Page 1

SERVICE MANUAL

Color Inkjet Printer

L120

CONFIDENTIAL

SEIJ13-005

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be

detected, SEIKO EPSON would greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this

manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or registered

trademarks of their respective owners. EPSON disclaims any and all rights in those marks.

Copyright 2014 SEIKO EPSON CORPORATION

Printer CS Quality Assurance Department

Confidential

Page 3

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this

product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral devices when servicing the product or

performing maintenance.

2. When performing works described in this manual, do not connect to a power source until instructed to do so.

Connecting to a power source causes high voltage in the power supply unit and some electronic components

even if the product power switch is off. If you need to perform the work with the power cable connected to a

power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1. Always wear protective goggles for disassembly and reassembly to protect your eyes from ink in working. If

any ink gets in your eyes, wash your eyes with clean water and consult a doctor immediately.

2. When using compressed air products; such as air duster, for cleaning during repair and maintenance, the use

of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified repair technician.

2. No work should be performed on this product by persons unfamiliar with basic safety knowledge required for

electrician.

3. The power rating of this product is indicated on the serial number/rating plate. Never connect this product to

the power source whose voltages is different from the rated voltage.

4. Replace malfunctioning components only with those components provided or approved by Epson;

introduction of second-source ICs or other non-approved components may damage the product and void any

applicable Epson warranty.

5. The capacitors on the Main Board may be electrically charged right after the power turns off or after driving

motors which generates counter electromotive force such as when rotating the PF Roller or when moving the

CR Unit. There is a risk to damage the Main Board if the Head FFC is short-circuited with the capacitors on

the Main Board electrically charged, therefore, after the power turns off or after motors are driven, leave the

printer untouched for approximately 30 seconds to discharge the capacitors before starting disassembly/

reassembly.

6. To prevent the circuit boards from short-circuiting, be careful about the following when handling FFC or

cables.

When handling FFC, take care not to let the terminal section of FFC touch metal parts.

When connecting cables/FFC to the connectors on circuit boards, connect them straight to the connectors to avoid

slant insertion.

Confidential

Page 4

7. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static

wrist straps, when accessing internal components.

8. Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several

times. Doing so may cause ink to leak from the product because it may take some time for the waste ink pads

to completely absorb ink wasted due to the ink charge.

9. Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with

soap and water immediately. If you have a skin irritation, consult a doctor immediately.

10. When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts

with sharp edges.

11. Use only recommended tools for disassembling, assembling or adjusting the printer.

12. Observe the specified torque when tightening screws.

13. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the Printhead

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Scanner Sensor

Exterior parts

14. Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may

damage the component or give bad influence on the printer function.

15. Apply the specified amount of grease described in this manual.

16. Make the specified adjustments when you disassemble the printer.

17. When cleaning this product, follow the procedure described in this manual.

18. When transporting this product after filling the ink in the printhead, pack the printer without removing the

ink cartridges in order to prevent the printhead from drying out.

19. Make sure to install antivirus software in the computers used for the service support activities.

20. Keep the virus pattern file of antivirus software up-to-date.

21. When disassembling/reassembling this product, if you find adhesive power of the double-sided tape which

secure the parts or FFC is not enough, replace the tape with new one and attach it correctly to the specified

points where the parts or FFC should be secured.

22. Unless otherwise specified in this manual, the labels attached on the returned product should be transferred to

the corresponding attachment positions on the new one referring to the labels on the returned product.

Confidential

Page 5

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information

necessary for properly performing maintenance and servicing the product.

CHAPTER 1. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 2. DISASSEMBLY / REASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product, and provides the

standard operation time for servicing the product.

CHAPTER 3. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 4. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 5. APPENDIX

Provides the following additional information for reference:

Connector Diagram

Protection for Transportation

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or

to warn of possible danger present during a procedure or an action. Pay attention to all symbols when they are

used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed,

could result in serious injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed,

could result in bodily injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to

accomplish a task efficiently. It may also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous action.

For Chapter 2 “Disassembly/Reassembly”, symbols other than indicated above are used to show additional

information for disassembly/reassembly. For the details on those symbols, see "2.2 Disassembly/Reassembly

Procedures (p28)".

Confidential

Page 6

Revision Status

Revision Date of Issue Description

A January 24, 2014 First Release

Confidential

Page 7

L120

Revision A

Contents

Chapter 1 Troubleshooting

1.1 Troubleshooting......................................................................................................................................................... 9

1.1.1 Troubleshooting Workflow .............................................................................................................................. 9

1.2 Power-On Sequence ................................................................................................................................................ 11

1.3 Fatal Error Code List ............................................................................................................................................... 13

1.3.1 Printer Fatal Error Code ................................................................................................................................. 13

Chapter 2 Disassembly/Reassembly

2.1 Overview ................................................................................................................................................................. 16

2.1.1 Tools ............................................................................................................................................................... 16

2.1.2 Jigs .................................................................................................................................................................. 16

2.1.2.1 Making the Spring Hook Jig.................................................................................................................. 16

2.1.3 Locations of the Parts/Units ........................................................................................................................... 17

2.1.4 Standard Operation Time for Servicing the Product ...................................................................................... 21

2.1.5 Checks and Precautions before Disassembling .............................................................................................. 23

2.1.5.1 Factors which Affect the Print Quality .................................................................................................. 23

2.1.5.2 Factors which Affect the Safety of Service Personnel such as Ink Leakage during Operation ............ 24

2.2 Disassembly/Reassembly Procedures ..................................................................................................................... 28

2.2.1 Disassembly Flowchart................................................................................................................................... 29

2.2.2 Disassembly Flowchart (Printhead/Main Board) ........................................................................................... 33

2.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit........................................................................... 34

2.4 Routing FFCs/cables ............................................................................................................................................... 40

Chapter 3 Adjustment

3.1 Required Adjustments ............................................................................................................................................. 43

3.2 Adjustment Program................................................................................................................................................ 47

3.2.1 Operating Environment .................................................................................................................................. 47

3.2.2 Details of the Adjustment Program ................................................................................................................ 47

3.2.2.1 CR Motor Heat Protection Control / PF Motor Heat Protection Control .............................................. 47

3.3 Mechanism Adjustment / Check ............................................................................................................................. 48

3.3.1 Checking the Platen Gap ................................................................................................................................ 48

3.3.2 CR/PF Belt Tension Check............................................................................................................................. 50

Chapter 4 Maintenance

4.1 Overview ................................................................................................................................................................. 53

4.1.1 Cleaning .......................................................................................................................................................... 53

4.1.2 Lubrication...................................................................................................................................................... 53

4.2 Lubrication Points and Instructions......................................................................................................................... 54

Chapter 5 Appendix

5.1 Connector Diagram ................................................................................................................................................. 57

5.2 Points to be checked before packing the printer...................................................................................................... 57

5.3 Protection for Transportation .................................................................................................................................. 58

5.3.1 Securing the CR Unit...................................................................................................................................... 58

5.3.2 Securing the Printer Cover ............................................................................................................................. 59

7

Confidential

Page 8

CHAPTER 1

TROUBLESHOOTING

Confidential

Page 9

L120

1.1 Troubleshooting

This section describes the troubleshooting workflow and fatal error information.

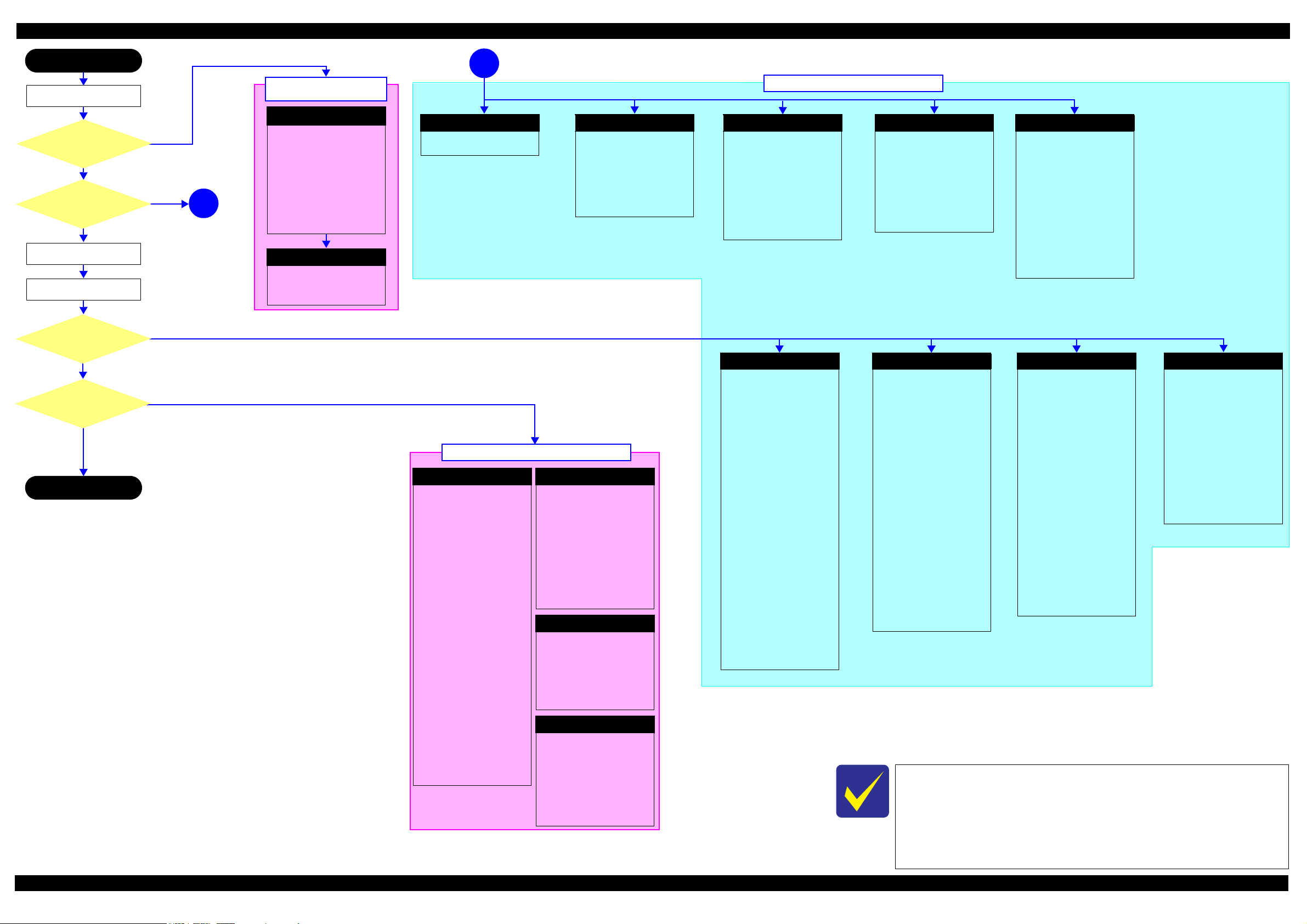

1.1.1 Troubleshooting Workflow

The following page describes the troubleshooting workflow. Follow the flow when troubleshooting problems.

