

Wi-Fi/Network Settings

---

Wi-Fi Setup

Wi-Fi Direct Setup

Wi-Fi Setup

Page 32

SC-P800 series Revision B

PRODUCT DESCRIPTION Control Panel Specifications 32

SE Group Confidential (Related Staff Only)

1.5.3 Inspection Mode

The Inspection Mode is intended to be used by a service person for servicing the printer.

HOW TO START & QUIT

1. Press and hold the [Power] button, [Back] button, and [Home] button together for 10 seconds or longer.

2. To exit the Inspection Mode, press the [Power] button to power OFF the printer.

INSPECTION MODE MENU LIST

Table 1-18. Inspection Mode

Menu

Explanation

1 2 3

1. Printer Inspection Mode Printer Inspection Mode Flag check

Mode used for adjustment at factory shipment

Mode used for adjustment at factory shipment

2. Special Inspection

1. Inspection ALL Mode used for adjustment at factory shipment

2. CSIC Check Mode used for adjustment at factory shipment

3. Maintenance Box Check Mode used for adjustment at factory shipment

4. Panel Key Test To check the operation of buttons on the touch panel and operation of the touch panel

5. LCD/LED Test To check for the color and dot missing on the LCD and check the operation of the screen

6. Sensor Check To check the operation of each sensor

7. Rom Ver.check To check the current ROM version

3. Touch Screen Inspection

1. Touch Screen Calibration To adjust the input position of the touch panel

2. Touch PNL Measurement Mode To check the sensitivity of the touch panel

4. Development Mode 1. Electricity Test Mode Mode used for adjustment at factory shipment

5. Status Sheet Print Mode Mode used for adjustment at factory shipment

6. Normal Mode Mode used for adjustment at factory shipment

Page 33

SE Group Confidential (Related Staff Only)

C H A P T E R

2

TROUBLE SHOOTING

Page 34

SC-P800 series Revision B

TROUBLE SHOOTING Overview 34

SE Group Confidential (Related Staff Only)

2.1 Overview

This section explains the basic procedure for troubleshooting problems on the printer

quickly and efficiently.

When carrying out the troubleshooting procedures, take a flexible measure following

your sales company's policy and considering the troubling situation.

2.1.1 Preliminary Check

Make sure to verify or perform the following basic items whenever servicing the

printer.

2.1.1.1 Before performing troubleshooting

Before troubleshooting, perform basic checks such as connection check of the power

cable and installation check of the ink cartridges.

2.1.1.2 Check for the usage environment

Check the user's usage environment.

Temperature/humidity of the installation site

(For the guaranteed environment,

see P.12.)

Drivers/RIP that the user uses

Genuine media or 3rd party's media?

Genuine ink or 3rd party's ink?

F/W version (the latest?)

Check also the following if necessary.

2.1.1.3 Recurrence check of the trouble

Check if the trouble the user claims recurs with the returned printer.

If RIP was used, check if the trouble recurs when the driver is used.

If 3rd party's media were used, check if the trouble recurs when a genuine

medium is used.

If 3rd party's ink was used, perform the repair according to the policy of each

local sales subsidiary.

If the F/W was not the latest, gain agreement with the user on the update of F/

W, and check if the trouble recurs when the latest F/W is used.

2.1.1.4 Check for the counter values/history

Download NVRAM and check the following with NVRAM Viewer. (For the check

method,

see P.211.)

Counter history of the periodic replacement parts. (if any part's life is near.)

Printer's operating history (if any cause for the trouble exists)

Error history (the frequency/history of errors related with the trouble)

2.1.1.5 Test print check

For the trouble related with print quality, carry out “Test Print” and check the current

adjustment status. (For the procedure of test print,

see P.219.)

Phenomenon Check Item

Bad print quality

The installation site inclined?

Any vibrating equipment near the site?

The user's panel settings

Is the interior dirty?

Clean it if dirty.

Missing dots/bad print quality Near a conditioner's ventilation duct?

Page 35

SC-P800 series Revision B

TROUBLE SHOOTING Overview 35

SE Group Confidential (Related Staff Only)

2.1.2 Troubleshooting Procedure

Refer to the following items according to the observed symptom, carry out the

corresponding troubleshooting following the procedures described in the next sections.