Revision A

Troubleshooting Troubleshooting 9

Confidential

Page 10

L120 Revision A

Start

Turn on the power

*1

Does printer turn on the

power?

Yes

Is Power-on sequence

finished without error?

Yes

Standby condition

Print check pattern

Does an error occur

when printing?

Yes

Is printing operation

finished without trouble?

Yes

*3

Finish

No

No

No

No

1

Major problem without

error message

No Power

[Presumable Cause]

• PS Unit damage

• Main Board damage

[Major Troubleshooting]

• PS Unit replacement

• Main Board replacement

[Main board replacement]

1

• EEPROM data copy for old

main board

• EEPROM data initial setting

for new Main board

Main board replacement

• EEPROM data copy for old

Main Board Assy

• EEPROM data initial setting

for new Main Board Assy

*2

Please refer to

List (p13)"

[Phenomenon]

• Poor printing quality

• Ink stain on paper

•Dot missing

• Paper eject without printing

[Presumable Cause]

• Driver / Panel mis-setting

• Contamination of CR scale

• Contamination of Printhead

• Printhead damage

• Ink clogging of Printhead

• Contamination on Cap Unit /

• Ink System Assy damage

• Float of Porous Pad on Paper

• Narrower/Wider PG

• PE Sensor Lever damage

• PE Sensor damage

[Major Troubleshooting]

• Driver / Panel re-setting

• CR Scale replacement

• Printhead cover cleaning

• Printhead cleaning

• Ink Cartridge replacement

• Printhead replacement

• Rubber cleaning of Cap Unit

• Ink System Assy replacement

• Porous Pad re-installation

• Printer replacement

• PE Sensor Lever replacement

• PE Sensor replacement

• Ink tank replacement

Fatal error

" 1.3 Fatal Error Code

.

Major problem without error message

Poor Printing

cover

Wiper of Ink System Assy

Guide Front

(out of standard)

(Main Board replacement)

Poor Paper Loading

[Presumable Cause]

• Use of 3rd party media

• Edge guide mis-setting

• Foreign material

• Part come-off

• Contamination of LD Roller or

PF roller

[Major Troubleshooting]

• Recommendation of EPSON

media

• Edge guide re-setting

• Foreign material removal

• Part re-installation

• Roller replacement

[Presumable Cause]

• Foreign material

• Insufficient grease

•Gear damage

[Major Troubleshooting]

• Foreign material removal

• Lubrication of grease

• Gear replacement

[Phenomenon]

Blank printing

[Presumable Cause]

• Ink tube crumples

• Ink tube connection is

incomplete.

[Major Troubleshooting]

• Ink tank replacement

• Ink tube re-installation

Incomplete Initial Ink Charge

[Occurrence Condition]

Ink LED is ON and STM

indicates "Initial ink charging is

not complete".

[Major Occurrence Timing]

Print start timing.

[Troubleshooting]

Perform initial ink charge

Abnormal Noise

Blank printing

[Occurrence Condition]

This error occurs when

maintenance counter in EEPROM

exceeds the specified value.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

[Troubleshooting]

• Porous Pad replacement &

Maintenance counter reset

[Occurrence Condition]

This error occurs when top/

bottom of paper is not detected by

PE Sensor in the specified steps of

paper loading / ejecting operation

correctly.

[Major Occurrence Timing]

• Power-on timing

• Paper loading timing

• Paper eject timing

[Major Troubleshooting]

1 Perform paper eject operation

from operation panel.

• Success

•Fail

2 If fail in the above 1, remove

the paper by opening Printer

Cover.

3 Perform paper eject operation

from operation panel again.

• Success

•Fail

4 If fail in the above 3, check

foreign material / part comeoff / PE Sensor Lever / PE

Sensor / Main board.

Major problem with error message

Maintenance error

Paper Jam error

Starts paper feeding

operation again if printer has

print data.

Occurs paper jam error

again.

Starts paper feeding

operation again if printer has

print data.

Occurs paper jam error

again.

Ink End error

[Occurrence Condition]

This error occurs when ink

counter reaches ink end level.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

[Troubleshooting]

• Refill ink and reset ink counter

by panel.

No Paper error

[Occurrence Condition]

This error occurs when top of

paper can not be detected

correctly by PE Sensor in the

specified steps up to completion

of the paper loading operation.

(No paper / No loading / large

paper skew)

[Major Occurrence Timing]

• Paper loading timing

[Major Troubleshooting]

1 Set paper in ASF and perform

paper feed operation.

2 If the paper stops before

reaching PE Sensor, remove it

and check the paper condition.

3 A) If paper is OK, set paper in

ASF and move edge guides to

appropriate position, and

perform 2 again.

B) If damage in the above 2,

check foreign materials /

parts come-off / parts

transformation in paper

path.

4 If not resolved by 3-A & 3-B,

check foreign material / Part

come-off / surface condition of

LD Roller or PF Roller / PE

Sensor Lever / PE Sensor /

Main Board / PF Motor.

Paper Jam Fatal error

[Occurrence Condition]

This error occurs when CR Unit is

blocked by jammed paper.

[Major Occurrence Timing]

• Power-on timing

[Major Troubleshooting]

• Remove jammed paper

[NOTE]

On this product, if CR Unit

touches jammed paper, CR Unit

moves back in the opposite

direction so that customer can

remove the paper. However, if CR

Unit cannot move in this

sequence, this error occurs.

Double Feed error

[Occurrence Condition]

When manual duplex printing is

selected using the printer driver,

this error occurs if the actual

paper length detected by PE

Sensor does not match with the

paper length specified in the

printer driver. (The error occurs

when the actual length is longer

than the theoretical length

specified in the driver.)

[Major Occurrence Timing]

• Paper loading timing

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

(Main Board replacement)

• Main Board replacement

[NOTE]

This error may occur in the

manual duplex printing if the

inverted sheet printed on the first

side sticks to the second sheet

when the first side printing is

complete and the sheet is inverted

and set to ASF to print on the

other side.

Paper Size Unmatch error

[Occurrence Condition]

This error occurs if the actual

paper length detected by PE

Sensor does not match with the

paper length specified in the

printer driver. (The error occurs

no matter when the actual length

is longer or shorter than the

theoretical length specified in the

driver.)

[Major Occurrence Timing]

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

(Main Board replacement)

• Main Board replacement

*1: If the Hopper of ASF on the returned product touches the LD Roller, the initial ink charge has

not been completed for the product yet.

*2: If the printer can turn on but turns off right away, the protection circuit may cut off the power

due to an error such as a circuit failure.

*3: In case of “Not Trouble Found”, check fatal error code.

If the reason for the return is evident, first check the phenomenon user

claims recurs, then proceed to the troubleshooting.

This flowchart is compiled based on the following contents.

• Our experience regarding the quality problem.

• ESK’s repair data.

• Printer Mechanism specification for the product.

Troubleshooting Troubleshooting Workflow 10

Confidential

Page 11

L120

1.2 Power-On Sequence

This section describes the power-on sequences in two conditions. The preconditions are as follows.

Condition 1: Normal power-on sequence (See Table 1-1.)

Turning on the printer after turning it off without an error.

Initial ink charge has finished and every cartridge has sufficient ink.

No paper on the paper path.

The Printhead is capped with the Cap Assy.

The CR Unit is normally fixed by the Change Lever.

Maintenance error recovery has never been performed.

Table 1-1. Condition 1: Normal Power-on Sequence

Operation

1. Printhead initialization and fuse inspection

1-1.Initializes the Printhead, and checks for the fuse on the circuit boards in the printer.

2. Checking for waste ink overflow

2-1.Checks the waste ink counter if the waste ink overflow is occurring.

3. Seeking the home position

3-1.The CR Unit moves to the 80-digit side slowly and confirms it touches the Change Lever (CR lock).

*1

*3

Revision A

CR Unit/PF Roller

movement and

position

*2

3-2.The CR Unit moves to the 0-digit side slowly.

3-3.After the PE Sensor checks if paper exists, the PF Motor rotates clockwise for one second and releases the CR lock.

3-4.While checking if the CR Unit does not touch the Change Lever (CR lock) or the foreign material, the CR Unit

moves to the 80-digit side slowly until it touches the Left Frame.

3-5.The distance from the position where the CR Unit touched to the Left Frame is regarded as the standard distance

from the origin position, and the home position is fixed.

From then on, the CR Unit position is monitored according to the signals from the CR Encoder.

3-6.The CR Unit moves to near its home position quickly.

4. PF Motor Measurement

4-1.The PF Motor rotates clockwise until the PF Roller turns five times to perform a load measurement.

5. Detecting ink cartridge and initializing ink system

5-1.The CR Unit returns to its home position.

6. Low temperature operation sequence

6-1.The CR Unit quickly moves back and forth between near the Change Lever and near the Left Frame for two times.

*5

*4

Note 1: The rotation directions of the PF Motor are as follows.

Clockwise: Paper is fed normally

Counterclockwise: Paper is fed backward

*2: The conditions of the CR lock are as follows.

Red CR lock is set

White CR lock is released

*3: The fatal error occurs if there is a problem such as the fuse blew.

*4: The empty suction operation may occur depending on the situation.

*5: Executed when the detected temperature is under 5

o

C (41oF) by the thermistor on the Printhead.

Troubleshooting Power-On Sequence 11

Confidential

Page 12

L120

Condition 2: Power-on sequence after recovering from a paper jam error (See Table 1-2.)

Turning on the printer after turning it off with a paper jam fatal error.

There still remains paper on the paper path out of the detecting area of the PE Sensor.

Maintenance error recovery has never been performed.

Revision A

Table 1-2. Condition 2: Power-on Sequence after Recovering from a Paper Jam Error

Operation

Executes No.1 to No.3 on the normal power-on sequence (Table 1-1).

4. Detecting remaining paper

4-1.5.The CR Unit returns to its home position.

4-2.The CR Unit moves to the 80-digit side and confirms there is no paper.

4-3.The CR Unit quickly returns to its home position, and displays on the LCD that the paper jam error has occurred.

When the user removes the paper and releases the paper jam error by panel operation, the normal power-on sequence from No.1 (Table 1-1) is executed

*2

again.

Note *1: “Paper exists” is detected when the CR Unit touches the paper. When “paper does not exist” is detected, the power-on sequence

of condition 1 (Table 1-1) is executed from No.4.

*2: If the paper jam error cannot be solved after repeating the power-on sequence on condition 2 (

into the paper jam fatal error for the third time.

CR Unit/PF Roller

movement and

position

*1

Table 1-2) twice, the printer turns

To recover from the maintenance error, the dedicated software that can be downloaded

from the web site which can be accessed from STM3 is required.

The printer operation related to the maintenance error recovery is as follows.

• When the waste ink counter reaches the threshold value (1) for the first time and the

maintenance error occurs, the counter threshold of the maintenance error is changed

to threshold value 2 after performing recovery from the maintenance error.

• After the threshold value (2) is enabled, the warning; to notify the possibility of ink

leakage out of the printer, is displayed every time the waste ink counter increases by

1%.

• If the waste ink counter reaches the threshold value (2), the maintenance error occurs.

Then, the waste ink counter is changed back to the threshold value (1) after recovering

from the maintenance error, and the warning is displayed repeatedly according to the

increment of the waste ink counter until the maintenance error occurs when the

threshold value (2) is reached.

(Recovery from the maintenance error can be performed up to the specified number

of times.)

Troubleshooting Power-On Sequence 12

Confidential

Page 13

L120

1.3 Fatal Error Code List

This section describes how to check the fatal error code, description, and the possible causes.

1.3.1 Printer Fatal Error Code

This section describes the printer fatal error code and the possible cause for this product.

Table 1-3. Fatal Error List (Printer)

Revision A

Error type

DC motor

error

Error

code

01H CR PID excess load error

02H CR PID excess speed error

03H CR PID reverse error

04H CR PID lock error

08H CR load position reverse error

09H CR load position excess speed error

0AH CR load position excess load error

F1H PF PID excess load error

F2H PF PID excess speed error

Error name Possible cause

• CR Motor failure

• CR Unit drive mechanism overload (paper jam, foreign object,

insufficient grease, deformation of the Main Frame)

• Some part may be detached. (Paper Guide Upper Assy, Cap Assy)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• Cable disconnection

• Main Board failure (Motor driver failure)

• CR Encoder failure (contaminated/detached scale, Encoder Sensor

failure)

• Main Board failure (Motor driver failure)

• CR Encoder failure (contaminated/detached scale, Encoder Sensor

failure)

• Some external force is applied to the printer such as stopping the CR Unit

during printer operation, vibration or the like.

• Tooth skip of the CR Timing Belt

• Paper jam

• Main Board failure (Motor driver failure)

• CR Encoder failure (contaminated/detached scale, Encoder Sensor

failure)

• CR Motor failure

• CR Unit drive mechanism overload (paper jam, foreign object,

insufficient grease, deformation of the Main Frame)

• Some part may be detached. (Paper Guide Upper Assy, Cap Assy)

• Cable disconnection

• Main Board failure (Motor driver failure)

• CR Encoder failure (contaminated/detached scale, Encoder Sensor

failure)

• Main Board failure (Motor driver failure)

• CR Encoder failure (contaminated/detached scale, Encoder Sensor

failure)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• Paper jam

• Main Board failure (Motor driver failure)

• CR Motor failure

• CR Unit drive mechanism overload (paper jam, foreign object, Change

Lever failure)

• Cable disconnection

• Main Board failure (Motor driver failure)

• PF Motor failure

• PF drive mechanism overload (paper jam, foreign object, insufficient

grease, deformation of the Main Frame)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• Cable disconnection

• Main Board failure (Motor driver failure)

• PF Encoder failure (contaminated/detached scale, Encoder Sensor failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• Main Board failure (Motor driver failure)

Troubleshooting Fatal Error Code List 13

Confidential

Page 14

L120

Revision A

Table 1-3. Fatal Error List (Printer)

Error type

DC motor

error

Motor drive

time error

Printhead

system error

Sequence

error

Circuit error 80H Circuit error (include blowout of a fuse) • Main Board failure

Error

code

F3H PF PID reverse error

F4H PF PID lock error

F8H PF load position reverse error

F9H PF load position excess speed error

FAH PF load position excess load error

D1H CR (PID) driving time error • Main Board failure (Firmware failure)

D2H CR (load position) driving time error

D3H PF (PID) driving time error • Main Board failure (Firmware failure)

D4H PF (BS) driving time error

40H Transistor temperature error • Main Board failure

41H X-Hot detect error (pre printing)

42H X-Hot detect error (after flushing)

43H Head temperature error

50H Home position error

56H

5BH Insoluble paper jam error

Contact error at ink replacement timing

(Power-off)

Error name Possible cause

• PF Encoder failure (contaminated/detached scale, Encoder Sensor failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• Paper jam

• Paper is pulled out from the ASF side when paper is fed

• Main Board failure (Motor driver failure)

• PF Encoder failure (contaminated/detached scale, Encoder Sensor failure)

• PF Motor failure

• PF drive mechanism overload (paper jam, foreign object, insufficient

grease, deformation of the Main Frame)

• Cable disconnection

• Main Board failure (Motor driver failure)

• PF Encoder failure (contaminated/detached scale, Encoder Sensor failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• PF Encoder failure (contaminated/detached scale, Encoder Sensor failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• Main Board failure (Motor driver failure)

• PF Motor failure

• PF drive mechanism overload (paper jam, foreign object)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• Cable disconnection

• Change Lever failure

• CR Motor failure

• Main Board failure (Motor driver failure)

• Change Lever failure

• CR Motor failure

• Main Board failure (Motor driver failure)

• Printhead failure

• Main Board failure

• Foreign object

• Deformation of the Main Frame

• Change Lever failure

• Paper jam

• Foreign object

• Ink Cartridges are not installed correctly

• Paper jam

• Foreign object

• Deformation of the Main Frame

• Change Lever failure

• Paper jam

Troubleshooting Fatal Error Code List 14

Confidential

Page 15

CHAPTER 2

DISASSEMBLY/REASSEMBLY

Confidential

Page 16

L120

Before folding

Fold here

Clip

40 mm or more

After folding

Fold appropriate length

to hitch a spring.

Clip

2.1 Overview

This chapter describes procedures for disassembling the main parts/units of this product. Unless otherwise

specified, disassembled parts/units can be reassembled by reversing the disassembly procedure. See the cautions

or tips for disassembly/reassembly described in "2.3 Detailed Disassembly/Reassembly Procedure for each Part/

Unit (p34)".

Read the "Safety Precautions(p3)" before disassembling and reassembling.

When you have to remove units or parts that are not described in this chapter, see the exploded diagrams of SPI

(Service Parts Information).

2.1.1 Tools

Use only specified tools to avoid damaging the printer.

Name Availability EPSON Part Code

(+) Phillips screwdriver #1 O 1080530

(+) Phillips screwdriver #2 O ---

Flathead screwdriver O ---

Flathead Precision screwdriver #1 O ---

Tweezers O ---

Longnose pliers O ---

Acetate tape --- 1003963

Note 1: Some of the tools listed above are commercially available.

2: EPSON provides the tools listed with EPSON part code.

Revision A

2.1.2 Jigs

Name Quantity EPSON Part Code

Spring hook jig* 1 Can be made with a commercial item See " Making the Spring Hook Jig (p16)".

Thickness gauge (1.5 mm) 2 Commercially available

Thickness gauge (2.0 mm) 2 Commercially available

Sonic tension meter 1 1294120

Note *: If performing the disassembling/reassembling procedure is difficult using tweezers such as when reassembling " Cap Lever/Cap

Assy (p35)", the spring hook jig helps you to remove/attach the spring easier.

2.1.2.1 Making the Spring Hook Jig

Fold a clip (commercial item) as shown in Fig. 2-1.