1. Trouble with a Maintenance Request or Service Call Error.

(See P.36, P. 37)

2. Trouble on print quality (See P.44)

3. Trouble on Paper Feeding (See P.47)

4. Other troubles (See P.48)

5. Trouble on Service Program (See P.49)

6. Trouble on NVRAM viewer (See P.50)

2.1.3 Procedure after troubleshooting

2.1.3.1 If the trouble has been successfully solved

Check if the movement of the covers is normal (without any damage, noises).

If any abnormality is found, lubricate or replace the faulty parts.

Carry out the cleaning after repair.

Prepare a report on the repair. (follow your company/local office's policy.)

2.1.3.2 If necessary to escalate the trouble case

Make a report with the following data.

Backed-up NVRAM data

Firmware version

Service program version

For bad print quality: a print sample with the marked symptom and a printed

test pattern.

For faulty parts: the faulty parts themselves and a photos of the troubling

section.

Information on the user/the repair listed below

This is a format of the escalation report. At least check out the items on the

list and register the case in the escalation system.

• Model name

• Serial number

• With or without options

• Content of the claim from the user

• Date of occurrence

• Trouble occurrence conditions/recurrence method

• What the service person actually observed

(Check items before check, the content of troubleshooting and repair.)

• Date of escalation

• Purpose of escalation

(Measures which the user/service person)

• Degree of urgency (S/A/B/C)

S: High (those which may cause a death, ignition, etc.)

A: Problems, bugs

B: Strong request

C: Inquiry

• Deadline for the response

• Repair history

• Part-replacement history

Page 36

SC-P800 series Revision B

TROUBLE SHOOTING Remedies for Maintenance Requests 36

SE Group Confidential (Related Staff Only)

2.2 Remedies for Maintenance Requests

This section describes the remedies for maintenance requests. Maintenance requests do not effect the printer’s operation; therefore, you can continue the current printing. When a

maintenance request error occurs, the printer displays on the LCD a hexadecimal code of “NNNN” which correspond to the bit numbers assigned to error statuses as shown in the

table below.

Note : Ex): When “Maintenance Request 0000048” is displayed.

As “0000048” in hexadecimal means “100 1000” in binary, you can find out the code is assigned to Bit-3 and Bit-6 referring to the above table. In this case, two errors are

occurring simultaneously. (Bit-3: battery exhaustion/ Bit-6: pump counter near end.)