Figure 2-1. Making the Spring Hook Jig

Disassembly/Reassembly Overview 16

Confidential

Page 17

L120

1

2

Front

Right

3 4

7

Rear

8

6

Left

5

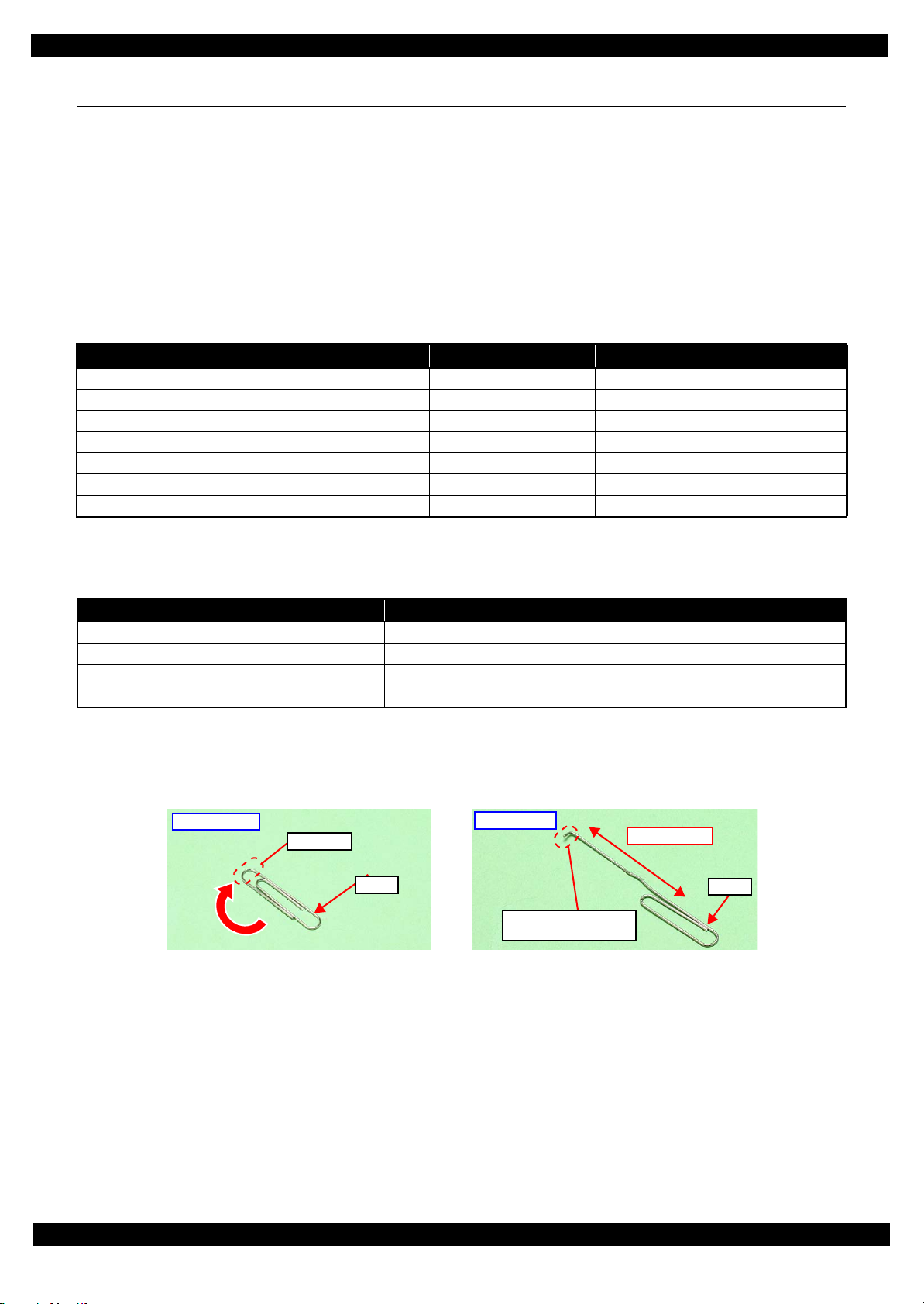

2.1.3 Locations of the Parts/Units

This section shows the locations of the main parts/units of this product.

The parts/units which can not be seen in the following pictures are indicated in dotted lines

().

Exterior parts

Revision A

No. Name No. Name

1 Housing Upper (p31) 5 Buttons (p31)

2 Printer Cover (p29) 6 Paper Support Assy (p29)

3 Cap Tank (p29) 7 Paper Support Joint (p29)

4 Ink Supply Tank Upper Housing (p29) 8 Frame Base Assy (p30)

Figure 2-2. Exterior Parts

Disassembly/Reassembly Overview 17

Confidential

Page 18

L120

1

2

3

5

8 11

7

10

4

9

6

9

7

8

6

5

4

3

1

2

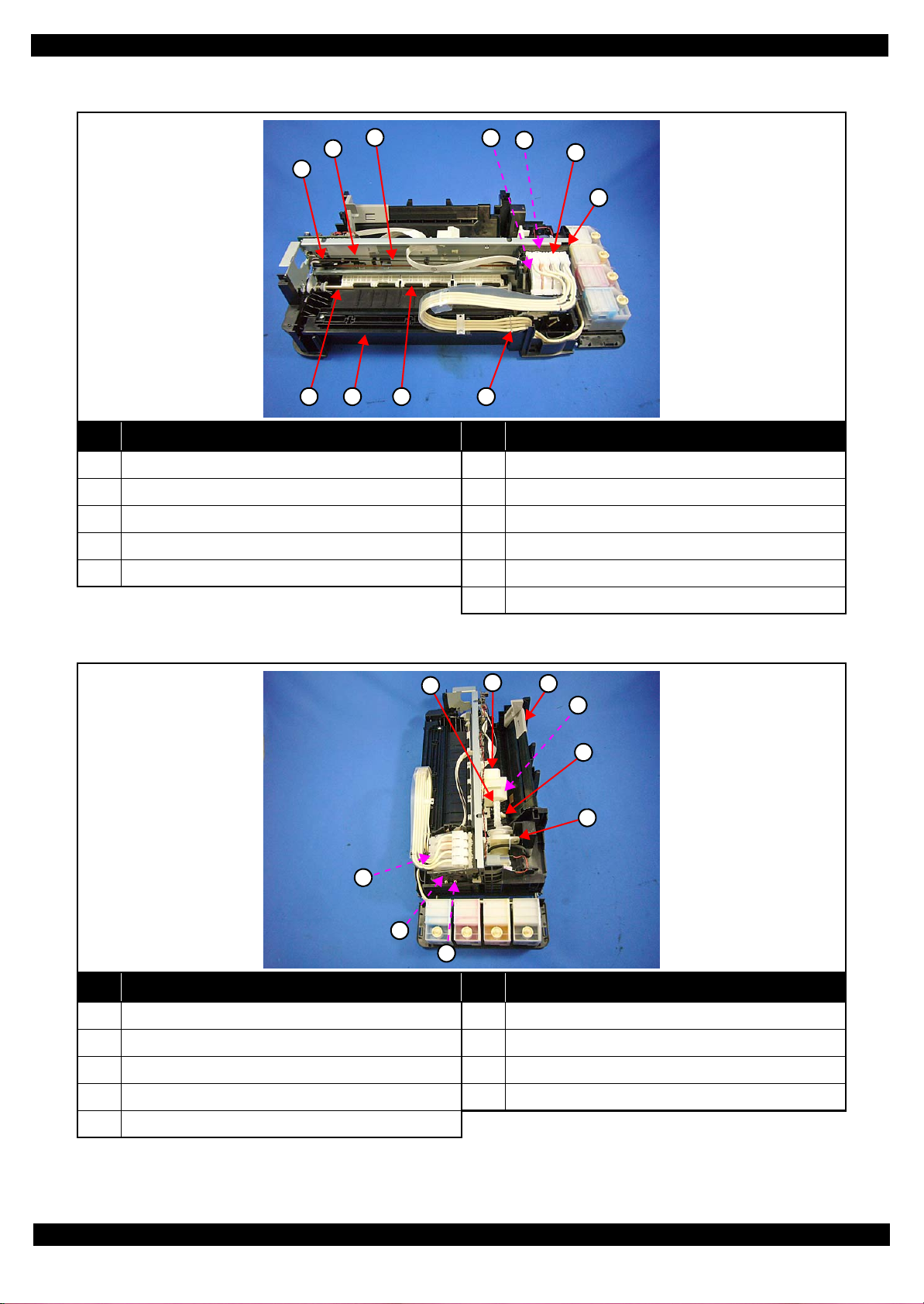

Printer mechanism

No. Name No. Name

1 CR Driven Pulley Assy (p30) 6 Adapter (p31)

2 CR Scale (p30) 7 CR Unit (p32)

Revision A

3 CR Timing Belt (p32) 8 PF Roller Unit (p32)

4 Printhead (p31) 9 Star Wheel Holder Assy (p31)

5 CR Encoder Sensor (p32) 10 Paper Guide Upper Assy (p32)

11 Joint (p31)

Figure 2-3. Printer Mechanism: Front

No. Name No. Name

1 LD Roller Assy (p30) 6 Pump Unit (p32)

2 LD Roller Cover (p30) 7 Cap Assy (p29)

3 Hopper (p30) 8 Porous Pad for Cap Assy (p29)

4 Retard Roller Assy (p29) 9 Cap Lever (p29)

5 Paper Back Lever (p29)

Figure 2-4. Printer Mechanism: Right

Disassembly/Reassembly Overview 18

Confidential

Page 19

L120

6

1

2

3

5 4

1

2

4

3

5

6

Revision A

No. Name No. Name

1 PF Encoder Sensor* (p29) 4 PF Scale (p29)

2 EJ Roller (p31) 5 PF Timing Belt (p29)

3 EJ Roller Gear (p29) 6 PF Motor Assy (p32)

Figure 2-5. Printer Mechanism: Left

No. Name No. Name

1 CR Motor (p30) 4 PE Sensor Lever (p30)

2 Head FFC (p32) 5 PS Unit (p29)

3 Main Board Assy (p30) 6 Waste Ink Pad Assy (p29)

Figure 2-6. Printer Mechanism: Rear

Disassembly/Reassembly Overview 19

Confidential

Page 20

L120

4

2

3

1

Ink Supply Tank Assy

No. Name No. Name

Revision A

1 Ink Supply Tank Tube Assy (p31)

2 Ink Supply Tube Assy (p31)

3 Ink Supply Tank Lower Housing (p31)

Ink Supply Tank

4

Ink Supply Tank (p31)/Ink Supply Tank (p31)/Ink

Supply Tank (p31)/Ink Supply Tank (p31)

Figure 2-7. Ink Supply Tank Assy

Disassembly/Reassembly Overview 20

Confidential

Page 21

L120

2.1.4 Standard Operation Time for Servicing the Product

The following are the standard operation time for servicing the product. Those are based on the MTTR result

measured using a prototype.

The underlined parts/units are supplied as After Service Parts.

Table 2-1. Standard Operation Time

Time (mm:ss)

Parts/Unit

Replacement

Ink Supply Tank Upper Housing 0:35 --- 0:35

Paper Support Assy

Printer Cover

Waste Ink Pad Assy

Paper Back Lever

Retard Roller Assy

Ink Supply Tank Assy 1:03 --- 1:03

Ink Supply Tank

Ink Supply Tank Tube Assy

Ink Supply Tank Lower Housing 2:35 --- 2:35

Housing Upper Assy 1:56 --- 1:56

Housing Upper

Buttons

PS Unit

Cap Assy

Porous Pad for Cap Assy 3:18 --- 3:18

PF Encoder Sensor 2:35 --- 2:35

PF Scale

PF Grounding Spring 2:54 --- 2:54

PF Driven Pulley Assy 3:40 1:10 4:50

PF Timing Belt 3:58 1:10 5:08

FFC Holder 2:10 --- 2:10

EJ Roller Gear

CR Scale

Hopper

Shield Plate 3:31 --- 3:31

LD Roller Assy

CR Motor

PE Sensor Lever

Main Board Assy

LD Roller Cover 2:44 --- 2:44

Transistor Cover 3:28 --- 3:28

CR Driven Pulley Assy 3:19 3:07 6:26

Main Frame Assy 10:21 --- 10:21

Paper Guide Upper Assy

Head FFC

EEPROM Data Copy OK 4:12 1:10 5:22

EEPROM Data Copy NG 4:12 27:58 32:10

0:02 --- 0:02

0:09 --- 0:09

0:44 0:65 1:49

1:46 --- 1:46

1:53 0:47 2:40

0:51 --- 0:51

1:31 --- 1:31

2:05 --- 2:05

2:22 --- 2:22

2:16 --- 2:16

3:12 --- 3:12

2:48 --- 2:48

2:23 --- 2:23

2:45 --- 2:45

2:41 5:03 7:44

4:11 0:47 4:58

6:07 --- 6:07

5:02 0:47 5:49

10:04 7:21 17:25

10:21 --- 10:21

Adjustment/

inspection

Revision A

Total

Disassembly/Reassembly Overview 21

Confidential

Page 22

L120

Table 2-1. Standard Operation Time

Time (mm:ss)

Parts/Unit

Replacement

CR Unit 9:55 --- 9:55

CR Timing Belt

CR Encoder Sensor 6:30 --- 6:30

Frame Base Assy 10:21 --- 10:21

Pump Unit

Spur Gear 16.5 12:47 --- 12:47

PF Roller Unit

PF Motor Assy

Frame Base 15:55 --- 15:55

Tube Guide Sheet Sub

Joint

Tube Pressing Plate

Star Wheel Holder Assy

EJ Roller

Ink Supply Tube Assy

Tube Guide Sheet

Adapter

Holder Board

Printhead

Cap Tank

6:28 --- 6:28

12:23 --- 12:23

15:08 5:51 20:59

15:55 1:08 17:03

2:26 --- 2:26

4:16 --- 4:16

2:12 --- 2:12

2:46 3:18 6:04

3:21 3:18 6:39

3:30 --- 3:30

2:58 --- 2:58

2:43 --- 2:43

2:58 --- 2:58

4:46 17:39 22:25

0:57 --- 0:57

Adjustment/

inspection

Total

Revision A

Disassembly/Reassembly Overview 22

Confidential

Page 23

L120

Ink Supply Tank Assy

Ink Supply Tank Assy

Air release hole

Do not place the Ink Supply Tank Assy with the air release hole down or to one of the sides. Otherwise, the ink in the Ink Supply

Tank Assy may come up to the hole and may leak or the print failure may occur.

OK

NG

Ink Supply Tank Assy

2.1.5 Checks and Precautions before Disassembling

2.1.5.1 Factors which Affect the Print Quality

HOW TO PLACE THE INK TANK ASSY WHEN DISASSEMBLING/REASSEMBLING

The Ink Supply Tank Assy of this printer has an air release hole on the upper part.

The ink in the ink tanks is vented to the atmosphere through this hole to stabilize ink supply to the Printhead. If

the Ink Supply Tank Assy is tilted, the ink in the tanks may leak from the air release hole. If the air release hole is

sealed up with the leaked ink, ventilation to the atmosphere cannot be done properly and the print quality may be

affected adversely.

In order to prevent this from happening, make sure to place the Ink Supply Tank Assy as shown below after

removing it.

Revision A

Figure 2-8. How to Place the Ink Tank Assy

Disassembly/Reassembly Overview 23

Confidential

Page 24

L120

A

C

B

Joint Ink Supply Tank Assy

Ink Supply Tank Tube Assy Ink Supply Tube Assy

Adapter

2.1.5.2 Factors which Affect the Safety of Service Personnel such as Ink Leakage during Operation

Ink may spill when removing the following parts from L120.

This section describes the parts that may cause ink spill and the means to minimize the ink spill when removing

the parts.

THE PARTS THAT MAY CAUSE INK SPILL WHEN REMOVING

Parts When ink may spill Location

Joint Removing the Ink Supply Tank Tube Assy / Ink Supply Tube Assy from the Joint A

Revision A

Ink Supply

Tank

Ink Supply

Tank Tube Assy

Adapter Removing the Ink Supply Tube Assy from the Adapter C

Ink Supply

Tube Assy

Note : These parts are indicated with the icon in disassembly/reassembly flowchart. (See "2.2 Disassembly/Reassembly Procedures

(p28)".)

• Removing the tubes of the Ink Supply Tank Tube Assy from the Joint

• Removing the tubes of the Ink Supply Tank Tube Assy from the Ink Supply Tank

• Removing the Ink Supply Tank Tube Assy / Ink Supply Tube Assy from the Joint

• Removing the Ink Supply Tube Assy from the Adapter

A, B

A, C

Figure 2-9. Location

Disassembly/Reassembly Overview 24

Confidential

Page 25

L120

Carriage

Film

Adapter

MEANS TO MINIMIZE THE INK SPILL

Even observing the points described in this section, ink may spill in the following situations.

Therefore, be careful not to contaminate the inside of the printer or its surroundings by

preparing the container to receive the leaked ink, or the like.

When removing the Ink Supply Tube Assy, all the ink in the tube will spill.

Adapter is removed

When disassembling/reassembling the Adapter, take care not to press the film on the Adapter.

Revision A

Figure 2-10. Adapter

Disassembly/Reassembly Overview 25

Confidential

Page 26

L120

Ink Supply Tank

Ink Supply Tank Tube

Container for discharged ink

Clip

DISCHRGING INK FROM THE INK SUPPLY TANK

Discharging ink is recommended only when disconnecting the Ink Supply Tank Tube Assy from the Ink Supply

Tank. Before performing the above disconnection, discharge ink from the Ink Supply Tank as follows.

Necessary tools

Containers (x 4) for each discharged ink

Clip (x 4)

Cotton swab (x 4)

When disconnecting the Ink Supply Tube/Ink Supply Tank Tube from the Joint, ink may

leak from the ink tube. Prepare a container to receive the leaking ink to prevent the

product from getting contaminated by the leaked ink.

After the Ink Supply Tube is disconnected from the Joint, insert a cotton swab into the

end of the Ink Supply Tube to prevent ink from leaking.

Discharging procedure

1. Remove the Ink Supply Tank Upper Housing/Housing Upper Assy/Tube Pressing Plate.

2. To minimize the ink leakage from the Ink Supply Tube/Ink Supply Tank Tube, pinch the Ink Supply

Tube/Ink Supply Tank Tube with clips (x 2).

Revision A

3. Disconnect the Ink Supply Tank Tube from the Joint, and remove the Ink Supply Tank Assy from the

printer.

4. Put the Ink Supply Tank Assy on a box or the like to keep the assy higher than the container, and insert

the tip of the Ink Supply Tank Tube of the color you want to discharge the ink from into the container.

5. Put the Ink Supply Tank of the ink to discharge on the other Ink Supply Tanks and remove the Cap Tank.

6. Move the clips (x 2) so that only the ink to discharge can flow in the Ink Supply Tank Tube.

7. The ink in the Ink Supply Tank is discharged into the container through the Ink Supply Tank Tube.

8. Repeat Step 4 to Step 7 for all ink tanks to discharge all ink in the Ink Supply Tank.

Figure 2-11. Discharging Ink

Disassembly/Reassembly Overview 26

Confidential

Page 27

L120

Ink supply hole

Ink Supply Tank Assy

Revision A

It is recommended that the ink in the Ink Supply Tank should be discharged completely

before proceeding to disassembling/reassembling.

After all the reassembling work is complete, the discharged ink of each color should be

refilled back to the Ink Supply Tank before performing the adjustment. Confirm the

colors indicated on the film of the Ink Supply Tank so as not to mistake them, and make

sure to refill each ink back to the correct tank from the corresponding ink supply hole.

Disassembly/Reassembly Overview 27

Confidential

Page 28

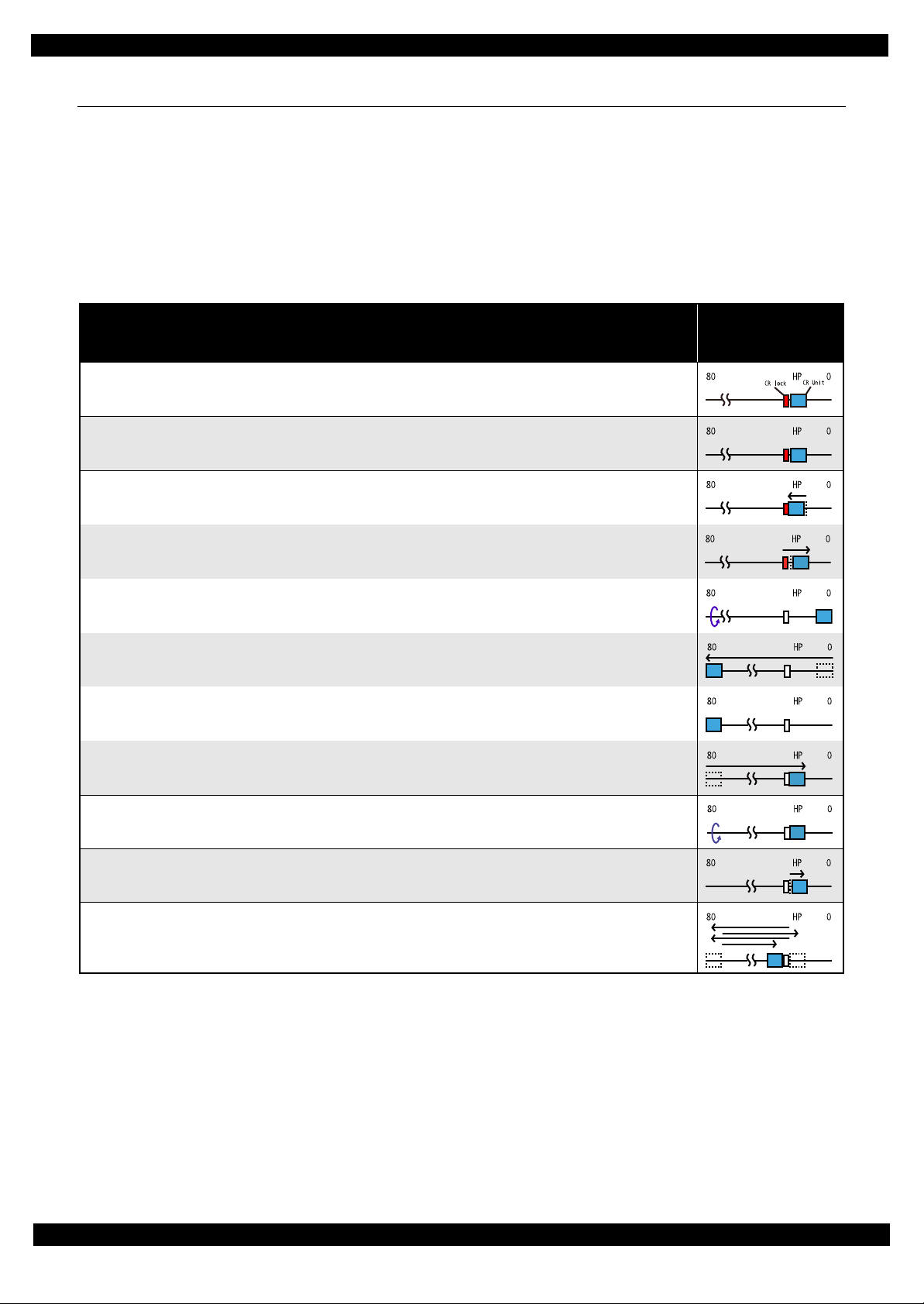

L120

Housing Upper

1

4

(p22) (p43)

Frame Base Assy

---

---

(p21) (p27)

Paper Guide

Upper Assy (p29)

CR Timing Belt

FFC/ Cable *5

Shows necessary

procedures before removing

the following parts.*

Black letters indicate a part/

unit not supplied as an ASP.