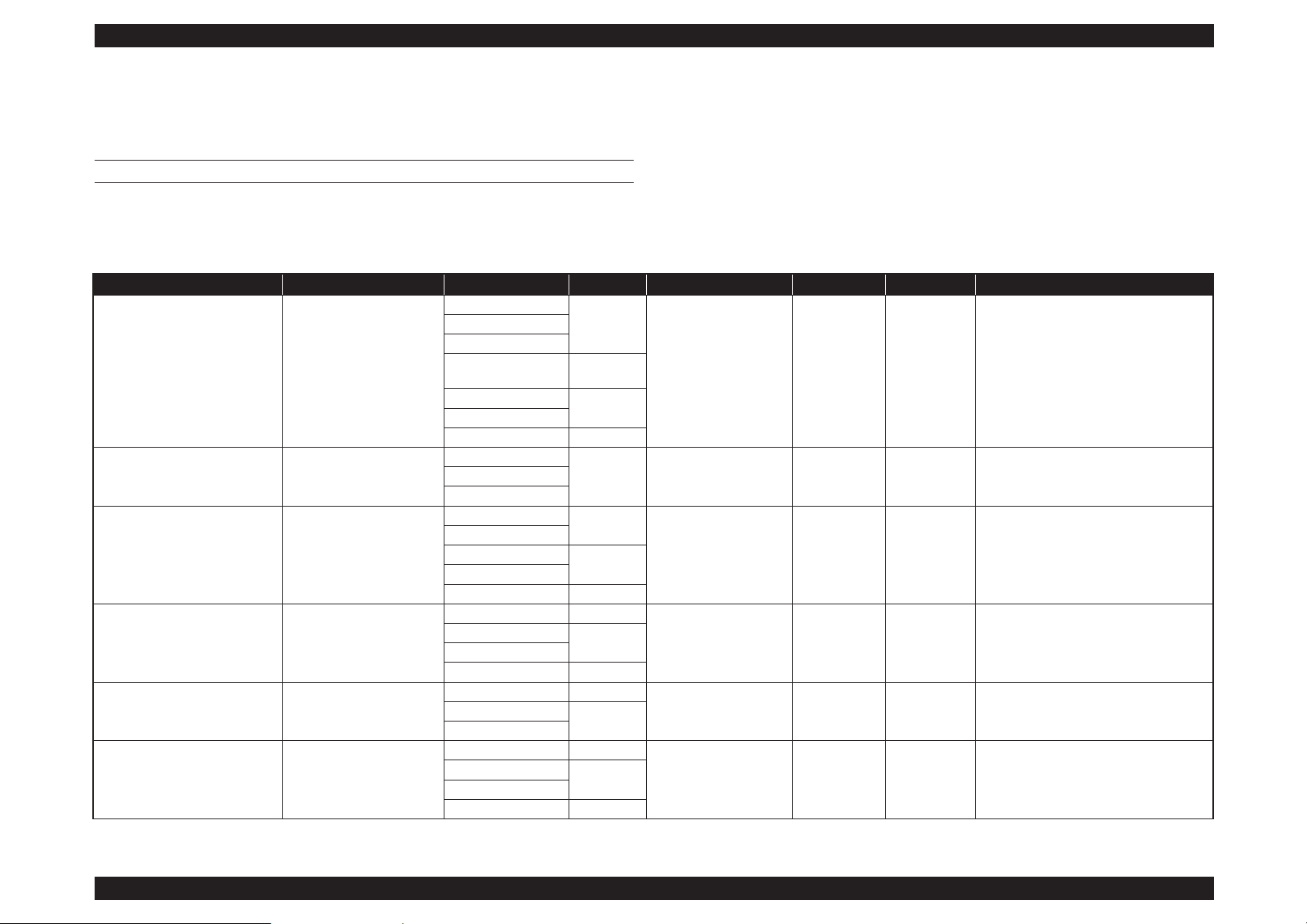

Table 2-1.

Maintenance Request Errors

Bit assignment (Binary)

XXXX

(Hexa-decimal)

Cause Remedy

12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 0 0 0 0 1 00000001

The waste ink counter of the Absorbers for

Borderless Printing has reached the near end.

Replace the Absorbers for Borderless Printing (POROUS PAD,

INK WASTE BOX, RIGHT/POROUS PAD, INK WASTE BOX,

LEFT), and clear the usage counter with the Service Program.

0 0 0 0 0 0 0 0 0 0 0

1 0 00000002

The life of the ink supply tube has reached the

near end.

Replace the ink supply tube (INK, SYSTEM, ASSY), and clear the

usage counter with the Service Program.

0 0 0 0 0 0 0 0 0 0

1 0 0 00000004 Reserved

0 0 0 0 0 0 0 0 0

1 0 0 0 00000008 The RTC backup battery has run out.

Replace the battery, and initialize the RTC with the Service

Program.

0 0 0 0 0 0 0 0

1 0 0 0 0 00000010 Reserved

0 0 0 0 0 0 0

1 0 0 0 0 0 00000020 Reserved

0 0 0 0 0 0

1 0 0 0 0 0 0 00000040 The pump counter has reached the near end.

Replace the pump cap unit (PUMP, CAP, ASSY), and clear the

usage counter with the Service Program.

0 0 0 0 0

1 0 0 0 0 0 0 0 00000080 Reserved

0 0 0 0

1 0 0 0 0 0 0 0 0 00000100 Reserved

0 0 0

1 0 0 0 0 0 0 0 0 0 00000200 Reserved

0 0 1 0 0 0 0 0 0 0 0 0 0 00000400 Reserved

0

1 0 0 0 0 0 0 0 0 0 0 0 00000800

The Ink Cartridge removal counter has reached

the near end.

Replace the Cartridge Holder Waste Ink Pads (POROUS PAD,

TRAY, INK EJECT), and clear the usage counter with the Service

Program.

1 0 0 0 0 0 0 0 0 0 0 0 0 00001000

The ink selector driving frequency has reached the

near end.

Replace the ink selector (INK, SYSTEM, ASSY), and clear the

usage counter with the Service Program.

Page 37

SC-P800 series Revision B

TROUBLE SHOOTING Remedies for Service Call Error 37

SE Group Confidential (Related Staff Only)

2.3 Remedies for Service Call Error

The following tables explains the Service Call error messages and remedies.