Item Description Reference

Parts/unit name

White-letter

Part/unit supplied as an ASP ---

Black-letter

Part/unit not supplied as an ASP ---

Icon

Indicates a practice or condition that could result in

injury or loss of life if not strictly observed.

Indicates the reference page in

blue-letter

Indicates a practice or condition that could result in

damage to, or destruction of equipment if not strictly

observed.

Indicates the reference page in

blue-letter

Indicates the parts that are inevitably broken in the

disassembling procedure, and should be replaced with

a new one for reassembly.

Indicates the reference page in

blue-letter

Indicates the parts that may cause the ink spill when

they are removed.

"2.1.5 Checks and Precautions

before Disassembling (p23)"

Indicates necessary check items in the disassembling/

assembling procedure.

Indicates the reference page in

blue-letter

Indicates supplementary explanation for disassembly

is given.

Indicates the reference page in

blue-letter

Indicates particular tasks to keep quality of the units

are required.

Indicates the reference page in

blue-letter

Indicates particular routing of cables is required.

Indicates the reference page in

blue-letter

Indicates particular adjustment(s) is/are required. Chapter 3 " Adjustment (p42)"

Indicates lubrication is required.

Chapter 4 " Maintenance

(p52)"

Indicates the number of screws securing the parts/

units.

---

Indicates the points secured with other than a screw

such as a hook, rib, dowel or the like.

---

White letters indicate a

part/unit supplied as an

ASP.

Shows the screw types and

the specified torque on the

“Screw type/torque list”.

Reference page

Shows removal/installation

as a unit/assy. is available.

The name enclosed in gray

indicate a part/unit that

must be removed on the

way to the target parts.

Note "*": The box with only part names means the removal of the parts. If the name of

FFC or a cable is shown, disconnect the FFC or cable from the connector.

Shows the procedure

number on the “FFC/

cable list”.

2.2 Disassembly/Reassembly Procedures

This section describes procedures for disassembling the parts/units in a flowchart format. For some parts/units,

detailed procedures or precautions are provided (accordingly indicated by icons and cell's color). Refer to the

explanations in the example chart below and perform an appropriate disassembling and assembling procedure.

(See "2.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit (p34) ".)

For routing cables, see "2.4 Routing FFCs/cables (p40)".

The example below shows how to see the charts on the following pages.

S4

Revision A

Disassembly/Reassembly Disassembly/Reassembly Procedures 28

Confidential

Page 29

L120 Revision A

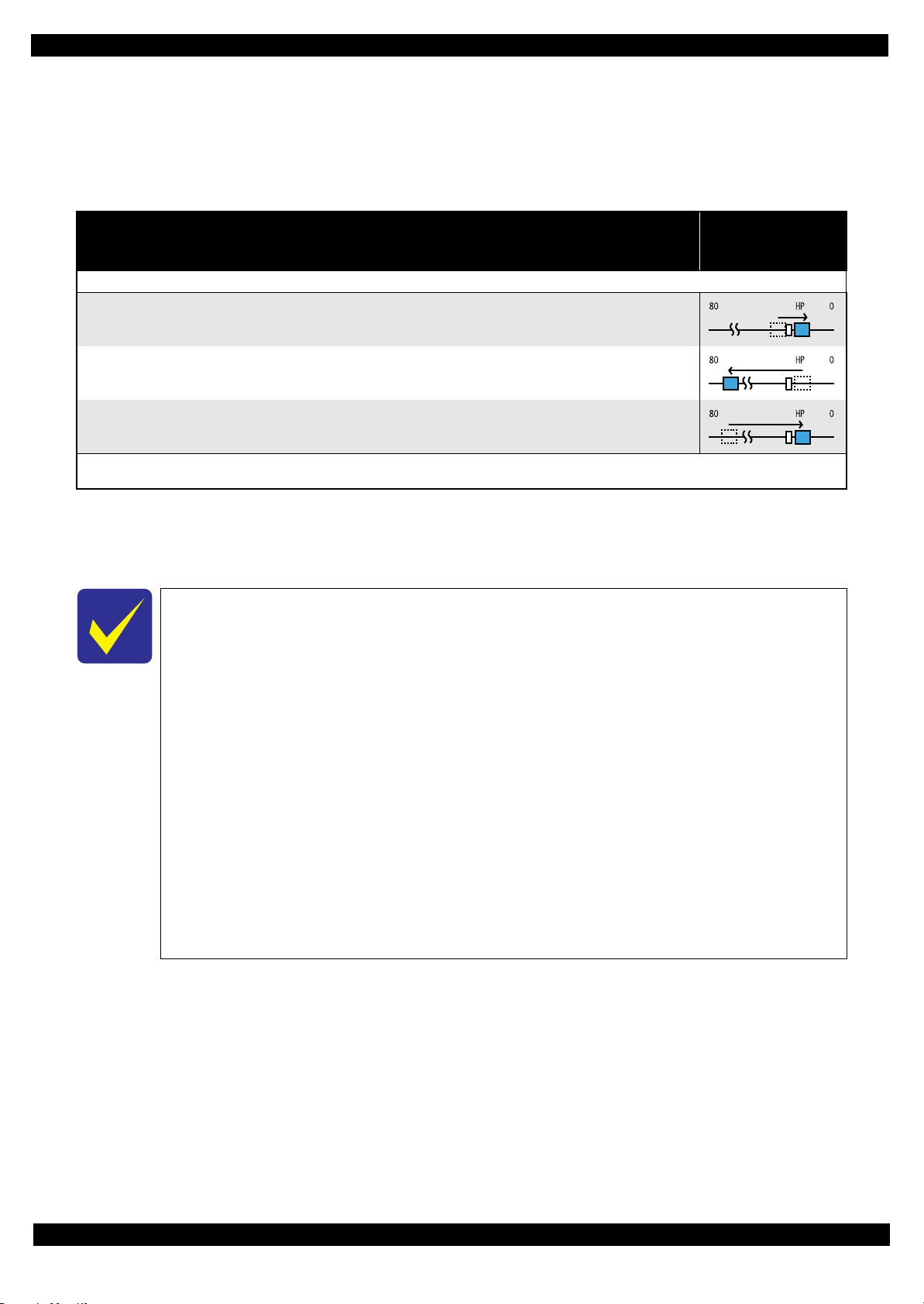

2.2.1 Disassembly Flowchart

START

Cap Tank

---

Ink Supply Tank

Upper Housing

S4

(p 37)

Housing Upper

Assy

S5

(p 34)

(p 29)

B

Paper Support

Assy

---

---

Paper Support

Joint

---

Printer Cover

---

Waste Ink Pad

Assy

1

PF Encoder

Sensor*

Note "*": Proceed to the next step

with the part detached

temporarily because the

1

part cannot be removed

fully there.

2

---

1

---

3

---

2

S5

(p 34) (p 42)

2

(p 36) (p 40)

S2

---

Extension Spring (x2)

Paper Back

2

2

Lever

---

2

(p 52)

Retard Roller

4

Assy

---

3

1

(p 31)

2

(p 42)

PF Scale

(p 36)

PF Driven Pulley

Assy

S7

(p 35) (p 42)

---

---

1

1

PF Grounding

Spring

---

1

(p 34)

A

(p 30)

Cable (CN501)

PS Unit

(p 34) (p 40)

(p 42)

Extension Spring (2)

EJ Roller Gear

---

FFC Holder

---

Pump Tube

B

C

Cap Assy

---

---

(p 34) (p 52)

(p 40)

2

1

---

(p 29)

(p 31)

3

(p 35)

Cap Lever

---

---

(p 35)

Porous Pad for

Cap Assy

---

---

---

Ink Supply Tank Tube

Assy

Ink Supply Tank

Assy

---

---

---

PF Timing Belt

---

---

(p 42)

2

(p 31)

Screw type/torque list

Symbol Screw Type Torque

S1

C.B.P-TITE SCREW 2.6x5 F/ZN-3C 2.55 0.05 kgf·cm

S2

C.B.P-TITE SCREW 2x8 F/ZN-3C 2.55 0.05 kgf·cm

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

C.B.P-TITE SCREW 2x8 F/ZN-3C 2

C.B.P-TITE SCREW 3x10 F/ZB-3C 6 1 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZN-3C 6

C.B.P-TITE SCREW 3x10 F/ZN-3C 7 1 kgf·cm

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 7

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 8 1 kgf·cm

C.B.S-TITE SCREW 3x6 F/ZN-3C 6

C.B.S-TITE SCREW 3x6 F/ZN-3C 7.3 0.1 kgf·cm

C.B.S-TITE SCREW 3x8 F/ZN-3C 7.3

C.P SCREW 2.6x3 F/ZN-3C 4 0.5 kgf·cm

C.P.S-TITE (S-P1) SCREW 3x6 F/ZN-3C 7.5

0.5 kgf·cm

1 kgf·cm

1 kgf·cm

1 kgf·cm

0.1 kgf·cm

0.5 kgf·cm

Flowchart 2-1. Disassembly Flowchart (1)

Disassembly/Reassembly Disassembly Flowchart 29

Confidential

Page 30

L120 Revision A

(p 29)

A

PF Encoder

Sensor* (p29)

PF Scale (p29)

CR Scale (p30)

Transistor Cover

(p30)

CR Driven Pulley

Assy (p30)

LD Roller Cover

(p30)

FFC/Cable* 1

Extension Spring (x3)

Main Frame Assy

S9

(p 36) (p 42)

(p 52)

Extension spring

CR Scale

---

2

(p 34)

Paper Support

Assy (p29)

Hopper

(p 42)

FFC/Cable* 2

LD Roller Cover

1

---

2

S5

---

---

Transistor Cover

---

4

(p 39)

CR Timing Belt

CR Driven Pulley

Assy

Shield Plate

2

5

---

S9

---

1

3

(p 32)

LD Roller Cover

(p30)

LD Roller Assy

(p 35) (p 42)

(p 52)

---

S13

(p 36) (p 42)

(p 52)

2

1

4

Frame Base Assy

(p 42)

FFC/cable list

---

---

4

(p 32)

CR Timing Belt

FFC/Cable* 3

CR Motor

S12

(p 41) (p 42)

LD Roller Cover

(p30)

Extension Spring

2

---

PE Sensor Lever

---

3

(p 42)

PF Encoder Sen-

sor* (p29)

FFC/Cable* 4

Main Board Assy

S10 S11

(p 34) (p 40)

(p 42)

3

---

No. FFC/Cable No. FFC/Cable

Remove/disconnect the

following.

PF Motor cable (CN13)

1

PS Unit cable (CN501)

CR Motor cable (CN12)

Remove/disconnect the

following.

2

PF Motor cable (CN13)

PS Unit cable (CN501)

Release the CR Motor cable

from the hooks of the Main

Frame and Frame Base.

3

Remove/disconnect all FFCs/

cables.

4

Screw type/torque list

Symbol Screw Type Torque

S1

C.B.P-TITE SCREW 2.6x5 F/ZN-3C 2.55 0.05 kgf·cm

S2

C.B.P-TITE SCREW 2x8 F/ZN-3C 2.55 0.05 kgf·cm

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

C.B.P-TITE SCREW 2x8 F/ZN-3C 2

C.B.P-TITE SCREW 3x10 F/ZB-3C 6 1 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZN-3C 6

C.B.P-TITE SCREW 3x10 F/ZN-3C 7 1 kgf·cm

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 7

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 8 1 kgf·cm

C.B.S-TITE SCREW 3x6 F/ZN-3C 6

C.B.S-TITE SCREW 3x6 F/ZN-3C 7.3 0.1 kgf·cm

C.B.S-TITE SCREW 3x8 F/ZN-3C 7.3

C.P SCREW 2.6x3 F/ZN-3C 4 0.5 kgf·cm

C.P.S-TITE (S-P1) SCREW 3x6 F/ZN-3C 7.5

0.5 kgf·cm

1 kgf·cm

1 kgf·cm

1 kgf·cm

0.1 kgf·cm

0.5 kgf·cm

Flowchart 2-2. Disassembly Flowchart (2)

Disassembly/Reassembly Disassembly Flowchart 30

Confidential

Page 31

L120 Revision A

(p 29)

C

Ink Supply Tube Assy

Adapter

(p 39)

Holder Board

---

Head FFC

Printhead

S6

(p 35) (p 42)

(p 29)

2

Ink Supply Tube Assy

Ink Supply Tank Tube Assy

Tube Guide

Sheet Sub

---

2

(p 38)

---

1

Joint

---

8

(p 38)

Tube Pressing

Plate (p31)

---

2

Tube Guide

Sheet

---

---

(p 38)

Tube Pressing

Plate

S1

(p 38)

Joint (p31)

Tube Guide

Sheet (p31)

Star Wheel

Holder Assy

S5

(p 42)

1

1

Ink Supply Tube

Assy

---

8

(p 38)

2

---

3

1

EJ Roller Gear

(p29)

Cap Tank (p29)

Ink Supply Tank Tube Assy

Ink Supply Tank

(p 37)

Ink Supply Tank

(p31)

Ink Supply Tank

(p31)

Ink Supply Tank

(p31)

Ink Supply Tank

Tube Assy

(p 37)

---

---

Ink Supply Tank Tube Assy

Ink Supply Tank

---

4

(p 37)

4

Ink Supply Tank Tube Assy

Ink Supply Tank

(p 37)

---

Ink Supply Tank Tube Assy

Ink Supply Tank

---

4

(p 37)

4

8

EJ Roller

1

Printer Cover

(p29)

Buttons (p31)

Housing Upper

---

(p 29)

---

---

Buttons

S5

---

---

1

(p 42) (p 52)

Ink Supply Tank

Lower Housing

---

---

---

Screw type/torque list

Symbol Screw Type Torque

S1

C.B.P-TITE SCREW 2.6x5 F/ZN-3C 2.55 0.05 kgf·cm

1

2

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

C.B.P-TITE SCREW 2x8 F/ZN-3C 2.55 0.05 kgf·cm

C.B.P-TITE SCREW 2x8 F/ZN-3C 2

0.5 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZB-3C 6 1 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZN-3C 6

1 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZN-3C 7 1 kgf·cm

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 7

1 kgf·cm

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 8 1 kgf·cm

C.B.S-TITE SCREW 3x6 F/ZN-3C 6

1 kgf·cm

C.B.S-TITE SCREW 3x6 F/ZN-3C 7.3 0.1 kgf·cm

C.B.S-TITE SCREW 3x8 F/ZN-3C 7.3

0.1 kgf·cm

C.P SCREW 2.6x3 F/ZN-3C 4 0.5 kgf·cm

C.P.S-TITE (S-P1) SCREW 3x6 F/ZN-3C 7.5

0.5 kgf·cm

Flowchart 2-3. Disassembly Flowchart (3)

Disassembly/Reassembly Disassembly Flowchart 31

Confidential

Page 32

L120 Revision A

(p 30) (p 30)

3 4

Cap Assy (p29)

Shield Plate

(p30)

Main Board Assy

(p30)

PE Sensor Lever

(p30)

Paper Guide

Upper Assy

(p 42)

Pump Tube

Pump Unit

CR Motor (p30)

FFC/Cable* 5

CR Unit

---

Antistatic Cloth

S8

---

---

1

1

S5

(p 36)

PF Grounding

Spring (p29)

1

---

---

6

(p 41) (p 42)

FFC Holder

(p29)

Head FFC

---

---

CR Timing Belt

---

(p 36) (p 42)

CR Encoder

Sensor

1

1

S3

(p 37) (p 40)

1

Spur Gear 16.5

---

EJ Roller Gear

(p29)

PF Driven Pul-

---

---

ley Assy (p29)

(p 40)

PF Timing Belt

(p29)

PF Roller Unit

---

2

(p 42) (p 52)

PF Motor Assy

1

S5

(p 40) (p 42)

---

Frame Base

---

---

(p 42) (p 52)

Flowchart 2-4. Disassembly Flowchart (4)

FFC/cable list

No. FFC/Cable

Disconnect the CR Encoder FFC.

5

Pull out the Head FFC from the hole of the CR Unit.

Screw type/torque list

Symbol Screw Type Torque

S1

C.B.P-TITE SCREW 2.6x5 F/ZN-3C 2.55 0.05 kgf·cm

S2

C.B.P-TITE SCREW 2x8 F/ZN-3C 2.55 0.05 kgf·cm

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

C.B.P-TITE SCREW 2x8 F/ZN-3C 2

C.B.P-TITE SCREW 3x10 F/ZB-3C 6 1 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZN-3C 6

C.B.P-TITE SCREW 3x10 F/ZN-3C 7 1 kgf·cm

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 7

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 8 1 kgf·cm

C.B.S-TITE SCREW 3x6 F/ZN-3C 6

C.B.S-TITE SCREW 3x6 F/ZN-3C 7.3 0.1 kgf·cm

C.B.S-TITE SCREW 3x8 F/ZN-3C 7.3

C.P SCREW 2.6x3 F/ZN-3C 4 0.5 kgf·cm

C.P.S-TITE (S-P1) SCREW 3x6 F/ZN-3C 7.5

0.5 kgf·cm

1 kgf·cm

1 kgf·cm

1 kgf·cm

0.1 kgf·cm

0.5 kgf·cm

Disassembly/Reassembly Disassembly Flowchart 32

Confidential

Page 33

L120 Revision A

2.2.2 Disassembly Flowchart (Printhead/Main Board)

Printhead Main Board

START START

Cap Tank

---

Ink Supply Tank

Upper Housing

S4

(p 37)

Housing Upper

Assy

S5

(p 34)

Ink Supply Tube Assy

Adapter

(p 39)

Holder Board

---

Head FFC

---

2

Printhead

3

S6

(p 35) (p 42)

1

2

2

Cap Tank

---

Ink Supply Tank

Upper Housing

S4

(p 37)

---

2

2

2

Housing Upper

Assy

4

3

S5

(p 34)

4

3

FFC/Cable* 6

Shield Plate

S9

---

PF Encoder

Sensor*

S2

(p 36) (p 40)

FFC/Cable* 7

Main Board Assy

2

1

Note "*": Proceed to the next step with the part

1

---

detached temporarily because the

part cannot be removed fully there.

3

Paper Support

Assy

---

---

2

---

1

S10 S11

(p 34) (p 40)

(p 42)

---

FFC/cable list

No. FFC/Cable

Remove/disconnect the following.

6

PF Motor cable (CN13)

PS Unit cable (CN501)

Hopper

---

---

2

(p 42)

2

7 Remove/disconnect all FFCs/cables.

Screw type/torque list

Symbol Screw Type Torque

S1

C.B.P-TITE SCREW 2.6x5 F/ZN-3C 2.55 0.05 kgf·cm

S2

C.B.P-TITE SCREW 2x8 F/ZN-3C 2.55 0.05 kgf·cm

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

C.B.P-TITE SCREW 2x8 F/ZN-3C 2

C.B.P-TITE SCREW 3x10 F/ZB-3C 6 1 kgf·cm

C.B.P-TITE SCREW 3x10 F/ZN-3C 6

C.B.P-TITE SCREW 3x10 F/ZN-3C 7 1 kgf·cm

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 7

C.B.S-TITE (P2) SCREW 3x6 F/ZN-3C 8 1 kgf·cm

C.B.S-TITE SCREW 3x6 F/ZN-3C 6

C.B.S-TITE SCREW 3x6 F/ZN-3C 7.3 0.1 kgf·cm

C.B.S-TITE SCREW 3x8 F/ZN-3C 7.3

C.P SCREW 2.6x3 F/ZN-3C 4 0.5 kgf·cm

C.P.S-TITE (S-P1) SCREW 3x6 F/ZN-3C 7.5

0.5 kgf·cm

1 kgf·cm

1 kgf·cm

1 kgf·cm

0.1 kgf·cm

0.5 kgf·cm

Flowchart 2-5. Disassembly Flowchart (Printhead/Main Board)

Disassembly/Reassembly Disassembly Flowchart (Printhead/Main Board) 33

Confidential

Page 34

L120 Revision A

Top

Housing Upper Assy

C.B.P-TITE SCREW 3x10 F/ZN-3C (6 ± 1 kgf·cm)

Right side

Bottom

Hook

Right side

Ink Supply

Tank Tube Assy

Do not pinch.