Table 2-2. Service Call Error

Code Category Error Name Cause Check Item Remedy

1101 IS CR life error

The CR scan path counter has reached

a predetermined level. (The end of life

of the Ink Supply Tube)

---

Replace the Ink Supply Tube (INK,

SYSTEM, ASSY) and reset the counter

using the Adjustment Program. In

addition, check the statuses of the CR

motor (MOTOR ASSY., CR), the driven

pulley, the Carriage Unit, and the Head

FFC, if any abnormal noise or wear is

found, replace the corresponding part(s)

along with the Ink Supply Tube.

(See

P.125)

1121 CR CR reversing error

An abnormal operation (reversed

operation) of the CR unit was detected.

Contamination on CR scale

CR encoder failure (cable failure)

CR scale failure

Motor driver failure

CR belt failure

Driver pulley failure

CR motor failure (cable failure)

Check the reading status of the CR encoder with the Service

Program.

1. Replace the CR scale.

2. Replace the driven pulley.

3. Replace the CR motor.

4. Lubricate the OIL PAD of the CR

unit.

(See P.284)

5. Replace the CR timing belt.

6. Replace the FFC of the CR encoder.

7. Replace the CR unit.

8. Replace the MAIN board.

1123 CR CR Duty over error

The load on the CR motor has

exceeded the expected level.P

Paper jam (such as paper left on the

print path)

Increase of load (such as the

damaged CR shaft, damaged CR

shaft bearing, insufficient grease,

the deformed CR sub shaft)

CR motor failure (cable failure)

CR encoder failure (cable failure)

Visually check whether paper is left on the print path, and

remove it if left.

1. Replace the CR scale.

2. Replace the driven pulley.

3. Replace the CR motor.

4. Lubricate the OIL PAD of the CR

unit.

(See P.284)

5. Replace the CR timing belt.

6. Replace the FFC of the CR encoder.

7. Replace the CR unit.

8. Replace the MAIN board.

1124 CR CR reversing error

Drive time of the CR motor exceeding

the predetermined time was detected.

Firmware becomes out of control.

---

Replace the MAIN board.

Page 38

SC-P800 series Revision B

TROUBLE SHOOTING Remedies for Service Call Error 38

SE Group Confidential (Related Staff Only)

1125 CR

CR home position

detection error

When the power is ON, the pump cap

unit does not operate and the lock of

the CR unit cannot be released. Thus,

the CR home position cannot be

detected.

False detection of the home due to

paper jam or any other obstacle

Misreading of the CR scale

The CR lock is damaged.

1. Is there any paper jammed inside the printer?

2. Does the CR scale have any scratches or dirt?

3. Check the reading status of the CR encoder with the Service

Program.

4. Does the CR lock function normally? (Check manually

whether the pump unit functions or not.)

1. Replace the pump cap unit.

2. Replace the CR scale.

3. Replace the CR encoder.

1126 CR CR lock release error

The lock of the CR unit cannot be

released.

Pump unit failure

The CR lock is damaged.

1. Check manually whether the pump unit functions.

2. Is the CR unit stopped at the home position?

3. Are there any foreign materials around the pump unit?

1. Replace the pump cap unit.

2. Replace the CR scale.

1135 CR CR encoder test error

The output of the CR encoder does not

change even though the CR motor is

commanded to rotate.

CR encoder failure (cable failure)

CR motor failure (cable failure)

Large CR unit load

Are there any problems, such as the FFC is damaged or

disconnected, in the connection below?

CR encoder to SUB board (CN1)

1. Replace the CR motor.

2. Replace the driven pulley.

3. Replace the CR timing belt.

4. Replace the FFC of the CR encoder.

5. Replace the CR unit.

6. Replace the MAIN board.

1222 PF

PF drive timeover

error

Drive time of the PF motor exceeding

the predetermined value was detected.

Firmware becomes out of control.

---

Replace the MAIN board.

1223 PF PF encoder test error

The output of the PF encoder does not

change even though the PF motor is

commanded to rotate.

PF encoder failure (cable failure)

PF motor failure (cable failure)

Large paper feed load

Are there any problems, such as the FFC is damaged or

disconnected, in the connection below?