Black triangle mark

Slit of CR Encoder Sensor

CR Unit

Extension spring

CR Scale

PS Unit

Hook

Rib

Bottom

Widen this rib to release the hook of PS Unit.

C.B.P-TITE SCREW 3x10 F/ZN-3C (6 ± 1 kgf·cm)

Hook and hole

Frame Base

Waste Ink Pad Assy

Bottom

Waste Ink Pad Assy

Rear

Rib and hole

PE Sensor Lever

Main Board AssyPE Sensor

1

2

3

EJ Roller Gear

Can not be reused because the rib

of the EJ Roller Gear is deformed

once removed from the EJ Roller.

Insert spring leg

A into groove.

PF Grounding

Spring

Left

Main Frame

Spring leg B

Cutout

PF Grounding

Spring

Spring leg B

Spring leg A

Frame Base

Assy

Hole

2.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit

Housing Upper Assy

Release the hooks shown above when removing the Housing Upper Assy.

When installing the Housing Upper Assy, take care not to let the Ink Supply Tank Tube Assy get pinched.

Tighten the screws in the order indicated in the figure above.

CR Scale

Attach the CR Scale to the hook on the left of the Main Frame

with the black triangle mark upward.

Make sure to put the CR Scale through the slit of the CR

Encoder Sensor.

PS Unit

Be careful not to damage the rib of the Frame Base when widen the

rib to release the hook of the PS Unit.

When removing the PS Unit, follow the procedure below.

1. Using a precision screwdriver or the like, widen the rib of the

Frame Base to release the hook of the PS Unit.

2. Remove the PS Unit from the Frame Base in the direction of

the arrow while releasing the rib of the PS Unit.

3. Disconnect the PS Unit cable from the connector on the PS

Unit and remove the PS Unit.

Waste Ink Pad Assy

When installing the Waste Ink Pad Assy, follow the procedure

below.

1. Place the Waste Ink Pad Assy under the Frame Base.

2. Slide the Waste Ink Pad Assy in the direction of the arrow to

align the hole of the Waste Ink Pad Assy with the hook of the

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 34

Frame Base.

3. Confirm the following first, and then tighten the screw to

secure the Waste Ink Pad Assy.

• The rib of the Waste Ink Pad Assy is correctly inserted into

the hole of the Frame Base.

• The Waste Ink Pad Assy is secured firmly with the hook of

the Frame Base.

Install the Main Board Assy with the PE Sensor Lever to the

rear. After installing the Main Board Assy, make sure the lever

part of the PE Sensor Lever is aligned with the slit of the PE

Sensor.

Tighten the screws in the order indicated in the figure above.

Main Board Assy

EJ Roller Gear

The rib on the contact point of the EJ Roller Gear with the EJ

Roller is deformed when removing the EJ Roller Gear. Therefore,

make sure to replace it with a new one when removing it in order to

maintain the paper feed accuracy.

PF Grounding Spring

When installing the PF Grounding Spring, follow the procedure below.

1. From the left side of the printer, insert the spring leg A of the

PF Grounding Spring into the hole of the Frame Base.

2. Insert the spring leg B of the PF Grounding Spring into the

groove of the Frame Base.

3. Attach the spring leg B of the PF Grounding Spring to the

cutout of the Main Frame to install the PF Grounding Spring.

Confidential

Page 35

L120 Revision A

LD Roller Assy

Paper Back Lever

Change Lever

Cam

Main Frame

Rear of printer

LD Roller

LD Roller Shaft

Extension Spring

Clutch

Spur gear

2 1

3

Main Frame

Printhead

CR Unit

C.B.P-TITE SCREW 3x10 F/ZN-3C (7 ± 1 kgf·cm)

Pinion gear of PF Motor

Hook

PF Motor Frame

Dowel

Rib

PF Driven Pulley Assy

Protrusion

Compression Spring 5.07

Combination Gear 29.2,42

PF Timing Belt

PF Driven Pulley Assy

C.B.S-TITE(P2) SCREW 3x6 F/ZN-3C

P.W. 3.4x0.43x7 (7 ± 1 kgf·cm)

Cap Lever

Extension Spring 1.329

Cap Assy

Extension Spring 0.65

Hook of Cap Assy

Hook of Frame Base

Step 6

Shaft BShaft A

Shaft C

Cap Assy

Step 2

Make sure the marking (10 ± 1 mm

from the tube end) on the tube cannot

be seen when viewed from the side.

Cap Slider

CutoutHole B

Cap Lever

Frame

Base

Hole A

Hole C

Step 1, 3-5

Hook of Frame Base

Hook of Cap Lever

Step 7

LD Roller Assy (1)

Install the LD Roller Assy with the following condition in order to avoid the Change Lever and Paper Back Lever.

Using a screw driver or the like, hold the Paper Back Lever to the rear as shown above not to let it touch the LD Roller Assy.

Push the Change Lever to the front to keep it in the hole of the Main Frame.

LD Roller Assy (2)

If each part shown above comes off when removing the LD Roller

Assy, attach them back in place as shown in the figure above.

Printhead

When removing/replacing the Printhead, do not apply excess

downward force when tightening the screws. Otherwise, the Main

Frame may be deformed by the applied perpendicular force when

screwing, and the print quality may be affected adversely.

Tighten the screws of the Printhead in the order indicated in the

figure above while pressing the Printhead in the direction of the

arrow.

PF Driven Pulley Assy / PF Timing Belt

When installing the Cap Lever/Cap Assy, follow the procedure below.

1. Attach the Cap Lever to the Frame Base, and attach one end of the Extension Spring 0.65 to the hook of the Frame Base.

2. Connect the tube of the Pump Unit to the joint on the bottom of the Cap Assy. Then, viewing from the side, confirm the marking (10

from the tube end) on the tube is covered by the Cap Slider.

3. Insert the shaft A of the Cap Assy through the hole of the Cap Lever to the hole A of the Frame Base.

4. Insert the shaft B of the Cap Assy through the cutout of the Frame Base and to the hole B of the Frame Base.

5. Insert the shaft C of the Cap Assy to the hole C of the Frame Base.

6. Using a “spring hook jig” (p 16), attach the other end of the Extension Spring 0.65 to the hook of the Cap Assy.

7. Attach the Extension Spring 1.329 to the hooks of the Cap Lever and Frame Base.

Do not hold the PF Driven Pulley Assy when securing it with the screw in order to prevent applying improper tension to the PF Timing Belt.

When installing the PF Driven Pulley Assy, follow the procedure below.

1. Align the rib of the PF Driven Pulley Assy with the hook of the PF Motor Frame, and install the PF Driven Pulley Assy.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 35

2. Attach the Compression Spring 5.07 to the protrusion of the PF Driven Pulley Assy and the dowel of the PF Motor Frame.

3. Attach the PF Timing Belt in the order of the pinion gear of the PF Motor, PF Driven Pulley and Combination Gear 29.2,42.

4. Rotate the Combination Gear 29.2,42 clockwise three times to confirm the PF Timing Belt is correctly attached, and then secure the PF Driven

Pulley Assy with the screw and washer to the PF Motor Frame.

Cap Lever/Cap Assy

Confidential

1 mm

Page 36

L120 Revision A

3

5

Align the screw holes of Main

Frame and PF Motor Frame.

PF Motor Frame

Main Frame

4

Tighten screw while pressing Main

Frame in the direction of the arrow.

C.B.P-TITE SCREW 3x10 F/ZN-3C (6 ± 1 kgf·cm)

C.B.S-TITE SCREW 3x6 F/ZN-3C (6 ± 1 kgf·cm)

1

2

Main Frame Assy

Change Lever must not

interfere with Main Frame.

Rib and groove

Positioning hole and dowel

Section A

Main Frame

Rib

CR Driven Pulley Assy

Dowel

Compression Spring 13.98

CR Timing Belt

Pinion gear of CR Motor

Main Frame

C.P.S-TITE (S-P1) SCREW 3x6 F/ZN-3C (7 ± 0.5 kg·fcm)

PF Scale

PF Encoder Sensor

PF Roller

PF Encoder Sensor

PF Scale

PF Roller

Step 4 Pump

Tube B

Marking

8 ± 1 mm

Hole of Frame Base

Hole of

Frame Base

Pump

Tube A

Step 1-2

Pump Unit

Route Pump Tube A through ribs of Frame

Base with their dashed line facing upward.

Insert Pump Tube B up to the marking (8 ± 1 mm

from tube end) to the hole of Frame Base.

C.B.P-TITE SCREW 3x10 F/ZN-3C (6 ± 1 kgf·cm)

Step 3

Frame Base

Rib

Main Frame Assy

Before installing the Main Frame Assy, shift the Change Lever back to the rear.

When installing the Main Frame Assy, make sure of the following.

• The Change Lever must not interfere with the Main Frame.

• The above shown ribs and grooves, positioning holes and dowels are correctly aligned.

• The section A of the Main Frame Assy is not deformed.

Tighten the screws in the order indicated in the figure above.

CR Driven Pulley Assy / CR Timing Belt

If the CR Timing Belt has to be replaced, it is necessary to extend the new CR Timing Belt by the tension of the Compression Spring 13.98 in

advance. If the CR Timing Belt is replaced without doing this extension process, misalignment of the belt or print failure may occur. Therefore, make

sure to follow the assembling procedure when installing the CR Timing Belt.

When installing the CR Driven Pulley Assy and CR Timing Belt, follow the procedure below.

1. Install the CR Driven Pulley Assy to the Main Frame.

2. Attach the Compression Spring 13.98 in the order from the dowel on the CR Driven Pulley Assy to the rib on the Main Frame.

3. Attach the CR Timing Belt to the CR Driven Pulley Assy.

4. Attach the CR Timing Belt on the pinion gear of the CR Motor while pushing the CR Driven Pulley Assy to the 0-digit side.

5. Wait five minutes for CR Timing Belt to be extended by the tension of the Compression Spring 13.98.

6. Secure the CR Driven Pulley Assy wit the screw.

PF Encoder Sensor / PF Scale

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 36

Do not reuse the removed PF Scale and make sure to replace it with a new one when removing it.

When installing the PF Scale, it is pressed into the PF Roller, therefore, the removed one is deformed. If it is re-installed to the printer, it does not

rotate properly and the paper feed accuracy may be reduced.

The PF Encoder Sensor cable which connects the PF Encoder Sensor and the Main Board cannot be removed solely because it is soldered on them. If

the PF Encoder Sensor should be removed, make sure to remove it together with the Main Board.

When installing the PF Scale to the PF Roller, press the PF Scale into the PF Roller vertically.