PF encoder to MAIN board (CN49)

1. Replace the PF motor.

2. Replace the FFC of the PF encoder.

3. Replace the PF encoder.

4. Replace the MAIN board.

5. Replace the printer mechanism unit.

122A PF PF overload error

The load on the PF motor has exceeded

the expected level.

Paper jam (paper left on the print

path)

Increase of load (such as the

damaged PF shaft, damaged PF

shaft bearing, or insufficient grease)

PF motor failure (cable failure)

PF encoder failure (cable failure)

Visually check whether paper is left on the print path, and

remove it if left.

1. Replace the PF motor.

2. Replace the FFC of the PF encoder.

3. Replace the PF encoder.

4. Replace the MAIN board.

5. Replace the printer mechanism unit.

Table 2-2. Service Call Error

Code Category Error Name Cause Check Item Remedy

Page 39

SC-P800 series Revision B

TROUBLE SHOOTING Remedies for Service Call Error 39

SE Group Confidential (Related Staff Only)

122C PF PF reversing error

An abnormal operation (reversing) of

the PF was detected.

Contamination on PF scale

PF encoder failure (cable failure)

PF scale failure

Motor driver failure

PF timing belt failure

PF motor failure (cable failure)

Check the reading status of the PF encoder with the Service

Program.

1. Replace the PF motor.

2. Replace the FFC of the PF encoder.

3. Replace the PF encoder.

4. Replace the PF scale.

5. Replace the MAIN board.

6. Replace the printer mechanism unit.

131B Head

Head driver

(transmission gate)

temp. error

The temperature of the head driver

rises, and has reached a

predetermined limit.

Head FFC insertion at an angle

Disconnection of the head FFC

SUB board failure

MAIN board failure

Check the connection of the head FFC for abnormalities, such

as whether it is inserted at an angle.

1. Replace the head FFC.

2. Replace the print head.

3. Replace the MAIN board.

1400 Pressure motor

Pressure motor drive

timeover

The pressure does not reach the

predetermined level despite

pressurization over a predetermined

time.

Pressure pump home sensor failure

Abnormal ink cartridge pack (air

leak)

Foreign materials are attached at the

I/C feed port. (Air leaks due to

incomplete seal.)

Check the connection part between the ink cartridge and ink

cartridge holder, and remove foreign materials if any.

1. Replace the ink cartridge.

2. Replace the pressure pump.

1403 Pressure motor

Pressure motor

pressure reducing

error

The pressure cannot be reduced.

Pressure pump failure

1. Are there any problems, such as the FFC is damaged or

disconnected, in the connection below?

Pressure motor to MAIN board (CN46)

Pressure sensor to MAIN board (CN52)

2. Is the pressure tube jammed?

Replace the pressure pump.

Table 2-2. Service Call Error

Code Category Error Name Cause Check Item Remedy

Page 40

SC-P800 series Revision B

TROUBLE SHOOTING Remedies for Service Call Error 40

SE Group Confidential (Related Staff Only)

1404 Pressure motor

Pump movement

cycle over error

The pressure does not reach the

predetermined level despite

pressurization over a predetermined

time.

• Pressure pump home sensor

failure

Air leaks.

• Abnormal ink cartridge pack

The seal of the I/C feed port is

incomplete, causing air to leak.

• Foreign materials are attached.

Check the connection part between the ink cartridge and ink

cartridge holder, and remove foreign materials if any.

1. Replace the ink cartridge.

2. Replace the pressure pump.

1410 PUMP

Drive time monitor

time-out (PUMP)

Drive time of the pump motor is longer

than the predetermined time.

Firmware becomes out of control.

---

Replace the MAIN board.

142D PUMP

Pump cap unit life

error

The pump counter has reached the

predetermined value.

---

Replace the pump cap unit.

1430 Waste ink Holder ink pad error

The ink cartridge replacement counter

has reached the predetermined value.

---

Replace the holder ink pad.

1431 Ink selector Ink selector error

The ink selector driving frequency has

reached the predetermined value.

---

Replace the ink selector (INK,

SYSTEM, ASSY).

1432 Ink selector

Ink selector drive

timeover

The ink selector does not finish

operating in the predetermined time.

Ink selector sensor failure

Ink selector motor failure

Perform the Ink Selector Operation Check using the Service

Program.

Replace the ink selector (INK,

SYSTEM, ASSY).

1434 Ink cover Ink cover unlock error

The cartridge cover does not open.